,

UMC-750

Operator’s Manual Supplement

96-8250

Revision G

December 2017

English

Original Instructions

© 2017 Haas Automation, Inc. All Rights Reserved. Copy by Permission Only. Copyright Strictly Enforced.

Haas Automation Inc.

2800 Sturgis Road

Oxnard, CA 93030-8933

U.S.A. | HaasCNC.com

© 2017 Haas Automation, Inc.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or

transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording, or

otherwise, without the written permission of Haas Automation, Inc. No patent liability is assumed with

respect to the use of the information contained herein. Moreover, because Haas Automation strives

constantly to improve its high-quality products, the information contained in this manual is subject to

change without notice. We have taken every precaution in the preparation of this manual; nevertheless,

Haas Automation assumes no responsibility for errors or omissions, and we assume no liability for

damages resulting from the use of the information contained in this publication.

i

This product uses Java Technology from Oracle Corporation and we request that you acknowledge that

Oracle owns the Java Trademark and all Java related Trademarks and agree to comply with the

trademark guidelines at www.oracle.com/us/legal/third-party-trademarks/index.html

Any further distribution of the Java programs (beyond this appliance/machine) is subject to a legally

binding End User License Agreement with Oracle. Any use of the commercial features for production

purposes requires a separate license from Oracle.

ii

.

LIMITED WARRANTY CERTIFICATE

Haas Automation, Inc.

Covering Haas Automation, Inc. CNC Equipment

Effective September 1, 2010

Haas Automation Inc. (“Haas” or “Manufacturer”) provides a limited warranty on all new

mills, turning centers, and rotary machines (collectively, “CNC Machines”) and their

components (except those listed below under Limits and Exclusions of Warranty)

(“Components”) that are manufactured by Haas and sold by Haas or its authorized

distributors as set forth in this Certificate. The warranty set forth in this Certificate is a

limited warranty, it is the only warranty by Manufacturer, and is subject to the terms and

conditions of this Certificate.

Limited Warranty Coverage

Each CNC Machine and its Components (collectively, “Haas Products”) are warranted by

Manufacturer against defects in material and workmanship. This warranty is provided only

to an end-user of the CNC Machine (a “Customer”). The period of this limited warranty is

one (1) year. The warranty period commences on the date the CNC Machine is installed at

the Customer’s facility. Customer may purchase an extension of the warranty period from

an authorized Haas distributor (a “Warranty Extension”), any time during the first year of

ownership.

Repair or Replacement Only

Manufacturer’s sole liability, and Customer’s exclusive remedy under this warranty, with

respect to any and all Haas products, shall be limited to repairing or replacing, at the

discretion of the Manufacturer, the defective Haas product.

Disclaimer of Warranty

This warranty is Manufacturer’s sole and exclusive warranty, and is in lieu of all other

warranties of whatever kind or nature, express or implied, written or oral, including, but not

limited to, any implied warranty of merchantability, implied warranty of fitness for a

particular purpose, or other warranty of quality or performance or noninfringement. All such

other warranties of whatever kind are hereby disclaimed by Manufacturer and waived by

Customer.

iii

Limits and Exclusions of Warranty

Components subject to wear during normal use and over time, including, but not limited to,

paint, window finish and condition, light bulbs, seals, wipers, gaskets, chip removal system

(e.g., augers, chip chutes), belts, filters, door rollers, tool changer fingers, etc., are excluded

from this warranty. Manufacturer’s specified maintenance procedures must be adhered to

and recorded in order to maintain this warranty. This warranty is void if Manufacturer

determines that (i) any Haas Product was subjected to mishandling, misuse, abuse,

neglect, accident, improper installation, improper maintenance, improper storage, or

improper operation or application, including the use of improper coolants or other fluids, (ii)

any Haas Product was improperly repaired or serviced by Customer, an unauthorized

service technician, or other unauthorized person, (iii) Customer or any person makes or

attempts to make any modification to any Haas Product without the prior written

authorization of Manufacturer, and/or (iv) any Haas Product was used for any

non-commercial use (such as personal or household use). This warranty does not cover

damage or defect due to an external influence or matters beyond the reasonable control of

Manufacturer, including, but not limited to, theft, vandalism, fire, weather condition (such as

rain, flood, wind, lightning, or earthquake), or acts of war or terrorism.

Without limiting the generality of any of the exclusions or limitations described in this

Certificate, this warranty does not include any warranty that any Haas Product will meet any

person’s production specifications or other requirements, or that operation of any Haas

Product will be uninterrupted or error-free. Manufacturer assumes no responsibility with

respect to the use of any Haas Product by any person, and Manufacturer shall not incur

any liability to any person for any failure in design, production, operation, performance, or

otherwise of any Haas Product, other than repair or replacement of same as set forth in the

warranty above.

Limitation of Liability and Damages

Manufacturer will not be liable to Customer or any other person for any compensatory,

incidental, consequential, punitive, special, or other damage or claim, whether in an action

in contract, tort, or other legal or equitable theory, arising out of or related to any Haas

product, other products or services provided by Manufacturer or an authorized distributor,

service technician, or other authorized representative of Manufacturer (collectively,

“authorized representative”), or the failure of parts or products made by using any Haas

Product, even if Manufacturer or any authorized representative has been advised of the

possibility of such damages, which damage or claim includes, but is not limited to, loss of

profits, lost data, lost products, loss of revenue, loss of use, cost of down time, business

good will, any damage to equipment, premises, or other property of any person, and any

damage that may be caused by a malfunction of any Haas product. All such damages and

claims are disclaimed by Manufacturer and waived by Customer. Manufacturer’s sole

liability, and Customer’s exclusive remedy, for damages and claims for any cause

whatsoever shall be limited to repair or replacement, at the discretion of Manufacturer, of

the defective Haas Product as provided in this warranty.

iv

Customer has accepted the limitations and restrictions set forth in this Certificate, including,

but not limited to, the restriction on its right to recover damages, as part of its bargain with

Manufacturer or its Authorized Representative. Customer realizes and acknowledges that

the price of the Haas Products would be higher if Manufacturer were required to be

responsible for damages and claims beyond the scope of this warranty.

Entire Agreement

This Certificate supersedes any and all other agreements, promises, representations, or

warranties, either oral or in writing, between the parties or by Manufacturer with respect to

subject matter of this Certificate, and contains all of the covenants and agreements

between the parties or by Manufacturer with respect to such subject matter. Manufacturer

hereby expressly rejects any other agreements, promises, representations, or warranties,

either oral or in writing, that are in addition to or inconsistent with any term or condition of

this Certificate. No term or condition set forth in this Certificate may be modified or

amended, unless by a written agreement signed by both Manufacturer and Customer.

Notwithstanding the foregoing, Manufacturer will honor a Warranty Extension only to the

extent that it extends the applicable warranty period.

Transferability

This warranty is transferable from the original Customer to another party if the CNC

Machine is sold via private sale before the end of the warranty period, provided that written

notice thereof is provided to Manufacturer and this warranty is not void at the time of

transfer. The transferee of this warranty will be subject to all terms and conditions of this

Certificate.

Miscellaneous

This warranty shall be governed by the laws of the State of California without application of

rules on conflicts of laws. Any and all disputes arising from this warranty shall be resolved

in a court of competent jurisdiction located in Ventura County, Los Angeles County, or

Orange County, California. Any term or provision of this Certificate that is invalid or

unenforceable in any situation in any jurisdiction shall not affect the validity or enforceability

of the remaining terms and provisions hereof, or the validity or enforceability of the

offending term or provision in any other situation or in any other jurisdiction.

v

Customer Feedback

The Haas Resource Center: DIY Documentation and Procedures

diy.haascnc.com

haasparts.com

Your Source for Genuine Haas Parts

www.facebook.com/HaasAutomationInc

Haas Automation on Facebook

www.twitter.com/Haas_Automation

Follow us on Twitter

www.linkedin.com/company/haas-automation

Haas Automation on LinkedIn

www.youtube.com/user/haasautomation

Product videos and information

www.ickr.com/photos/haasautomation

Product photos and information

If you have concerns or questions regarding this Operator’s Manual, please contact us on

our website, www.HaasCNC.com

to the Customer Advocate.

You can find an electronic copy of this manual and other useful information on our website

in the “Resource Center”. Join Haas owners online and be a part of the greater CNC

community at these sites:

. Use the “Contact Haas” link and send your comments

vi

Customer Satisfaction Policy

Dear Haas Customer,

Your complete satisfaction and goodwill are of the utmost importance to both Haas

Automation, Inc. and the Haas distributor (HFO) where you purchased your equipment.

Normally, your HFO will rapidly resolve any concerns you have about your sales

transaction or the operation of your equipment.

However, if your concerns are not resolved to your complete satisfaction, and you have

discussed your concerns with a member of the HFO’s management, the General Manager,

or the HFO’s owner directly, please do the following:

Contact Haas Automation’s Customer Service Advocate at 805-988-6980. So that we may

resolve your concerns as quickly as possible, please have the following information

available when you call:

• Your company name, address, and phone number

• The machine model and serial number

• The HFO name, and the name of your latest contact at the HFO

• The nature of your concern

If you wish to write Haas Automation, please use this address:

Haas Automation, Inc. U.S.A.

2800 Sturgis Road

Oxnard CA 93030

Att: Customer Satisfaction Manager

email: customerservice@HaasCNC.com

Once you contact the Haas Automation Customer Service Center, we will make every effort

to work directly with you and your HFO to quickly resolve your concerns. At Haas

Automation, we know that a good Customer-Distributor-Manufacturer relationship will help

ensure continued success for all concerned.

International:

Haas Automation, Europe

Mercuriusstraat 28, B-1930

Zaventem, Belgium

email: customerservice@HaasCNC.com

Haas Automation, Asia

No. 96 Yi Wei Road 67,

Waigaoqiao FTZ

Shanghai 200131 P.R.C.

email: customerservice@HaasCNC.com

vii

viii

Declaration of Conformity

Product: Mill (Vertical and Horizontal)*

*Including all options factory- or field-installed by a certified Haas Factory Outlet (HFO)

Manufactured By: Haas Automation, Inc.

2800 Sturgis Road, Oxnard, CA 93030

805-278-1800

We declare, in sole responsibility, that the above-listed products, to which this declaration

refers, comply with the regulations as outlined in the CE directive for Machining Centers:

• Machinery Directive 2006/42/EC

• Electromagnetic Compatibility Directive 2014/30/EU

• Additional Standards:

– EN 60204-1:2006/A1:2009

– EN 614-1:2006+A1:2009

– EN 894-1:1997+A1:2008

– CEN 13849-1:2015

RoHS: COMPLIANT by Exemption per producer documentation. Exempt by:

a) Large scale stationary industrial tool

b) Monitoring and control systems

c) Lead as an alloying element in steel, aluminum, and copper

Person authorized to compile technical file:

Jens Thing

Address:

Haas Automation Europe

Mercuriusstraat 28

B-1930 Zaventem

Belgium

ix

ETL LISTED

CONFORMS TO

NFPA STD 79

ANSI/UL STD 508

UL SUBJECT 2011

CERTIFIED TO

CAN/CSA STD C22.2 NO.73

All Haas CNC machine tools carry the ETL Listed mark,

certifying that they conform to the NFPA 79 Electrical

Standard for Industrial Machinery and the Canadian

equivalent, CAN/CSA C22.2 No. 73. The ETL Listed and

cETL Listed marks are awarded to products that have

successfully undergone testing by Intertek Testing

Services (ITS), an alternative to Underwriters'

Laboratories.

C

Haas Automation has been assessed for conformance

with the provisions set forth by ISO 9001:2008. Scope of

Registration: Design and Manufacture of CNC Machines

Tools and Accessories, Sheet Metal Fabrication. The

conditions for maintaining this certificate of registration are

set forth in ISA's Registration Policies 5.1. This

registration is granted subject to the organization

maintaining compliance to the noted stardard. The validity

of this certificate is dependent upon ongoing surveillance

audits.

USA: Haas Automation certifies this machine to be in compliance with the OSHA and ANSI

design and manufacturing standards listed below. Operation of this machine will be

compliant with the below-listed standards only as long as the owner and operator continue

to follow the operation, maintenance, and training requirements of these standards.

• OSHA 1910.212 - General Requirements for All Machines

• ANSI B11.5-1983 (R1994) Drilling, Milling, and Boring Machines

• ANSI B11.19-2003 Performance Criteria for Safeguarding

• ANSI B11.23-2002 Safety Requirements for Machining Centers and Automatic

Numerically Controlled Milling, Drilling, and Boring Machines

• ANSI B11.TR3-2000 Risk Assessment and Risk Reduction - A Guideline to Estimate,

Evaluate, and Reduce Risks Associated with Machine Tools

CANADA: As the original equipment manufacturer, we declare that the listed products

comply with regulations as outlined in the Pre-Start Health and Safety Reviews Section 7

of Regulation 851 of the Occupational Health and Safety Act Regulations for Industrial

Establishments for machine guarding provisions and standards.

Further, this document satisfies the notice-in-writing provision for exemption from Pre-Start

inspection for the listed machinery as outlined in the Ontario Health and Safety Guidelines,

PSR Guidelines dated April 2001. The PSR Guidelines allow that notice in writing from the

original equipment manufacturer declaring conformity to applicable standards is acceptable

for the exemption from Pre-Start Health and Safety Review.

Original Instructions

x

How to Use This Manual

To get the maximum benefit of your new Haas machine, read this manual thoroughly and

refer to it often. The content of this manual is also available on your machine control under

the HELP function.

IMPORTANT: Before you operate the machine, read and understand the Operator’s

Manual Safety chapter.

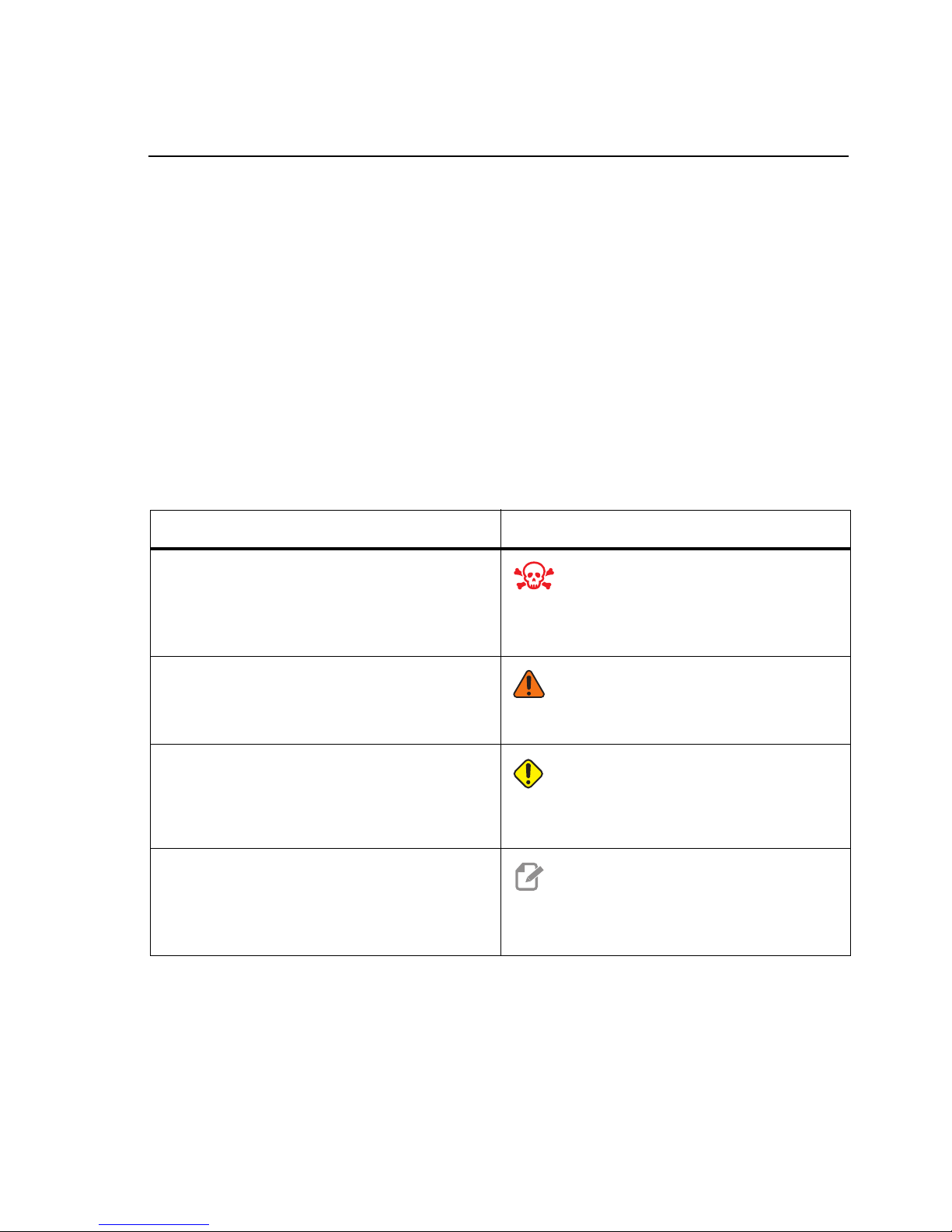

Declaration of Warnings

Throughout this manual, important statements are set off from the main text with an icon

and an associated signal word: “Danger,” “Warning,” “Caution,” or “Note.” The icon and

signal word indicate the severity of the condition or situation. Be sure to read these

statements and take special care to follow the instructions.

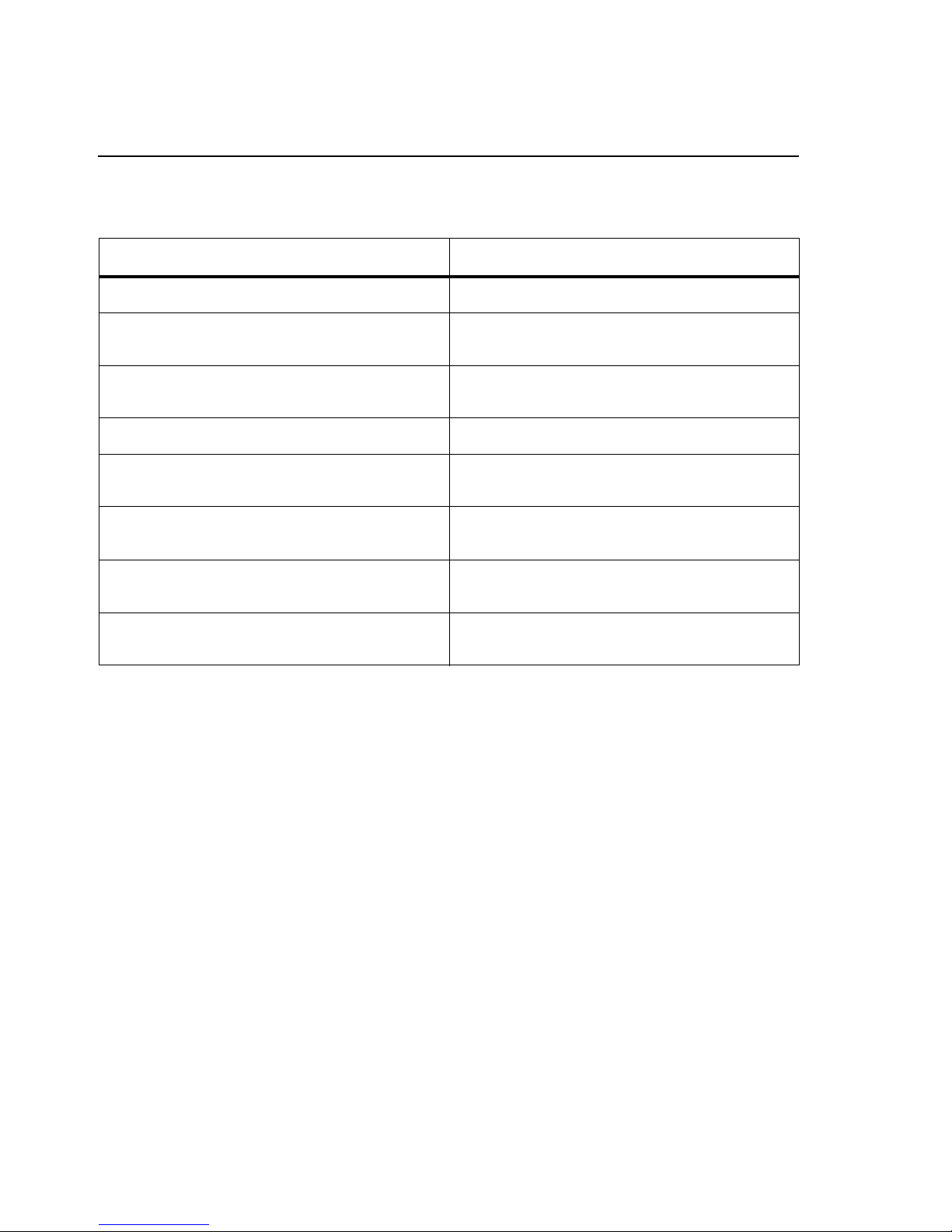

Description Example

Danger means that there is a condition or situation

that will cause death or severe injury if you do not

follow the instructions given.

DANGER: No step. Risk of electrocution, bodily

injury, or machine damage. Do not climb or stand

on this area.

Warning means that there is a condition or situation

that will cause moderate injury if you do not follow

the instructions given.

Caution means that minor injury or machine

damage could occur if you do not follow the

instructions given. You may also have to start a

procedure over if you do not follow the instructions in

a caution statement.

Note means that the text gives additional

information, clarification, or helpful hints.

WARNING: Never put your hands between the

tool changer and the spindle head.

CAUTION: Power down the machine before you

do maintenance tasks.

NOTE: Follow these guidelines if the machine is

equipped with the optional extended

Z-clearance table.

xi

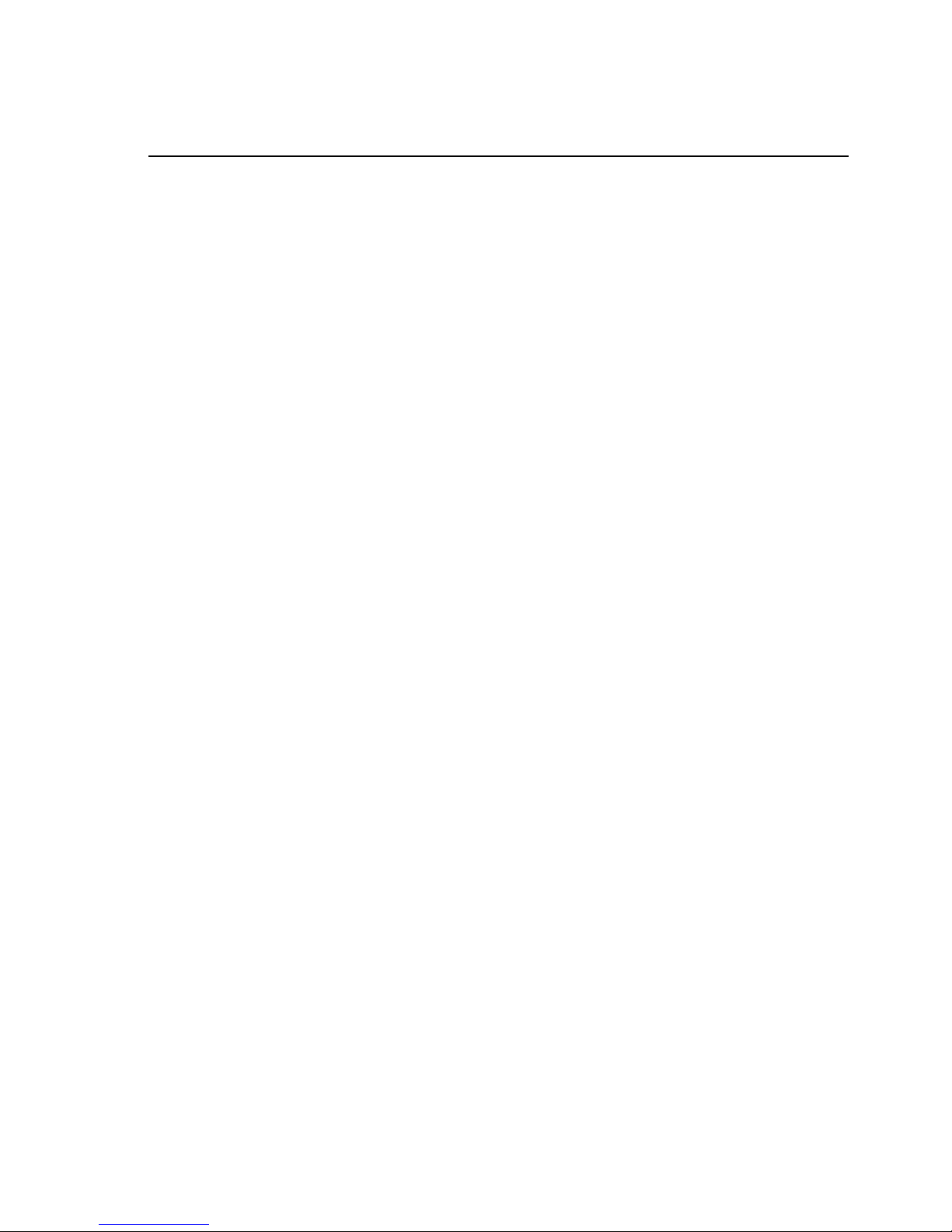

Text Conventions Used in this Manual

Description Text Example

Code Block text gives program examples.

A Control Button Reference gives the name of a

control key or button that you are to press.

A File Path describes a sequence of file system

directories.

A Mode Reference describes a machine mode. MDI

A Screen Element describes an object on the

machine’s display that you interact with.

System Output describes text that the machine

control displays in response to your actions.

User Input describes text that you should enter into

the machine control.

Variable n indicates a range of non-negative integers

from 0 to 9.

Press

Service > Documents and Software >...

Select the

PROGRAM END

G04 P1.;

Dnn represents D00 through D99.

G00 G90 G54 X0. Y0.;

[CYCLE START].

SYSTEM tab.

xii

Contents

Chapter 1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 General Safety Notes . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1.1 Summary of Types of Operation for Haas Automation

Machine Tools . . . . . . . . . . . . . . . . . . . . . . . 2

1.1.2 Read Before Operating . . . . . . . . . . . . . . . . . . 4

1.1.3 Machine Environmental Limits. . . . . . . . . . . . . . . 6

1.1.4 Machine Noise Limits . . . . . . . . . . . . . . . . . . . 7

1.2 Unattended Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.3 Setup Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.3.1 Machine Behavior with the Door Open . . . . . . . . . . 8

1.3.2 Robot Cells . . . . . . . . . . . . . . . . . . . . . . . . 9

1.3.3 Mist Extraction / Enclosure Evacuation . . . . . . . . . . 10

1.4 Modifications to the Machine . . . . . . . . . . . . . . . . . . . . . . 10

1.5 Improper Coolants . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.6 Safety Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.6.1 Decal Symbols Reference . . . . . . . . . . . . . . . . . 12

1.6.2 Other Safety Information. . . . . . . . . . . . . . . . . . 16

1.7 More Information Online . . . . . . . . . . . . . . . . . . . . . . . . . 16

Chapter 2 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.2 UMC-750 Workstations . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.3 Axis Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.4 UMC-750 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.5 UMC-750P Specifications . . . . . . . . . . . . . . . . . . . . . . . . 21

Chapter 3 Integrated Coolant Tank . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.1.1 Coolant Pump Location . . . . . . . . . . . . . . . . . . 26

3.2 Coolant Tank Clean-Out. . . . . . . . . . . . . . . . . . . . . . . . . 26

Chapter 4 Wireless Intuitive Probing System (WIPS). . . . . . . . . . . . . . . . 29

4.1 UMC WIPS Basics. . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.2 UMC VPS Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

4.3 Machine Rotary Zero Point (MRZP) Offsets . . . . . . . . . . . . . . . 30

4.3.1 Check MRZP Offsets with VPS . . . . . . . . . . . . . . 30

xiii

Chapter 5 G234 - Tool Center Point Control (TCPC). . . . . . . . . . . . . . . . . 33

5.1 G234 - Tool Center Point Control (TCPC) (Group 08) . . . . . . . . . 33

Chapter 6 G254 - Dynamic Work Offset (DWO) . . . . . . . . . . . . . . . . . . .37

6.1 G254 - Dynamic Work Offset (DWO) (Group 23) . . . . . . . . . . . . 37

Chapter 7 Setting Work and Tool Offsets . . . . . . . . . . . . . . . . . . . . . . 41

7.1 Set the B-Axis Work Offset . . . . . . . . . . . . . . . . . . . . . . . 41

7.2 Set the C-Axis Work Offset . . . . . . . . . . . . . . . . . . . . . . . 41

7.3 Set the X-, Y-, and Z-Axis Work Offsets Manually. . . . . . . . . . . . 42

7.4 Set the X-, Y-, and Z-Axis Work Offsets with WIPS . . . . . . . . . . . 46

Chapter 8 Rotary Unwind and Setting 247 . . . . . . . . . . . . . . . . . . . . . .49

8.1 Quick Rotary G28 (Home) . . . . . . . . . . . . . . . . . . . . . . . . 49

8.2 247 - Simultaneous XYZ Motion in Tool Change . . . . . . . . . . . . 49

Chapter 9 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

9.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

9.2 UMC-750 Maintenance Schedule . . . . . . . . . . . . . . . . . . . . 51

9.3 More Information Online . . . . . . . . . . . . . . . . . . . . . . . . . 54

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

xiv

Chapter 1: Safety

1.1 General Safety Notes

CAUTION: Only authorized and trained personnel may operate this equipment.

You must always act in accordance with the Operator's manual, safety

decals, safety procedures, and instructions for safe machine

operation. Untrained personnel present a hazard to themselves and

the machine.

IMPORTANT: Do not operate this machine until you have read all warnings, cautions,

and instructions.

CAUTION: The sample programs in this manual have been tested for accuracy,

but they are for illustrative purposes only. The programs do not define

tools, offsets, or materials. They do not describe workholding or other

fixturing. If you choose to run a sample program on your machine, do

so in Graphics mode. Always follow safe machining practices when

you run an unfamiliar program.

Safety

All CNC machines present hazards from rotating cutting tools, belts and pulleys, high

voltage electricity, noise, and compressed air. When you use CNC machines and their

components, you must always follow basic safety precautions to reduce the risk of personal

injury and mechanical damage.

The work area must be adequately illuminated to allow clear view and safe operation of the

machine. This includes the operator work area and all areas of the machine that might be

accessed during maintenance or cleaning. Adequate illumination is the responsibility of the

user.

Cutting tools, workholding, workpiece and coolant are beyond the scope and control of

Haas Automation, Inc. Each of these potential hazards associated with it (sharp edges,

heavy lifting considerations, chemical composition, etc) and it is the responsibility of the

user to take appropriate action (PPE, training, etc).

Cleaning of the machine is required during normal use and prior to maintenance or repair.

Optional equipment is available to aid cleaning such as washdown hoses, chip conveyors

and chip augers. Safe use of this equipment requires training and might require appropriate

PPE and is the responsibility of the user.

This operator’s manual is intended as a reference guide and is not to be the sole source of

training. Complete operator training is available from the authorized Haas distributor.

1

General Safety Notes

1.1.1 Summary of Types of Operation for Haas Automation

Machine Tools

Haas CNC Mills are intended for cutting and shaping of metals and other hard materials.

They are general purpose in nature and a list of all of those materials and types of cutting

would never be complete. Almost all cutting and shaping is performed by a rotating tool

mounted in a spindle. Rotation of the mill is not required. Some cutting operations require

liquid coolant. That coolant is also an option depending on the type of cutting.

Operations of Haas Mills are separated into three areas. They are: Operations,

Maintenance, and Service. Operations and Maintenance are intended to be performed by

a trained and qualified machine operator. This Operator's Manual contains some of the

information necessary to operate the machine. All other machine operations are to be

considered Service. Service is only to be performed by specially trained service personnel.

Operation of this machine consists of the following:

1. Machine Setup

• Machine setup is done to initially set up the tools, offsets, and fixtures required

to perform a repetitive function that later is called machine operation. Some

machine setup functions can be done with the door open but are limited to

“hold to run”.

2. Machine operating in Automatic Mode

• Automatic operation is initiated with Cycle-Start and can only be done with the

doors closed.

3. Operator loading and unloading of materials (parts)

• Parts loading and unloading is what precedes and follows an automatic

operation. This must be done with the doors open and all machine automatic

motion is stopped when the door is open.

4. Operator loading and unloading of cutting tools

• Tool loading and unloading is done less often than setup. It is often required

when a tool has become worn and must be replaced.

Maintenance only consists of the following:

1. Adding and maintaining condition of coolant

• Adding coolant and maintaining coolant concentration is required at regular

intervals. This is a normal operator function and is either done from a safe

location outside of the work enclosure or with the doors open and the machine

stopped.

2

2. Adding lubricants

• Adding lubricants for spindle and axes is required at regular intervals. These

are often months or years in length. This is a normal operator function and is

always done from a safe location outside of the work enclosure.

3. Cleaning chips out of the machine

• Cleaning out of chips is required at intervals dictated by the type of machining

performed. This is a normal operator function. It is performed with the doors

open and all of the machine operation is stopped.

Service only consists of the following:

1. Repairing of a machine that is not operating correctly

• Any machine that is not operating correctly requires service by factory trained

personnel. This is never an operator function. It is not considered

maintenance. Installation and service instructions are provided separately

from the Operator’s Manual.

2. Machine moving, unpacking, and installation

• Haas machines are shipped to a user’s location almost ready to operate. They

still require a trained service person to complete the installation. Installation

and service instructions are provided separately from the Operator’s Manual.

Safety

3. Machine packing

• Machine packing for shipment requires the same packing material supplied by

Haas in the original shipment. Packing requires a trained service person to

complete the installation. Shipping instructions are provided separately from

the Operator’s Manual.

4. Decommission, dismantle and disposal

• Machine is not expected to be disassembled for shipment; it can be moved in

its entirety in the same manner in which it was installed. Machine can be

returned to the manufacturer’s distributor for disposal; manufacturer accepts

any/all components for recycling per Directive 2002/96/EC.

5. End-of-life disposal

• End-of-life disposal must conform to the laws and regulations in the region the

machine is located. This is a jointly the responsibility of the owner and seller of

the machine. The risk analysis does not address this phase.

3

General Safety Notes

1.1.2 Read Before Operating

DANGER: Do not enter the machining area any time the machine is in motion, or

at any time that machine motion is possible. Severe injury or death

may result. Motion is possible when the power is on and the machine

is not in [EMERGENCY STOP].

Basic safety:

• This machine can cause severe bodily injury.

• This machine is automatically controlled and may start at any time.

• Consult your local safety codes and regulations before you operate the machine.

Contact your dealer if you have questions about safety issues.

• It is the machine owner’s responsibility to make sure that everyone who is involved

in installing and operating the machine is fully acquainted with the operation and

safety instructions provided with the machine, BEFORE they work with the machine.

The ultimate responsibility for safety rests with the machine owner and the individuals

who work with the machine.

• Use appropriate eye and ear protection when you operate the machine.

• Use appropriate gloves to remove processed material and to clean the machine.

• Replace windows immediately if they are damaged or severely scratched.

• Keep the side windows locked during operation (if available).

Electrical safety:

• The electrical power must meet the required specifications. Attempting to run the

machine from any other source can cause severe damage and will void the warranty.

• The electrical panel should be closed and the key and latches on the control cabinet

should be secured at all times, except during installation and service. At those times,

only qualified electricians should have access to the panel. When the main circuit

breaker is on, there is high voltage throughout the electrical panel (including the

circuit boards and logic circuits) and some components operate at high

temperatures; therefore, extreme caution is required. Once the machine is installed,

the control cabinet must be locked, with the key available only to qualified service

personnel.

• Do not reset a circuit breaker until the reason for the fault is investigated and

understood. Only Haas-trained service personnel should troubleshoot and repair

Haas equipment.

• Do not press [POWER UP] on the control pendant before the machine is fully

installed.

4

Safety

Operation Safety:

• Do not operate the machine unless the doors are closed and the door interlocks are

functioning correctly.

• Check for damaged parts and tools before you operate the machine. Any part or tool

that is damaged should be properly repaired or replaced by authorized personnel. Do

not operate the machine if any component does not appear to be functioning

correctly.

• Rotating cutting tools can cause severe injury. When a program runs, the mill table

and spindle head can move rapidly at any time.

• Improperly clamped parts machined at high speeds/feeds may be ejected and

puncture the enclosure. It is not safe to machine oversized or marginally clamped

parts.

Release of person trapped in the machine:

• No person should ever be located inside the machine during operation.

• In the unlikely event that a person is trapped inside the machine the emergency stop

button should be immediately be depressed and the person removed.

• If the person is pinched or entangled the machine should be powered off; then the

machine axes can be moved by use of a large external force in the direction required

to free the person.

Recover from a jam or blockage:

• Of the chip conveyor - Follow the cleaning instructions on the Haas Resource Center

(diy.haascnc.com). If necessary, close the doors and reverse the conveyor so the

jammed part or material is accessible, and remove. Use lifting equipment or get

assistance for lifting heavy and awkward parts.

• Of a tool and material/part - Close the doors, press [RESET] to clear and displayed

alarms. Jog the axis so the tool and material are clear.

• Of the Automatic Tool Changer/tool and spindle - Press [RECOVER] and follow the

on-screen instructions.

• If the alarms do not reset or you are unable to clear a blockage, contact your Haas

Factory Outlet (HFO) for assistance.

Follow these guidelines when you work with the machine:

• Normal operation - Keep the door closed and guards in place (for non-enclosed

machines) while the machine operates.

• Part loading and unloading – An operator opens the door, completes the task, closes

the door, and then presses [CYCLE START] (starting automatic motion).

• Machining job set-up – When set-up is complete, turn the set-up key to lock out

set-mode and remove the key.

• Maintenance / Machine Cleaner– Press [EMERGENCY STOP] or [POWER OFF] on

the machine before you enter the enclosure.

5

General Safety Notes

Periodic maintenance of machine safety features:

• Inspect door interlock mechanism for proper fit and function.

• Inspect safety windows and enclosure for damage or leaks.

• Verify all enclosure panels are in place.

Door Safety Interlock maintenance:

• Inspect the door interlock, verify the door interlock key is not bent, misaligned, and

that all fasteners are installed.

• Inspect the door interlock itself for any signs of obstruction or misalignment.

• Immediately replace an components of the Door Safety Interlock system that do not

meet this criteria.

Door Safety Interlock testing:

• With the machine in run mode, close the machine door, run the spindle at 100 RPM,

pull the door and verify the door does not open.

Machine Enclosure and Safety Glass maintenance and testing:

Routine Maintenance:

• Visually inspect the enclosure and safety glass for any signs of distortion, breakage

or other damage.

• Replace the Lexan windows after 7 years or if they are damaged or severely

scratched.

• Keep all safety glass and machine windows clean to allow proper viewing of the

machine during operations.

• A daily visual inspection of the machine enclosure to verify all panels are in place

should be performed.

Testing of machine enclosure:

• No testing of the machine enclosure is necessary.

6

1.1.3 Machine Environmental Limits

This table list the environmental limits for safe operation:

T1.1: Environmental Limits (Indoor Use Only)

Minimum Maximum

Operating Temperature 41 °F (5.0 °C) 122 °F (50.0 °C)

Storage Temperature -4 °F (-20.0 °C) 158 °F (70.0 °C)

Ambient Humidity 20% relative, non-condensing 90% relative, non-condensing

Altitude Sea Level 6,000 ft. (1,829 m)

CAUTION: Do not operate the machine in explosive atmospheres (explosive

vapors and/ or particulate matter).

Safety

1.1.4 Machine Noise Limits

CAUTION: Take precautions to prevent hearing damage from machine/machining

noise. Wear ear protection, change your application (tooling, spindle

speed, axis speed, fixturing, programmed path) to reduce noise, or

restrict access to machine area during cutting.

Typical noise levels at the operator’s position during normal operation are as follows:

• A-Weighted sound pressure level measurements will be 69.4dB or lower.

• C-Weighted instantaneous sound pressure levels will be 78.0dB or lower.

• LwA (sound power level A-weighted) will be 75.0dB or lower.

NOTE: Actual noise levels while cutting material are greatly affected by the

user’s choice of material, cutting tools, speeds and feeds, workholding

and other factors. These factors are application specific and are

controlled by the user, not Haas Automation Inc.

7

Unattended Operation

1.2 Unattended Operation

Fully enclosed Haas CNC machines are designed to operate unattended; however, your

machining process may not be safe to operate unmonitored.

As it is the shop owner’s responsibility to set up the machine safely and use best practice

machining techniques, it is also the owner’s responsibility to manage the progress of these

methods. You must monitor your machining process to prevent damage, injury, or loss of

life if a hazardous condition occurs.

For example, if there is the risk of fire due to the material machined, then you must install

an appropriate fire suppression system to reduce the risk of harm to personnel, equipment,

and the building. Contact a specialist to install monitoring tools before machines are

allowed to run unattended.

It is especially important to select monitoring equipment that can immediately detect a

problem and perform an appropriate action without human intervention.

1.3 Setup Mode

All Haas CNC machines are equipped with locks on the operator doors and a key switch

on the side of the control pendant to lock and unlock setup mode. Generally, setup mode

status (locked or unlocked) affects how the machine operates when the doors are opened.

Setup mode should be locked out (the keyswitch in the vertical, locked position) at most

times. In locked mode, the enclosure doors are locked closed during CNC program

execution, spindle rotation or axis movement. The doors automatically unlock when the

machine is not in cycle. Many machine functions are unavailable with the door open.

When unlocked, setup mode allows a skilled machinist more access to the machine to set

up jobs. In this mode, machine behavior is dependent on whether the doors are opened or

closed. Opening the doors when the machine is in cycle stops motion and reduces spindle

speed. The machine allows several functions in setup mode with the doors opened, usually

at reduced speed. The following charts summarize the modes and allowed functions.

Machines with software version 100.17.000.1016 or higher have Parameter 2083, Setup

Mode Safety Type, that affects the machine’s Setup mode. When Parameter 2083 is set to

Normal, the machine Setup and Run modes behave as outlined in the table that follows.

When Parameter 2083 is set to Strict, both the Setup and Run modes adhere to the Run

mode behaviors. Contact your local Haas Factory Outlet to set Parameter 2083 to your

desired setting on your machine.

DANGER: Do not attempt to override safety features. Doing so makes the

machine unsafe and voids the warranty.

8

1.3.1 Machine Behavior with the Door Open

CW

CCW

750 RPM Max.

750

RPM Max.

0%

0%

CHIP

FWD

CHIP

REV

CHIP

FWD

CHIP

REV

YX

Z

G00

G01

For safety, machine operations stop when the door is open and the setup keyswitch is

locked. The unlocked position allows limited machine functions with the door open.

T1.2: Setup / Run Mode Limited Overrides with the Machine Doors Open

Machine Function Keyswitch Locked Keyswitch Unlocked

Maximum Rapid Not allowed. Not allowed.

Safety

Cycle Start Not allowed. No machine

motion or program execution.

Spindle

Tool Change Not allowed. Not allowed.

Next Tool Not allowed. Not allowed.

Opening the doors while a

program runs

Conveyor motion Allowed, but you must press

[CW] / [CCW]

Allowed, but you must press

and hold

Maximum 750 RPM.

Not allowed. The door is

locked.

and hold

in reverse.

[CW] or [CCW].

[CHIP REV] to run

Not allowed. No machine motion

or program execution.

Allowed, but maximum 750 RPM.

Allowed, but axis motion stops

and the spindle slows to a

maximum of 750 RPM. The doors

lock during tool changes and

some canned cycles.

Allowed, but you must press and

hold [CHIP REV] to run in

reverse.

9

Modifications to the Machine

1.3.2 Robot Cells

A machine in a robot cell is allowed to run a program while the door is open, regardless of

the position of the Run-Setup key. While the door is open, the spindle speed is limited to

the lower of the factory RPM limit or Setting 292, Door Open Spindle Speed Limit. If the

door is opened while the spindle RPM is above the limit, the spindle will decelerate to the

limit RPM. Closing the door removes the limit and the programmed RPM is restored.

This open-door condition is allowed only while a robot communicates with the CNC

machine. Typically, an interface between the robot and the CNC machine addresses the

safety of both machines.

Robot cell setup is beyond the scope of this manual. Work with a robot-cell integrator and

your HFO to correctly set up a safe robot cell.

1.3.3 Mist Extraction / Enclosure Evacuation

The Mill products have a provision installed that will allow for a mist extractor to be attached

to the machine (except CM & GR models). There is also an optional enclosure exhaust

system available that helps keep the mist out of the machine enclosure.

It is entirely up to the owner/operator to determine if and what type of mist extractor is best

suited for the application.

The owner/operator assumes all responsibility for the installation of the mist extraction

system.

1.4 Modifications to the Machine

Haas Automation, Inc. is not responsible for damage caused by modifications you make to

your Haas machine(s) with parts or kits not manufactured or sold by Haas Automation, Inc.

The use of such parts or kits may void your warranty.

Some parts or kits manufactured or sold by Haas Automation, Inc. are considered

user-installable. If you choose to install these parts or kits yourself, be sure to completely

read the accompanying installation instructions. Make sure you understand the procedure,

and how to do it safely, before you begin. If you have any doubts about your ability to

complete the procedure, contact your Haas Factory Outlet (HFO) for assistance.

1.5 Improper Coolants

Coolant is an important part of many machining operations. When it is correctly used and

maintained, coolant can improve part finish, lengthen tool life, and protect machine

components from rust and other damage. Improper coolants, however, can cause

significant damage to your machine.

Such damage can void your warranty, but it can also introduce hazardous conditions to

your shop. For example, coolant leaks through damaged seals could create a slipping

hazard.

10

Improper coolant use includes, but is not limited to, these points:

• Do not use plain water. This causes machine components to rust.

• Do not use flammable coolants.

• Do not use straight or “neat” mineral-oil products. These products cause damage to

rubber seals and tubing throughout the machine. If you use a minimum-quantity

lubrication system for near-dry machining, use only the recommended oils.

Machine coolant must be water-soluble, synthetic oil-based or synthetic-based coolant or

lubricant.

NOTE: Be sure to maintain your coolant mixture to keep the coolant

concentrate at acceptable levels. Improperly maintained coolant

mixtures can allow machine components to rust. Rust damage is not

covered by your warranty.

Ask your HFO or your coolant dealer if you have questions about the specific coolant that

you plan to use. The Haas Resource Center website has videos and other general

information about coolant use and maintenance. You can also scan the code below with

your mobile device to directly access this information.

Safety

1.6 Safety Decals

The Haas factory puts decals on your machine to quickly communicate possible hazards.

If decals become damaged or worn, or if you need additional decals to emphasize a

particular safety point, contact your Haas Factory Outlet (HFO).

NOTE: Never alter or remove any safety decal or symbol.

Be sure to familiarize yourself with the symbols on the safety decals. The symbols are

designed to quickly tell you the type of information they give:

• Yellow Triangle - Describes a hazard.

• Red Circle with Slash-Through - Describes a prohibited action.

11

Safety Decals

123

• Green Circle - Describes a recommended action.

• Black Circle - Gives information about machine or accessory operation.

F1.1: Example Safety Decal Symbols: [1] Hazard Description, [2] Prohibited Action, [3]

Recommended Action.

1.6.1 Decal Symbols Reference

This section gives explanations and clarifications for the safety symbols you will see on

your machine.

T1.3: Hazard Symbols – Yellow Triangles

Symbol Description

Moving parts can entangle, trap, crush, and cut.

Keep all parts of your body away from machine parts when they move, or

whenever motion is possible. Motion is possible when the power is on and

the machine is not in [EMERGENCY STOP].

Secure loose clothing, hair, etc.

Remember that automatically controlled devices can start at any time.

Do not touch rotating tools.

Keep all parts of your body away from machine parts when they move, or

whenever motion is possible. Motion is possible when the power is on and

the machine is not in

Sharp tools and chips can easily cut skin.

[EMERGENCY STOP].

12

Symbol Description

The Regen is used by the spindle drive to dissipate excess power and will

get hot.

Always use care around the Regen.

There are high voltage components on the machine that can cause

electrical shock.

Always use care around high voltage components.

Long tools are dangerous, especially at spindle speeds higher than 5000

RPM. The tools can break and eject from the machine.

Remember that machine enclosures are intended to stop coolant and

chips. Enclosures may not stop broken tools or thrown parts.

Always check your setup and tooling before you start machining.

Safety

Machining operations can create hazardous chips, dust or mist. This is

function of the materials being cut, the metalworking fluid and cutting tools

used and the machining speeds/feeds.

It is up to the owner/operator of the machine to determine if personal

protective equipment such as safety goggles or a respirator is required

and also if a mist extraction system is needed. All enclosed models

have a provision for connecting a mist extraction system.

Always read and understand the Safety Data Sheets (SDS) for the

workpiece material, the cutting tools and the metalworking fluid.

13

Safety Decals

T1.4: Prohibited Action Symbols – Red Circles with Slash-Through

Symbol Description

Do not enter the machine enclosure when the machine is capable of

automatic motion.

When you must enter the enclosure to complete tasks, press

[EMERGENCY STOP] or power off the machine. Put a safety tag on

the control pendant to alert other people that you are inside the machine,

and that they must not turn on or operate the machine.

Do not machine ceramics.

Do not attempt to load tools with the spindle dogs misaligned with the

cutouts in the toolholder V-Flange.

14

Do not machine flammable materials.

Do not use flammable coolants.

Flammable materials in particulate or vapor form can become explosive.

The machine enclosure is not designed to contain explosions or extinguish

fire.

Do not use pure water as coolant. This will cause machine components to

rust.

Always use a rust-inhibitive coolant concentrate with water.

T1.5: Recommended Action Symbols – Green Circles

Symbol Description

Keep the machine doors closed.

Always wear safety glasses or goggles when you are near a machine.

Airborne debris can cause eye damage.

Always wear hearing protection when you are near a machine.

Machine noise can exceed 70 dBA.

Safety

Make sure the spindle dogs are correctly aligned with the cutouts in the

toolholder V-flange.

Note the location of the tool release button. Press this button only when

you are holding the tool.

Some tools are very heavy. Handle these tools carefully; use both hands

and have someone press the tool release button for you.

15

More Information Online

T1.6: Informational Symbols – Black Circles

Symbol Description

Maintain the recommended coolant concentration.

A “lean” coolant mixture (less concentrated than recommended) may not

effectively prevent machine components from rusting.

A “rich” coolant mixture (more concentrated than recommended) wastes

coolant concentrate without further benefit over the recommended

concentration.

1.6.2 Other Safety Information

You may find other decals on your machine, depending on the model and options installed.

Be sure to read and understand these decals. These are examples of other safety decals

in English. You can contact your Haas Factory Outlet (HFO) to get these decals in other

languages.

1.7 More Information Online

For updated and supplemental information, including tips, tricks, maintenance procedures,

and more, go to DIY.HaasCNC.com

You can also scan this code with your mobile device to directly access the “Best Practices”

page on the Resource Center, which includes information about safety.

.

16

Chapter 2: Introduction

A

B

C

2.1 Overview

This operator’s manual supplement describes the unique features and functions of the

UMC series of machines. Refer to your Mill Operator’s Manual for control operation,

programming, and other general mill information.

You can find specific details about the UMC family, including information that is beyond the

scope of this document, at www.HaasCNC.com.

2.2 UMC-750 Workstations

F2.1: This diagram illustrates the UMC-750 three operator zones.

• A: Operator Station.

• B: Check and Maintain Lubricants.

• C: Check and Maintain Coolant, Coolant Pumps and Chip Conveyor.

Introduction

17

Axis Definitions

B

C

-35°

+110°

-

+

2.3 Axis Definitions

F2.2: This diagram illustrates the (5) axes available on the UMC-750 / UMC-750SS.

18

F2.3: This diagram illustrates the (5) axes available on the UMC-750P.

A

+

-

B+

B-

+ 45°

- 45°

Introduction

19

UMC-750 Specifications

2.4 UMC-750 Specifications

T2.1: UMC-750 Specifications

Travels

S.A.E Metric

X Axis 30" 762 mm

Y Axis 20" 508 mm

Z Axis 20" 508 mm

C-Axis Rotation 360° Rotation

B-Axis Tilt -35° to +110°

Spindle Nose to Table (~ min.) 4" 102 mm

Spindle Nose to Table (~ max.) 24" 610 mm

For detailed machine dimensions, including work envelope information, refer to the UMC-750

Machine Layout Drawing on www.haascnc.com.

Table

Width 19.7" 500 mm

Length 24.8" 630 mm

T-Slot Width 5/8" 16 mm

T-Slot Center Distance 2.48" 63 mm

Number of Standard T-Slots 7

Max. Weight on Table (evenly

distributed)

660 lb 300 kg

20

T2.2: General Requirements

General Requirements

Air Required 4 scfm, 100 psi 113 L/min, 6.9 bar

Coolant Capacity 75 gal 284 L

Power Requirement, Low Voltage 195-260 VAC / 100A

Power Requirement, High Voltage 354-488 VAC / 50A

Machine Weight 18,000 lb 8165 kg

T2.3: Standard Features

Standard Features

Tool Center Point Control (TCPC), Dynamic Work Offsets (DWO), Remote Jog Handle*,

Second Home*, Macros*, Spindle Orientation (SO)*, Coordinate Rotation and Scaling (COORD)*,

TSC-Ready, Wireless Intuitive Probing System (WIPS)

*Refer to the Mill Operator’s Manual (96-8210) for information on these features.

Introduction

2.5 UMC-750P Specifications

T2.4: UMC-750P Specifications

Travels

S.A.E Metric

X Axis 30" 762 mm

Y Axis 20" 508 mm

Z Axis 20" 508 mm

A-Axis Rotation 360° Rotation

B-Axis Tilt -45° to +45°

Spindle Nose to Table (max.) 25" 635 mm

21

UMC-750P Specifications

Travels

S.A.E Metric

Spindle Nose to Table (min.) 5" 127 mm

For detailed machine dimensions, including work envelope information, refer to the UMC-750

Machine Layout Drawing on www.haascnc.com.

Table

Width 14.75" 375 mm

Length 33" 838 mm

T-Slot Width 5/8" 16 mm

T-Slot Center Distance N/A

Number of Standard T-Slots 1

Max. Weight on Table (evenly

distributed)

660 lb 300 kg

T2.5: General Requirements

General Requirements

Air Required 4 scfm, 100 psi 113 L/min, 6.9 bar

Coolant Capacity 75 gal 284 L

Power Requirement, Low Voltage 195-260 VAC / 100A

Power Requirement, High Voltage 354-488 VAC / 50A

Machine Weight 18,000 lb 8165 kg

22

T2.6: Standard Features

Standard Features

Tool Center Point Control (TCPC), Dynamic Work Offsets (DWO), Remote Jog Handle*,

Second Home*, Macros*, Spindle Orientation (SO)*, Coordinate Rotation and Scaling (COORD)*,

TSC-Ready, Wireless Intuitive Probing System (WIPS)

*Refer to the Mill Operator’s Manual (96-8210) for information on these features.

Introduction

23

UMC-750P Specifications

24

Integrated Coolant Tank

Chapter 3: Integrated Coolant Tank

3.1 Introduction

The UMC-750 coolant tank is integrated into the machine base.

F3.1: UMC -750 Integrated Coolant Tank

25

Coolant Tank Clean-Out

2

4

5

3

1

3.1.1 Coolant Pump Location

The coolant pumps are on the tool changer side of the machine, behind the chip conveyor.

The standard coolant box filter is mounted below the standard coolant pump.

F3.2: UMC-750 Coolant Pump Location: [1] Chip Tray, [2] Gate Filter, [3] Coolant Box Filter, [4]

Standard Coolant Pump, [5] TSC Coolant Pump

3.2 Coolant Tank Clean-Out

To clean out the coolant tank:

1. Remove the coolant pumps.

2. Remove and empty the coolant box filter.

3. Remove and empty the chip tray.

4. Remove and clean the gate filter.

5. Use a wet/dry vacuum or similar device to remove the used coolant from the tank.

6. For more thorough cleaning, open the coolant tank access panels in the bottom of

the work space.

26

F3.3: Coolant Tank Access Panels

7. Add coolant to the tank and install the gate filter, coolant box filter, chip tray, and

coolant pumps. Install the coolant tank access panels if you removed them.

Integrated Coolant Tank

27

Coolant Tank Clean-Out

28

Wireless Intuitive Probing System (WIPS)

Chapter 4: Wireless Intuitive Probing

System (WIPS)

4.1 UMC WIPS Basics

The Wireless Intuitive Probing System (WIPS) comes standard with the UMC-750. This

system can perform all of the standard probe routines found in the WIPS templates, and

also includes special probe routines specifically for the UMC. These special probe routines

use a tooling ball on a magnetic base to automatically find the machine’s centers of rotation.

Refer to page 5 for more information on this process.

Normally, you use WIPS to set tool and work offsets, but the UMC-750 includes a master

gauge length tool in case you need to set offsets manually (if, for example, a probe stylus

breaks or the batteries lose power). The gage length tool included with your machine has

a unique length that is etched on the tool.

NOTE: If you set the tool length offsets manually, you must also set the Z-Axis

work offset manually.

4.2 UMC VPS Basics

The Visual Programing System (VPS) (which contains Wireless Intuitive Probing (WIPS))

comes standard with the UMC-750. This system can perform all of the standard probe

routines found in the WIPS templates, and also includes special probe routines specifically

for the UMC. These special probe routines use a tooling ball to automatically find the

machine’s centers of rotation. Refer to page 5 for more information on this process.

Normally, you use WIPS to set tool and work offsets, but the UMC-750 includes a master

gauge length tool in case you need to set offsets manually (if, for example, a probe stylus

breaks or the batteries lose power). The gage length tool included with your machine has

a unique length that is etched on the tool.

NOTE: If you set the tool length offsets manually, you must also set the Z-Axis

work offset manually.

29

Machine Rotary Zero Point (MRZP) Offsets

4.3 Machine Rotary Zero Point (MRZP) Offsets

The Machine Rotary Zero Point (MRZP) Offsets are control settings that define the location

of the centers of rotation for the rotary table relative to the linear axes home position.

Settings 255, 256, and 257 define the following:

255 – MRZP X Offset

Location of the B Axis rotary center point relative to the X Axis home position.

256 – MRZP Y Offset

Location of the C Axis rotary center point relative to the Y Axis home position.

257 – MRZP Z Offset

Location of the B Axis rotary center point relative to the Z Axis home position.

The value stored in these settings is the distance from the home position of a linear axis to

the center of rotation of a rotary axis. Setting 9 determines if the values are shown in inches

or millimeters.

The Machine Rotary Zero Point (MRZP) Offsets are set at the factory.

4.3.1 Check MRZP Offsets with VPS

The MRZP offsets can change over time. To make sure the UMC-750, UMC-750SS MRZP

Offsets are correct do the following:

1. Place the tooling ball in the center of the X axis.

IMPORTANT: Make sure that the tooling ball is tightly attached to the calibration

assembly. Do not over tighten the tooling ball.

30

F4.1: Calibration Tooling Ball

2. Place the work probe in the spindle.

3. Position the work probe over the tooling ball.

4. Navigate to [EDIT]>VPS>PROBING>CALIBRATION>MRZP and select B-Axis Tilt

C-Axis Rotary Finish Set and press [ENTER].

Wireless Intuitive Probing System (WIPS)

5. Type gage ball diameter and press [ENTER].

6. Follow the prompts to generate the probe program. Enter MDI mode and press

[CYCLE START].

The program generates the G-code and runs the program.

F4.2: B-Axis Tilt C-Axis Rotary MRZP Finish Set Generated Program

7. The program automatically places values in macro variables #10121 through

#10123. These variables show the machine rotary zero point axis travel distance

from the home position in the X, Y, and Z Axes.

8. If the MRZP locations have changed, enter the values from macro variables #10121,

#10122, and #10123 into Settings 255, 256, and 257.

31

Machine Rotary Zero Point (MRZP) Offsets

32

G234 - Tool Center Point Control (TCPC)

Chapter 5: G234 - Tool Center Point

Control (TCPC)

5.1 G234 - Tool Center Point Control (TCPC)

(Group 08)

G234 Tool Center Point Control (TCPC) is a software feature in the Haas CNC control that

allows a machine to correctly run a contouring 4- or 5-axis program when the workpiece is

not located in the exact location specified by a CAM-generated program. This eliminates

the need to repost a program from the CAM system when the programmed and the actual

workpiece locations are different.

The Haas CNC control combines the known centers of rotation for the rotary table (MRZP)

and the location of the workpiece (e.g., active work offset G54) into a coordinate system.

TCPC makes sure that this coordinate system remains fixed relative to the table; when the

rotary axes rotate, the linear coordinate system rotates with them. Like any other work

setup, the workpiece must have a work offset applied to it. This tells the Haas CNC control

where the workpiece is located on the machine table.

The conceptual example and illustrations in this section represent a line segment from a

full 4- or 5-axis program.

NOTE: For clarity, the illustrations in this section do not depict workholding.

Also, as conceptual, representative drawings, they are not to scale

and may not depict the exact axis motion described in the text.

The straight line edge highlighted in Figure F5.1 is defined by point (X0, Y0, Z0) and point

(X0, Y-1., Z0). Movement along the Y Axis is all that is required for the machine to create

this edge. The location of the workpiece is defined by work offset G54.

33

G234 - Tool Center Point Control (TCPC) (Group 08)

X0, Y0, Z0

(G54)

X0, Y-1., Z0

X

Y

Z

F5.1: Location of Workpiece Defined by G54

In Figure F5.2, the B and C Axes have been rotated 15 degrees each. To create the same

edge, the machine needs to make an interpolated move with the X, Y, and Z Axes. Without

TCPC, you would need to repost the CAM program for the machine to correctly create this

edge.

F5.2: G234 (TCPC) Off and the B and C Axes Rotated

TCPC is invoked in Figure F5.3. The Haas CNC control knows the centers of rotation for

the rotary table (MRZP), and the location of the workpiece (active work offset G54). This

data is used to produce the desired machine motion from the original CAM-generated

program. The machine follows an interpolated X-Y-Z path to create this edge, even though

the program simply commands a single-axis move along the Y Axis.

34

F5.3: G234 (TCPC) On and the B and C Axes Rotated

X0, Y-1., Z0

X0, Y0, Z0

G234 Program Example

%

O00003 (TCPC SAMPLE)

G20

G00 G17 G40 G80 G90 G94 G98

G53 Z0.

T1 M06

G00 G90 G54 B47.137 C116.354 (POSITION ROTARY AXES)

G00 G90 X-0.9762 Y1.9704 S10000 M03 (POSITION LINEAR AXES)

G234 H01 Z1.0907 (TCPC ON WITH LENGTH OFFSET 1, APPROACH IN

Z-AXIS)

G01 X-0.5688 Y1.1481 Z0.2391 F40.

X-0.4386 Y0.8854 Z-0.033

X-0.3085 Y0.6227 Z-0.3051

X-0.307 Y0.6189 Z-0.3009 B46.784 C116.382

X-0.3055 Y0.6152 Z-0.2966 B46.43 C116.411

X-0.304 Y0.6114 Z-0.2924 B46.076 C116.44

X-0.6202 Y0.5827 Z-0.5321 B63.846 C136.786

X-0.6194 Y0.5798 Z-0.5271 B63.504 C136.891

X-0.8807 Y0.8245 Z-0.3486

X-1.1421 Y1.0691 Z-0.1701

X-1.9601 Y1.8348 Z0.3884

G49 (TCPC OFF)

G00 G53 Z0.

G53 B0. C0.

G53 Y0.

M30

%

G234 Programmer’s Notes

G234 - Tool Center Point Control (TCPC)

35

G234 - Tool Center Point Control (TCPC) (Group 08)

These key presses and program codes cancel G234:

•[EMERGENCY STOP]

•[RESET]

•[HANDLE JOG]

•[LIST PROGRAM]

• M02 – Program End

• M30 – Program End and Reset

• G43 – Tool Length Compensation +

• G44 – Tool Length Compensation -

• G49 – G43 / G44 / G143 Cancel

These codes will NOT cancel G234:

• M00 – Program Stop

• M01 – Optional Stop

These key presses and program codes impact G234:

• G234 invokes TCPC and cancels G43.

• When using tool length compensation, either G43 or G234 must be active. G43 and

G234 cannot be active at the same time.

• G234 cancels the previous H-code. An H-code must therefore be placed on the same

block as G234.

• G234 cannot be used at the same time as G254 (DWO).

36

These codes ignore 234:

• G28 – Return to Machine Zero Through Optional Reference Point

• G29 – Move to Location Thru G29 Reference Point

• G53 – Non-Modal Machine Coordinate Selection

• M06 – Tool Change

Invoking G234 (TCPC) rotates the work envelope. If the position is close to the travel limits,

the rotation can put the current work position outside of travel limits and cause an over

travel alarm. To solve this, command the machine to the center of the work offset (or near

the center of the table on a UMC), and then invoke G234 (TCPC).

G234 (TCPC) is intended for simultaneous 4- and 5-axis contouring programs. An active

work offset (G54, G55, etc.) is required to use G234.

G254 - Dynamic Work Offset (DWO)

Chapter 6: G254 - Dynamic Work Offset

(DWO)

6.1 G254 - Dynamic Work Offset (DWO) (Group 23)

G254 Dynamic Work Offset (DWO) is similar to TCPC, except that it is designed for use

with 3+1 or 3+2 positioning, not for simultaneous 4- or 5-axis machining. If the program

does not make use of the tilt and rotary Axes, there is no need to use DWO.

CAUTION: The B-Axis value of the work offset you use with G254 MUST be zero.

With DWO, you no longer need to set the workpiece in the exact position as programmed

in the CAM system. DWO applies the appropriate offsets to account for the differences

between the programmed workpiece location and the actual workpiece location. This

eliminates the need to repost a program from the CAM system when the programmed and

actual workpiece locations are different.

The control knows the centers of rotation for the rotary table (MRZP) and the location of the

workpiece (active work offset). This data is used to produce the desired machine motion

from the original CAM-generated program. Therefore, it is recommended that G254 be

invoked after the desired work offset is commanded, and after any rotational command to

position the 4th and 5th axes.

After G254 is invoked, you must specify an X, Y, and Z Axis position before a cutting

command, even if it recalls the current position. The program should specify the X- and Y

Axis position in one block and the Z Axis in a separate block.

CAUTION: Before rotary motion, use a G53 Non-Modal Machine Coordinate

motion command to safely retract the tool from the workpiece and

allow clearance for the rotary motion. After the rotary motion finishes,

specify an X-, Y-, and Z-Axis position before a cutting command, even

if it recalls the current position. The program should specify the X- and

Y-Axis position in one block and the Z-Axis position in a separate

block.

CAUTION: Be sure to cancel G254 with G255 when your program does

simultaneous 4- or 5-axis machining.

37

G254 - Dynamic Work Offset (DWO) (Group 23)

X0, Y0, Z0

X1, Y-1, Z0

NOTE: For clarity, the illustrations in this section do not depict workholding.

The block in the figure below was programmed in the CAM system with the top center hole

located at the center of the pallet and defined as X0, Y0, Z0.

F6.1: Original Programmed Position

In the figure below, the actual workpiece is not located in this programmed position. The

center of the workpiece is actually located at X1, Y-1, Z0, and is defined as G54.

F6.2: Center at G54, DWO Off

DWO is invoked in the figure below. The control knows the centers of rotation for the rotary

table (MRZP), and the location of the workpiece (active work offset G54). The control uses

this data to apply the appropriate offset adjustments to make sure that the proper toolpath

is applied to the workpiece, as intended by the CAM-generated program. This eliminates

the need to repost a program from the CAM system when the programmed and actual

workpiece locations are different.

38

F6.3: Center with DWO On

X0, Y0, Z0

G254 Program Example

%

O00004 (DWO SAMPLE) ;

G20 ;

G00 G17 G40 G80 G90 G94 G98 ;

G53 Z0. ;

T1 M06 ;

G00 G90 G54 X0. Y0. B0. C0. (G54 is the active work offset

for) ;

(the actual workpiece location) ;

S1000 M03 ;

G43 H01 Z1. (Start position 1.0 above face of part Z0.) ;

G01 Z-1.0 F20. (Feed into part 1.0) ;

G00 G53 Z0. (Retract Z with G53) ;

B90. C0. (ROTARY POSITIONING) ;

G254 (INVOKE DWO) ;

X1. Y0. (X and Y position command) ;

Z2. (Start position 1.0 above face of part Z1.0) ;

G01 Z0. F20. (Feed into part 1.0 ) ;

G00 G53 Z0. (Retract Z with G53) ;

B90. C-90. (ROTARY POSITIONING) ;

X1. Y0. (X and Y position command) ;

Z2. (Start position 1.0 above face of part Z1.0) ;

G01 Z0. F20. (Feed into part 1.0 ) ;

G255 (CANCEL DWO) ;

B0. C0. ;

M30 ;

%

G254 Programmer’s Notes

G254 - Dynamic Work Offset (DWO)

39

G254 - Dynamic Work Offset (DWO) (Group 23)

These key presses and program codes will cancel G254:

•[EMERGENCY STOP]

•[RESET]

•[HANDLE JOG]

•[LIST PROGRAM]

• G255 – Cancel DWO

• M02 – Program End

• M30 – Program End and Reset

These codes will NOT cancel G254:

• M00 – Program Stop

• M01 – Optional Stop

Some codes ignore G254. These codes will not apply rotational deltas:

• *G28 – Return to Machine Zero Through Optional Reference Point

• *G29 – Move to Location Through G29 Reference Point

• G53 – Non-Modal Machine Coordinate Selection

• M06 – Tool Change

*It is strongly recommended that you not use G28 or G29 while G254 is active, nor when

the B and C Axes are not at zero.

40

1. G254 (DWO) is intended for 3+1 and 3+2 machining, where the B and C Axes are

used to position only.

2. An active work offset (G54, G55, etc.) must be applied before G254 is commanded.

3. All rotary motion must be complete before G254 is commanded.

4. After G254 is invoked, you must specify an X-, Y-, and Z-Axis position prior to any

cutting command, even if it recalls the current position. It is recommended to specify

the X and Y Axes in one block, and the Z Axis in a separate block.

5. Cancel G254 with G255 immediately after use and before ANY rotary motion.

6. Cancel G254 with G255 any time simultaneous 4- or 5-axis machining is performed.

7. Cancel G254 with G255 and retract the cutting tool to a safe location before the

workpiece is repositioned.

Setting Work and Tool Offsets

Chapter 7: Setting Work and Tool

Offsets

7.1 Set the B-Axis Work Offset

If the fixture or workpiece requires you to adjust the B Axis to achieve the proper alignment

for machining, use this procedure to adjust and record the B-Axis work offset.

CAUTION: Do not use a B-Axis offset if your program uses Dynamic Work Offsets

(G254). The B-Axis offset value must be zero.

1. Adjust the B Axis until the workpiece is positioned to the same orientation established

in the program. Typically, the top surface of the fixture or workpiece is perpendicular

to the Z Axis.

2. Navigate to [OFFSET]>Work. Scroll to the work offset value used in the program

(G54 in this example).

3. Highlight the value in the B Axis column. Press [PART ZERO SET] to record the

offset.

7.2 Set the C-Axis Work Offset

NOTE: If the fixture or workpiece requires you to adjust the C Axis to achieve

the proper alignment for machining, use the following procedure to

adjust and record the C-Axis work offset.

41

Set the X-, Y-, and Z-Axis Work Offsets Manually

F7.1: Setting the C-Axis Workpiece Orientation

1. Place the workpiece on the platter (workholding not shown). Adjust the C Axis until

the workpiece is positioned to the same orientation established in the program.

Typically, a reference feature on the fixture or workpiece is parallel to the X or Y Axis.

2. Navigate to [OFFSET]>Work. Scroll to the work offset value used in the program

(G54 in this example).

3. Highlight the value in the C Axis column. Press [PART ZERO SET] to record

the offset.

7.3 Set the X-, Y-, and Z-Axis Work Offsets

Manually

NOTE: Use this procedure if the WIPS probe is disabled.

NOTE: Refer to the Haas Mill Operator’s Manual for basic offset and

toolsetting methods.

42

1. Jog the X and Y Axes to the zero position established in the program.

F7.2: UMC-750 X- and Y-Axis Zero Position

2. Navigate to [OFFSET]>Work. Scroll to the work offset value used in the program

(G54 in this example).

3. Select the X Axis column of your work coordinate offset and press [PART ZERO

SET] to set the X-Axis zero position.

4. Press [PART ZERO SET] again to set the Y-Axis zero position.

Setting Work and Tool Offsets

F7.3: X-Axis Zero Position Set and Y-Axis Zero Position Set

5. Determine a tool set plane to be used for setting all tool length offsets; for example,

use the top surface of the workpiece.

43

Set the X-, Y-, and Z-Axis Work Offsets Manually

F7.4: Example Tool Set Plane (Top of the Part)

6. Load the master gage tool included with WIPS into the spindle.

F7.5: Master Gage Tool

7. Make sure that the B and C Axes are at the same work zero point set earlier.

(G00 G90 G54 B0 C0)

44

8. Select the Z AXIS column of your work coordinate offset.

9. Jog the Z Axis to the tool set plane. Make sure that the end of the gage tool you are

using just touches the tool set plane. You will touch-off all of your tools on this

surface.

F7.6: Jog the End of the Gage Tool to the Tool Set Plane

Setting Work and Tool Offsets

10. With the Z Axis column of the work offset used in the program highlighted (G54 in this

example), press [PART ZERO SET].

11. Subtract the length of the master gage tool supplied with the machine from the value

shown in the Z Axis column. Enter this value as the offset in the Z Axis column.

For example, if the Z-Axis work offset is -7.0000 and the master gage tool length is

5.0000, the new Z-Axis work offset is -12.0000.

12. Touch-off each of the tools in your program to the Z set plane to establish their length

offsets.

45

Set the X-, Y-, and Z-Axis Work Offsets with WIPS

7.4 Set the X-, Y-, and Z-Axis Work Offsets with

WIPS

If you are not using the WIPS system, go to the Set the X-, Y-, and Z-Axis Work Offsets

Manually section, starting on page 41.

NOTE: Make sure that the tool setting probe and the work probe are

calibrated. Refer to the Haas WIPS manual (96-10002) for the

calibration procedure.

F7.7: UMC-750 Work Offset with WIPS

46

F7.8: UMC Z-Axis Work Zero Offset Start

0.25"

(6 mm)

1. Load the work probe into the spindle.

2. Make sure that the B and C Axes are at the same work zero point set earlier.

(G00 G90 G54 B0 C0). Refer to the Set the B-Axis Work Offset and Set the C-Axis

Work Offset sections if these values are not correct.

3. Set the X- and Y-Axis offsets using the standard WIPS templates as appropriate.

Refer to the WIPS manual for more information.

4. Position the work probe tip approximately 0.25" (6 mm) above the Z-Axis zero

surface.