Page 1

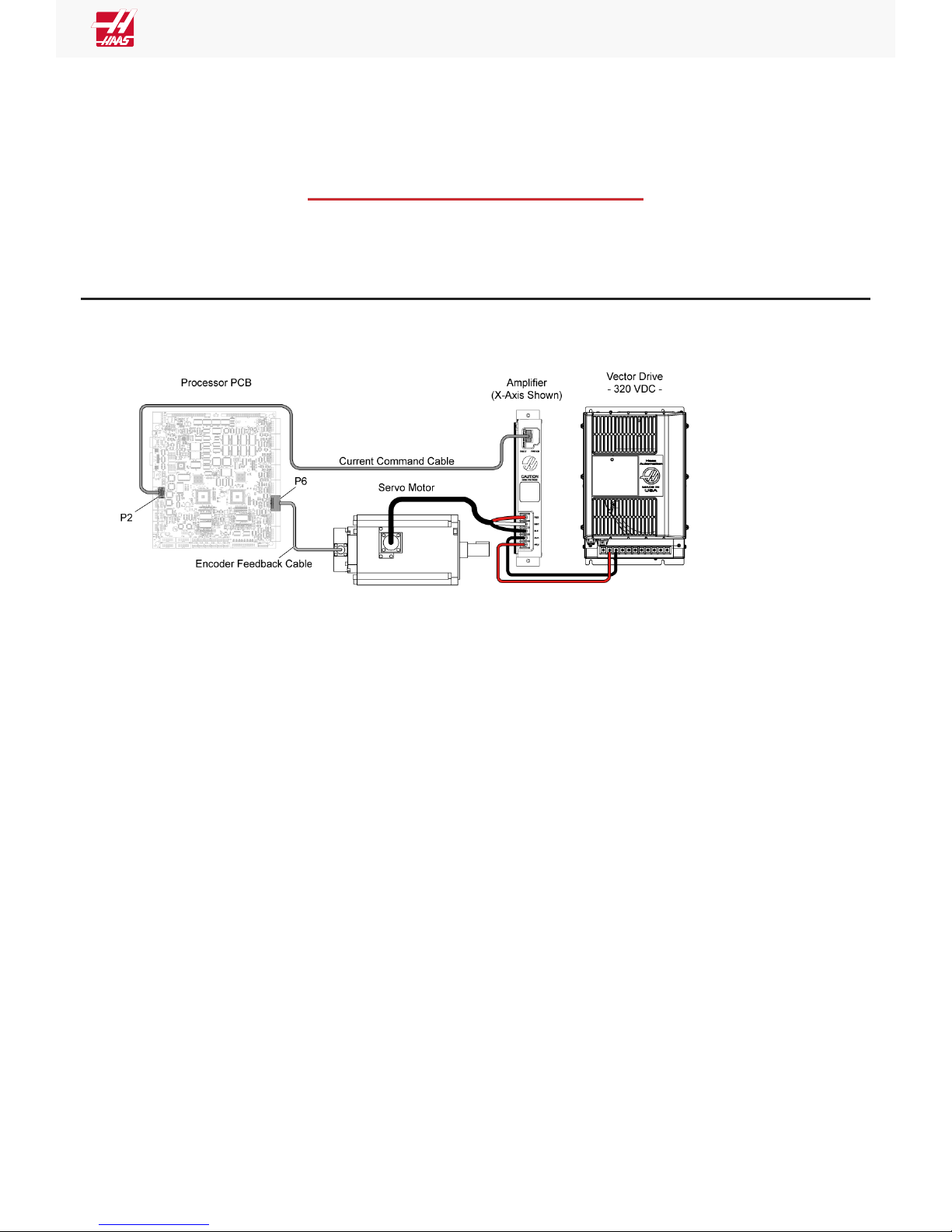

Sigma 1 - Axis Servo Motor and Cables - Troubleshooting Guide

LAST UPDATED: 12/21/2018

Sigma 1 - Axis Servo Motor and Cables - Troubleshooting Guide

Introduction

Press [POWER OFF]. Set the main circuit breaker to the OFF position. Wait until the high voltage LED on the vector drive

is completely off before disconnecting any cables.

Page 1 of 7 pages

Page 2

Sigma 1 - Axis Servo Motor and Cables - Troubleshooting Guide

Symptom Table

Page 2 of 7 pages

Page 3

Sigma 1 - Axis Servo Motor and Cables - Troubleshooting Guide

SYMPTOM PROBABLE CAUSE CORRECTIVE ACTION

Check the corresponding amplifier assembly.

Refer to Servo Amplifier - Troubleshooting Guide to

troubleshoot the amplifier.

Inspect the cables and connectors. Refer to the Power

Cable section below.

Alarm 161 - 164 AXIS DRIVE

FAULT.

Alarm 993 AMPLIFIER SHORT

CIRCUIT

Faulty servo amplifier.

Faulty power cable.

Alarm 103 - 105, 270,

709 AXIS SERVO ERROR TOO

LARGE.

Faulty servo motor.

Faulty encoder cable/

connection or faulty

encoder.

The axis motor brake, is not

disengaging when servos

are enabled.

The axis ballscrew is

damaged.

Classic Haas Control Only The machine parameters are

not correct.

Check the corresponding servo motor. Refer to Servo

Motor section below.

Inspect the cables and connectors. Refer to the Main

Processor/Encoder Cable section below. Check the

encoder steps/revolution versus and ball screw pitch

and verify the encoder counts are accurate per each

rotation.

See the Motor Brake section below:

Check the corresponding axis ballscrew.

Refer to Ballscrew - Troubleshooting Guide to

troubleshoot the ballscrew.

Make sure you have the correct parameters for the type

of axis motor.

1. Determine if machine has Sigma-1 or

Sigma-5 motors.

Note: The Sigma-5 axis motor have a

push-lock connector for the encoder

plug.

Alarm 103 - 105 AXIS SERVO

ERROR TOO LARGE, during

the zero return process. The

axis zero returns in the wrong

direction.

Alarm 135 - 137 AXIS MOTOR

OVERHEAT.

The home sensor is being

made during the zero return

process causing the axis to

zero return in the opposite

direction.

Faulty encoder cable/

connection or faulty

encoder.

The Mocon/Maincon PCB

axis channel is defective.

2. Run parameter checker and select either

Sigma-1 or Sigma-5 option.

Check the axis home switch to make sure there are no

metal chips on top of the sensor.

Inspect the cables and connectors. Refer to the Main

Processor/Encoder Cable section below. Check the

encoder steps/revolution versus and ball screw pitch

and verify the encoder counts are accurate per each

rotation..

Swap the Encoder/Drive channels with another axis, if

the alarm stays with the encoder/drive channel then the

Mocon/Maincon PCB is defective.

Page 3 of 7 pages

Page 4

Sigma 1 - Axis Servo Motor and Cables - Troubleshooting Guide

Alarm 139 - 142 190,

273 MOTOR Z FAULT.

Alarm 153 - 156 Z CHANNEL

MISSING

Alarm 182 - 185, 194,

278 AXIS ENCODER CABLE

FAULT.

Alarm 217, 218, 219 AXIS

PHASE ERROR

Alarm 224 - 228 AXIS

TRANSITION FAULT

The low-volt-power-supply

is defective.

The parameter OVER TEMP

NC bit 14 for the axis is

incorrect.

Faulty encoder cable or

connection.

Faulty encoder on servo

motor.

Check the +5V / +12V / -12V DC voltages going to the

Mocon/ Maincon PCB.

Make sure this parameter bit is set correctly. This is

normally a 1.

Inspect the cables and connectors. Refer to the Main

Processor/Encoder Cable section below.

Check the motor for coolant contamination. Check the

encoder steps/revolution versus and ball screw pitch

and verify the encoder counts are accurate per each

rotation.

Power Cable

Corrective Action:

Make sure the cables are connected correctly to the corresponding amplifier. Inspect the connector at the motor. Look for

loose connections or contamination.

Look for signs of damage or stiffness on the cable. Disconnect the power cable from the amplifier and motor. Measure the

resistance from leg to leg, and from leg to ground. Make sure the measurements result in an open connection. Check

each leg from one end of the cable to the corresponding leg on the other end of the cable for continuity. If there is an open

connection, there is a problem with the cable.

Page 4 of 7 pages

Page 5

Sigma 1 - Axis Servo Motor and Cables - Troubleshooting Guide

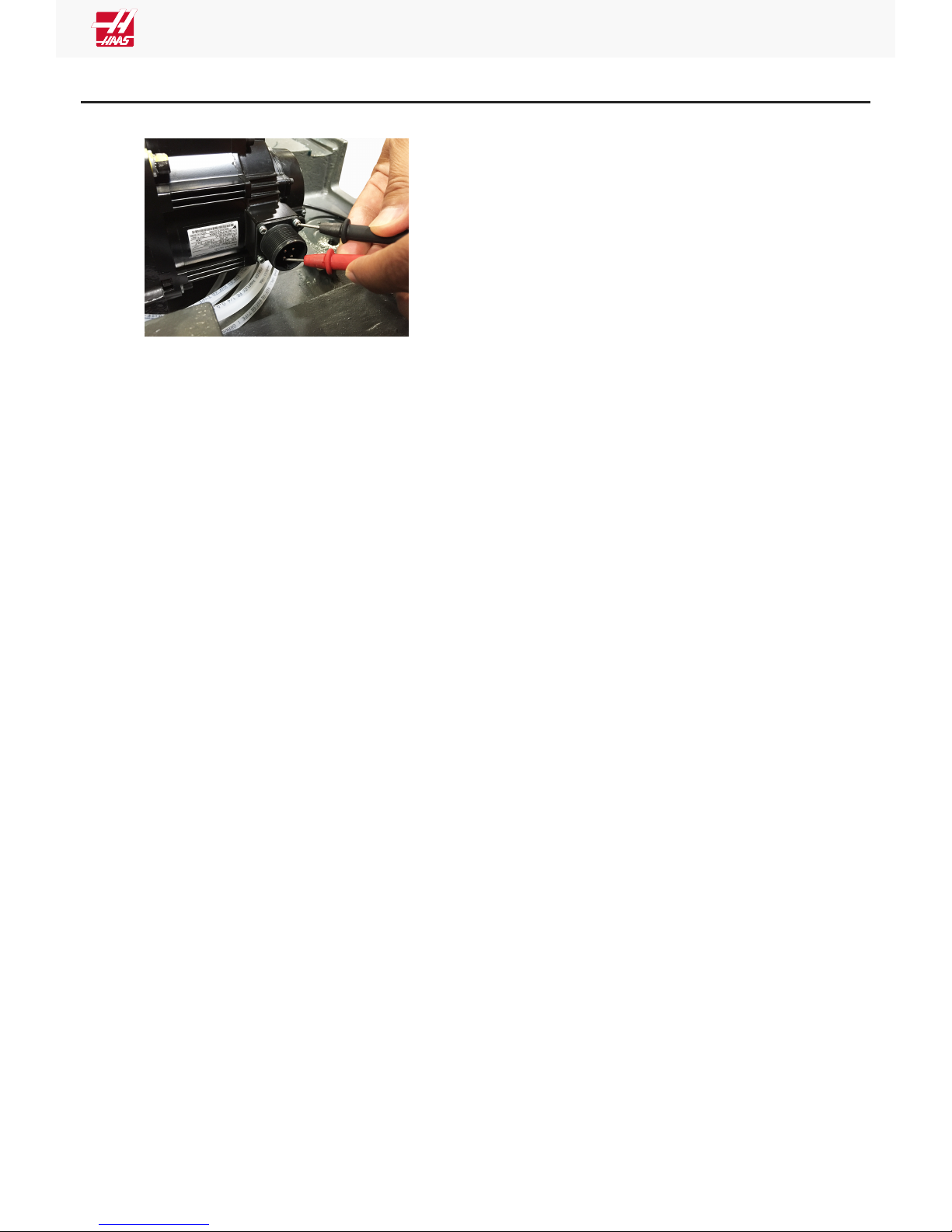

Servo Motor

Corrective Action:

Make sure the motor's connectors are not

contaminated. Disconnect and inspect the power

cable connector at the motor. Make sure that there

is no coolant contamination. Coolant contamination

can generate drive fault alarms and damage the

amplifier. Measure the resistance from the pins

labeled A, B and C at the motor connector to

chassis ground.

• The reading must show an open circuit.

• If the reading does not show an open

circuit, the servo motor is at fault.

Page 5 of 7 pages

Page 6

Sigma 1 - Axis Servo Motor and Cables - Troubleshooting Guide

Main Processor/Encoder Cable/Encoder

Corrective Action - Main Processor/Cable:

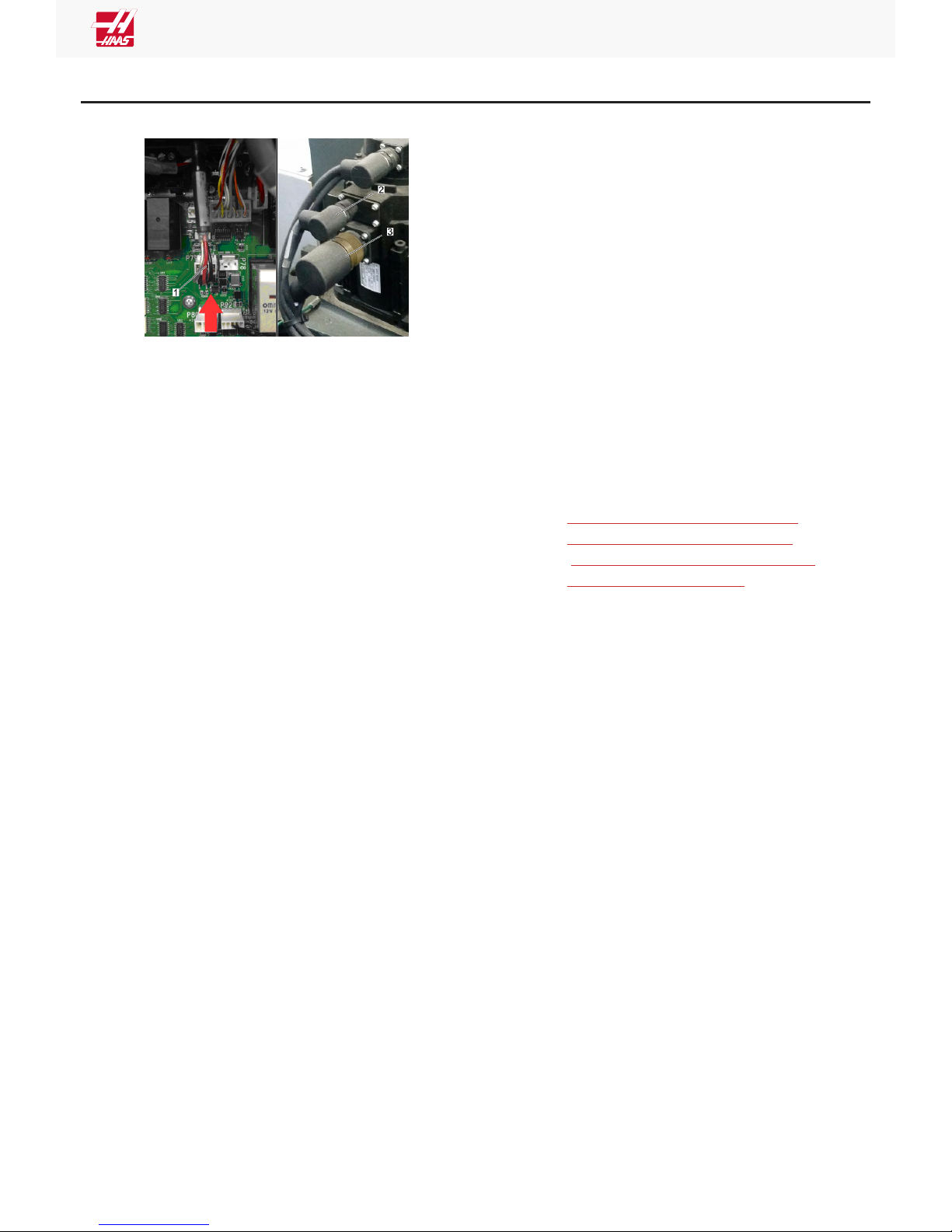

Examine the connector [1] on the Maincon or

MOCON PCB. Make sure it is not damaged.

Examine the cable. Look for signs of damage or

stiffness. The connector [4] has two housings [2,3]

for the cable pins.

Measure the resistance on the encoder cable from

leg to leg, and from leg to ground. Make sure each

measurement results in an open connection.

Make sure the cable is firmly connected at both

ends. Reseat both connections. Make sure the

cable is installed in the correct connector at the

Maincon or MOCON PCB.

Corrective Action - Servo Motor Encoder:

Check the encoder steps/revolution in the

configuration file. Jog the axis and based on the

distance the ball screw travels per revolution (ball

screw pitch), verify the encoder counts are accurate

per each rotation. View the diagnostic>axis page as

you jog the axis. The raw encoder count will show

you how many encoder steps have been counted.

The z axis channel will also show how many steps

have been counted, but will reset each time the zpulse is passed. The z-pulse is the encoder zero

point, so it will reset every time the encoder does

one revolution. Based on this information, you will

know if the encoder works if the correct amount of

steps per revolution are counted each time you jog

the axis the distance of the ball screw pitch length.

If the numbers do not match up, you have a

problem.

Page 6 of 7 pages

Page 7

Sigma 1 - Axis Servo Motor and Cables - Troubleshooting Guide

Motor Brake

Corrective Action:

Reseat the the connection for connectors P79 or

P78 [1] on the I/O PCB.

Measure the voltage across the red and black

cables.

Press [EMERGENCY STOP]. There should be no

voltage.

Press [RESET] to clear the alarms. The voltage

should be between 20-30 VDC.

Examine the connection at the motor's brake [2]

and power connectors [3] for contamination. Reseat

the connections.

If no voltage is present, refer to:

• NEXT GENERATION CONTROL - I/O

PCB - TROUBLESHOOTING GUIDE

• I/O PCB -TROUBLESHOOTING GUIDE

(CLASSIC HAAS CONTROL)

Page 7 of 7 pages

Loading...

Loading...