Page 1

Haas Technical Publications

Manual_Archive_Cover_Page Rev A

any other party automatically voids the factory warranty.

June 6, 2013

HAAS SERVICE AND OPERATOR MANUAL ARCHIVE

Electrical Service Manual 96-0284E RevE English June 2008

• This content is for illustrative purposes.

• Historic machine Service Manuals are posted here to provide information for Haas machine owners.

• Publications are intended for use only with machines built at the time of original publication.

• As machine designs change the content of these publications can become obsolete.

• You should not do mechanical or electrical machine repairs or service procedures unless you are qualied

and knowledgeable about the processes.

• Only authorized personnel with the proper training and certication should do many repair procedures.

WARNING: Some mechanical and electrical service procedures can be

extremely dangerous or life-threatening.

Know your skill level and abilities.

All information herein is provided as a courtesy for Haas machine owners

for reference and illustrative purposes only. Haas Automation cannot be held

responsible for repairs you perform. Only those services and repairs that are

provided by authorized Haas Factory Outlet distributors are guaranteed.

Only an authorized Haas Factory Outlet distributor should service or repair a

Haas machine that is protected by the original factory warranty. Servicing by

Page 2

SAFETY

RED

WHT

40

BLK

ON

OFF

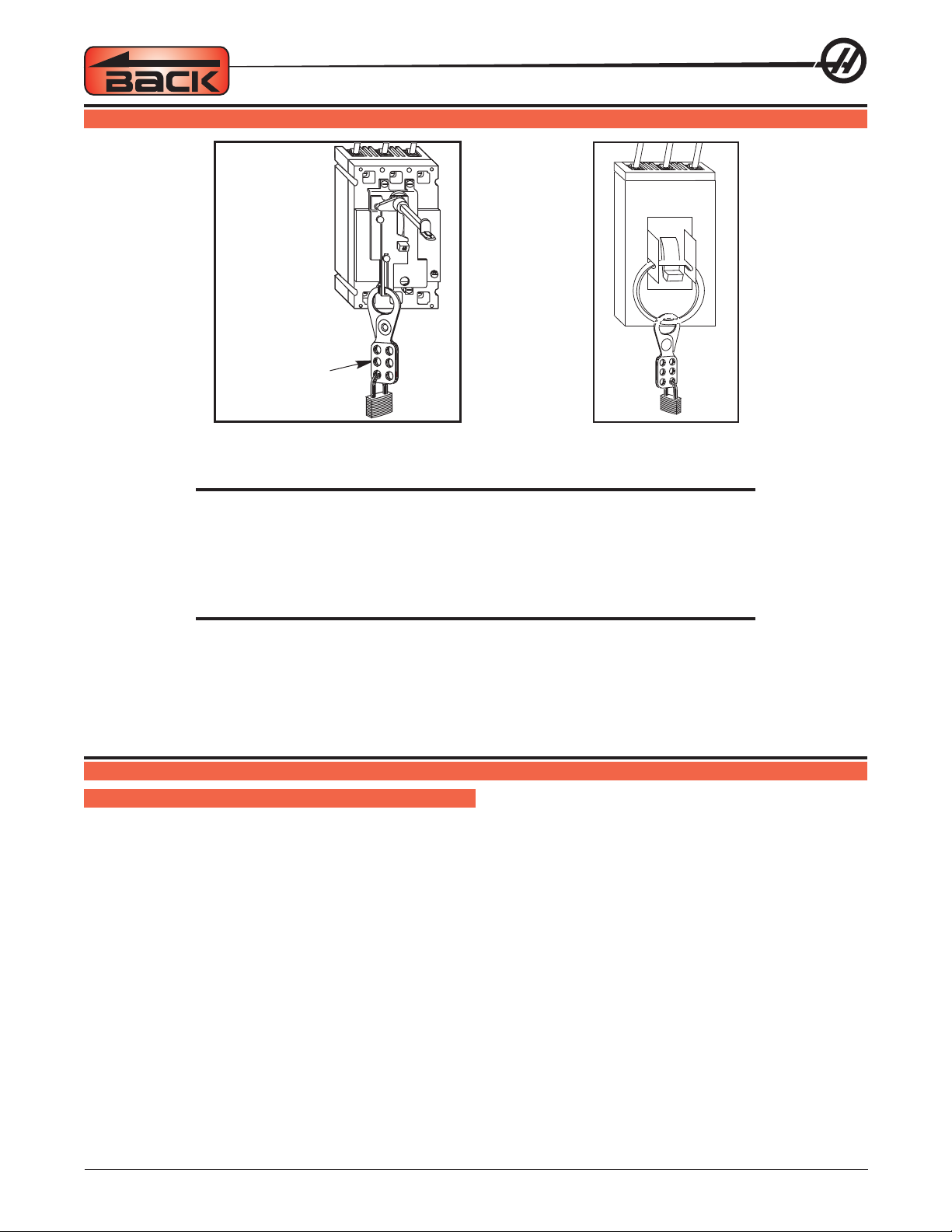

Install lock-out clasp

and lock with padlock

to secure Circuit

Breaker in the

OFF position.

To avoid possible shock, make sure circuit breakers are appropriately locked off before attempting any electrical work.

CAUTION! Working with the electrical services required for the machine can be extremely

hazardous. The electrical power must be off and steps must be taken to ensure

that it will not be turned on while you are working with it. In most cases this means

turning off a circuit breaker in a panel and then locking the panel door. However ,

if your connection is different or you are not sure how to do this, check with the

appropriate personnel in your organization or otherwise obtain the necessary

help before you continue.

WARNING!

The electrical panel should be closed and the three screws/latches on the

door should be secured at all times except during installation and service. At

those times, only qualifi ed electricians should have access to the panel. When

the main circuit breaker is on, there is high voltage throughout the electrical

panel (including the circuit boards and logic circuits) and some components

operate at high temperatures. Therefore extreme caution is required.

GENERAL ELECTRICAL TROUBLESHOOTING

MACHINE NOT RUNNING

Machine cannot be powered on.

• Check input voltage to machine.

• Check main circuit breaker at top right of electrical cabinet; switch must be at the on position.

• Check overvoltage fuses.

• Check wiring to Power Off button on front control panel.

• Check wiring to Auto Off relay to I/O PCB.

• Check connection between 24V transformer (T5) and K1 contactor.

• Check 24V transformer (T5) bracket has jumper in correct position (measure voltage at main circuit breaker

and connect jumper to corresponding connector on T5 transformer bracket).

• Check I/O PCB.

• Check Power PCB.

96-0284 rev E June 2008

Electrical Service

1

Page 3

Machine can be powered on, but turns off by itself.

• Check Settings #1 and #2 for Auto Off Timer or Off at M30.

• Check alarm history for Overvoltage or Overheat shutdown.

• Check AC power supply lines for intermittent supply.

• Check low voltage power supply for intermittent supply.

• Check wiring to Power Off button on front control panel.

• Check connection between 24V transformer and K1 contactor.

• Check I/O PCB.

• Check Parameter 57 for Power off at E-Stop.

• Check MOTIF or MOCON PCB.

Machine turns on, keyboard beeps, but no LCD/CRT display.

• Check for power connections to LCD/CRT from I/O PCB (LVPS power from Power PCB for 15” monitor).

Check for green Power LED at front of a CRT.

• Close doors and zero return machine (possible bad monitor).

• Check video cable from Video PCB to LCD/CRT.

• Check for lights on the processor.

• Replace LCD/CRT.

Machine turns on, LCD works, but keyboard keys do not work.

• Check keyboard cable (700) from Video to SKBIF PCB.

• Check keypad.

• Check SKBIF PCB.

Constant E-Stop Condition (will not reset) (Vertical Machines).

• Check hydraulic counterbalance pressure, low pressure switches, and cabling.

Quad APC trouble shooting

The Quad APC uses an additional PC board to control pallets 3 and 4.

The pallet chain motor receives 160VDC from plug 6A on this board (32-3078A). The PC board receives

power (115V) from the power card, which plugs into P4 on the APC board.

The solenoid for the left, air operated, automatic door plugs into P3; this cable is part of 33-6038A. Pallet 3

and 4 signals are sent through cable 33-1516, which plugs into P1. The cable’s other end plugs into the I/O

board P62.

LECTRICAL ALARM TROUBLESHOOTING

E

Axis Drive Fault Alarm

• Blown amplifi er - indicated by light at bottom of amplifi er when power is on. Replace the fuse in the amplifi er.

• Amplifi er or MOCON is noise sensitive. If this is the case, the alarm can be cleared and the axis will run

normally for a while.

To check an amplifi er, switch the motor leads and control cables between the amplifi er and the one next to

it. If the same problem occurs with the other axis, the amplifi er must be replaced. If the problem stays on the

same axis, either the MOCON or control cable. The problem could also be the axis motor itself, with leads

either shorted to each other or to ground.

2

Electrical Service

96-0284 rev E June 2008

Page 4

• Amplifi er faulting out for valid reason, such as overtemp, overvoltage, or +/-12V undervoltage condition. This

usually results from running a servo intensive program, or unadjusted 12V power supply. Adjust voltage to

correct specifi cations or replace the power supply.

Overvoltage could occur if regen load is not coming on, but this does not usually happen. The problem could

also be the axis motor itself, with leads either shorted to each other or to ground.

Axis Overload

• The fuse function built into the MOCON has been overloaded. This may be caused by a lot of motor accel/

decels, or hitting a hard stop with the axis. This safety function protects the amplifi er and motor. If the current

program is the cause, change the program. If the axis hits a hard stop the travel limits may be set wrong.

Phasing Error

• The MOCON did not receive the proper phasing information from the motors. Do not reset the machine if

this alarm occurs. Power the machine down and back up. If the problem persists, it is probably a broken wire

or faulty MOCON connectors. This problem could also be related to the Low Voltage Power Supply. Check to

see if the LVPS is functioning properly.

Servo Error Too Large

• This alarms occurs when the difference between the commanded axis position and the actual position becomes larger than the maximum that is set in the parameter.

This condition occurs when the amplifi er is blown, is not receiving the commands, or the 320V power source

is dead. If the MOCON is not sending the correct commands to the amplifi er, it is probably due to a broken

wire, or a Phasing Error that was generated.

Axis Z Fault or Z Channel Missing

• During a self-test, the number of encoder counts was found to be incorrect. This is usually caused by a noisy

environment, and not a bad encoder. Check all shields and grounds on the encoder cables and the motor

leads that come into the amplifi ers. An alarm for one axis can be caused by a bad grounding on the motor

leads of another axis.

Axis Cable Fault

• During a self-test, the encoder cable signals were found to be invalid. This alarm is usually caused by a bad

cable, or a bad connection on the motor encoder connectors. Check the cable for any breaks, and the encoder connectors at the motor controller board. Machine noise can cause this alarm, although it is less common.

Alarm 101, “MOCON Comm. Failure”

• During a self-test of communications between the MOCON and main processor, the main processor does

not respond, and is suspected to be dead. This alarm is generated and the servos are stopped. Check all ribbon cable connections, and all grounding. Machine noise can also cause this alarm, although it is less common.

Alarm 157, MOCON Watchdog Fault

• The self-test of the MOCON has failed. Replace the MOCON.

Alarm 212, Program Integrity Error/Alarm 250, Program Data Error

• If a program has been corrupted in the system or a corrupted program has been loaded into the machine,

a Program Data Error (250) or Program Integrity Error (212) might occur. This occurrence can be recognized

by an exclamation point (!) next to a program when turning to the list program page. Following is the common

procedure to perform when this happens.

1. Save all programs to disk except the program with the exclamation point error signal. The exclamation

point (!) indicates the program that is corrupt. This will be your back-up disk to reload the programs into the

machine.

2. Delete all the programs. This should delete all the programs including the one with the “!” error signal.

3. If the program with the exclamation point (!) does not erase then the control needs to be initialized.

96-0284 rev E June 2008

Electrical Service

3

Page 5

4. If the machine still has the program with the exclamation point or the control now refuses to load a good

program, it may be necessary to clear memory and reload software.

5. If problem persists, replace main processor board.

Alarm 261, Rotary CRC Error (Horiz & Vert)

• This alarm is normally the result of an incomplete software installation. To correct this error, Change Setting 30 to any selection but Off (note the original selection), then go to Parameter 43 and change one of the

bits from 1 to 0 or vice versa and press Write (the bit must be changed from its original value to its alternate

value). Simply changing the Setting and Parameter bit from one value to another and then back again corrects the fault, and will clear any further occurrences of the alarm. Change the bit and Setting 30 back to their

original values. Press Reset to clear the alarms or cycle power to the machine.

Alarm 354, Aux Axis Disconnected (Lathe)

When this alarm is generated, do not press Reset. Turn Setting 7 Off. Enter Debug mode, then view the

Alarms/Messages page. On the Messages page, a code will appear similar to WO1. The list of codes and

their descriptions follows :

WO1 Power was just turned on or failed. Check the ribbon cables from the Aux Axis PCB to the proces-

sor for correct routing. Check for communication problems between the processor and the Aux

Axis PCB.

WO2 Servo following error too large. Check the encoder for contamination or dirt. Check for an intermit-

tent connection at both ends of the motor cable.

WO3 Emergency Stop. The E-STOP button was pressed, or an E-STOP condition occurred.

WO4 High load. Check for binding in the tool changer gearbox and motor. Rotate the carousel by hand

and feel for any binding. Make sure the toolholders are the correct weight.

WO5 Remote RS-232 commanded off. Check the ribbon cable and the voltage to the Aux Axis PCB.

Check for 115V AC (minimum) to the Aux Axis PCB from the main transformer. Check the fuse

holder and the fuse that is protecting this circuit.

WO6 Air or limit switch or motor overheat. Check that the motor is not hot. Check for any binding in the

motor. Check for overweight tooling.

WO7 Z channel fault. Either the encoder or the cable is bad. Change the encoder fi rst, as it is easier to

change than the cable. If the problem persists, change the cable.

WO8 Over-current limit, stalled or PCB fault. Check for binding in the tool changer gearbox. Make sure

the belt is not too tight. Ohm out the motor cable, checking pins G to F (should be open), G to H

(should be open), and F to H (should read between 2.5 and 5 ohms). Check all the connections

on the Aux Axis PCB and motor cable.

WO9 Encode ES. Z channel is missing. Bad encoder or cable. See WO7.

WOA High voltage. Check the incoming voltage to the Aux Axis PCB. Incoming voltage must be 115V

AC. See WO5.

WOB Cable fault. Check the cable from the motor to the Aux Axis PCB. Check for loose connections at

each end.

4

Electrical Service

96-0284 rev E June 2008

Page 6

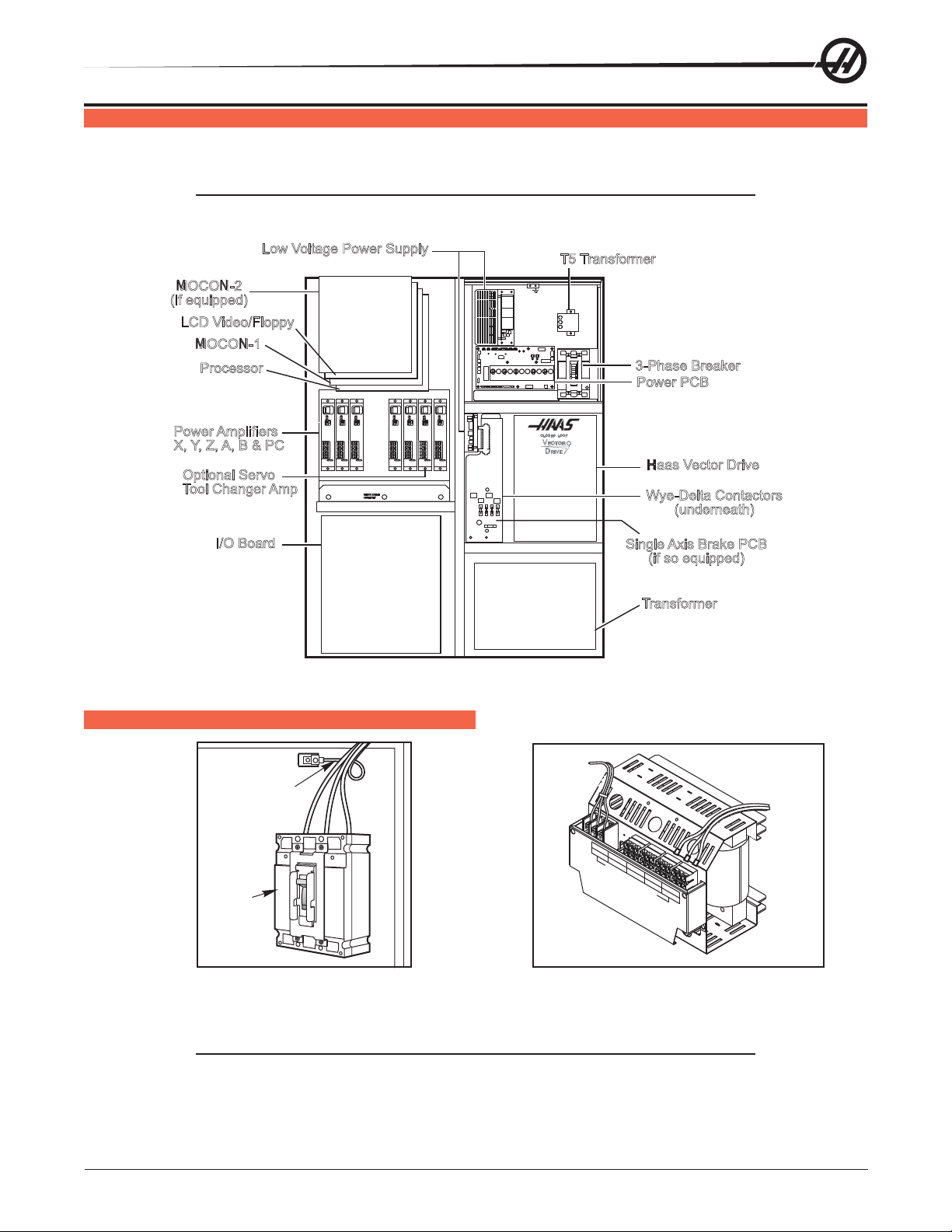

LINE VOLTAGE ADJUSTMENTS

Please read this section in its entirety before attempting to adjust the line voltage.

Tools Required: Large fl at tip screwdriver, Digital voltmeter

NOTE: The machine must have air pressure at the air gauge, or a “Low Air Pressure” alarm

will be present on power up.

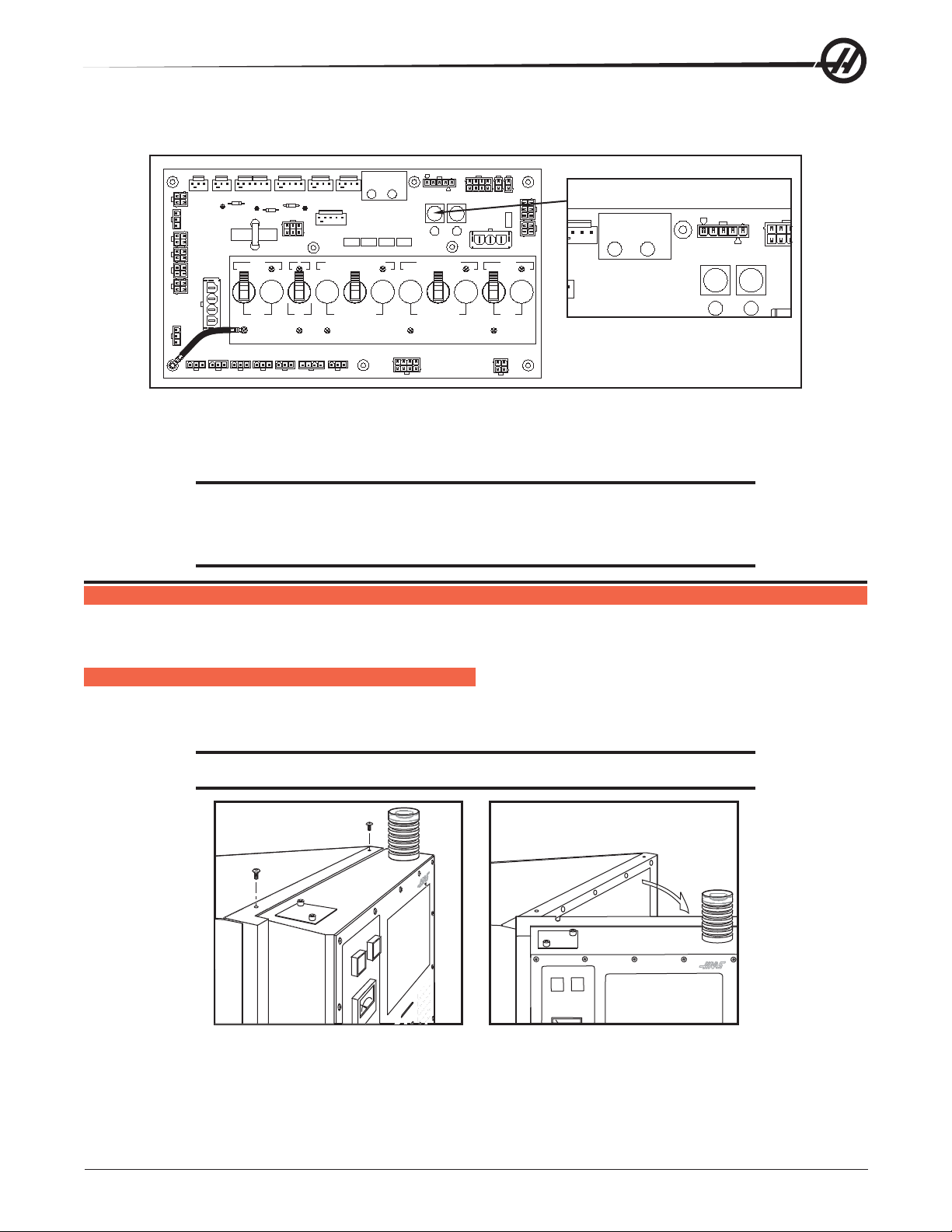

Low Voltage Power Supply

T5 Transformer

MOCON-2

(if equipped)

LCD Video/Floppy

MOCON-1

Processor

3-Phase Breaker

Power PCB

Power Amplifiers

X, Y, Z, A, B & PC

Optional Servo

Tool Changer Amp

SERVODRIVE

ASSEMBLY

Haas Vector Drive

Wye-Delta Contactors

(underneath)

I/O Board

Single Axis Brake PCB

(if so equipped)

Transformer

Control Cabinet General Overview

ELECTRICAL CONNECTIONS

Ouput

Power

Ground Line

Main

Circuit

Breaker

L1 L2

L3

TB2

240VOUT

D

A

488-458V

N

G

E

R

!

120VOUT

457-429V

260-244V

INCOMINGLINE VOLTAGETAPS (74,75, 76)

428-403V

243-227V

!

!

H

I

G

H

V

O

L

TB1

T

A

402-377V

226-211V

376-354V

210-195V

G

E

D

A

N

G

E

R

!

!

!

Input

Power

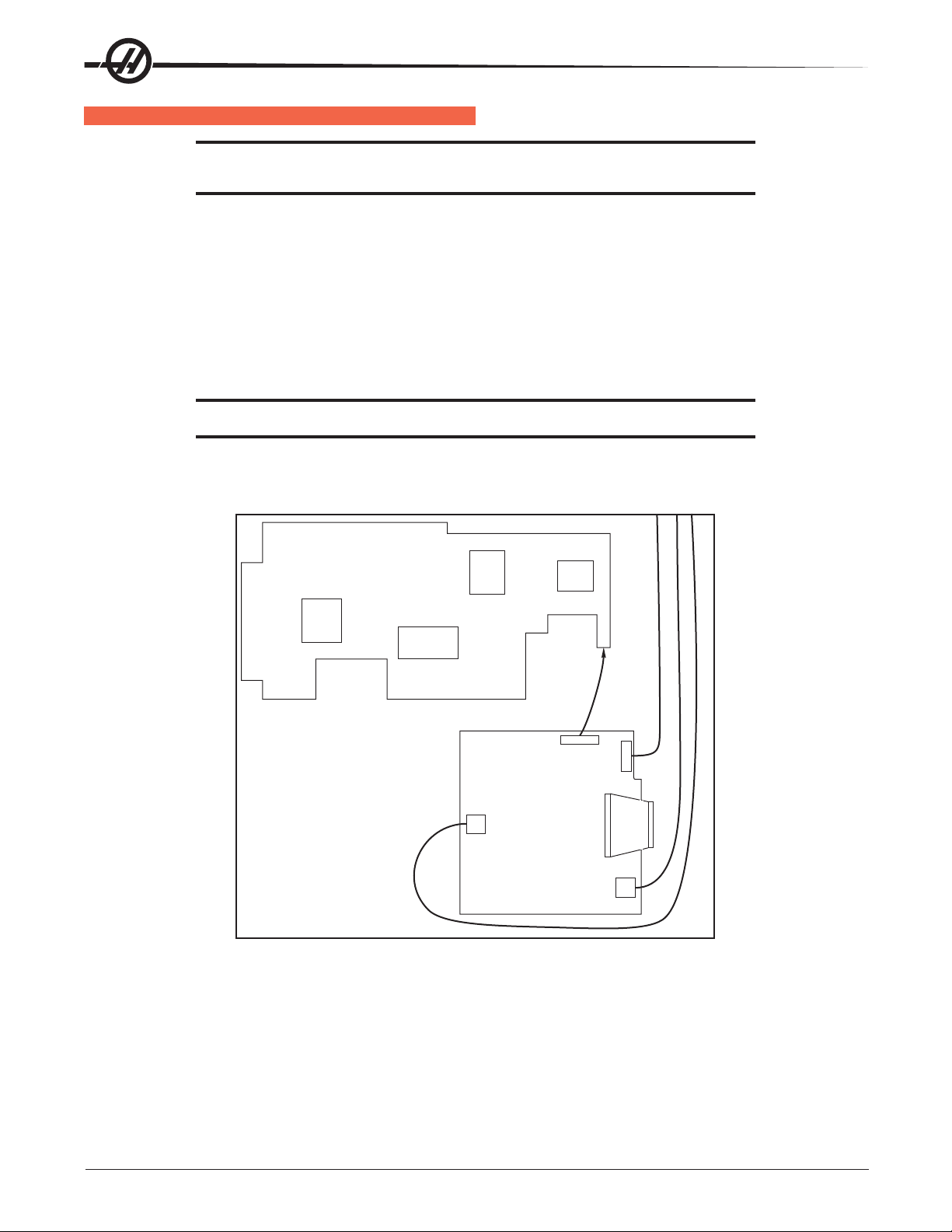

1. Place the main circuit breaker in the Off position and hook up the three power lines to the terminals on top

of the main circuit breaker at the upper right-hand side of the electrical panel. Connect the separate ground

line to the ground bus to the left of the terminals.

NOTE: Ensure service wires go into terminal-block clamps. (Do not miss clamp and tighten

screw. Connection looks fi ne but machine runs poorly - servo overloads.) To check,

pull on wires after screws are tightened.

96-0284 rev E June 2008

Electrical Service

5

Page 7

2. After the line voltage is connected to the machine, make sure that main circuit breaker is off. Turn on the

power at the source. Using an accurate digital voltmeter and appropriate safety procedures, measure the voltage between all three pair phases at the main circuit breaker and write down the readings. The voltage must

be between 195 and 260V (360 and 480V for high voltage option).

NOTE: Wide voltage fl uctuations are common in many industrial areas; you need to know

the minimum and maximum voltage which will be supplied to the machine while it is

in operation. U.S. National Electrical Code specifi es that machines should operate

with a variation of +5% to -5% around an average supply voltage. If problems with

the line voltage occur, or low line voltage is suspected, an external transformer may

be required. If you suspect voltage problems, the voltage should be checked every

hour or two during a typical day to make sure that it does not fl uctuate more than

+5% or -5% from an average.

CAUTION! Make sure the main circuit breaker is set to off and the power is off at the supply

panel before changing the transformer connections. Make sure that all three

black wires are moved to the correct terminal block and are tight.

3. Check the connections on the transformer at the bottom-right corner of the rear cabinet. The three black

wires labeled 74, 75, and 76 must be moved to the terminal block triple which corresponds to the average

voltage measured in step 2 above. There are four positions for the input power for the 260V transformer and

fi ve positions for the 480V transformer. The labels showing the input voltage range for each terminal position

are as shown in the previous illustration.

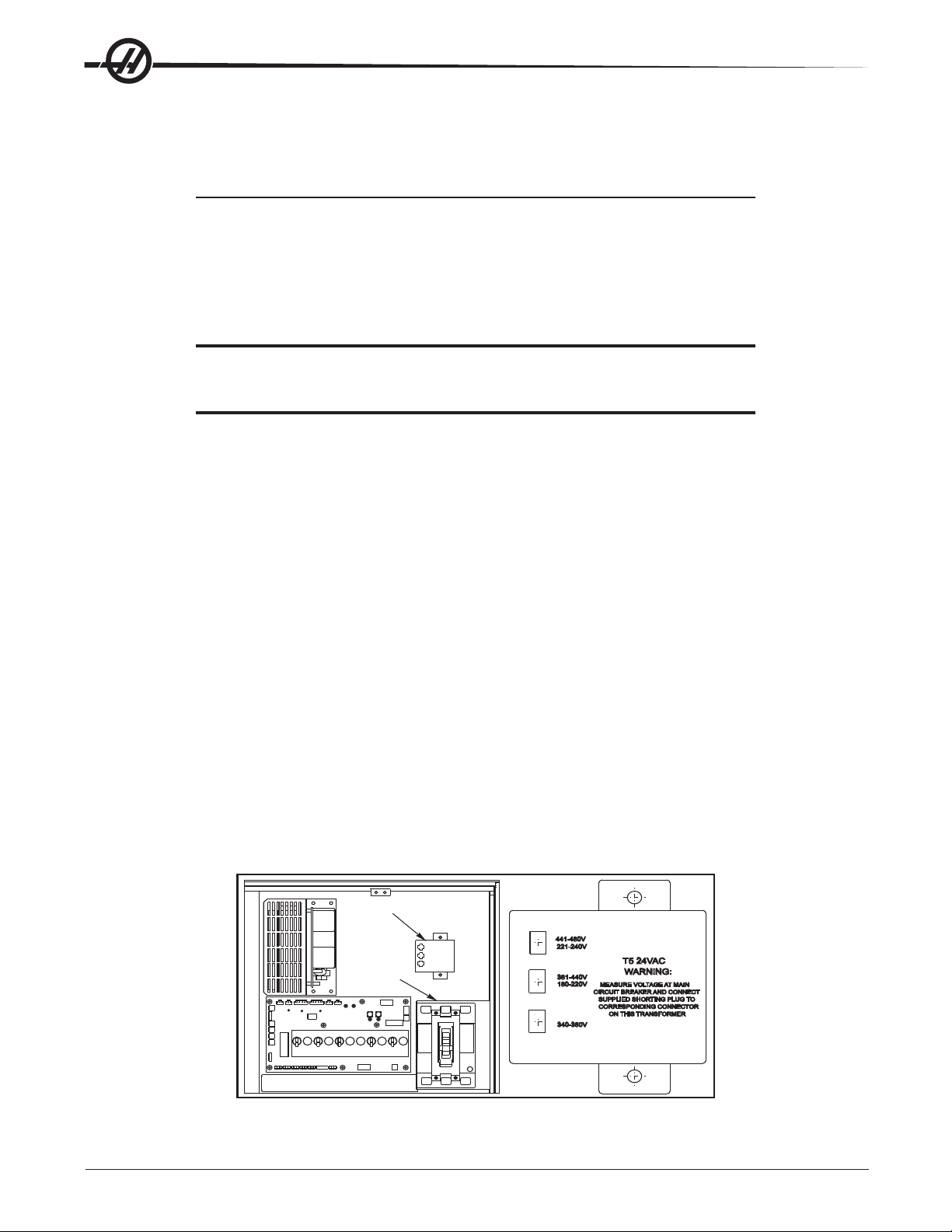

4. Transformer T5 supplies 24VAC used to power the main contactor. There are two versions of this transformer for use on 240 and 400V machines (32-0964B and 32-0965B, respectively). The 240V transformer has

two input connectors located on the transformer bracket, which allow it to be connected to either a 221-240V

range or 180 to 220V range. Users that have 180-240V input power should place the jumper on the appropriate connector.

The 400V transformer has three input connectors located on the transformer bracket, which allow it to be connected to either a 441-480V range, 381-440V range or 340-380V range. Users with the External High Voltage

Option should place the jumper on the connector marked with the appropriate input voltage. Failure to place

the jumper on the correct input connector will result in either overheating of the main contactor or failure to

reliably engage the main contactor.

A jumper must also be placed on the plate covering the T5 transformer, Measure the voltage at the main

circuit breaker and connect the supplied shorting plug to the corresponding connector on the T5 transformer

plate.

5. Set the main circuit breaker to ON and check for evidence of problems, such as the smell of overheating

components or smoke. If such problems are indicated, immediately set the main circuit breaker to OFF and

call the factory before proceeding.

T5 Transformer

441-480V

Main

Circuit

Breaker

6

Electrical Service

221-240V

381-440V

180-220V

MEASURE VOLTAGEAT MAIN

CIRCUIT BREAKER AND CONNECT

SUPPLIED SHORTING PLUG TO

CORRESPONDING CONNECTOR

340-380V

ON THIS TRANSFORMER

T5 24VAC

WARNING:

96-0284 rev E June 2008

Page 8

Through the Spindle Coolant (TSC) pump is a three phase pump and must

be phased correctly! Improper phasing will cause damage to the TSC pump

and void the warranty. Refer to the TSC start up section if your machine is

equipped with TSC.

6. After the power is on, measure the voltage across the bottom terminals on the main circuit breaker. It

should be the same as the measurements where the input power connects to the main circuit breaker. If there

are any problems, check the wiring.

7. Apply power to the control by pressing the Power On switch on the front panel. Check the high voltage

buss on the Vector Drive (pin 2 with respect to pin 3 on the terminal bus at the bottom of the drive). It must be

between 310 and 360V. If the voltage is outside these limits, turn off the power and recheck steps 2 and 3.

If the voltage is still outside these limits, call the factory. Next, check the DC voltage displayed in the second

page of the Diagnostic data on the display screen. It is labeled DC BUS. Verify that the displayed voltage

matches the voltage measured at pins 2 and 3 of the Vector Drive +/- 7V DC.

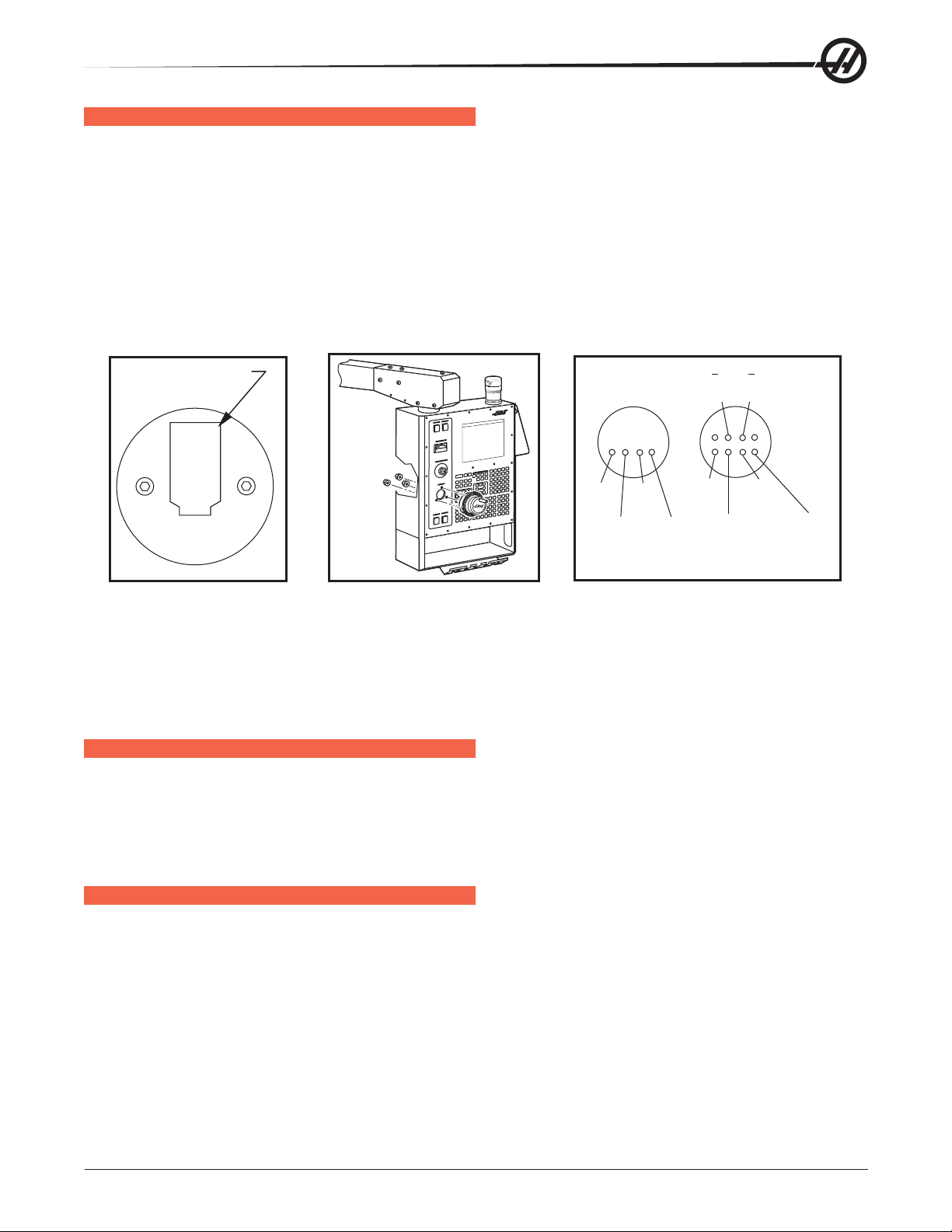

8. Electrical power must be phased properly to avoid damage to your equipment. The Power Supply Assembly PC board incorporates a “Phase Detect” circuit with neon indicators, shown below (disregard for single

phase machines). When the orange neon is lit (NE5), the phasing is incorrect. If the green neon is lit (NE6),

the phasing is correct. If both neon indicators are lit, you have a loose wire. Adjust phasing by placing the

main circuit breaker in the Off position and swapping L1 and L2 of the incoming power lines at the main circuit

breaker.

PHASE DETECT

(FOR 3 PHASE ONLY)

PASS FAIL

WARNING!

NE5NE6

WARNING!

All power must be turned off at the source prior to adjusting phasing.

9. Close the door, lock the latches, and turn the power back on.

10. Remove the key from the control cabinet and give it to the shop manager.

96-0284 rev E June 2008

Electrical Service

7

Page 9

FUSE REPLACEMENT

Please read this section in its entirety before attempting to replace any fuses.

Some of the brushless amplifi ers have one 15 amp fuse, F1. If this fuse blows, the associated motor will stop;

a light on the amplifi er will tell of a blown fuse. Use the Amplifi er Fuse Kit (Haas P/N 93-1089) to replace the

fuse. If the fuse blows again, the amplifi er may be damaged, and needs to be replaced.

The Power PCB contains three ½-amp fuses located at the top right (FU1, FU2, FU3). If the machine is subject to a severe overvoltage or a lightning strike, these fuses will blow and turn off all power. Replace these

fuses only with the same type and ratings. FU 4, 5, and 5A protect the chip conveyor (FU6 is only used with 3

phase motors).

Size Fuse Name Type Rating (amps) Voltage Location

5mm FU1-FU3 Slo-Blo ½ 250V PSUP pcb, upper right

1/4 F1 Ultra fast 15 250V Amplifi er (X, Y, Z, A, B)

5mm FU4, 5 Fast blow 5A 250V PSUP, bottom right corner

15” and Thin Pendant Machines

Size Fuse Name Type Rating (amps) Voltage Location

5x20mm F1/F3 Fast Acting 1 250V PSUP pcb, upper right

OVERVOLTAGE FUSES

The electrical panel will have residual voltage, even after power has been

shut off and/or disconnected . Never work inside this cabinet until the small

green Power On light on the servo amplifi ers (servo drive assembly on brush

machines) goes out. The servo amplifi ers/servo drive assembly is on the left

side of the main control cabinet and about halfway down. This light(s) is at the

top of the circuit card at the center of the assembly. Until this light goes out,

there are dangerous voltages in the assembly even when power is shut off.

1. Turn machine power off.

2. Place the main circuit breaker (upper right of electrical cabinet) in the off position.

WARNING!

Main

Switch

3. Open the cabinet door and wait until the red charge light on the servo drive assembly goes out before beginning any work inside the electrical cabinet.

8

Electrical Service

96-0284 rev E June 2008

Page 10

4. The two overvoltage fuses are located beside each other at the upper right of the Power Supply board. An

orange light will be on to indicate the blown fuse(s).

PHASE DETECT

(FOR3 PHASE ONLY)

+5V

GND

10A230V

FAILPASS

GND

+5V

NE6

WORKLIGHT

GFI/

71 73

NE5

F1

NE1

TSC COOLANTPUMP

TSCCOOLANT PUMP

930

COOLANT/TSC

1A250V

10A230V

POWER SUPPLYASSY

SEC

PRI

TOT5

F3

NE3

PSUP-K

230VIN

CHIPCONVEYOR

CHIPCONVEYOR

170

AUTOOFF/CONTACTOR

740

ON/OFF

P10

5A230V

CB4

160

CHIPC230V

GND

+5V

PHASE DETECT

(FOR 3 PHASE ONLY)

GND

+5V

NE6

FAILPASS

71 73

NE5

F1

NE1

1A 250V

PRI

TO T5

F3

NE3

IOPCB

GND

GND

+5V

+12V

P30

GND

GND

-12V

+12V

COOLANTPUMP

COOLANTPUMP

92A

DELTA-WYE

LOWVOLT PS

SWDOOR FAN

MONITOR

PROBEPS

SERVOFAN

90A

AC GROUND

90C

MCD1

MCD2

LVINPUT

GND

GND

GND

GND

+12V

90A

90A

90A

90A

96

90C

95

94/N

-12V

+12V

+12V

LE2

Z3

LE3

+12V

-12V

TS1

MAIN115V XFRMR

P1

ON ON ON ON ON

10A115V

115VINPUT

MAIN

XFRMR

CB2

115VSPARES

90C 90C

90C90C 90C

MOTIF

MOCON2

GND

GND

+5V

+5V

+5V

-12V

+12V

Z4

+12V

LE1

Z1

+5V

P18

AMPS

GND

+12V

-12V

GFI

7A115V

GFI

CB6 CB3 CB5

90

3PH115V TOIOPCB

Power Supply Board; Fuse Locations

5. Using a fl at tip screwdriver, turn the fuse(s) counterclockwise to remove the fuses. Replace the fuse(s) with

one having the same type and rating (½ amp, type AGC, 250V).

CAUTION! When the left fuse is blown, it is still possible to operate the machine, thereby

making an overvoltage situation possible. Verify absolute voltage to the machine

does not exceed 200V (max 260 leg to leg or leg to ground, or 400V on high

voltage machines - max 520V leg to leg or leg to ground).

FRONT PANEL

Please read this section in its entirety before attempting to replace any control panel component.

SL-10 PENDANT COMPONENTS ACCESS

The SL-10 pendant door hinges on the left side. Remove the two (2) screws on top of the pendant in order to

open the pendant door.

CAUTION! Do not pinch the cable as the door is closed.

96-0284 rev E June 2008

Electrical Service

9

Page 11

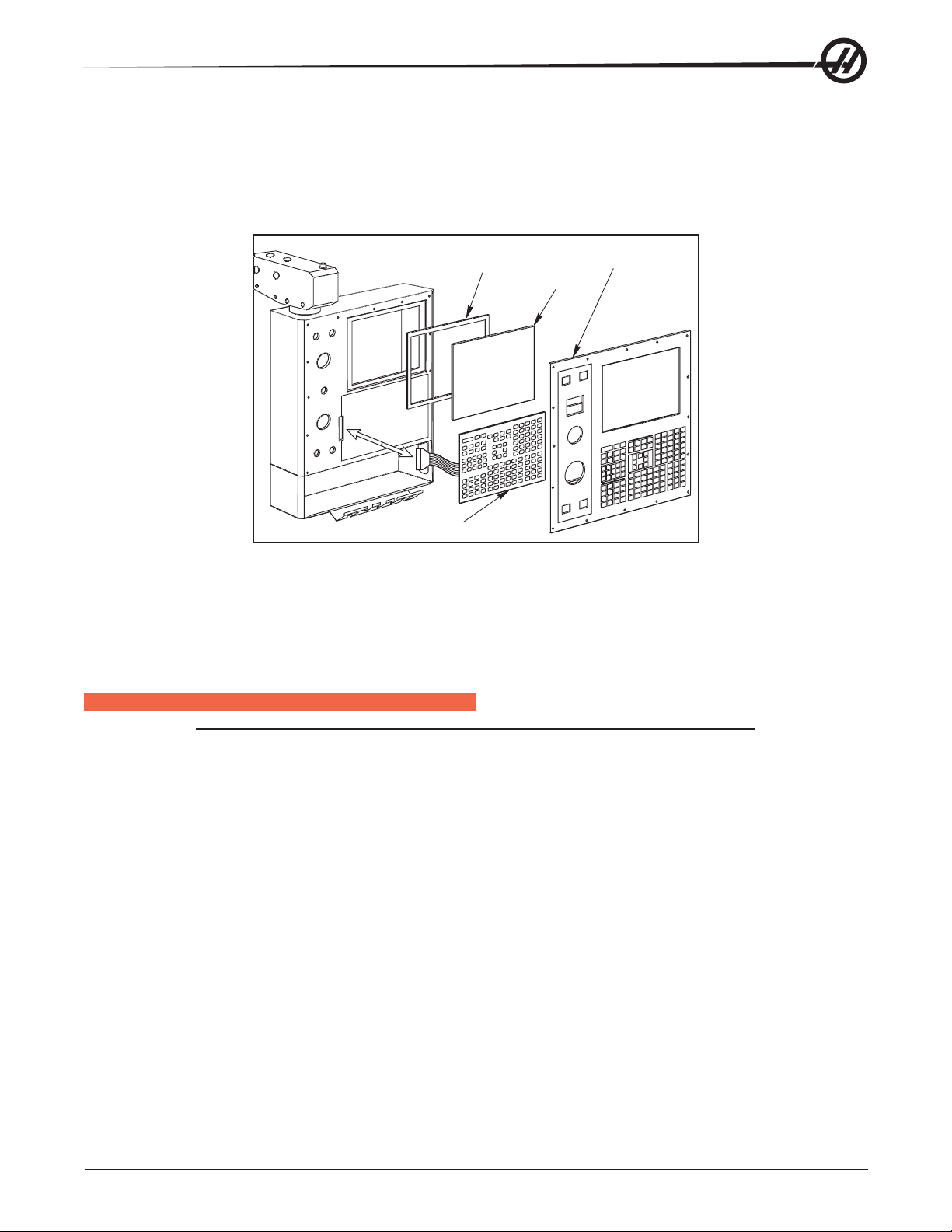

LCD ASSEMBLY REPLACEMENT

CAUTION! Use an electrostatic discharge (ESD) strap on wrist when working inside the

pendant.

1. Turn the power off and disconnect power to the machine.

2. Remove the screws holding the cover on the back of the control panel. Take care to hold the cover in place

until all screws have been removed.

3. Disconnect the data cable from the receiver board on the LCD assembly (J3). Disconnect the power cable

and ground wire from the power supply board on the LCD assembly (TB1). Disconnect the cables to the keyboard from the receiver assembly (P1) and power supply (TB2) on the LCD assembly.

4. Remove the four (4) hex nuts and washers beginning with the bottom, then remove the LCD assembly and

set aside in a safe place.

CAUTION! Do not drop or damage the LCD when removing it from the control panel.

5. Use gloves to avoid getting fi ngerprints on the new LCD. Position the assembly onto the four bolts (two

each on top and bottom). Place the washers and hex nuts on the bolts to hold in place. Once all washers

have been attached and nuts have been hand-tightened, tighten down completely.

Video Out

to LCD Pnl

Video

In

RS-232 Data

to/from

Microprocessor

SKBIF

Power

In

Kybd

Data

In

Back of Operator’s Pendant

6. Plug the keyboard cables into the new receiver board (P1) and the power supply (TB2). Plug the power

cable into the power supply board (TB1) and attach the green wire to ground. Plug the data cable into the

receiver board (J3).

7. Replace the back cover panel and attach with the four screws previously removed.

10

Electrical Service

96-0284 rev E June 2008

Page 12

JOG HANDLE

The Jog handle is actually a 100-line-per-revolution encoder, used to move one axis at a time. If no axis is selected for jogging, turning the handle has no effect. When the axis moved reaches its travel limits, the handle

inputs will be ignored in the direction that would exceed the travel limits. Parameter 57 bit 0 can be used to

reverse the direction of operation of the handle.

Jog Handle Replacement

1. Turn the machine power off.

2. Remove the screws holding the cover on the back of the pendant. Take care to hold the cover in place until

all screws have been removed.

3. Unplug the cable leading to the jog handle encoder.

Blank pin goes to this

side of connector

+5V

BLK

Jog Handle Encoder Jog Handle Removal Jog Handle Wiring Diagram

A

RED

GND

WHT

+5V

RED

B

GRN

A

YEL

GND

WHT/

RED

B

BRN

A

WHT/

YEL

4. Using the 5/64” allen wrench, loosen the two screws holding the knob to the control panel and remove.

5. Remove the three screws holding the jog handle encoder to the control panel and remove.

6. Replacement is reverse of removal. Important! The blank pin side of the connector must face as shown

below when reconnecting; otherwise, damage may occur to the machine.

POWER ON/OFF SWITCHES

The Power On switch engages the main contactor. The On switch applies power to the contactor coil and the

contactor thereafter maintains power to its coil. The Power Off switch interrupts power to the contactor coil

and turns power off. Power On is a normally open switch and Power Off is normally closed. The maximum

voltage on the Power On and Power Off switches is 24V AC and is present any time the main circuit breaker

is on.

B

WHT/

BRN

EMERGENCY STOP SWITCH

The Emergency Stop switch is normally closed. If the switch opens or is broken, servo power is removed instantly. This will also shut off the turret, spindle drive, and coolant pump. The Emergency Stop switch will shut

down motion even if the switch opens for as little 0.005 seconds. Note that if Parameter 57 bit 3 is set to 1, it

will cause the control to be powered down when Emergency Stop is pressed.

You should not normally stop a tool change with Emergency Stop as this will leave the tool changer in an

abnormal position that takes special action to correct

If the lathe turret or mill tool changer (T/C) becomes jammed, the control will automatically come to an alarm

state. To correct this, push the Emergency Stop button and remove the cause of the jam. Push the Reset key

to clear any alarms. Push Zero Return and the Auto All Axes to reset the Z-axis and turret or T/C. Never put

your hands near the turret or T/C when powered unless E-Stop is pressed.

96-0284 rev E June 2008

Electrical Service

11

Page 13

KEYBOARD BEEPER

There is a beeper under the control panel that is used as an audible response to pressing keyboard buttons

and as a warning beeper. The beeper is a one kHz signal that sounds for about 0.1 seconds when any

keypad key, Cycle Start, or Feed Hold is pressed. The beeper also sounds for longer periods when an autoshutdown is about to occur and when the “Beep at M30” setting is selected.

If the beeper is not audible when buttons are pressed, the problem could be in the keypad, keyboard interface

PCB or in the speaker. Check that the problem occurs with more than one button and check that the beeper

volume is not turned down or disconnected. If lamps do not turn on, check the GFCI plug.

LAMP ON/OFF SWITCH

An on/off switch is supplied for the work lamp. It is located on the side of the operator’s pendant. The lamp

uses 115V AC taken from P19 on the main power distribution board.

SWITCH REPLACEMENT

1. Turn the machine power off. Remove the screws holding the cover on the back of the pendant. Take care to

hold the cover in place until all screws have been removed.

2. Disconnect all leads to the switch connectors. Ensure all leads are properly marked for reconnecting later.

3. Unscrew the two small set screws, one on top and one on the bottom, and turn the switch counterclockwise

to loosen. Separate from the front portion and pull out.

4. To replace, screw the front and rear portions together (reverse of removal) and tighten down the two small

set screws when the switch is properly positioned.

NOTE: The Power On, Power Off, and Emergency Stop switches must all have the con-

nectors on the bottom of the switch.

5. Reconnect all leads to the correct switch.

SPINDLE LOAD METER

Load meter measures load on spindle motor as a percentage of rated continuous power of motor, with a slight

delay between a load and actual meter refl ection. The eighth A-to-D input also provides a measure of spindle

load for cutter wear detection. Second page of diagnostic data displays % of spindle load. Meter should agree

with display within 5%. Spindle drive display #7 should also agree with load meter within 5%. There are different types of spindle drives used in the control, all are equivalent in performance but are adjusted differently.

Spindle Load Meter Replacement

1. Turn the power off and disconnect power to the machine. Remove the screws holding the cover panel on

the back of the pendant. Take care to hold the cover panel in place until all screws are removed.

2. Disconnect the two leads at the back of the spindle load meter assembly. Ensure the two leads are properly

marked for reconnecting later.

3. Unscrew the four screws that hold the spindle load meter assembly to the control panel. Take care to hold

the assembly in place until all screws have been removed. Remove the assembly.

4. Installation is reverse of removal. Ensure leads go to the correct location.

KEYPAD REPLACEMENT

1. Turn the power off and disconnect power to the machine. Remove the screws holding the rear cover to the

back of the pendant. Take care to hold the cover in place until all screws are removed.

2. Unplug the keypad’s 24-pin ribbon cable from the Keyboard Interface board.

12

Electrical Service

96-0284 rev E June 2008

Page 14

3. Remove the screws from the front of the pendant. Take care to hold the cover in place until all screws have

been removed. Remove the pieces and set aside in a safe place.

4. Using a fl at, blunt tool, such as putty knife, pry the keypad away from the control panel. Pull the ribbon

cable through the opening in the control to remove.

5. To replace, fi rst put the bezel spacer in place and fasten temporarily with screws in the top corners.

Gasket

Glass

Keypad

Keypad Installation

Front Bezel

6. Insert the ribbon cable through the opening in the control panel. Expose the adhesive strip on the back of

the keypad and press it into place in the upper right corner of the keypad recess. Press to the control panel to

mount. Plug the ribbon cable into the Keyboard Interface board, taking care to not bend the pins.

7. Replace the front and rear cover panels and fasten with the screws that were previously removed.

SERIAL KEYBOARD INTERFACE REPLACEMENT

NOTE: Refer to “Cable Locations” for a diagram of this board.

1. Follow all precautions noted previously before working in the control cabinet.

2. Turn the main switch (upper right of electrical cabinet) to the off position.

3. Remove the four screws on the back of the control box, then remove the cover panel. Take care to hold the

panel in place until all screws have been removed.

4. Disconnect all leads to the Serial Keyboard Interface (SKBIF) board. Ensure all cables are properly labeled.

5. After all cables have been disconnected, unscrew the four screws holding the Serial KBIF board to the

control box. Take care to hold the board in place until all screws have been removed. Place the screws and

standoffs aside for later use.

6. Replace the Serial KBIF board, using the four screws previously removed. Starting at the top right, attach

each screw and standoff loosely, until all are mounted, then tighten down.

7. Reconnect all cables to the Serial KBIF board at their proper locations.

8. Verify whether the machine is equipped with either a speaker or a beeper. Align the toggle switches of

Switch 1 on the Serial KBIF board to their appropriate positions. Beeper operation requires that both S1

switches be set to ‘B’; speaker operation requires that both S1 switches be set to ‘S’.

96-0284 rev E June 2008

Electrical Service

13

Page 15

SOLENOIDS

Please read this section in its entirety before attempting to replace any solenoid assemblies.

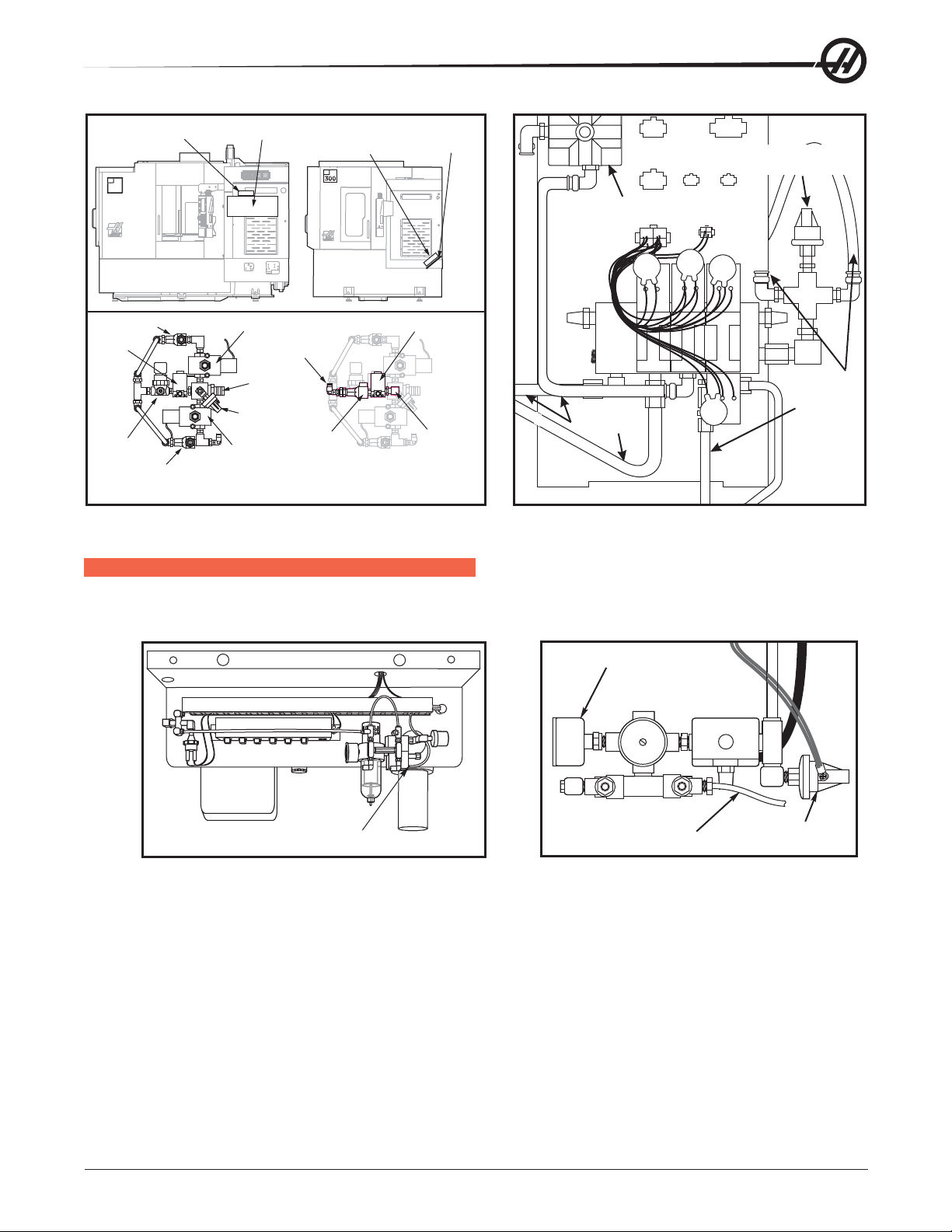

TOOL RELEASE PISTON (TRP) AIR SOLENOID ASSEMBLY (HORIZ & VERT)

Removal

1. Turn machine power on and raise spindle head to uppermost position, then turn the power off. Remove air

supply from machine.

2. Remove sheet metal at rear and/or top of machine to access the back of the spindle (Mechanical Service

manual).

3. Disconnect all air lines from the air solenoid assembly (Do not remove fi ttings). Disconnect the two leads

from the low air pressure sensor.

4. Unscrew the air solenoid assembly from the tool release piston assembly, taking care not disturb the position of the clamp/unclamp switches. It may be necessary to remove the tool release piston to access the

solenoid assembly.

5. Unplug the wiring leading to the plug marked on the solenoid bracket as “880 from I/O PCB to Solenoid

Valves” and the plug marked “Spare”.

6. Unscrew the air solenoid from the air solenoid assembly. Remove the SHCS holding the assembly to the

bracket and remove the assembly.

Installation

1. Install the new air solenoid. Take care to not disturb the position of the clamp/unclamp switches.

2. Replace air solenoid assembly and attach to bracket with the SHCS previously removed. Tighten securely.

3. Reinstall the tool release piston assembly if removed (see Mechanical Service).

4. Reconnect the two leads to the low air preassure sensor. Reconnect wiring to plugs on solenoid bracket.

5. Ensure all air lines are reconnected to their proper fi ttings. Reconnect air supply to the machine, and check

for leaks.

6. Replace the sheet metal.

14

Electrical Service

96-0284 rev E June 2008

Page 16

Air Solenoid

Assembly

EC

400

Motor Shroud

Air Solenoid

Assembly

EC

Sheet Metal

Tray

Low air pressure

sensor

Air solenoid

assembly

Check Valve Switch

Pre-

Charge

TRP Solenoid

To TSC

TSC Solenoid

Inlet

Pressure

Switch

Regulator

Check Valve Switch

TRP

Solenoid

Basic Air Solenoid Assembly

Check

Valve

Switch

Junction

Elbow

Air Solenoid Assembly

With TSC Feature Added

Disconnect

all air lines

Locations of EC-300 and EC-400 TRP Solenoids VF-Series Air Solenoid Assembly

SPINDLE LUBE AIR SOLENOID

Removal

1. Turn the machine power off and remove the air supply from the machine.

Pressure Gauge

Disconnect

all air lines

Spindle

Lube

Solenoid

Lube Line

Main Air Line

Pressure Switch

Lube/Air Panel (Rear View) Spindle Lube/Air Solenoid Assembly (Top View)

2. a. Lathe: Disconnect the lube line from the spindle lube air solenoid assembly.

b. Mill: Disconnect the air lines from the spindle lube air solenoid assembly.

3. Disconnect the electrical leads from the main air line pressure switch.

4. Lathe: Unscrew the solenoid assembly pressure gauge from the assembly.

5. Unscrew the entire solenoid assembly from the T-fi tting.

Installation

1. Reattach the solenoid assembly at the T-fi tting.

2. a. Lathe: Replace the pressure gauge on the solenoid assembly and reconnect the lube line.

b. Mill: Reconnect all air lines.

96-0284 rev E June 2008

Electrical Service

15

Page 17

3. Reconnect the electrical leads to the main air line pressure switch.

4. Restore the air supply to the machine.

NEUMATIC CHUCK/TURRET CLAMP/UNCLAMP SOLENOID (LATHE)

P

Removal

1. Turn machine power off and remove the air supply from the machine.

2. Pneumatic Chuck: Disconnect the two air hoses from the pneumatic chuck clamp/unclamp solenoid.

Turret: Disconnect the three air hoses from the turret clamp/unclamp solenoid (see the Turret In/Out

Adjustment), and disconnect exhaust lines.

3. Unplug the solenoid electrical lead (located on the rear of the lube air panel).

4. Remove the two SHCS holding the assembly to the bracket and remove the assembly.

Installation

1. Replace the air solenoid assembly and attach it to the bracket with the two SHCS. Tighten securely.

2. Reconnect the electrical connection to the solenoid at the switch bracket.

3 Reconnect the two (three for Turret) air lines and turret exhaust lines, ensuring that all connections are tight

and do not leak.

4. Restore the air supply to the machine.

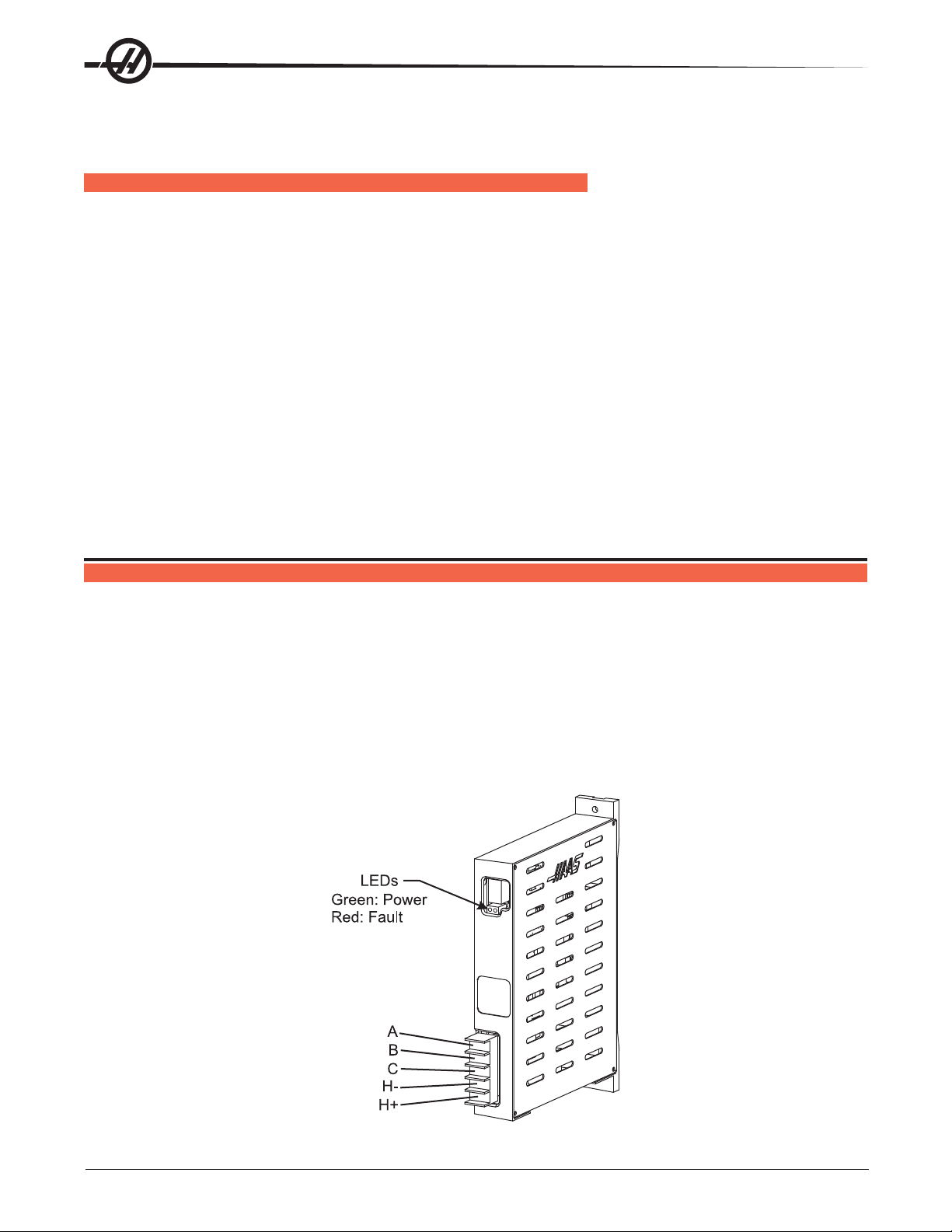

SMART AMPLIFIER

The Smart Amplifi er has a microprocessor incorporated in the design. This allows the amplifi er to detect and

report detailed alarms. The software level necessary to display these new alarms is 15.02A or newer.

The Smart Amplifi er is backward compatible to any machine that has a Vector Drive. New Smart Amplifi ers

and standard amplifi ers may be used in any combination in the machine. However, if the machine does not

have at least 15.02A software or newer the specifi c Smart Amplifi er will not be displayed. The Smart Ampli-

fi er and the standard amplifi er use the same Parameters. On non-thin pendant machines, at least two of the

standard amplifi ers must be used.

The Smart Amplifi er does not have a 12VDC connector, and both the Fault (Red LED) and the Run (Green

LED) are relocated. The 320VDC (H+ and H-) and the X, Y and Z-axis connections are also relocated.

16

Electrical Service

96-0284 rev E June 2008

Page 18

The smart amplifi er will calibrate utilizing the microprocessor that is present in each of the Smart Amplifi ers at

power up. When power is applied to the Control Cabinet the Fault (Red LED) will illuminate and stay illuminated for a short time (approximately 5 seconds), this is called the “A” Phase Calibration. Then both LEDs will

be out for a few seconds; this is called the “B” Phase Calibration. Next the Run (Green LED) will illuminate,

indicating the Smart Amplifi er is ready with no faults.

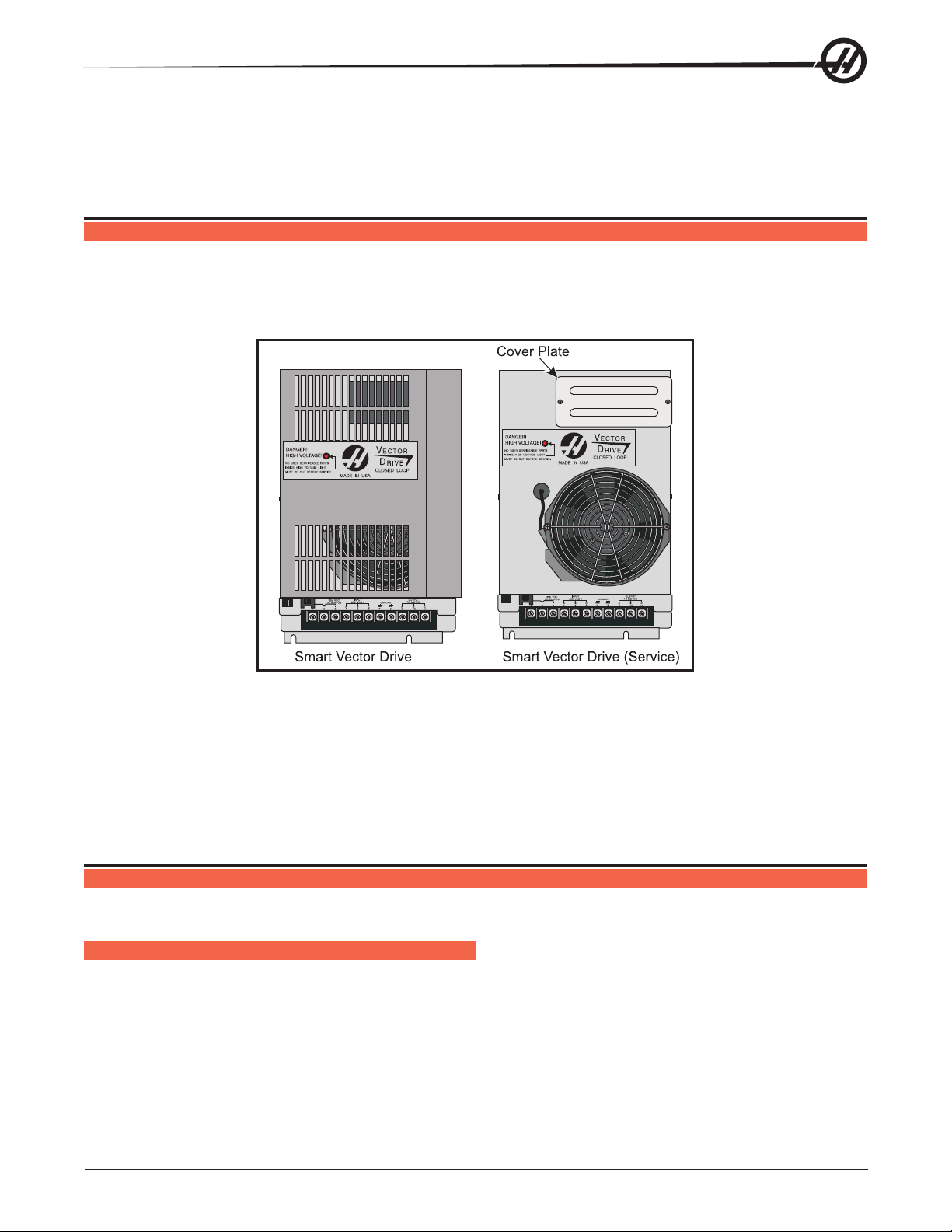

MART VECTOR DRIVE

S

The smart vector drive features a microprocessor that allows it to detect and display specifi c alarms (software

version 15.02A or newer only). It is backward compatible to any machine with a vector drive regardless of

software version; however, the drive-specifi c alarms will not display in older software. Such alarms will dis-

play in the same way as with old-style drives.

Smart vector drives installed in new machines include a cover, and the machines electrical cabinet door is

cut to accommodate it. Service drives are shipped without the cover for installation in older machines. When

replacing a drive in a machine built to accommodate the cover, use the cover from the old drive.

When installing a smart vector drive without the cover, install the cover plate to the front of the vector drive.

When installing with the cover, install the cover plate to the top of the vector drive.

You will also need several cables. Please see 93-32-5558A for the 40 HP drive and 93-32-5559A for the 20

HP drive.

PCB REPLACEMENT

Please read this section in its entirety before attempting to replace any PCBs

MICROPROCESSOR ASSEMBLY

The microprocessor assembly is in the control cabinet at the top left position. It contains three large boards.

They are: Microprocessor, the Video/Keyboard and the MOCON. All three boards of the processor assembly

receive power from the low voltage power supply. The three PCBs are interconnected by a local buss on dual

50-pin connectors. At power-on, some diagnostic tests are performed on the processor assembly and any

problems found will generate Alarms 157 or 158. In addition, while the control is operating, it continually tests

itself and a self test failure will generate Alarm 152.

96-0284 rev E June 2008

Electrical Service

17

Page 19

MOCON, VIDEO/KEYBOARD, & MICROPROCESSOR

The electrical panel will have residual voltage, even after power has been

shut off and/or disconnected. Never work inside this cabinet until the small

red Charge light on the servo amplifi ers go out. The servo amplifi ers are on

the left side of the main control cabinet and about halfway down. This light

is at the top of the circuit card at the center of the assembly. Until this light

goes out, there are dangerous voltages in the assembly even when power

is shut off.

Ground straps must be used when handling boards.

WARNING!

NOTE: Board arrangement may differ from the order of replacement that follows. Steps for

MOTOR CONTROLLER (MOCON)

Machines are equipped with a microprocessor-based brushless motor controller board (MOCON) that replaces the motor interface in the brush type controls. It runs in parallel with the main processor, receiving axis

commands and closing the loop around the axis motors.

In addition to controlling the axis and detecting axis faults, the motor controller board (MOCON) is also in

charge of processing discrete inputs, driving the I/O board relays, commanding the spindle, and processing

the jog handle input. It also controls 6 axes, so there is no need for an additional board for a 5-axis machine.

Four LEDs are used to diagnose MOCON problems:

The RUN” LED will turn on, indicating that Mocon code was found in ROM and is being executed. This LED

will turn off if a processor exception causes the Mocon code to abort execution.

replacement will only differ in which board may need to be removed before getting

to the necessary board.

The “STAT” LED indicates the following (Specifi c to Mocon 11.00 or later software)

a. Continuously ON - Normal status. board has passed all power-on tests, and no problems have been

encountered

b. Blinks 3 times - Communication with main processor failed

c. Blinks 4 times - Internal ±12V testing failed

d. Blinks 5 times - Internal watchdog circuit failed

e.Blinks rapidly - EPROM CRC failed

The “Halt” LED glows when the board is in use (processing).

The “+5” LED lights when the board has power.

MOCON Board Replacement

1. Turn machine power off and turn the main switch (upper right of electrical cabinet) to the off position.

2. Open the cabinet door enough to safely work on the electrical panel. Wait until the red charge light on the

servo amplifi ers (servo drive assembly on brush machines) goes out before beginning any work.

3. Disconnect all leads to the Motor Controller (MOCON) board, and ensure all cables are properly labeled.

4. After all cables have been disconnected, unscrew the standoffs, taking care to hold the board in place until

all standoffs have been removed.

NOTE: If the Video/Keyboard or Processor boards need replacing, skip the next step.

5. Replace the MOCON board, attaching it to the Video/Keyboard (beneath the MOCON board) with the

standoffs, and reconnect all leads (previously removed) to their proper connections.

6. If a second MOCON board is present, be sure to connect the jumper on the second MOCON board.

18

Electrical Service

96-0284 rev E June 2008

Page 20

VIDEO/KEYBOARD

The Video/Keyboard PCB generates the video data signals for the monitor and the scanning signals for the

keyboard. In addition, the keyboard beeper is generated on this board. There is a single jumper on this board

used to select inverse video. The video PCB connectors are:

P1 Power connector J11 SPARE

J3 Keyboard (700) J12 Floppy

J4 Address bus J13 Video (760)

J5 Data J14 RS422 B

J10 Floppy V+ J15 RS422 A

Video/Keyboard Replacement

1. Remove the MOCON board as previously described.

2. Disconnect all leads to the Video/Keyboard. Ensure all cables are properly labeled for reconnecting later.

3. After all cables have been disconnected, unscrew the standoffs, taking care to hold the board in place until

all standoffs have been removed.

NOTE: If the Processor board needs replacing, skip the next step.

4. Replace the Video/Keyboard, attaching it to the Processor board with the standoffs.

5. Reconnect all leads (previously removed) to their proper connections.

6. Replace the MOCON board.

MICROPROCESSOR PCB (68ECO30)

The Microprocessor PCB contains the 68ECO30 processor running at 40 MHz, one 128K EPROM; between

1MB and 16MB of CMOS RAM and betwen 512K and 1.5MB of Fast Static RAM. It also contains a dual serial

port, a battery to backup RAM, buffering to the system buss, and eight system status LED’s.

Two ports on this board are used to set the point at which an NMI is generated during power down and the

point at which Reset is generated during power down.

The eight LEDs are used to diagnose internal processor problems. As the system completes power up testing, the lights are turned on sequentially to indicate the completion of a step. The lights and meanings are:

RUN Program Running Without Fault Exception. (Normally On) - If this light does not come on, or goes

out after coming on, there is a problem with the microprocessor or the software running in it. Check all

of the buss connectors to the other two PCBs and ensure all three cards are getting power.

PGM Program Signature Found in Memory. (Normally On) - If this light does not come on, it means that

the main CNC program package was not found in memory, or that the auto-start switch was not set.

Check that Switch S1-1 is on and the EPROM is plugged in.

CRT CRT/LCD Video Initialization Complete. (Normally On) - If the light does not come on, there is a

problem communicating with the Video PCB. Check buss connectors to ensure it is getting power.

MSG Power-on Serial I/O Message Output Complete. (Normally On) - If this light does not come on,

there is a problem with serial I/O or interrupts. Disconnect anything on the external RS-232 and

retest.

SIO Serial I/O Initialization Complete. (Normally On) - If this light does not come on, there is a problem

with the serial ports. Disconnect anything on the external RS-232 and test again.

POR Power-On-Reset Complete. (Normally On) - If this light does not come on, there is a problem with

the Processor PCB. Check that the EPROM is plugged in. Test the card with buss connectors off.

96-0284 rev E June 2008

Electrical Service

19

Page 21

HALT Processor Halted in Catastrophic Fault. (Normally Dim) - If this light comes on, there is a problem

with the Processor PCB. Check that the EPROM is plugged in. Test the card with buss connectors off.

+5V +5V Logic Power Supply is Present. (Normally On) - If this light does not come on, check the low

voltage power supply and check that all three phases of 230V input power are present.

There is 1 two-position DIP switch on the Processor PCB labled S1. Switch S1-1 must be ON to auto-start the

CNC operational program. If S1-1 is OFF, the PGM light will remain off. Switch S2-1 is used to enable Flash.

If it is disabled it will not be possible to write to Flash.

The processor connectors are:

J1 Address buss J5 Serial port #2 (for auxiliary 5th axis) (850A)

J2 Data buss J3 Power connector

J4 Serial port #1 (for upload/download/DNC) (850) J6 Battery

Memory Retention Battery

The memory retention battery (3.3V Lithium battery) is soldered into the Processor PCB. It maintains the contents of CMOS RAM during power off periods. A minimum voltage of 2.5V DC is required for proper operation.

Prior to this battery being unusable, an alarm is generated indicating low battery. If the battery is replaced

within 30 days, no data is lost. The battery is not needed when the machine is powered on. Connector J6 on

the Processor PCB can be used to connect an external battery.

To replace the battery, the 4-pin jumper, attached to a fresh battery, has to be temporarily attached to J6 before the old battery is removed. With the jumper in place, un-solder the old battery and remove. Install a new

battery and solder in place, then remove the temporary jumper.

NOTE: Do not attach the jumper after the old battery has been removed or remove the

jumper if a fresh battery has not been installed. This will result in complete ma-

chine memory loss, which cannot be reversed.

Processor Board Replacement

1. Remove the MOCON board, and the Video/Keyboard as previously described.

2. Disconnect all leads to the Processor board. Ensure all cables are properly labeled for reconnecting later.

3. After all cables have been disconnected, unscrew the standoffs, taking care to hold the board in place until

all standoffs have been removed.

4. Replace the Processor board, attaching it to the electrical cabinet with the standoffs, reconnect all leads

(previously removed) to their proper connections, and replace Video/Keyboard and MOCON board.

INPUT/OUTPUT ASSEMBLY

The Input/Output Assembly consists of a single printed circuit board called the I/O PCB.

The I/O PCB also contains a circuit for sensing a ground fault condition of the servo power supply. If more

than 1.75 amps is detected fl owing through the grounding connection of the 160V DC buss, a ground fault

alarm is generated and the control will turn off servos and stop.

Relay K6 is for the coolant pump 230V AC. It is a plug-in type and is double-pole. Relays K9 through K12 are

also plug-in types for controlling the tool changer motors.

I/O Board Replacement

1. Follow all precautions noted previously before working in the electrical cabinet.

2. Disconnect all leads to the Input/Output board and move aside for removal. Ensure all cables are properly

labeled for reconnecting later.

3. Remove the board by fi rst removing the twelve screws that fasten it to the cabinet. Take care to hold the

board in place until all screws have been removed.

20

Electrical Service

96-0284 rev E June 2008

Page 22

4. Replace the I/O board, attaching it to the cabinet with the twelve screws previously removed, and reconnect all leads to the I/O board. Check for any additional jumper settings per I/O release notes.

OWER TRANSFORMER ASSEMBLY (T1)

P

The power transformer assembly converts three-phase input power (50/60Hz) to three-phase 230V and 115V

power. Two transformers are used, depending on the input voltage range. The low voltage transformer has

four input connections to allow for a range of voltages from 195V RMS to 260V RMS. The high voltage trans-

former has fi ve input connections and will accept a range of voltages from 354V RMS to 488V RMS.

The 230V is used to power the spindle drive. THe 230V also supplies the power to the vector drive, which

supplies 325V DC power for the axis servo amplifi ers. The 115V is used by the video monitor, solenoids, fans

and pumps, in addition to supplying power to the main LVPS used by the control electronics.

The transformer assembly is located in the lower right hand corner of the main cabinet. Besides the high/low

voltage variations, two different power levels are available depending on the spindle motor used. The small

and large transformers have power ratings of 14 KVA and 28 KVA, respectively, and are protected by the main

circuit breaker.

Ouput

Power

Input

Power

TB2

240VOUT

488-458V

457-429V

260-244V

D

A

INCOMINGLINE VOLTAGETAPS (74,75, 76)

N

428-403V

G

E

243-227V

R

!

!

402-377V

!

H

226-211V

I

G

TB1

120VOUT

376-354V

H

V

210-195V

O

L

T

A

G

E

D

A

N

G

E

R

!

!

!

.

Polyphase Bank Transformer

Primary Connection To T1

Input power to T1 is supplied through CB1, the main circuit breaker. Three-phase 230 to T1 is connected to

the fi rst three terminals of TB10.

Circuit breaker CB1 is used to protect the spindle drive and to shut off all power to the control. A trip of this

breaker indicates a serious overload problem and should not be reset without investigating the cause of the

trip.

Main Contactor K1

Main contactor K1 is used to turn the control on and off. The Power On switch applies power to the coil of K1

and after it is energized, auxiliary contacts on K1 continue to apply power to the coil. The Power Off switch on

the front panel will always remove power from this contactor.

When the main contactor is off, the only power used by the control is supplied through two ½ amp fuses to

the circuit that activates the contactor. An overvoltage or lightning strike will blow these fuses and shut off the

main contactor.

The power to operate the main contactor is supplied from a 24V AC control transformer that is primary fused

at ½ amp. This ensures that the only circuit powered when the machine is turned off is this transformer and

only low voltage is present at the front panel on/off switches.

Voltage Selection Taps

There are four labeled plastic terminal blocks. Each block has three connections for wires labeled 74, 75, and

76. Follow the instructions printed on the transformer.

96-0284 rev E June 2008

Electrical Service

21

Page 23

Secondary Connection To T1

The secondary output from T1 is 115V AC three-phase CB2 that protects the secondary of transformer T1 and

is rated at 25 amps.

Optional 480V Transformer

60Hz 50Hz

Input Voltage Range Tap Input Voltage Range Tap

493-510 1 (504) 423-440 1 (504)

481-492 2 (492) 412-422 2 (492)

469-480 3 (480) 401-411 3 (480)

457-468 4 (468) 391-400 4 (468)

445-456 5 (456) 381-390 5 (456)

433-444 6 (444) 371-380 6 (444)

420-432 7 (432) 355-370 7 (432)

Power-Up Low Voltage Control Transformer (T5)

The low voltage control transformer, T5, supplies power to the coil of the main contactor K1. It guarantees that

the maximum voltage leaving the Power Supply assembly when power is off is 12V AC to earth ground. It is

connected via P5 to the Power PCB.

Operator’s Work Light

Main transformer (T1) outputs 115V AC to the work light.

POWER SUPPLY ASSEMBLY

All control power passes through a power supply assembly on the upper right corner of the control cabinet.

Power PCB (PSUP)

Low voltage power distribution and high voltage fuses and circuit breakers are mounted on a circuit board

called the Power PCB.

Secondary Circuit Breakers

The following circuit breakers are located on the Power supply assembly:

CB2 Controls the 115V power from the main transformer to the I/O PCB and, if tripped, will turn off all

inputs and outputs. CB2 could be tripped by a short circuit in the cables.

CB3 Controls the power to coolant pump only. It can be tripped by an overload of the coolant pump

motor or a short in the wiring to the TSC motor, or lathe hydraulic pump.

CB4 Controls the power to chip conveyor only.

CB5 Controls power to the TSC coolant pump only. It can be tripped by an overload of the TSC coolant

pump motor or a short in the wiring to the motor.

CB6 Single-phase 115V protected ground fault interrupt circuit and output for the worklight.

Power PCB (PSUP) Replacement

1. Follow all precautions noted previously before working in the electrical cabinet

2. Disconnect all leads to the Power PCB (PSUP) and set aside for removal. Ensure all cables are properly

labeled for reconnecting later.

3. After all cables have been disconnected, remove the seven screws holding the Power board to the cabinet

and remove the board. Take care to hold the Power board in place until all screws have been removed.

NOTE: If you need to replace the Low Voltage Power Supply board, please skip the next

step.

4. Replace the Power board, attaching it with the seven screws previously removed. Do not forget to use the

lower left screw for a ground connection.

5. Reconnect all cables to Power board at proper location. Refer to release notes for additional information.

22

Electrical Service

96-0284 rev E June 2008

Page 24

LOW VOLTAGE POWER SUPPLY

The low voltage power supply provides +5V DC, +12V DC, and -12V DC to all of the logic sections of the control. It operates from 115V AC nominal input power, and continues to operate correctly over 90 to 133V AC.

Low Voltage Power Supply (LVPS) Replacement

1. Remove the Power Distribution (Power) board as previously described.

2. Disconnect all leads to the Low Voltage Power Supply (LVPS) board. Ensure all cables are properly labeled

for reconnecting later.

3. After all cables have been disconnected, unscrew the two standoffs at the bottom of the board. Unscrew

the remaining two screws at the top of the LVPS board, taking care to hold the board in place until all screws

have been removed.

4. Replace the LVPS board, attaching it to the cabinet with the two screws and standoffs previously removed.

5. Replace the Power board as previously described.

RS-232 SERIAL INTERFACE

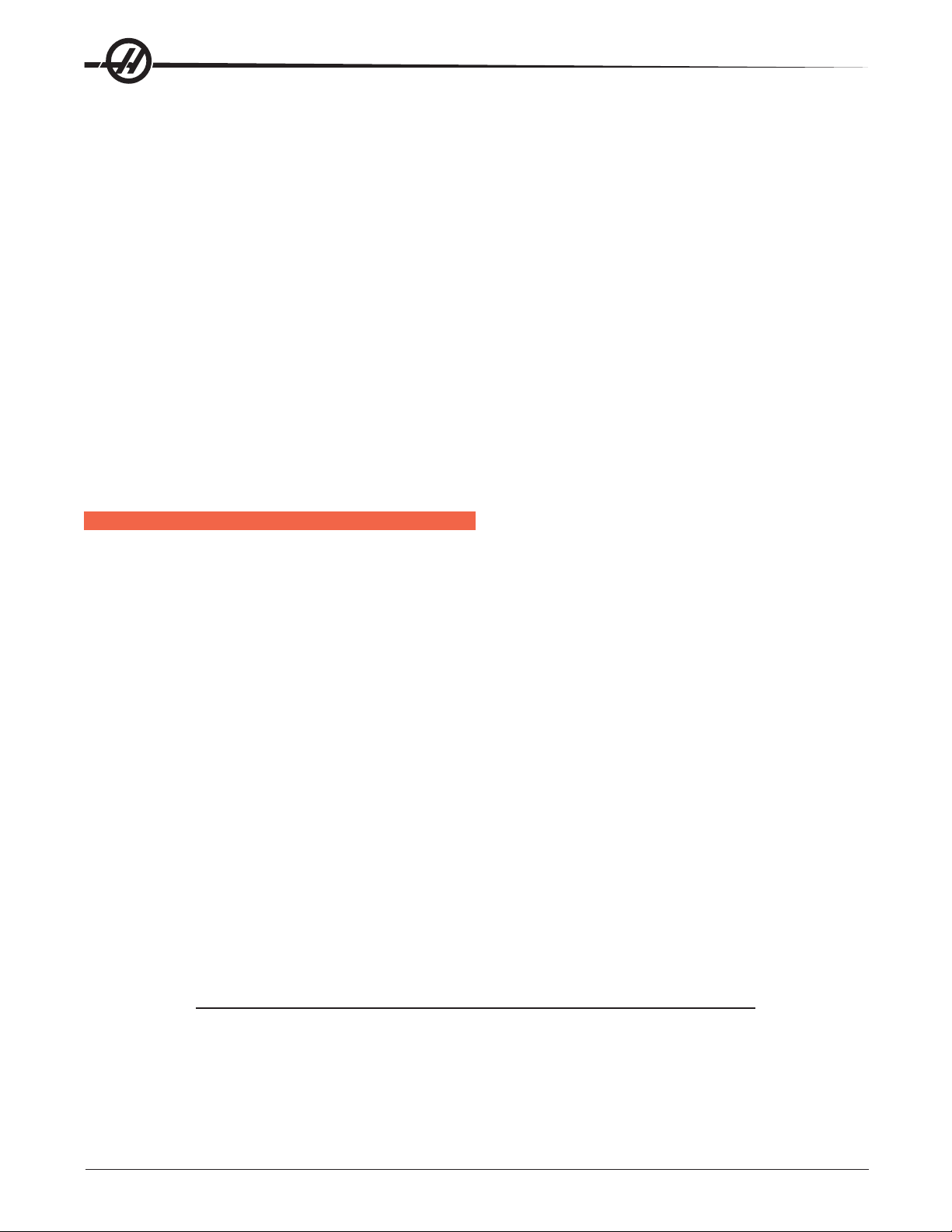

There are two connectors used for the RS-232 interface. The RS-232 connector on most PCs is a male DB25, so only one type of cable is required for connection to the controller, or between controllers. This cable

must be a DB-25 male on one end and a DB-25 female on the other. Pins 1, 2, 3, 4, 5, 6, 7, 8, and 20 must

be wired one-to-one. It cannot be a Null Modem cable, which inverts pins 2 and 3. To check cable type use

a cable tester to check that communication lines are correct. The controller is DCE (Data Communication

Equipment). This means that it transmits on the RXD line (pin 3) and receives on the TXD line (pin 2). The

RS-232 connector on most PCs is wired for DTE (Data Terminal Equipment), requiring no special jumpers.

The Down Line DB-25 connector is only used when more than one controller is to be used. The fi rst control-

ler’s down line connector goes to the second controller’s up line connector, etc.

Interfacing a Haas Rotary Control to the mill

The RS-232 interface sends and receives seven data bits, even parity, and two stop bits. The interface must

be set correctly. The data rate can be between 110 and 19200 bits per second. When using RS-232, it is

important to make sure that Parameter 26 (RS-232 Speed) and 33 (X-on/X-off Enable) are set to the same

value in the controller and PC.

If Parameter 33 is set to on, the controller uses X-on and X-off codes to control reception, so be sure your

computer is able to process these. It also drops CTS (pin 5) at the same time it sends X-off and restores CTS

when is sends X-on. The RTS line (pin 4) can be used to start/stop transmission by the controller or the X-on/

Xoff codes can be used. The DSR line (pin 6) is activated at power-on of the controller and the DTR line (pin

20 from the PC) is not used. If Parameter 33 is 0, the CTS line can still be used to synchronize output.

When more than one Haas controller is daisy-chained, data sent from the PC goes to all of the controllers at

the same time, requiring an axis selection code (Parameter 21). Data sent back to the PC from the controllers

is ORed together so that, if more than one box is transmitting, the data will be garbled. Because of this, the

axis selection code must be unique for each controller.

RS-232 Remote Command Mode

Parameter 21 must be non-zero for the remote command mode to operate as the controller looks for an axis

select code defi ned by this parameter. The controller must also be in RUN mode to respond to the interface.

Since the controller powers-on in Run mode, remote unattended operation is thus possible.

RS-232 Line Noise

To minimize line noise on the serial port, reroute the cables straight up the left-hand side of the control to the

processor stack. Do not run them above the I/O PCB or up the center wire channel to the processor.

Transmission errors may be best minimized with a good common ground between the PC and CNC control.

96-0284 rev E June 2008

Electrical Service

23

Page 25

RS-232 Loop Back Test

If you have a communications problem between Port #1 of the machine and your external computer, use the

following procedure to isolate the problem to either internal or external causes.

1. Unplug the cable from Port #1 of the Control Panel, and plug the cable tester in (port #1).

PLUG TESTER

BACK VIEW

The RS-232 Plug Tester is a 25-pin male connector with the following pins shorted.

Pins 2 & 3

Pins 14 & 16

In order to properly perform the test, Setting 14 must be set to CTS/RTS.

2. If the machine is on, cycle the power (power down then turn back on).

3. Press List Prog, followed by press Param Dgnos twice, then press Send RS232.

4. If the internal serial port is working, the lower left-hand part of the screen will display Serial Passed. (This

means that the system, to the output of the control panel, is working. Check the cable to the computer

set-up if you still have a communications problem.)

If the internal serial port is bad, the lower left-hand part of the screen will display Serial Failed. (This means

there is a problem inside the control panel, or that the test connector is unplugged or missing.)

RS-232 PCB Replacement

1. Follow all precautions noted previously before working in the electrical cabinet.

NOTE: It is necessary, when replacing the RS-232 board, to work from the inside and

2. On the left side of the cabinet, at the top of the side panel, are two serial port connections labeled “Serial

Port #1” and “Serial Port #2”. Serial Port #1 is the upper connection.

1

2

3

R

R

R

V

V

V

1

RS-232

PORT 1

RS-232

PORT 2*

* Requires second RS-232 Board (34-4089)

P

PIN1

2

3

1

C

C

C

D

N

G

outside of the cabinet at the same time.

5

4

R

R

V

V

J13

J14

Video &

Keyboard

PCB

Micro

Processor

J4

2

P

5

R

4

R

3

R

2

R

1

R

4

5

C

C

3

P

RS-232 Wiring Diagram (with Serial Keyboard)

To

SKBIF

P1

5

1

2

3

4

R

R

R

R

R

V

V

V

V

V

2

1

P

RS-232

PORT 1

RS-232

PORT 2*

P

5

R

4

R

3

R

2

R

1

R

PIN1

2

3

4

5

1

C

C

C

C

C

D

N

3

P

G

J3

Coldfire

Processor

J14

* Requires second RS-232 Board (34-4090)

J4

Micro

To

SKBIF

P1

3. To remove the RS-232 board, unscrew the two hex screws (on the exterior of the cabinet) holding the connector to the cabinet. From the inside of the cabinet, pull the connector through the panel, and disconnect the

cable.

24

Electrical Service

96-0284 rev E June 2008

Page 26

4. Replace the RS-232 board by fi rst connecting the appropriate cable to the board (850 to Serial Port #1,

850A to Serial Port #2, then inserting the board (cable side up) through the left side panel. Attach with the two

hex screws previously removed. Ensure the board for Serial Port #1 is the upper connector and the board for

Serial Port #2 is the lower connector.

PARE USER M CODE INTERFACE

S

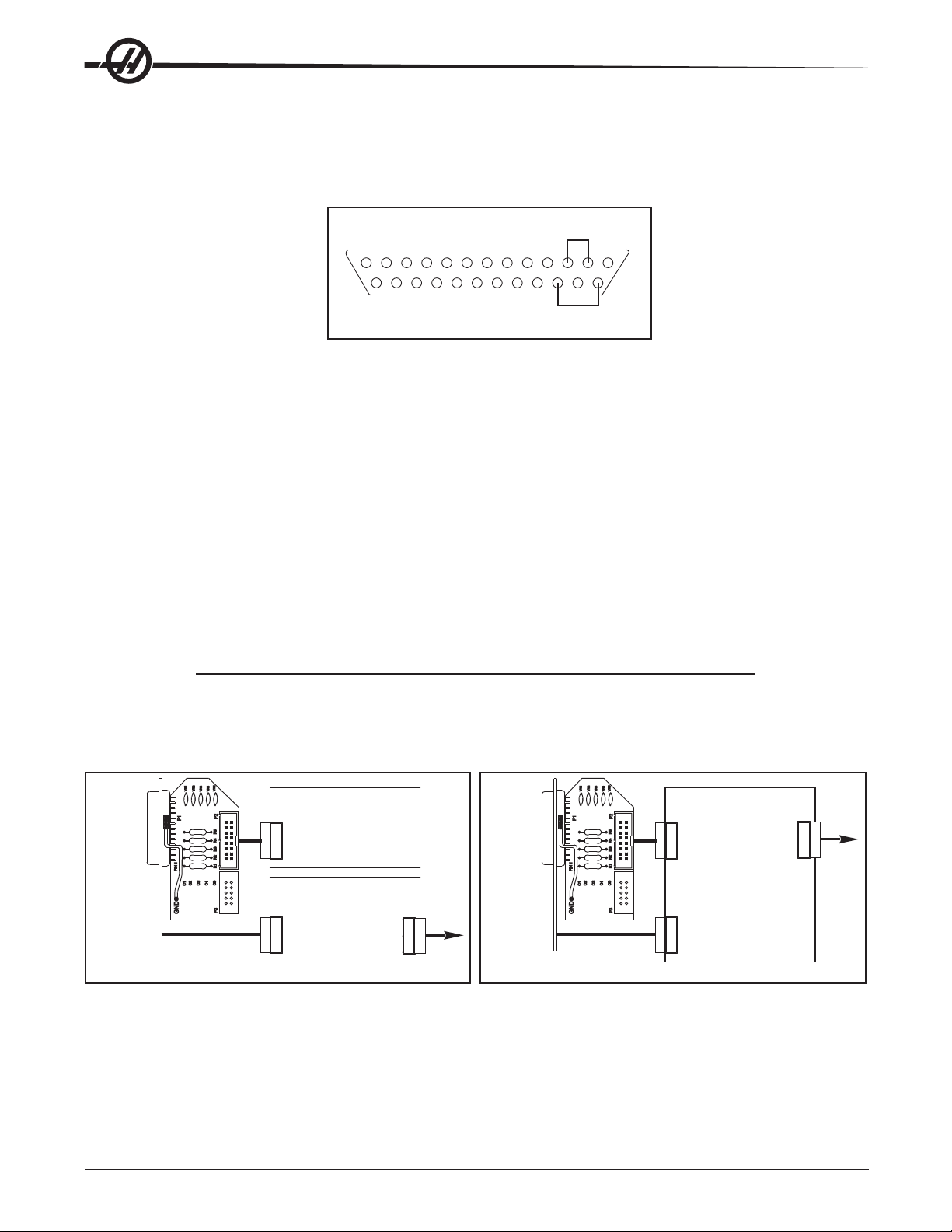

The M code interface uses outputs M21-25 and one discrete input circuit. M codes M21 through M25 will

activate relays labeled M21-25. These relay contacts are isolated from all other circuits and may switch up to

120V AC at three amps. The relays are SPDT (Single Pole Double Throw).

Power circuits and inductive loads must have snubber protection.

The M-FIN circuit is a normally open circuit that is made active by bringing it to ground. The one M-FIN applies to all of the user M codes.

The timing of a user M function must begin with all circuits inactive (open). The timing is as follows:

WARNING!

M21

M-FIN Discrete

Input 1009

CNC is:

Running Waiting

for M-fin

.05 ms

delay

Waiting for

end M-fin

Running

The Diagnostic Data display page may be used to observe the state of these signals.

M FUNCTION RELAYS (M-FIN)

The I/O PC board has relays that are available to the user. M21 is already wired out to P12 at the side of the

control cabinet. This is a four-pin DIN connector and includes the M-FIN signal.

NOTE: Refer to Diagnostic Data for specifi c machine Inputs and Outputs.

3

M-Code

Output Relay

Normally Open

4

1 M-FIN, Input Signal

2 Input GND

NOTE: Some or all of the M21-25 on the I/O PCB may be used for factory installed options.

Inspect the relays for existing wires to determine which are in use.

M-FIN DISCRETE INPUT

The M-FIN discrete input is a low voltage circuit. When the circuit is open, there is +12V DC at this signal.

When the line is brought to ground, there is about 10 milliamps of current. M-FIN is discrete input 1009 and

is wired from input 1009 on the I/O PCB (usually P10). The return line for grounding the circuit should come

from that PCB. For reliability, these two wires should be routed in a shielded cable where the shield is grounded at one end only. The diagnostic display shows a “1” when the circuit is open and a “0” when it is grounded.

96-0284 rev E June 2008

Electrical Service

25

Page 27

WIRING THE RELAYS

Relays are marked on the I/O PCB, with their respective terminals forward of them. If the optional 8M relay

board is installed, connections on the I/O PCB are unused, since they are replaced by relays on the optional

board. Refer to the fi gure, and the Probe Option fi gure in the Electrical Diagrams section for terminal labeling.

SWITCHES

X, Y, Z Travel Limit Switches

Machine zero position is defi ned by a limit switch for each of the X, Y, and Z axes. After the search for ma-

chine zero is complete, these switches are used to limit travel in the positive direction. Travel in the negative

direction is limited by stored stroke limits. It is not normally possible to command the servo axes past the machine zero as servo travel lookahead will decelerate and stop each motor prior to exceeding the stroke limits.

Prior to performing a Power Up/Restart or an Auto All Axes operation, there are no travel limits. You can jog

into the hard stops in either direction for X, Y, or Z. After a Zero Return has been performed, the travel limits

will operate unless an axis hits the limit switch. When the limit switch is hit, the zero returned condition is reset

and an Auto All Axes must be done again to ensure you can still move the servo back away from it.

The limit switches are normally closed. When a search for zero operation is being performed, the X, Y, and Z

axes will move towards the limit switch unless it is already active (open); then move away from the switch until

it closes again; then continue to move until the encoder Z channel is found. This position is machine zero.

On some mills, the auto search for zero in the Z-axis is followed by a rapid move from the limit switch position

down to the tool change position, making the Z-axis a little different from the other axes. The position found

with the limit switch is not machine zero but is the position used to pull tools out of the spindle. Machine zero

for Z is below this by Parameter 64. Be careful during the Z zero search and stay clear of that rapid move.

What Can Go Wrong With Switches?

Proximity switches are distance sensitive, and must be set no farther than .012” (3mm) away from an assem-

bly or limit fl ag. An improperly set proximity switch will give inconsistence results, which may be interrupted as

another problem. Any time a switch is replaced ensure the proper distance is set.

• If the machine is operated with Limit Switch inputs disabled, a Low Lube and Door Open alarm is generated.

In addition, Home search will not stop at the limit switch and instead runs into the physical stops on each axis.

• If the switch is damaged and permanently open, the zero search for that axis will move in the negative direc-

tion at about 0.5 in/min until it reaches the physical travel stops at the opposite end of travel.

• If the switch is damaged and permanently closed, the zero search for that axis will move at about 10 in/min

in the positive direction until it reaches the physical stops.

• If the switch opens or a wire breaks after the zero search completes, an alarm is generated, the servos are

turned off, and all motion stops. The control will operate as though the zero search was never performed.

Reset can be used to turn servos on, but you can jog that axis slowly.

Clamp/Unclamp Switches

There are two switches used to sense the position of the turret or tool clamping mechanism. They are both

normally closed and one will activate at the end of travel during unclamping and the other during clamping.

When both switches are closed, it indicates that the turret or drawbar is between positions.

The diagnostic display can be used to display the status of the relay outputs and the switch inputs.

Door Hold Switch

The switch is normally closed. When the door opens, the switch opens and the machine stops with a “Door

Hold” function. When the door is closed again, operation continues normally.

If the door is open, it is not possible to start a program. Door hold will not stop a tool change operation, will not

turn off the spindle, and will not turn off the coolant pump. The door hold function can be temporarily disabled

with Setting 51, but this setting will return to Off when the control is turned off.

26

Electrical Service

96-0284 rev E June 2008

Page 28

Tool #1 Sense Switch

The tool rotation turret has a switch that is activated when tool one is in position or facing toward the spindle.

At Power On this switch can indicate that tool #1 is in the spindle. If this switch is not active at power-on, the

fi rst tool change will rotate the turret until the switch engages and then move to the selected tool. The diag-

nostic display will show the status of this input switch as “Tool #1”. A “1” indicates that tool #1 is in position.

Umbrella Tool Changer Geneva Wheel Position Mark (Vert)

The turret rotation mechanism has a switch mounted so that it is activated for about 30o of travel of the

Geneva mechanism. When activated, this switch indicates that the turret is centered on a tool position. This

switch is normally closed. The diagnostic display will show this status of this input switch as “TC MRK”. A “1”

indicates the Geneva wheel is in position.

Umbrella Tool Changer Shuttle In/Out Switches (Vert)

Two switches are used to sense the position of the tool changer shuttle and the arm that moves it. One switch

is activated when the shuttle is moved to full travel inward and one is activated when it is in full travel outward.

These switches are normally closed, so that both are closed between in and out. The diagnostic display will

show the status of the input switch. A “1” indicates the associated switch is activated or open.

Transmission High/Low Gear Position Switches

On machines with a two-speed transmission, there are two switches in the gearbox used to sense the position of the gears. One switch indicates “High” by opening and the other indicates “Low” by opening. Between

gears, both switches are closed, indicating a between-gear condition. The diagnostic display shows the status

of these switches and the Curnt Comds display shows which gear is selected. If the switches indicate that the

gearbox is between gears, the display will indicate “No Gear”.

NOTE: The Transmission High/Low Gear Position Switches are located at the bottom of the

CONTROL MEMORY

The Haas processor board contains three types of memory: