Page 1

DOC022.97.80338

Lachat QuikChem In-Line Module

05/2017, Edition 3

User Manual

Manuel d'utilisation

Manual del usuario

用户手册

Page 2

English...................................................................................................................................................................................................3

Français.............................................................................................................................................................................................. 19

Español............................................................................................................................................................................................... 35

中文.......................................................................................................................................................................................................51

2

Page 3

Table of contents

Specifications on page 3 Operation on page 11

General information on page 3 Maintenance on page 12

Installation on page 6 Troubleshooting on page 16

User interface and navigation

on page 10

Replacement parts and accessories

on page 17

Specifications

Specifications are subject to change without notice.

Specification Details

Dimensions (W x D x H) 23 x 54 x 14 cm (9 x 21.3 x 5.5 in.)

Weight 4.5 kg (10 lb)

Power requirement 115 VAC, 60 Hz, 1.2 A

230 VAC, 50 Hz, 0.8 A

Fuse 1.6 A, 250 VAC, slow blow

Operating temperature 5 to 40 °C (41 to 104 °F)

Pollution degree 2

Protection class 1

Installation category II

Storage/operating humidity Maximum relative humidity is 80% for temperatures

up to 31 °C (87.8 °F), decreases linearly to 50%

relative humidity at 40 °C (104 °F)

Location Indoor or laboratory

Specification Details

UV lamp1—(most common) 354 nm (dark blue), Ushio type F6T5BLB (50717).

Use with the cyanide determination.

254 nm (clear), G6T5 (50775). Use with the total

nitrogen or the total phosphorous determination.

Certifications CE mark; listed by ETL to UL and CSA safety

standards (cETLus) for North America.

Warranty 1 year

General information

In no event will the manufacturer be liable for direct, indirect, special,

incidental or consequential damages resulting from any defect or

omission in this manual. The manufacturer reserves the right to make

changes in this manual and the products it describes at any time, without

notice or obligation. Revised editions are found on the manufacturer’s

website.

Safety information

N O T I C E

The manufacturer is not responsible for any damages due to misapplication or

misuse of this product including, without limitation, direct, incidental and

consequential damages, and disclaims such damages to the full extent permitted

under applicable law. The user is solely responsible to identify critical application

risks and install appropriate mechanisms to protect processes during a possible

equipment malfunction.

Please read this entire manual before unpacking, setting up or operating

this equipment. Pay attention to all danger and caution statements.

Failure to do so could result in serious injury to the operator or damage

to the equipment.

Make sure that the protection provided by this equipment is not impaired.

Do not use or install this equipment in any manner other than that

specified in this manual.

1

Refer to the specific QuikChem method for lamp specifications for an application.

English 3

Page 4

Use of hazard information

D A N G E R

Indicates a potentially or imminently hazardous situation which, if not avoided, will

result in death or serious injury.

W A R N I N G

Indicates a potentially or imminently hazardous situation which, if not avoided,

could result in death or serious injury.

C A U T I O N

Indicates a potentially hazardous situation that may result in minor or moderate

injury.

N O T I C E

Indicates a situation which, if not avoided, may cause damage to the instrument.

Information that requires special emphasis.

Precautionary labels

Read all labels and tags attached to the instrument. Personal injury or

damage to the instrument could occur if not observed. A symbol on the

instrument is referenced in the manual with a precautionary statement.

This symbol, if noted on the instrument, references the instruction

manual for operation and/or safety information.

Electrical equipment marked with this symbol may not be disposed of

in European public disposal systems after 12 August of 2005. In

conformity with European local and national regulations (EU Directive

2002/96/EC), European electrical equipment users must now return

old or end-of-life equipment to the Producer for disposal at no charge

to the user.

This symbol indicates that a risk of electrical shock and/or

electrocution exists.

This symbol indicates the need for protective eye wear.

This symbol, when noted on the product, identifies the location of a

fuse or current limiting device.

This symbol identifies a risk of chemical harm and indicates that only

individuals qualified and trained to work with chemicals should handle

chemicals or perform maintenance on chemical delivery systems

associated with the equipment.

This symbol identifies the presence of a strong corrosive or other

hazardous substance and a risk of chemical harm. Only individuals

qualified and trained to work with chemicals should handle chemicals

or perform maintenance on chemical delivery systems associated

with the equipment.

This symbol indicates that the marked item can be hot and should not

be touched without care.

This symbol indicates the presence of devices sensitive to Electrostatic Discharge (ESD) and indicates that care must be taken to

prevent damage with the equipment.

Certification

Canadian Radio Interference-Causing Equipment Regulation,

IECS-003, Class A:

Supporting test records reside with the manufacturer.

This Class A digital apparatus meets all requirements of the Canadian

Interference-Causing Equipment Regulations.

Cet appareil numérique de classe A répond à toutes les exigences de la

réglementation canadienne sur les équipements provoquant des

interférences.

FCC Part 15, Class "A" Limits

4

English

Page 5

Supporting test records reside with the manufacturer. The device

complies with Part 15 of the FCC Rules. Operation is subject to the

following conditions:

1. The equipment may not cause harmful interference.

2. The equipment must accept any interference received, including

interference that may cause undesired operation.

Changes or modifications to this equipment not expressly approved by

the party responsible for compliance could void the user's authority to

operate the equipment. This equipment has been tested and found to

comply with the limits for a Class A digital device, pursuant to Part 15 of

the FCC rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated

in a commercial environment. This equipment generates, uses and can

radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference

to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference, in which case the user will be

required to correct the interference at their expense. The following

techniques can be used to reduce interference problems:

1. Disconnect the equipment from its power source to verify that it is or

is not the source of the interference.

2. If the equipment is connected to the same outlet as the device

experiencing interference, connect the equipment to a different

outlet.

3. Move the equipment away from the device receiving the interference.

4. Reposition the receiving antenna for the device receiving the

interference.

5. Try combinations of the above.

Electrostatic discharge (ESD) considerations

N O T I C E

Potential Instrument Damage. Delicate internal electronic components

can be damaged by static electricity, resulting in degraded

performance or eventual failure.

Refer to the steps in this procedure to prevent ESD damage to the

instrument:

• Touch an earth-grounded metal surface such as the chassis of an

instrument, a metal conduit or pipe to discharge static electricity from

the body.

• Avoid excessive movement. Transport static-sensitive components in

anti-static containers or packages.

• Wear a wrist strap connected by a wire to earth ground.

• Work in a static-safe area with anti-static floor pads and work bench

pads.

Product overview

This instrument contains a UV lamp and a heater block that prepare a

sample for an analyzer. This instrument is for indoor use only. Refer to

Figure 1.

English 5

Page 6

Figure 1 Product overview

1 Display panel 5 Power switch 9 Thumbscrews

2 UV lamp 6 Heater block 10 Access cover

3 Thermocouple 7 Power connector 11 UV lamp indicator

4 Heat rod 8 Fuse box 12 Sample in/out ports

Product components

Make sure that all components have been received. Refer to Figure 2. If

any items are missing or damaged, contact the manufacturer or a sales

representative immediately.

Figure 2 Instrument components

1 Instrument 3 Clips with unions

2 Power cord 4 Heater block

Installation

W A R N I N G

Multiple hazards. Only qualified personnel must conduct the tasks

described in this section of the document.

6 English

Page 7

Install the heater block

Refer to the illustrated steps that follow.

English 7

Page 8

8 English

Page 9

Instrument placement

C A U T I O N

Ozone inhalation hazard. Under certain conditions, this instrument

produces ozone concentrations above safe exposure limits. Plumb

waste gases to a fume hood or to the building exterior in accordance

with local, regional and national requirements.

This instrument is rated for an altitude of 2000 m (6562 ft) maximum.

Use of this instrument at an altitude higher than 2000 m can slightly

increase the potential for the insulation to breakdown, which can result in

an electric shock hazard. The manufacturer recommends that users with

concerns contact technical support.

Put the instrument in a position that makes it easy to disconnect the

instrument from the power source.

Put the instrument in a position so that the fan ventilation opening on the

left side is not blocked. Do not allow the power cord to contact hot

surfaces on the QC8500 measurement channels.

There are two placement options:

• Put the instrument on top of the QuikChem System Core (Figure 3).

Make sure that the heater controller is on the left side of the system.

• Put the instrument below the peristaltic pump if the space on top of

the QuikChem system is not available. The peristaltic pump is located

on the left side of the QuikChem system.

Figure 3 Coupler installation

1 Analyzer 3 Sample outlet tubes

2 Sample tubes to analyzer 4 Sample inlet tubes

Plumbing

Make sure to use the specified tubing size. Refer to the QuikChem

method for details.

English

9

Page 10

Prepare the reagent and standards

1. Refer to the QuikChem method for details about the reagent and

standards preparation.

2. Read all system notes.

3. Connect the manifold as shown in the manifold diagram of the

QuikChem method.

Connect the power cord

Items to collect:

• Surge-protected power strip

1. Connect the power cord to the instrument. The power cord must be

rated for the supply voltage and current.

2. Connect the power cord to a power strip.

3. Turn the power strip on.

4. Turn the instrument power switch on.

Start the peristaltic pump

Refer to the pump operation section in the QuikChem user manual for

details on pump tube installation and peristaltic pump operation.

Look for leaks

1. After the manifold is installed and all pump tubes are securely

attached, put all reagent lines in deionized water.

2. Make sure that there are no leaks on the manifold, the injection valve

or the instrument.

User interface and navigation

Figure 4 shows the instrument display and keypad. Table 1 gives the key

functions.

Figure 4 Display and keypad

1 PV LED display 3 UP arrow 5 Show/change

2 SV LED display 4 DOWN arrow 6 Enter

Table 1 Key functions

Key Function

Saves the change.

Shows or changes the temperature setting.

Decreases the value.

Increases the value.

10 English

Page 11

Operation

W A R N I N G

Chemical exposure hazard. Obey laboratory safety procedures and wear all of

the personal protective equipment appropriate to the chemicals that are handled.

Refer to the current material safety data sheets (MSDS) for safety protocols.

Set the temperature

Note: Do not make the temperature higher than 60 ºC (140 ºF) without water or

reagents in the tubing.

1. Push until the display shows SP (set point).

2. Push the UP or DOWN arrows to raise or lower the set point. The

display continues to show the SP mode.

3. When the temperature is set, push to save the information in

memory.

4. Push once. The display shows the current temperature in

Celsius. A red light shows the heater is on.

5. Let the temperature stabilize.

Find the correct timing

To find the correct timing in the Omnion FIA:

Items to collect:

• Stop watch or other timer

• Dye (provided with the system) - red dye gives the best results

Note: Due to differences in the viscosity and boiling point of each reagent, do not

use water in place of reagents during the dye test.

1. Put some dye in a test tube.

2. Create a method in Omnion. Enter all valve timing parameters (cycle

period, sample reaches first valve, load period and inject period) and

sampler timing parameters.

3. Run the dye as a sample. Start the timer when the probe goes into

the test tube.

4. Follow the dye through the system. When the sample gets to Port

6 at the injection valve, stop the timer.

5. Record the time, which is the sample reaches first valve time. Make

sure to change this time in the valve timing of the method.

6. Save the method and run the dye again to measure the next

parameter.

7. Run the dye and follow it through the system. When the dye gets to

Port 6, start the timer. This is the instant when the valve toggles for

the first time.

8. When the sample slug gets to Port 6, stop the timer.

9. Record this time and subtract 5 seconds to get the load period that is

specified in the valve timing of the Omnion method.

• The cycle period is specified in the method (cycle period = load

period + inject period).

• The inject period is automatically set by the software once the

cycle period and load period are defined.

Calibrate the instrument

1. Put all reagent lines in their respective reagent bottles.

2. Put the standard solutions into the standard vials.

3. Refer to the analyzer user manual to start a calibration run.

Brackish timing in Omnion FIA

Some of the in-line methods make Brackish (or manual) integration

timing necessary. The QuikChem method shows when the brackish

timing is needed.

To learn more about how to set brackish timing, refer to the software

manual or search for the keywords graphical events programming or

brackish events in the Omnion help system.

Tips

• Do not use the stand-by speed of the peristaltic pump.

• Put reagent lines in deionized water to avoid wasting reagents.

English

11

Page 12

• Make sure that the deionized water flows through the wash reservoir.

• The sample line is usually not a green-green pump tube. Refer to the

QuikChem method for the correct pump tube.

• Set the peristaltic pump to 35.

• Get to the required temperature before a run is started.

• Allow the reagents to flow at normal speed through the entire system

for at least 15 minutes before a run is started.

• Change the bubble trap membrane once a month or when the

precision is poor or air bubbles are a constant problem.

• Look at the method support data in the QuikChem method and

compare the data to the results. Make sure that the peak height and

area are similar for standards of the same concentration.

• If the instrument and other standard FIA channels run simultaneously,

the sample line for the standard channels can be changed from

green-green to orange-orange. Cut the pump tube like any other

sample line pump tube. Use a dye solution to make sure that the

timing is correct. This change uses less sample.

Maintenance

D A N G E R

Multiple hazards. Only qualified personnel must conduct the tasks

described in this section of the document.

D A N G E R

Electrocution hazard. Remove power from the instrument before doing

maintenance or service activities.

W A R N I N G

Chemical exposure hazard. Obey laboratory safety procedures and

wear all of the personal protective equipment appropriate to the

chemicals that are handled. Refer to the current safety data sheets

(MSDS/SDS) for safety protocols.

Maintenance schedule

Table 2 shows the recommended schedule of maintenance tasks.

Facility requirements and operating conditions may increase the

frequency of some tasks.

Table 2 Maintenance schedule

Task Daily Annually As necessary

Clean the instrument on page 12 X

Replace a fuse on page 13 X

Prepare the tubing on page 13 X X

Replace the lamp on page 14 X

Replace the heater block on page 15 X

For the maintenance tasks specific to an individual method, refer to the

QuikChem method.

Clean the instrument

N O T I C E

Do not use any cleaning or decontamination procedures other than those

recommended by the manufacturer. Other procedures can damage the

instrument. Contact technical support to make sure that the procedures do not

damage the instrument.

1. Set the instrument to off. Remove power from the instrument.

2. Clean up any spills before the instrument is cleaned.

a. Use baking soda to neutralize acidic spills.

b. Use water to remove the baking soda solution.

c. Dry the area with a lint-free cloth.

3. Clean all surfaces of the instrument with water.

4. Dry all surfaces of the instrument with a lint-free cloth.

12

English

Page 13

Replace a fuse

D A N G E R

Fire hazard. Use the same type and current rating to replace fuses.

To replace a fuse, refer to the illustrated steps in Figure 5.

Figure 5 Fuse replacement

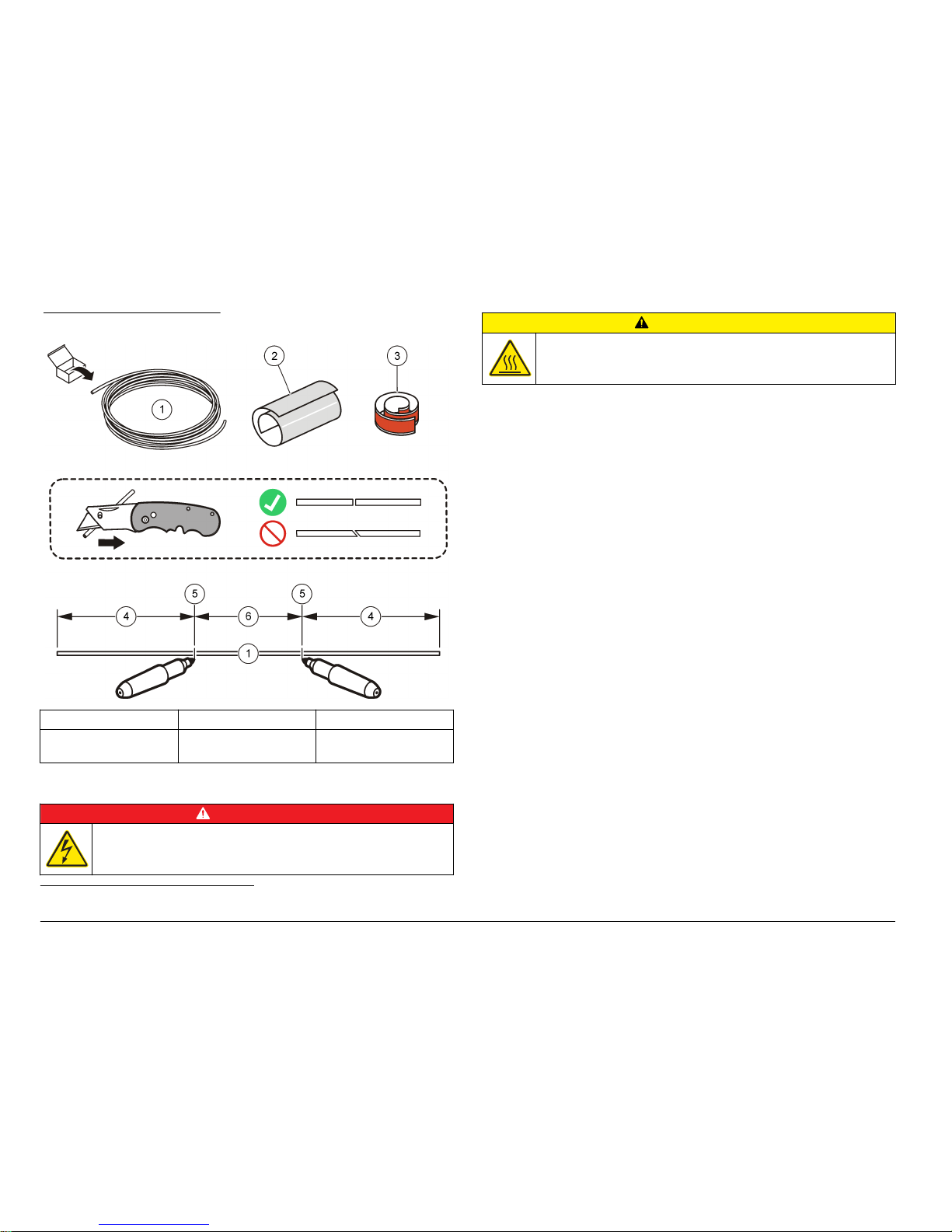

Prepare the tubing

To prepare the tubing, refer to the QuikChem method and Figure 6.

English

13

Page 14

Figure 6 Tubing preparation

1 Tubing 3 Thermal tape, heater 5 Start and stop marks

2 Thermal tape, high

temperature

4 Tubing for other

connections

2

6 Tubing winds around

the lamp/heater block

Replace the lamp

D A N G E R

Electrocution hazard. Remove power from the instrument before doing

maintenance or service activities.

C A U T I O N

Burn hazard. Turn off power and allow the instrument to cool before

this procedure.

Never disconnect the lamp when the power is turned on.

Disconnect the AC input before any part of the instrument is opened.

If the lamp has been recently used, let the instrument temperature cool.

The time required depends upon the temperature set point.

1. Remove all power to the instrument.

2. Remove the top right cover panel.

3. Disconnect the lamp tubing.

4. Remove the lamp from the brackets.

5. Remove the aluminum thermal tape and tubing from the lamp. If the

thermal tape is still in good condition after it is removed, use it on the

new part.

6. To prepare the tubing, refer to Prepare the tubing on page 13.

7. To add tubing around the new lamp, refer to Figure 7.

8. Install the lamp.

9. Connect the tubing.

10. Install the cover panel and secure it.

11. Apply power to the instrument.

2

For lengths and other information, refer to the QuikChem method.

14 English

Page 15

Figure 7 Tubing replacement on the lamp

Replace the heater block

D A N G E R

Electrocution hazard. Remove power from the instrument before doing

maintenance or service activities.

C A U T I O N

Burn hazard. Turn off power and allow the instrument to cool before

this procedure.

Never disconnect the thermocouple and heat stick when the power is

turned on. The result is uncontrolled heating.

Disconnect the AC input before any part of the instrument is opened.

If the heater has been recently used, let the instrument temperature cool.

The time required depends upon the temperature set point.

1. Remove all power to the instrument.

2. Remove the top right cover panel.

3. Disconnect the heater block tubing.

4. Refer to the QuikChem method to make sure that the type and

amount of tubing required for an application is correct.

5. To add tubing around the heater block, refer to Prepare the tubing

on page 13 and Figure 8.

6. To install the heater block, refer to Install the heater block on page 7.

English 15

Page 16

Figure 8 Tubing replacement on the heater block

Troubleshooting

C A U T I O N

Burn hazard. Obey safe handling protocols during contact with hot

sample components.

Decrease the temperature on the instrument to 70 ºC (158 ºF) or less

before the pump tubes are examined. The typical amount of time to

decrease the temperature from 140 ºC (284 ºF) to 70 ºC (158 ºF) is

approximately 10 minutes.

General troubleshooting considerations

The in-line manifolds are different than the standard FIA manifolds. The

main differences are:

• Sample line—The sample line used is usually not a green-green pump

tube. Smaller pump tubes are chosen so that the sample (mixed with

a digestion solution) is put on the heater and on the UV lamp for a

longer period of time.

• Pre-valve sample preparation—The sample line from the sampler

does not go directly to Port 6 of the injection valve. The sample line

mixes with a digestion solution, gets heated, gets UV irradiated, then

goes through the diffusion block or bubble tap membrane, and travels

to Port 6 of the injection valve.

Table 3 shows the most common problems encountered:

Table 3 Troubleshooting guide

Problem Solution

Air spikes in the FIAgram Make sure that the timings agree with the

information in Find the correct timing

on page 11.

Do a degass procedure on the reagents.

Replace the membrane in the dialysis block or

replace the bubble trap membrane.

16 English

Page 17

Table 3 Troubleshooting guide (continued)

Problem Solution

Poor recovery of a QC sample

that consists of complexcyanide

Make sure that the reagents are made fresh.

Make sure that sample flows through all pump

lines.

Make sure that the temperature agrees with

the QuikChem method.

Look at the small hole on the top of the

instrument to see if the UV lamp is turned on. If

not, replace the lamp.

Poor or no recovery of a QC

sample

Examine the pump tubes for flow.

Examine the temperature setting.

Make sure that the reagents are made

correctly.

For the cyanide determination, make sure that

the acid line is put in the digestion solution.

Examine the pump tubes for the acid, the

sample and the acceptor.

Read the QuikChem method notes to learn

more about the expected recoveries.

Table 3 Troubleshooting guide (continued)

Problem Solution

Air flow though the diffusion

block gets very fast, then slows

almost to a stop

Make sure that there are no blockages or

crimps in the reagent and samples tubing.

Make sure that the waste tubing flows freely. If

not, there is excessive back pressure.

Make sure that the instrument waste goes into

a waste container that is applicable for that

solution. Make sure that the tubing is above

the liquid level and that the container is vented

to prevent pressure inside the container. To

prevent cavitation and vapor lock, the waste

container must be at the same level as the

instrument.

Examine the reagent and water bath tubing for

plugs or crimps. Small dirt particles or algae

from a dirty water bath causes flow problems.

Imprecision when running

replicates

Examine the timings in Find the correct timing

on page 11.

Replace the bubble trap membrane.

Make sure that all pump tubes are in good

condition and that there is good liquid flow.

Replacement parts and accessories

W A R N I N G

Personal injury hazard. Use of non-approved parts may cause

personal injury, damage to the instrument or equipment malfunction.

The replacement parts in this section are approved by the

manufacturer.

Note: Product and Article numbers may vary for some selling regions. Contact the

appropriate distributor or refer to the company website for contact information.

English

17

Page 18

Replacement parts

Description Item no.

Tubing, heater block 50028

Tubing, lamp 50728

UV lamp, 6 W —

3

UV lamp, 8 W —

3

Heater block only 25008

4

Thermal tape, heater block 31182

Thermal tape, high temperature, 4-inch 31184

Fuse, 1.6 A, 250 V, slow blow 20205

3

Refer to the QuikChem method, and then contact technical support.

4

Contact technical support.

18 English

Page 19

Table des matières

Caractéristiques à la page 19 Fonctionnement à la page 27

Généralités à la page 19 Maintenance à la page 28

Installation à la page 23 Dépannage à la page 32

Interface utilisateur et navigation

à la page 26

Pièces de rechange et accessoires

à la page 34

Caractéristiques

Les caractéristiques techniques peuvent être modifiées sans préavis.

Caractéristique Détails

Dimensions (l x P x H) 23 x 54 x 14 cm (9 x 21.3 x 5.5 pouces)

Poids 4.5 kg (10 lb)

Exigences électriques 115 VCA, 60 Hz, 1.2 A

230 VCA, 50 Hz, 0.8 A

Fusible 1,6 A, 250 VCA, action retardée

Température de

fonctionnement

5 à 40 °C (41 à 104 °F)

Niveau de pollution 2

Classe de protection 1

Catégorie d’installation II

Humidité de stockage/de

fonctionnement

L'humidité relative maximale s'élève à 80 %

jusqu'à 31 ºC (87,8 °F) avec une diminution

linéaire jusqu'à 50 % d'humidité relative à

40 ºC (104 °F)

Emplacement En intérieur ou en laboratoire

Caractéristique Détails

Lampe UV1— (la plus courante) 354 nm (bleu foncé), type Ushio F6T5BLB

(50717). Utilisée pour la détermination du

cyanure.

254 nm (transparente), G6T5 (50775). Utilisée

pour la détermination de l'azote total ou du

phosphore total

Certifications Marquage CE ; répertorié par les normes de

sécurité ETL à UL et CSA (cETLus) en

Amérique du Nord.

Garantie 1 an

Généralités

En aucun cas le constructeur ne saurait être responsable des

dommages directs, indirects, spéciaux, accessoires ou consécutifs

résultant d'un défaut ou d'une omission dans ce manuel. Le constructeur

se réserve le droit d'apporter des modifications à ce manuel et aux

produits décrits à tout moment, sans avertissement ni obligation. Les

éditions révisées se trouvent sur le site Internet du fabricant.

Consignes de sécurité

A V I S

Le fabricant décline toute responsabilité quant aux dégâts liés à une application

ou un usage inappropriés de ce produit, y compris, sans toutefois s'y limiter, des

dommages directs ou indirects, ainsi que des dommages consécutifs, et rejette

toute responsabilité quant à ces dommages dans la mesure où la loi applicable le

permet. L'utilisateur est seul responsable de la vérification des risques

d'application critiques et de la mise en place de mécanismes de protection des

processus en cas de défaillance de l'équipement.

Veuillez lire l'ensemble du manuel avant le déballage, la configuration ou

la mise en fonctionnement de cet appareil. Respectez toutes les

déclarations de prudence et d'attention. Le non-respect de cette

1

Reportez-vous à la méthode QuikChem spécifique pour connaître les spécifications de la lampe selon l'application.

Français 19

Page 20

procédure peut conduire à des blessures graves de l'opérateur ou à des

dégâts sur le matériel.

Assurez-vous que la protection fournie avec cet appareil n'est pas

défaillante. N'utilisez ni n'installez cet appareil d'une façon différente de

celle décrite dans ce manuel.

Interprétation des indications de risques

D A N G E R

Indique une situation de danger potentiel ou imminent qui, si elle n'est pas évitée,

entraîne des blessures graves, voire mortelles.

A V E R T I S S E M E N T

Indique une situation de danger potentiel ou imminent qui, si elle n'est pas évitée,

peut entraîner des blessures graves, voire mortelles.

A T T E N T I O N

Indique une situation de danger potentiel qui peut entraîner des blessures

mineures ou légères.

A V I S

Indique une situation qui, si elle n'est pas évitée, peut occasionner

l'endommagement du matériel. Informations nécessitant une attention

particulière.

Etiquettes de mise en garde

Lisez toutes les informations et toutes les étiquettes apposées sur

l’appareil. Des personnes peuvent se blesser et le matériel peut être

endommagé si ces instructions ne sont pas respectées. Un symbole sur

l'appareil est référencé dans le manuel et accompagné d'une déclaration

de mise en garde.

Si l'appareil comporte ce symbole, reportez-vous au manuel

d'utilisation pour consulter les informations de fonctionnement et de

sécurité.

En Europe, depuis le 12 août 2005, les appareils électriques

comportant ce symbole ne doivent pas être jetés avec les autres

déchets. Conformément à la réglementation nationale et européenne

(Directive 2002/96/CE), les appareils électriques doivent désormais

être, à la fin de leur service, renvoyés par les utilisateurs au fabricant,

qui se chargera de les éliminer à ses frais.

Ce symbole indique qu'il existe un risque de choc électrique et/ou

d'électrocution.

Ce symbole indique la nécessité de porter des lunettes de protection.

Ce symbole, s'il figure sur le produit, indique l’emplacement d’un

fusible ou d'un dispositif limiteur de courant.

Ce symbole identifie un risque chimique et indique que seules les

personnes qualifiées et formées pour travailler avec des produits

chimiques sont autorisées à les manipuler ou à réaliser des

opérations de maintenance sur les systèmes associés à l'équipement

et utilisant des produits chimiques.

Ce symbole identifie la présence d’une substance fortement corrosive

ou autre substance dangereuse et donc, un risque de blessure

chimique. Seuls les individus qualifiés et formés pour travailler avec

des produits chimiques doivent manipuler des produits chimiques ou

procéder à des travaux de maintenance sur les systèmes de

distribution chimique associés à l’équipement.

20 Français

Page 21

Ce symbole indique que l’élément signalé peut être chaud et que des

précautions doivent être prises avant de le toucher.

Ce symbole indique la présence d'appareils sensibles aux décharges

électrostatiques et indique que des précautions doivent être prises

afin d'éviter d'endommager l'équipement.

Certification

Règlement canadien sur les équipements causant des

interférences radio, IECS-003, Classe A:

Les données d'essai correspondantes sont conservées chez le

constructeur.

Cet appareil numérique de classe A respecte toutes les exigences du

Règlement sur le matériel brouilleur du Canada.

Cet appareil numérique de classe A répond à toutes les exigences de la

réglementation canadienne sur les équipements provoquant des

interférences.

FCC part 15, limites de classe A :

Les données d'essai correspondantes sont conservées chez le

constructeur. L'appareil est conforme à la partie 15 de la règlementation

FCC. Le fonctionnement est soumis aux conditions suivantes :

1. Cet équipement ne peut pas causer d'interférence nuisible.

2. Cet équipement doit accepter toutes les interférences reçues, y

compris celles qui pourraient entraîner un fonctionnement inattendu.

Les modifications de cet équipement qui n’ont pas été expressément

approuvées par le responsable de la conformité aux limites pourraient

annuler l’autorité dont l’utilisateur dispose pour utiliser cet équipement.

Cet équipement a été testé et déclaré conforme aux limites définies pour

les appareils numériques de classe A, conformément à la section 15 de

la réglementation FCC. Ces limites ont pour but de fournir une protection

raisonnable contre les interférences néfastes lorsque l’équipement

fonctionne dans un environnement commercial. Cet équipement génère,

utilise et peut irradier l'énergie des fréquences radio et, s'il n'est pas

installé ou utilisé conformément au mode d'emploi, il peut entraîner des

interférences dangereuses pour les communications radio. Le

fonctionnement de cet équipement dans une zone résidentielle risque de

causer des interférences nuisibles, dans ce cas l'utilisateur doit corriger

les interférences à ses frais Les techniques ci-dessous peuvent

permettre de réduire les problèmes d'interférences :

1. Débrancher l'équipement de la prise de courant pour vérifier s'il est

ou non la source des perturbations

2. Si l'équipement est branché sur le même circuit de prises que

l'appareil qui subit des interférences, branchez l'équipement sur un

circuit différent.

3. Éloigner l'équipement du dispositif qui reçoit l'interférence.

4. Repositionner l’antenne de réception du périphérique qui reçoit les

interférences.

5. Essayer plusieurs des techniques ci-dessus à la fois.

Remarques relatives aux décharges électrostatiques

A V I S

Dégât potentiel sur l'appareil Les composants électroniques internes

de l'appareil peuvent être endommagés par l'électricité statique, qui

risque d'altérer ses performances et son fonctionnement.

Reportez-vous aux étapes décrites dans cette procédure pour éviter

d'endommager l'appareil par des décharges électrostatiques.

• Touchez une surface métallique reliée à la terre (par exemple, le

châssis d'un appareil, un conduit ou un tuyau métallique) pour

décharger l'électricité statique de votre corps.

• Evitez tout mouvement excessif. Transportez les composants

sensibles à l'électricité statique dans des conteneurs ou des

emballages antistatiques.

• Portez un bracelet spécial relié à la terre par un fil.

• Travaillez dans une zone à protection antistatique avec des tapis de

sol et des sous-mains antistatiques.

Français

21

Page 22

Présentation du produit

Cet instrument contient une lampe UV et un bloc chauffant qui préparent

l'échantillon pour un analyseur. Cet instrument est conçu pour être utilisé

uniquement à l'intérieur. Voir Figure 1.

Figure 1 Présentation du produit

1 Panneau d'affichage 5 Interrupteur

marche/arrêt

9 Vis de serrage

2 Lampe UV 6 Bloc chauffant 10 Couvercle d'accès

3 Thermocouple 7 Connecteur

d'alimentation

11 Témoin de la lampe

UV

4 Tige chauffante 8 Boîte à fusibles 12 Orifices

d'entrée/sortie

d'échantillon

22 Français

Page 23

Composants du produit

Assurez-vous d'avoir bien reçu tous les composants. Voir Figure 2. Si

des éléments manquent ou sont endommagés, contactez

immédiatement le fabricant ou un représentant commercial.

Figure 2 Composants de l'instrument

1 Instrument 3 Clips avec raccords

2 Cordon d'alimentation 4 Bloc chauffant

Installation

A V E R T I S S E M E N T

Dangers multiples. Seul le personnel qualifié doit effectuer les tâches

détaillées dans cette section du document.

Installation du bloc chauffant

Reportez-vous aux illustrations suivantes.

Français 23

Page 24

24 Français

Page 25

Positionnement de l'instrument

A T T E N T I O N

Risque d'inhalation d'ozone. Dans certaines conditions, cet instrument

produit des concentrations d'ozone supérieures aux limites

d'exposition en toute sécurité. Branchez l'évacuation des gaz

d'échappement à une hotte ou vers l'extérieur du bâtiment

conformément aux réglementations locales, régionales et nationales.

Cet instrument peut être utilisé jusqu'à une altitude de 2 000 m

(6 562 pieds). Son utilisation à une altitude supérieure à 2 000 m peut

légèrement augmenter le risque de défaillance de l'isolation, et entraîner

un risque de choc électrique. Le fabricant conseille aux utilisateurs ayant

des questions de contacter l'assistance technique.

Placez l'instrument dans une position où il est facile de le débrancher de

la source d'alimentation.

Placez l'instrument dans une position qui n'obstrue pas l'ouverture

d'aération du ventilateur sur le côté gauche. Evitez tout contact du

cordon d'alimentation avec les surfaces brûlantes des canaux de

mesure QC8500.

Il existe deux options de positionnement :

• Placez l'instrument au-dessus de la partie centrale du système

QuikChem (Figure 3). Vérifiez que le contrôleur du chauffage se

trouve bien sur le côté gauche du système.

• Placez l'instrument en dessous de la pompe péristaltique s'il n'y a pas

de place au-dessus du système QuikChem. La pompe péristaltique se

trouve sur le côté gauche du système QuikChem.

Figure 3 Installation du coupleur

1 Analyseur 3 Tubes de sortie d'échantillon

2 Tubes d'échantillon vers l'analyseur 4 Tubes d'admission d'échantillon

Plomberie

Veillez à utiliser des tubes à la dimension indiquée. Reportez-vous à la

méthode QuikChem pour plus de détails.

Français

25

Page 26

Préparation du réactif et des étalons

1. Reportez-vous à la méthode QuikChem pour en savoir plus sur la

préparation du réactif et des étalons.

2. Lisez toutes les remarques sur le système.

3. Branchez le distributeur comme illustré sur le schéma du distributeur

de la méthode QuikChem.

Branchement du cordon d'alimentation

Eléments à préparer :

• Bloc multiprise protégé contre les surtensions

1. Branchez le cordon d'alimentation à l'instrument. Le cordon

d'alimentation doit correspondre à la tension et au courant

d'alimentation.

2. Branchez le cordon d'alimentation sur un bloc multiprise.

3. Mettez le bloc multiprise sous tension.

4. Mettez l'instrument sous tension.

Démarrage de la pompe péristaltique

Reportez-vous à la section relative au fonctionnement de la pompe dans

le manuel d'utilisation QuikChem pour en savoir plus sur l'installation du

tube de la pompe et l'exploitation de la pompe péristaltique.

Recherchez les fuites

1. Une fois le distributeur installé et tous les tubes de pompe

correctement raccordés, placez toutes les conduites de réactif dans

de l'eau déminéralisée.

2. Vérifiez que le distributeur, la vanne d'injection ou l'instrument ne fuit

pas.

Interface utilisateur et navigation

Figure 4 illustre l'écran et le clavier de l'instrument. Tableau 1 indique les

fonctions des touches.

Figure 4 Ecran et clavier

1 Ecran LED PV 3 Flèche HAUT 5 Afficher/Modifier

2 Ecran LED SV 4 Flèche BAS 6 Enter

Tableau 1 Fonctions des touches

Touche Fonction

Enregistre la modification.

Indique ou modifie le paramètre de température.

Diminue la valeur.

Augmente la valeur.

26 Français

Page 27

Fonctionnement

A V E R T I S S E M E N T

Risque d'exposition chimique. Respectez les procédures de sécurité du

laboratoire et portez tous les équipements de protection personnelle adaptés aux

produits chimiques que vous manipulez. Reportez-vous aux fiches techniques de

sécurité des matériaux (MSDS) pour connaître les protocoles de sécurité.

Réglez la température

Remarque : Ne dépassez pas une température de 60 ºC (140 ºF) sans eau ni

réactif dans le tube.

1. Appuyez sur jusqu'à ce que l'écran affiche SP (PC) (point de

consigne).

2. Appuyez sur les flèches HAUT ou BAS pour augmenter ou diminuer

le point de consigne. L'écran continue à afficher le mode SP (PC).

3. Lorsque vous avez réglé la température, appuyez sur pour

enregistrer les informations dans la mémoire.

4. Appuyez une fois sur . L'écran affiche la température actuelle en

Celsius. Un témoin rouge indique que le chauffage est en marche.

5. Laissez la température se stabiliser.

Recherche de la bonne temporisation

Pour trouver la bonne temporisation dans la méthode fluorométrique

Omnion :

Eléments à préparer :

• Chronomètre ou autre minuterie

• Colorant (fourni avec le système), le colorant rouge offre les meilleurs

résultats

Remarque : En raison des différences de viscosité et de point d'ébullition de

chaque réactif, n'utilisez pas d'eau à la place des réactifs pendant l'essai

colorimétrique.

1. Versez du colorant dans un tube à essai.

2. Créez une méthode dans Omnion. Saisissez tous les paramètres de

temporisation des vannes (période de cycle, l'échantillon atteint la

première vanne, période de charge et période d'injection) et les

paramètres de temporisation de l'échantillonneur.

3. Faites circuler le colorant à la place de l'échantillon. Démarrez la

minuterie lorsque la sonde pénètre dans le tube à essai.

4. Suivez le cheminement du colorant dans le système. Lorsque

l'échantillon arrive à l'orifice 6 au niveau de la vanne d'injection,

arrêtez la minuterie.

5. Notez le temps indiqué, qui correspond au temps mis par

l'échantillon pour atteindre la première vanne. N'oubliez pas de

modifier ce temps au niveau de la temporisation de la vanne dans la

méthode.

6. Enregistrez la méthode et refaites circuler le colorant pour mesurer le

paramètre suivant.

7. Faites circuler le colorant et suivez son cheminement dans le

système. Lorsque le colorant arrive à l'orifice 6, démarrez la

minuterie. C'est à cet instant que la vanne bascule pour la première

fois.

8. Lorsque l'échantillon entre dans l'orifice 6, arrêtez la minuterie.

9. Relevez ce temps et retranchez 5 secondes pour obtenir la période

de charge spécifiée dans la temporisation de la vanne dans la

méthode Omnion.

• La période de cycle est spécifiée dans la méthode (période de

cycle = période de charge + période d'injection).

• La période d'injection est paramétrée automatiquement par le

logiciel une fois la période de cycle et la période de charge

définies.

Etalonnage de l'instrument

1. Placez toutes les conduites de réactif dans leurs flacons de réactif

respectifs.

2. Versez les solutions étalons dans les fioles à étalon.

3. Reportez-vous au manuel d'utilisation de l'analyseur pour lancer un

étalonnage.

Français

27

Page 28

Temporisation de l'eau saumâtre dans la méthode

fluorométrique Omnion

Il est nécessaire de temporiser l'intégration de l'eau saumâtre (ou

manuelle) avec certaines méthodes en ligne. La méthode QuikChem

indique quand une temporisation de l'eau saumâtre est nécessaire.

Pour en savoir plus sur le réglage de la temporisation de l'eau saumâtre,

reportez-vous au manuel du logiciel ou effectuez une recherche avec les

mots-clés programmation événements graphiques ou événements

saumâtre dans le système d'aide Omnion.

Conseils

• N'utilisez pas la vitesse de ralenti de la pompe péristaltique.

• Placez les conduites de réactif dans de l'eau déminéralisée pour

éviter de gaspiller du réactif.

• Vérifiez que l'eau déminéralisée traverse bien le réservoir de lavage.

• En général, la conduite d'échantillon n'est pas un tube de pompe

vert/vert. Reportez-vous à la méthode QuikChem pour connaître le

bon tube de pompe.

• Réglez la pompe péristaltique sur 35.

• Parvenez à la température nécessaire avant de lancer un cycle.

• Laissez les réactifs s'écouler à vitesse normale dans tout le système

pendant au moins 15 minutes avant de lancer un cycle.

• Remplacez la membrane du débulleur une fois par mois, lorsque la

précision laisse à désirer ou en cas de présence constante de bulles

d'air.

• Reportez-vous aux données relatives à la méthode dans la méthode

QuikChem et comparez-les aux résultats. Vérifiez que la hauteur et la

zone du pic sont semblables à celles des étalons de la même

concentration.

• En cas d'utilisation simultanée de l'instrument avec d'autres canaux

fluorométriques standard, vous pouvez utiliser un tube orange/orange

à la place de la conduite d'échantillon vert/vert des canaux standard.

Coupez le tube de la pompe comme n'importe quel autre tube de

pompe de la conduite d'échantillon. Utilisez un colorant pour vérifier

que la temporisation est correcte. Cette modification permet d'utiliser

moins d'échantillon.

Maintenance

D A N G E R

Dangers multiples. Seul le personnel qualifié doit effectuer les tâches

détaillées dans cette section du document.

D A N G E R

Risque d'électrocution Coupez l'alimentation de l'instrument avant

d'effectuer des activités de maintenance ou d'entretien.

A V E R T I S S E M E N T

Risque d'exposition chimique. Respectez les procédures de sécurité

du laboratoire et portez tous les équipements de protection

personnelle adaptés aux produits chimiques que vous manipulez.

Consultez les fiches de données de sécurité (MSDS/SDS) à jour pour

connaître les protocoles de sécurité applicables.

Calendrier de maintenance

Le Tableau 2 présente le calendrier recommandé pour les tâches

d'entretien. Les exigences du site comme les conditions d'utilisation

peuvent augmenter la fréquence de certaines tâches.

Tableau 2 Calendrier d'entretien

Tâche Tous les

jours

Tous les ans Au besoin

Nettoyage de l'instrument

à la page 29

X

Remplacer un fusible à la page 29 X

Préparation des tubes

à la page 30

X X

28 Français

Page 29

Tableau 2 Calendrier d'entretien (suite)

Tâche Tous les

jours

Tous les ans Au besoin

Remplacement de la lampe

à la page 30

X

Remplacement du bloc chauffant

à la page 31

X

Pour connaître les opérations d'entretien spécifiques à une méthode en

particulier, reportez-vous à la méthode QuikChem.

Nettoyage de l'instrument

A V I S

N'exécutez aucune procédure de nettoyage ou de décontamination autre que

celle recommandée par la fabricant. Les autres procédures peuvent

endommager l'instrument. Contactez l'assistance technique pour vérifier que les

procédures n'endommagent pas l'instrument.

1. Eteignez l'instrument. Coupez l'alimentation de l'instrument.

2. Essuyez toutes les projections avant de nettoyer l'instrument.

a. Utilisez de l'hydrogénocarbonate de sodium pour neutraliser les

projections acides.

b. Utilisez de l'eau pour nettoyer la solution d'hydrogénocarbonate

de sodium.

c. Essuyez la surface avec un chiffon non pelucheux.

3. Nettoyez avec de l'eau toutes les surfaces de l'instrument.

4. Essuyez toutes les surfaces de l'instrument avec un chiffon non

pelucheux.

Remplacer un fusible

D A N G E R

Risque d’incendie. Remplacez les fusibles par des fusibles de même

type et de même calibre.

Pour remplacer un fusible, reportez-vous aux étapes illustrées dans

Figure 5.

Figure 5 Remplacement des fusibles

Français 29

Page 30

Préparation des tubes

Pour préparer les tubes, reportez-vous à la méthode QuikChem et à la

Figure 6.

Figure 6 Préparation des tubes

1 Tuyaux 3 Ruban thermique,

chauffage

5 Repères de

démarrage et d'arrêt

2 Ruban thermique,

haute température

4 Tubes pour les autres

raccords

2

6 Le tube s'enroule

autour de la lampe/du

bloc chauffant

Remplacement de la lampe

D A N G E R

Risque d'électrocution Coupez l'alimentation de l'instrument avant

d'effectuer des activités de maintenance ou d'entretien.

A T T E N T I O N

Risque de brûlure. Débranchez l'appareil et laissez-le refroidir avant

d'effectuer cette procédure.

Ne débranchez jamais la lampe si l'instrument est sous tension.

Débranchez l'entrée CA avant d'ouvrir une partie de l'instrument.

Si vous venez d'utiliser la lampe, laissez refroidir la température de

l'instrument. La durée nécessaire dépend du point de consigne de la

température.

1. Mettez l'instrument hors tension.

2. Déposez le panneau de couvercle en haut à droite.

3. Débranchez les tubes de la lampe.

4. Retirez la lampe des supports.

5. Retirez le ruban thermique en aluminium et les tubes de la lampe. Si

le ruban thermique est toujours en bon état après son retrait, utilisezle sur la pièce neuve.

6. Pour préparer le tube, reportez-vous à Préparation des tubes

à la page 30.

7. Pour ajouter du tube autour de la lampe neuve, reportez-vous à la

Figure 7.

8. Posez la lampe.

9. Raccordement du tube.

10. Installez le panneau de couvercle et fixez-le.

11. Mettez l'instrument sous tension.

2

Pour connaître les longueurs et obtenir d'autres informations, reportez-vous à la méthode QuikChem.

30 Français

Page 31

Figure 7 Remplacement du tube sur la lampe

Remplacement du bloc chauffant

D A N G E R

Risque d'électrocution Coupez l'alimentation de l'instrument avant

d'effectuer des activités de maintenance ou d'entretien.

A T T E N T I O N

Risque de brûlure. Débranchez l'appareil et laissez-le refroidir avant

d'effectuer cette procédure.

Ne débranchez jamais le thermocouple et la tige chauffante lorsque

l'instrument est sous tension. Le chauffage ne serait plus contrôlé.

Débranchez l'entrée CA avant d'ouvrir une partie de l'instrument.

Si vous venez d'utiliser le chauffage, laissez retomber la température de

l'instrument. La durée nécessaire dépend du point de consigne de la

température.

1. Mettez l'instrument hors tension.

2. Déposez le panneau de couvercle en haut à droite.

3. Débranchez les tubes du bloc chauffant.

4. Reportez-vous à la méthode QuikChem pour vérifier le type et la

quantité de tubes nécessaires selon l'application.

5. Pour ajouter du tube autour du bloc chauffant, reportez-vous à

Préparation des tubes à la page 30 et à la Figure 8.

6. Pour installer le bloc chauffant, reportez-vous à Installation du bloc

chauffant à la page 23.

Français

31

Page 32

Figure 8 Remplacement du tube sur le bloc chauffant

Dépannage

A T T E N T I O N

Risque de brûlure. Respectez les protocoles de sécurité lorsque vous

manipulez des composants d'échantillon chauds.

Réduisez la température sur l'instrument à 70 ºC (158 ºF) ou moins

avant d'examiner les tubes de la pompe. En général, il faut environ

10 minutes pour faire baisser la température de 140 ºC (284 ºF) à 70 ºC

(158 ºF).

Remarques générales sur le dépannage

Les distributeurs en ligne diffèrent des distributeurs fluorométriques

standard. Les principales différences sont :

• Conduite d'échantillon : la conduite d'échantillon n'est en général pas

un tube de pompe vert/vert. On opte pour des tubes de pompe plus

petits afin de placer l'échantillon (mélangé à une solution de digestion)

sur le chauffage et sur la lampe UV de manière prolongée.

• Préparation d'échantillon en amont de la vanne : la conduite

d'échantillon provenant de l'échantillonneur ne va pas directement à

l'orifice 6 de la vanne d'injection. La conduite d'échantillon se mélange

à une solution de digestion, est chauffée, est irradiée aux UV, puis

traverse le bloc de diffusion ou la membrane du débulleur avant

d'arriver à l'orifice 6 de la vanne d'injection.

Le Tableau 3 répertorie les problèmes les plus fréquents :

Tableau 3 Guide de dépannage

Problème Solution

Pointes d'air dans le mesureur

fluorométrique

Vérifiez que les temporisations correspondent

aux informations de la section Recherche de

la bonne temporisation à la page 27.

Effectuez une procédure de dégazage sur les

réactifs.

Remplacez la membrane du bloc de dialyse

ou remplacez la membrane du débulleur.

32 Français

Page 33

Tableau 3 Guide de dépannage (suite)

Problème Solution

Mauvais rendement d'un

échantillon QC composé de

cyanure complexe

Vérifiez la fraîcheur des réactifs.

Vérifiez que l'échantillon traverse bien toutes

les conduites de pompe.

Vérifiez que la température correspond à la

méthode QuikChem.

Regardez par le petit trou en haut de

l'instrument pour voir si la lampe UV est

allumée. Sinon, remplacez la lampe.

Mauvais rendement ou aucun

rendement d'un échantillon QC

Examinez la circulation dans les tubes de

pompe.

Examinez le réglage de la température.

Vérifiez la bonne composition des réactifs.

Pour la détermination du cyanure, vérifiez

que la conduite d'acide est placée dans la

solution de digestion. Recherchez de l'acide,

de l'échantillon et de l'accepteur dans les

tubes de pompe.

Lisez les remarques de la méthode

QuikChem pour en savoir plus sur les

rendements escomptés.

Tableau 3 Guide de dépannage (suite)

Problème Solution

Le flux d'air qui traverse le bloc

de diffusion est très rapide, puis

ralentit jusqu'à pratiquement

s'arrêter

Vérifiez que les tubes de réactif et

d'échantillon ne sont pas obstrués ou pincés.

Vérifiez que le flux circule librement dans le

tube d'évacuation. Sinon, la contre-pression

est trop élevée.

Vérifiez que l'évacuation de l'instrument est

bien acheminée dans un conteneur de

récupération adapté à la solution. Vérifiez

que les tubes sont au-dessus du niveau de

liquide et que le conteneur est ventilé pour

éviter une pressurisation à l'intérieur du

conteneur. Pour éviter une cavitation ou un

bouchon de vapeur, le conteneur de

récupération doit se trouver au même niveau

que l'instrument.

Vérifiez que les tubes de réactif et de bainmarie ne sont pas obstrués ni pincés. Les

petites particules de saleté ou les algues des

bains-marie souillés créent des problèmes de

circulation.

Imprécision en cas de répétitions Examinez les temporisations à la section

Recherche de la bonne temporisation

à la page 27.

Remplacez la membrane du débulleur.

Vérifiez que tous les tubes de pompe sont en

bon état et que le flux y circule bien.

Français 33

Page 34

Pièces de rechange et accessoires

A V E R T I S S E M E N T

Risque de blessures corporelles. L'utilisation de pièces non

approuvées comporte un risque de blessure, d'endommagement de

l'appareil ou de panne d'équipement. Les pièces de rechange de cette

section sont approuvées par le fabricant.

Remarque : Les numéros de référence de produit et d'article peuvent dépendre

des régions de commercialisation. Prenez contact avec le distributeur approprié ou

consultez le site web de la société pour connaître les personnes à contacter.

Pièces de rechange

Description Article n°

Tube, bloc chauffant 50028

Tube, lampe 50728

Lampe UV, 6 W —

3

Lampe UV, 8 W —

3

Bloc chauffant seul 25008

4

Ruban thermique, bloc chauffant 31182

Ruban thermique, haute température, 4 pouces 31184

Fusible, 1.6 A, 250 V, écoulement faible 20205

3

Reportez-vous à la méthode QuikChem, puis contactez l'assistance technique.

4

Contactez l’assistance technique.

34 Français

Page 35

Tabla de contenidos

Especificaciones en la página 35 Operación en la página 43

Información general en la página 35 Mantenimiento en la página 44

Instalación en la página 39 Solución de problemas

en la página 48

Interfaz del usuario y navegación

en la página 42

Piezas de repuesto y accesorios

en la página 50

Especificaciones

Las especificaciones están sujetas a cambios sin previo aviso.

Especificación Detalles

Dimensiones (An x Pr x Al) 23 x 54 x 14 cm (9 x 21,3 x

5,5 pulg.)

Peso 4,5 kg (10 libras)

Requisitos de energía 115 V CA, 60 Hz, 1,2 A

230 V CA, 50 Hz, 0,8 A

Fusible 1,6 A, 250 V CA, quemado lento

Temperatura de funcionamiento 5 a 40 °C (41 a 104 °F)

Grado de contaminación 2

Clase de protección 1

Tipo de instalación II

Humedad en

almacenamiento/funcionamiento

La humedad máxima relativa es del

80% para temperaturas de hasta

31°C (87,8 °F), y disminuye de

forma lineal hasta una humedad

relativa del 50% a 40 °C (104 °F)

Ubicación En interior o en laboratorio

Especificación Detalles

Lámpara UV1—(más común) 354 nm (azul oscuro), tipo Ushio

F6T5BLB (50717). Utilícese con la

determinación de cianuro.

254 nm (transparente),

G6T5 (50775). Utilícese con la

determinación de nitrógeno total o

de fósforo total.

Certificaciones Marca CE; cumple con los

requisitos de seguridad

establecidos por ETL, UL y CSA

(CETLus) para Norteamérica.

Garantía 1 año

Información general

En ningún caso el fabricante será responsable de ningún daño directo,

indirecto, especial, accidental o resultante de un defecto u omisión en

este manual. El fabricante se reserva el derecho a modificar este

manual y los productos que describen en cualquier momento, sin aviso

ni obligación. Las ediciones revisadas se encuentran en la página web

del fabricante.

Información de seguridad

A V I S O

El fabricante no es responsable de ningún daño debido a un mal uso de este

producto incluyendo, sin limitación, daños directos, fortuitos o circunstanciales y

reclamaciones sobre los daños que no estén recogidos en la legislación vigente.

El usuario es el responsable de la identificación de los riesgos críticos y de tener

los mecanismos adecuados de protección de los procesos en caso de un posible

mal funcionamiento del equipo.

Lea todo el manual antes de desembalar, instalar o trabajar con este

equipo. Ponga atención a todas las advertencias y avisos de peligro. El

no hacerlo puede provocar heridas graves al usuario o daños al equipo.

1

Consulte el método QuikChem específico si desea obtener las especificaciones de la lámpara para una aplicación.

Español 35

Page 36

Asegúrese de que la protección proporcionada por el equipo no está

dañada. No utilice ni instale este equipo de manera distinta a lo

especificado en este manual.

Uso de la información sobre riesgos

P E L I G R O

Indica una situación potencial o de riesgo inminente que, de no evitarse,

provocará la muerte o lesiones graves.

A D V E R T E N C I A

Indica una situación potencial o inminentemente peligrosa que, de no evitarse,

podría provocar la muerte o lesiones graves.

P R E C A U C I Ó N

Indica una situación potencialmente peligrosa que podría provocar una lesión

menor o moderada.

A V I S O

Indica una situación que, si no se evita, puede provocar daños en el instrumento.

Información que requiere especial énfasis.

Etiquetas de precaución

Lea todas las etiquetas y rótulos adheridos al instrumento. En caso

contrario, podrían producirse heridas personales o daños en el

instrumento. El símbolo que aparezca en el instrumento se comentará

en el manual con una declaración de precaución.

Este símbolo (en caso de estar colocado en el equipo) hace

referencia a las instrucciones de uso o a la información de seguridad

del manual.

El equipo eléctrico marcado con este símbolo no se podrá desechar

por medio de los sistemas europeos públicos de eliminación después

del 12 de agosto de 2005. De acuerdo con las regulaciones locales y

nacionales europeas (Directiva UE 2002/96/EC), ahora los usuarios

de equipos eléctricos en Europa deben devolver los equipos viejos o

que hayan alcanzado el término de su vida útil al fabricante para su

eliminación sin cargo para el usuario.

Este símbolo indica que hay riesgo de descarga eléctrica y/o

electrocución.

Este símbolo indica la necesidad de usar protectores para ojos.

Este símbolo, cuando aparece en un producto, identifica la ubicación

de un fusible o de un limitador de corriente.

Este símbolo identifica un peligro químico e indica que el trabajo se

debe ejecutar exclusivamente por personal cualificado y entrenados

en el manejo de productos químicos, el cual debe realizar también

los trabajos de mantenimiento en el sistema de alimentación de

productos químicos asociado con este equipo.

Este símbolo identifica la presencia de una sustancia corrosiva fuerte

u otras sustancias peligrosas, y el riesgo de lesiones químicas.

Solamente los individuos calificados y entrenados para trabajar con

químicos deben manejar estos productos y realizar mantenimiento de

los sistemas de entrega de químicos asociados con el equipo.

Este símbolo indica que la pieza marcada podría estar caliente y que

debe tocarse con precaución.

Este símbolo indica la presencia de dispositivos susceptibles a

descargas electrostáticas. Asimismo, indica que se debe tener

cuidado para evitar que el equipo sufra daño.

Certificación

Reglamentación canadiense sobre equipos que provocan

interferencia, IECS-003, Clase A

Registros de pruebas de control del fabricante.

Este aparato digital de clase A cumple con todos los requerimientos de

las reglamentaciones canadienses para equipos que producen

interferencias.

36

Español

Page 37

Cet appareil numérique de classe A répond à toutes les exigences de la

réglementation canadienne sur les équipements provoquant des

interférences.

FCC Parte 15, Límites Clase "A"

Registros de pruebas de control del fabricante. Este dispositivo cumple

con la Parte 15 de las normas de la FCC estadounidense. Su operación

está sujeta a las siguientes dos condiciones:

1. El equipo no puede causar interferencias perjudiciales.

2. Este equipo debe aceptar cualquier interferencia recibida, incluyendo

las interferencias que pueden causar un funcionamiento no deseado.

Los cambios o modificaciones a este equipo que no hayan sido

aprobados por la parte responsable podrían anular el permiso del

usuario para operar el equipo. Este equipo ha sido probado y

encontrado que cumple con los límites para un dispositivo digital Clase

A, de acuerdo con la Parte 15 de las Reglas FCC. Estos límites están

diseñados para proporcionar una protección razonable contra las

interferencias perjudiciales cuando el equipo está operando en un

entorno comercial. Este equipo genera, utiliza y puede irradiar energía

de radio frecuencia, y si no es instalado y utilizado de acuerdo con el

manual de instrucciones, puede causar una interferencia dañina a las

radio comunicaciones. La operación de este equipo en un área

residencial es probable que produzca interferencia dañina, en cuyo caso

el usuario será requerido para corregir la interferencia bajo su propio

cargo. Pueden utilizarse las siguientes técnicas para reducir los

problemas de interferencia:

1. Desconecte el equipo de su fuente de alimentación para verificar si

éste es o no la fuente de la interferencia.

2. Si el equipo está conectado a la misma toma eléctrica que el

dispositivo que experimenta la interferencia, conecte el equipo a otra

toma eléctrica.

3. Aleje el equipo del dispositivo que está recibiendo la interferencia.

4. Cambie la posición de la antena del dispositivo que recibe la

interferencia.

5. Trate combinaciones de las opciones descritas.

Indicaciones para la descarga electroestática

A V I S O

Daño potencial al instrumento. Los delicados componentes

electrónicos internos pueden sufrir daños debido a la electricidad

estática, lo que acarrea una disminución del rendimiento del

instrumento y posibles fallos.

Consulte los pasos en este procedimiento para evitar daños de

descarga electrostática en el instrumento:

• Toque una superficie metálica a tierra como el chasis de un

instrumento, un conducto metálico o un tubo para descargar la

electricidad estática del cuerpo.

• Evite el movimiento excesivo. Transporte los componentes sensibles

a la electricidad estática en envases o paquetes anti-estáticos.

• Utilice una muñequera conectada a tierra mediante un alambre.

• Trabaje en una zona sin electricidad estática con alfombras de piso y

tapetes para mesas de trabajo antiestáticas.

Descripción general del producto

Este instrumento contiene una lámpara UV y un bloque calefactor que

preparan la muestra para el analizador. Este instrumento está diseñado

sólo para uso en interior. Consulte la Figura 1.

Español 37

Page 38

Figura 1 Descripción general del producto

1 Panel de

visualización

5 Interruptor de

encendido

9 Tornillo de mariposa

2 Lámpara UV 6 Bloque calefactor 10 Cubierta de acceso

3 Termopar 7 Conector de

alimentación

11 Indicador de

lámpara UV

4 Bastón de calor 8 Caja de fusibles 12 Puertos de

entrada/salida de la

muestra

Componentes del producto

Asegúrese de haber recibido todos los componentes. Consulte la

Figura 2. Si faltan artículos o están dañados, póngase en contacto con

el fabricante o el representante de ventas inmediatamente.

Figura 2 Componentes del instrumento

1 Instrumento 3 Clavijas con uniones

2 Cable de alimentación 4 Bloque calefactor

38 Español

Page 39

Instalación

A D V E R T E N C I A

Peligros diversos. Sólo el personal cualificado debe realizar las tareas

descritas en esta sección del documento.

Instalación del bloque calefactor

Consulte los pasos ilustrados que se muestran a continuación.

Español 39

Page 40

40 Español

Page 41

Colocación del instrumento

P R E C A U C I Ó N

Peligro de inhalación de ozono. En determinadas condiciones, este

instrumento produce concentraciones de ozono superiores a los

límites de exposición segura. Dirija los gases residuales a una

campana extractora o al exterior del edificio de acuerdo con las

normativas locales, regionales y nacionales.

Este instrumento está clasificado para una altitud de 2000 m (6562 pies)

como máximo. El uso de este instrumento a una altitud superior a los

2000 m puede aumentar ligeramente la posibilidad de fallo del

aislamiento, lo que puede generar riesgo de descarga eléctrica. El

fabricante recomienda ponerse en contacto con el servicio de asistencia

técnica en caso de dudas.

Coloque el instrumento en una posición que permita desconectarlo

fácilmente de la fuente de alimentación.

Coloque el instrumento de forma que la abertura de ventilación situada

en el lateral izquierdo no quede bloqueada. No permita que el cable de

alimentación entre en contacto con superficies calientes en los canales

de medición del QC8500.

Existen dos opciones de colocación del instrumento:

• Coloque el instrumento sobre el módulo principal del sistema

QuikChem (Figura 3). Asegúrese de que el controlador del calefactor

se encuentre en el lateral izquierdo del sistema.

• Si no hay espacio disponible sobre el sistema QuikChem, coloque el

instrumento debajo de la bomba peristáltica. La bomba peristáltica se

encuentra en el lateral izquierdo del sistema QuikChem.

Figura 3 Instalación del manguito de unión

1 Analizador 3 Tubos de salida de la muestra

2 Tubos de muestra en dirección al

analizador

4 Tubos de entrada de la muestra

Fontanería

Asegúrese de utilizar el tamaño de tubos especificado. Consulte el

método del QuikChem para ver más información.

Español

41

Page 42

Preparación de los reactivos y las soluciones

estándar

1. Consulte el método QuikChem para obtener información sobre la

preparación de reactivos y soluciones estándar.

2. Lea todas las notas del sistema.

3. Conecte el distribuidor como se muestra en el gráfico del método

QuikChem.

Conexión del cable de alimentación

Recopilación de elementos:

• Regleta de alimentación con protección contra sobrevoltaje

1. Conecte el cable de alimentación al instrumento. Debe evaluarse la

corriente y la tensión de alimentación del cable de alimentación.

2. Conecte el cable de alimentación a la regleta de alimentación.

3. Encienda la regleta de alimentación.

4. Encienda el interruptor de alimentación del instrumento.

Inicie la bomba peristáltica

Consulte la sección de funcionamiento de la bomba en el manual de

usuario de QuikChem si desea obtener información sobre la instalación

de los tubos de la bomba y sobre el funcionamiento de la bomba

peristáltica.

Comprobación de fugas

1. Cuando el distribuidor esté instalado y todos los tubos de la bomba

están acoplados de forma segura, coloque todos los tubos de

reactivos en agua desionizada.

2. Asegúrese de que no existen fugas en el distribuidor, la válvula de

inyección o el instrumento.

Interfaz del usuario y navegación

Figura 4 muestra el teclado y la pantalla del instrumento. Tabla 1 indica

las funciones de las teclas.

Figura 4 Pantalla y teclado

1 Pantalla de LED con

valor acutal (PV)

3 Flecha ARRIBA 5 Mostrar/cambiar

2 Pantalla de LED con

valor establecido (SV)

4 Flecha ABAJO 6 Intro

Tabla 1 Funciones de las teclas

Tecla Función

Almacena el cambio

Muestra o cambia el ajuste de temperatura.

Reduce el valor.

Incrementa el valor.

42 Español

Page 43

Operación

A D V E R T E N C I A

Peligro por exposición química. Respete los procedimientos de seguridad del

laboratorio y utilice el equipo de protección personal adecuado para las

sustancias químicas que vaya a manipular. Consulte los protocolos de seguridad

en las hojas de datos actuales de seguridad de los materiales (MSDS).

Ajuste de la temperatura

Nota: No deje que la temperatura del instrumento supere los 60 ºC (140 ºF) sin

que haya agua o reactivos en los tubos.

1. Pulse hasta que la pantalla muestre SP (set point [punto de

control]).

2. Pulse las flechas hacia ARRIBA o hacia ABAJO para aumentar o

disminuir el punto de control. El monitor seguirá mostrando el modo

SP.

3. Cuando haya ajustado la temperatura, pulse para guardar la

información en la memoria.

4. Pulse una vez. La pantalla muestra la temperatura actual en

grados Celsius. Una luz roja muestra que el calefactor está

encendido.

5. Deje que la temperatura se estabilice.

Ajuste del tiempo correcto

Para averiguar el tiempo correcto del sistema de análisis por inyección

en flujo de Omnion:

Recopilación de elementos:

• Cronómetro o cualquier otro temporizador

• Tinte (suministrado con el sistema): el tinte rojo proporciona los

mejores resultados

Nota: Debido a las diferencias entre la viscosidad y el punto de ebullición de cada

reactivo, no utilice agua el lugar de reactivos durante la prueba de tinción.

1. Introduzca tinte en el tubo de ensayo.

2. Cree un método en Omnion. Introduzca los parámetros de tiempo de

la válvula (período de cada ciclo, momento en que la muestra

alcanza la primera válvula, período de carga y período de inyección)

y los parámetros de tiempo del muestreador.

3. Analice el tinte como una muestra. Inicie el temporizador cuando la

sonda entre en el tubo de ensayo.

4. Siga el recorrido del tinte por el sistema. Cuando la muestra llegue al

puerto 6, en la válvula de inyección, detenga el temporizador.

5. Registre el tiempo, es decir, el tiempo que tarda la muestra en llegar

a la primera válvula. Asegúrese de cambiar este valor en el ajuste de

tiempo de la válvula del método.

6. Guarde el método y realice un nuevo análisis con el tinte para medir

el parámetro siguiente.

7. Realice el análisis y vuelva a seguir el tinte por todo el sistema.

Cuando el tinte llegue al puerto 6, inicie el temporizador. En este

instante, la válvula se activará por primera vez.

8. Cuando la masa de líquido de la muestra llegue al puerto 6, detenga

el temporizador.

9. Registre este tiempo y reste 5 segundos para obtener el período de

carga que se especifica en el ajuste de tiempo de la válvula del

método Omnion.

• El período del ciclo se especifica en el método (período del ciclo =

período de carga + período de inyección).

• El software establece automáticamente el período de inyección

cuando se introducen los períodos del ciclo y de carga.

Calibración del instrumento

1. Coloque todos los tubos de reactivo en sus respectivas botellas.

2. Vierta las soluciones patrón en los viales.

3. Consulte el manual de usuario del analizador para comenzar una

calibración.

Español

43

Page 44

Tiempos de salobridad en el sistema de análisis por

inyección en flujo de Omion

Algunos de los métodos en línea hacen necesaria ajustar el tiempo de la

integración de salobridad (o manual). El método QuikChem muestra

cuándo es necesario ajustar el tiempo de salobridad.

Si desea obtener más información sobre cómo ajustar el tiempo de

salobridad, consulte el manual de software o realice una búsqueda de

las palabras clave "programación de eventos gráficos" o "eventos de

salobridad" en el sistema de ayuda de Omnion.

Consejos

• No utilice la velocidad en espera de la bomba peristáltica.

• Introduzca los tubos de reactivo en agua desionizada para evitar

desperdiciar reactivo.

• Asegúrese de que el agua desionizada fluye a través del depósito de

lavado.

• El tubo de muestra generalmente no es un tubo de bomba verdeverde. Consulte el método QuikChem para averiguar cuál es el tubo

correcto de la bomba.