Haas+Sohn HRT 160, HRT 160SP, HRT 210SP, HRT 210, HRT 310SP Operator's And Service Manual

...

Haas Technical Publications

Manual_Archive_Cover_Page Rev A

any other party automatically voids the factory warranty.

June 6, 2013

HAAS SERVICE AND OPERATOR MANUAL ARCHIVE

HRT Operator Manual 96-5047 RevL English June 2005

• This content is for illustrative purposes.

• Historic machine Service Manuals are posted here to provide information for Haas machine owners.

• Publications are intended for use only with machines built at the time of original publication.

• As machine designs change the content of these publications can become obsolete.

• You should not do mechanical or electrical machine repairs or service procedures unless you are qualied

and knowledgeable about the processes.

• Only authorized personnel with the proper training and certication should do many repair procedures.

WARNING: Some mechanical and electrical service procedures can be

extremely dangerous or life-threatening.

Know your skill level and abilities.

All information herein is provided as a courtesy for Haas machine owners

for reference and illustrative purposes only. Haas Automation cannot be held

responsible for repairs you perform. Only those services and repairs that are

provided by authorized Haas Factory Outlet distributors are guaranteed.

Only an authorized Haas Factory Outlet distributor should service or repair a

Haas machine that is protected by the original factory warranty. Servicing by

Back

1. INTRODUCTION

1.1 D

ESCRIPTION

The HAAS rotary table is a fully automatic, programmable, rotary positioning device. The unit is made up of two

parts: the mechanical table that holds the workpiece and the electronic unit that controls the rotation of the

table. Positioning of the workpiece is accomplished by programming the angular movements into the memory

of the control and then pushing the CYCLE STAR T button on the front panel.

The unit was specifically designed for rapid positioning of parts in secondary operations such as milling,

drilling, and tapping. The device is especially suited to automatic machines such as NC mills and automatic

production machines. The control can be remotely activated by your equipment and does not require human

assistance, resulting in fully automatic operation. Furthermore, one unit can be used on several different

machines, thereby eliminating the need for multiple units.

TABLE

The rotary table can be used in almost all of the applications where a manual rotary table can be used. Positioning of the table is accomplished through a deep-tooth engaging, self-locking worm and worm gear set. The

worm is connected to a AC (DC) servo motor through a timing belt and pulley set. Odd number bolt circles and

uneven hole spacing are easily handled with simple programming. The table is equipped with a pneumatic

brake (HRT 450 uses air over oil). A regular shop air line of approximately 100 PSI is all that is needed to

activate the brake.

The HRT210SHS (Super-High Speed) Table is unique from the other rotary t ables. It has no worm gear set, belt,

or pulleys but uses a “Harmonic Drive” gear. It is directly driven by an AC servo motor and is 6 times faster than

our standard HRT210.

The HRT320FB uses a facegear (Hirth coupling) for extreme indexing accuracy and rigidity . It positions the

platter in multiples of exactly 1° . The platter lifts .070” during indexing and the table positioning is done at full

rapid speed. The HRT320FB cannot be used as a full forth axis.

CONTROL

The rotary table servo control incorporates the latest in high-speed microprocessors and drive technology . The

control was designed using extensive software to replace discrete components, thereby reducing possible

failure areas. This same software also checks out the computer system upon power-up, and alerts you to

component failures. Only one printed circuit board is used to control all major functions.

The optional RS-232 interface can be used to upload, download, enter data, read position, start, and stop motor

operation.

96-5047 rev L June 2005

1

1.2 LIMITATIONS

The control and table are described as a “semi-fourth axis”. This means that the table cannot do simultaneous

interpolation with other axes. Linear moves or spirals can be generated by having an axis of your mill move at

the same time the rotary table moves (see the "Programming" section for details).

1.3 MACHINABLE P ART S IZE

The HRT series was designed for positioning and continuous milling of medium to large size parts. When

selecting a rotary table, the size of a typical workpiece and fixture must be considered and the size of the

rotary table should be matched to the expected loads. As a general rule, the diameter of the part should not

exceed the diameter of the rotary table platter . Also, the combined part and fixture weight should not exceed

the weight of the rotary table. However , these are only guidelines. A part with a diameter larger than the platter

diameter or a long overhung and unsupported part might require that the weight be less than the weight of the

rotary table. Likewise, if the part is well supported (i.e. tailstock or pillow block), and the fixture and support

have less than 0.003" T.I.R, then the weight might be able to be more than the rotary table weight. Common

sense and good fixturing technique will generally make it possible to machine larger parts.

The HRT210SHS Table was designed for lighter size part s which may require numerous tool changes and

indexes, so the speed is important to reduce the cycle time. It has no brake, so this will also be a limiting

factor to the size of the part. Maximum part diameter is 8.00” and maximum part weight should not exceed 40

lbs.

1.4 FEATURES

RIGID DESIGN

Large bearing surfaces support heavy cutting forces on large or small parts.

CLASS 30 GREY IRON

For added damping capacity

QUICK REPLACEMENT CONDUIT

For faster replacement and shorter downtime.

PRE-LOADED ANGULAR CONTACT BEARINGS

For better reliability and less wear.

HARDENED AND PRECISION ROT ARY GROUND PLATTER

Ensures more accurate part machining.

CNC HOBBED WORM GEAR*

For high accuracy.

DEEP TOOTH ENGAGEMENT

For gear set; designed to provide greater accuracy and continuous milling capacity .

ALUMINUM BRONZE WORM GEAR*

For long life.

HARDENED AND GROUND WORM GEAR*

Made from 8620 chromium-nickel-molybdenum steel, hardened to Rc 60.

AIR BRAKE*

Built-in air brake with 100 to 1500 ft.-lb. of holding torque @ 100 PSI. (Except HRT210SHS)

2

96-5047 rev L June 2005

AC SERVO DRIVE*

Closed loop 3.0HP (HA5CHD, HRT 160, HRT 210), 5.0 HP (HRT 310, HRT 450, HRT 600), 1.5 HP (HA5C)

DC SERVO DRIVE

Closed loop 0.5 HP(HRT160, HA5C), or 1.5 HP(HRT210, HRT310, HRT450, HRT600).

V ARIABLE FEED RATES*

V ariable from .001 deg./sec. to 100 deg./sec (100 deg./sec. for HRT160 and HRT320FB, 75 deg./sec. for

HRT210, 60 deg./sec. for HRT310, 50 deg./sec. for HRT450, 40 deg./ sec for HRT600).

RESOLUTION

St andard motor resolution of .001 degrees (.001

0

).

PROGRAMMING

Absolute or incremental programming. Up to 99 different steps can be stored in memory, and each step can be

looped 999 more times. The ease and flexibility of programming the Haas control enables a single unit to serve

you in many ways.

SIMPLE EDITING

Edit a program by simply writing over existing steps, or inserting or deleting a line (or several lines) between

steps, with automatic program line re-numbering.

SUBROUTINES

Allows sequences to be repeated up to 999 times, saving programming time and memory space.

AUTOMA TIC CIRCLE DIVISION

Program a step that automatically divides a circle into any number of equal parts (between 2 and 999).

PROGRAMMABLE P ARAMETERS

Alter many of the basic features by performing your own basic programming.

PROGRAM STORAGE

Store and recall from up to seven dif ferent programs.

MEMORY

A non-volatile memory retains a program even when power is turned off. It also remembers the current spindle

position and step number.

INTERFACING

Most CNC mills can be interfaced with the HRT Series quickly and easily by using a spare M function that

provides a switch-closer as a signal between your mill and the RT.

EMERGENCY STOP/FEED-HOLD

EMERGENCY STOP can be used to feed-hold spindle movement without losing position on restart.

ZERO RETURN

A programmable HOME position returns the spindle to its original starting position from any point.

LINEAR & SPIRAL MILLING

For semi fourth-axis capability .

FAST SET -UPS

All connectors are “quick-disconnect”, ensuring fast and easy set-ups.

ST ANDARD POWER

Operates on 1 15V AC ±5% @ 15 Amps.

96-5047 rev L June 2005

3

OPTIONAL RS-232 INTERF ACE

For computer control of sending and receiving programs.

12-MONTH WARRANTY

Against any defects in materials or workmanship.

SYNTHETIC GEAR OIL

Provides greater worm gear wear protection than conventional gear oils.

*Except HRT210SHS; see below:

FEATURES E XCLUSIVE TO THE HRT210SHS

Harmonic Drive gear set.

3 HP A.C. Servo Motor

V ariable feed rates from .001 deg./sec. to 270 deg./sec. with rapids to 360 deg./sec.

4

96-5047 rev L June 2005

1.5 SPECIFICATIONS

:LEDOM)PS(061TRH)PS(012TRH)PS(013TRHBF023TRH054TRH006TRH

ELDNIPS

)sbl/.tf(euqroTelbaT

CD/CA

).ces/.ged(setardeeF

CD/CA

001/051012/012002/003003523/004083/054

001ot100.CA

08ot100.CD

CD063ot100.

001ot100.CA

06ot100.CD

1

031ot100.0CD

2

06ot100.CA

05ot100.CDylnoces/°08

)sehcni(tuonuReldnipS5000.5000.100.100.5100.5100.

)ni(tuonuRecaFrettalP5000.5000.5000.5000.5000.5000.

).ces-cra(hsalkcaB03

03

1

54

03A/N0303

)sehcni(thgieHretneC100.-/+000.5100.-/+000.6100.-/+000.9100.-/+000.9100.-/+005.11100.-/+005.41

euqroTgnidloHekarB

).sbl/.tf(ISP001@

001

002

2

A/N

005005300510051

GNIXEDNI

ycaruccAgnixednI

).ces/cra(

51-/+

).cescra(ytilibataepeR01nihtiw01nihtiw01nihtiw1-/+01nihtiw01nihtiw

).ged(noituloseR100.100.100.0.1100.100.

).ged(noituloseR.xaM999.999999.999999.9990.999999.999999.999

51-/+

2

03-/+

3

6-/+

51-/+3-/+51-/+51-/+

05ot100.CA

04ot100.CD

05ot100.CA

04ot100.CD

)"ni(aiDraeGmroW7.43.64.94.95.315.31

ROTOM

3,1

PH0.3

)sselhsurB(ovreSCA

)hsurB(ovreSCD

tleBgnimiT(oitaRevirD

)teSyelluPdna

oitaRraeGmroW1:36

noitcudeRraeGlatoT1:621

PH0.3

PH5.0

1:2

0.5/

2

PH

PH5.1

1:2

1

2

1:1

A/N/

1:09

2

A/N

1:081

1

1:09

2

1:05

PH0.5

PH5.1

PH0.5

PH0.5

PH5.1

1:21:21:31:5.3

1:271:271:271:27

1:4411:4411:6121:252

PH0.5

PH5.1

SNOITACIFICEPSGNITAREPO

erusserPriA.xaM

stnemeriuqeRrewoP

noitacirbuL

)BF023TRHrofmuminimisp04(ISP021

spmA51@%5-/+CAV511

lioraegcitehtnys036-CHSliboM

2

lioraegcitehtnys626-CHSliboM

TNEMNORIVNEGNITAREPO

erutarepmeTmumixaM FseergeD001

1

2

3

SH012TRH

SHS012TRH

CS012TRH

96-5047 rev L June 2005

5

1.6 MACHINE D IMENSIONS

MODEL DIMENSIONS

A BCD E F G H J

HRT160 160 mm (6.30") 1.50 5.50 16.20 3.63 5.000 ±0.001 4.50 Ø1.50

HRT 210 210 mm (8.27") 1.75 5.84 17.80 4.63 6.000±0.001 5.25 Ø2.00

HRT210 (Brush) 210 mm (8.27") 1.75 5.84 20.00 4.63 6.000±0.001 5.25 Ø2.00

HRT210SC 210mm (8.27”) 1.75 7.65 17.80 4.63 6.000 +/-.001 7.025 Ø2.00

HRT 310 310 mm (12.20") 2.00 7.82 22.80 6.88 9.000±0.001 7.875 Ø3.25

HRT320FB (*The platter lifts .065” during positioning)

HRT310 (Brush) 310 mm (12.20") 2.00 7.82 24.30 6.88 9.000±0.001 7.875 Ø3.25

HRT450 450 mm (17.72") 2.25 9.00 28.55 9.26 11.500±0.001 9.00 Ø7.50

HRT600 600 mm (23.62') 2.50 9.00 34.82 12.13 14.500"±0.001 9.00 Ø7.50

+0.0005

+0.0005

+0.0005

+0.0005

+0.0005

+0.0005

+0.00

+0.001

10.4

12.4

12.4

12.4

17.7

17.7

22.4

28.4

6

96-5047 rev L June 2005

HRT SP DIMENSIONS

B

A

F

14'

C

G

D

E

WRENCH

ACCESS

0.530” W x 0.50” DP

Front & Rear Tie Down Slots

MODEL DIMENSIONS

A B C D E F G

HRT 160SP 10.80” 12.25” 10.39” 8.63” 5.000” ±0.001” 4.78” 1.500∅ x 6.00 Depth

HRT 210SP 12.28” 13.77” 12.39” 10.64” 6.000” ±0.001” 5.26” 2.000∅ x 7.000 Depth

HRT 310SP 16.26” 17.80” 17.60” 15.90” 9.000” ±0.001” 6.88” 3.250∅ x 9.875 Depth

96-5047 rev L June 2005

7

HRT210SHS MACHINE D IMENSIONS

8

96-5047 rev L June 2005

1.7 OPTIONAL S ERVO C ONTROL B RACKET

Designed to work specifically with the Haas line of CNC mills. This bracket keeps the Servo Control in easy

reach of the operator, allowing for easy programming between the Haas mill and Rotary t able. Contact your

Haas dealer to order. (Haas p art number: SCPB)

Installed Servo Control Bracket

1.8 HAAS T AILSTOCKS

T ailstocks must be properly aligned to the rot ary table before using.

Clean bottom surface of tailstock casting before mounting to mill table. If there are any noticeable burrs or

nicks on the mounting surface, clean them with a deburring stone.

See the Haas tailstock manual (96-5000) for pneumatic tailstock’s operating pressure.

T ailstocks cannot be used with the HR T320FB table.

96-5047 rev L June 2005

9

2.1 GENERAL S ETUP

1. Fill out the warranty card and mail it in. (V ery Important).

2. Place the indexer on your machine. Route the cable from the table such that it avoids tool chang-

ers and table edges. Slack must be provided for your machine's movements. If the cable is cut, the

motor will fail prematurely . Secure the HRT Rot ary Table to your machine’s T-Slot t able as shown

below.

NOTE: The HRT 160, 210, 450, and 600 Rotary Tables can be secured as shown:

1/2-13UNC T-Nuts, Studs,

Remove TopCover

to Access Toe-Clamp

Pockets

Flange nuts and Washers*

2. SETTING UP THE HAAS ROTARY TABLE

Bottom View

of Casting

Clamping Tool

Assembly (2)

1/2-13UNC T-Nuts,Studs,

Flange Nuts, and Washers

*

ToeClamp

Assembly

1/2-13UNC T-Nuts,

Studs, Flange nuts,

and Washers

*

1/4-20UNC

SHCS (4)

Toe-Clamp

Assembly (2)*

*NOTE: Toe-Clamp Fasteners are not supplied. *Standard stud mounting, front and

rear For extra rigidity , use

additional T oe-Clamps.

NOTE: The HRT 310 can be secured as shown:

0.781” Thru

3/4-10UNC X 8”

SHCS (4)

7.875”

1” Req.

Fixture Plate

C’Bore 1.188 X 0.80 DP

1/2-13UNC T-Nuts,

Studs, Flange nuts

and Washers

3. Connect the indexer to run as a full-fourth or semi-fourth axis. See the following figure. For fullfourth axis, the indexer is connected directly to the HAAS mill control at the connector labeled “AAxis”, and is the desired connection.

10

96-5047 rev L June 2005

SEMI-FOURTH AXIS OPERATION

POWER

ServoControl

DEGREES

SERVO

ON

OVER

LOAD

STEP

SCAN

HIGH

LOAD

CYCLE

START

EMERGENCY

STOP

JOG

ZERO

RETURN

CLEAR

DISPLAY

SCAN

ZERO

SET

RUN

PROG

TO MILL

INTERFACE CABLE PORT

ON

POWER

ServoControl

SERVO

ON

STEP

RUNNING

C

Y

C

L

S

E

T

A

R

T

E

M

E

R

G

DEGREES

E

N

C

7

S

Y

TO

P

8

OVER

-

LOAD

0

HIGH

4

J

O

LOAD

G

9

MODE

+

5

RUN

PROG

9

Z

E

R

1

R

O

E

6

T

DISPLAY

U

R

N

2

CLEAR

SCAN

ZERO

SET

3

0

STEP

SCAN

4TH AXIS

-

FULL-FOURTH AXIS OPERATION

4TH AXIS

RS232 PORT OR

SERVO

CONTROLLER

TO MILL

4TH AXIS PORT

Note: Your HAAS mill must have the 4th axis option to run full-fourth and must be

configured as brush or brushless to be compatible with your indexer. Brush

configuration uses one cable and one connection at the A-axis port on the

control. Brushless uses two cables and two connectors at the A-axis port.

(HRT320FB cannot be run directly from a mill)

4. Route the cable over the back of the mill sheetmetal and install the cable clamp. The bottom plate

of the clamp assembly must be removed and discarded before installing the clamp to the mill.

Assemble the clamp to the mill as shown.

49-0001

79-0001

Shipping

Plate

96-5047 rev L June 2005

11

5. If adding an indexer to a Haas mill the settings must be set for the specific table. Refer to the

instructions in the mill manual or call the Haas service department.

6. Semi-Fourth Axis: Secure the servo control in servo pendant bracket (Haas part number SCPB)

as seen at the end of the introduction section.

7. Connect the large black cable from the table to the controller .

CAUTION: Never connect or disconnect this cable with the power on! Instant failure

will result!

8. Semi-Fourth Axis: Connect the AC line cord to a 120V AC grounded recept acle. The cord is a

three-wire ground type, and the ground must be connected. Power is 120VAC. The power service

must supply a minimum of 15 amps continuously . Conduit wire must be 12 gauge or larger and

fused for at least 20 amps. If an extension cord is to be used, use a three-wire ground type and the

ground line must be connected. A void outlets that have large electric motors connected to them.

Use only heavy duty 12 gauge extension cords capable of 20 amp load. Do not exceed a length of

30 feet.

9. Semi-Fourth Axis: Connect the remote interface lines. See “Interfacing to Other equipment”

section.

10. Connect the table to a standard shop air line (120 PSI Max). The line pressure to the brake is not

regulated. Do not exceed the maximum pressure.

NOTE: HAAS recommends the use of an in-line air filter/regulator for all tables. The

air filter will keep contaminates from entering the air solenoid valve.

11. Check the oil level. If it is low, add oil. Use MOBIL SHC-630 synthetic gear oil (V iscosity Grade

ISO 220). For the HRT210SHS use Mobil SHC-626 synthetic gear oil (Viscosity Grade ISO 68).

12. Save the packing materials in case you need to ship the unit.

13. At the end of the workday or shift, it is important to clean the rotary table. The table should be free

of any chips or grime. Clean with a chip brush and apply a coat of a rust preventative.

CAUTION! Do not use air gun around front or rear seals. Chips may damage seal if

blown in with an airgun.

14. Turn on the mill (and servo control, if applicable) and home the table by pressing the Zero Return

button. All Haas indexers home in the clockwise direction as viewed from the platter . If the t able

homes counter-clockwise, press E-stop and call the Haas service department.

12

96-5047 rev L June 2005

2.2 INTERFACING TO O THER E QUIPMENT

Semi-Fourth Axis Operation

Interfacing is an unfriendly word that inspires fear in most non-electrical people. In reality , you are interfacing

objects all the time. Hooking up a stereo, computer , or VCR requires many connections, or interfaces. Plugging a lamp into the wall and turning the switch on is really interfacing a 100 watt incandescent lamp up to a 15

Megawatt generating plant. While there are hundreds of connections between your lamp and the power company, it is really a simple process. The HAAS control is just as simple.

The control can be installed to communicate with your mill two different ways: RS-232 Interface or CNC

Interface Cable. These connections are detailed in the following sections.

The HAAS control has two signals: one input and one output. Your equipment tells the HAAS control to index

(an input), it indexes, and then sends a signal back to your equipment that the index (an output) has been

completed. These signals are simply switch closures, or in mechanical terms, relays. A switch (relay) is closed

inside your machine that tells us to index, we index and then close a switch (relay) inside our control to tell

your machine that we are done. This inferface requires four wires; two for each signal. They are from the remote

input on the back of the HAAS control and from your equipment or CNC (Computer Numerically Controlled)

machine.

The Relay In The HAAS Control

The relay inside the control has a maximum rating of 2 amps at 30 volts D.C./ 120V AC. It is programmed as

either a normally closed or a normally open relay , closed during cycle or after cycle (see "Parameters" section). It is intended to drive other logic or small relays. It will not drive other motors, magnetic starters, or loads

exceeding 100 watts. If you use the feedback relay to drive another D.C. relay (or any inductive load), remember to install a snubber diode across your relay’s coil in the opposite direction of coil current flow . Failure to

use this diode or other arc suppression circuitry on inductive loads, no matter how small they may be, will

result in the contacts of the relay arcing together in a very short time.

To test the relay, use an ohmmeter to measure the resistance across pins 1 and 2. With the control off, the

reading should be infinite. If a lower resistance is measured, the contact points have failed and the relay must

be replaced. Radio Shack sells a relay that can be used as a replacement (Cat. #275-241) but it should only

be replaced by a qualified technician.

2.3 THE RS-232 INTERFACE

There are two connectors used for the RS-232 interface. They are both DB-25 connectors, one male and one

female. Multiple controllers are connected by daisy-chaining the boxes. The cable from the computer connects

to the female connector. Another cable can connect the first box to the second by connecting the male connector of the first box to the female connector of the second. This can be repeated for up to nine controllers.

Since the RS-232 connector on the back of most PC's is a male DB-9, only one type of cable is required for

connection to the controller, or between controllers. This cable must be a DB-25 male on one end and a DB-9

female on the other. Pins 1, 2, 3, 4, 5, 6, 7, 8, and 9 must be wired one-to-one. It cannot be a Null Modem

cable, which inverts pins 2 and 3. To check cable type, use a cable tester to check that communication lines

are correct. The controller is DCE (Data Communication Equipment). This means that it transmits on the RXD

line (pin 3) and receives on the TXD line (pin 2). The RS-232 connector on most PC's is wired for DTE (Data

T erminal Equipment), so no special jumpers should be required.

The Down Line (RS-232 out) DB-25 connector is only used when more than one controller is to be used. The

first controller's down (RS-232 out) line connector goes to the second controller's up (RS-232 in) line connector,

etc.

96-5047 rev L June 2005

13

The RS-232 interface sends and receives seven data bits, even p arity, and two stop bits. The data rate can

be between 110 and 19200 bit s per second. When using RS-232, it is important to make sure that Parameters

26 (RS-232 Speed) and 33 (X-on/X-off Enable) are set to the same value in the controller and PC. Parameter 12

must be set to 3 in order to coordinate mill and controller motion. This will prevent Aux. axis position mismatch

alarm (355) when in handle jog mode.

If Parameter 33 is set to on, the controller uses X-on and X-off codes to control reception, so be sure your

computer is able to process these. It also drops CTS (pin 5) at the same time it sends X-off and restores CTS

when is sends X-on. The RTS line (pin 4) can be used to start/stop transmission by the controller or the X-on/Xoff codes can be used. The DSR line (pin 6) is activated at power-on of the controller and the DTR line (pin 20

from the PC) is not used. If Parameter 33 is 0, the CTS line can still be used to synchronize output.

When more than one HAAS controller is daisy-chained, data sent from the PC goes to all of the controllers at

the same time. That is why an axis selection code (Parameter 21) is required. Data sent back to the PC from

the controllers is OR’ed together so that, if more than one box is transmitting, the data will be garbled. Because of this, the axis selection code must be unique for each controller.

The serial interface may be used in either a remote command mode or as just an Upload/Download path.

RS-232 Remote Command Mode

Parameter 21 must be non-zero for the remote command mode to operate, as the controller looks for an axis

select code defined by this parameter . The controller must also be in RUN mode to respond to the interface.

Since the controller powers-on in RUN mode, unattended remote operation is possible.

Commands are sent to the controller in ASCII code and terminated by a carriage return (CR). All commands,

except for the B command, must be preceded by the axis select code (U,V ,W ,X,Y,Z). The B command does

not require the select code, as it is used to activate all axes simultaneously. The ASCII codes used to command the controller are shown below.

RS-232 Commands

The following are the RS-232 commands, where X is the selected axis:

xSnn.nn Specify step size or absolute position.

xFnn.nn Specify feed rate in units/second.

xGnn S pecify G code.

xLnnn Specify loop count.

xP Specify servo status or position.

(This command causes the addressed controller to respond with the servo position if

normal operation is possible or otherwise with the servo status.)

xB Begin programmed step on X-axis.

B Begin programmed step on all axes at once.

xH Return to HOME position or use home offset.

xC Clear servo position to zero and establish zero.

xO Turn servo on.

xE Turn servo off.

14

96-5047 rev L June 2005

RS-232 Responses

The xP command is presently the only command that responds with data. It will return a single line consisting

of:

xnnn.nnn (servo at standstill at position nnn.nnn) OR

xnnn.nnnR (servo in motion past position nnn.nnn) OR

xOn (servo is off with reason n) OR

xLn (servo HOME position lost with reason n)

2.4 THE R EMOTE I NPUT

The CNC Interface Cable provides a basic method of communication between a non-Haas mill and Haas Servo

Control/Rotary Head. Since most CNC machine tools are equipped with spare M-codes, Semi-fourth axis

machining can be achieved by connecting one end of the CNC Interface Cable to any one of these spare relays

(switches), and the other to a Haas Servo Control unit. Indexing commands for the rotary unit are stored only in

the Servo Control’s memory , and each pulse of the host machine’ s relay triggers the control to index to its next

programmed position. Af ter finishing the index, the Servo Control signals that it has finished and is ready for the

next pulse.

A remote socket is provided on the back panel of the control unit. The remote input consists of a cycle start

line and a cycle finish line. To connect to the remote, you will need a connector supplied by HAAS (or one

obtained from a local source) that can be used to trigger the controller from any one of several sources. The

cable connector used is a male four-pin DIN connector. The Haas Automation part number is 74-1510

(Amphenol part number is 703-91-T -3300-1). The The Haas Automation part number is 74-1509 for the panel

receptacle in the control box is (Amphenol part number 703-91-T -3303-9).

Cycle Start

Figure 2 shows the connector as viewed from the rear panel of the control unit. When pins 3 and 4 are connected to each other for a minimum of 0.1 seconds, the control will index the head one cycle or step. To index

again, pins 3 and 4 must be opened for a minimum of 0.1 seconds. Under no circumstances should power be

applied to pins 3 and 4. A relay closure is the safest way to interface the control to your equipment.

When a cycle start is implemented, pin 3 supplies a positive 12 volts at 20 milliamps and pin 4 is connected to

the diode of an opto-isolator that grounds to chassis. Connecting pin 3 to pin 4 causes a current to flow through

the diode of the opto-isolator, triggering the control.

If the control is used around high frequency equipment such as electric welders or induction heaters, you will

need to use shielded wire to prevent false triggering by radiated EMI (electromagnetic interference). The shield

should be attached to earth ground.

96-5047 rev L June 2005

15

Figure 2. A Typical CNC Interface.

Cycle Finish

If your application is in an automatic machine, such as a CNC mill, the feedback lines (pins 1 and 2) should be

utilized. Pins 1 and 2 are connected to the contacts of a relay inside the control and have no polarity or power

on them. They are used to synchronize the automatic equipment with the controller

The feedback lines provide a switch closure through a relay inside the Haas control box to let your machine

know when the table has finished indexing. The relay can be used to “Feed Hold” NC machine movements or it

can be used to cancel the M function. If your machine is not equipped with such an option, another alternative

may be to dwell for a period of time longer than it takes the control to index the head. The relay will trigger for

all cycle start closures except a no-operation code of 97.

16

96-5047 rev L June 2005

2.5 REMOTE O PERATION WITH M ANUAL E QUIPMENT

The remote connection is used when you wish to index the unit other than by the ST ART switch on the front

panel. This frees the operator from having to touch the control to start indexing. For example, using our optional

remote quill switch (Haas P/N RQS) for Bridgeport milling machines, every time the quill handle is retracted it

touches a micro switch on the clamp and the indexing head will rotate automatically . This eliminates the need

to remove your hand from the quill, increasing production dramatically. Using a magnetic base, an aluminum

bracket, and a micro-switch you can get the unit to index almost anywhere you wish. Use the switch to index

the unit when you are milling. Every time the table comes back to a certain position, a simple bolt on the table

can close the switch, indexing the unit.

Refer to Figure 2. By simply connecting pins 3 and 4 together, the control will index. Be careful that you do not

apply power to these lines (3 and 4 only). You do not need to hook up the feedback pins 1 and 2 unless you

want the control to start another mechanism such as an automatic drilling head. The feedback pins (1 and 2)

do not need to be connected for the control to operate.

Color-coded remote interface cables are available, as an option, to help the users understand the M-function

hookup. They are coded as follows:

1 = red 3 = black

2 = green 4 = white

2.6 REMOTE O PERATION WITH CNC EQUIPMENT

NOTE: All Haas controls come standard with 1 CNC interface cable. Additional CNC

interface cables can be ordered (Haas P/N CNC).

CNC machines have Miscellaneous functions called M functions. These control external switches (relays) that

turn things on or off (i.e., spindle, coolant, etc.). Most CNC controls provide some degree of access to the M

functions, with most late model machines providing several spare relays just for this purpose. The HAAS

remote cycle start line is hooked into the normally open contacts of a spare M function relay . Our remote

feedback lines are then connected to the M function finished line (MFIN), which is an input to the CNC control,

to cancel the M function and proceed to the next block of information.

On late model CNC machines, interfacing the unit is relatively simple, if you know where to make the connections. Y our machinery dealer is the best source for this information.

96-5047 rev L June 2005

17

2.7 REMOTE O PERATION WITH A FANUC CNC CONTROL

SERVO

ON

OVER

LOAD

STEP

SCAN

HIGH

LOAD

CYCLE

START

EMERGENCY

STOP

JOG

ZERO

RETURN

ZERO

SET

RUN

PROG

FANUC control set-up requirements

There are several requirements that must be met before a Haas Servo Control can be interfaced with FANUC

controlled mill. These are as follows:

1. FANUC control with custom macro enabled and parameter 6001, bits 1 and 4 set to “1”.

2. A serial port on the FANUC control must be available for exclusive use by the Haas Servo Control

while DPRNT program is running.

3. Single axis Haas Servo Control and Indexer/Rotary table. Note: A dual axis control will not work in

this application as the RS-232 communications port is being used for internal communication.

4. RS-232 shielded cable 25’ DB25M / DB25M (null modem not required) Radio Shack Catalogue

no.RSU 10524 114 (see pinout below)

5. Shielded M-code relay cable Haas Automation Part Number : CNC

DB25 pinout: 1- 1 2- 2

3-3 4-4

5-5 6-6*

7-7 8-8*

20-20*

*Not connected in the brushless control

CNC MILL W/FANUC CONTROL

RS-232

M Function

Relay

+24 Volts

M FIN Signal

CNC MILL

HAAS ROTARY CONTROL

Cable

ON

POWER

SERVO

ON

STEP

RUNNING

C

Y

C

LE

S

T

A

R

T

E

M

E

R

G

DEGREES

E

N

C

7

STOP

Y

8

OVER

-

LOAD

0

HIGH

J

4

O

LOAD

G

9

MODE

+

5

RUN

PROG

9

ZERO

1

RETURN

6

DISPLAY

2

CLEAR

SCAN

ZERO

SET

3

0

STEP

SCAN

-

CNC INTERFACE CABLE

4 Pin Din Connector

Rear of Controller

Figure 3. A Typical CNC Interface.

Control Cable

680 OHM

1

4

3

2

HAAS INTERNAL

HAAS ROTARY CONTROL

CYCLE

START

+12 Volts

CYCLE

FINISH

18

96-5047 rev L June 2005

Haas parameters

Once the above requirements have been met you can revise the parameters of the Haas control. Listed below

are the parameters that will need to be changed.

Parameter 1= 1 Parameter 2 = 0

Parameter 5 = 0 Parameter 8 = 0

Parameter 10 = 0 Parameter 12 = 3*

Parameter 13 = 65535 Parameter 14 =65535

Parameter 21 = 6* (see table 1) Parameter 26 = 3* (see table 2)

Parameter 31 = 0* Parameter 33 = 1

Table 1 Table 2

0= RS 232 upload / download programs 1= U 0 = 1 10 1 = 300 8 = 19200

2= V 3= W 2 = 600 3 = 1200

4= X 5=Y 4 = 2400 5 = 4800

6= Z 7,8 AND 6 = 7200 7 = 9600

9 RESERVED

Fanuc Parameters

The Fanuc control parameters must be set as follows to successfully communicate with Haas Control.

Baud Rate 12 00*

Parity Even (Required setting, do not experiment)

Data Bits 7 or ISO (If CNC control defines Data bits as word length + parity

bit then set to 8)

Stop bits 2 (Required setting, do not experiment)

Flow control XON / XOFF

Character Coding (EIA/ISO) ISO (Required setting, EIA will not work)

DPRNT EOB LF CR CR (CR is required, lf is always ignored by Servo control)

DPRNT Leading zeroes as blanks off

*Initial settings. Experiment with these settings only AFTER interface is functional.

NOTES:

1. Be certain to set FANUC p arameters related to actual serial port connected to Haas Servo Control.

The parameters have been set for remote operation. Y ou can now program, or run an existing program. There

are several key items you need to consider to insure your program will run successfully . First and foremost

DPRNT must proceed every command sent to the Haas Control. The commands are sent to the controller in

ASCII code and terminated by a carriage return (cr.). All commands must be proceeded by an axis select code

(U, V , W, X, Y , Z), p arameter 21 = 6. For this explanation Z will represent the axis code.

96-5047 rev L June 2005

19

RS 232 Command Blocks:

DPRNT[ ] Clear / Reset receive buffer

DPRNT [ZGnn ] Loads G-code nn into step no. 00, “0”is a place holder

DPRNT[ ZSn n.n nn ] Loads Step Size nnn.nnn into S tep no. 00

DPRNT[ ZFnn.nnn ] Loads Feed Rate nnn.nnn into Step no. 00

DPRNT[ZLnnn] *Loads Loop Count into Step no. 00

DPRNT[ZH] Return home immediatley without M-FIN

DPRNT [ZB] *Activates Remote Cycle Start without M-FIN

DPRNT [B] *Activates Remote Cycle St art without M-FIN regardless of Haas Servo Control

Parameter 21 setting

*Not for general use in this application.

NOTES:

1. Use of “ Z “ above assumes Haas Servo Control Parameter 21 = 6.

2. Leading and trailing “0” must be included ( Correct: S045.000, Wrong: S45).

3. When writing your program in the FANUC format it is important not to have blank spaces or

carriage returns (CR) in your DPRNT statement.

DPRNT PROGRAM EXAMPLE

The following is an Example of one way to program the FANUC.

O0001

G00 G17 G40 G49 G80 G90 G98

T101 M06

G54 X0 Y0 S1000 M03

POPEN ( OPEN FANUC SERIAL PORT)

DPRNT [ ] ( CLEAR /RESET HAAS)

G04 P64

DPRNT [ZG090] ( SERVO CONTROL STEP SHOULD NOW READ “00“ )

G04 P64

DPRNT [ZS000.000] ( LOADS STEP SIZE 000.000 INTO STEP 00)

G04 P64

DPRNT [ZF050.000] ( LOADS FEED RATE 50 UNITS / SEC INTO STEP 00)

G04 P64

Mnn (REMOTE CYCLE START, MOVES TO P000.0000, SENDS M-FIN)

G04 P250 (DWELLS TO AVOID DPRNT WHILE M-FIN IS STILL HIGH)

G43 Z1. H01 M08

G81 Z-.5 F3. R.1 (DRILLS AT: X0 Y0 P000.000)

DPRNT [ ] (MAKE CERTAIN HAAS INPUT BUFFER IS CLEAR )

G04 P64

#100 = 90. (EXAMPLE OF CORRECT MACRO SUBSTITUTION)

DPRNT [ZS#100[33] ] ( LOADS STEP SIZE 090.000 INTO STEP 00)

(LEADING ZERO CONVERTED TO SPACE PARAM. MUST BE OFF)

G04 P64

Mnn (REMOTE CYCLE START MOVES TO P090.000, SENDS M-FIN)

G04 P250

X0 (DRILLS AT: X0 Y0 P090.000)

G80 (CANCELS DRILL CYCLE)

PCLOS (CLOSE FANUC SERIAL PORT)

G00 Z0 H0

M05

M30

20

96-5047 rev L June 2005

2.8 UPLOAD / DOWNLOAD

The serial interface may be used to upload or download a program the same as with almost any other CNC in

use today. All data is sent and received in ASCII code. Lines sent by the controller are terminated by a carriage

return (CR) and line feed (LF). Lines sent to the controller may contain a LF, but it is ignored and the lines are

terminated by a CR. It is important that parameter 21 be set to “1” in the Servo Control prior to attempting

Uploading or Downloading programs.

An upload or download is started from the PROGRAM mode with the G code displayed. To start an upload or

download, press the minus (-) key while the G code is displayed and blinking. The display will then show:

Prog n

Where n is the currently selected program number . Y ou can select a different program by pressing a number

key and then ST ART to return to PROGRAM mode or MODE to return to RUN mode. Or you can press the

minus (-) key again and the display will show:

SEnd n

Where n is the currently selected program number . Y ou can select a different program by pressing a number

key and then STAR T to begin sending that selected program. Or you can press the minus (-) key again and the

display will show: rEcE n

Where n is the currently selected program number . Y ou can select a different program by pressing a number

key and then ST ART to begin receiving that selected program. Or you can press the minus (-) key again and

the display will return to PROGRAM mode. Both uploading and downloading can be terminated by pressing the

CLR button.

Programs sent or received by the controller have the following format: (Sample Only)

%

N01 G91 S045.000 F080.000 L002

N02 G90 S000.000 F080.000

N03 G98 F050.000 L013

N04 G96 P02

N05 G99

%

The % must be found before the controller will process any input and it will always begin output with a %. The

N code and G code are found on all lines and the remaining codes are present as required by the G code. The

N code is the same as the step number display in the controller. All N codes must be continuous starting from

The controller will always end output with a % and input to it is terminated by a %, N99 or G99. Sp aces are

only allowed where shown.

The controller will display SEnding while sending a program, and the line number will change with information

sent. The controller will display LoAding while a program is being loaded into the controller , and the line

number will change with information received. An error message will be displayed on the controller if bad

information is sent, and the display will indicate the last line received. If an error occurs, first make sure that

the letter O was not inadvertantly used in the program instead of a zero. If not, refer to the "Troubleshooting"

section.

When using an RS-232 interface, it is recommended that the programs be written in DOS Edit, Wordstar ,

Notepad Editor , or other ASCII program. Word processing programs, such as Word Perfect or Word 6.0, are

not recommended, as they will insert extra, unnecessary information.

Upload/Download functions do not need an axis select code as they are manually initiated by an operator at

the front panel. However, if the select code (Parameter 21) is not zero, an attempt to send a program to the

control will fail, as the lines do not begin with the correct axis select code.

96-5047 rev L June 2005

21

2.9 HAAS A6AC AIR C OLLET C LOSER

The A6AC collet closer easily bolt s to the back of the HRT A6 (see Figure 1a). The drawbar and collet adapters

are designed to mate with the Haas A6/5C spindle nose. The optional A6/3J and A6/16C may be obtained from

your local tooling distributor.

NOTE: A special drawtube adaptor is required for the 16C and 3J. Make sure to supply

tooling distributor with spindle/drawbar details as shown in figure 1-b.

Figure 1-a. A6AC collet closer shown mounted to an HRT A6.

A - MAX.

B-MIN.

D

EF

C

G

A - MAX. (Tube Extended)

B - MIN. (TubeRetracted)

C - Spindle Type and Size

D - Draw Tube Thread Data

1 - Diameter of Thread

2 - Pitch

3 - Internal Thread

4 - Length of Thread

E - Draw Tube I.D.

F - Draw Tube O.D.

G - Spindle I.D.

@ 100 psi line pressure

Figure 1-b. Drawtube to spindle dimensions (extended/retracted).

.640*

.760

A1-6

17/8-16UN-2B

1.834 / 1.841

1.25

1.75

2.029

2.0300

22

96-5047 rev L June 2005

Clamping Force and Air Supply

The A6AC is a 1-3/4 diameter thru-hole type closer which is adjust able from the rear . It holds parts by utilizing

spring force to provide up to 0.125 of longitudinal movement and up to 5000 lbs. of draw force at 120 PSI shop

air pressure.

Adjustment

To adjust the collet closer, align a collet with the keyway, push the collet into the spindle, and turn the drawbar

clockwise to pull the collet in. To make the final adjustment, place a part in the collet, turn the air valve to the

UNCLAMPED position to charge the cylinder and compress the spring mechanism, then tighten the drawbar

until it stops. Back off 1/4 - 1/2 turn and turn the air valve to the CLAMPED position. This will be adjusted for

maximum clamping force. T o reduce the clamping force, back of f further on the drawbar or regulate the air

pressure down before adjusting.

Collet Sticking

NOTE: To prevent excessive wear and collet sticking, make sure collets are in good

condition and free from burrs. A light coat of Molybdenum grease on the collet

wear surfaces will extend the life of the spindle / collet and help prevent

sticking.

When the air supply is turned on, the drawbar is kicked forward and releases the collet. Increasing the air

pressure can help stop the collet sticking; however, do not exceed 200p si into the cylinder . Backing off further

on the drawbar during final adjustment may also reduce collet sticking.

WARNING!

Do not index the Rotary Table while the A6AC air valve is in the ON

position. This will put excessive friction on the worm gear system

and cause premature wear.

96-5047 rev L June 2005

23

3. OPERATION

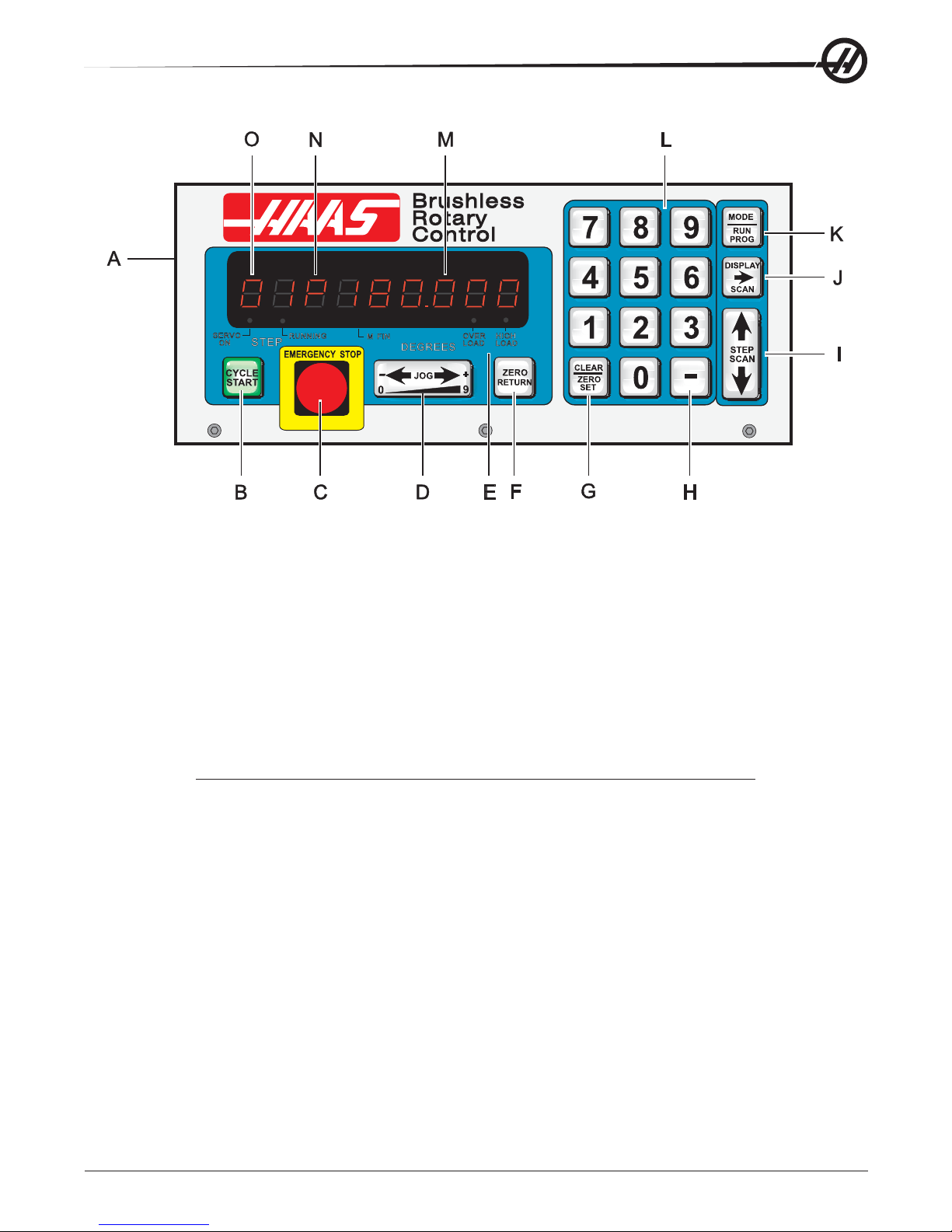

3.1 THE F RONT P ANEL D ISPLAY

The Light Emitting Diode (LED) front panel display tells you what is going on inside the controller . There are

nine characters that are displayed. The left two characters are the step number and go from 1 to 99. They

cannot be changed with the numeric keys and are selected by using the STEP SCAN arrow buttons. The

remaining seven characters display data that is stored in memory . Every step (or block) contains several

pieces of information that are necessary for your program, but they cannot be displayed simultaneously . In

order to overcome this, use the DISPLAY SCAN button to view the pieces of data for each step. The data is

preceded by a letter to indicate which piece of information is being displayed. For example, if an F precedes

the number, the displayed data is for feed rates. There are five such registers. They are:

1) current spindle position (indicated by a letter P)

2) step size and direction (indicated by no letters),

3) feed rate (indicated by a letter F),

4) loop count (indicated by a letter L)

5) G code (indicated by a letter G)

Successive pushes of the right arrow button will cause the display to cycle to the next register, that is,

POSITION - STEP SIZE - FEED RA TE - LOOP COUNT - G CODE - POSITION - etc. In RUN mode, the right

arrow button can select among any of these five displays. In PROGRAM mode, all of these but the position

may be displayed.

Refer to the diagram on the following page. When you are in the PROGRAM mode, you are editing the numbers (or registers) inside the dotted lines. Think of the LED displays as a window that allows you to see only

one number of the program at a time. The DISPLA Y SCAN button allows you to scan sideways and see all the

information for a single step. Pushing the DISPLA Y SCAN button shif ts the window one place to the right,

looping from left to right at the end of the row . Pushing the up arrow allows you to view the previous step, while

pushing the down arrow allows you to view the next step. Using these three keys, you can scan to anywhere

in the program. If you enter a new number in that position, the number will be stored when you scan to another

position or return to RUN mode.

24

96-5047 rev L June 2005

A) Main POWER switch to turn the unit on (back panel).

B) CYCLE START begins a step, stops a continued operation, inserts a step, or turns the servo on.

C ) EMERGENCY STOP turns off the servo when on and aborts the step in progress.

D ) JOG causes the servo to move in either the forward or backward direction at a rate defined by the last

numeric key pressed.

E) Load meter LED. If LEDs are illuminated continuously during a low feed rate or when stationary, the

following conditions apply:

HIGH LOAD: Indicates overload level, excessive load or workpiece support misalignment. Hi-LoAd or Hi

Curr alarms may occur if not corrected. (See "Troubleshooting" section)

OVERLOAD: Indicates 2x overload level, excessive load or workpiece misalignment. Hi LoAd or Hi Curr

alarms will occur if not corrected. Damage to motor or table may result. (See "Troubleshooting" section)

NOTE: It is normal for the LEDs to be illuminated during a rapid movement or high duty

cycle.

F) ZERO RETURN causes the servo to return to HOME position, search for mechanical HOME, delete a step,

or move forward to the mechanical offset.

G ) ZERO SET clears the entered data, resets program to 0, or defines the present servo position as HOME.

H ) MINUS KEY selects negative step values or Prog/Upload/Download functions.

I ) STEP SCAN scans step numbers from 1 through 99.

J ) DISPLA Y SCAN scans the display to show either Position, S tep Angle, Feed Rate, Loop Counts, or G

Code.

K) MODE / RUN PROG switches from RUN mode to PROGRAM mode (blinking display).

L) Data entry keys and jog speed selection.

M) Displays show current data, i.e., a current spindle position of 180.

N ) Indicates what data is being displayed. Either P, F, L, blank, or G for Position, Feed Rates, Loop Count,

Step Angle, or G Code.

O ) Present step number. Step numbers 1 to 99 are available. Also displays errors at turn on.

96-5047 rev L June 2005

25

3.2 TURNING T HE S ERVO O N

There is a single 115V AC @ 15 amp supply required by the controller . Ensure that the front p anel power switch

is turned off (Brushless units have the power switch on the rear) and connect the motor cable from the table

and the power cord.

Turn the controller on. The display will show:

HAAS nn

where nn is the sof tware revision number . That number should be used when describing problems to HAAS. If

any other message is displayed, refer to the "Error Codes" section of this manual. The number only remains in

the display for about one second. The front panel displays should indicate:

Por On

This indicates that the servo is turned off (no power is applied to the closed-loop motor).

In addition, the internal battery is checked at power-on and if the battery is low the following message is

displayed:

Lo bAt

Pressing any key will allow you to continue operation, but the low battery may have caused loss of your

program parameters.

Press the front panel ST ART switch once. The panel should now indicate:

01 no Ho

This indicates that the motor is powered, but the zero position is not yet defined.

3.3 AUTOMATICALLY F INDING T HE Z ERO POSITION

Press the ZERO RETURN button to start the automatic homing operation. When the table stops, the display

will indicate:

01 Pnnn.nnn

3.4 MANUALLY F INDING THE Z ERO P OSITION

Use the left/right JOG switch to position the table to the position that you want to use as zero and then press

and hold the CLR key for three seconds. The display should now indicate:

01 P 000.000

This indicates that the zero position is established and the controller is ready to begin normal operations. If a

different position is to be used as zero, jog the table to the new position and press the CLR key for three

seconds. The display will again indicate:

01 P 000.000

If you had previously cleared a new HOME position for the table, the display will show a non-zero position. In

this case, press the ZERO RETURN button once more and the table will move forward to the pre-defined zero

position.

26

96-5047 rev L June 2005

3.5 JOGGING

Jogging of the motor can be done with the front panel JOG switch. The jog speed is selected with the front

panel number keys and is a fraction of the maximum feed rate set by the parameters. The jog speeds (for the

HRT 160) are:

Number pressed Speed (% of maximum) Jog speed (for 80 deg/sec max.)

0 0.008 0.006 Deg/sec

1 0.015 0.012 Deg/sec

2 0.031 0.024 Deg/sec

3 0.062 0.049 Deg/sec

4 0.125 0.100 Deg/sec

5 0.25 (default) 0.200 Deg/sec

6 0. 5 0.400 Deg/sec

7 1. 0 0.800 Deg/sec

8 4. 0 3.200 Deg/sec

9 16.0 12.800 Deg/sec

If the control is set up for linear motion, positive and negative travel limits are possible. If a step is started which

would have caused the control to exceed travel limits, the following message is shown:

2 FAr

and the control will not execute the step. (See parameter 13 and 14, travel range)

3.6 ERROR C ODES

When the controller is first turned on, a set of self tests is run and the results may indicate a controller fault.

Any of these could result in an En display of one of the following codes:

Blank front panel Program CRC failure (bad RAM, or cycle power if bad ROM to RAM program transfer.)

E0 EProm EPROM CRC error

FP Short Front panel switch closed (or PIO fault)

rE Short Remote ST ART switch closed and enabled

E3 rAm RAM cannot store data

E4 bAtt Saved program is in error (low battery)

E5 Pio2 PIO2 is bad

E6 Pio3 PIO3 is bad

Lo V olt Power-fail interrupt (low line voltage)

E8 Encod Encoder chip bad

E9 intEr Interrupt problem

EA no go Keep alive circuit failure

Eb nmi NMI sense bad

Ec Pwm PWM generation bad

Ed cloc 1 kHz signal missing

EE Au in Auxiliary input 2 shorted

Lo bAt Low battery (Get serviced)

rLS Err Exceeding maximum allowed rotary scales compensation. HRT210SC only

Intermittent low voltage errors or power failures may be the result of inadequate power to the controller . Use

heavy duty extension cords only and keep them as short as possible. Make sure power service is a minimum

of 15 amps at the plug and that the voltage is a minimum of 115 V AC.

96-5047 rev L June 2005

27

0 too SL (Zero margin too small) Zero margin too small is the distance between the home switch

and the final stopped motor position, after seeking home, is either less than 1/8 or greater

than 7/8 of a motor revolution.

This alarm may occur while homing the rotary table. The distance between the home switch and the final motor

position at zero is less than 1/8 of a motor revolution. To prevent this alarm, parameter 45 must be set properly.

Start with the default value for p arameter 45 (0) and add 1/2 of a motor revolution (1/2 motor revolution is equal

to the value in parameter 28 divided by 2). Home the rotary table after the new value for parameter 45 has been

entered.

There are no user-serviceable parts inside, so refer all problems to HAAS Automation for

repair.

3.7 SERVO O FF C ODES

At any time the servo is turned off, a reason code is displayed along with the following codes:

Por On Power was just turned on (or failed prev.)

Ser Err Servo following error too large

E-StoP Emergency stop

Hi LoAd Software fuse

rS-232 Remote RS-232 commanded off

Air-Hot Motor overheat sensor

EncodEr Z channel fault (bad encoder or cable)

REncodEr Rotary scale Z channel fault (bad rotary scale encoder or cable) HRT210SC only

Hi Curr Over current limit (stalled or PCB fault)

EncodES Z channel missing (bad encoder or cable)

rEncodES Rotary scale Z channel missing (bad rotary scale encoder or cable) HRT210SC only

Hi V oLt Regen overheat (high line voltage)

CABLE Break detected in encoder cable wiring

rCABLE Break detected in rotary scale cable wiring (HRT210SC only)

PHAS Er Power up phase error (Brushless units only)

dr FLt An overcurrent or drive fault.( Brushless units only)

trAnS Encoder transition fault had been detected by the brushless circuitry.

Indr dn Platter not fully up (HRT320FB only). Can be caused by low air pressure.

3.8 EMERGENCY S TOP

Pushing the EMERGENCY STOP button will turn the servo off and cause the spindle to decelerate and stop.

Position will not be lost. If the step was not completed you will still be on that step. Push CYCLE ST AR T to

turn the servo on. The remote cycle start and cycle finish will not function until the EMERGENCY STOP is

removed by pushing the ST ART button. If an EMERGENCY STOP is performed, the display will indicate an:

E-StoP

CE machines have an Emergency-stop switch on the top of the control. Pressing the E-stop switch will turn off

the servo and aborts the step in progress.

28

96-5047 rev L June 2005

4. PROGRAMMING THE CONTROLLER

4.1 INTRODUCTION

Programming is done through the square 15-key keypad on the right side of the front panel. The three buttons

on the right column of the keypad are used for program control. They are the:

MODE / RUN PROG button,

DISPLA Y SCAN (RIGHT ARROW) button

STEP SCAN (UP/DOWN ARROWS) button

The MODE button is the most important. It selects between the RUN mode and PROGRAM mode. You can tell

which mode you are in by looking at the display .

IF THE DISPLA Y IS STEADY, YOU ARE IN THE RUN MODE.

IF IT IS FLASHING ON AND OFF, YOU ARE IN THE PROGRAM MODE.

The RUN mode is where pre-programmed commands may be executed and the PROGRAM mode where

commands are entered into memory . The servo loop can be turned on in either mode and will hold the motor to

a commanded position when at standstill.

When the controller is first turned on, it is in RUN mode but the servo is turned off. This is indicated by:

Por On

Pressing any key will allow you to continue operation.

Some buttons have more than one function depending upon which mode you are in. Always release a button

immediately after pressing it. Holding a button down will cause it to repeat.

Feedrate will default to maximum (rapid) for HRT320FB.

4.2 HOW D ATA IS S TORED IN THE C ONTROLLER'S M EMORY

Step Number Step Size Feed Rate Loop Count G code

1 90.000 80 01 91

2 -30.000 05 01 91

3 0 80 01 99

through

9 9 0 80 01 99

- your program data -

window Pushing the right arrow key moves the window to the right.

Pushing the up arrow or down arrow keys moves the window up or down.

96-5047 rev L June 2005

29

4.3 ENTERING A STEP

To enter a step into the controller's memory, press the MODE button. This will put the controller into the

PROGRAM mode. The display will begin blinking and show a step size. Clear the last program by pressing and

holding the CLR key for three seconds. To enter a 45 degree (45o) step, press the following keys:

4 5 0 0 0

The display should now indicate:

01 45.000

Press the right arrow button. This will cause the 45 degree (45o) step to be stored and the feed rate to be

displayed. To enter a feed rate of 80 degrees (80o) per second, press the following keys:

8 0 0 0 0

The display should now indicate:

01 F 80.000

T o return the controller to the RUN mode, press the MODE button. The display should now indicate:

01 P 000.000

St art the 45 degree (45o) step by pressing the CYCLE ST ART button. The table should move to the new

position and at the end of the step, the display should indicate:

01 P045.000

4.4 PUTTING A PROGRAM I NTO MEMORY

Programming begins with ensuring that the controller is in PROGRAM mode and at step number 01. To do this,

press the MODE button while the servo is NOT in motion. The displays must be blinking. Next, push and

HOLD the clear (CLR) key for five seconds. Y ou have now cleared the memory and are at step one and ready

to begin programming. “01 000.000 “ should be displayed. Please note that you do not have to clear the

memory each time you wish to enter or change data. Data in the program can be changed simply by writing

the new data over the old.

Up to 7 programs can be stored, numbered 0 to 6. To access a different program, press the minus key while

showing a G code. The display will change to:

Prog n

Press a number key to select a new program and then press the MODE key to return to RUN mode or the

ST ART key to continue with the PROGRAM mode.

Every one of the possible 99 steps in a program may contain the following:

1. a step size or position command (shown as a number with possible minus sign),

2. a feed rate shown with a preceding F,

3. a loop count shown with a preceding L,

4. a G code shown with a preceding G, and

5. a jump destination with a preceding Loc.

Every step must contain at least one G code. The following section describes the possible G codes.

30

96-5047 rev L June 2005

To display the additional codes associated with a step, press the right arrow key. Possible data entry includes:

Step size (no code letter but possible minus sign),

Feed rate (F),

Loop count (L),

G code (G), and

Subroutine jump destination step number (Loc).

Some of these entries are not allowed for particular G codes and either cannot be entered or are ignored. Most

steps are incremental position commands and this is the default G code (91). The G codes 86, 87, 89, 92, and

93 should be used with the CNC relay function disabled (Parameter 1 = 2).

Enter your step size in degrees to three decimal places. The decimal places must always be entered, even if

they are zero. Enter a (-) minus sign for opposite rotation. If you need to edit a feed rate or loop count, push the

right arrow key to view that register and input the data.

If you are programming for a part that does not utilize feed rates or loop counts, simply push the down arrow to

go to the next step. Insert the G code and step size and move on to the next step. The step will automatically

be set to the fastest feed rate and a loop count of one.

The data you input is automatically stored in memory whenever you push one of the control buttons.

If you enter a wrong number or one that is out of limits the control will display an error message:

Error

T o correct this, push the CLR button and re-enter the correct number . If you are entering the correct number

and Error still appears, check Parameter 7 for memory protect.

When the last step has been entered, an end code must be present at the following step. Step s 2 through 99

are set to the end code when a clear memory is performed. This means that you usually do not need to set the

last step to 99. If you are removing steps from an existing program, make sure that you have entered a (99)

after the last step.

Note: The HRT320FB will not allow a feedrate to be entered. It only indexes at maximum speed.

4.5 G CODES

The following G codes are possible:

G28 return to HOME position (same as G90 with step 0)

G73 peck cycle (linear operation only)

G85 fractional circle division

G86 turn CNC relay on

G87 turn CNC relay off

G88 return to HOME position (same as G90 with step 0)

G89 wait for remote input

G90 absolute position command

G91 incremental command

G92 pulse CNC relay and wait for remote input

G93 pulse CNC relay

G94 pulse CNC relay and run next L steps automatically

G95 end of program/return but more steps follow

G96 subroutine call/jump (destination is a step number)

G97 delay by L count/10 seconds (down to 0.1 second)

G98 circle division (circular operation only)

G99 end of program/return and end of steps

96-5047 rev L June 2005

31

4.6 ABSOLUTE / INCREMENTAL M OTION

G90 and G91 are used to select absolute (G90) or incremental (G91) motion. G90 is the only command

allowing absolute positioning.

4.7 FEED R ATES

The feed rate display ranges between 00.001 and 080.000 (Maximum 080.000 for HRT 160, 060.000 for HRT

210, 050.000 for HRT 310, and 050.000 for HRT 450), preceded by an F. It displays the feed rate that will be

used for the selected step. The feed rate corresponds to degrees rotated per second. A feed rate of 080.000

means the platter will rotate 80 degrees (80o) in one second.

4.8 LOOP C OUNTS

Loop Counts allow you to repeat a step up to 999 times before going on to the next step. The loop count

display is three digits between 1 and 999 preceded by an L. In RUN mode, it displays the remaining loop

counts for the selected step. It is also used in conjunction with the Circle Division function to enter the

number of divisions in the circle from 2 to 999. Used in conjunction with G96, the Loop Count specifies the

number of times you wish to repeat that subroutine.

4.9 SUBROUTINES (G96)

Subroutines allow you to repeat a particular step sequence up to 999 times. A subroutine is invoked by entering

96 into the G code. Af ter entering 96 you must DISPLA Y SCAN over to the LOC (short for location) register to

enter the step you wish to jump to. The location register replaces the feed rate register and is only present on

G96 steps. Af ter executing a G96 step, the control will jump to the step called out in the LOC register , execute

that step and the ones following until it reaches G code 95 or 99, the end of subroutine call. The program then

jumps back to the step following G96.

A subroutine can be repeated a number of times by utilizing the loop count of the G96 step. To end the subroutine, you must insert a G code of 95 or 99 after the last sequence step. A subroutine call is not considered a

step by itself since it will always execute itself and the first step of the subroutine. Nesting of subroutine calls

is not permitted.

4.10 DELAY C ODE (G97)

G97 is used to program a dwell or delay time into a program. G97 does not pulse the CNC relay at step

completion. As an example, programming a G97 and setting L=10 will produce a 1 second dwell.

4.11 CIRCLE DIVISION (G98)

Circle division is selected with a G98. The L count defines how many equal sized parts a circle is to be divided

into. After the L count steps, the servo will be in the same position as it started. Circle division is only available

in the circular modes (i.e., Parameter 12=0, 5, or 6).

32

96-5047 rev L June 2005

4.12 AUTO C ONTINUE C ONTROL

If Parameter 10 is set to 2, the controller can be run like a single axis CNC. The entire program will be executed until the last step is encountered. In all cases, the last step is the one with a G99. Actually, the step

preceding the G99 is the last one to be executed. Step 99 may also be the last step if all of memory is used.

When running automatically , the sequence of step operation can be stopped by pressing and holding the

ST ART switch until the current step is finished. The program can then be continued by pressing ST AR T again.

4.13

II

INSERTING A L INE

II

A new step may be inserted into a program by pressing and holding the CYLE START button for three seconds

while in PROGRAM mode. It will cause the present step and all following steps' contents to be moved down

and the present step to be initialized to default values. All subroutine jump s are also renumbered.

4.14 DELETING A L INE

A step may be deleted from a program by pressing and holding the ZERO RETURN button for three seconds

while in PROGRAM mode. It will cause the next step and all following steps to be moved up by one. All

subroutine jumps are also renumbered.

4.15 DEFAULT V ALUES

For all steps, the default values are:

000.000 (step size zero)

F (maximum feed rate defined by Parameters)

L 001

G 91 (incremental)

If an entry is cleared or set to 0 by the operator, the controller will be set to the default value. All entries are

stored when selecting the next display function, step number, or returning to RUN mode.

4.16 SELECTING A S TORED P ROGRAM

There can be more than one stored program, and selection of that program is done by pressing the minus (-)

key while showing a G code in PROGRAM mode. The display will change to:

Prog n

Press a number key to select a new program and then press the MODE key to return to RUN mode or the

ST ART key to continue with the PROGRAM mode. There are seven programs available, numbered 0-6.

4.17 CLEARING A P ROGRAM

T o initialize or clear a stored program (not including Parameters), go to PROGRAM mode (press the MODE

button if displays are not blinking) and press and hold the CLR button for three seconds. The displays will cycle

through all 99 steps and set all but the first to G99. The first step is set to G91, step size of 0, maximum feed

rate, and a loop count of 1.

96-5047 rev L June 2005

33

4.18 OPERATING H INTS

1. You can select another display while in the RUN mode by pushing the DISPLA Y SCAN button.

This way you could view the particular feed rate for a step or view the remaining loop counts left.

2. You can start your program on any step by using the UP/DOWN scan keys.

3. Make sure your CNC has the same number of M functions programmed as you have steps in the

HAAS control.

4. DO NOT program two M functions one directly after another in your CNC control to index the

HAAS control, as this may cause a timing hang-up in your CNC. Use a dwell of 1/4 second

between them.

5. If all else fails, read the manual again.

4.19 SIMULTANEOUS R OTATION AND M ILLING

G94 can be used to perform simultaneous milling. The CNC relay is pulsed at the beginning of the step so that

your NC machine will proceed to the next block. The controller then executes the following L steps automatically without waiting for start commands. Normally the L count on the G94 is set to 1 and that step is followed

by a step that is to be run simultaneously with an NC mill.

4.20 SPIRAL M ILLING

The simultaneous rotation and milling feature of the controller will permit machining of certain cam forms, spiral,

and angular cuts. S piral milling is when the spindle rotates and an axis on your mill moves at the same time.

Insert a G94 into the control and the desired rotation and feed rate on the next step. The control will execute

G94 (this pulses the MFIN relay and allows your CNC to proceed) and the following step or steps as one step.

If you wish to do more than one step, then insert the number into the L register. By selecting a rot ation feed

rate and varying the mill feed rate, any spiral is possible. In order to spiral mill, you will have to calculate the

feed rate for your mill so that the HAAS spindle and your axis will stop at the same instant.

In order to calculate the feed rate for your mill you need to know:

1. The angular rotation of the spindle (this should come from the print)

2. A feed rate for the spindle (arbitrarily select a reasonable one, five degrees (5o) per second is a

good starting point)

3. The distance you wish to travel on X-axis (this should come from the print)

For example, we wish to mill a spiral that is 72 degrees (72o) of rotation and moves 1.500 inches on the X-axis

at the same time.

1. Compute the amount of time it will take the HAAS index head to rotate through the angle

# of degrees /(divided by) feed rate of spindle = time to index

72 degrees/ five degrees per sec = 14.40 seconds for indexing head to rotate.

2. Now we need to compute the feed rate for the mill that will travel the X distance in 14.40 seconds.

(length to travel in inches/(divided by) # of seconds of rotation) x 60 seconds = feed rate for mill in

inches per minute.

1.500 inches/14.4 seconds = 0.1042 inches per second x 60 = 6.25 inches per minute.

34

96-5047 rev L June 2005

Therefore, if you set the indexer to step 72 degrees (72o) at a feed rate of five degrees (5o) per second you

will have to program your mill to travel 1.500 inches at a feed rate of 6.25 inches per minute for the spiral to be

generated.

The program for the HAAS control would be as follows:

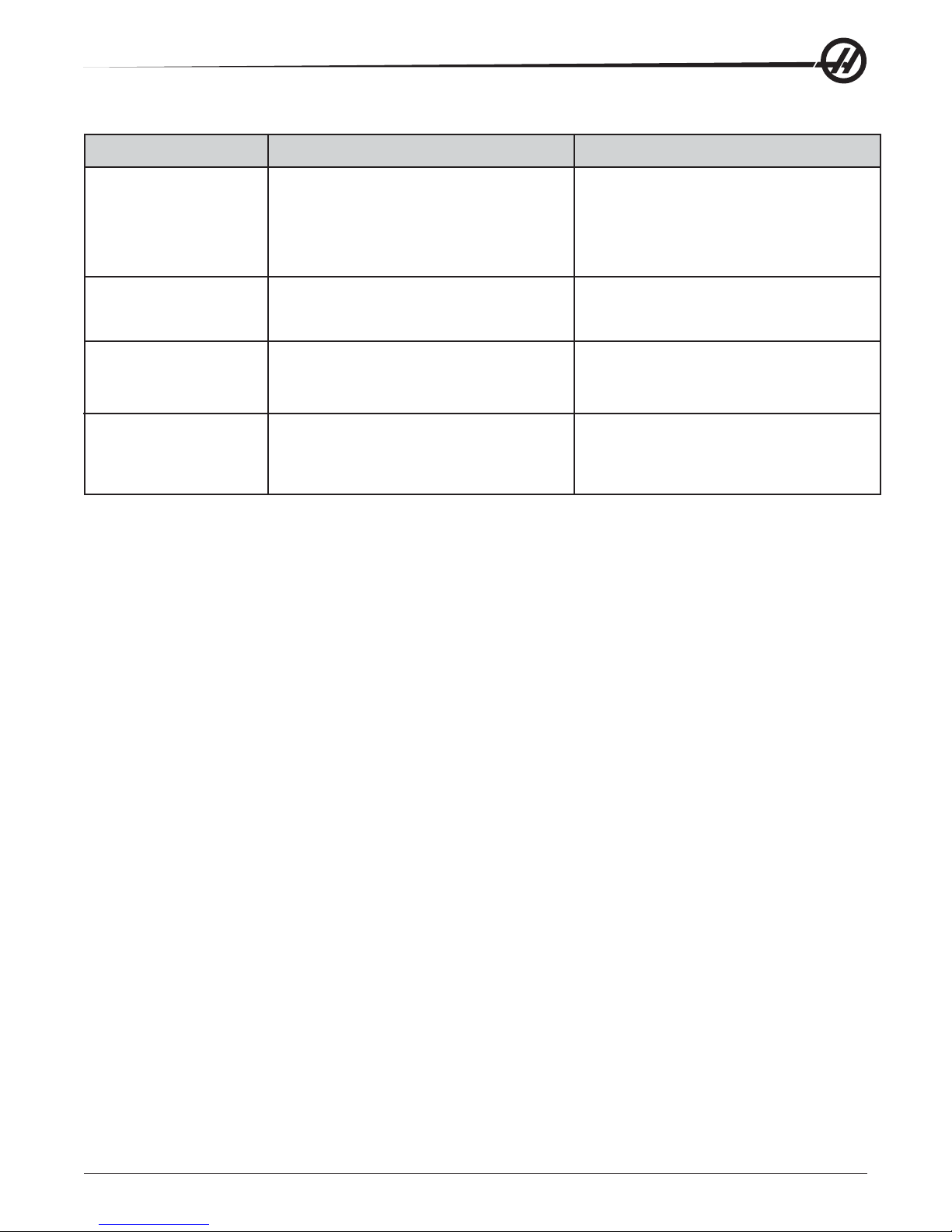

STEP STEP SIZE FEED RATE LOOP COUNT G CODE

01 0 080.000 1 [94]

02 [72000] [5.000] 1 [91]

03 0 080.000 1 [88]

04 0 080.000 1 [99]

The program for your mill would generally look like this:

N1 G00 G91 (rapid in incremental mode)

N2 G01 F10. Z-1.0 (feed down in Z-axis)

N3 M21 (to start indexing program above at step one)

N4 X-1.5 F6.25 (index head and mill move at same time here)

N5 G00 Z1.0 (rapid back in Z-axis)

N6 M21 (return indexer HOME at step three)

N7 M30

4.21 POSSIBLE T IMING P ROBLEMS

When the HRT executes a G94, a 250 millisecond delay is required before executing the following step. This

may (it usually doesn’t) cause your axis to move before the table rotates, leaving a flat spot in the cut. If this is

a problem, a solution is to insert a G04 dwell (from 0 to 250 milliseconds) in your CNC after the M function to

prevent axis movement. By selecting the right dwell, the HRT and your mill should start moving at the same

instant. In the same manner , a problem may exist at the end of the spiral, but this can be eliminated by slightly

altering the feed rate on your mill. Don’t adjust the feed rate on the HAAS control because your mill has a

much finer feed rate adjustment than the HAAS control. If the undercut appears to be in the X-axis direction,

then speed up slightly (0.1 change in feed rate) your mill’s feed rate. If the undercut appears in the radial

direction of the spindle of the indexer, then slow down your mill’ s feed rate.

If the timing is off by several seconds such that your mill completes movement before the indexer completes

it’s movement, and you have several spiral moves one right after another (such as in retracing a spiral cut), this

may cause your CNC to stop for no reason. The reason for this is your CNC will send a cycle start signal (for

next cut) to the HAAS control before it has completed its first move, thereby causing a timing hang-up. The

HAAS control will not accept another cycle start until it is finished with the first. If you are doing multiple moves

it is very important to check your timing calculations. A way to verify if this is actually the problem is to single

block your control, allowing five seconds between steps. If you can single block the control but it will not

successfully run in the continuous mode, then your timing is off somewhere.

96-5047 rev L June 2005

35

Example #1

5. PROGRAMMING EXAMPLES

We want to index the platter 90 degrees (90o).

1. Turn [POWER] switch on. (The power switch is located on the rear panel.)

2. Push the [CYCLE ST ART] switch.

3. Push the [ZERO RETURN] switch.

4. Push the [MODE] button and release. Displays must be blinking.

5. Push and hold [CLR] button for five seconds. “01 000.000” displayed.

6. Enter [9 0 0 0 0]

7. Push [MODE] button. Steady displays.

8. Push [CYCLE ST ART] to index.

36

96-5047 rev L June 2005

Example #2

Continuing the previous example, we want to index the platter 90 degrees (Step 1), rotate at five degrees/sec

(F5) in the opposite direction for 10.25 degrees (Step 2), and then return home (S tep 3).

9. Push the [MODE] button. Displays blinking.

10. Push the [DOWN ARROW] once. You should be on Step 2.

11. Enter [- 1 0 2 5 0] on the key pad. Use CLR if you make a mistake.

12. Push the [DISPLAY SCAN] button once.

13. Enter [5 0 0 0] on the keypad.

14. Push the [DISPLAY SCAN] button twice. A “G 91” will be displayed.

15. Push the [DOWN ARROW] once. You should be on Step 3.

16. Enter [8 8] on the keypad.

17. Push the [UP ARROW] twice. You should be on Step 1.

18. Push the [MODE] button. S teady displays.

19. Push the [CYCLE ST ART] switch three times. The table should index 90 degrees (90o),

slow feed in the opposite direction for 10.25 degrees (10.25o), and return home.

96-5047 rev L June 2005

37