Page 1

Mill Operator’s Manual

HAAS AUTOMATION INC. • 2800 STURGIS ROAD • OXNARD, CA 93030

TEL. 888-817-4227 FAX. 805-278-8561

96-8000 revR

JUNE 2007

www.HaasCNC.com

Page 2

Warranty Certificate

Covering Haas Automation, Inc., CNC Equipment

Effective January 1, 2003

LIMITED WARRANTY COVERAGE

All new Haas mills are warranted exclusively by the Haas Automation’s ("Manufacturer") limited warranty as follows:

Each Haas CNC machine ("Machine") and its components ("Components") (except those listed below under limits and

exclusions) is warranted against defects in material and workmanship for a period of one (1) year

and Mini-Mills, which are six (6) months) from the date of purchase, which is the date that a machine is installed at the

end user. The foregoing is a limited warranty and it is the only warranty by manufacturer. Manufacturer disclaims all other

warranties, express or implied, including but not limited to all warranties of merchantability and fitness for a particular

purpose.

REPAIR OR REPLACEMENT ONLY: MANUF ACTURER'S LIABILITY UNDER THIS AGREEMENT SHALL BE LIMITED T O

REP AIRING OR REPLACING , A T THE DISCRETION OF MANUF ACTURER, P ARTS, OR COMPONENTS.

An additional warranty extension may be purchased from your authorized Haas distributor.

LIMITS and EXCLUSIONS of WARRANTY

Except as provided above, buyer agrees that all warranties express or implied, as to any matter whatsoever, including but

not limited to warranties of merchantability and fitness for a particular purpose are excluded.

Components subject to wear during normal use and over time such as paint, window finish and condition, light bulbs,

seals, chip removal system, etc., are excluded from this warranty.

Factory-specified maintenance procedures must be adhered to and recorded in order to maintain this warranty.

This warranty is void if the machine is subjected to mishandling, misuse, neglect, accident, improper installation, improper

maintenance, or improper operation or application, or if the machine was improperly repaired or serviced by the customer

or by an unauthorized service technician. Warranty service or repair service is available from the authorized Haas distributor.

Without limiting the generality of any of the exclusions or limitations described in other paragraphs, manufacturer's warranty does not include any warranty that the machine or components will meet buyer's

production specifications or other requirements or that operation of the machine and components will be uninterrupted or error-free. Manufacturer assumes no responsibility with respect to the use of the

Machine and Components by Buyer, and manufacturer shall not incur any liability or Seller to Buyer for any failure in design, production, operation, performance or otherwise of the Machine or

Components other than repair or replacement of same as set forth in the Limited Warranty above. Manufacturer is not responsible for any damage to parts, machines, business premises or other property

of Buyer,or for any other incidental or consequential damages that may be caused by a malfunction of the Machine or Components.

(except Tooroom Mills

LIMIT ATION OF LIABILITY AND DAMAGES: MANUF ACTURER IS NOT LIABLE TO BUYER, SELLER OR ANY CUSTOMER OF

BUYER FOR LOSS OF PROFITS, LOST DA T A, LOST PRODUCTS, LOSS OF REVENUE, LOSS OF USE, COST OF DOWN

TIME, BUSINESS GOOD WILL, OR ANY OTHER INCIDENT AL OR CONSEQUENTIAL DAMAGE, WHETHER IN AN ACTION IN

CONTRACT OR TORT, ARISING OUT OF OR RELA TED T O THE MACHINE OR COMPONENTS, OTHER PRODUCTS OR

SERVICES PROVIDED BY MANUF ACTURER OR SELLER, OR THE F AILURE OF PAR TS OR PRODUCTS MADE BY USING

THE MACHINE OR COMPONENTS, EVEN IF MANUFACTURER OR SELLER HAS BEEN ADVISED OF THE POSSIBILITY OF

SUCH DAMAGES. MANUFACTURER'S LIABILITY FOR DAMAGES FOR ANY CAUSE WHA TSOEVER SHALL BE LIMITED TO

REP AIR OR REPLACEMENT , A T THE DISCRETION OF MANUF ACTURER, OF THE DEFECTIVE P AR TS, COMPONENTS OR

MACHINE.

Buyer has accepted this restriction on its right to recover incidental or consequential damages as part of its bargain with

Seller. Buyer realizes and acknowledges that the price of the equipment would be higher if Seller or Manufacturer were

required to be responsible for incidental or consequential damages, or punitive damages.

This Warranty Certificate supersedes any and all other agreements, either oral or in this writing, between the parties hereto with respect to the warranties, limitations of liability and/or damages regarding

the Machine or Components, and contains all of the covenants and agreements between the parties with respect to such warranties, liability limitations and/or damages. Each party to this Warranty

Certificate acknowledges that no representations, inducements, promises, or agreements, orally or otherwise, have been made by any party , or anyone acting on behalf of any party, which are not embodied

herein regarding such warranties, liability limitations and/or damages, and that no other agreement, statement, or promise not contained in this Warranty Certificate shall be valid or binding regarding

such warranties, liability limitations and damages.

TRANSFERABILITY

This warranty is transferrable from the original end-user to another party if the machine is sold via private sale before the

end of the warranty period.

Haas Automation, Inc. 2800 S turgis Road, Oxnard, CA 93030-8933 Phone: (805) 278-1800 F AX: (805) 278-8561

96-8000 rev R June 2007

T able Of Contents

I

Page 3

Warranty Registration

Certificate

LIMITED WARRANTY COVERAGE

All new Haas mills are warranted exclusively by the Haas Automation’ s ("Manufacturer") limited warranty as follows:

Each Haas CNC machine ("Machine") and its components ("Components") (except those listed below under limits

and exclusions) is warranted against defects in material and workmanship for a period of one (1) year (except

T ooroom Mills and Mini-Mills, which are six (6) months) from the date of purchase, which is the date that a machine

is installed at the end user . The foregoing is a limited warranty and it is the only warranty by manufacturer . Manufacturer disclaims all other warranties, express or implied, including but not limited to all warranties of merchantability

and fitness for a particular purpose.

REPAIR OR REPLACEMENT ONL Y: MANUFACTURER'S LIABILITY UNDER THIS AGREEMENT SHALL

BE LIMITED TO REP AIRING OR REPLACING , A T THE DISCRETION OF MANUFACTURER, P ARTS, OR

COMPONENTS.

An additional warranty extension may be purchased from your authorized Haas distributor.

LIMITS and EXCLUSIONS of W ARRANTY

Except as provided above, buyer agrees that all warranties express or implied, as to any matter whatsoever , including but not limited to warranties of merchantability and fitness for a particular purpose are excluded.

Components subject to wear during normal use and over time such as paint, window finish and condition, light bulbs,

seals, chip removal system, etc., are excluded from this warranty .

Factory-specified maintenance procedures must be adhered to and re corded in order to maintain this warranty .

This warranty is void if the machine is subjected to mishandling, misuse, neglect, accident, improper installation,

improper maintenance, or improper operation or application, or if the machine was improperly repaired or serviced by

the customer or by an unauthorized service technician. Warranty service or repair service is available from the

authorized Haas distributor.

Without limiting the generality of any of the exclusions or limitations described in other paragraphs, manufacturer's

warranty does not include any warranty that the machine or components will meet buyer's production specifications

or other requirements or that operation of the machine and components will be uninterrupted or error-free. Manufacturer assumes no responsibility with respect to the use of the Machine and Components by Buyer , and manufacturer

shall not incur any liability or Seller to Buyer for any failure in design, production, operation, performance or otherwise of the Machine or Components other than repair or replacement of same as set forth in the Limited Warranty

above. Manufacturer is not responsible for any damage to parts, machines, business premises or other property of

Buyer, or for any other incidental or consequential damages that may be caused by a malfunction of the Machine or

Components.

LIMITATION OF LIABILITY AND DAMAGES: MANUFACTURER IS NOT LIABLE TO BUYER, SELLER

OR ANY CUSTOMER OF BUYER FOR LOSS OF PROFITS, LOST DA T A, LOST PRODUCTS, LOSS OF REVENUE, LOSS OF USE, COST OF DOWN TIME, BUSINESS GOOD WILL, OR ANY OTHER INCIDENT AL OR

CONSEQUENTIAL DAMAGE, WHETHER IN AN ACTION IN CONTRACT OR TORT, ARISING OUT OF OR RELA TED TO THE MACHINE OR COMPONENTS, OTHER PRODUCTS OR SERVICES PROVIDED BY MANUFACTURER OR SELLER, OR THE F AILURE OF P ARTS OR PRODUCTS MADE BY USING THE MACHINE OR COMPONENTS, EVEN IF MANUFACTURER OR SELLER HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH

DAMAGES. MANUFACTURER'S LIABILITY FOR DAMAGES FOR ANY CAUSE WHATSOEVER SHALL BE

LIMITED TO REP AIR OR REPLACEMENT , A T THE DISCRETION OF MANUF ACTURER, OF THE DEFECTIVE

P ARTS, COMPONENTS OR MACHINE.

II

T able Of Contents

96-8000 rev R June 2007

Page 4

Buyer has accepted this restriction on its right to recover incidental or consequential damages as part of its

bargain with Seller. Buyer realizes and acknowledges that the price of the equipment would be higher if Seller or

Manufacturer were required to be responsible for incidental or consequential damages, or punitive damages.

This Warranty Certificate supersedes any and all other agreements, either oral or in this writing, between the

parties hereto with respect to the warranties, limitations of liability and/or damages regarding the Machine or

Components, and contains all of the covenants and agreements between the parties with respect to such

warranties, liability limitations and/or damages. Each party to this Warranty Certificate acknowledges that no

representations, inducements, promises, or agreements, orally or otherwise, have been made by any p arty , or

anyone acting on behalf of any party , which are not embodied herein regarding such warranties, liability limitations and/or damages, and that no other agreement, statement, or promise not contained in this Warranty

Certificate shall be valid or binding regarding such warranties, liability limitations and damages.

TRANSFERABILITY

This warranty is transferrable from the original end-user to another party if the machine is sold via private sale

before the end of the warranty period.

Should you have a problem with your machine, please consult your operator's manual first. If this does not

resolve the problem, call your authorized Haas distributor. As a final solution, call Haas directly at the number

indicated below.

Haas Automation, Inc.

2800 Sturgis Road

Oxnard, California 93030-8933 USA

Phone: (805) 278-1800

FAX: (805) 278-8561

In order to record the end-user of this machine for updates and for product safety notices, we must have the

machine registration returned immediately . Please fill out completely and mail to the above address to A TTENTION

(VF-1, GR-510, VF-6, etc. — whichever is applicable) REGISTRA TIONS. Please include a copy of your invoice

to validate your warranty date and to cover any additional options you may have purchased.

Company Name:Company Name:

Company Name:

Company Name:Company Name:

Address:Address:

Address:

Address:Address:

______________________________________________________________________________________________________________________________________________________________________________________

___________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________

___________________________________________________________________________________________

______________________________________________________________________________________________________________________________________________________________________________________

Dealer:Dealer:

Dealer:

Dealer:Dealer:

Model No.Model No.

Model No.

Model No.Model No.

Telephone: (Telephone: (

Telephone: (

Telephone: (Telephone: (

This machine is equipped with an electronically-recorded serial number that cannot be altered. This is done to

protect you in case of theft and to track machines when sold to other owners. After approximately 800 hours of use,

the machine will automatically shut down if it has not been electronically unlocked by the Haas Factory Outlet. T o

unlock the machine, we must have the above registration with the serial number. Y ou will receive a number from the

Haas Factory Outlet that you will write in over the serial number on the setting page (#26). If, for any reason, the

serial number of the machine is erased in memory, the machine will revert back to a 200 hour limit for your

protection.

__________________________________________________________________________________________________________________________________________________________________

_________________________________________________________________________________

__________________________________________________________________________________________________________________________________________________________________

________________________________________________________________________________

________________________________________

________________________________________________________________________________

::

________________________________________________________________________

:

____________________________________

::

________________________________________________________________________

IMPORIMPOR

IMPOR

IMPORIMPOR

__________________________________________________________

_____________________________

__________________________________________________________

______

) )

___

______

TT

T

TT

______________________________________________________

)

___________________________

) )

______________________________________________________

ANT NOANT NO

ANT NO

ANT NOANT NO

TICE!!! PLEASE READ IMMEDIATICE!!! PLEASE READ IMMEDIA

TICE!!! PLEASE READ IMMEDIA

TICE!!! PLEASE READ IMMEDIATICE!!! PLEASE READ IMMEDIA

Contact Name:Contact Name:

Contact Name:

Contact Name:Contact Name:

Date Installed:Date Installed:

Date Installed:

Date Installed:Date Installed:

Serial Number:Serial Number:

Serial Number:

Serial Number:Serial Number:

FAX: (FAX: (

FAX: (

FAX: (FAX: (

__________

_____

__________

))

______________________________________________________

)

___________________________

))

______________________________________________________

________________________________________________

________________________

________________________________________________

________________________________________________

________________________

________________________________________________

________________________________________________

________________________

________________________________________________

TELTEL

Y!!!Y!!!

TEL

Y!!!

TELTEL

Y!!!Y!!!

96-8000 rev R June 2007

T able Of Contents

III

Page 5

Customer Satisfaction Procedure

Dear Haas customer,

Your complete satisfaction and goodwill are of the utmost importance to both Haas Automation, Inc.,

and the Haas distributor where you purchased your equipment. Normally, any concerns you may have

about the sales transaction or the operation of your equipment will be rapidly resolved by your

distributor.

However, if your concerns are not resolved to your complete satisfaction, and you have discussed your

concerns with a member of the dealership’s management, the General Manager or the dealership’s owner

directly, please do the following:

Contact Haas Automation’s Customer Service Center by calling 800-331-6746 and ask for the Customer

Service Department. So that we may resolve your concerns as quickly as possible, please have the

following information available when you call:

• Your name, company name, address and phone number

• The machine model and serial number

• The dealership name, and the name of your latest contact at the dealership

• The nature of your concern

If you wish to write Haas Automation, please use this address:

Haas Automation, Inc.

2800 Sturgis Road

Oxnard, CA 93030

Att: Customer Satisfaction Manager

e-mail: Service@HaasCNC.com

Once you contact the Haas Automation Customer Service Center, we will make every effort to work

directly with you and your distributor to quickly resolve your concerns. At Haas Automation, we know

that a good Customer-Distributor-Manufacturer relationship will help ensure continued success for all

concerned.

Customer Feedback

If you have any concerns or questions in regards to the Haas Operator’s manual, please contact us via our

E-mail, pubs@haascnc.com. We look forward to any suggestions you may have.

Certification

All Haas CNC machine tools carry the ETL Listed

mark, certifying that they conform to the NFP A 79

Electrical Standard for Industrial Machinery and

the Canadian equivalent, CAN/CSA C22.2 No. 73.

The ETL Listed and cETL Listed marks are awarded

to products that have successfully undergone

testing by Intertek Testing Services (ITS), an

alternative to Underwriters’ Laboratories.

The ISO 9001:2000 certification from TUV

Management Service (an ISO registrar) serves as

an impartial appraisal of Haas Automation’s quality

management system. This achievement affirms

Haas Automation’ s conformance with the standards

set forth by the International Organization for

Standardization, and acknowledges the Haas

commitment to meeting the needs and requirements

of its customers in the global marketplace.

IV

T able Of Contents

96-8000 rev R June 2007

Page 6

The Information contained in this manual is constantly being updated.

The latest updates, and other helpful information is available online as a

free download in .pdf format (go to

www .HaasCNC.com and click on

“Manual Updates” under the “Customer Services” drop-down menu in

the navigation bar).

T able of Contents

SAFETY ................................................................................................................................................................... 4

OPERA TION ............................................................................................................................................................ 9

PENDANT KEYBOARD INTRODUCTION ............................................................................................................. 11

FUNCTION KEYS ........................................................................................................................................ 12

JOG KEYS ................................................................................................................................................ 12

OVERRIDE KEYS ....................................................................................................................................... 13

DISPLA Y KEYS ........................................................................................................................................... 14

CURSOR KEYS .......................................................................................................................................... 15

ALPHA KEYS ............................................................................................................................................. 15

MODE KEYS ............................................................................................................................................. 16

NUMERIC KEYS ......................................................................................................................................... 17

POSITION DISPLAYS .................................................................................................................................... 17

OFFSETS DISPLAY ...................................................................................................................................... 18

CURRENT COMMANDS DISPLAY ..................................................................................................................... 18

ALARMS / MESSAGES DISPLAY ...................................................................................................................... 19

SETTING / GRAPHIC DISPLAY FUNCTION ......................................................................................................... 20

DATE AND TIME ......................................................................................................................................... 21

SCREEN SAVER......................................................................................................................................... 21

HELP / CALCULATOR FUNCTION .................................................................................................................... 21

SPINDLE WARM-UP PROGRAM ..................................................................................................................... 24

RUN-STOP-JOG-CONTINUE.......................................................................................................................... 24

COOLANT LEVEL GAUGE ............................................................................................................................. 25

OPTIONS .................................................................................................................................................. 25

RJH-E SCREENS ............................................................................................................................... ....... 28

PROGRAMMING ................................................................................................................................................... 31

MACHINE POWER-UP ................................................................................................................................. 31

PROGRAMMING INTRODUCTION ..................................................................................................................... 31

ALPHABETICAL ADDRESS CODES .................................................................................................................. 38

PART SETUP............................................................................................................................................. 38

TOOLING ................................................................................................................................................. 39

TOOL CHANGER ........................................................................................................................................ 40

JOG MODE .............................................................................................................................................. 48

PALLET CHANGER (EC-SERIES AND MDC-500) ............................................................................................. 56

TIPS AND TRICKS ...................................................................................................................................... 62

96-8000 rev R June 2007

T able Of Contents

V

Page 7

INTUITIVE PROGRAMMING SYSTEM (IPS)......................................................................................................... 65

NTRODUCTION .......................................................................................................................................... 65

I

AUTOMATIC MODE ...................................................................................................................................... 65

SYSTEM MODE .......................................................................................................................................... 65

SUBROUTINES ..................................................................................................................................................... 68

L

OCAL SUBROUTINES ................................................................................................................................68

SUBROUTINE CANNED CYCLE EXAMPLE ......................................................................................................... 69

SUBROUTINES WITH MULTIPLE FIXTURES ...................................................................................................... 69

ADV ANCED EDITOR ............................................................................................................................................. 70

THE PROGRAM MENU ................................................................................................................................70

THE EDIT MENU ....................................................................................................................................... 71

THE SEARCH MENU .................................................................................................................................. 71

THE MODIFY MENU ................................................................................................................................... 71

THE I/O MENU......................................................................................................................................... 72

THE F1: HELP MENU ................................................................................................................................72

ADVANCED EDITOR SHORTCUTS ................................................................................................................... 73

QUICK CODE ........................................................................................................................................................ 74

VISUAL QUICK CODE ................................................................................................................................. 79

CUTTER COMPENSATION.................................................................................................................................... 80

ENTRY AND EXIT FROM CUTTER COMPENSATION ............................................................................................... 81

FEED ADJUSTMENTS IN CUTTER COMPENSATION .............................................................................................. 81

MACROS ............................................................................................................................................................... 83

INTRODUCTION .......................................................................................................................................... 83

OPERATION NOTES ..................................................................................................................................... 84

SYSTEM VARIABLES IN-DEPTH ...................................................................................................................... 89

VARIABLE USAGE ....................................................................................................................................... 93

ADDRESS SUBSTITUTION ............................................................................................................................ 94

G65 MACRO SUBROUTINE CALL ................................................................................................................101

COMMUNICATION WITH EXTERNAL DEVICES - DPRNT[ ] .................................................................................102

FANUC-STYLE MACRO FEATURES NOT INCLUDED IN HAAS CNC CONTROL .........................................................104

4TH AND 5TH AXIS PROGRAMMING .................................................................................................................105

CREATING FIVE-AXIS PROGRAMS .................................................................................................................105

INSTALLING AN OPTIONAL FOURTH AXIS ........................................................................................................107

INSTALLING AN OPTIONAL FIFTH AXIS ...........................................................................................................108

AUXILIARY AXIS .......................................................................................................................................108

DISABLEING THE AXES ..............................................................................................................................109

G CODES (PREPARA T ORY FUNCTIONS)............................................................................................................ 111

M CODES (MISCELLANEOUS FUNCTIONS) .......................................................................................................167

SETTINGS............................................................................................................................................................175

MAINTENANCE ....................................................................................................................................................193

INDEX...................................................................................................................................................................207

This manual and all of its contents are copyright protected 2007, and may not be reproduced without written

permission from Haas Automation, Inc.

VI

T able Of Contents

96-8000 rev R June 2007

Page 8

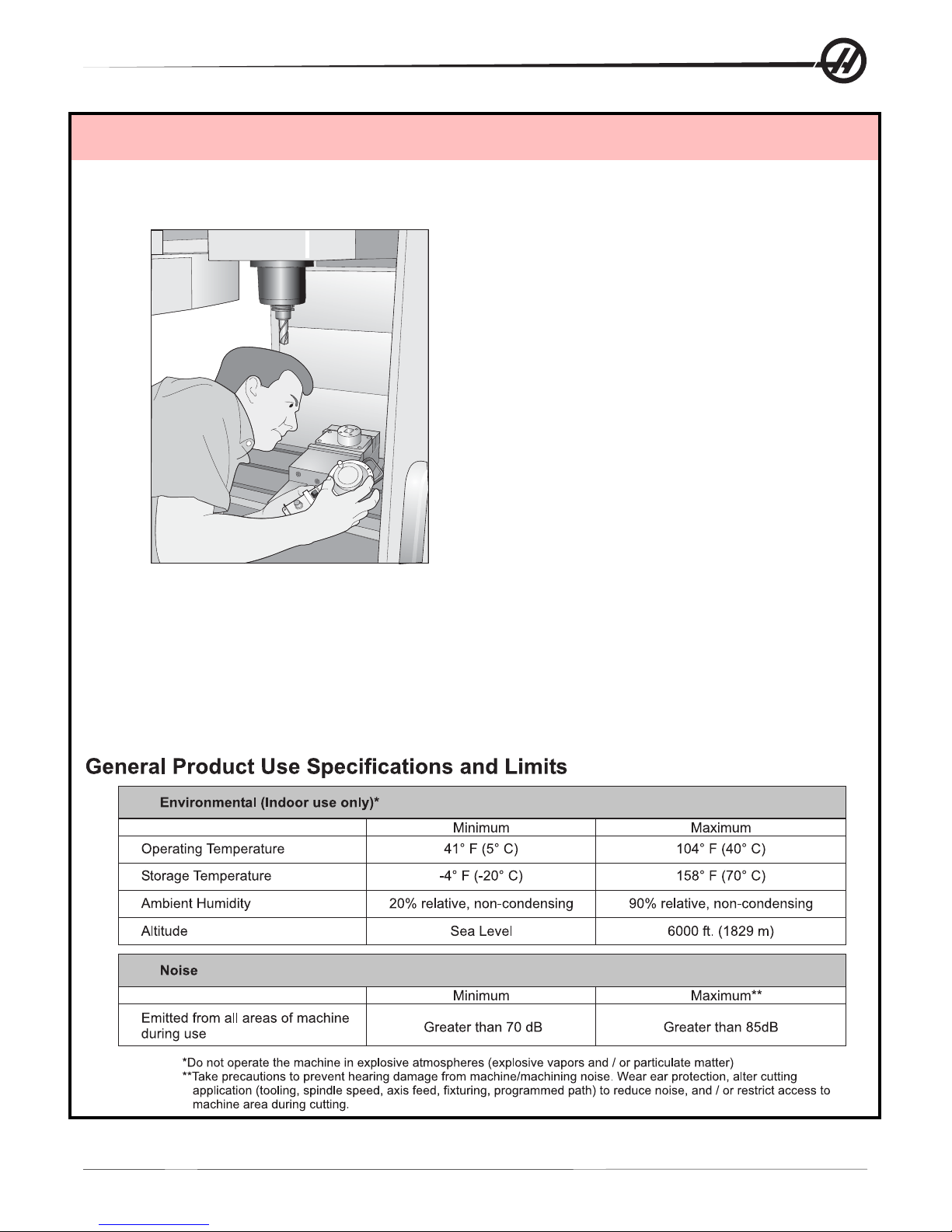

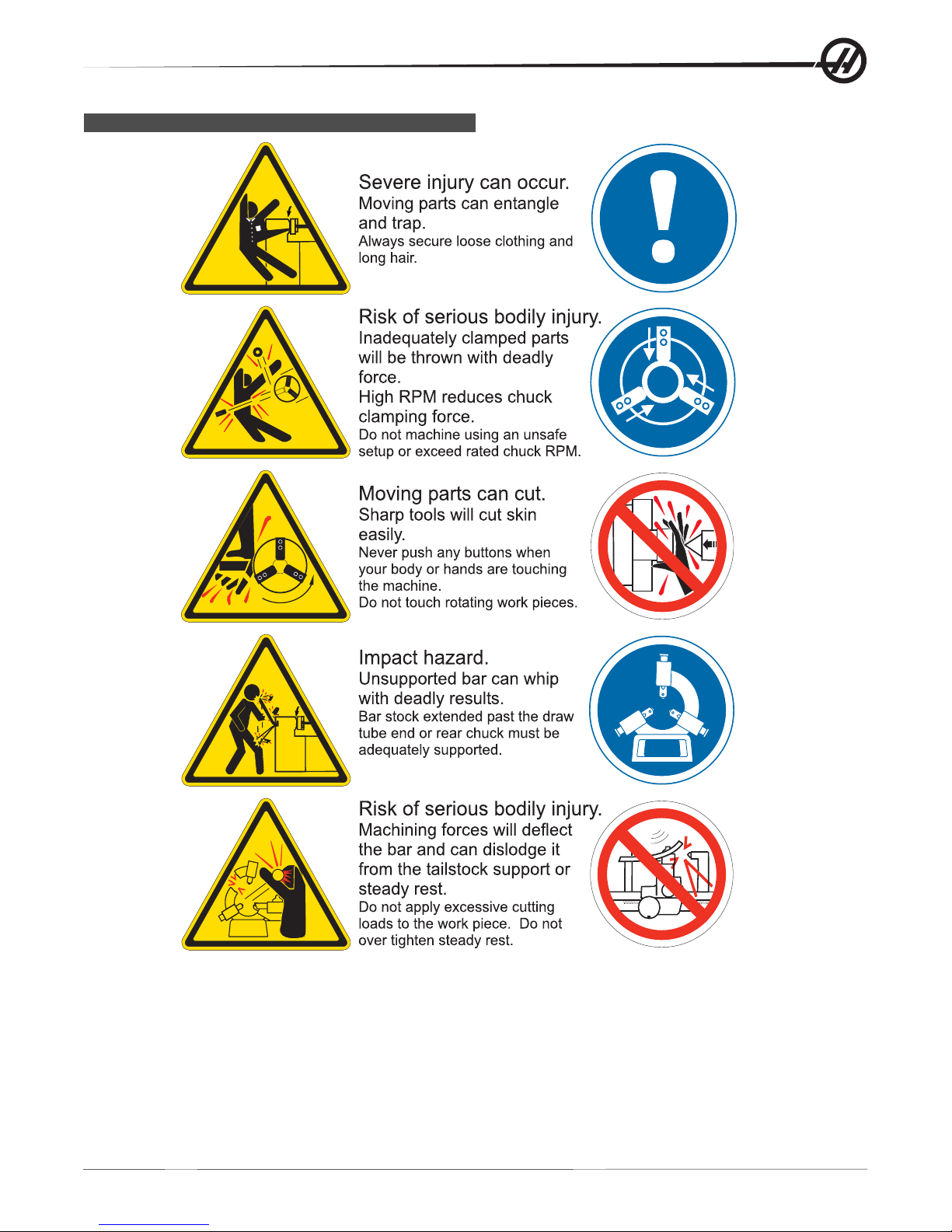

HAAS SAFETY PROCEDURES

T HINK SAFETY!

DON’T GET CAUGHT UP

IN YOUR WORK

All milling machines contain hazards from rotating

parts, belts and pulleys, high voltage electricity,

noise, and compressed air. When using CNC

machines and their components, basic safety

precautions must always be followed to reduce the

risk of personal injury and mechanical damage.

Important – This machine to be operated only

by trained personnel in accordance with the

Operator’s manual, safety decals, safety

procedures and instructions for safe machine

operation.

SafSaf

Saf

SafSaf

USES AND GUIDELINES FOR PROPER MACHINE OPERA TION........................................................................... 4

MODIFICA TIONS TO THE MACHINE ....................................................................................................................... 4

SAFETY PLACARDS............................................................................................................................................... 4

MILL WARNING DECALS ........................................................................................................................................ 6

DECLARA TION OF WARNINGS, CAUTIONS, AND NOTES..................................................................................... 6

LA THE WARNING DECALS..................................................................................................................................... 7

ety Contentsety Contents

ety Contents

ety Contentsety Contents

96-8000 rev R June 2007

Safety

1

Page 9

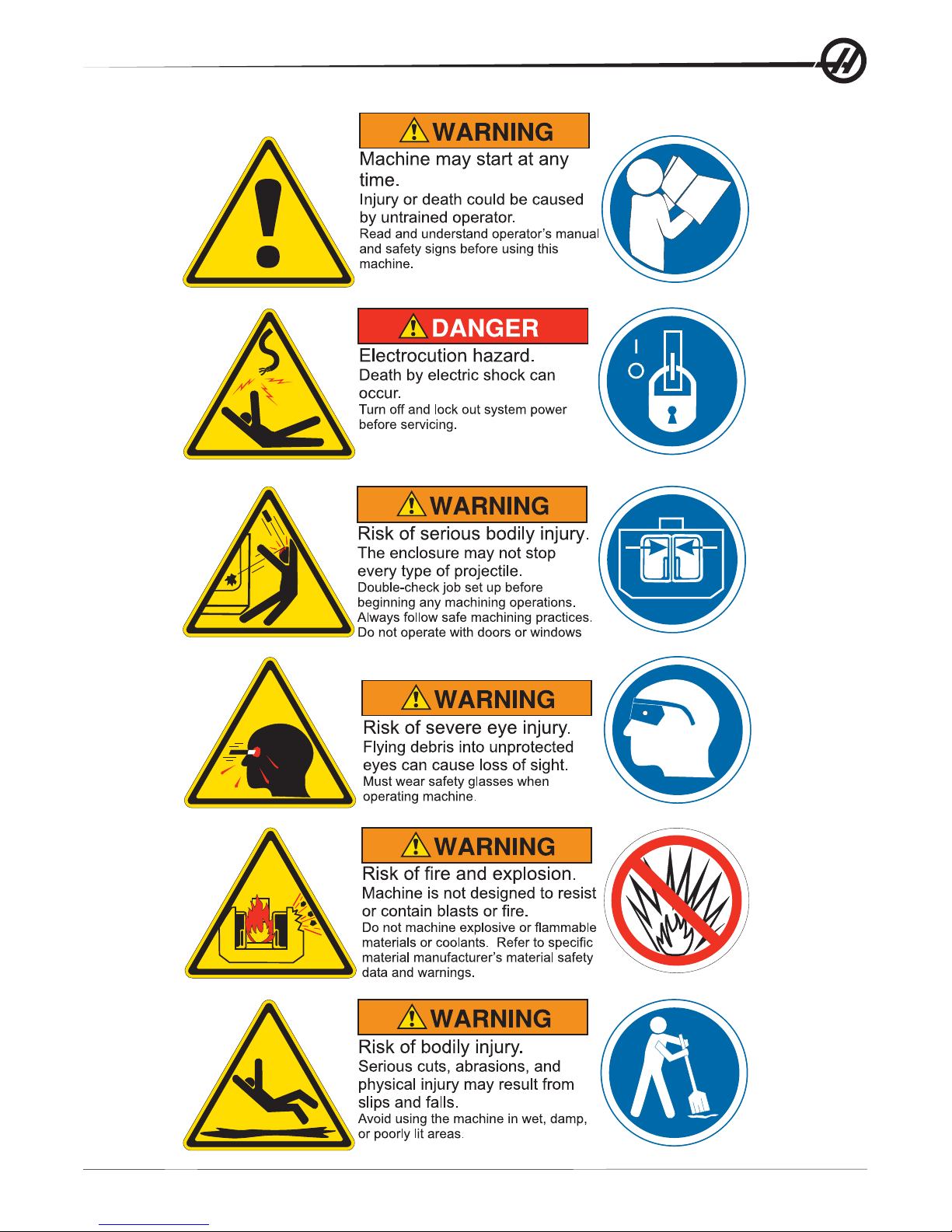

READ BEFORE OPERATING THIS MACHINE:

♦ Only authorized personnel should work on this machine. Untrained personnel present a hazard to

themselves and the machine, and improper operation will void the warranty .

♦ Check for damaged parts and tools before operating the machine. Any part or tool that is damaged should be

properly repaired or replaced by authorized personnel. Do not operate the machine if any component does not

appear to be functioning correctly . Contact your shop supervisor .

♦ Use appropriate eye and ear protection while operating the machine. ANSI-approved impact safety goggles and

OSHA-approved ear protection are recommended to reduce the risks of sight damage and hearing loss.

♦ Do not operate the machine unless the doors are closed and the door interlocks are functioning properly .

Rotating cutting tools can cause severe injury . When a program is running, the mill table and spindle head can

move rapidly at any time in any direction.

♦ The Emergency Stop button (also known as an Emergency Power Of f button) is the large, circular red switch

located on the Control Panel. Pressing the Emergency Stop button will instantly stop all motion of the machine, the

servo motors, the tool changer, and the coolant pump. Use the Emergency S top button only in emergencies to avoid

crashing the machine.

♦ The electrical panel should be closed and the three latches on the control cabinet should be secured at all times

except during installation and service. At those times, only qualified electricians should have access to the panel.

When the main circuit breaker is on, there is high voltage throughout the electrical panel (including the circuit boards

and logic circuits) and some components operate at high temperatures. Therefore, extreme caution is required.

Once the machine is installed, the control cabinet must be locked and the key available only to qualified service

personnel.

♦♦

♦ DO NOT modify or alter this equipment in any way . If modifications are necessary, all such requests must be

♦♦

handled by Haas Automation, Inc. Any modification or alteration of any Haas Milling or Turning Center could lead to

personal injury and/or mechanical damage and will void your warranty .

♦ It is the shop owner’s responsibility to make sure that everyone who is involved in installing and operating the

machine is thoroughly acquainted with the installation, operation, and safety instructions provided with the machine

BEFORE they perform any actual work. The ultimate responsibility for safety rests with the shop owner and the

individuals who work with the machine.

♦♦

♦ This machine is automatically controlled and may start at any time.

♦♦

♦♦

♦ This machine can cause severe bodily injury .

♦♦

♦♦

♦ Do not operate with the doors open.

♦♦

2

Safety

96-8000 rev R June 2007

Page 10

OBSERVE ALL OF THE WARNINGS AND CAUTIONS BELOW:

♦♦

♦ Avoid entering the machine enclosure.

♦♦

♦♦

♦ Do not operate without proper training.

♦♦

♦♦

♦ Always wear safety goggles.

♦♦

♦♦

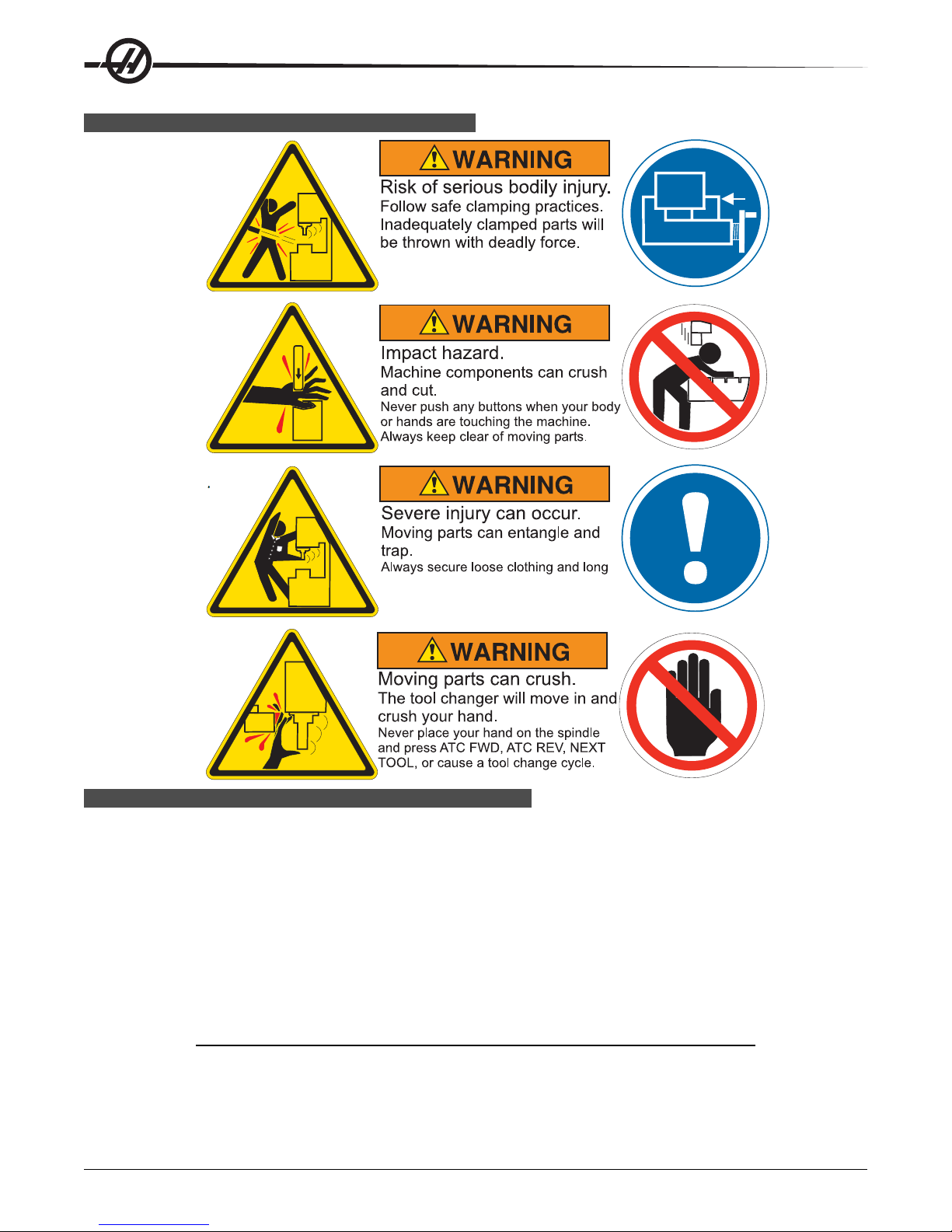

♦ Never place your hand on the tool in the spindle and press A TC FWD, A TC REV ,

♦♦

NEXT TOOL, or cause a tool change cycle. The tool changer will move in and

crush your hand.

♦♦

♦ T o avoid tool changer damage, ensure that tools are properly aligned with the

♦♦

spindle drive lugs when loading tools.

♦♦

♦ The electrical power must meet the specifications in this manual. Attempting to

♦♦

run the machine from any other source can cause severe damage and will void the

warranty.

♦♦

♦ DO NOT press POWER UP/REST ART on the control panel until after the

♦♦

installation is complete.

♦♦

♦ DO NOT attempt to operate the machine before all of the installation instructions

♦♦

have been completed.

♦♦

♦ NEVER service the machine with the power connected.

♦♦

♦♦

♦ Improperly clamped parts machined at high speeds/feeds may be ejected and

♦♦

puncture the safety door . Machining oversized or marginally clamped parts is not

safe.

♦♦

♦ Windows must be replaced if damaged or severely scratched - Replace damaged

♦♦

windows immediately .

♦♦

♦ Do not process toxic or flammable material. Deadly fumes can be present. Consult

♦♦

material manufacturer for safe handling of material by-products before processing.

96-8000 rev R June 2007

Safety

3

Page 11

USES AND GUIDELINES FOR PROPER MACHINE OPERATION

All milling machines contain hazards from rotating cutting tools, belts and pulleys, high voltage electricity,

noise, and compressed air. When using milling machines and their component s, basic safety precautions

should always be followed to reduce the risk of personal injury and mechanical damage. READ ALL APPRO-

PRIATE W ARNINGS, CAUTIONS, AND INSTRUCTIONS BEFORE OPERA TING THIS MACHINE.

MODIFICATIONS TO THE M ACHINE

DO NOT modify or alter this equipment in any way . If modifications are necessary, all such requests must be

handled by Haas Automation, Inc. Any modification or alteration of any Haas machining center could lead to

personal injury and/or mechanical damage and will void your warranty .

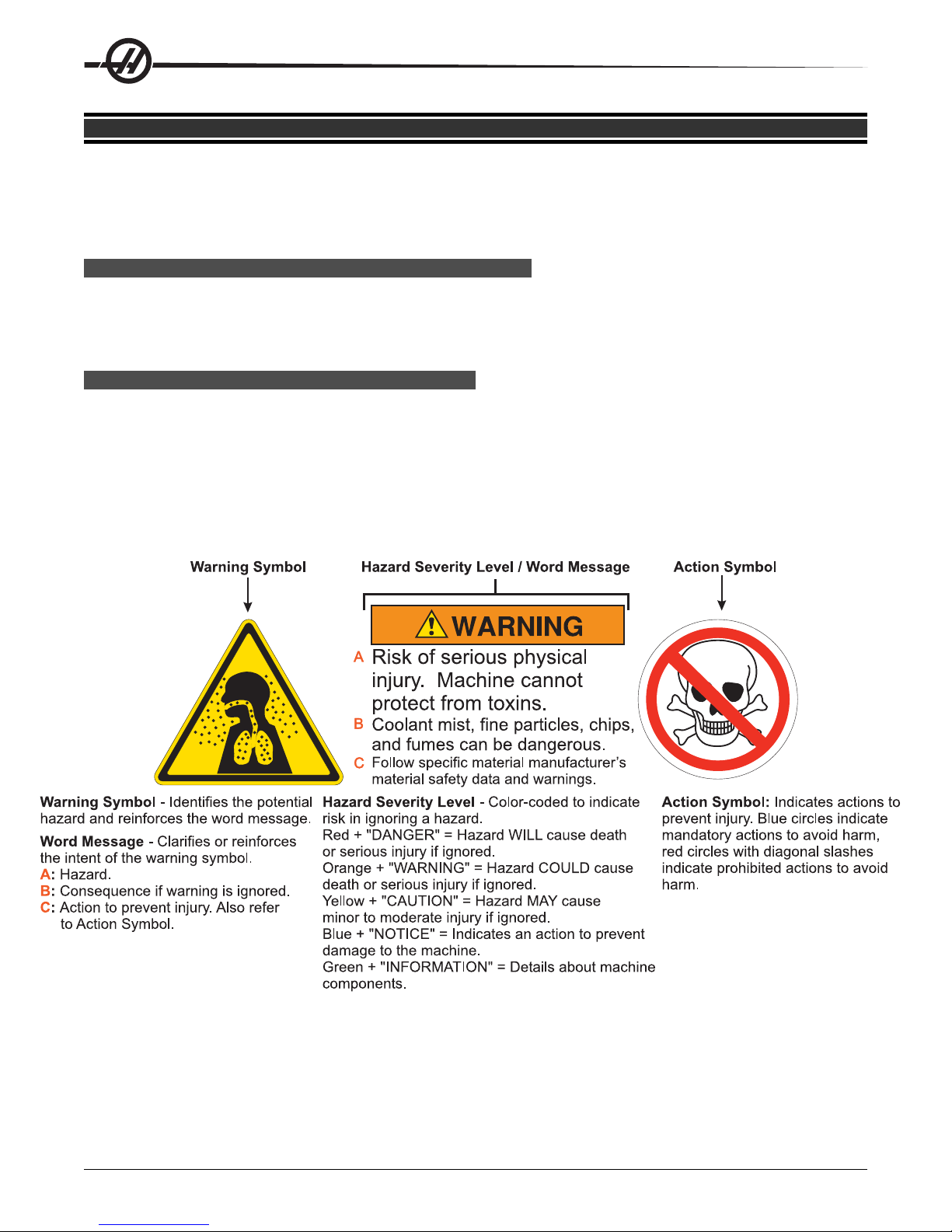

SAFETY P LACARDS

T o help ensure that CNC tool dangers are quickly communicated and understood, hazard symbol decals are placed on

Haas Machines in locations where hazards exist. If decals become damaged or worn, or if additional decals are needed

to emphasize a particular safety point, contact your dealer or the Haas factory. Never allow anyone to alter or

remove any safety decal or symbol.

Each hazard is defined and explained on the general safety decal, located at the front of the machine. Particular locations of hazards are marked with warning symbols. Review and understand the four parts of each safety warning, explained below, and familiarize yourself with the symbols on the following p ages.

4

Safety

96-8000 rev R June 2007

Page 12

96-8000 rev R June 2007

Safety

5

Page 13

MILL W ARNING D ECALS

DECLARATION OF W ARNINGS, CAUTIONS, AND N OTES

Throughout this manual, important and critical information is prefaced with the word “Warning”, “Caution” and “Note”

Warnings are used when there is an extreme danger to the operator and/or to the machine. Take all steps neces-

sary to heed the warning given. Do not continue if you cannot follow the warning instructions. An example warning is:

NEVER PUT HANDS BETWEEN TOOL CHANGER AND SPINDLE HEAD.

Cautions are used when there is the potential for minor personal injury or mechanical damage, for example:

CAUTION! Power down the machine before performing any maintenance tasks.

Notes give additional information to the operator about a particular step or procedure. This information should be

taken into consideration by the operator as the step is performed to ensure there is no confusion, for example:

NOTE: If machine is equipped with the optional extended Z-clearance table, follow

these guidelines:

• Avoid extreme loads on the center of table or far end of table. The weight

of the part should be distributed evenly over the table or one pad.

• Flatness of part should be within 0.002".

6

WARNING!

Safety

96-8000 rev R June 2007

Page 14

LATHE W ARNING D ECALS

96-8000 rev R June 2007

Safety

7

Page 15

8

Safety

96-8000 rev R June 2007

Page 16

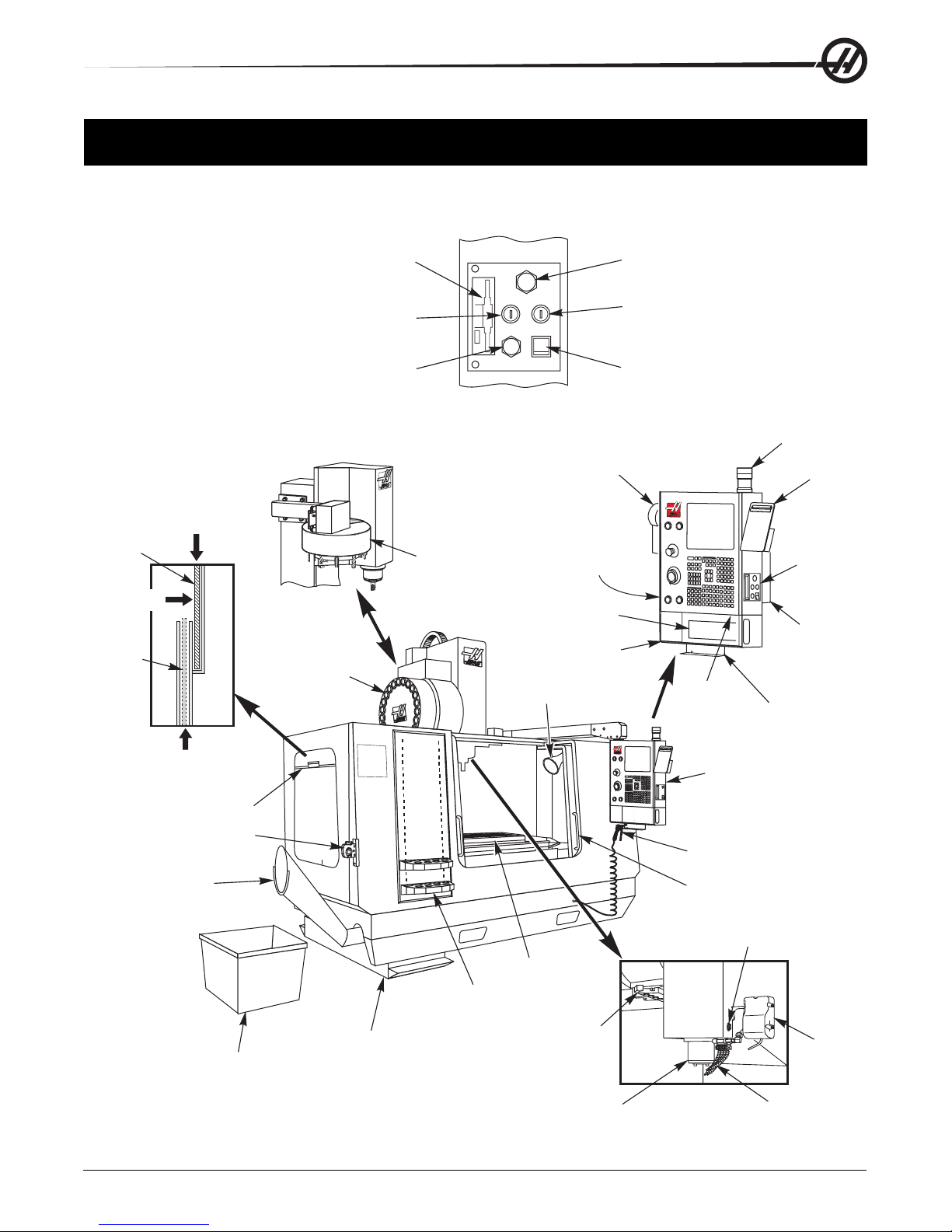

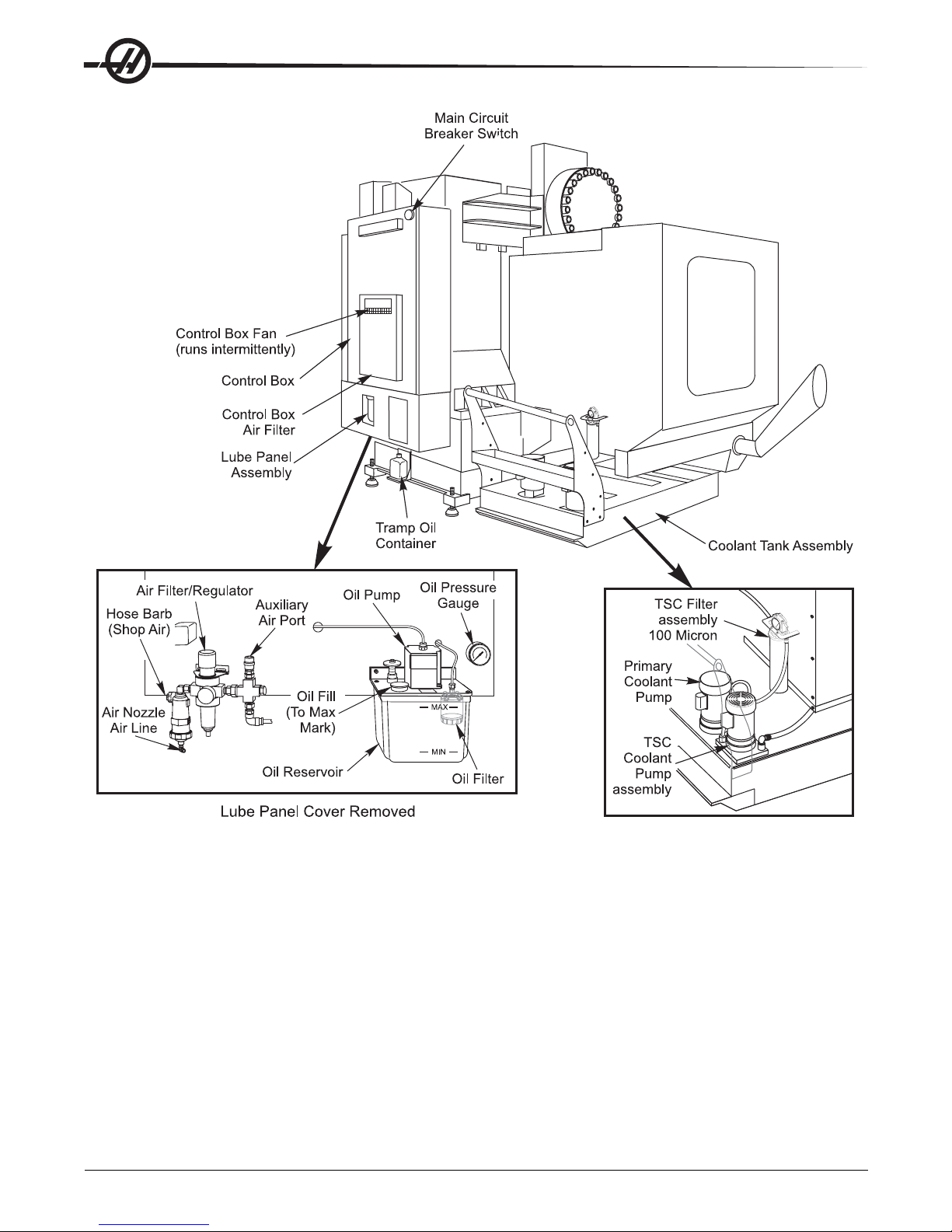

OPERATION

The following is a visual introduction to a HAAS mill. Some of the features shown will be highlighted in their

appropriate sections.

Window

Open

Position

Push in

Window

Closed

Position

Pull down

to Lock in

Place

2

Floppy Disk Drive

Key Memory Lock

Hold to Run Button

MEMORY

LOCK

HOLD TO

RUN

USB

RUN

MODE MODE

WORK LIGHT

GFI

PROTECTED

I

O

SETUP

USB Memory Device

Run/Setup Mode Key

Switch

Work Light Switch

(GFI Protected)

Detail A

(Some Features are Optional)

Remote Jog Control

3

Tool Changer

(Umbrella Type)

Optional

Second

Home

Switch

G & M Code

Reference List

Side Mount

Tool Changer

(SMTC)

1

2

11

1

3

0

14

1

15

9

16

8

17

7

18

6

1

9

5

Work Light (2)

Tool Tray

Beeper

Work Beacon

Clip Board

(See

Detail A)

Operator

Manual &

Assembly

Data

Vise Handle

Holder

1

Pull up

Window

Tool Holding Vise

Chip Chute

Chip Basket

96-8000 rev R June 2007

2-SPEED

2

0

H

P

GEAR

D

RIVE

10,000

RPM

Coolant Tank

Assembly

Tool Crib

Introduction

Table

SMTC

Double Arm

Spindle

Control Pendant

Air Gun

Operator Door (2)

Tool Release Button

Optional

P-Cool

Assembly

Coolant Nozzles

View Rotated 90 CW8

9

Page 17

10

Introduction

96-8000 rev R June 2007

Page 18

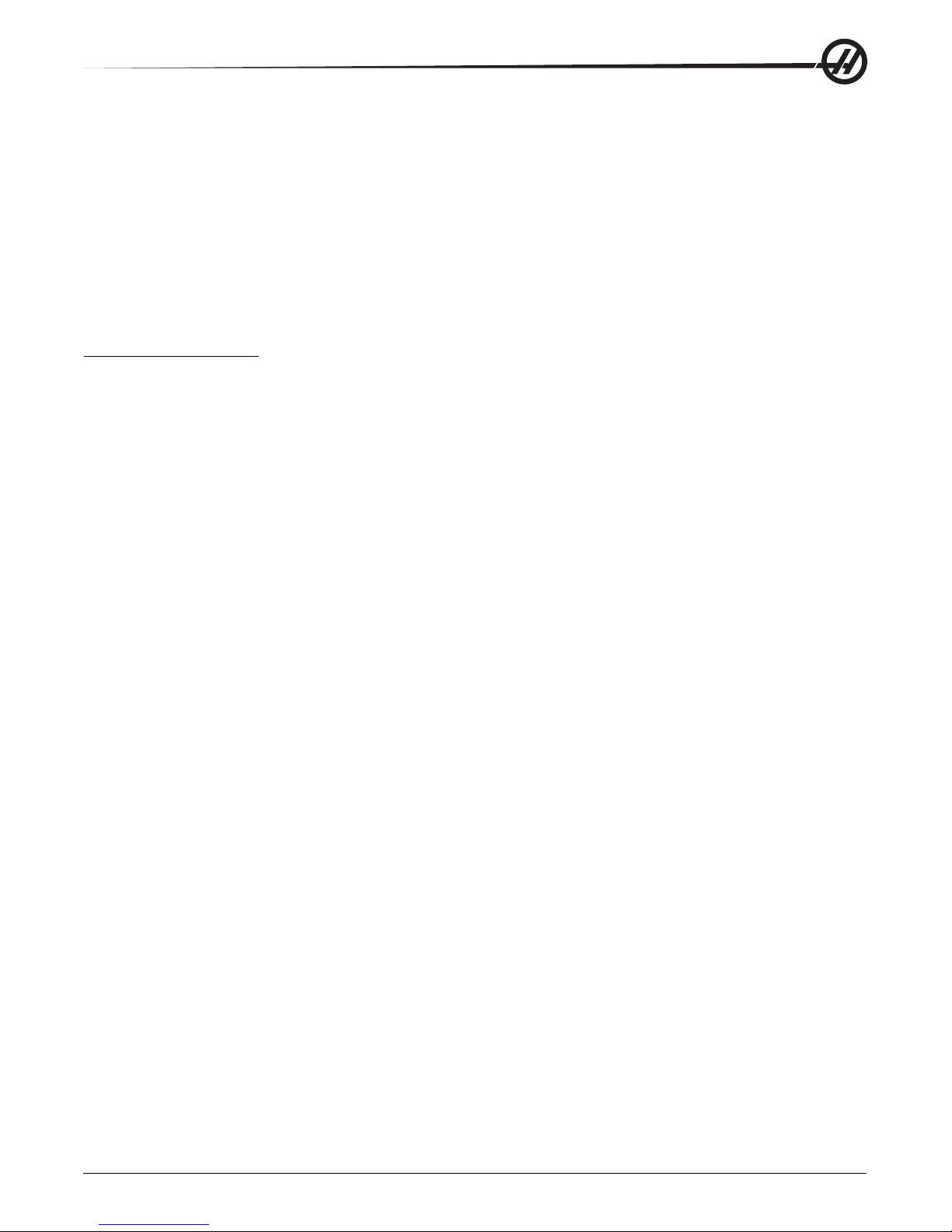

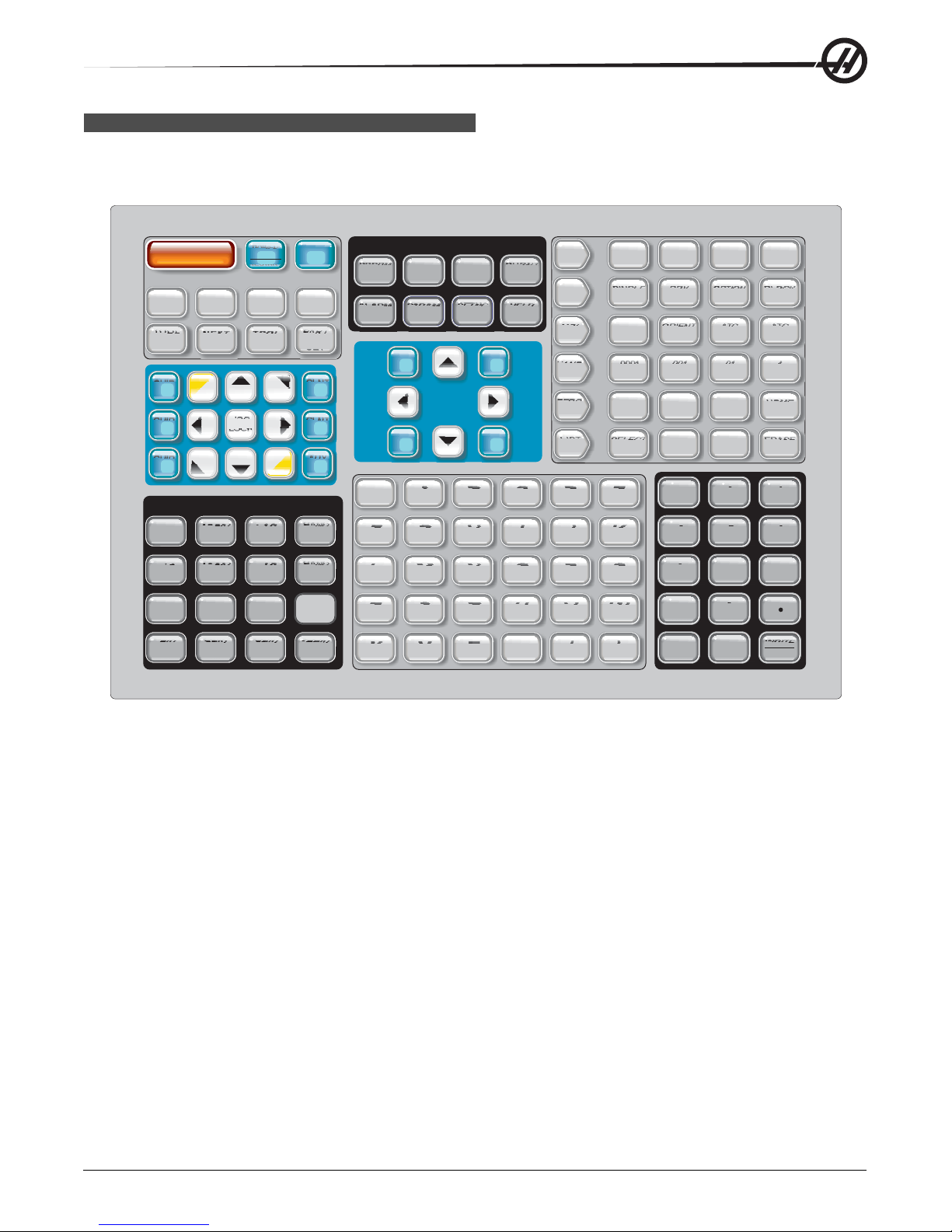

PENDANT K EYBOARD I NTRODUCTION

The keyboard is broken up into eight sections: Function Keys, Jog Keys, Override Keys, Display Keys, Cursor

Keys, Alpha Keys, Mode Keys and Number Keys. In addition there are miscellaneous keys and features

located on the pendant and keyboard which are described briefly .

POWER

RESET

UP

RESTART

RECOVER

F1 F2 F3 F4

TOOL

OFFSET

MEASURE

CHIP

FWD

CHIP

STOP

CHIP

REV

NEXT

TOOL

+B

+A

+X -X

+Y

RELEASE

+Z -Y

JOG

LOCK

-Z

TOOL

OVERRIDES

-10

-10

CW

100%

FEED RATE

100%

SPINDLE SPINDLE

STOP

25% 50% 100%

FEED RATE

SPINDLE

RAPID5%RAPID RAPID RAPID

+10

FEED RATE

+10

CCW

PART

ZERO

SET

CLNT

CLNT

DOWN

-A

-B

CLNT

HAND

CNTRL

FEED

HAND

CNTRL

SPIN

SPINDLE

UP

AUX

PRGRM

CONVRS

ALARM

MESGS

SHIFT

SHIFT

SHIFT

F

L

R

X

HOM E

END

PARAM

DGNOS

DISPLAY

POSIT

CURSOR

G

M

S

Y

OFFSET

SETNG

GRAPH

H

N

T

Z

PAG E

UP

PAG E

DOWN

CURNT

COMDS

HELP

CALC

I

O

U

/

/

EOB

EDIT

MEM

MDI

DNC

HAND

JOG

ZERO

RET

LIST

PROG

J

P

V

[

[

(

INSERT ALTER

SINGLE DRY

BLOCK RUN

COOLNT

SELECT

PROG

EDCBA

K

Q

W

]

]

)

ORIENT

SPINDLE

.0001 .001

.1 1.

ALL

ORIGIN

SEND

&

&

%

%

*

*

+

+

CANCEL

DELETE

OPTION

STOP

SINGL

RECV

@

@

7

$

$

4

,

,

1

=

=

-

SPACE

ATC

FWD

.01

10.

8

5

2

0

UNDO

BLOCK

DELETE

ATC

REV

.1

100.

HOME

G28

ERASE

PROG

:

:

9

!

!

6

?

?

3

#

#

WRITE

ENTER

Power On- Turns the machine on.

Power Off- Turns the machine off.

Spindle Load Meter - Displays the spindle load, in percent.

Emergency Stop - This stops all axes motion, stops the spindle and tool changer, and turns off the coolant

pump.

Jog Handle - This is used to jog all axes. Can also be used to scroll through program code or menu items

while editing.

Cycle Start - S t arts a program. This button is also used to start a program in Graphics mode.

Feed Hold - Will stop all axis motion. Note: Spindle will continue to turn during cutting.

Reset - Will stop the machine (axes, spindle, coolant pump, and tool changer are stopped). This is not a

recommended method to stop the machine, as it may be difficult to continue from that point.

Power Up / Restart - When this key is pressed, the axes will return to the machine zero position and a tool

change may occur. See Setting 81 in the Settings chapter for more information.

Recover - This button aids the operator in recovering the tool changer from an abnormal stop. See the tool

changer section for more information.

96-8000 rev R June 2007

Introduction

11

Page 19

Memory Lock Key Switch - This switch prevent the operator from editing programs and from altering settings

when turned to the locked position. The following describes the hierarchy of locks:

Key switch locks Settings and all programs.

Setting 7 locks parameters.

Setting 8 locks all programs.

Setting 23 locks 9xxx programs.

Setting 119 locks offsets.

Setting 120 locks macro variables.

Second Home Button - This button will rapid all axes to the coordinates specified in work Offset G129. The

sequence is as follows: First, the Z axis is returned to machine zero, then the X and Y axes are moved, then

the Z axis is moved to its second home position. This feature will work in any mode except DNC.

Work Light Switch - This switch will turn on the work light inside of the machine.

Keyboard Beeper - Located at the top of the parts tray . The volume can be adjusted by turning the cover .

FUNCTION K EYS

F1- F4 Keys - These buttons have different functions depending upon which mode of operation you are in. For

example, F1-F4 will cause a different action in Editing mode, than Program mode, than Offset mode. See the

specific mode section for further descriptions and examples.

T ool Offset Meas (T ool Of fset Measure) - Used to record tool length offsets during part setup.

Next T ool - Used to select the next tool from the tool changer (usually used during part setup).

T ool Release - Releases the tool from the spindle when in MDI mode, zero return mode, or handle jog mode.

Part Zero Set - Used to automatically set work coordinate offsets during part setup (see Setting Offsets in the

Operation section).

JOG K EYS

Chip FWD (Chip Auger Forward) - S tarts optional chip auger in the “Forward” direction, moving chip s out of the

machine.

Chip Stop (Chip Auger S top) - S tops auger movement.

Chip REV (Chip Auger Reverse) - S tarts the optional chip auger in the “Reverse” direction, which is useful in

clearing jams and debris from auger.

X/-X, Y/-Y, Z/-Z, A/-A and B/-B (axis keys)- Allows the operator to manually jog axis by holding down the

individual button or pressing the desired axes and using the jog handle.

Jog Lock - Works with the axes buttons. Press jog lock and then an axis button and the axis will move to

maximum travel or until jog lock is pressed again.

CLNT Up (Coolant Up) - Moves the optional Programmable Coolant (P-Cool) nozzle up.

CLNT Down (Coolant Down) - Moves the optional P-Cool nozzle down.

AUX CLNT (Auxiliary Coolant) - Pressing this key while in MDI mode will turn on the optional Through the

Spindle Coolant (TSC) system; pressing it a second time will turn of f TSC.

12

Introduction

96-8000 rev R June 2007

Page 20

OVERRIDE K EYS

These keys give the user the ability to override the speed of non-cutting (rapid) axes motion, programmed feeds

and spindle speeds.

-10 - Decreases current feedrate by 10%.

100% - Sets overridden feedrate to programmed feedrate.

+10 - Increases current feedrate by 10%.

-10 - Decreases current spindle speed by 10%.

100% - Sets overridden spindle speed to programmed speed.

+10 - Increases current spindle speed by 10%.

Hand Cntrl Feed (Handle Control Feedrate) - Pressing this button allows the jog handle to be used to control

the feedrate in ±1% increments.

Hand Cntrl Spin (Handle Control Spindle) - Pressing this button allows the jog handle to be used to control

spindle speed in ±1% increments.

CW - S tarts the spindle in the clockwise direction. This button is disabled on CE (export) machines.

CCW - Start s the spindle in the counterclockwise direction. This button is disabled on CE (export) machines.

The spindle can be started or stopped with the CW or CCW buttons any time the machine is at a Single Block

stop or the Feed Hold button has been pressed. When the program is restarted with Cycle St art, the spindle

will be turned back on to the previously defined speed.

STOP - S top s the spindle.

5% / 25% / 50% / 100% Rapid - Limits machine rapids to the value on the key. The 100% Rapid button allows

maximum rapid.

Override Usage

The feedrate can be varied from 0% to 999% of the programmed value while in operation. This is done with the

feedrate +10%, -10% and 100% buttons. The feedrate override is ineffective during G74 and G84 tapping

cycles. Feedrate override does not change the speed of any auxiliary axes. During manual jogging, the feedrate

override will adjust the rates selected from the keypad. This allows for fine control of the jog speed.

The spindle speed can also be varied, from 0% to 999%, using the spindle overrides. It is also ineffective for

G74 and G84. In the Single Block mode, the spindle may be stopped. It will automatically start up upon

continuing the program (pressing Cycle St art).

By pressing the Handle Control Feedrate key , the jog handle can be used to control feedrate from 0% to 999%

in ±1% increments. By pressing the Handle Control S pindle key , the jog handle can be used to control spindle

speed in ±1% increments (from 0% to 999%).

Rapid moves (G00) may be limited to 5%, 25%, or 50% of maximum using the keypad. If the 100% rapid is too

fast, it may be set to 50% of maximum by Setting 10.

In the Settings page, it is possible to disable the override keys so that the operator cannot select them. These

are Settings 19, 20 and 21.

96-8000 rev R June 2007

Introduction

13

Page 21

The Feed Hold button acts as an override button as it sets the rapid and feed rates to zero when it is pressed.

The Cycle Start button must be pressed to proceed af ter a Feed Hold. The door switch on the enclosure also

has a similar result but will display “Door Hold” when the door is opened. When the door is closed, the control

will be in Feed Hold and Cycle Start must be pressed to continue. Door Hold and Feed Hold do not stop any

auxiliary axes.

The operator can override the coolant setting by pressing the COOLNT button. The pump will remain either on

or off until the next M-code or operator action (see Setting 32).

Overrides can be reset to defaults with an M30 and/or pressing Reset (See Setting 83).

DISPLAY K EYS

Displays keys provide access to the machine displays, operational information and help pages. Some of these

keys will display additional screens when pressed more than once.

Prgrm/Convrs - Displays the currently selected program. In Edit mode, pressing the button twice will enter the

Quick Code (See Quick Code section) feature and pressing it three times will enter the Visual Quick Code

feature (See Visual Quick Code section in Quick Code).

Posit (Position) - Displays the position of the machine axes. Pressing the Page Up/Down buttons scroll

through operator, machine, work, and distance-to-go format s and displays them in larger formats.

Offset - Displays the tool length geometry , radius offsets, wear of fsets, and coolant position. Pressing Offset

button twice or pressing the Page Up button will access the work offsets page.

Curnt Comds (Current Commands) - Displays the current program details (for example G , M, H and T codes),

Spindle load information and machine axes positions while the program runs. Press Page Up/ Down to view

tool load/vibration (See the tool load/vibration section), tool life (See the tool life section), maintenance, macro

variables, program timers and program code details.

Alarm / Mesgs (Alarms / Messages) - Displays the alarm viewer and message screens. There are three alarm

screens, the first shows the currently active alarms (first press of the Alarm/Mesgs button). Pressing the Right

Arrow button switches to the Alarm History screen, which keep s a history of recent alarms.

Pressing Right Arrow again switches to the alarm viewer screen. This screen shows one alarm at a time with

its description. The default will be the last alarm in the alarm history. The user can then scroll through the

alarms by pressing the Up and Down Arrow buttons. Also, the user can enter an alarm number and press

Enter/Write and the name and description will be displayed.

Pressing Alarm/mesgs a second time will display a page for user messages and notes. Use the keyp ad to

enter messages for other operators/programmer or write notes for a current project. If there is a message, every

time the machine is powered on the messages page will display . Messages are displayed at power up until

they are erased. See Message section for more details.

Param / Dgnos (Parameters / Diagnostics) - Displays parameters that define the machine's operation. To find

a known parameter, type in the number and press the up or down arrow . Parameters are set at the factory and

should not be modified by the user.

A second press of the Param / Dgnos key will display the first page of diagnostic data. This information is

mainly used for troubleshooting by a certified Haas service technician. The first page of diagnostic data is

discrete inputs and outputs. Pressing Page Down will display the additional pages of diagnostic data.

Setng / Graph (Settings / Graphics) - Displays and allows changing of user settings. (Note that the settings

are grouped; these groups are for a specific subject). To find a known setting, type in the number and press the

up or down arrow.

14

Introduction

96-8000 rev R June 2007

Page 22

Pressing the Setng / Graph key a second time enables Graphics mode. In Graphics mode the user can view

the generated tool path of the program and, if necessary , debug the program before running it (See Graphics

Mode in the Operation section)

Help / Calc (Help / Calculator) - Displays an abbreviated manual. In this on-screen manual there are brief

descriptions of G and M codes, definitions of control features, troubleshooting and maintenance issues.

Pressing Help/ Calc a second time will display the help calculator. Press the Page Down button to scroll

through the calculator pages (see the calculator section).

CURSOR K EYS

Cursor Keys give the user the ability to move to various screens and fields in the control and are used in the

editing of CNC programs.

Home - This button will move the cursor to the top-most item on the screen; in editing, this is the top left block

of the program.

Up / Down Arrows - moves up/down one item, block or field.

Page Up / Down - Used to change displays or move up/down one page when viewing a program.

Left Arrow - Used to select individually editable items when viewing a program; moves cursor to the left. It is

used to scroll through setting selections.

Right Arrow - Used to select individually editable items when viewing a program; moves cursor to the right. It

is used to scroll through setting selections and moves the zoom window right when in graphics mode.

End - This button generally moves the cursor to the bottom-most item on the screen. In editing, this is the last

block of the program.

ALPHA K EYS

The alpha keys allow the user to enter the letters of the alphabet along with some special characters. Some of

the special characters are entered in by first pressing the “Shift” key .

Shift - The shift key provides access to additional characters on the keyboard. The additional characters are

seen in the upper left of some of the alpha and number keys. Pressing Shift and then the character will enter

that character on the data entry line. When entering text, UPPER CASE is the default, to enter lower case

characters, press and hold the Shift key .

When a control has a fifth axis installed, the B axis is selected for jogging by pressing the Shift button and

then the +/-A jog keys.

EOB - This is the End-Of-Block character . It is displayed as a semicolon (;) on the screen and it signifies the

end of a program line.

( ) - Parentheses are used to separate CNC program commands from user comments. They must always be

entered as a pair . Note: Any time an invalid line of code is received through the RS-232 port while receiving a

program, it is added to the program between parenthesis.

/ - The right slash is used in the Block Delete feature and in Macro expressions. If this symbol is the first

symbol in a block and a Block Delete is enabled, then that block is ignored at run time. The symbol is also

used for division (divide by) in macro expressions (see the Macro section).

[ ] - Square brackets are used in macro functions. Macros are an optional software feature (see the Macro

section).

96-8000 rev R June 2007

Introduction

15

Page 23

MODE K EYS

Mode keys change the operational state of the CNC machine tool. Once a mode button is pressed, the buttons

in the same row are made available to the user. The current mode is always displayed on the top line just to

the right of the current display in between parenthesis.

Edit- Selects edit mode. This mode is used to edit programs in control's memory.

Insert - Pressing this button will enter commands into the program in front of the cursor. This button will also

insert the text from the clipboard to the current cursor location, and is also used to copy blocks of code in a

program (See Advanced Editor Section)

Alter - Pressing this button will change the highlighted command or text to the newly entered commands or

text. This button will also change the highlighted variables to the text stored in the clipboard, or move a selected block to another location.

Delete - Deletes the item that the cursor is on, or deletes a selected program block.

Undo - Undoes up to the last 9 edit changes, and deselects a highlighted block.

MEM (Memory) - Selects the memory mode. This page displays the current program that is selected in the list

of programs.

Single Block - Turns single block on or off. When single block is on, only one block of the program is ex-

ecuted, for every press of Cycle Start.

Dry Run - This is used to check actual machine movement without cutting a part. (See the Dry Run section in

the Operation Chapter)

Opt Stop (Optional Stop) - T urns on and off optional stops. Also see G103 in the G-Code chapter .

When this feature is ON and an M01 (optional stop) code is programmed, the machine will stop when it

reaches the M01. The machine will continue once Cycle S tart is pressed. However , depending on the lookahead function (G103), it may not stop immediately (See block look ahead section). In other words, the block

look-ahead feature may cause the Optional Stop command to ignore the nearest M01.

If the Optional Stop button is pressed during a program it will take ef fect on the line after the highlighted line

when the Opt Stop button is pressed.

Block Delete - Turns On/Off block delete function. Blocks with a slash (“/”) as the first item are ignored (not

executed) when this option is enabled. If a slash is within a line of code, the commands after the slash will be

ignored if this feature is enabled. Block Delete will take effect two lines after Block Delete is pressed, except

when cutter compensation is used, in this case, block delete will not take effect until at least four lines after

the highlighted line. Processing will slow down for paths containing block deletes during high-speed machining.

Block Delete will stay active when power is cycled.

MDI/DNC - MDI mode is the “Manual Data Entry” mode where a program can be written but it is not entered

into memory. DNC mode “Direct Numeric Control”, allows large programs to be “drip fed” into the control so it

can be executed (See DNC mode section)

Coolnt (Coolant) - Turns the optional coolant on and off.

Orient Spindle - Rotates the spindle to a given position and then locks the spindle. Can be used during setup

to indicate parts.

A TC FWD - Rotates the tool turret to the next tool. To load a specific tool into the spindle, enter MDI mode,

type a tool number (T8) and press A TC FWD.

A TC REV - Rotates the tool turret to the previous tool. To load a specific tool into the spindle, enter MDI mode,

type a tool number (T10) and press ATC REV.

Handle Jog - Selects axis jogging mode .0001, .1 - 0.0001 inches (metric 0.001mm) for each division on the

jog handle. For dry run, .1 inches/min.

16

Introduction

96-8000 rev R June 2007

Page 24

.0001/.1, .001/1., .01/10., .1/100. - The first number (top number), when in inch mode, selects that amount to

be jogged for each click of the jog handle. When the mill is in MM mode the first number is multiplied by ten

when jogging the axis (e.g. .0001 becomes 0.001mm). The second number (bottom number) is used for dry run

mode and is used to select the speed feedrate and axis motions.

Zero Ret (Zero Return) - Selects Zero Return mode, which displays axis location in four different categories,

they are; Operator, W ork G54, Machine and Dist (distance) to go. You can page up or down to view each

category in a larger format by itself.

All - Returns all axes to machine zero. This is similar to Power Up/Restart except a tool change will not occur .

This can be used to establish the initial axes zero position.

Origin - Sets selected displays and timers to zero.

Singl (Single) - Returns one axis to machine zero. Press the desired axis letter and then press the Singl Axis

button. This can be used to establish the initial axis zero position.

HOME G28 - Returns all axes to machine zero in rapid motion. Home G28 will also home a single axis in the

same manner if you enter an axis letter and press the home G28 button. CAUTION! There is no warning

message to alert the operator of any possible collision. For example, if the Z-axis is down in amongst parts on

the table when X or Y is zeroed, a crash can result.

List Prog (List Programs) - Displays the programs stored in the control.

Select Prog - Makes the highlighted program, in the program list, the current program. Note: The current

program will have an “*” preceding it in the program list.

Send - Transmits programs out the RS-232 serial port. (See RS-232 section)

Recv - Receives programs from the RS-232 serial port. (See RS-232 section)

Erase Prog - Erases the highlighted program in Memory mode or the entire program when in MDI mode.

NUMERIC K EYS

The numeric keys give the user the ability to enter numbers and a few special characters into the control.

Cancel - The Cancel key is used to delete the last character entered.

Space - Used to format comments placed into programs or in the message area.

Write / Enter - General purpose enter key .

- (Minus sign)- Used to enter negative numbers.

. (Decimal Point)- Used for decimal precision.

POSITION D ISPLAYS

The following are the position displays.

Home Page

This display shows the four displays (Operator, W ork, Machine and Distance-to-go) simultaneously . Use the

Page Up/Down keys or the UP/Down Arrows to scroll through these p ages.

Operator Display

This display is used to show the distance the operator has jogged any of the axes. This does not represent the

actual distance the axis is from machine zero. Axes can be zeroed by selecting an axis (X, Y or Z) and

pressing the Origin key .

96-8000 rev R June 2007

Introduction

17

Page 25

Work Display

This displays the position of X, Y and Z in relation to the part; not machine zero. On power-up, it will display the

value in work offset G54 automatically . The position can only be changed by entering values in work of fsets

G54 through G59, G1 10 through G129, or by commanding a G92 in a program.

Machine Display

This display is the actual axes position away from machine zero.

Distance T o Go

This display shows the distance remaining before the axes reaches its commanded position.

OFFSETS D ISPLAY

There are two offsets pages. The first offset page is the Tool Geometry/Wear page. The second is the Work

Zero offset page.

Tool Geometry/Wear

The Tool/Geometry page is displayed by pressing the Offset button. This page displays tool numbers, tool

length geometry and wear values, tool radius geometry and wear values, flutes values and actual diameter

values. If the mill has the optional programmable coolant unit, this page will also display the coolant position

entered for each tool. To enter values into these fields key in a number and press F1. Keying in a number and

pressing F2 will set the negative of the entered value into the offsets. Entering a value and pressing Write/Enter

will add the value to what is currently entered. To clear all the values on the page press Origin, the mill will

prompt the operator with "Zero All (Y/N) press Y to zero all or press N to leave all the values unchanged.

Work Zero Offset

The Work Zero Offset page is displayed by pressing the Offset button twice. This page displays the values

entered so that each tool knows where the part is located on the table. A value can be set for each axis (X,Y

and Z). The operator can scroll to each column by using the arrow key or by pressing the Page Up or Down

buttons to access the other offsets in the Work Zero section. In order for each tool to locate the part, the tools

used in a program must be "T ouched of f" the part. A value can be entered by typing in a number and pressing

F1, or the value added to an existing value by pressing Enter/Write. Keying in a number and pressing F2 will

set the negative of the entered value into the offsets. To clear all the values on the page press Origin, the mill

will prompt the operator with "Zero All (Y/N) press Y to zero all or press N to leave all the values unchanged.

CURRENT C OMMANDS D ISPLAY

The following are several Current Command pages in the control. Press the Current Commands button and use

the Page Up/Down buttons to navigate through the pages.

Program Command Check Display This display shows a current overview of the important commands. It

shows the programmed spindle speed (PGM), the commanded spindle speed commanded by the program

(CMD), and the actual spindle speed (ACT). In addition, this display shows the CW, CCW , or stopped command being sent to the spindle and the current transmission gear (if equipped) position.

This display also shows the position of the axes. There are four coordinates displayed (operator , work, machine, or distance to go) and are selected using the cursor Up/Down or Page Up/Down keys.

If the machine has the optional Programmable Coolant (P-Cool), the current spigot position will be displayed as

well.

Current Display Command This display shows the current program codes and their current value. These

values may not be changed in this display.

Macro Variables Display This display shows a list of the macro variables and their present values. As the

control runs the program, the variables will be updated. In addition the variables may be modified in this display;

refer to the “Macros” section for more information.

18

Introduction

96-8000 rev R June 2007

Page 26

Operation Timers Display This display shows the current power-on time, cycle start time (the amount of total

time the machine has been running a program), and the feed time (total amount of time the machine has been

feeding). These times may be reset to zero by using the cursor up and down keys to highlight the desired title

and pressing the ORIGIN button.

Listed below these times are two M30 counters, these counters are used for counting completed parts. They

may be set to zero independently to provide for the number of parts per shift and total parts.

T ool Life display This display shows the time the tool is used in a feed (Feed-Time), the time the tool is in the

spindle (T ot al-Time), and the number of times the tool has been selected (Usage). This information is used to

assist in predicting tool life. The values in this display can be reset to zero by highlighting the value and

pressing the Origin button. Note: The maximum value is 32767, once this value is reached, the control will start

back at zero.

This display may also be used to generate an alarm when a tool has been used a specific number of times.

The last column is labeled “Alarm,” entering a number in that column will cause the machine to generate an

alarm (#362 T ool Usage Alarm) when that count is reached.

T ool Load Monitor and Display The operator can enter the maximum amount of tool load, in %, that is

expected for each tool. The operator can select the appropriate action to be taken when this load is exceeded.

This display provides for the entry of this alarm point and also displays the largest load that tool has seen in a

previous feed.

NOTE: Surface Feet per Minute (SFM) and Chip Load are displayed on the Current Commands page. SFM is

displayed as fpm (feet per minute) or mpm (meters per minute).

The tool load monitor function operates whenever the machine is in a feed operation (G01, G02, or G03). If the

limit is exceeded the action specified in Setting 84 will occur (See settings section for a description).

Axis Load Monitor Axis load is 100% to represent the maximum continuous load. Up to 250% can be shown,

however an axis load above 100%, for an extended period of time, can lead to an overload alarm.

Maintenance This page allows the operator to activate and deactivate a series of checks (see Maintenance

section).

ALARMS / MESSAGES D ISPLAY

Alarms

The Alarms display is selected by pressing the ALARM / MESGS button. There are three types of Alarms

screens. The first shows any current alarms. Pressing the Right Arrow key switches to the Alarm History

screen, which shows the previously received alarms. Pressing Right Arrow again switches to the alarm viewer

screen. This screen shows one alarm at a time with its description. The user can then scroll through all the

alarms by pressing the Up and Down Arrow keys. Also, the user can enter an alarm number and press W rite/

Enter and the name and description will be displayed. Pressing Page Down will display a page for user messages and notes.

Note: The Cursor and Page Up and Page Down buttons can be used to move through a large number of alarms.

Messages

The Message Display can be selected by pressing the Alarm/Mesgs button twice. This is an operator message

display and has no other effect on operation of the control. Use the keypad to enter the messages. The cancel

and space buttons can be used to remove existing messages and the Delete button can be used to remove an

entire line. Data is automatically stored and maintained even in a power-off state. The message display page

will come up during power-up if there are no alarms present.

96-8000 rev R June 2007

Introduction

19

Page 27

SETTING / GRAPHIC D ISPLAY F UNCTION

The Settings are selected by pressing the Setng/Graph button. There are some special functions in the

settings which change the way the mill behaves; refer to the “Settings” section for a more detailed description.

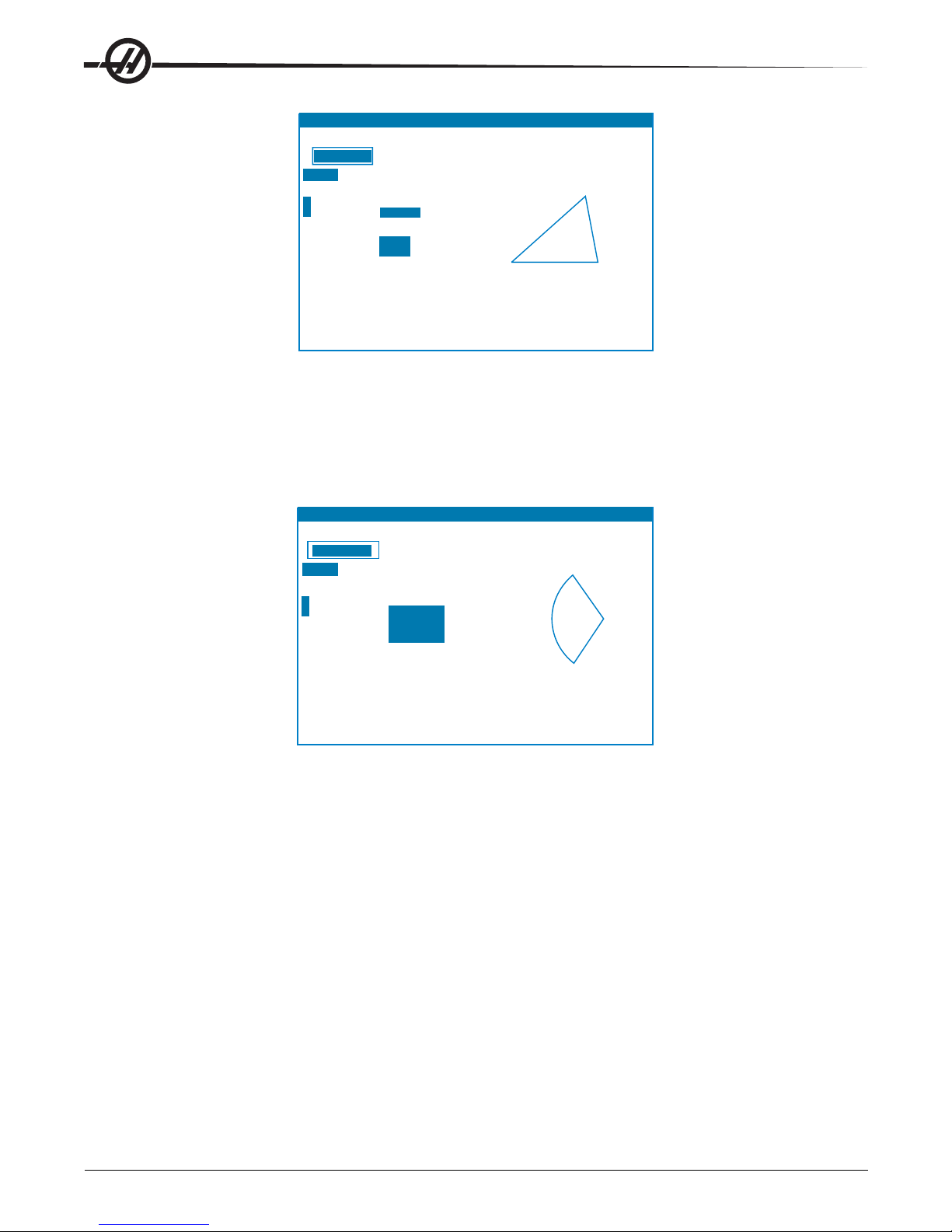

The Graphics function is selected by pressing the Setng/Graph button twice. Graphics is a visual dry run of

your part program without the need to move the axes and risk tool or part damage from programming errors.

This function may be considered more useful than the Dry Run mode, because all of your work offsets, tool

offsets, and travel limits can be checked before running the machine. The risk of a crash during setup is greatly

reduced.

Graphics Mode Operation

T o run a program in Graphics, a program must be loaded and the control must be in either MEM or MDI mode.

Press the Setng/Graph key twice to select the Graphics Mode.

The Graphics display has a number of features within it.

Key Help Area The right side of the top line is the function key help area. Function keys that are currently

available are displayed here with a brief description of their usage.

Locator Window The lower right part of the screen has two modes. It can display the whole table area and

indicate where the tool is currently located during simulation. Or it can be used to display four lines of the

program that is being executed. The F4 key is used to toggle between these two modes.

T ool Path Window In the center of the display is a large window that represent s a top view of the X and Y

axes. It displays tool paths during a graphics simulation of the program. Rapid moves are displayed as dotted

lines, while feed motion is displayed as fine continuous lines. (Note: Setting 4 can disable the rapid path.) The

places where a drilling canned cycle is used are marked with an X. Note: Setting 5 can disable the drill mark.

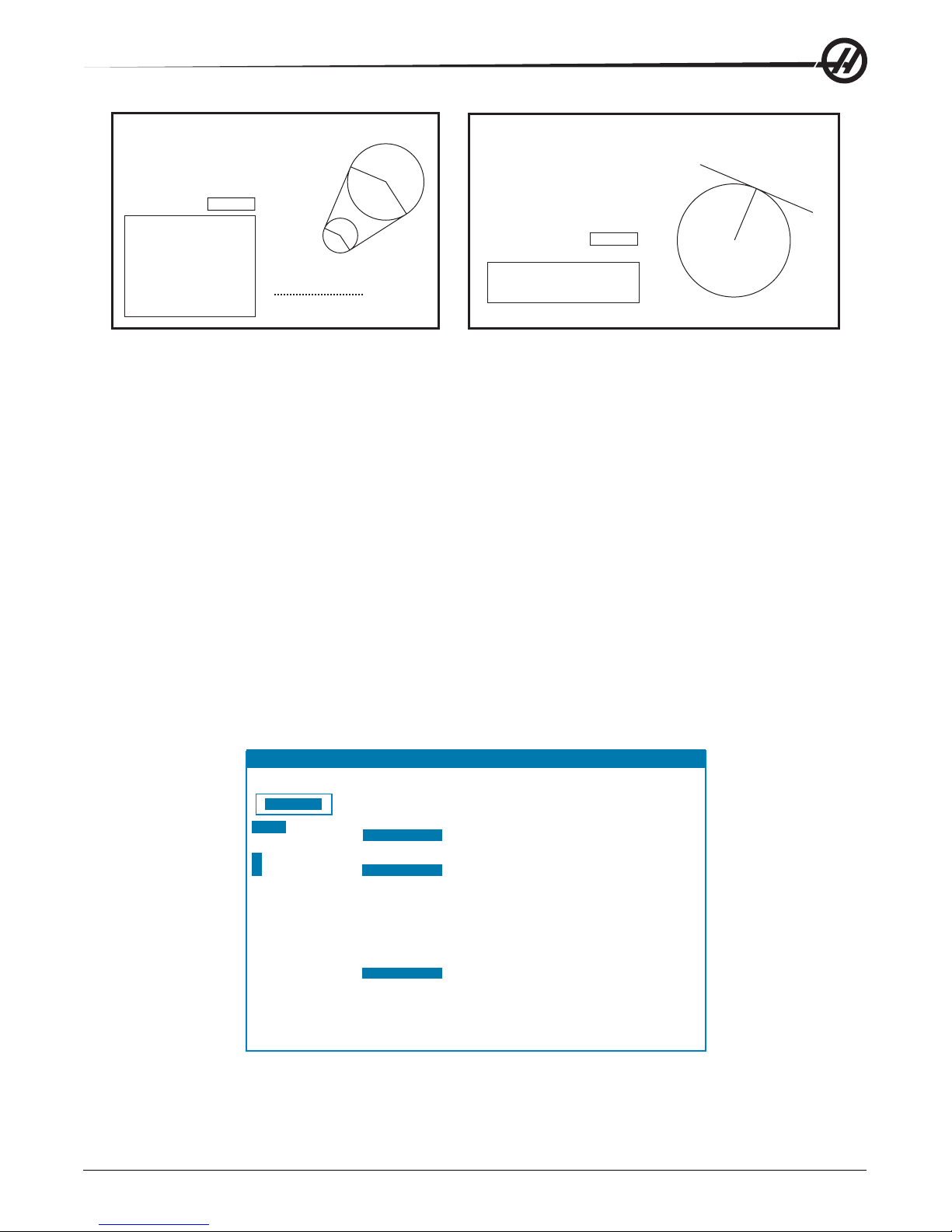

Scaling the Tool Path W indow The tool p ath window can be scaled. After running a program, pressing F2

will scale the tool path. Use the Page Down key and the arrow keys to select the portion of the tool path to be

magnified. Pressing F2 will display a rectangle (zoom window) indicating the magnified area. Note: The Help

area will flash, indicating the view rescaling process. The locator window (small view at the bottom right) shows

the entire table with an outline of where the Tool Path window is zoomed. The Page Up key reduces the zoom

(unzooms) the rectangle one step. After sizing and/or moving the zoom window , pressing the Write/Enter key

will complete the zoom process and re-scale the Tool Path window . After the Tool Path window is re-scaled, the

T ool Path window is cleared and the program must be re-run to see the tool p ath.

The scale and position of the Tool Path window is saved in Settings 65 through 68. Leaving graphics to edit the

program and then returning to Graphics will keep the previous scaling in effect.

Pressing F2 and then the Home key will expand the Tool Path window to cover the entire table.

Z Axis Part Zero Line This feature consists of a horizontal line displayed on the Z-axis bar at the top-right

corner of the graphics screen to indicate the position of the current Z-axis work offset plus the length of the

current tool. While a program is running, the shaded portion of the bar indicates the depth of Z-axis motion. The

user is able to watch the position of the tool tip relative to the Z-axis part zero position as the program runs.

Control Status The lower left portion of the screen displays control status. It is the same as the last four lines

of all other displays.

Position Window The location of all enabled axes can be viewed in this window. Press F3 to open this