Page 1

DOC022.53.80072

MP Series Portable Meters

USER MANUAL

October 2009, Edition 1

© Hach Company, 2009. All rights reserved. Printed in the U.S.A. hh/dk

Page 2

2

Page 3

Table of contents

Section 1 Specifications .................................................................................. 7

Section 2 General information ..................................................................... 11

2.1 Safety information ..................................................................................... 11

2.1.1 Use of hazard information .............................................................. 11

2.1.2 Precautionary labels ....................................................................... 11

2.2 General product information .....................................................................12

2.2.1 Overview ......................................................................................... 12

2.2.2 Features common to all models ...................................................... 12

2.2.3 User mode features ....................................................................... 12

2.3 Conductivity and pH/ORP sensor cups .....................................................13

Section 3 Operation ........................................................................................ 15

3.1 System startup ..........................................................................................15

3.2 Display description ....................................................................................15

3.3 Keypad description ................................................................................... 16

3.4 Take a measurement ................................................................................ 17

3.5 Measure conductivity ................................................................................17

3.6 Measure resistivity (MP-4 and MP-6 models) ........................................... 17

3.7 Measure mineral/salt (MP-6p model only) ................................................ 18

3.8 Measure TDS ............................................................................................ 18

3.9 Measure ORP/Redox (MP-6 and MP-6p models) ..................................... 18

3.10 Measure pH (MP-6 and MP-6p models) ................................................. 18

3.11 Select a solution .....................................................................................19

3.11.1 Temperature compensation ..........................................................19

3.12 Change the user-selected temperature compensation factor ................. 20

3.12.1 Disable temperature compensation ............................................. 20

3.13 Change the user-selected conductivity/TDS ratio ................................... 20

3.14 Settings ................................................................................................... 21

3.14.1 Store a value in the memory ......................................................... 21

3.14.2 View the memory recall ................................................................ 22

3.14.3 Clear all records ...........................................................................22

3.15 Time and date ......................................................................................... 22

3.15.1 Set the time .................................................................................. 22

3.15.2 Set the date .................................................................................. 23

3.15.3 Set the date format ....................................................................... 24

3.16 Temperature format ................................................................................ 24

3.17 Return to factory settings ........................................................................25

3.18 Cell check ...............................................................................................25

3.19 Auto off ................................................................................................... 26

3.20 User mode calibration Linc

3.20.1 Calibrate meter for User mode ..................................................... 27

3.20.2 Set User mode calibration Linc ..................................................... 27

3.20.3 Cancel User mode calibration Linc ...............................................28

3.21 Download stored data ............................................................................. 29

Section 4 Calibration ...................................................................................... 31

TM

function .................................................... 27

3

Page 4

Table of contents

4.1 Calibration intervals ...................................................................................31

4.2 Calibration limits ........................................................................................31

4.3 Calibration records ....................................................................................31

4.4 Calibrate the meter ....................................................................................31

4.5 Exit calibration mode .................................................................................32

4.6 Calibrate conductivity, mineral/salt or TDS ................................................32

4.7 Calibrate resistivity ....................................................................................33

4.8 Reset factory calibration—conductivity, mineral/salt or TDS .....................33

4.9 pH calibration .............................................................................................33

4.10 Set multiple point pH calibrations ............................................................34

4.11 ORP calibration .......................................................................................35

4.12 Temperature calibration ...........................................................................35

Section 5 Maintenance ...................................................................................37

5.1 Temperature extremes ..............................................................................37

5.2 Battery replacement ..................................................................................37

5.2.1 Maintain the conductivity cup ..........................................................38

5.2.2 Maintain the pH/ORP sensor cup ....................................................38

5.3 pH/ORP sensor replacement .....................................................................38

5.4 Clean the sensors ......................................................................................38

5.4.1 Clean the conductivity/resistivity/TDS sensor .................................38

5.4.2 Clean the pH/ORP sensor ...............................................................39

Section 6 Troubleshooting ............................................................................41

Section 7 Contact Information ......................................................................43

Section 8 Replacement parts and accessories ......................................45

8.1 Replacement parts ....................................................................................45

8.2 Accessories ...............................................................................................45

8.3 Consumables .............................................................................................45

8.4 Recommended cleaning consumables ......................................................46

Section 9 Limited Warranty ...........................................................................47

Appendix A Temperature compensation ..................................................49

A.1 Compensation to 25 ºC .............................................................................49

A.2 Changes in temperature compensation ....................................................49

A.3 Graph of comparative error .......................................................................50

A.4 Other solutions ..........................................................................................50

Appendix B Conductivity conversion .........................................................51

B.1 How conductivity conversion works ..........................................................51

B.2 Solution characteristics .............................................................................51

Appendix C Temperature compensation and TDS derivation ...........53

C.1 Conductivity characteristics ......................................................................53

C.2 Temperature compensation of unknown solutions ...................................53

C.2.1 Find temperature compensation by calculation ..............................53

C.2.2 Find temperature compensation by adjustment ..............................53

C.3 TDS ratio of unknown solutions ................................................................54

4

Page 5

Table of contents

Appendix D Additional information on pH and ORP (MP-6

and MP-6p models) .........................................................................................55

D.1 pH ............................................................................................................. 55

D.1.1 pH as an indicator .......................................................................... 55

D.1.2 pH units .......................................................................................... 55

D.1.3 pH sensor ....................................................................................... 55

D.1.4 Sources of error .............................................................................56

D.1.5 Temperature compensation ........................................................... 57

D.2 Oxidation Reduction Potential/Redox (ORP) .............................. 57

D.2.1 ORP as an indicator ....................................................................... 57

D.2.2 ORP units ....................................................................................... 57

D.2.3 ORP sensor ................................................................................... 57

D.2.4 Sources of error .............................................................................57

5

Page 6

Table of contents

6

Page 7

Section 1 Specifications

Specifications are subject to change without notice.

General

Display 4-digit LCD

Dimensions (L x W x H) 196 x 68 x 64 mm (7.7 x 2.7 x 2.5 in.)

Weight 352 g (12.4 oz)

Case material VALOX

COND/RES/TDS cell material VALOX

COND/TDS electrodes (4) 316 stainless steel

COND/RES/TDS cell cup capacity 5 mL (0.2 oz)

pH /ORP sensor cup capacity 1.2 mL (0.04 oz)

Power 9V alkaline battery

Battery life >100 hours (5000 readings)

Operating/Storage Temperature 0 to 55 ºC (32 to 132 ºF)

Protection Ratings IP67/NEMA 6

Warranty

Ranges

pH (MP-6 and MP-6p models) 0 to 14 pH

ORP (MP-6 and MP-6p models) ±999 mV

Conductivity

TDS

Mineral/Salt (MP-6p model only)

Resistivity (MP-6 and MP-6p models) 10 KΩ to 30 MΩ

Temperature 0 to 71 ºC (32 to 160 ºF)

®1

MP Series Meter Warranty: Two years from date

of shipment (see Section 9 on page 47)

pH/ORP Sensor Warranty: Six months from date

of shipment (see Section 9 on page 47)

0 to 9999 µS

10 to 200 mS/cm

in 5 autoranges

0 to 9999 ppm

10 to 200 ppt

in 5 autoranges

0 to 9999 ppm

10 to 200 ppt

in 5 autoranges

/cm

7

Page 8

Specifications

Resolution

pH ±0.01 pH

ORP ±1 mV

0.01 (<100 µ

0.1 (<1000 µ

Conductivity

TDS

Mineral/Salt

Resistivity

Temperature 0.1 ºC/ºF

1.0 (<10 mS)

0.01 (<100 mS)

0.1 (<200 mS)

0.01 (<100 ppm)

0.1 (<1000 ppm)

1.0 (<10 ppt)

0.01 (<100 ppt)

0.1 (<200 ppt)

0.01 (<100 ppm)

0.1 (<1000 ppm)

1.0 (<10 ppt)

0.01 (<100 ppt)

0.1 (<200 ppt)

0.01 (<100 KΩ)

0.1 (<1000 KΩ)

0.1 (>1 MΩ)

Accuracy

pH ±0.01 pH

ORP ±1 mV

Conductivity ±1% of reading

TDS ±1% of reading

Mineral/salt ±1% of reading

Resistivity ±1% of reading

Temperature ±0.1 ºC

Auto temperature compensation

pH 0 to 71 ºC (32 to 160 ºF)

Conductivity 0 to 71 ºC (32 to 160 ºF)

TDS 0 to 71 ºC (32 to 160 ºF)

Mineral/Salt 0 to 71 ºC (32 to 160 ºF)

Resistivity 0 to 71 ºC (32 to 160 ºF)

Adjustable temperature compensation

Conductivity 0 to 9.99%/ºC

TDS 0 to 9.99%/ºC

Mineral/Salt 0 to 9.99%/ºC

Resistivity 0 to 9.99%/ºC

S)

S)

2

8

Page 9

Specifications

COND/TDS ratios pre-programmed

Conductivity

TDS

Mineral/salt

Adjustable COND/TDS ratio factor

Conductivity

Mineral/salt

1

Trademark of SABIC Innovative Plastics IP BV

2

± 0.2 pH in presence of RF fields 3 V/m and >300 MHz.

3

Trademark of Myron L Company

KCl, NaCl, 442™

0.20 to 7.99TDS

3

9

Page 10

Specifications

10

Page 11

Section 2 General information

In no event will the manufacturer be liable for direct, indirect, special, incidental or

consequential damages resulting from any defect or omission in this manual. The

manufacturer reserves the right to make changes in this manual and the products it

describes at any time, without notice or obligation. Revised editions are found on

the manufacturer’s website.

2.1 Safety information

Please read this entire manual before unpacking, setting up or operating this

equipment. Pay attention to all danger, warning and caution statements. Failure to

do so could result in serious injury to the operator or damage to the equipment.

Make sure that the protection provided by this equipment is not impaired, do not

use or install this equipment in any manner other than that specified in this manual.

2.1.1 Use of hazard information

DANGER

Indicates a potentially or imminently hazardous situation which, if not avoided, will

result in death or serious injury.

WA RN IN G

Indicates a potentially or imminently hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, could result in

minor or moderate injury.

NOTICE

Indicates a situation that is not related to personal injury.

2.1.2 Precautionary labels

Electrical equipment marked with this symbol may not be disposed of in

European public disposal systems after 12 August of 2005. In conformity with

European local and national regulations (EU Directive 2002/96/EC), European

electrical equipment users must now return old or end-of life equipment to the

Producer for disposal at no charge to the user.

Note: For return for recycling, please contact the equipment producer or supplier

for instructions on how to return end-of-life equipment, producer-supplied

electrical accessories, and all auxiliary items for proper disposal.

11

Page 12

General information

2.2 General product information

The MP-4, MP-6 and MP-6p (see Figure 2 on page 14) handheld meters allow

users to test water for pH, ORP, conductivity, resistivity, TDS (Total Dissolved

Solids), mineral/salt concentration and temperature.

2.2.1 Overview

The MP Series portable meters measure various parameters in water. Data can be

stored and (with the optional MP-Dock) transferred to a printer, PC, or USB storage

device.

•MP-4—Measures conductivity, resistivity, TDS and temperature

•MP-6p—Measures pH, ORP, conductivity, mineral/salt concentration, TDS and

temperature. The mineral/salt measurement is a TDS value based on an NaCl

profile.

•MP-6—Measures pH, ORP, conductivity, resistivity, TDS and temperature

2.2.2 Features common to all models

• 4-digit LCD • User-adjustable conductivity/TDS

• IP67 rating • Accuracy of ±1% of reading or

• Internal electrode sensors for

maximum protection

• Time and date-stamped data logging • Memory stores 100 readings

• Automatic temperature

compensation

• Download capability with optional

MP-Dock

conversion ratio

better

• Autorange

conductivity/TDS/resistivity

• Factory-stored calibrations

• Adjustable auto shut-off

2.2.3 User mode features

• Adjustable conductivity/TDS conversion

factor

• Programmable temperature

compensation factor

12

Page 13

General information

2.3 Conductivity and pH/ORP sensor cups

Figure 1 Model MP-6 conductivity and pH/ORP sensor cups

1 Temperature sensor 5 pH glass electrode

2 Conductivity cup (built-in

electrodes)

3 ORP electrode 7 pH/ORP sensor protective cap

4 pH/ORP sensor cup (replaceable

sensor)

6 Reference junction under glass pH

bulb

13

Page 14

General information

Figure 2 Model MP-6

1 Conductivity cup 4 Display

2 pH/ORP sensor cup 5 Keypad

3 pH/ORP sensor protective cap 6 Wrist strap slot (customer supplied)

14

Page 15

Section 3 Operation

3.1 System startup

There is no ON key or OFF key. Press any measurement key to power on the

meter. After 15 seconds of inactivity, the meter turns off (60 seconds in CAL mode).

Users can adjust the automatic shut off time up to 75 seconds (see section 3.19 on

page 26).

3.2 Display description

The meter display shows the temperature, units, parameter, test values, user mode,

memory recall, memory store, calibration, date and time (Figure 3).

Figure 3 Model MP-6 display

1 Test value—Shows the test value.

2 Units of measurement—Shows the units of measurements.

3 Parameters—Shows the parameters being measured.

4 Multiple value readout—Shows the temperature value readout, user

temperature compensation or conductivity/TDS ratio. Memory record location

numbers or pH calibration. Also shows same date readout as the time and

date indicator.

5 Time and date—Shows the time and date.

6 Selected solution—Shows the solution profile that is selected.

15

Page 16

Operation

3.3 Keypad description

The MP-6 meter is used as an example for keypad description and function.

16

Figure 4 Keypads on MP Series meters

Page 17

Operation

1COND—

Turns on the meter, measures conductivity, and exits any function

2RES1 (MP-4 and MP- 6 only)—Turns on the meter, measures resistivity, and exits

any function

3TDS—Turns on the meter, measures TDS, and exits any function

4ORP (MP-6 and MP-6p only)—

function

Turns on the meter, measures pH, and exits any

5UP/MS—Scrolls up and stores value to memory

6 MR/DOWN—Scrolls down and recalls stored memory information

7 CAL/CMC LR—Enters the calibration mode, clears the memory, and provides

confirmation

1

The MP-6p meter has a MIN/SALT key instead of the RES key. The mineral/salt

measurement is a TDS value based on an NaCl profile.

3.4 Take a measurement

To take a measurement:

1. Rinse the sensor cup with test solution three times and refill.

Note: If testing solutions that are highly concentrated or at extreme temperatures, more

rinsing is required.

2. Push the desired measurement key.

Note: To prevent auto shut off, push the measurement key again and as needed.

3. Observe or record the value displayed, or push UP/MS to store the reading.

3.5 Measure conductivity

To measure conductivity:

1. Rinse the conductivity cup three times with the sample to be measured. This

conditions the temperature compensation sensor and prepares the cell.

2. Fill the conductivity cup with the solution.

3. Push the COND key.

4. Observe or record the value displayed, or push UP/MS to store the reading. A

display of [----] indicates an over range condition.

Note: Carefully fill conductivity cup to ensure that the air bubbles do not cling to the cell wall.

3.6 Measure resistivity (MP-4 and MP-6 models)

Resistivity is measured in low conductivity solutions. In the conductivity cup, the

value can drift due to trace contaminants or absorption from atmospheric gasses.

Therefore, measuring a flowing sample is recommended.

1. Make sure the pH/ORP sensor protective cap is secure to avoid contamination

(MP-6 model).

17

Page 18

Operation

2. Hold the meter at a 30 degree angle and let the sample flow into the

conductivity cup continuously with no aeration.

3. Push the RES key.

4. Observe or record the value displayed.

Note: If reading is lower than 10 kΩ, [- - - -] is shown. Measure conductivity for these samples.

3.7 Measure mineral/salt (MP-6p model only)

To measure mineral/salt:

1. Rinse the conductivity cup three times with the sample to be measured. This

conditions the temperature compensation sensor and prepares the cell.

2. Fill the conductivity cup with the solution.

3. Push the MIN/SALT key.

4. Observe or record the value displayed, or push UP/MS to store the reading.

3.8 Measure TDS

To measure TDS:

1. Rinse the conductivity cup three times with the sample to be measured. This

conditions the temperature compensation sensor and prepares the cell.

2. Fill the conductivity cup with the solution.

3. Push the TDS key.

4. Observe or record the value displayed, or push UP/MS to store the reading.

3.9 Measure ORP/Redox (MP-6 and MP-6p models)

To measure the ORP/Redox:

1. Remove the protective pH/ORP sensor cap. Squeeze the sides and pull up.

2. Rinse the sensor cup three times with the sample to be measured.

3. Shake the meter after each rinse to remove residual liquid.

4. Fill both sensor cups with the sample.

5. Push the ORP key.

6. Observe or record the value displayed, or push UP/MS to store the reading.

Important Note: After the test, fill the pH/ORP sensor cup with pH Storage Solution

and replace the protective cap. Do not allow the pH/ORP sensor cup to dry out.

3.10 Measure pH (MP-6 and MP-6p models)

To measure pH:

1. Remove the protective pH/ORP sensor cap. Squeeze the sides and pull up.

2. Rinse the pH/ORP sensor cup three times with the sample to be measured.

3. Shake the meter after each rinse to remove residual liquid.

4. Fill both sensor cups with the sample.

18

Page 19

Operation

5. Push the pH key.

6. Observe or record the value displayed, or push UP/MS to store the reading.

Important Note: After the test, fill the pH/ORP sensor cup with pH Storage Solution

and replace the protective cap. Do not allow the pH/ORP sensor cup to dry out.

3.11 Select a solution

Conductivity, resistivity and TDS (including mineral/salt) require temperature

compensation to 25 °C. The solution profile selection determines the temperature

compensation of conductivity and calculation of TDS and mineral/salt from

compensated conductivity.

There are four solution types:

• KCl

• NaCl

• 442

• User

On the left side of the display is the salt solution characteristic used to model

temperature compensation of conductivity and its TDS conversion. By default, KCI

is used for conductivity, NaCl is used for resistivity (and mineral/salt), and 442

(natural water characteristic) is used for TDS. The User selection allows a custom

value to be entered for the temperature compensation of conductivity and the

conversion ratio if measuring TDS.

Check the display to see if the solution profile displayed is the solution type desired

for that measurement. To change a solution:

1. Push the COND key, the RES key, the MIN/SALT key or the TDS key to select

the parameter to change the solution type.

2. Push and hold the CAL/MCLR key for three seconds and wait for SEL to

appear in the display.

3. Push UP/MS or MR/DOWN to scroll to the desired solution type.

4. Push the CAL/MCLR key to accept the new solution.

3.11.1Temperature compensation

Electrical conductivity indicates solution concentration and ionization of the

dissolved material. Because temperature affects ionization, conductivity

measurements change with temperature and must be corrected to read at 25 ºC.

Temperature compensation uses the characteristics of salt solutions. The selected

salt solution is displayed on the left side of the display. By default, the meter uses

KCl for conductivity, NaCl for resistivity and 442 for TDS (see Appendix B on page

51).

The User mode customizes the temperature compensation and the conversion ratio

if measuring TDS.

Note: Calibration of each solution type is performed separately and calibration of one solution

does not affect the calibration of the other solution types.

19

Page 20

Operation

3.12 Change the user-selected temperature compensation factor

Select the User mode to change the temperature compensation factor. This feature

does not apply to pH or ORP. For user mode information, (see section 2.2.3 on

page 12).

1. Select the User mode (see section 3.11 on page 19).

2. Push the CAL/MCLR key.

3. Push UP/MS or MR/DOWN to adjust the temperature compensation factor

from 0-9.99%/ºC.

4. Push the CAL/MCLR key twice to skip calibration adjustment and accept the

new temperature compensation (three times if in TDS or MIN/SALT mode).

5. Measure samples with the new temperature compensation factor.

3.12.1 Disable temperature compensation

1. Select the User mode (see section 3.11 on page 19).

2. Push the CAL/MCLR key. Hold the MR/DOWN key until the temperature

compensation shows .00%/

ºC.

3. Push the CAL/MCLR key twice (three times for TDS or MIN/SALT).

4. Temperature compensation is now disabled (=0) for measurements in the User

mode.

3.13 Change the user-selected conductivity/TDS ratio

Select the User mode to change a custom conductivity/TDS conversion ratio in the

range of 0.20 to 7.99.

To determine the conversion ratio for a custom solution of a known TDS ppm value,

measure the solution conductivity at 25 ºC with the MP Series meter and divide the

20

Page 21

Operation

ppm value by the µS value. For example, a solution of known 75 ppm TDS and

measured

To enter a new conversion ratio:

1. Push the TDS key.

2. Select the User mode (see section 3.11 on page 19).

3. Push the CAL/MCLR key twice (to skip over temperature compensation

4. Push UP/MS or MR/DOWN until the new conversion ratio is displayed.

5. Push the CAL/MCLR key twice (to skip over calibration adjustment) to accept

6. Use the new conductivity/TDS ratio to measure samples.

100µS conductivity at 25ºC has a conversion ratio of 75/100 or 0.75.

adjustment) and the ratio will appear.

the new conversion ratio.

3.14 Settings

3.14.1 Store a value in the memory

The MP series handheld meters have memory storage for up to 100 readings. Time

and date is recorded with each stored reading.

To download this stored data to a computer, see section 3.21 on page 29.

1. Push the UP/MS key to record a value.

2. The MEMORY icon appears and the temperature display is briefly replaced by

a number (1-100) that shows the position of the record. Figure 5 shows a

reading of 1806 µS stored in memory record # 4.

Figure 5

21

Page 22

Operation

3.14.2 View the memory recall

To view the records in memory:

1. Push any measurement key.

2. Push the MR/DOWN key. The MEMORY icon appears, and shows the last

record stored.

3. Push UP/MS or MR/DOWN to scroll to the location desired.

Note: The temperature display alternates between temperature recorded and location

number.

4. Push the CAL/MCLR key to show the time and date stamp.

5. Push any measurement key to leave memory recall.

3.14.2.1 Clear a single record

After the user recalls a specific record location, push and hold the CAL/MCLR key

to clear that memory location. This memory location is used for the next stored

memory record unless the user scrolls to another empty memory position before

the recall sequence ends.

3.14.3 Clear all records

To clear all records in the memory:

1. Push the MR/DOWN key.

2. Scroll down until CLR ALL is displayed.

3. Push the CAL/MCLR key. This clears all records.

3.15 Time and date

Change the time and date for travel or for a battery replacement that takes longer

than three minutes.

3.15.1 Set the time

Time is displayed in a 24-hour format.

1. Push the any measurement key.

2. Push the MR/DOWN key repeatedly until the time is displayed. To quickly scroll

through all stored memory records, hold down the MR/DOWN key.

22

Page 23

Operation

3. Push the CAL/MCLR key to begin. The CAL icon shows the time.

4. Push UP/MS or MR/DOWN to change the time.

5. Push the CAL/MCLR key to accept the new time.

3.15.2 Set the date

To change the date format, refer to section 3.15.3 on page 24. The default format

for the date is US (mo/dy/yr).

1. Push any measurement key. To quickly scroll through all stored memory

records, hold down the MR/DOWN key.

2. Push the MR/DOWN key repeatedly until the date shows in the display. For

example: 01.05/05 (January 5, 2005)

3. Push the CAL/MCLR key to begin. The CAL icon displays above the year.

4. Push UP/MS or MR/DOWN to change the year.

5. Push CAL/MCLR to accept the new setting for the year.

6. Push UP/MS or MR/DOWN to change the month.

7. Push CAL/MCLR to accept the new setting for the month.

23

Page 24

Operation

8. Push UP/MS or MR/DOWN to change the day.

9. Push CAL/MCLR to accept the new setting for the day.

3.15.3 Set the date format

To set the date format:

1. Push any measurement key.

2. Push the MR/DOWN key repeatedly until US or Int displays. To quickly scroll

through all stored memory records, hold down the MR/DOWN key.

3. Push CAL/MCLR to change the date format. The new format is now displayed.

3.16 Temperature format

To set the temperature format:

1. Push any measurement key.

2. Push the MR/DOWN key repeatedly until C or F is displayed. To quickly scroll

through all stored memory records, hold down the MR/DOWN key.

24

Page 25

Operation

3. Push the CAL/MCLR key to switch units.

4. Push any measurement key to accept the unit preference for all temperature

readings.

Note: Temperature compensation is always displayed in %/ ºC.

3.17 Return to factory settings

To set all calibrations to factory settings or to erase all records, follow the steps

below.

1. Push any measurement key.

2. Push the MR/DOWN key repeatedly until FAC SEL is displayed. To quickly

scroll through all stored memory records, hold down MR/DOWN.

3. Push the CAL/MCLR key to accept the factory reset. The meter returns to the

measurement mode.

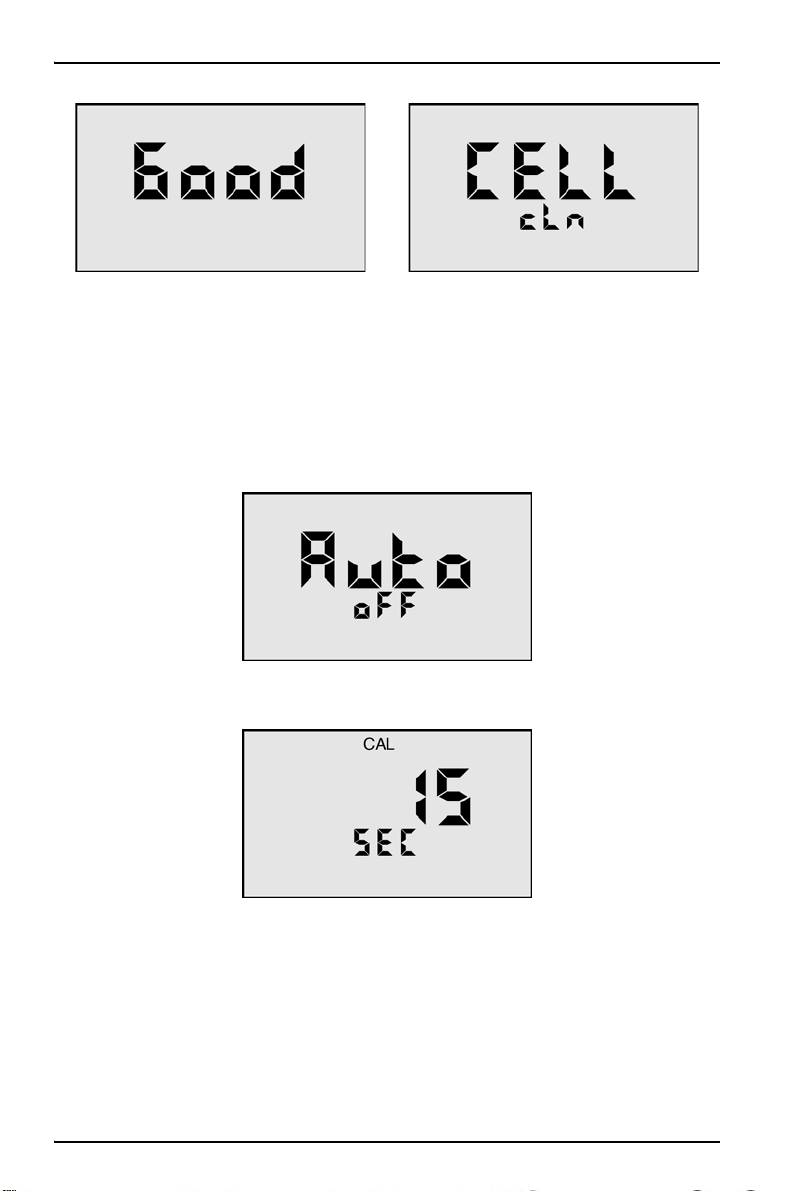

3.18 Cell check

The cell check verifies the cleanliness of the conductivity/TDS/resistivity sensor. If

the display shows .00 when the cell cup is dry, the sensor is probably clean.

In normal use, the conductivity cell may become dirty or coated and require

cleaning. To perform a cell check:

1. Push the COND key.

2. Push the MR/DOWN key repeatedly until the display shows CELL ch. To

quickly scroll through all stored memory records, hold down MR/DOWN.

3. Push the CAL/MCLR key to test. If the cell is clean, “Good” displays briefly. If

cell is dirty, “Cell cLn” displays. To clean the sensors, (see section 5.4 on

page 38).

25

Page 26

Operation

3.19 Auto off

Auto off turns the meter off when there is no activity for a period of time after a key

is pushed. The default time is 15 seconds, and 60 seconds in the CAL (calibration)

mode. This time may be adjusted up to 75 seconds.

1. Push any measurement key.

2. Push the MR/DOWN key repeatedly until the display shows Auto oFF. To

quickly scroll through all stored memory records, hold down MR/DOWN.

3. Push the CAL/MCLR key to begin. The CAL icon displays above the 15 SEC

display.

26

Page 27

Operation

4. Push UP/MS or MR/DOWN to change the time. The maximum time is 75

seconds.

5. Push the CAL/MCLR key to accept the new auto shut off time.

3.20 User mode calibration Linc

The Linc

the user does not have a user standard solution to calibrate the meter. This ensures

more accurate measurements. When the Linc function is used, the User mode is

linked to another standard solution. For example: If User and KCl are linked, a KCl

standard solution is used to calibrate the instrument.

Note: When a “Linc” is established for the User mode, the Linc applies to all measurement

modes using the User solution selection.

TM

function allows for calibration when the meter is in the User mode and

TM1

function

3.20.1 Calibrate meter for User mode

To calibrate the meter for the User mode:

1. Push the COND key, the MIN/SALT key, or the TDS key.

2. Calibrate the meter using a standard solution (see section 4.4 on page 31).

3. Select the User mode (see section 3.11 on page 19).

4. Set the calibration Linc.

3.20.2 Set User mode calibration Linc

The Linc function sets the calibration offset factor of a standard solution to the User

solution mode. The Linc stays intact in future calibrations until it is canceled (see

section 3.20.3 on page 28).

Follow the steps below to set the KCl, NaCl or 442 calibration factor to the User

solution mode.

1. Push a measurement key to Linc (i.e., COND, RES, MIN/SALT or TDS).

2. Select the User mode (see section 3.11 on page 19).

1

Trademark of Myron L Company

27

Page 28

Operation

3. Push the MR/DOWN key until Linc displays.

4. Push the CAL/MCLR key. SEL displays with the User icon.

Note: Any additional display of KCl, NaCl or 442 icons indicates a Linc between the

additional solution and the User solution. If none of the solution selection icons are

displayed, nothing is linked to the User mode.

5. Push UP/MS or MR/DOWN to select a standard solution to link to the User

mode calibration constant.

6. Push the CAL/MCLR key to accept the setting. The User mode now uses the

calibration offset constant that was created here.

Note: To exit without changing the setting, push any measurement key.

3.20.3 Cancel User mode calibration Linc

To cancel the User mode calibration Linc:

Note: The MP series meter must be in User linked mode to cancel the “Linc.”

1. Push a (linked) measurement key such as COND, RES, MIN/SALT, or TDS.

Two solutions are displayed on the left side of the display: User and another,

such as KCl.

2. Push the MR/DOWN key until Linc displays.

3. Push the CAL/MCLR key. SEL, User and the linked solution appear on the

display.

28

Page 29

Operation

4. Push the MR/DOWN key until User is the only solution icon that displays.

5. Push the CAL/MCLR key. The User mode Linc is now canceled.

3.21 Download stored data

The MP-Dock accessory package (HMPDOCK) allows the user to download stored

test data to a PC or spreadsheet. The MP-Dock receives power through the USB

port, and requires no external power source. The data is transferred through the

Infrared (IR) data port on the bottom of the MP meter (Figure 6) to the MP-Dock,

and then to the PC.

The MP Datalink software, which is included with the MP-Dock, operates on

Windows 2000 and XP, and Macintosh OS9.2 and OSX-based operating systems.

For the latest instructions on communication port selection and data download,

refer to the Hach Company MP-Dock User Manual.

1 Infrared data port

Figure 6 MP meter—bottom view

29

Page 30

Operation

30

Page 31

Section 4 Calibration

4.1 Calibration intervals

The MP Series meters are designed to not require frequent calibration. Calibration

is recommended about once per month with conductivity or TDS solutions. Check

the calibration with pH solution twice per month. Some applications may require

calibration frequencies to differ from these suggested guidelines.

4.2 Calibration limits

The MP Series meters have built in calibration limits. A nominal “FAC” value is an

ideal value stored by the factory. Attempts to calibrate too far (±10% or ±1 pH unit)

from this value causes the displayed value to be replaced with “FAC”. If the

CAL/MCLR key is pushed, the value is accepted, and the original default factory

calibration for this measurement is shown. The need to calibrate so far out that

“FAC” appears indicates a procedural problem, incorrect standard solution, a very

dirty cell cup or an aging pH/ORP sensor.

4.3 Calibration records

To minimize calibration efforts, keep records. If the calibration adjustments are

minimal, calibration can occur less often. Record the following information:

• Record changes in conductivity in percentages.

• Record changes in pH calibration in pH units.

• Conductivity cell calibration is purposely limited to

indicate damage, not drift.

• Calibration changes are limited to

end of the sensor’s lifetime and replacement is recommended.

±1 pH unit. Changes beyond that indicate the

±10%. Changes beyond that

4.4 Calibrate the meter

1. Push the measurement key for the parameter to be calibrated.

2. Push CAL/MCLR.

3. Measuring continues. The CAL icon is on. This indicates that calibration can

occur now.

4. Push UP/MS or MR/DOWN to change the reading to the known value.

5. Calibration for each of the four solution types can be performed in either

conductivity, mineral/salt or TDS mode.

Note: The number of steps to calibrate depends on what is to be calibrated.

31

Page 32

Calibration

Parameter KCl, NaCl or 442 User

COND Gain only Temperature compensation, then Gain

RES Done in conductivity Done in conductivity or TDS

TDS Gain only

MIN/SALT Gain only

pH 7, acid, and/or base

ORP Zero set with pH 7 automatically

Temperature compensation, Ratio,

then Gain

Temperature compensation, Ratio,

then Gain

6. Push the CAL/MCLR key to accept the new calibration value. The meter

accepts the value and presents the next value for adjustment. If there are no

more adjustments, the meter exits CAL mode.

Note: In the CAL mode, the CAL/MCLR key becomes an ACCEPT key. To bypass a

calibration step, push the CAL/MCLR key to accept the present value.

4.5 Exit calibration mode

When the CAL icon turns off, calibration is complete. To exit calibration mode when

the CAL icon is still on, push any measurement key. This cancels any changes not

accepted and exits the CAL mode. When CAL mode for pH is exited after the

second buffer, the meter enters the same gain for the third buffer.

4.6 Calibrate conductivity, mineral/salt or TDS

To make sure calibration is accurate, follow the items listed below.

1. Clean oily films or organic material from the conductivity cell with foaming

cleaner or mild acid.

2. Do not scrub inside the conductivity cell.

3. Rinse the conductivity cup with pure water after taking measurements.

4. Rinse the conductivity cup three times with the standard solution to be used for

calibration (KCl, NaCl, or 442).

Note: Failure to rinse can cause crystals to form in the cup and contaminate future

samples.

5. Fill the conductivity cup with same standard.

6. Push the COND key, the MIN/SALT key or the TDS key.

7. Push the CAL/MCLR key. The CAL icon appears on the display.

8. Push the UP/MS key or the MR/DOWN key to adjust to the standard value, or

hold down the key to adjust rapidly.

9. Push the CAL/MCLR key once to confirm the new value and end the

calibration sequence for this solution type.

10. To calibrate another solution type, change solution type (e.g., KCl, NaCl, or

442) and repeat this procedure.

32

Page 33

Calibration

4.7 Calibrate resistivity

Resistivity is the reciprocal of conductivity. Resistivity is automatically calibrated

based on the solution type used during a conductivity calibration.

4.8 Reset factory calibration—conductivity, mineral/salt or TDS

If calibration is suspect or known to be incorrect, and no standard solution is

available, it is possible to replace the calibrated value with the original factory value

for that solution. This ideal factory (FAC) value is the same for all MP Series

meters, and it returns to a known state without solution in the cup.

The FAC internal electronic calibration is not intended to replace calibration with

conductivity standard solutions.

1. Push the COND key, the MIN/SALT key or the TDS key.

2. Push the CAL/MCLR key twice in COND or three times in TDS.

Note: In the User mode, push the CAL/MCLR key twice in the COND mode and three

times in the TDS mode or the MIN/SALT

and ratio adjustments.)

3. Push the UP/MS key until the FAC icon appears.

4. Push the CAL/MCLR key to accept the factory calibration setting.

5. If another solution needs to be reset, select another solution type and repeat

the procedure.

mode. (This bypasses temperature correction

4.9 pH calibration

Note: Always zero-out the MP Series meter with a pH 7 buffer solution before calibrating with

acid or base buffers such as pH 4 or pH 10 solutions.

To perform a pH calibration:

1. Rinse the sensor cups three times with a pH 7 buffer solution.

2. Fill both sensor cups with pH 7 buffer solution.

3. Push the pH key to verify the pH calibration. If the display shows 7.00, skip the

pH zero calibration and proceed to section 4.10 on page 34.

33

Page 34

Calibration

4. Push the CAL/MCLR key to enter calibration mode. The CAL, BUFFER and 7

icons appear. The value displayed is for the uncalibrated sensor.

Note: If a wrong buffer is added (outside of pH 6-8), 7 and BUFFER will flash and the

meter does not adjust. The uncalibrated pH value that shows in step 4 assists in

determining the accuracy of the pH sensor. If the pH reading is below pH 6 or above pH 8

with pH 7 buffer solution, the sensor cup needs more rinses, or the pH sensor is defective

and needs to be replaced.

5. Push UP/MS or MR/DOWN until the display reads 7.00.

Note: Attempted calibration of > 1 pH point from factory calibration causes the FAC icon

to appear. This means that either sensor replacement (see Section 6 on page 41) or a

fresh buffer solution is needed. Push the CAL/MCLR key to accept the preset factory

value.

6. Push the CAL/MCLR key to accept the new value.

The pH zero calibration is now complete. It is recommended that the user performs

the multiple point pH calibration (see section 4.10). If the user does not wish to

continue, push any measurement key to exit.

4.10 Set multiple point pH calibrations

Important Note: Acid or base solution can be used for the second point calibration

and then use the other solution for the third point. To verify that a buffer is in the

sensor cup, the display shows either the Acd icon or the bAS icon.

Note: If the Acd icon or the bAS icon flash, fill the sensor cup with either an acid or base

solution to resolve the error.

1. Push the CAL/MCLR key twice while in the pH measurement mode to

complete the pH zero calibration or verify the pH 7 buffer. The CAL, BUFFER

and Acd or bAS icons are displayed.

2. Rinse the sensor cups three times with acid or base buffer solution.

3. Fill both sensor cups again with the same solution.

4. Push UP/MS or MR/DOWN until the display agrees with the buffer value.

5. Push the CAL/MCLR key to accept the second point of calibration. The display

indicates the next type of buffer to be used.

The two point calibration is complete now. The user can continue with the third

point of the calibration or exit the calibration process. Push any measurement

34

Page 35

Calibration

key to exit. If the user exits, the gain value accepted for the buffer is used for

both acid and base measurements.

6. Rinse the sensor cup three times with the third buffer solution.

7. Fill the sensor cups again with the same solution.

8. Push UP/MS or MR/DOWN until the display agrees with the buffer value.

9. Push the CAL/MCLR key to accept the third point of calibration. The calibration

procedure is now complete.

Note: Fill the pH/ORP sensor cup with pH storage solution and replace the protective sensor

cap when the meter is not in use. Do not allow the cup to dry.

4.11 ORP calibration

The ORP electrodes rarely give false readings unless there is a problem in the

reference electrode. For this reason, and because the calibration solutions for ORP

are highly reactive and potentially hazardous, the MP meter has an electronic ORP

calibration. This causes the zero point on the reference electrode to be set

whenever the pH 7 calibration is done.

4.12 Temperature calibration

Temperature calibration is not necessary in the MP series meters.

35

Page 36

Calibration

36

Page 37

Section 5 Maintenance

Practice the following care and maintenance of the MP series handheld meters:

• Rinse with clean water after each use

• Always fill the pH/ORP sensor cup with Hach pH storage solution and replace

the protective cap when not in use.

• Avoid solvents

• Avoid drops. Shock damage can damage the meter and void the warranty

5.1 Temperature extremes

Solutions in excess of 71 ºC (160 ºF) should not be placed in the sensor cups. This

activity can damage the meter. The pH sensor can fracture if the meter’s

temperature falls below 0 ºC (32 ºF). Take care not to exceed operating

temperatures.

Note: Do not leave an MP series meter in a vehicle or a storage shed on a hot day. This

activity can subject the meter to temperatures in excess of 66 ºC (150 ºF) and void the

warranty.

5.2 Battery replacement

NOTICE

If the meter is not completely dry before you open the meter, damage to the internal

electronics of the meter can occur.

Perform the following steps to replace the battery:

1. Dry the meter completely.

2. Remove the four screws from the base of the meter.

3. Open the meter carefully.

4. Take care to detach the battery from the circuit board.

5. Replace the battery with a new 9V alkaline battery.

6. Replace the bottom housing, ensuring that the sealing gasket is installed in the

groove of the top half of the case.

7. Replace the screws; tighten evenly and securely. Do not overtighten.

Note: All data stored in memory and all calibration settings are protected during power loss or

battery replacement. Loss of time and date can occur, however, if the battery is removed for

more than 3 minutes (180 seconds).

37

Page 38

Maintenance

5.2.1 Maintain the conductivity cup

Rinse the conductivity cup with clean water after taking measurements to prevent

buildup on the electrodes. Do not scrub the cup. For oily films, add a few drops of

foaming, non-abrasive cleaner or isopropyl alcohol, then rinse.

Note: When sampling low-conductivity solutions, make sure the pH/ORP sensor cap is

well-seated so that solution does not wash from the pH/ORP sensor cup into the conductivity

cup.

5.2.2 Maintain the pH/ORP sensor cup

Keep the pH/ORP sensor cup hydrated with Hach pH Storage Solution. Before

replacing the pH/ORP sensor cap, rinse and fill the sensor cup with the storage

solution. Never use distilled water to store the sensor cup.

5.3 pH/ORP sensor replacement

Complete installation instructions are included with each replacement sensor. Tools

required include a #2 Phillips screwdriver and 1/4-inch wrench.

Note: When the pH/ORP sensor is replaced, it is also a good time to replace the battery.

5.4 Clean the sensors

Perform these procedures to clean the various sensors.

5.4.1 Clean the conductivity/resistivity/TDS sensor

Keep the conductivity cell cup (Figure 7) as clean as possible.

Note: Flush with clean water after use to prevent buildup on electrodes.

When a dirty sample is left in the cup, a film forms. This film reduces accuracy.

To clean a visible film of oil, dirt or scale that is in the cell cup or on the electrode:

1. Use isopropyl alcohol or a foaming, non-abrasive household cleaner. Hach

acid electrode cleaning solution may also be used less frequently.

2. Pour any of these solutions in the cell cup and allow it to soak for no more than

five minutes.

3. Use a cotton swab to gently clean the electrodes.

4. Rinse out the cleaning solution.

38

Page 39

Maintenance

Figure 7 Model MP-6 sensor cups

1 Temperature sensor 5 pH glass electrode

2 Conductivity cell (built-in electrodes) 6 Reference junction under glass pH

bulb

3 ORP electrode 7 pH/ORP sensor protective cap

4 pH/ORP sensor (replaceable)

5.4.2 Clean the pH/ORP sensor

The pH/ORP sensor in the MP series meters is non-refillable and features a porous

liquid junction. It should not be allowed to dry out. If it does dry out, the sensor can

sometimes be restored by following the steps below.

1. Clean the sensor cup with isopropyl alcohol.

2. Rinse well. Do not scrub or wipe the pH/ORP sensor.

3. Follow the hot solution method described below:

a. Pour a hot salt solution ~60 ºC (140 ºF), such as pH storage solution in the

sensor cup.

b. Allow the liquid to cool.

c. Retest.

4. If the hot solution method does not work, follow the Deionized (DI) water

method below:

a. Pour DI water into the sensor cup.

39

Page 40

Maintenance

b. Allow to stand for no more than four hours (more standing time can deplete

the reference solution and damage the glass bulb).

c. Retest.

5. If neither of the above methods are successful, the sensor must be replaced.

5.4.2.1 Drifting test results

A film on the pH sensor bulb or the reference can cause drifting. Use isopropyl

alcohol to clean the glass bulb.

Note: The sensor bulb is very thin and delicate. Do not scrub the pH/ORP sensor.

To clean the sensor:

1. Use isopropyl alcohol or a foaming, non-abrasive household cleaner. Hach

acid electrode cleaning solution may also be used less frequently.

2. Pour any of these solutions in the cell cup and allow it to soak for no more than

five minutes.

3. Use a cotton swab to gently clean the electrodes.

4. Rinse out the cleaning solution.

5. Fill the sensor cup with Hach pH storage solution before the pH/ORP sensor

cap is replaced.

5.4.2.2 Solutions that damage the pH/ORP sensor

Samples that contain chlorine, sulfur or ammonia can damage the pH electrode.

Rinse the sensor thoroughly with clean water immediately after any measurement

of these liquids.

Samples that reduce (add an electron to) silver, such as cyanide will attack the

reference electrode.

Leaving alkaline solutions in the pH sensor cup for long periods of time can

damage the sensor.

40

Page 41

Section 6 Troubleshooting

Symptom Possible cause Action

No display even though

measurement key is

pushed

Inaccurate pH reading

No response to pH

changes (MP-6 and MP-6p

models)

Meter does not adjust

down to pH 7 (MP-6 and

MP-6p models)

pH readings drift or

respond slowly to change

or

FAC displays repeatedly

Unstable conductivity, TDS

or resistivity readings

Meter cannot calibrate

Conductivity or TDS

Resistivity reading is much

lower than expected

Battery is weak or not

connected.

pH calibration is needed

(see section 4.9 on page 33)

Cross-contamination from

residual buffers or samples

in sensor cup

Calibration with expired pH

buffers

Sensor bulb is cracked or an

electromechanical short is

caused by an internal crack.

pH sensor has lost KCl

Temporary condition due to

memory of solution in pH

sensor cup for long periods

Bulb dirty or dried out

Reference junction clogged

or coated

Dirty electrodes Clean the cell cup and the

Test samples that are

greater than 1 MΩ

Film or deposits on

electrodes

Contamination from previous

samples or from the pH

sensor cup

Carbon dioxide in the test

sample

Check the connections or

replace the battery (see

section 5.2 on page 37).

Recalibrate the meter.

Rinse the sensor cup.

Recalibrate using fresh

buffers.

Replace the pH/ORP sensor

(see section 5.3 on page 38).

Clean and restore the sensor

(see section 5.4 on page 38)

and recalibrate. If there is no

improvement, replace the

pH/ORP sensor (see

section 5.3 on page 38).

Clean and restore the sensor

(see section 5.4 on page 38)

and recalibrate. If there is no

improvement, replace the

pH/ORP sensor (refer to

section 5.3 on page 38).

electrodes (see section 5.4 on

page 38).

Minimize the test sample

exposure to air (see

section 3.6 on page 17).

Clean the cell cup and the

electrodes (see section 5.4 on

page 38

).

Rinse the sensor cup more

thoroughly before

measurement.

Make sure the pH cap is

snugly in place

(see section 5.4 on page 38).

41

Page 42

Troubleshooting

42

Page 43

Section 7 Contact Information

HACH Company World

Headquarters

P.O. Box 389

Loveland, Colorado

80539-0389 U.S.A.

Tel (800) 227-HACH

(800) 227-4224

(U.S.A. only)

Fax (970) 669-2932

orders@hach.com

www.hach.com

Repair Service in Latin

America, the Caribbean,

the Far East, Indian

Subcontinent, Africa,

Europe, or the Middle

East:

Hach Company World

Headquarters,

P.O. Box 389

Loveland, Colorado,

80539-0389 U.S.A.

Tel +001 (970) 669-3050

Fax +001 (970) 669-2932

intl@hach.com

HACH LANGE LTD

Unit 1, Chestnut Road

Western Industrial Estate

IRL-Dublin 12

Tel. +353(0)1 46 02 5 22

Fax +353(0)1 4 50 93 37

info@hach-lange.ie

www.hach-lange.ie

HACH LANGE FRANCE

S.A.S.

33, Rue du Ballon

F-93165 Noisy Le Grand

Tél. +33 (0)1 48 15 68 70

Fax +33 (0)1 48 15 80 00

info@hach-lange.fr

www.hach-lange.fr

HACH LANGE APS

Åkandevej 21

DK-2700 Brønshøj

Tel. +45 36 77 29 11

Fax +45 36 77 49 11

info@hach-lange.dk

www.hach-lange.dk

Repair Service in the

United States:

HACH Company

Ames Service

100 Dayton Avenue

Ames, Iowa 50010

Tel (800) 227-4224

(U.S.A. only)

Fax (515) 232-3835

HACH LANGE GMBH

Willstätterstraße 11

D-40549 Düsseldorf

Tel. +49 (0)2 11 52 88-320

Fax +49 (0)2 11 52 88-210

info@hach-lange.de

www.hach-lange.de

HACH LANGE GMBH

Hütteldorferstr. 299/Top 6

A-1140 Wien

Tel. +43 (0)1 9 12 16 92

Fax +43 (0)1 9 12 16 92-99

info@hach-lange.at

www.hach-lange.at

HACH LANGE SA

Motstraat 54

B-2800 Mechelen

Tél. +32 (0)15 42 35 00

Fax +32 (0)15 41 61 20

info@hach-lange.be

www.hach-lange.be

HACH LANGE AB

Vinthundsvägen 159A

SE-128 62 Sköndal

Tel. +46 (0)8 7 98 05 00

Fax +46 (0)8 7 98 05 30

info@hach-lange.se

www.hach-lange.se

Repair Service in

Canada:

Hach Sales & Service

Canada Ltd.

1313 Border Street, Unit 34

Winnipeg, Manitoba

R3H 0X4

Tel (800) 665-7635

(Canada only)

Tel (204) 632-5598

Fax (204) 694-5134

canada@hach.com

HACH LANGE LTD

Pacific Way

Salford

GB-Manchester, M50 1DL

Tel. +44 (0)161 872 14 87

Fax +44 (0)161 848 73 24

info@hach-lange.co.uk

www.hach-lange.co.uk

DR. BRUNO LANGE AG

Juchstrasse 1

CH-8604 Hegnau

Tel. +41(0)44 9 45 66 10

Fax +41(0)44 9 45 66 76

info@hach-lange.ch

www.hach-lange.ch

DR. LANGE NEDERLAND

B.V.

Laan van Westroijen 2a

NL-4003 AZ Tiel

Tel. +31(0)344 63 11 30

Fax +31(0)344 63 11 50

info@hach-lange.nl

www.hach-lange.nl

HACH LANGE S.R.L.

Via Riccione, 14

I-20156 Milano

Tel. +39 02 39 23 14-1

Fax +39 02 39 23 14-39

info@hach-lange.it

www.hach-lange.it

43

Page 44

Contact Information

HACH LANGE S.L.U.

Edif. Arteaga Centrum

C/Larrauri, 1C- 2ª Pl.

E-48160 Derio/Vizcaya

Tel. +34 94 657 33 88

Fax +34 94 657 33 97

info@hach-lange.es

www.hach-lange.es

HACH LANGE S.R.O.

Lešanská 2a/1176

CZ-141 00 Praha 4

Tel. +420 272 12 45 45

Fax +420 272 12 45 46

info@hach-lange.cz

www.hach-lange.cz

HACH LANGE

8, Kr. Sarafov str.

BG-1164 Sofia

Tel. +359 (0)2 963 44 54

Fax +359 (0)2 866 04 47

info@hach-lange.bg

www.hach-lange.bg

ÇÁCH LANGE E.Ð.Å.

БхлЯдпт 27

GR-115 27 БиЮнб

Фзл. +30 210 7777038

Fax +30 210 7777976

info@hach-lange.gr

www.hach-lange.gr

HACH LANGE LDA

Av. do Forte nº8

Fracção M

P-2790-072 Carnaxide

Tel. +351 214 253 420

Fax +351 214 253 429

info@hach-lange.pt

www.hach-lange.pt

HACH LANGE KFT.

Hegyalja út 7-13.

H-1016 Budapest

Tel. +36 (06)1 225 7783

Fax +36 (06)1 225 7784

info@hach-lange.hu

www.hach-lange.hu

HACH LANGE SU

ANALÝZ SÝSTEMLERÝ

LTD.ÞTÝ.

Hilal Mah. 75. Sokak

Arman Plaza No: 9/A

TR-06550 Çankaya/ANKARA

Tel. +90 (0)312 440 98 98

Fax +90 (0)312 442 11 01

bilgi@hach-lange.com.tr

www.hach-lange.com.tr

HACH LANGE E.P.E.

27, Avlidos str

GR-115 27 Athens

Tel. +30 210 7777038

Fax +30 210 7777976

info@hach-lange.gr

www.hach-lange.gr

HACH LANGE SP.ZO.O.

ul. Opolska 143 a

PL-52-013 Wroc³aw

Tel. +48 (0)71 342 10-83

Fax +48 (0)71 342 10-79

info@hach-lange.pl

www.hach-lange.pl

HACH LANGE S.R.L.

Str. Leonida, nr. 13

Sector 2

RO-020555 Bucuresti

Tel. +40 (0) 21 201 92 43

Fax +40 (0) 21 201 92 43

info@hach-lange.ro

www.hach-lange.ro

HACH LANGE D.O.O.

Fajfarjeva 15

SI-1230 Domžale

Tel. +386 (0)59 051 000

Fax +386 (0)59 051 010

info@hach-lange.si

www.hach-lange.si

44

Page 45

Section 8 Replacement parts and

accessories

8.1 Replacement parts

Description Item No.

pH/ORP sensor HMPSENS

9V alkaline battery 00024Q

8.2 Accessories

Description Item No.

MP-Dock (facilitates data download to PC or spreadsheet) HMPDOCK

8.3 Consumables

Description Quantity Item No.

Buffer solution, pH 4.01 50 mL 2283426

Buffer solution, pH 4.01 500 mL 2283449

Buffer solution, pH 4.01 4L 2283456

Buffer solution, pH 4.01 20 L 2283461

Buffer solution, pH 7.00 50 mL 2283526

Buffer solution, pH 7.00 500 mL 2283549

Buffer solution, pH 7.00 4 L 2283556

Buffer solution, pH 7.00 20 L 2283561

Buffer solution, pH 10.01 50 mL 2283626

Buffer solution, pH 10.01 500 mL 2283649

Buffer solution, pH 10.01 4 L 2283656

Buffer solution, pH 10.01 20 L 2283661

pH electrode storage solution, 500 mL 500 mL 2756549

pH electrode storage solution, 50 mL 50 mL 2756526

0.001M KCl Conductivity Standard Solution, 148 µS/cm 500 mL 2974249

0.001M KCl Conductivity Standard Solution, 148 µS/cm 50 mL 2974226

0.01M KCl Conductivity Standard Solution, 1413 µS/cm 500 mL 2974349

0.01M KCl Conductivity Standard Solution, 1413 µS/cm 50 mL 2974326

0.1M KCl Conductivity Standard Solution, 12.88 mS/cm 500 mL 2974449

0.1M KCl Conductivity Standard Solution, 12.88 mS/cm 50 mL 2974426

45

Page 46

Replacement parts and accessories

8.3 Consumables (continued)

Description Quantity Item No.

442-30 Natural Water™1 TDS Standard Solution, 30

ppm

442-30 Natural Water TDS Standard Solution, 30 ppm 50 mL 2974526

442-300 Natural Water TDS Standard Solution,

300 ppm

442-300 Natural Water TDS Standard Solution,

300 ppm

442-1000 Natural Water TDS Standard Solution,

1000 ppm

442-1000 Natural Water TDS Standard Solution,

1000 ppm

442-3000 Natural Water TDS Standard Solution,

3000 ppm

442-3000 Natural Water TDS Standard Solution,

3000 ppm

100 µS/cm NaCl Conductivity Standard Solution 500 mL 2971849

100 µS/cm NaCl Conductivity Standard Solution 50 mL 2971826

1000 µS/cm NaCl Conductivity Standard Solution 500 mL 1440049

1000 µS/cm NaCl Conductivity Standard Solution 50 mL 1440026

10,000 µS/cm NaCl Conductivity Standard Solution 500 mL 2972249

10,000 µS/cm NaCl Conductivity Standard Solution 50 mL 2972226

18.00 mS/cm NaCl Conductivity Standard Solution 500 mL 2307449

18.00 mS/cm NaCl Conductivity Standard Solution 50 mL 2307426

1

Trademark of Myron L Company

500 mL 2974549

500 mL 2974649

50 mL 2974626

500 mL 2974749

50 mL 2974726

500 mL 2974849

50 mL 2974826

8.4 Recommended cleaning consumables

Description Quantity Item No.

Isopropyl alcohol 100 mL 1227642

Isopropyl alcohol prep pads 200/pk 2938200

Cotton swabs 100/pkg 2554300

Acid electrode cleaning solution 50 mL 2975126

Acid electrode cleaning solution 500 mL 2975149

46

Page 47

Section 9 Limited Warranty

Hach Company warrants to the original purchaser against any defects that are due

to faulty material or workmanship for a period of two years from date of shipment

unless otherwise noted in the product manual.

In the event that a defect is discovered during the warranty period, Hach Company

agrees that, at its option, it will repair or replace the defective product or refund the

purchase price excluding original shipping and handling charges. Any product

repaired or replaced under this warranty will be warranted only for the remainder of

the original product warranty period.

This warranty does not apply to consumable products such as chemical reagents;

or consumable components of a product, such as, but not limited to, lamps and

tubing.

Contact Hach Company or your distributor to initiate warranty support. Products

may not be returned without authorization from Hach Company.

Warranty Limitations

This warranty does not cover:

• Damage caused by acts of God, natural disaster, labor unrest, acts of war

(declared or undeclared), terrorism, civil strife or acts of any governmental

jurisdiction

• Damage caused by misuse, neglect, accident or improper application or

installation

• Damage caused by any repair or attempted repair not authorized by Hach

Company

• Any product not used in accordance with the instructions furnished by Hach

Company

• Freight charges to return merchandise to Hach Company

• Freight charges on expedited or express shipment of warranted parts or product

• Travel fees associated with on-site warranty repair

This warranty contains the sole express warranty made by Hach Company in

connection with its products. All implied warranties, including without limitation, the

warranties of merchantability and fitness for a particular purpose, are expressly

disclaimed.

Some states within the United States do not allow the disclaimer of implied

warranties and if this is true in your state the above limitation may not apply to you.

This warranty gives you specific rights, and you may also have other rights that vary

from state to state.

This warranty constitutes the final, complete, and exclusive statement of warranty

terms and no person is authorized to make any other warranties or representations

on behalf of Hach Company.

Limitation of Remedies

The remedies of repair, replacement or refund of purchase price as stated above

are the exclusive remedies for the breach of this warranty. On the basis of strict

liability or under any other legal theory, in no event shall Hach Company be liable

for any incidental or consequential damages of any kind for breach of warranty or

negligence.

47

Page 48

Limited Warranty

48

Page 49

Appendix A Temperature compensation

Electrical conductivity indicates solution concentration and ionization of the

dissolved material. Because temperature greatly affects ionization, conductivity

measurements are temperature dependent, and are normally corrected to read

what they would be at 25 ºC.

A.1 Compensation to 25 ºC

The MP series handheld meters includes temperature compensation to 25 ºC.

Temperature compensation can be set to KCl, NaCl or 442 solutions or tailored for

special measurements or applications.

A.2 Changes in temperature compensation

Most conductivity meters approximate the temperature characteristics of solutions,

and assume a constant value, such as, 2%/ºC. In fact, KCl temperature

compensation changes with concentration and temperature in a non-linear fashion.

Other solutions change even more. The MP series handheld meters use

compensations that change with concentration and temperature instead of single

average values (Figure 8).

Figure 8

49

Page 50

Temperature compensation

A.3 Graph of comparative error

In the range of 1000 µS, the error of using a KCl temperature compensation on a

solution that should be calculated as NaCl or 442 is shown in the chart below

(Figure 9).

Figure 9

To measure natural water-based solutions to 1%, users must alter the internal

temperature compensation to the more suitable, pre-loaded 442 values or stay

close to 25 ºC.

A.4 Other solutions

A salt solution like sea water or liquid fertilizer acts like NaCl. The NaCl solution

compensation provides the greatest accuracy for these solutions.

Many solutions differ greatly from KCl, NaCl or 442. A sugar solution, a silicate, or a

calcium salt at a high or low temperature may require a User value to provide

readings close to the true compensated conductivity. This is determined

experimentally.

The chosen solution characteristic should closely match the sample being tested to

achieve accuracy of ±1%.

50

Page 51

Appendix B Conductivity conversion

B.1 How conductivity conversion works

When the effect of temperature is removed, the corrected conductivity depends on

the concentration (TDS). Temperature compensation of the conductivity of a

solution is performed automatically by the meter’s internal processor with data

derived from chemical tables. Any dissolved salt at a known temperature has a

known ratio of conductivity to concentration. Tables of conversion ratios referenced

to 25 ºC have been published by chemists for decades.

B.2 Solution characteristics

Real-world applications have to measure a wide range of materials and mixtures of

electrolyte solutions. To address this problem, industry applications tend to use the

characteristics of a standard material as a model for their solution, such as KCl,

which is favored by chemists for its stability.

Users who deal with sea water, etc., use NaCl as the model for their concentration

calculations. Users who deal with freshwater work with mixtures including sulfates,

carbonates and chlorides. These are modeled in the 442 standard solutions.

The meter contains algorithms for these three most commonly referenced

compounds. The solution type in use is shown on the left side of the display. In

addition to KCl, NaCl, and 442, a User choice is available. The User mode allows

the user to enter the temperature compensation and TDS ratio by hand. This

increases the accuracy of readings for a specific solution. That value remains a

constant for all measurements, and should be reset for different dilutions or

temperatures.

51

Page 52

Conductivity conversion

52

Page 53

Appendix C Temperature compensation and TDS derivation

The MP series handheld meters contain internal algorithms for characteristics of the

three most commonly referenced compounds. The selected solution type is shown

on the left of the display. In addition to KCl, NaCl and 442, a User choice is

available. The User mode allows the user to enter the temperature compensation

and the TDS conversion ratio of a unique solution.

C.1 Conductivity characteristics

When taking conductivity measurements, the Solution Selection determines the

characteristic assumed as the instrument reports what a measured conductivity

would be if it were at 25 °C. The characteristic is represented by the temperature

compensation, expressed in %/°C.

If a solution of 100 µS at 25 °C increases to 122 µS at 35 °C, then a 22% increase

has occurred over this change of 10 °C. The solution is then said to have a

temperature compensation of 2.2%/°C.

Temperature compensation always varies among solutions because it is dependent

on their individual ionization activity, temperature and concentration. This is why the

MP meters feature mathematically generated models for known salt characteristics

that also vary with concentration and temperature.

C.2 Temperature compensation of unknown solutions

The user may need to find the corrected conductivity of a solution that differs from

the three standard salts. In order to enter a custom fixed temperature compensation

for a limited measurement range, enter a specific value through the User function.

The temperature compensation can be determined by two different methods.

C.2.1 Find temperature compensation by calculation

1. Heat or cool a sample of the solution to 25 ºC, and measure its conductivity.

2. Heat or cool the solution to a typical temperature where it is normally

measured.

3. Select the User function.

4. Set the temperature compensation to 0%/ºC (see section 3.12.1 on page 20).

5. Measure the new conductivity and the new temperature.

6. Divide the percentage decrease or percentage increase by the 25 ºC value.

7. Divide that result by the temperature difference.

C.2.2 Find temperature compensation by adjustment

1. Heat or cool a sample of the solution to 25 ºC, and measure its conductivity.

2. Heat or cool the solution to a typical temperature where it is normally

measured.

53

Page 54

Temperature compensation and TDS derivation

3. Set the temperature compensation to an expected value (see section 3.12 on

page 20).

4. See if the compensated value is the same as the 25 ºC value.

5. If the value is not the same, raise or lower the temperature compensation and

measure again until the 25 ºC value is read.

C.3 TDS ratio of unknown solutions

When the effect of temperature is removed, the compensated conductivity varies

with the concentration (TDS). The ratio of TDS to compensated conductivity for any

solution also varies with concentration. The ratio is set during calibration in the User

mode (see section 3.13 on page 20). Measure the TDS of an unknown solution by

evaporation and weighing. Then measure the conductivity of the solution, with the

now-known TDS, and calculate the ratio. The next time this solution is measured,

the ratio is known.

54

Page 55

Appendix D Additional information on pH and ORP (MP-6 and MP-6p models)

D.1 pH

D.1.1 pH as an indicator

pH measures the acidity or alkalinity of an aqueous solution. Another way to

describe pH is as the hydrogen ion activity of a solution.

pH measures the effective, not the total acidity of a solution. A 4% solution of acetic

acid (pH 4, vinegar) can be quite palatable, but a 4% solution of sulfuric acid (pH 0)

is a violent poison. pH provides the needed quantitative information by expressing

the degree of activity of an acid or base.

In a solution of one known component, pH indicates concentration directly. Very

dilute solutions may be very slow reading because very few ions take time to

accumulate.

D.1.2 pH units

The acidity or alkalinity of a solution measures the relative availability of hydrogen

+

) and hydroxide (OH-) ions. An increase in H+ ions increases acidity, while an

(H

increase in OH

pH is defined as the negative logarithm of hydrogen ion concentration. Where

+

concentration falls below 10-7 mol/liter, solutions are less acidic than neutral, and

H

therefore are alkaline. A concentration of 10

ions than OH

-

ions increases alkalinity.

-9

-

ions and is an alkaline solution of pH 9.

mol/liter of H+ has 100 times less H+

D.1.3 pH sensor

The active part of a pH sensor is a thin glass surface that is selectively receptive to

hydrogen ions. Available hydrogen ions in a solution accumulate on this surface

and a charge builds up across the glass interface. The voltage can be measured

with a high impedance voltmeter circuit.

The glass surface encloses a captured solution of potassium chloride that holds an

electrode of silver wire coated with silver chloride. This is the most inert connection

possible from a metal to an electrolyte. It can still produce an offset voltage, but

using the same materials to connect to the solution on the other side of the

membrane cancels the two equal offsets.

The other electrode, also called the reference junction, allows the junction fluid to

contact the test solution, without significant migration of liquids, through the plug

material.

The pH/ORP sensor in the MP series meters (MP-6 and MP-6p) (Figure 10) is a

single construction in an easy-to-replace package. The sensor body holds an

oversize solution supply for long life. The reference junction is a wick that is porous

so that it can provide a stable, low, permeable interface. It is located under the

glass pH sensing electrode.

55

Page 56

Additional information on pH and ORP (MP-6 and MP-6p models)

.

Figure 10 pH/ORP sensor construction

1 Glass surface 5 KCl solution

+

ions 6 Glass

2 H

3 Junction plug 7 Electrode wires

4 Platinum button

D.1.4 Sources of error

D.1.4.1 Reference junction

The most common sensor problem is a clogged junction because a sensor is