Page 1

DOC024.98.93051

ORBISPHERE Model

3100 Portable Analyzer

07/2016, Edition 7

Basis-Bedienungsanleitung

Manuale di base per l'utente

Manuel d'utilisation de base

Manual básico del usuario

Manual de operações básicas

Grundlæggende brugerhåndbog

Basisgebruikershandleiding

Podstawowa instrukcja obsługi

Grundläggande bruksanvisning

Основно ръководство за потребителя

Alapvető felhasználói útmutató

Manualul de bază al utilizatorului

Osnovni korisnički priručnik

Βασικό εγχειρίδιο χειριστή

Basic User Manual

Základní návod k použití

Peruskäyttöohje

Temel Kullanım Kılavuzu

Page 2

English..............................................................................................................................3

Deutsch.......................................................................................................................... 24

Italiano............................................................................................................................ 47

Français......................................................................................................................... 70

Español.......................................................................................................................... 93

Português.................................................................................................................... 116

Čeština......................................................................................................................... 140

Dansk............................................................................................................................162

Nederlands................................................................................................................. 183

Polski............................................................................................................................ 206

Svenska....................................................................................................................... 230

Suomi............................................................................................................................251

български................................................................................................................... 272

Magyar......................................................................................................................... 296

Română....................................................................................................................... 318

Türkçe...........................................................................................................................340

Hrvatski........................................................................................................................ 361

Ελληνικά...................................................................................................................... 383

2

Page 3

Specifications

Specifications are subject to change without notice

Specification Details

Sample Non-flammable gaseous or liquid samples

Sample temperature -5 to 45°C (23 to 113°F)

Sample pressure 0 to 10 bar (0 to 140 psi)

Measurement range 0 to 2000 ppb

Accuracy ± 0.8 ppb or ± 2% of reading whichever is the greater

Repeatability r95 ± 0.4 ppb or ± 1% of reading whichever is the greater

Detection limits 0.6 ppb

Response time t90 Usually less than 15 seconds but will vary depending on the sampling method

Measurements Holds up to

Display units O2 concentration ppb, ppm, μg/L, mg/L, mL/L, %O2, %air, %Vbar, ppmVbar

Operating conditions Ambient temperature -5 to 45°C (23 to 113°F)

Weight 3.4 kg (7.5 lbs)

Dimensions (L x W x H) 200 x 170 x 190 mm (7.87 x 6.69 x 7.48 ins)

Waterproof protection Stainless steel IP66 with polycarbonate sides

Power supply Internal rechargeable battery pack: Li-Ion 46Wh

Battery life > 10 hours of continuous measurement

Battery charge time < 4 hours

EMC requirements EN61326-1: EMC Directive

Korean registration

CE compliance EN61010-1: LVD Directive

5,760 measurements

Pressure mbar, bar, Pa, hPa, kPa, MPa, psia, psig, atm, kgf/cm2

Temperature °C, °F, K

Relative humidity 0 to 95% non-condensing for temperatures less than

External power supply input: 100-240 VAC ±10% @ 47-63 Hz

External power supply output: 12 VDC, 3.75 A

Note: External power supply is not IP66

Note: Charge time increases by 20% at a temperature above 35°C (95°F)

User Guidance for EMC Class B Equipment

가정용을 포함하는 EMC 등급 B 장치에

대한 사용자 지침

사용자안내문

B 급 기기 ( 가정용 방송통신기자재 )

이 기기는 가정용 (B 급 ) 전자파적합기기로서 주로 가정에서 사용하는 것을 목적으로

하며 , 모든 지역에서 사용 할 수 있습니다.

8 hours of data at a sampling frequency of 5 seconds

96 hours of data at a sampling frequency of 1 minute

30°C (86°F)

0 to 70% non-condensing for temperatures from 30 to

45°C (86 to 113°F)

English 3

Page 4

Specification Details

Safety standard IEC/UL/CSA 61010-1

Overvoltage category Cat II

Digital display TFT color display 72 x 54 mm (2.83 x 2.13 ins)

Digital connections 1 x USB (5 VDC) Input/Output mass storage device

1 x RS232 (0-5 V) Serial output

General information

In no event will the manufacturer be liable for direct, indirect, special, incidental or consequential

damages resulting from any defect or omission in this manual. The manufacturer reserves the right to

make changes in this manual and the products it describes at any time, without notice or obligation.

Revised editions are found on the manufacturer’s website.

Safety information

N O T IC E

The manufacturer is not responsible for any damages due to misapplication or misuse of this product including,

without limitation, direct, incidental and consequential damages, and disclaims such damages to the full extent

permitted under applicable law. The user is solely responsible to identify critical application risks and install

appropriate mechanisms to protect processes during a possible equipment malfunction.

Please read this entire manual before unpacking, setting up or operating this equipment. Pay

attention to all danger and caution statements. Failure to do so could result in serious injury to the

operator or damage to the equipment.

Make sure that the protection provided by this equipment is not impaired. Do not use or install this

equipment in any manner other than that specified in this manual.

Use of hazard information

D A N GE R

Indicates a potentially or imminently hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a potentially or imminently hazardous situation which, if not avoided, could result in death or serious

injury.

Indicates a potentially hazardous situation that may result in minor or moderate injury.

Indicates a situation which, if not avoided, may cause damage to the instrument. Information that requires special

emphasis.

W A R NI N G

C A U TI O N

N O T IC E

Safety precautions

The 3100 Oxygen Analyzer is powered with a lithium battery pack. To ensure the safe use of this

instrument, read and pay close attention to the safety related information that follows.

When using the analyzer (also includes storage):

4

English

Page 5

W A R NI N G

Burn Hazard, Fire, Explosion.

• The temperature range over which the battery can be used, stored or discharged is -10 to 60°C. Use of the

battery outside of this temperature range may result in:

• Damage to the analyzer's battery, resulting in a potential fire hazard from a battery rupture and electrolyte

leakage, and

• Reduced battery life expectancy

• Immediately discontinue use of the instrument if, while using or charging the battery, the battery emits an

unusual smell, smoke or the enclosure feels unusually hot to the touch. Contact your Hach Lange Service

Center, if any of these problems are observed.

• In the event of a battery electrolyte leakage from the enclosure, avoid contact of the electrolyte with the eyes.

Do not rub the eye. Rinse well with water and immediately seek medical care. If left untreated the battery fluid

could cause damage to the eye.

• Never place the analyzer and its batteries in microwave ovens, high-pressure containers, or on induction

cookware.

Burn Hazard, Fire, Explosion.

• Use of the analyzer should immediately be discontinued if the battery compartment is exposed to flooding due

to leakage, wear or misuse.

• Misuse of the analyzer may cause the internal battery to get hot, explode, or ignite and cause serious injury.

• Do not expose the internal battery to any liquid such as water, beer or salt water, or allow the battery to get

wet.

• Do not disassemble or modify the analyzer or its battery. The internal battery pack contains safety and

protection devices which, if damaged, may cause the battery to generate heat, explode or ignite.

• Do not place the battery/instrument on or near fires, stoves, or other high temperature locations (above 60°C).

Do not place the battery/instrument in direct sunlight, or use or store the battery inside cars in hot weather.

Doing so may cause the battery to generate heat, explode, or ignite. Using the battery in this manner may also

result in a loss of performance and a shortened life expectancy.

W A R NI N G

When charging the battery:

W A R NI N G

Burn Hazard, Fire, Explosion.

Be sure to follow the rules listed below while charging the battery. Failure to do so may cause the battery to

become hot, explode, or ignite and cause serious injury.

• The temperature range over which the battery can be charged is 10 to 45°C. Charging the battery at

temperatures outside of this range may cause the battery to become hot or to rupture. Charging the battery

outside of this temperature range may also harm the performance of the battery or reduce the battery's life

expectancy.

• When charging the batteries use the specified battery charger provided with the instrument.

• When charging batteries, do not place the analyzer in or near fire, or into direct sunlight. The additional heat

can result in increased battery heating that can damage the battery's built-in protection circuitry necessary for

prevention of ignition of the battery. Additionally, increased heat may cause activation of the batteries built-in

protection circuitry, thus preventing the battery from charging further.

• Do not continue charging the battery if it does not recharge within the specified charging time. Doing so may

cause the battery to become hot, explode, or ignite. Contact your Hach Lange Service Center, if any charging

problems are observed.

Hach Lange assumes no liability for problems that occur when the precautions listed above are not

followed.

English

5

Page 6

Precautionary labels

Read all labels and tags attached to the product. Personal injury or damage to the product could

occur if not observed. A symbol on the instrument is referenced in the manual with a precautionary

statement.

This symbol, when noted on a product, indicates a potential hazard which could cause serious

personal injury and/or death. The user should reference this instruction manual for operation and/or

safety information.

This symbol, when noted on a product enclosure or barrier, indicates that a risk of electrical shock

and/or electrocution exists and indicates that only individuals qualified to work with hazardous

voltages should open the enclosure or remove the barrier.

This symbol, when noted on the product, indicates the presence of devices sensitive to electrostatic

discharge and indicates that care must be taken to prevent damage to them.

This symbol, when noted on a product, indicates the instrument is connected to alternate current.

Electrical equipment marked with this symbol may not be disposed of in European domestic or

public disposal systems. Return old or end-of-life equipment to the manufacturer for disposal at no

charge to the user.

Products marked with this symbol indicates that the product contains toxic or hazardous substances

or elements. The number inside the symbol indicates the environmental protection use period in

years.

Overview

The ORBISPHERE 3100 instrument is a self-contained portable analyzer, configured to make

oxygen concentration measurements in gaseous or liquid samples. Up to 5,760 measurement values

can be stored in memory and downloaded to a personal computer for further analysis.

The analyzer is available in 3 different versions (for 4mm, 6mm and 1/4 inch connections).

Installation

Carefully remove the analyzer and its accessories from the box and packing material, referring to the

packing list included to confirm that everything has been delivered. Please visually inspect the

analyzer for shipping damage. If anything is missing or damaged, contact the manufacturer or your

dealer immediately.

A thin protective film has been placed over the screen to protect it from damage during

transportation. For a clear view of the screen, this film must be peeled off before using the analyzer.

N O T IC E

A secondary more robust protective film has been factory installed over the screen to protect it from damage and

moisture ingress. Under no circumstances should this protection be removed. If it becomes damaged in any way,

please contact your local Hach Lange representative.

Installation startup checklist

1. Reconnect the battery pack in order to supply power to the instrument as described in Reconnect

battery power on page 7.

2. Switch the machine ON using the ON/OFF switch (No. 2 in Figure 1 on page 8). If the

batteries need charging, connect the instrument to an external power source as described in

External power on page 8.

3. Next, familiarize yourself with using the instrument by reading the next section in this manual

entitled User interface on page 11.

6

English

Page 7

4. Set the date and time of the instrument's internal clock, as described in Basic settings

on page 15.

5. Install the 3100 PC software on your PC as described in PC software installation on page 10.

6. Set up the user configuration table using the PC software as described in Create new user table

on page 10.

7. Set up the measurement configuration table using the PC software as described in Create new

measurement configuration table on page 10.

8. Upload the user and measurement configuration tables to the instrument as described in Transfer

files to the instrument on page 10.

Reconnect battery power

For safety reasons, the battery pack will not be connected during shipment. Once the instrument has

been unpacked, the battery power should be reconnected using the following procedure:

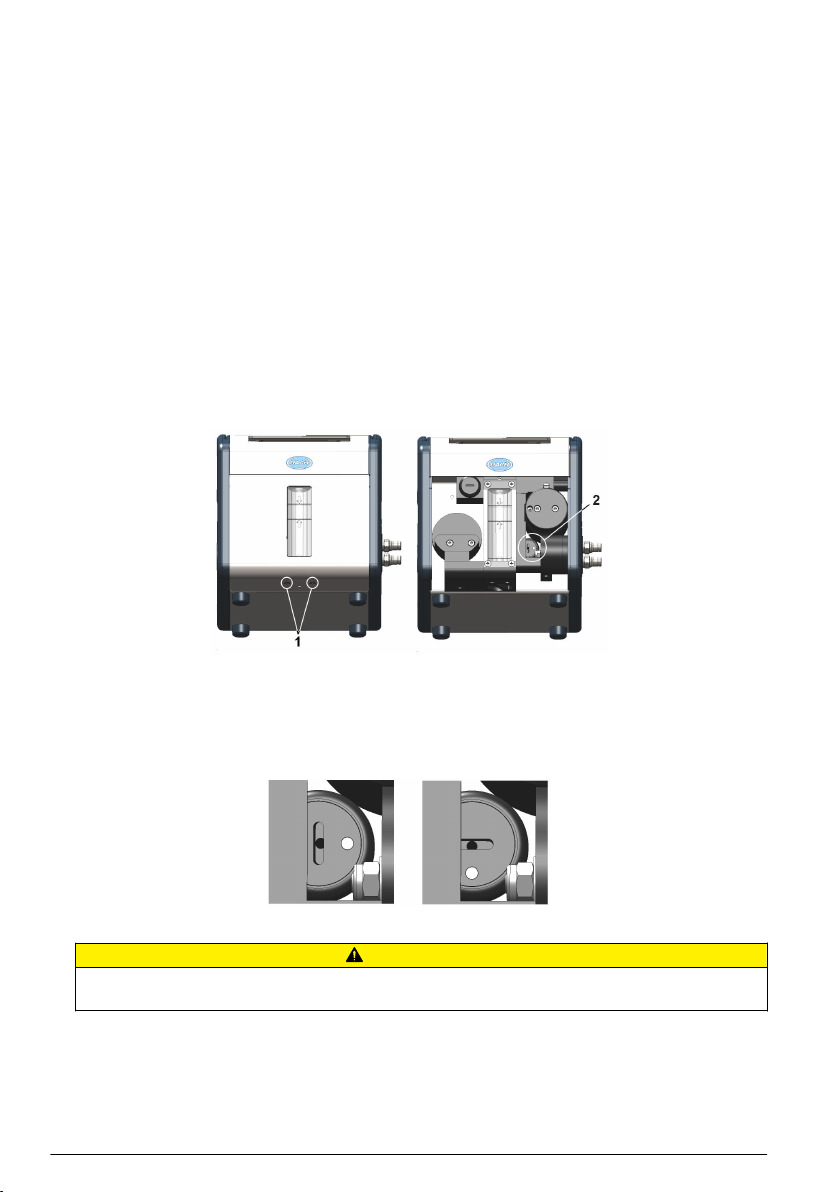

1. Tilt the instrument towards the rear, to reveal two screws underneath (No. 1) that hold the

instrument front panel in place.

2. Using the cross screwdriver supplied in the tool kit, unscrew and remove these screws. Lift off the

front panel to reveal the internal battery power switch (No. 2).

3. Using the long-bladed flat-head screwdriver supplied in the tool kit, turn the switch a quarter of a

turn clockwise to reconnect the battery power. The diagrams below show the switch in the OFF

position as delivered (left) and in the ON position (right).

4. Replace the front panel and secure back in place with the two screws.

C A U TI O N

To avoid any damage to the instrument, it will be necessary to perform the above procedure in reverse (i.e.

turn the connection OFF) prior to any future transportation of this instrument.

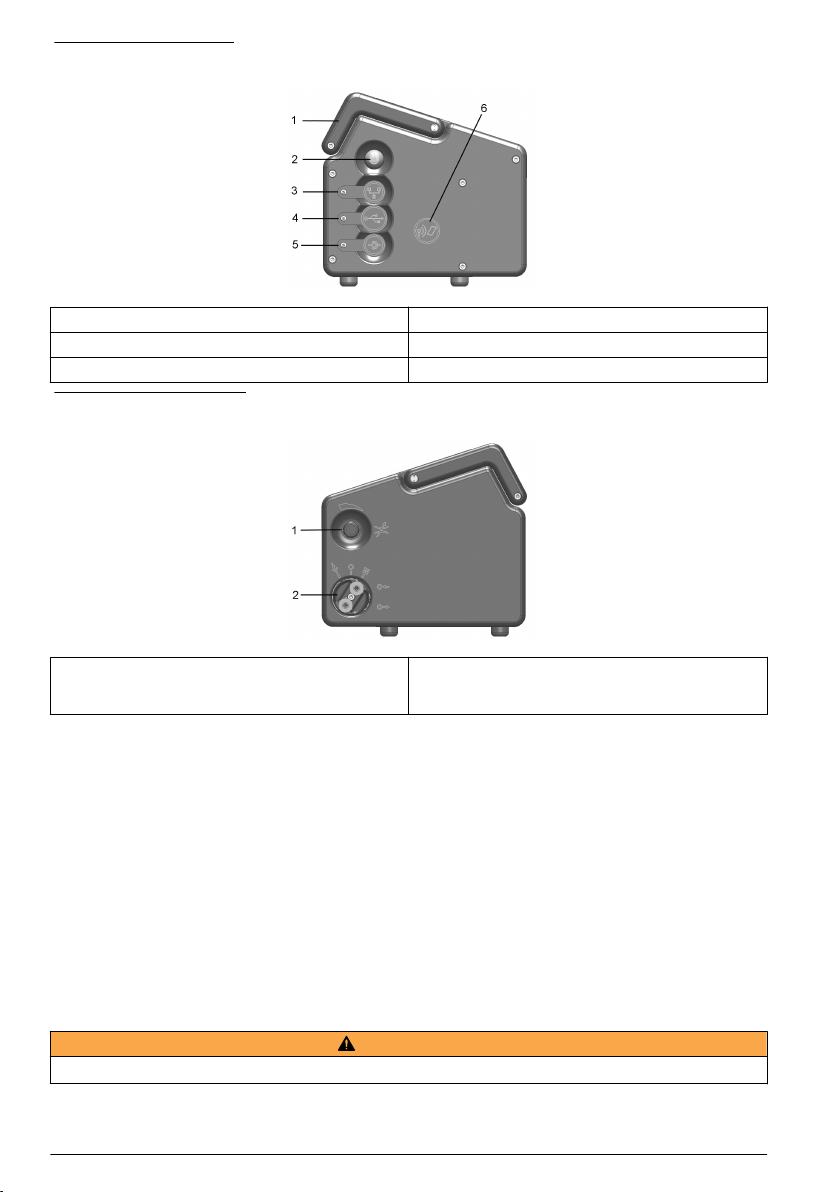

Instrument switches and connectors

The following diagrams illustrate the side views of the instrument and their key features:

English

7

Page 8

Figure 1 Left side view

1 Handle 4 USB connection

2 Instrument ON/OFF switch 5 External power supply connection

3 RS232 connection 6 Card identification system (option not yet available)

Figure 2 Right side view

1 Sample flow adjustment valve 2 Sample flow valve with inlet and outlet connections

(the sample inlet is at the top of the valve and the

outlet at the bottom).

Sample flow valve

The sample flow valve has three positions:

• Sample line PURGE

• Sample flow ON

• Sample flow OFF

The PURGE position is used to clear the sample line of any build up of air bubbles. For a thorough

purge, it is recommended to keep the valve in this position for 5 seconds. During this operation, the

sample flows directly from the inlet tubing to the outlet tubing. All measurements are suspended

during this time as the sample does not come into contact with the sensor.

The ON and OFF positions turn the sample flow on and off respectively.

Instrument connections

External power

W A R NI N G

When using an external power supply to power the instrument, ensure the external power socket is earthed.

In addition to the internal rechargeable battery pack, the instrument can be powered by an external

power source using the supplied adapter and cable. Connect the adapter to the power supply

8

English

Page 9

connection socket on the instrument (No. 5 in Figure 1 on page 8), and plug into an external power

supply socket.

Note: When the instrument is connected to an external power source, the internal battery pack is automatically

recharged.

RS232 connection

This connection can be used to download measurement data and for real-time monitoring of the

measurements.

The data sent to the PC via this link is identical in format and content to that stored in the

measurement file on the instrument and which can be transferred using the USB mass storage

device (see Exported files on page 19 for details).

USB connection

The USB connection (No. 4 in Figure 1 on page 8) is used for exporting and importing data from and

to the instrument. Tables can be set up on the PC using the 3100 PC software application and then

uploaded to the instrument using a USB mass storage device.

In addition, tables can be exported from the instrument to the USB storage device and then imported

to other 3100 instruments to standardize configurations.

For more details on this, refer to Import / Export on page 18.

Connecting sample lines

Measurements can be taken on a continuous or sample by sample basis. In either mode, the

instrument must be connected to the sample line as follows:

1. The sample inlet and outlet connections on the instrument are located on the ON/OFF sample

flow valve (No. 8 in Figure 2 on page 8 and enlarged in the diagram below):

1 Sample inlet 2 Sample outlet

2. Connect the inlet and outlet tubing to the sample source and to the drain, respectively. The

diagram above, shows the valve in the OFF position. To turn the sample flow fully ON, turn the

valve counter-clockwise until it clicks into position (about 1/8th of a turn). To remove any residual

air bubbles from the sample line, turn the valve to the PURGE position for 5 seconds before

turning to the ON position.

Note: A length of stainless steel tubing is supplied in the tool kit (4mm instrument version only) and can be

used instead of the plastic tubing on the outlet valve if the pressure in the instrument is high enough to cause

excessive movement of the plastic tubing.

3. If the sample contains particles, it is recommended to use a filter on the inlet tube to avoid any

clogging of the sample flow. The filter (including a box of 10 meshes) is contained in the tool kit

supplied with the instrument. It is also available separately as spare part number DG33216 (4mm

instrument), DG33317 (6mm instrument) or DG33318 (1/4 inch instrument) and the set of

10 meshes as spare part number DG33217.

4. Control the sample flow using the adjustment valve (No. 7 in Figure 2 on page 8) located above

the sample flow valve.

Flow rate guidelines:

• For cans and bottles the minimum recommended flow rate is 150mL/min. For small volume

packages a lower flow rate can be used but this should not be below 100mL/min.

English

9

Page 10

• For tank and in-line applications the recommended flow rate should be above 200mL/min and

up to a maximum of having the flow adjustment valve fully open.

Note: The flow rates indicated with arrows on the flow meter (as illustrated below) are approximately

150mL/min (lower arrow) and 200mL/min (upper arrow). The silver bead gives an indication of the flow rate.

PC software installation

The instrument is delivered with default user and measurement configuration tables. However, to

personalize the instrument by setting up your own tables you will need to use the PC software which

is included on the USB key supplied with the tool kit.

Install the PC software by inserting the USB key into your PC and running the setup program

(entitled setup.exe) from the directory Orbisphere 3100\Installation Files\PC Software on the USB

drive. Follow the on-screen instructions and the software will be installed on your hard disk in a new

directory: C:\Program Files\Hach Lange\3100 PC Software\.

Once the software has been installed, click on the desktop icon on the PC to launch the application.

Create new user table

From the application’s File menu, select New and then User Table.

A default user is created automatically, with an ID of “0”, a User Name of “Default”, and a level of

“User”. None of these fields can be changed. The password is set automatically to “1234”, but this

can be changed.

Use the Add option to add new users, and Delete to remove existing users. Copy and Paste can

also be used to add new users, and Cut can be used to delete existing users. Double click on a field

to edit the contents.

Create new measurement configuration table

From the application’s File menu, select New and then O2 Instrument to create a new

measurement configuration table.

A default entry is created automatically, with an ID of “0”, a Location Name and Product Name of

“Default”. None of these fields can be changed.

Use the same functionality as described for the user table, to add entries to the table.

Transfer files to the instrument

When the two tables have been populated, they can be transferred to the instrument using a USB

storage device (typically a USB key).

1. From the PC copy the files to the USB storage device in a top-level directory of 3100. The files

will typically be located in: C:\Program Files\Hach Lange\3100 PC Software\ with file

extensions of .cdm (for measurement configurations) and .ndu (for user tables).

Note: It is important that the file name extensions (.cdm and .ndu) are not changed as they will not be

recognized by the instrument software. Similarly, the files must be located in a top-level directory of 3100.

2. With the instrument switched ON, insert the USB storage device into the USB connection on the

left side of the instrument, and press the USB icon on the instrument front panel.

3. The first screen is for exporting files from the instrument to a USB storage device, so press the

right arrow to move to the next screen.

10

English

Page 11

4. The next screen is the Import User Table screen. The user table will be recognized by the

instrument and the file name displayed in the highlighted box. If more than one user table is on

the USB storage device, press the Enter key to view a list of all the user tables, and use the

up/down arrows to scroll through the list. Press the Enter key to select. When a table has been

selected, press the down arrow key until the Import File text is highlighted and press the Enter

key to import the file. On completion, a message will appear saying the instrument will have to be

turned off and on again for the new table to take effect, but as the measurement configuration

table is still to be imported this message can be ignored at this stage.

5. Press the right arrow to move to the Import Measurement Configurations screen. As with the

user table, select the measurement configuration table to import and press the down arrow key

until the Import File text is highlighted. Press the Enter key to import the file. Again, on

completion, a message will appear saying the instrument will have to be turned off and on again

for the new table to take effect.

6. As both tables have now been transferred to the instrument, turn the instrument OFF and then

back ON again for the new tables to take effect. When switched ON the two default table entries

will be loaded (i.e. default user and default measurement configuration).

User interface

Keypad and function keys

1 Cancel key 5 Enter key

2 USB key 6 RFID key

3 Sample or continuous mode key 7 Measurement key

4 Arrow keys

The user interface of the instrument consists of a display screen, 6 function keys and a set of 4 arrow

keys in the center. A green light at the bottom left of the keypad indicates if the instrument is ON. No

light indicates the instrument is OFF. The keypad is touch sensitive and will respond to each key

being pressed. As the key is touched a blue light will be appear underneath to indicate selection of

that key. If a key is selected that is not available or has no meaning during the current operation, then

the key will be displayed above the measurement value with a line drawn through it.

Note: The keypad can be locked and unlocked pressing the keys RFID, USB and RFID in sequence.

The keys have the following functions:

• Cancel data input.

• Exit from a menu and display the measurement screen.

• Display the main menu.

• Select an option.

• Validate the input and go on to the next step.

English 11

Page 12

• Import data from a USB mass storage device.

• Export data to a USB mass storage device.

• Card identification system (not yet available).

• When pressed twice in quick succession a screenshot will be taken (maximum of 10) that can be

transferred to a USB key using the Import / Export option from the Main Menu.

• Define if measurements are in sample or continuous mode. Continuous mode displays the bottle

symbol with a cross through it in the top right of the measurement screen. Sample mode displays

the bottle symbol without the cross.

• When in sample mode use this icon to Start/Stop measurements. When started the bottle symbol is

shown in green. When stopped the symbol is greyed out and a “Measurement stopped” message

displayed.

• Up arrow - Scroll up through a list or menu.

• Down arrow - Scroll down through a list or menu.

• Left arrow - Go back to the previous screen (or data element) in sequence.

• Right arrow - Go to the next screen (or data element) in a sequence.

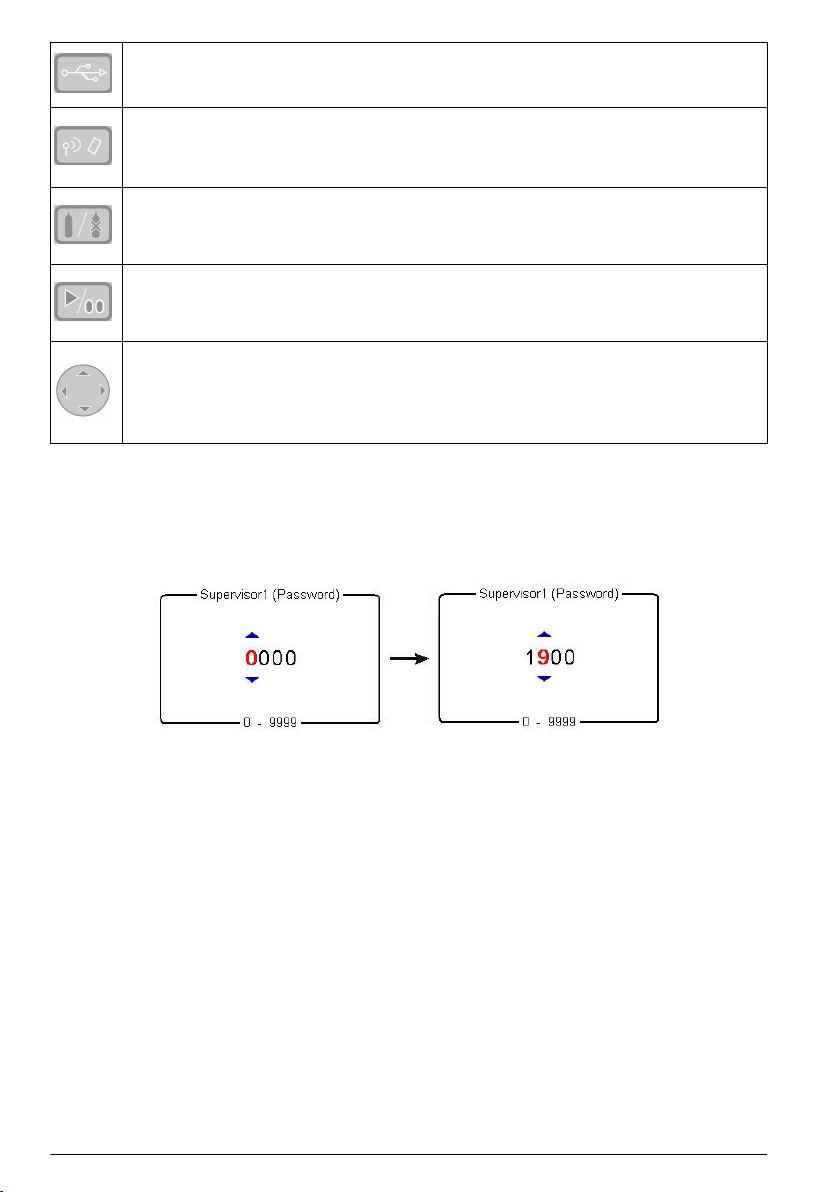

Data entry

To select a data item from a list, use the up and down arrow keys to highlight the required value,

followed by the Enter key to select it.

When required to enter data (e.g. a password in the following example), a screen will be displayed

showing the field default value (0000) and the valid range (0 - 9999) below it.

The first character will be highlighted in red with arrows above and below. Press the up and down

arrow keys to increase or decrease the value. When the correct value is showing, press the right

arrow key to move to the next character and enter that value until all characters have been entered.

User access

Two access levels are available:

• User - basic measurement functions

• Supervisor - password protected with access to additional views and the Main Menu

From the measurement screen, press the right arrow key until the list of users stored in the

instrument is displayed. Standard users will be displayed in green and supervisors in blue.

Note: These user lists are defined by the user on the PC (see Create new user table on page 10) and imported into

the instrument (see Transfer files to the instrument on page 10).

Press the up and down arrow keys to scroll through the list of users. When the required one is

highlighted press the Enter key to select it. If a supervisor level user is selected a password will be

required (by default Supervisor1 is 5678). On completion, the display returns to the measurement

screen.

12

English

Page 13

Standard measurement display

1 Instrument date and time 7 Battery life remaining

2 Measurement location and product name 8 USB symbol indicates USB key attached

3 User name 9 Measurement mode (continuous shown)

4 Sample temperature 10 High level alarm value (if set)

5 Measured gas 11 Low level alarm value (if set)

6 Measurement unit 12 Measurement value

• The user name will be displayed in green for a standard user, or blue for a supervisor

• The battery life remaining will not be displayed if using mains power supply, instead the icon will

show the battery recharging symbol

• The measurement value is normally displayed in blue, but will be displayed in red if it is outside the

high or low value alarm limits

• If measurement is in sample mode, the bottle icon is displayed at the top right of the screen. If

measurement mode is set to continuous, the bottle icon will be displayed with a cross through it

• The measurement display is refreshed every 5 seconds

Graphical measurement display

To access this display from the standard measurement display screen, press the right arrow key on

the keypad until the graphic screen is displayed:

This screen gives a graphical representation of the measurement with the numeric value of the

measurement displayed at the end of the curve. The above example shows the measurement in

sample mode.

The numeric measurement value at the end of the curve is refreshed every 5 seconds. The curve is

refreshed every 5 seconds in sample mode. In continuous mode, the refreshment rate is the same as

that defined as the storage interval parameter.

The graphic timescale is displayed at the bottom of the screen. This value can be increased or

decreased (4 zoom levels) by pressing the up and down arrows on the keyboard. These values are

also dependant on the storage interval parameter; the greater the storage interval, the greater the

available timescale.

The measurement scale is calculated automatically with the maximum and minimum values

displayed at the top and bottom of the y axis respectively.

In sample mode, a square symbol is displayed to denote the end of the measurement . This is

displayed in green if the stop criteria are met, or red to denote an erroneous measurement.

English

13

Page 14

The color of the curve has the following meaning:

• Grey (normal): The channel is out or the measurement is out of range

• Green (bold): The channel is being calibrated

• Grey (bold): The measurement has not started (sample mode only)

• Red (bold): An alarm has been activated

• Blue (bold): Normal measurement

Measurement configuration list

From the measurement screen, press the right arrow key until the list of measurement configurations

stored in the instrument is displayed.

Note: These configurations are defined by the user on the PC (see Create new measurement configuration table

on page 10) and imported into the instrument (see Transfer files to the instrument on page 10). Only the default

configuration (ID0) can be edited by the user from the instrument. To do this the user must be logged on at

supervisor level and the default parameters can then be edited from the Main Menu as described in Default

measurement configuration settings on page 17.

Press the up and down arrow keys to scroll through the list of measurement configurations. When the

required one is highlighted press the Enter key to select it. The selected configuration details will be

displayed on screen.

Press the Enter key again to select this configuration and return to the measurement screen, or

Cancel to reject it and return to the measurement configuration list screen.

Measurement alarms

If a problem occurs during measurement, the system will alternate every second between the

measurement screen and the error message screen.

The measurement value is displayed in red to indicate a measurement outside the pre-defined alarm

limits. The alarm low value on the right side of that screen is also displayed in red to indicate the

reason the measurement value is in error.

The error message screen gives the reason why the measurement is invalid.

Note: If the measured value goes back above this low value, the value is again displayed in blue and the error

message screen is no longer shown.

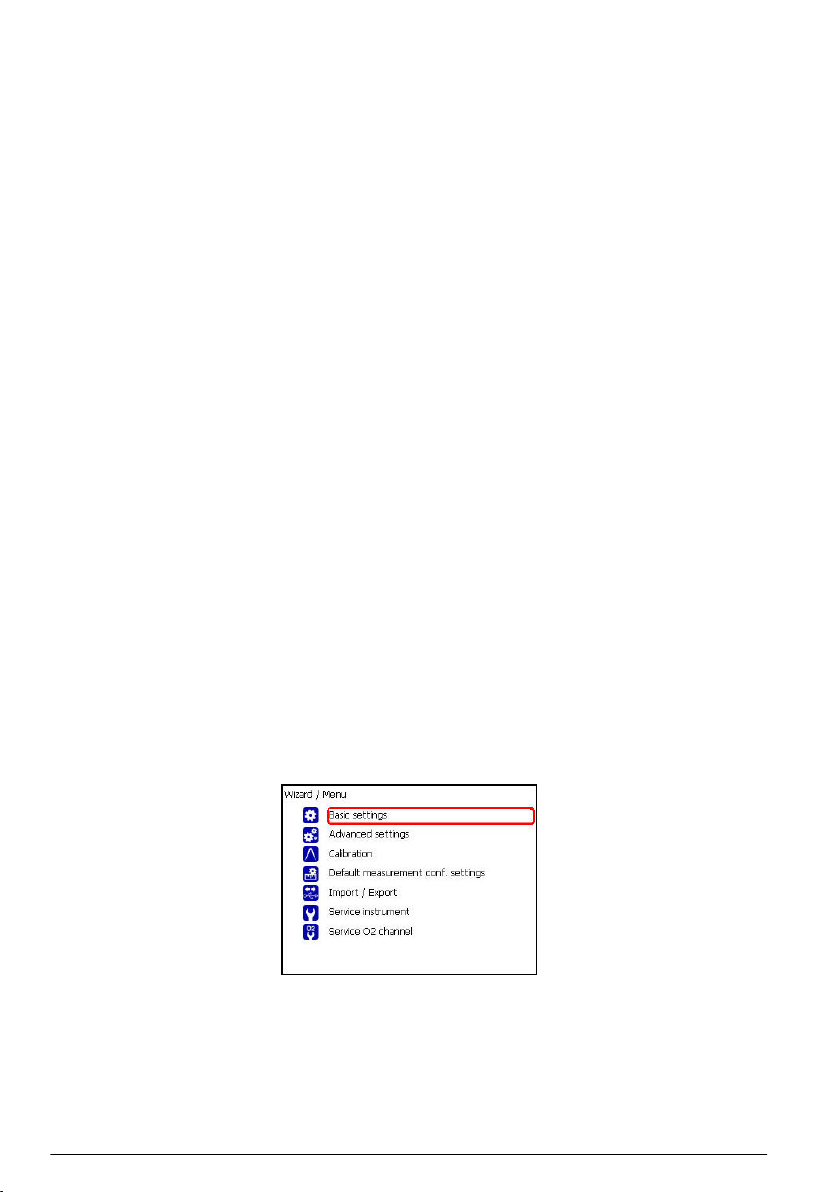

Main menu

The main menu is only available to users logged on at supervisor level.

To access the main menu from the measurement screen, press the Enter key on the main keypad to

display the following options:

Scroll through the menu using the up and down arrow keys. When the required option is highlighted,

press the Enter key to select it and display the sub option screens.

14

English

Page 15

Basic settings

1. Language selection

Option Description

Language Select the working language for the instrument from the list available

2. Date and time adjustment

Option Description

Date format Define the display format for the date (DD/MM/YY or MM/DD/YY)

Date Enter the day, the month and the year in the format defined above

Time format Enter the display format for the time using a 12 or 24 hour clock

Time Enter the hour and minutes in the format defined above

3. Backlight management

Option Description

Backlight level Enter the scale of brightness (max, comfortable, standard, economy or min)

4. Units management

Option Description

Pressure unit Choose the barometric pressure unit from the list available

Temperature unit Choose the temperature unit from the list available

Advanced settings

1. File measurement management

Option Description

Storage

mode

Choose from a rolling buffer or store once:

• Rolling buffer: When the file is full, the latest measurement set replaces the oldest one

continuously (first-in, first-out)

• Store once: When the file is full (5,760 positions), the recording of measurement stops

Storage

interval

Clear data Select this option to erase the measurement storage file

Define the interval for storing measurements from the list available.

The interval is in seconds with the number of hours of measurements available shown in

brackets e.g. 10s (16h) indicates measurements are stored every 10 seconds, which will

give 16 hours of continuous storage

Note: This parameter also defines the refreshment rate for the graphic measurement

display.

2. Communication

Option Description

RS232 Check the box if the RS232 link is required

Baud rate Select the baud rate from the list available

3. Miscellaneous

Option Description

Miscellaneous This option allows the default measurement configuration parameters to be restored

English 15

Page 16

Calibration

Barometric sensor calibration

1. The upper box shows the current barometric pressure as measured by the instrument. Using a

precision certified barometer, measure the barometric pressure in the location where the

instrument is used. If the values differ, enter the correct value in the box provided and select

Validate calibration

Gas sensor calibration

There are two calibration modes available

• Zero calibration

• High level adjustment

The zero calibration method is the best method to guarantee the sensor specifications.

To get more accurate measurements for samples with higher oxygen concentrations (above 1%

oxygen which corresponds to about 400 ppb dissolved O2) a high level adjustment can be performed

using a gas mixture containing 2% oxygen. However, this should not be done without first ensuring

the zero point is accurate (i.e. by performing a zero calibration first).

Zero calibration

1. Rinse flow path with 20 mL of ethanol (EtOH) using the syringe and connectors supplied in the

tool kit

2. Connect a cylinder of oxygen free gas (minimum 99.9% purity) to the instrument and adjust the

flow to approximately 100 mL/min

3. Let the oxygen free gas run through the instrument for 5 minutes

4. Press the Enter key to start the calibration

5. Wait until the Signal in range and Stability reached fields display Yes which indicates the

calibration is within acceptable limits. The Calibration possible field should also display Yes at

this point. Press the Enter key to complete the calibration

6. Accept (OK) or reject (Cancel) the new calibration data

High level adjustment

There are three possible modes for high level adjustments:

• Using a reference gas mixture (gas cylinder)

• Using a known oxygen sample (reference sample)

• Enter a factory parameter provided by Hach Lange (this option is only required when the sensor

spot has been replaced)

If the calibration mode displayed is not the required mode, then press the Enter key and select the

required mode from the three options available in the drop-down list:

• Factory parameter

• Reference sample

• Ref. gas bottle

Factory parameter

1. In the Calibration mode window select Factory parameter

2. Scroll down to the Reference value window and enter the factory parameter as found on the

package of the LDO spot (model number DG33218)

3. Scroll down to the Start Calibration window and press the Enter key to start the calibration

4. Accept (OK) or reject (Cancel) the new calibration data

16

English

Page 17

Reference sample

1. Run the reference sample through the instrument and adjust the flow to approximately

150 mL/min.

2. In the Calibration mode window select Reference sample

3. Scroll down to the Reference value window and enter the oxygen value of the sample

4. Let the sample run through the instrument for 5 minutes to stabilize the measurement

5. Scroll down to the Start Calibration window and press the Enter key to start the calibration

6. Wait until the Signal in range and Stability reached fields display Yes which indicates the

calibration is within acceptable limits. The Calibration possible field should also display Yes at

this point. Press the Enter key to complete the calibration

7. Accept (OK) or reject (Cancel) the new calibration data

Ref. gas bottle

1. Rinse flow path with 20 mL of ethanol (EtOH) using the syringe and connectors supplied in the

tool kit

2. In the Calibration mode window select Ref. gas bottle

3. Scroll down to the Reference value window and enter the oxygen value of the reference gas in

%Vbar

4. Connect the gas sample to the instrument and adjust the flow to approximately 100 mL/min.

5. Let the gas mixture run through the instrument for 5 minutes to stabilize the measurement

6. Scroll down to the Start Calibration window and press the Enter key to start the calibration

7. Wait until the Signal in range and Stability reached fields display Yes which indicates the

calibration is within acceptable limits. The Calibration possible field should also display Yes at

this point. Press the Enter key to complete the calibration

8. Accept (OK) or reject (Cancel) the new calibration data

Default measurement configuration settings

1. Instrument settings

Option Description

Instrument mode Select between continuous or sample mode.

Continuous mode is typically used for process measurement, whereas sample mode is

aimed at lab measurements of small volume individual samples such as cans, bottles,

etc.

Sample type Select the sample type from the list available

2. O2 channel settings

Option Description

O2 gas unit type Select the gas unit type from the list available

O2 gas unit Select the display unit from the list available

English 17

Page 18

Option Description

O2 high alarm Check the box to set the measurement high alarm.

If set, enter the high level value to trigger the alarm. When measurements exceed this

value an alarm will be triggered

O2 low alarm Check the box to set the measurement low alarm.

If set, enter the low level value to trigger the alarm. When measurements fall below this

value an alarm will be triggered

3. O2 advanced settings

Option Description

O2 measurement offset If required, enter a value (positive or negative) for the measurement offset. This

value will be used to adjust the measurement accordingly

Import / Export

Note: To import files into the instrument from a USB mass storage device, they must be under a top-level directory

of 3100 for them to be recognized.

1. Export files

Option Description

Export

files

2. Import user table

Option Description

Import

user table

3. Import measurement configuration table

Option Description

Import

measurement

configuration

table

This option allows you to export a number of different files to a USB mass storage device. Once

written to the USB device, it can then be used to load these files to other 3100 instruments or to

a PC.

Make sure a USB device is connected and then press the Enter key to start the process. A

progress bar is displayed at the bottom of the screen.

Wait until the export complete message is displayed on screen before removing the USB

device.

This option allows you to import user tables from a USB mass storage device. These tables

could be exported from other 3100 instruments or from the 3100 software application installed

on your PC. The tables are recognized by having an extension of .ndu. If more than one table is

found on the device, you will need to select the table you want from the list.

Press the down arrow key to highlight the Import File option and press the Enter key to start

the process. You will need to restart the instrument before the new table takes effect.

This option allows you to import measurement configuration tables from a USB mass

storage device. These tables could be exported from other 3100 instruments or from the

3100 software application installed on your PC. The tables are recognized by having an

extension of .cdm. If more than one table is found on the device, you will need to select

the table you want from the list.

Press the down arrow key to highlight the Import File option and press the Enter key to

start the process. You will need to restart the instrument before the new table takes

effect.

18 English

Page 19

4. Import solubility parameters

Option Description

Import

solubility

parameters

This option allows you to import solubility parameters from a USB mass storage device.

The tables are recognized by having an extension of .sol. If more than one file is found on

the device, you will need to select the file you want from the list.

Press the down arrow key to highlight the Import File option and press the Enter key to

start the process. You will need to restart the instrument before the new table takes effect.

5. Import instrument basic settings

Option Description

Import

instrument

basic settings

This option allows you to import instrument user settings from a USB mass storage

device. The tables are recognized by having an extension of .ius. If more than one file is

found on the device, you will need to select the file you want from the list.

Press the down arrow key to highlight the Import File option and press the Enter key to

start the process. You will need to restart the instrument before the new table takes effect.

Exported files

The following files will be automatically exported from the instrument to the USB mass storage device

under a top-level directory of 3100:

• All measurement configuration tables (*.cdm)

• All user tables (*.ndu)

• All solubility tables (*.sol)

• All user settings tables (*.ius)

• Instrument configuration details (InstrumentConf.txt)

• Measurement details (Measurements.txt)

• Instrument model details (Model.txt)

• A number of internal files (*.dat)

The following files can be found under sub-directories CalibrationReports and Screenshots:

• Calibration reports (O2CalibrationReport*.txt)

• Screenshots (View*.bmp)

The text files (*.txt extension) are in a readable format for your PC. Most document editors can be

used to open these files, as well as spreadsheet and other reporting tools.

The measurement configuration tables and user tables can be modified using the PC software (see

PC software installation on page 10).

Service instrument

1. Board information

Option Description

Board information This option is useful for troubleshooting purposes and displays information about the

mother board, measurement board and battery

2. Temperature checking

Option Description

Temperature checking This option is useful for troubleshooting purposes and displays the temperature

readings of the measurement board, pigtail, battery pack and sample

English 19

Page 20

3. Sample temperature calibration

Option Description

Sample temperature

calibration

You will need a sensor simulator for this option. Follow the on-screen

instructions to calibrate the sample temperature

4. Miscellaneous

Option Description

Enable raw

data logger

Activate

service timer

Note: The total uptime of the instrument is displayed at the bottom of the screen.

Check the box to enable the capture of raw data which is useful for troubleshooting

purposes

Check the box to activate the service timer option.

When activated, the instrument will automatically remind the user when the next sensor

service is due.

Enter the Nb of days between services in the box provided. This defines the due date of

the next sensor service.

If activated, select the Reset service timer option each time the instrument has been

serviced. This automatically sets the Last service date parameter to the current date.

Service O2 channel

1. O2: Calibration parameters

Option Description

O2: Calibration

parameters

2. O2: DC measurement parameters

Option Description

O2: DC measurement

parameters

3. O2: AC diagnostic parameters

Option Description

O2: AC diagnostic

parameters

4. O2: Calibration timer

Option Description

Activate

calibration

timer

Check the box to activate the calibration timer option.

When activated, the instrument will automatically remind the user when the next sensor

calibration is due.

The Last calibration date parameter is shown for information. This is automatically

updated each time a calibration is performed on the sensor.

Enter the Nb of days between calibrations in the box provided. This defines the due

date of the next sensor calibration.

This option is useful for troubleshooting purposes and will display a number of

values associated with the measurement channel

This option is useful for troubleshooting purposes and will display the

values of the fluorescent and reference LED current

This option is useful for troubleshooting purposes and will display the values of

the fluorescent and reference amplitude and phase, plus the phase shift value

20 English

Page 21

Maintenance

Maintenance schedule

This following table shows the recommended maintenance schedule for the ORBISPHERE

3100 instrument. This proposed schedule should be modified according to operating conditions.

Interval Item

Daily Clean outside of the instrument with a damp cloth and run clean water through the

Weekly Clean outside of the instrument with a damp cloth and run 20 mL of ethanol (EtOH)

Monthly Run warm water through the instrument followed by 20 mL of ethanol (EtOH).

Yearly Calibrate the oxygen sensor

Every 4 years Replace the oxygen sensor spot and perform a sensor calibration

Batteries

The instrument is designed to operate on rechargeable batteries. When battery power becomes low,

the batteries can be recharged by connecting the instrument to the mains power supply using the

supplied power adapter and cable. When connected, the batteries are automatically recharged.

Sensor

If the instrument is being powered by mains power, disconnect the instrument from the power supply before

carrying out this procedure.

Based on instrument usage of 8 hours/day and 365 days/year, the sensor spot will need to be

replaced about once every 4 years. The procedure is very simple and takes no more than a few

minutes.

Before starting, ensure you have the replacement flow chamber assembly as supplied with the

maintenance kit (part number DG33228). Switch the instrument OFF and make sure it is

disconnected from any mains power supply.

Follow these instructions referring to the illustrations below:

instrument to clean the internal passageways

through the instrument to clean the internal passageways

Dry by flowing dry air or N2 through the instrument

W A R NI N G

1. Remove the front panel from the instrument by unscrewing the 2 screws underneath the

instrument (No. 1) that secure it in place. Use the cross screwdriver supplied in the tool kit for this

purpose.

2. Once removed, the flow chamber assembly (No. 2) can be seen located to the right of the flow

meter.

English

21

Page 22

3. Remove the holding screw from the flow chamber assembly.

4. Holding the assembly between thumb and forefinger, gently ease it out of the instrument and

discard.

5. Replace the assembly with the new one from the maintenance kit, Put the new assembly back in

place in the instrument and secure with the holding screw. A guide rod is in place to ensure

correct positioning.

6. Replace the front guard and secure in place with the 2 screws underneath the instrument.

7. After changing the spot, a sensor calibration must be performed before using the instrument for

measurement purposes.

Troubleshooting

Measurement

Symptom Possible solution

Display appears to be frozen - no

active cursor

Display appears to be frozen out

of range

Degassing in flow meter Adjust flow rate to between 150 and 200 mL/min

Measurement spiking Ensure all tubing is tightly and correctly connected to the sample inlet and

Response time too long Use tubes supplied with instrument (low O2 permeable material)

Channel out Change LDO spot

Silver bead does not move freely

in the sample

Check measurement mode (continuous or sample)

When “Out of Range”, measurement interval is 60 seconds

Verify that the filter (if using) is not blocked

outlet connections

Remove any residual air bubbles from the sample line by turning the sample

inlet/outlet valve to the PURGE position for 5 seconds

Check flow rate and connections

Prior to package sampling, purge the piercer with N2 gas

Perform the monthly cleaning procedure

Contact Hach Lange service

Perform the monthly cleaning procedure

Zero calibration

Symptom Possible solution

Signal not in range - calibration

value very different from last

calibration value

Stability not reached - signal not

stable

22 English

Open sample flow adjustment valve completely

Calibration gas has too much oxygen, use quality 50 N2 or CO2 bottle

Oxygen leaks between reference bottle and instrument. Can be checked by

increasing gas flow rate and checking partial pressure (mbar) decrease

Wait for stability and check N2 gas flow rate

Presence of liquid on LDO membrane. Check presence of liquid in flow

meter and if so, dry by injecting 20 mL of EtOH then 5 minutes of N2 gas

Page 23

High level calibration

Symptom Possible solution

Signal not in range - calibration

value very different from last

calibration value

Stability not reached - signal not

stable

Check your theoretical sample O2 content and reference configuration

If gas bottle calibration, completely open the sample flow adjustment valve

to avoid gas overpressure, hence wrong O2 concentration

Wait for stability and check reference gas or liquid flow rate

Presence of liquid on LDO membrane. Check presence of liquid in flow

meter and if so, dry by injecting 20 mL of ethanol (EtOH) then 5 minutes of

N2 gas

Instrument storage when not used

General guidelines

When not in use, ensure the instrument is turned OFF by pressing the ON/OFF switch (No. 2 in

Figure 1 on page 8) until the green indicator light is extinguished.

C A U TI O N

If the instrument is to be stored in an environment where the temperature is likely to be 0°C (32°F) or below, then

to avoid any damage to the instrument make sure there is no liquid inside. Do this by first running warm water

through the instrument and dry by flowing dry air or N2 through it. Then turn the sample flow valve (No. 8 in

Figure 2 on page 8) to the OFF position.

Short term storage

For short term storage (between measurements or up to a maximum of 6 hours), leave the sample in

the instrument by turning the sample flow valve (No. 8 in Figure 2 on page 8) to the OFF position.

Overnight or weekend storage

When storing the instrument overnight or over a weekend, run clean water through the instrument to

prevent passageways from becoming clogged and then turn the sample flow valve (No. 8 in Figure 2

on page 8) to the OFF position. Wipe down the outside of the instrument with a clean damp cloth.

Long term storage

For long term storage (more than 1 week), run warm water through the instrument followed by 20 mL

of ethanol (EtOH). Dry by flowing dry air or N2 through the instrument, and then turn the sample flow

valve (No. 8 in Figure 2 on page 8) to the OFF position. Wipe down the outside of the instrument with

a clean damp cloth. It is recommended to fully charge the battery prior to any long term storage.

Note: If the instrument has been in storage for more than 4 weeks, remember to fully recharge the battery pack

before use.

English

23

Page 24

Spezifikationen

Die Spezifikationen können ohne Vorankündigung Änderungen unterliegen

Spezifikation Details

Probe nicht entzündbare gasförmige oder flüssige Proben

Probentemperatur -5 bis + 45°C

Probendruck 0 bis 10 bar (0 bis 140 psi)

Arbeitsbereich 0 bis 2000 ppb

Genauigkeit ± 0,8 ppb oder ± 2% der Anzeige, je nachdem, welcher Wert größer ist

Wiederholbarkeit r95 ± 0,4 ppb oder ± 1% der Anzeige, je nachdem, welcher Wert größer ist

Erfassungsgrenzen 0,6 ppb

Reaktionszeit t90 Im Allgemeinen weniger als 15 Sekunden, die tatsächliche Zeit hängt aber von dem

Messungen bis zu 5.760 Messungen 8 Stunden Daten bei einer Probenfrequenz von

Anzeigeeinheiten O2 Konzentration ppb, ppm, μg/L, mg/L, mL/L, %O2, %air, %Vbar, ppmVbar

Betriebsbedingungen Umgebungstemperatur -5 bis + 45°C

Gewicht 3,4 kg

Abmessungen (L x B xH)200 x 170 x 190 mm

Probenverfahren ab.

5 Sekunden

96 Stunden Daten bei einer Probenfrequenz von 1 Minute

Druck mbar, bar, Pa, hPa, kPa, MPa, psia, psig, atm, kgf/cm2

Temperatur °C, °F, K

Relative Feuchtigkeit 0 bis 95% nicht kondensierend für Temperaturen unter

30°C

0 bis 70% nicht kondensierend für Temperaturen von

30 bis 45°C

Wasserdichtigkeit IP66-Gehäuse aus Edelstahl mit Seitenteilen aus Polykarbonat

Stromversorgung Aufladbarer Akkupack: Li-Ion 46 Wh

Externer Netzeingang: 100 - 240 V AC ±10%, 47 - 63 Hz

Externer Netzausgang: 12 VDC, 3,75 A

Hinweis: Die externe Stromversorgung verfügt nicht über die Schutzart IP66.

Batterieautonomie > 10 Stunden bei kontinuierlichen Messungen

Batterieladezeit < 4 Stunden

Hinweis: Die Ladezeit verlängert sich um 20% bei Temperaturen über 35°C.

EMV-Anforderungen EN61326-1: EMV-Richtlinie

User Guidance for EMC Class B Equipment

가정용을 포함하는 EMC 등급 B 장치에

Korean registration

대한 사용자 지침

사용자안내문

B 급 기기 ( 가정용 방송통신기자재 )

이 기기는 가정용 (B 급 ) 전자파적합기기로서 주로 가정에서 사용하는 것을 목적으로

하며 , 모든 지역에서 사용 할 수 있습니다.

24 Deutsch

Page 25

Spezifikation Details

CE-Konformität EN61010-1: Niederspannungsrichtlinie

Sicherheitsnorm IEC/UL/CSA 61010-1

Überspannungskategorie Kategorie II

Digitalanzeige TFT Farbdisplay 72 x 54 mm

Schnittstellen 1 x USB (5V DC) Ein-/Ausgang Massenspeicher

1 x RS232 (0-5 V) Serielle Ausgabe

Allgemeine Informationen

Der Hersteller ist nicht verantwortlich für direkte, indirekte, versehentliche oder Folgeschäden, die

aus Fehlern oder Unterlassungen in diesem Handbuch entstanden. Der Hersteller behält sich

jederzeit und ohne vorherige Ankündigung oder Verpflichtung das Recht auf Verbesserungen an

diesem Handbuch und den hierin beschriebenen Produkten vor. Überarbeitete Ausgaben der

Bedienungsanleitung sind auf der Hersteller-Webseite erhältlich.

Sicherheitshinweise

H I N WE IS

Der Hersteller ist nicht für Schäden verantwortlich, die durch Fehlanwendung oder Missbrauch dieses Produkts

entstehen, einschließlich, aber ohne Beschränkung auf direkte, zufällige oder Folgeschäden, und lehnt jegliche

Haftung im gesetzlich zulässigen Umfang ab. Der Benutzer ist selbst dafür verantwortlich, schwerwiegende

Anwendungsrisiken zu erkennen und erforderliche Maßnahmen durchzuführen, um die Prozesse im Fall von

möglichen Gerätefehlern zu schützen.

Bitte lesen Sie dieses Handbuch komplett durch, bevor Sie dieses Gerät auspacken, aufstellen oder

bedienen. Beachten Sie alle Gefahren- und Warnhinweise. Nichtbeachtung kann zu schweren

Verletzungen des Bedieners oder Schäden am Gerät führen.

Stellen Sie sicher, dass die durch dieses Messgerät bereitgestellte Sicherheit nicht beeinträchtigt

wird. Verwenden bzw. installieren Sie das Messsystem nur wie in diesem Handbuch beschrieben.

Bedeutung von Gefahrenhinweisen

G E F AH R

Kennzeichnet eine mögliche oder drohende Gefahrensituation, die, wenn sie nicht vermieden wird, zum Tod oder

zu schweren Verletzungen führt.

Kennzeichnet eine mögliche oder drohende Gefahrensituation, die, wenn sie nicht vermieden wird, zum Tod oder

zu schweren Verletzungen führen kann.

Kennzeichnet eine mögliche Gefahrensituation, die zu geringeren oder moderaten Verletzungen führen kann.

Kennzeichnet eine Situation, die, wenn sie nicht vermieden wird, das Gerät beschädigen kann. Informationen, die

besonders beachtet werden müssen.

W A R NU N G

V O R SI C H T

H I N WE IS

Sicherheits-Vorsichtsmaßnahmen

Der Sauerstoffanalysator 3100 wird mit einer Lithiumbatterie betrieben. Um den sicheren Betrieb des

Geräts zu gewährleisten, lesen Sie bitte die nachfolgend aufgeführten Sicherheitshinweise

aufmerksam durch.

Beachten Sie bei der Verwendung (einschließlich Lagerung):

Deutsch

25

Page 26

W A R NU N G

Brand- und Explosionsgefahr

• Die Batterie kann in einem Temperaturbereich von -10 bis 60°C betrieben, gelagert und entsorgt werden. Bei

der Verwendung außerhalb dieses Bereichs:

• besteht Brandgefahr, weil die Batterie aufbrechen und auslaufen kann.

• kann sich die Lebensdauer der Batterie verkürzen.

• Schalten Sie das Gerät sofort aus, wenn beim Benutzen oder Aufladen der Batterie ein ungewöhnlicher

Geruch oder Rauch entstehen oder das Batteriegehäuse ungewöhnlich heiß wird. Kontaktieren Sie in dem Fall

immer den örtlichen Hach Lange Kundendienst.

• Vermeiden Sie den Augenkontakt mit eventuell ausgelaufener Batterieflüssigkeit im Gehäuse. Reiben Sie

niemals die Augen. Spülen Sie die Augen gründlich mit Wasser aus und suchen Sie sofort einen Arzt auf.

Batterieflüssigkeit kann schwerwiegende Verletzungen an den Augen verursachen, wenn diese nicht

behandelt werden.

• Stellen Sie den Analysator und dessen Batterien niemals in Mikrowellenherde, Hochdruckbehälter oder

Induktionskochgeräte.

Brand- und Explosionsgefahr

• Schalten Sie den Analysator sofort aus, wenn die Batterie ausgelaufen ist oder aufgrund von

Verschleißerscheinungen oder unsachgemäßem Gebrauch Flüssigkeit in das Batteriefach eindringt.

• Bei unsachgemäßem Gebrauch kann die Batterie zu heiß werden, explodieren oder sich entzünden und

dadurch schwerwiegende Verletzungen verursachen.

• Die interne Batterie nicht mit Flüssigkeiten wie Wasser, Bier oder Salzwasser in Berührung bringen. Die

Batterie darf niemals feucht werden.

• Den Analysator oder die Batterie unter keinen Umständen modifizieren. Der interne Akku verfügt über

Sicherheits- und Schutzvorrichtungen, die, wenn sie beschädigt werden, eine starke Erhitzung, Explosion oder

Entzündung der Batterie verursachen können.

• Gerät und Batterie niemals in der Nähe von offenen Flammen, Öfen oder sonstigen Hitzequellen (über 60°C)

aufstellen. Gerät und Batterie niemals in die Sonne stellen oder bei heißem Wetter in Fahrzeugen verwenden.

Die Batterie kann sich erhitzen oder entzünden bzw. explodieren. Außerdem werden die Leistungen der

Batterie dadurch beeinträchtigt bzw. die Lebensdauer verkürzt.

W A R NU N G

Beachten Sie beim Aufladen der Batterie:

W A R NU N G

Brand- und Explosionsgefahr

Beim Aufladen der Batterie müssen folgende Hinweise beachtet werden. Bei Missachtung dieser

Sicherheitsvorschriften kann sie sich erhitzen oder entzünden bzw. explodieren und schwerwiegende

Verletzungen verursachen.

• Die Batterie kann in einem Temperaturbereich von 10 bis 45°C geladen werden. Wird die Batterie außerhalb

dieses Bereichs geladen, kann sich die Batterie erhitzen bzw. aufbrechen. Außerdem können sich die

Leistungen oder die Lebensdauer der Batterie reduzieren, wenn diese außerhalb des o. g. Temperaturbereichs

aufgeladen wird.

• Die Batterie nur mit dem mitgelieferten Ladegerät aufladen.

• Während des Aufladevorgangs den Analysator nicht in der Nähe von offenen Flammen oder in der Sonne

aufstellen. Zusätzliche Hitze kann zu einer Erhitzung der Batterie führen und die in die Batterie integrierten

Schutzschaltungen, die verhindern sollen, dass sich die Batterie entzündet, beschädigen. Die zusätzliche Hitze

kann aber auch dazu führen, dass sich die Schutzschaltungen aktivieren, wodurch verhindert wird, dass sich

die Batterie weiter auflädt.

• Unterbrechen Sie den Ladevorgang, wenn sich die Batterie nicht innerhalb der vorgegebenen Zeit aufgeladen

hat. Anderfalls kann sich die Batterie erhitzen oder entzünden bzw. explodieren. Treten beim Ladevorgang

Störungen auf, kontaktieren Sie bitte Ihren Hach Lange Kundendienst.

Hach Lange übernimmt keine Haftung für Störungen, die auf die Mißachtung der oben aufgeführten

Sicherheitshinweise zurückzuführen sind.

26

Deutsch

Page 27

Warnaufkleber

Bitte lesen Sie alle Aufkleber und Schilder, die am Produkt angebracht sind. Die Nichtbeachtung

kann zu Verletzungen von Personen oder Beschädigungen des Produkts führen. Im Handbuch

werden auf die am Gerät angebrachten Symbole in Form von Warnhinweisen verwiesen.

Dieses Symbol auf einem Produkt zeigt eine potenzielle Gefahr an, die zu ernsthaften Verletzungen

und/oder zum Tod führen kann. Der Benutzer soll dieses Handbuch bei der Bedienung des Geräts

und/oder für Sicherheitsinformationen verwenden.

Dieses Symbol auf einer Verkleidung oder Schranke des Produkts weist auf die Gefahr von

Stromschlägen hin und macht darauf aufmerksam, dass ausschließlich für die Arbeit mit

gefährlichen Spannungen qualifiziertes Personal die Verkleidung öffnen oder die Schranke

entfernen sollte.

Dieses Symbol auf dem Produkt weist auf das Vorhandensein von Bauteilen hin, die durch

elektrostatische Entladungen gestört werden können und macht darauf aufmerksam, dass mit

Vorsicht vorgegangen werden muss, um Schäden an diesen Bauteilen zu vermeiden.

Dieses Symbol weist darauf hin, dass das Instrument an Wechselstrom angeschlossen werden

muss.

Elektrogeräte, die mit diesem Symbol gekennzeichnet sind, dürfen in der Europäischen Union nicht

als Haushaltsabfall oder in öffentlichen Abfallentsorgungssystemen entsorgt werden. Altgeräte

können ohne zusätzliche Kosten für den Verbraucher an den Hersteller für die Entsorgung

zurückgegeben werden.

Produkte, die mit diesem Symbol gekennzeichnet sind, enthalten toxische oder gefährliche

Substanzen oder Elemente. Die Ziffer in diesem Symbol gibt den Umweltschutzzeitraum in Jahren

an.

Übersicht

Der ORBISPHERE 3100 ist ein tragbarer Analysator für die Messung der Sauerstoffkonzentration in

gasförmigen und flüssigen Proben. Bis zu 5.760 Messwerte können im Speicher abgespeichert und

für die zukünftige Analyse auf einen PC heruntergeladen werden.

Der Analysator ist in 3 verschiedenen Versionen lieferbar (4-mm-, 6-mm- und 1/4-Zoll-Anschlüsse)

Installation

Nehmen Sie den Analysator und die Zubehörteile vorsichtig aus der Verpackung. Prüfen Sie anhand

der Packliste, ob die Lieferung vollständig ist. Nehmen Sie eine Sichtprüfung des Analysators im

Hinblick auf eventuelle Transportschäden vor. Bitte wenden Sie sich umgehend an den Hersteller

oder Ihren Händler, falls etwas beschädigt ist oder fehlt.

Das Display wird durch einen Schutzfilm vor eventuellen Transportschäden geschützt. Entfernen Sie

den Schutzfilm vor der ersten Inbetriebnahme des Analysators.

H I N WE IS

Werkseitig wurde außerdem ein zweiter, weitaus stärkerer Schutzfilm auf das Display aufgebracht, um dieses vor

Beschädigungen und Feuchtigkeit zu schützen. Diesen Schutzfilm unter keinen Umständen entfernen!

Kontaktieren Sie bitte Ihre örtliche Hach Lange Vertretung, wenn dieser Schutzfilm Schäden aufweist.

Checkliste vor der Installation

1. Setzen Sie das Akkupack wie in Setzen Sie das Akkupack ein. auf Seite 28 beschrieben in das

Instrument ein.

2. Setzen Sie den Betriebsschalter des Geräts (Nr. 2 in Abbildung 1 auf Seite 29 auf EIN). Wenn

das Akkupack aufgeladen werden muss, schließen Sie das Gerät wie in Externe Stromspeisung

auf Seite 29 beschrieben an die Stromversorgung an.

Deutsch

27

Page 28

3. Lesen Sie zunächst den nachfolgenden Abschnitt Benutzeroberfläche auf Seite 32 des

vorliegenden Handbuchs, um sich mit den Betriebsfunktionen des Geräts vertraut zu machen.

4. Stellen Sie vor dem Abspeichern der Daten das Datum und die Uhrzeit der internen Uhr des

Instruments wie in Grundeinstellungen auf Seite 36 beschrieben ein.

5. Installieren Sie die 31000 PC-Software wie in Installation der PC-Software auf Seite 31

beschrieben auf Ihrem PC.

6. Richten Sie mithilfe der PC-Software eine neue Benutzertabelle wie in Neue Benutzertabelle

erstellen auf Seite 31 beschrieben ein.

7. Richten Sie mithilfe der PC-Software eine Messkonfigurationstabelle wie in beschrieben Neue

Messkonfigurationstabelle erstellen auf Seite 31 ein.

8. Laden Sie Benutzer- und Konfigurationstabelle wie in Dateien in das Instrument übertragen

auf Seite 32 beschrieben auf das Instrument.

Setzen Sie das Akkupack ein.

Aus Sicherheitsgründen wird das Akkupack für den Transport ausgebaut. Nach dem Auspacken des

Geräts setzen Sie das Akkupack wie im Folgenden wieder ein:

1. Kippen Sie das Gerät nach hinten. Jetzt sind die beiden unteren Befestigungsschrauben (Nr. 1)

des Frontpaneels sichtbar.

2. Lösen Sie die Schrauben mit dem im Tool-Kit enthaltenen Kreuzkopfschraubendreher und

entfernen Sie diese. Nehmen Sie das Frontpaneel ab. Jetzt haben Sie Zugriff auf den

Batterieschalter (Nr. 2).

3. Für den Ausbau des Akkupacks drehen Sie den Schalter mit dem im Tool-Kit enthaltenen

Flachkopfschraubendreher mit langer Klinge eine Viertelumdrehung im Uhrzeigersinn. In der

Abbildung sind links die Position OFF (bei Lieferung) und rechts die Position ON dargestellt.

4. Setzen Sie das Frontpaneel wieder ein und befestigen Sie es mit den zwei Schrauben.

V O R SI C H T

Um Schäden an dem Instrument zu vermeiden, muss der oben beschriebene Vorgang vor jedem Transport in

umkehrter Reihenfolge (d. h. Schalter auf OFF setzen) ausgeführt werden .

Schalter und Anschlüsse des Geräts

Die folgende Abbildung zeigt die Geräteseiten und die Bedienelemente, die sich hier befinden:

28

Deutsch

Page 29

Abbildung 1 Ansicht der linken Seite

1 Handgriff 4 USB-Anschluss

2 Betriebsschalter EIN/AUS 5 Externer Netzanschluss

3 RS232-Anschluss 6 Kartenidentifizierungssystem (optional, noch nicht

verfügbar)

Abbildung 2 Ansicht der rechten Seite

1 Probenflusseinstellventil 2 Probenflussventil mit Probeneinlass- und

Auslassanschlüssen (der Probeneinlass befindet

sich oben am Ventil und der Auslass unten).

Probenflussventil

Das Probenflussventil hat drei Positionen:

• Probenfluss PURGE (Spülen)

• Probenfluss ON (Ein)

• Probenfluss OFF (Aus)

Die Position PURGE (Spülen) wird verwendet, um eventuell auftretende Luftblasen aus der

Probenleitung zu entfernen. Für eine gründliche Spülung wird empfohlen, das Ventil mindestens

5 Sekunden in dieser Position zu lassen. Bei dieser Einstellung läuft der Probenfluss direkt von der

Einlassleitung in die Auslassleitung. In dieser Phase werden keine Messungen vorgenommen, da die

Probe keinen Kontakt mit dem Sensor hat.

Mit den Positionen ON und OFF wird der Probenfluss ein- bzw. ausgeschaltet.

Anschlüsse des Instruments

Externe Stromspeisung

W A R NU N G

Stellen Sie sich, dass die für den Anschluss an das Stromnetz verwendete Steckdose geerdet ist.

Deutsch 29

Page 30

Zusätzlich zu dem internen aufladbaren Akkupack kann das Gerät extern mit dem mitgelieferten

Netzkabel einschließlich Adapter über die Stromversorgung gespeist werden. Schließen Sie das

Netzkabel an den Netzanschluss am Gerät (Nr. 5 in Abbildung 1 auf Seite 29) und an die externe

Stromversorgung an.

Hinweis: Beim Anschluss des Geräts an die externe Stromversorgung wird das interne Akkupack automatisch

aufgeladen.

RS232-Anschluss

Über diesen Anschluss können Messdaten heruntergeladen oder Echtzeitüberwachungen von

Messungen durchgeführt werden.

Die Daten, die über diese Verbindung an den PC übertragen werden, sind hinsichtlich ihres Formats

und Inhalts identisch mit den Daten, die in der Messungsdatei des Instruments gespeichert sind.

Diese Daten können auch mit dem USB-Speicherstick (siehe Dateien exportieren auf Seite 41 für

weitere Informationen) übertragen werden.

USB-Anschluss

Der USB-Anschluss (Nr. 4 in Abbildung 1 auf Seite 29 wird für den Export und Import von Daten auf

und von dem Instrument verwendet. Mit der 3100 PC-Software können auf dem PC Tabellen erstellt

und anschließend mit dem USB-Speicherstick auf das Instrument geladen werden.

Umgekehrt können mit dem USB-Speicherstick Tabellen aus dem Instrument exportiert und in

andere Instrumente der Serie 3100 importiert werden, um Konfigurationen zu vereinheitlichen.

Hinweise hierzu finden Sie unter Import / Export auf Seite 40.

Probenleitungen anschließen

Die Messungen können in den Modalitäten kontinuierlich oder Probe durchgeführt werden. In beiden

Fällen muss das Instrument wie im Folgenden beschrieben an die Probenleitung angeschlossen

werden:

1. Die Probeneinlass- und Auslassanschlüsse befindet sich auf dem Probenflussventil (Nr. 8 in

Abbildung 2 auf Seite 29 und vergrößert in der Abbildung unten):

1 Probeneinlass 2 Probenauslass

2. Schließen Sie den Ein- und Auslassschlauch an die Probenquelle und den Ablauf an. Die

Abbildung oben zeigt das Ventil in der Position OFF. Um den Probenfluss vollständig zu öffnen

(ON), drehen Sie das Ventil bis zum Anschlag im Uhrzeigersinn (ca. eine Achtelumdrehung). Um

eventuelle Luftblasen aus der Probenleitung zu entfernen, setzen Sie das Ventil 5 Sekunden auf

die Position PURGE (Spülen) und anschließend auf die Position ON.

Hinweis: Zum Toolkit des Geräts (ausschließlich 4 mm Instrumentenversion) gehört auch ein Edelstahlrohr,

das statt der Kunststoffleitung an das Ablassventil angeschlossen werden kann, wenn der hohe Druck in dem

Instrument übermäßige Bewegungen der Kunststoffleitung verursacht.

3. Wenn in der Probe Partikel enthalten sind, empfiehlt sich die Verwendung eines Filters an der

Einlassleitung, um Verstopfungen während des Probenflusses zu verhindern. Der Filter

(einschließlich 10 Filtereinsätze) ist in dem Tool-Kit, das zum Lieferumfang des Instruments

gehört, enthalten. Er kann außerdem separat als Ersatzteil mit der Bautteilnummer DG33216 (4mm- Instrument), DG33317 (6-mm-Instrument) oder DG33318 (1/4-Zoll-Instrument) angefordert

werden. Ebenso ist ein Satz mit 10 Maschen mit der Bautteilnummer DG33217 lieferbar.

4. Regulieren Sie den Probenfluss mithilfe des Einstellventils (Nr. 7 in Abbildung 2 auf Seite 29)

über dem Probenflussventil.

Hinweise zu den Flussraten

30

Deutsch

Page 31

• Für Dosen und Flaschen liegt die empfohlene Mindestflussrate bei 150 ml/min. Bei Gebinden

mit kleineren Volumen kann auch eine niedrigere Flussrate verwenden werden, die aber nicht

unter 100 ml/min liegen darf.

• Bei Tank- und Leitungsanwendungen liegt die empfohlene Flussrate bei über 200 ml/min und

maximal bei dem Wert, der bei vollständig geöffnetem Einstellventil für die Flussrate erreicht

wird.

Hinweis: Die mit Pfeilen auf dem Flussmesser gekennzeichnete Flussrate (siehe Abbildung unten) liegt bei ca.

150 ml/min (unterer Pfeil) und 200 ml/min (oberer Pfeil). Die Silberperle zeigt die Flussrate an.

Installation der PC-Software

Das Instrument wird mit einer Standard Benutzertabelle und einer StandardMesskonfigurationstabelle geliefert. Um das Instrument anzupassen und Ihre eigenen Tabellen zu

erstellen, benötigen Sie die PC-Software, die in dem USB-Speicherstick, der zum Lieferumfang des

Tool-Kits gehört, enthalten ist.

Schließen Sie für die Installation der Software den USB-Speicherstick an Ihren PC an und starten

Sie das Setup-Programm (setup.exe) in dem Verzeichnis Orbisphere 3100\Installation Files\PC

Software. Folgen Sie den Anweisungen auf dem Bildschirm. Das Programm wird in einem neu

angelegten Verzeichnis auf Ihrer Festplatte installiert: C:\Program Files\Hach Lange\3100 PC

Software\.

Nach Abschluss der Installation klicken Sie auf die Ikone auf Ihrem Desktop, um die Anwendung zu

starten.

Neue Benutzertabelle erstellen

Wählen Sie im Menü File die Option New und anschließend User Table.

Automatisch wird ein Standard-Benutzer der Bediener-Ebene “User” mit dem Benutzer-ID “0” und

dem Benutzernamen “Default” erstellt. Die Einträge in diesen Feldern können nicht geändert werden.

Für das Kennwort wird automatisch der Wert “1234” eingestellt. Dieser Wert kann aber geändert

werden.

Wählen Sie die Option Add um einen neuen Benutzer hinzuzufügen, und Delete, um einen Benutzer

der Liste zu löschen. Die Optionen Copy und Paste können ebenfalls verwendet werden, um

einen neuen Benutzer hinzuzufügen, und mit Cut kann ein bestehender Benutzer gelöscht