Page 1

DOC026.97.80340

MET ONE 6000: 6003, 6005,

6013, 6015

05/2013, Edition 2

Basic User Manual

Manuel d'utilisation de base

Manual básico del usuario

基本用户手册

基本取扱説明書

기본 사용 설명서

Page 2

English...................................................................................................................................................................................................

Français..............................................................................................................................................................................................24

Español...............................................................................................................................................................................................48

中文.......................................................................................................................................................................................................72

日本語..................................................................................................................................................................................................91

한글.....................................................................................................................................................................................................113

3

2

Page 3

Table of contents

Specifications on page 3 Startup on page 15

General information on page 4 Operation on page 16

Installation on page 8 Maintenance on page 23

Specifications

Specifications are subject to change without notice.

Specification Details

Dimensions (W x D xH)13.56 x 8.93 x 12.06 cm (5.34 x 3.52 x 4.75 in.)

Enclosure 304 stainless steel

Light source Long Life Laser™ diode , Class 3B laser

Weight 0.82 kg (1.8 lb)

Pollution degree 2

Installation category I

Protection class III

Power requirements 9–28 VDC (source: Class 2 limited energy, < 150 VA)

Power consumption

(maximum)

Operating

temperature

Storage temperature –40 to 70 °C (–40 to 158 °F)

Humidity Operating and storage: 5 to 95% relative humidity, non-

Altitude 2000 m (6562 ft) maximum

Serial and pulse units: 3.3 W; Ethernet unit: 4.3 W;

Analog: 3.5 W; 1 A maximum

5 to 40 °C (40 to 104 °F); best performance: 10 to 32 °C

(50 to 90 °F)

condensing

Specification Details

Port sizes Model 6003, 6005: barb fitting for 0.32 cm (1/8-in.) ID

Output signal options Pulse, analog 4–20 mA, serial RS232 with Modbus RTU

Data storage 1000 samples/records (oldest records are written over

Sample flow rate Model 6003, 6005: 0.1 cfm (2.83 Lpm) ± 5%

Inlet pressure Ambient to 2.5 mm (0.1 in) Hg vacuum

Vacuum requirement ≥ 406 mm (16 in.) Hg (542 mbar) minimum vacuum

Range Model 6003: 0.3 μm to 10.0 μm at 0.1 cfm (2.83 L/min)

Sensitivity Model 6003: 0.3 μm at 0.1 cfm (2.83 L/min)

Counting efficiency Model 6003: 50% (± 20%) for 0.3 μm, (100% ± 10% at

Coincidence loss Model 6003, 6005 (all output options): 10% at

inlet tubing, 0.64 cm (¼-in.) ID outlet tubing

Model 6013, 6015: barb fitting for 0.64 cm (¼-in.) ID inlet

tubing, 0.64 cm (¼-in.) ID outlet tubing

or FXB communication protocol (no networking), serial

RS485 with Modbus RTU or FXB communication

protocol, Ethernet with ModbusTCP protocol

when the buffer is full)

Model 6013, 6015: 1.0 cfm (28.3 Lpm) ± 5%

measured at each instrument with flow through all

instruments.

Model 6005: 0.5 μm to 10.0 μm at 0.1 cfm (2.83 L/min)

Model 6013, 6015: 0.5 μm to 10.0 μm at 1.0 cfm

(28.3 L/min)

Model 6005: 0.5 μm at 0.1 cfm (2.83 L/min)

Model 6013: 0.3 μm at 1.0 cfm (28.3 L/min)

Model 6015: 0.5 μm at 1.0 cfm (28.3 L/min)

1.5 times the minimum sensitivity)1.

Model 6005, 6013, 6015: 50% (± 20%) for 0.5 μm, (100%

± 10% at 1.5 times the minimum sensitivity)1.

140,000,000 particles /m3 (4,000,000 particles /ft3)

Model 6013, 6015 (all output options except for pulse):

10% at 20,000,000 particles/m3 (566,000/ft3)

English 3

Page 4

Specification Details

False count rate One or less in 5 minutes

Certifications CE

1

Fully complies with ISO21501-4.

General information

In no event will the manufacturer be liable for direct, indirect, special,

incidental or consequential damages resulting from any defect or

omission in this manual. The manufacturer reserves the right to make

changes in this manual and the products it describes at any time, without

notice or obligation. Revised editions are found on the manufacturer’s

website.

Expanded manual version

For additional information, refer to the CD for an expanded version of

this manual.

Safety information

N O T I C E

The manufacturer is not responsible for any damages due to misapplication or

misuse of this product including, without limitation, direct, incidental and

consequential damages, and disclaims such damages to the full extent permitted

under applicable law. The user is solely responsible to identify critical application

risks and install appropriate mechanisms to protect processes during a possible

equipment malfunction.

Please read this entire manual before unpacking, setting up or operating

this equipment. Pay attention to all danger and caution statements.

Failure to do so could result in serious injury to the operator or damage

to the equipment.

Make sure that the protection provided by this equipment is not impaired.

Do not use or install this equipment in any manner other than that

specified in this manual.

Use of hazard information

D A N G E R

Indicates a potentially or imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially or imminently hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a potentially hazardous situation that may result in minor or moderate

injury.

Indicates a situation which, if not avoided, may cause damage to the instrument.

Information that requires special emphasis.

W A R N I N G

C A U T I O N

N O T I C E

Precautionary labels

Read all labels and tags attached to the instrument. Personal injury or

damage to the instrument could occur if not observed. A symbol on the

instrument is referenced in the manual with a precautionary statement.

This symbol, if noted on the instrument, references the instruction

manual for operation and/or safety information.

This symbol, when noted on a product enclosure or barrier, indicates

that a risk of electrical shock and/or electrocution exists.

4 English

Page 5

This symbol indicates a laser device is used in the equipment.

Electrical equipment marked with this symbol may not be disposed of

in European public disposal systems after 12 August of 2005. In

conformity with European local and national regulations (EU Directive

2002/96/EC), European electrical equipment users must now return

old or end-of-life equipment to the Producer for disposal at no charge

to the user.

Note: For return for recycling, please contact the equipment producer or supplier

for instructions on how to return end-of-life equipment, producer-supplied

electrical accessories, and all auxillary items for proper disposal.

Laser safety information

This instrument is a CLASS 1 LASER PRODUCT, CDRH Accession No.

9022243-029. Invisible laser radiation is present when opened. Avoid

direct exposure to the beam. Service of the internal components must be

done by factory-authorized personnel only.

The instrument complies with IEC/EN 60825-1 and 21 CFR

1040.10 except for deviations pursuant to Laser Notice No. 50, dated

June 24, 2007.

Certification

Canadian Radio Interference-Causing Equipment Regulation,

IECS-003, Class A:

Supporting test records reside with the manufacturer.

This Class A digital apparatus meets all requirements of the Canadian

Interference-Causing Equipment Regulations.

Cet appareil numèrique de classe A répond à toutes les exigences de la

réglementation canadienne sur les équipements provoquant des

interférences.

FCC Part 15, Class "A" Limits

Supporting test records reside with the manufacturer. The device

complies with Part 15 of the FCC Rules. Operation is subject to the

following conditions:

1. The equipment may not cause harmful interference.

2. The equipment must accept any interference received, including

interference that may cause undesired operation.

Changes or modifications to this equipment not expressly approved by

the party responsible for compliance could void the user's authority to

operate the equipment. This equipment has been tested and found to

comply with the limits for a Class A digital device, pursuant to Part 15 of

the FCC rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated

in a commercial environment. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference

to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference, in which case the user will be

required to correct the interference at their expense. The following

techniques can be used to reduce interference problems:

1. Disconnect the equipment from its power source to verify that it is or

is not the source of the interference.

2. If the equipment is connected to the same outlet as the device

experiencing interference, connect the equipment to a different

outlet.

3. Move the equipment away from the device receiving the interference.

4. Reposition the receiving antenna for the device receiving the

interference.

5. Try combinations of the above.

Product overview

This instrument

and collection optics. Refer to Figure 1. Room air is pulled through the

particle counter by an attached, external vacuum system.

Multiple instruments can be installed at different locations in a clean

room to monitor the air quality. Count data is sent to the user-supplied

central monitoring software through the applicable communication

protocols. The central monitoring software is used to remotely operate

the instrument.

The sensor flow path is resistant to vaporous hydrogen peroxide (VHP)

for VHP-based standard clean room disinfection and cleaning cycles.

counts airborne particles with a laser diode light source

English 5

Page 6

Figure 1 Product overview

Table 1 Status indicator light (continued)

Color Indication System status

Blue On Sensor failure

One short flash, one long flash Air flow failure

Flashing Communication failure

Red On or flashing Count alarm

Yellow On Initialization

Flashing Count alert

Purple Flashing Setup utility is being used

1

The user-supplied central monitoring software can be used to make the yellow

light flash when a count alert occurs with ModBus protocol, not FX protocol.

The count alert settings are selected with the central monitoring software.

1

1 Power input and communication

connector, 10-pin

2 Vacuum source fitting (or quick-

connect fitting)

3 Sample air inlet fitting 9 Connection indicator lights

4 Status indicator light (Table 1) 10 Ethernet RJ45 connector

5 Service port and optional light stack

port

6 DIP switch, network address

1

All units except Ethernet

2

Ethernet units only

1

1

7 Relative humidity (RH) and

temperature sensor port

8 Vacuum source fitting (alternate

location)

(Table 2)

11 Power input connector, 5-pin

Table 1 Status indicator light

Color Indication System status

Green Flashing (3 seconds) Normal, sampling

On Normal, not sampling

6 English

Table 2 Ethernet indicator lights

Color Indication Status

Yellow On Connected

2

2

2

Green Off 10Base-T

On 100Base-T

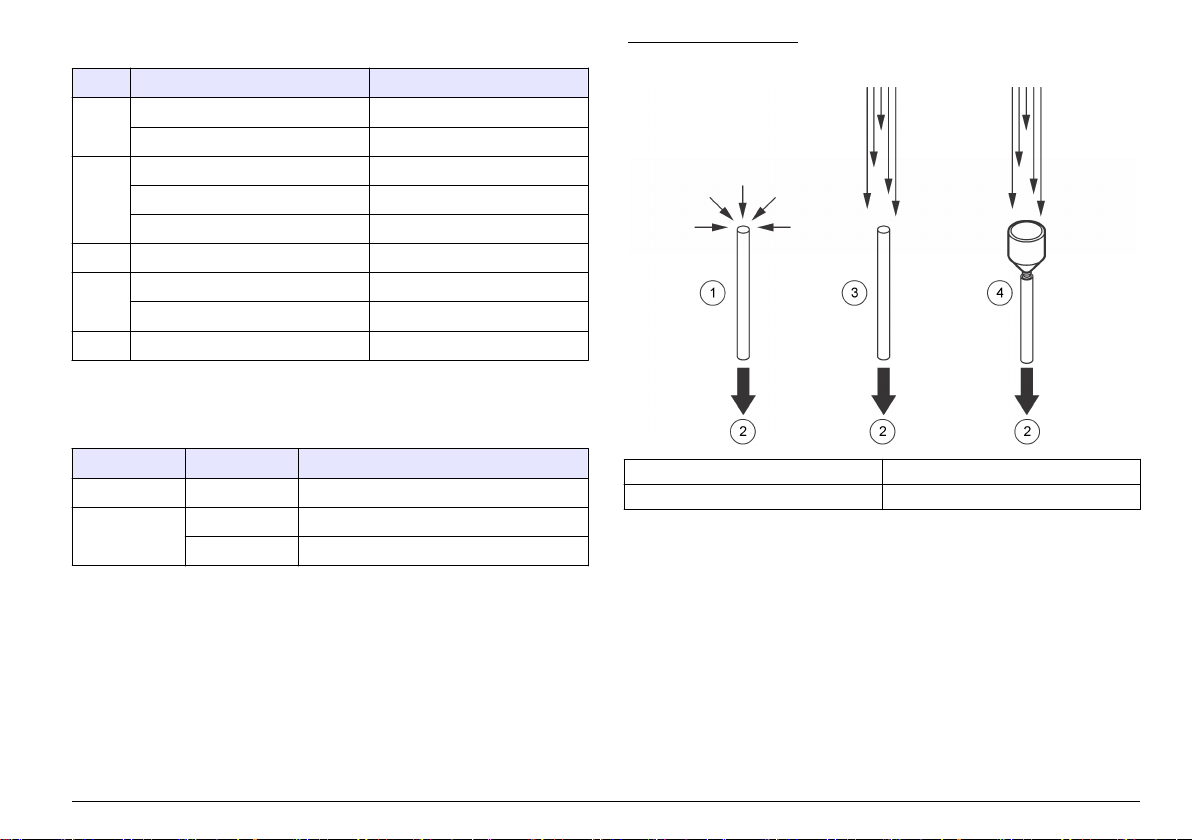

Isokinetic probe

For the best accuracy in laminar flow environments, always use the

supplied isokinetic probe with this

instrument. The velocity of air in the

probe is similar to that of a typical vertical or horizontal laminar flow

environment such as a clean room or clean hood. The supplied

isokinetic probe supplies the same vertical (or horizontal) flow speed of

the air in order to collect representative samples of the clean room

laminar flow for the instrument. Refer to Figure 2 for a comparison of

sampling with and without the isokinetic probe.

Page 7

Figure 2 Isokinetic probe function

1 No probe in non-laminar air flow 3 No probe in laminar air flow—

particles are missed

2 To particle counter 4 Isokinetic probe in laminar air flow

—most accurate

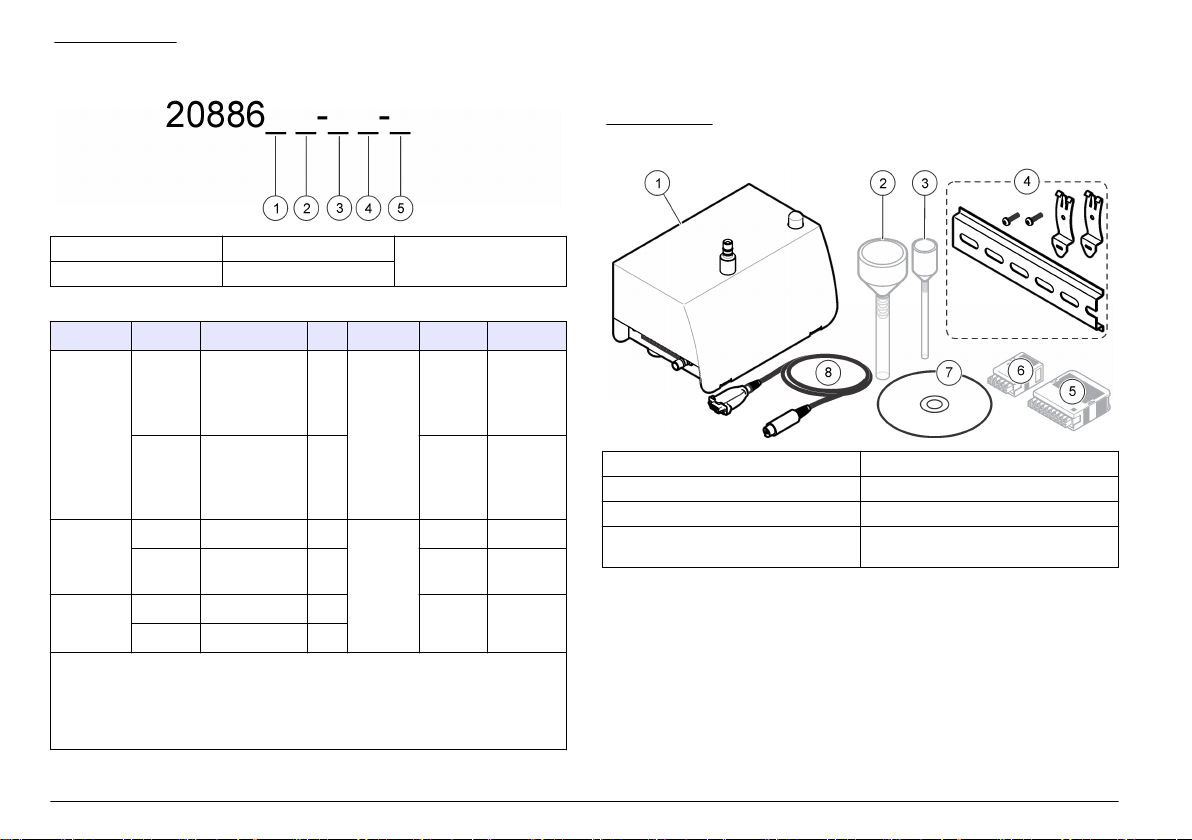

Instrument configurations

This instrument is available in many configurations. Each configuration

has a different part number. Figure 3 shows the part number structure.

Table 3 gives descriptions of the part number codes.

Figure 3 Part number structure

1 Flow rate 3 Exhaust location 5 Communication

2 Sensitivity (minimum) 4 Flow measurement

Table 3 Parameter codes

Parameter Code Description Parameter Code Description

Flow rate 0 0.1 cfm

(for 0.3 µm

and 0.5 µm

sensitivity)

1 1.0 cfm

(for 0.5 µm

sensitivity

only)

Sensitivity

(minimum)

Exhaust

location

Example: An instrument with a 0.1 cfm flow rate, 0.5 μm sensitivity, bottom

exhaust port, flow measurement and RS485 communication will have the part

numbers 2088605-DF-S and 20888600-485. The second part number is

necessary to identify the type of serial communication (RS232 = 20888600-232,

RS485 = 20888600-485 or Pulse = 20888600-PLS). The second part number is

not necessary for any other communication type.

3 0.3 µm Communication E Ethernet

5 0.5 µm S Serial I/O

D Down

(bottom)

S Side

Flow

measurement

F With flow

measurement

N Without flow

measurement

options

A Analog

English 7

Page 8

Product components

Make sure that all components have been received. Refer to Figure 4. If

any items are missing or damaged, contact the manufacturer or a sales

representative immediately.

Figure 4 Instrument components

1 MET ONE 6000 series particle

counter

2 Sample (isokinetic) probe with

1

tube

3 Sample (isokinetic) probe with

2

tube

4 DIN rail mounting kit 8 Service port cable (8-pin DIN to 9-

1

1.0 cfm units only

2

0.1 cfm units only

3

All units except Ethernet

4

Ethernet only

5

Only one service port cable is supplied per order.

5 10-pin connector with clam shell

6 5-pin connector with clam shell

7 Setup utility CD

pin serial connector)

5

3

4

Installation

Installation guidelines

N O T I C E

Before a cleaning or disinfecting cycle is started, stop the vacuum pump and put

a cover on the air inlet fitting.

High internal temperatures cause damage to the instrument components.

• Install the instrument indoors in a clean, dry, well ventilated,

temperature controlled location with minimum vibration.

•

If the room is washed down at regular intervals, install the instrument

outside of the room. Only the air inlet and vacuum tubes will go into

the clean room. As an alternative, put the instrument in the clean room

in a sealed box. Connect all tubes and cables to the instrument

through the box. Operation of the instrument in an enclosed box may

increase the temperature around the instrument and decrease the

performance and life of the instrument.

• Do not operate the instrument in direct sunlight or next to a heat

source.

• Install the instrument as close to the sample source as possible. Make

sure that the distance is not more than 3 m (10 ft). An inlet tube length

longer than 3 m (10 ft) can cause a loss of particles larger than 1 μm.

If an inlet tube length longer than 3 m (10 ft) is necessary, compare

the results between a portable particle counter and this instrument.

• Keep the air flow in a constant downward direction. When possible,

mount the instrument directly below the sample point.

Vacuum system guidelines

• Put the vacuum pump in a central location. There must be sufficient

vacuum for all instruments in the network.

• Use a distribution manifold that keeps vacuum loss to a minimum.

Typical materials used for vacuum distribution include brazed copper

pipe, schedule 80 PVC pipe or tubing such as Cobolite®.

N O T I C E

8 English

Page 9

• Use short tubing lengths to supply the vacuum from the distribution

manifold to the individual

barb fitting of the correct dimension at each instrument location.

• Keep the number of junctions, elbows and the tubing length from the

vacuum source to the instruments to a minimum to keep the vacuum

loss in a system to a minimum.

instrument. Use a distribution valve and a

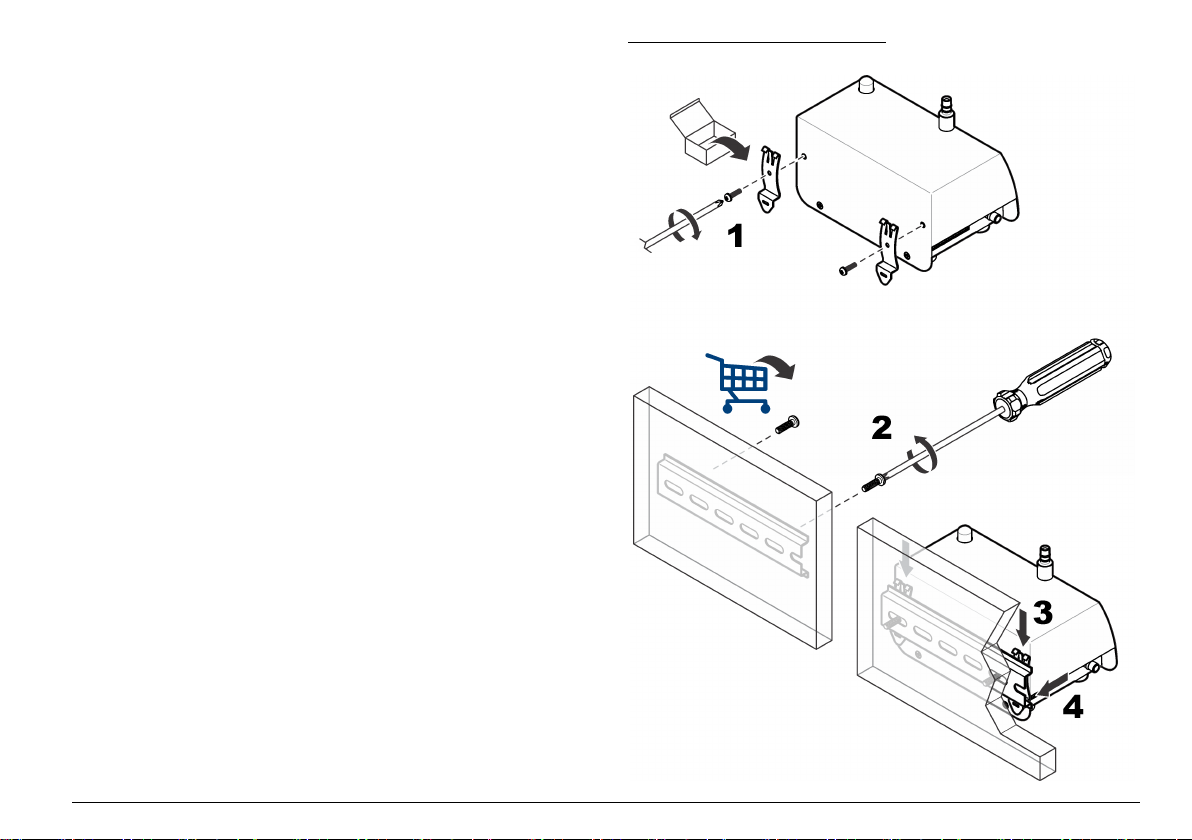

Mechanical installation

Instrument mounting

Install the instrument on a level surface or on a wall with one of these

mounting kits:

• DIN rail kit (supplied with the instrument)—use to quickly remove the

instrument from the wall.

• Wall mounting bracket (optional)—use for permanent installation.

Refer to the instructions supplied with the kit.

Refer to the illustrated steps in Figure 5 for DIN rail installation. To

remove the instrument from the rail, lift the bottom of the instrument.

Figure 5 DIN rail installation

English 9

Page 10

Install the sample probe

Refer to Sample probe guidelines on page 10

prevent contamination of the instrument and to get a representative

sample of the area. The position of the sample (isokinetic) probe is

important for count accuracy.

Sample probe options

Optional kits are available for sample probe installation. Refer to

Figure 6.

• Direct mount—No kit is necessary. The sample probe is installed on

a short piece of tubing directly on top of the sample air inlet fitting on

the instrument. Use direct mount installation when the instrument can

be put in the location where the sample is collected. Use the direct

mount installation to keep particle loss to a minimum.

• Wall mount, 90 degree—The probe is connected to a stainless steel

tube (90 degree) and a wall bracket.

• T-type wall bracket—The sample probe is installed in a wall bracket.

The tubing is cut to connect the probe to the counter.

• Vertical wall mount—The sample probe is connected to a stainless

steel tube and bracket. Use vertical wall mount installation on

equipment with stainless steel tubing.

before the installation to

Figure 6 Sample probe installation options

1 Direct mount 3 Vertical wall mount

2 Wall mount, 90 degree 4 T-type wall bracket

Sample probe guidelines

N O T I C E

Do not use this instrument to monitor air that contains vapors from drying

adhesives or other chemicals. These vapors can permanently coat the sensor

optics or other internal parts.

Do not use this instrument to monitor air that contains vapors with corrosives.

These vapor will quickly cause permanent damage to the optics or electronics of

the counter.

• Laminar flow—Install at least one sample probe for every 2.3 m

N O T I C E

2

(25 ft2) of surface area.

10 English

Page 11

• Turbulent flow—Install at least two sample probes in each clean room.

•

Make sure that the sample (isokinetic) probe points to the direction of

flow. Refer to Figure 2 on page 7.

• Keep the sample probe a minimum of 30 cm (12 in.) from loose

materials, dust, liquids and sprays.

• Keep the sample probe a minimum of 30 cm (12 in.) from potential

contamination sources such as an instrument exhaust fan.

• Do not use this instrument to monitor air that contains the substances

shown in Table 4.

Table 4 Contaminants

Substance Damage

Powders Contaminates the sensor and causes incorrect results or

Liquids Contaminates the internal optics of the sensor and changes the

Smoke Contaminates the sensor

instrument failure

calibration of the instrument

Note: Liquids can be in the air in the form of oil droplets.

Install the tubing

Use tubing hooks or cable ties to hold the tubing and prevent a bend in

the tubing. A bend in the tubing will decrease the air flow and cause the

problem that follow

• A decrease in air inlet flow can cause particles to collect on the interior

walls of the tubing. The particles will not be counted. The collected

particles can release at random, which will cause spikes in the count

level.

Items to collect:

• Air inlet tubing—Hytrel® Bevaline, Tygon® or equivalent

• Vacuum tubing—Hytrel Bevaline, Tygon or equivalent

• Tubing hooks or cable ties

1. Cut the air inlet tubing to a length sufficient to connect the instrument

to the sample probe. Keep the tube length to a minimum. Make sure

that the length is not more than 3 m (10 ft).

s:

2. Cut the vacuum tubing to connect the counter to the vacuum source.

Keep the tube length to a minimum.

3. Put a cover on the tube ends to make sure that unwanted material

does not go in the tubes during installation.

4. Attach the tubing with hooks or cable ties at intervals that are not

more than 1.2 m (4 ft) apart. Make sure that the tubing has a

minimum bend radius of 10 cm (4 in.) so air flow is not decreased.

5. Connect the air inlet tubing to the air inlet fitting on the

instrument.

Connect the other end of the tubing to the supplied sample probe.

6. Connect the vacuum tubing to the fitting on the bottom (or side) of

the counter. Do not connect the other end to the vacuum until the

room is ready for sampling.

Electrical installation

Wiring safety information

W A R N I N G

Electrocution hazard. Make sure that there is easy access to the local

power disconnect.

N O T I C E

Always disconnect power to the instrument before electrical connections are

made.

Obey all safety statements while connections are made to the

instrument.

Connect to power

Connect an external power source (24 VDC) to the 5-pin or 10-pin

connector. Refer to Figure 7 and Table 5 or Figure 8 and Table 6 for

wiring information. Make sure that the output voltage of the external

power source does not exceed 28 VDC.

The maximum number of

power source can change with the communication option. Contact

technical support for more information.

Refer to the illustrated steps in Figure 9 for 5-pin connector wiring. Refer

to the illustrated steps in Figure 10 for 10-pin connector wiring.

instruments that can connect to one external

English 11

Page 12

Figure 7 5-pin connector

Table 5 5-pin connector wiring

Pin Description Pin Description

1 — 4 Unit main power (9–28 VDC, 1 A

maximum)

2 — 5 Common

3 Common (shield ground)

Figure 8 10-pin connector

Table 6 10-pin connector wiring

Pin RS485 unit RS232 unit Pulse unit Analog unit

1 RS485 A — Ch 1+ 24 VDC external loop power

source

2 RS485 B — Ch 1- Channel 1 loop out

3 RS485 A RS232 TX Ch 2+ Channel 2 loop out

4 RS485 B RS232 RX Ch 2- Channel 3 loop out

Table 6 10-pin connector wiring (continued)

Pin RS485 unit RS232 unit Pulse unit Analog unit

5 — — — Channel 4 loop out

6 — — Status + —

7 — — Status - —

8 Common (shield ground)

9 Unit main power (9–28 VDC, 1 A maximum)

10 Common

12 English

Page 13

Figure 9 5-pin connector wiring Figure 10 10-pin connector wiring

English 13

Page 14

Install serial communications

Refer to Figure 8 on page

instrument with serial communication (RS485, RS232 or pulse).

Network wiring

Up to 32 instruments (12 K load each) can be included in a

RS485 (EIA-485) network with RS485 Modbus or FXB communication.

Use a high-grade wire for serial communications such as Belden 9841.

The manufacturer recommends that the length of the network is not

more than 1200 m (3937 ft).

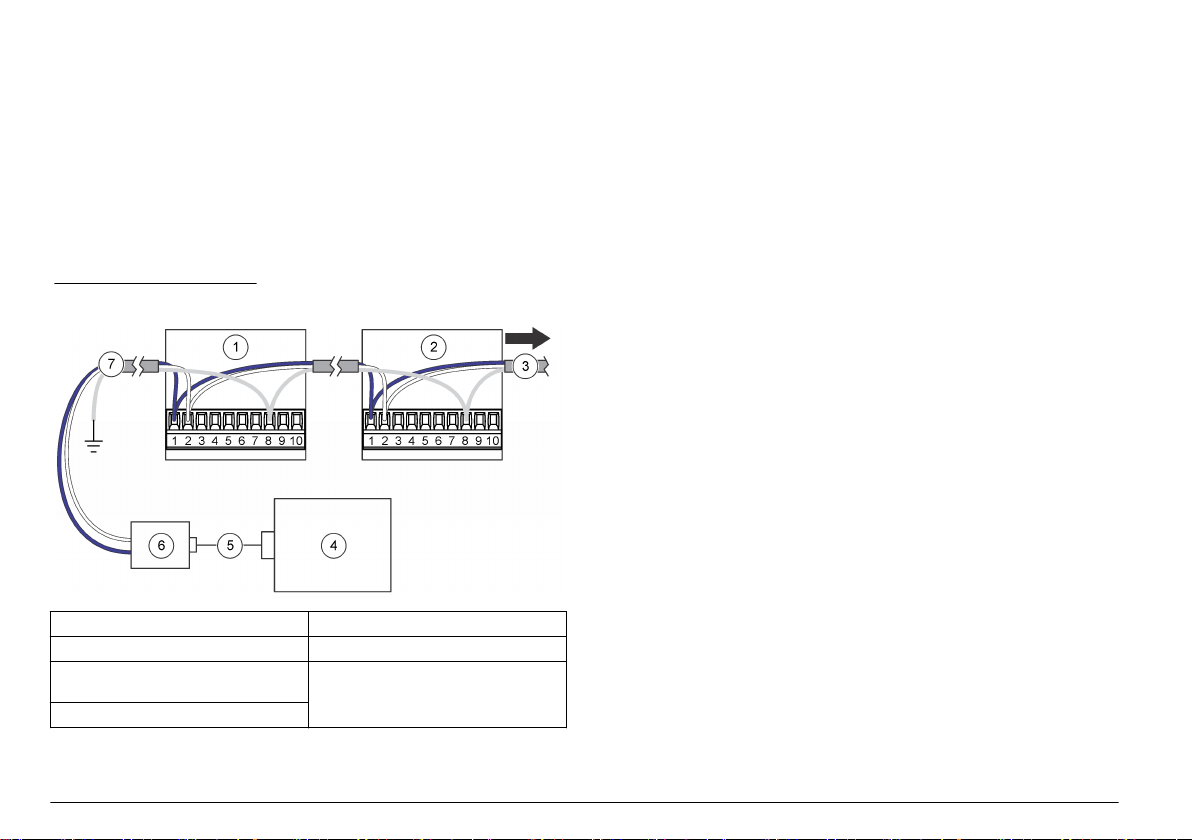

Figure 11 shows a typical network wiring diagram.

Figure 11 Network wiring

1 Particle counter 5 Cable

2 Particle counter 6 RS232 to RS485 converter

3 To additional particle counters 7 Network cable

4 PC

12 and Table 6 on page 12 to connect an

Connect to the Ethernet

Connect

standard 10Base-T or 100Base-T network. Make sure that the wiring is

applicable for the speed of the network to prevent intermittent problems.

instruments with Ethernet communication to an Ethernet

For this instrument, Ethernet standard 10Base-T is sufficient to transmit

data and is more tolerant of installation errors.

•

Length—100 m (328 ft) maximum, single wire length (repeaters can

be used to increase the distance)

• Repeaters—4 (maximum)

• Connector type—RJ45 (standard Ethernet wiring convention T-568B)

Connect the analog outputs

Connect instruments with the analog output feature to a data acquisition

system. Refer to Figure 8 on page 12 and Table 6 on page 12 for wiring

information.

When a +24 VDC power supply is used, the power supply can also be

used as the 4–20 mA loop power source if there is sufficient output for

the loop. Refer to Figure 12. Figure 13 shows the maximum limit of total

loop resistance (load and wiring combined) that is allowed.

Instruments with the analog output feature send a 4–20 mA signal that is

proportional to the number of counts in a given sampling time. The

analog outputs are updated at the end of each sample period. A data

acquisition system receives the signal. Instruments with the analog

output feature can have two or four channel sizes. Analog units cannot

be used in a network configuration.

Use the setup utility software to set the maximum number of counts that

correspond to the 20 mA signal. Refer to Configure the instrument

on page 17.

When power is applied, the analog outputs on the channels is 4 mA.

When power is removed or there is a sensor failure or flow failure, the

analog output on the channels is less than 2 mA. If a channel is disabled

by the user, the channel output is less than 2 mA. Any signal less than

4 mA (zero count value) causes a negative number in the data

acquisition system which identifies that there is a problem with the signal

from the instrument.

Configure the central monitoring software to alarm on any signal less

than 4 mA (zero count value) to get a sensor, flow or power loss alarm

as necessary.

14 English

Page 15

Figure 12 Configuration for loop power

Figure 13 Maximum limit for current loop operation

1 Configuration for common loop

power supply

2 Configuration for separate loop

power supply

3 24 VDC loop power supply 7 24 VDC power supply

4 + Loop supply 8 + Power

5 Common

6 4–20 mA collection system

1 Loop supply voltage 3 Outside the operating range (below

2 Acceptable operating range (above

line)

line)

4 Maximum limit of total loop

resistance

Startup

Clean the exterior surfaces

N O T I C E

Never spray the instrument directly with liquid or a vaporous hydrogen peroxide

(VHP) stream. When liquid solutions get into the counter flow path or electronics,

sensor damage occurs.

Do not allow disinfecting chemical vapor to get into the instrument enclosure and

come in contact with the

instrument electronics.

Wipe the exterior surfaces with a lint-free tissue made moist with

isopropyl alcohol (IPA). The sample (isokinetic) probe can be autoclaved

for cleaning.

N O T I C E

English 15

Page 16

Clean the interior surfaces

Use a

zero count filter to remove contaminants such as particles, lint or

dust from the interior surfaces of the instrument and the air inlet tubing.

When the count goes to zero, the interior surfaces and inlet air tubing

are clean.

Items to collect: zero count filter

1. Attach the zero count filter to the air inlet tube.

The zero count filter prevents any external particles from going in the

instrument.

2. Start sample collection and operate the instrument for at least

30 minutes. Refer to Manual operation on page 22.

3. Monitor the room air in 5-minute intervals and continue until the

particle count is 0–1.

Optional: To record the data, set the Sample Timing: Sample setting

to 5 minutes. Refer to Configure the instrument on page 17.

4. If the particle count does not go to 0–1 after nine or ten 5-minute

sample periods, purge the instrument overnight. Refer to Purge the

instrument on page 16.

Purge the instrument

Do a purge to get a particle count of 0–1. Typically, a purge is done

before a test to make sure that there is a baseline reference for the

instrument.

1. Remove approximately 2.5 cm (1 in.) of tubing from the sample

probe-end of the air inlet tube to remove any stretched or scored

section.

2. Attach a zero count filter to the air inlet tube.

3. Operate the instrument for 24 hours.

4. If a particle count of 0–1 is not shown after 24 hours, identify if the

source of the particles is the air inlet tubing.

a. Install the zero count filter directly on the air inlet fitting.

b. Operate the instrument for another 15 minutes.

c. Monitor the room air for 5 minutes and record the results. Do this

step up to four times until the particle count is 0–1 in a 5-minute

sample.

d. If a particle count of 0–1 is shown, the air inlet tubing is the

source of the particles. Replace the air inlet tubing.

e. If the particle count does not go to 0–1, contact technical support.

Operation

Configuration

For initial configuration, connect the

After initial configuration, change the configuration settings as necessary

by direct connection to a PC or through a ModbusTCP connection. For

configuration through a network, only the LAN settings can be changed.

Refer to Configure the LAN settings through a network on page 19.

Connect to a PC

Items to collect:

• Setup utility CD

• Service port cable

• PC with Windows® 2000 Professional, Windows XP Professional,

Windows Vista (32-bit), Windows 7 (32-bit or 64-bit in XP emulation

mode)

• USB to RS232 adapter if the PC does not have a RS232 port

1. Make sure that Microsoft .Net Framework is installed on the PC. If

not installed, open the dotnetfx.exe file on the setup utility CD and

install the application.

Note: The user must be logged on to the PC as an Administrator.

2. Copy and paste the SetupUtility.exe file from the setup utility CD to

the PC.

3. Connect the Service port cable to the Service port on the instrument

and a COM port on the PC.

instrument to a PC.

16 English

Page 17

Configure the instrument

Use the setup utility software to configure the parameters kept on each

instrument

configuration. If a new configuration is not found, the previously saved

configuration is used.

1. Open the SetupUtility.exe file that is installed on the PC to start the

2. Select the Basic Setup tab.

3. Find the Port field on the right side of the window. Select the COM

4. Click Read Instrument. The utility reads the data that is saved on

5. Make sure that the data in the Instrument Information section is

6. In the General section, select the settings.

. When power is applied to the instrument, it looks for a new

setup utility program.

port on the PC to which the instrument is connected.

the instrument.

correct (model number, communication option, firmware version and

communication address, if applicable).

Option Description

Count Mode Sets the count mode. Does not affect the analog

Sample Timing:

Sample

Sample Timing: Hold Sets the length of time that data collection stops

Count Cycles Sets the number of samples taken before data

output of analog units.

Differential—The particle counts shown for each

channel are the counts for each channel size.

Cumulative (default)—The particle counts shown

for each channel are the counts for each channel

size plus the larger channel sizes. For example, if

the channel is 0.3 µm, particles that are 0.3 µm and

larger in size are included in the count.

Sets the length of time for each sample (default =

00:01:00 = 1 minute).

after samples are taken (default = 00:00:00).

collection stops and the hold time starts (0 =

continuous sampling).

Option Description

Slave

Address/Location ID

Comm Timeout Sets the number of seconds after a communication

Location Name Sets a unique identifier for the instrument.

System Date/Time Sets the date (YYYY/MM/DD) and time

Moving Cumulative

Counts

Store Partial Records Enables partial sample data to be saved to the

Temp Units °C Changes the temperature units from Fahrenheit

Remote LCD Not available (disabled)

Count Alarms Sets the minimum number of particles for each

Do not change (default = 1).

failure before a communication (Comm) alarm

occurs. To disable communication alarms, set to 0.

For instruments with the analog output feature, set

to 0.

(HH:MM:SS, 24-hour format).

Sets the number of sample counts for Channel 1 or

Channel 2 that are added together and shown in

Channel 3 and Channel 4. Channel 3 shows the

cumulative counts for Channel 1. Channel 4 shows

the cumulative counts for Channel 2.

buffer. Partial sample data occurs when a sample

is stopped before it is completed.

(default) to Celsius.

channel that will trigger a count alarm.

To see the channel sizes, select the Data Display

tab. Refer to Figure 15 on page 22.

English 17

Page 18

Option Description

Sample Mode Sets the sample mode.

Flow Units Sets the air flow units. Options: CFM (cubic feet per

7. If an optional external light stack is connected to the

Auto—Sample data collection starts automatically

when power is applied to the instrument.

Manual—Sample data collection does not start

automatically when power is applied to the

instrument. Sample data collection must be started

manually. Refer to Manual operation on page 22.

Note: Ethernet units with analog output cannot be

set to Manual because there is no bi-directional

communication with the central monitoring

software. These units always start in Auto mode.

minute) or LPM (liters per minute).

instrument, use

the Diagnostics section to set the status indicator light to flash or not

flash for one of the colors to identify that the wiring is correct.

Note: It is not possible to save the diagnostic settings and they have no effect

on the instrument operation.

8. For units with analog output, change the settings for the 4–20 mA

analog output in the Analog section.

Option Description

Full Scale Sets the particle count for each channel that corresponds to a

Output

State

20 mA output signal (default = 1000). A zero particle count

corresponds to a 4 mA output signal.

Note: Count alarms are not reported to the central monitoring

software. Configure the central monitoring software to trigger

count alarms as necessary.

Sets the output state. Set to Normal for normal operation.

Zero—Holds the output at 4 mA.

Span—Holds the output at 20 mA.

9. For serial communication (RS485 units only), change the

communication setting in the Serial section. Options: FXB, Modbus,

R48XX Compatibility, FXB1. If Modbus is selected, enter the slave

address. When the address is 31 or less, use the dip switches on the

bottom of the instrument to set the address. Refer to RS485 serial

output with Modbus RTU protocol on page

Note: If an address of 32 or higher is entered, the dip switch setting are

ignored and the entered value is used.

20.

10. For pulse communication (RS485 units only), select the channel size

for the Channel 2 pulse output in the Pulse section (default = Count

Channel 2). The Channel 1 pulse output always corresponds to the

Channel 1 particle size.

11. For Ethernet communication (Ethernet units only), refer to Configure

the Ethernet settings on page 18.

12. Click Save Settings to save the changes.

Configure the Ethernet settings

1. For Ethernet units without the analog output feature, change the

Ethernet settings in the Ethernet section. The Ethernet settings

should only be changed by a network professional.

Option Description

MAC Media access control—Shows the unique permanent

DHCP/APIPA Enables or disables static or dynamic IP addressing by

IP Address For static IP addresses, each LAN-based instrument

Subnet Mask Instruments of the same type that communicate with a

hardware address (read-only)

connection to a DHCP server (default = disabled). When

enabled, the instrument gets an IP address and subnet

mask automatically when power is applied.

If a DHCP server is not available, the instrument uses

APIPA for an IP address and subnet mask.

• APIPA IP address range: 169.254.0.0 to

169.254.255.255

• Subnet mask: 255.255.0.0 (Class B network)

must have a unique IP address. Range: 169.254.0.0 to

169.254.255.255 (default = 169.254.1.2).

single software package (i.e., FMS) use the same

subnet mask (default = 255.255.0.0). Range: 0 to 255,

integer only.

18 English

Page 19

Option Description

Server Port ModbusTCP server listen port (default = 502). Range:

Client Port Not available (disabled)

Gateway Router or access point to another network (default =

Remote ServerIPNot available (disabled)

Ethernet

Protocol

0 to 65535, integer only.

169.254.1.5)

Sets the Ethernet protocol to Modbus or FXB.

2. For Ethernet units with the analog output feature, refer to Configure

the LAN settings through a network on page 19

to configure the

Ethernet settings.

3. Click Save Settings to save the changes.

Configure the LAN settings through a network

1. In the setup utility software, select the LAN Setup tab. The software

looks for LAN instruments. The LAN instruments found are shown.

2. Select an instrument to show the LAN instrument settings.

3. Change the LAN settings. Refer to the options table in Configure the

Ethernet settings on page 18.

4. Click Save Settings to save the changes.

Do an analog output test

For instruments with the analog output feature, do an analog output test.

1. Connect the analog outputs to the load resistors of the data

acquisition system.

Note: As an alternative, install a set of load resistors with 0.1% accuracy and

at least 0.25 W capability across the analog output. Load resistor values of

100, 250 or 500 ohms are typically used.

2. Let a tiny amount of particles flow through the instrument to get a

count in the test channel.

Note: One method to get counts is to use a zero count filter, and put a pin-hole

in the tubing that is between the filter and the

instrument.

3. On the Basic Setup tab of the setup utility software, temporarily set:

• Count Cycles—1

• Sample Timing: Hold—10 seconds or more

4. Click Save Settings.

5. Select the Data Display tab, then click Monitor if shown so the data

shown can update continuously as each sample is taken.

6. Click Sample if shown to start sample collection.

7. When the Status value changes from "Count" to "Stop", measure the

voltage across the load resistors for each channel. Also note the

counts shown in the display for each channel.

8. Use the equation that follows to calculate the expected voltage from

the counts shown. Make sure that the measured and calculated

voltages agree.

Voltage = (((SC ÷ FC × 16) + 4) ÷ 1000) × RL

Where:

SC = sample count at the end of the sample period

FC = full-scale channel count. Refer to the analog settings in the

setup utility software.

RL = value of the load resistor in ohms

The expected output voltage when the full-scale channel count is

1000 with a 100, 250 and 500-ohm resistor is shown in Table 7.

9. To do the test again, do steps 7–8.

10. For units with a flow monitor, temporarily remove the central vacuum

from the instrument.

11. While a flow alarm is active, measure the voltage across the load

resistors for each channel.

12. Use the equation that follows to calculate the expected voltage.

Make sure that the measured and calculated voltages agree.

Voltage = < (0.002 × RL)

Where: RL = value of the load resistor in ohms

Example: for a 100-ohm resistor, the voltage should be less than

0.20 V.

English 19

Page 20

13. On the Basic Setup tab, change the settings back to the previous

values.

14. Click Save Settings.

Table 7 Output voltage with 100, 250 and 500-ohm resistors

Sample count 100 Ω 250 Ω 500 Ω

0 0.40 V 1.00 V 2.00 V

100 0.56 V 1.40 V 2.80 V

200 0.72 V 1.80 V 3.60 V

300 0.88 V 2.20 V 4.40 V

400 1.04 V 2.60 V 5.20 V

500 1.20 V 3.00 V 6.00 V

600 1.36 V 3.40 V 6.80 V

700 1.52 V 3.80 V 7.60 V

800 1.68 V 4.20 V 8.40 V

900 1.84 V 4.60 V 9.20 V

1000 2.00 V 5.00 V 10.00 V

RS485 serial output with Modbus RTU protocol

Instruments with the RS485 Modbus communication option use industrystandard Modbus RTU protocol. In this communication mode, a series of

registers hold data about measurement results and operation

parameters.

When a ModbusTCP connection is made, the user can use all the

configuration options in the Modbus register map. Refer to the company

website for the Modbus register map. Write drivers to communicate with

the instrument through these registers with the Modbus RTU protocol.

The RS485 serial network circuit supplies communications for a

maximum of 32 instrument

instrument can transmit data at a time. Each instrument must have a

unique instrument address.

s and a control computer. Only one

1. Turn the instrument over. The DIP switch is on the bottom of the

instrument.

2. Change the DIP switch setting to select a unique network address for

the instrument. Refer to Table 8.

Note: Address 0 can only be used with FXB protocol. Address 0 is reserved for

use as a broadcast address for Modbus RTU. If address 0 is set with Modbus

protocol, the instrument will use address 1.

Table 8 DIP switch settings for network address

Network address Switch 1 Switch 2 Switch 3 Switch 4 Switch 5

0 Off Off Off Off Off

1 On Off Off Off Off

2 Off On Off Off Off

3 On On Off Off Off

4 Off Off On Off Off

5 On Off On Off Off

6 Off On On Off Off

7 On On On Off Off

8 Off Off Off On Off

9 On Off Off On Off

10 Off On Off On Off

11 On On Off On Off

12 Off Off On On Off

13 On Off On On Off

14 Off On On On Off

15 On On On On Off

16 Off Off Off Off On

17 On Off Off Off On

20 English

Page 21

Table 8 DIP switch settings for network address (continued)

Network address Switch 1 Switch 2 Switch 3 Switch 4 Switch 5

18 Off On Off Off On

19 On On Off Off On

20 Off Off On Off On

21 On Off On Off On

22 Off On On Off On

23 On On On Off On

24 Off Off Off On On

25 On Off Off On On

26 Off On Off On On

27 On On Off On On

28 Off Off On On On

29 On Off On On On

30 Off On On On On

31 On On On On On

RS485 serial output with FXB protocol

Instruments with the RS485 FXB communication option use industrystandard FXB protocol. Refer to the company website for FXB protocol

information.

1 particle size is detected. Channel 2 sends a pulse signal when the

channel size that is selected by the user is detected.

Pulse communication includes a status output signal that goes from low

to high when there is an active alarm. Pulse communication cannot be

used in a network configuration.

Set the network address for pulse communication

instruments to 1.

Refer to Table 8 on page 20.

The pulse signal can be sent in one of two count modes:

• Differential mode (default)—A signal is sent on Channel 1 when a

particle is between the first and the second channel size thresholds. A

signal is sent on the Channel 2 when a particle is larger than the userselected channel size threshold.

• Cumulative mode—A signal is sent on Channel 1 when a particle is

larger than the first or second channel size threshold. A signal is sent

on Channel 2 when a particle is larger than the user-selected channel

size threshold.

Figure 14 Differential versus cumulative count mode example

Pulse communication

Instruments with the pulse communication option send an 8-µs pulse

signal when a particle is detected. Refer to Figure 14. An external pulse

counter or data acquisition system receives the pulse signal and counts

the pulses as particles.

Instruments with pulse communication have two pulse output channels

(Ch 1 and Ch 2). Channel 1 sends a pulse signal when the Channel

1 Pulse signal sent from counter 4 Channel 1

2 Data transfer in differential versus

cumulative mode

3 Channel 2 6 Cumulative count—three 0.3 µm

5 Differential count—one 0.3 µm and

two 5.0 µm particles

and two 5.0 µm particles

English 21

Page 22

Manual operation

Use the setup utility software with a direct PC connection or over a LAN

connection to manually operate the

1. Open the SetupUtility.exe file to start the setup utility software.

2. Select the Data Display tab. Refer to Figure 15 for the data shown.

3. Use the buttons to operate the instrument.

Note: The buttons change depending on the system status.

Option Description

Monitor Shows the updated data continuously in real time.

Stop Monitor Stops changes to the data shown.

Sample Starts sample collection. Samples are taken according

Stop Count Stops sample collection.

Active Mode Sets the internal laser to on. Enables alarms.

Inactive Mode Sets the internal laser to off. Disables alarms.

Display Buffered

Data

Download Buffer Saves a copy of the data records in the buffer to the

Erase Buffer Erases all data records from the buffer.

to the settings on the Basic Setup tab. Changes the

instrument to active mode if in inactive mode.

Shows the data from the last sample completed.

Updates as each sample is completed.

PC as a text (CSV) file.

instrument.

Figure 15 Real-Time data display

1 Active alarms (Sensor, Flow,

Comm, Count1)

2 Channel sizes and particle counts 8 Air volume collected for the sample

3 Sample time 9 Values from the optional relative

4 Last sample start time and date 10 Not available

5 System status 11 Cal voltage—identifies the

6 Service use only

1

When a count alarm occurs, the high particle count is shown in red.

7 Air flow (cfm or L/min)

(cfm or L/min)

humidity (RH) and temperature

sensor

cleanliness of the sensor optics

22 English

Page 23

Calibration

The instrument

manufacturer for instrument calibration.

cannot be calibrated by the user. Contact the

Maintenance

C A U T I O N

Personal injury hazard. Only qualified personnel should conduct the tasks

described in this section of the manual.

Do not disassemble the instrument for maintenance. If the internal components

must be cleaned or repaired, contact the manufacturer.

Maintenance schedule

Table 9 shows the recommended schedule of maintenance tasks.

Facility requirements and operating conditions may increase the

frequency of some tasks.

Table 9 Maintenance schedule

Task 1 year

Replace the inlet tubing on page

Calibration on page 23 X

Replace the inlet tubing

Replace the air inlet tubing regularly to prevent organic growth or

inorganic particle contamination on the tube walls. Contamination can

result in false high particle counts.

The manufacturer recommends that the air inlet tubing of typical FMS

installations in life science and pharmaceutical manufacturing clean

rooms be replaced at least once a year.

N O T I C E

23 X

English 23

Page 24

Table des matières

Caractéristiques à la page 24 Mise en marche à la page 38

Généralités à la page 25 Fonctionnement à la page 39

Installation à la page 30 Maintenance à la page 47

Caractéristiques

Les caractéristiques techniques peuvent être modifiées sans préavis.

Caractéristique Détails

Dimensions

(l x P x H)

Boîtier Acier inoxydable 304

Source lumineuse Diode Long Life Laser™ , laser classe 3B

Poids 0,82 kg (1,8 lb)

Niveau de pollution 2

Catégorie

d’installation

Classe de protection III

Alimentation requise 9–28 VCC (source: Classe 2 limitation d'énergie, <

Consommation

électrique (maximum)

Température de

fonctionnement

Température de

stockage

Humidité Fonctionnement et stockage : humidité relative 5 à 95 %,

Altitude 2 000 m (6 562 pieds) maximum

13,56 x 8,93 x 12,06 cm (5,34 x 3,52 x 4,75 pouces)

I

150 VA)

Unités série et impulsions : 3,3 W ; unité Ethernet :

4,3W ; sortie analogique : 3,5 W ; 1 A maximum

5 à 40 °C (40 à 104 °F) ; meilleures performances : 10 à

32 °C (50 à 90 °F)

–40 à 70 °C (–40 à 158 °F)

sans condensation

Caractéristique Détails

Tailles des ports Modèle 6003, 6005 : raccord cannelé sur 0,32 cm

Options de signal de

sortie

Stockage des

données

Débit d'échantillon Modèle 6003, 6005 : 0,1 cfm (2,83 Lpm) ± 5 %

Pression

d’alimentation

Exigences du vide ≥ 406 mm (16 po) Hg (542 mbar) : vide minimum mesuré

Plage de mesures Modèle 6003 : de 0,3 μm à 10,0 μm à 0,1 cfm

Sensibilité Modèle 6003 : 0,3 μm à 0,1 cfm (2,83 l/min)

(1/8 po) Diamètre intérieur du tuyau d'arrivée : 0,64 cm

(¼ po) Diamètre intérieur du tuyau d'évacuation

Modèle 6013, 6015 : raccord cannelé sur 0,64 cm (¼po.) Diamètre intérieur du tuyau d'arrivée : 0,64 cm

(¼ po) Diamètre intérieur du tuyau d'évacuation

Impulsion, 4 à 20 mA analogique, RS232 série avec

protocole (sans mise en réseau) de communication FXB

ou Modbus RTU, RS485 série avec protocole de

communication FXB ou Modbus RTU, Ethernet avec

protocole Modbus TCP

1 000 échantillons/enregistrements (les enregistrements

les plus anciens sont écrasés lorsque le tampon est

saturé)

Modèle 6013, 6015 : 1,0 cfm (28,3 Lpm) ± 5 %

Ambiant à to 2.5 mm (0.1 in) Hg de vide

à chaque instrument lorsqu'un débit traverse tous les

instruments.

(2,83 l/min)

Modèle 6005 : de 0.5 μm à 10,0 μm à 0,1 cfm

(2,83 l/min)

Modèle 6013, 6015 : de 0,5 μm à 10,0 μm à 1,0 cfm

(28,3 l/min)

Model 6005 : 0,5 μm à 0,1 cfm (2,83 /min)

Modèle 6013 : 0,3 μm à 1 cfm (28,3 l/min)

Modèle 6015 : 0,5 μm à 1 cfm (28,3 l/min)

24 Français

Page 25

Caractéristique Détails

Efficacité de

comptage

Erreur de

coïncidences

Faux comptage Un ou moins en 5 minutes

Certifications CE

1

Totalement conforme à la norme ISO21501-4.

Modèle 6003 : 50 % (± 20 %) pour 0,3 μm, (100 % ±

10 % à 1,5 fois la sensibilité minimum)1.

Modèles 6005, 6013, 6015 : 50 % (± 20 %) pour 0,5 μm,

(100 % ± 10 % à 1,5 fois la sensibilité minimum)1.

Modèles 6003, 6005 (toutes les options de sortie) : 10 %

à 140 000 000 particules / m3 (4 000 000 particules /

pied3)

Modèles 6013, 6015 (toutes les options de sortie sauf

l'impulsion) : 10 % à 20 000 000 particules / m

(566 000 / pied3)

3

Généralités

En aucun cas le constructeur ne saurait être responsable des

dommages directs, indirects, spéciaux, accessoires ou consécutifs

résultant d'un défaut ou d'une omission dans ce manuel. Le constructeur

se réserve le droit d'apporter des modifications à ce manuel et aux

produits décrits à tout moment, sans avertissement ni obligation. Les

éditions révisées se trouvent sur le site Internet du fabricant.

Version enrichie de ce manuel

Pour plus d'informations, reportez-vous au CD qui contient la version

enrichie de ce manuel.

Consignes de sécurité

A V I S

Le fabricant décline toute responsabilité quant aux dégâts liés à une application

ou un usage inappropriés de ce produit, y compris, sans toutefois s'y limiter, des

dommages directs ou indirects, ainsi que des dommages consécutifs, et rejette

toute responsabilité quant à ces dommages dans la mesure où la loi applicable le

permet. L'utilisateur est seul responsable de la vérification des risques

d'application critiques et de la mise en place de mécanismes de protection des

processus en cas de défaillance de l'équipement.

Veuillez lire l'ensemble du manuel avant le déballage, la configuration ou

la mise en fonctionnement de cet appareil. Respectez toutes les

déclarations de prudence et d'attention. Le non-respect de cette

procédure peut conduire à des blessures graves de l'opérateur ou à des

dégâts sur le matériel.

Assurez-vous que la protection fournie avec cet appareil n'est pas

défaillante. N'utilisez ni n'installez cet appareil d'une façon différente de

celle décrite dans ce manuel.

Interprétation des indications de risques

Indique une situation de danger potentiel ou imminent qui, si elle n'est pas évitée,

entraîne des blessures graves, voire mortelles.

A V E R T I S S E M E N T

Indique une situation de danger potentiel ou imminent qui, si elle n'est pas évitée,

peut entraîner des blessures graves, voire mortelles.

Indique une situation de danger potentiel qui peut entraîner des blessures

mineures ou légères.

Indique une situation qui, si elle n'est pas évitée, peut occasionner

l'endommagement du matériel. Informations nécessitant une attention

particulière.

D A N G E R

A T T E N T I O N

A V I S

Français 25

Page 26

Étiquettes de mise en garde

Lisez toutes les étiquettes et tous les repères apposés sur l'instrument.

Des personnes peuvent se blesser et le matériel peut être endommagé

si ces instructions ne sont pas respectées. Un symbole sur l'appareil est

désigné dans le manuel avec une instruction de mise en garde.

Si l'appareil comporte ce symbole, reportez-vous au manuel

d'utilisation pour consulter les informations de fonctionnement et de

sécurité.

S'il se trouve sur l’emballage d'un produit ou une barrière, ce symbole

indique la présence d’un danger de choc électrique et/ou

d’électrocution.

Ce symbole indique qu'un dispositif laser est utilisé dans

l'équipement.

En Europe, depuis le 12 août 2005, les appareils électriques

comportant ce symbole ne doivent pas être jetés avec les autres

déchets. Conformément à la réglementation nationale et européenne

(Directive 2002/96/CE), les appareils électriques doivent désormais

être, à la fin de leur service, renvoyés par les utilisateurs au fabricant,

qui se chargera de les éliminer à ses frais.

Remarque : Pour le retour à des fins de recyclage, veuillez contactez le fabricant

ou le fournisseur d'équipement afin d'obtenir les instructions sur la façon de

renvoyer l'équipement usé, les accessoires électriques fournis par le fabricant, et

tous les articles auxiliaires pour une mise au rebut appropriée.

Informations de sécurité relatives à l'utilisation d'un laser

Cet instrument est un PRODUIT LASER DE CLASSE 1, référence

CDRH 9022243-029. Un rayonnement laser invisible est émis à

l'intérieur de l'appareil. Évitez toute exposition directe au faisceau laser.

L'entretien des composants internes doit être mené exclusivement par

un personnel autorisé par le fabricant.

Cet instrument est conforme aux normes IEC/EN 60825-1 et 21 CFR

1040.10, à l'exception des différences faisant suite à la notice Laser n°

50 datée du 24 juin 2007.

Certification

Règlement canadien sur les équipements causant des

interférences radio, IECS-003, Classe A:

Les données d'essai correspondantes sont conservées chez le

constructeur.

Cet appareil numérique de classe A respecte toutes les exigences du

Règlement sur le matériel brouilleur du Canada.

Cet appareil numérique de classe A répond à toutes les exigences de la

réglementation canadienne sur les équipements provoquant des

interférences.

FCC part 15, limites de classe A :

Les données d'essai correspondantes sont conservées chez le

constructeur. L'appareil est conforme à la partie 15 de la règlementation

FCC. Le fonctionnement est soumis aux conditions suivantes :

1. Cet équipement ne peut pas causer d'interférence nuisible.

2. Cet équipement doit accepter toutes les interférences reçues, y

compris celles qui pourraient entraîner un fonctionnement inattendu.

Les modifications de cet équipement qui n’ont pas été expressément

approuvées par le responsable de la conformité aux limites pourraient

annuler l’autorité dont l’utilisateur dispose pour utiliser cet équipement.

Cet équipement a été testé et déclaré conforme aux limites définies pour

les appareils numériques de classe A, conformément à la section 15 de

la réglementation FCC. Ces limites ont pour but de fournir une protection

raisonnable contre les interférences néfastes lorsque l’équipement

fonctionne dans un environnement commercial. Cet équipement génère,

utilise et peut irradier l'énergie des fréquences radio et, s'il n'est pas

installé ou utilisé conformément au mode d'emploi, il peut entraîner des

interférences dangereuses pour les communications radio. Le

fonctionnement de cet équipement dans une zone résidentielle risque de

causer des interférences nuisibles, dans ce cas l'utilisateur doit corriger

les interférences à ses frais Les techniques ci-dessous peuvent

permettre de réduire les problèmes d'interférences :

26 Français

Page 27

1. Débrancher l'équipement de la prise de courant pour vérifier s'il est

ou non la source des perturbations

2. Si l'équipement est branché sur le même circuit de prises que

l'appareil qui subit des interférences, branchez l'équipement sur un

circuit différent.

3. Éloigner l'équipement du dispositif qui reçoit l'interférence.

4. Repositionner l’antenne de réception du périphérique qui reçoit les

interférences.

5. Essayer plusieurs des techniques ci-dessus à la fois.

Présentation du produit

Cet instrument compte les particules en suspension dans l'air à l'aide

d'une source lumineuse laser et d'un système optique d'acquisition.

Reportez-vous à la Figure 1. L'air ambiant est amené à travers le

compteur de particules à l'aide d'un

Plusieurs instruments peuvent être installés à différents emplacements

d'une salle blanche pour surveiller la qualité de l'air. Les données de

comptage sont envoyées au logiciel de surveillance centralisée fourni

par l'utilisateur par le biais des protocoles de communication appropriés.

Le logiciel de surveillance centralisée permet d'utiliser l'instrument à

distance.

Le circuit d'écoulement du capteur résiste à la vapeur de peroxyde

d'hydrogène (VHP) lors des cycles de nettoyage et de désinfection

standard de la pièce par vapeur de peroxyde d'hydrogène.

système de vide externe fixé.

Figure 1 Présentation du produit

1 Alimentation et connecteur de

communication à 10 broches

2 Raccord de la source de vide (ou

système de raccordement rapide)

3 Raccord de l'arrivée d'air de

l'échantillon

4 Voyant d'état (Tableau 1) 10 Connecteur RJ45 Ethernet

5 Port de service et port de la

colonne lumineuse fournie en

option

6 Commutateur DIP, adresse réseau

1

Toutes les unités sauf Ethernet

2

Unités Ethernet uniquement

7 Port du capteur de température et

1

d'humidité relative

8 Raccord de la source de vide (autre

emplacement)

9 Voyants de connexion2 (Tableau 2)

11 Connecteur d'alimentation à

5 broches

1

2

2

Français 27

Page 28

Tableau 1 Voyant d'état

Couleur Indication Etat du système

Vert Clignotant (3 secondes) Normal, échantillonnage

On (Marche) Normal, sans échantillonnage

Bleu On (Marche) Panne de capteur

Un clignotement court, un

clignotement long

Clignotant Panne de communication

Rouge Allumé ou clignotant Alarme comptage

Jaune On (Marche) Initialisation

Clignotant Alerte de comptage

Pourpre Clignotant L'utilitaire de configuration est en

1

A l'aide du logiciel de surveillance centralisée fourni par l'utilisateur, il est

possible de faire clignoter le voyant jaune lorsqu'une alerte de comptage se

produit avec le protocole ModBus et non le protocole FX. Les paramètres de

l'alerte de comptage peuvent être sélectionnés à l'aide du logiciel de

surveillance centralisée.

Défaillance du débit d'air

1

cours d'utilisation

Tableau 2 Voyants Ethernet

Couleur Indication Statut

Jaune On (Marche) Connecté

Vert Off (Arrêt) 10Base-T

On (Marche) 100Base-T

Sonde isocinétique

Pour une précision optimale du flux laminaire, utilisez toujours la sonde

isocinétique fournie avec cet

sonde est proche de celle du flux laminaire horizontal ou vertical d'une

salle blanche. La sonde isocinétique fournie assure le même débit d'air

vertical (ou horizontal) afin de collecter des échantillons représentatifs

instrument. La vélocité de l'air dans la

du flux laminaire de la salle blanche pour l'instrument. Se référer à la

Figure 2 pour une comparaison d'échantillon avec et sans sonde

isocinétique.

Figure 2 Fonctionnement de la sonde isocinétique

1 Pas de sonde pour un écoulement

d'air non laminaire

2 Vers le compteur de particule 4 Sonde isocinétique avec un

3 Pas de sonde pour un écoulement

d'air laminaire- des particules ne

sont pas captées

écoulement d'air laminaire- plus de

précision

Configurations de l'instrument

Cet instrument est disponible dans de nombreuses configurations. Un

numéro de référence différent est associé à chaque configuration. La

Figure 3 explique la composition du numéro de référence. Le Tableau 3

fournit une description des codes de référence utilisés.

28 Français

Page 29

Figure 3 Composition du numéro de référence

1 Débit 3 Emplacement de

l'évacuation

2 Sensibilité (minimum) 4 Mesure du débit

5 Communication

Tableau 3 Codes des paramètres

Paramètre Code Description Paramètre Code Description

Débit 0 0,1 cfm (pied

cube par

minute)

(pour une

sensibilité de

0,3 µm et

0,5 µm)

1 1,0 cfm (pied

cube par

minute)

(pour une

sensibilité de

0,5 µm)

Mesure du débit F Avec

mesure du

débit

N Sans

mesure du

débit

Tableau 3 Codes des paramètres (suite)

Paramètre Code Description Paramètre Code Description

Sensibilité

(minimum)

Emplacement

de

l'évacuation

Exemple : un instrument avec un débit de 0,1 cfm, une sensibilité de 0,5 , un

orifice d'évacuation situé au fond, une mesure du débit et une communication

RS485 sera associé aux références 2088605-DF-S et 20888600-485. La

deuxième partie de la référence sert à identifier le type de la communication

série (RS232 = 20888600-232, RS485 = 20888600-485 ou Impulsion =

20888600-PLS). La deuxième partie de la référence est inutile pour les autres

types de communication.

3 0,3 µm Communication E Ethernet

5 0,5 µm S Options E/S

série

D Bas (fond) A Analogique

S Latéral

Composants du produit

Assurez-vous d'avoir bien reçu tous les composants. Voir Figure 4. Si

des éléments manquent ou sont endommagés, contactez

immédiatement le fabricant ou un représentant commercial.

Français 29

Page 30

Figure 4 Composants de l'instrument

1 Compteur de particules MET ONE

série 6000

2 Sonde d'échantillonnage

(isocinétique) avec tuyau

3 Sonde d'échantillonnage

(isocinétique) avec tuyau

4 kit de montage du rail DIN 8 Câble du port de service

1

Unités 1,0 cfm uniquement

2

Unités 0,1 cfm uniquement

3

Toutes les unités sauf Ethernet

4

Ethernet uniquement

5

Un seul câble de port Service est fourni par commande.

1

2

5 Connecteur à 10 broches avec

3

boîtier

6 Connecteur à 5 broches avec

4

boîtier

7 CD de l'utilitaire de configuration

(connecteur série 8 broches à

9 broches DIN)

5

Installation

Conseils d'installation

A V I S

Avant de démarrer un cycle de nettoyage ou de désinfection, arrêtez la pompe à

vide et installez un couvercle sur le raccord d'arrivée d'air.

Des températures internes élevées endommagent les composants de

l'instrument.

• Installez l'instrument en intérieur, dans un lieu propre, sec, bien aéré

avec un contrôle de la température et un niveau de vibration

minimum.

•

Si la pièce est régulièrement lavée à grande eau, installez l'instrument

à l'extérieur de la pièce. Seuls les tubes d'arrivée d'air et de vide

doivent être installés dans la salle blanche. L'instrument peut

également être installé dans un boîtier hermétique puis dans la salle

blanche. Raccordez toute la tuyauterie et les câbles à l'instrument à

travers le boîtier. Tout fonctionnement de l'instrument à l'intérieur d'un

boîtier hermétique risque d'augmenter la température autour de

l'instrument et de diminuer ses performances et sa durée de vie.

• N'utilisez pas l'instrument à la lumière directe du soleil ou à proximité

d'une source de chaleur.

• Installez l'instrument le plus près possible de la source

d'échantillonnage. S'assurer que la distance n'est pas supérieure à

3 m (10 pieds). Tout tuyau d'arrivée d'une longueur supérieure à 3 m

risque d'entraîner une perte des particules de plus de 1 μm. Si un

tuyau d'arrivée d'une longueur de plus de 3 m est nécessaire,

essayez d'utiliser un compteur de particules portatif et comparez les

résultats avec cet instrument.

• Le flux d'air doit systématiquement être dirigé vers le bas. Si possible,

montez l'instrument directement sous le point d'échantillonnage.

A V I S

30 Français

Directives pour le système de vide

• Mettre la pompe à vide dans un endroit central. Il doit y avoir un vide

suffisant pour tous les instruments du réseau.

Page 31

• Utilisez un collecteur de distribution qui maintient les pertes de vide à

un niveau minimum. Les matériels types utilisés pour la distribution du

vide incluent des tubes en cuivre roulé-brasé, des tuyaux normalisés

80 PVC, ou une tuyauterie telle Colobite®.

•

Utilisez des tuyaux de courte longueur pour fournir du vide entre le

collecteur de distribution et chaque instrument. Utilisez une vanne de

distribution et un raccord cannelé de la dimension correcte à chaque

emplacement d'instrument.

• Utilisez le moins de raccords et de coudes possibles, et faites en sorte

que la longueur de la tuyauterie entre la source de vide et

l'instruments soit la plus courte possible pour limiter au maximum les

pertes de vide.

Installation mécanique

Montage de l'instrument

Installez l'instrument sur une surface plane ou sur un mur à l'aide de l'un

de ces kits de montage :

• Kit pour rail DIN (fourni avec l'instrument) : permet de retirer

rapidement l'instrument du mur.

• Fixation pour montage mural (en option) : convient à une installation

permanente. Reportez-vous aux instructions fournies avec le kit.

Reportez-vous aux étapes illustrées à la Figure 5 pour l'installation du

rail DIN. Pour retirer l'instrument du rail, soulevez l'instrument par le bas.

Figure 5 Installation du rail DIN

Français 31

Page 32

Installation de la sonde d'échantillonnage

Reportez-vous aux Directives de sonde d'échantillonnage à la page 32

préalablement à l'installation pour éviter toute contamination de

l'instrument et pour obtenir un échantillon représentatif de la zone. La

position de la sonde d'échantillonnage (isocinétique) est importante pour

la précision du comptage.

Options d'installation de la sonde d'échantillonnage

Des kits d'installation de la sonde d'échantillonnage sont disponibles en

option. Voir Figure 6.

• Montage direct : aucun kit nécessaire. La sonde d'échantillonnage

est installée dans une petite section de tuyau, directement au-dessus

du raccord d'arrivée d'air d'échantillonnage de l'

le montage direct lorsque l'instrument peut être installé au même

endroit que le prélèvement d'échantillons. Le montage direct permet

de limiter au maximum la perte de particules.

• Support mural 90 degrés : la sonde est raccordée à un tube en acier

inoxydable (90 degrés) et à une fixation murale.

• Fixation murale en équerre: la sonde d'échantillonnage est installée

sur une fixation murale. Le tube est coupé pour connecter la sonde au

compteur.

• Support mural vertical : la sonde d'échantillonnage est raccordée à

un support et à un tube en acier inoxydable. Choisissez l'installation

avec support mural vertical sur des équipements comprenant une

tuyauterie en acier inoxydable.

instrument. Choisissez

Figure 6 Options d'installation de la sonde d'échantillonnage

1 Montage direct 3 Support mural vertical

2 Support mural 90 degrés 4 Support mural en T

Directives de sonde d'échantillonnage

A V I S

N'utilisez pas cet instrument pour surveiller de l'air contenant des vapeurs de

colle desséchée ou d'autres produits chimiques. Ces vapeurs risquent de

recouvrir les verres du capteur ou d'autres pièces internes de façon irréversible.

N'utilisez pas cet instrument pour surveiller de l'air contenant des vapeurs

chargées de substances corrosives. Ces vapeurs endommageraient rapidement

et de façon permanente les verres ou les composants électroniques du

compteur.

A V I S

32 Français

Page 33

• Flux laminaire : installez au moins une sonde d'échantillonnage tous

les 2,3 m2 (25 pieds2).

•

Turbulence : installez au moins deux sondes d'échantillonnage dans

chaque salle blanche.

• Assurez-vous que la sonde d'échantillonnage (isocinétique) est

orientée dans le sens du flux. Voir Figure 2 à la page 28.

• Placez la sonde d'échantillonnage à au moins 30 cm de matériaux

épars, poussières, liquides et vaporisations.

• Placez la sonde d'échantillonnage à au moins 30 cm de toute source

de contamination potentielle, telle que le ventilateur d'extraction d'un

instrument.

• N'utilisez pas cet instrument pour surveiller de l'air contenant des

substances mentionnées au Tableau 4.

Tableau 4 Contaminants

Substance Dommage causé

Poudres Contamination du capteur et génération de résultats incorrects ou

Liquides Contamination des verres internes du capteur et modification de

Fumée Contamination du capteur

de défaillance de l'instrument

l'étalonnage de l'instrument

Remarque : Des liquides peuvent être présents dans l'air sous la forme de

gouttelettes d'huile.

Eléments à réunir :

Tuyauterie d'arrivée d'air : Hytrel® Bevaline, Tygon® ou équivalent

•

• Tuyauterie du vide—Hytrel Bevaline, Tygon ou équivalent

• Crochets de tube ou attaches de câble

1. Coupez la tuyauterie d'entrée d'air de sorte à obtenir une longueur

suffisante pour raccorder l'instrument à la sonde d'échantillonnage.

Garder une longueur de tuyau minimum. S'assurer que la longueur

n'est pas supérieure à 3 m (10 pieds).

2. Couper la tuyauterie à vide pour connecter le compteur à la source

de vide. Garder une longueur minimum de tube.

3. Recouvrir les extrémités pour s'assurer que des matériels non

désirés ne rentrent pas dans les tuyaux durant l'installation.

4. Fixez la tuyauterie à l'aide de crochets ou d'attaches de câbles à des

intervalles de 1,2 m maximum. Assurez-vous que la tuyauterie

dispose d'un rayon de courbure minimum de 10 cm de sorte à ne

pas réduire le débit d'air.

5. Raccordez le tuyau d'arrivée d'air au raccord d'arrivée d'air de

l'instrument. Raccordez l'autre extrémité du tuyau à la sonde

d'échantillonnage fournie.

6. Connecter la tuyauterie du vide au raccord situé sur le bas (ou le

coté) du compteur. Ne pas connecter l'autre extrémité au vide tant

que la salle n'est pas prête pour l'échantillonnage.

Installation de la tuyauterie

Utilisez des crochets ou des attaches de câbles pour maintenir la

tuyauterie en place et l'empêcher de se plier. Toute courbure de la

tuyauterie risque de réduire le débit d'air et d'entraîner les

problèmesuivant

• Une réduction du débit d'arrivée d'air risque d'amener les particules à

se déposer sur les parois de la tuyauterie. Les particules ne seront

pas comptées. Les particules impactées peuvent être relarguées de

manière aléatoire, ce qui causera des pics dans le niveau de

comptage.

s :

Installation électrique

Information de sécurité du câblage

A V E R T I S S E M E N T

Risque d'électrocution Assurez-vous de disposer d'un accès facile à la

coupure d'alimentation locale.

Toujours débrancher l'appareil de l'alimentation avant d'effectuer tout

branchement électrique.

A V I S

Français 33

Page 34

Respectez toutes les mesures de sécurité pendant que l'appareil est

branché.

Branchement de l'alimentation

Branchez une source d'alimentation externe (24 V CC) au connecteur à

5 broches ou à 10 broches. Reportez-vous à la Figure 7

ou à la Figure 8 et au Tableau 6 pour obtenir des informations sur le

câblage. Assurez-vous que la tension de sortie de la source

d'alimentation externe ne dépasse pas 28 V CC.

Le nombre maximal d'instruments qui peuvent être connectés à une

source d'alimentation externe peut varier en fonction de l'option de