Page 1

Art. no. 0541708009030

V11 D19

Pelletto / Pallazza Stove

417.08 / 432.08 / 517.08

Installation and operating instructions

! Important manufacturer’s instructions!

Please observe the following instructions:

Quality of wood pellets:

Depending on the manufacturer there are light, dark, shorter and longer pellets. And the quality of one delivery may

differ from another even from the same supplier. The standards for wood pellets are becoming more and more strict

but wood is wood and has its own characteristics regarding ash and clinker.

Your HAAS+SOHN stove

Cleaning requirements:

As soon as you find ash and clinker deposits in the cold combustion pot, it must be cleaned. See operating

instructions! If this is not done, there will be more and more clinker. Then the device will no longer be able to ignite

properly. Pellets may pile up in the combustion pot. In extreme cases, this can reach all the way back to the pellet

chute. Backfire in the pellet container and smouldering in the pellet tank might possibly result. This will destroy

your device and is not covered by the guarantee.

For maximum working life:

• Arrange for commissioning by your trained stove supplier.

• Observe the daily check as described and more frequently if you have received new pellet deliveries or when

the device is brought back into use after the summer.

• Carefully read through all the operating instructions and retain them.

Space for type number and manufacturer’s number:

Type number:

Manufacturer’s number:

Page 2

2

Index of contents

1.

Description 3

2. General instructions, safety instructions 3

3. Installation of the pellet stove and

connection to the chimney 4

4. The pellet stove’s functional

characteristics 6

5. The pellet stove’s operating statuses: 6

5.1. Ignition phase 6

5.2. Heating mode 6

5.3. Burner test 7

5.4. Cooling down 7

5.5. Standby 7

5.6. Safety shutdown (shutdown) 7

5.7. Faults 7

5.8. Switching off – operating status OFF 8

5.9. Power cut 8

5.10. Overheating 8

5.11. Low temperature shutdown 8

6. Description of operator console keys 8

6.1. Operator console 8

6.2. Information screens 9

6.2.1 Info screen 1 (standard screen) 9

6.2.2 Main menu 9

6.2.3 Setting the operating mode 9

6.2.4 Setting the time and date 9

6.2.5 Setting the times and target room

temperatures in automatic mode 9

6.2.6 Setting target room temperature in

heating mode 9

6.2.7 Fault screen 10

6.3 Setting the language 10

6.4 Description – Heating profile 10

6.5 Description – Key lock (child-safe) 10

6.6 Description – Display brightness – contrast

setting 10

7. Operating the pellet stove 10

7.1. Fuel 10

7.2. Commissioning your pellet stove 11

7.3. Selecting the operating mode 11

7.3.1 “Heating” operating mode 12

7.3.2 Setting the target room temperature

in “Heating” operating mode 12

7.3.3 “Auto” operating mode (weekly

programme) 12

7.3.3.1 Setting date and time 12

7.3.3.2 “Auto” operating mode (weekly

programme) 12

7.3.3.3 Setting the target room temperature in

“Auto” operating mode (weekly

programme) 12

7.3.3.4 Example of programming for

“Monday” 13

8. Cleaning and maintenance work 13

8.1 Cleaning the surface 13

8.2 Cleaning the glass panel 13

8.3 Cleaning the combustion pot 13

8.4 Removing the ash from the combustion

chamber 14

8.5 Cleaning the pellet container 14

8.6 Cleaning the flue gas passes and the flue tubes

15

8.7 Cleaning the induced draught housing and fan15

9. Description of the components 166

9.1 Storage container (pellet tank) 16

9.2 Screw conveyor motor and screw conveyor 166

9.3 Combustion pot with tray: 16

9.4 Electric ignition 16

9.5 Control unit 17

9.6 Operator console 17

9.6.1 Backlighting 18

9.6.2 Activating the backlighting 18

9.7 Induced draught fan with rotation speed

feedback 18

9.8 Flame or combustion chamber temperature

sensor (combustion chamber thermosensor) 18

9.9 Flue gas thermosensor 18

9.10 Room temperature sensor 18

9.11 OC Overheat cutout 19

9.12 Combustion chamber cladding 19

9.13 Flue tube connection 19

9.14 Mains cable and master switch 19

10. Technical data 19

11. Faults, causes, correction 22

12. Type plate: Symbol 27

13. Replacement parts list 30

14. Circuit diagram 31

15. Guarantee 33

Page 3

3

Congratulations! You are the owner of a HAAS + SOHN

pellet stove, a quality product. Please read through

these instructions carefully. They will tell you all about

the functions and operation of this stove, which will

increase the utility of this device and extend its working

life. What is more, with the correct heating you can save

fuel and protect the environment.

We can only give a guarantee on our products if you

observe the following instructions in these installation

and operating instructions. In addition, the stove must be

correctly installed so as to prevent possible accidents.

Look after these instructions well, then you will be able

to familiarise yourself with the correct operation of your

stove at the start of every heating period.

Note:

The installation and operating instructions given in this

manual may differ entirely or in part from public authority

instructions. In that event, the public authority

instructions always apply! The drawings in these

instructions are not to scale and serve only as

illustrations.

1. Description

Pellet stoves are particularly suitable for the constant

heating of residential and work rooms. The

HAAS+SOHN pellet stove is set up to operate in fully

automatic mode, with a choice of 2 operating modes

(“Heating” and “Auto” with a weekly programme).

Depending on the room temperature and on the model,

a volume of fuel for a maximum of 30 hours of constant

operation may be stored in the built-in storage container.

The fuel is fed automatically from the pellet tank to the

grate via a screw conveyor, with the quantity of fuel

automatically being adjusted to the relevant heat output.

The internal control unit regulates the ignition phase, the

heating phase and the cooling down phase, thereby

guaranteeing safe operation of the pellet stove. The

operator console, which consists of a display and four

function keys, is built into the pellet tank cover.

On the display’s information screen the operator can

read the operating status that the stove is currently in,

this being displayed as text. Any error messages are

shown on the display as text complete with the date and

time.

The heating of the air in the room and the creation of

comfortable living conditions is mainly achieved by

convection. This allows you to quickly warm up even

cold

rooms that have been unheated for a lengthy period.

The cooler air of the room enters the stove at the bottom

of the cladding, is heated and flows out again at the top

in the area of the slats. The proportion of radiant heat is

given off by radiation in the area of the viewing window

of the combustion chamber door and from the stove’s

metal surfaces.

2. General instructions, safety instructions

• Before commissioning the pellet stove read the

entire installation and operating instructions through

thoroughly.

• Only permitted handling gear with sufficient

loadbearing capacity may be used for moving your

device.

• Your heating device is not suitable for use as a

ladder or mounting frame.

• For the installation of your stove, the fire protection

authority’s regulations and the local building

regulations in force at the installation site are to be

observed and you should also discuss this with the

district heating inspector. He will also check that the

connection of the device to the fireplace is carried

out correctly.

• All the checks required by law have been performed

on your stove. The mandatory indices regarding

technical combustion efficiency and flue gas

emissions are observed.

• The pellet stove may be connected to a multiple-use

chimney provided that the chimney dimensions

permit this according to DIN EN 13384-1 or DIN EN

13384-2. The supply pressure must be at least 6

Pa and should be 15 Pa as a maximum.

•

L The combustion chamber door may be opened

only

for cleaning and maintenance during operating

status “Off”. Otherwise it is to be kept closed – even

when the stove is not operating in order to avoid

affecting other heating appliances and the

associated risks.

• An adequate supply of fresh air must be guaranteed

to the room where the stove is installed. However,

the pellet stove offers you the option of a direct

connection to the outside air via a suitable air duct.

So operation independent of the air in the room is

possible. (See Section 3 “Installation of the pellet

stove and connection to the chimney”).

•

L Attention! The pellet stove may not be set

up to be operated jointly with the home’s air

conditioning and ventilation units.

Page 4

4

• The chimney (fireplace or flue) must be made of

stainless steel or ceramics (glazed internally) and

suitable for wet operation so that it cannot rot.

• The pellet stove cannot be connected to the mains

electricity until it has been correctly connected to the

fireplace.

• The pellet stove may not be installed in the open

air!

•

L Attention! The mains cable plug must remain

freely accessible after installation.

• The pellet stove may only be operated with standard

wood pellets (6 mm diameter). (See Section 7.1

“Fuel”).

• The protective grille located in the pellet container

must not be removed.

•

L Attention! The Pelletto stove may only be

operated with the tank cover closed.

• Placing non-heat-resistant materials or objects on

the stove or within the specified minimum distances

is forbidden. Here please note in particular that

during “Standby” operating status, the stove may

unexpectedly and unintentionally start heating when

the room temperature falls below the desired

temperature.

• Never use liquid fuels to ignite the pellet stove or to

revive existing embers.

• With the burning up of fuels, heat energy is

released, leading to strong heating of the heating

device’s surfaces (e.g. doors, door and control

handles, viewing window panels, side walls, front

wall, flue tubes). Touching these parts without

suitable heat protection gloves or a tool is to be

avoided!

• The device ignites by itself in “Standby” mode.

Because of the heat generated on the panel, make

sure that no-one who is unfamiliar with the operation

of the pellet stove is unsupervised in the room where

it is installed.

• Bring these risks to your children’s and guests

attention!

• In particular, any cleaning staff should be informed

and instructed regarding the possible unexpected

heating up of the stove.

• Placing non-heat-resistant objects on or near the

heating device (even when it is cold, since it can

ignite again by itself) is forbidden!

• Do not lay any laundry on the stove to dry!

• Clotheshorses for drying clothes and the like must

be positioned at sufficient distance from the heating

device – fire risk!

• When operating your heating device, it is forbidden

to work with highly flammable or explosive

substances in the same room or an adjacent one!

3. Installation of the pellet stove and connection to

the chimney

The packaging on your new pellet stove gives it optimum

protection against damage. Nevertheless, damage may

have occurred to the stove or to accessories in transit.

Please therefore check your stove after unpacking for

damage and completeness! Report any defects or

anything missing to your specialist stove dealer without

delay!

Remark: Combustion chamber cladding that is loose or

has come off its fastenings and the like are not defects.

(See Section 7.2. “Commissioning your pellet stove”).

The packaging on your stove is by and large

environmentally neutral. The timber packaging is not

untreated. The timber, the cardboard and the films can

be taken without problems to your local recycling centre.

For the correct operation of your pellet stove it is

important that it stands horizontally

.

The room temperature sensor that is located on the back

wall has a length of about 1.5 m and should be

positioned hanging free at the back.

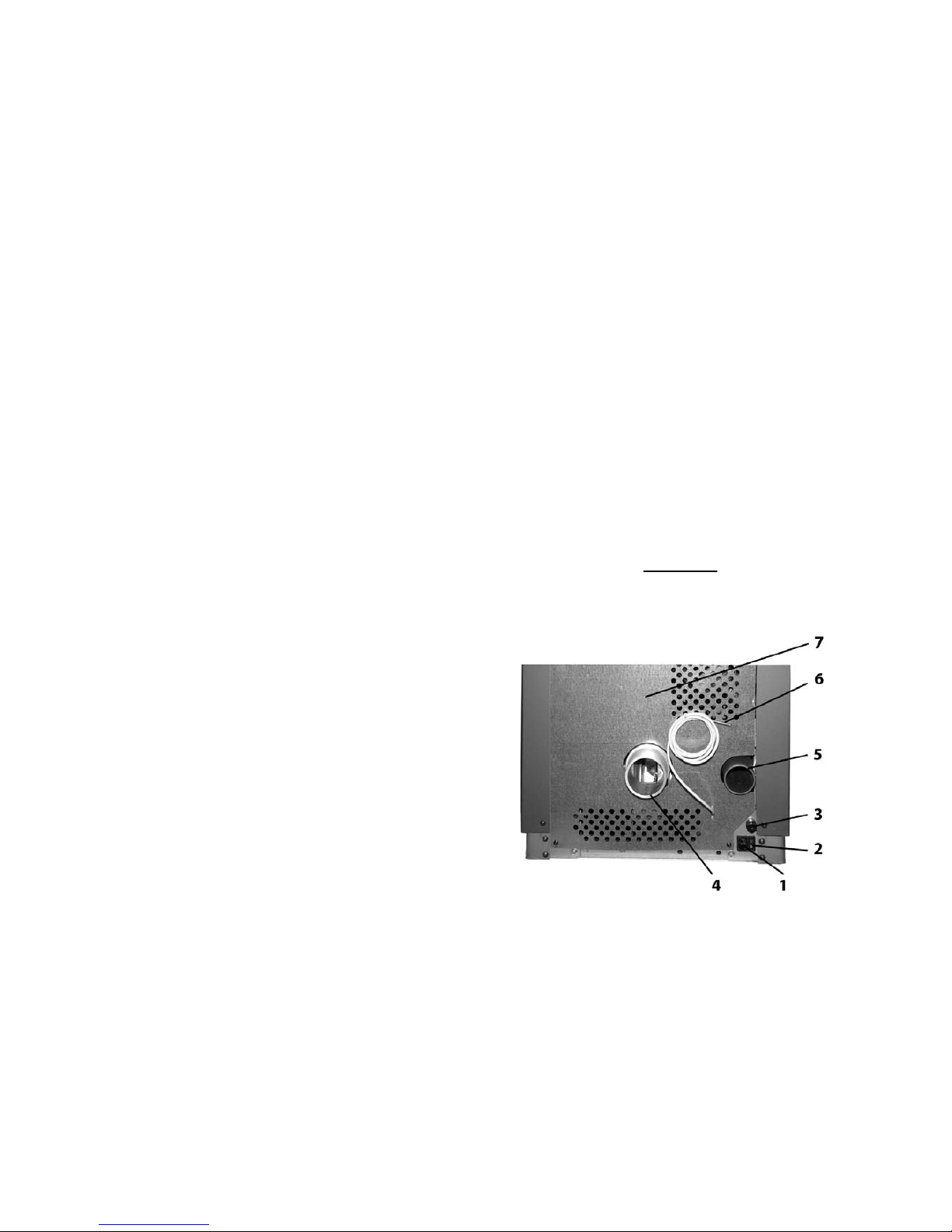

Figure 1: Back connections

1 = Mains electricity socket

2 = Main On/Off switch

3 = OC overheat cutout

4 = Fume elbow 80 mm

5 = Outside air connection 50 mm

6 = Room temperature sensor

7 = Bottom of back wall

Page 5

5

Floor protection

The floor is to be protected from the radiant heat from

the area of the viewing window (combustion chamber).

In addition, for practical reasons associated with

cleaning it is recommended that you install your pellet

stove on a fireproof base that extends beyond the device

at the back and on the sides by at least 5 cm and at the

front by at least 50 cm. We have floor protection plates

(underlay plates or U plates) in our range of accessories.

If required, you may order them from your specialist

stove dealer. As an alternative, a tile or stone floor is of

course very suitable.

Safety gaps (minimum gaps):

During installation of the stove it is absolutely essential

to observe the official fire protection regulations. Ask

your district heating inspector about this.

The following must be maintained as the minimum

distances from flammable or temperature-sensitive

materials (e.g. furniture, wallpaper, wooden cladding)

and from loadbearing walls. (See drawing):

A 5 cm from the back wall

B 10 cm from the side walls and

C 80 cm in the direction of radiation.

Figure 2: Safety gaps

The chimney (fireplace or flue) must for example be

made of stainless steel or ceramics (glazed internally) so

that it cannot rot. This is necessary because of the low

temperature of flue gases from your pellet stove.

Standard trade flue tubes may be used for the

connection to the fireplace. Approved Flex steel flues

are also suitable.

Since excess pressure may build up at the smoke outlet

because of the way that the pellet stove works with an

induced draught fan, all fume outlet pipes as far as the

intake to the fireplace must be gas-tight. It is also

essential to ensure that the flue tube does not stick out

into the open cross-section of the chimney. The use of

wall lagging is recommended for the insertion into the

chimney. (See Figure 3).

With longer flue gas pipework, horizontal sections and

constrictions must be avoided and specially insulated

flue tubes should be used. Pipework rising in the

direction of the chimney is recommended.

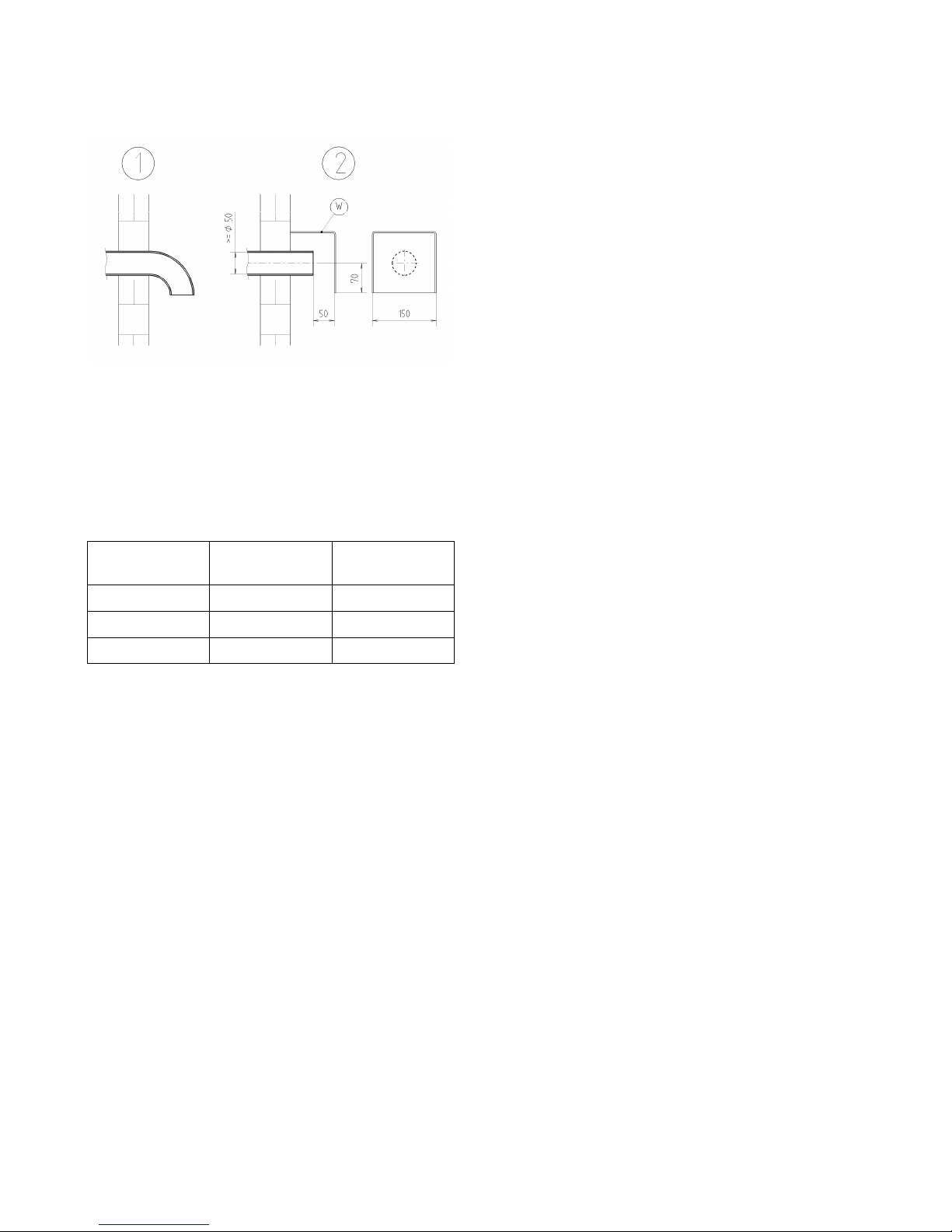

Figure 3: Chimney connection

1 = Wall lagging

2 = Gas-tight pipework

3 = Underlay plate

External air intake:

In airtight buildings, whilst the pellet stove is operating, a

reduction in the oxygen level in the room where the

stove is installed may occur, so adequate ventilation

must be ensured. For this the pellet stove offers you the

option of operating independently of the air in the room.

To do this, connect the air intake elbow located on the

back (diameter: 50 mm) to a hose or a similar suitable

air duct. The end of the air duct must be located in the

open air or in a well-ventilated room within the building.

When installing the pellet stove in combination with

controlled residential room ventilation, the end of the air

intake duct must not be connected to the ventilation

system in an adjacent room with the air connection

system. To ensure sufficient volume of air intake, the

pipe should not be longer than about 3 m and not have

too many bends. This pipe should have a

Page 6

6

minimum diameter of 5 cm. (The bigger, the better). If

the pipe goes to the open air, it must end with a

downward 90° bend or with wind protection. (See Figure

4).

Figure 4: Wind protection of the air intake pipe

The following table applies to the sizing of the air intake

pipe:

Diameter of the

intake pipe *

Maximum

length *

Max. number of

90° bends

50 mm 0.5 m 1

70 mm 1 m 1

100 mm 3 m 3

*The figures given apply as appropriate. With a flat duct

or similar, a suitable cross-section is to be chosen.

If the pipes are narrower than these dimensions, it may

be that the volume of combustion air is insufficient. This

will result in heavier buildup of clinker in the grate and

thereby to safety shutdowns.

Connection to the electricity supply:

Connect the stove to the electricity supply with the mains

cable supplied. (See Figure 1).

4. The pellet stove’s functional characteristics

Your pellet stove is designed to operate in such a way

as to maintain a constant comfortable room temperature.

The generation of heat in the stove is therefore

automatically controlled by the desired room

temperature (target temperature) set by the operator.

Depending on the difference between the target

temperature and the current room temperature (actual

temperature) the control unit selects output or “Standby”

mode in a modular fashion. So the pellet stove

guarantees the best possible adjustment of

the combustion behaviour of the pellet stove for the

situation in the room where it is installed without

constant manual corrective measures.

5. The pellet stove’s operating statuses:

The operation of the pellet stove is characterised by 8

operating statuses:

The ignition phase begins if the current room

temperature falls below the set target temperature by

1ºC and the stove has cooled down to a temperature of

below 80C°.

5.1. Ignition phase

In the “Ignition phase” the grate is filled with a precisely

defined quantity of fuel and this quantity of fuel is ignited

with a glow igniter.

The “Ignition phase”, which is divided into 10 zones, is

ended after reaching a precisely defined temperature on

the “flame temperature sensor” and the control unit

switches to “Heating Mode” operating status.

The duration of the “Ignition phase” may vary but it is

restricted to a maximum length of about 20 minutes.

If during these 20 minutes no flame is formed or the

required temperature is not reached at the “flame

temperature sensor – flue gas”, a safety shutdown is

initiated.

Here the rotation speed of the induced draught fan is

constantly measured and checked by means of the

rotation speed feedback.

5.2. Heating mode

After successful completion of the “Ignition phase”, the

stove automatically switches to “Heating mode”

operating status.

In “Heating mode” operating status, the stove’s heat

output is adjusted in modular fashion on the basis of the

room temperature or the difference between the actual

room temperature and the target room temperature.

If there is a great difference between the target room

temperature and the actual room temperature, then the

stove will operate with greater heat output (maximum 8

kW).

The closer the actual room temperature comes to the

target room temperature, the more the heat output of the

stove is reduced (minimum heat output = 2.5 kW).

Depending on the required heat output, the relevant

quantity of fuel will be supplied at a regular rate via the

pellet chute to the grate by means of the screw

conveyor.

During the “Heating mode” operating status, the flame or

combustion chamber temperature is measured just

above the flame by means of a special thermosensor

whose signals are processed in the control unit and are

the basis

Page 7

7

for the relationship of the “energy level in the grate” and

the combustion air volume taken in, which ensures “ideal

combustion” and a high level of efficiency.

During the “Heating mode” operating status, the rotation

speed of the induced draught fan is monitored by means

of rotation speed feedback and constant comparison

between the target and actual rotation speeds.

In the event of a large difference between the actual

rotation speed and the target rotation speed, a safety

shutdown will be initiated and an error message is

shown on the operator console display.

During the “Heating mode” operating status, the

maximum and minimum heat output are each controlled

by safety limits (maximum and minimum flue gas

temperature) i.e. if during the “Heating mode” operating

status the maximum flue gas temperature is exceeded

or if the flue gas temperature falls below the minimum, a

safety shutdown will be initiated.

5.3. Burner test

Every 30 minutes during the “Heating mode” operating

status, a burner test is performed.

The burner test is performed regardless of the heat

output currently being delivered by the stove.

This process takes about 2 minutes.

5.4. Cooling down

If the set target room temperature is reached i.e. the

actual room temperature and the target room

temperature match, then the control unit switches to

“Cooling down” operating status.

The fuel supply is stopped i.e. the screw conveyor that is

located in the screw conveyor tube, stops, the rotation

speed of the induced draught fan is regulated to a

precisely defined rotation speed and the fuel which is

still in the grate is burnt.

The cooling down phase is restricted by timing control

(duration about 15 minutes).

After the end of the “Cooling down” operating status, the

device switches to “Standby” operating status.

5.5. Standby

There is no combustion process going on in this

operating status, all the components, the induced

draught fan and the screw conveyor are stopped, the

ignition is switched off and the device is in a “waiting

position.”

Before the stove can switch back from “Standby”

operating status to the “Ignition phase” operating status,

two ignition conditions must be fulfilled:

1. The room temperature must be at least 1.0ºC

below the set target room temperature.

2. The flue gas temperature measured with the

thermosensor must be lower than 70°C.

It is only when both these ignition conditions have been

fulfilled that the device switches back from “Standby”

operating status to “Ignition phase” operating status.

L Attention!

The device starts by itself in “Standby mode”.

Because of the heat generated on the panel, you

must ensure that there is no-one who is unfamiliar

with the operation of the pellet stove unsupervised

in the room where it is installed.

Placing non-heat-resistant materials or objects on

the stove or within the specified minimum distances

is forbidden.

5.6. Safety shutdown (shutdown)

If a fault occurs, regardless of in which operating status

or which operating mode, a safety shutdown is initiated.

The safety shutdown process is precisely defined.

During the safety shutdown, the components are

switched on or off as follows:

Induced draught fan – ON

Screw conveyor – OFF

Ignition – OFF

The ending of the safety shutdown is temperaturedependent i.e. the “Safety shutdown” operating status is

maintained until the stove has cooled down to a flue gas

temperature of below 80°C.

Once the safety shutdown is ended, the control unit

switches to the “Fault” operating status.

5.7. Faults

The stove can no longer be automatically started up.

The operator can see the fault on the display.

Once the fault has been properly corrected and the error

message on the operator console has been cleared, the

stove may be started up again.

Page 8

8

5.8. Switching off – operating status OFF

Procedure:

Press the left key on the operator console until the

information screen appears.

Press the right key (Menu), then move the cursor to

Operating Mode with the two middle keys – press the

right key (Select) – move the cursor to “OFF” operating

mode with the two middle keys – press the right key

(Save).

The stove initiates the Cooling down operating status

and can no longer switch to Heating mode by itself, even

if the room temperature falls below the set room

temperature.

During OFF operating status, the operator console and

parts of the control system continue to be supplied with

power. (About 9 Watts per hour).

5.9. Power cut

The control unit has a backup battery so that the data

are retained during a power cut.

A distinction is made between a short power cut and a

long power cut.

Short power cut – duration of the power cut shorter than

30 seconds:

Once the electricity supply has been restored, the stove

continues its operation from where it was before the

power cut.

Long power cut – duration of the power cut longer than

30 seconds:

Once the electricity supply is restored, the stove

switches to Safety shutdown operating status.

A small amount of flue gas may escape during a power

cut.

5.10. Overheating

If the maximum permitted flue gas temperature is

exceeded, a safety shutdown is initiated and the

following error message is shown on the display:

“Shutdown flue gas temperature in Heating mode too

high”.

The stove cannot restart its heating mode until the error

message has been cleared on the operator console and

the desired operating mode has been reset.

5.11. Low temperature shutdown

If during the Heating mode operating status the stove

cools down below a minimum temperature, a safety

shutdown is initiated and the following error message is

shown on the display:

“Shutdown flue gas temperature heating mode too low”

The stove cannot restart its heating mode until the error

message has been cleared on the operator console and

the desired operating mode has been reset.

6. Description of operator console keys

6.1. Operator console

As can be seen in the figure, the display is divided into

five areas.

The screen title contains the name of the relevant

screen which the operat or is currently in. On the same

line, right justified is shown the screen number.

In the Menu/Info area there are four columns with 21

characters each available for the text display.

In the information screens, the operator switches

between individual information screens with keys 2 and

3.

If the operator is in the Selection menu, he will be shown

4 submenu items at the same time. He can choose

between the individual menu items with keys 2 and 3,

with the menu item just selected being indicated with a

black background. If key 3 is pressed again after the

selection of the fourth menu item, the operator will be

taken to further selection items (scrolldown menu).

With key 4 the operator selects a menu item and is then

taken to the relevant submenu or, if a parameter is

selected, to the appropriate window in which the

parameter may be adjusted.

Inactive menu items and information:

Inactive menu items are not shown in the selection

menu.

Nor are inactive measurement values shown by the

relevant configuration on the information screens or in

the values information.

Screen title Screen no.

Description of

left key

Description of

right key

Description of

middle keys

1

2

3

4

Operating mode Heating

Operating status Standby

Target/actual room temp. 20/20°C

Time Date

Page 9

9

6.2. Information screens

6.2.1 Info screen 1 (Standard screen)

This screen is always displayed after switching on.

1

Menu

Room target/actual: 0/28°C

15:00 We,23.01.2004

Information

O p e rati ng mode : Au t o

Operatin g s tatus : Ig n. Phase

Functions of the keys:

Left: Starts up the heating process

immediately.

Middle top: Display the error window with Error key,

otherwise inactive

Middle bottom: Parametrisation of the weekly

programme or the target room temperature depending

on the operating mode.

Right: Display the main menu

6.2.2 Main menu

This menu is shown as a scrolldown menu.

1

Back Select

Lan guage German

Main menu

>O perat ing mode Auto<

Dat e/Time

It contains the entries:

• Operating mode (The operating mode can be

changed here: Off, Heating, Automatic)

• Date/Time (The date and time of the control unit can

be set here)

• Factory setting = always “German”

Functions of the keys:

Left: Display Info screen 1

Middle top: Up selection arrow

Middle bottom: Down selection arrow

Right: Enter the selected menu item

6.2.3 Setting the operating mode

Back Select

> Heating <

Auto

Ope rating mode

Off

Functions of the keys:

Left: Display Info screen 1

Middle top: Selection up

Middle bottom: Selection down

Right: Save the selected operating status

6.2.4 Setting the time and date

Back Select

15:00 24.01.2005

Infor mation

Time / Date

Functions of the keys:

Left: Display Info screen 1

Middle top: Selection up

Middle bottom: Selection down

Right: Save the selected time

6.2.5 Setting the times and target room temperatures

in automatic mode

Back <> Select

2 E:13 :00 A:24: 00 26°

3 E:14 :00 A:24: 00 27°

Wkly Programme

Mo T u We Th Fr Sa Su

1 E:12 :00 A:24: 00 25°

Functions of the keys:

Left: Display Info screen 1

Middle top: Set the day of the week or time

Middle bottom: Set the day of the week or time

Right: Jump between times

6.2.6 Setting target room temperature in Heating

mode

r001

Back Save

(21) 21 [°C]

Room target

Targ et room

temp erature

Functions of the keys:

Left: Display Info screen 1

Middle top: Raise target room temperature

Middle bottom: Lower target room temperature

Right: Save the selected target room

temperature

Page 10

10

6.2.7 Fault screen

Quit

15:00 24.01.2004

Fa ult scree n

Ther mose nsor flue gas

Inte rruption

Functions of the keys:

Left: Key inactive

Middle top: Key inactive

Middle bottom: Display Info screen 1

Right: Clear the fault on the display

6.3 Setting the language

With all devices, the language factory setting is set to

“German”.

If you would like to set another language, proceed as

follows:

In the main menu, place the cursor on “Language”.

Press the right “Select” key.

Select the desired language with the two middle keys.

Then press the right “Save” key.

If you would like to quit this screen without saving, press

the left “Back” key.

After saving, switch off the master switch and switch it

back on. It is only then that the texts will be displayed in

the language just selected.

6.4 Description – Heating profile

Setting range from 80 to 600

Factory setting: 80

The value to be set depends on the size of the room that

is to be heated.

Guideline values:

• Room size 20m² - Value 80

• Room 25m² - Value 200

• Room 30m² - Value 400

• Room bigger than 30m² - Value 600

With older stoves a higher value should be set (over

400) so as to avoid excess condensation in the fireplace.

The value of the heating profile is set as follows:

In the main menu, place the cursor on “Heating profile”

Press the right “Select” key.

Adjust the value with the two middle keys

Then press the right “Save” key.

If you would like to quit this menu screen without saving,

press the left “Back” key.

6.5 Description – Key lock (child-safe)

1

Menu

Room target/actual: 0/28°C

15:00 We,23.01.2 004

Information

O p e rati ng mode : Au t o

Operati ng status:S tandby

In Info screen 1 you can activate a key lock.

Activating the key lock:

• Hold the Menu key down for about 10 seconds

until “Key lock activated” appears on the display.

Deactivating the key lock:

• Hold the Menu key down for about 10 seconds

until “Key lock activated” is no longer shown on

the display.

6.6 Description – Display brightness - contrast

setting

Left key: Hold key down for about 10 seconds until

“Contrast mode” appears on the display.

Now release the left key and set the desired brightness

or contrast with the two middle keys.

7. Operating the pellet stove

The pellet stove may only be heated by adults. Make

sure that children are never left alone with the pellet

stove. (Do not leave the pellet stove unsupervised for a

long period). The pellet stove may only be used in

accordance with these operating instructions.

Please observe the safety instructions set out in Section

2.

7.1. Fuel

The pellet stove may only be operated with “pellet” fuel.

With this fuel you have chosen CO

2

-neutral heating for

your home.

Pellets are made from wood waste from sawmills and

planing works and from wood collected from forestry

businesses. These raw materials are therefore of 100%

natural origin and are ground, dried and pressed into

“pellet” fuel without the addition of binding agents.

This fuel is standardised (e.g. DIN 5173, Ö-Norm [Eco

standard] M 7135, EN 14961-2).

1

Back Select

>Lang uage German<

Main menu

Oper ating mode Auto

Date / Time

1

Back Select

>Heating profile<

Main menu

Date / Time

Language German

Page 11

11

L Important: Your HAAS+SOHN Pelletto pellet

stove may only be operated with standardised wood

pellets with a 6 mm diameter.

You can identify good quality wood pellets by eye by:

smooth, shiny surface, uniform length, little dust. Wood

pellets of lower quality are characterised by: Lengthwise

and crosswise cracks, a high proportion of dust, different

lengths. Precise quality features may however only be

identified with suitable technical analysis equipment.

A simple quality test: Put a few wood pellets in a glass of

water:

Good quality: Pellets sink

Lower quality: Pellets float.

The use of lower-quality or unauthorised fuel adversely

affects the operation of your pellet stove and may in

addition lead to the lapse of the guarantee and the

associated product liability. Unauthorised fuels include

woodchips, straw and maize. Burning wood pellets of

poor quality leads to shortening of the cleaning intervals

and to increased fuel consumption, so the pellet tank

has to be filled more frequently.

Wood pellets are packed in plastic or paper sacks. To

ensure problem-free combustion of the wood pellets it is

necessary to dry the fuel as much as possible and to

transport and store it free from dirt. On contact with

moisture, pellets swell considerably.

When filling the storage container with wood pellets,

make sure that the pellet sacks do not come into contact

with the hot surfaces of the stove.

Two kilograms of wood pellets have about the same

energy content as a litre of “extra light heating oil.” In

terms of volume, 3 m

3

of wood pellets are equivalent to

about 1,000 litres of heating oil. Variations in heat output

by the pellet stove are caused not only by the quality of

the pellets but also by the raw material of the wood (type

of wood).

7.2. Commissioning your pellet stove

The materials making up your pellet stove must

gradually get used to the heat generation. By careful

warming up you avoid cracks in the combustion

chamber plates, damage to the paintwork and warping

of materials. So do not set the target temperature too

high on the control unit (about 1.5°C to 2°C higher than

the current room temperature).

• Before commissioning, remove any stickers and any

accessories from the ash pan and the combustion

chamber. This also applies to any

transportation/handling securing materials.

• Check that the combustion chamber cladding is

attached to its fastenings. (This might have slipped

out

of its position as a result of the transportation or

installation of the stove).

• Check that the combustion pot fits perfectly in its

frame.

• Close the combustion chamber door.

• Fill the storage container with standard wood pellets

(Ø 6 mm).

• Insert the mains cable.

• Set the On-Off toggle switch to “1”.

• Once the toggle switch has been set to ON, the

control unit commences initialisation. This process

takes a few seconds.

• After initialisation, the Information screen appears –

press the right key (Menu) – move cursor to

Operating mode – press the right key (Select) –

select the desired operating mode with the cursor –

press the right key (Save).

Tip!!

Only when commissioning, place about 30

pellets in the burner. This will speed up the

ignition process.

General:

If the ignition phase could not be successfully

run i.e. no flame generation or the required

temperature could not be reached at the flue

gas thermosensor, then a safety shutdown is

initiated and an error message generated

(“Ignition phase target temp. flue gas not reached –

check burner – date and time”).

Correcting the fault:

Once the stove has cooled down, empty the burner and,

if necessary, clean it. Take care! There may still be

residual embers in the ash! Then press the left key on

the operator console repeatedly until the error message

appears – then press the right key of the operator

console (Clear) – now the Info screen appears – press

the right key (Menu) – move the cursor to Operating

mode and press the right key (Select) – the screen in

which the operating mode may be selected appears –

select desired operating mode with the cursor and press

the right key (Save). The stove begins the ignition

phase.

Note: Any smoke generation caused by further drying of

the paint stops after a short while. Please properly

ventilate the room where the stove is installed. However,

the paint does not contain any toxic vapours.

7.3. Selecting the operating mode

The control unit allows easy selection of operating mode

from the “Heating” and “Auto” weekly programme

modes.

Page 12

12

7.3.1 “Heating” operating mode

The keys on the operator console are explained in

Section 6.

In this operating mode the operator may set the desired

target room temperature (between 10°C and 30°C) by

means of the four operator keys on the operator

console.

The stove heats the room to the relevant target room

temperature and after reaching this and going through

the Cooling down programme it switches to “Standby”

operating status.

Whilst the stove is operated in this operating mode, the

room is repeatedly heated to the set target room

temperature by day and night i.e. during this operating

mode, no distinction is made between day and night or

any other times with regard to the desired room

temperature.

7.3.2 Setting the target room temperature in

“Heating” operating mode

¾ Press the left key repeatedly until the Info

screen appears.

¾ Then press the middle bottom key

¾ Now the programming window in which the

desired target room temperature is set is

opened. The explanations of the keys or their

functions are shown in the bottom line of this

programming window.

¾ With the upper middle key the desired target

room temperature is increased in “jumps of 1ºC”

at a time. With the lower middle key the desired

target room temperature is reduced in “jumps of

1ºC” at a time.

¾ With the left key, the programming window is

closed without saving a new target room

temperature.

¾ With the right key this programming window is

closed and the just input target room

temperature is saved.

7.3.3 “Auto” operating mode (weekly programme)

In this operating mode, the operator is free to select

three switching on and three switching off times per day

(per 24 hours) for each of the seven days of the week

with the relevant associated target room temperatures

desired by the operator (between 10°C and 30°C).

7.3.3.1 Setting date and time

Before operation with the weekly programme, it is

necessary to input the date and time.

Procedure:

¾ Press the left key on the operator console

repeatedly until the information screen appears

¾ In the Info screen, press the right key (Menu)

¾ Now the main menu appears

¾ In the main menu, place the cursor on

Date/Time with the two middle keys

¾ Press the right key (Select)

¾ Now the programming window for the d ate and

time appears

¾ In the programming window, press right key

(Edit).

¾ Now programming is activated – select the field

to be edited with the right key (arrow)

¾ With the two middle keys (+ / -) perform the edit

¾ With the right key (arrow) scroll through the

programming window until the function “Save”

appears in the bottom text line

¾ Press the right key (Save) – the change is saved

¾ Press the left key (Back) – the main menu

appears.

7.3.3.2 “Auto” operating mode (weekly programme)

In this operating mode programming must be done for

each day of the week.

The stove heats up the room to the relevant target room

temperature and after reaching it and after going through

the Cooling down programme switches to the “Standby”

operating status

This operating mode permits adjustment of the target

room temperature to suit individual heating

requirements.

7.3.3.3 Setting the target room temperature in

“Auto” operating mode (weekly programme)

¾ Press the left key repeatedly until the Info

screen appears.

¾ Then press the middle bottom key.

¾ Now the programming window in which the days

of the week can be selected is opened.

¾ With the two middle keys, the day of the week

can be selected in the second line with the

cursor. (The selected day is the one which is

highlighted by the cursor).

¾ After completing the selection with the cursor,

press the right key (Edit)

¾ Now the programming window for the selected

day appears.

¾ The first column contains position numbers 1, 2

and 3

¾ In the second column, the switch on times

(marked by the letter E) are programmed in 15

minute jumps with the two middle keys.

¾ With the right key (arrow) you can move from

the left column to the right.

¾ In the third column, the switch off times (marked

by the letter A) are programmed in 15 minute

jumps with the two middle keys.

¾ In the fourth column, the desired target room

temperature is assigned to each period that falls

Page 13

13

between the relevant switch on and switch off

times.

¾ After the completion of the day of the week

programming, the programming window for this

day of the week can be saved and quitted by

pressing the left key (Back).

¾ The other days of the week must be

programmed in the same way.

7.3.3.4 Example of programming for “Monday”

¾ Press the left key repeatedly until the Info

screen appears.

¾ Then press the middle bottom key.

¾ Now the screen in which the days of the week

can be selected appears.

¾ Move the cursor with the two middle keys so

that the MO field (MO – means Monday) is

highlighted with the cursor.

¾ Then press the right key (Edit).

¾ Now the programming window for “Monday”

appears

¾ The first column contains position numbers 1, 2

and 3

¾ In the second column, the switch on times

(marked by the letter E) are programmed in 15

minute jumps with the two middle keys.

o You can move from the left column to

the right with the right key (arrow).

¾ In the third column, the switch off times (marked

by the letter A) are programmed in 15 minute

jumps with the two middle keys.

¾ In the fourth column, the desired target room

temperature is assigned to the period that falls

between the relevant switch on and off times.

¾ After completion of the programming of the day

of the week, the programming window for this

day of the week can be saved and quitted by

pressing the left key (Back).

8. Cleaning and maintenance work

The functioning of your device depends to a large

extent on regular expert maintenance. Because of the

ash accumulation resulting from the combustion of wood

pellets, constantly recurring cleaning and maintenance

work needs to be carried out. This will permit operation

to be as trouble-free as possible.

The frequency of maintenance in turn depends to a large

extent on the pellet quality (ash content). Quality pellets

have a low ash content of about 0.2-0.3%. However, if

the ash content is higher (0.5% and over), the interval

from maintenance to maintenance is reduced and the

accumulation of ash increases by 2 or 3 times. This

results in lower heat output and an increased fan

rotation speed.

We therefore recommend checking and/or

cleaning the flue gas passes after 1,000 kg of

pellets at the latest. (See Figure 8 a+d).

L Attention!

Devices that are not maintained in accordance with

our specifications must not be operated. Failure to

observe this point will invalidate all guarantee

claims.

As soon as you detect ash and clinker deposits in the

cold combustion pot, it must be cleaned. (See Figures 5

+6). If this is not done, the clinker will continue to

accumulate. Then the device will no longer be able to

ignite properly. Pellets can pile up in the combustion pot.

In extreme cases, this can reach all the way back to the

pellet chute. Backfire in the pellet container and

smouldering in the pellet tank might possibly result.

This will destroy your device and is not covered in

your guarantee.

L Attention!

Before cleaning work starts, the stove must be

cooled down, the On/Off toggle switch must be in

the “0” position and the mains cable must be

disconnected!

Once the cleaning work is completed, the correct

operating status of the device must be reestablished: Put the combustion pot in correctly,

close the combustion chamber door.

8.1 Cleaning the surface

Dirt on the upper surface of the stove may be cleaned

off with a damp cloth or if necessary with mild soapy

water. You are advised against using corrosive cleaning

agents and solvents since these might damage the

surfaces.

8.2 Cleaning the glass panel

To clean the viewing panel, you must first open the

stove door. Dirt on the glass panel can be removed with

a glass cleaner or with a damp sponge on which you

have sprinkled some of the wood ash present.

(Environmentally friendly).

Cleaning the glass panel may only be done with a

cooled down stove in the OFF operating mode.

8.3 Cleaning the combustion pot

During operation, deposits may form in the combustion

pot. How quickly the combustion pot becomes dirty

depends solely on fuel quality. The deposits or

encrustations must be removed from time to time.

Page 14

14

Cleaning the combustion pot may only be done

with a cooled down stove in “OFF” operating mode.

Otherwise there is a risk of burns!

To this end the combustion pot must be removed from

the stove. Once the combustion pot has been removed,

any residual ash that is in the stove underneath the

combustion pot must also be removed.

After cleaning, the combustion pot is to be put back into

the right position in the burner seat. Check the correct

seating of the combustion pot again so as to avoid poor

seals.

A visual check of the dirt on the burner and the

combustion chamber for combustion residues must

be carried out by the operator at regular intervals!!!

Figure 5: Burner dirty

Figure 6: Burner clean

The cleaning intervals for the combustion pot and the

glass panel depend directly on the quality of the wood

pellets (high ash content) and may vary between a few

hours of combustion and several days.

8.4 Removing the ash from the combustion

chamber

To thoroughly clean the ash out of the combustion pot

and the combustion chamber, the pellet stove must be in

a cooled down condition and in the OFF operating

mode.

Procedure:

Press the left key on the operator console repeatedly

until the Info screen appears – then press the right key

(Menu) – with the two middle keys move the cursor to

Operating Modes – press the right key (Select) – with

the two middle keys move the cursor to OFF – press the

right key (Save) - the stove begins to cool down.

Once the stove has completely cooled down, cleaning

work can begin.

Attention!!

The stove’s Cooling down programme is ended after

about 15 minutes. The stove may still be hot after

the end of the cooling down phase.

Do not start cleaning until the stove is completely

cooled down! “Risk of burns!”

The frequency of ash removal depends directly on the

quality of the wood pellets used. We recommend

removing the ash from the combustion chamber with an

ash vacuum cleaner.

8.5 Cleaning the pellet container

Heat the pellet stove until the storage tank is completely

empty. Then the protective grille (2) in the pellet tank

may be removed. Then clean the tank and the intake of

the screw conveyor housing with a vacuum cleaner.

After cleaning, it is essential to put back the protective

grille. When doing this, make sure that no screws fall

into the pellet tank so as to avoid consequential damage

to the screw conveyor.

Figure 7: Pellet tank

1 = Pellet tank cover

2 = Protective grille

3 = Tank cover seal

Page 15

15

8.6 Cleaning the flue gas passes and the flue

tubes

Normally it is sufficient to clean the flue gas passes and

the flue tubes once a year. First pull the stove away from

the wall so as to create enough room to work at the

back.

To clean the flue gas passes, proceed as follows:

Disconnect the

flue baffle (1)

from the guide

by lifting it. Draw

the right

cladding (2)

down out of the

guide and place

it down in the

ash space. Then

the flue baffle

can be removed

and the upper

part of the

combustion

chamber can be

cleaned. (See

Figure 8a).

Figure 8a: Removing the flue baffle

Then remove the right side wall. This is fixed with

screws (1) at the back and at the front with 3 connectors.

Remove the

screws from

the back and

pull the side

wall off

sideways.

(See Figure

8b).

Figure 8b: Removing the side wall

Undo the screws and remove both the covers of the

openings. Now you can clean the exposed insides of the

flue gas passes. (See Figure 8 c+d).

After completion of the cleaning make sure that

when putting back the covers, the seals are seated

in the right positions. It is essential to replace

defective seals.

Figure 8c: Cleaning covers

Figure 8d: Cleaning covers open

8.7 Cleaning the induced draught housing and

fan

This housing is made accessible for cleaning by undoing

the 4 nuts shown in Figure 9. (See arrows).

Remove the induced draught motor by pulling it out.

Now clean the flue gas passes, the induced draught fan

and the flue tubes with a brush and an ash vacuum

cleaner.

Then reassemble the components in reverse order.

Make sure that the seal is seated in the right position

again. It is essential to replace defective seals.

Make sure of the electrical connections on the fan motor

and their correct positions.

Figure 9: Induced draught fan

Page 16

16

9. Description of the components

9.1 Storage container (pellet tank)

17 kg of wood pellets can be stored in the storage

container. This quantity permits constant operation for

up to 30 hours.

9.2 Screw conveyor motor / screw conveyor

The screw conveyor motor drives the screw conveyor.

This delivers the wood pellets from the storage container

to the combustion chamber (combustion pot). The screw

conveyor motor’s rotation speed is regulated and it

therefore delivers the required supply quantity to the

modular heat output (2.5 kW to 8 kW).

If the screw conveyor becomes blocked because of

foreign bodies in the wood pellets or a too-high level of

fine particles, it can often be unblocked by simply

moving the screw conveyor motor housing back and

forth. To do this, you must first remove the back wall by

pulling it down. (See Figure 1, no. 7).

L Attention!! First pull out the mains

plug!

Any fault with the screw conveyor motor is detected by

the control unit and this initiates the cooling down phase.

Figure 10: Screw conveyor motor

1 = Screw conveyor motor

2 = Condenser

3 = Thermosensor, flue gas

4 = Induced draught fan

5 = Overheat cutout

6 = Master switch

7 = Mains socket

8 = Heat exchanger

9 = Outside air connection

9.3 Combustion pot with tray:

The combustion pot is made of high-grade stainless

steel. The special design of the combustion pot

guarantees clean and extremely efficient combustion of

the wood pellets.

Figure 11: Combustion pot correctly installed

9.4 Electric ignition

The built-in electric ignition is made of stainless steel

(see Figures 13+14) and generates the ignition

temperature required to ignite the wood pellets. The

period during which ignition is activated depends on how

quickly the required flame temperature is reached so

that the system can switch from the Ignition phase to

Heating mode. The average ignition glow time is 10 to

12 minutes (depending on pellet quality). The ignition

phase is restricted to a maximum time of 20 minutes and

therefore the maximum ignition glow time is also

restricted to 20 minutes. Depending on the fuel quality,

the flame should be formed in 3 to 7 minutes.

Page 17

17

Figure 12: Electrical components

1 = Pellet tank

2 = Flame temperature sensor

3 = Screw conveyor motor

4 = Bottom temperature sensor

5 = Ignition

6 = Control unit

7 = Backup battery

Figure 13: Stainless steel ignition

9.5 Control unit

The microprocessor control unit ensures safe,

automatic operation of the pellet stove. The control

unit controls the interaction of the components e.g.

induced draught fan, screw conveyor motor, flame

temperature sensor, room temperature sensor etc..

The pellet stove’s electrical fuses are incorporated

into the control unit.

To change these fuses you must remove the left

side wall.

Figure 14:

1. Screw conveyor motor

2. Control unit

3. Fuses T 3,15A

4. Fuse T 0,315A

5. Backup battery

6. Condenser, screw conveyor motor

9.6 Operator console

The operator console is built into the pellet tank in

such a way that the display with its four function keys

is easily accessible.

All the parameters necessary for the operation of the

stove can be set with this operator console.

Access to these parameters is divided into two levels.

The first level is intended for the stove operator.

The second level is intended for customer service and

may only be accessed by inputting a special access

code.

Description of the first level – the one for the operator:

The operator can make the following adjustments with

or read the following information on the display of the

operator console:

• Start or stop the device

• Set the desired target room temperature (in

“Heating” operating mode).

Page 18

18

• Select “Heating” or “Auto” operating mode

• Set up a weekly programme with the desired

target room temperature and the associated

switch on and off times in “Auto” operating

mode

• Read off the relevant operating mode and the

relevant operating status which the device is

currently in and the date and time

• Read every error message shown as text and

number

• Make the selection of language for the menu

on the operator console.

Figure 15: Operator console

9.6.1 Backlighting

The backlighting of the display is switched off 5

minutes after the operator console was last operated.

9.6.2 Activating the backlighting

The backlighting is switched on by pressing any key.

It is only after the backlighting is activated that the

function keys are active.

The backlighting is also activated by any error

message generated.

9.7 Induced draught fan with rotation speed

feedback

The induced draught fan generates low pressure in

the combustion chamber and thereby supplies the

required volume of air for combustion to the

combustion chamber or through the combustion pot.

The induced draught fan is equipped with rotation

speed feedback. This permits detection of any

difference between the target and actual operating

status and countermeasures to be taken or, in the

case of greater differences, permits the stove to be

shut down (safety shutdown).

9.8 Flame or combustion chamber temperature

sensor (combustion chamber thermosensor)

The flame temperature is measured in “Heating

mode” operating mode.

The flame temperature measured is an indicator of

the energy level in the grate and hence the basis of

the air volume required for the combustion of the

energy level located in the grate.

Here the ACTUAL flame temperature is compared

with the TARGET in combination with the processorregulated control unit and the appropriate combustion

air volume required for the combustion of the energy

level in the grate is supplied by means of the induced

draught fan.

9.9 Flue gas thermosensor

The flue gas thermosensor is located on the housing

of the induced draught fan and protrudes into the flue

gas duct across the direction of the flow of the flue

gas, where the flue gas flows around it, and thus

measures its temperature and temperature change.

(See Figure 10).

With the thermosensor, the temperature and its

change can be measured directly (accurate to about

2ºC) in the flue gas and so be accessed for the

control unit and regulation.

9.10 Room temperature sensor

The room temperature sensor measures the

ACTUAL room temperature in the area of the

stove.

The room temperature sensor is an instrument for

the TARGET – ACTUAL comparison between the

TARGET room temperature and the ACTUAL room

temperature and is therefore the basis for the

specification of the required heat output for the

stove.

Page 19

19

Figure 16:

1 = Mains socket

2 = Main On/Off switch

3 = OC overheat cutout

4 = Flue elbow 80 mm

5 = Outside air connection 50 mm

6 = Room temperature sensor

7 = Bottom of back wall

9.11 OC – Overheat cutout

The overheat cutout sensor is located on the

screw conveyor tube. When a certain temperature

is reached, the OC is triggered independently of the

control unit and it cuts the stove off from the

electricity supply. (Thermo protection).

9.12 Combustion chamber cladding

The combustion chamber is clad on its three

casing surfaces, the left side wall, the right side

wall and the back wall with the material Vermiculite.

Figure 17 : Combustion chamber

1 = Combustion chamber cladding, left

2 = Combustion chamber cladding, back

3 = Combustion chamber cladding, right

4 = Flame temperature sensor

5 = Bottom temperature sensor

6 = Combustion pot

7 = Combustion tray

8 = Pellet chute

9 = Door contact switch

9.13 Flue tube connection

The diameter of the flue elbow is 80 mm. The flue

tube must be connected to the fireplace in

accordance with official regulations. For questions

in connection with this, please contact your local

chimneysweep. Because of the way the pellet

stove works with a combustion air fan, high

pressure is generated at the flue gas outlet and

possibly in the fireplace. This means that the flue

gas pipes must be designed to be gas-tight as far

as their entry into the fireplace.

9.14 Mains cable and master switch

Important! The electricity supply to the pellet stove

must always be present! No time switches or other

electric switches may be inserted in or before the

stove’s mains cable. Otherwise your pellet stove

may suffer damage. The master switch for your

pellet stove is located next to the mains cable

socket.

Figure 18:

1. Master switch

2. OC (overheat cutout)

3. Mains cable socket

4. Room temperature sensor (output)

10. Technical data

Page 20

20

Pelletto 417.08 Pelletto 432.08 Pallazzo 517.08

Heat output range:

1.8 – 8.1 kW 1.8 – 8.1 kW 1.8 – 8.1 kW

Nominal heat output

8.0 kW 8.0 kW 8.0 kW

Height:

986 mm 1177 mm 1001 mm

Width:

525 mm 525 mm 560 mm

Depth:

498 mm 498 mm 495 mm

Weight:

86kg 100kg 86kg

Diameter of flue elbow:

80 mm 80 mm 80 mm

Flue gas temperature

160°C 160°C 160°C

Minimum supply pressure:

6 Pa 6 Pa 6 Pa

Flue gas flow rate in g/s

-/6.0 -/6.0 -/6.0

CO level in flue gas (%) (min./max.)

0.1/0.007 0.1/0.007 0.1/0.007

Efficiency:

90.4/97.2% 90.4/97.2% 90.4/97.2%

CO level in flue gas:

87.5/125 mg/m³ 87.5/125 mg/m³ 87.5/125 mg/m³

NOx level in flue gas:

- /146 mg/m³ - /146 mg/m³ - /146 mg/m³

OGC level in flue gas:

5.8/3.1 mg/m³ 5.8/3.1 mg/m³ 5.8/3.1 mg/m³

Proportion of dust in flue gas:

-/5 mg/ m³ -/5 mg/ m³ -/5 mg/ m³

Contents of storage container (pellet tank):

about 17 kg about 17 kg about 17 kg

Duration of burn with one charge (min./max.):

about 10 hrs / 30 hrs about 10 hrs / 30 hrs about 10 hrs / 30 hrs

Permitted fuel: Low-dust wood pellets to Ö-Norm

(Eco-standard) M 7135, DIN 51731, EN 14961-2

Diameter: 6 mm,

Length: max. 30 mm

Diameter: 6 mm,

Length: max. 30 mm

Diameter: 6 mm,

Length: max. 30 mm

Room heating capacity to Ö-Norm M 7521:

max. 230 m

3

max. 230 m

3

max. 230 m

3

Room heating cap’y to DIN 18893, constant heating:

250m3/145m3/98m3 250m3/145m3/98m3 250m3/145m3/98m3

Room heating cap’y to DIN 18893, timed heating:

165m3/95m3/65m3 165m3/95m3/65m3 165m3/95m3/65m3

Electricity supply:

230 V (50 Hz) 230 V (50 Hz) 230 V (50 Hz)

Electricity supply input (min./max.)

in normal operation:

Electric ignition (for max. 15 minutes on ignition):

30 to 50 W

400 W

30 to 50 W

400 W

30 to 50 W

400 W

Electronics fuses: (F3)

T 0.315 A, 250 V T 0.315 A, 250 V T 0.315 A, 250 V

Fuses for the ignition, screw conveyor motor, induced

draught, (F1,) (F2 reserve)

T 3,12 A, 250 V T 3,12 A, 250 V T 3,12 A, 250 V

Figure 19: Dimensions of Pelletto 417.08

Page 21

21

Figure 20: Dimensions of Pelletto 432.08

Figure 21: Dimensions of Pallazza 517.08

Page 22

22

11. Faults, causes, correction

You can correct simple faults yourself with the following guide. For further information please

consult your specialist dealer.

L Attention! All devices are equipped with a large number of safety devices. If a fault occurs,

you will be shown this on the display.

In the event of a fault, leave the mains plug in so that the internal safety functions can

continue to operate fully. Do not pull out the mains plug until you are about to work on the cold

device.

11.1 Error messages on the display

1. OC initiated Check burner

(Error number 1)

Cause:

• OC triggered because of overheating

• Or fuse ( F4 ) in the central unit is

defective

Correction:

¾ Change fuse ( F 4 )

¾ If the OC has been triggered, you must

contact the service engineer

2. Ignition phase target temp. flue gas not

reached (Error 2) Check burner

Cause:

• The transition temperature from the

Ignition phase to Heating mode was not

reached.

Correction:

¾ Check pellet stock. (See Instructions 7.2)

¾ Check that the chute between the burner

and the screw conveyor is clear

¾ Contact the service engineer

3. Shutoff materials correction (3) Check

burner

Cause:

• The automatic fuel reduction has initiated

a safety shutdown

Correction:

¾ Contact the service engineer

4. Shutoff flue gas temp. Heating mode (5)

Cause:

• Flue gas temperature is starting to fall

rapidly despite maximum heat output for

a long period

The following circumstances might lead to this:

• No pellets present

• The screw conveyor is not rotating, it is

jammed, the screw conveyor motor is

defective or the chute is not clear

• The required combustion air cannot be

supplied to the stove e.g. via a vapour

extractor hood that is located in the

vicinity of the installation site and

switched on.

• Air volume sensor dirty or defective

• Burner dirty

• Suction filter dirty

• Room too airtight – required combustion

air cannot be replenished in the room

• Poor seals on the pellet stove (door,

seals)

• Flame temperature sensor wrong

• Flue gas temperature wrong

Correction

¾ Check pellet stock

¾ Check that the chute between the pellet

tank and the burner is clear.

¾ Clean the burner, suction filter and air

volume sensor (paintbrush).

¾ Check whether there is a vapour

extractor hood present and in operation

¾ Make sure for instance that a window is

left open a crack to supply the required

combustion air

¾ Contact the service engineer

Page 23

23

5. Shutoff flue gas temp. in Heating mode too

low (21)

Cause:

• Temperature fell below the minimum

temperature in Heating mode operating

status

The following circumstances might lead to this:

• No pellets present

• The screw conveyor is not rotating, it is

jammed, the screw conveyor motor is

defective or the chute is not clear

• The required combustion air cannot be

supplied to the stove e.g. via a vapour

extractor hood that is located in the

vicinity of the installation site and is

switched on.

• Room too airtight – required combustion

air cannot be replenished in the room

• Air volume sensor dirty or defective

• Suction filter dirty

• Burner dirty

• Poor seals on the pellet stove (door,

seals)

• Flame temperature sensor defective

• Flue gas temperature sensor defective

Correction:

¾ Check pellet stock

¾ Check that the chute between the pellet

tank and the burner is clear.

¾ Clean the burner, suction filter and air

volume sensor (paintbrush).

¾ Check whether there is a vapour

extractor hood present and whether it is

in operation

¾ Make sure for instance that a window is

left open a crack to supply the required

combustion air

¾ Contact the service engineer

6. Shutoff flue temp. in Heating mode too

high (22)

Cause:

• The highest permitted flue gas

temperature was exceeded

The following circumstances might lead to this:

• Too much fuel is being supplied to the

burner

• Flue gas temperature sensor defective

Correction:

¾ Contact the service engineer

7. Shutoff, combustion chamber door open

(6) or (9)

Cause:

• The door is open for longer than 1 minute

during operation

• The damper at the bottom of the door is

not in the right position

• Cable broken in the electric wiring to the

door contact switch

• The connector has come out on the door

contact switch or on the central unit

Correction:

¾ Close the door

¾ Move the damper at the bottom of the

door to the right position so that the

switch is operated when the door is

closed

¾ Check door contact switch, cable and

connector

8. Flue gas sensor interruption (7)

Cause:

• Flue gas temperature sensor defective or

not connected

Correction

¾ Contact the service engineer

9. Flue gas sensor short circuit (8)

Cause:

• Flue gas temperature sensor defective

Correction:

¾ Contact the service engineer

10. Room temperature sensor interruption

(11)

Cause:

• Room temperature sensor defective or

not connected

Correction:

¾ Contact the service engineer

11. Room temperature sensor short circuit

(12)

Cause:

• Room temperature sensor defective

Correction:

¾ Contact the service engineer

Correction:

¾ Contact the service engineer

Page 24

24

12. Flame temp. sensor interruption (23)

Cause:

• Flame temperature sensor defective or

not connected

Correction:

¾ Contact the service engineer

13. Flame temp. sensor short circuit (24)

Cause:

Flame temperature sensor defective

Correction:

¾ Contact the service engineer

14. Induced draught fan cannot reach

target rotation speed (15)

Cause:

The induced draught fan is not

running at the correct rotation

speed

The following circumstances might lead to this:

¾ Induced draught fan defective

¾ Connection cable from the rotation speed

sensor (Hallsensor) is broken or poor

contact in the connector on this

connection cable

¾ Electricity supply to the fan motor

interrupted

Correction:

¾ Contact the service engineer

15. No connection to the boiler board –

Check cable (17)

Cause:

• The connection between the central unit

and the operator console is interrupted.

The following circumstances might lead to this:

• Connection cable is not connected to the

operator console or to the central unit

• Connection cable is damaged

Correction:

¾ Check that the connection cable is

connected to both units, the operator

console and the central unit.

¾ Contact the service engineer

16. Shutdown after power cut (18)

Cause:

• A safety shutdown was triggered after a

power cut

Correction:

¾ Clear the fault on the operator console

and restart the device

17. Bottom flame temp. sensor 2

interruption ( 24 )

Cause:

• Bottom flame temperature sensor

defective or not connected

Correction:

¾ Contact the service engineer

18. Safety shutdown tolerance variation,

flame temperature ( 26 )

Cause:

• Burner dirty, pellets have low calorific

value.

Correction:

¾ Clean burner, if necessary change pellet

type

19. Bottom flame temperature TFL max.

exceeded ( 27 )

Cause:

• Burner dirty

Correction:

¾ Clean burner

20. “Clean combustion chamber” function

instruction

The display on the operator console starts flashing.

(The backlighting switches on and off and the

“Clean combustion chamber” instruction appears).

The instruction to clean the combustion chamber

refers not just to the cleaning of the burner but also

to the cleaning of the entire combustion chamber

with an ash vacuum cleaner.

The process of the “Clean combustion chamber”

function looks like this:

The entire combustion chamber is to be cleaned

with an ash vacuum cleaner at intervals of no

longer than 50 operating hours.

The number of operating hours is measured within

the control unit during Heating mode. After 50

operating hours, the display on the operator

console starts flashing. This flashing is an

instruction not to defer cleaning the combustion

chamber beyond this time. However, this

instruction to clean the combustion chamber

(display flashing) does not trigger an error

message during Heating mode. But after the

display has started flashing, if the stove switches

Page 25

25

back to “Standby” mode, the stove can no longer

be automatically ignited before the combustion

chamber has been cleaned.

To clean the combustion chamber, the stove has to

be switched to “Off” operating status.

If the combustion chamber is now cleaned, then

the “Clean combustion chamber” error message

will thereafter be cleared automatically. A

precondition for the automatic clearance of this

error message is that the combustion chamber

door is open for longer than 60 seconds in “Off”

operating status. This time is required for cleaning

the combustion chamber including the burner

thoroughly with an ash vacuum cleaner.

If the door is open longer than 60 seconds in “Off”

operating status, then the operating hours counter,

which is responsible for the “Clean combustion

chamber” instruction, is automatically reset to zero.

This reset of the operating hours counter occurs

even if the cleaning of the combustion chamber is

performed before the 50 operating hours have run

provided that the stove is in “Off” operating status

and the door is open for longer than 60 seconds

during cleaning.

21. Error in parameters

Factory settings have been uploaded –

Fault has been cleared (60)

Cause:

• Program fault