Page 1

Haas Technical Publications

Manual_Archive_Cover_Page Rev A

any other party automatically voids the factory warranty.

June 6, 2013

HAAS SERVICE AND OPERATOR MANUAL ARCHIVE

Mechanical Service Manual 96-0283A RevA English June 2006

• This content is for illustrative purposes.

• Historic machine Service Manuals are posted here to provide information for Haas machine owners.

• Publications are intended for use only with machines built at the time of original publication.

• As machine designs change the content of these publications can become obsolete.

• You should not do mechanical or electrical machine repairs or service procedures unless you are qualied

and knowledgeable about the processes.

• Only authorized personnel with the proper training and certication should do many repair procedures.

WARNING: Some mechanical and electrical service procedures can be

extremely dangerous or life-threatening.

Know your skill level and abilities.

All information herein is provided as a courtesy for Haas machine owners

for reference and illustrative purposes only. Haas Automation cannot be held

responsible for repairs you perform. Only those services and repairs that are

provided by authorized Haas Factory Outlet distributors are guaranteed.

Only an authorized Haas Factory Outlet distributor should service or repair a

Haas machine that is protected by the original factory warranty. Servicing by

Page 2

GENERAL MACHINE TROUBLESHOOTING

Before You Begin:

Use Common Sense

Many problems are easily overcome by correctly evaluating the situation. All machine operations are composed

of a program, tools, and tooling. Y ou must look at all three before blaming one as the fault area. If a bored hole

is chattering because of an overextended boring bar, don’t expect the machine to correct the fault. Don’t

suspect machine accuracy if the vise bends the part. Don’t claim hole mis-positioning if you don’t first centerdrill the hole.

Find the Problem First

Many mechanics tear into things before they understand the problem, hoping that it will appear as they go. We

know this from the fact that more than half of all warranty returned parts are in good working order . If the spindle

doesn’t turn, remember that the spindle is connected to the gear box, which is connected to the spindle motor,

which is driven by the spindle drive, which is connected to the I/O Board, which is driven by the MOCON, which

is driven by the processor. The moral here is don’t replace the spindle drive if the belt is broken. Find the

problem first; don’t just replace the easiest part to get to.

Don’t Tinker with the Machine

There are hundreds of parameters, wires, switches, etc., that you can change in this machine. Don’t start

randomly changing parts and parameters. Remember , there is a good chance that if you change something,

you will incorrectly install it or break something else in the process. Consider for a moment changing the

processor’s board. First, you have to download all parameters, remove a dozen connectors, replace the board,

reconnect and reload, and if you make one mistake or bend one tiny pin, it won’t work. You always need to

consider the risk of accidentally damaging the machine anytime you work on it. It is cheap insurance to

double-check a suspect part before physically changing it. The less work you do on the machine the better .

This manual presents information for Horizontal machines, Lathes, and V ertical machines:

Horiz is used to indicate Horizontal machines.

Lathe is used to indicate Lathes.

Vert is used to indicate Vertical machines.

VIBRATION

Vibration is a subjective evaluation, which makes it difficult to determine, in mild cases, if there is an actual

problem. In obvious cases, it is a matter of determining the source. Vibrations need to be distinguished from

noise such as a bad bearing. Assuming that vibrations would be something that could be felt by putting your

hand on the spindle covers or spindle ring, a dial indicator may help prove this. This crude method is to take a

dial indicator on a magnetic base extended 10 inches between the table and spindle housing and observe the

reading of the indicator. A reading of more than .001” would indicate excessive vibration. The two common

sources of noise are the spindle and axis drives. Most complaints about vibration, accuracy , and finish can be

attributed to incorrect machining practices such as poor quality or damaged tooling, incorrect speeds or feeds,

or poor fixturing. Before concluding that the machine is not working properly , ensure that good machining

practices are used. These symptoms will not occur individually (Ex. A machine with backlash may vibrate

heavily , yielding a bad finish.) Put all of the symptoms together to arrive at an accurate picture of the problem.

Machine vibrates while spindle is on and is not cutting. Sometimes only at specific RPM.

• If the spindle alone causes vibration of the machine, it is usually caused by the belt/pulley drive system or the

chuck jaws not centered correctly.

Machine vibrates while jogging the axis with the hand wheel/jog handle.

• The Haas control uses very high gain acceleration curves. This vibration as you jog is simply the servos

quickly trying to follow the handle divisions. If this is a problem, try using a smaller division on the handle. You

will notice the vibration more at individual clicks than when you are turning the handle faster. This is normal.

96-0283 rev A June 2006

Mechanical Service

1

Page 3

Machine vibrates excessively in a cut

• This can be caused by a number of factors as machining practices come into play. Generally speaking, the

least rigid element of a cut is the tool because it is the smallest part. Any cutter will vibrate if pushed beyond

its tensile strength. In order to eliminate the machine as the source of the problem, you need to check the

spindle and the backlash of the axes as described in the following sections. Once machining practices have

been eliminated as the source of vibration, observe the machine in both operation and “cutting air.” Move the

axes (individually) without the spindle turning and then turn the spindle without moving the axes. Isolate

whether the vibration comes from the spindle head or from an axis.

ACCURACY

Before you complain of an accuracy problem, please make sure you follow these simple do’s and don’ts:

• Ensure that the machine has been sufficiently warmed up before cutting parts. This will eliminate

mispositioning errors caused by thermal growth of the ballscrews (see "Thermal Growth" section).

• Don’t ever use a wiggler test indicator for linear dimensions. They measure in an arc and have sine/cosine

errors over larger distances.

• Don’t use magnetic bases as accurate test stops. High accel/decel of the axis can cause movement.

• Don’t attach magnetic base/test points to the sheet metal of the machine.

• Don't mount the magnetic base on the spindle dogs (mills).

• Don’t check for accuracy/repeatability using an indicator with a long extension.

• Ensure that test indicators and stops are absolutely rigid and mounted to machined casting surfaces (e.g.

spindle head casting, spindle nose, or the table).

• Don't rapid to position when checking accuracy. The indicator may get bumped and give an inaccurate

reading. For best results, feed to position at 5-10 inches per minute (mills).

• Check a suspected error with another indicator or method for verification.

• Ensure that the indicator is parallel to the axis being checked to avoid tangential reading errors.

• Center drill holes before using jobber length drills if accuracy is questioned.

• Once machining practices have been eliminated as the source of the problem, determine specifically what the

machine is doing wrong.

Mills

Machine will not interpolate a round hole.

• Check that the machine is level (see "Installation" section of the Reference manual).

• Check for backlash ("Ball Screw Removal and Installation" section).

Bored holes do not go straight through the workpiece.

• Check that the machine is level (see "Installation" section of the Reference manual).

• Check for squareness in the Z axis.

Machine bores holes out-of-round.

• Check that the machine is level (see "Installation" section of the Reference manual).

• Check the sweep of the machine (see "Draw Bar Replacement" section).

Bored holes are out of round or out of position.

• Check for thermal growth of the ball screw (see "Thermal Growth" section).

• The spindle is not parallel to the Z-axis. Check sweep of the machine ("Draw Bar Replacement").

2

Mechanical Service

96-0283 rev A June 2006

Page 4

Machine mis-positions holes.

• Check for thermal growth of the ball screw (see "Thermal Growth" section).

• Check that the machine is level (see "Installation" section of the Reference manual).

• Check for backlash (see "Ball Screw Removal and Installation" section).

• Check the squareness of the X-axis to the Y-axis.

Machine leaves large steps when using a shell mill.

• Check that the machine is level (see "Installation" section of the Reference manual).

• Check the sweep of the machine (see "Draw Bar Replacement" section).

• Cutter diameter too large for depth of cut.

Boring depth inaccurate.

• Check for thermal growth of the ballscrew (see "Thermal Growth" section).

• Check the hydraulic counterbalance system. Check for:

Abnormal noises from counterbalance system.

Oil leaks (esp. at fittings and at filter at top of cylinder).

Bound cylinder.

Lathes

Diameters are out of round

• Check that tooling and machining practices are correct. Bores will be out of round due to tool deflection much

more frequently than due to spindle bearing problems.

Drill

Diameters are incorrect in X-axis

• Ensure the tool probe is set up correctly (settings, etc.).

• Ensure tool offsets are correct. Note that the coordinate system (FANUC, YASNAC, HAAS) must be

selected before setting tools.

• Ensure Parameter 254, Spindle Center, is set correctly.

• Check for thermal growth of the X-axis ballscrew (see “Thermal Growth” section).

Center holes are malformed

• Ensure tooling is tight.

• Ensure Parameter 254, Spindle Center, is set correctly.

• Check spindle to turret pocket alignment. It may be out of alignment due to a crash or misadjustment.

• Check for thermal growth of the X-axis ballscrew (see “Thermal Growth” section).

Part faces are conical

• Wedge may be out of alignment due to a crash.

• Check tooling setup. Turning long, unsupported parts may cause conical part faces.

• Check for thermal growth of the ballscrews (see Thermal Growth” section).

96-0283 rev A June 2006

Mechanical Service

3

Page 5

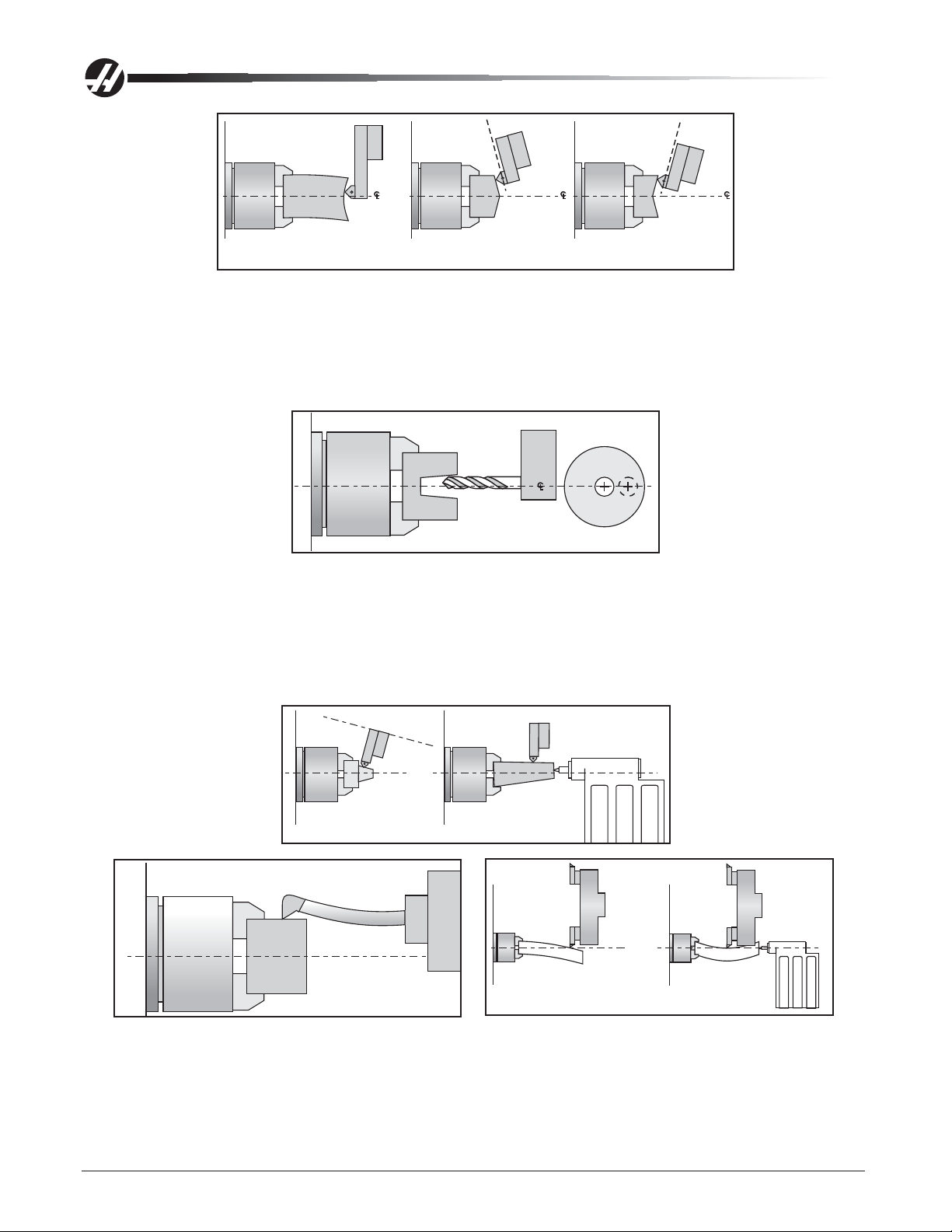

C

L

C

L

C

L

Part/Tooling Problem Geometry Problem

Bores are tapered

• Check that tooling and machining practices are correct. Bores will be tapered if the tooling is inappropriate,

the speeds and feeds are incorrect, or coolant is not getting to the cutting tool.

• Although it is rare, the spindle may be out of alignment due to a crash.

• Check that the turret face is parallel with X-axis.

C

L

Outside diameter (O.D.) is tapered

• Check tooling setup. Turning long, unsupported parts can cause a tapered O.D.

• Check tailstock setup. Excessive hold pressure on the tailstock can distort parts.

• Spindle to Z-axis may be out of alignment (not parallel).

• Program around it. Reduce depth of final rough cut and finish pass to reduce part deflection.

C

L

Poor Geometry

C

L

C

L

C

L

Poor Technique

Material left after facing a part

• Ensure tooling is correct.

• Ensure turret is aligned to X-axis travel.

C

L

4

Mechanical Service

96-0283 rev A June 2006

Page 6

• Ensure Parameter 254, Spindle Center, is set correctly.

Material LeftAfter Facing Part

FINISH

Machining yields a poor finish

• Check for backlash ("Ball Screw Removal and Installation" section).

• Check the condition of the tooling and the spindle.

Vertical & Horizontal Machines

• Check for gearbox vibration.

• Check for spindle failure.

• Check the condition of the axis/servo motors.

• Check that the machine is level (see the Installation section of the Reference manual).

Lathes

• Check turret alignment.

• Ensure turret is clamped.

• Ensure tooling is tight.

• Check tooling for chatter or lack of rigidity.

• Check the balance of the chuck, part, and fixture.

Chuck

Part

THERMAL GROWTH

A possible source of accuracy and positioning errors is thermal growth of ballscrews. As the machine warms

up, ballscrews expand in all linear axes, causing accuracy and positioning errors (or inaccurate boring depths

for vertical and horizontal machines). This is especially critical in jobs that require high accuracy , machining

multiple parts in one setup, or machining one part with multiple setups.

NOTE: On machines with linear scales, thermal growth will not affect machine

positioning or accuracy. However, it is recommended that the machine be

warmed up before cutting parts. The ballscrew always expands away from the

motor end. Thermal growth in a lathe ballscrew will be more noticeable in the

X-axis, since errors will be doubled when cutting a diameter.

96-0283 rev A June 2006

Mechanical Service

5

Page 7

Verify Thermal Growth

There are a number of ways to verify the problem. The following procedure will verify thermal growth of the X-

axis (reverse-anchored for lathes) ballscrew in a machine that has not been warmed up:

1. Home the machine. In MDI mode, press Posit and Page Down to the Oper page.

2. Jog to an offset location on the table (example: X-15.0" Y-8.0" for vert & horiz). Select the X-axis and press

the Origin key to zero it. Select the Y-axis for mills and zero it.

3. Press the Ofset key, then scroll down to G110 (or any unused offset). Cursor to X and press Part Zero Set

once to set X0, then press again to set Y0. Press Z Face Meas once for a lathe.

4. Enter the following program. It will start at the new zero position, rapid 10 inches in the X direction, feed the

final .25 inches at 10 inches/min., and then repeat the X movement.

G00 G110 X0 Y0;

X10.0;

G01 X10.25 F10. ;

M99;

5. In order to set up the indicator, run the program in Single Block mode, and stop it when X is at 10.25" (or

end of its set travel for Lathes). Set the magnetic base on the table, with the indicator tip touching the

spindle housing in the X-axis for vert & horiz, or for lathes, set it on the spindle retainer ring or other rigid

surface, with the indicator tip touching the turret in the X-axis, and zero it.

6. Exit Single Block mode, and run the program for a few minutes. Enter Single Block mode again, stop the

program when X is at 10.25" for vert & horiz or at the beginning of its travel for lathes, and take a final

reading on the indicator. A difference in the X position indicates a thermal growth problem.

NOTE: Ensure indicator setup is correct as described in "Accuracy" section. Setup

errors are commonly mistaken for thermal growth.

7. A similar program can be written to test for thermal growth in the Y- and Z-axes, if necessary.

Solutions

Since there are many variables that affect thermal growth, such as the ambient temperature of the shop and

program feed rates, it is difficult to give one solution for all problems.

Thermal growth problems can generally be eliminated by running a warm-up program for approximately 20

minutes before machining parts. The most effective warm-up is to run the current program, at an offset Z

position before the part for lathes, or above the part or table, with the spindle "cutting air" for vert & horiz. This

allows ball screws to warm up to the correct temperature and stabilize. Once at temperature, ball screws won't

expand any further , unless allowed to cool down. A warm-up program should be run after each time the machine is left idle.

Compensation for Thermal Growth

During normal operation, small inaccuracies in the work pieces may develop due to thermal expansion of the

ball screws. Ball screws are made of steel which expands at the rate of 1 1 millionths of an inch per degree C.

The Haas control contains built-in features to electronically correct for ball screw growth. This compensation

works by estimating the heating of the screw based on the amount of travel over the length of the screw and is

measured from the motor. Adjustment s can be made to the settings as needed. The user can fine-tune this

compensation up to plus or minus 30% with the use of settings 158, 159 and 160. If the part size is too big,

decrease the amount of compensation for the appropriate axis. For example, increasing the value in Setting

158, “X Screw Thermal Comp%”, can increase the amount of thermal compensation.

6

Mechanical Service

96-0283 rev A June 2006

Page 8

WAY COVERS/HEAD COVERS

Recommended T orque V alues for Machine Fasteners - The following chart should be used as a reference

guide when replacing way covers/head covers for torquing machine fasteners where specified.

DIAMETER TORQUE

8-32 30 in-lb

1/4 - 20 15 ft-lb

5/16 - 18 30 ft-lb

3/8 - 16 50 ft-lb

M10 - 100 50 ft-lb

M12 - 65 100 ft-lb

1/2 - 13 80 ft-lb

3/4 - 10 275 ft-lb

1 - 8 450 ft-lb

X-AXIS WAY COVER REMOVAL (HORIZ)

Left/Right Way Cover Removal

1. Jog the X-axis to the center of travel and Power Off the machine.

2. Remove the SHCS that fasten the way covers to the table and remove the SHCS that fasten the way

covers to the outside casting.

Y-AXIS WAY COVER REMOVAL (HORIZ)

Removal - Upper

1. Jog the X-axis to the center of travel and the Y-axis all the way down.

2. Power Off the machine.

3. Remove the BHCS that fasten the way cover to the spindle head and the vertical guides to the column.

4. Remove the top way cover.

Install the way cover in the reverse order above; however, make sure that all necessary gaskets and sealants

are replaced and repaired as necessary .

Removal - Lower

1. Jog the X-axis to the center of travel and the Y-axis all the way up.

2. Power Off the machine.

3. Remove the three (3) BHCS that fasten the way cover to the spindle head.

4. Remove the seven (7) BHCS on each side that fasten the vertical guides to the column.

5. Remove the lower way cover .

Install way covers in the reverse order above; however , make sure that all necessary gaskets and sealants are

replaced and repaired as necessary .

Z-AXIS WAY COVER (HORIZ)

Right Way Cover - Removal

1. Jog the Z-axis (receiver) all the way in the +Z direction (away from the spindle).

2. Power Off the machine.

3. Remove the 14 BHCS that fasten the front of the way cover to the receiver.

96-0283 rev A June 2006

Mechanical Service

7

Page 9

4. Remove the 14 BHCS that fasten the rear of the way cover to the column.

5. Remove the way cover .

Right Way Cover - Installation

1. Power On the machine.

2. Replace the way cover . The end with the smallest section goes toward the receiver .

3. Fasten the column end using fourteen (14) BHCS.

4. Fasten the receiver end using fourteen (14) BHCS.

Left Way Cover - Removal

1. Jog the Z-axis (receiver) all the way in the -Z direction (toward the spindle).

2. Rotate the H-frame 45° counterclockwise.

3. Remove the thirteen (13) BHCS that fasten the rear way cover to the receiver assembly.

4. Remove the rear way cover through the door.

Install way covers in the reverse order above; however , make sure that all necessary gaskets and sealants are

replaced and repaired as necessary .

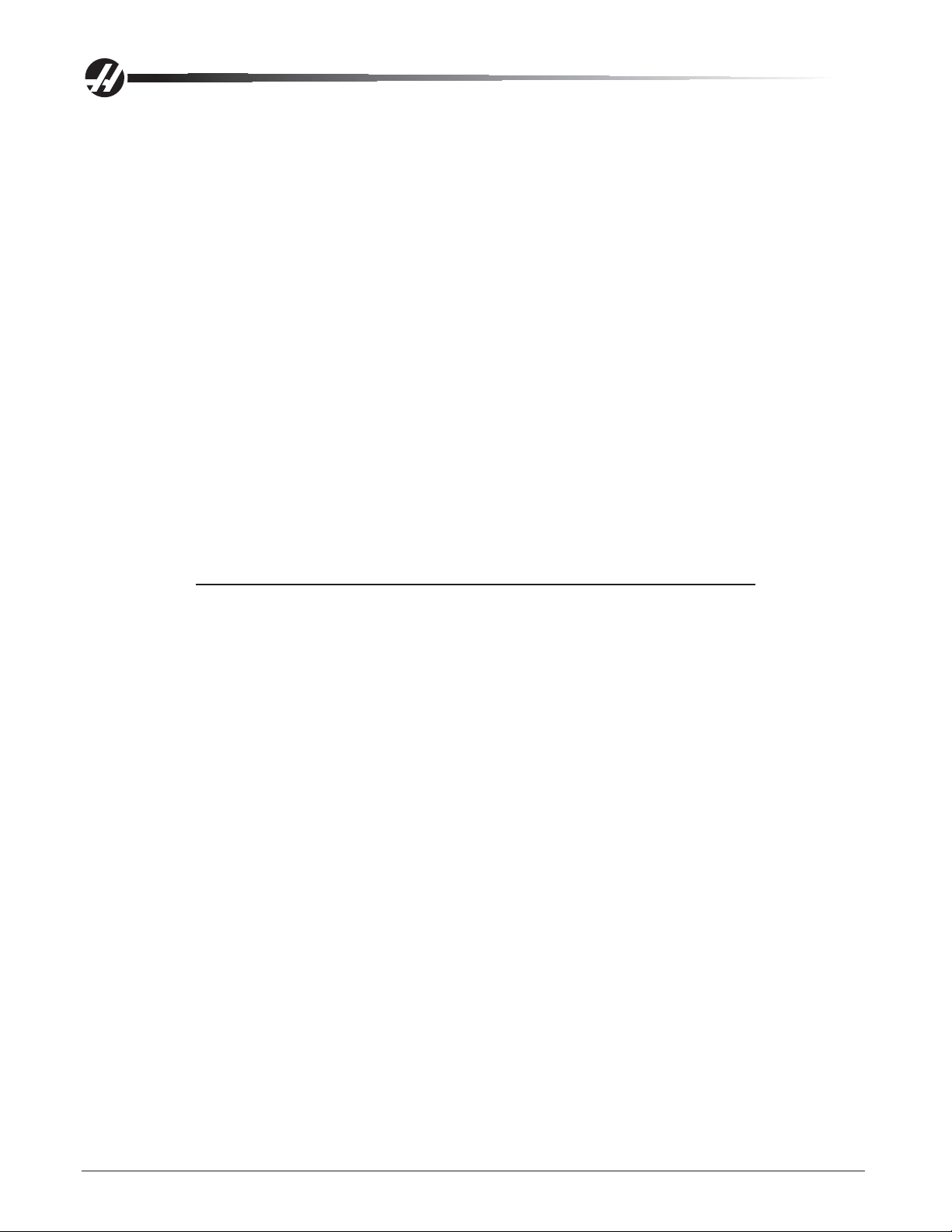

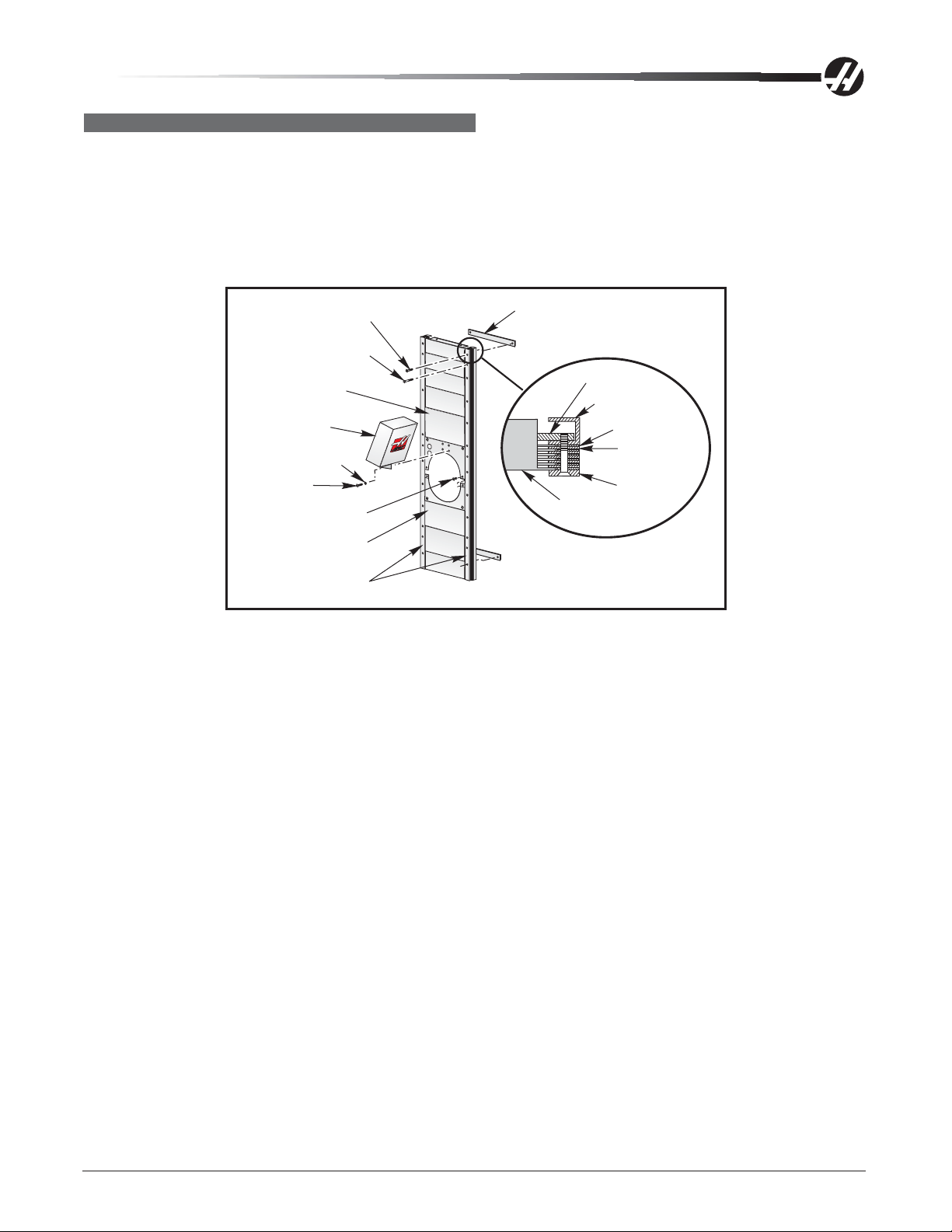

EC-300 X-AXIS WAY COVER ADJUSTMENT

The front of the column on either side of the spindle is covered by heavy shades kept taut by spring loaded

canisters. If the shades should need adjusting, refer to the following procedure.

Shades

Shade Rotation

Set Screw

Flat

Left When

Facing Machine

Right When

Facing Machine

1. Clamp the shaft at the flat with clamping pliers or other such clamping device to hold the shaft when

adjusting of the spring tension.

2. Loosen the set screw so that the spring tension may be adjusted.

3. Rotate the shaft one complete revolution against the force of the spring (counterclockwise for the left

canister and clockwise for the right canister). Retighten the set screw.

4. Check the tension of the shade. Repeat this process as needed for proper tension one revolution at a time.

Do not overtighten the spring.

8

Mechanical Service

96-0283 rev A June 2006

Page 10

EC-300 Y-AXIS WAY COVER ADJUSTMENT

Upper Way Cover - Removal

1. Handle jog the X-axis to center of travel. Handle jog the Y-axis down fully.

2. Power Off the machine.

3. Remove the twenty six (26) FHCS that attach the vertical guides to the way cover.

4. Remove the six BHCS that the attach the upper way cover to the spindle head and the lower way cover.

20X 1/4-20 UNC

x 1-1/4 SS FHCS

6X 1/4-20 UNC

x 2-1/2 SS FHCS

Upper Y-Axis

Waycovers

P-Cool

(Optional)

4X Lockwasher

4X BHCS

6X BHCS

Lower Y-Axis

Waycovers

Waycover Guide

Rails

2X Holding Bar

Holding Bar

2X Guide Rail

6X Spacer

5X Guide

Bar

Front Bar

Y-Axis

Waycovers

Upper Way Cover - Installation

1. Install the four SHCS at the top of the way cover. Slide it up and down to ensure it moves freely.

2. Slide the way cover down until the bottom flange goes under the spindle head cover and fasten it with four

BHCS.

3. Fasten the left and right vertical guides using FHCS.

Lower Y-Axis Way Cover - Removal

1. Handle jog the X-axis to center of travel. Handle jog the Y-axis up fully.

2. Power Off the machine.

3. Remove the SHCS that attach the left and right vertical guides and remove.

4. Remove the four FHCS that attach the top of the lower Y-axis way cover to the spindle head casting.

Collapse the way cover down fully .

5. Remove the way cover from the bottom.

Lower Y -Axis W ay Cover - Inst allation

1. Install the four SHCS at the bottom of the way cover, and tighten evenly.

2. Slide the bottom of the way cover up and down to ensure it moves freely.

3. Slide the top flange of the waycover under the spindle head cover plate and fasten it to the spindle head

cover and upper waycover using four BHCS.

4. Replace the left and right vertical guides using BHCS.

96-0283 rev A June 2006

Mechanical Service

9

Page 11

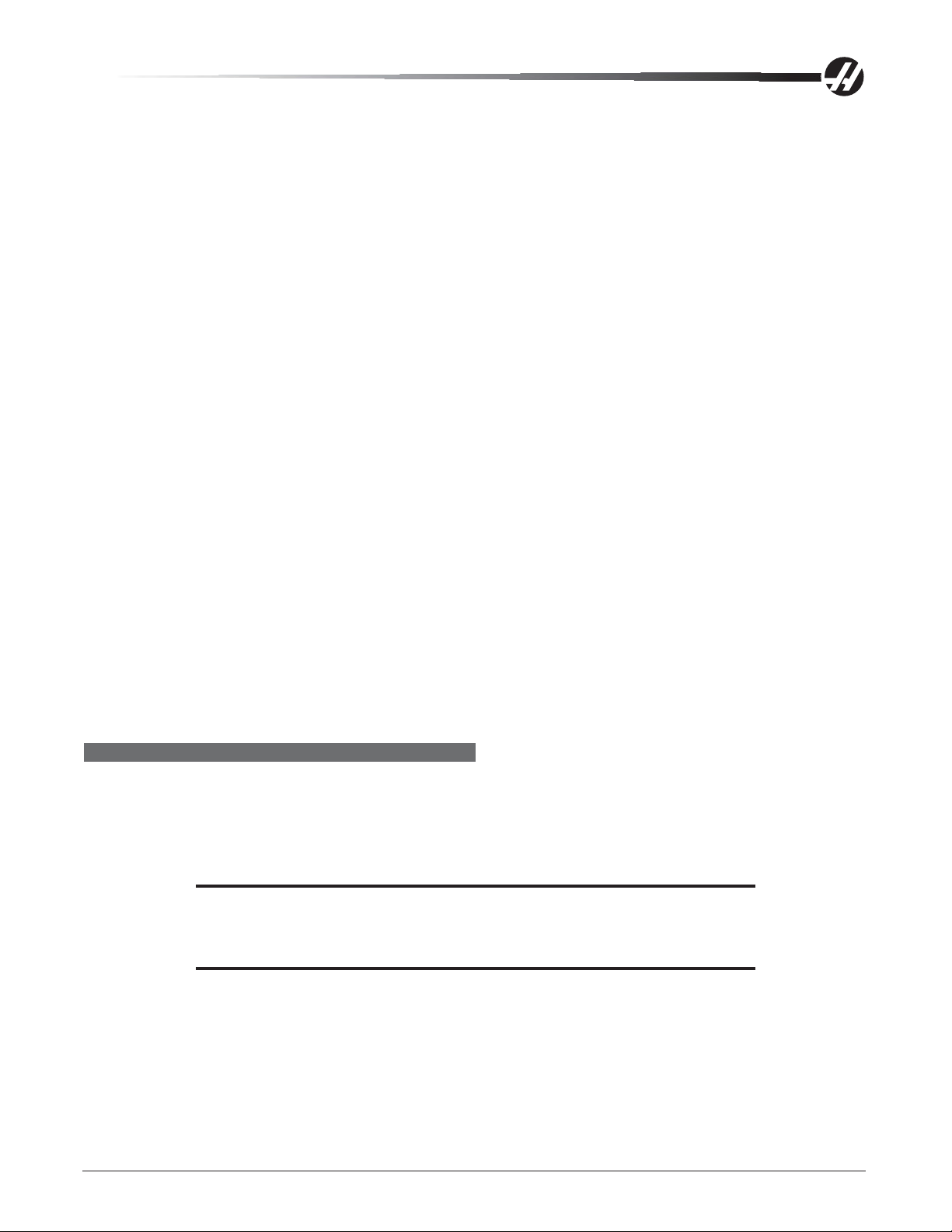

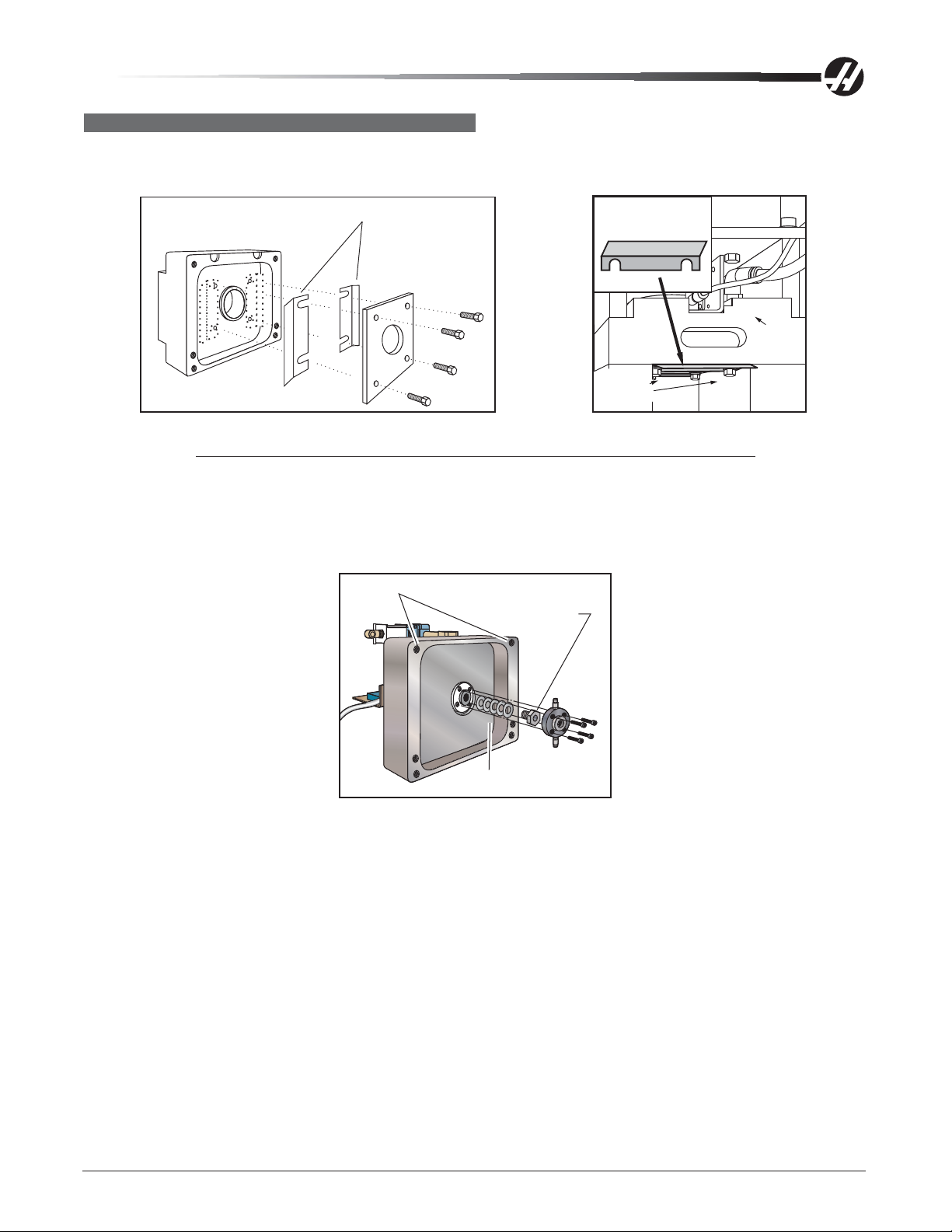

HEAD COVERS REMOVAL/INSTALLATION (VERT)

Removal

NOTE: This procedure is for the VF-3/4. However, the procedure varies only slightly

for other models.

50 T aper machines: Before removing the head cover , remove the fan assembly and disconnect the tool

release and fan electrical connectors.

10-32 x 3/8" SHCS

VF-3/4 Head Covers

Remove side

covers from

top side

1. Zero return (Zero Ret) all axes, then Handle Jog to center X- and Y-axes under spindle. Protect table

surface with a piece of cardboard.

2. Remove the top and rear covers.

3. Pull front cover from the bottom until you can disconnect the tool release cable (quick disconnect), then

remove cover. Remove the side covers. Jog Z-axis as necessary to make screw removal easier.

Installation

1. Protect table surface with a piece of cardboard. Replace each side cover from the top. Jog Z-axis as

necessary to make access to screws easier.

2. Reconnect tool release cable, if equipped, then replace front cover from the bottom. Replace rear cover and

top cover.

TOOL RELEASE PISTON (TRP) ASSEMBLY

Please read this section in its entirety before attempting to replace the tool release piston

assembly.

Overview

The tool release piston is actuated by air. It forces the tool draw bar down against the spring st ack, releasing

the old tool and permitting the new tool to be inserted. Normally the piston is in the upper, retracted position.

During a tool change cycle the piston is forced down by air pressure, pushing the draw bar down until the pull

stud on the top of the tool is released.

As the piston finishes its downward stroke a hole in the side of the tool release shaft comes clear of the

cylinder housing and is exposed to the compressed air within the cylinder. The air flows down through the shaft

to the tool release nut at the lower end of the shaft. This nut presses on the end of the tool draw bar and the air

flows through a central hole drilled through both the tool release nut and the tool draw bar to blow any chips out

of the tapered area of the spindle shaft.

10

Mechanical Service

96-0283 rev A June 2006

Page 12

The spring retainer captures the compression spring that returns the tool change piston and shaft to the normal

position when the air is released from the cylinder. The upper and lower limit switches are actuated by the

spring retainer . The position of these switches is monitored by the computer control system during a tool

change cycle.

There are different tool release pistons for 40 and 50 taper spindles. In addition The tool change pistons have

different subassemblies that will need to be adjusted, or may need replacing. The section(s) that follow the

installation instructions must be completed as well or serious damage to the machine could result.

T ool Clamp/Unclamp

The tool holder drawbar is held clamped by spring pressure. Air pressure is used to release the tool clamp.

When the tool is unclamped, air is directed down the center of the spindle to clear the taper of water , oil, or

chips. Tool unclamp can be commanded from a program (but this is quite dangerous), from the keyboard, and

from the button on the side of the spindle head. The two manual buttons only operate in MDI or Jog modes.

T ool Clamp/Unclamp Air Solenoids

A single solenoid controls the air pressure to release the tool clamp. This corresponds to relay K15. When the

relay is activated, 1 15V AC is applied to the solenoid. This applies air pressure to release the tool. Relay K15

is on the I/O PCB. Circuit breaker CB4 will interrupt power to this solenoid.

Tool Clamp/Unclamp Sense Switches

There are two switches located on the tool release piston assembly that are used to sense the position of the

tool clamping mechanism. They are both normally closed, but one open once clamped and the other when

unclamped. When both switches are closed, it indicates that the draw bar is between positions.

A tool change operation will wait until the unclamped switch is sensed before the Z-axis pulls up from the tool.

This prevents any possibility of breaking the tool changer or its support mounts. The diagnostic display can be

used to display the status of the relay outputs and the switch inputs. The Precharge and TSC system applies

low air pressure and releases the clamped switch.

Remote Tool Unclamp Switch

The Remote Tool Unclamp switch is mounted on the side of the cover to the spindle head. It operates the same

as the button on the keyboard. It must be held for ½ second before the tool will be released and the tool will

remain released for ½ second after the button is released. While the tool is unclamped, air is forced down the

spindle to clear chips, oil, or coolant from the tool holder .

SPINDLE TRP REMOVAL

1. For TSC equipped machines, place a tool holder in the spindle.

2. Remove cover panels from headstock area in accordance with "Head Covers Removal and Installation".

3. For 50 Taper TSC equipped machines the coolant union and extension tube must be removed before

proceeding. They both have left handed threads.

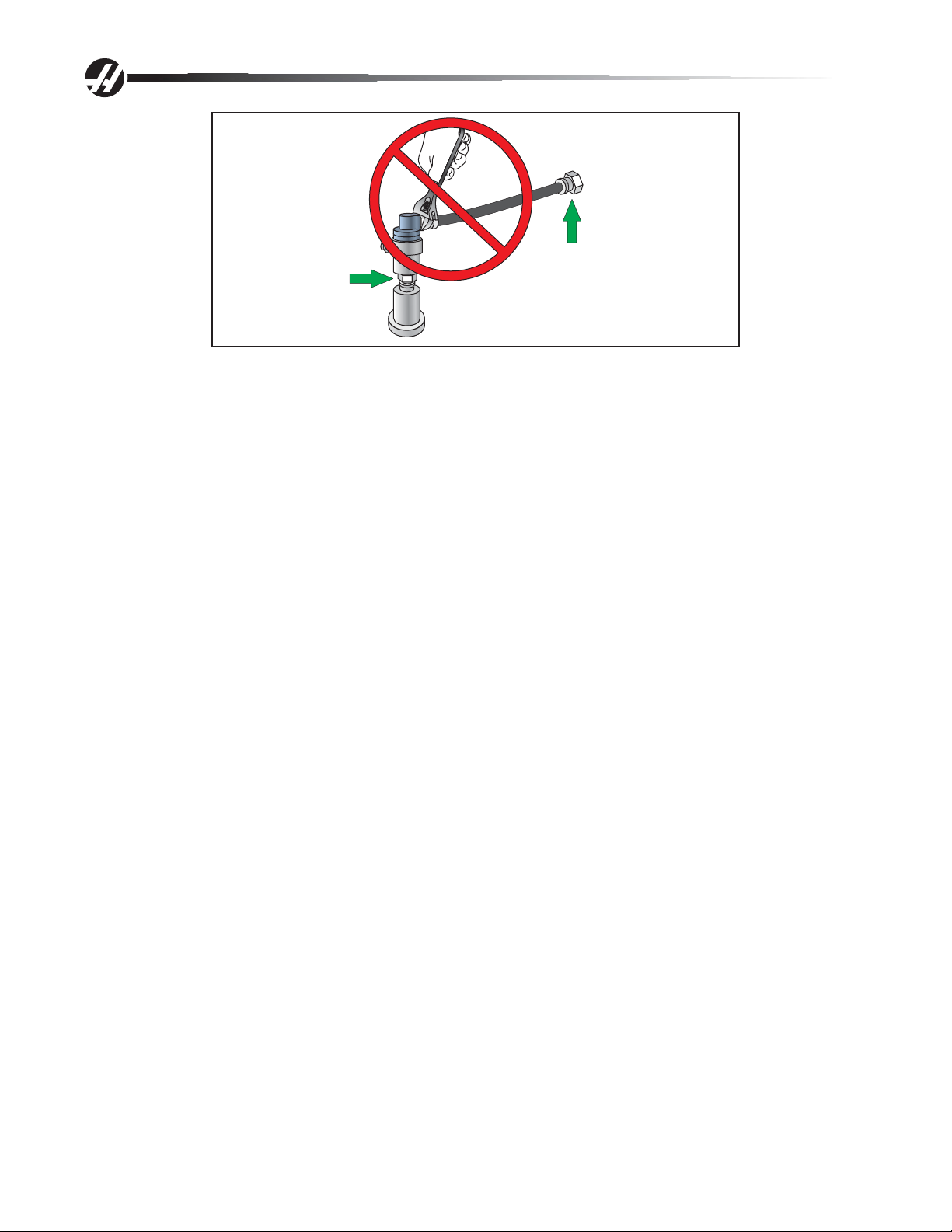

CAUTION: Do not remove pipe connectors from the coolant union! Remov-

ing any pipe connector from the union will void your warranty on

the union. Use wrenches only on the SAE hose connector and

the bottom nut of the Coolant Union. See arrows below:

96-0283 rev A June 2006

Mechanical Service

11

Page 13

SAE Hose Connector

Left Hand Threads

a. Loosen the SAE hose connector at the check valve assembly with a wrench (right arrow in

diagram). Do not use a wrench on the pipe connector attached to the coolant union; the union will

be damaged and the warranty voided.

b. Carefully cut off the clear plastic drain hose at the side of the coolant union. It is safest to use

scissors or snips. Cut it close to the connector , since the hose will be re-used on the replacement

union. Do not cut the black coolant hose. (Note that if you are not replacing the union, leave the

drain hose attached to the union.)

c. Remove the coolant union from the extension tube (bottom arrow in diagram) using two

wrenches (7/8 and 15/16). This is a left-hand thread.

d. Return the coolant union with all pipe thread connectors and black coolant hose intact to Haas

Automation for warranty. Removal of any of the pipe connectors from the union will void any

claims for warranty.

4. Disconnect the air line at the lube/air panel.

5. Disconnect the clamp/unclamp cables (quick disconnect) and the assembly's solenoid wiring located on

the solenoid bracket.

6. a. 40 Taper - Remove the tool release air hose and precharge hose at the fitting shown in the following

figure. If machine is equipped with TSC, also remove the coolant hose.

b. 50 T aper - Remove the three tool release air hoses.

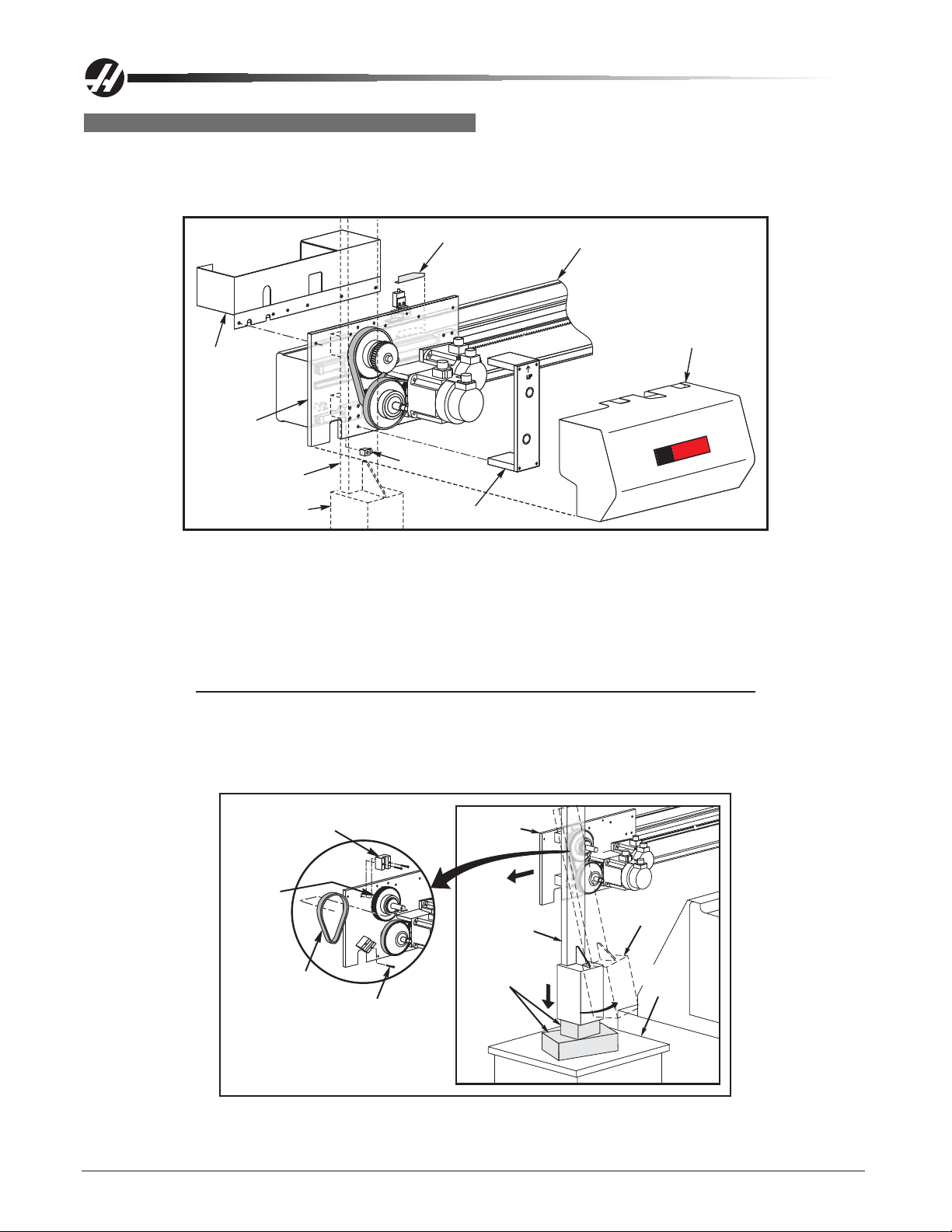

7. Use a strap and overhead lifting device to hold the TRP in position. Remove the four shoulder screws

holding the tool release piston assembly to the head casting. Keep all washers and shims.

12

Mechanical Service

96-0283 rev A June 2006

Page 14

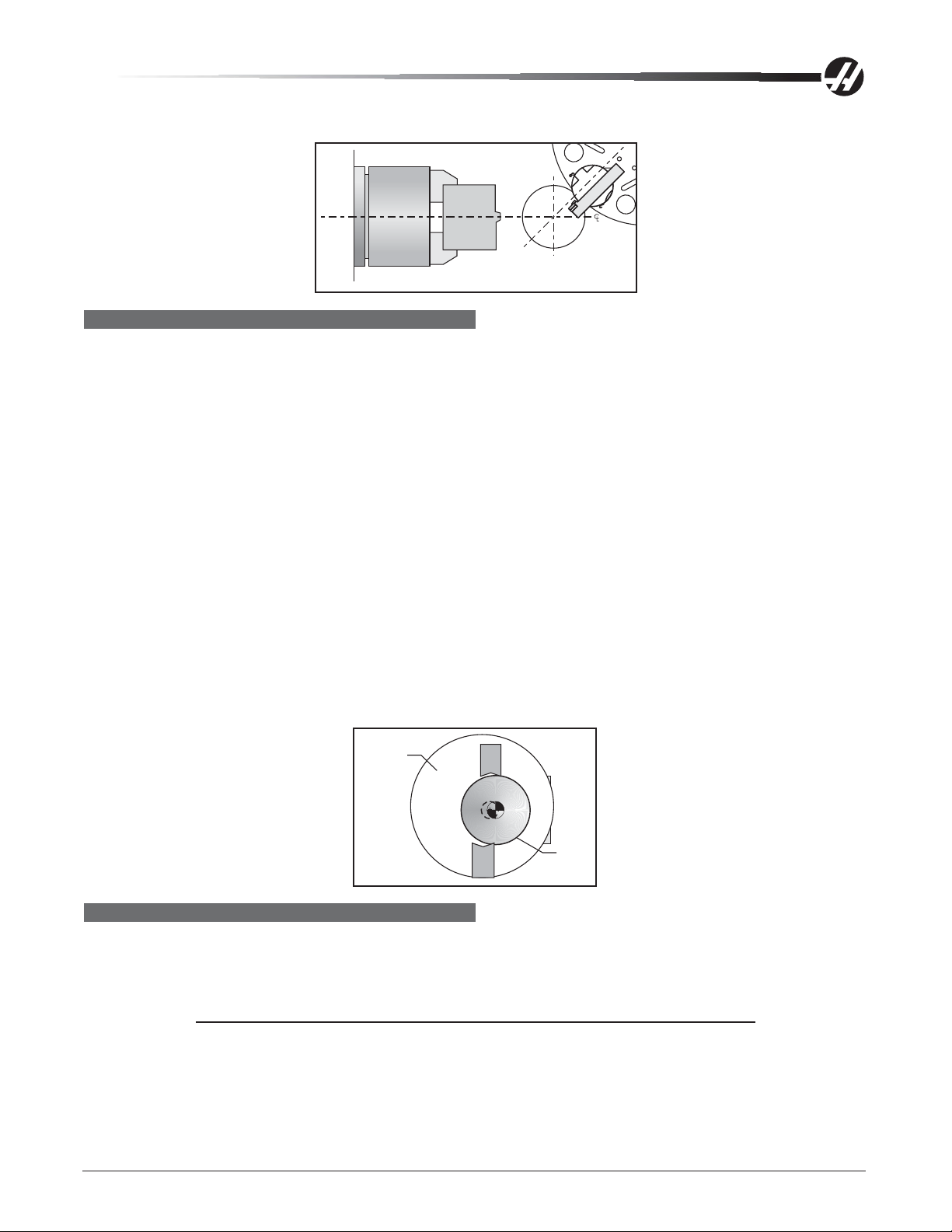

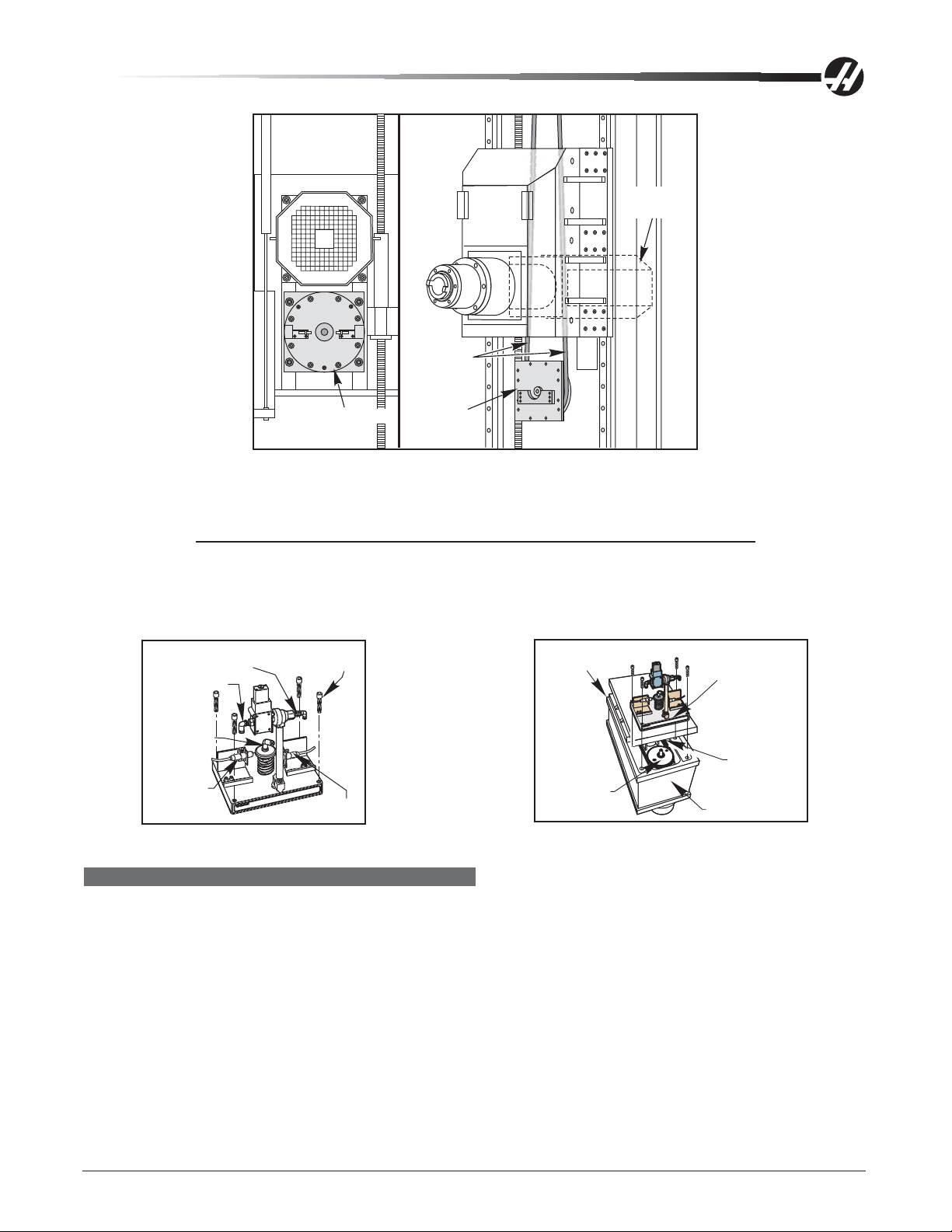

Lifting

Strap

Motor and

Transmission

TRP in Position

TRP

Rear View

TRP Shown in Position and as it is Lowered

8. Remove entire tool release piston assembly, by sliding it forward then lifting it upward. The assembly is

heavy so use great care when removing it.

NOTE: Steps 9 and 10 apply only to machines with TSC.

9. Remove the drain and purge lines from the seal housing.

10. Remove the seal housing from the TRP.

1/4" Air Hose

Fitting

3/8" Air Hose

Fitting

TSC Fitting

(Optional)

Clamp

switch

Tool Release Piston with Optional TSC Fitting Mounting Location for Tool Release Piston Assembly

3/8" - 16 X

1 3/4" SHCS

Unclamp

switch

Transmission

(Optional)

Spindle

Pulley

Tool Release

Piston Assembly

CAUTION

Drive Belt

Head Casting

SPINDLE TRP INSTALLATION

The following sections must be completed after installation:

40 T aper

• Set pre-charge

• Adjust the tool clamp/unclamp switches

• Set the draw bar height

50 T aper

• Tool push out adjustment

• Setting TRP switches

• Extension tube Installation (TSC)

1. 40 T aper - Ensure drive belt has been properly replaced as described in "Belt Replacement and

T ensioning" section.

96-0283 rev A June 2006

Mechanical Service

13

Page 15

2. 40 Taper - Verify spindle sweep adjustment is correct (as shown in "Draw Bar Replacement" section)

before proceeding. If not correct, re-shim as necessary .

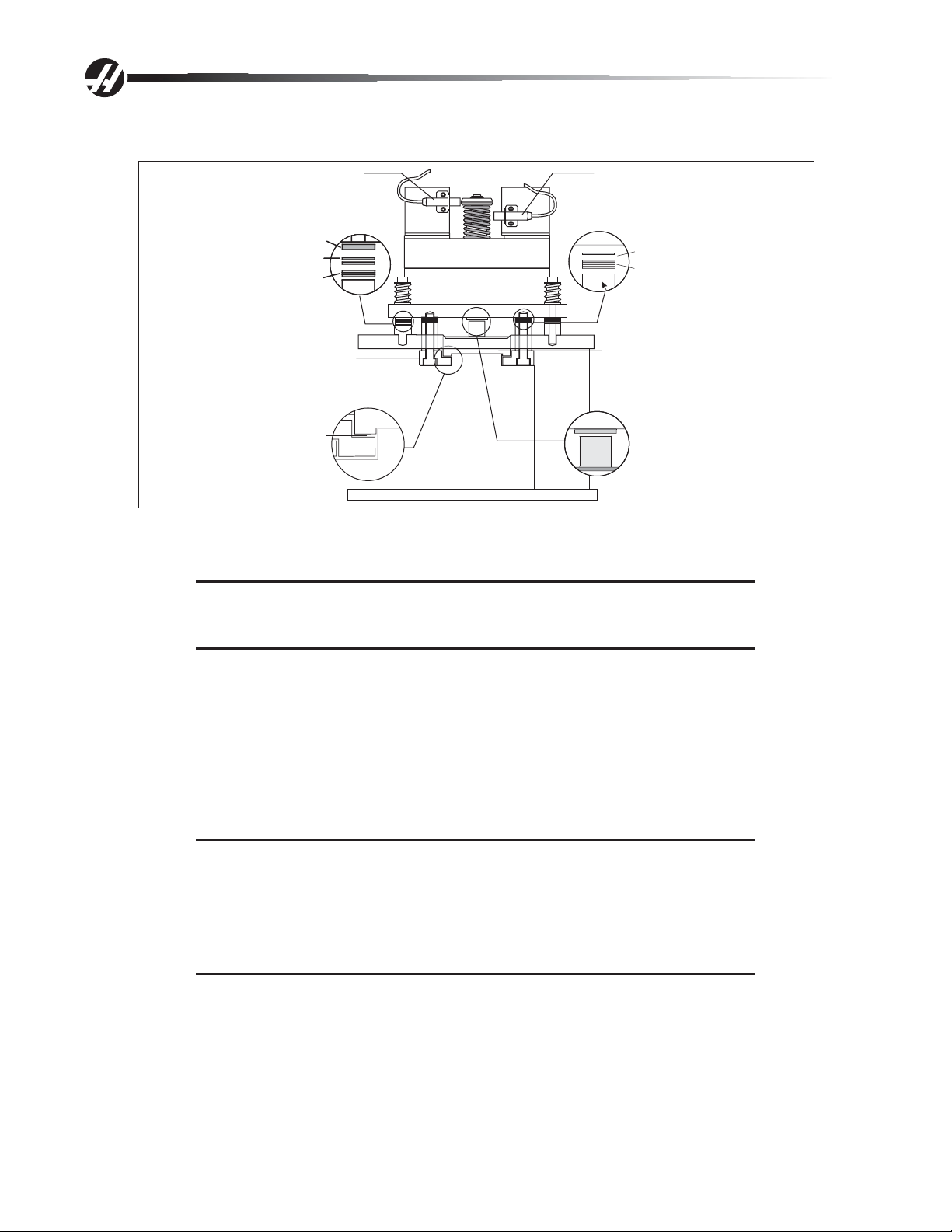

Tool Clamped Switch

TRP Shims

(1 ea.) 0.093 Nylon Washer

(2 ea.) 0.010 Shim Washer

(3 ea.) 0.015 Shim Washer

TRP Fork

Fork Gap

Tool Unclamped Switch

Fork Shims

Spindle Endcap

Shim and Spacer Location Diagram

1. Place the TRP on the machine. The TRP will rest on the spindle lift fork.

CAUTION! Be careful of the spindle lift fork. Place the assembly toward the

front of the machine before lowering it. The assembly is heavy so

use great care when replacing it.

(1ea.) 0.010 Shim Washer

(7ea.) 0.018 Shim Washer

Drawbar Gap

2. Install the 4 bolts, with the shim stock and spacers under the TRP.

Part No. Description 30-0013A (New) 30-0013 (Old Style)

Fork: (45-0014) 0.010 Shim Washer 1 ea. None

(45-0015) 0.018 Shim Washer 7 ea. 5 ea.

TRP: (45-0019) 0.093 Nylon Washer 1 ea. 1 ea.

Spacers: (45-0017) 0.010 Shim Washer 2 ea. 2 ea.

(45-0018) 0.015 Shim Washer 3 ea. 2 ea.

NOTE: TRP Spacers: the nylon washer goes on top of the shims.

3. Reinstall tool release piston assembly loosely if the machine is equipped with TSC. Otherwise tighten the

four mounting bolts securely .

4. 50 Taper - If the machine is equipped with TSC, re-install the extension tube and rotating union in the

following manner. Otherwise, skip this step.

NOTE: If the spindle, draw bar or extension tube has been replaced, the extension

tube runout must be adjusted.

14

Mechanical Service

96-0283 rev A June 2006

Page 16

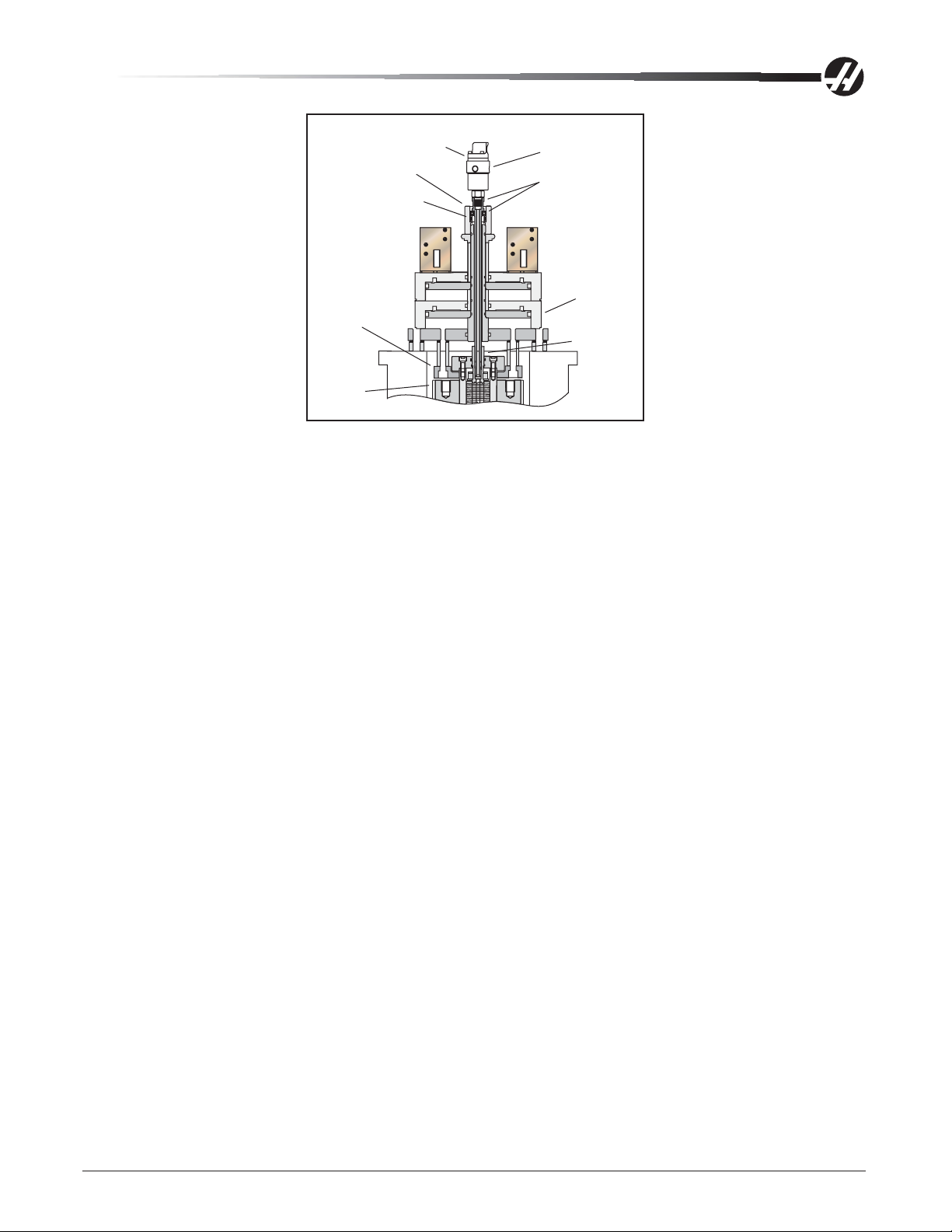

Measure Runout Of

Rotating Union Here

Bearing Holder

Wave Spring

TRP Fork

Spindle

Pulley

Rotating Union

Extension Tube

Assembly

50 Taper

TRP

Draw Bar

a) Place a tool holder in the spindle.

b) Insert a 5/8 Allen wrench into the lower end of the piston shaft. Loosen the 1/4-20 screw in the

clamp collar on top of the piston shaft. Insert a large flat blade screwdriver into the slot in the

clamp collar, and twist the collar of f.

c) Screw the bearing holder (20-7655) onto the piston shaft. Tighten using a large wrench or pliers.

d) Wipe clean the hole in the end of the draw bar.

e) Replace the tool release piston.

f) Apply a light layer of molybdenum grease to the inside of the bearing holder . Insert the wave

spring (59-0176) into the bearing holder.

g) Lightly grease the o-ring on the end of the extension tube assy (30-1242). Apply blue Loctite to

the thread on the end. Insert the extension tube down into the draw bar. Tighten by hand as far as

possible (it has left hand threads).

h) Block spindle rotation with a bolt, bar or socket inserted into one of the pulley holes. It will stop

against the TRP fork.

i) Tighten the extension tube to 15-20 f t-lb. Remove the bolt from the spindle pulley .

j) Install the rotating union. Lightly grease the o-ring. Do not put Loctite on the threads.

1) Thread the coolant union onto the end of the extension tube (it has left hand threads).

Do not use Loctite. Tighten the threads snugly using two wrenches.

2) Attach the clear plastic drain hose to the barb connector on the side of the union. Use a

hose clamp if one is available. The hose must travel downward (below the union) to drain

off collected coolant. The union will be damaged if coolant collects inside the union.

3) Thread the black coolant hose onto the connector on the check valve assembly . T ighten

with a wrench. Do not over-tighten!

k) Measure the runout at the top of the rotating union with a dial indicator . Runout should not

exceed .006"

l) Check the tool clamp and unclamp switches. They should not have moved.

m) Test run the TSC system to check for leaks before putting the head covers back on.

96-0283 rev A June 2006

Mechanical Service

15

Page 17

5. Reconnect the air hoses at the applicable fittings on the tool release piston assembly.

6. Reconnect the clamp/unclamp cables and solenoid wire to the sides of the solenoid bracket.

7. 50 Taper - Set the main air regulator to 85 psi. Tool push out and TRP switch adjustments must be

completed.

Steps 8-10 only apply to 40 Taper machines with TSC

8. Connect the 5/32" drain line and 5/32" purge line to the seal housing and install the seal housing on the

TRP (use Loctite on the screws). The drain line connector should point toward the rear of the machine.

NOTE: The drain line must run straight through the cable clamp guide on the

transmission, and must not interfere with the pulley or belts.

9. Apply precharge pressure several times to allow the seal to center it self with the draw bar . While holding

down precharge, tighten the bolts.

10. Install the coolant hose. A wrench must be used, tighten snug. Do not overtig hten!!

1 1 . Adjust the clamp/unclamp switches in accordance with the appropriate section.

SETTING PRE-CHARGE

Do not perform on machines equipped with Through the Spindle Coolant (TSC). It will

damage the machine. Refer to the "Precharge Regulator Adjustment" section and perform

those adjustments.

NOTE: Set the air pressure regulator to 30 psi on Super Speed machines with an in-

1. Turn the air pressure regulator to zero (0). The knob must be pulled out to unlock before adjusting. In-Line

drive machines - Disconnect the air hose from the precharge regulator. Inst all a test gauge between the

regulator and the solenoid. Command the precharge (Macro #1 120-1), the pressure should be 30 psi.

NOTE: At "0" pressure on the precharge regulator, the adjustment knob is out as far

line drive, to 4 psi on standard 40 Taper machines, and do not set a precharge

on 50 Taper machines.

as it will turn.

Air Pressure Regulator Adjustment Knob

2. Verify Parameter 149, Precharge Delay, is set to 300.

16

Mechanical Service

SPINDLELOCKED

STATUSSWITCH

WITHOUTGEARBOX

TOOLCLAMPED

STATUSSWITCH

LOW

STATUSSWITCH

JUMPER

GEARBOX

HIGHGEAR

STATUSSWITCH

GEAR

WITHOUT

96-0283 rev A June 2006

Page 18

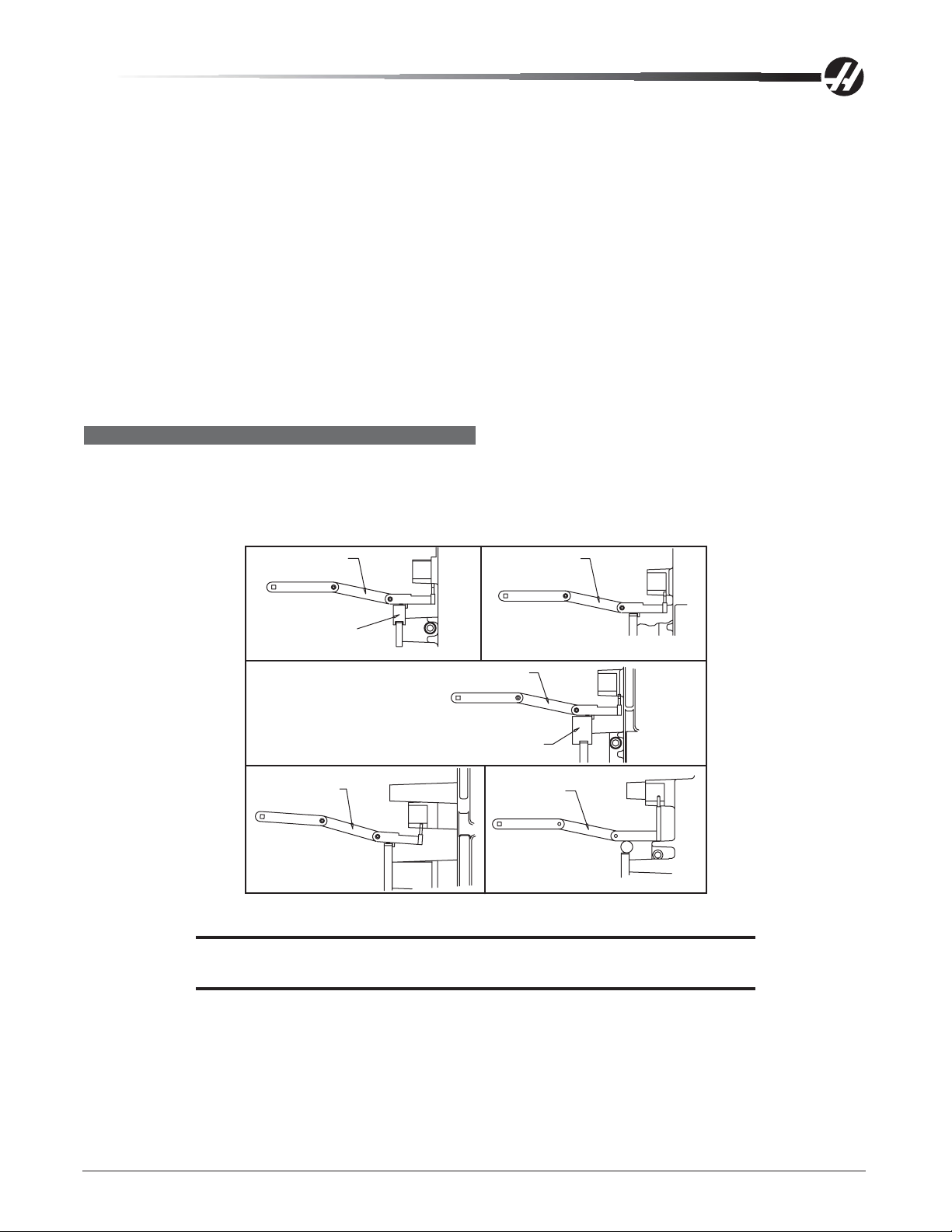

TRP SWITCH ADJUSTMENT

This tool release piston (TRP) switch adjustment procedure applies to 40 Taper, 40 Taper In-Line, and 50 Taper

machines. The switches should indicate that the tool is released from the spindle with the tool 0.060” out of the

taper and that the tool is not released with the tool 0.050” out of the taper .

Lower (Unclamp) Switch

1. Draw bar height must be set properly before adjusting switches. Add or subtract shim washers to the TRP

until proper height is achieved. In-line drive machines must also have the precharge pressure verified.

In-Line drive machines - Disconnect the air hose from the precharge regulator. Install a test gauge

between the regulator and the solenoid. Command the precharge (Macro #1120-1), the precharge pressure

should be 30 psi.

2. Push Param/Dgnos twice to enter the diagnostic mode and confirm DB OPN = 0 and DB CLS = 1.

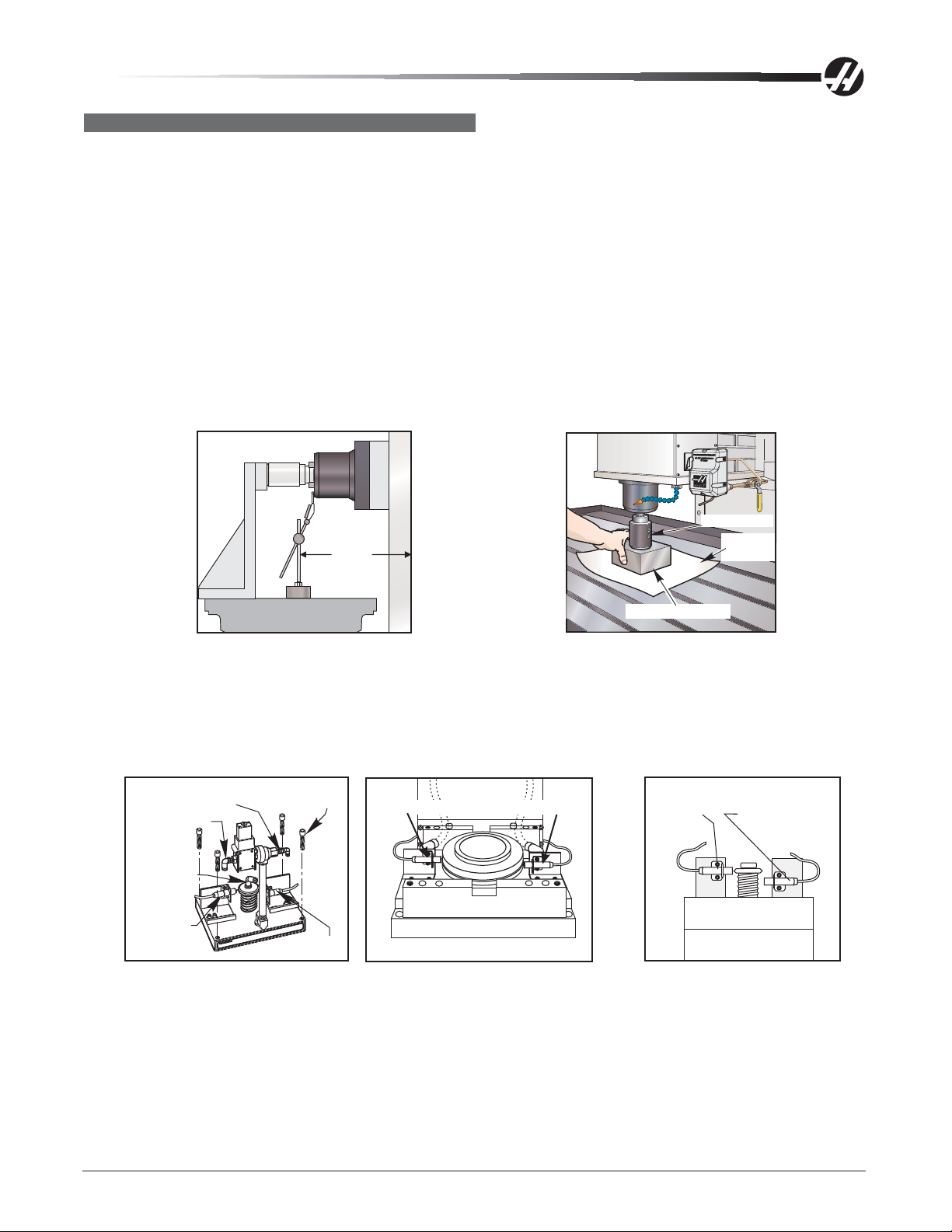

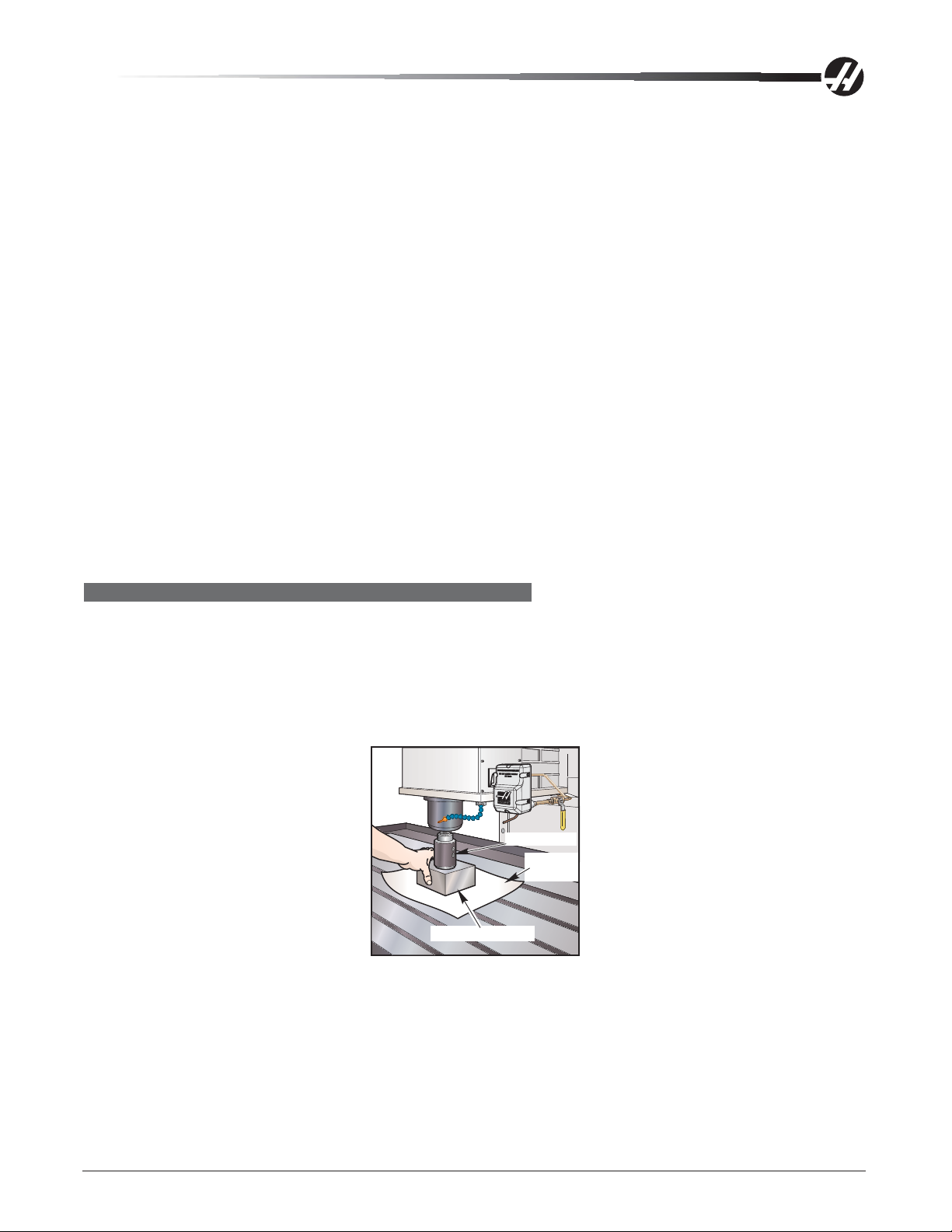

3. Place a tool into the spindle and place a machined aluminum block on the table under the tool holder. Be

sure to place a clean piece of paper under the block to protect the table surface.

Tool Holder

Sheet of

Z-Axis

paper

Aluminum Block

Z-Axis with Angle Block 50 Taper Pushout Adjustment

50 T aper machines - Plug the air blast output at the TRP solenoid so no air is sent to the TRP shaf t.

4. Jog the Z-axis down until the tool holder is about 0.030” above the aluminum block. Switch to .001” incre-

ments. Jog down one increment at a time until the tool holder just presses the block firmly against the

table surface. This is the Zero point. Do not press the Tool Release button, it will cause a Z-axis overload.

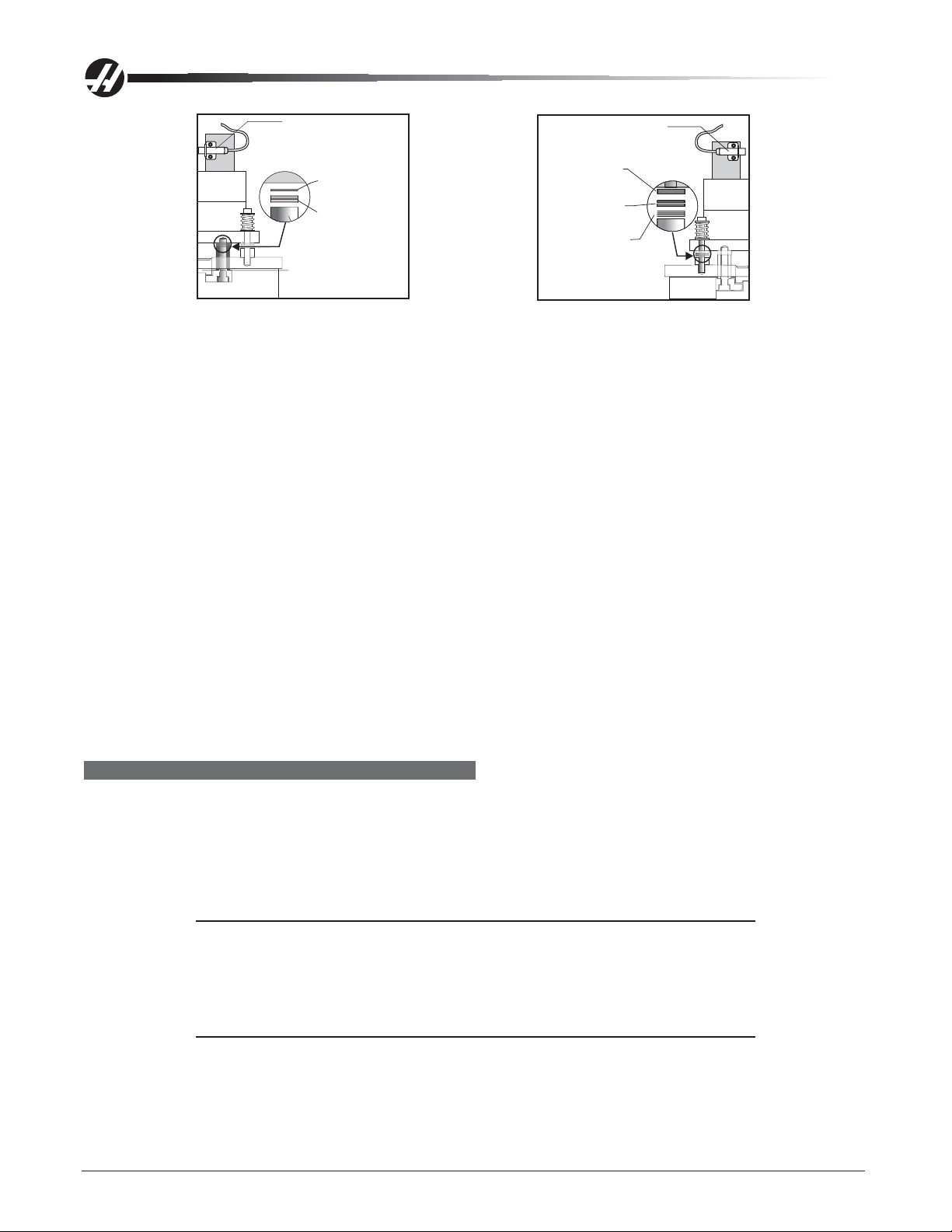

1/4" Air Hose

Fitting

3/8" Air Hose

Fitting

TSC Fitting

(Optional)

Clamp

switch

40 Taper TRP Assembly 40 Taper In-Line Drive TRP Assembly 50 Taper Tool Clamp/Unclamp Switches

3/8" - 16 X

1 3/4" SHCS

Unclamp

switch

Clamp Switch

Unclamp Switch

Tool Clamped

Switch

Tool Unclamped

Switch

5. Change Parameter 76, Low Air Delay, to 45,000 to eliminate a low air pressure alarm.

96-0283 rev A June 2006

Mechanical Service

17

Page 19

The following notes in Step 6 are for 50 Taper machines only.

6. Jog the Z-axis to 0.060” above where the tool holder was touching the aluminum block and press the Tool

Release button. Add or remove shims from the tool release fork to make adjustments. The shims come in

0.010 and 0.018 thicknesses.

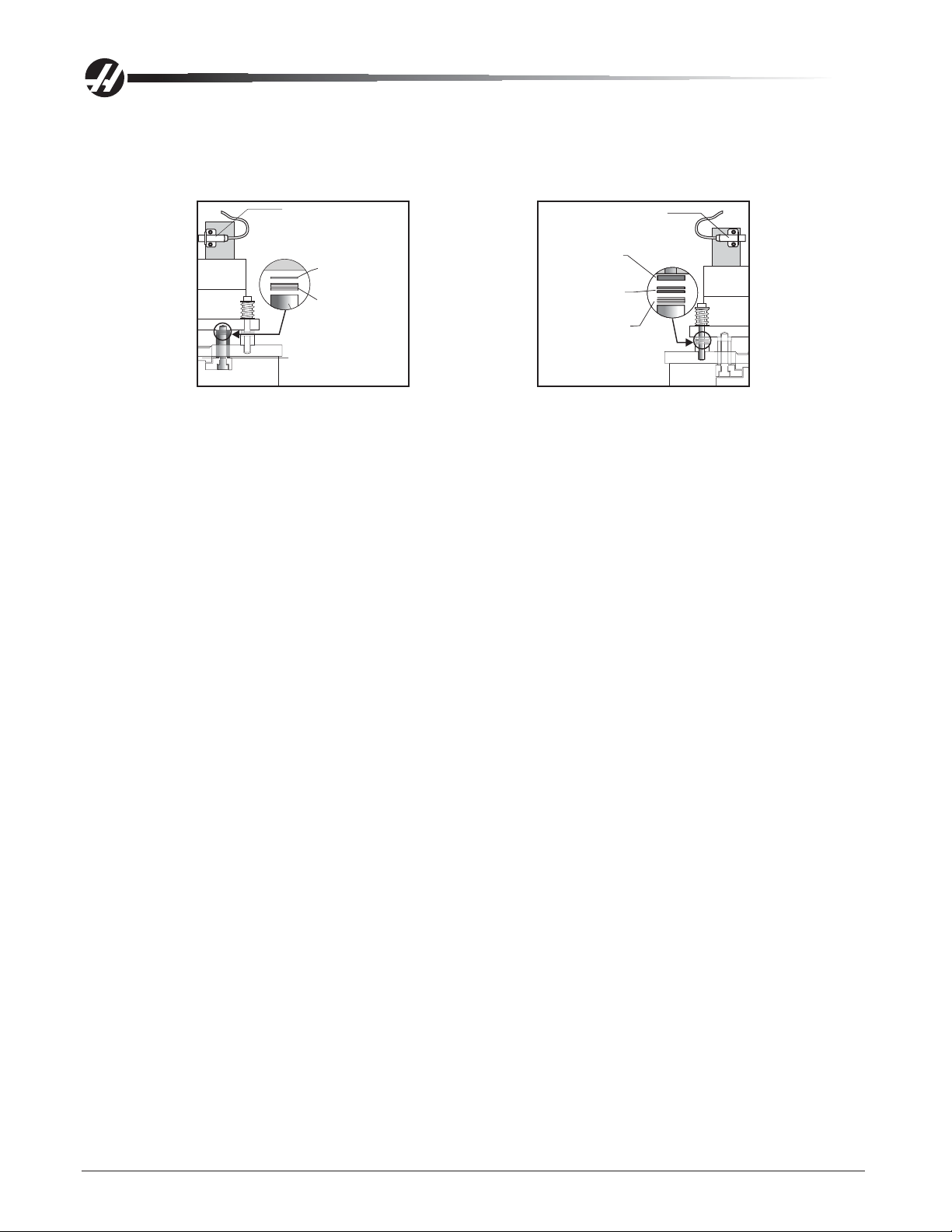

Tool Unclamped

Switch

Fork Shims

(1ea.) 0.010

Shim Washer

(7ea.) 0.018

Shim Washer

Spindle Endcap

50 Taper Fork Shim Location 50 Taper TRP Shim Location

Tool Clamped

Switch

(1 ea.) 0.093

Nylon Washer

(2 ea.) 0.010

Shim Washer

(3 ea.) 0.015

Shim Washer

TRP Shims

• If the block is tight when the button is pressed, shims may have to be added to the tool release

fork. If the block is loose, shims may have to be removed from the tool release fork.

• If the aluminum block is tight at 0.060, release the Tool Release button and jog the Z-axis up

0.001” and press the Tool Release button again. Feel for movement in the aluminum block. Repeat

this until movement is felt. Note the last position where the block was tight. If the position is 0.070”

or more from the Zero point, add shims to the tool release fork.

• If the aluminum block is loose at 0.060, jog the Z-axis downward 0.001” at a time and check for

movement in the aluminum block. If the position where the block becomes tight is 0.050” or less,

remove shims from the tool release fork.

If shims were added to the TRP fork, add half that amount to the TRP spacers supporting the TRP. This will

keep the two clearance gaps between the TRP and the rotating Spindle equal (approximately 0.095” each).

If shims were removed from the TRP fork, remove half that number of shims from the spacers.

Apply red grease to the shoulder bolts used to mount the TRP when shim adjustments are complete.

7. In order to limit the spindle head deflection during this next part of the procedure, the air pressure needs to

be reduced to lower the output force of the TRP. For the Mini-Mill and Toolroom Mill, lower the air pressure

to 75 psi (be sure to back the regulator down past 75 psi, then adjust back up to 75 psi) and proceed to

the next step. For all other 40 Taper mills (including in-line), reduce the air regulator to about 60 psi.

For 50 T aper machines, reduce the air regulator to about 70 psi.

8. Place a 0.0005” test indicator between the table and the bottom of the front face of the spindle head to

measure axial deflection when the tool release piston is energized. Press and hold the Tool Release button

and check that the block is tight and the head deflection is between 0.002” and 0.004” (0.001” and 0.002”

for 50 Taper machines). If the head deflection is too high, reduce the air pressure. If the head deflection is

too low, or there is no deflection, increase the air pressure.

18

Mechanical Service

96-0283 rev A June 2006

Page 20

Z-Axis

T est Indicators

9. Press the Tool Release button and hold it in. Adjust the switch in or out toward the spring retainer until the

switch changes status (DB OPN = 1). The switch should now be indicating that the tool is unclamped and

out of the spindle.

10. Cycle the tool release several times and confirm the switch is tripping. Confirm on the Diagnostics Page

that (DB OPN = 1) and (DB CLS = 0). For a 50 Taper machine, tighten down the screws that secure the

switch bracket to the TRP.

11. Check the adjustment. Jog the Z-axis down until the tool is .050 above the block (0.020” for 50 T aper

machines) and confirm that DB OPN = 0 when the Tool Release button is pressed. The switch must trip

(DB OPN = 1) at 0.060" above the block and not trip (DB OPN = 0) at 0.050" above the block.

12. Re-adjust and repeat steps 4-11 if necessary.

13. Set the pressure regulator back to 85 psi.

14. Set Parameter 76 back to its original setting.

Upper (Clamp) Switch

1. If the machine is equipped with TSC, remove the seal housing before continuing. This step does not apply

to In-line drives with TSC.

2. Remove the tool holder from the spindle.

3. Delete everything in MDI mode and write “#1 120 = 1”.

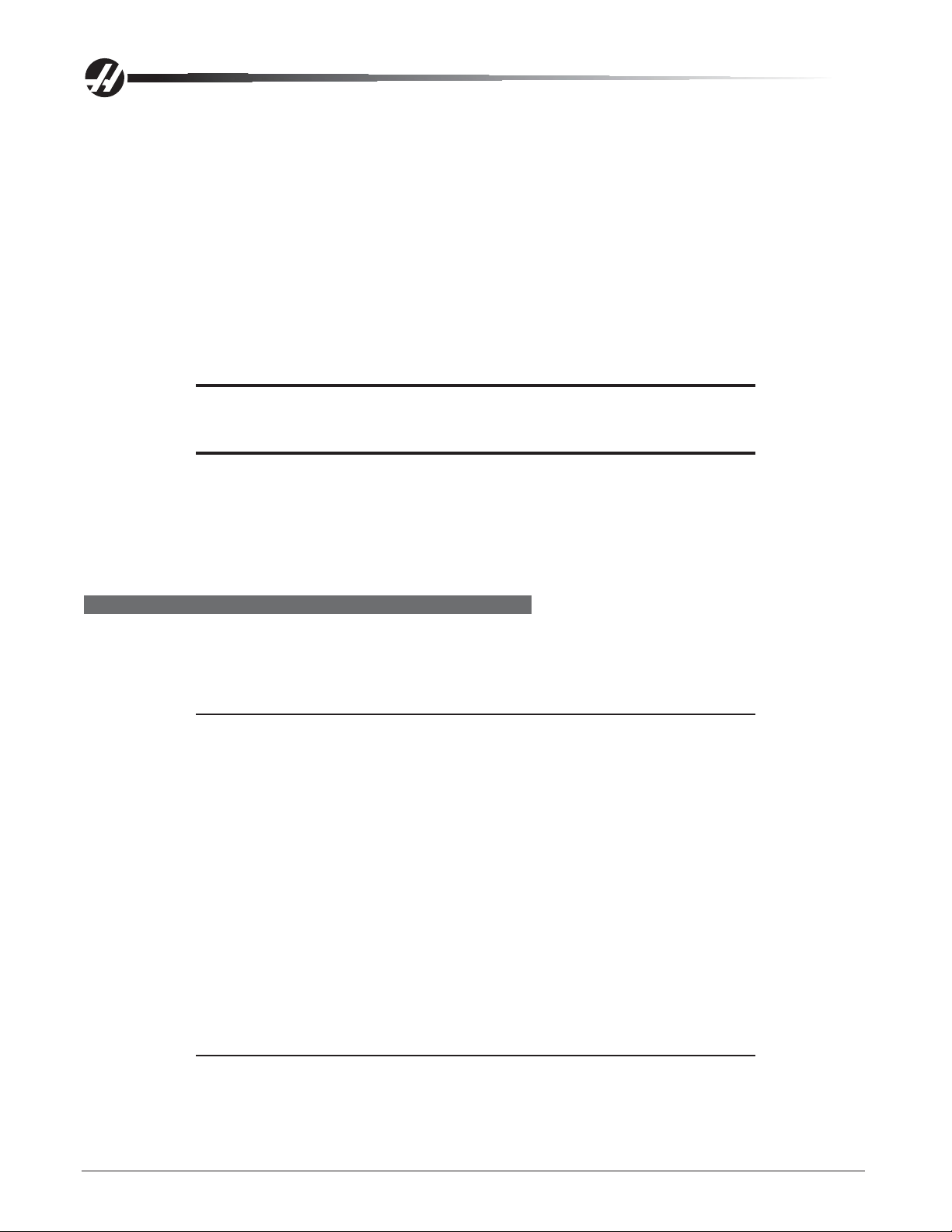

4. Start with the upper switch all the way in. Place a 0.020” shim between the TRP adjustment bolt and the

draw bar.

Tool Release

Tool Release

Drawbar

Spindle Cartridge

Placement of Shim before Checking Switch Adjustment Placement of Shim (In-Line Drive Motor)

96-0283 rev A June 2006

Piston

Shim

Assembly

Drawbar

Spindle Cartridge

Mechanical Service

Assembly

Piston

Shim

Shim

19

Page 21

In-Line drive machines only - Apply pre-charge.

5. Push the Param/Dgnos button twice to enter the diagnostics mode.

6. Press Cycle Start.

7. If DB CLS = 0 (Tool Unclamp) you are done (do not check with 0.040” shim). If not, adjust the upper switch

out until the switch is just un-tripped (DB CLS = 0) and continue with the next step.

8. This step is not necessary for In-Line Drive machines. Press Reset. Replace the 0.02” shim with a

0.04” shim (checking with the 0.04” shim assures that the switch is not backed off too far. If switch is all

the way in, this check is not needed). Press Cycle Start. See that DB CLS = 1. Readjust and repeat steps

2-8 if necessary.

9. In-Line drive machines only - T ighten the switch mounting bracket and test the adjustment. Apply pre-

charge with a 0.020” shim. Ensure that DB CLS = 0.

CAUTION! Remove the tool holder from the spindle before performing the Clamp

switch adjustment. Failure to remove it could result in damage to the tool

holder, the mill table, or cause severe personal injury.

50 Taper Only

Push the upper switch in slowly toward the spring retainer at the top of the TRP. When the switch LED

changes state, it is indicating that the draw bar is closed. Confirm this on the Diagnostics Page that (DB CLS

= 1). Tighten down the screws that secure the switch bracket to the TRP. Double-Check the switch by turning

on the TRP a few times. DB CLS in the Diagnostics Page should always turn on (1) when the TRP is com-

pletely retracted.

TRP INSTALLATION AND ADJUSTMENT - OM-1A/OM-2A

Upon installation of the TRP, the top of the spindle gear must sit flush with the bottom of the subplate of the

TRP casting. If the TRP subplate casting sit s above the spindle, add .01” shims as necessary. Connect an air

pressure gauge to the TRP Pre-Charge, and adjust the pressure until it reads 6 psi upon tool release. Insert

shoulder bolts and torque to 18 ft-lb.

NOTE: Upon tightening of the fasteners, the TRP must fully return to its original

position.

Draw Bar Height Adjustment

1. Place a machined aluminum block on the table under the tool holder (with no tool in the spindle). Be sure

to place a clean piece of paper under the block to protect the table surface.

2. Jog the Z-axis down until the tool holder is about 0.030” above the aluminum block. Set the clearance from

the tool holder to the block to zero by pressing Tool Release, switching to .001” increments, and jogging

down one increment at a time. Move the Z-axis, then press Tool Release while feeling for movement of the

tool holder (place finger between tool holder and spindle). Repeat process until no movement is felt. This is

the zero point.

3. In .01” increments, handle jog the Z-axis to .100” above the block.

4. Press and hold the Tool Release button. Try to move the block. The block should be tight at .100”, and

loose at .110”. If the block moves at .100”, repeat the process, jogging the Z-axis down one increment at a

time until the block is tight. If the block is tight at .110”, repeat the process, jogging the Z-axis up one

increment at a time until the block is loose.

NOTE: The number of increments jogged up or down is equal to the number of shims

20

to add or remove. If the block was tight at .110”, remove shim washers. If the

block was loose at .100”, add shim washers.

Mechanical Service

96-0283 rev A June 2006

Page 22

Shim Washer Addition/Removal

T o add or subtract shim washers, remove the TRP assembly .

1. Check the condition of the tool release tip and draw bar and replace damaged parts before setting draw bar

height.

2. Remove the tool release bolt.

3. Add or remove the required number of shim washers.

4. Reinstall the tool release bolt.

5. Inst all the TRP assembly and recheck settings. Adjust as required.

Upper (Clamp) Switch

1. Delete everything in MDI mode and write #1 120 = 1.

2. Start with the upper switch all the way in.

3. Place a 0.020” shim between the tool release piston adjustment bolt and draw bar and press Cycle Start.

4. If DB CLS = 0 (tool unclamp), the process is complete. If not, adjust the upper switch out until the switch

untrips (DB CLS = 0), and test the adjustment.

5. Press Reset.

6. Replace the 0.020” shim with a 0.040” shim and press Cycle Start.

7. Verify that DB CLS = 1. Readjust if necessary.

TOOL PUSH OUT ADJUSTMENT

1. Put tool holder in spindle.

2. Plug the spindle taper air blast.

3. Place an angle plate (machined aluminum block - V ert) on machine t able. Place a clean aluminum block

between the angle plate and the tool holder (Horiz), or protect the table by using a clean sheet of paper

under the block (Vert).

Tool Holder

Sheet of

paper

Aluminum Block

Pushout Adjustment (V ert)

4. Jog the Z-axis until the tool holder is about .030” from the aluminum block. Switch the jog increments to

.001” and jog the Z-axis one increment at a time until the tool holder just presses the block firmly against

the angle plate (table surface for V ert). This is the zero point.

96-0283 rev A June 2006

Mechanical Service

21

Page 23

Tool Unclamped

Switch

Fork Shims

(1ea.) 0.010

Shim Washer

(7ea.) 0.018

Shim Washer

Spindle Endcap

Fork Shim Location TRP Shim Location

Tool Clamped

Switch

(1 ea.) 0.093

Nylon Washer

(2 ea.) 0.010

Shim Washer

(3 ea.) 0.015

Shim Washer

TRP Shims

5. The tool push out adjustment is 0.060” +/-0.010”. Add or remove shims from the tool release fork to make

adjustments. The shims come in 0.010” and 0.018” thicknesses. Jog away from the plate (upward for V ert)

0.060. Press and hold the T ool Release button, and feel for movement in the aluminum block.

• If the block is tight when the button is pressed, shims may have to be added to the TRP fork.

• If the block is loose when the button is pressed, shims may have to be removed from the TRP

fork. (This is the opposite of 40 taper adjustment.)

• If the aluminum block is tight at 0.060”, release the button and jog the Z-Axis away from the

block 0.001” and press the T ool Release button again. Feel for movement in the aluminum block.

Repeat this until movement is felt. Note the last position where the block was tight. If the position `

is 0.070” or more, add shims to the TRP fork.

• If the aluminum block is loose at 0.060”, jog the Z-Axis toward the block 0.001 at a time and

check for movement in the aluminum block. If the position where the block becomes tight is 0.050”

or less, remove shims from the TRP fork.

7. If shims were added to the TRP fork, add half that amount to the spacers supporting the TRP. This will

keep the two clearance gaps between the TRP and the rotating spindle equal (approximately 0.095 each).

If shims were removed from the TRP fork, remove half that number of shims from the spacers.

8. Apply red grease to the shoulder bolts used to mount the TRP when shim adjustments are complete. Use

blue Loctite on the threads.

SETTING TRP HEIGHT

1. Press MDI and turn hand wheel to zero (0).

2. Press Handle Jog button and set increments to .01. Jog the Z-axis in the positive (+) direction 0.100".

3. Press and hold the Tool Release button, grasp the block and try to move it. The block should be tight at

.100 and loose at .110. If block moves at .100, jog Z-axis in the negative (-) direction one increment at a

time. Press the Tool Release button and check for movement between increments until block is tight.

NOTE: The increments jogged in the Z negative (-) direction are the amount of shim

washers that must be added to the tool release bolt (or coolant tip for TSC).

Refer to the "TRP Shims" section.

4. If the block is tight at .110, move the Z-axis in the positive (+) direction one increment at a time. Press the

T ool Release button and check movement between increments until block is loose.

22

NOTE: The increments jogged in the Z positive (+) direction are the amount of shim

washers that must be removed ("TRP Shims" section).

Mechanical Service

96-0283 rev A June 2006

Page 24

TRP SHIMS

The draw bar uses a 1-piece shim which can be added or removed without having to remove the TRP assembly .

Once the shims have been adjusted, the TRP is reinstalled and the final torque on the bolts is 35 ft-lb.

Shims

T ool Release Piston Shims

NOTE: Shims may need to be added or removed when spindle cartridge, tool release

piston assembly, or draw bar is replaced. If none have been replaced, skip this

section.

2 Bolts

On Each

Side

Shim

TRP

1. Check the condition of the tool release bolt and the draw bar . Rep air or replace these items before setting

the draw bar height.

Mounting Bolt Locations

Tool Release

Bolt

Shim Washers

TRP Assembly (TSC Shown)

2. Remove tool release bolt. Note that it has a left hand thread. If the machine is equipped with TSC, loosen

the three set screws and remove the TSC coolant tip.

3. Add or subtract required shim washers (see previous section for correct amount to add or remove).

4. Before installing tool release bolt, put a drop of serviceable (blue) Loctite on the threads and install. If

replacing TSC coolant tip, put a drop of Loctite on the threads of the three set screws before installing.

5. Install tool release piston assembly in accordance with the "Spindle TRP Installation" section and recheck

settings. If within specifications, continue; if not, readjust.

In-Line Drive Spindle Draw Bar Height

The draw bar height is set as for the belt driven spindle; however, the shim washers are set up dif ferently . The

draw bar uses a one-piece shim which can be added or removed without having to remove the TRP assembly .

Once the shims have been adjusted, the TRP is re-installed, and the final torque on the bolts is 35 ft-lb.

96-0283 rev A June 2006

Mechanical Service

23

Page 25

TRP DISASSEMBLY

1. Loosen and remove the shaf t clamp. A punch and mallet may be required to break the clamp loose.

2. Remove the switch trip and compression spring.

3. Remove the 50T upper spacer.

4. Push the TRP shaft down.

5. Remove the 8 bolt s holding the TRP assembly together , separate and remove upper half of the housing.

6. Remove the upper TRP piston and remove the lower half of the TRP housing.

7. Remove the TRP lower spacer , the lower TRP 50T piston and the TRP sub plate.

O-ring Replacement

1. Remove and replace the 4 o-rings (57-0027) on the TRP 50T shaft

2. Remove and replace the 2 o-rings (57-0092) on the TRP 50T piston, 1 o-ring per piston.

3. Remove and replace the 3 o-rings (57-0095); 2 in the center of the TRP 50T housing and 1 in the center of

the TRP 50T sub plate.

TRP ASSEMBLY

1. Place the TRP sub plate over the TRP shaft, the lower TRP piston, grooved side up, and the TRP lower

spacer over the TRP shaft.

2. Install the lower TRP housing, the upper TRP piston, grooved side up, and the upper TRP housing over the

TRP shaft.

3. Replace the 8 bolt s holding the TRP assembly together . Pattern torque to 50 f t-lb.

4. Place the TRP upper spacer over the TRP shaft.

5. Push the TRP shaft up from the bottom, using the mallet handle. The shaft will bottom out with approxi-

mately 1/4" of the shaft still showing.

6. Place the switch trip and compression spring over the TRP shaft.

7. Tighten the shaft clamp on the TRP shaft, then the shaft clamp locking bolt.

24

Mechanical Service

96-0283 rev A June 2006

Page 26

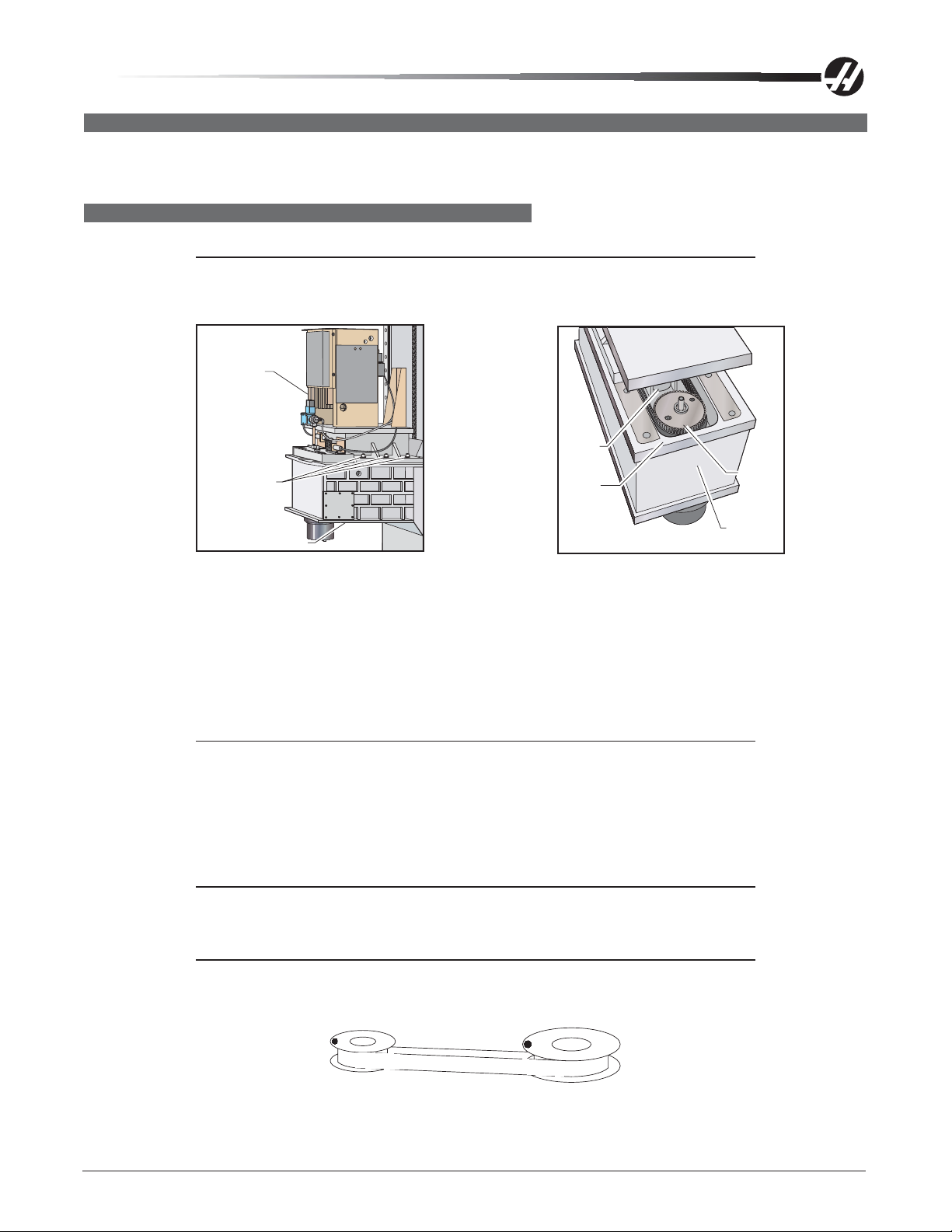

BELT REPLACEMENT & TENSIONING

Please read this section in its entirety before attempting to replace the Vertical or ECSeries drive belt.

DRIVE BELT RPLACEMENT (VERT & EC-SERIES)

Removal

NOTE: For easier removal, place transmission in high gear before beginning.

1. Remove cover panels from headstock area in accordance with "Head Covers Removal/Installation".

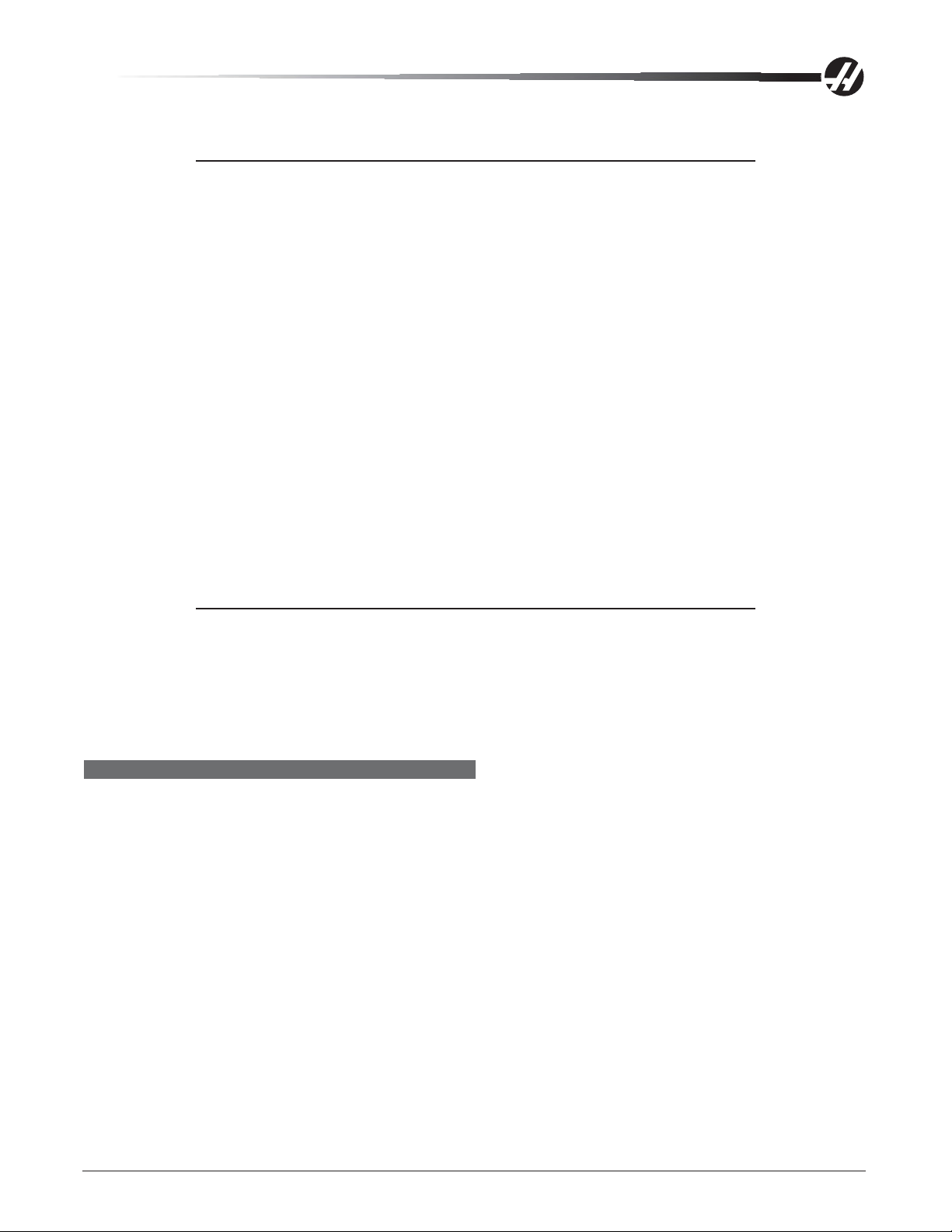

Transmission

(Optional)

Motor

Shifter

Drive

Belt

Spindle

Pulley

3/8 - 16 x 1"

SHCS

C

A

U

TIO

N

-TOOLCLAMP/UNCLAMP SWITCHESMUSTBEPROPERLY

ADJUSTEDBYTRAINED PERSONNELORSEVEREDAMAGE TOTOOLCHANGER

WILLRESULT.PLEASE CONSULTSERVICEMANUALBEFORE ADJUSTMENT.

Head

Inspection Cover

Casting

Spindle Head Casting Disconnect Points Head Casting Area Showing Belt Location

2. Remove tool release piston assembly in accordance with "Spindle TRP Removal".

3. a. Vert: Remove the six SHCS holding the transmission to the head casting and pull the transmission

forward enough (½" to ¾" max.) to allow the drive belt to be pulled upward over the spindle pulley .

b. Horiz: Remove the four large SHCS that attach the transmission mount plate to the spindle head and

pull the transmission/motor assembly toward the front of the machine slightly to remove the tension on the

drive belts, and remove the drive belts.

NOTE: On direct drive machines, remove the four SHCS holding the mounting plate

to the spindle head casting. Slide the assembly forward enough to allow the

drive belt to be pulled up over the spindle pulley.

4. Remove the inspection cover from the bottom of the spindle head casting and carefully slide the drive belt

between the sump tank and the web in the casting.

5. Pull the belt up over the spindle pulley, push the other end down to clear the shifter, and pull out.

NOTE: Do not bend or kink the belt in any way; damage to the fibers in the belt may

Installation

NOTE: Belt clocking must be correct before placing replacement belt(s) onto the

96-0283 rev A June 2006

result, and the belt will fail soon after installation.

pulley(s). Rotate the pulleys until the alignment dots are in line, but not facing

each other, as shown in the following illustration.

Belt Clocking

Mechanical Service

25

Page 27

1. a. Vert: Slide the replacement belt(s) under the sump tank and onto the pulley.

NOTE: Do not wrap the belts over the pulley. The pulley can be rather sharp, and may

cut the belts. Do not bend or kink the belt in any way; damage to the fibers in

the belt may result, causing belt failure.

b. Horiz: Slide on the drive belts.

2. a. Vert: Ensuring the belt is properly seated, push the transmission back, tightening the belt. Pull belt

forward from rear of head casting. Pull belt over spindle pulley .

b.Horiz: Replace the TRP solenoid assembly and TSC valve bracket. Orient the transmission/motor

assembly and replace the transmission mount plate to the spindle head.

3. a. Vert: Tighten the drive belt in accordance with the following section.

b. Horiz: Use a belt tensioning tool to tighten the drive belts. Do not over tighten.

4. Set the spindle orientation (“Spindle Orientation” section).

NOTE: The following step is necessary only if the spindle or transmission was

exchanged prior to belt replacement.

5. Double-check the spindle sweep to assure that nothing has moved during the previous steps. If sweep is

within tolerance, continue; if not, sweep must be readjusted.

NOTE: Drive belt tension must be adjusted after every installation.

DRIVE BELT TENSIONING (VERT & EC-SERIES)

NOTE: The drive belt tension should be adjusted after every service on the transmis-

sion or spindle of the machine. Information placed in parentheses applies to

Direct Drive machines.

1. Turn the machine On. Jog the spindle head down to a level that will allow easy access to the drive belt.

2. Remove the cover panels from the head stock area as shown in "Head Covers Removal/Installation".

3. Remove the tool release piston assembly in accordance with “Spindle TRP Removal”.

4. Loosen the six (four) SHCS holding the transmission (motor mounting plate) to the spindle head casting.

Ensure the transmission (motor) is broken free by moving it slightly by hand.

5. Set the belt tension tool in place. Mount it to the head casting by inserting the two SHCS into the two front

TRP mounting holes. Tighten the SHCS finger tight. Turn the handle until the tool is flat against the trans-

mission casting (motor mounting plate). Ensure the transmission (motor) is straight, and not cocked,

before tensioning belt.

Outer Tube

Plunger

Belt Tension Tool

26

Belt T ension Tool

Mechanical Service

96-0283 rev A June 2006

Page 28

6. Turn the handle until the edge of the tool's plunger and the outer tube are flush, and then 1/2 turn more.

This will set the belt at the proper tension.

NOTE: A belt that is correctly tensioned will whine slightly, and requires approximately

12 hours of break-in time.

7. Check if the belt is too loose or too tight. If the belt is set too tight, the belt will whine excessively when the

assembly is at speed; and if it is set too loose, it will vibrate during accelerations and decelerations.

8. With the tool still in place, tighten the six (four) SHCS holding the transmission (motor mounting plate) to

the spindle head casting.

9. Loosen the two SHCS and remove the belt tension tool.

30K Spindle

There are two types of belts (3 rib and 4 rib) used on the 30K Spindle Drive. To ensure maximum performance,

the spindle drive belt should be checked for proper tension every 6 months or 1000 hours of operation. The

tension is measured using a Gates Sonic Tension Meter, model number 505C or 507C (used for all belt tension

measurements).

The following table displays the proper lbf(pounds force)/Hz tension readings.

Belt New Belt Used Belt

Number of Ribs Minimum Maximum Minimum Maximum

3 Rib 53.7 lb

f

174 Hz 180 Hz 161 Hz 167 Hz

4 Rib 60.8 lb

f

159 Hz 165 Hz 148 Hz 154 Hz

NOTE: Specific settings must be entered into the tension meter to obtain a correct

tension reading, and are listed below. The Gates Sonic Tension Meter is

capable of retaining 10 to 20 separate combinations of settings depending

upon model. Be sure that you are on the correct belt drive storage register

before taking a reading.

57.6 lb

64.8 lb

f

f

46.2 lb

52.0 lb

f

f

50.1 lb

56.4 lb

f

f

Setting for 3 rib belt: Weight 13.1, Width 3, Span 225

Setting for 4 rib belt: Weight 13.1, Width 4, Span 225

SPINDLE BELT TENSIONING (OM-1A/OM-2A)

The spindle belt tension is measured using a Gates Sonic Tension Meter, model number 505C or 507C.

1. Place the Gates Sonic Tension Meter in Setting #1.

2. Place the meter’s sensor within 3/8” of the belt, and pluck the belt like a guitar string, taking care that the

sensor does not touch the belt.

3. Set belt tension for the Office Mill 30,000 RPM spindle at 43# to 47#.

4. Torque spindle motor fasteners to 30 ft-lb.

96-0283 rev A June 2006

Mechanical Service

27

Page 29

APL MOTOR BELT REPLACEMENT

W-Axis Motor Belt Replacement

A lathe’ s W-axis motor belt s control the raising and lowering of the APL arm. The following instructions are to

service the belts in case a belt is in need of replacement. It is recommended to replace both belts at a time.

Cable

Junction

Carriage

Assembly

W-Axis Ram

RotatorAssembly

Home Switch

Trip Bracket

Hard Stop

Bearing Support

Beam

Carriage Cover

AUTOMATIC

PARTSLOADER

APL

Replacing the Belt(s)

1. Jog the APL U-axis as far to the left of the machine as possible and disable the axis by selecting Parameter 354 and changing the bit value from 0 to 1.

2. Remove the hard stop and home switch trip bracket, remove the APL carriage cover, and press E-Stop.

3. Manually push the carriage away from the machine until the two metal linear rail guide pads (held by 2

bolts each) are exposed. The entire arm assembly has to clear the table.

NOTE: Only push as far as needed to be able to access the four bolts on the two guide

rail blocks.

4. Using a sufficient block (which will have to be taller than the parts table) jog the APL down and support the

bottom of the rotating head.

Remove Upper

Guide Rail Block

with two SHCS

Pinion

Gear

Remove

Upper Belt

Remove One SHCS

(Right Side Only

Carriage

Assembly

B-Axis

Ram

Support

Blocks

Rotator

Assembly

Support

Table

28

Mechanical Service

96-0283 rev A June 2006

Page 30

5. Remove the top linear rail guide block (2 bolts) which will drop down to the bottom block. Only remove

the inside bolt on the bottom linear guide block. The remaining bolt (outside) on the bottom guide

block should only be loose.

6. Remove the bearing support bracket and position the ram outwards so that there is sufficient clearance to

remove the pinon gear which will yield access to the rear motor belt.

7. Loosen the W -axis motor support housing so that there is enough slack to position the belt. After the belts

have been installed, replace the pinion gear and bearing support. Torque the W-axis motor bolts to 30 ft-lb,

swing the arm back into place, and re-install the linear guide pads. Leave the bolts loose to jog the ram up,

use a level to make sure the arm is straight, then torque the bolts.

8 Manually push the APL back past the home switch plate to the center of the parts table, Zero Return the

W-axis, re-fasten the rubber stop and home plate on the beam.

9. Re-enable the U-axis by changing the bit in Parameter 354 and Zero Return the axis.

10. Finally, re-check the offsets for the U- and W-axis.

VERIFYING BELT TENSION (LATHE)

1. Apply proper tension to belt s by wedging the T -shaped belt tensioner tool underneath the spindle head

casting web, between the spindle head pulleys and motor/gearbox pulleys and the motor/gearbox mounting

plate. Att ach the 1/2" drive torque wrench to tensioner tool and apply required torque value. The path of the

applied torque should be inline with the motor assembly . A belt tensioning chart follows.

T-1537

T-1961

SL 20/20B

95 ft-lb

T-1537

SL 30/30GB

(New Spindle Center Line)

From 11/98

95 ft-lb

T-1537

SL 30B

230 ft-lb

(Encoder Pulley

Must be Removed)

T-1537

HL-3/-4 & HL-3/-4GB

Through 10/98

95 ft-lb

T-1961

T-1650

SL 40/40B

230 ft-lb

2. While applying correct torque amount, tighten the four mounting motor/gearbox plate bolts.

CAUTION! This procedure should be performed with two service persons;

one to apply torque, the other to tighten bolts.

3. Use a Gates Sonic Tension Meter to measure the belt tension.

4. Mount the encoder onto the spindle housing below the spindle shaft with four mounting bolts.

96-0283 rev A June 2006

Mechanical Service

29

Page 31

5. Place the 3/8" timing belt on the spindle pulley, with the other end on the encoder pulley.

6. Align and att ach the hydraulic cylinder adapter onto the spindle shaft with the mounting bolts. Tolerance on

the face of the adapter plate perpendicular to centerline should be within .001". Check tolerance of large

I.D. bore circular to within .002".

7. Slide the hydraulic cylinder into spindle shaft. Insert and snug the mounting bolts.

8. Att ach and clamp the oil drain hose and coolant drain hose onto hydraulic cylinder . Att ach and screw in

clamp and unclamp hoses.

9. Set magnetic base on top of the spindle housing with indicator touching the top of the hydraulic cylinder.

10. Spin the hydraulic cylinder and verify that the runout is under 0.001". If runout is over 0.001", rotate the

hydraulic cylinder to its high point and tap cylinder with a rubber mallet. Tighten and torque the bolts.

1 1. Replace all previously removed sheet metal.

SUB SPINDLE MOTOR BELT REPLACEMENT

1. Remove all sheet met al covering the sub spindle motor.

2. Remove the chuck and unhook the hoses to the union.

3. Disconnect the electrical wiring to the encoder .

4. Loosen the set screw that holds the encoder to the motor shaft.

5. Remove the screw that holds the encoder bracket to the motor .

6. Loosen but do not remove the four sub spindle motor mounting bolts.

7. Remove and replace the motor belt.

8. Reassemble in reverse steps to remove. Make sure the motor wiring is connected and secured properly .

30

Mechanical Service

96-0283 rev A June 2006

Page 32

SPINDLES

Operation

Spindle speed functions are controlled primarily by the S address code. The S address specifies RPM in

integer values from 1 to maximum spindle speed (Parameter 131).

Speeds from S1 to the Parameter 142 value will automatically select low gear, and speeds above Parameter

142 will select high gear. Two M codes, M41 and M42 can be used to override the gear selection; M41 for low

gear and M42 for high gear. Low gear operation above S1250 is not recommended. High gear operation below

S100 may lack torque or speed accuracy. Spindle speed accuracy is best at higher speeds and in low gear.

If there is no gear box in your machine, the gear box is disabled by parameters and is always in high gear. M41

and M42 commands are ignored.

The spindle is hardened and ground to precise tool holder dimensions providing an excellent fit to the holder.

Live Tooling

Live tooling provides the ability to utilize standard 40mm VDI-driven tools, operated by a 5HP motor. This

auxiliary motor is capable of 0-3000 RPM, controllable in 1 RPM increments. Live tool motor speed is controlled primarily by the P address codes. The P address specifies RPM in integer values from 1 to the maximum spindle speed of 3000 RPM.

15K & 50 TAPER HIGH SPEED SPINDLE

Non-Serviceable, Anti-Rotation Draw Bar

The draw bar and the spindle are not serviceable as separate items on the 15K spindle. The 15K spindle uses

an extra high clamp draw bar and may be used in both TSC and non-TSC applications. If there is a need to

replace the spindle or the draw bar, the entire spindle must be replaced.

NOTE: The spindle and the draw bar are balanced at the factory as a matched

assembly.

The anti-rotation draw bar does not allow the draw bar to turn in the spindle shaft. By not changing the position

of the draw bar, changes in vibration output of the spindle are minimized. The balance is also retained when the

draw bar does not turn.

Oil Flow

The specification for oil flow is 0.15 - 0.18 cc per 0.5 hour when measured from the spindle restrictor with no

airflow. This oil flow is measured on each machine. The flow rate is adjusted by changing the restrictor used

and by changing the total output of the pump. The pump nominally puts out 3 cc per 0.5 hour. The pump has a

0.5 hour cycle time. The pump runs only when the spindle is running or one of the axes is moving. Different

sized restrictors are used to control flow. A 3/0 restrictor has twice the flow of a 4/0, which has twice the flow of

a 5/0 restrictor.

STALLING/LOW TORQUE

Generally, complaints of stalling or low torque relate to incorrect tooling or machining practices. A spindle that

is tending to seize will yield a poor finish machining, run very hot and very loud. Investigate machining problems

before concluding the problem exists with the spindle or spindle drive.

SPINDLE DRIVE

Low line voltage may prevent the spindle from accelerating properly. If the spindle takes a long time to accelerate, slows down, or stays at a speed below the commanded speed with the load meter at full load, the spindle

drive and motor are overloaded. High load, low voltage, or too fast accel/decel can cause this problem.

96-0283 rev A June 2006

Mechanical Service

31

Page 33

A resistor bank (regen resistors) located on the top of the control cabinet is used by the spindle drive to

dissipate excess power caused by the regenerative effects of decelerating the spindle motor . If the spindle

motor is repeatedly accelerated and decelerated in rapid succession, this resistor will get hot. In addition, if the

line voltage into the control is above 255V , this resistor will begin to heat.

There is an overtemperature sense switch mounted near the regen resistors. This sensor is a normally-closed

switch that opens at about 100

0

C. It will generate an alarm and all motion will stop. Af ter the overheat time

period specified by Parameter 297, an automatic shutdown will occur in the control.

If the regen load resistors are not connected or open, it may result in an overvoltage alarm. A functional resistor

will have a reading of 8 ohms.The overvoltage occurs because the regenerative energy being absorbed from the

motor while decelerating is turned into voltage by the spindle drive. If this problem occurs, the possible fixes are

to slow the decel rate or reduce the frequency of spindle speed changes.

32

Mechanical Service

96-0283 rev A June 2006

Page 34

SPINDLE TROUBLESHOOTING

NOT TURNING

Spindle not turning

• If there are any alarms, refer to "Alarms" section.

• Check that the spindle turns freely when machine is off.

• If motor turns but spindle does not, see the "Belt Replacement and Tensioning" and "Spindle Motor and

Transmission".

• Command spindle to turn at 1800 RPM (vert & horiz) and check spindle drive display. If display blinks “bb”,

check spindle orientation switch.

• If spindle drive does not light the Run LED, check forward/reverse commands from I/O PCB.

• Check the wiring of analog speed command from MOTIF PCB to spindle drive (cable 720).

• If spindle is still not turning, replace MOCON PCB.

• If spindle is still not turning, replace spindle drive.

• Check for gearbox or motor rotation (if applicable). If the motor or gearbox operates, check the drive belt.

• Disconnect the drive belt (vert). If the spindle will not turn, it is seized and must be replaced.

NOTE: Before installing a replacement spindle, the cause of the previous failure must

be determined.

NOISE

Check the tooling (mills); balanced tooling will run smoother; possibly reducing the noise.

Check for misalignment between the motor and the spindle. If misalignment is noted, loosen the motor mount-

ing bolts, run the spindle at 1000 RPM, and then tighten the mounting bolts.

Remove the coolant union and run the spindle, if the spindle is quieter, the coolant union may need replacing.

Excessive noise coming from the spindle head area

Most noises attributed to the spindle actually lie in the motor/gearbox or drive belt of a machine. Isolate the