Page 1

Turret Indexer Assembly - SL-10/30 ST-10/15 - Troubleshooting Guide

Turret Indexer Assembly - SL-10/30 ST-10/15 - Troubleshooting Guide

Turret Indexer Assembly

LAST UPDATED: 11/27/2018

1. Air Cylinder

Assembly

2. Motor

3. Worm Housing 21. TC Turret Cams (2)

4. Coupling Assembly 22. 15/16 Steel Balls (3)

5. Coolant Line

Assembly

6. Worm Shaft 24. TC Turret Shaft

7. TC Transfer Shaft 25. TC Cam Lever

8. Turret Home Switch 26. Die Spring Retainer

9. TC Switch Ring 27. Die Spring

10. Turret Switch

Bracket

11. Bulkhead Fitting 29. Male Turret Coupling

12. Coolant Valve 30. Female Turret Coupling

13. Coolant Knob 31. Turret Mount Coupling

14. Bearing Nut N-13 32. TC Cluster Gear

15. Coolant Line 33. TC Turret Housing

16. TC Spur Gear

(keyed)

17. Belleville Washers

(2)

18. TC Belleville

Spacer

19. Coolant Elbow

20. Coolant Transfer

Assembly

23. Turret Retainer

28. Cam Cage

34. Turret Unclamp Sensor

35. Turret Clamp Sensor

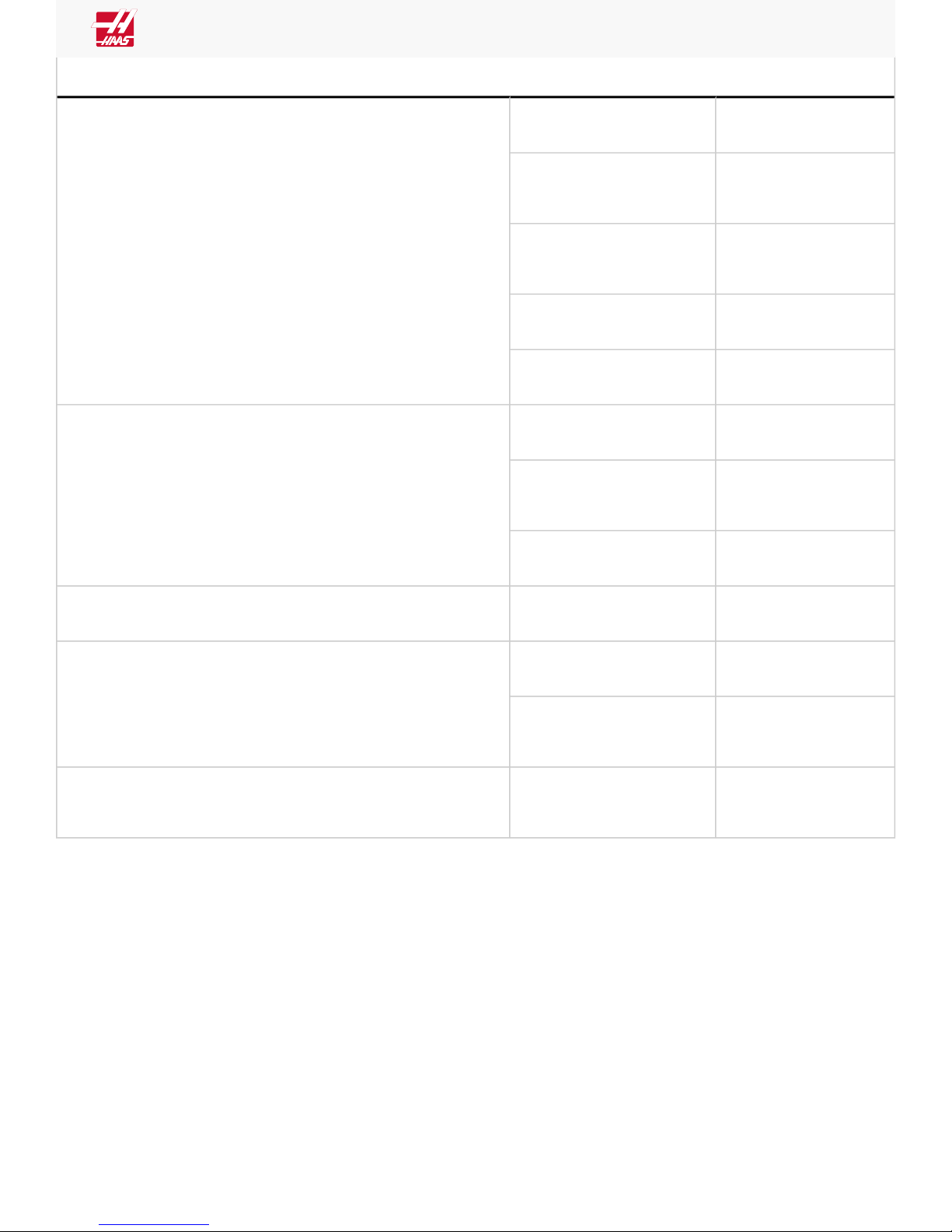

Symptom Table

Page 1 of 5 pages

Page 2

Turret Indexer Assembly - SL-10/30 ST-10/15 - Troubleshooting Guide

SYMPTOM POSSIBLE CAUSE CORRECTIVE ACTION

Alarm 113 Turret failure to reach the Unclamp switch,

Alarm 2022 Turret failure to leave clamp switch, Alarm 8113 Turret

failed to reach the unclamp switch

Alarm 114 TURRET failure to reach the Clamp switch Alarm 2023 Turret

failure to leave unclamp switch

The incoming air pressure or air

flow is incorrect.

There is a problem with the

voltage to the turret clamp /

unclamp solenoid.

There is a problem with the

turret clamp / unclamp

solenoid.

There is a problem with the

clamp/unclamp cylinder.

The turret unclamp sensor is

faulty or out of adjustment.

Turret is out of alignment.

Mechanical binding of turret.

The turret clamp sensor is

faulty or out of adjustment.

Check the incoming air

supply.

Check the voltage to the

turret clamp / unclamp

solenoid.

Check the turret clamp /

unclamp solenoid.

Test the air cylinder for

faulty piston seal.

Check the turret unclamp

sensor.

Check Turret/Motor

coupling adjustment.

Check turret for possible

turret o-ring damage or

chip intrusion.

Check the turret clamp

sensor.

Unusual noise as the turret rotates

Alarm 106 A-AXIS POSITION ERROR

Axis rotating slowly, hesitating to rotate.

Tool Turret Die springs are

broken.

The servo motor has an

electrical fault.

Mechanical obstruction.

Contaminated HPC Pressure

Sensor cable.

Remove Tool Turret to

inspect or replace springs.

Go to DIY servo system

trouble shooting.

Inspect turret for possible

obstruction or binding

during rotation.

Check the HPC Pressure

cable for coolant

contamination.

Page 2 of 5 pages

Page 3

Turret Indexer Assembly - SL-10/30 ST-10/15 - Troubleshooting Guide

Solenoid

Corrective Action:

CALM System (All solenoids located in the lube panel)

Use needle tipped probes and take care not to touch probes tips together when checking voltage.

Set the meter to AC voltage.

In MDI command an M43 and press cycle start to unclamp the turret.

Measure the voltage to the clamp and unclamp solenoid. The solenoids are inside the CALM (consolidated air/lubrication

manifold) panel. The voltage should measure 120 VAC.

If there is no voltage, refer to:

• NEXT GENERATION CONTROL - I/O PCB - TROUBLESHOOTING GUIDE

• I/O PCB - TROUBLESHOOTING GUIDE (CLASSIC HAAS CONTROL)

If voltage at the I/O is correct inspect the cable.

If the solenoid appears to be faulty, go to SOLENOID TROUBLESHOOTING GUIDE.

Pre CALM System

Power off, lock and tag out the machine.

Remove the left rear machine enclosure panel.

Locate the clamp/unclamp solenoid and power connection behind the Tool Turret assembly.

Remove lock out tags, power up and zero return the machine.

Use needle tipped probes and take care not to touch probes tips together when checking voltage.

Set the meter to AC voltage.

In MDI command an M43 and press cycle start to unclamp the turret.

Measure the voltage at the solenoid power connection. Do Not unplug the cable. The voltage should measure 120 VAC.

If there is no voltage, refer to:

• NEXT GENERATION CONTROL - I/O PCB - TROUBLESHOOTING GUIDE

• I/O PCB - TROUBLESHOOTING GUIDE (CLASSIC HAAS CONTROL)

If voltage at the I/O is correct inspect the cable.

If the solenoid appears to be faulty, go to SOLENOID TROUBLESHOOTING GUIDE.

Page 3 of 5 pages

Page 4

Turret Indexer Assembly - SL-10/30 ST-10/15 - Troubleshooting Guide

Air Cylinder

Clamp/Unclamp Sensors

Corrective Action:

With the turret clamped test the air cylinder for

faulty piston seal.

Remove the upper hose (unclamp) on the cylinder.

If air is escaping from the upper hose (unclamp)

connection on the cylinder the cylinder piston seal

is bad and piston should be replaced.

Corrective Action:

Turret Die Springs

Check the turret unclamp and clamp sensors.

Use a magnet and pass it over the sensors. Watch

the diagnostics screen to make sure they activate

with the magnet.

If the magnet did not activate the sensors inspect

the cables. If the cables are not damaged then the

sensor will need to be replaced.

If the sensors were activated then they may need to

be adjusted. Verify the motor coupler alignment

before adjusting sensors. Refer to ST-10/10Y,

SL-10-30, TL-15/25, HL-1-6 - TURRET LOCK AND

UNLOCKED SENSORS - ADJUSTMENT procedure.

Corrective Action:

With the turret clamped, rotate the turret back and

forth by hand. If there is movement in the turret the

die springs are broken and need to be replaced.

Refer to HL/SL/ST-10 - TURRET -

REPLACEMENT from the manual. Once the turret is

removed the springs can be replaced.

Page 4 of 5 pages

Page 5

Turret Indexer Assembly - SL-10/30 ST-10/15 - Troubleshooting Guide

Mechanical Binding

Corrective Action:

If the o-ring under the rear turret chip skirt fails it can cause binding and prevent the turret from rotating into position. A

failed o-ring will also allow for coolant and chip intrusion into the back side of the turret. In this case the turret should be

removed to clear the chips and inspected for possible damage.

A failed o-ring will also allow for coolant and chip intrusion into the back side of the turret. In this case the turret should be

removed to clear the chips and inspect for possible damage.

Alignment

If the turret is knocked out of alignment you may have to re-align the turret motor coupler.

Refer to SL-10/20/30, ST-10/10Y - MOTOR COUPLING - ALIGNMENT procedure.

If the turret is knocked out of alingment a full geometry inspection should be done. Make corrections as needed.

Servo Motor

Corrective Action:

The servo motor has an electrical fault. Possible failed motor, bad or contaminated cable connection, a damaged cable, or

failed amplifier.

Refer to SIGMA 1 - AXIS SERVO MOTOR AND CABLES - TROUBLESHOOTING GUIDE or SIGMA 5 - AXIS SERVO

MOTOR AND CABLES - TROUBLESHOOTING GUIDE for detailed information.

Page 5 of 5 pages

Loading...

Loading...