Page 1

Haas Technical Publications

Manual_Archive_Cover_Page Rev A

any other party automatically voids the factory warranty.

June 6, 2013

HAAS SERVICE AND OPERATOR MANUAL ARCHIVE

VMC Service Manual 96-8100 English December 15 1994

• This content is for illustrative purposes.

• Historic machine Service Manuals are posted here to provide information for Haas machine owners.

• Publications are intended for use only with machines built at the time of original publication.

• As machine designs change the content of these publications can become obsolete.

• You should not do mechanical or electrical machine repairs or service procedures unless you are qualied

and knowledgeable about the processes.

• Only authorized personnel with the proper training and certication should do many repair procedures.

WARNING: Some mechanical and electrical service procedures can be

extremely dangerous or life-threatening.

Know your skill level and abilities.

All information herein is provided as a courtesy for Haas machine owners

for reference and illustrative purposes only. Haas Automation cannot be held

responsible for repairs you perform. Only those services and repairs that are

provided by authorized Haas Factory Outlet distributors are guaranteed.

Only an authorized Haas Factory Outlet distributor should service or repair a

Haas machine that is protected by the original factory warranty. Servicing by

Page 2

VMC

Troubleshooting

SERVICE MANUAL

SERVICE TROUBLE

TROUBLESHOOTING

This section is intended for use in determining the solution to a known problem. Solutions given are

intended to give the individual servicing the CNC a pattern to follow in, first, determining the problems

source and, second, solving the problem.

The troubleshooting tips are organized in this section according to the area of the CNC that may be

giving sign of a problem. (Ex.: Out-of round circles in drilling will be found under the heading General

Machine Operation - Accuracy).

If the problem you are experiencing cannot be found under the heading you expect, please try

several other possible headings. If the problem is still not found, contact Haas Automation for further

details.

BEFORE YOU BEGIN:

l USE COMMON SENSE

Many problems are easily overcome by correctly evaluating the situation. All machine opera

tions are composed of a program, tools, and tooling. You must look at all three before blaming

one as the fault area. If a bored hole is chattering because of an overextended boring bar, dont

expect the machine to correct the fault. Dont suspect machine accuracy if the vise bends the

part. Dont claim hole mis-positioning if you dont first center-drill the hole.

l FIND THE PROBLEM FIRST

Many mechanics tear into things before they understand the problem, hoping that it will appear

as they go. We know this from the fact that more than half of all warranty returned parts are in

good working order. If the spindle doesnt turn, remember that the spindle is connected to the

gear box, which is connected to the spindle motor, which is driven by the spindle drive, which

is connected to the I/O BOARD, which is driven by the computer. The moral here is dont

replace the spindle drive if the belt is broken. Find the problem first; dont just replace the

easiest part to get to.

l DONT TINKER WITH THE MACHINE

There are hundreds of parameters, wires, switches, etc., that you can change in this machine.

Dont start randomly changing parts and parameters. Remember, there is a good chance that if

you change something, you will incorrectly install it or break something else in the process.

Consider for a moment changing the processors board. First, you have to download all param

eters, remove a dozen connectors, replace the board, reload and reconnect, and if you make

one mistake or bend one tiny pin it WONT WORK. You always need to consider the risk of

accidentally damaging the machine anytime you work on it. It is cheap insurance to doublecheck a suspect part before physically changing it. The less work you do on the machine the

better.

12-15-94 96-8100

HAAS AUTOMATION, INC.

1

Page 3

VMC

SERVICE TROUBLE

SERVICE MANUAL

G

eneral Machine Operation

1. GENERAL MACHINE OPERATION

1.1 MACHINE NOT RUNNING

´ Machine cannot be powered on.

l Check input voltage to machine (Section 2,Electrical Service).

l Check main circuit breaker at top right of electrical cabinet; switch must be at the on position.

l Check overvoltage fuses (Section 3.1,Electrical Service).

l Check wiring to POWER OFF button on front control panel.

l Check wiring to AUTO OFF relay to IOPCB.

l Replace IOPCB (Section 4.3, ElectricalService).

l Replace POWER PCB (Section 4.4 Electrical Service).

´ Machine can be powered on, but turns off by itself.

l Check settings #1 and #2 for Auto Off Timer or Off at M30.

l Check alarm history for OVERVOLTAGE or OVERHEAT shutdown.

l Check AC power supply lines for intermittent supply.

l Check wiring to POWER OFF button on front control panel.

l Replace IOPCB (Section 4.3, Electrical Service).

l Check Parameter 57 for Power Off at E-STOP.

l Replace MOTIF PCB (Section 4.1, Electrical Service).

´ Machine turns on, keyboard beeps, but no CRT display.

l Check for green POWER LED at front of CRT.

l Check for power connections to CRT from IOPCB.

l Check video cable (760) from VIDEO PCB to CRT.

l Replace CRT (Section 5.1, Electrical Service).

´ Any LED on Microprocessor PCB goes out (except HALT).

l Replace Microprocessor PCB (Section 4.1, Electrical Service).

l Replace VIDEO PCB (Section 4.1, ElectricalService).

l Replace MOTIF PCB (Section 4.1, Electrical Service).

´ Machine turns on, CRT works, but no keyboard keys work.

l Check keyboard cable (700) from VIDEO to KBIF PCB.

l Replace keypad (Section 5.5, Electrical Service).

l Replace KBIF PCB (Section 4.6, Electrical Service).

2

96-8100 12-15-94

HAAS AUTOMATION, INC.

Page 4

VMC

Vibration

1.2 VIBRATION

Vibration is a subjective evaluation with perceptions varying among individuals, making it difficult to

determine in mild cases if there is an actual problem. Because the VF Series uses a gear head, it will

be noisier than a direct drive or belt system. In obvious cases, it is a matter of determining the source

_ which is not easy, since all parts rotate together and sound can be transferred readily. Vibrations also

need to be distinguished from noise such as a bad bearing. We will assume that vibrations would be

something that could be felt by putting your hand on the spindle covers. One crude method of measurement would be to take an indicator on a magnetic base extended 10 inches between the table and

spindle housing and observe the reading of the indicator. A reading of more than .001 would indicate

excessive vibration. The two common sources of noise are the spindle and axis drives. Most complaints about vibration, accuracy, and finish can be attributed to incorrect machining practices such as

poor quality or damaged tooling, incorrect speeds or feeds, or poor fixturing. Before concluding that

the machine is not working properly, ensure that good machining practices are being observed. These

symptoms will not occur individually (Ex. A machine with backlash may vibrate heavily, yielding a bad

finish.). Put all of the symptoms together to arrive at an accurate picture of the problem.

´ Machine vibrates while spindle is on and is not cutting. Sometimes only at

specific RPM.

l If the spindle alone causes vibration of the machine this is usually caused by the belt/pulley

drive system. This occurs because a pulley is either out of balance, misaligned, or belt tension

is incorrect. It is extremely important that when servicing the spindle transmission that pulleys

are checked for runout. Balance is almost impossible to check except by trial and error. This

method can be accomplished by putting additional washers under one of the allen bolts of

the locking collar and observing the effect. By moving from bolt to bolt you should see better or

worse results and take action accordingly. Vibrations at different speeds are usually caused

by all of the above except that harmonics are in play. If the problem is severe and cannot

simply be corrected, you may have to consider replacing the gearbox and spindle with factorybalanced units.

SERVICE MANUAL

SERVICE TROUBLE

´ Machine vibrates while jogging the axis with the hand wheel.

l The HAAS control uses very high gain accelerations curves. This vibration as you jog is simply

the servos quickly trying to follow the handle divisions. If this is a problem, try using a smaller

division on the handle. You will notice the vibration more at individual clicks than when you are

turning the handle faster. This is normal.

´ The machine vibrates excessively in a cut.

l This is a tough one to call because machining practices come into play. Generally speaking, the

least rigid element of a cut is the tool because it is the smallest part. Any cutter will vibrate if

pushed beyond its tensile strength. In order to eliminate the machine as the source of the

problem, you need to check the spindle and the backlash of the axes as described in the

following sections. Once machining practices have been eliminated as the source of vibration,

observe the machine in both operation and cutting air. Move the axes (individually) without

the spindle turning and then turn the spindle without moving the axes. Isolate whether the

vibration comes from the headstock or from an axis. Isolate the source of vibration per Sec

tions 2.2, 3.2, and Section 6.

12-15-94 96-8100

HAAS AUTOMATION, INC.

3

Page 5

VMC

SERVICE TROUBLE

SERVICE MANUAL

1.3 ACCURACY

Before you complain of an accuracy problem, please make sure you follow these simple dos

and donts.

l Dont ever use a wiggler test indicator for linear dimensions. They measure in an arc and have

sine/cosine errors over larger distances.

l Dont use magnetic bases as accurate test stops. The high accel/decel of the axis can cause

them to move.

l Dont attach test points to the sheet metal of the spindle head or table.

l Dont check for thermal growth with an indicator on a long extension magnetic base.

l Do insure that test indicators and stops are absolutely rigid and mounted to machined casting

surfaces.

l Do check a suspected error with another indicator or method for verification.

l Do ensure that the indicator is parallel to the axis being checked to avoid tangential reading

errors.

l Do center drill holes before using jobber length drills if accuracy is questioned.

l Once machining practices have been eliminated as the source of the problem, determine

specifically what the machine is doing wrong.

Accuracy

´ Machine will not interpolate a round hole.

l Check the levelness of the machine (See the Installation Manual).

l Check for backlash (Section 3.3).

´ Bored holes do not go straight through the workpiece.

l Check the levelness of the machine (See the Installation Manual).

l Check for squareness in the Z axis.

´ Machine bores holes out-of-round.

l Check the levelness of the machine (See the Installation Manual).

l Check the sweep of the machine (Section 5.3, Mechanical Service).

´ Bored holes are out of round, or you bore a hole at a given X/Y position and then

check at the same location using a test indicator and it indicates you are out of

position.

l The spindle is not parallel to the Z axis. Check the spindle sweep to the table and the

squareness of the Z axis with a cylinder square. If available use a spindle master bar and

indicate the spindle to the Z axis.

´ Machine mis-positions holes.

l Check the levelness of the machine (See the Installation Manual).

l Check for backlash (Section 3.3).

l Check the squareness of the X axis to the Y axis.

4

96-8100 12-15-94

HAAS AUTOMATION, INC.

Page 6

VMC

Finish

´ Machine leaves large steps when using a shell mill.

l Check the levelness of the machine (See the Installation Manual).

l Check the sweep of the machine (Section 5.3, Mechanical Service).

l Cutter diameter too large for depth of cut.

´ Boring depth inaccurate (VF-6)

Insufficient counterbalance pressure due to:

l Hose corrupted.

l regulator bad.

l check valve bad.

l air cylinder bad.

l bound cylinder

l surge tank leak

1.4 FINISH

SERVICE MANUAL

SERVICE TROUBLE

´ Machining yields a poor finish.

l Check for backlash (Section 3.3).

l Check the condition of the tooling and the spindle (Section 2).

12-15-94 96-8100

HAAS AUTOMATION, INC.

5

Page 7

VMC

SERVICE TROUBLE

SERVICE MANUAL

Spindle

2. SPINDLE

2.1 NOT TURNING

´ Spindle not turning.

l If there are any alarms, see Section 6.

l Check that the spindle turns freely when machine is off.

l If motor turns but spindle does not, see Sections 3 and 9, Mechanical Service.

l Command spindle to turn at 1800 RPM and check spindle drive display. If display blinks bb,

check spindle orientation switch (Section 7, Mechanical Service). If spindle drive does not light

the RUN LED, check forward/reverse commands from IOPCB (Section 4.3, Electrical Service).

l Check the wiring of analog speed command from MOTIF PCB to spindle drive (cable 720).

l If spindle is still not turning, replace MOTIF PCB (Section 4.1, Electrical Service).

l If spindle is still not turning, replace spindle drive (Section 5, Mechanical Service).

l Check for rotation of the gearbox (VF-1, VF-2, VF-3) or the motor (VF-0). If the motor or gearbox

operates, check the drive belt (Section 3, Mechanical Service).

l Disconnect the drive belt. If the spindle will not turn, it is seized and must be replaced (Section

5, Mechanical Service).

NOTE: Before using the replacement spindle, the cause of the previous failure must be deter

mined.

2.2 NOISE

Most noises attributed to the spindle actually lie in the motor/gearbox or drive belt of the ma

chine. Isolate the sources of noise as follows:

´ Excessive noise coming from the spindle head area.

On VF-1, VF-2, and VF-3 models, first determine if the noise is related to the RPM of the motor or the

RPM of the spindle. For example: If the noise appears at 2000 RPM in high gear, listen for a

similar noise at 500 RPM in low gear. If the same noise persists, the problem lies with the

gearbox. If the noise disappears, the problem could be either the gearbox or the spindle, and

further testing is necessary.

l Check the alignment of the pulleys to the belt. Correct as necessary (Sections 3 and 4,

Mechanical Service).

l Remove the head covers and check the machines drive belt tension (Section 3.3, Mechanical

Service).

ØIf the noise persists, turn the drive belt over on the pulleys. If the noise is significantly

different, the belt is at fault. Replace the belt (Section 3, Mechanical Service).

ØIf the noise does not change, remove the belt and go on to the next step.

l Check the pulleys for excessive runout (more than 0.003" axial or radial).

l Run the motor (VF-0) or the gearbox (VF-1, VF-2, VF-3) with the drive belt disconnected. If the

noise persists, the problem lies with the gearbox/motor. If it disappears, go on to the next step.

l Check for the correct amount of lubrication to the spindle bearings (1-2 cc every two hours) in a

an air mist-lubricated spindle.

ØIf the spindle is not getting lubrication, correct the problem per the lube and air dia

gram at the back of this manual and replace the spindle (Section 5,Mechanical Service).

ØIf the spindle is getting lubrication, replace the spindle (Section 5,Mechanical Service).

6

96-8100 12-15-94

HAAS AUTOMATION, INC.

Page 8

VMC

Spindle

2.3 OVERHEATING

When investigating complaints of overheating, a temperature probe must be used to accurately

check the temperature at the top of the spindle taper. The temperature displayed in Diagnostics is not

relevant. A machine that runs at high RPM continuously will have a much warmer spindle than a machine that runs at a lower RPM. New spindles tend to run much warmer than spindles that have already been broken in. In order to run a valid test on a new spindle, ensure that it is properly broken in.

To break in a spindle, do the following:

l Run the spindle at 300 RPM for at least two (2) hours.

l Increase the spindle speed to 1000 RPM for 20 minutes.

l Increase the spindle speed to 3000 RPM for 20 minutes.

l Increase the spindle speed to 7000 RPM for 20 minutes.

l Stop the spindle and allow to cool to room temperature.

l Turn the spindle on to 7000 RPM and monitor the temperature inside the spindle taper at 15-

minute intervals until the temperature drops off, then stabilizes. This will take about two

(2)hours.

l Temperatures of about 140

If the spindle fails this test, check the following:

l Check for correct amount of lubrication (1-2 cc every two hours).

o

are possible at the end of this test.

SERVICE MANUAL

SERVICE TROUBLE

NOTE: Over lubrication is a common source of overheating. Check the oil flow carefully.

l Check the drive belt tension (Section 3, Mechanical Service). Too-tight belts will cause heating

of the top bearing in the spindle housing.

l Ensure that the correct oil is being used (Lubrication Chart, page 131).

Spindle Motor Overheat Sense Switch

There is a normally closed thermal switch in the spindle motor. Should the temperature reach 210 F

the switch will trigger an alarm- Spindle Drive Fault.

12-15-94 96-8100

HAAS AUTOMATION, INC.

7

Page 9

VMC

SERVICE TROUBLE

SERVICE MANUAL

2.4 STALLING/LOW TORQUE

Generally, complaints of stalling or low torque relate to incorrect tooling or machining practices. A

spindle that is tending to seize will yield a poor finish machining, run very hot and very loud. Investigate machining problems before concluding the problem exists with the spindle or spindle drive.

It is important to consider what horsepower and torque is available in various speed ranges of the

spindle. If your machine is a VF-1 or VF-2 (with a transmission), the following horsepower and torque

are available in low gear:

SPEED (RPM) TORQUE (ft-lb) HORSEPOWER

0-100 45-90 less than 2

100-500 90 3 to 7.5

500-1250 90-35 7.5

1250-1840 35-25 7.5 to 5

If your machine is a VF-0 (no transmission) or a VF-1 or VF-2 and you are in high gear, the following

are available:

Spindle

SPEED (RPM) TORQUE (ft-lb) HORSEPOWER

0-400 11-22 less than 2

400-2000 22 3 to 7.5

2000-5000 22-9 7.5

5000-7500 9-6 7.5 to 5

If your machine is a VF-3, the following horsepower and torque are available in low gear:

SPEED (RPM) TORQUE (ft-lb) HORSEPOWER

0-125 60-120 less than 3

125-625 120 4 to 10

625-1550 120-45 10

1550-1840 45-32 10 to 7

If your machine is a VF-3 and you are in high gear, the following are available:

SPEED (RPM) TORQUE (ft-lb) HORSEPOWER

0-600 15-30 less than 3

600-2500 30 4 to 10

2500-6250 30-11 10

6250-7500 11-9 10 to 7

If you still have spindle torque problems and there is no mechanical cause such as binding or

friction in the transmission or spindle, the motor or spindle drive are the cause. The first choice for

replacement is the spindle drive. If there is still a problem, the entire motor/transmission assembly

must be replaced.

8

96-8100 12-15-94

HAAS AUTOMATION, INC.

Page 10

VMC

Spindle

2.5 SPINDLE DRIVE

Low line voltage may prevent the spindle from accelerating properly. If the spindle takes a long

time to accelerate, slows down or stays at a speed below the commanded speed with the load meter

at full load, the spindle drive and motor are overloaded. High load, low voltage, or too fast accel/decel

can cause this problem. See Section 28 for adjustment.

If the spindle is accelerated and decelerated frequently, the regenerative load resistor inside the

control may heat up. If this resistor heats beyond 100oC, a thermostat will generate an overheat

alarm.

If the regen load resistors are not connected or open, this could then result in an overvoltage alarm.

The overvoltage occurs because the regenerative energy being absorbed from the motor while decelerating is turned into voltage by the spindle drive. If this problem occurs, the possible fixes are to slow

the decel rate or reduce the frequency of spindle speed changes.

2.6 ORIENTATION

SERVICE MANUAL

SERVICE TROUBLE

´ Spindle loses correct orientation.

l Check alarm history, looking for spindle overload and axis overcurrent alarms. These alarms

indicate the machine is not being properly operated.

l Check the orientation ring for tightness (Section 7, Mechanical Service). Ensure the shaft on

which the ring mounts is free of grease.

l Check the orientation ring for cracks near the bolt holes or near the balancing holes.

> If there are cracks, replace the ring (Section 7, Mechanical Service).

> If there are no cracks, remove the drive belt (Section 3, Mechanical Service) and verify that

the pulley on the transmission output shaft is tight. On most machines, there is no key on the

transmission pulley.

l Check the shot pin on the gearbox for binding, damage, and proper operation. Replace it if it is

damaged.

l Check the switch on the shot pin against the Diagnostic display. Replace the switch if it is

found to be faulty.

2.7 TOOLS STICKING IN TAPER

´ Tool sticking in the taper causes ATC to be pulled up; accompanied by a popping

noise as the tool holder pops out of the spindle taper.

NOTE: This problem may occur after loading a cold tool into a hot spindle (a result of thermal

expansion of the tool holder inside the spindle taper), or after heavy milling. If sticking only occurs

during these situations, no service is necessary.

l Check the condition of the customers tooling, verifying the taper on the tooling is ground and

not turned. Look for damage to the taper caused by chips in the taper or rough handling. If the tooling

is suspected, try to duplicate the symptoms with different tooling.

l Check the condition of the spindle taper. Look for damage caused by chips or damaged

tooling. Also, look for damage such as deep gouges in the spindle taper caused by tool

12-15-94 96-8100

HAAS AUTOMATION, INC.

9

Page 11

VMC

SERVICE TROUBLE

crashing. See Section 5, Mechanical Service, for spindle cartridge replacement.

l Duplicate the cutting conditions under which the deflection occurs, but do not execute an

automatic tool change. Try instead to release the tool using the tool release button on the front

of the spindle head. If sticking is observed, the deflection is not caused by improper ATC

adjustment, but is a problem in the spindle head on the machine. See Section 5, Mechanical

Service, for spindle cartridge replacement.

l Ensure the spindle is not running too hot (Section 2.3).

SERVICE MANUAL

Servos / Leadscrews

3. SERVO MOTORS / LEADSCREWS

There is very little that a user might do to repair a servo motor. Problems with servo motors may

include open-circuited motor, shorted winding of motor, motor shorted to case, water (coolant) in motor,

or overheat damage to motor. None of these can be fixed by the user so the motor must be replaced.

All of the above problems would generate alarms identifying one of the servo motors as having failed.

These alarms are 103-106 (following error too large), 108-111 (servo overload), 135-138 (overheat),

139-142 (Z channel fault), 153-156 (Z channel missing), and 161-164 (overcurrent).

Attached to each DC servo motor, there is an incremental encoder that is 2000 lines per revolution.

These encoders also supply a Z channel pulse once per revolution. The encoders and Z channel are

continuously monitored to ensure the number of pulses matches for each revolution of the motor. If the

encoders become contaminated, these pulse counts will be wrong and an alarm will be generated.

This ensures that the data from the encoders is reliable. There can never be a loss of servo position

due to accumulated encoder errors. The alarms generated will indicate that either the Z pulse occurred

and the encoder pulse was wrong or, after one and one half motor revolutions, the Z pulse did not

occur.

Encoders faults can be caused by contamination of the encoder or by a wiring problem. If the

encoder is contaminated, it must be replaced. Wiring problems may be a broken wire, shorted wire, or

missing shield. All wires to the encoder are enclosed in their own shielded cable. In addition, all

power wires to the motor are enclosed in a separately shielded cable. Failure of either of these shields

may cause noise in the encoder circuits and result in the encoder fault alarms.

Never connect or disconnect the servo motor cables with the control powered as this will cause an

apparent encoder fault.

Servo Characteristics

This machine is not capable of instantly changing speed. That is, it takes some non-zero time to

accelerate and decelerate. Acceleration and deceleration in this machine have both a constant accel/

decel mode and an exponential mode. Constant acceleration is used at the beginning of a rapid move

and at the end of any move whose speed exceeds the exponential accel/decel time constant.

Constant acceleration is a type of motion when the amount of speed change over time is constant.

This constant is set by Parameters 7, 21, 35, and 49. It has units of encoder increments per second

per second.

Exponential acceleration and deceleration is a type of motion where the speed is proportional to the

10

96-8100 12-15-94

HAAS AUTOMATION, INC.

Page 12

VMC

Servos / Leadscrews

distance remaining in a programmed travel. The exponential accel/decel time constant is set by Para

meters 113, 114, 115, and 116. It has units of 0.0001 seconds. The speed limit at which exponential

accel/decel is not available is defined by the relationship between Parameters 7 and 113 (for the Xaxis). Thus if Parameter 7 is 1200000 steps/sec/sec and Parameter 113 is 750 (0.075 seconds); the

maximum velocity for accurate interpolation should be:

1200000 x 0.075 = 90000 steps/second

For a 2000 line encoder and 6 mm screw, this would be:

60 x 90000 / 33867 = 159 inches/minute

In the normal feed cutting mode, with G64 active, giving continuous cutter motion, deceleration of

the axes in motion begins at some distance away from the end point. If look-ahead has provided

another motion, the acceleration for that motion will begin at the same instant. This means that two

motions, at right angles to each other, will not produce a perfectly square corner. The corner will be

rounded. It also means that if the two motions are parallel or nearly parallel, there will be a smooth

transition from one stroke to the next.

Rapid moves have a slightly different operation when continuous cutter mode is active. Acceleration for the next motion is started when the axes being moved all fall within the In Position Limit Parameters 101, 102, 103, and 104. These parameters have units of encoder steps. Rapid moves will

also decelerate at the constant accel/decel limit until the speed drops below that for exponential accel/

decel (see example above giving 159 inches per minute). Parameter 57 can be used to override this.

SERVICE MANUAL

SERVICE TROUBLE

To prevent the rounding of corners, you can specify exact stop either with G09 (non-modal) or with

G61 (modal). When either of these is active in a motion, all of the axes are brought to an exact stop, at

zero speed, before the next motion is started.

The tool path in a circular move (G02 or G03) is not changed by the exponential acceleration/

deceleration so there is no error introduced in the radius of the cut unless the speed exceeds that for

exponential accel/decel (see example above giving 159 inches per minute).

The servo motor encoders are differential line drivers. This means that the A, B, and Z signals are

transmitted to the control as signal pairs. A cable test is performed on these signals to ensure the

differential pair are always present.

Overheat Sense Switches

Each servo motor contains a normally-open overtemperature sense thermostat. When the motor

case temperature exceeds 150° F, an alarm will be generated and operation of the machine will stop.

This alarm should not occur under any normal operating circumstances and usually indicates that there

is serious problem with the motor or drive circuit. After September 1990, the overheat sensor was

changed to normally closed. This change is specified in the parameters.

Overcurrent Sensor

Each servo motor drive circuit contains a current limit setting and an overcurrent sense circuit.

When an overcurrent condition persists for more than 0.01 second, an alarm will be generated and

operation of the machine will stop. This current limit is presently set at 20 amps.

Ground Fault Detector

This control has a ground fault sense circuit added to the servo drive power supply. This circuit will

12-15-94 96-8100

HAAS AUTOMATION, INC.

11

Page 13

VMC

SERVICE TROUBLE

SERVICE MANUAL

detect a short to ground on any of the servo motor power leads or in the internal 115V AC power. A

ground fault can be caused by arcing brushes in the servo motors and will shut off all servo power.

3.1 NOT OPERATING

All problems that are caused by servo motor failures should also register an alarm. Check the

alarm history to determine the problems cause before any action is taken.

´ Servo motor is not functioning.

l Check the power cable from rear electrical cabinet to ensure connection is tight.

l Encoder is faulty or contaminated (Alarms 139-142, 153-156, 165-168, 182-185). Replace motor

assembly (Section 10, Mechanical Service).

l Open circuit in motor (Alarms 139-142, 153-156, 182-185). Replace motor assembly (Section

10 , Mechanical Service).

l Motor has overheated, resulting in damage to the interior components (Alarms 135-138, 176).

Replace motor assembly (Section 10, Mechanical Service).

l Wiring is broken, shorted, or missing shield (Alarms 153-156, 175, 182-185).

l Dust in the motor from brushes has shorted out the motor (Alarms 153-156, 175, 182-185).

Replace motor assembly (Section 10, Mechanical Service).

l Motor has overheated; no damage to the interior components. OVERHEAT alarm has been

triggered. After thorough check of motor (DO NOT DISASSEMBLE!), take necessary steps to

eliminate the problem and alarm to resume operation. If motor is still inoperable, replace motor

assembly (Section 10, Mechanical Service).

l Check for broken or loose coupling between the servo motor and the lead screw. Replace or

repair the coupling (Section 10.4, Mechanical Service)

l Check for a broken lead screw. If cracked or broken, replace (Section 10, Mechanical Service).

Servos / Leadscrews

NOTE: If a lead screw fails, it is most often due to a failed bearing sleeve. When replacing the lead

screw in an older machine, always replace the bearing sleeve with the current angular contact

bearing sleeve (Section 12, Mechanical Service).

3.2 NOISE

Lead screw noise is usually caused by a lack of lubrication and is usually accompanied by heating. Other causes are misalignment, bearing sleeve damage, or ball nut damage. Check the alarm

history of the machine and look for axis overcurrent and following error alarms.

NOTE: Do not replace lead screws or bearing sleeves without due consideration; they are extremely durable and reliable. Verify that customer complaints are not due to tooling, programming, or

fixturing problems.

´ Servo motor noise.

l Disconnect the servo motor from the lead screw and rotate by hand. If the noise persists,

replace the motor assembly (Section 10, Mechanical Service).

l Noise is caused by motor brushes. No problems will occur and noise should eventually go

away.

l Noise is caused by bearings. Rolling, grinding sound is heard coming from the motor. EN

SURE NOISE IS NOT COMING FROM THE BRUSHES. If bearings are making a consistently

loud sound, replace the bearing sleeve (Section 12, Mechanical Service).

12

96-8100 12-15-94

HAAS AUTOMATION, INC.

Page 14

VMC

Servos / Leadscrews

´ Lead screw noise.

l Ensure oil is getting to the lead screw through the lubrication system (See Air and Oil Diagrams,

pages 129 & 130). Look for a plugged metering valve.

l Check for damage to the bearing sleeve.

l Check the pre-load on old-style bearing sleeves (Section 12, Mechanical Service).

NOTE: The current angular contact design sleeve has a fixed pre-load; it cannot be adjusted.

l Run the axis back and forth. The motor will get very hot if the bearing sleeve is damaged. If

so, turn the axis by hand and feel for roughness in the lead screw. Loosen the clamp nuts at

both ends of the lead screw. If the symptom disappears, replace the bearing sleeve (Section

12, Mechanical Service). Be certain to check for damage to the lead screw shaft where the

bearing sleeve is mounted.

Ø If the noise persists, the lead screw is damaged and must be replaced (Section 11, Mechani

cal Service). When replacing the lead screw in an older machine, always replace the bearing

sleeve with the current angular contact design bearing sleeve (Section 12, Mechanical Service).

l Check the lead screw for misalignment. If incorrect, align as outlined in Section 11, Mechanical

Service.

SERVICE MANUAL

SERVICE TROUBLE

Misalignment in the lead screw itself will tend to cause the lead screw to tighten up and make

excessive noise at both ends of the travel. The ballnut may get hot. Misalignment radially at the yoke

where the lead screw ball nut mounts is indicated by heating up of the ball nut on the lead screw, and

noise and tightness throughout the travel of the lead screw. Misalignment at the yoke where the ball nut

mounts is indicated by noise and tightness at both ends of the travel of the lead screw. The ball nut

may get hot.

´ Noise in Z - Motion (VF-6)

l Brake won't release (leadscrew won't rotate)

Ø alarm not cleared

Ø low pressure switch blown

Ø brake power fuse blown

Ø brake power transformer blown

Ø brake power rectifier blown

Ø cabling pinched

Ø brake failed

3.3 ACCURACY/BACKLASH

Accuracy complaints are usually related to tooling, programming, or fixturing problems. Eliminate

these possibilities before working on the machine.

´ Poor mill table-positioning accuracy.

l Check for a loose encoder on the servo motor. Also, ensure the key in the motor or the

lead screw is in place and the coupling is tight (Sections 10, 11, Mechanical Service).

12-15-94 96-8100

HAAS AUTOMATION, INC.

13

Page 15

VMC

SERVICE TROUBLE

l Check for backlash in the lead screw as outlined below:

SERVICE MANUAL

INITIAL PREPARATION -

Turn the VMC ON. ZERO RET the machine and move the mill table to the approximate center of its

travel in the X and Y directions. Move the spindle head to approximate center of the Z-axis travel, also.

CHECKING X-AXIS:

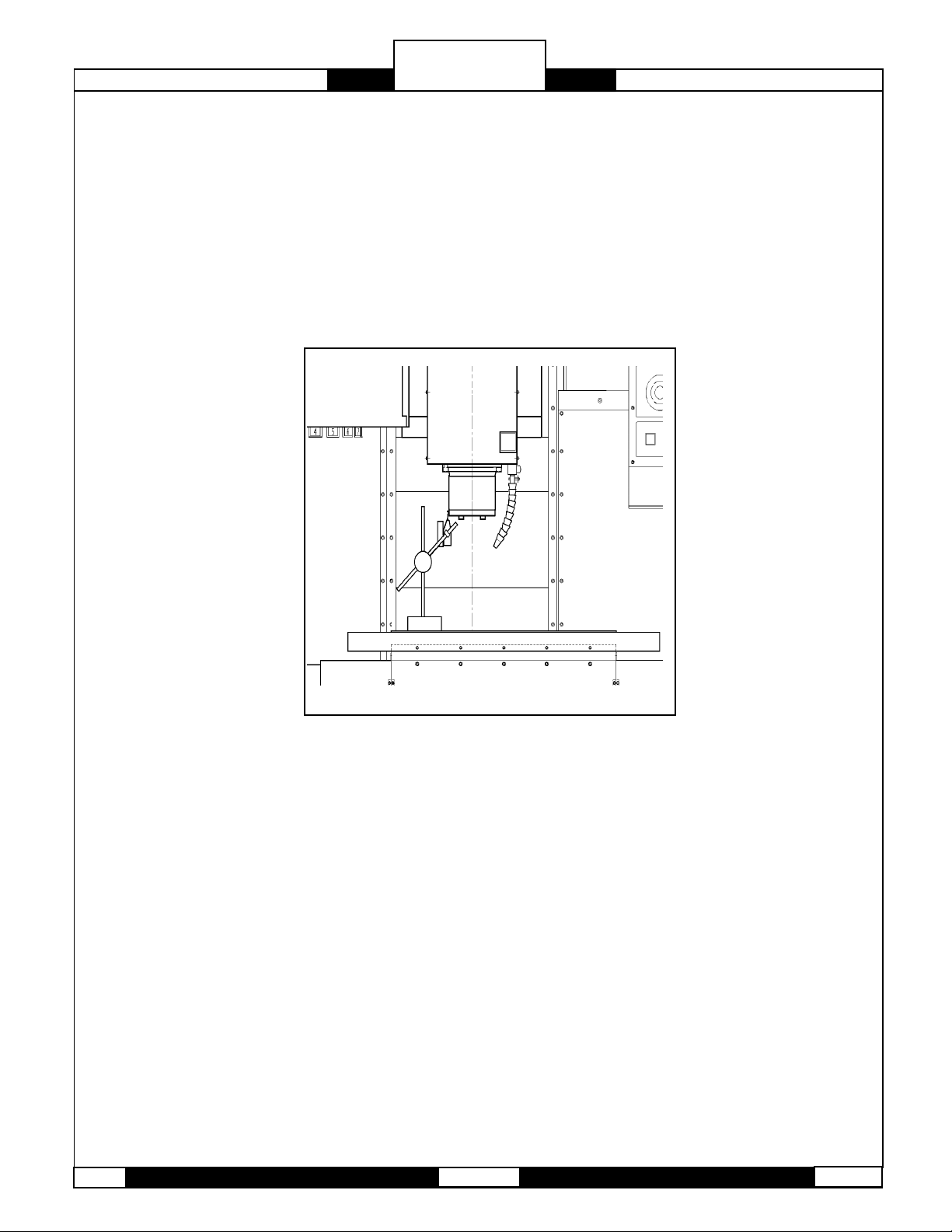

1. Set up a dial indicator and base on the mill table as shown in Fig. 3-1.

Servos / Leadscrews

Fig. 3-1 Dial indicator in position to check X-axis.

2. Set dial indicator and the Distance to go display in the HANDLE JOG mode to zero as fol

lows: - Zero the dial indicator. - Press the MDI button on the control panel. - Press the HANDLE

JOG button on the control panel. The Distance to go display on the lower right hand corner

should read: X=0 Y=0 Z=0

3. Set the rate of travel to .001 on the control panel and jog the machine .010 in the positive (+) X

direction. Jog back to zero (0) on the display. The dial indicator should read zero (0) ± .0001.

4. Repeat step three in the negative (-) direction.

TOTAL DEVIATION BETWEEN THE DIAL INDICATOR AND THE CONTROL PANEL DISPLAY

SHOULD NOT EXCEED .0002.

An alternate method for checking backlash is to place the dial indicator as shown in Fig. 3-1 and

14

96-8100 12-15-94

HAAS AUTOMATION, INC.

Page 16

VMC

Servos / Leadscrews

manually push on the mill table in both directions. The dial indicator should return to zero after releasing

the table. NOTE: The servos must be on to check backlash by this method.

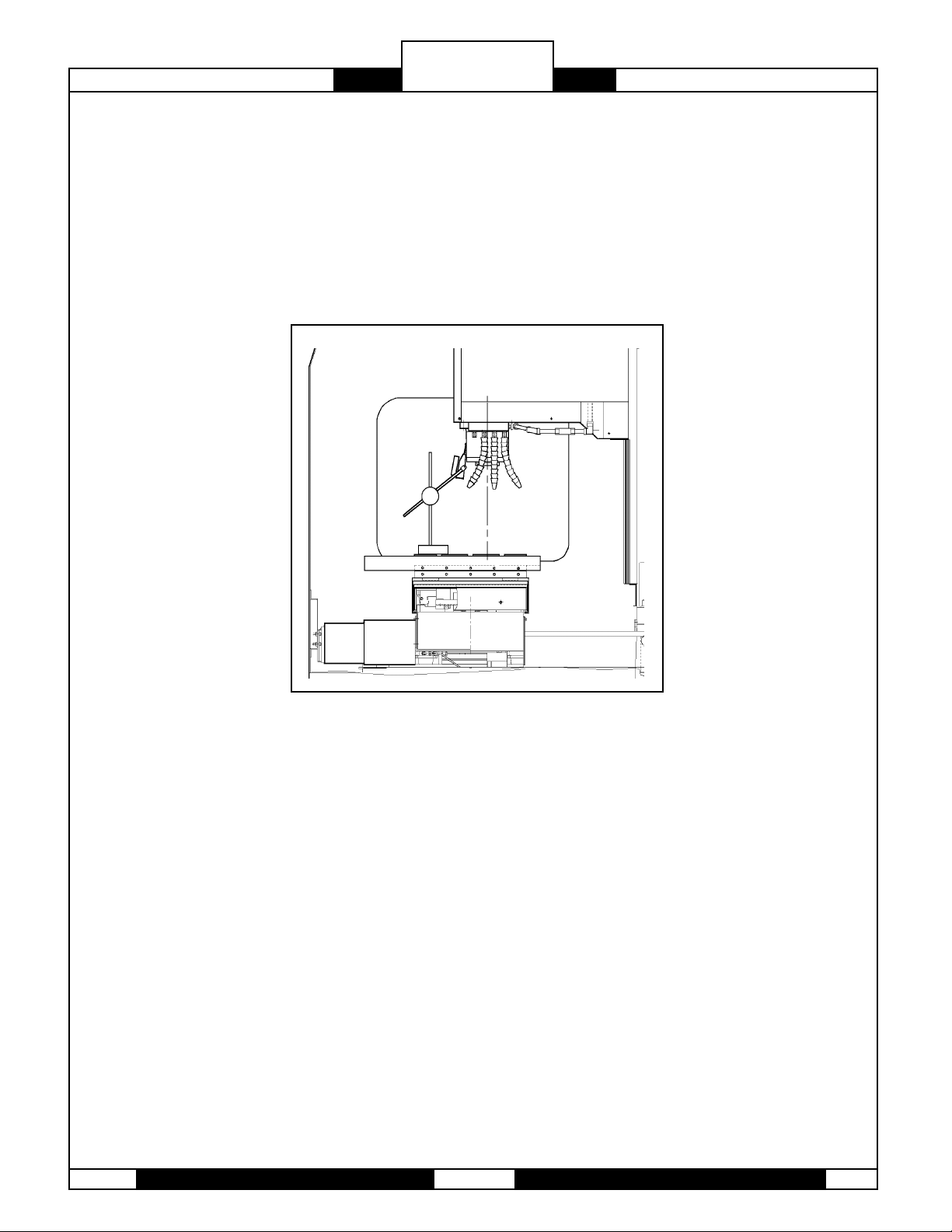

CHECKING Y-AXIS:

1. Set up a dial indicator and base on the mill table as shown in Fig. 3-2.

SERVICE MANUAL

SERVICE TROUBLE

Fig. 3-2 Dial indicator in position to check Y-axis.

2. Set dial indicator and the Distance to go display in the HANDLE JOG mode to zero as fol

lows: - Zero the dial indicator. - Press the MDI button on the control panel. - Press the HANDLE

JOG button on the control panel. The Distance to go display on the lower right hand corner

should read: X=0 Y=0 Z=0

3. Set the rate of travel to .001 on the control panel and jog the machine .010 in the positive (+) Y

direction. Jog back to zero (0) on the display. The dial indicator should read zero (0) ± .0001.

4. Repeat step three in the negative (-) direction.

TOTAL DEVIATION BETWEEN THE DIAL INDICATOR AND THE CONTROL PANEL DISPLAY

SHOULD NOT EXCEED .0002.

An alternate method for checking backlash is to place the dial indicator as shown in Fig. 3-2 and

manually push on the mill table in both directions. The dial indicator should return to zero after releasing

the table.

NOTE: The servos must be on to check backlash by this method.

12-15-94 96-8100

HAAS AUTOMATION, INC.

15

Page 17

VMC

SERVICE TROUBLE

SERVICE MANUAL

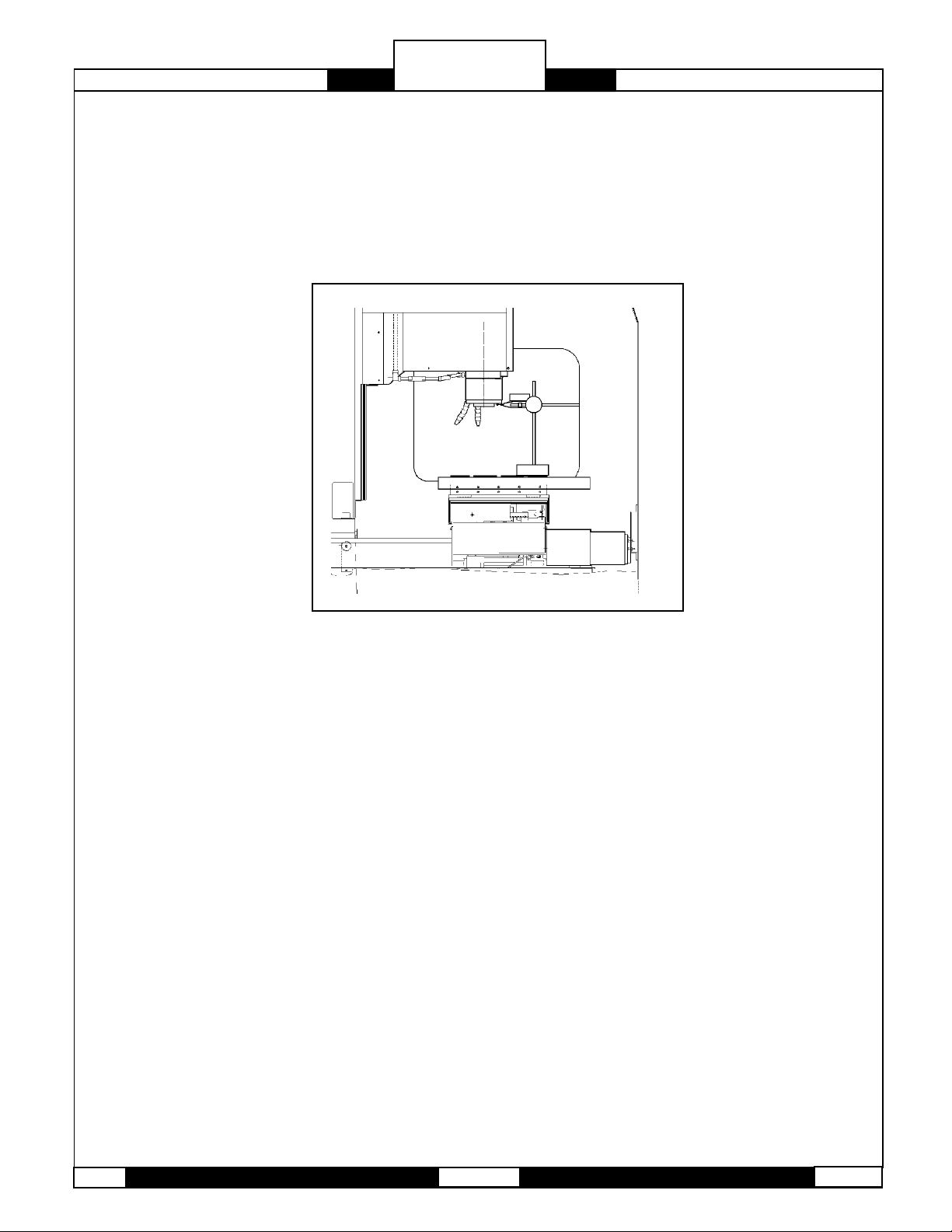

CHECKING Z-AXIS:

1. Set up a dial indicator and base on the mill table as shown in Fig. 3-3.

2. Manually push up and down on the spindle head while listening for a clunk. Also, watch for any

rapid change in the dial indicator. Either of these indicate possible backlash.

NOTE: Servos must be on to check for backlash in the Z-axis.

NOTE: Do not mistake deflection for backlash in the system.

Servos / Leadscrews

Fig. 3-3 Dial indicator in position to check Z-axis.

> If backlash is found in the system, check for the following possible causes:

l Loose SHCS attaching the ball nut to the nut housing. Tighten the SHCS as described in

Section 11, Mechanical Service.

l Loose SHCS attaching the nut housing to the mill table, spindle head, or saddle, depending on

the axis. Tighten the SHCS as described in Section 11, Mechanical Service.

l Loose clamp nut on the bearing sleeve. Tighten the SHCS on the clamp nut.

l Loose motor coupling. Tighten as described in Section 10.4, Mechanical Service.

l Broken or loose flex plates on the motor coupling. (NOTE: The coupling cannot be serviced in

the field and must be replaced as a unit if it is found to be defective. See Section 10.4, Mechani

cal Service.)

l Loose SHCS attaching the bearing sleeve to the motor housing. Tighten as described in Sec

tion12, Mechanical Service.

l Defective thrust bearings in the bearing sleeve. Replace the bearing sleeve as outlined in

Section 12, Mechanical Service.

l Loose SHCS attaching the axis motor to the motor housing. If the SHCS are found to be loose,

inspect the motor for damage and if none is found, tighten as described in Section 10, Mechani

cal Service. If damage is found, replace the motor (Section 10, Mechanical Service.)

l Incorrect backlash compensation number in the parameter in the machine. Check Parameters

13, 27, and 41.

l Worn lead screw. Replace as outlined in Section 11, Mechanical Service.

16

96-8100 12-15-94

HAAS AUTOMATION, INC.

Page 18

VMC

Servos / Leadscrews

3.4 VIBRATION

´ Excessive servo motor vibration.

l If no A axis is present, swap the suspected bad servo motor with the A driver and check to

see if there is a driver problem. If needed, replace the DRIVER PCB (Section 4.2, Electrical

Service).

l Check all Parameters of the suspected axis against the Parameters as shipped with the ma

chine. If there are any differences, correct those and determine how the Parameters were

changed. PARAMETER LOCK should normally be on.

l A bad motor can cause vibration if there is an open or short in the motor. A short would normally

cause a GROUND FAULT or OVERCURRENT alarm; check the ALARMS. An ohmmeter

applied to the motor leads should show between 1 and 3 ohms between leads, and over 1 me

gohm from leads to chassis. If the motor is open or shorted, replace (Section 10, Mechanical

Service).

3.5 OVERHEATING

´ Servo motor overheating.

l If a motor OVERHEAT alarm occurs (ALARMS 135-138), check the Parameters for an incorrect

setting. Axis flags in Parameters 1, 15, or 29 can invert the overheat switch (OVER TEMP NC).

l If the motor is actually getting hot to the touch, there is excessive load on the motor. Check the

users application for excessive load or high duty cycle. Check the lead screw for binding

(Section 3.3). If the motor is binding by itself, replace (Section 10, Mechanical Service).

SERVICE MANUAL

SERVICE TROUBLE

3.6 FOLLOWING ERROR

´ Following error alarms occur on one or more axes sporadically.

l Check DC bus voltage on diagnostics page #2. If it is at the low side of the recommended

voltages, change the transformer tap to the next lower voltage group as explained in the Installa

tion Manual.

l Check motor wiring.

l Replace driver card (Section 4.2, Electrical Service).

l Replace servo motor (Section 10, Mechanical

´ Z-axis motor overcurrent (VF-6)

l Brake won't release (leadscrew won't rotate)

Ø alarm not cleared

Ø low pressure switch blown

Ø brake power fuse blown

Ø brake power transformer blown

Ø brake power rectifier blown

Ø cabling pinched

Ø brake failed

12-15-94 96-8100

HAAS AUTOMATION, INC.

17

Page 19

VMC

SERVICE TROUBLE

SERVICE MANUAL

Tool Changer

4. AUTOMATIC TOOL CHANGER

4.1 DEFLECTION

Deflection is usually caused by ATC misalignment, and sometimes caused by damaged or

poor quality tooling, a damaged spindle taper, or a damaged drawbar. Before beginning any troubleshooting, observe the direction of the ATC deflection.

´ During a tool change, ATC appears to be pushed down.

l Check to see if pull studs on the tool holder are correct and tight.

l Check the adjustment of the Z offset (Parameter 64, section 8, Mechanical Service).

NOTE: If the offset is incorrect a tool changer crash has occured and a thorough inspection of the

ATC is necessary at this time.

l Check the adjustment of the Z offset check parameters 71, 72, and 143 against the values

that are in the documentation sent with the machine.

l Ensure the tool holders are held firmly in place by the extractor forks.

l Ensure the balls on the drawbar move freely in the holes in the drawbar when the tool release

button is pressed. If they do not move freely, the a ATC will be pushed down about 1/4" before

the tool holder is seated in the taper, resulting in damage to the roller bolts on the ATC

shuttle. Replace the drawbar. (Section 5.3, Mechanical Service)

´ Tool holder sticking in the spindle taper causes the ATC to be pulled up as the

spindle head is traveling up after depositing the tool holder in the carousel; ac

companied by a popping noise as the tool holder pops out of the spindle taper.

NOTE: This problem may occur after loading a cold tool into a hot spindle (a result of thermal

expansion of the tool holder inside the spindle taper), or after heavy milling. If sticking occurs only

during these circumstances, no service is necessary.

l Check the condition of the customers tooling, verifying the taper on the tool holder is ground

and not turned. Look for damage to the taper caused by chips in the taper or rough handling.

If the tooling is suspected, try to duplicate the symptoms with different tooling.

l Check the condition of the spindle taper. Look for damage caused by chips or damaged

tooling. Also, look for damage such as deep gouges in the spindle taper caused by tool

crashing. See Section 5, Mechanical Service, for spindle cartridge replacement.

l Duplicate the cutting conditions under which the deflection occurs, but do not execute an auto

matic tool change. Try instead to release the tool using the tool release button on the front of the

spindle head. If sticking is observed, the deflection is not caused by improper ATC adjustment,

but is a problem in the spindle head on the machine. See Section 5, Mechanical Service, for

spindle cartridge replacement.

18

96-8100 12-15-94

HAAS AUTOMATION, INC.

Page 20

VMC

Tool Changer

´ During a tool change, ATC appears to be pulled up; no popping noises.

l Check the adjustment of the Z offset (Parameter 64, Section 8, Mechanical Service). NOTE: If

the offset is incorrect, a tool changer crash has occurred, and a thorough inspection of the ATC

is necessary at this time.

l Ensure the roller bolts on the shuttle of the ATC are tight against the v-guides on the ATC

holding arm. If the lower right roller bolt is loose against the v-guide, the upper right bolt is

probably bent. See the following section (ATC Crashing) or Section 14.2, Mechanical Service,

for roller bolt replacement. NOTE: Bent roller bolts are a symptom of another problem with the

ATC. Repair the bent roller bolt and then isolate the ATC problem.

l Check Parameter 71 against the values that are in the documentation sent with the machine.

l Ensure the balls on the drawbar move freely in the holes in the drawbar when the tool release

button is pressed. If they do not move freely, the ATC will be pushed down about ¼ before the

tool holder is seated in the taper, resulting in damage to the roller bolts on the ATC shuttle.

Replace drawbar (Section 5.3, Mechanical Service).

´ Tool holders twist against extractor fork during a tool change.

l Check the alignment of the ATC in the X and Y axes (Section 14.3, Mechanical Service).

SERVICE MANUAL

SERVICE TROUBLE

´ Tool holders spin at all pockets of the ATC when the ATC shuttle retracts.

l ATC is misaligned in the Y axis. Realign ATC (Section 14.3, Mechanical Service). NOTE:

Observe the direction the tool holder rotates, as this will be the direction in which the Y axis of

the ATC needs to be moved.

´ Tool holders spin only at certain pockets of the ATC when the ATC shuttle

retracts.

l Check all the extractor forks to ensure they are centered in the pocket of the ATC. Also, see

above. See Section 14.6, Mechanical Service, for extractor fork replacement.

NOTE: If the ATC shows the problem as described here, each extractor fork must be checked and

centered to eliminate the possibility of the ATC being aligned against an incorrectly-centered fork.

4.2 CRASHING

Crashing of the ATC is usually a result of operator error. The most common ATC crashes are

outlined as follows:

´ Shuttle crashes into spindle when a tool change is commanded (tool holder is in

the pocket facing the spindle head).

l Rotate the carousel to an empty pocket. Refer to the Programming and Operation manual for

correct operation.

NOTE: This crash is fairly common and is a result of operator error. If the ATC is stopped in the

middle of tool change cycle, the operator must command the ATC to an empty pocket before the

machine will operate correctly. Repeated crashes of this type can damage the I/O board, the slip

clutch, and the shuttle motor in the ATC.

12-15-94 96-8100

HAAS AUTOMATION, INC.

19

Page 21

VMC

SERVICE TROUBLE

SERVICE MANUAL

´ Spindle crashes into top of the tool holder after a turret rotation during a tool

change.

When the spindle head moves down over the top of the tool holder during a tool change, the pull

stud will bind inside the drawbar bore of the spindle, forcing the ATC down, bending the upper right

roller bolt on the ATC shuttle or completely breaking it off. Tool holder is not held correctly in the extractor fork, possibly held only in one side of the extractor and at an odd angle.

l Check all of the extractor forks on the ATC. Replace, if needed (Section 14.6, Mechanical

Service).

´ Spindle crashes into top of the tool holder after a turret rotation during a tool

change.

The balls in the drawbar do not move freely, causing the ATC to be forced down far enough to bend

the upper right roller bolt or completely break it off.

l Ensure the balls on the drawbar move freely in the holes in the drawbar when the tool release

button is pressed. If this failure occurs, check all of the extractor forks on the ATC for damage

and repair the spindle drawbar. See Section 14.1 for ATC shuttle replacement, Section 5.3,

Mechanical Service, for drawbar replacement, and 14.2, Mechanical Service, for extractor fork

replacement.

Tool Changer

´ ATC properly deposits a tool holder in the spindle, but the tools are dropped onto

the machine table when the shuttle retracts.

l Inspect the balls and the Belleville springs in the drawbar. See Section 5.3, Mechanical Service,

for drawbar replacement.

´ The part or fixture on the mill table crashes into long tooling or into the ATC

itself during a tool change.

l Program the machine to move the part out of the way of the ATC. Inspect the pocket involved in

the crash for damage and replace parts as necessary.

´ The part or fixture on the mill table crashes into long tooling or into the ATC

itself when machining.

l Either reposition the tools to remove the interference, or program the carousel to rotate long

tooling out of the way of the part (USE THIS ONLY AS A LAST RESORT). CAUTION! If the carou

sel has to be programmed to rotate long tools clear of the part, the correct carousel position

must be programmed back in before a tool change can be executed. NOTE: If these crashes

occur, thoroughly inspect the ATC for damage. Pay close attention to the extractor forks, the

sliding covers on the ATC carousel, and the roller bolts on the ATC shuttle. See Section 14.2,

Mechanical Service for extractor fork replacement and Section 14.7, Mechanical Service, for

sliding door replacement.

20

96-8100 12-15-94

HAAS AUTOMATION, INC.

Page 22

VMC

Tool Changer

4.3 BREAKAGE

Breakage of the ATC is caused by either very hard or repeated crashes.

´ ATC shuttle is broken off of the holding plate.

l Carefully inspect the bosses on the shuttle casting (where the roller bolts mount) for damage to

the threads or cracks. If any of the bosses are cracked, replace the casting. Realign the tool

changer after repairing the machine (Section 14, Mechanical Service).

´ ATC extractor forks are damaged after breakage.

l Check the condition of the mounting holes in the carousel. If the threads are damaged, they

must be repaired or the carousel replaced. See Section 14.6, Mechanical Service, for extractor

fork replacement.

SERVICE MANUAL

SERVICE TROUBLE

4.4 NOISY OPERATION

To isolate noise(s) in the ATC, carefully observe the ATC in operation and look for the following:

´ ATC makes noise as the shuttle moves.

l Check the adjustment of the roller bolts on the ATC (Section 14.2, Mechanical Service). Loose

roller bolts can cause the ATC to make a clunking noise when the shuttle is commanded to

move. Tight roller bolts can cause the shuttle motor to labor excessively, possibly damaging

the motor or the I/O board. In this case, the shuttle may also move too slowly.

l Check for damage to the trap door on the ATC cover. See Section 14.11, Mechanical Service,

for trap door replacement.

l Check for missing plastic riders on the ATC shutter. See Section 14.11, Mechanical Service, for

shutter replacement.

l Ensure the guide pin mounted to the holding plate is not bent and does not scrape the ATC

cover during movement. See Section 14.11, Mechanical service, for guide pin replacement.

l Listen for damage to the gear train in the shuttle motor. If the motor is found to be the source of

the noise, replace the motor (Section 14.8, Mechanical Service). DO NOT try to repair the motor

or to further isolate the noise in the motor. ATC makes noise during carousel rotation.

l Check to ensure the Geneva driver on the turret motor is tight and properly adjusted (Section

14.8, Mechanical Service). If the Geneva driver is found to be loose, check for damage to the

Geneva star. Any roughness in the slots will require that it be replaced (Section 14.10, Mechani

cal Service).

l Check the adjustment of the Geneva driver in relation to the Geneva star (Section 14.10, Me

chanical Service). If the adjustment is too loose, the carousel will vibrate heavily and make a

loud clanking noise during carousel rotation. If the adjustment is too tight, the turret motor will

12-15-94 96-8100

HAAS AUTOMATION, INC.

21

Page 23

VMC

SERVICE TROUBLE

labor excessively and the carousel may appear to move erratically. NOTE: If the turret motor

adjustment is tight for extended periods, the turret motor, Geneva star, and the I/O board may

be damaged. If the adjustment of the Geneva star appears tight at some pockets and loose at

others, the problem lies with the Geneva star. Check the concentricity of the star relative to the

bearing housing on the carousel assembly. If the concentricity of the star is proven to within

specification and the problem still persists, the Geneva star must be replaced (Section 14.10,

Mechanical Service).

Ensure the screws holding the turret motor to the mounting plate are tight (Section 14.9,

Mechanical Service).

l Ensure the screws attaching the motor mounting plate to the shuttle casting are tight.

l Check for excessive noise in the gear train of the turret motor. See Section 14.9, Mechanical

Service, for turret motor replacement.

NOTE: If the motor is found to be the source of noise, replace the motor assembly (motor, mounting

plate, and Geneva driver).

DO NOT attempt to repair the motor or to further isolate the problem in the motor.

SERVICE MANUAL

Tool Changer

4.5 SPINDLE ORIENTATION

A switch is used to sense when the pin drops in to lock the spindle. When the pin drops the switch

opens, indicating orientation is complete. The normally-closed side of this switch is wired to the spindle

drive and commands it into the COAST STOP condition. This is done to make sure that the spindle

motor is not powered when the pin is locking the spindle. If, during a tool change, the dogs on the

spindle shaft do not align with the keys on the ATC carousel, the spindle orientation may be at fault.

The orientation of the spindle is as follows:

1) If the spindle is turning, it is commanded to stop,

2) Pause until spindle is stopped,

3) Spindle orientation speed is commanded forward,

4) Pause until spindle is at orientation speed,

5) Command spindle lock air solenoid active,

6) Pause until spindle locked status is active and stable,

7) If not locked after time-out time, alarm and stop.

´ ATC out of orientation with the spindle. Incorrect spindle orientation will cause

the ATC to crash as the shuttle moves. Alarm 113 will be generated.

l Check the orientation of the machine (Section 7, Mechanical Service).

´ ATC WILL NOT RUN

In all cases where the tool changer will not run, an alarm is generated to indicate either a shuttle

in/out problem or a turret rotation problem. These alarms will occur either on an attempt to change tools

(ATC FWD) or ZERO RETURN the machine (AUTO ALL AXES). Use the appropriate alarm to select one

of the problems following:

22

96-8100 12-15-94

HAAS AUTOMATION, INC.

Page 24

VMC

Tool Changer

´ ATC shuttle will not move; shuttle is getting power (Command a tool change and

feel for power being applied to the shuttle motor).

l Disconnect the slip clutch arm from the ATC shuttle and ensure the shuttle can move

freely. If not, see Sections 14.1, 14.3, and 14.4, Mechanical Service, for shuttle adjustment.

l Command a tool change with the shuttle disconnected.

Ø If the shuttle cycles, check the slip clutch on the ATC. See Section 14.8, Mechanical Service,

for slip clutch replacement.

NOTE: The slip clutch should move the shuttle with a fair amount of force, but not so much that the

shuttle cannot be made to slip when holding it back by hand. If the slip clutch is frozen, replace it. It

cannot be rebuilt in the field.

Ø If the shuttle does not cycle, the motor has failed and must be replaced. Turn the motor by

hand and feel for binding in the gear train in the motor. See Section 14.8, Mechanical Service.

NOTE: The motor uses a large amount of gear reduction and should be hard to turn by hand.

SERVICE MANUAL

SERVICE TROUBLE

´ ATC shuttle will not move; shuttle is not getting power (Command a tool change

and feel for power being applied to the shuttle motor).

l Check that the TC IN/TC OUT LED on the I/O PCB is illuminated when a tool change takes

place.

Ø If the LED lights, check the fuse FU5 on the POWER PCB. Otherwise, replace the I/O PCB

(Section 4.3, Electrical Service).

Ø If the LED does not light, check cables 510 and 520.

´ ATC turret will not rotate; turret motor is getting power (command a tool change

and feel for power being applied to the turret motor).

l If power is applied but the output shaft on the motor does not turn, check for binding between

the turret motor assembly and the Geneva star (Section 14.9, Mechanical Service). Check for

damage to the Geneva star or the Geneva driver. See Section 14.10, Mechanical Service, for

Geneva star replacement, and 14.9 for turret motor replacement. Check for a broken turret

motor (See Section 14.9, Mechanical Service for turret motor replacement). NOTE: Do not at

tempt to repair the motor or to further isolate the problem in the motor.

´ ATC turret will not rotate; turret motor is not getting power (command a tool

change and feel for power being applied to the turret motor).

l Check that the TC CW/ TC CCW LED on the I/O PCB is illuminated when a tool change takes

place.

Ø If the LED lights, check the fuse FU5 on the POWER PCB. Otherwise, replace the I/O PCB

(Section 4.3, Electrical Service).

Ø If the LED does not light, check cables 510 and 520.

12-15-94 96-8100

HAAS AUTOMATION, INC.

23

Page 25

VMC

SERVICE TROUBLE

SERVICE MANUAL

Gearbox / Spindle Motor

5. GEARBOX AND SPINDLE MOTOR

The gearbox cannot be serviced in the field and must be replaced as a unit. NEVER remove a

motor from a VF-1, VF-2, or VF-3 gearbox as this will damage the gearbox and void the warranty.

5.1 NOISE

When investigating complaints of gearbox noise, also refer to Section 2 (Spindle Troubleshooting).

Gearboxes can be damaged by failed air solenoids, gearshift cylinders, or bearings, resulting in noisy

operation. It is not likely that poor finish on a workpiece can be attributed to a bad gearbox.

´ Excessive or unusual noise coming from the gearbox and/or spindle motor.

Operate the machine in both high and lowgears. Monitor the gearbox for noise

in both gear positions and if the pitch of the noise varies with the motor or the output shaft

speed.

Ø If the noise only occurs in one gear throughout the entire RPM range of that gear position, the

problem lies with the gearbox, and it must be replaced (Section 9, Mechanical Service).

Ø If the noise occurs in both gear positions, disconnect the drive belt and repeat theprevious

step. If the noise persists, the gearbox is damaged and must be replaced, (Section 9, Me

chanical Service).

Ø With the drive belt disconnected, run the machine at 1000 RPM in high gear. Command a

change of direction and listen for a banging noise in the gearbox as the machine slows to zero

RPM and speeds back up to 1000 RPM in reverse. If the noise occurs, the motor has failed

and the gearbox must be replaced (Section 9, Mechanical Service).

5.2 GEARS WILL NOT CHANGE

´ Machine will not execute a gear change.

NOTE: Whenever a gear change problem occurs, an alarm will also occur. Refer ALARMS

section (Section 6) to diagnose each problem before working on the machine.

When a gear change is performed, the following sequence of events occurs:

1) If the spindle is turning, it is commanded to stop,

2) Pause until spindle is stopped,

3) Gear change spindle speed is commanded forward,

4) Pause until spindle is at speed,

5) Command high or low gear solenoid active,

6) Pause until in new gear or reversal time,

7) Alarm and stop if max gear change time elapsed,

8) If not in new gear, reverse spindle direction,

9) Turn off high and low gear solenoids.

24

96-8100 12-15-94

HAAS AUTOMATION, INC.

Page 26

VMC

Gearbox / Spindle Motor

l Check the air solenoid assembly on the solenoid bracket (rear of gearbox).

If the solenoid operates properly and the limit switches on the gearbox operate

properly, the problem lies with the gear change piston.

Replace the gearbox (Section 9, Mechanical Service).

l Check contactor CB4.

SERVICE MANUAL

SERVICE TROUBLE

12-15-94 96-8100

HAAS AUTOMATION, INC.

25

Page 27

VMC

SERVICE TROUBLE

SERVICE MANUAL

Electrical

6. ELECTRICAL TROUBLE SHOOTING

6.1 WHAT CAN GO WRONG WITH LIMIT SWITCHES

If the machine is operated without connector P5, a LOW LUBE and DOOR OPEN alarm will be

generated. In addition, the Home search will not stop at the limit switch and will instead run into the

physical stops on each axis.

If the switch is damaged and permanently open, the zero search for that axis will move in the

negative direction at about 0.5 in/min until it reaches the physical travel stops at the opposite end of

travel.

If the switch is damaged and permanently closed, the zero search for that axis will move at about

10 in/min in the positive direction until it reaches the physical stops.

If the switch opens or a wire breaks after the zero search completes, an alarm is generated, the

servos are turned off, and all motion stops. The control will operate as though the zero search was

never performed. The RESET can be used to turn servos on but you can jog that axis only slowly.

6.2 SUPPLY VOLTAGE SENSOR

A sensor circuit on the SDIST circuit board is used to monitor the voltage applied to the control. It

actually monitors the DC buss voltage developed for the servo drives. When this voltage drops below

a set point, an alarm is generated. The voltage being monitored is rectified from the 115V AC secondary of transformer T1. Cable 980 carries the analog voltage from the SDIST PCB to the MOTIF PCB.

6.3 SUPPLY VOLTAGE DISPLAY

The Diagnostic Data display page is used to display this voltage. It has a range of zero to 200V

DC. If the machine is wired for 230V AC, a primary service voltage of 230V will provide a secondary

voltage of about 120V; that will produce a servo buss voltage of about 168V DC.

Note that load variations on the servo motors and spindle drive will cause slight variations in this

display. If the voltage varies by more than 10V under load, it indicates that the wiring to the control is

dropping too much voltage and may need a larger gauge wire.

6.4 LOW VOLTAGE TRIP POINT

If this voltage drops below the following limits:

205V AC when wired for nominal 230V AC service 190V AC when wired for nominal 208V AC

service

an alarm will be generated. The sensor actually converts the servo DC buss analog voltage to

digital and monitors the digital value. Both alarm trip points correspond to 140V DC on the servo buss.

If one leg of the three-phase incoming power is lost, there may not be an alarm. In this case, the

machine may turn off completely, the electronics may shut down, or the servos and the video monitor

may shut off.

26

96-8100 12-15-94

HAAS AUTOMATION, INC.

Page 28

VMC

Electrical

6.5 UNDER/OVER VOLTAGE SENSORS

An overvoltage sensor monitors the DC servo motor buss. When this voltage exceeds 185V DC, a

load is applied to the servo buss. That load is called the regen load resistor. When this voltage exceeds 190V DC, an alarm is generated and machine operation stops. If the voltage remains between

these two values for more than a few seconds, an overtemperature alarm may be generated. That

alarm is caused by an overheat of the regen resistor.

The overvoltage alarm will be generated for different input service voltages depending on how the

machine is configured. The following limits apply:

260V AC when wired for nominal 230V AC service 235V AC when wired for nominal 208V AC

service

It is also possible that an overvoltage condition will be detected first by the spindle drive. This

would initially show only a spindle drive fault. A check of the status on the spindle drive LEDs will

show what the actual alarm is.

In controls built after April 1990, there is an undervoltage sensor that monitors the voltage of all

three inputs power phases. If this voltage drops below 180V AC for 208 input or drops below 200 for

230 input for any phase, an alarm will be generated. This phase sensor is built into the IOPCB circuit

board in the lower left hand corner of the control.

SERVICE MANUAL

SERVICE TROUBLE

6.6 CORRECTING ALARMS

´ Alarm 179 (Low Pressure Spindle Coolant) has been triggered.

l Check for low oil supply in reservoir.

l Check to see that pump motor is running.

l Check for an air leak in the suction side of the pump.

l Check for a bad pressure sensor.

l Check for a broken or damaged cable.

l Check for a worn pump head.

12-15-94 96-8100

HAAS AUTOMATION, INC.

27

Page 29

VMC

SERVICE TROUBLE

SERVICE MANUAL

Alarms

ALARMS

Any time an alarm is present, the lower right hand corner will have a blinking ALARM. Push the

ALARM display key to view the current alarm. All alarms are displayed with a reference number and a

complete description. If the RESET key is pressed, one alarm will be removed from the list of alarms.

If there are more than 18 alarms, only the last 18 will be displayed and the CURSOR DOWN key must

be used to see the rest. The presence of any alarm will prevent the operator from starting a program.

Note that the tool changer alarms can be easily corrected by first correcting any mechanical problem, pressing RESET until the alarms are clear, selecting ZERO RET mode, and selecting AUTO ALL

AXES. Some messages are displayed while editing to tell the operator what is wrong, but these are not

alarms.

The following list shows the alarm number and the cause of the alarm. Please refer to this list

before resuming normal operation when an alarm occurs.

102 SERVOS OFF

This is not an alarm; but indicates that the servo motors are off, the tool changer is disabled, the

coolant pump is off, and the spindle motor is stopped. Caused by EMERGENCY STOP, motor f

faults, tool changer problems, or power fail.; check for other causes.

103 X FOLLOWING ERROR TOO LARGE

104 Y FOLLOWING ERROR TOO LARGE

105 Z FOLLOWING ERROR TOO LARGE

106 A FOLLOWING ERROR TOO LARGE

These alarms can be caused by power problems, motor problems, driver problems, the slide

being run into the mechanical stops, or excessive axis load. The difference between the motor

position and the commanded position has exceeded a parameter. The motor may also be

stalled, disconnected, or the driver failed. The servos will be turned off and a RESET must be

done to restart. See Section 2, Electrical Service, to check line voltage adjustments. See

Section 3.1, Electrical Service, check the servo motors, servo drivers, and ball screw adjust

ment.

107 EMERGENCY OFF

EMERGENCY STOP button was pressed. Servos are also turned off. After the E-STOP is

released, the RESET button must be pressed at least twice to correct this; once to clear the ESTOP alarm and once to clear the Servo Off alarm. This is an operator-initiated condition. If you

do not know why it occurred, check wiring to emergency stop circuit.

108 X SERVO OVERLOAD

109 Y SERVO OVERLOAD

110 Z SERVO OVERLOAD

111 A SERVO OVERLOAD

Excessive load on X-axis motor. This can occur if the load on the motor over a period of several

seconds or even minutes is large enough to exceed the continuous rating of the motor. The

servos will be turned off when this occurs. This can be caused by running into the mechanical stops but not much past them. It can also be caused by anything that causes a very high load

on the motors. See Section 3.1, Electrical Service, to check the servo motors, servo drivers, and ball

28

96-8100 12-15-94

HAAS AUTOMATION, INC.

Page 30

Alarms

screw adjustment.

112 NO INTERRUPT

This alarm can be caused by electrical interference or an electronics problem. See

Section 4.1, Electrical Service, to replace Microprocessor and Motor Interface PCBs.

113 SHUTTLE IN FAULT

114 SHUTTLE OUT FAULT

Tool changer not completely to right or left. During a tool changer operation the tool in/out

shuttle failed to get to the in or out position. Parameters 62 and 63 can adjust the time-out

times. This alarm can be caused by anything that jams the motion of the slide or by the

presence of a tool in the pocket facing the spindle. A loss of power to the tool changer can

also cause this, so check fuse FU5 and relays 1-8, 2-1, and 2-2. See Section 4 for troubleshooting of the tool changer.

115 TURRET ROTATE FAULT

Tool carousel motor not in position. During a tool changer operation the tool turret failed to

start moving or failed to stop at the right position. Parameters 60 and 61 can adjust the timeout times. This alarm can be caused by anything that jams the rotation of the turret. A loss of

power to the tool changer can also cause this, so check fuse FU5 and relays 1-8, 2-3, and 2-

4. See Section 4 for troubleshooting of the tool changer.

VMC

SERVICE MANUAL

SERVICE TROUBLE

116 SPINDLE ORIENTATION FAULT

Spindle did not orient correctly. During a spindle orientation function, the spindle is rotated

until the lock pin drops in; but the lock pin never dropped. Parameters 66, 70, 73, and 74 can

adjust the time-out times. This can be caused by a trip of circuit breaker CB4, a lack of air

pressure, or too much friction with the orientation pin. See Section 4.5 to troubleshoot spindle

orientation.

117 SPINDLE HIGH GEAR FAULT

118 SPINDLE LOW GEAR FAULT

Gearbox did not shift into high or low gear. During a gear change, the spindle is rotated

slowly while air pressure is used to move the gears but the high/low gear sensor was not

detected in time. Parameters 67, 70 and 75 can adjust the time-out times. Check the air

pressure, the solenoids circuit breaker CB4, and the spindle drive. See Section 5 for troubleshooting of gear change problems.

119 OVER VOLTAGE

Incoming line voltage is above maximum (about 255V when wired for 240 or 235 when

wired for 208). The servos will be turned off and the spindle, tool changer, and coolant pump

will stop. If this condition remains for 4.5 minutes, an automatic shutdown will begin. This can

also be caused by an electronic problem. See Section 2, Electrical Service, to check line

voltage adjustment taps. See Section 4.2, Electrical Service, to replace SDIST PCB. Also

check that servo regen load resistor is installed (cable 920).

120 LOW AIR PRESSURE

Air pressure dropped below 80 PSI for a period defined by Parameter 76. Check your

incoming air pressure for at least 100 PSI and ensure the regulator is set at 85 PSI. If this is

not caused by low air pressure, check pressure sensor at spindle head and wiring back to

IOPCB. Check Parameter 76, which is used to delay the low air alarm condition for short

12-15-94 96-8100

HAAS AUTOMATION, INC.

29

Page 31

VMC

SERVICE TROUBLE

outages. Air blast during tool change can cause your air supply to drop pressure; monitor

the pressure drop during a tool unclamp.

SERVICE MANUAL

121 LOW LUB OR LOW PRESSURE

Way lube is low or empty or there is no lube pressure or too high a pressure. Check tank

at rear of mill and below control cabinet. Also check connector P5 on the side of the control

cabinet. Check that the lube lines are not blocked. This can be caused by failure of the pump

to provide pressure, failure of the lube pressure sensor, a wiring error, or a parameter error.

See Air and Oil Line Diagrams (p.133) to check level switch and pressure switch (cable 960).

122 CONTROL OVER HEAT

The control internal temperature is above 1500 F. This can be caused by almost anything

in the control overheating. But is usually caused by overheat of the two regen resistors for

servos and spindle drive. This alarm will also turn off the servos, spindle drive, coolant pump,

and tool changer. One common cause of this overheat condition is an input line voltage too

high. If this condition remains for 4.5 minutes, an automatic shutdown will begin. It is also

caused by incorrect transformer tapping, SDIST PCB problem, or Spindle Drive problem.

See Section 2, Electrical Service, to check line voltage adjustment taps. See Section 4.2,

Electrical Service, to replace SDIST PCB. See Section 2.3 to check the spindle drive.

Alarms

123 SPINDLE DRIVE FAULT

Overheat or failure of spindle drive or motor. The exact cause is indicated in the LED

window of the spindle drive inside the control cabinet. This can be caused by a stalled motor,

shorted motor, overvoltage, undervoltage, overcurrent, overheat of motor, or drive failure. See

Section 2.3 for check of the Spindle Drive. Front of Drive indicates type of problem. If not a

Drive problem, check wiring to IOPCB (cable 780).

124 LOW BATTERY

Memory batteries need replacing within 30 days. This alarm is only generated at POWER

ON and indicates that the 3.3V Lithium battery is below 2.5V. If this is not corrected within

about 30 days, stored programs, parameters, offsets, and settings may be lost. See Section

4.1, Electrical Service, for replacement of Microprocessor PCB or battery.

125 SHUTTLE FAULT

Tool shuttle not initialized at power on, CYCLE START or spindle motion command. This

means that the tool shuttle was not fully retracted to the out position. See Section 4 for tool

changer problem.

126 GEAR FAULT

Gearshifter is out of position when a command is given to rotate the spindle. This means