Page 1

Haas Technical Publications

Manual_Archive_Cover_Page Rev A

any other party automatically voids the factory warranty.

June 6, 2013

HAAS SERVICE AND OPERATOR MANUAL ARCHIVE

SL Series Service Manual 96-8710G RevG English June 2003

• This content is for illustrative purposes.

• Historic machine Service Manuals are posted here to provide information for Haas machine owners.

• Publications are intended for use only with machines built at the time of original publication.

• As machine designs change the content of these publications can become obsolete.

• You should not do mechanical or electrical machine repairs or service procedures unless you are qualied

and knowledgeable about the processes.

• Only authorized personnel with the proper training and certication should do many repair procedures.

WARNING: Some mechanical and electrical service procedures can be

extremely dangerous or life-threatening.

Know your skill level and abilities.

All information herein is provided as a courtesy for Haas machine owners

for reference and illustrative purposes only. Haas Automation cannot be held

responsible for repairs you perform. Only those services and repairs that are

provided by authorized Haas Factory Outlet distributors are guaranteed.

Only an authorized Haas Factory Outlet distributor should service or repair a

Haas machine that is protected by the original factory warranty. Servicing by

Page 2

June 2003

TROUBLESHOOTING

COMMON ABBREVIATIONS USED IN HAAS MACHINES

AC Alternating Current

AMP Ampere

APC Automatic Pallet Changer

APL Automatic Parts Loader

ASCII American Standard Code for Information Interchange

ATC Automatic Tool Changer

ATC FWD Automatic Tool Changer Forward

ATC REV Automatic Tool Changer Reverse

AWG American Wire Gauge

BHCS Button Head Cap Screw

BT British Tooling (Common usage)

CAD Computer Assisted Design

CAM Computer Assisted Manufacturing (Assisted Machining)

CAT-5 Category 5 Cable

CB Circuit Breaker

CC Cubic Centimeter

CCW Counter Clock Wise

CFM Cubic Feet per Minute

CNC Computerized Numeric Control

CNCR SPINDLE Concurrent Spindle with axis motion

CRC Cyclic Redundancy Check digit

CRT Cathode Ray Tube

CT Caterpillar Tooling

CTS Clear To Send

CW Clock Wise

DB Draw Bar

DC Direct Current

DGNOS Diagnostic

DHCP Dynamic Host Configuration Protocol

DIR Directory

DNC Direct Numerical Control

DOS Disk Operating System

DTE Data Terminal Equipment

ENA CNVR Enable Conveyor

EOB End Of Block

EOF End Of File

EPROM Erasable Programmable Read Only Memory

E-STOP Emergency Stop

FHCS Flat Head Cap Screw

FT Foot

FU Fuse

FWD Forward

GA Gauge

HHB Hex Head Bolts

HP Horse Power

HS Horizontal Series of Machining Centers

ID Inside Diameter

IGBT Isolated Gate Bipolar Transistor

IN Inch

IOPCB Input Output Printed Circuit Board

LAN Local Area Network

LB Pound

LED Light Emitting Diode

LO CLNT Low Coolant

96-8710 rev G

1

Page 3

TROUBLESHOOTING

LOW AIR PR Low Air Pressure

L VPS Low V oltage Power Supply

MB Megabyte (1 million)

MCD RL Y BRD M -Code Relay Board

MD I Manual Data Input

MEM Memory

M-FIN M -code Finished

MM MilliMeter

MOCON Motor Control

MOTIF Motor Interface

MSG Message

MSHCP Metric Socket Head Cap Screw

N C Numerical Control

N C Normally Closed

NO Normally Open

O D Outside Diameter

OPER Operator

P Pocket

P ARAM Parameter

PCB Printed Circuit Board

PGM Program

PO R Power On Reset

POSIT Positions

PROG Program

PSI Pounds per Square Inch

PS T Pallet Schedule T able

PWM Pulse Width Modulation

RAM Random Access Memory

RET Return

REV CNVR Reverse Conveyor

RJ H Remote Jog Handle

RPDBDN Rotary Pallet Draw Bar Down

RPDBUP Rotary Pallet Draw Bar Up

RPM Revolutions Per Minute

RT S Request To Send

R X D Receive Data

S Spindle S peed

SDIST Servo Distribution PCB

SFM Surface Feet per Minute

SHCS Socket Head Cap Screw

SI O Serial Input/Output

SKBIF Serial Key Board Inter Face PCB

SMTC Side Mount T ool Changer

SP Spindle

T T ool Number

T C T ool Changer

T I R Total Indicated Runout

T N C T ool Nose Compensation

TR P Tool Release Piston

TS Tail Stock

TS C Thru the S pindle Coolant

T XD Transmit Data

VD I Verein Deutscher Ingenieure

VMC Vertical Machining Center

WAN Wide Area Network

June 2003

2

96-8710 rev G

Page 4

June 2003

TROUBLESHOOTING

1. TROUBLESHOOTING

This section is intended for use in determining the solution to a known problem. Solutions given are intended to

give the individual servicing the CNC a pattern to follow in, first, determining the problem’s source and second,

solving the problem.

The troubleshooting tips are organized in this section according to the area of the CNC that may be giving sign

of a problem. (Ex.: Out-of round circles in drilling will be found under the heading General Machine Operation Accuracy).

If the problem you are experiencing cannot be found under the heading you expect, please try several other

possible headings. If the problem is still not found, contact Haas Automation for further details.

BEFORE YOU BEGIN:

USE COMMON SENSE

Many problems are easily overcome by correctly evaluating the situation. All machine operations are composed

of a program, tools, and tooling. Y ou must look at all three before blaming one as the fault area. If a bored hole

is chattering because of an overextended boring bar, don’t expect the machine to correct the fault. Don’t

suspect machine accuracy if the vise bends the part. Don’t claim hole mis-positioning if you don’t first centerdrill the hole.

FIND THE PROBLEM FIRST

Many mechanics tear into things before they understand the problem, hoping that it will appear as they go. We

know this from the fact that more than half of all warranty returned parts are in good working order . If the

spindle doesn’t turn, remember that the spindle is connected to the gear box, which is connected to the

spindle motor, which is driven by the spindle drive, which is connected to the I/O BOARD, which is driven by

the MOCON, which is driven by the processor. The moral here is don’t replace the spindle drive if the belt is

broken. Find the problem first; don’t just replace the easiest part to get to.

DON’T TINKER WITH THE MACHINE

There are hundreds of parameters, wires, switches, etc., that you can change in this machine. Don’t start

randomly changing parts and parameters. Remember , there is a good chance that if you change something,

you will incorrectly install it or break something else in the process. Consider for a moment changing the

processor’s board. First, you have to download all parameters, remove a dozen connectors, replace the board,

reconnect and reload, and if you make one mistake or bend one tiny pin it WON’T WORK. You always need to

consider the risk of accidentally damaging the machine anytime you work on it. It is cheap insurance to

double-check a suspect part before physically changing it. The less work you do on the machine the better .

96-8710 rev G

3

Page 5

TROUBLESHOOTING

1.1 GENERAL MACHINE OPERATION

MACHINE NOT R UNNING

Machine cannot be powered on.

• Check input voltage to machine (see "Electrical Service").

• Check main circuit breaker at top right of electrical cabinet; switch must be at the on position.

• Check overvoltage fuses (see "Electrical Service").

• Check wiring to POWER OFF button on front control panel.

• Check wiring to AUT O OFF relay to IOPCB.

• Check connection between 24V transformer and K1 contactor

• Check IOPCB (see "Electrical Service").

• Check POWER PCB (see "Electrical Service").

Machine can be powered on, but turns off by itself.

June 2003

• Check settings #1 and #2 for Auto Of f T imer or Of f at M30.

• Check alarm history for OVERVOL T AGE or OVERHEA T shut down.

• Check AC power supply lines for intermittent supply.

• Check wiring to POWER OFF button on front control panel.

• Check connection between 24V transformer and K1 contactor.

• Check IOPCB (see "Electrical Service").

• Check Parameter 57 for Power Off at E-STOP.

• Check MOTIF or MOCON PCB (see "Electrical Service").

Machine turns on, keyboard beeps, but no CRT display.

• Check for power connections to CRT from IOPCB. Check for green POWER LED at front of CRT.

• Close doors and Zero Return machine (possible bad monitor).

• Check video cable (760) from VIDEO PCB to CRT .

• Check for lights on the processor.

Machine turns on, CRT works, but no keyboard keys work.

• Check keyboard cable (700B) from VIDEO to KBIF PCB.

• Check keypad (see "Electrical Service").

• Check KBIF PCB (see "Electrical Service").

4

96-8710 rev G

Page 6

June 2003

TROUBLESHOOTING

VIBRATION

Vibration is a subjective evaluation with perceptions varying among individuals, making it difficult to determine in

mild cases if there is an actual problem. In obvious cases, it is a matter of determining the source - which is

not easy , since all parts rotate together and sound can be transferred readily. V ibrations also need to be

distinguished from noise such as a bad bearing. We will assume that vibrations would be something that could

be felt by putting your hand on the spindle ring. One crude method of measurement would be to take an

indicator on a magnetic base extended 10 inches between the turret and spindle housing and observe the

reading of the indicator. A reading of more than .001 would indicate excessive vibration. The two common

sources of noise are the spindle and axis drives. Most complaints about vibration, accuracy , and finish can be

attributed to incorrect machining practices such as poor quality or damaged tooling, incorrect speeds or feeds,

or poor fixturing. Before concluding that the machine is not working properly , ensure that good machining

practices are being observed. These symptoms will not occur individually (Ex. A machine with backlash may

vibrate heavily, yielding a bad finish). Put all of the symptoms together to arrive at an accurate picture of the

problem.

Machine vibrates while spindle is on and is not cutting. Sometimes only at specific RPM.

• If the spindle alone causes vibration of the machine this is usually caused by the belt/pulley drive system

or the chuck jaws are not centered correctly.

Machine vibrates while jogging the axis with the jog handle.

• The HAAS control uses very high gain accelerations curves. This vibration as you jog is simply the

servos quickly trying to follow the handle divisions. If this is a problem, try using a smaller division on

the handle. Y ou will notice the vibration more at individual clicks than when you are turning the handle

faster. This is normal.

The machine vibrates excessively in a cut.

• This is a tough one to call because machining practices come into play . Generally speaking, the least

rigid element of a cut is the tool because it is the smallest part. Any cutter will vibrate if pushed beyond

its tensile strength. In order to eliminate the machine as the source of the problem, you need to check

the spindle and the backlash of the axes as described in the following sections. Once machining

practices have been eliminated as the source of vibration, observe the machine in both operation and

“cutting air.” Move the axes (individually) without the spindle turning and then turn the spindle without

moving the axes. Isolate whether the vibration comes from the spindle head or from an axis.

96-8710 rev G

5

Page 7

TROUBLESHOOTING

ACCURACY

Before you complain of an accuracy problem, please make sure you follow these simple do’s and don’ts:

• Ensure that the machine has been sufficiently warmed up before cutting parts. This will eliminate

mispositioning errors caused by thermal growth of the ballscrews (see "Thermal Growth" section).

• Don’t ever use a wiggler test indicator for linear dimensions. They measure in an arc and have sine/cosine

errors over larger distances.

• Don’t use magnetic bases as accurate test stops. The high accel/decel of the axis can cause them to

move.

• Don’t attach test points to the sheet metal of the spindle head.

• Don’t check for accuracy/repeatability using an indicator with a long extension.

• Ensure that test indicators and stops are absolutely rigid and mounted to machined casting surfaces

• Check a suspected error with another indicator or method for verification.

• Ensure that the indicator is parallel to the axis being checked to avoid tangential reading errors.

• Center drill holes before using jobber length drills if accuracy is questioned.

• Once machining practices have been eliminated as the source of the problem, determine specifically what

the machine is doing wrong.

June 2003

Diameters are out of round

• Check that tooling and machining practices are correct. Bores will be out of round due to tool deflection

much more frequently than due to spindle bearing problems.

Drill

Diameters are incorrect in X-axis

• Ensure the tool probe is set up correctly (settings, etc.)

• Ensure tool offsets are coorect. Note that the coordinate system (F ANUC, YASNAC, HAAS) must be

selected before setting tools.

• Ensure Parameter 254, Spindle Center , is set correctly .

• Check for thermal growth of the X-axis ballscrew (see “Thermal Growth” section).

Center holes are malformed

• Ensure tooling is tight.

• Ensure Parameter 254, Spindle Center , is set correctly .

• Check spindle to turret pocket alignment. It may be out of alignment due to a crash or misadjustment.

• Check for thermal growth of the X-axis ballscrew (see “Thermal Growth” section).

6

96-8710 rev G

Page 8

June 2003

TROUBLESHOOTING

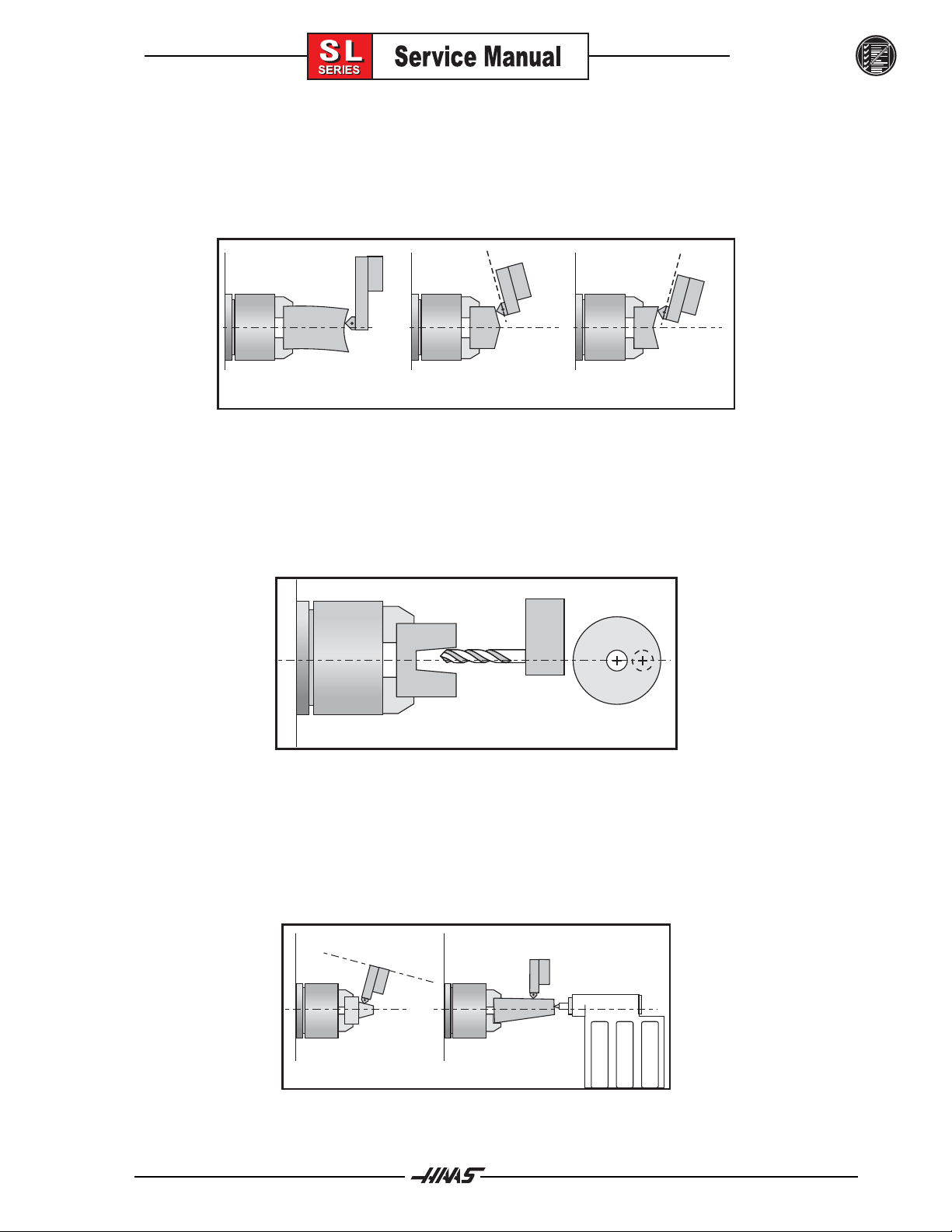

Part faces are conical

• Wedge may be out of alignment due to a crash.

• Check tooling setup. Turning long, unsupported parts may cause conical part faces.

• Check for thermal growth of the ballscrews (see Thermal Growth” section).

C

L

Part/Tooling Problem Geometry Problem

C

L

C

L

Bores are tapered

• Check that tooling and machining practices are correct. Bores will be tapered if the tooling is inappropriate,

the speeds and feeds are incorrect, or coolant is not getting to the cutting tool when required.

• Although it is rare, the spindle may be out of alignment due to a crash

• Check that the turret face is parallel with x-axis.

C

L

96-8710 rev G

Outside diameter (O.D.) is tapered

• Check tooling setup. Turning long, unsupported parts can cause a tapered O.D.

• Check tailstock setup. Excessive hold pressure on the tailstock can distort parts.

• Spindle to Z-axis may be out of alignment (not parallel).

• Program around it. Reduce depth of final rough cut and finish pass to reduce part deflection.

C

L

Poor Geometry

C

L

7

Page 9

TROUBLESHOOTING

C

L

C

L

Poor Technique

June 2003

C

L

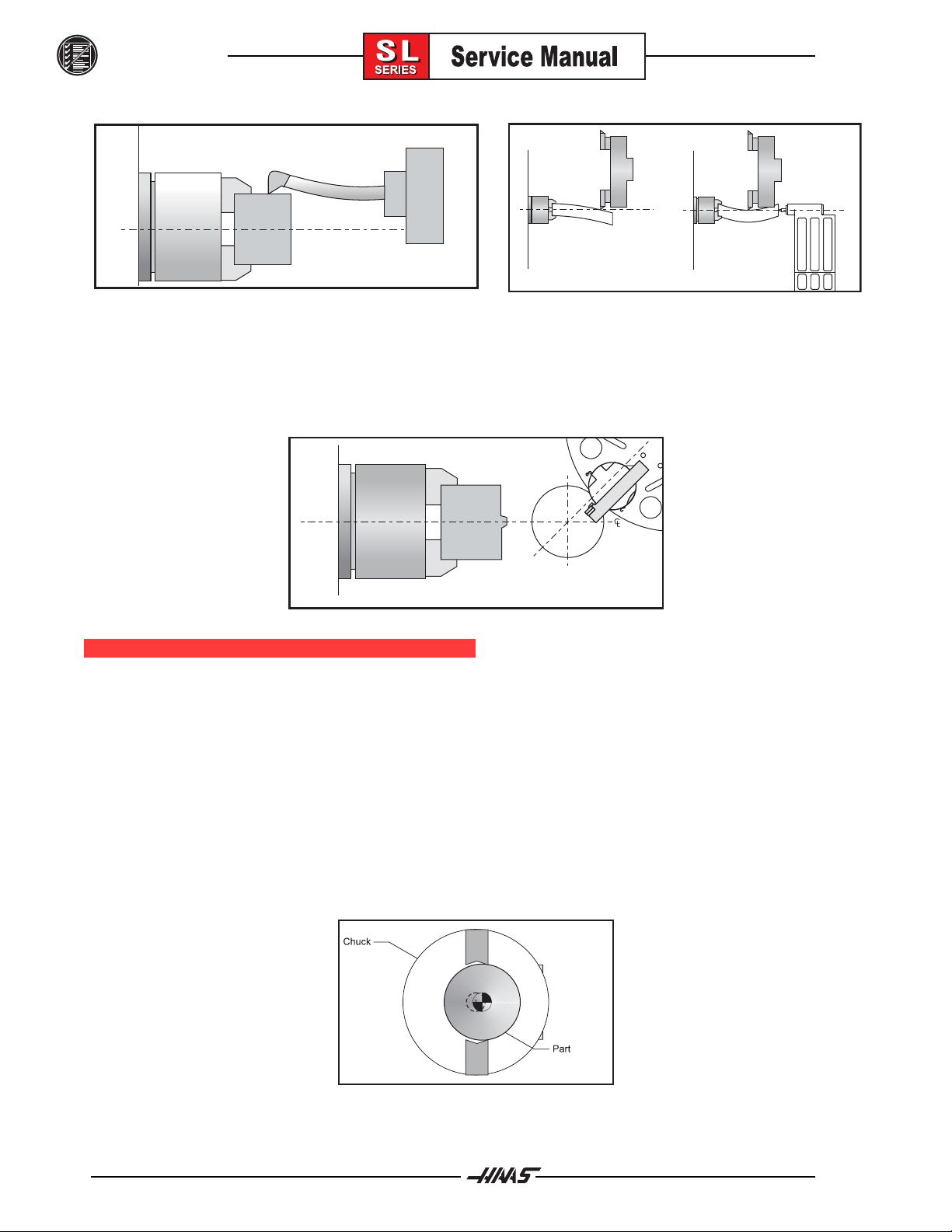

Material left after facing a part

• Ensure tooling is correct.

• Ensure turret is aligned to X-axis travel.

• Ensure Parameter 254, Spindle Center , is set correctly .

Material Left After Facing Part

FINISH

Machining yields a poor finish

• Check the condition of the tooling and the spindle.

• Ensure turret is clamped.

• Ensure tooling is tight.

• Check tooling for chatter or lack of rigidity .

• Check the balance of the chuck, part, and fixture.

• Check for backlash.

• Check turret alignment.

8

96-8710 rev G

Page 10

June 2003

TROUBLESHOOTING

THERMAL GROWTH

A possible source of accuracy and positioning errors is thermal growth of the ballscrews. As the machine

warms up, the ballscrews expand in both linear axes (X and Z), causing accuracy and positioning errors. This

is especially critical in jobs that require high accuracy .

NOTE: Thermal growth will be more noticeable in the X-axis, since errors will be

doubled when cutting a diameter.

Verify Thermal Growth

There are a number of ways to verify the problem. The following procedure will verify thermal growth of the Xaxis reversed-anchored ballscrew in a machine that has not been warmed up:

1. Home the machine. In MDI mode, press POSIT and P AGE DOWN to the OPER p age.

2. Jog to an offset location. Select the X-axis and press the ORIGIN key to zero it.

3. Press the OFSET key, then scroll down to G1 10 (or any unused offset). Cursor to X and press the

P AR T ZERO SET key. This will set X) at this position.

4. Enter a program that will start at the new zero position, rapid a certain distance in the X direction,

feed the final .25 inches slowly , and then repeat the X movement.

5. In order to set up the indicator , run the program in SINGLE BLOCK mode, and stop it when X is at

the end of its set travel. Set the magnetic base on the spindle retainer ring or other rigid surface,

with the indicator tip touching the turret in the X-axis, and zero it.

6. Exit SINGLE BLOCK mode, and run the program for a few minutes. Enter SINGLE BLOCK mode

again, stop the program when X is at the beginning of its travel, and take a final reading on the

indicator. If the problem is thermal growth, the indicator will show a dif ference in the X position.

96-8710 rev G

NOTE: Ensure the indicator setup is correct as described in “Accuracy” section. Error

in setup are common, and often incorrectly appear to be thermal growth.

7. A similar program can be written to test for thermal growth in the Z-axis.

Solutions

Since there are many variables that affect thermal growth, such as the ambient temperature of the shop and

program feed rates, it is difficult to give one solution for all problems.

Thermal growth problems can generally be eliminated by running a warm-up program for approximately 20

minutes before machining parts. The most effective warm-up is to run the current program, at an offset Z

position before the part. This will allow the ballscrews to warm up to the correct temperature and stabilize.

Once the machine is at temperature, the ballscrews won't expand any further , unless they are allowed to cool

down. A warm-up program should be run after each time the machine is lef t idle.

9

Page 11

TROUBLESHOOTING

1.2 SPINDLE

NOT TURNING

Spindle not turning

• If there are any alarms, see “Alarms” section.

• Check that the spindle turns freely when machine is off.

• If spindle is still not turning, replace MOCON PCB.

• Disconnect the drive belt. If the spindle will not turn, it is seized and must be replaced.

For Brush machines only:

• If spindle drive does not light the RUN LED, check forward/reverse commands from IOPCB.

Check that the drawtube piston is not bound against the spindle shaft on the air cylinder style.

• Check the wiring of analog speed command from MOTIF PCB to spindle drive (cable 720).

• Disconnect the drive belt. If the spindle will not turn, it is seized and must be replaced.

June 2003

NOTE: Before using the replacement spindle, the cause of the previous failure must

be determined.

NOISE

Most noise attributed to the spindle actually lie in the motor or drive belt of the machine. Isolate the sources of

noise as follows:

Excessive noise coming from the spindle head area.

• Remove the left end covers and check the machine’s drive belt tension.

• Run the motor with the drive belt disconnected. If the noise persists, the problem lies with the motor . If it

disappears, go on to the next step.

• Check for the correct amount of lubrication to the spindle bearings (1cc per hour) in an air mist lubricated

spindle.

VECTOR DRIVE

T o properly troubleshoot the V ector Drive, use the following questions as a guide:

• What alarms are generated?

• When does the alarm occur?

• Is the Vector Drive top fault light on?

• Is there a fault light on any of the servo amplifiers?

• Does the alarm reset?

• Does the spindle motor turn at all?

• Does the spindle turn freely by hand?

• Have the C-axis parameters been confirmed?

• What is the input voltage to the vector drive unit?

• What does the DC Bus voltage measure? (320 VDC to 345 VDC)

• Does the DC Bus voltage displayed on the diagnostic page match the measured DC Bus voltage?

10

96-8710 rev G

Page 12

June 2003

TROUBLESHOOTING

All of the questions above must be answered. The DC Bus voltage should be between 320 VDC to 345 VDC

with the machine powered up but not running. If the voltage is not in this range, adjust the taps on the main

line transformer until this voltage range is achieved. There is a possibility the drive is faulty , but low Bus

voltage can also be caused by a shorted REGEN load or a shorted amplifier .

If the DC Bus voltage is below 50 VDC and never goes any higher, perform Steps 1-6.

1. With the machine powered up, is the green “POWER-ON” L.E.D. lit? If not, replace the Vector

Drive unit.

2. Power down the machine. Disconnect the REGEN load (terminals 1 and 2 on the V ector Drive

unit) and measure the resistance from each wire-to-chassis ground (open) and between the wire

leads. The resistance should be 8.6 ohms for machines with 20/15 V ector drives and HT10K

lathes equipped with 40/30 drives. All other machines with 40/30 drives should measure 6 ohms.

If not, replace the REGEN load or cabling.

3. Disconnect cable 490 at terminals 2 and 3 of the V ector Drive and from the servo amplifiers. With

a multimeter in the diode mode, place the red meter lead to the +HV terminal and the black meter

lead to the -HV terminal of each amplifier. The meter should read open.

4. Reverse the leads: Place the red meter lead on the -HV terminal and the black lead on the +HV

terminal. The meter should read .7 ohms in both instances. If not, replace the faulty amplifier .

5. Measure the resist ance between terminals 1 and 3 of the Vector Drive. The meter should read

greater than 100K ohms. If not, the Vector Drive is faulty.

6. If the green “POWER-ON” L.E.D. was lit (from S tep 2), leave both 490 cables (2 and 3) disconnected from the drive and power up the machine.

a. Does the DC Bus voltage come up? If not, the Vector Drive is faulty .

b. Measure the voltage between terminals 1 and 3. The voltage should be 300

VDC or more. If not, the Vector Drive is faulty.

If both ‘a’ and ‘b’ check out okay, there is a problem with either the amplifiers or the REGEN load.

If the fault occurs upon acceleration -or- the spindle accelerates slowly -or- the spindle

makes noise, do the following:

7. Disconnect the output cables to the spindle motor. T urn on the machine and press <RESET>. Do

not command the spindle to turn. With a volt meter, measure the DC voltage between each output

phase (terminals 9, 10, and 11) to the 320V R TN (terminal 3). The meter should read 165 VDC in

each case, else one phase is faulty .

8. Measure the resistance across the motor wires from phase to phase and from each phase to

chassis. The meter should read .1 ohms phase-to-phase and open phase-to-chassis.

96-8710 rev G

11

Page 13

TROUBLESHOOTING

If the fault occurs upon deceleration or acceleration just as the spindle reaches its specified speed, or if an overvoltage alarm (119) occurred, do the following:

9. Disconnect the REGEN load resistors (terminals 1 and 2) and measure the resistance from each

wire lead-to-chassis ground and between the wire leads. The meter should read open lead-toground, and 6 ohms between the leads for machines with 40/30 Vector drives and 8.6 ohms

between the leads on machines with 20/15 Vector drives and HT10K mills.

10. Measure the resistance from terminal 1 to terminal 3. If the resistance is less than 100K, the drive

is faulty.

1 1. With the REGEN load left disconnected, power-up the machine and command a spindle speed of

700 RPM (300 RPM for lathes in high gear). Press <RESET> while monitoring the DC voltage

between terminal 1 and terminal 3. The voltage should read 330 VDC and then drop to less than

50 VDC momentarily . If not, that drive is faulty . If the volt age at RESET was okay and the alarm

was resettable, the REGEN load should be replaced even if the resistance appears to be

June 2003

12

96-8710 rev G

Page 14

June 2003

TROUBLESHOOTING

1.3 TRANSMISSION (SL 30 AND 40)

The transmission cannot be serviced in the field and must be replaced as a unit. Never remove the motor from

the transmission, as this will damage the transmission and void the warranty .

NOISE

Excessive or unusual noise coming from transmission.

Operate the machine in both high and low gears. Monitor for noise in both gear positions, and determine if the

noise varies with the motor or output shaft speed.

• If the noise only occurs in one gear throughout the entire RPM range of that gear position, the problem lies

with the transmission, and it must be replaced.

• If the noise occurs in both gear positions, disconnect the drive belts (see “Transmission” section, Mechani-

cal Service) and repeat the previous step. If the noise persists, the transmission is damaged and must be

replaced.

• Disconnect the drive belts (see “Transmission” section, Mechanical Service) and run the machine in high

gear. Command a change of direction and listen for a banging noise in the transmission as the machine

slows down to zero RPM and speeds back up in reverse. If the noise occurs, the motor has failed and the

transmission must be replaced.

GEARS W ILL NOT C HANGE

Machine will not execute a gear change.

• Check the voltage to the gear shifter motor . The voltage between pins 2 and 3 should be approximately

+28V when high gear is commanded and -28V when low gear is commanded. If these voltages are correct,

the gear shifter motor has failed and the transmission must be replaced. If these voltages are incorrect, the

cabling or transmission power supply is at fault.

INCORRECT GEAR SELECTED OR SENSED

Spindle speed is not consistent with selected gear.

• Monitor the discrete inputs and outputs SP HIG and SP LOW on the diagnostics display while command-

ing high and low gear. The output SP HIG should be 1 when high gear is selected, and SP LOW should be

1 when low gear is selected. The inputs SP HIG and SP LOW should be 0 when that gear is engaged, and

should both be 1 when the transmission is between gears. These inputs should never read 0 at the same

time.

If any of these inputs/outputs are incorrect, either the gear change limit switches or the wiring to the I/O PCB is

at fault. The limit switches are located inside the transmission, and cannot be replaced.

96-8710 rev G

13

Page 15

TROUBLESHOOTING

1.4 SERVO MOTORS / BALLSCREWS

NOT OPERATING

All problems that are caused by servo motor failures should also register an alarm. Check the alarm history to

determine the cause of the problem before any action is taken.

Servo motor is not functioning.

• Check the power cable from rear electrical cabinet to ensure connection is tight.

• Encoder is faulty or contaminated (Alarms 139-142, 153-156, 165-168, 182-185). Replace motor

assembly on brushless machines

• Open circuit in motor (Alarms 139-142, 153-156, 182-185). Replace motor assembly ("Axis Motor

Removal / Installation").

• Motor has overheated, resulting in damage to the interior components (Alarms 135-138, 176).

Replace motor assembly ("Axis Motor Removal/Installation").

• Wiring is broken, shorted, or missing shield (Alarms 153-156, 175, 182-185).

• Motor has overheated; no damage to the interior components. OVERHEA T alarm has been

triggered. Af ter thorough check of motor (DO NOT DISASSEMBLE!), take necessary steps to

eliminate the problem and alarm to resume operation. If motor is still inoperable, replace motor

assembly ("Axis Motor Removal/Installation").

• Check for broken or loose coupling between the servo motor and the ball screw. Replace or rep air

the coupling ("Axis Motor Removal/Installation")

• Check for a damaged ball screw, and replace if necessary ("Ball Screw Removal and Inst allation"

section).

June 2003

NOTE: If a ball screw fails, it is most often due to a failed bearing sleeve. When

replacing the ball screw in an older machine, always replace the bearing

sleeve with the current angular contact bearing sleeve ("Bearing Sleeve

Removal and Installation" section).

NOISE

Ball screw noise is usually caused by a lack of lubrication and is usually accompanied by heating. Other

causes are misalignment, bearing sleeve damage, or ball nut damage. Check the alarm history of the machine

and look for axis overcurrent and following error alarms.

NOTE: Do not replace ball screws or bearing sleeves without due consideration; they

are extremely durable and reliable. Verify that customer complaints are not due

to tooling, programming, or fixturing problems.

Servo motor noise.

•Disconnect the servo motor from the ball screw and rotate by hand. If the noise persists, replace

the motor assembly ("Axis Motor Removal/Installation" section).

•If motor noise is caused by motor bearings, replace motor.

14

96-8710 rev G

Page 16

June 2003

TROUBLESHOOTING

Ball screw noise.

• Ensure oil is getting to the ball screw through the lubrication system. Look for a plugged metering

valve.

• Check for damage to the bearing sleeve.

NOTE: The current angular contact design sleeve has a fixed pre-load; it cannot be

adjusted.

• Run the axis back and forth. The motor will get very hot if the bearing sleeve is damaged. If so, turn

the axis by hand and feel for roughness in the ball screw. Loosen the clamp nut s at both ends of

the ball screw. If the symptom disappears, replace the bearing sleeve. Be cert ain to check for

damage to the ball screw shaft where the bearing sleeve is mounted. If the noise persists, the ball

screw is damaged and must be replaced. When replacing the ball screw in an older machine,

always replace the bearing sleeve with the current angular contact design bearing sleeve.

• Misalignment in the ball screw itself will tend to cause the ball screw to tighten up and make

excessive noise at both ends of the travel. The ballnut may get hot. Misalignment radially at the

yoke where the ball screw ball nut mounts is indicated by heating up of the ball nut on the ball

screw, and noise and tightness throughout the travel of the ball screw . Misalignment at the yoke

where the ball nut mounts is indicated by noise and tightness at both ends of the travel of the ball

screw. The ball nut may get hot.

NOTE: Customer complaints of Ball Screw noise may not indicate a bad screw.

Screws from different manufacturers produce varying levels of noise. Often

machines are built with two or more different brands of screws in the same

machine. If complaints are generated about one axis screw in comparison to

another, it is possible that the screws are simply sourced from different

manufacturers.

ACCURACY / BACKLASH

Accuracy complaints are usually related to tooling, programming, or fixturing problems. Eliminate these

possibilities before working on the machine.

Poor Z-axis accuracy .

• Check for a loose encoder on the servo motor. Also, ensure the key in the motor or the ball screw is in

place and the coupling is tight (Brush motors only).

• Check parameters for that axis.

• Check for backlash in the ball screw as outlined below.

Initial Preparation-

Turn the lathe ON. ZERO RET the machine and move the carriage to the approximate center of its travel in the

Z-axis. Move the turret to the approximate center of the X-axis travel.

96-8710 rev G

15

Page 17

TROUBLESHOOTING

X-Axis:

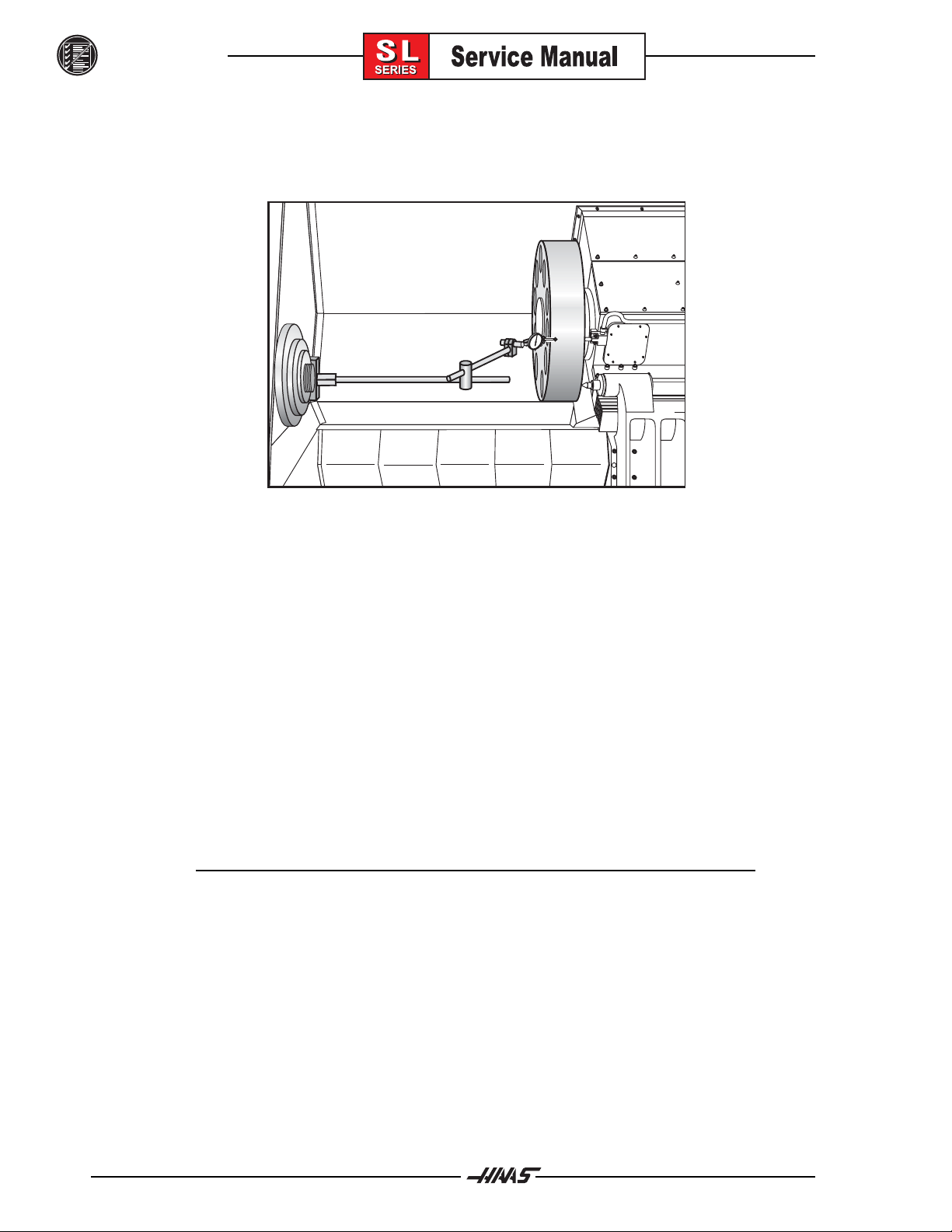

1. Place a dial indicator and base on the spindle retaining ring with the tip of the indicator positioned

on the outside diameter of the turret, as shown in Fig. 1.4-1

June 2003

Fig. 1.4-1 Dial indicator in position to check X-axis.

2. Set dial indicator and the “Distance to go” display in HANDLE JOG mode to zero as follows:

• Zero the dial indicator.

• Press the MDI button on the control panel.

• Press the HANDLE JOG button on the control panel.

The “Distance to go” display on the lower right hand corner should read: X=0 Z=0

3. Set the rate of travel to .001 on the control panel and jog the machine .010 in the positive (+) X

direction. Jog back to zero (0) on the display. The dial indicator should read zero (0) ± .0001.

4. Repeat step 3 in the negative (-) direction.

TOTAL DEVIATION BETWEEN THE DIAL INDICATOR AND THE CONTROL PANEL DISPLAY

SHOULD NOT EXCEED .0002.

An alternate method for checking backlash is to place the dial indicator as shown in Fig. 4-1 and manually

push on the turret in both directions. The dial indicator should return to zero after releasing the turret.

NOTE: The servos must be on to check backlash by this method.

Z-Axis:

1. Place a dial indicator and base on the spindle retaining ring with the indicator tip positioned on the

face of the turret as shown in Fig. 1.4-2.

16

96-8710 rev G

Page 18

June 2003

TROUBLESHOOTING

Fig. 1.4-2 Dial indicator in position to check Z-axis

2. Set dial indicator and the “Distance to go” display in the HANDLE JOG mode to zero as follows:

• Zero the dial indicator.

• Press the MDI button on the control panel.

• Press the HANDLE JOG button on the control panel. The “Distance to go: display on the lower

right hand corner should read: X=0, Z=0

3. Set the rate of travel to .001 on the control panel and jog the machine .010 in the positive (+) Z

direction. Jog back to zero (0) on the display . The dial indicator should read (0) ± .001.

4. Repeat S tep 3 in the negative (-) direction.

TOTAL DEVIATION BETWEEN THE DIAL INDICATOR AND THE CONTROL PANEL DISPLAY

SHOULD NOT EXCEED .0002.

An alternate method for checking backlash is to place the dial indicator as shown in Fig. 4-2 and manually

push on the turret in both directions. The dial indicator should return to zero after releasing the turret.

NOTE: The servos must be on to check backlash by this method.

VIBRATION

Excessive servo motor vibration.

• Check all Parameters of the suspected axis against the Parameters as shipped with the machine. If

there are any differences, correct those and determine how the Parameters were changed.

• A bad motor can cause vibration if there is an open or short in the motor . A short would normally

cause a GROUND FAUL T or OVERCURRENT alarm; check the ALARMS. An ohmmeter applied to the

motor leads should show between 1 and 3 ohms between leads, and over 1 megohm from leads to

chassis. If the motor is open or shorted, replace.

96-8710 rev G

17

Page 19

TROUBLESHOOTING

OVERHEATING

Servo motor overheating.

• If a motor OVERHEA T alarm occurs (ALARMS 135-138), check the Parameters for an incorrect

setting. Axis flags in Parameters 1, 15, or 29 can invert the overheat switch (OVER TEMP NC).

• If the motor is actually getting hot to the touch, there is excessive load on the motor. Check the user’s

application for excessive load or high duty cycle. Check the ball screw for binding ("Accuracy/

Backlash" section). If the motor is binding by itself, replace in accordance with "Axis Motor Removal/

Installation".

SERVO ERROR

“Servo Error Too Large” alarms occur on one or more axes sporadically.

• Check motor wiring for shorts.

• Driver card may need replacement.

• Servo motor may need replacement.

• Check for binding in motion of ball screw.

June 2003

BALL S CREWS - VISUAL INSPECTION

The three main causes of Ball Screw failure are:

Loss of Lubrication

Contamination

Machine Crash

Wear of the nut balls and the screw threads is generally not an issue under proper operating conditions.

Each type of suspect cause will leave telltale signs on the Ball Screw itself.

Loss of Lubrication:

The lubrication system of the machine provides a layer of oil for the Ball Screw components to operate on,

eliminating metal-to-metal contact. Should a problem with the lubrication system develop, that failure will

accelerate all wear issues.

1. Dry metal-to-metal contact following lube breakdown will create intense heat at the contact points.

The nut balls will weld to the nut races due to the heat and pressure of the preload. When movement of the Ball Screw continues, the welds will be broken, ripping off particles of both the balls

and the races. This loss of diameter will reduce the preload, reducing machine accuracy .

Ball Screws with this type of wear, but no screw surface marring, can be rep aired by the factory .

2. A second cause of wear of the Ball Screws is material fatigue. Material fatigue typically occurs at

the end of the Ball Screw service life. Signs of material fatigue include black, contaminated

coolant, pitting of the screw surface, loss of preload, and metal flakes on the Ball Screw .

Ball Screws suffering from material fatigue are not repairable and are considered scrap.

18

96-8710 rev G

Page 20

June 2003

TROUBLESHOOTING

Contamination:

Contamination of the lubrication and/or coolant systems of the machine will produce problems with the Ball

Screws.

Check the condition of the lube on the Ball Screw threads.

1. If the lube is wet and clean, this indicates a properly functioning lube system.

2. If the lube is thick and dark, but free of metal chips, the lube itself is old and must be changed out.

The entire system should be cleaned of the old lube.

3. If the lube is wet and black, the lube system has been contaminated by metal particles. Inspect

the Ball Screws for wear.

Contamination of the lube and/or coolant systems can be caused by a wearing Ball Screw , or by metal chips

entering the systems through open or loose way covers. Check all way covers and seals for excessive clearances.

Machine Crash:

A hard machine crash can cause a Ball Screw to lock up. The static overload created during a machine crash

can break apart the Nut balls, denting the thread surfaces. Turning the Nut by hand will result in an obvious

grinding feeling and/or sound.

1. Check the screw for straightness.

2. Look for ball dents at the ends of the screw length. These indents will be a sure sign of a hard

machine crash. The inertia of the table is transferred, due to the sudden stop, directly to the balls

inside the Nut, creating impressions on the screw surface.

CLEANING

In most cases, a thorough cleaning of the suspect Ball Screw will resolve “bad screw” issues, including noise

complaints.

1. Manually jog the Nut to one end of the screw.

2. Visually inspect the screw threads. Look for metal flakes, dark or thick lube, or contaminated

coolant: See Visual Inspection - Contamination above.

3. Use alcohol, or other approved cleaning agent s, to wash the screw.

CAUTION! Do not use detergents, degreasers, or solvents to clean Ball Screws

or their components. Do not use water-based cleaners to avoid rust.

4. Jog the Nut to the other end of its travel. If metal flakes are now present on the screw threads, you

may have wear issues.

96-8710 rev G

5. Re-lubricate screw threads before returning the machine to service.

19

Page 21

TROUBLESHOOTING

1.5 TURRET CLAMP / UNLCAMP

Alarm 113 and 1 14

1) Check the tool changer solenoid.

A) Does the solenoid appear to be activating.?

I) If no, check power to the solenoid during a tool change. If there is voltage replace the solenoid.

II) If yes, go on.

B) Are the exhaust mufflers dirty?

I) If yes, remove the muffler and do a tool change. If the alarm goes away then replace the muffler

II) If no, proceed to the next step.

C) Is there water in the airlines?

I) If yes, insure that the air is now dry and replace the solenoid.

II) If no, proceed to the next step.

2) Check air pressure.

A) Is the main regulator set to a minimum 85 psi?

B) Does the air pressure drop more than 10 psi during a tool change?

I) If no, go to the next check.

II) If yes, the lathe has an insufficient volume of air . Must have a supply of 100 psi at 4 sfm at the

regulator. A small diameter air supply hose, hose length, and fitting size may restrict the volume

of air going to the machine.

June 2003

3) Remove the top toolchanger cover. Confirm that the air cylinder is fully clamping (1 14 alarm) or fully

unclamping (1 13 alarm).

A) If yes, go to the next check,.

B) If no, try to push the air cylinder into position.

I) If the air cylinder will not fully clamp or unclamp disconnect the air cylinder from the cam lever

and retry . If the air cylinder still does not fully clamp or unclamp, replace the air cylinder.

II) If the air cylinder fully clamps and unclamps then:

1) Cam balls fell out of time with each other. This would be more common on the original

style cams. This design does not have a cage. Fully clamping the air cylinder by hand

should position the 3 balls correctly.

2) If this problem persists then the cams might be damaged. Replace with part numbers

93-8138 “cam upgrade kit”. This is a cam assembly with the cage. It is compatible with

all lathes.

4) Clamp switch or unclamp switch is failing or is out of adjustment. (Reed style or telemecanique switches).

A) Switch identification and adjustment.

I) Reed style switches- these types of clamp/unclamp switches are mounted on the air cylinder to

detect the clamp and unclamp position of the turret. The air cylinder has a magnetic piston,

which activates the switch when the magnetic piston is under it. This style detects the move ment of the piston, not the turret shaft.

1) Adjust the switch by first confirming that the air cylinder is fully clamped. While observ ing the diagnostic data for the control, slide the switch in one direction until the bit

changes from a “1” to a “0”. Mark the position with a pen then do the same while sliding

the switch in the other direction. Position the switch between the two markings and

tighten the clamp.

20

96-8710 rev G

Page 22

June 2003

TROUBLESHOOTING

2) If the alarm still persists then the switch might be failing. Change the clamp switch with

the unclamp switch at the air cylinder and at the lube panel. If the problem goes away

or changes to an unclamp alarm then replace the switch.

II) T elemecanique clamp/unclamp switches at the rear of the turret shaf t- these

types of switches detect the position of the turret shaft during a tool change,

these switches are installed on the same bracket which supports the turret

home switch, also called the a-axis home switch.

The amount of shaft movement or turret pop out is very important with this style

of switch. The switches are a direct indication of the position of the shaft. If the

turret in/out travel is not adjusted correctly or the switch bracket is holding the

switches too far apart then alarms during a tool change will occur .

96-8710 rev G

21

Page 23

TROUBLESHOOTING

1.6 HYDRAULIC SYSTEM

HYDRAULIC PRESSURE

“Low hydraulic pressure” alarm (143).

• Check for any leaks.

• Check that the oil level is above the black line.

• Check that the oil pressure is within 50-500 psi. If the hydraulic unit needs to be replaced, see “Hydraulic

Unit Removal/Installation” section.

• Check that the temperature is less than 150 degrees. If the hydraulic unit needs to be replaced, see “Hydrau-

lic Unit Removal/Installation” section.

• Phasing changes cause the hydraulic unit to change directions resulting in alarm 134.

• Make sure the filter has been replaced within the last 6 months.

• If pressure drops below 40 PSI during activation of chuck or tailstock, an alarm will occur .

HYDRAULIC CHUCK

June 2003

Chuck won’t clamp/unclamp.

• Check for alarm condition.

• Check display for “Low Hydraulic Pressure” alarm (134).

• Check that the oil pressure gauge is within 50-500 psi.

• Use a voltage meter to check the solenoid circuit breaker . Replace solenoid valve if faulty .

NOISE IN HYDRAULIC P OWER UNIT

Hydraulic power unit noise

NOTE: Noise in hydraulic unit should decrease a few minutes after start up

• Check for leaks in hose.

• Check that the oil level is above the black line.

• Check for loose pieces/hardware.

• Check for debris in motor/cooling fins.

• Remove, clean, and reinstall adjustment valves.

HYDRAULIC TAILSTOCK

Tailstock pulsates as it moves

Check operating pressure (Minimum operating pressure is 120 psi.).

Check for leaks at hydraulic cylinder.

Check for leaks at hose fittings.

22

96-8710 rev G

Page 24

June 2003

TROUBLESHOOTING

1.7 ELECTRICAL TROUBLESHOOTING

CAUTION! Before working on any electrical components, power off the machine

ELECTRICAL ALARMS

and wait approximately 10 minutes. This will allow the highvoltage

power on the brushless amplifiers to be discharged.

Axis Drive Fault Alarm

• Blown amplifier - indicated by a light at bottom of amplifier when power is on. Replace amplifier.

• Amplifier or MOCON is noise sensitive. If this is the case, the alarm can be cleared and the axis

will run normally for a while.

T o check an amplifier , switch the motor leads and control cables between the amplifier and the one

next to it. If the same problem occurs with the other axis, the amplifier must be replaced. If the

problem stays on the same axis, It is either the MOCON or control cable. The problem could also

be the axis motor itself, with leads either shorted to each other or to ground, which is very rare.

• Amplifier faulting out for valid reason, such as overtemp, overvoltage, or +/-12 volt undervoltage

condition. This usually results from running a servo intensive program, or unadjusted 12 volt power

supply. Adjust volt age to correct specifications or replace the power supply .

Overvoltage could occur if regen load is not coming on, but this does not usually happen. The

problem could also be the axis motor itself, with leads either shorted to each other or to ground,

which is very rare.

Axis Overload

• The fuse function built into the MOCON has been overloaded, due to a lot of motor accel/decels, or

hitting a hard stop with the axis. This safety function protects the amplifier and motor , so find the

cause and correct it. If the current program is the cause, change the program. If the axis hits a

hard stop, the travel limits may be set wrong.

Phasing Error

• The MOCON did not receive the proper phasing information from the motors. DO NOT RESET the

machine if this alarm occurs. Power the machine down and back up. If the problem persists, it is

probably a broken wire or faulty MOCON connectors. This problem could also be related to the

Low Volt age Power Supply. Check to see if the L VPS is functioning properly.

Servo Error Too Large

• This alarms occurs when the difference between the commanded axis position and the actual

position becomes larger than the maximum that is set in the parameter .

This condition occurs when the amplifier is blown, is not receiving the commands, or the 320 volt

power source is dead. If the MOCON is not sending the correct commands to the amplifier, it is

probably due to a broken wire, or a PHASING ERROR that was generated.

Axis Z Fault or Z Channel Missing

• During a self-test, the number of encoder counts was found to be incorrect. This is usually caused

by a noisy environment, and not a bad encoder. Check all shields and grounds on the encoder

cables and the motor leads that come into the amplifiers. An alarm for one axis can be caused by

a bad grounding on the motor leads of another axis.

96-8710 rev G

23

Page 25

TROUBLESHOOTING

Axis Cable Fault

• During a self-test, the encoder cable signals were found to be invalid. This alarm is usually caused

by a bad cable, or a bad connection on the motor encoder connectors. Check the cable for any

breaks, and the encoder connectors at the motor controller board. Machine noise can also cause

this alarm, although it is less common.

Alarm 101, "MOCON Comm. Failure"

• During a self-test of communications between the MOCON and main processor, the main

processor does not respond, and is suspected to be dead. This alarm is generated and the servos

are stopped. Check all ribbon cable connections, and all grounding. Machine noise can also

cause this alarm, although it is less common.

Alarm 157, "MOCON Watchdog Fault"

• The self-test of the MOCON has failed. Replace the MOCON.

Alarm 354 - Aux Axis Disconnected

When this alarm is generated, do not press RESET. Turn Setting 7 OFF. Enter DEBUG mode, then view the

Alarms/Messages page. On the Messages page, a code will appear similar to WO1. The list of codes and

their descriptions appears below:

June 2003

WO1 Power was just turned on or failed. Check the ribbon cables from the Aux Axis PCB to the proces-

sor for correct routing. Check for communication problems between the processor and the Aux

Axis PCB.

WO2 Servo following error too large. Check the encoder for contamination or dirt. Check for an intermit-

tent connection at both ends of the motor cable.

WO3 Emergency Stop. The E-STOP button was pressed, or an E-ST OP condition occurred.

WO4 High load. Check for binding in the tool changer gearbox and motor. Rotate the carousel by hand

and feel for any binding. Make sure the tool holders are the correct weight.

WO5 Remote RS-232 commanded off. Check the ribbon cable and the voltage to the Aux Axis PCB.

Check for 1 15V AC (minimum) to the Aux Axis PCB from the main transformer . Check the fuse

holder and the fuse that is protecting this circuit.

WO6 Air or limit switch or motor overheat. Check that the motor is not hot. Check for any binding in the

motor. Check for overweight tooling.

WO7 Z channel fault. Either the encoder or the cable is bad. Change the encoder first, as it is easier to

change than the cable. If the problem persists, change the cable.

WO8 Over-current limit, stalled or PCB fault. Check for binding in the tool changer gearbox. Make sure

the belt is not too tight. Ohm out the motor cable, checking pins G to F (should be open), G to H

(should be open), and F to H (should read between 2.5 and 5 ohms). Check all the connections on

the Aux Axis PCB and motor cable.

WO9 Encode ES. Z channel is missing. Bad encoder or cable. See WO7.

WOA High voltage. Check the incoming voltage to the Aux Axis PCB. Incoming voltage must be 115

VAC. See WO5.

WOB Cable fault. Check the cable from the motor to the Aux Axis PCB. Check for loose connections at

each end.

24

96-8710 rev G

Page 26

June 2003

TROUBLESHOOTING

PROCESSOR STACK DIAGNOSTIC

(DISCONNECT CABLES FROM A NORMAL OPERATING SYSTEM)

Remove low voltage cable from the Video & Keyboard PCB

• Processors LED's are normal.

• Runs fine and the CRT is Normal.

• No keypad beep.

Remove the Data & or Address buss from the Video & Keyboard PCB

• Processors LED's Normal - then Run goes out.

Remove the Data & or Address buss from the Micro Processor PCB

• Processors LED's - CRT and Run are out.

96-8710 rev G

25

Page 27

TROUBLESHOOTING

KEYBOARD DIAGNOSTIC

June 2003

NOTE: Refer to the "Cable Locations" section of this manual for a drawing of the

Keyboard Interface PCB.

NOTE: This Keyboard Grid is for machines with a Keyboard Interface only. This

Keyboard Grid is not for machines with a Serial Keyboard Interface.

The following is an example of how to troubleshoot the keypad:

NOTE: Keypad Diodes 1-24 correspond to chart numbers 1-24.

Example

1. Pressing the RESET button will cause diodes 1 and 17 to conduct.

• With the POWER OFF read across diode 1.

• A typical reading is between .400-.700 ohms, note your reading.

26

96-8710 rev G

Page 28

June 2003

TROUBLESHOOTING

2. Press and hold the RESET button. If the diode is conducting, the reading should drop about .03 ohms.

• (If your reading was .486 and it dropped to .460, for a difference of .026; the diode is

good).

• The same will hold true for diode 17 in this example. If the reading stays the same or there

is no change, the diode is not conducting. Pull P2 and read between pins 1 and 17.

• Press and hold <RESET>. The meter should read a short (0 ohms) if not the keypad is

bad.

ETHERNET

Error 53 The computer name specified in the network path cannot be located

This error usually happens when NET USE C: \\SERVER\HAAS/PERSISTENT: NO /YES is entered during the

setup phase.

T o fix this error first verify the following:

1. A 10 Base-T network is present.

2. The network cable is coming from a hub (not the server).

3. The server name that you specified in yo

2. u NET USE command is correct.

4. Y our network is running IPX/SPX protocol.

If all of the above is correct and communications between the Haas CNC and the network are not established,

there may be compatibility issues between an older Novell network and an NT 4.0 server . If the NWLink IPX/

SPX Compatible Transport on the NT server is set to auto detect the protocol’s frame, the NT server may be

detecting the Novell server first and setting the NWLink IPX/SPX Compatible Transport frame protocol to 802.3

The NWLink IPX/SPX Compatible Transport required for the lathes to connect to an NT server is 802.2. Since

these two frame protocols are different the lathe would never connect to the desired NT server . To remedy this

check the following:

1. On the Ethernet boot disk, edit the protocol.ini file in the NETI directory.

2. Find the line FRAME=ETHERNET_802.2 and change it to FRAME=ETHERNET_802.3

3. Save the file

4. Insert the boot disk back into the CNC and cycle the power.

If an Error 53 is still present, restore the protocol.ini file to its previous state and do the following to the NT

server:

1. Open the control panel

2. Double click on the Network icon

3. Select the Protocols tab.

4. Highlight NWLINK IPX/SPX Compatible Transport.

5. Select properties.

6. Select Manual Frame T ype Detection.

7. Click on Add.

8. Select Ethernet 802.2

9. Click on Add.

10. Click OK.

1 1. Close all windows and reboot the NT server .

96-8710 rev G

Once the NT server is rebooted the NWLINK IPX/SPX Compatible Transport Frames is set to 802.2 and the

lathe will be able to see the desired server.

27

Page 29

TROUBLESHOOTING

Lathe code will not work

Make sure the command in the server routes back to the machine.

CRT TEST PATTERN

This is current commands page displays a grid of 6 x 9 blocks which allows technicians to align the display on

the CRT and make sure the display is centered and ‘square’. The page is accessed by entering DEBUG mode

from the alarms screen, pressing CURNT COMDS, and then pressing P AGE UP.

1.8 BARFEEDER TROUBLESHOOTING

Push finger works but the pushrod will not load (during initial installation), ensure there are relays installed in

the top two tool changer locations on the IOPCB. (K9 and K10). This can occur when installing a barfeeder on

an older machine.

Problem with accuracy or incorrect pushes: Try doing a new set up as G105 Q2, Q4 or Q5 may have inadvertently been changed. Once the barfeeder is installed and running the set up procedures should not have to be

repeated unless the bar feeder is moved or the the collet or chuck is is changed.

The End of Bar switch at the right of the transfer tray has a switch paddle that can stick in the down position.

This will cause erroneous bar lengths and other problems. The switch paddle can be formed slightly to assure

clearance in the opening in the transfer tray.

June 2003

There is a small ampount of play in between the ball screw and the ball nut. This can set up a small amount of

vibration when very fast spindle speeds are used. This is normal operation and will not affect finished part.

Any time the transport assembly on the bar feeder is disassembled or changed, parameters 240, 1st Aux Max

Travel, and 244, 1st Aux Min T ravel, may be affected. If these parameters are not correctly set, malfunctioning

of the pushrod can occur and in some instances the barfeeder can crash. These parameters can be checked

by the following procedure:

1. Zero the bar feeder .

2. In handle jog mode, jog in the minus direction, until the V position on the screen

matches parameter 244.

3. Push down on the control arm positioner on the right side of the pushrod to ensure the rotation

control arm moves smoothly in and out of the notch on the left end. Loosen the two screws on the

fork activator and adjust if necessary.

4. On the left end of the pushrod control arm is a pin that drops onto a notch when the pushrod is

loaded. This pin shopuld be just far enough to the left to clear the lobe in the notch. If this pin is

not in the correct position, use the jog handle to adjust it and enter the new number from the

screen into parameter 244.

5. To adjust p arameter 240 ensure the pushrod is unloaded and jog the push finger all the way to the

right. Paramter 240 should be set such that the carriage comes within about 3/8” of the ball screw

support end without hitting it. If not, adjust it using the jog handle and enter the V position from the

CRT into parameter 240.

28

96-8710 rev G

Page 30

June 2003

ALARMS

2. ALARMS

Any time an alarm is present, the lower right hand corner of the screen will have a blinking "ALARM". Push the

ALARM display key to view the current alarm. All alarms are displayed with a reference number and a complete description. If the RESET key is pressed, one alarm will be removed from the list of alarms. If there are

more than 18 alarms, only the last 18 are displayed and the RESET must be used to see the rest. The presence of any alarm will prevent the operator from starting a program.

The ALARMS DISPLAY can be selected at any time by pressing the ALARM MESGS button. When there are

no alarms, the display will show NO ALARM. If there are any alarms, they will be listed with the most recent

alarm at the bottom of the list. The CURSOR and P AGE UP and P AGE DOWN buttons can be used to move

through a large number of alarms. The CURSOR right and left buttons can be used to turn on and off the

ALARM history display .

Note that tool changer alarms can be easily corrected by first correcting any mechanical problem, pressing

RESET until the alarms are clear , selecting ZERO RET mode, and selecting AUTO ALL AXES. Some messages are displayed while editing to tell the operator what is wrong but these are not alarms. See the editing

topic for those errors.

The following alarm list shows the alarm numbers, the text displayed along with the alarm, and a detailed

description of the alarm, what can cause it, when it can happen, and how to correct it.

Alarm number and text: Possible causes:

101 MOCON Comm. Failure During a self-test of communications between the MOCON and main

processor the main processor does not respond, and one of them is

possibly bad. Check cable connections and boards. This alarm

could also be caused by a memory fault, which was detected on the

MOCON.

102 Servos Off Indicates that the servo motors are off, the tool changer is disabled,

the coolant pump is off, and the spindle motor is stopped. Caused by

EMERGENCY STOP, motor faults, tool changer problems, or power

fail.

103 X Servo Error Too Large Too much load or speed on X-axis motor. The difference between the

motor position and the commanded position has exceeded a

parameter. The servos will be turned off and a RESET must be done

to restart. This alarm can be caused by problems with the driver,

motor, or the slide being run into the mechanical stops. The motor

may also be stalled, disconnected, or the driver failed.

104 Y Servo Error Too Large Same as alarm 103.

105 Z Servo Error Too Large Same as alarm 103.

106 A Servo Error Too Large Same as alarm 103.

107 Emergency Off EMERGENCY STOP button was pressed. Servos are also turned

off. After the E-STOP is released, the RESET button must be

pressed at least twice to correct this; once to clear the E-STOP

alarm and once to clear the Servos Off alarm.

96-8710 rev G

108 X Servo Overload Excessive load on X-axis motor. This can occur if the load on the

motor is large enough to exceed the continuous rating of the motor

over a period of several seconds or even minutes. The servos will be

turned off when this occurs. This can be caused by running into the

mechanical stops but not much past them. It can also be caused by

anything that causes a very high load on the motors.

29

Page 31

ALARMS

June 2003

109 Y Servo Overload Same as alarm 108.

110 Z Servo Overload Same as alarm 108.

11 1 A Servo Overload Same as alarm 108.

112 No Interrupt Electronics fault. Call your dealer.

113 Turret Unlock Fault The turret took longer to unlock and come to rotation position than

allowed for in Parameter 62. The value in Parameter 62 is in millisec-

onds. This may occur if the air pressure is too low, the tool turret

clamp switch is faulty or needs adjustment, or there is a mechanical

problem.

114 Turret Lock Fault The turret took longer to lock and seat than allowed for in Parameter

63. The value in Parameter 63 is in milliseconds. This may occur if

the air pressure is too low, the tool turret clamp switch is faulty or

needs adjustment, or there is a mechanical problem.

115 Turret Rotate Fault During a tool changer operation the tool turret failed to start moving or

failed to stop at the right position. Parameters 62 and 63 can adjust

the time-out times. This alarm can be caused by anything that jams

the rotation of the turret. A loss of power to the tool changer can also

cause this, so check CB5 and relays 1-8, 2-3, and 2-4.

116 Spindle Orientation Fault Spindle did not orient correctly. During a spindle orientation function,

the spindle is rotated until the lock pin drops in; but the lock pin never

dropped. Parameters 66, 70, 73, and 74 can adjust the delays and

orient spindle speed. This can be caused by a trip of circuit breaker

CB4, a lack of air pressure, or too much friction with the orientation

pin.

117 Spindle High Gear Fault Gearbox did not shift into high gear. During a change to high gear, the

high gear sensor was not detected in time. Parameters 67, 70 and

75 can adjust the delays. Check circuit breaker CB4, the circuit

breaker for the air pressure solenoids and the spindle drive.

118 Spindle Low Gear Fault Gearbox did not shift into low gear. During a change to low gear, the

low gear sensor was not detected in time. Parameters 67, 70 and 75

can adjust the delays. Check the solenoid’s circuit breaker CB4, and

the spindle drive.

119 Over Voltage Incoming line voltage is above maximum. The tool changer, and

coolant pump will stop. If this condition persists, an automatic

shutdown will begin after the time specified by parameter 296.

120 Low Air Pressure Air pressure dropped below 80 PSI for a period of time defined by

Parameter 76. Check your incoming air pressure for at least 100 PSI

and ensure that the regulator is set at 85 PSI.

121 Low Lub or Low Pressure Way lube is low or empty or there is no lube pressure or too high a

pressure. Check tank at rear of machine and below control cabinet.

Also check connector on the side of the control cabinet. Check that

the lube lines are not blocked.

122 Regen Overheat The control is overheating. This alarm will turn off the spindle drive,

coolant pump, and tool changer. One common cause of this overheat

condition is an input line voltage too high. If this condition persists,

an automatic shutdown will begin after the interval specified by

parameter 297. It can also be caused by a high start/stop duty cycle

of the spindle.

30

96-8710 rev G

Page 32

June 2003

ALARMS

123 Spindle Drive Fault Overheat or failure of spindle drive or motor. The exact cause is

indicated in the LED window of the spindle drive inside the control

cabinet. This can be caused by a stalled motor, shorted motor,

overvoltage, undervoltage, overcurrent, overheat of motor, or drive

failure.

124 Low Battery Memory batteries need replacing within 30 days. This alarm is only

generated at power on and indicates that the 3.3 volt Lithium battery

is below 2.5 volts. If this is not corrected within 30 days, you may lose

your stored programs, parameters, offsets, and settings.

125 Tool Turret Fault Turret has not seated itself properly. There may be something

obstructing the turret between the housing and the turret itself.

126 Gear Fault Transmission is out of position when a command is given to start a

program or rotate the spindle. This means that the two speed

transmission is not in either high or low gear but is somewhere in

between. Check the air pressure, the solenoid’s circuit breaker CB4,

and the spindle drive. Use the POWER UP/RESTART button to

correct the problem.

127 Door Fault The control failed to detect a low signal at the Door Switch input after

the door was commanded and the Door Switch input was not

received after the door was commanded to close and the time set in

parameter #251 has elapsed.

129 M Fin Fault M-code relays were active at power on. Check the wiring to your M

code interfaces. This test is only performed at power-on.

130 Chuck Unclamped The control detected that the chuck is unclamped. This is a possible

fault in the air solenoids, relays on the I/O Assembly, or wiring.

131 Tool Not Clamped When clamping or powering up the machine, the Tool Release

Piston is not Home. This is a possible fault in the air solenoids,

relays on the I/O Assembly, the drawbar assembly, or wiring.

132 Power Down Failure Machine did not turn off when an automatic power-down was com-

manded. Check wiring to the Power Interface card on power supply

assembly, relays on the IO assembly, and the main contactor K1.

133 Spindle Brake Engaged The brake is engaged. It must be released before the spindle can

turn.

134 Low Hydraulic Hydraulic pressure is sensed to be low. Check pump pressure

and Pressure hydraulic tank oil level. Verify proper pump and ma-

chine phasing.

135 X Motor Over Heat Servo motor overheat. The temperature sensor in the motor indicates

over 150 degrees F. This can be caused by an extended overload of

the motor such as leaving the axes at the stops for several minutes.

136 Y Motor Over Heat Same as alarm 135.

137 Z Motor Over Heat Same as alarm 135.

96-8710 rev G

138 A Motor Over Heat Same as alarm 135.

139 X Motor Z Fault Encoder pulse count failure. This alarm usually indicates that the

encoder has been damaged and encoder position data is unreliable.

This can also be caused by loose connectors at P1-P4.

31

Page 33

ALARMS

June 2003

140 Y Motor Z Fault Same as alarm 139.

141 Z Motor Z Fault Same as alarm 139.

142 A Motor Z Fault Same as alarm 139.

143 Spindle Not Locked Shot pin not fully engaged when a tool change operation is being per

formed. Check air pressure and solenoid circuit breaker CB4. This

can also be caused by a fault in the sense switch that detects the

position of the lock pin.

144 Time-out-Call Your Dealer Time allocated for use prior to payment exceeded. Call your dealer.

145 X Limit Switch Axis hit limit switch or switch disconnected. The stored stroke limits

should stop the slides before they hit the limit switches. Verify the

value of parameter Grid Offset and check the wiring to the limit switch

and connector P5 at the side of the main cabinet. Can also be

caused by a loose encoder shaft at the back of the motor or coupling

of motor to the screw.

146 Y Limit Switch Same as alarm 145.

147 Z Limit Switch Same as alarm 145.

148 A Limit Switch Normally disabled for rotary axis.

149 Spindle Turning Spindle not at zero speed for tool change. A signal from the spindle

drive indicating that the spindle drive is stopped is not present while

a tool change operation is going on.

150 I Mode Out Of Range Cycle power on the machine. If the alarm reoccurs, call your dealer

and report the sequence of events that lead to the alarm.

151 HPC LOW PRESSURE A low coolant pressure condition has been detected. To disable this

alarm, set parameter 209 Common Switch 2 DSBL CLNT IN to 1.

152 Self Test Fail Control has detected an electronics fault. All motors and solenoids

are shutdown. This is most likely caused by a fault of the proces-

sors. Call your dealer.

153 X-axis Z Ch Missing Broken wires or encoder contamination. All servos are turned off.

This can also be caused by loose connectors at P1-P4.

154 Y-axis Z Ch Missing Same as alarm 153.

155 Z-axis Z Ch Missing Same as alarm 153.

156 A-axis Z Ch Missing Same as alarm 153.

157 MOCON Watchdog Fault The self-test of the MOCON has failed. Call your dealer.

158 Video/Keyboard PCB Failure Internal circuit board problem. This could also be caused by a short

in the front panel membrane keypad. Call your dealer.

159 Keyboard Failure Keyboard shorted or button pressed at power on. A power-on test of

the membrane keypad has found a shorted button. It can also be

caused by a short in the cable from the main cabinet or by holding a

button down during power-on.

160 Low Voltage The line voltage to control is too low. This alarm occurs when the AC

line voltage drops below 190 when wired for 230 volts or drops below

165 when wired for 208 volts.

32

96-8710 rev G

Page 34

June 2003

ALARMS

161 X-Axis Drive Fault Current in X servo motor beyond limit. Possibly caused by a stalled

or overloaded motor. The servos are turned off. This can be caused

by running into a mechanical stop. It can also be caused by a short in

the motor or a short of one motor leads to ground.

162 Y-Axis Drive Fault Same as alarm 161.

163 Z-Axis Drive Fault Same as alarm 161.

164 A-Axis Drive Fault Same as alarm 161.

165 X Zero Ret Margin Too Small This alarm indicates that the zero return position may not be consis-

tent from one zero return to the next. The encoder Z channel signal

must occur between 1/8 and 7/8 revolution of where the home switch

releases. This will not turn the servos off but will stop the zero return

operation. This alarm can occur if the home/limit switches are moved

or misadjusted.

166 Y Zero Ret Margin Too Small Same as alarm 165.

167 Z Zero Ret Margin Too Small Same as alarm 165.

168 A Zero Ret Margin Too Small Same as alarm 165.

169 Spindle Direction Fault Problem with rigid tapping hardware. The spindle started turning in

the wrong direction.

170 Phase Loss Problem with incoming line voltage between legs L1 and L2. This

usually indicates that there was a transient loss of input power to the

machine.

171 Rpm Too High To Unclamp The spindle speed exceeded the max speed allowed in parameter

248 to unclamp.

173 Spindle Ref Signal Missing The Z channel pulse from the spindle encoder is missing for hard

tapping synchronization.

174 Tool Load Exceeded The tool load monitor option is selected and the maximum load for a

tool was exceeded in a feed. This alarm can only occur if the tool

load monitor function is installed in your machine.

175 Ground Fault Detected A ground fault condition was detected in the 115V AC supply. This can

be caused by a short to ground in any of the servo motors, the tool

change motors, the fans, or the oil pump.

176 Overheat Shutdown An overheat condition persisted longer than the interval specified by

parameter 297 and caused an automatic shutdown.

177 Over Voltage Shutdown An overvoltage condition persisted longer than the interval specified

by parameter 296 and caused an automatic shutdown.

178 Divide by Zero! There are some parameters that are used as a divisor and therefore

must never be set to zero. If the problem cannot be corrected by

parameters, cycle power on the machine. If the alarm reoccurs, call

your dealer and report the sequence of events that lead to the alarm.

96-8710 rev G

181 Macro not completed-spindle disabled Macro code operating Haas optional equipment (bar feeder, etc.) was

not completed for some reason (ESTOP, RESET, Power Down, etc.).

Check optional equipment and run recovery procedure.

182 X Cable Fault Cable from X-axis encoder does not have valid differential signals.

33

Page 35

ALARMS

183 Y Cable Fault Same as alarm 182.

184 Z Cable Fault Same as alarm 82.

185 A Cable Fault Same as alarm 182.

186 Spindle Not Turning Trying to feed while spindle is in the stopped position.

187 B Servo Error Too Large Same as alarm 103.

188 B Servo Overload Same as alarm 108.

189 B Motor Overheat Same as alarm 135.

190 B Motor Z Fault Same as alarm 139.

191 B Limit Switch Same as alarm 145.

192 B Axis Z Ch Missing Same as alarm 153.

193 B Axis Drive Fault Same as alarm 161.

194 B Zero Ret Margin Too Small Same as alarm 165.

195 B Cable Fault Same as 182.

June 2003

197 100 Hours Unpaid Bill Call your dealer.

198 Spindle Stalled Control senses that no spindle fault has occurred, the spindle is at

speed, yet the spindle is not turning. Possibly the belt between the

spindle drive motor and spindle has slipped or is broken.

199 Negative RPM Cycle power on the machine. If the alarm reoccurs, call your dealer

and report the sequence of events that lead to the alarm.

201 Parameter CRC Error Parameters lost maybe by low battery. Check for a low battery and

low battery alarm.

202 Setting CRC Error Settings lost maybe by low battery. Check for a low battery and low

battery alarm.

203 Ball Screw CRC Error Ball screw compensation tables lost maybe by low battery. Check for

Cyclic Redundancy Check error, low battery, and low battery alarm.

204 Offset CRC Error Offsets lost maybe by low battery. Check for a low battery and low

battery alarm.

205 Programs CRC Error Users program lost maybe by low battery. Check for a low battery and