H3C SecPath U200 Series, SecPath U200-CA, SecPath U200-A, SecPath U200-M, SecPath U200-CS Installation Manual

...Page 1

H3C SecPath U200-A/U200-M/U200-S

Unified Threat Management Products

Installation Guide

Hangzhou H3C Technologies Co., Ltd.

http://www.h3c.com

Document version: 6PW106-20130820

Page 2

Copyright © 2008-2013, Hangzhou H3C Technologies Co., Ltd. and its licensors

All rights reserved

No part of this manual may be reproduced or transmitted in any form or by any means without prior

written consent of Hangzhou H3C Technologies Co., Ltd.

Trademarks

H3C, , H3CS, H3CIE, H3CNE, Aolynk, , H

3

Care, , IRF, NetPilot, Netflow,

SecEngine, SecPath, SecCenter, SecBlade, Comware, ITCMM and HUASAN are trademarks of

Hangzhou H3C Technologies Co., Ltd.

All other trademarks that may be mentioned in this manual are the property of their respective owners

Notice

The information in this document is subject to change without notice. Every effort has been made in the

preparation of this document to ensure accuracy of the contents, but all statements, information, and

recommendations in this document do not constitute the warranty of any kind, express or implied.

Environmental protection

This product has been designed to comply with the environmental protection requirements. The storage,

use, and disposal of this product must meet the applicable national laws and regulations.

Page 3

Preface

The H3C SecPath U200-A/U200-M/U200-S Unified Threat Management Products Installation Guide

includes seven chapters, which describe the product overview, preparing for installation, installing the

firewall, accessing the firewall for the first time, replacement procedures, hardware management and

maintenance, and troubleshooting.

This preface includes:

• Audience

• Conventions

• About the H3C SecPath U200-A/U200-M/U200

-S UTM products documentation set

• Obtaining documentation

• Technical support

• Documentation feedback

Audience

This documentation is intended for:

• Network planners

• Field technical support and servicing engineers

• Network administrators working with the H3C SecPath U200-A/U200-M/U200-S UTM device

Conventions

This section describes the conventions used in this documentation set.

Command conventions

Con

v

ention Description

Boldface Bold text represents commands and keywords that you enter literally as shown.

Italic Italic text represents arguments that you replace with actual values.

[ ] Square brackets enclose syntax choices (keywords or arguments) that are optional.

{ x | y | ... }

Braces enclose a set of required syntax choices separated by vertical bars, from which

you select one.

[ x | y | ... ]

Square brackets enclose a set of optional syntax choices separated by vertical bars, from

which you select one or none.

{ x | y | ... } *

Asterisk marked braces enclose a set of required syntax choices separated by vertical

bars, from which you select at least one.

[ x | y | ... ] *

Asterisk marked square brackets enclose optional syntax choices separated by vertical

bars, from which you select one choice, multiple choices, or none.

Page 4

Convention Description

&<1-n>

The argument or keyword and argument combination before the ampersand (&) sign can

be entered 1 to n times.

# A line that starts with a pound (#) sign is comments.

GUI conventions

Convention Descri

p

tion

Boldface

Window names, button names, field names, and menu items are in Boldface. For

example, the New User window appears; click OK.

> Multi-level menus are separated by angle brackets. For example, File > Create > Folder.

Symbols

Convention Description

WARNING

An alert that calls attention to important information that if not understood or followed can

result in personal injury.

CAUTION

An alert that calls attention to important information that if not understood or followed can

result in data loss, data corruption, or damage to hardware or software.

IMPORTANT

An alert that calls attention to essential information.

NOTE

An alert that contains additional or supplementary information.

TIP

An alert that provides helpful information.

Network topology icons

Represents a generic network device, such as a router, switch, or firewall.

Represents a routing-capable device, such as a router or Layer 3 switch.

Represents a generic switch, such as a Layer 2 or Layer 3 switch, or a router that supports

Layer 2 forwarding and other Layer 2 features.

Represents an access controller, a unified wired-WLAN module, or the switching engine

on a unified wired-WLAN switch.

Represents an access point.

Represents a security product, such as a firewall, a UTM, or a load-balancing or security

card that is installed in a device.

Represents a security card, such as a firewall card, a load-balancing card, or a

NetStream card.

Port numbering in examples

The port numbers in this document are for illustration only and might be unavailable on your device.

Page 5

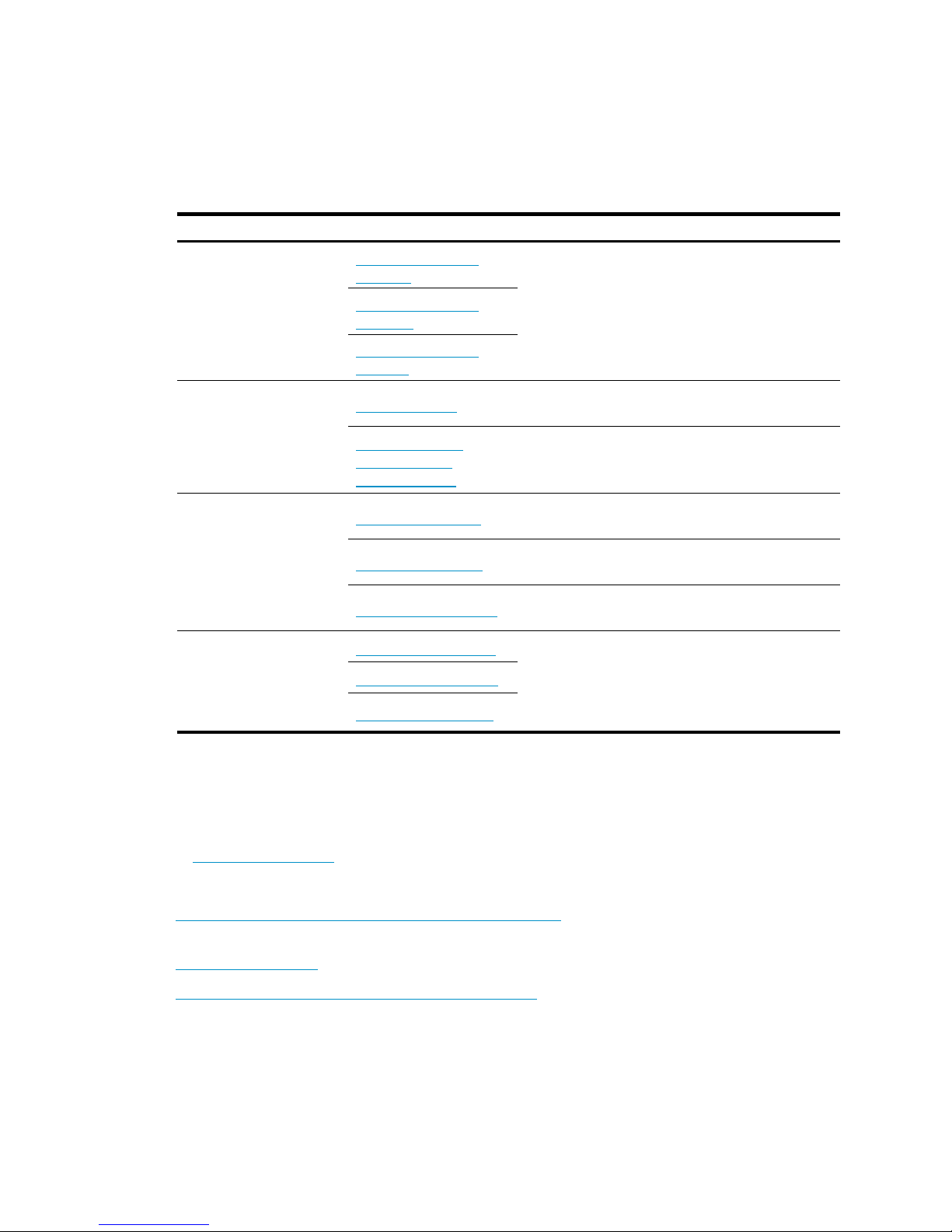

About the H3C SecPath U200-A/U200-M/U200-S

UTM products documentation set

The H3C SecPath U200 series UTM products documentation set includes:

Cate

gory

Documents

Purposes

Product description and

specifications

Marketing brochures

(U200-A)

Describe product specifications and benefits.

Marketing brochures

(U200-M)

Marketing brochures

(U200-S)

Hardware specifications

and installation

Installation guide

Provides a complete guide to hardware installation

and hardware specifications.

H3C UTM License

Registration and

Activation Guide

Describes how to apply for a license and register the

license.

Software configuration

Configuration guides

Describe software features and configuration

procedures.

Command references

Provide a quick reference to all available

commands.

Configuration examples

Describe typical network scenarios and provide

configuration examples and instructions.

Operations and

maintenance

Release notes (U200-A)

Provide information about the product release,

including the version history, hardware and software

compatibility matrix, version upgrade information,

technical support information, and software

upgrading.

Release notes (U200-M)

Release notes (U200-S)

Obtaining documentation

You can access the most up-to-date H3C product documentation on the World Wide Web

at http://www.h3c.com

.

Click the links on the top navigation bar to obtain different categories of product documentation:

[Technical Support & Documents > Technical Documents]

—Provides hardware installation, software

upgrading, and software feature configuration and maintenance documentation.

[Products & Solutions]

—Provides information about products and technologies, as well as solutions.

[Technical Support & Documents > Software Download]

—Provides the documentation released with the

software version.

Page 6

Technical support

service@h3c.com

http://www.h3c.com

Documentation feedback

You can e-mail your comments about product documentation to info@h3c.com.

We appreciate your comments.

Page 7

i

Contents

Product overview ·························································································································································· 1

Chassis views ···································································································································································· 1

U200-A ······································································································································································ 1

U200-M ····································································································································································· 2

U200-S ······································································································································································ 3

Interface modules ······························································································································································ 3

2GE ············································································································································································ 3

NSQ1GT2UA0 ························································································································································· 4

NSQ1GP4U0 ··························································································································································· 4

Interface module and UTM device compatibility matrix ······························································································· 5

Preparing for installation ············································································································································· 6

Safety recommendations ·················································································································································· 6

Safety symbols ·························································································································································· 6

Electricity safety ························································································································································ 6

Laser safety ································································································································································ 6

Handling safety ························································································································································ 6

Examining the installation site ········································································································································· 7

Weight support ························································································································································· 7

Temperature and humidity ······································································································································· 7

Cleanness ·································································································································································· 8

Cooling ······································································································································································ 8

ESD prevention ························································································································································· 9

EMI ·········································································································································································· 10

Lightning protection ··············································································································································· 10

Rack installation ····················································································································································· 11

Power supply ·························································································································································· 11

Installation tools ······························································································································································ 11

Accessories ····································································································································································· 11

Checklist before installation ·········································································································································· 12

Installing the UTM device ·········································································································································· 14

Unpacking the UTM device ··········································································································································· 14

Mounting the UTM device on a workbench ················································································································ 14

Installing the UTM device in a 19-inch rack ················································································································ 15

Grounding the UTM device··········································································································································· 17

Attaching the ring terminal ··································································································································· 17

Connecting the grounding cable ························································································································· 18

Installing a CF card ························································································································································ 19

Connecting interface cables ········································································································································· 19

Connecting a copper Ethernet port ····················································································································· 19

Connecting a fiber port ········································································································································ 19

Connecting a power cord ············································································································································· 20

Verifying the installation ················································································································································ 21

Installing FRUs ···························································································································································· 22

Installing a Mini interface module ································································································································ 22

Installing a MIM interface module ································································································································ 22

Installing a lightning protector for a network port ······································································································ 23

Installation procedure ··········································································································································· 23

Page 8

ii

Installation precautions ········································································································································· 23

Connecting the AC power supply to a power strip with lightning protection ························································· 24

Logging in and performing basic configurations ····································································································· 25

Logging in to the CLI through the console port ··········································································································· 25

Connecting the terminal to the UTM device ······································································································· 25

Configuring communication parameters on the terminal ·················································································· 26

Powering on the UTM device ······························································································································· 29

Verifying the UTM device boot information ······································································································· 29

Logging in to the CLI by using Telnet ··························································································································· 30

Logging in to the Web interface··································································································································· 31

Performing basic configurations ··································································································································· 32

Performing basic configurations at the CLI ········································································································· 32

Performing basic configurations in the Web interface ······················································································ 33

Configuring IP addresses for interfaces ·············································································································· 36

Replacement procedures ··········································································································································· 40

Precautions ······································································································································································ 40

Replacing a Mini interface module ······························································································································ 40

Replacing a MIM interface module ······························································································································ 40

Replacing a CF card ······················································································································································ 41

Replacing a transceiver module ··································································································································· 42

Hardware management and maintenance ·············································································································· 43

Displaying hardware information································································································································· 43

Displaying software and hardware version information ··················································································· 43

Displaying running status data ···························································································································· 43

Displaying detailed information about interface modules ················································································ 45

Displaying the electrical label data ····················································································································· 45

Displaying CPU usage statistics ··························································································································· 46

Displaying memory usage statistics ····················································································································· 47

Displaying information about the CF card ········································································································· 47

Displaying the operating states of fans ··············································································································· 47

Displaying power supply information ················································································································· 48

Displaying temperature information ···················································································································· 48

Verifying and diagnosing transceiver modules ·········································································································· 48

Verifying transceiver modules ······························································································································ 49

Diagnosing transceiver modules ·························································································································· 49

Troubleshooting system exceptions ······························································································································ 49

Configuring the exception handling methods ···································································································· 49

Displaying the exception handling method ········································································································ 49

Rebooting the UTM device ············································································································································ 50

Troubleshooting ·························································································································································· 51

Troubleshooting power supply system failures ············································································································ 51

Troubleshooting fan failures ·········································································································································· 51

Troubleshooting configuration system failures ············································································································ 51

No display on the configuration terminal ··········································································································· 52

Garbled characters on the configuration terminal ····························································································· 52

No response from the serial port ························································································································· 52

Troubleshooting password loss ····································································································································· 52

Troubleshooting cooling system failures ······················································································································ 53

Troubleshooting interface module, cable, and connection failures ·········································································· 53

Appendix A Technical specifications ························································································································ 54

Dimensions and weight ················································································································································· 54

Power input ····································································································································································· 54

Page 9

iii

Storages ·········································································································································································· 54

Fixed interfaces ······························································································································································ 55

Fixed interfaces and slots ····································································································································· 55

Console port ·························································································································································· 55

Ethernet ports ························································································································································· 55

Interface module (optional) ··········································································································································· 56

2GE ········································································································································································· 56

NSQ1GT2UA0 ······················································································································································ 57

NSQ1GP4U0 ························································································································································ 57

Lightning protector for a network port (optional) ········································································································ 57

Power strip with lightning protection (optional) ·········································································································· 58

Appendix B LEDs ························································································································································ 59

UTM device panel LEDs ················································································································································· 59

Interface module LEDs ···················································································································································· 60

2GE ········································································································································································· 60

NSQ1GT2UA0 ······················································································································································ 60

NSQ1GP4U0 ························································································································································ 61

Appendix C Cabling recommendations ··················································································································· 62

General cabling requirements ······································································································································ 62

Cable management requirements ································································································································ 62

Cabling examples ·························································································································································· 65

Appendix D Numbering interfaces ··························································································································· 67

Numbering interfaces ···················································································································································· 67

Examples ········································································································································································· 67

Appendix E Cables ···················································································································································· 68

Ethernet twisted pair cable ············································································································································ 68

Introduction ···························································································································································· 68

Making an Ethernet twisted pair cable ··············································································································· 71

Optical fiber ··································································································································································· 71

Index ··········································································································································································· 73

Page 10

1

Product overview

The H3C SecPath U200 Series is a line of new generation security products developed for enterprise

network protection. This series includes models in Table 1.

Table 1 Se

cPath U200 Series models

Device model Tar

g

et networks

UTM products:

H3C SecPath U200-A Small- and medium-sized enterprises, branch offices

H3C SecPath U200-M Small- and medium-sized enterprises, branch offices

H3C SecPath U200-S Small-sized enterprises, branch offices

Firewalls:

H3C SecPath U200-CA Small- and medium-sized enterprises, branch offices

H3C SecPath U200-CM Small-sized enterprises, branch offices

H3C SecPath U200-CS Small-sized enterprises, branch offices

This installation guide only covers the UTM products. For installing or maintaining a U200 firewall, see

H3C SecPath U200-C New Generation Multi-Functional Firewall Series Installation Guide.

Chassis views

U200-A

Figure 1 U200-A front view

(1) Copper Ethernet ports (GE0 to GE5) (2) Console port (CONSOLE)

(3) USB port (4) CF ejector button

(5) CF card slot

Page 11

2

Figure 2 U200-A rear view

(1) Grounding screw and sign (2) Power switch (ON/OFF)

(3) AC-input power receptacle (4) Interface module slot 1 (SLOT1)

(5) Interface module slot 2 (SLOT2)

U200-M

Figure 3 U200-M front view

(1) Copper Ethernet ports (GE0 to GE5) (2) Console port (CONSOLE)

(3) USB port (4) CF ejector button

(5) CF card slot

Figure 4 U200-M rear view

(1) Grounding screw and sign (2) Power switch (ON/OFF)

(3) AC-input power receptacle (4) Interface module slot 1 (SLOT1)

3

4

5

1

2

Page 12

3

U200-S

Figure 5 U200-S front view

(1) Copper Ethernet ports (GE0 to GE4) (2) Console port (CONSOLE)

(3) USB port (4) CF ejector button

(5) CF card slot

Figure 6 U200-S rear view

(1) AC-input power receptacle (2) Interface module slot (SLOT)

(3) Grounding screw and sign

Interface modules

Interface modules must be purchased separately.

2GE

The 2GE interface module provides two 10/100/1000BASE-T ports (RJ-45 connectors), which can be

set to operate as Layer 3 interfaces or Layer 2 interfaces.

Page 13

4

Figure 7 2GE interface module panel view

(1) Captive screw

(2) Copper Ethernet port (GE0)

(3) Copper Ethernet port (GE1)

NSQ1GT2UA0

The NSQ1GT2UA0 interface module provides two 10/100/1000BASE-T ports (RJ-45 connectors),

which can be set to operate as Layer 3 interfaces or Layer 2 interfaces.

Figure 8 NSQ1GT2UA0 panel view

(1) Captive screw

(2) Copper Ethernet port (GE0)

(3) Copper Ethernet port (GE1)

NSQ1GP4U0

The NSQ1GP4U0 interface module provides four 1000BASE-X SFP ports, which can be set to operate

as Layer 3 interfaces or Layer 2 interfaces.

Figure 9 NSQ1GP4U0 panel view

(1) Captive screw

(2) Fiber Ethernet SFP ports (SFP0 to SFP3)

1 2 3

Page 14

5

Interface module and UTM device compatibility

matrix

Interface module

U200-A

U200-M

U200-S

2GE × ×

NSQ1GT2UA0 ×

NSQ1GP4U0 ×

Page 15

6

Preparing for installation

Safety recommendations

To avoid possible bodily injury and equipment damage, read all safety recommendations carefully

before installation. Note that the recommendations do not cover every possible hazardous condition.

Safety symbols

When reading this document, note the following symbols:

WARNING means an alert that calls attention to important information that if not understood or

followed can result in personal injury.

CAUTION means an alert that calls attention to important information that if not understood or

followed can result in data loss, data corruption, or damage to hardware or software.

Electricity safety

• Locate the emergency power-off switch in the room before installation. Shut the power off at once

in case accident occurs.

• Make sure the UTM device has been correctly grounded.

• Use an uninterrupted power supply (UPS).

• Do not work alone when the UTM device has power.

• Always check that the power is off.

Laser safety

The UTM device is a Class 1 laser product.

W

ARNING!

• Do not stare into any fiber port when the UTM device has power. The laser light emitted from the

optical fiber may hurt your eyes.

• Use a fiber test equipment, rather than a microscope or magnifier to observe an operating fiber

connector or port when you test link connectivity or system parameters.

Handling safety

When you move the UTM device, follow these guidelines:

• Remove all external cables, including the power cords, before moving the chassis.

• Lift and put down the chassis slowly and never move suddenly.

• When you move multiple UTM devices, use a pallet jack.

Page 16

7

• If the UTM device needs to be moved over a long distance, remove all field-replaceable units

(FRUs), such as interface modules, and package them separately, and install the filler panels

supplied with UTM device.

• If the UTM device needs to be moved over a short distance, make sure all FRUs are securely seated

in slot and the screws are fastened.

• Make sure the accessories of the UTM device are not lost or damaged during UTM device moving.

• Make sure the ground is dry and flat and anti-slip measures are in place.

• Keep the chassis and installation tools away from walk areas.

• Only trained and qualified personnel are allowed to install or service the UTM device.

Examining the installation site

The UTM devices must be used indoors. To ensure normal operation and long service life of your UTM

device, the installation site must meet the requirements in this section.

Weight support

Make sure the floor can support the total weight of the rack, chassis, cards, and all other components.

For more information, see "Dimensions and weight."

Temperature and humidity

Maintain appropriate temperature and humidity in the equipment room.

• Lasting high relative humidity can cause poor insulation, electricity creepage, mechanical property

change of materials, and metal corrosion.

• Lasting low relative humidity can cause washer contraction and ESD and bring problems including

loose captive screws and circuit failure.

• High temperature can accelerate the aging of insulation materials and significantly lower the

reliability and lifespan of the UTM device.

For the temperature and humidity requirements of the UTM device, see Table 2.

Table 2 Temperature r

equirements

Item Tem

p

erature

Operating temperature 0°C to 45°C (32°F to 113°F)

Storage temperature –40°C to +70°C (–40°F to +158°F)

Table 3 Humidity requirements

Item Relative humidit

y

Operating humidity 10% to 95%, noncondensing

Storage humidity 5% to 95%, noncondensing

Page 17

8

Cleanness

Dust buildup on the chassis may result in electrostatic adsorption, which causes poor contact of metal

components and contact points, especially when indoor relative humidity is low. In the worst case,

electrostatic adsorption can cause communication failure.

Table 4 Dust concentration limit in the equipment room

Substance Concentration limit (

p

articles/cu m)

Dust particles

3 x 104

(No visible dust on desk in three days)

NOTE:

Dust particle diameter 5 m

The equipment room must also meet strict limits on salts, acids, and sulfides to eliminate corrosion and

premature aging of components, as shown in Table 5.

Table 5 Harmful gas li

mits in an equipment room

Gas Max. (m

g

/m3)

SO2 0.2

H2S 0.006

NH

3

0.05

Cl

2

0.01

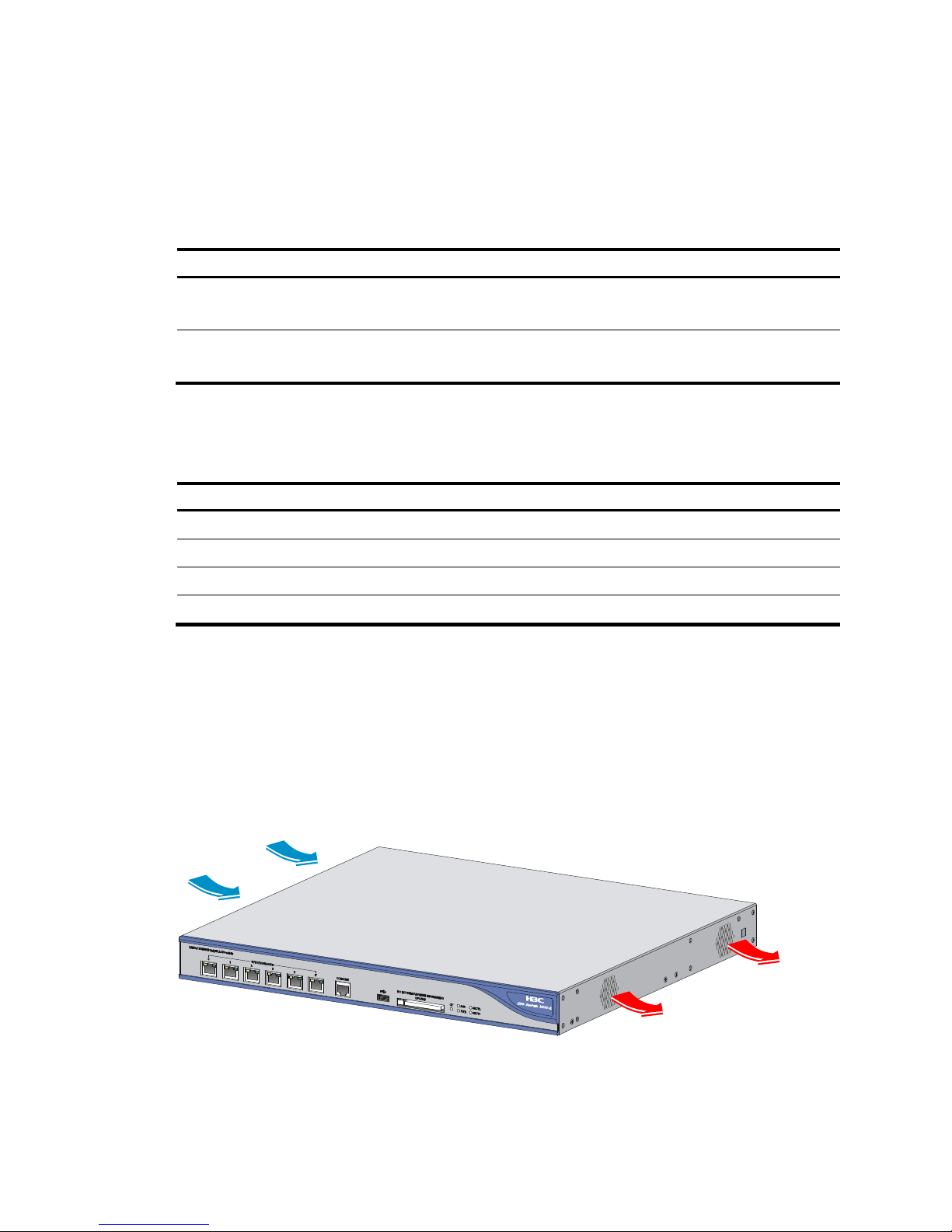

Cooling

The UTM device adopts left to right airflow for heat dissipation. Plan the installation site for adequate

ventilation.

• Leave at least 10 cm (3.94 in) of clearance at the inlet and outlet air vents.

• The installation site has a good cooling system.

Figure 10 Airflow through the chassis (U200-A)

Page 18

9

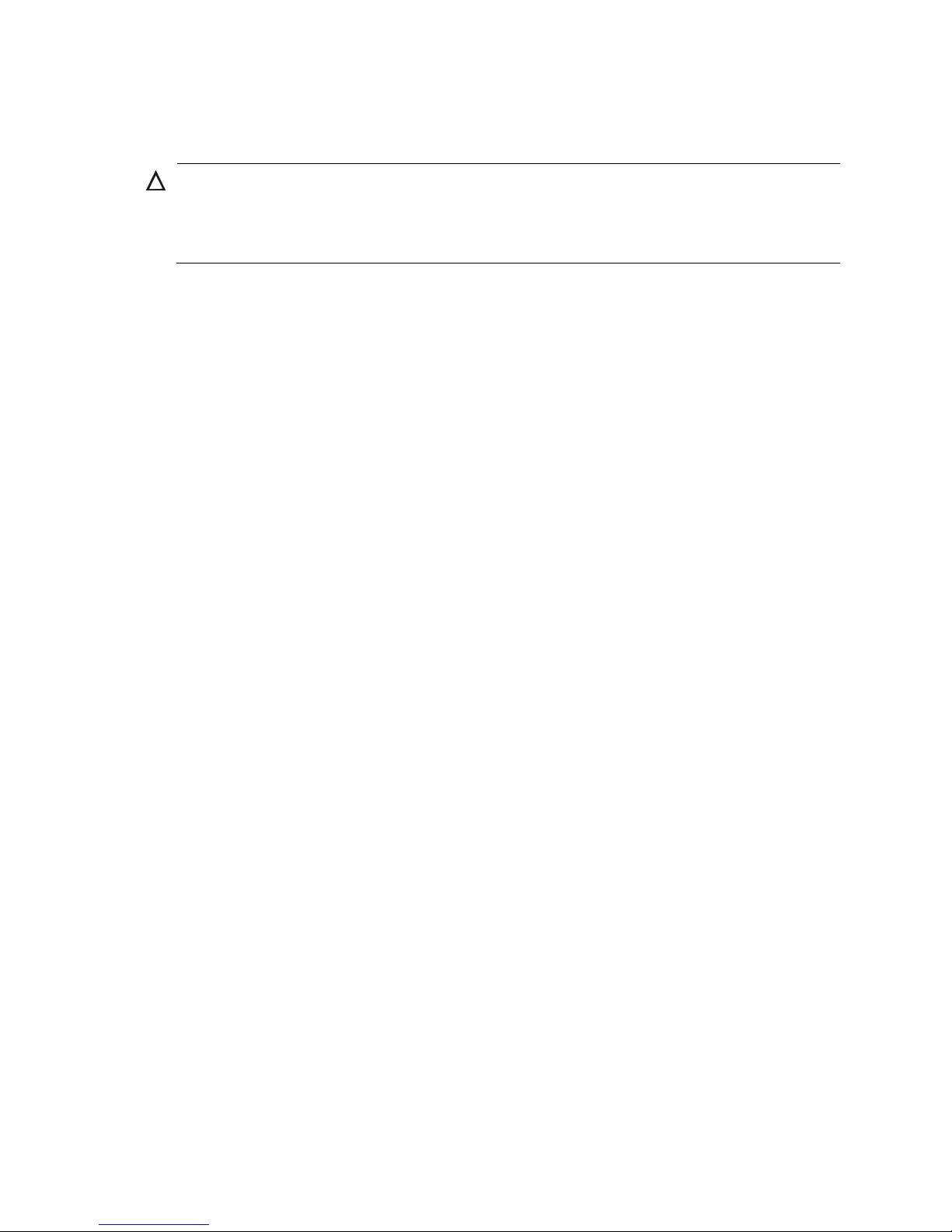

ESD prevention

CAUTION:

• Check the resistance of the ESD-preventive wrist strap for safety. The resistance readin

g

should be in

the range of 1 to 10 megohm (Mohm) between human body and the ground.

• The UTM device does not provide any ESD-preventive wrist strap. Prepare it yourself.

To prevent electrostatic discharge (ESD), follow these guidelines:

• Make sure the UTM device and rack are properly grounded.

• An anti-static floor is installed and properly grounded.

• Maintain the humidity and temperature at a proper level in the equipment room. For more

information, see "Temperature and humidity."

• Always wear an ESD-preventive wrist strap and ESD-preventive cloth when touching an interface

module or transceiver module.

• Place the removed CF card or interface module on an antistatic workbench, with the face upward,

or put it into an antistatic bag.

• Touch only the edges, instead of electronic components when observing or moving a removed CF

card or interface module.

Make sure the rack is properly grounded before you wear an ESD-preventive wrist strap.

To use the ESD-preventive wrist strap:

1. Wear the wrist strap on your wrist.

2. Lock the wrist strap tight around your wrist to keep good contact with the skin.

3. Insert the ESD-preventive plug into the ESD-preventive socket in the chassis.

4. Attach the alligator to the chassis.

Page 19

10

Figure 11 Using an ESD-preventive wrist strap

(1) ESD-preventive wrist strap (2) Lock

(3) Alligator clip

EMI

All electromagnetic interference (EMI) sources, from outside or inside of the UTM device and

application system, adversely affect the UTM device in a conduction pattern of capacitance coupling,

inductance coupling, electromagnetic wave radiation, or common impedance (including grounding

system) coupling. To prevent EMI, perform the following steps:

• Take measures against interference from the power grid.

• Do not use the UTM device together with the grounding equipment or lightning-prevention

equipment of power equipment, and keep the UTM device far away from them.

• Keep the UTM device far away from high-power radio launchers, radars, and equipment with high

frequency or high current.

• Use electromagnetic shielding when necessary.

Lightning protection

To protect the UTM device from lightning, do as follows:

• Make sure the chassis is properly grounded. For how to ground the UTM device, see "Grounding

the UTM de

vice."

• Make sure the grounding terminal of the AC power receptacle is properly grounded.

Page 20

11

• Install a lightning protector at the input end of the power supply to enhance lightning protection

capability. For how to install a lightning protector, see "Connecting the AC power supply to a

power strip with lightning protection."

Rack installation

• Reserve at least 1 m (3.28 ft) of clearance between the rack and walls or other UTM devices.

• Reserve at least 10 cm (3.94 in) of clearance at the air inlet and exhaust vents for ventilation.

• The equipment room is at least 3 m (9.84 ft) high and an air conditioner is installed.

Power supply

Make sure the power source of the installation site is steady and can satisfy the input requirements of

the power modules and parameters such as rated voltage. For power module specifications, see "Power

input."

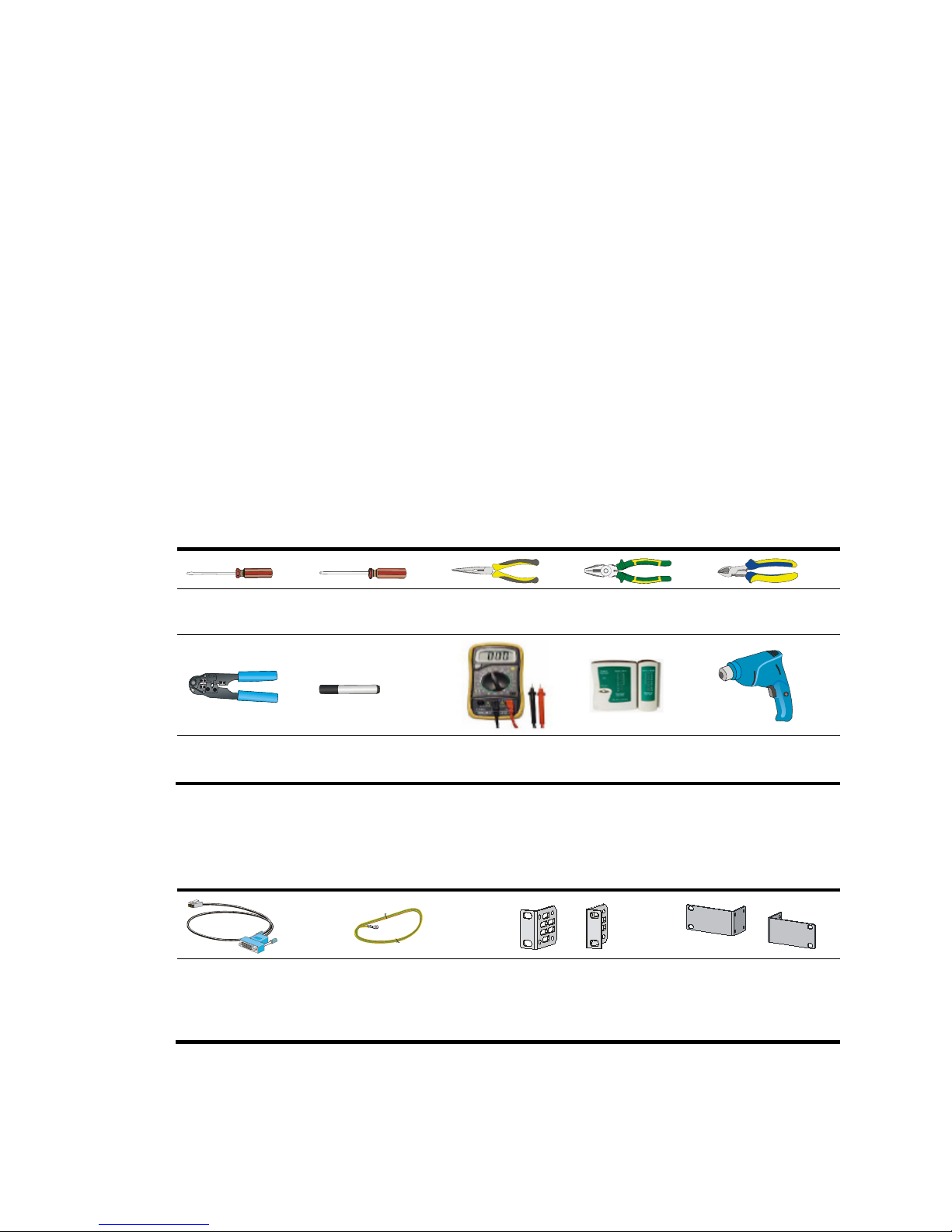

Installation tools

The tools in the table may be used for installing the UTM device. Prepare them yourself.

Flat-blade

screwdriver

Phillips screwdriver Needle-nose pliers

Wire-stripping

pliers

Diagonal pliers

RJ-45 crimping

pliers

Marker Multimeter

Network cable

tester

Hot air blowing

gun

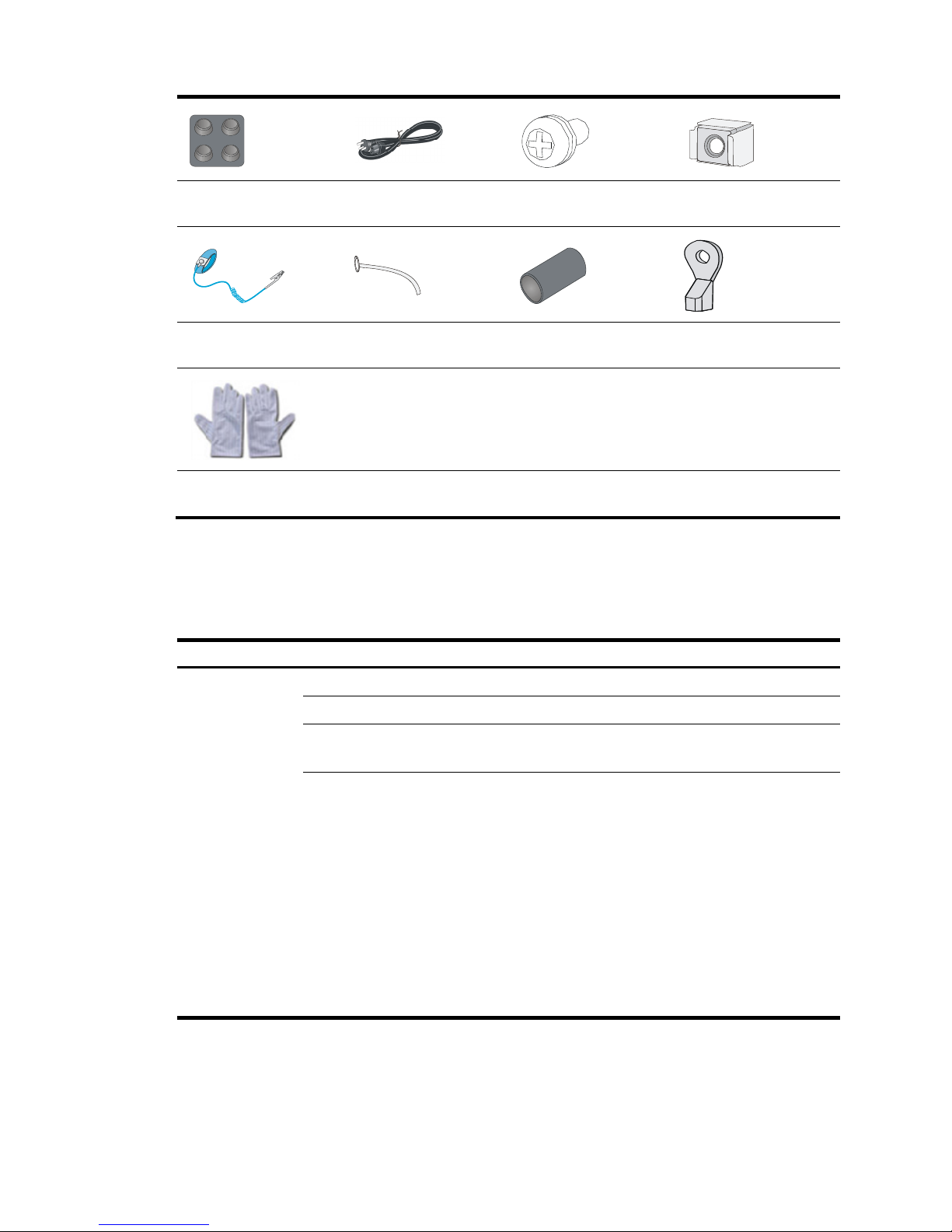

Accessories

Console cable (supplied

with UTM device)

Grounding cable

(supplied with UTM

device)

U200-A and U200-M

front mounting brackets

(supplied with UTM

device)

U200-S mounting

brackets (supplied with

UTM device)

Page 21

12

Rubber feet (supplied

with UTM device)

AC power cord (supplied

with UTM device)

M6 screw (user-supplied) Cage nuts (user-supplied)

ESD-preventive wrist

strap (user-supplied)

Cable tie (user-supplied)

Insulation sheath

(user-supplied)

Ring terminal

(user-supplied)

ESD-preventive gloves

(user-supplied)

Checklist before installation

Table 6 Checklist before installation

Item Re

q

uirements

Result

Installation site

Temperature 0°C to 45°C (32°F to 113°F)

Relative humidity 10% to 95% (noncondensing)

Cleanness

• Dust concentration ≤ 3 × 10

4

particles/m3

• No dust on desk within three days

ESD prevention

• The equipment and floor are well grounded.

• The equipment room is dust-proof.

• The humidity and temperature are at a proper

level.

• Wear an ESD-preventive wrist strap and uniform

when touching a circuit board.

• Place the removed interface module or CF card

on an antistatic workbench, with the face

upward, or put it into an antistatic bag.

• Touch only the edges, instead of electronic

components when observing or moving a

removed interface module or CF card.

Page 22

13

Item Requirements

Result

EMI prevention

• Take effective measures to protect the power

system from the power grid system.

• Separate the protection ground of the UTM

device from the grounding UTM device or

lightning protection grounding UTM device as far

as possible.

• Keep the UTM device far away from radio

stations, radar and high-frequency UTM devices

working in high current.

• Use electromagnetic shielding when necessary.

Lightning

protection

• The grounding cable of the chassis is well

grounded.

• The grounding terminal of the AC power

receptacle is well grounded.

• A port lightning arrester is installed. (Optional)

• A power lightning arrester is installed. (Optional)

Electricity safety

• Equip an uninterrupted power supply (UPS).

• In case of emergency during operation, switch off

the external power switch.

Space

• Reserve at least 10 cm (3.94 in) of clearance at

the air inlet and exhaust vents for ventilation.

• The rack or workbench has a good ventilation

system.

Workbench The workbench is sturdy and well grounded.

Rack-mounting

requirements

• Install the UTM device in an open rack if possible.

If you install the UTM device in a closed cabinet,

make sure the cabinet is equipped with a good

ventilation system.

• The rack is sturdy enough to support the weight of

the UTM device and installation accessories.

• The size of the rack is appropriate for the UTM

device.

• The front and rear of the rack are at least 0.8 m

(2.62 ft) away from walls or other UTM devices.

Safety

recommendations

• Do not place the switch near water or in a damp environment.

Prevent water or moisture from entering the switch chassis.

• Locate the emergency power-off switch in the room before

installation. Shut the power off at once in case accident occurs.

Tools

• Installation accessories supplied with the UTM device

• User supplied tools

Reference

• Documents shipped with the UTM device

• Online documents

Page 23

14

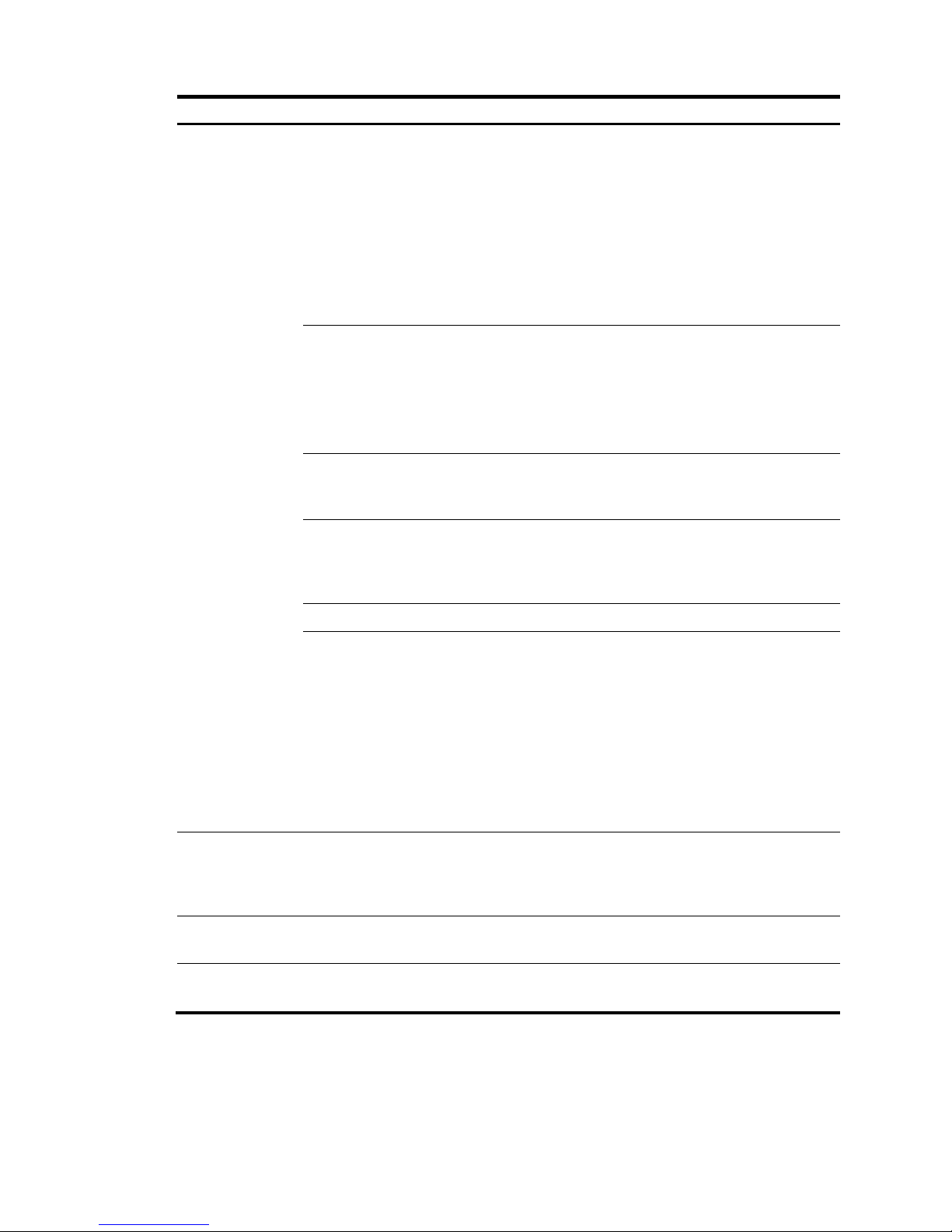

Installing the UTM device

Figure 12 UTM device installation flow

Unpacking the UTM device

Figure 13 Unpacking the UTM device

Mounting the UTM device on a workbench

IMPORTANT:

• Ensure good ventilation and 10 cm (3.94 in) of clearance around the chassis for heat dissipation.

• Avoid placing heavy objects on the UTM device.

Page 24

15

To mount the UTM device on a workbench:

1. Verify that the workbench is sturdy and well grounded.

2. Place the UTM device with bottom up, and clean the round holes in the chassis bottom with dry

cloth.

3. Attach the rubber feet to the four round holes in the chassis bottom.

4. Place the UTM device with upside up on the workbench.

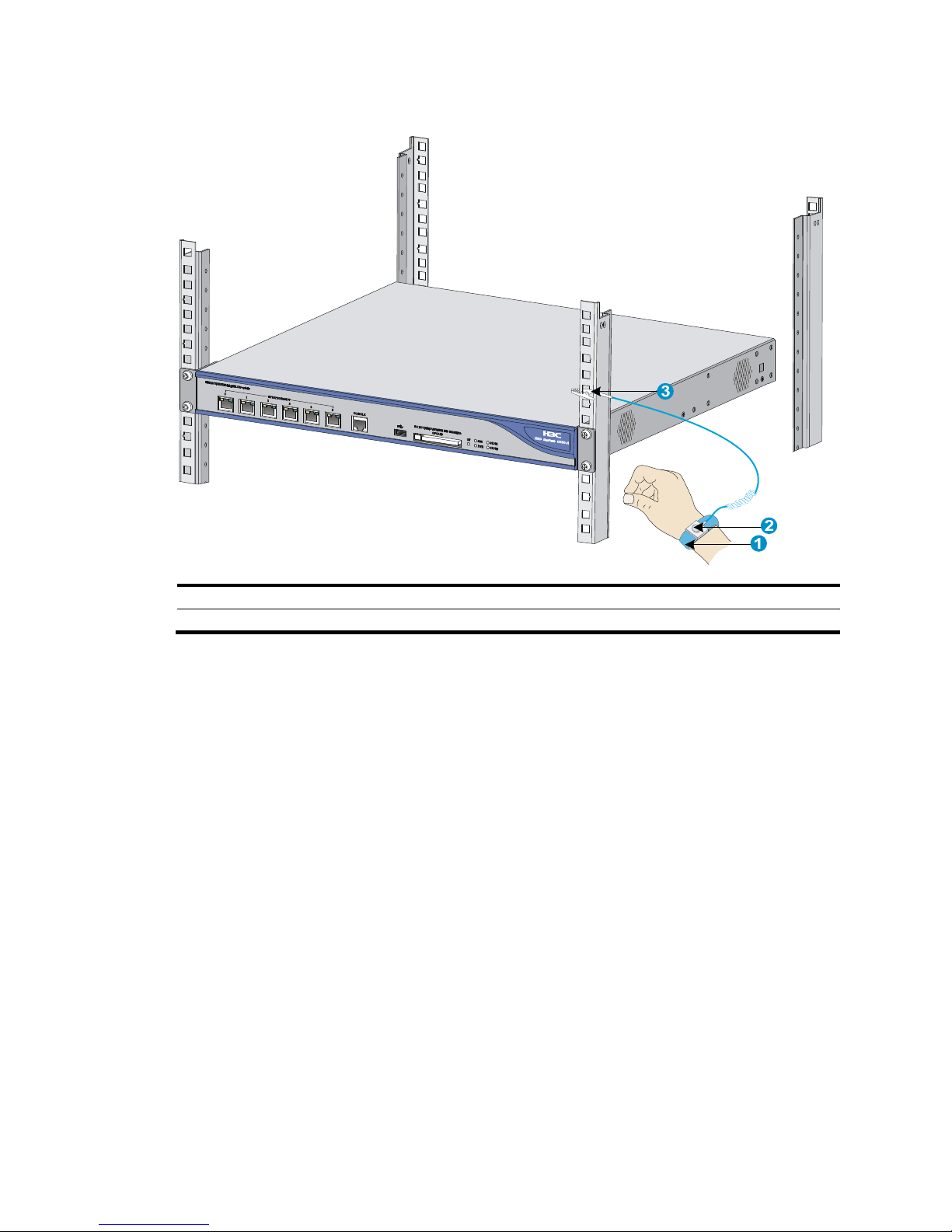

Installing the UTM device in a 19-inch rack

The installation procedures for the U200 series UTM devices are similar. This section uses a U200-A as

an example.

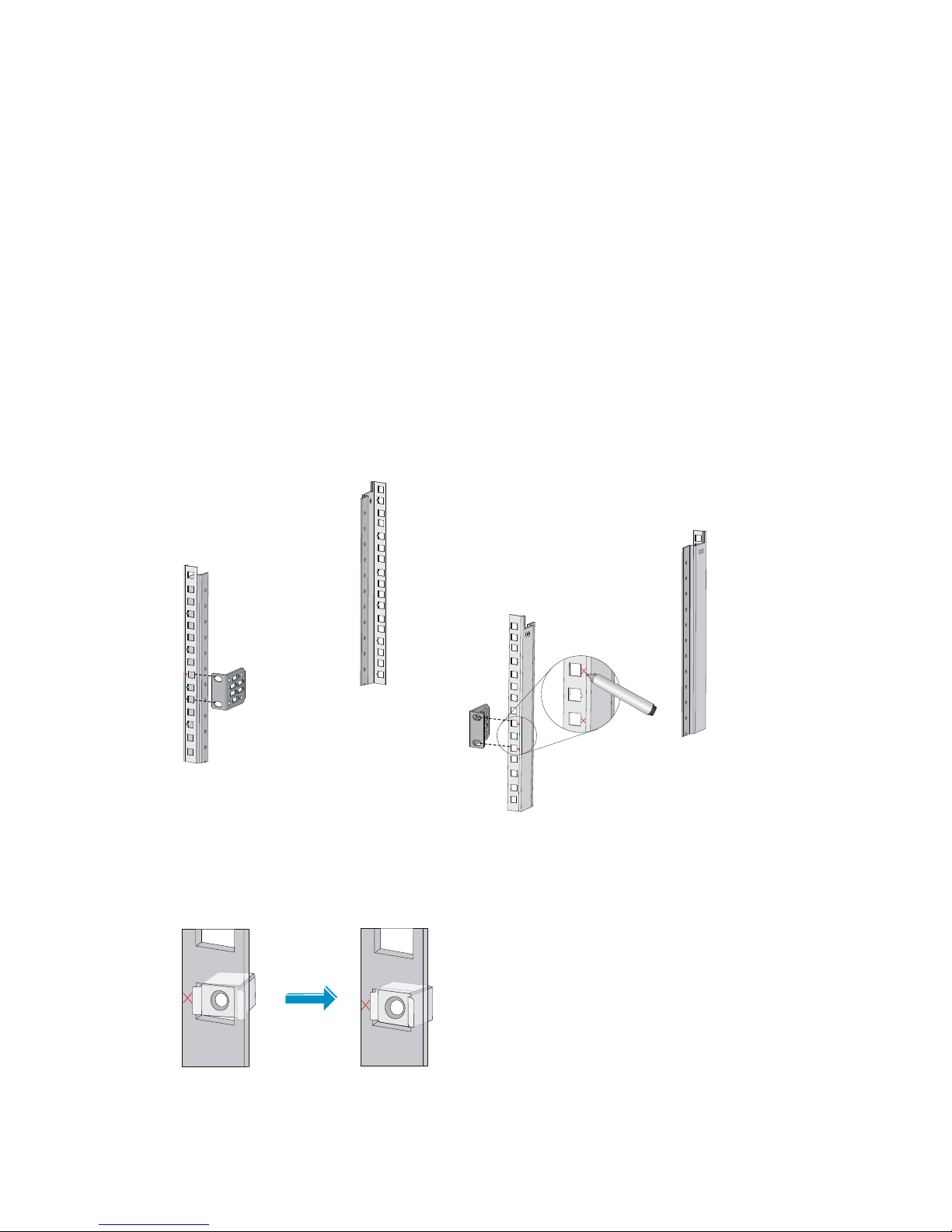

To install the UTM device in the rack:

1. As shown in Figure 14, mar

k the positions of the cage nuts on the front rack posts by using a front

mounting bracket.

Figure 14 Marking the positions of the cage nuts

2. As shown in Figure 15, insert one edge of a cage nut into the hole, and compress the other edge

of the cage nut to push the cage nut fully into the hole.

Figure 15 Installing cage nuts

Page 25

16

3. Use the screws supplied with the UTM device to attach the mounting brackets to the UTM device,

as shown in Figure 16.

Figure 16 Attaching th

e mounting brackets

4. Supporting the bottom of the UTM device with one hand, hold the UTM device with the other

hand, and slide the UTM device into the rack.

Figure 17 Sliding the UTM device into the rack

5. Attach the UTM device horizontally by fastening the mounting brackets to the rack with M6

screws.

Page 26

17

Figure 18 Mounting the UTM device to the rack

Grounding the UTM device

W

ARNING!

Correctly connecting the UTM device grounding cable is crucial to lightning protection and EMI

protection.

The power input end of the UTM device has a noise filter, whose central ground is directly connected to

the chassis to form the chassis ground (commonly known as PGND). You must securely connect this

chassis ground to the earth so the faradism and leakage electricity can be safely released to the earth to

minimize EMI susceptibility of the UTM device.

Attaching the ring terminal

1. Cut the grounding cable as appropriate for connecting to the grounding strip.

2. Peel 5 mm (0.20 in) of insulation sheath by using a wire stripper, and insert the bare metal part

through the black insulation covering into the end of the ring terminal.

3. Secure the metal part of the cable to the ring terminal with a crimper.

4. Cover the joint with the insulation covering, and heat the insulation covering with a blow dryer to

completely cover the metal part.

Page 27

18

Figure 19 Attaching the ring terminal

Connecting the grounding cable

1. Remove the grounding screw from the rear panel of the UTM device chassis.

2. Attach the grounding screw to the ring terminal of the grounding cable.

3. Use a Phillips screwdriver to fasten the grounding screw into the grounding screw hole.

4. Connect the other end of the grounding cable to the grounding strip of the rack.

Figure 20 Connecting the grounding cable to the grounding hole of UTM device

NOTE:

• The resistance reading should be smaller than 5 ohms between UTM device chassis and the ground.

• To guarantee the grounding effect, use the grounding cable provided with the UTM device to connec

t

to the grounding strip in the equipment room as long as possible.

Page 28

19

Installing a CF card

1. Push the CF card eject button all the way into the slot and make sure the button does not project

from the panel.

2. Insert the CF card into the slot following the direction shown in Figure 21, and

make sure it does

not project from the slot.

Figure 21 Inserting the CF card into the slot

Connecting interface cables

Connecting a copper Ethernet port

1. Plug one end of a twisted pair cable into the port.

2. Plug the other end of the twisted pair cable into the RJ-45 Ethernet port of the peer device.

3. Examine the port LED status.

For more information about the LED status, see "UTM device panel LEDs."

A

fter you connect the UTM device to the network, execute the ping or tracert command to test network

connectivity. For more information about the commands, see the command reference of the UTM device.

For more information about Ethernet twisted pair cables, see "Ethernet twisted pair cable."

Connecting a fiber port

W

ARNING!

Do not stare into any fiber port when you connect an optical fiber. The laser li

g

ht emitted from the optical

fiber may hurt your eyes.

CAUTION:

• Be sure to install the dust cover if the fiber port is not connected to a fiber connector.

• Never bend or curve a fiber when connecting it. The bend radius must be at least 10 cm (3.94 in).

• Keep the end of the fiber clean.

• Make sure the Tx and Rx ends of the SFP transceiver module are properly connected.

The UTM device has SFP and XFP fiber ports, which only support LC connectors.

Page 29

20

To connect a fiber port to a peer device through optical fibers:

1. Remove the dust plug from the SFP port.

2. Remove the dust cover from the transceiver module, and plug the end without a pull latch into the

SFP port.

3. Remove the dust cover from the fiber connector.

4. Identify the Rx and Tx ports. Plug the LC connector at one end of one fiber cable into the Rx port

of the UTM device and the LC connector at the other end into the Tx port of the peer device. Plug

the LC connector at one end of another fiber cable into the Tx port of the UTM device and the LC

connector at the other end to the Rx port of the peer device.

Figure 22 Connecting the fiber port

5. View the LINK LED after connection:

{ On means a link is present.

{ Off means no line is present. Try to change the Rx and Tx ends of the fiber. For more

information about the LEDs, see "UTM device panel LEDs."

Connecting a power cord

1. Make sure the UTM device is properly grounded. For the U200-A and U200-M, make sure the

power is OFF.

2. Connect one end of the power cord to the receptacle on the UTM device, and the other end to the

AC power source.

Page 30

21

Figure 23 Connecting a power cord to the UTM device

Verifying the installation

To ensure normal operation of the UTM device, verify the following items before you power on the UTM

device:

• There is enough space for heat dissipation around the UTM device.

• The grounding cable is securely connected.

• The correct power source is used.

Page 31

22

Installing FRUs

You can install a Mini/MIM interface module, a lightning protector for a network port, and AC power

supply lightning protector on a UTM device. These components do not come with the UTM device.

Prepare them yourself.

Installing a Mini interface module

1. Loosen the screws on the filler panel with a Phillips screwdriver to remove the filler panel.

Put the removed filler panel and screws in an antistatic bag for future use.

2. Push the Mini interface module with its components facing upwards along the guide rails into the

slot.

Figure 24 Pushing the interface module into the slot

3. Fasten the captive screws on the interface module with a Phillips screwdriver.

Installing a MIM interface module

1. Loosen the captive screws on the filler panel with a Phillips screwdriver to remove the filler panel.

Put the removed filler panel and screws in an antistatic bag for future use.

2. Push the MIM interface module with its components facing upwards along the guide rails into the

slot.

Figure 25 Pushing the MIM interface module into the slot

3. Fasten the captive screws on the interface module with a Phillips screwdriver.

Page 32

23

Installing a lightning protector for a network port

Installation procedure

IMPORTANT:

Read the instructions for the lightning protector carefully before you install it.

To install a lightning protector:

1. Use a double-faced adhesive tape to stick the lightning protector onto the UTM device chassis,

and make sure it is close to the grounding screw of the UTM device as possible.

2. Measure the distance between the protector and the grounding screw of the UTM device, cut the

ground wire of the protector as appropriate, and securely tighten the ground wire to the

grounding screw of the UTM device.

3. Use the multimeter to measure whether the ground wire of the protector contacts well with the

grounding screw of chassis.

4. Insert the outdoor network cable into the protector's IN end, and the cable connected to the UTM

device into the OUT end, and check the indicators on the lightning protector to verify that the

connection is correct.

5. Use nylon ties to bundle the cables neatly.

Figure 26 Installing a lightning protector

(1) Lightning protector for a network port

(2) Grounding wire

Installation precautions

The performance of the port lightning protector may be affected in the following cases:

• The port lightning protector is installed in reverse direction. Connect the IN end to the outdoor

network cable and the OUT end to the network port on the UTM device.

• The port lightning protector is not well grounded. After the connection, use the multimeter to

confirm that the ground wire for the protector is as short as possible to ensure its good contact with

the grounding screw of the UTM device.

• The installed port lighting protectors are not sufficient. If the UTM device has more than one

network port connected with other devices through cables outdoor, install a lightning protector for

each network port.

Page 33

24

Connecting the AC power supply to a power strip

with lightning protection

CAUTION:

Make sure the PE terminal of the power socket has been securely grounded.

If part of the AC power line is routed outdoors, use a power strip with lightning protection to connect the

AC power cord of the UTM device to the AC power line to protect the UTM device from being damaged

by lightning strikes.

You can attach the power strip to the rack, workbench, or wall of equipment room.

After you connect the AC power cord from the UTM device to a socket on the power strip, verify that the

green RUN LED on the strip is on and the red LED is off.

If the red LED is on, use a multimeter to check the polarity of the wires in the power socket for wrong

connections. If the zero wire (left) and the live wire (right) are correctly connected, check for missing

grounding connection.

Figure 27 Power strip with lightning protection

(1) Operating LED (green) On means the circuit is operating properly.

Off means the circuit is damaged.

(2) Grounding/pole detection

LED (red)

On indicates a wrong wire connection (the wire is not grounded or the

live line and null line are reversely connected), and you need to check the

power supply line.

(3) Power switch

(4) IEC standard socket It is used to connect to the power supply in the equipment room through a

power cord.

(5) Overload automatic protector The protector automatically opens the electric circuit when the current

exceeds the threshold and closes the electric circuit when the current

drops below the threshold.

(6) Multifunctional socket It is used to connect the power supply of the UTM device.

N

NNN

L

LL

L

Page 34

25

Logging in and performing basic

configurations

The first time you access the UTM device, you can log in to the CLI through the console port or log in to

the Web interface by using a Web browser. After login, you can configure Telnet for remote access.

Logging in to the CLI through the console port

To log in to the CLI through the console port, you must have a console cable and a terminal (for example,

a PC).

The terminal can be any character terminal with an RS-232 port or a PC. Typically, a PC running a

terminal emulation program (such as HyperTerminal on a Windows operating system) is used. In the

following sections, a PC running Windows XP HyperTerminal is used.

The console cable can be an 8-core shielded cable that has an RJ-45 connector at one end for

connecting to the console port of the UTM device and a DB-9 female connector at the other end for

connecting to the serial port on the terminal.

Connecting the terminal to the UTM device

1. Plug the DB-9 female connector of the console cable to the serial port of the PC.

2. Plug the RJ-45 connector of the console cable to the console port of the UTM device.

Figure 28 Connecting the terminal to the UTM device

IMPORTANT:

• Identify the mark on the console port and make sure you are connecting to the correct port.

• The serial ports on PCs do not support hot swapping. If the UTM device has been powered on, always

connect the console cable to the PC before connecting it to the UTM device, and when you disconnec

t

the cable, first disconnect it from the UTM device.

Page 35

26

Configuring communication parameters on the terminal

1. On the PC, select Start > Programs > Accessories > Communications > HyperTerminal.

2. Enter a name for the connection and click OK.

Figure 29 Creating a HyperTerminal connection

3. Select the serial port used to connect to the UTM device and click OK.

Figure 30 Selecting the serial port

4. Configure serial port properties as described in Table 7.

Page 36

27

Figure 31 Configuring serial port properties

Table 7 Serial port properties

Pro

p

erty Value

Bits per second 9600 bps (the default)

Data bits 8

Parity None

Stop bits 1

Flow control None

To restore the default settings, click Restore Defaults.

5. Click OK.

The HyperTerminal window appears.

Page 37

28

Figure 32 HyperTerminal window

6. Select File > Properties and then click the Settings tab.

Figure 33 Selecting the emulation type

Page 38

29

7. Select VT100 or Auto detect for Emulation and click OK.

Powering on the UTM device

Before powering on the UTM device, confirm the following:

• You know where the emergency power-off switch for the equipment room is located.

• The power cables and grounding cables have been correctly connected.

• The input power voltage meets the requirement of the UTM device.

• The terminal is properly connected to the UTM device and operating normally, and the

communication parameters have been configured as required.

• The CF card used to store the applications, if any, is tightly fixed in the UTM device.

• The interface modules, if any, are properly installed, and the interface cables are correctly

connected.

To power on the U200-S device, turn on the power source.

To power on the U200-A or U200-M device, turn on the power source and then turn on the power

switch of the device.

After powering on the device, verify the following items:

1. The LEDs on the front panel show that the device is operating properly. For more information

about the LED behaviors, see "UTM device panel LEDs."

2. The cooling system is working, and you can hear fan rotating noise and feel air being blown out.

3. The boot information on the terminal shows that the UTM device is starting up normally. For more

information, see "Verifying the UTM device boot information."

4. After the devic

e starts up, a prompt for pressing Enter appears.

Verifying the UTM device boot information

After the UTM device is powered on, the following information appears on the terminal:

System is starting...

Press Ctrl+D to access BASIC-BOOTWARE MENU

Booting Normal Extend BootWare..

The Extend BootWare is self-decompressing....................

Done!

****************************************************************************

* *

* H3C SecPath U200-S BootWare, Version 1.36 *

* *

****************************************************************************

Copyright (c) 2004-2013 Hangzhou H3C Technologies Co., Ltd.

Compiled Date : Apr 9 2013

CPU Type : XLS404

CPU L1 Cache : 32KB

CPU Clock Speed : 800MHz

Memory Type : DDR2 SDRAM

Page 39

30

Memory Size : 512MB

Memory Speed : 533MHz

BootWare Size : 512KB

Flash Size : 32MB

cfa0 Size : 224MB

CPLD Version : 2.0

PCB Version : Ver.B

BootWare Validating...

Press Ctrl+B to enter extended boot menu...

Starting to get the main application file--cfa0:/u200s.bin!.................

............................................................................

............................................................................

............................................................................

..................................

The main application file is self-decompressing.............................

............................................................................

..........................................................................

Done!

System application is starting...

Press Ctrl+F to load firewall system...

##### start UTM mode #####

User interface con0 is available.

Press ENTER to get started.

After pressing Enter, you are placed in user view:

<H3C>

Now, you can configure and manage the UTM device.

Logging in to the CLI by using Telnet

This section provides only a simplified procedure for logging in to the CLI by using Telnet. For more

information, see the UTM device configuration guides.

The UTM device does not support Telnet login by default, but is provided with the following default

Telnet login information:

• Username—admin.

• Password—admin.

• IP address for interface GigabitEthernet 0/0— 1 9 2 .16 8 . 0 .1 / 2 4 .

To log in to the CLI by using Telnet:

1. Log in to the UTM device through the console port, execute the telnet server enable command in

system view to enable the Telnet service.

Page 40

31

2. Connect a PC to the UTM device's interface GigabitEthernet 0/0 by using a crossover Ethernet

cable.

3. Assign the PC an IP address in the network segment 192.168.0.0/24 (except for 192.168.0.1),

for example, 192.168.0.2.

4. Run the Telnet client on the PC to Telnet to the UTM device.

Logging in to the Web interface

The UTM device supports Web login by default, and is provided with the following default Web login

information:

• Username—admin.

• Password—admin.

• IP address for interface GigabitEthernet 0/0— 1 9 2 .16 8 . 0 .1 / 2 4 .

To log in to the Web interface:

1. Connect a PC to the UTM device's interface GigabitEthernet 0/0 by using a crossover Ethernet

cable.

2. Assign the PC an IP address in the network segment 192.168.0.0/24 (except for 192.168.0.1),

for example, 192.168.0.2.

3. Launch a Web browser on the PC and enter 192.168.0.1 in the address bar.

The Web login page appears.

Figure 34 Web login page

4. Enter the correct username, password, and verify code, select English as the language, and click

Login.

NOTE:

A

user uses the default accont admin to log in to the Web network management page for the first time.To

ensure the system security, the user must create a new administrator account and delete the default user

account after logging in.For information about how to create a new administrator account and delete the

default user account, see

H3C SecPath Series Firewalls and UTM Devices Getting Started Guide.

Page 41

32

Performing basic configurations

To enable the UTM device to communicate with other devices on the network, you must perform some

basic configurations on the UTM device. To do so, first log in to the CLI or Web interface of the UTM

device.

To use an interface as a service interface, you must add it to a non-management security zone in the

Web interface before configuring relevant service functions. For more information, see the UTM device

configuration guides.

This section describes the steps for performing basic configurations on the UTM device. For how to

configure protocols and features on the UTM device, see the UTM device configuration guides.

The syntax of commands and the Web interface vary with software versions.

Performing basic configurations at the CLI

Step Command

Remarks

1. Enter system view.

system-view N/A

2. Set the device name.

sysname sysname

Optional.

H3C by default.

3. Enable the Telnet server.

telnet server enable

Optional.

Disabled by default.

4. Configure a one-to-one static

NAT mapping.

nat static local-ip [ vpn-instance

local-name ] global-ip

Optional.

By default, no static NAT mapping

is configured.

5. Enter Ethernet interface view.

interface interface-type

interface-number

N/A

6. Assign an IP address to the

interface.

ip address ip-address

{ mask-length | mask } [ sub ]

Optional.

By default, only GigabitEthernet

0/0 has an IP address

(192.168.0.1).

7. Enable static NAT on the

interface.

nat outbound static [ track vrrp

virtual-router-id ]

N/A

8. Add the interface to a security

zone.

See the UTM device

configuration guides.

This task is not supported at the

CLI. Complete this task in the Web

interface.

9. Return to the upper-level view.

quit N/A

10. Save the running configuration

to the root directory of the

storage medium and specify

the file as the configuration file

for the next startup.

save [ safely ] N/A

11. Display the running

configuration.

display current-configuration Optional.

Page 42

33

Performing basic configurations in the Web interface

This section describes the procedure for performing basic configuration in the Web interface.

Launching the basic configuration wizard

1. In the Web interface, select Wizard from the navigation tree.

2. Click the Basic Device Information link to enter the first basic configuration page.

Figure 35 Basic configuration wizard—1/6

Configuring the system name and user password

1. Click Next on the first basic configuration page to enter the username and password

configuration page.

Page 43

34

Figure 36 Basic configuration wizard—2/6 (username and password configuration)

2. Configure the system name and user password as described in Table 8.

Table 8 Configuration items

Item Descri

p

tion

Sysname Set the system name. The default system name is H3C.

Modify Current User

Password

Specify whether to change the login password.

To change the password, enter the new password and confirm it.

The default username and password are both admin.

New Password

Confirm Password

Password Encryption

Set the password encryption mode:

• Reversible—The firewall encrypts the user password with a reversible algorithm

and saves the password.

• Irreversible—The firewall encrypts the user password with an irreversible

algorithm and saves the password.

Configuring services

1. Click Next on the username and password configuration page to enter the service management

page.

Page 44

35

Figure 37 Basic configuration wizard—3/6 (service management)

2. Configure services as described in Table 9.

Table 9 Configuration items

Item Descri

p

tion

FTP

Specify whether to enable the FTP service on the UTM device.

By default, the FTP service is disabled.

Telnet

Specify whether to enable the Telnet service on the UTM device.

By default, the Telnet service is disabled.

HTTP

Specify whether to enable the HTTP service on the UTM device.

To enable the HTTP service on the UTM device, select the Enable option and select

the HTTP service port number.

By default, the HTTP service is enabled.

IMPORTANT:

• If you are using the HTTP service, disabling the HTTP service or changing the

service port number breaks your connection to the UTM device.

• Make sure no other services are using the specified service port number.

Page 45

36

Item Description

HTTPS

Specify whether to enable the HTTPS service on the UTM device.

To enable the HTTPS service on the UTM device, select the Enable option and select

the HTTPS service port number.

By default, the HTTP service is disabled.

To improve the security of your connection to the UTM device, use HTTPS, which is

based on SSL.

IMPORTANT:

• If you are using the HTTPS service, disabling the HTTPS service or changing the

service port number breaks your connection to the UTM device.

• Make sure no other services are using the specified service port number.

• HTTPS uses the PKI domain default by default. If the PKI domain does not exist,

you will see an error message at the end of the wizard. However, the other

configurations are not affected.

Configuring IP addresses for interfaces

1. Click Next on the service management page to enter the interface IP address configuration page.

The list shows the IP address configuration information for all Layer 3 Ethernet interfaces and

VLAN interfaces.

Figure 38 Basic configuration wizard—4/6 (interface IP address configuration)

2. Click the link for an interface to perform IP address configuration as described in Table 10.

Page 46

37

Table 10 Configuration items

Item Descri

p

tion

IP Configuration

Select an IP address acquisition approach for the

interface:

• None—Assigns no IP address to the interface.

• Static Address—If you select this option, you must

manually assign an IP address and a mask to the

interface.

• DHCP—Enables the interface to automatically obtain

an IP address through the DHCP protocol.

• Do not change—Leaves the IP address of the interface

unchanged.

IMPORTANT:

Changing the IP

address of the interface

you are using

disconnects you from

the UTM device.

IP Address Configure an IP address and a mask for the interface.

These two fields are available only when the value of the IP

Configuration field is Static Address.

Mask

Configuring NAT

1. Click Next on the interface IP address configuration page to enter the NAT configuration page.

Figure 39 Basic configuration wizard—5/6 (NAT configuration)

2. Complete NAT configuration as described in Table 11.

Table 11 Configuration items

Item Descri

p

tion

Interface

Select the interface to which the NAT configuration will be applied, typically the

outbound interface of the UTM device.

Page 47

38

Item Description

Dynamic NAT

Specify whether to enable dynamic NAT on the interface.

If dynamic NAT is enabled, the IP address of the interface will be used as the IP

address of a matched packet after the translation.

By default, dynamic NAT is disabled.

Source IP/Wildcard

Specify the source IP address and wildcard for matching packets.

These fields are available only when dynamic NAT is enabled.

Destination

IP/Wildcard

Specify the destination IP address and wildcard for matching packets.

These fields are available only when dynamic NAT is enabled.

Protocol Type

Specify the protocol type for matching packets. Valid values include TCP, UDP, and

IP (IP indicates any protocol carried by the IP protocol).

This field is available only when dynamic NAT is enabled.

Internal Server

Specify whether to enable the internal server.

If the internal server is enabled, when an external user accesses the internal server,

the NAT function translates the destination address of the request packets into the

private IP address of the internal server. Accordingly, when the internal server

replies, the NAT function translates the source address (private IP address) of reply

packets into the public IP address.

By default, the internal server is disabled.

IMPORTANT:

Configuring the internal server might break your connection to the UTM device. For

example, if you specify the IP address of your local host or the IP address of your access

interface as the external IP address, your connection will be broken.

External IP: Port

Specify the IP address and service port number for external user access.

These fields are available only when the internal server is enabled.

Internal IP: Port

Configure the IP address and service port number of the internal server.

These fields are available only when the internal server is enabled.

Completing the configuration wizard

1. Click Next on the NAT configuration page.

All configurations you have made in the basic configuration wizard are displayed.

Page 48

39

Figure 40 Basic configuration wizard—6/6

2. To modify your configuration, click Back to go back to the previous page.

3. To save the current configuration to the startup configuration file for the next device boot when

you submit the configurations, select Save Configuration.

4. Click Finish to complete the configuration.

Page 49

40

Replacement procedures

Precautions

• Always wear an ESD-preventive wrist strap or ESD-preventive gloves when servicing the UTM

device.

• No interface modules for the UTM device are hot-swappable. Power off the UTM device before

replacing hardware.

• When removing FRUs (such as Mini or MIM interface modules, and the CF card):

{ Ensure good alignment with the slot and use uniform force to avoid damage to the FRUs.

{ Completely loosen each captive screw before removing Mini or MIM interface modules to

keep their panels in good condition.

{ Hold a PCB by its edges. Do not touch any electronic components.

{ Put the removed FRUs on an antistatic workbench with the PCB side facing upward or place

them in antistatic bags.

Replacing a Mini interface module

1. Loosen the two captive screws with a Phillips screwdriver.

2. Holding the front part of the Mini interface module, gently pull it out along the slide rails.

3. Install a new Mini interface module.

For the installation procedures, see "Installing a Mini interface module."

If no new Min

i interface module is to be installed to the slot, install a filler panel to prevent dust

from entering the chassis.

Figure 41 Pulling out a Mini interface module

Replacing a MIM interface module

1. Loosen the captive screws with a Phillips screwdriver.

Page 50

41

2. Holding the clasp of the MIM interface module, gently pull out the MIM interface module along

the slide rails.

3. Install a new MIM interface module.