Page 1

Art. No.0499132299030

V09 G22

Fireplace inserts EN13229-W

Installation and Operating Manual

Nameplate:

Our supply program: Oil heaters

Chimney stoves

Pellet stoves

Glazed tile and slow-burning stoves for wood and coal

Slow-burning stoves and cooking stoves for wood, coal and

oil

Fireplace inserts for wood

Accessories for stove and fireplace

Accessories for central oil supply

Air humidifiers

HAAS+SOHN Sales & Distribution in Germany

OFENTECHNIK GMBH HAAS+SOHN Ofentechnik GmbH

Urstein Nord 67 Herborner Straße 7-9

A-5412 Puch D-35764 Sinn

Phone:0043 (0) 662 44955-0 Telephone: 0049 (0) 2772 5010-0

Fax: 0043 (0) 662 44955 210 Facsimile: 0049 (0) 2772 5010-99

eMail: office@haassohn.com eMail:info@haassohn.com

http://www.haassohn.com

Important notes:

- Inform your district chimney sweep or district master chimney sweep!

- Please thoroughly read the Installation and Operating Manual!

- Observe the regulations and instructions provided in it when installing and operating the

fireplace insert!

- Please keep this Manual in a safe place!

- The enclosed Equipment Sheet is part of this Installation and Operating Manual.

1

Page 2

TABLE OF CONTENTS

1.DESCRIPTION 3

2. GENERAL INSTRUCTIONS, SAFETY

INSTRUCTIONS 3

3. COMBUSTION AIR SUPPLY: 3

4. SUITABLE CHIMNEY: 4

5. DATA FOR CHIMNEY CALCULATION: 4

7. INSTALLATION OF FIREPLACE INSERT AND

CONNECTION TO THE CHIMNEY 5

7.1 Connecting piece (flue gas pipe): 5

7.2 Protection of installation ceiling (floor): 5

7.3 Floor in front of the fireplace insert: 5

7.4 Chimney connection: 6

7.5 Primary walling and heat insulation of the

back and side walls: 6

7.6 Necessary primary walling and heat

insulation: 6

7.7 Permissible heat insulation and primary

walling material (minimum requirements) : 7

8. INSTALLATION OF THE FIREPLACE INSERT:7

8.1 Expansion joint: 7

8.2 Covering: 7

8.3 Convection air openings: 7

8.4 Convection air space: 7

8.5 Ornamental beams: 8

8.6 Fire protection within the radiation range: 8

8.7 Fire protection outside the radiation

protection: 8

9. INSTALLATION DRAWING: 9

10. OPERATION OF FIREPLACE: 9

10.1 Suitable fuels: 9

10.2 Combustion air supply: 10

10.3 Convection air: 10

10.4 Fire protection outside the radiation range:

10

10.5 Fire protection within the radiation range:

10

10.6 Protection against burns: 10

11. USE AND START-UP: 10

11.1 Initial start-up: 10

11.2 Lighting: 10

11.3 Maximum fuel charge quantity of

approximately 1 hour: 11

11.4 Air setting with closed operation: 11

11.5 Adding fuel: 11

11.6 Operating mode in the transition period: 11

11.7 De-ashing: 11

12. CLEANING AND CARE: 11

13. WARRANTY: 11

13.1 General 11

13.2 Warranty directives: 12

2. HAAS + SOHN does not accept any guaranty

for damages and defects on equipment or their

parts caused through: 12

13.3 Complaints: 12

14. INSTRUCTIONS FOR ORDERING

REPLACEMENT PARTS: 12

Congratulations! You are the owner of a HAAS +

SOHN fireplace insert, a quality product. Please

read the Operating Manual carefully. You will find

information about how to use and operate your

chimney stove which will enable you to increase

the practical value of the device and extend its

working life. In addition you can save fuel by

burning it correctly and protect the environment.

The accompanying Equipment Sheet is part of this

Operating Manual.

Please keep this Manual with the Equipment Sheet

in a safe place so that you can refamiliarise

yourself with the correct operation of your chimney

stove at the start of every heating period.

We can only guarantee our products if you adhere

to the following guidelines of this Installation and

Operating Manual.

2

Page 3

1.Description

Fireplace inserts are highly suitable for the heating

of living and working rooms.

The stove body consists of a welded steel

structure. At the bottom is a wood storage

compartment and above it the ash box, on top of

that the firebox and a heat exchanger at the top.

Between the latter the smoke gas draughts are

arranged above the firebox.

Heating the room air and creating a comfortable

living climate in connection with a covering is

substantially achieved through convection heat.

Because of this you can rapidly heat even cool

rooms that have not been heated for an extended

period of time. The room air enters the wood

storage compartment, is heated in the convection

duct between inner body and outer wall as it rises

and flows out again through openings provided at

the top of the stove. The component of radiation

heat is obtained through heat radiation in the area

of the view window of the firebox door from the

metal surfaces of the stove and - if available - from

the ceramic surfaces on the sidewalls.

2. General instructions, safety instructions

Adhere to national and European standards, local

regulations, planning and building regulations as

well as fire safety regulations. When installing your

stove you must observe the fire prevention

regulations and the national building regulations

applicable at the place of installation in agreement

with the responsible master chimney sweep of the

district. He will also inspect the appropriate

connection of the device to the chimney.

Prior to installation, verify that the carrying capacity

of the substructure is suitable to support the

heating insert. If the carrying capacity is

insufficient, suitable measures (e.g. slab for load

distribution) have to be taken to achieve this.

Your fireplace insert has been subjected to all

inspections required by the legislator. It meets the

specified characteristics in terms of firing efficiency

and smoke gas emissions.

Your fireplace insert of design 1 described in this

Manual has been tested according to DIN 18895

("Fireplace inserts for solid fuels") and EN13229.

The fireplace inserts of design 1 (see Equipment

plate) may be connected to a multiple-use chimney

if the chimney dimension according to DIN 4705

Part 2 allows this.

The fireplace insert is a limited time burning

fireplace.

Basic requirement:

- Ensure that the entire structure, i.e. also

connecting pieces and chimney, are

operationally safe and fireproof and can be

cleaned without effort!

Place of installation:

- Fireplace inserts must only be installed in

rooms and in places where, according to

position, structural circumstances and type of

use no hazards will develop. In the installation

area of the covered heating insert no electrical

wiring must be present in walls and ceilings. In

particular there must be an adequate inflow of

air for combustion in the installation rooms.

The surface area of the installation room must

be configured and of a size that allows proper

operation of the fireplace.

- Fireplace inserts must not be installed in:

staircases (except in residential buildings with

more than two apartments); generally

accessible hallways; rooms in which easily

flammable or explosive substances or mixtures

are processed, stored or produced in such a

quantity that hazards are created through

ignition or explosion; rooms or apartments

from which air is removed through ventilation

systems or warm air heating systems with the

help of fans, unless the operation of the open

fireplace without danger is ensured.

- The operation of open fireplaces is not

threatened if the systems circulate air only

within a room, the systems have safety

devices which automatically and reliably

prevent vacuum in the room of installation or

the volumetric combustion airflows required for

the fireplace inserts and the volumetric flows of

the ventilation systems despite adjustment or

removal of easily accessible control devices of

ventilation systems altogether will not bring

about a vacuum in the installation rooms of the

fireplace inserts and the rooms of the

combined ventilation greater than 4 PA.

3. Combustion air supply:

Ensure that the fireplace will have a minimum

inflow of 360 m³/h of combustion air per each m² of

firebox opening from the outside. Ask your master

chimney sweep responsible for your district.

Installation rooms of fireplace inserts must:

- Have at least one door into the open or which

are connected with other rooms of this type.

Only rooms of the same apartment or

utilization unit apply. If this is not sufficient, the

installation room must have a combustion

airline leading into the open and the firebox

opening with at least 360 m³/h of combustion

air for each m². If there are other fireplaces in

the same combustion air system, there must

3

Page 4

be a minimum inflow to the heating inserts of

540 m³/h of combustion air for each m² of

firebox opening and additionally at least 1.6 m³

of combustion air per hour for other fireplaces

and for each kW of total rated heat output with

a calculated pressure differential of 4 Pa

relative to the outside. (Not considered are

fireplaces which are independent of room air,

do not require a flue gas system or are located

in rooms from which the operational safety of

the heating inserts cannot be endangered).

- We recommend feeding the fireplace insert

with combustion air in the area of the

convection chamber.

- In accordance with the national building

regulations, combustion airlines in buildings

with more than two full storeys and combus tion

airlines bridging firewalls shall be established

such that fire and smoke cannot be transmitted

to other storeys or fire sections.

- When designing the combustion airlines,

resistances have to be taken in account which

in particular applies to the installation of bends

and deflections or long lines.

4. Suitable chimney:

Before installing the heating insert the responsible

master chimney sweep for the district must be

informed. Should the fireplace insert be connected

to an already existing chimney, the latter has to be

swept and checked by the chimney sweep for

condition and tightness. He would also establish if

the chimney is suitable for connecting the heating

insert.

If no chimney is present or the existing chimney is

not suitable, the master chimney sweep for the

district determines the dimensions of the chimney

to be newly erected according to DIN 4705 Part 1

and Part 2.

The effective chimney height starting from the flue

gas inlet must be at least 4 m.

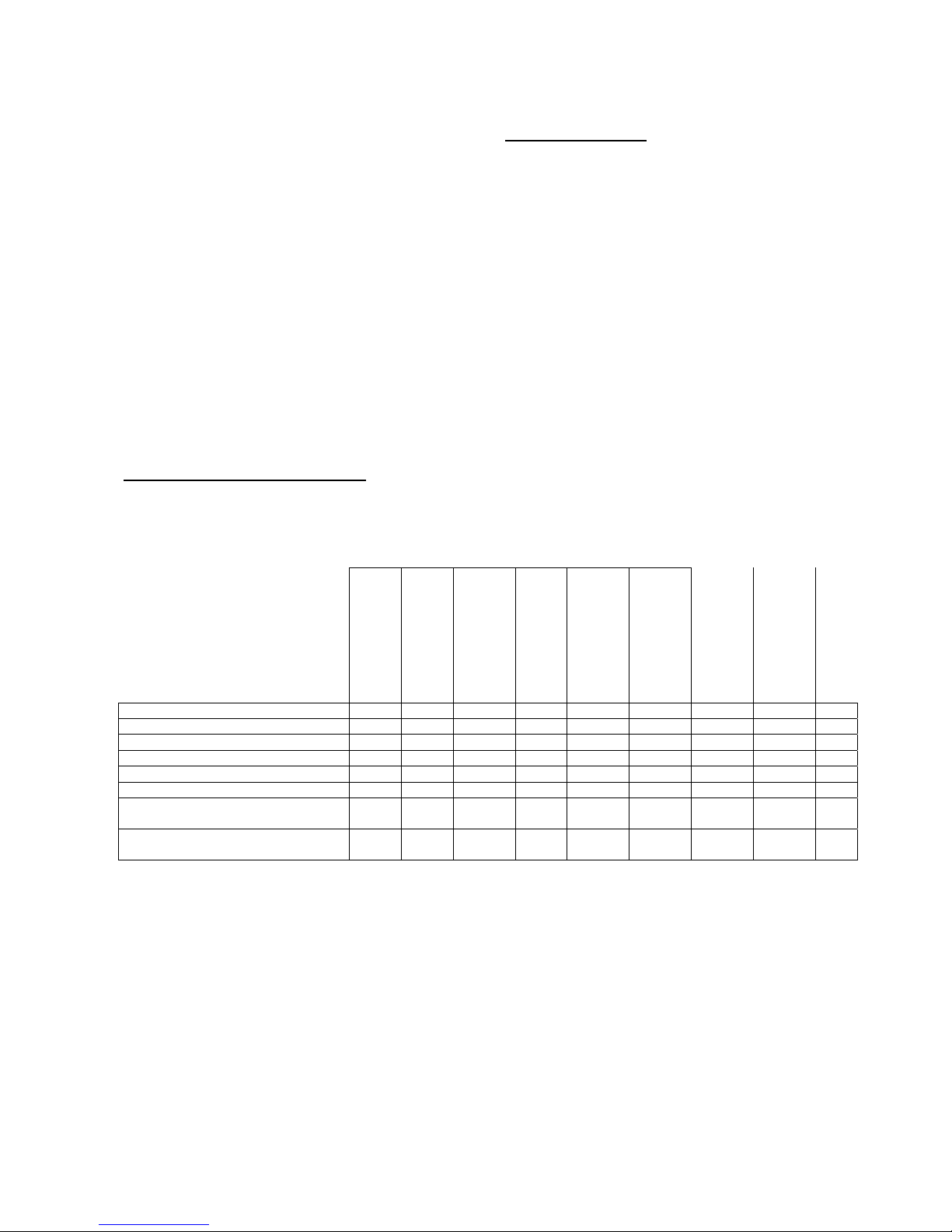

5. Data for chimney calculation:

The following data apply for dimensioning the chimney according to DIN 4705:

Operation with closed firebox:

Insert

Esprit

185.16

NHO

Insert

Esprit

185.16

Part

load

Insert

Trend

184.18

NHO

Insert

Trend

184.18

Part

load

Inserts

Komfort

180.18 +

Prestige

181.18 +

Exquisit

182.18

NHO

Inserts

Komfort

180.18 +

Prestige

181.18 +

Exquisit

182.18

Partload

Insert

Opus

186.18-1

NHO

Inserts

Opus

186.18-1

Part load

Net heat output 7 8 8 8 kW

Heat output area 8 3,7 8,5 4,6 9,2 4,7 8,5 4,5 kW

Flue gas mass flow 7 6,12 8 6,8/7,9 g/s

Mean flue gas connector temperature 290 272 330 320

o

C

Efficiency 80,7 83,2 81,7 80,3 %

CO 0,09 0,08 0,08 0,1 %

Minimum delivery pressure at rated

heat output

12 12 12 12/15

Pa

Minimum delivery pressure at 0.8

times the rated heat output

10 9 10 10/12

Pa

No data is listed for operation with open firebox since your fireplace insert must only be operated with the selfclosing door (A 1).

4

Page 5

6. Room heating capacity according to DIN 18893:

In this regard, please note the details on the Equipment sheet.

The values relate to rooms which do not correspond to the heat protection regulations. For rooms with a room

volume in excess of 200m

3

a heat requirement calculation according to DIN 4701 has to be carried out.

Insert

Esprit 185.16

Inserts

Komfort 180.18,

Prestige 181.18,

Exquisit 182.18

Trend 184.18

Opus 186.18

The rated heat output stated

on the equipment

plate with

7 kW 8 kW

- favourable 144 186 m

3

- less favourable 84 107 m

3

- unfavourable

Heating conditions are

adequate for:

56 73 m

3

7. Installation of fireplace insert and connection to the chimney

7.1 Connecting piece (flue gas pipe):

The connecting piece has to be technically

matched to chimney and fireplace insert and be

designed to suit the requirements of DIN 18160

Part 2.

In the case of metal connecting pieces the wall

thickness must be at least 2 mm.

If the connecting piece penetrates components

with combustible building materials (e.g. walls to

be protected), protective measures according to

DIN 18160 Part 1 and Part 2 have to be taken.

7.2 Protection of installation ceiling (floor):

Installation ceilings without adequate transverse

distribution (e.g. wooden ceilings) must be

protected through an additional 6 cm thick proven

concrete slab and a 6 cm thick heat insulation

layer according to AGI Working Sheet Q 132 in the

area of the heating insert. We recommend you

seek advice from a structural engineer.

If the installation floor has adequate transverse

distribution a 6 cm thick heat insulation layer is

sufficient.

7.3 Floor in front of the fireplace insert:

In front of the heating insert the floor of

combustible materials has to be protected through

a sufficiently thick covering of non-combustible

materials or replaced. The minimum dimensions of

this non-combustible area in front of the firebox

opening are:

To the front in accordance with the height (H) of

the firebox floor above the floor plus 300 mm.,

however at least 500 mm.

To the sides, in accordance with the height (H) of

the firebox floor above the floor plus 200 mm,

however at least 300 mm.

5

Page 6

7.4 Chimney connection:

If the existing chimney does not have a suitable

shaped connection piece for the fireplace insert a

subsequent connection has to be established. The

chimney connection height is obtained from the

correctly placed fireplace insert plus fitted smoke

gas bend and connecting piece, measured from

the upper edge of the support plate to the centre of

the connecting pipe in the inlet area of the

connection point. Please take into account the

necessary distances for primary walling, heat

insulation, expansion joint etc.

7.5 Primary walling and heat insulation of the

back and side walls:

Once a suitable chimney connection piece has

been installed the required primary walling and

heat insulation can be carried out.

7.6 Necessary primary walling and heat insulation:

The required minimum heat insulation in front of components to be protected was established during the

testing of the fireplace inserts Haas + Sohn according to DIN 18895 and EN 13229. The following protective

measures were determined:

Fireplace insert

ESPRIT 185.16

Fireplace

insert Op s

u

186.18

Fireplace inserts

KOMFORT 180.18,

PRESTIGE 181.18,

EXQUISIT 182.18,

TREND 184.18

Thickness in mm

Back wall

100

100

100

Primary walling

Side wall

100

100

100

(Primary walling replacement,

insulating material according

to AGI Q 132)

Room ceiling within

covering

60 60 60

Floor

40

40

Side wall

120

40

Termax

SN 400

120

Back wall

120

40

Termax

SN 400

130

Convection air ceiling

/intermediate ceiling

110 120 120

Heat insulation layer

Flue gas pipe outside the

convection jacket

60 60 60

1. Primary walling: 10 cm thick mineral primary

walling must be erected directly on the building

wall (back wall and if applicable side wall) to

be protected. The primary walling must be

erected up to the insulation layer and the

building wall to be protected, however protrude

at least 20cm over the connecting piece (flue

gas pipe). Primary walling can be omitted if the

building wall is at least 10cm thick and

consists of non-combustible components and

is not a carrying reinforced concrete wall.

2. Room ceiling above the heating insert (primary

walling replacement): If the cavity or the

covering above the fireplace insert reaches up

to the room ceiling this must be protected if it

consists of combustible materials or serves as

a carrying element. The protection consists of

an at least 6 cm (better 10 cm) thick heat

insulation layer (insulating material code

number: 12.07.21.75.11 according to AGI Q

132). This protective measure is

recommended as load-bearing intermediate

ceiling (e.g. of plate) with heat insulation layer

arranged on top.

3. Heat insulation: Convection jacket and

convection hood (external equipment shape)

must be covered with a heat insulation layer

on all sides. The heat insulation must be butt

joined without any gap and installed in an

overlapping arrangement on the sides. If these

insulation panels are not held by walls,

coverings or adjoining panels, these shall be

attached at a distance of approximately 30 cm.

The room-side covering (apron) need not be

heat-insulated if the heating insert design is

such that the free surfaces of the covering and

the surfaces of the recesses for fuel storage

can heat to a maximum of 85°C. In the case

of surfaces of mineral building materials,

except surfaces on which items can be placed,

the value of 85°C is replaced with the value of

120°C. The heat insulation layers of mineral

wool or comparable must be tightly covered

towards the installation room and convection

air room to prevent flying fibres.

6

Page 7

7.7 Permissible heat insulation and primary

walling material (minimum requirements) :

1. Insulation materials: Insulation materials

according to AGI working sheet Q 132:

12.07.21.70.09 (=insulation material code

number).

This means: Insulation material group 12, Type:

stone wool,

Form of delivery group 07, Shape: Tiles,

Heat conductivity Group 21, Supply form:

G.-Curve 2

Upper application limit temperature

Group 70 corresponds to 700°C

Rated pipe density Group 9 corresponds to

90 kg/m³

2. Primary walling:

Brick tiles according to DIN 105 Part 1 and

Part 3

Bricks according to DIN 106 Part 1, DIN

4163, DIN 18151 or DIN 18152

Wall building tiles according to DIN 4166,

DIN 18162 or DIN 18163

3. Alternative primary walling and insulating

materials:

These are approved by the German Institute for

Building Technology, Berlin (DIBt). They also

mostly meet the material requirements of heat

insulation and primary walling. Details on these

building materials can be obtained from your

specialist suppliers.

8. Installation of the fireplace insert:

Once the heat insulation has been carried out

according to the insulation instructions, the

fireplace insert can be placed on the prepared

surface. Align the fireplace insert with the adjusting

screws and connected to the chimney using the

connecting piece (smoke pipe).

The chimney connection must be carried out in

keeping with DIN 18160 Part 1 and Part 2 (see

Page 5, Paragraph 7.1).

8.1 Expansion joint:

An expansion joint must be provided between

insert and covering which is closed with sealing

cord or sealing band.

8.2 Covering:

The covering of the fireplace insert on the room

side must consist of non-combustible

materials of fire protection Class

A1 (e.g. glazed bricks, plaster on

plaster substrates, metal or ceramic

oven tile). There must be no direction

connection between

covering and fireplace

insert.

Caution! The covering of

the chimney apron must

only rest on a separate support

frame which is normally mounted to the wall.

8.3 Convection air openings:

The free non-obstrutable cross section for the air

inlet and air outlet openings must be at least 600

cm

2

each.

Caution: After the installation of the entire chimney

neither the convection air inlet nor the outlet must

be obstructed by any components whatsoever. To

avoid heat congestion, convection air inlet and

outlet openings or grilles have to be always open

during heating operation. No closable grilles, fins,

louvers and the like may be installed in such

openings. Convection air cross sections between

heating insert and covering as well as rear

insulation: free minimum distance between

fireplace insert and lateral covering of noncombustible material: 50mm.

Free minimum distance between fireplace insert

and rear insulation or placement wall of noncombustible material: 100mm.

Note: The minimum distance stated above must be

maintained over the entire height of the fireplace

insert over the entire width in each case so that the

convection air is able to flow through freely.

8.4 Convection air space:

Since the fireplace insert does not have a

prefabricated convection air chamber device a

distance to both sides of 60 mm must be taken into

account between fireplace insert and heat

insulation layer. The heat insulation layer as

radiation protection equaliser and protection

against flying fibres must be covered with a tight

sheet metal jacket of galvanized sheet metal.

The convection air openings must at least meet

the cross section mentioned above.

7

Page 8

8.5 Ornamental beams:

Ornamental beams in front of the covering of

the fireplace insert are permissible at a

distance of at least 1 cm if the ornamental

beam is not part of the building and the

intermediate spaces to the covering are clear

so that no heat congestion can develop and

the ornamental beam is not located in the

radiation range of the fireplace insert.

Figure:

1 = Fireplace

insert

2 = Expansion

joint

3 = Covering

4 = Ornamental

beam

5 = Support frame

6 = Radiation

protection

8.6 Fire protection within the radiation

range:

At least 80 cm distance has to be maintained

from the firebox opening to the front and to

the sides (6). If radiation protection that is

ventilated on both sides is arranged, a

distance of 40 cm is sufficient.

8.7 Fire protection outside the radiation

protection:

From the outer surfaces of the covering of the

fireplace insert at least 5 cm distance to

combustible components must be maintained.

The intermediate space must be open for

airflow so that no heat congestion develops

(8).

Components which cover only small areas of

the fireplace insert covering such as floors,

butt-joining wall coverings and insulation

layers on ceilings and walls may be joined up

to the covering without spacing (9). Other

wider, strip-shaped and combustible

components such as ornamental beams are

permissible at a distance of 1 cm from the

covering of the fireplace insert (see

ornamental beam).

8

Page 9

9. Installation drawing:

fireplace insert according to DIN 18895 /EN13229 without factory-made convection air jacket

1. Ceiling to be protected of combustible

components or as carrying building

element

2. Substitute material:

Carry out heat protection measure

according to DIN 18160

4. Connecting pieces of steel plate

5. Heat insulation layer:

Rear wall (see Page 5),

Side wall ceiling (see Page 5),

Convection air chamber (see Page 5)

6. Primary walling

7. Wall to be protected of combustable

building materials or carrying building

element of concrete or reinforced

concrete

8. Combustion air supply

9. Outside airflap

10. Heat insulation layer

11. Support plate

12. Installation floor to be protected of

combustible building materials or carrying

building element

13. Shielding floor protection of noncombustible building materials

14. Convection air inlet (circulating air)

15. Covering

16. Fireplace insert

17. Support frame

18. Ornamental beam

19. Throttle valve

21. Air outlet grille

22. Support element

23. Heat insulation layer (primary walling

substitute) 6 cm thick

24. 80 cm radiation ran ge

25. Sheet metal covering convection air

chamber

10. Operation of fireplace:

The fireplace inserts of Haas + Sohn with self-closing door have the designation fireplace insert EN13229-W

Design 1 which means they are only suitable for operation with closed fire box and must only be operated with

closed firebox.

In the case of stoves of Design 1 the closing springs of the firebox door must not be removed if such a device

is connected to a chimney with multiple connections. The inclusion in Design 1 is defined by the self-closing

firebox doors. The firebox doors must only

be opened only to charge fuel and for removing ash. Otherwise

these must be kept closed even if the stoves are not operated in order to avoid interference with other

fireplaces and hazards connected with this.

10.1 Suitable fuels:

The fireplace inserts must only be operated with the following fuels and closed firebox:

• Plain dry billet wood

• Wood briquettes according to DIN 51 731 HP 2

9

Page 10

Caution! Wood it not a slow-burning fuel so that

continuous heating of the fireplace with fuel

overnight is not possible.

The fireplace insert is intended for the burning of

dry billet wood with a maximum water content of

30% of the dry weight. Billet wood should be

stored in airy and dry places for 2 years.

Excessively moist wood increasingly results in

smouldering with tar and condensate formation

which can damage the chimney. At any rate,

excessive device contamination occurs. The billet

wood length should be around 33 or 50 cm.

If incorrect or excessively moist fuel is used a

chimney fire can occur because of deposits in

the chimney. Immediately close all air

openings in the stove and inform the fire

brigade. Once the chimney has burnt out have

it inspected for cracks or leaks by an expert.

Wood is a highly de-gassing fuel and requires a lot

of top air (secondary air). Light or slow-burning

control with this fuel is not possible. The heat

output in the combustion of wood is always

determined by the amount charged.

Firing of properly dried wood is the most

economical and most environmentally friendly

combustion since the calorific value of fresh wood

is substantially less than that of dry wood.

The burning of waste, especially plastic, packaging

material, coated and treated wood harms your

fireplace insert and is additionally prohibited by the

Federal Emission Protection Law. Brush wood,

paper and small wood pieces must only be used

for lighting.

Caution: Never use easily combustible liquids

such as petrol, spirits for lighting and always

keep such liquids away from your fireplace

insert.

10.2 Combustion air supply:

With both the open and closed operation of the

fireplace carries a high demand for fresh air. Do not

change existing precautions for combustion air

supply. Ensure that the necessary combustion

airlines are open while the fireplace is operated.

10.3 Convection air:

To avoid heat congestion the convection air inlet

and outlet grilles must always be open during

heating operation.

10.4 Fire protection outside the radiation

range:

No objects of combustible building materials (e.g.

shelves) must be placed closer to the open fireplace

than a distance of 5 cm.

10.5 Fire protection within the radiation range:

Seen from the firebox opening forward and to the

sides, no combustible components must be

present (e.g. furniture, carpets, flowers etc.) in a

range of at least 80 cm.

10.6 Protection against burns:

It is imperative to note that there are hot surfaces or

operating handles present on heating devices which

are in operation. Please use the enclosed protective

glove to operate the fireplace. Presence in the 80

cm radiation range is only advisable to charge the

fuel, prolonged presence there can result in skin

burns. Keep children away from fireplaces in

operation.

When operating the device ensure that adequate air

is supplied to the room from the outside.

11. Use and start-up:

11.1 Initial start-up:

When using the fireplace insert for the first time

burn it with moderate output to avoid possible

damages due to heating it up too quickly

(especially drying of the refractory brick lining). On

initial heating, smell and smoke will develop due to

the curing of the surface coating. Ensure the room

is well ventilated during initial start-up.

11.2 Lighting:

The fireplace insert is charged with fuel through

the firebox door.

Initially place 3 to 4 wood billets (approx. 2.0 to 2.5

kg) on the firebox floor or grate, uncoated paper on

top, cardboard or an igniting cube, brushwood,

small wood pieces or briquette pieces on top of

this. Open all existing air control dampers to the

maximum. After igniting, close the firebox door.

Then set the air control dampers in accordance

with the instructions on the enclosed Equipment

Sheet.

Your fireplace insert is equipped with a typical

design flat firing system which means that only one

layer of fuel must be charged on the basic embers.

Please note that the quantity, the size of the

pieces and the kind of the wood charged has a

direct influence on the heat output.

When feeding excessive fuel quantities your fire

insert can be heated in excess of what is intended

by the design. This can damage the fireplace

insert, other parts of the chimney of the building

itself. Never charge more than the stated fuel

quantities at one time on the existing basic

embers.

10

Page 11

11.3 Maximum fuel charge quantity of approximately 1 hour:

Total quantity Fuel Quantity

Esprit

185.16

Komfort 180.18, Prestige 181.18,

Exquisit 182.18 Trend 184.18, Opus

186.18

Billet wood 2 – 3 billets 2,0 kg 2,5 kg

Wood

briquettes

4 – 5 small pieces

(Divide large briquettes if required)

1,8 kg 2,1 kg

11.4 Air setting with closed operation:

The fireplace inserts of Haas + Sohn have an

adjustable air damper. The required combustion

air enters as primary air through the grate and the

lateral ducts and the firebox as window flushing air

above the firebox door.

11.5 Adding fuel:

In addition to the use of suitable fuel and

adequate fuel draught the manner in

which the fireplace is operated also has

major influence on keeping the view

window clean. In this connection we

recommend to charge only one layer of

fuel, to use preferably long (approx.. 33 or

50 cm) which largely fill the firebox width.

Briquettes should be arranged in the

firebox so that they preferably fill one layer

(approx. 5 to 10 mm distance between the

briquettes).

Caution! Add additional fuel only on the basic

embers (no flames present).

Approximately 5 to 10 seconds before opening the

firebox door completely close the primary air

damper or dampers (see Equipment sheet) to

prevent the leaking of smoke gases from the

combustion chamber into the living room. Having

charged the fuel, please close the firebox door

again. After this, immediately set all air dampers to

maximum opening to keep the time span to the

igniting of the fuel as short as possible. As soon

as the fuel burns lively re-establish the control

setting as described on the enclosed Equipment

Sheet.

11.6 Operating mode in the transition period:

In the transition period or with elevated outside

temperatures, problems with the chimney draught

can occur in the event of a sudden temperature

increase so that the flue gases are not fully

extracted. For this reason, always operate the

stove in the transition period only with the least

amount of fuel possible in order to be able to

improve the combustion and draught situation in

such cases by opening the air dampers.

11.7 De-ashing:

Following prolonged burning, at least once per

day, remove the ash with the help of a poker

through the grate in the ash box and empty the

ash box. This is best done in the morning after the

embers has left the fireplace in a relatively cold

state. Please ensure that the ash box is emptied

when approximately half full so that the ash cone

does not grow up too closely to the grate.

If the grate is packed in the ash cone there is a risk

that it is damaged through overheating since it

cannot be circulated by any air.

Caution!

Before emptying ash always ensure that there is

not residual embers in the ash. Even if the ash is

cold remnants of embers may still be present and

result in a fire in a waste container.

Wood ash can be composted and used as

fertilizer.

12. Cleaning and care:

At least once per year, if required more frequently,

clean and look after your fireplace insert in the cold

state. When doing so, remove the ash deposits in

the smoke pipe and on the smoke deflection plates

or draught deflection plates. Draught deflection

plates of vermiculite can be removed for cleaning

(see Equipment sheet). Please reinstall these

carefully in the same position after cleaning. For

cleaning the smoke gas draughts an ash extractor

with fine particle filter is best suitable. Dirt on the

view windowpane is best and most

environmentally friendly removed with a scouring

pad moistened in water which you dip in the wood

ash or other domestic glass cleaners. The chimney

must likewise be regularly cleaned by the chimney

sweep.

Your master chimney sweep will inform you on the

necessary intervals.

The chimney stove should be checked by an

expert once per year.

13. Warranty:

13.1 General

HAAS + SOHN accept three years guarantee for

this device within the scope of the warranty

directives with the exception of parts which are

directly exposed to the fire (wear parts). The

guaranty commences on the day of delivery. The

invoice must be presented as proof.

11

Page 12

13.2 Warranty directives:

1. HAAS + SOHN accept guaranty for the duration

of three years calculated from the delivery to the

end user for

a) unobjectionable material condition and

workmanship to suit the purpose,

b) expert assembly,

c) Adherence to the rated heat output (watt)

according to DIN 18895/ EN 13229 and the

room heating capacity according to DIN 18893

(see Equipment plate, technical data on the

enclosed Equipment sheet or catalogue

details).

The warranties a) to c) extend to the repair of the

device or the parts subject of the complaint free of

charge. Entitlement exists only for the free of

charge replacement of parts having defects in the

material and in the workmanship. Claims beyond

this are excluded.

We provide 6 months guaranty for wear parts in

the fire area such as refractory, vermiculite, fire

grate, glass ceramic and seals as well as

operating elements such as handles and painted

surfaces.

2. HAAS + SOHN does not accept any guaranty for

damages and defects on equipment or their parts

caused through:

• External, chemical or physical effects during

transport, storage, installation and utilisation of the

device (e.g. quenching with water, food cooking

over, condensate, overheating due to incorrect

operation (e.g. open firebox door), or hair crack

formation in natural stones or enamelled parts are

not considered a quality defect,

• Incorrect choice of chimney stove size,

• Failure to heed the building regulations applicable

from time to time,

• Errors in the installation and connection of the

device,

• Insufficient or excessive chimney draught,

• Incorrectly performed repair operations or other

especially subsequent changes to the fireplace or

flue gas pipe (smoke pipe and chimney),

• Use of unsuitable fuels,

• Incorrect operation: Overloading the devices (see

Operating Instructions of the manufacturer)

• Wear on the parts of steel, glass ceramic seals,

refractory or vermiculite directly exposed to the

flames insofar as not included in the warranty (1a),

• Incorrect treatment,

• Insufficient care, use of unsuitable cleaning agents.

13.3 Complaints:

Please present your complaints only to your

specialist dealer. When doing so, it is

imperative that you should name the type

and manufacturing number of your chimney

stove. This information can be found on the

nameplate of the device (in the wood

storage compartment of the device).

14. Instructions for ordering replacement parts:

When ordering replacement parts please state the

complete type and manufacturing number of your

chimney stove. These details can be found on the

nameplate of the device (in the wood storage

compartment of the device).

Also pay attention to the technical drawings and

tables on the Equipment Sheet where you will find

the correct designation of the required

replacement parts. For ordering refractory

replacement parts, the refractory bricks in these

drawings are numbered and the refractories are

viewed from the top in these drawings (top view).

Caution! Do not change the fireplace!

Use only replacement parts that have been

expressly approved or are offered by the

manufacturer.

If required, please contact your specialist dealer.

12

Loading...

Loading...