Instruction Manual

Shaking Water Bath

SWB25

Part No. 003-4190

1-1-067-2 / 09.1998

Gebr. HAAKE GmbH HAAKE (USA) Rheo s.a. ( France)

Dieselstraße 4 53 W. Century Road 99 Route de Versailles

D-76227 Karlsruhe Paramus, NJ 07652 91160 Champlan

Tel.+49(0)18050HAAKE

oder+49(0)721 4094-444 Tel.201 265 7865 Tel.+33 1 64 54 0101

Fax +49(0)721 4094-418 Fax 201 265 1977 Fax +33 1 64 54 0187

E-mail:helpdesk@haake.de http://www.haake-usa.com http://www.rheo.fr

Table of Contents

1

1. Key to Symbols 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Symbols used in this manual 3. . . . . . . . . . . . . .

1.2 Symbols used on the unit 3. . . . . . . . . . . . . . . . .

2. Quality Assurance 4. . . . . . . . . . . . . . . . . . . . . . . . . .

3. Your Contacts at HAAKE 4. . . . . . . . . . . . . . . . . . . .

4. Safety Notes 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. Unit Description 7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Safety features 7. . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Safety element 7. . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Applications 7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. Unpacking / Setting Up 8. . . . . . . . . . . . . . . . . . . . . .

6.1 Transportation damage? 8. . . . . . . . . . . . . . . . .

6.2 Information concerning the CE sign 8. . . . . . . .

6.3 Contents 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 Ambient conditions according

to DIN EN 61010 9. . . . . . . . . . . . . . . . . . . . . . . .

7. Panel Controls and Indicators 10. . . . . . . . . . . . . . .

8. Assembly/Connecting Up 11. . . . . . . . . . . . . . . . . . . .

8.1 Connecting the platform to the guide rod 11. . .

8.2 Connecting to a mains socket 11. . . . . . . . . . . . .

8.3 Changing the mains plug

(e.g. for Great Britain) 11. . . . . . . . . . . . . . . . . . . .

8.4 Fuses on the unit 11. . . . . . . . . . . . . . . . . . . . . . . .

9. Setting up and starting 12. . . . . . . . . . . . . . . . . . . . . .

9.1 Attaching clamps for vessels to the platform 12

9.2 Filling in the bath liquid 12. . . . . . . . . . . . . . . . . . .

9.3 Ideal operating conditions for the shaking

movement 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4 Operational safety 13. . . . . . . . . . . . . . . . . . . . . . .

9.5 Draining 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10. Operating 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.1 Switching on 14. . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.2 Displaying the preset temperature 14. . . . . . . . .

10.3 Adjusting the set temperature 14. . . . . . . . . . . . .

10.4 Heating control lamp 15. . . . . . . . . . . . . . . . . . . . .

10.5 Displaying the shaking frequency 15. . . . . . . . . .

10.6 Adjusting the shaking frequency 16. . . . . . . . . . .

11. Special functions 17. . . . . . . . . . . . . . . . . . . . . . . . . . .

11.1 Adjusting the default values 17. . . . . . . . . . . . . . .

11.2 Adjusting the RTA values (CT) 17. . . . . . . . . . . .

Table of Contents

2

12. Excess Temperature Protection 18. . . . . . . . . . . . . .

12.1 Excess temperature protection dial 18. . . . . . . .

12.2 Setting the excess temperature 18. . . . . . . . . . .

13. Fault display 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.1 Sensor bath/short circuit 19. . . . . . . . . . . . . . . . . .

13.2 Motor 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13.3 Range sensor 19. . . . . . . . . . . . . . . . . . . . . . . . . . .

14. Special Accessories 20. . . . . . . . . . . . . . . . . . . . . . . .

15. Maximum clamp number for the moveable

platform for ... 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16. Technical Specifications 24. . . . . . . . . . . . . . . . . . . . .

16.1 Unit 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

16.2 Fuse values 24. . . . . . . . . . . . . . . . . . . . . . . . . . . .

!

+

_

C

°

n

stop

Key to Symbols

3

1. Key to Symbols

1.1 Symbols used in this manual

Warns the user of possible damage to the unit, draws

attention to the risk of injury or contains safety notes

and warnings.

Denotes an important remark.

1

Indicates the next operating step to be carried out

and…

⇒ …what happens as a result thereof.

1.2 Symbols used on the unit

Caution: Read the instruction manual!

Adjustment possibility for setting the cut-off point for

excess temperature protection

Instrument in ”off” position

Instrument in ”on” position

Menu selection

Value alteration (+) higher / ( – ) lower

Stop / Enter key

Temperature key

Shaking frequency

Quality Assurance / Your Contacts at HAAKE

4

2. Quality Assurance

Dear customer,

HAAKE implements a Quality Management System certified

according to EN 29001.

This guarantees the presence of organizational structures

which are necessary to ensure that our products are developed, manufactured and managed according to our customers expectations. Internal and external audits are carried out

on a regular basis to ensure that our QMS system is fully

functional.

We also check our products during the manufacturing process to certify that they are produced according to the specifications as well as to monitor correct functioning and to confirm that they are safe. This is why we initiate this monitoring

process of important characteristics already during

manufacturing and record the results for future reference.

The “Final Test” label on the product is a sign that this unit

has fulfilled all requirements at the time of final manufacturing.

Please inform us if, despite our precautionary measures,

you should find any product defects. You can thus help us to

avoid such faults in future.

3. Your Contacts at HAAKE

Please get in contact with us or the authorized agent who

supplied you with the unit if you have any further questions.

Gebrüder HAAKE GmbH,

Dieselstrasse 4,

D-76227 Karlsruhe

GERMANY

Tel. +49 (0)18050HAAKE

or +49 (0)721 4094-444

Fax +49 (0)721 4094-418

E-mail helpdesk@haake.de

The following specifications should be given when product

enquiries are made:

– Unit name printed on the front of the unit,

– TYP as specified on the name plate.

!

!

!

!

!

!

!

!

!

Safety Notes

5

4. Safety Notes

These notes are intended to draw your attention to risks

which only YOU can recognize and avoid or overcome. They

are intended t o enhance your own safety consciousness.

We have set the highest quality standards for ourselves and

this unit during development and production. Every unit

meets relevant safety regulations. The correct unit usage

and proper h andling i s h owever s olely your r esponsibility.

The intended workplace should correspond to a laboratory

or pilot plant environment. The user should have an education level which is at least equivalent to a trained laboratory

worker or specialized chemist. The following list should be

seen as an example.

The device may not be operated if there are any doubts

regarding a safe operation due to the outer appearance

(e.g. damages).

A safe operation of the instrument cannot be guaranteed if the user does not comply with this instruction

manual.

Ensure that this manual is always at hand for every unit

operator.

Only use this unit solely for the intended application.

Repairs, alterations or modifications must only be car-

ried out by specialist personnel. Considerable damage

can be caused by improper repairs. The HAAKE service

department is at your disposal for repair work.

Do not operate the unit with wet or oily hands.

Do not clean the unit with solvents (fire risk!) – a wet

cloth soaked in household detergent is normally sufficient.

This device is not designed according to the standard

EN 60601-1: 1990 (DIN VDE 0750-1 and IEC 601-1) and

should not be operated in rooms used for medical purposes and/or in the vicinity of patients.

Only use heat transfer liquids recommended by HAAKE.

Please refer to the respective EC – Safety Data Sheet.

!

!

Safety Notes

6

The temperature controlling i.e. immersing o f test tubes,

Erlenmeyer flasks or similar objects directly within the

unit constitutes normal circulator practise.

We do not know which substances are contained within

thes e vessel s. Many substances are dangerous:

• inflammable, easily ignited or explosive

• hazardous to health

• environmentally unsafe

Y ou alone are responsible for the handling of these substances! Our advice:

• If in doubt, consult a safety specialist.

• Read the product manufacturer’s or supplier’s

“

EC – SAFETY DATA SHEET

”

• Read relevant regulations concerning dangerous

materials

• Observe relevant guidelines for laboratories in your

country

The following measures were taken for the protection of

the operator:

• Protection Class I according to VDE 0106 T1

i.e. protection against electric shocks by grounding all

parts which carry the risk of electric contact.

The device must only be connected to mains receptacles with a protective ground.

• Protection IP 20 according to EN 60529

i. e. regarding the protection against accidently touching live parts and damage by foreign matter, it has been

ensured that foreign bodies with a thickness or diameter of more than 12 mm cannot penetrate.

No special precautions were taken against the penetration of water and dust. The device should therefore not be used in a dusty atmosphere or in the neighborhood of spray water.

Do not insert wires or tools in any of the openings.

Complete separation from the mains is required

when:

• all dangers caused by this device are to be

avoided,

• cleaning is carried out,

• repairs or maintenance by specialist personnel is

about to be carried out

Complete separation means:

Pull out the mains plug!

Unit Description

7

5. Unit Description

5.1 Safety features

The comprehensive safety system is designed on the principle of the concept of the “single fault” (EN 61010). This assumes that two separate faults do not occur simultaneously .

This system therefore offers protection against

one

(single)

fault. This one fault will effectively occur automatically if

you...

• do not read this manual,

• do not correctly set the excess temperature protection,

i.e. your safety reserves have already been used up.

5.2 Safety element

The unit is equipped with an excess temperature protection.

The unit can only be used with non-flammable liquids such

as

water

or

water with antifreeze

.

The safety element measures the surface temperature of the

heating element. If this exceeds a certain temperature (due

to e.g. a leakage in the liquid circuit or a liquid shortage), the

safety element is triggered.

If a safety feature is triggered…

• fault display lights indicate the fault,

• the safety-relevant components of the heating unit

(heating element ) are switched off immediately i.e. the

safety circuit transfers the unit to a stable, safe condition,

• the water in unit gradually adjusts to ambient tempera-

ture.

5.3 Applications

Temperature controlling and shaking of samples directly in

the bath vessel.The samples have to be inserted into flasks

or beakers.

Unpacking / Setting Up

8

6. Unpacking / Setting Up

6.1 Transportation damage?

• Notify carrier (forwarding merchant, railroad) etc.

• Compile a damage report.

Before return delivery:

• Inform dealer or manufacturer

(Small problems can often be dealt with on the spot).

6.2 Information concerning the CE sign

HAAKE circulators and cryostats carry the CE sign which confirms that they are compatible with the EU guideline

89/336/EEC (electromagnetic compatibility). The tests are carried out according to module H (official sheet L380 of the European Community) as our quality assurance system is certified

according to DIN / ISO 9001.

It was tested according to the strict EMV test requirements of

the EN61326 (EMV requirements for electrical equipment for

measuring technology, conduction technology and laboratory

usage). This means it was tested for interference resistance

and interference emission according to industrial conditions.

The following basic standards were applied in detail:

Interference resistance:

EN61000–4–2 electrostatic discharge

EN61000–4–3 electromagnetic fields

EN61000–4–4 fast transients

EN61000–4–5 surge voltages

EN61000–4–6 wire–guided HF–signals

EN61000–4–8 magnetic field of mains frequency

EN61000–4–11 voltage drop/short–time interruption

Interference emission:

CISPR16/class A wire–guided interference emission

CISPR16/class A radiated interference emission

The application in industrial environments is thus possible.

A declaration of conformity is supplied with the ordered unit on

request.

Our strict standards regarding operating quality and the resulting considerable amount of time and money spent on development and testing reflect our commitment to guarantee the high

level of quality of our products even under extreme electromagnetic conditions. Practice however also shows that even units

which carry the CE sign such as monitors or analytical instruments can be affected if their manufacturers accept an interference (e.g. the flimmering of a monitor) as the minimum operating quality under electromagnetic compatibility conditions. For

this reason we recommend you to observe a minimum distance

of approx. 1 m from such units.

The CE–sign also certifies the conformity with the EU–directive

72/23/EWG (low voltage regulation). The applied standards

are EN 61010–1 and EN 61010–2–010.

Unpacking / Setting Up

9

6.3 Contents

1 Base unit with mains cable

1 Moveable platform with 4 rollers

1 Rubber connection piece

1 Instruction manual

1 Warranty card (please fill out and return)

6.4 Ambient conditions according to DIN EN 61010

• indoors, max. 2000 meters above sea level,

• ambient temperature 5 ... 40° C,

• relative humidity max. 80%/31°C (→ 50%/40°C)

• excess voltage category II, contamination level 2

Panel Controls and Indicators

10

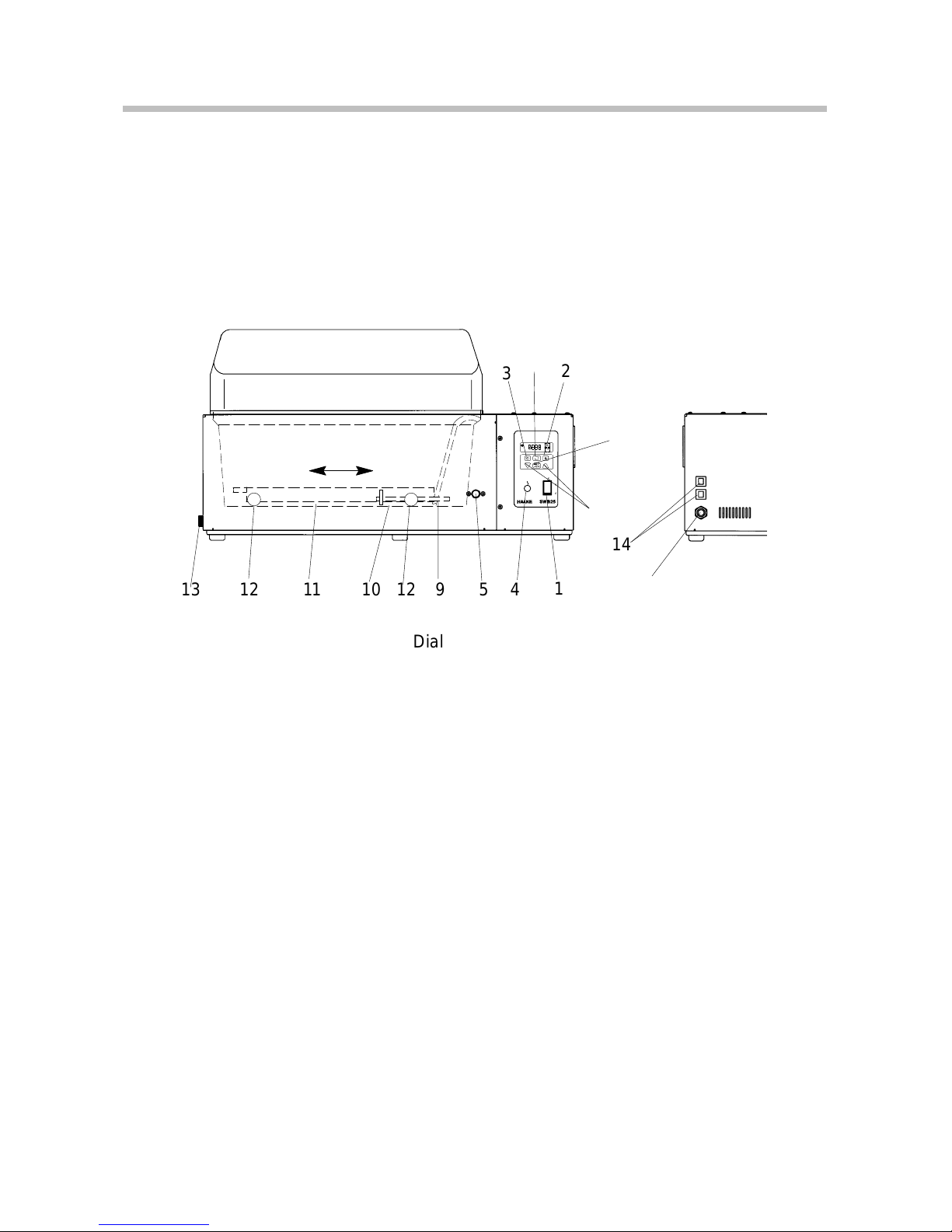

7. Panel Controls and Indicators

14

13 12 11 10 12 9

2

3

45

1

7

8

6

15

(1) Main switch

(2) Dial for shaking frequency

(3) Preset temperature dial

(4) Malfunction indicator light

(5) Excess temperature dial

(6) Changing the value

(7) Menu selection key

(8) Stop / Input key (Enter)

(9) Guide rod

(10) Rubber connection

(11) Moveable platform

(12) Rollers

(13) Drain plug nozzle

(14) Fuses

(15) Mains cable

230 V

115 V

!

!

!

Assembly/Connecting Up

11

8. Assembly/Connecting Up

8.1 Connecting the platform to the guide rod

Lift left end of the platform (11) until the rubber connection

(10) at the bathbottom can be picked up and placed over the

pin at the underside of the platform.

8.2 Connecting to a mains socket

The unit should only be connected to a grounded mains sokket. Before the unit is actually connected to the mains,

please compare the voltage indication on the name plate.

Voltage tolerances up to +/– 10% are acceptable.

8.3 Changing the mains plug (e.g. for Great Britain)

This should only be carried out by qualified spe-

cialist personnel!

The mains cable wires have the following colors:

Brown = Live

Blue = Neutral

Green/Yellow= Earth

8.4 Fuses on the unit

All units are equipped with automatic thermally-triggered

fuses.

If the fuse has triggered…

• the fuse does not have to be exchanged – resetting suf-

fices;

• a white marking is visible;

• a certain cooling down time should be allowed (approx.

5 min) before the (dip) switch can be pressed again.

Do not use tools; do not use force. Both destroy the

fuse.

If the fuse should be triggered again after resetting,

the unit probably has a defect. In this case the unit

should be sent in for servicing.

Setting up and Starting

12

9. Setting up and starting

9.1 Attaching clamps for vessels to the platform (11)

Spring clips can be supplied to secure round vessels, e.g.

Erlenmeyer flasks or beakers, to the platform.

Maximum clamp number see chapter 11.

9.2 Filling in the bath liquid

Liquid level: Can be selected anywhere between 50 and

180 mm (Thus, filling level dependent on objects used in the

bath.)

Only use

water

or

water with antifreeze

.

9.3 Ideal operating conditions for the shaking

movement

The following should be considered in order to warrant ideal

operating conditions:

a) Type and level of the bath liquid.

b) Number, size, and weight of the test vessels.

c) Amplitude of the shaking carriage movement.

d) Number of carriage cycles per time unit

(shaking frequency).

The limiting conditions for the shaking movement:

1) Too large a shaking movement will cause high

waves on the bath surface so that the liquid will

splash over the top.

2) Large and heavy test vessels are attached to the

platform and the amplitude and /or the frequency

are too high. This means an overload for the

shaking drive:

An overload could lead to a standstill of the driving

motor and eventually to its destruction if such

operating conditions are kept up over a longer

period of time.

!

Setting up and Starting

13

The following rule will help to arrive at ideal operating conditions:

At the beginning of the test, a small amplitude and a small

frequency should be selected. Then the values of these two

parameters may gradually be increased until the contents

of the test vessels are sufficiently shaken and mixed.

The shaking mechanism is also activated when the unit is

switched on. Please observe the notes above regarding the

shaking movement. It should especially be ensured that the

shaking motor is not blocked due to the choice of unsuitable

shaking motor parameters.

If the SWB25 is only to be used as a waterbath, the rubber

connection piece (10) of the platform (11) should be

removed.

9.4 Operational safety

The units are provided with an excess temperature safety

circuit, the cut-off temperature of which has to be set at the

dial button (5). In case of a temperature control malfunction

which could overheat the bath, the heater of the water bath

will be cut off. The malfunction indicator light (4) will then

come on.

9.5 Draining

The unit is drained at the nozzle 13.

1

Place a suitable vessel underneath nozzle.

Bear in mind that the liquid will run out in a slight arc.

2

Turn plug slowly until it becomes disengaged from the

thread.

The liquid will start to run out.

3

Possible residues can be drained by tilting the circulator slightly.

Hot heat transfer liquid should not be drained!

When certain conditions make draining necessary ,

please act safety conscious: Wear protective

clothing and protective gloves!

!

Operating

14

10. Operating

10.1 Switching on

Switch the unit on at the mains switch 1.

⇒ The display 16 briefly shows the device identification

”Sb25”, thereafter the version number of the operating

software, e.g. ”1.00” and then the actual shaking frequency.

⇒ The shaking mode is started. The motor slowly reaches

the set shaking frequency. Heating is started.

If the shaking frequency is too high, then interrupt

by pressing the ”Stop” key 8.

10.2 Displaying the preset temperature

Only possible in the temperture displaying mode

(Display 17 ”°C” is lit).

1

Press menu key 7:

⇒ Select preset temperature set temperature

Small display ”°C” blinks.

⇒ In display 16 the adjusted preset temperature is

shown.

10.3 Adjusting the set temperature

Only possible in the temperature displaying mode

(Display 17 ”°C” is lit).

1

Press the menu button 7:

⇒ Small display ”°C” blinks.

2

Press the temperature button 3:

⇒ Displayed temperature value in the display.

3

Increase (+) or decrease (–) the value shown in the display with the buttons 7.

The first degree of temperature change is thereby

passed slowly and thereafter the rate of temperature

change in the display is five times faster.

16

19

17

18

1

2

6

8

7

3

Operating

15

4

Press the enter button 8.

⇒ The selected value is stored as new set tempera-

ture and activated.

The new value is not saved until the Enter button

has been pressed. The circulator continues to use

the old set value.

The display 16 automatically switches back to actual temperature display after a short time.

10.4 Heating control lamp

The display 19 lights up when the heating is switched on (set

temperature is higher than the actual temperature).

⇒ display 19 lights up constantly during the heating up

phase,

⇒ display 19 flashes on and off during the control phase.

The display 19 does not light up if the heating is not activated

(set temperature is lower than the actual temperature).

The heat transfer is carried out by convection from the

heated bath bottom upwards. There are therefor small temperature gradients in the bath from the top to the bottom or

from the bath side to the bath middle. This should be

accounted for if a correction of the set temperature should be

necessary.

10.5 Displaying the shaking frequency

Only possible in the speed displaying mode

(Display 17 ”n” is lit).

1

Press menu key 7 :

⇒ Select shaking frequency.

Small display ”n” blinks.

⇒ In display 16 the adjusted shaking frequency is

shown.

16

19

17

18

1

2

6

8

7

3

Operating

16

10.6 Adjusting the shaking frequency

Only possible in the speed displaying mode

(Display 17 ”n” is lit).

1

Press the menu button 7:

⇒ Small display ”n” blinks.

2

Press the shaking frequency button 2:

⇒ Displayed shaking frequency in the display.

3

Increase (+) or decrease (–) the value shown in the display with the buttons 6.

The first shaking frequency change is thereby passed

slowly and thereafter the rate of shaking frequency

change in the display is five times faster.

4

Press the enter button 8.

⇒ The selected value is stored as new shaking fre-

quency and activated.

⇒ The motor slowly increases the shaking fre-

quency. By pressing the enter button 8 once

again, the actually reached frequency is stored

as new set frequency.

The new value is not saved until the Enter button

has been pressed. The unit continues to use the

old value.

The display 16 automatically switches back to actual shaking frequency display after a short time.

16

19

17

18

1

2

6

8

7

3

Operating

17

11. Special functions

11.1 Adjusting the default values

1

Switch on the unit and press both keys 6

(”–” and ”+”).

⇒ All adjusted parameters are set back on default

values.

SOLL = 20.0°C

n = 20 rpm

RTA CT = 0.00°C

⇒ In display 16 the message”CodE”appears.

11.2 Adjusting the RT A values (CT) (Temperature offset)

Only possible in the temperature displaying mode.

1

Change from actual value display to preset value

adjustment with key 7.

⇒ Preset value (LED 17 blinks fast)

2

Change from SOLL to RTA with key 7

⇒ ”c” (c0.00) appears on display 16.

⇒ RTA value (LED 17 blinks every 2 seconds)

3

Change the value shown on the display with the keys

6 up ”+” or down ”–” . The setting range for the temperature/RTA value is ±10°C

⇒ With negative values the display changes from

”c” to ”–”.

4

Press input key 8 (Enter).

⇒ The selected value is stored and activated as new

value.

Without pressing the Enter key the new value is not

stored. The unit goes on operating with the old

value.

16

19

17

18

1

2

6

8

7

3

5

5 4

1

5a

Excess Temperature Protection

18

12. Excess Temperature Protection

If a safety feature is triggered:

• The fault control lamp 4 lights up.

• all voltage conducting unit components (the heating

element) are switched off immediately i.e. the safety

circuit transfers the unit to a stable, safe condition.

The fault cause must be identified and remedied.

After the fault has been eliminated the unit can be started

again by pressing the outer ring 5a.

12.1 Excess temperature protection dial

It offers protection against dangers caused by an uncontrolled heating up of the heat transfer liquid above the desired set temperature.

The cut-off temperature is adjusted with the excess temperature setting dial 5.

Proper protection can only be guaranteed if the

cut-off point has been correctly set.

12.2 Setting the excess temperature

The cut-off point is set with the excess temperature dial 5

with a rough scale of temperature values arranged around

it. This scale, of course, can only serve as an approximate

setting means for this cut-off point. However, the cut-off point

can be determined to act exactly if the following procedure

is adhered to:

If for instance a bath liquid has a fire point of 60°C the unit

should cut off after reaching 35°C at the latest:

1

First set the desired set value using keys 6 (+), (–) to

exactly 35°C.

2

After the SWB25 has reached this temperature, turn

the excess temperature dial 5 backwards very slowly

(to the left) until the unit cuts off (acoustic signal, fault

message).

3

Starting the unit after the heat transfer liquid has cooled

down somewhat.

4

Then set the set temperature to the actual temperature

(< 35°C).

⇒ The unit can now be used for temperatures below

35°C. As soon as 35°C is reached, it is securely

switched off.

Fault Display

19

13. Fault display

13.1 Sensor bath/short circuit

At faults of the measured value recognition the message

”AL-F” is shown.

⇒ The display part ”AL” blinks, the heater is

switched of f , the shaking process is not interfered

as long as the fault is present.

When the measured value recognition has

regenerated itself the normal operation is contin-

ued.

13.2 Motor

Motor is set on drive speed setting >0 rpm

f there is no rotation at a drive speed setting of >0 the message ”AL-d” is shown.

⇒ The display part ”AL” blinks, the heater is

switched off as long as the defect is present.

When the motor starts rotating the normal opera-

tion is continued.

13.3 Range sensor

When any parameter (preset value, RTA) is out of its scope.

Change values according to chapter 11.

Should the defects appear regularly the unit has to be sent

to the service.

Special Accessories

20

14. Special Accessories

Order No.: Description: Additional information

333-0642 (1) Bath cover, roof shaped,

plastic

827-0310 (2) Plastic balls for covering

bath,

500 balls sufficient

for 0.2 m

2

000-8581 (3) Cooling coil for tap

water cooling

333-0259 (4) Basic rack, without any

attachments (with special

clamping device for shaking

platform)

w/o inserts

Special Accessories

21

Order No.: Description: Additional information

333-0129 (5) Universal basic rack for

test tubes

Can be used only as

normal water bath.

333-0130

333-0131

333-0132

(6) 2 Inserts for

86 tubes, 10 mm ø

2 Inserts for

46 tubes, 16 mm ø

2 Inserts for

23 tubes, 25 mm ø

Per basic rack (4)

2 sets (4 pieces)

333-0134

333-0135

(7) Plastic snappers for the

holes of the inserts to

accommodate tubes/flasks

with variable diameters.

Plastic snappers, 50 pieces

outside 16 mm ø,

inside 2 – 10 mm ø

Plastic snappers, 25 pieces

outside 25 mm ø,

inside 5 – 17 mm ø

Special Accessories

22

Order No.: Description: Additional information

000-8732

000-1980

000-1982

000-1990

000-1994

000-1995

(8) Clamps for flasks/

beakers

for 25 ml, flasks/beakers

up to 42 mm ø

for 50 ml, flasks/beakers

up to 51 mm ø

for 100 ml, flasks/beakers

up to 64 mm ø

for 250 ml, flasks/beakers

up to 85 mm ø

for 500 ml, flasks/beakers

up to 105 mm ø

for 1000 ml, flasks/beakers

up to 131 mm ø

These clamps can be fixed

directly to the shaking

platform or for quick

changing onto the basic

rack 333-0259

NOTE: If the basic rack 333-0259 is used, the four tapered pins

have to be assembled first. They are screwed into the movable

platform in place of the four screws. Now the rack can be positioned on the pins.

Maximum Clamp Number

23

15. Maximum clamp number for the moveable

platform for ...

40 x 25 ml ( 000-8732 ) 32 x 50 ml ( 000-1980 )

18 x 100 ml ( 000-1982 ) 12 x 250 ml ( 000-1990 )

8 x 500 ml ( 000-1994 ) 5 x 1000 ml ( 000-1995 )

Technical Specifications

24

16. Technical Specifications

16.1 Unit

Working temperature

range

°C 25 - 90°C

with tap water cooling °C 20 - 90°C

Temperature Accuracy ± K 0.2

Heater power 230V

115V

WW1500

1500

Control type PID

Excess temp. protection yes

Shaking amplitude mm 15

Shaking frequency min-120...200 (continuous)

Bath opening/depth mm 500 x 300 / 200

Bath capacity l 8 - 26

Bath vessel stainless steel, rust-free

Dimensions: (WxLxH) mm 650 x 340 x 260

Weight kg 18

Mains supply V/Hz 230/50-60 or 115/60

Total wattage VA 1600

16.2 Fuse values

Mains voltage

Fuse(s) at the

rear panel

Fuse(s)

in the unit

230V 2x10 A 1xT 0.63 A

115V 1x16 A 1xT 1.6 A

Part No. 003-4190

Subject to alterations Printed in Germany 1.1.067.2–09.98

Loading...

Loading...