Page 1

H3C S9500 Series Routing Switches

Installation Manual

Hangzhou H3C Technologies Co., Ltd.

http://www.h3c.com

Manual Version: T2-08048H-20071025-C-2.03

Product Version: S9500-CMW520-R2127

Page 2

Copyright © 2006-2007, Hangzhou H3C Te chnologie s Co., Ltd . and it s licen sors

All Rights Reserved

No part of this manual may be reproduced or transmitted in any form or by any means

without prior written consent of Hangzhou H3C Technologies Co., Ltd.

Trademarks

H3C, , Aolynk, , H3Care,

Neocean, NeoVTL, SecPro, SecPoint, SecEngine, SecPath, Comware, Secware,

Storware, NQA, VVG, V

HUASAN are trademarks of Hangzhou H3C Technologies Co., Ltd.

All other trademarks that may be mentioned in this manual are the property of their

respective owners.

Notice

The information in this document is subject to change without notice. Every effort has

been made in the preparation of this document to ensure accuracy of the content s, but

all statements, information, and recommendations in this document do not constitute

the warranty of any kind, express or implied.

To obtain the latest information, please access:

http://www. h3c.com

Technical Support

customer_service@h3c.com

http://www. h3c.com

, TOP G, , IRF, NetPilot,

2

G, VnG, PSPT, XGbus, N-Bus, TiGem, InnoVision and

Page 3

About This Manual

Related Documentation

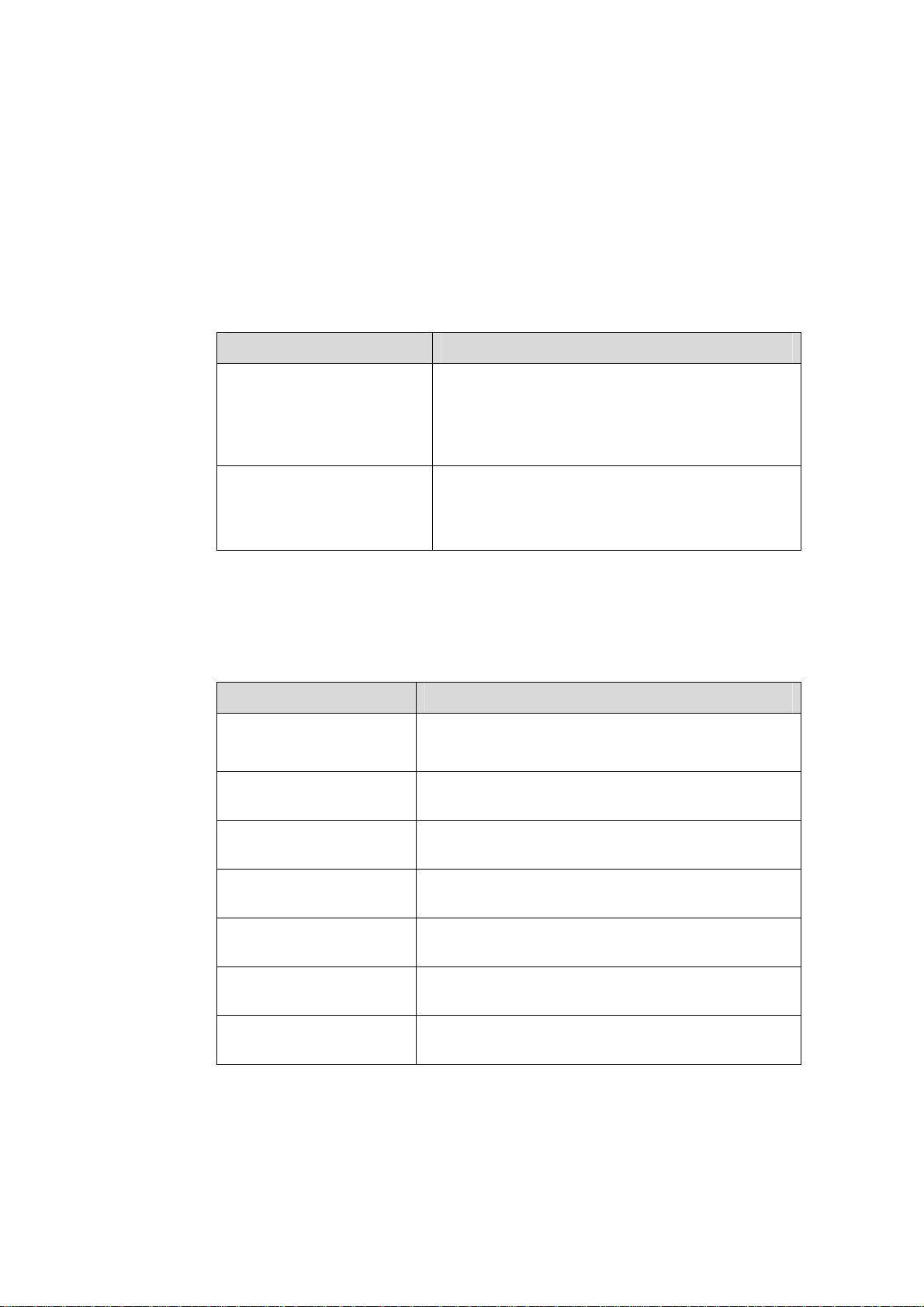

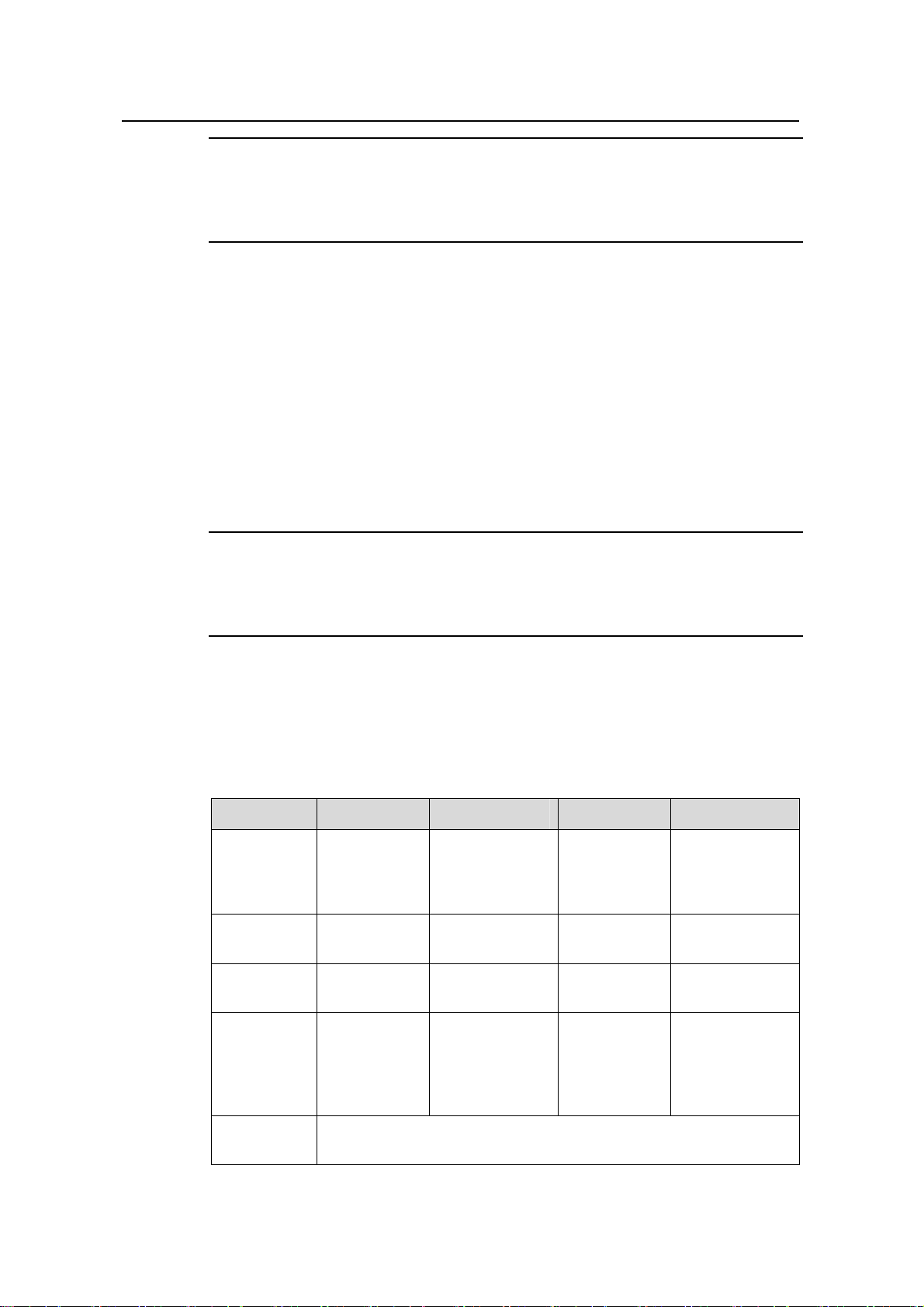

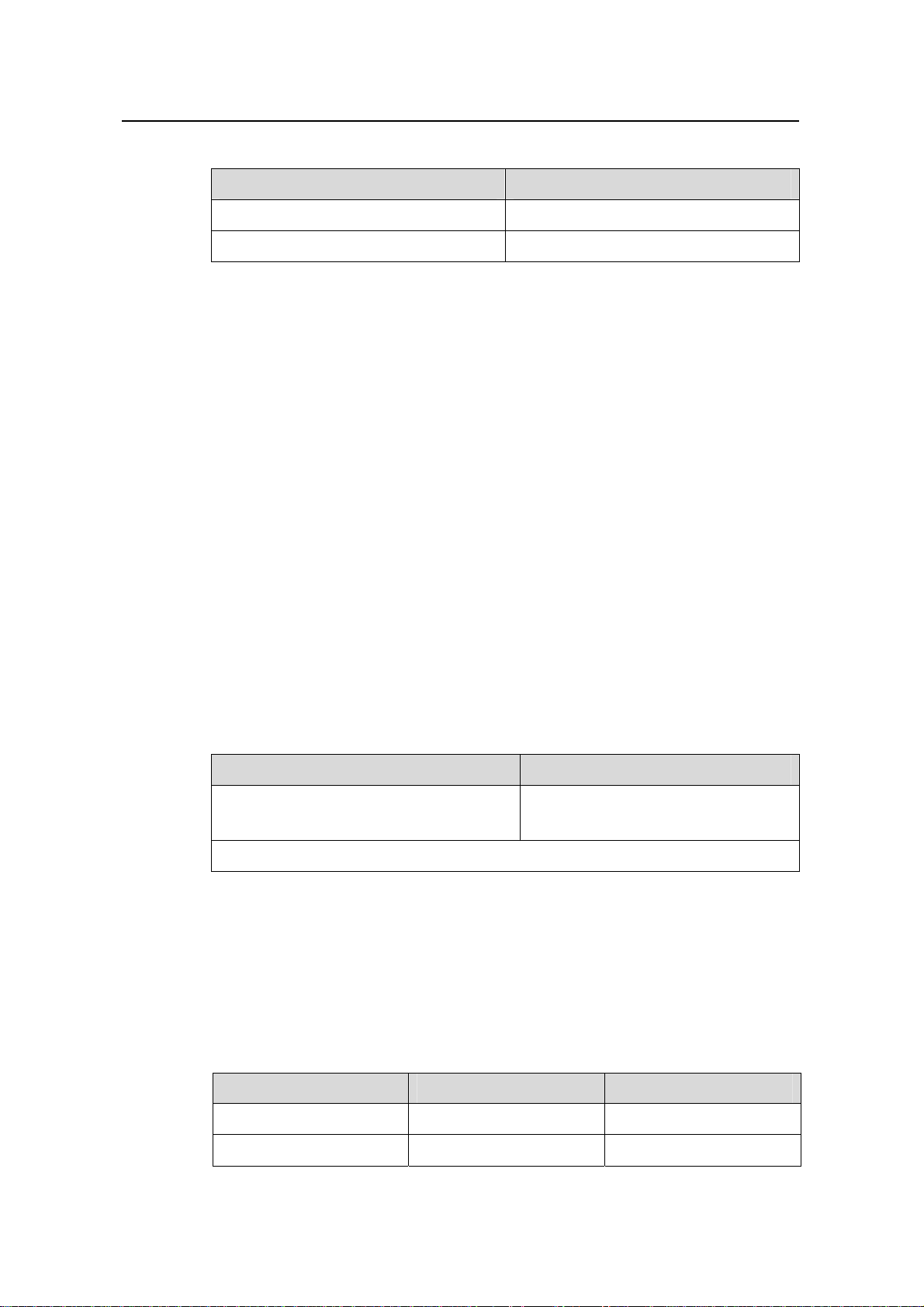

The related manuals are listed in the following table.

Manual Description

H3C S9500 Series Routing

Switches Operation Manual

It provides an operation guide. It consists of access

volume, IP service volume, IP routing volume, IP

multicast volume, MPLS/VPN volume, QoS/ACL

volume, security volume, system volume, and

acronyms.

Organization

H3C S9500 Series Routing Switches Installation Manual is organized as follows:

H3C S9500 Series Routing

Switches Command Manual

Chapter Contents

1 Product Overview

2 Preparing for Installation

3 Installing the Switch

4 Commissioning the

Switch

It explains all commands available in the S9500

series and provides a list of commands the S9500

series do not support. It consists of the same

modules as the operation manual.

Introduces the appearance, architecture and system

features of the S9500 series.

Lists the preparations and precautions for the

installation.

Details the installation of the chassis, PSUs, boards

and cable connection for the S9500 series.

Concentrates on the initial power-on and booting of

the S9500 series.

5 Troubleshooting and

Maintaining the Switch

6 Appendix A Cable

Management

7 Appendix B Engineering

Labels for Cables

Presents troubleshooting the switch ,the hardware

and software upgrade.

Introduces how to bind cables.

Introduces the use of engineering labels.

Page 4

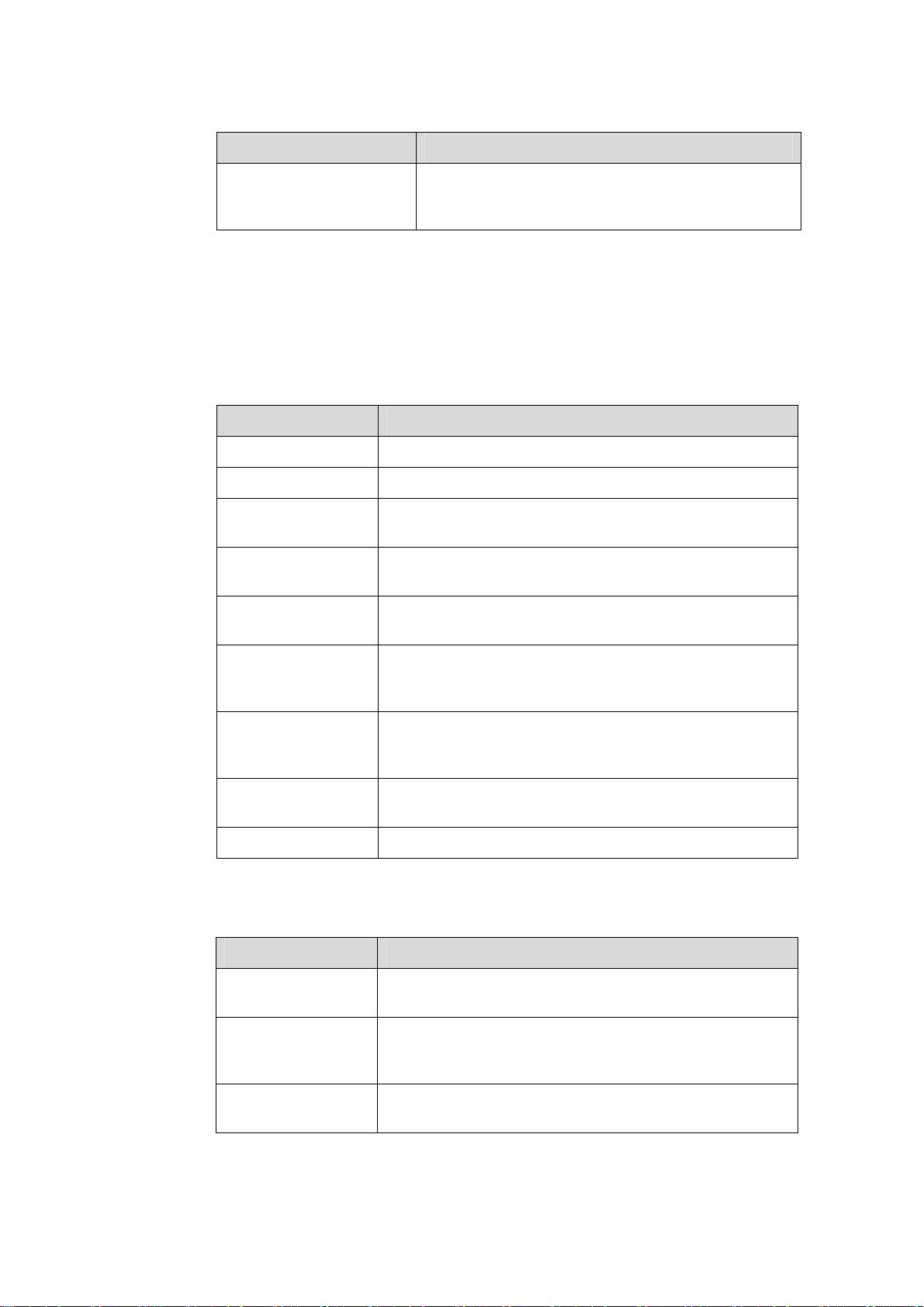

Chapter Contents

Conventions

The manual uses the following conventions:

I. Command conventions

8 Appendix C Installation

of Lightning Arrester for

AC Power

Convention Description

Boldface

italic

[ ]

{ x | y | ... }

[ x | y | ... ]

Introduces the installation of lightning arrester for AC

power of S9500 series routing switches.

The keywords of a command line are in Boldface.

Command arguments are in italic.

Items (keywords or arguments) in square brackets [ ] are

optional.

Alternative items are grouped in braces and separated by

vertical bars. One is selected.

Optional alternative items are grouped in square brackets

and separated by vertical bars. One or none is selected.

Alternative items are grouped in braces and separated by

{ x | y | ... } *

[ x | y | ... ] *

&<1-n>

# A line starting with the # sign is comments.

vertical bars. A minimum of one or a maximum of all can be

selected.

Optional alternative items are grouped in square brackets

and separated by vertical bars. Many or none can be

selected.

The argument(s) before the ampersand (&) sign can be

entered 1 to n times.

II. GUI conventions

Convention Description

< >

[ ]

/

Button names are inside angle brackets. For example, click

<OK>.

Window names, menu items, data table and field names

are inside square brackets. For example, pop up the [New

User] window.

Multi-level menus are separated by forward slashes. For

example, [File/Create/Folder].

Page 5

III. Symbols

Convention Description

Warning

Caution

Note Means a complementary description.

Environmental Protection

This product has been designed to comply with the requirements on environmental

protection. For the proper storage, use and disposal of this product, national laws and

regulations must be observed.

Means reader be extremely careful. Improper operation

may cause bodily injury.

Means reader be careful. Improper operation may cause

data loss or damage to equipment.

Page 6

Installation Manual

H3C S9500 Series Routing Switches Table of Contents

Table of Contents

Chapter 1 Product Overview........................................................................................................1-1

1.1 Introduction........................................................................................................................1-1

1.2 Physical Structure..............................................................................................................1-1

1.2.1 Chassis and Slots ...................................................................................................1-2

1.2.2 Backplane................................................................................................................1-5

1.2.3 Power System.........................................................................................................1-6

1.2.4 PoE Power Supply..................................................................................................1-8

1.2.5 Fan Tray................................................................................................................1-10

1.3 Switching and Routing Processing Unit........................................................................... 1-11

1.4 Line Processing Unit........................................................................................................1-12

1.5 Service Board .................................................................................................................. 1-14

1.6 System Specifications...................................................................................................... 1-14

i

Page 7

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

Chapter 1 Product Overview

1.1 Introduction

The S9500 Series Routing Switches (hereinafter referred to as the S9500 series) are

developed by Hangzhou H3C Technologies Co., Ltd. (hereinafter referred to as H3C)

for use on business-oriented enterprise networks, the distribution layer of la rge MANs,

the core layer of small MANs, and the backbone of large enterprise networks and

campus networks. They can serve as switching cores and convergence centers.

Currently, the S9500 series consist of the following models:

z S9505: This model provides a switching capacity of up to 600 Gbps. It allows for

the concurrent wire-speed forwarding on 240 GE ports, 20 × 10GE ports, 240 FE

electrical ports, or 100 FE optical ports.

z S9508: This model provides a switching capacity of up to 960 Gbps. It allows for

the concurrent wire-speed forwarding on 384 GE ports, 32 × 10GE ports, 384 FE

electrical ports, or 160 FE optical ports.

z S9508V: This model provides a switching capacity of up to 960 Gbps. It allow for

the concurrent wire-speed forwarding on 384 GE ports, 32 × 10GE ports, 384 FE

electrical ports, or 160 FE optical ports. This model adopts upright slots.

z S9512: This model provides a switching capacity of up to 1.44 Tbps. It allows for

the concurrent wire-speed forwarding on 576 GE ports, 48 × 10GE ports, 576 FE

electrical ports, or 240 FE optical ports.

Note:

Unless otherwise specified in this document, the S9508V and the S9508 have the

same configuration.

1.2 Physical Structure

The S9500 series use integrated chassis, which consists of a power area, board area,

backplane, and fan area.

1-1

Page 8

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

Note:

z Two switching and routing processor units (SRPUs) can be installed on the S9500

series to support active-standby switchover.

z Two power supply units (PSUs) can be installed on the S9500 series to provide

hot-standby 1+1 redundancy.

z The S9500 series support PoE and an external PoE power supply is optional.

z Boards, fan tray, and AC/DC PSUs are hot-swappable.

1.2.1 Chassis and Slots

I. S9505

(1) SRPU slots (2) LPU slots (3) Cable management bracket

(4) PSUs (5) PoE power entry module (6) Fan tray

Figure 1-1 Front view of the S9505

z The S9505 chassis provides seven slots in its board area: The top two

accommodate SRPUs, which can operate in 1+1 re dundancy mode; the remaining

five accommodate LPUs/service boards.

z At the bottom of the chassis is the power area that contains one PoE entry module

and two PSUs. The two PSUs are hot-swappable; they can operate in 1+1

redundancy mode. The switch supports both A C and DC power inputs. So you can

select AC or DC PSUs as needed.

1-2

Page 9

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

z On the right of the chassis is the fan area that contains one vertical fan tray. The

fans draw air in from the left and exhausts air from the right.

II. S9508

(1) LPU slots (2) SRPU slots (3) PSUs

(4) PoE power entry module (5) Fan tray

Figure 1-2 Front view of the S9508

z The S9508 chassis provides ten slots in its board area: The middle two

accommodate SRPU modules; the remaining eight accommodate LPUs/service

boards.

z At the bottom of the chassis is the power area that contains one PoE power entry

module and two PSUs. The switch supports both AC and DC power inputs. So you

can select AC or DC PSUs as needed.

z On the right of the chassis is the fan area that contains one vertical fan tray. The

fans draw air in from the left and exhausts air from the right.

1-3

Page 10

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

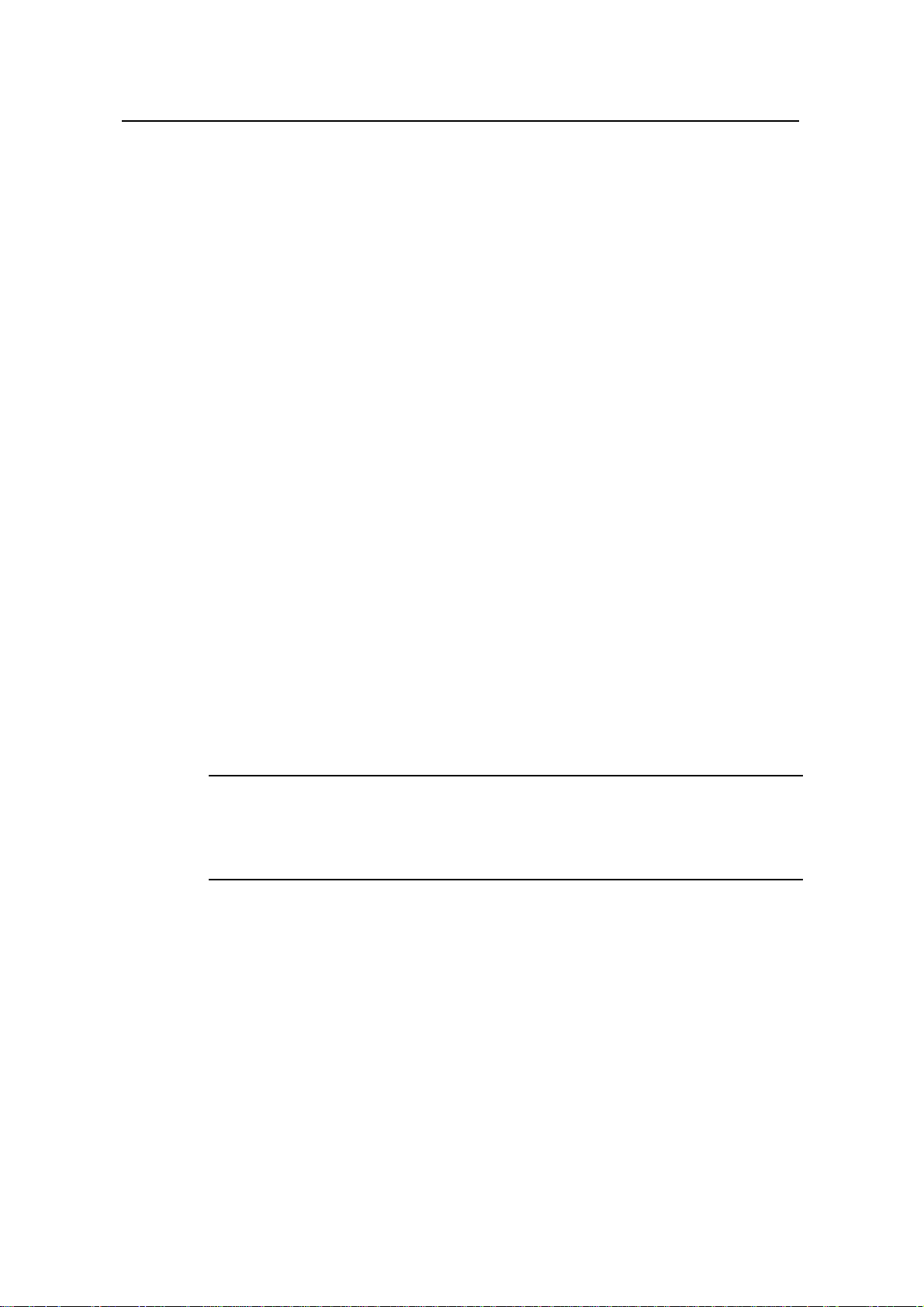

III. S9508V

(1) Fan tray (2) LPU slots (3) SRPU slots

(4) Air filter (5) PSUs (6) PoE power entry module

Figure 1-3 Front view of the S9508V

z The S9508V chassis provides ten vertical slots in its board area: The middle two

accommodate SRPU modules; the remaining eight accommodate LPU/service

boards.

z At the bottom of the chassis is the power area that contains one PoE power entry

module and two PSUs. The switch supports both AC and DC power inputs. So you

can select AC or DC PSUs as needed.

z Above the power area is the air filter, which can be removed from the chassis in

the case of replacement or regular cleaning.

z On the top of the chassis is the fan area that contains one horizontal fan tray. The

fans draw air in from the bottom and exhaust air from the top.

1-4

Page 11

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

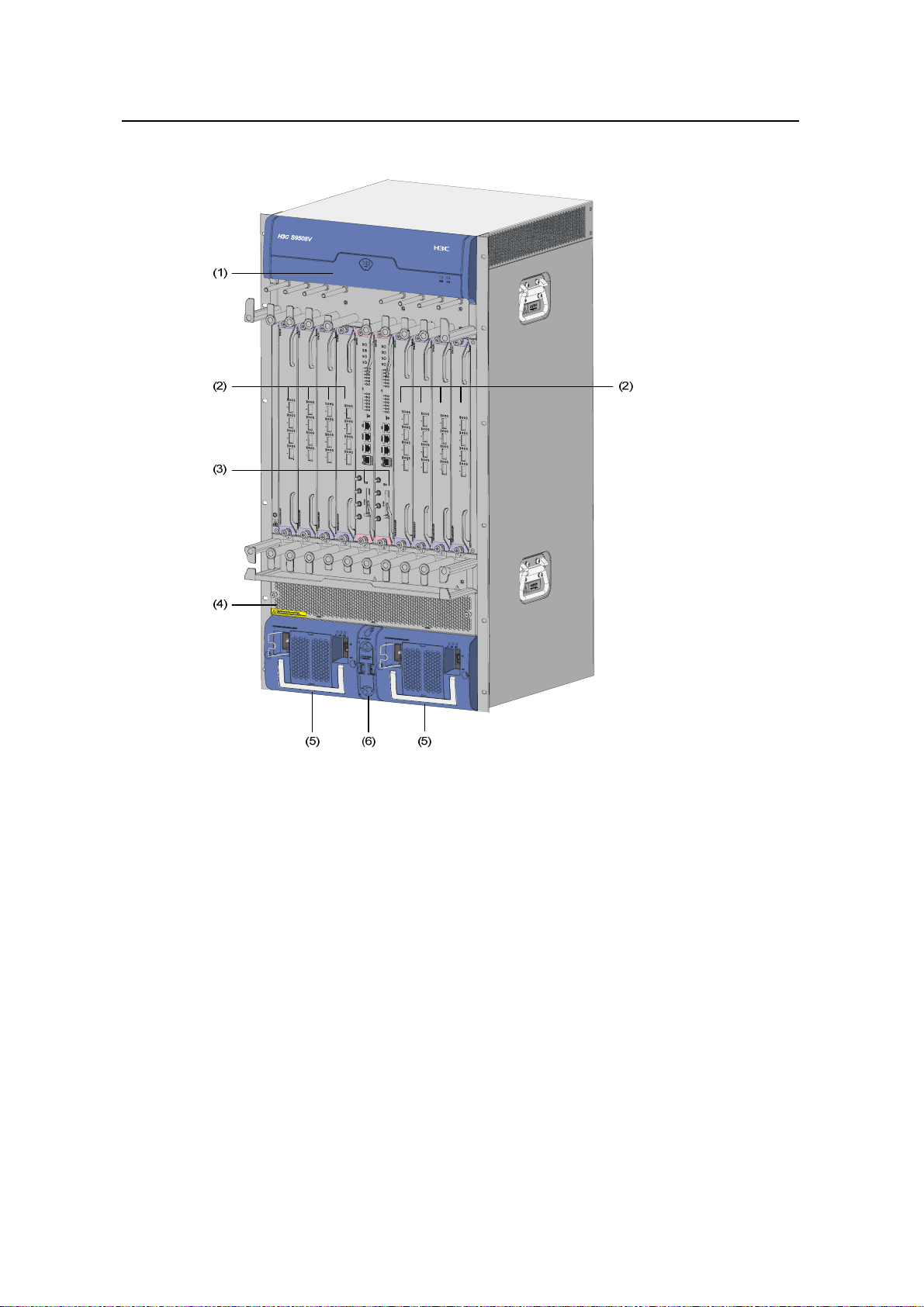

IV. S9512

(1) LPU slots (2) SRPU slots (3) PSUs

(4) PoE power entry module (5) Fan trays

Figure 1-4 Front view of the S9512

z The S9512 chassis provides fourteen slots in its board area: The middle two

accommodate SRPU modules and the remaining twelve accommodate

LPUs/service boards.

z At the bottom of the chassis is the power area that contains one PoE entry module

and two PSUs. The switch supports both AC and DC power inputs. So you can

select AC or DC PSUs as needed.

z On the right of the chassis is the fan area that contains two vertical fan trays. The

fans draw air in from the left and exhaust air from the right.

1.2.2 Backplane

The backplane of the S9500 series allows high-speed data exchange between SRPUs

and LPUs, as well as the exchange of various management and control signals in the

system.

1-5

Page 12

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

I. Functions

The following are the main functions of the backplane:

z Providing communication channels for signal exchange between boards

z Supporting board hot-swapping

z Supporting board auto-discovery in slots

z Connecting PSUs to distribute power SRPUs, LPUs/service boards, and fan tray(s)

and providing monitor channels for them.

II. Structure

The S9500 series use a passive backplane, which provides multiple board slot s, one or

two fan interfaces, and two –48V power interfaces (one for PSUs and the other for PoE

power entry module).

1.2.3 Power System

Note:

z The S9500 series support both AC and DC power inputs. So you can choose A C or

DC PSUs as needed.

z The S9500 series support 1+1 power supply redundancy.

z The PSUs of the S9500 series are hot-swappable.

The power system is at the bottom of the chassis. In the PSU slot s, you can insert either

two AC PSUs or two DC PSUs. The PSUs are cooled by the built-in fans, which draw

air into the chassis from the front and exhaust air from the rear.

z AC PSU

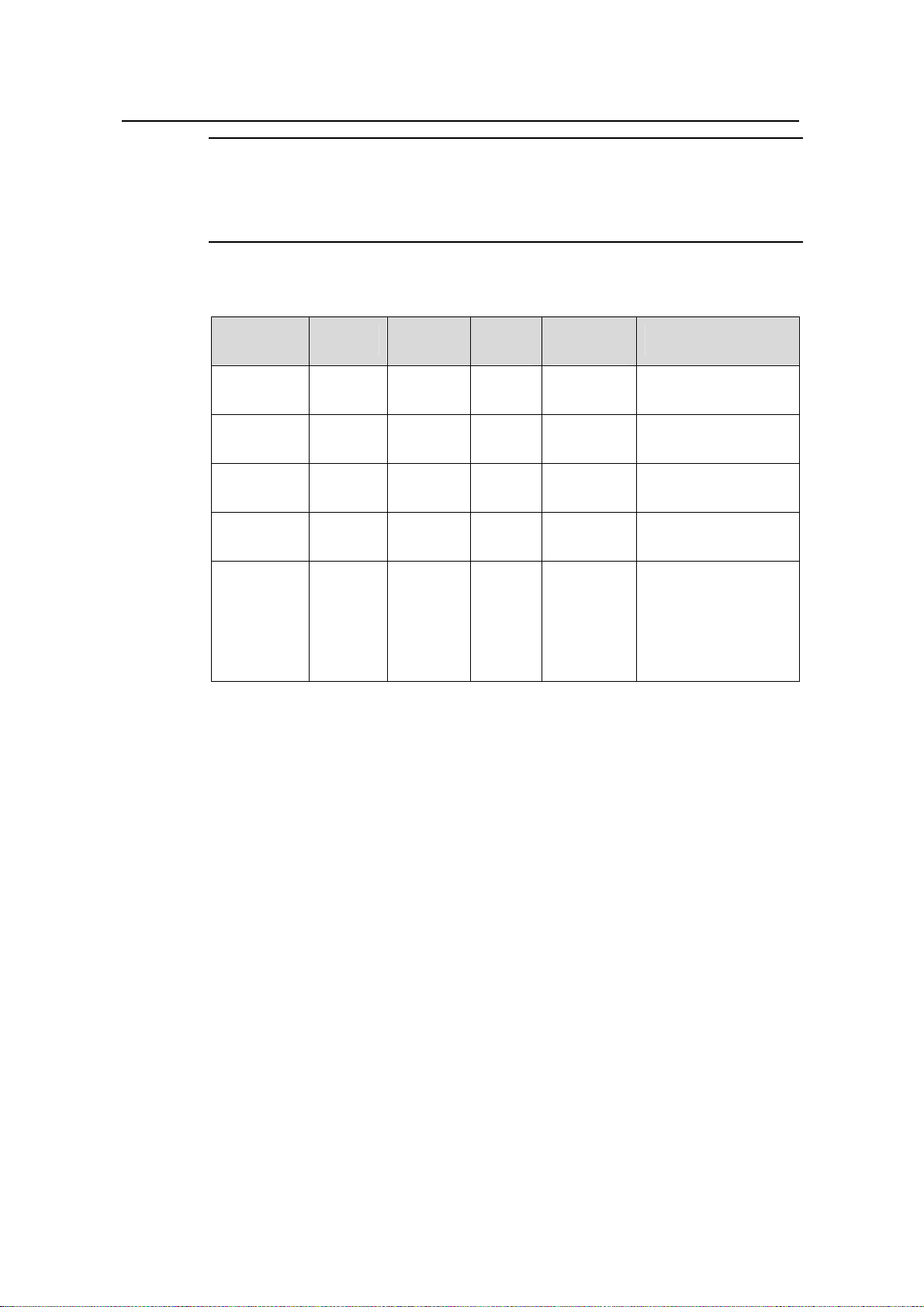

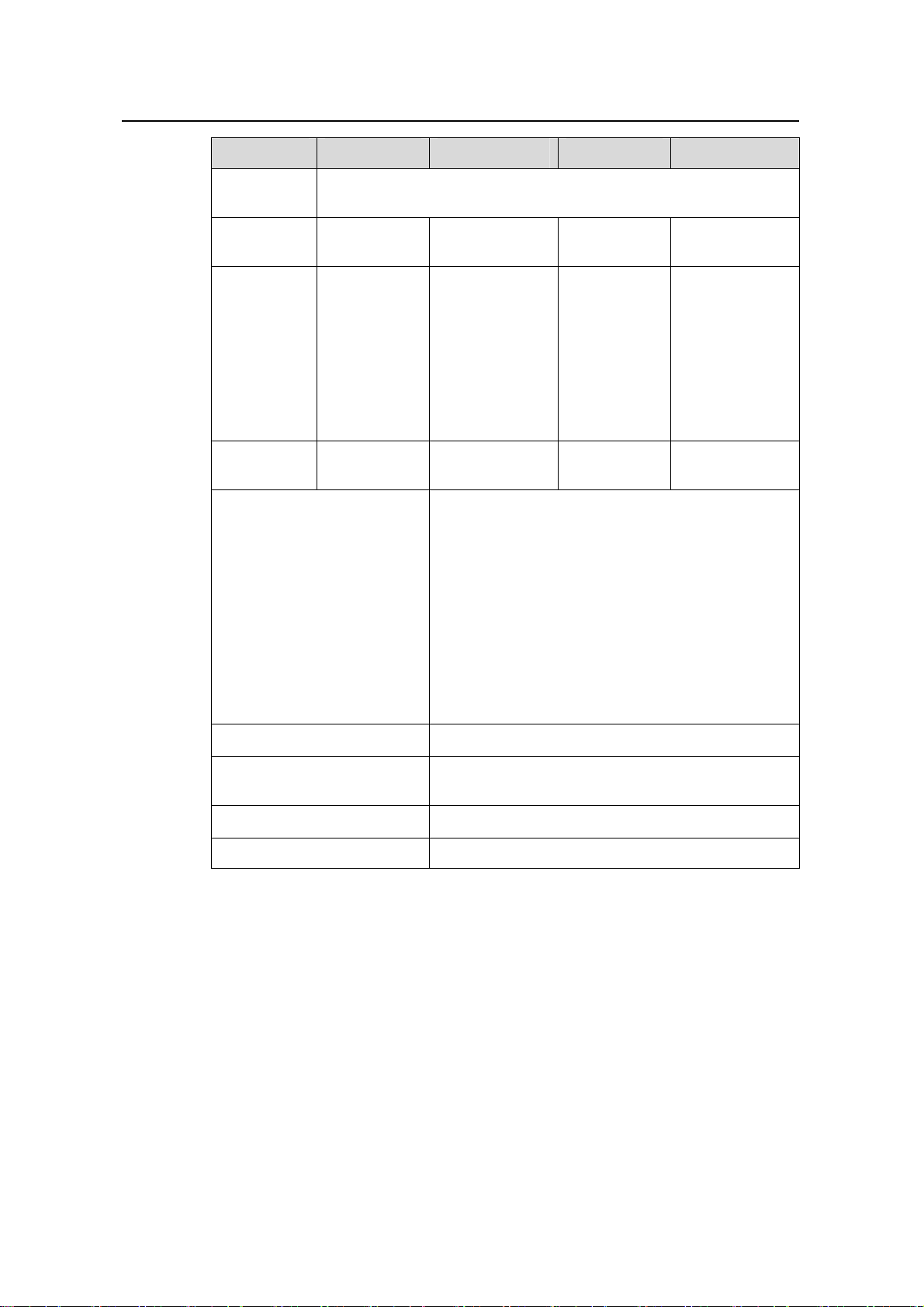

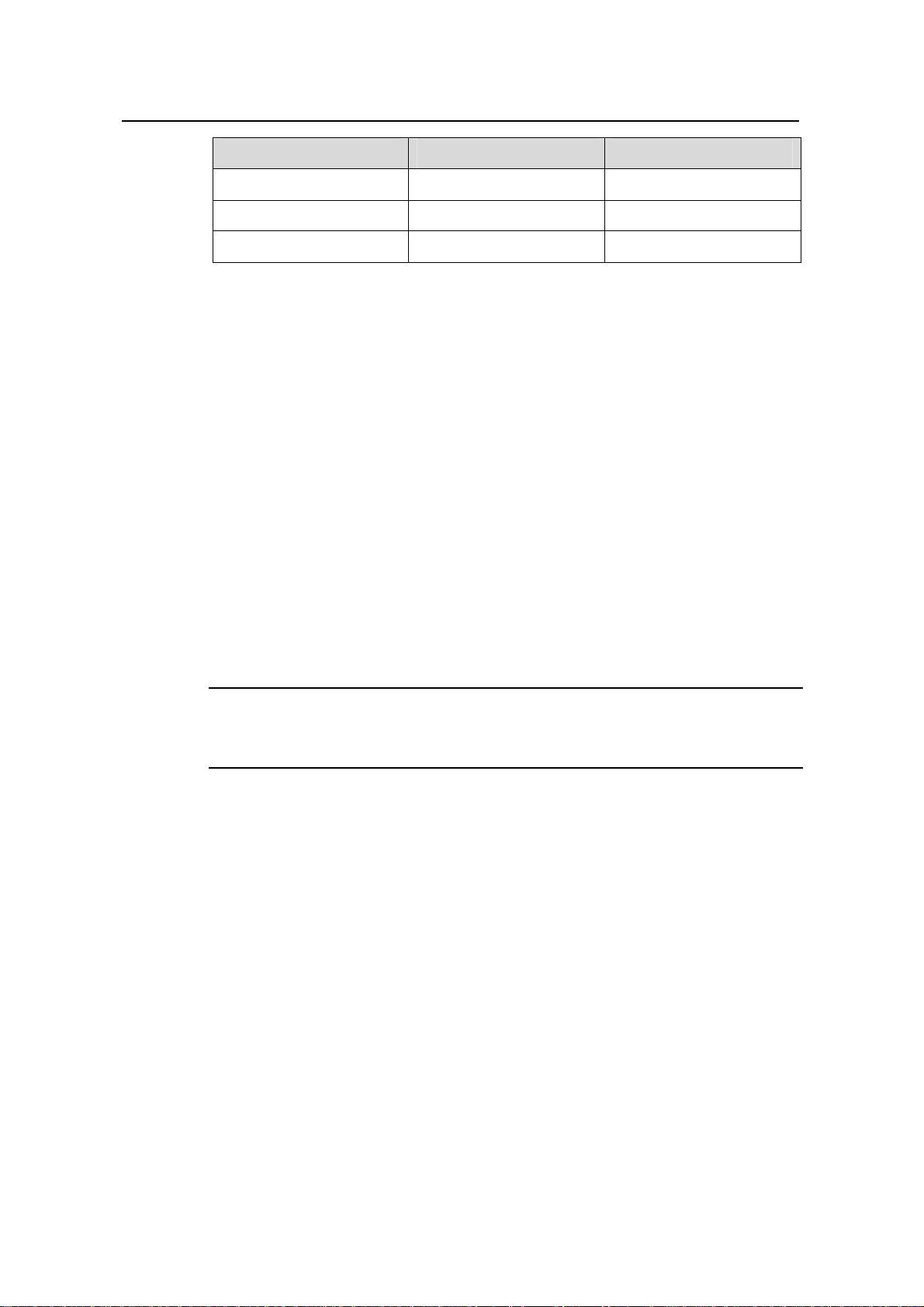

Table 1-1 Specifications for AC PSUs

Specifications

Item

NEPS1200-A NEPS2000-A NEPS3500-A

Model S9505 S9508/S9512 S9508/S9512

Rated

voltage

range

100 to 240 VAC, 50

Hz or 60 Hz

100 to 120 VAC, 60 Hz

200 to 240 VAC, 50 Hz

100 to 240 VAC,

50 Hz or 60 Hz

Input

voltage

range

90 to 264 VAC, 50 Hz

or 60 Hz

90 to 264 VAC, 50 Hz or

60 Hz

1-6

90 to 264 VAC, 50

Hz or 60 Hz

Page 13

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

Specifications

Item

NEPS1200-A NEPS2000-A NEPS3500-A

Max

input

15 A 15 A

current

Table 1-2 Configuration and output power of AC PSUs

PSU Configuration

NEPS1200-A

NEPS2000-A

1 × NEPS1200-A, no redundancy

2 × NEPS1200-A, 1+1 redundancy

1 × NEPS2000-A, no redundancy

2 × NEPS2000-A, 1+1 redundancy

1 × NEPS3500-A enclosure + 1 ×

sub-PSU, no redundancy

1 × NEPS3500-A enclosure + 2 ×

sub-PSU, 1+1 redundancy

1 × NEPS3500-A enclosure + 2 ×

sub-PSU, no redundancy

NEPS3500-A

2 × NEPS3500-A enclosure + 3 ×

sub-PSU, 2+1 redundancy

2 × NEPS3500-A enclosure + 4 ×

sub-PSU, 2+2 redundancy backup

Single 1800 W

sub-PSU :15 A

Two 1800W

sub-PSUs: 30 A

Maximum output

power

1200 W (90 V to 264 V)

1200 W (90 V to 160 V)

2000 W (160 V to 264 V)

1200 W (90 V to 180 V)

1800 W (180 V to 264 V)

2400 W (90 V to 180 V)

3500 W (180 V to 264 V)

2 × NEPS3500-A enclosure + 3 ×

sub-PSU, no redundancy

2 × NEPS3500-A enclosure + 4 ×

3500 W (90 V to 180 V)

sub-PSU, 3+1 redundancy

z DC PSU

Table 1-3 Specifications for DC PSUs

Specifications

Item

NEPS1200-D NEPS2000-D NEPS3500-D

Model S9505 S9508/S9512 S9508/S9512

Rated

voltage

–48 to –60 VDC –48 to –60 VDC –48 to –60 VDC

range

Input

voltage

–36 to –72 VDC –36 to –72 VDC –36 to –72 VDC

range

1-7

Page 14

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

Specifications

Item

NEPS1200-D NEPS2000-D NEPS3500-D

Max

input

25 A 42 A 75 A

current

Max

output

1,200 W 2,000 W 3,500 W

power

1.2.4 PoE Power Supply

The S9500 series support power over Ethernet (PoE). With this feature, an S9500

switch equipped with an external PoE power supply and PoE-capa ble LPUs can deliver

–48 VDC to its remotely powered devices (PDs), such as IP phones, wireless LAN

(WLAN) access points (APs) and network cameras, through Ethern et cables.

Currently, among the LPUs of the S9500 series, only GV48 is PoE capabl e.

z The S9500 series can supply power to remote PDs through Ethernet electrical

ports on the LPUs. Each LPU can simultaneously supply power to up to 48 PDs

with the maximum distance of 100 m (328.1 feet).

z Each Ethernet port can deliver up to 15.4 W to its PD.

z The S9500 series determine whether to deliver power to a newly detected PD

according to the following condition: If the remaining PoE power of the switch is

greater than what is required by a newly detected PD, the switch supplies powe r to

it. Otherwise, the switch does not supply power to it.

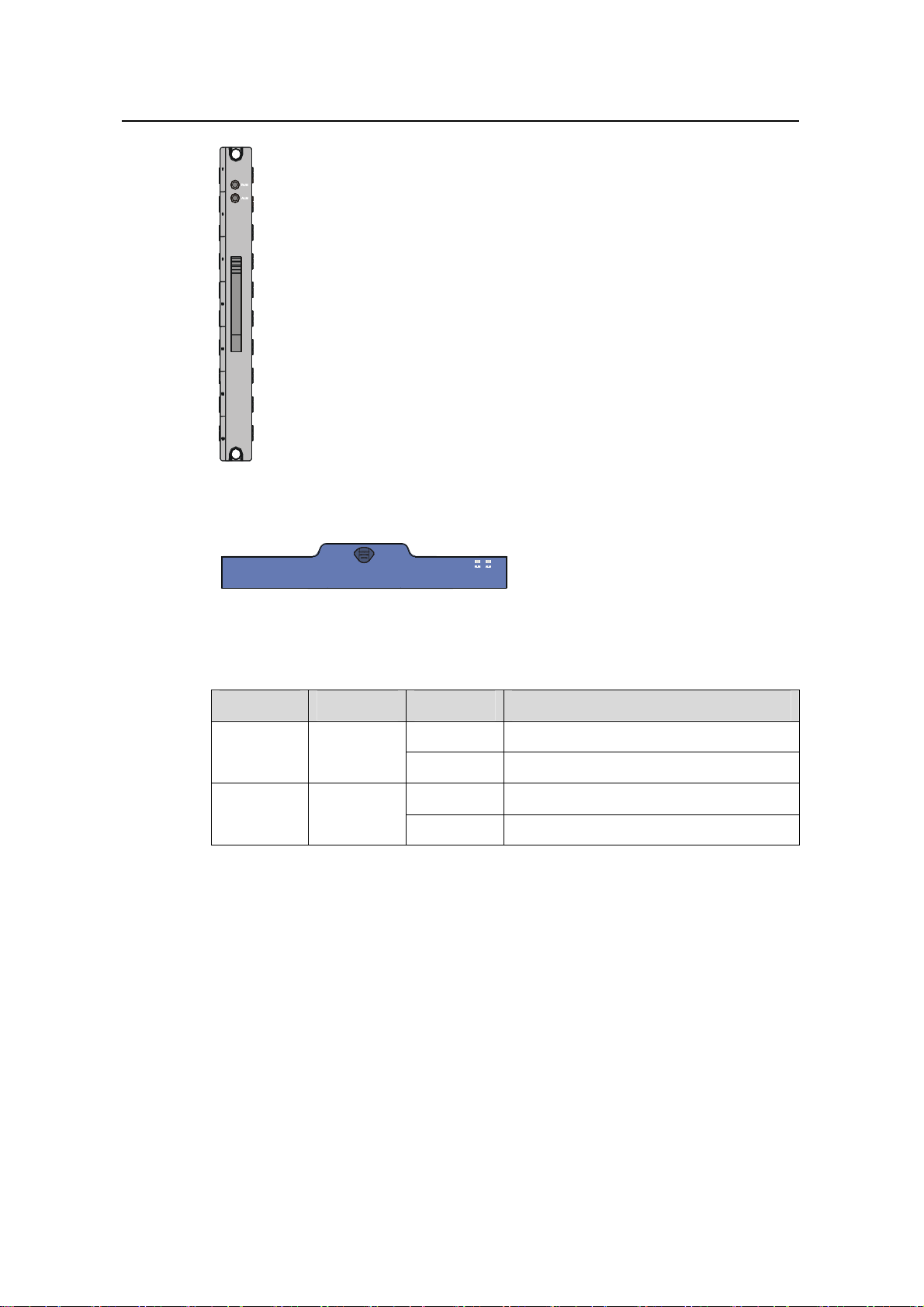

I. PoE power entry module

The PoE-supported S9505/S9508/S9508V/S9512 switch chassis has a PoE power

entry module between the two PSUs. You can co nnect this PoE power entry mo dule to

an external PoE power supply PSE4500-A.

Figure 1-5 PoE power entry module

1-8

Page 15

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

II. External PoE power supply

The S9505/S9508/S9508V/S9512 uses the PSE4500-A power system as an external

PoE power supply.

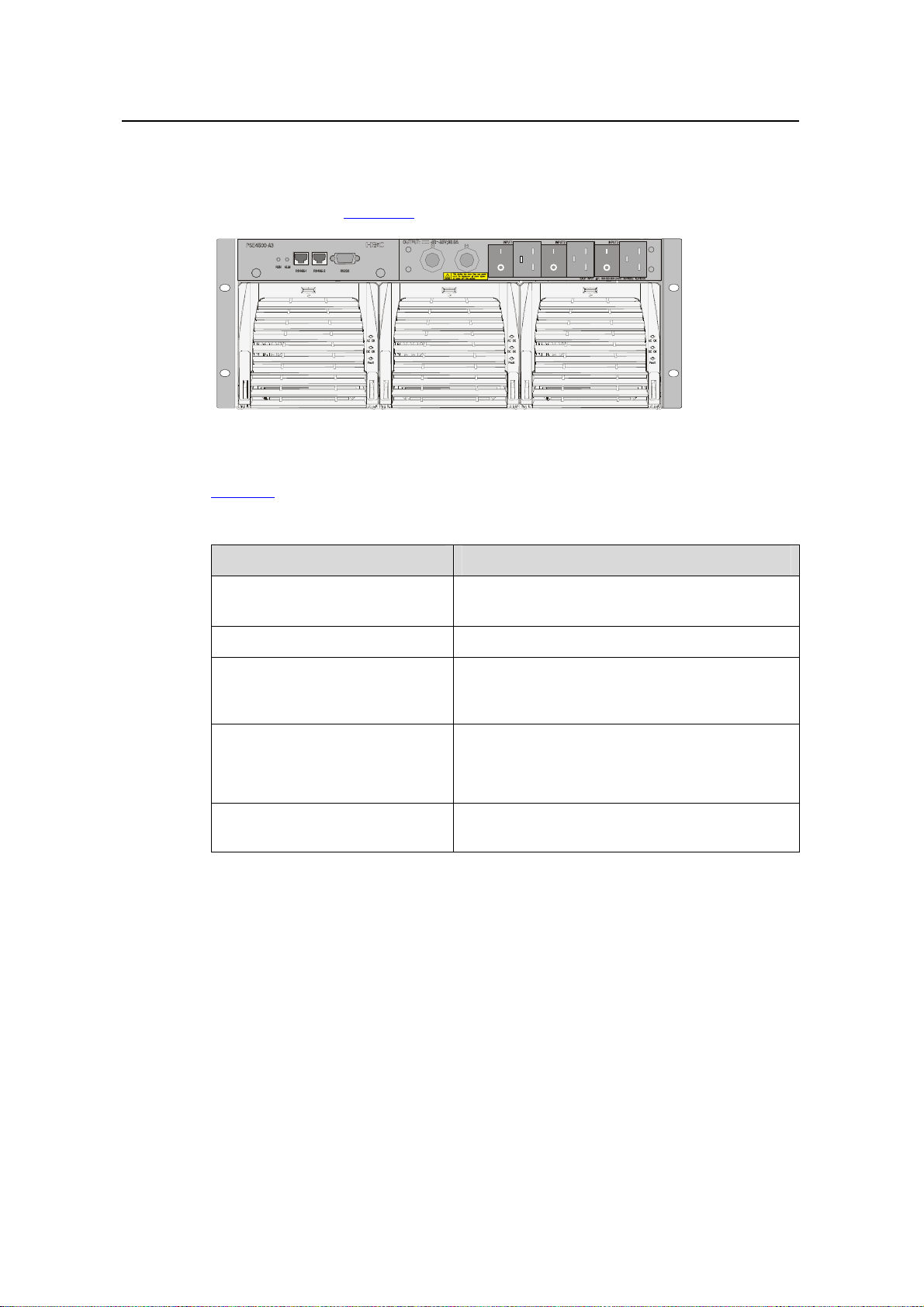

Figure 1-6 shows the PSE4500-A front panel.

Figure 1-6 PSE4500-A front panel

Table 1-4 describes typical equipment configurations and specifications of PSE4500-A.

Table 1-4 Typical equipment configurations and specifications of PSE4500-A

Item Specifications

Physical dimensions (H × W × D)

175 × 482.6 × 320.5 mm (6.89 × 19.00 × 12.62

in.)

System controller One

Two NP2500UACs (required) + one redundant

Rectifiers (NP2500UAC)

NP2500UAC (optional); NP2500UAC is

hot-swappable

Three AC inputs and switches

AC accessories

Three AC voltage detection circuits

Input voltage range: 90 to 264 VAC

DC accessories

A single DC output, with a max output power of

4500 W (220 V)/2400 W (110 V)

The external PoE power system has the monitoring function. It provides one RS232

and two RS485 monitoring interfaces. The external PoE power supply can display

alarm information through the ALM LED. The system can learn th e running information

of the rectifiers by connecting a monitoring port to the SRPU. You can use cables to

connect the monitoring ports from the front or the rear of the external PoE power

supply.

1-9

Page 16

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

Note:

The external PoE power system for the S9500 series only support RS485 monitoring

ports.

Table 1-5 LEDs of external PoE power system

LED Label Color

Input power

LED

Output

power LED

Fault LED Fault Red OFF ON

Running

status LED

Alarm LED ALM Red OFF ON

1.2.5 Fan Tray

Normal

state

Abnormal

state

AC Green ON OFF

DC Green ON OFF

RUN Green ON OFF

Abnormal reason

Loss of AC input

power, or blown fuse

No DC output from

PSU

Irreversible fault

occurred in PSU

PSU shutdown or

PSU running trouble

Loss of AC input

power, under-voltage

or over-voltage input,

over-voltage output,

output short-circuit,

or PSU fault

z The S9505 uses one 25 W fan tray, which contains four 120 × 120 × 25.4 mm (4.7

× 4.7 × 1.0 in.) DC fan units.

z The S9508 uses one 35 W fan tray, which contains six 120 × 120 × 25.4 mm (4.7 ×

4.7 × 1.0 in.) DC fan units.

z The S9508V uses one 70 W fan tray, which contains six 120 × 1 20 × 38 mm (4.7 ×

4.7 × 1.5 in.) DC fan units.

z The S9512 uses two 25 W fan trays, each of which contains four 120 × 120 × 25.4

mm (4.7 × 4.7 × 1.0 in.) DC fan units.

The fans of the S9505/S9508/S9508V/S9512 operate at –48 VDC supplied from the

backplane.

1-10

Page 17

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

Figure 1-7 Fan tray panel of the S9505/S9508/S9512

Figure 1-8 Fan tray panel of the S9508V

Table 1-6 LEDs on fan tray panel

LED Color Status Meaning

OFF The fan tray is faulty.

RUN Green

ON The fan tray is operating normally.

OFF The fan tray is operating normally.

ALM Red

ON The fan tray is faulty.

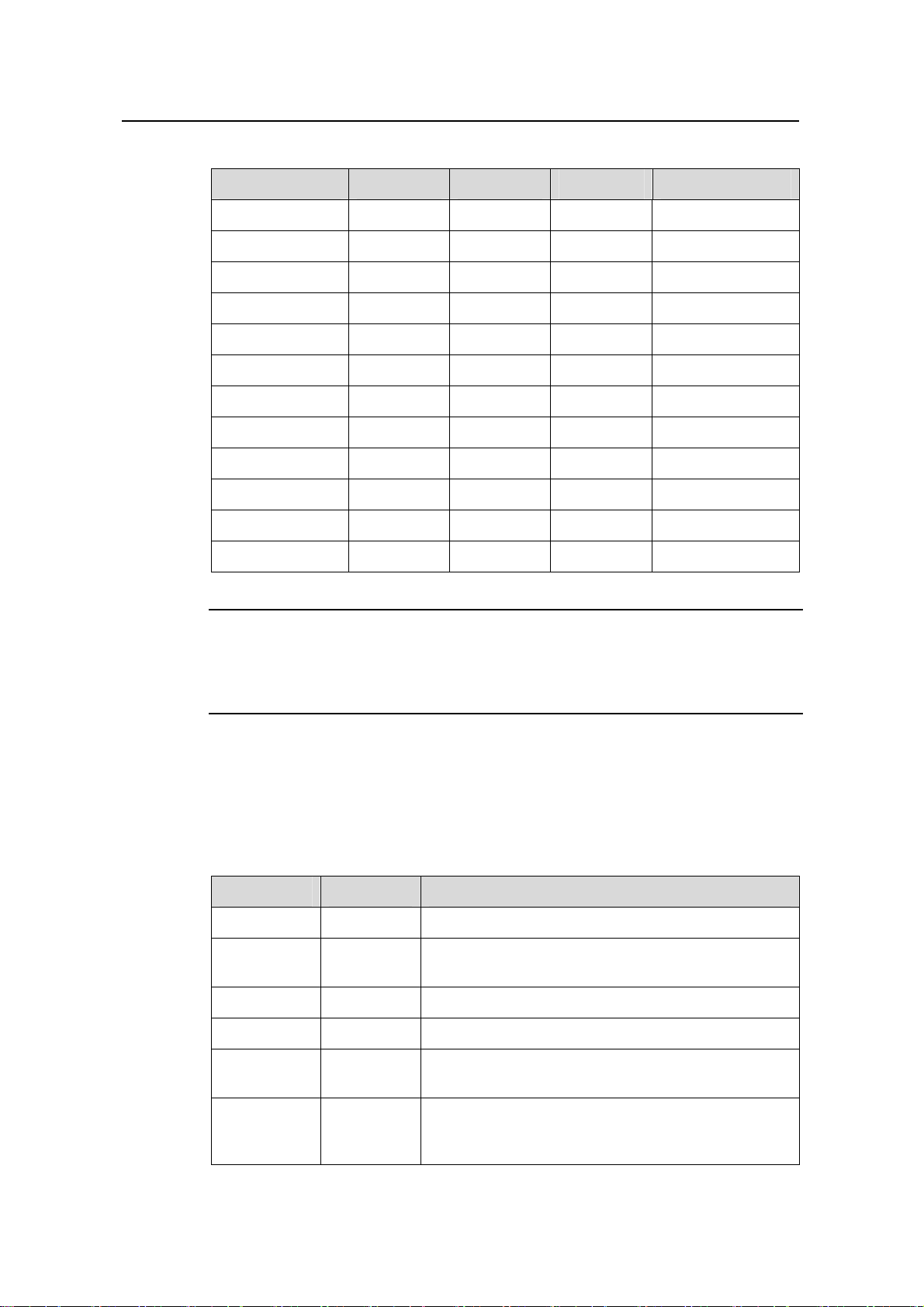

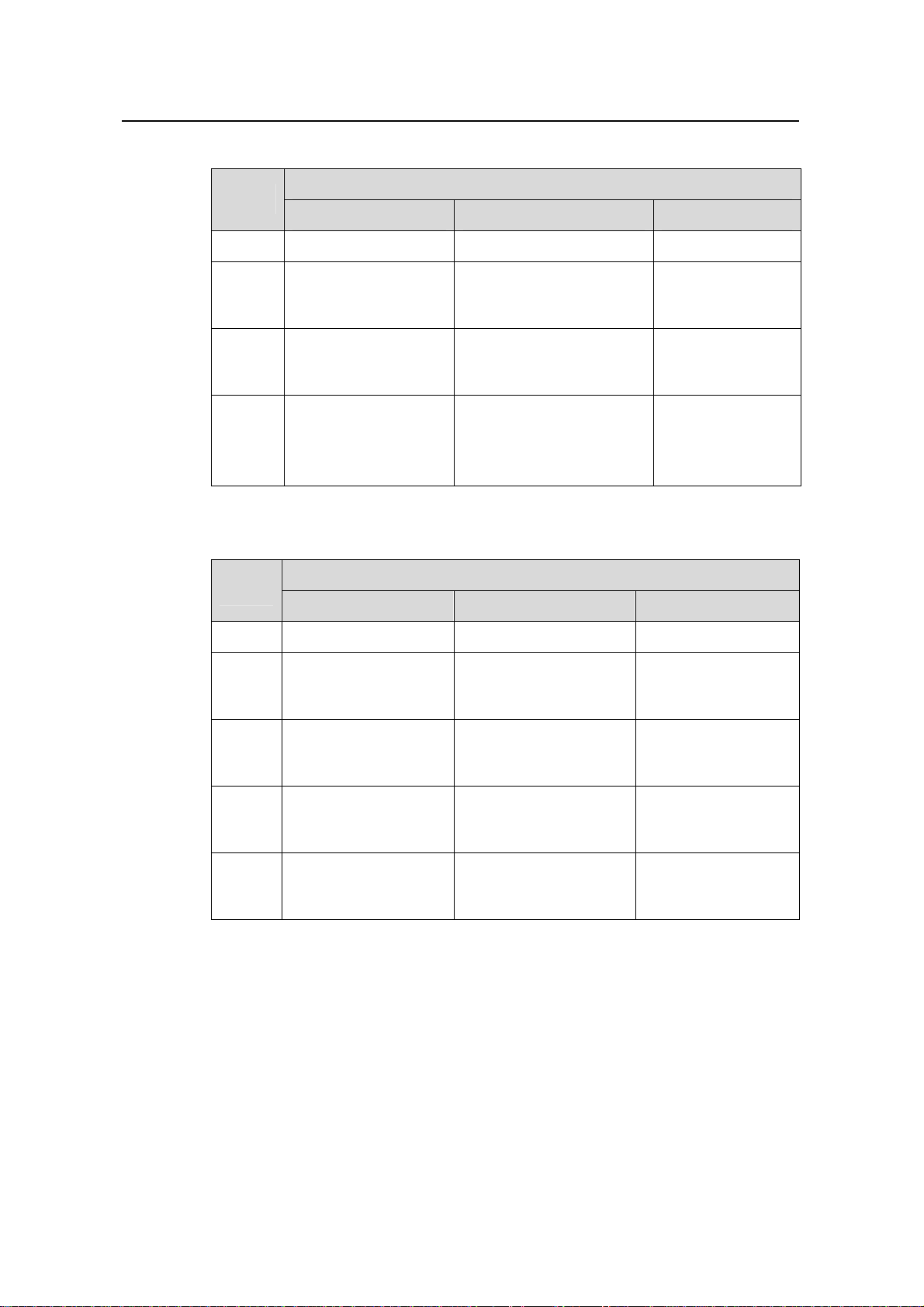

1.3 Switching and Routing Processing Unit

SRPUs serve as the core of the S9500 series. They mainly have the following

functions:

z Route calculation and forwarding table maintenance.

z Integrating crossbar switching fabric to accomplish service exchange between

different boards.

z Providing system configuration and monitoring functions, which allows the syste m

to monitor other boards and upgrade/reset service board software.

The following table lists the SRPUs applicabl e to the S9500 series.

1-11

Page 18

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

Table 1-7 SRPUs applicable to the S9500 series

SRPU S9505 S9508 S9508V S9512

LSB1SRP1N4

9

LSB1SRP1N5

LSB1SRP1N6

LSB1SRP1N7

LSB1SRP2N4

LSB1SRP2N5

LSB1SRP2N6

LSB1SRP2N7

LSB2SRP2N4

LSB2SRP2N5

LSB2SRP2N6

LSB2SRP2N7

Note:

The tick 9 indicates that the SRPU is applicable to the switch. SRP2N’s forwarding

capacity is twice the SRP1N’s.

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

1.4 Line Processing Unit

The following LPUs are available:

Table 1-8 LPUs available

LPU Suffix User interface

LSB1FP20 B0, CA0 20 × 100 Mbps SFP/LC optical ports

LSB1F32G B0, CA0

LSB1FT48 B0 48 × auto-sensing 10/100 Mbps RJ-45 electrical ports

LSB2FT48 CA0 48 × auto-sensing 10/100 Mbps electrical ports

LSB1GP12

LSB1GP24

B0, CA0,

DB0

B0, CA0,

CB0, DB0,

DC0

4 × 1000 Mbps SFP/LC optical ports and 32 ×

auto-sensing 10/100 Mbps RJ-45 ports

12 × 1000 Mbps SFP/LC optical ports

24 × 1000 Mbps SFP/LC optical ports

1-12

Page 19

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

LPU Suffix User interface

LSB2GP24 DB0, DC0 24 × 1000 Mbps SFP/LC optical ports

LSB1GP48 DB0

48 × 1000 Mbps SFP/LC optical ports (1:4

convergence)

LSB1GP48L DB0 48 × 1000 Mbps SFP/LC optical ports (wire-speed)

LSB1GV48 DB0

LSB2GV48 DB0

LSB1GT24

B0, CA0,

DB0

LSB2GT24 DB0

LSB1GT48L DB0

LSB1P4G8 CA0

LSB1GT8P CA0

B0, CA0,

LSB1XP2

CB0, DB0,

DC0

48 × auto-sensing 10/100/1000 Mbps RJ-45

electrical ports (PoE-capable)

48 × auto-sensing 10/100/1000 Mbps RJ-45

electrical ports (PoE-capable)

24 × auto-sensing 10/100/1000 Mbps RJ-45

electrical ports

24 × auto-sensing 10/100/1000 Mbps RJ-45

electrical ports

48 × auto-sensing 10/100/1000 Mbps RJ-45

electrical ports (wire-speed)

8 × 1000 Mbps SFP/LC optical ports and 4 × OC-3c

SFP/LC POS optical ports

4 × 1000 Mbps SFP/LC optical ports and 8 ×

auto-sensing 10/100/1000 Mbps RJ-45 ports

2 × 10GBase-R XFP/LC/10GBase-W XFP/LC optical

ports

LSB1XP4

B0, CA0,

DB0

LSB1XP4L DB0

LSB1XP4T DB0

LSB1XK1

B0, CA0,

DB0

4 × 10GBase-R XFP/LC/10GBase-W XFP/LC optical

ports (1:2 convergence)

4 × 10GBase-R XFP/LC/10GBase-W XFP/LC optical

ports (wire-speed)

4 × 10GBase-R XFP/LC/10GBase-W XFP/LC optical

ports

1 × 10GBase-R XENPAK/SC port

LSB1SP4 CA0 4 × OC-48c SFP/LC POS optical ports

LSB1UP1 CA0 1 × OC-192c XFP/LC POS optical port

LSB1VP2 CA0 2 × OC-192c XFP/LC RPR optical ports

LSB1RSP2 CA0 2 × OC-48c SFP/LC RPR optical ports

1-13

Page 20

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

Note:

The first column and the second column in the above table form an LPU model, for

example, LSB1XP2B0.

1.5 Service Board

Each kind of service board is specially designed for high-speed p rocessing of a cert ain

service and has partial or no functions of LPU.

Currently, the following service boards are available:

z LSB1NATB0: for NAT service, no service port

z LSB1VPNB0: for VPLS service, no service port

z LSB1NAMB0: for NAM service, no service port

Note:

For detailed specifications for the SRPUs, LPUs, and service boards, visit the website

at www. h3c.com.

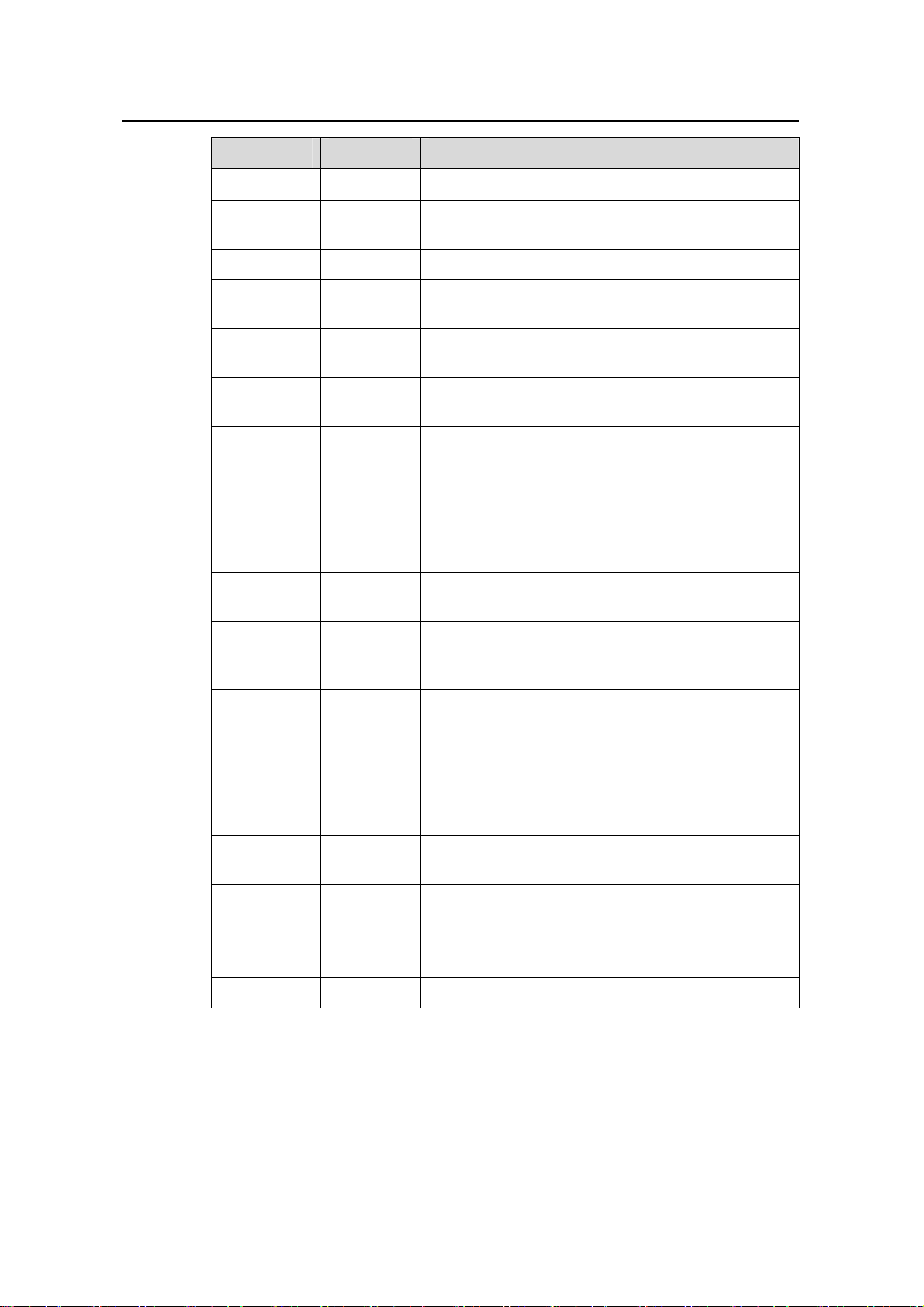

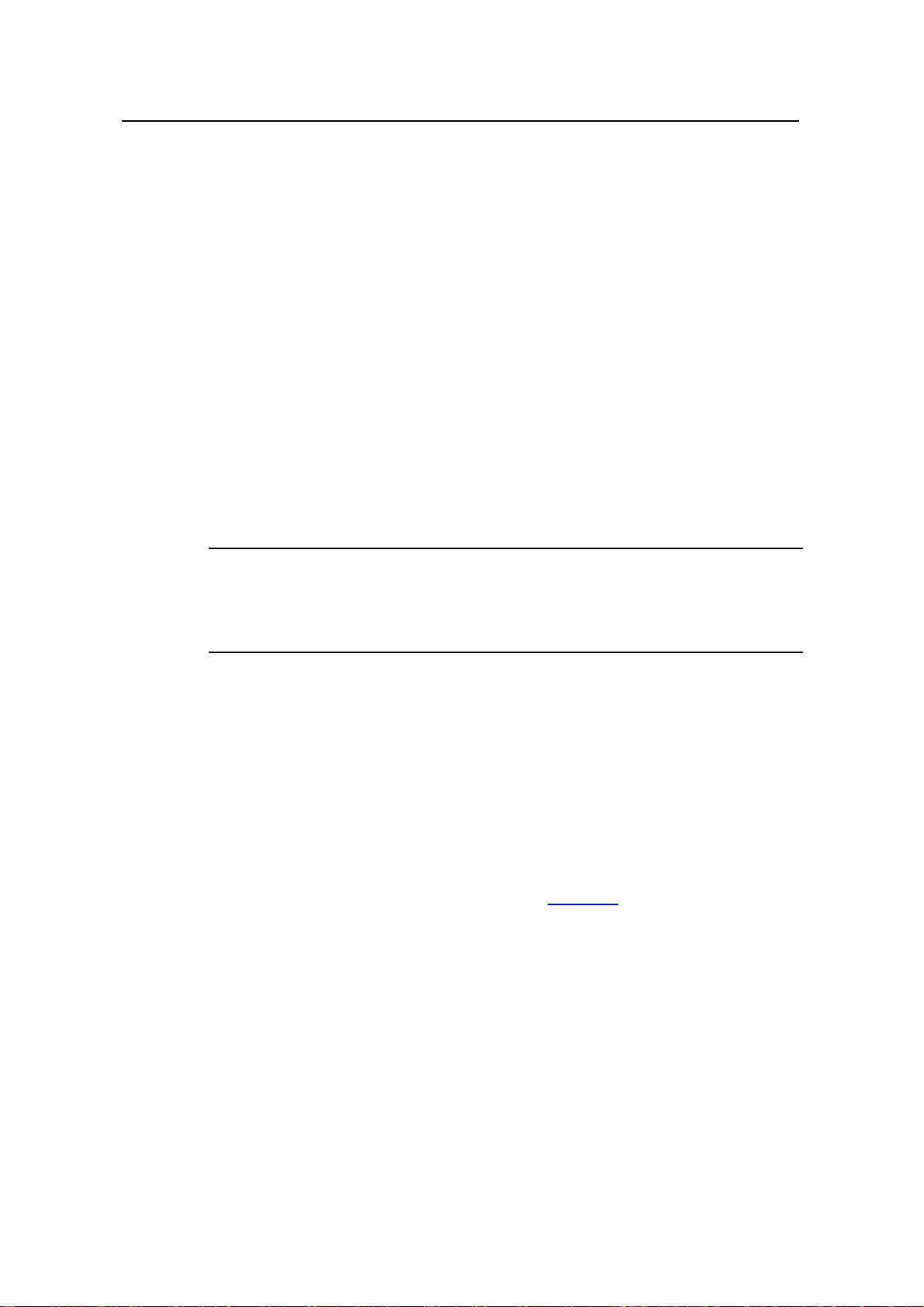

1.6 System Specifications

The following table summarizes the physical specifications of the S9500 series.

Table 1-9 Technical specifications of the S9500 series

Item S9505 S9508 S9508V S9512

486 × 436 ×

Dimensions

(H × W × D)

Weight (full

load)

Max power

consumption

450 mm (19.1

× 17.2 × 17.7

in.)

≤ 65 kg (143

lb)

1,200 W 2,000 W 2,000 W

619 × 436 × 450

mm (24.4 × 17.2

× 17.7 in.)

≤ 80 kg (176 lb)

888 × 436 ×

450 mm (35 ×

17.2 × 17.7

in.)

≤ 90 kg

(198.4 lb)

753 × 436 × 450

mm (29.6 × 17.2

× 17.7 in.)

≤ 100 kg (220

lb)

2,000 W/3,500

W

Overall

switching

capacity

Number of

VLANs

SRP1N6:

300 Gbps

SRP2N6: 600

Gbps

4 K

SRP1N5:

480 Gbps

SRP2N5:

960 Gbps

1-14

SRP1N5:

480 Gbps

SRP2N5:

960 Gbps

SRP1N4:

720 Gbps

SRP2N4:

1.44 Tbps

Page 21

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

Item S9505 S9508 S9508V S9512

Forwarding

table entries

Number of

SRPU slots

SRPU type

Number of

LPU slots

User interface

128 K/256 K/512 K

2 2 2 2

LSB1SRP1N

6

LSB1SRP1N

7

LSB1SRP2N

6

LSB1SRP2N

7

LSB1SRP1N5

LSB1SRP1N7

LSB1SRP2N5

LSB1SRP2N7

LSB1SRP1N

5

LSB1SRP1N

7

LSB1SRP2N

5

LSB1SRP2N

7

LSB1SRP1N4

LSB1SRP1N7

LSB1SRP2N4

LSB1SRP2N7

5 8 8 12

z 10/100/1000BASE-TX RJ45

z 10/100BASE-TX RJ45

z 1000BASE-X-SFP/LC

z 100BASE-FX SFP/LC

z 10GBASE-R XENPAK/SC

z 10GBASE-R/W XFP/LC

z OC-3c SFP/LC POS

z OC-48c SFP/LC POS

z OC-192c SFP/LC POS

z OC-48c SFP/LC RPR

z OC-192c SFP/LC RPR

Operating temperature

Operating humidity

(noncondensing)

Storage temperature

0°C to 45°C (32°F to 113°F)

10% to 90%

–40°C to 70°C (–40°F to 158°F)

Storage humidity 5% to 95%

1-15

Page 22

Installation Manual

H3C S9500 Series Routing Switches Table of Contents

Table of Contents

Chapter 2 Preparing for Installation............................................................................................2-1

2.1 Safety Recommendations.................................................................................................. 2-1

2.1.1 General Safety Recommendations.........................................................................2-1

2.1.2 Electrical Safety.......................................................................................................2-1

2.1.3 ESD Damage Prevention........................................................................................ 2-1

2.1.4 Handling Safety.......................................................................................................2-2

2.1.5 Laser Safety............................................................................................................2-2

2.2 Examining Installation Site................................................................................................. 2-3

2.2.1 Temperature Requirements....................................................................................2-3

2.2.2 Humidity Requirements...........................................................................................2-3

2.2.3 Cleanness Requirements........................................................................................2-4

2.2.4 EMS Requirements................................................................................................. 2-5

2.2.5 Grounding Requirements........................................................................................2-5

2.2.6 Power Supply Requirements...................................................................................2-5

2.2.7 Space Requirements............................................................................................... 2-6

2.3 Cabinet-Mounting Requirements.......................................................................................2-7

2.3.1 Cabinet Requirements ............................................................................................ 2-7

2.3.2 Requirements of Supports ...................................................................................... 2-8

2.4 Requirements of Power Distribution Box...........................................................................2-9

2.4.1 Installing the AC Power Distribution Box ................................................................2-9

2.4.2 Installing DC Power Distribution Box....................................................................2-12

2.5 Installation Tools.............................................................................................................. 2-16

i

Page 23

Installation Manual

H3C S9500 Series Routing Switches Chapter 2 Preparing for Installation

Chapter 2 Preparing for Installation

2.1 Safety Recommendations

T o avoid po ssible bodily injury and equipment damage, please read the following safety

recommendations carefully before installing the S9500 series. The recommendations

do not cover every possible hazardous condition.

2.1.1 General Safety Recommendations

z Take necessary safety measures to avoid injury and device damage. For example,

wear an ESD-preventive wrist strap.

z Make sure that the ground is dry and flat and you have adopted anti-slip

measures.

z Keep the chassis clean and dust-free. Do not place the switch on a moist area and

avoid liquid flowing into the switch.

z Keep the chassis and installation tools away from walk areas.

2.1.2 Electrical Safety

z Look carefully for possible hazards in your work area, such as un grou nde d power

extension cables, missing safety grounds, and moist floors.

z Locate the emergency power-off switch in the room before installation. Shut the

power off at once in case accident occurs.

z Unplug all the external cables (including power cords) before moving the chassis.

z Better not maintain the equipment alone when it has been powered.

z Never assume but check each time that power has been disconnected from a

circuit.

2.1.3 ESD Damage Prevention

To prevent the electronic components from being damaged by the electrostatic

discharge (ESD), you should not only take ESD measures where the switch is located,

but also take the following precautions:

z Always wear an ESD-preventive wrist strap when installing components,

especially the electronic printed circuit boards.

z Hold the edges of the PCB when necessary. Do not touch any electronic

components or printed circuit.

Take the following steps to use the ESD-preventive wrist strap.

1) Wear the wrist strap on your wrist.

2) Lock the wrist strap tight around your wrist to keep good contact with the skin.

2-1

Page 24

Installation Manual

H3C S9500 Series Routing Switches Chapter 2 Preparing for Installation

3) Insert the ESD-preventive wrist strap into the specially designed hole on the

switch chassis or attach it to the grounding screw of the chassis th e alligator clips.

4) Make sure that the ESD-preventive wrist strap is well grounded.

Caution:

For the sake of safety, check the resistance of the ESD-preventive wrist strap. The

resistance reading should be in the range of 1M to 10 M ohm between human body and

the ground.

2.1.4 Handling Safety

Since the S9500 series are rather large and heavy, you should follow the

recommendations below:

z Remove all the external cables (including power cords) before moving the chassi s.

z Do not move the switch alone.

z Move the switch slowly and stably. Keep in step with your partner and balance

your bodies when moving the switch.

Caution:

You can only hold the handles at both sides of the chassis when mov ing the switch, but

not the plastic panel of the chassis, the handle of the fan frame, the handle of the PSUs,

the handle of the back cover of the chassis, or the air vents of chassis.

Any attempt to carry the switch with these parts may cause equipment damage or even

bodily injury.

2.1.5 Laser Safety

S9500 series routing switches are class 1 laser products.

When an optional optical interface board of an S9500 switch is operating, do not stare

into the open optical port because the laser emitted from it has very high power density

and is harmful to your retina.

2-2

Page 25

Installation Manual

H3C S9500 Series Routing Switches Chapter 2 Preparing for Installation

Caution:

The laser inside the optical fibre may hurt your eyes.

2.2 Examining Installation Site

The S9500 series can only be used indoors. To ensure that the switch works normally

and to prolong its service lifetime, the following requirement s shoul d be met in terms of

installation environment.

2.2.1 Temperature Requirements

To ensure the normal operation of a switch, the temperature in the room should be

maintained within a proper range.

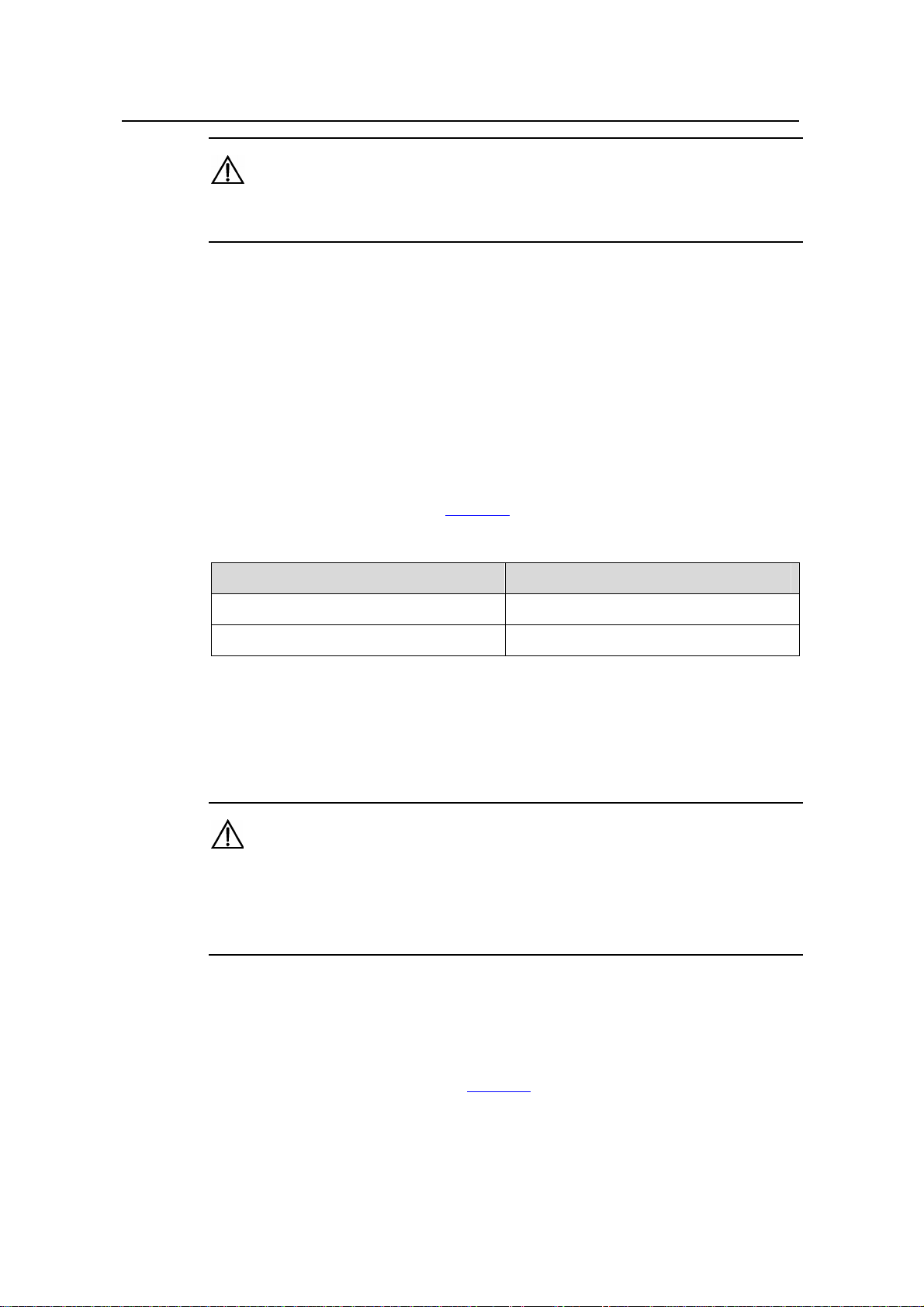

Table 2-1 Temperature requirements

Table 2-1 describes temperatu re requirements.

Temperature Range

Operating temperature 0°C to 45°C (32°F to 113°F)

Storage temperature –40°C to +70°C (–40°F to 158°F)

The higher the temperature, the greater the damage it will do to the switch. Long-lasting

high temperature will speed up the aging process of the insulating materials, greatly

lower the reliability of the switch, and therefore affect its service life seriously.

Caution:

After the switch is moved to a high-temperature location, if condensate appears on the

switch, you must dry the switch before power-on, thus to avoid damaging interior

components due to short circuit.

2.2.2 Humidity Requirements

To ensure the normal operation of a switch, the humidity in the equipm ent room should

be maintained within a proper range.

Table 2-2 describes humidity req uirements.

2-3

Page 26

Installation Manual

H3C S9500 Series Routing Switches Chapter 2 Preparing for Installation

Table 2-2 Humidity requirements

Humidity Range

Operating humidity (noncondensing) 10% to 90%

Storage humidity (noncondensing) 5% to 95%

Long-lasting high humidity in the equipment room is prone to poor insulation or even

leakage of the insulating material. Sometimes, the mechanical performance

deterioration, the rustiness and corrosion of some metal parts are also more likely to

occur.

If the relative humidity is too low, the captive screws may become loose due to the

insulation washer contraction. Meanwhile, the electrostatic is likely to be produced in

the dry environment, which will jeopardize the CMOS circuit of the switch.

2.2.3 Cleanness Requirements

Dust is a hazard to the operating safety of the switch. The indoor dust accum ula ted on

the chassis can cause electrostatic adsorption, whi c h may result in the poor contact of

the connector or metal contact point. This happens more frequently when indoor

relative humidity is low, which will not onl y shorten the service life of the switch, but also

cause communication failure.

The required specifications on dust content and particle diameter in an equipment room

are shown in the following table.

Table 2-3 Limitation on dust content and particle diameter in the equipment room

Mechanical active material Content limit (particles/m³)

4

Dust particle

≤ 3 x 10

(No visible dust on desk in three days)

Note: Dust particle diameter ≥ 5 µm

Besides the dust specifications, the equipment room of the switch should al so meet the

rigorous requirements for the content of salt, acid and sulfide in the air. These harmful

gases could accelerate the metal erosion and the aging process of some parts.

Incursion of harmful gases, su ch as SO

, H2S, NO2, NH3, and Cl2, should be prevented.

2

The specific limitation values of these harmful gases are given in the following table.

Table 2-4 Harmful gas limits in an equipment room

Gas Average (mg/m³) Max. (mg/m³)

SO2 0.3 1.0

H2S 0.1 0.5

2-4

Page 27

Installation Manual

H3C S9500 Series Routing Switches Chapter 2 Preparing for Installation

Gas Average (mg/m³) Max. (mg/m³)

NO2 0.004 0.15

NH

Cl

3

2

1.0 3

0.1 0.3

2.2.4 EMS Requirements

Any possible interference sources, no matter whether outside or inside the system,

affect the switch in use through capacitive coupling, inductive coupling,

electromagnetic radiation, common impedance (including the grounding system)

coupling or conducting line (power line, signalling line and transmission line etc). To

prevent the interference, you should:

z Take effective measures against electrical net interference for power supply

system.

z Separate the working ground of the switch from the grounding device of the power

supply equipment or lightning-protection grounding device as far as possible.

z Keep the switch far away from the radio launcher, radar launcher, and

high-frequency devices working in the high current.

z Adopt electromagnetic shielding if necessary.

Note:

If necessary, take electromagnetic shielding measures against the interference.

2.2.5 Grounding Requirements

A good groun ding system is not only the basis essential to the stable and reliable swit ch

operation, but also an important guarantee of lightning protection, anti-interference a nd

ESD-prevention. The user must provide good grounding system for the switch. The

resistance between the chassis and the ground must be less than 1 ohm.

2.2.6 Power Supply Requirements

The following tables describe the specifications for AC and DC PSUs.

2-5

Page 28

Installation Manual

H3C S9500 Series Routing Switches Chapter 2 Preparing for Installation

Table 2-5 Specifications for AC PSUs

Item

Specifications

NEPS1200-A NEPS2000-A NEPS3500-A

Model S9505 S9508/S9512 S9508/S9512

Rated

voltage

range

Input

voltage

range

Max

input

current

100 to 240 VAC, 50

Hz or 60 Hz

90 to 264 VAC, 50 Hz

or 60 Hz

15 A 15 A

100 to 120 VAC, 60 Hz

200 to 240 VAC, 50 Hz

90 to 264 VAC, 50 Hz or

60 Hz

100 to 240 VAC,

50 Hz or 60 Hz

90 to 264 VAC, 50

Hz or 60 Hz

Single 1800W

sub-PSU:15 A

Two 1800W

sub-PSUs: 30 A

Table 2-6 Specifications for DC PSUs

Specifications

Item

NEPS1200-D NEPS2000-D NEPS3500-D

Model S9505 S9508/S9512 S9508/S9512

Rated

voltage

–48 VDC to –60 VDC –48 VDC to –60 VDC –48 VDC to –60 VDC

range

Input

voltage

–36 VDC to –72 VDC –36 VDC to –72 VDC –36 VDC to –72 VDC

range

Max

input

25 A 42 A 75 A

current

Max

output

1,200 W 2,000 W 3,500 W

power

2.2.7 Space Requirements

For the sake of adequate ventilation and easy equipment maintenance, you are

recommended to keep one meter of clearance between the rear/front of the switch

cabinet and the wall surface or other devices. If the optional cabinet is desired, the clea r

height of the equipment room must be more than 3 meters inclusive.

2-6

Page 29

Installation Manual

H3C S9500 Series Routing Switches Chapter 2 Preparing for Installation

2.3 Cabinet-Mounting Requirements

Before mounting the switch in a cabinet, make sure that the cabinet meet s the following

requirements.

2.3.1 Cabinet Requirements

I. Dimensions

A standard 19-inch cabinet is required.

You can install the switch in an N68 cabi net develope d by H3C. There a re two types of

N68 cabinets available for the S9500 series:

z N68-18 model: 1.8-meter-high N68 cabinet (600 × 800 × 1800 mm, or 23.6 × 31.5

× 70.9 in.)

z N68-22 model: 2.2-meter-high N68 cabinet (600 × 800 × 2200 mm or 23.6 × 31.5 ×

86.7 in.)

Note:

For the procedure of installing and remodeling an N68 cabinet, refer to H3C N68

Cabinet Installation and Remodel Introduction.

You can also install the swit ch in a 19-in ch cabin et provided by oth er vend ors.

II. Weight bearing capacity and power

The cabinet must be able to bear the weight of the switch and its accessories. A 20%

power margin should be reserved.

III. Grounding requirements

You must provide a good grounding system for the switch. The cabinet must be

equipped with a grounding terminal, as shown in

Figure 2-1.

2-7

Page 30

Installation Manual

H3C S9500 Series Routing Switches Chapter 2 Preparing for Installation

(1) Grounding cable (2) Grounding terminal

Figure 2-1 Ground the cabinet

IV. Heat dissipation

Air enters from the left of the S9500 series and exhausts from the right. Therefore, a

clearance of at least 15.2 cm (6.0 in.) is required between the side panels of the cabinet

and the switch. If the switch is to be installed in a closed cabinet, make sure that the

cabinet has a good ventilation system.

2.3.2 Requirements of Supports

1) The length of supports depends on the cabinet depth.

2) You can use supports such as shelf or angles to install the switch into the cabinet.

The supports must be able to bear the weight of the switch and its accessories.

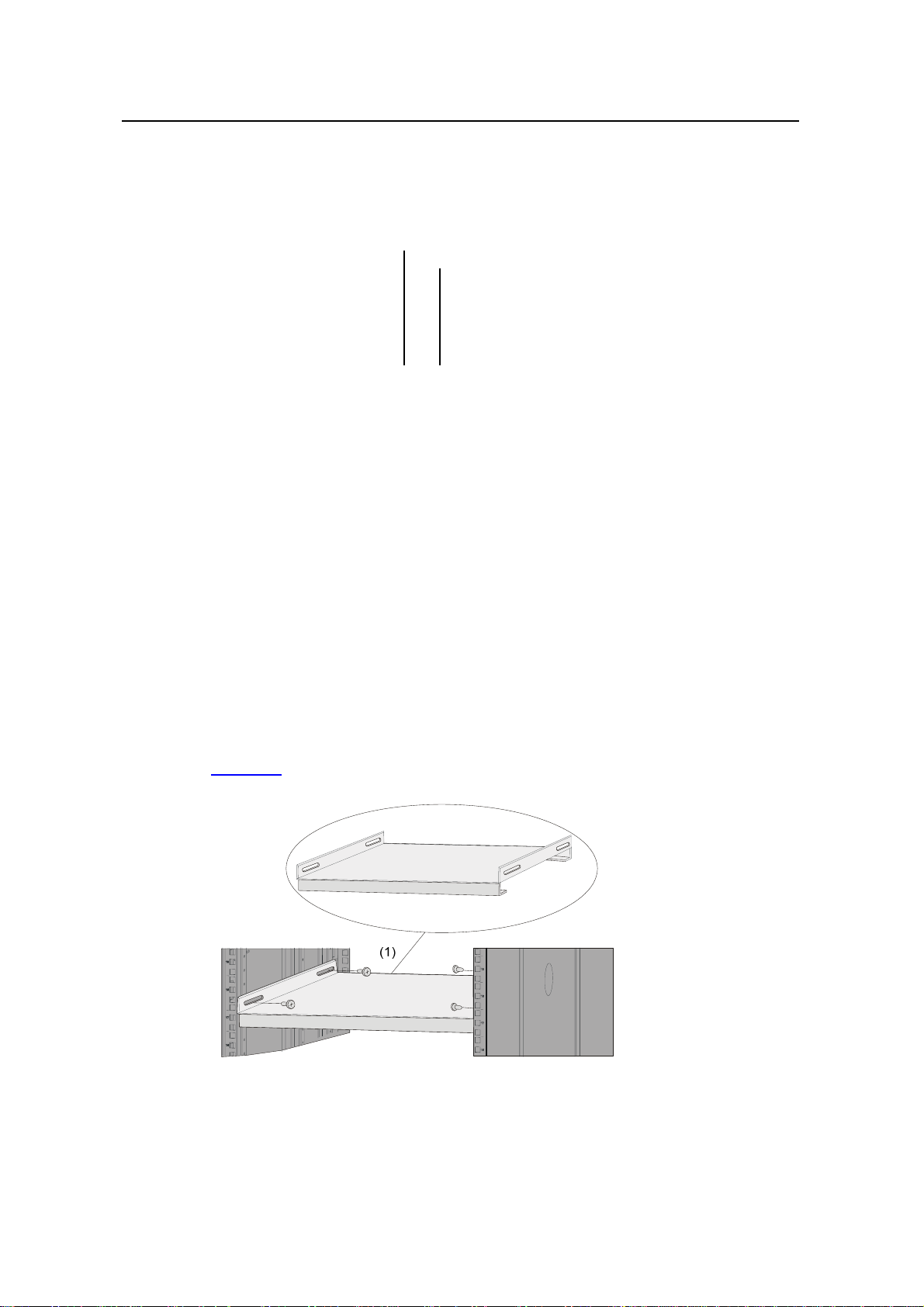

Figure 2-2 shows a shelf.

(2)(1) (2)(1)

(1) Shelf

Figure 2-2 Shelf

2-8

Page 31

Installation Manual

H3C S9500 Series Routing Switches Chapter 2 Preparing for Installation

Figure 2-3 shows an angle support.

(1) Angle support

Figure 2-3 Angle support

2.4 Requirements of Power Distribution Box

You can install a power distribution box in the cabi net as required.

2.4.1 Installing the AC Power Distribution Box

I. Terminal Block

The terminal block is set on the bottom of a power distribution box.

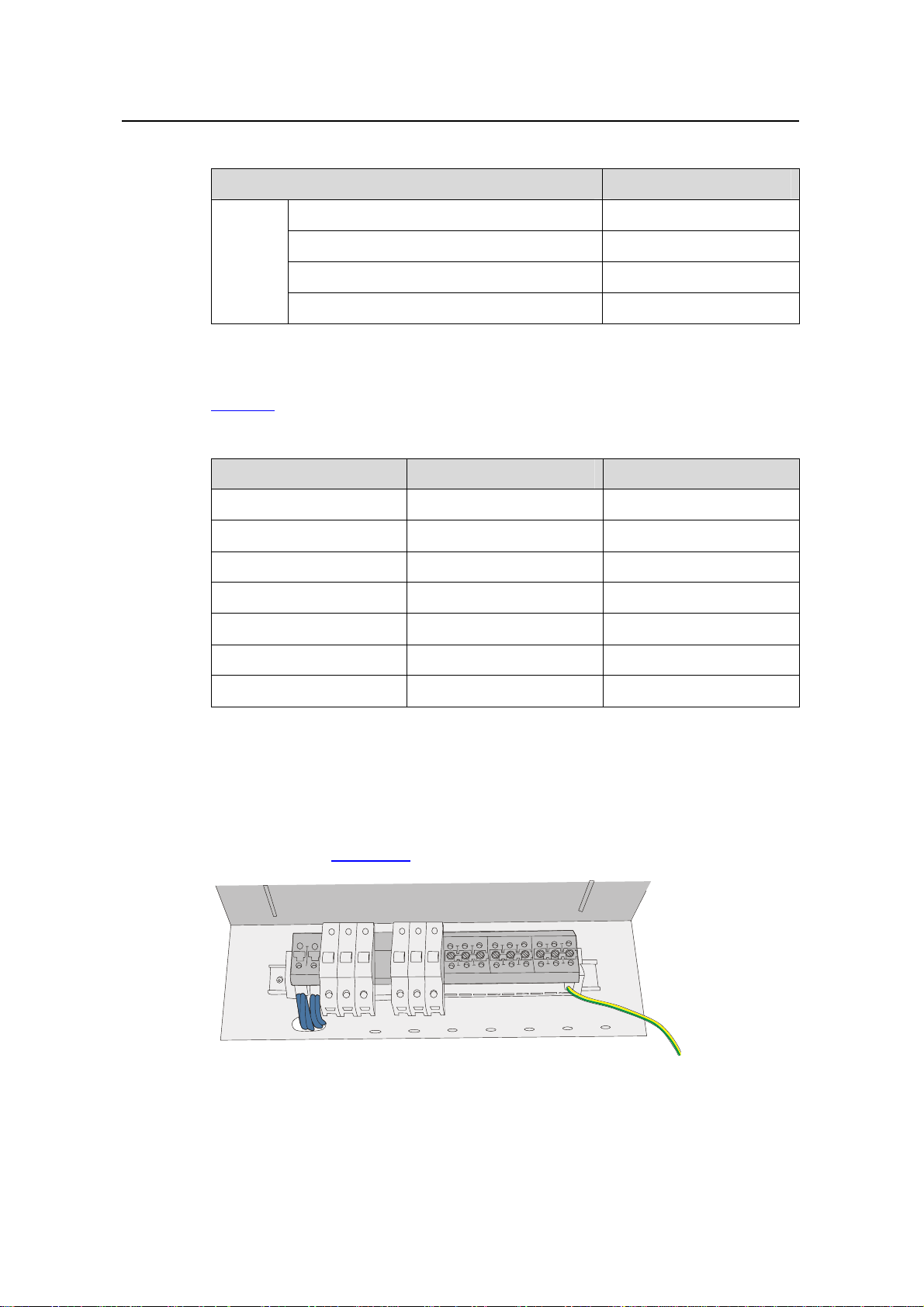

Figure 2-4 Terminal block structure diagram

The terminal block has 21 terminals to connect power cords: seven grey terminals,

seven blue terminals and seven yellow-green terminals.

z The grey terminals from L1 to L7 are output ports for live wire. These ports are

connected to each other.

z The blue terminals from N1 to N7 are output ports for neutral wire. These ports are

connected to each other.

z The yellow-green terminals from PE1 to PE7 are output ports for earth wire. These

ports are connected to each other and connected to the cabinet.

2-9

Page 32

Installation Manual

H3C S9500 Series Routing Switches Chapter 2 Preparing for Installation

Table 2-7 Electrical specifications of the terminal block

Item Specification

Rated current 76A

Input

Rated voltage 1000V

Rated cross-sectional area 16 mm2

Maximum current/maximum crimping area 101A/25 mm

Output seven loop outputs

II. Power Distribution Box Appearance

Figure 2-5 Front view of the power distribution box

2

Figure 2-6 Top view of the power distribution box

Caution:

Make sure the power cord ports are covered with protection tube such that no wire

tailpiece is exposed at any joint.

III. Connect power cords to the power distribution box

2-10

Page 33

Installation Manual

H3C S9500 Series Routing Switches Chapter 2 Preparing for Installation

Caution:

The power distribution box takes AC high voltage. Do not operate it before breaki ng its

power.

1) Use three cables to connect the client power distribution box to the terminal block

of the cabinet power distribution box. You are recommended to use the cables

2

with 16 mm

cross-sectional area (the colors of the cables differ depending on the

cable specifications in different countries). Connect the power cords according to

the following relations:

z Live wire L in the client power distribution box — Live wire L in the cabinet power

distribution box

z Neutral wire N in the client power distribution box — Neutral wire N in the cabinet

power distribution box

z Earth wire G in the client power distribution box — Earth wire PE in the cabinet

power distribution box

2) Use 3.5 m (11.5 ft) long cables to connect the cabinet power distribution box to the

system power supply and PoE power supply. The three wires of ea ch cable should

be respectively connected to the ports L, N and PE of the power distribution box.

Make sure the protection tubes are used and no wire tailpiece is exposed during

the connection. You should connect power cord 1 to L1, N1 and PE1, power cord 2

to L2, N2 and PE2, and so on. The number of power cords d epends on the cabinet

configuration. Note that you should connect the brown wire to L (live wire), the blue

wire to N (neutral wire), and yellow-green wire to PE (earth wire).

3) After finishing the connection of the cables, bind these cables in order with cable

strap, wire them along the right side of the cabinet down, and connect them to the

input ports of the system power supply and PoE power supply. You should make

sure the cables are not loose.

IV. Installing the power distribution box

You should install the power distrib ution box on the top of the back of the N68 cabinet.

You can adjust the location of the box in a little range.

Figure 2-7 describes the cable connections on the cabinet power distribution box.

2-11

Page 34

Installation Manual

H3C S9500 Series Routing Switches Chapter 2 Preparing for Installation

(1) User-supplied

power distribution box

(5) PoE power entry

module

(9) External PoE

power supply

(19) Terminal block

(2) Guide rail

(6) S9505

chassis

(10) PoE AC

socket

Figure 2-7 Cable connections on the power distribution box

2.4.2 Installing DC Power Distribution Box

I. Terminal Block

1) Terminal block structure diagram

(3) Power distribution

box of the cabinet

(7) System power input

(11)~(17) No.1 to No.7

power cable

(4) S9505 chassis

(8) Interface area on

external PoE power

supply panel

(18) N68 cabinet

2-12

Page 35

Installation Manual

H3C S9500 Series Routing Switches Chapter 2 Preparing for Installation

BGND

BGND

BGND

BGND

BGND

BGND

PGND

PGND

PGND

(1) Air switch 1 (2) Air switch 2 (3) Guide rails

(4) PGND wiring terminal block (5) BGND wiring terminal block (6) Isolator

(7) Input terminal block

Figure 2-8 Terminal block structure

As illustrated in

Figure 2-8, the two leftmost input terminal blocks are DC input terminal

blocks. Next to them are two air switches, each of which has a through-current capacity

of 63A. On the rightmost side are 9 terminal blocks, 6 of which are BGND terminal

blocks and the rest are PGND terminal blocks.

2) Diagram for connecting terminal blocks

(1) Connected to user-supplied DC power

(3) Connected to the positive terminal of –48

V DC power

(2) Connected to the negative terminal of –48

V DC power

(4) Grounded and connected to the cabinet

Figure 2-9 Diagram for connecting DC input terminal blocks

3) Electrical performance of the terminal blocks

2-13

Page 36

Installation Manual

H3C S9500 Series Routing Switches Chapter 2 Preparing for Installation

Table 2-8 Electrical performance of the terminal block

Item Specification

Rated current 63 A

Input

Rated voltage 600 V

Rated cross-sectional area 16 mm2

2

Maximum current/maximum crimping area 63A/16 mm

4) Terminal block components

Table 2-9 illustrates terminal block components.

Table 2-9 Terminal block components

NO Name Quantity

1 End bracket 2

2 Cross connector 3

3 Marker 6

4 Terminal 11

5 Clapboard 7

6 Rail 1

7 Circuit breaker 6

II. Installing DC Power Distribution Box

To install power distribution box, take the following steps:

1) Install the DC input terminal blocks and air switches to the cabinet via the rail, as

illustrated in

Figure 2-10.

Figure 2-10 Install the DC input terminal blocks and air switches

2-14

Page 37

Installation Manual

H3C S9500 Series Routing Switches Chapter 2 Preparing for Installation

2) Connect the DC input terminal blocks and the air switches with 6 mm2 cables and

2

fix the cable properly. Also use a 6 mm

cable for grounding, as illustrated in

Figure 2-11.

Figure 2-11 Backplane diagram for connecting DC input terminal blocks and air

switches

3) Fix the DC power distribution box onto the back of the cabinet.

Figure 2-12 Diagram for fixing the power distribution box to the rear of the N68 cabinet

4) You can make the air switches to supply power to DC power modules by

connecting the lower terminals of the air switches to DC power input terminal s and

supply voltages to DC power. (Refer to

diameters of the cables need to be 6 mm

Figure 2-9 for detail. Note that the

2

or 10 mm2.)

5) You can use the BGND and PGND terminal blocks as needed. The rightmost

2

PGND terminals must be connected to the cabinet using 6 mm

illustrated in

Figure 2-12.

cables, as

6) Fasten the connected power cables with a wire and secure them onto the power

distribution box.

2

7) Use two 16 mm

cables to connect the cabinet and the DC power distribution box.

You need to connect the two cables to the leftmost terminal blocks of the cabinet,

as illustrated in

Figure 2-9.

2-15

Page 38

Installation Manual

H3C S9500 Series Routing Switches Chapter 2 Preparing for Installation

2.5 Installation Tools

Table 2-10 Required installation tools

Measure

and

lineation

tools

Long tape, ruler (1 meter in length), gradienter, marking

pen, powder marker, pencil

General

tools

Drills

Fastening

tools

Small tools

Auxiliary

tools

Special tools

Meters

One percussion drill, several drill bits, one vacuum

cleaner

Plain screwdriver P4 - 75 mm

Cross-head screwdriver P1 – 100 mm, P2 – 150 mm

and P3 – 250 mm

Box wrench M5

Ring spanner M6

Double ring spanner (10-12) or open ended spanner

(10-12)

Sharp-nose pliers, diagonal pliers, vices, hand-held

electric drill, file, handsaw, crowbar, rubber hammer

Brush, tweezers, paper knife, hand bellows, electric

iron, solder wire, fork, ladder

ESD-preventive wrist strap, cable stripper, crimping

pliers, RJ-45 crimping pliers, wire punch-down tool

Multimeter, 500 V Meg-ohmmeter (used for measuring

the insulation resistance), error detector, optical power

meter, earth resistance tester

Note:

The instruments and tools are not shipped with the S9500 serie s. Therefore, you need

to prepare the required instruments and tools.

2-16

Page 39

Installation Manual

H3C S9500 Series Routing Switches Table of Contents

Table of Contents

Chapter 3 Installing the Switch .......................................................................... 3-1

3.1 Installa tion Flow....................................................................................... 3-1

3.2 Confirming Installatio n Preparation ........................................................... 3-1

3.3 Mountin g the Swi tch in a Rac k.................................................................. 3-2

3.3.1 Prepar ations ................................................................................... 3-2

3.3.2 Installing the Cable Management Bracket and Rack-Mounting Ears .. 3-2

3.3.3 Mountin g the Switch ........................................................................ 3-3

3.3.4 Verify ing the Inst allation.................................................................. 3-3

3.4 Install ing the Switc h on a Workbench........................................................ 3- 4

3.4.1 Prepar ations ................................................................................... 3-4

3.4.2 Procedur e ....................................................................................... 3-4

3.5 Connecting the PGND Wire ...................................................................... 3-4

3.5.1 In a com mon grounding environment ............................................... 3-5

3.5.2 In ot her Groun ding Envir onments .................................................... 3-5

3.6 Installin g a PSU ....................................................................................... 3-9

3.6.1 Installation P reparation ................................................................... 3-9

3.6.2 Installation P rocedure ..................................................................... 3-9

3.6.3 Conne cting Power Cable(s) ............................................................ 3-11

3.7 Installin g a Board....................................................................................3-15

3.7.1 Installa tion Prepar ations ................................................................3-15

3.7.2 Installation P rocedure .................................................................... 3-16

3.8 Installin g PoE Power Supply .................................................................... 3-16

3.8.1 Installation P rocedure .................................................................... 3-17

3.8.2 Instal ling the PoE P ower Entry Mod ule ........................................... 3-17

3.8.3 Connec ting PoE Power Cables ....................................................... 3-18

3.9 Connecting Inter face Cables.................................................................... 3-20

3.9.1 Cable Routing R ecommenda tions ................................................... 3-20

3.9.2 Connectin g Console Cable ............................................................. 3-21

3.9.3 Connec ting the AUX Cable............................................................. 3-23

3.9.4 Conne cting Netw ork Cables ...........................................................3-23

3.9.5 Conne cting Fiber ...........................................................................3-23

3.10 Verifyi ng the Insta llation........................................................................3-27

i

Page 40

Installation Manual

H3C S9500 Series Routing Switches Chapter 3 Installing the Switch

Chapter 3 Installing the Switch

The S9500 series are designed for indoor applications.

Warning:

Do not touch any exposed wires, terminals or any parts labelled with a

high-voltage hazard warning to avoid bodily injury.

3.1 Installation Flow

Mount the switch in a rack

Start

Confirm installation preparation

Confirm installation position

Connect the PGND wire

Install a PSU

Install boards

Install PoE power supply

(optional)

Connect interface cables

Verify the installation

Finish

Install the switch on a workbench

Figure 3-1 Installation flow

3.2 Confirming Installation Preparation

z Make sure that you have read Chapter 2 Preparing for the Installation

carefully.

3-1

Page 41

Installation Manual

H3C S9500 Series Routing Switches Chapter 3 Installing the Switch

z All requirements mentioned in Chapter 2 Preparing for the Installation

have been met.

3.3 Mounting the Switch in a Rack

3.3.1 Preparations

Before installation, make sure that:

z The cabinet is grounded and stable. The layout inside the cabinet for

switch installation has been well done and there is no obstacle inside

or around the cabinet.

z The switch is ready for installation and has been carried to a place

near the cabinet.

3.3.2 Installing the Cable Management Bracket and Rack-Mounting Ears

For your convenience, a cable management bracket is shipped with the

S9500 series. Take the following steps to install the cable management

bracket.

1) Facing the LPU slots of the switch, insert the shipped cable

management bracket into the left rack-mounting ear on which there is

a recessed hole for installing the cable managem ent b racket, a nd fix it

with screws. (One cable management bracket for the

S9505/S9508/S9508V and two for the S9512).

2) Install the rack-mounting ears onto the both sides of the switch, as

shown in

Figure 3-2.

Figure 3-2 Install the cable management bracket and rack-mounting ears

3-2

Page 42

Installation Manual

H3C S9500 Series Routing Switches Chapter 3 Installing the Switch

3.3.3 Mounting the Switch

Note:

Make sure that supports have been installed in corresponding positions

and the supports can bear the switch weight.

1) Two people are required to lift the switch. Put the switch on the

supports and slide it into the cabinet until the rack-mounting ears

touch against the front square-holed columns.

2) Fix the rack mounting ears onto the square-holed columns with

screws.

Figure 3-3 Install the switch into a standard 19-inch rack

3.3.4 Verifying the Installation

After installing the switch into t he rack, check the items li st ed in Table 3-1.

Table 3-1 Checklist for switch installation

Item

The cable management bracket is well fixed

on the left rack-mounting ear.

Result

Remarks

Yes No

3-3

Page 43

Installation Manual

H3C S9500 Series Routing Switches Chapter 3 Installing the Switch

Item

Result

Remarks

Yes No

The rack-mounting ears are well fixed on the

switch.

The installation position is right.

The rack-mounting ears are well fixed on the

rack

3.4 Installing the Switch on a Workbench

When no 19-inch cabinet is available, you can place the switch on a clean

and stable workbench.

3.4.1 Preparations

z Make sure that the workbench is sturdy enough to bear the weight of

the switch and cables.

z Make sure that the workbench is flat and well grounded.

3.4.2 Procedure

Lift the switch onto the workbench with another person.

Caution:

Reserve at least 15.2 cm (6.0 in.) of clearance around the switch for heat

dissipation.

3.5 Connecting the PGND Wire

Caution:

For the safety of operators and equipment, the switch must be well

grounded. The resistance reading between switch chassis and the ground

must be less than 1 ohm.

3-4

Page 44

Installation Manual

H3C S9500 Series Routing Switches Chapter 3 Installing the Switch

3.5.1 In a common grounding environment

Follow these steps to connect the PGND wire in a common grounding

environment:

1) Remove the screw from the grounding hole in the switch chassis.

2) Wear the connector of the PGND wire accompanied with the switch on

the grounding screw.

3) Insert the grounding screw into the grounding hole and screw it down.

4) Connect the other end of the PGND wire to the groun d bar of the switch,

as shown in

Figure 3-4.

Figure 3-4 Connect the PGND wire

Note:

Generally, the cabinets installed in equipment rooms are equipped with

ground bar. In this case, you can connect the PGND wire of the switch to

the ground bar for it.

3.5.2 In other Grounding Environments

The following are some methods for grounding the switch in different

grounding environments.

3-5

Page 45

Installation Manual

H3C S9500 Series Routing Switches Chapter 3 Installing the Switch

Note:

Rather than specifying the switch model or sh owing the actual loca tion of

the switch power input or grounding screw, the following figures are

primarily intended for illustrating the switch grounding, either via

grounding screw or power input, in spec ific grounding environments.

z If a ground bar is available, attach one end of the yellow -green PGND

wire of the switch to a grounding bolt of the ground bar and fasten the

captive screws.

Caution:

Note that neither the fire hydrant nor lightning rod of a building is suitable

for grounding the switch. The PGND wire of the switch should be

connected to the grounding device in the equipment room. (For the S9500

series, the grounding screw is on the rear panel. Connect it as illustrated in

Figure 3-5).

(1)

(1)

(1) Rear panel of the switch (2) Grounding screw

(3) PGND wire (4) Ground bar of the equipment room

(2)

(2)

(3)

(3)

(4)

(4)

Figure 3-5 Ground the switch when a ground bar is available

3-6

Page 46

Installation Manual

H3C S9500 Series Routing Switches Chapter 3 Installing the Switch

z If there is no ground bar but earth nearby and the grounding body is

allowed to be buried, you can simply hammer an angle iron or steel

pipe no shorter than 0.5 m into the earth.

Caution:

The yellow-green PGND wire should be welded with the angle iron (steel

pipe) and the joint should be processed against eroding. (For the S9500

series, the grounding screw is on the rear panel. Connect it as illustrated in

Figure 3-5).

(1)

(1)

(2)

(2)

(3)

(3)

(4)

(4)

(5)

(5)

(1) Rear panel of the switch (2) Grounding screw

(3) PGND wire (4) Ground

(5) Angle steel (steel pipe)

Figure 3-6 Ground the switch when allowed to bury grounding body

nearby

z If both ground bar and the conditions for burying the grounding body

are not available, an AC-powered Ethernet switch can be grounded

using the PE wire of the AC power supply.

3-7

Page 47

Installation Manual

H3C S9500 Series Routing Switches Chapter 3 Installing the Switch

Caution:

Make sure that the PE wire of the AC power supply has been well grounded

at the side of the power distribution room or AC power supply transformer.

(1)

(1)

(2)

(2)

(4)

(4)

(4)

(3)

(3)

(3)

(5)

(5)

(5)

(1) Front panel of the switch (2) AC power input

(3) 3-core AC power cord (4) Transformer

(5) Protection earth (PE) wire

Figure 3-7 Ground the switch through the AC PE wire

z If no ground bar or condition for burying the grounding body is

available, a DC-powered Ethernet switch can be g rounded throu gh the

PGND strip of the power distribution frame (PDF).

Caution:

Make sure the RTN wire is well connected to the ground at the DC output

of the PDF.

3-8

Page 48

Installation Manual

H3C S9500 Series Routing Switches Chapter 3 Installing the Switch

(1)

(1)

(2)

(2)

(5)

(9)

(9)

(5)

(6)

(6)

(7)

(7)

(8)

(8)

(1) Front panel of the

switch

(4) RTN terminal (5) PDF (6) -48V strip

(7) RTN strip (8) PGND strip (9) Earth ground

(10) PGND wire (11) Grounding screw (12) Rear panel of the

(3)

(3)

(4)

(4)

(10)

(10)

(2) DC power input (3) NEG terminal

switch

(12)

(12)

(11)

(11)

Figure 3-8 Ground the switch through the PGND strip of the PDF

3.6 Installing a PSU

3.6.1 Installation Preparation

z Wear an ESD-preventive wrist strap and verify the ESD-preventive

wrist strap is properly grounded.

z If there is a filler panel in the position where you will install a PSU,

remove the filler panel.

Caution:

When you move a PSU, hold its bottom with one hand. Do not move it by

just holding its handle. Otherwise, the PSU may be damaged.

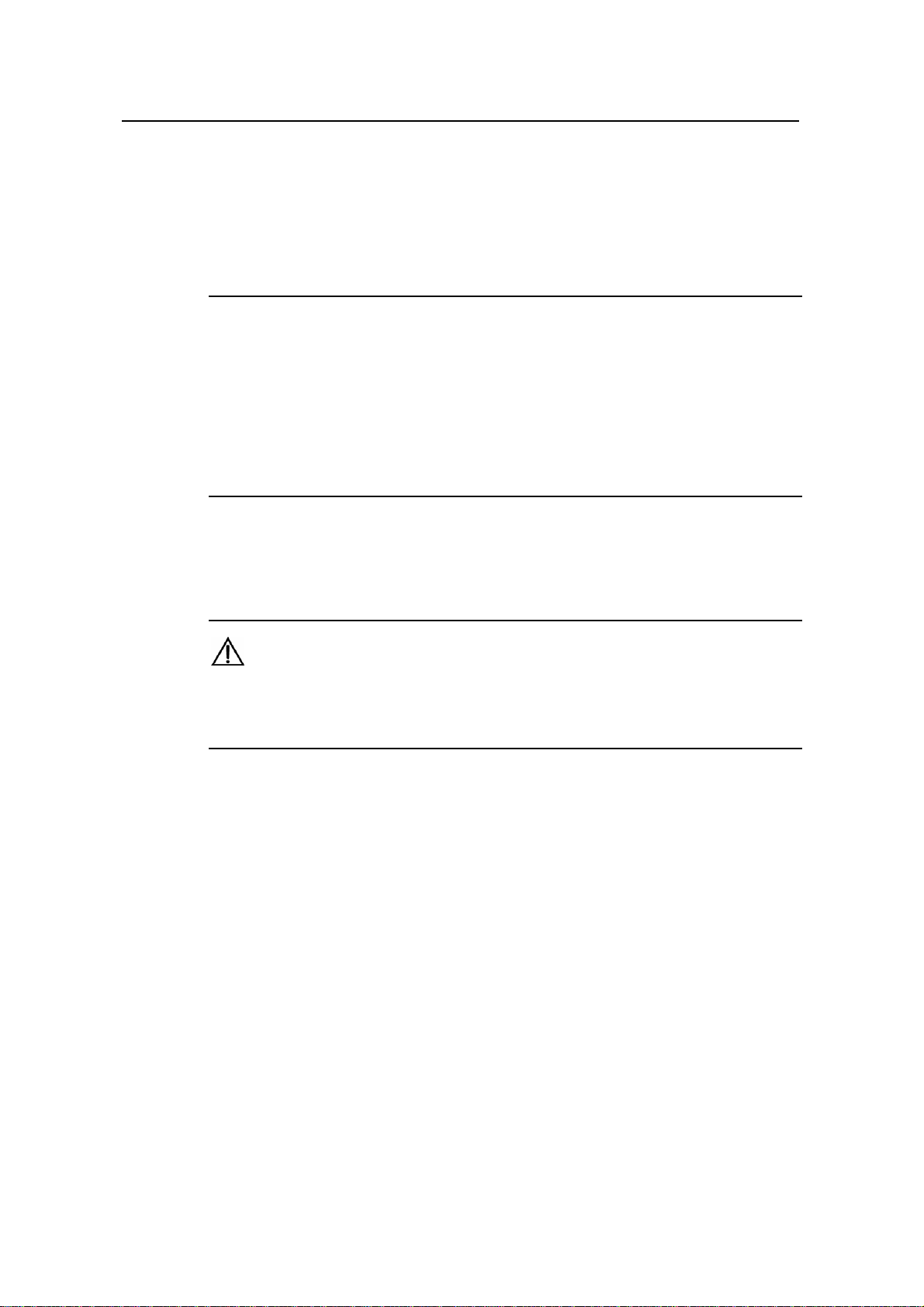

3.6.2 Installation Procedure

I. Removing a PSU other than NEPS3500-A

The following procedure applies to all NEPS PSUs except NEPS3500-A.

3-9

Page 49

Installation Manual

H3C S9500 Series Routing Switches Chapter 3 Installing the Switch

1) Clutch the air filter cov er by th e uppe r and lower ed ges with yo ur index

finger and the thumb, and gently remove the air filter cover from a

PSU.

Note:

You can pull out the PSU handle only after removing the air filter cover.

2) Slide the PSU smoothly along the guide rails, until it snaps into the

backplane.

Figure 3-9 Install an AC PSU

3) Fasten the captive screws on both sides of the PSU with a Philips

screwdriver and install the removed air filter cover onto the PSU.

4) Check that the power switch on the PSU is in the OFF position.

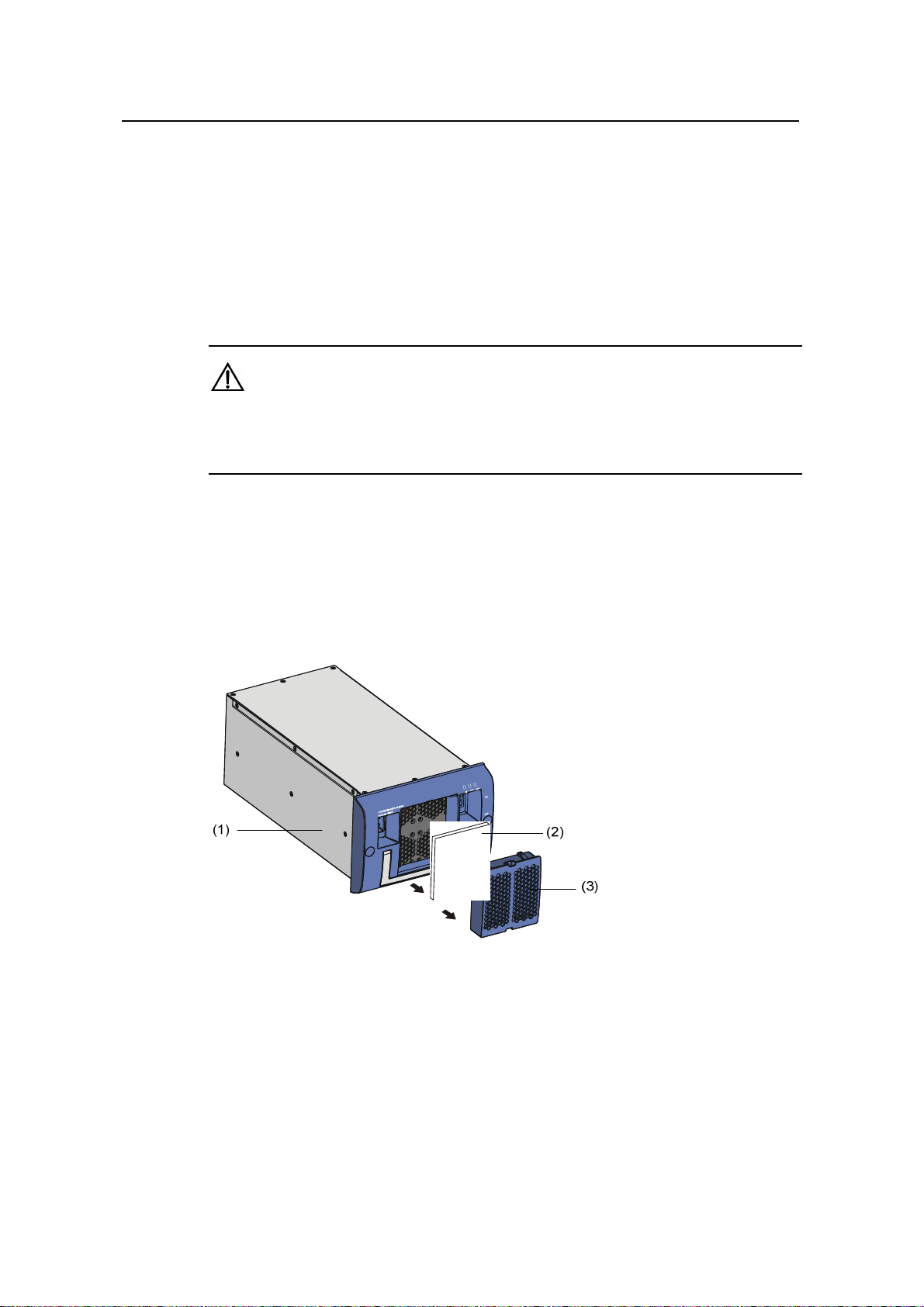

II. Installing NEPS3500-A

NEPS3500-A contains two sub-PSU slots. You can configure one or two

1800 W sub-PSUs. Follow these steps to install NEPS3500-A:

1) Install a NEPS3500-A enclosure into the switch.

2) Install one to two 18 00 W sub-PSUs into the N EPS3500-A enclosure.

3-10

Page 50

Installation Manual

H3C S9500 Series Routing Switches Chapter 3 Installing the Switch

Table 3-2 Procedure of installing NEPS3500-A

Step Sub-step

1) Hold the handle on the enclosure with one hand and

Install the

NEPS3500-A

enclosure

into the

switch

the bottom with the other hand, and gently slide the

enclosure along the guide rails into the switch.

2) Fasten the captive screws on both sides of the

enclosure with a Philips screwdriver.

3) Check that the power switc h on the enc losur e is in the

OFF position.

1) Pull down the handle on the sub-PSU (refer to the

Install 1800

W

sub-PSU(s)

to the

NEPS3500-A

enclosure

leftmost graph in

2) Slide the sub-PSU smoothly along the guide rails, until

it snaps into the backplane.

3) Push the h andle upward so that the sub-PSU moves

further inside about 1 cm (0.39 in) until the handle

locks the sub-PSU in place, as shown in the rightmost

graph in

Figure 3-10.

Figure 3-10).

Figure 3-10 Install a 1800 W sub-PSU

3.6.3 Connecting Power Cable(s)

I. Connecting the AC power cord

Caution:

z For lightning protection, the AC power supply should be led through an

external lightning device into the switch.

z Make sure the power switch on the PSU is in the OFF position before

connecting the AC power cord.

Take the following steps to connect the AC power cord to NEPS1200-A, or

NEPS2000-A:

1) Turn the clamp at the left of the PSU front panel rightwards.

2) Insert the plug at one end of the AC power cord into the socket of the

PSU.

3) Turn the clamp leftwards until it grips the plug.

3-11

Page 51

Installation Manual

H3C S9500 Series Routing Switches Chapter 3 Installing the Switch

4) Insert the other end of the power cord into an external power socket.

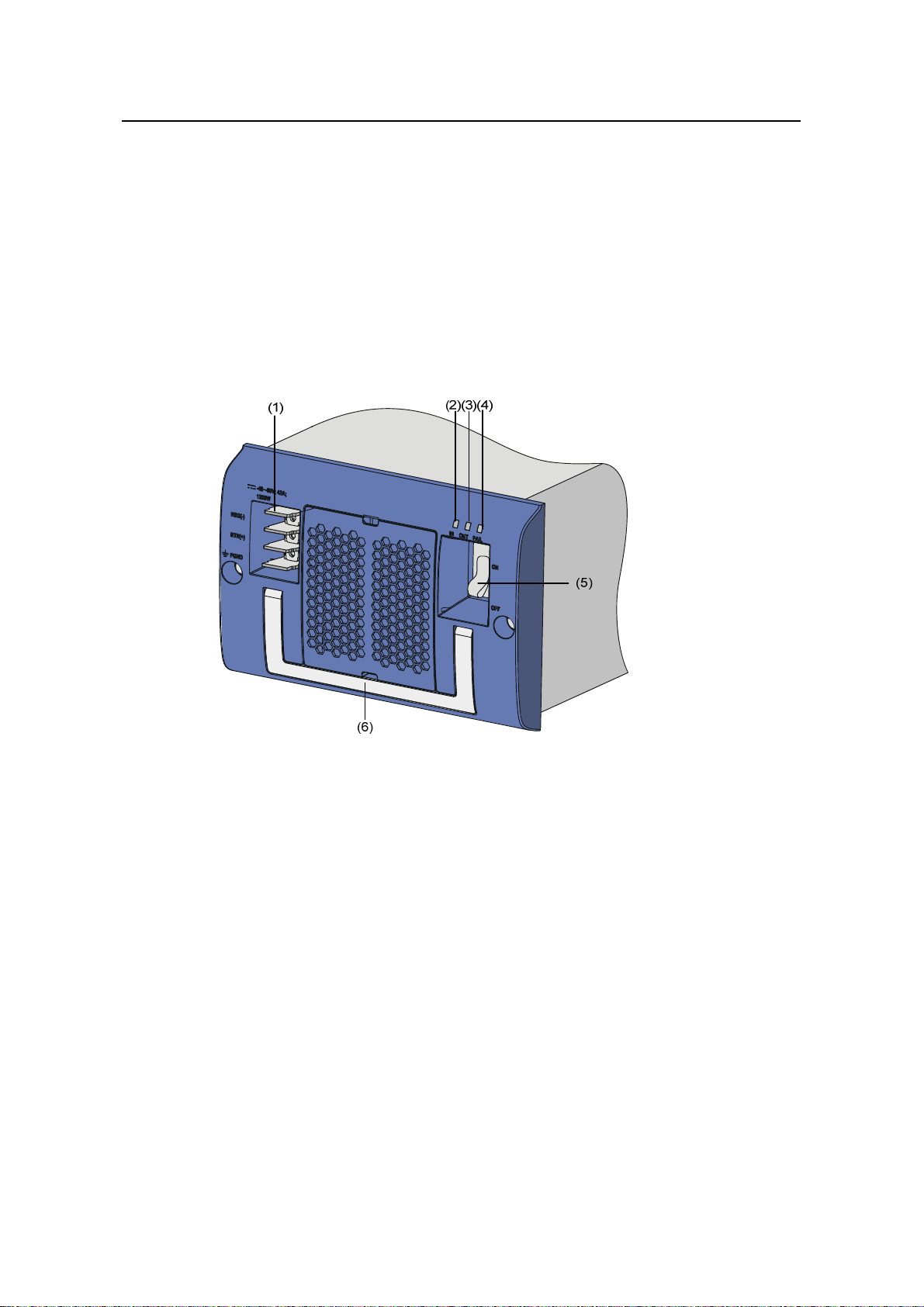

(1) Connector-retention clamp (2) Input LED

(3) Output LED (4) Fail LED

(5) Power switch (6) PSU handle

(7) AC power cord

Figure 3-11 NEPS1200-A appearance

(1) Connector-retention clamp (2) Input LED

(3) Output LED (4) Fail LED

(5) Power switch (6) PSU handle

(7) AC power cord

Figure 3-12 NEPS2000-A appearance

Take the following steps to connect the AC power cord to NEPS3500-A:

1) Insert the plug at one end of the AC power cord into the socket on the

PSU.

3-12

Page 52

Installation Manual

H3C S9500 Series Routing Switches Chapter 3 Installing the Switch

2) Install the clamp to the socket of the PSU until it grips the plug.

3) Insert the other end of the power cord into an external power socket.

(1) (1)

(2)

(3)

(6)

(4)

(5)

(1) Power switch (2) Input LED

(3) Output LED (4) Fail LED

(5) PSU handle (6) AC power cord

Figure 3-13 NEPS3500-A appearance

II. Connecting DC Power Cables

The DC power cables are connected to the terminal block, and are fixed

with screws. A plastic cover plate is installed in front of the terminal block

for the sake of connection reliability.

Caution:

z Completely power off the switch before connecting th e DC power cord.

z Before removing or installing the DC power cables , you need to remo ve

the plastic cover plate. Install it after installing/removing the DC power

cables.

Take the following steps to connect the DC power cables:

1) Remove the plastic cover plate and loosen the fixing screws on the

terminal block of the DC PSU with a Philips screwdriver.

2) Connect one end of the cable with –48V OT terminals (blue) to the

NEG(–) terminal on the PSU and fasten the correspo nding fixing screw.

3-13

Page 53

Installation Manual

H3C S9500 Series Routing Switches Chapter 3 Installing the Switch

Connect the other end to the NEG (–) terminal of the source power

supply.

3) Connect one end of the cable with GND OT terminals (black) to the

RTN (+) terminal on the PSU and fasten the corresponding fixing

screw. Connect the other end to the RTN (+) terminal of the power

source.

4) Connect one end of the cable with PGND OT terminals (yellow-green)

to the PGND terminal on the PSU and fasten the corresponding fixing

screw. Connect the other end to the ground bar of the switch.

5) Install the plastic cover plate.

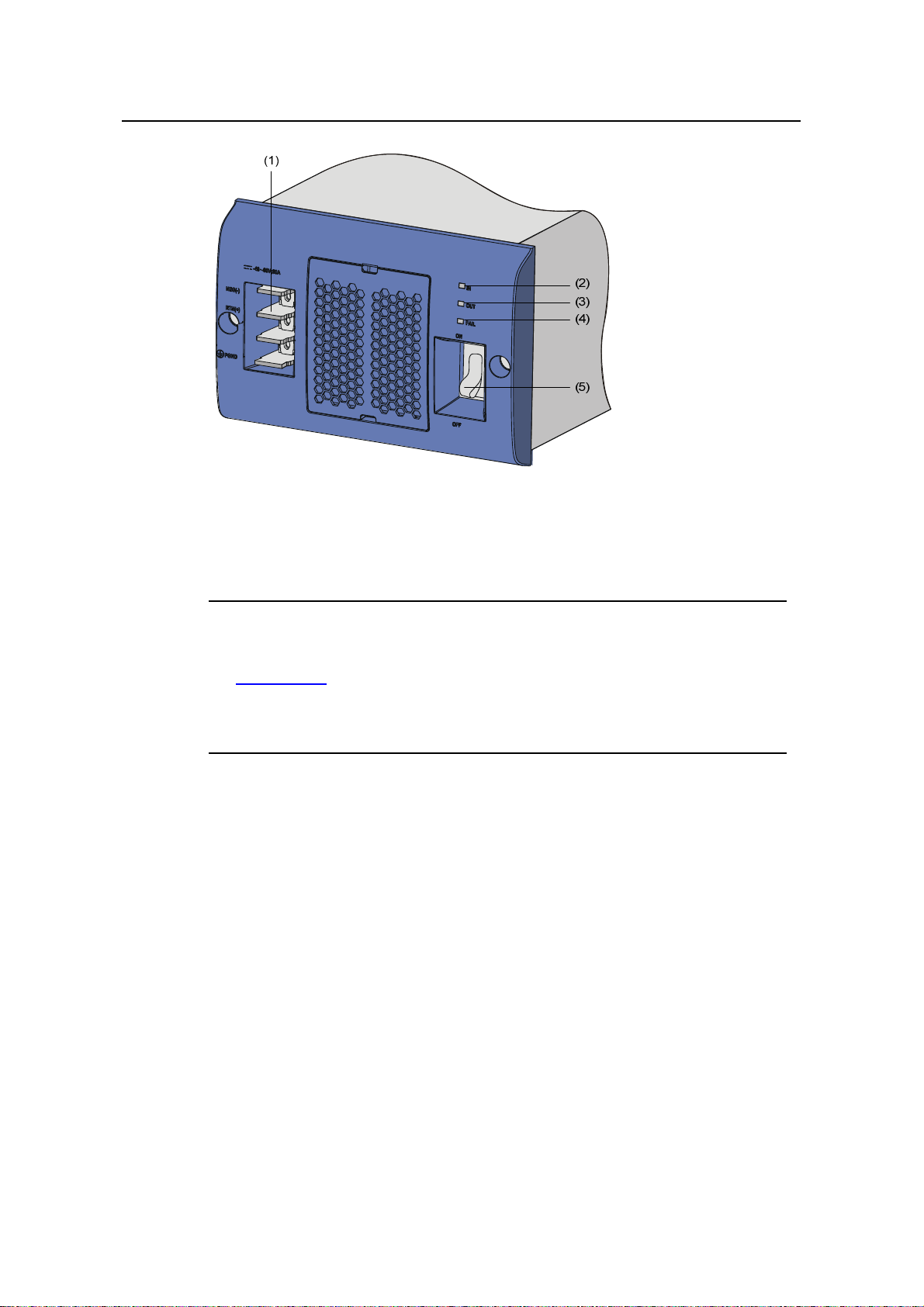

(1) Terminal block (2) Input LED (3) Output LED

(4) Fail LED (5) Power switch (6) PSU handle

Figure 3-14 NEPS1200-D appearance

3-14

Page 54

Installation Manual

H3C S9500 Series Routing Switches Chapter 3 Installing the Switch

(1) Terminal block (2) Input LED (3) Output LED

(4) Fail LED (5) Power switch

Figure 3-15 NEPS2000-D appearance

Note:

z NEPS3500-D is similar to NEPS2000-D in appearance, as shown in

Figure 3-15.

z The DC PSUs shown in the above figures are not equipped with plastic

cover plates.

3.7 Installing a Board

The installation procedures of SRPUs, LPUs, and service boards are

almost the same. The following section describes the installation

procedure of LPUs.

3.7.1 Installation Preparations

z Wear the ESD-preventive wrist strap, making sure that it is properly

grounded.

z Loosen the mounting screws on the blank filler panel where the SRPU

is to be installed using a Phillips screwdriver and remove the blank

filler panel.

z Prepare the LPU to be installed.

3-15

Page 55

Installation Manual

H3C S9500 Series Routing Switches Chapter 3 Installing the Switch

Note:

z Put the removed blank filler panel away for future use.

z The LPUs of the S9500 series are hot-swappable.

3.7.2 Installation Procedure

Follow the procedure below to install an LPU:

1) Turn the ejector levers on the LPU outward simultaneously with both

hands, insert the LPU straight into the chassis along the guide rails

until it stops sliding (that is, the positioning pins on the ejector levers

touch the positioning holes on the chassis).

2) Turn the ejector levers towards the front panel to drive the positioning

pins into the positioning holes.

Figure 3-16 Install an LPU

3) Fix the LPU by fastening the mounting screws on the LPU with a

Phillips screwdriver.

3.8 Installing PoE Power Supply

The S9505/S9508/S9512 uses PSE4500-A as an external PoE power

supply, which is connected to the switch through the PoE power entry

module at the front bottom of the switch to provide power for connected

powered devices (PDs ).

The following introduces the installation of PoE power supply on the

S9505.

3-16

Page 56

Installation Manual

H3C S9500 Series Routing Switches Chapter 3 Installing the Switch

3.8.1 Installation Procedure

z Wear the ESD-preventive wrist strap, making sure that it is properly

grounded.

z Remove blank filler panels in the power supply area if applicable.

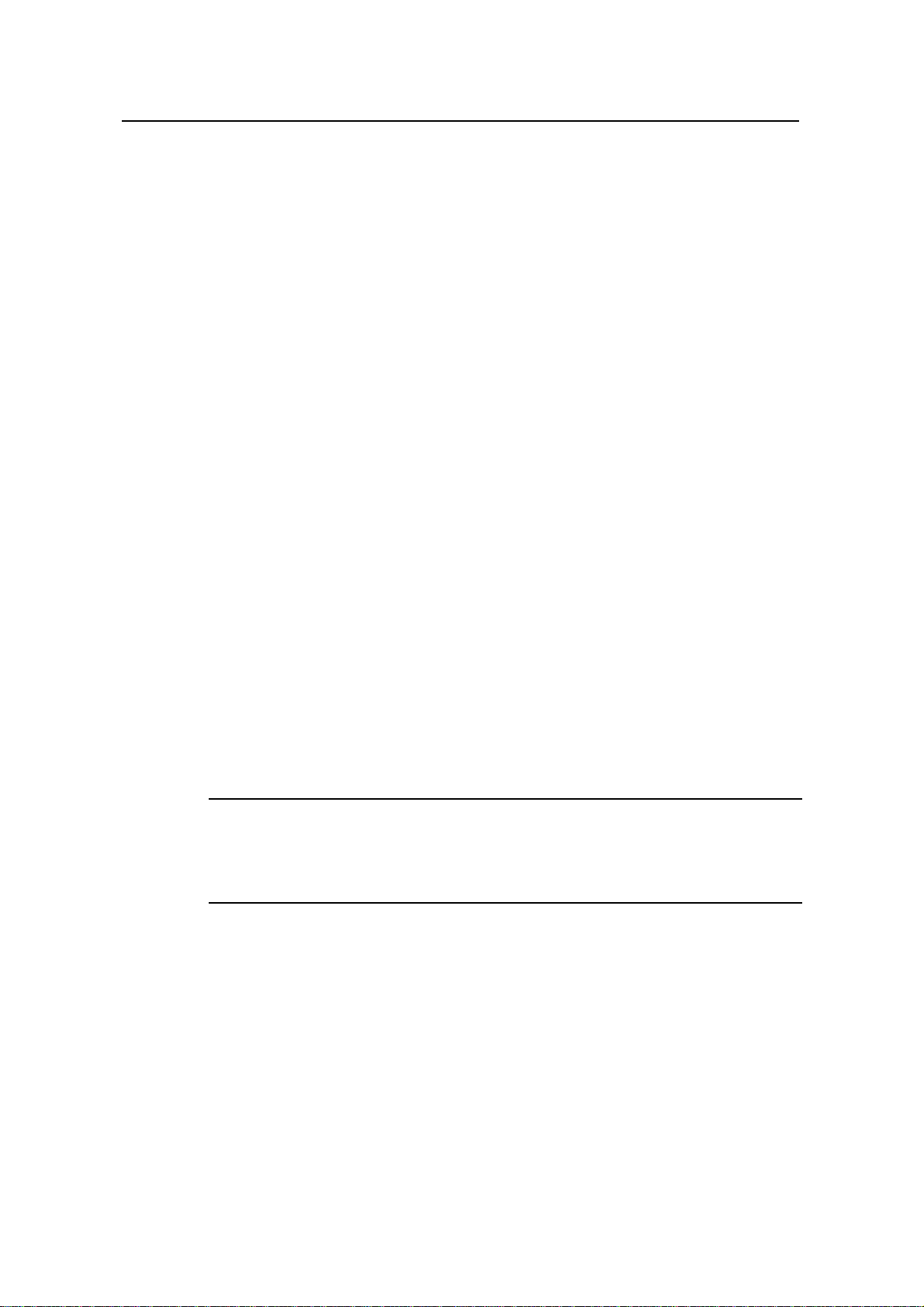

3.8.2 Installing the PoE Pow er Entry Module

The PoE power entry module is hot-swa ppable.

Follow the steps below to install the PoE power entry module:

1) Unpack the PoE power entry module, which is shown in

Figure 3-17.

Figure 3-17 PoE power entry module

2) Keep the PoE power entry module in the correct letter direction. (Do

not turn it upside down. Otherwise, you will not be able to fully insert it

into the chassis due to mis-plug prevention design of the module, nor

can you fasten the chassis fixing screw.) Hold the bottom with one

hand and the front panel with the other, and then slide it smoothly

along the guide rails into the slot, until it snaps into the chassis. Make

sure the plug of the PoE power entry mod ule is fully conne cted with the

socket inside the chassis. See

Figure 3-18.

3-17

Page 57

Installation Manual

H3C S9500 Series Routing Switches Chapter 3 Installing the Switch

Figure 3-18 Install the PoE power entry module

3) Fasten the screws on the top of the PoE entry module with a Philips

screwdriver.

3.8.3 Connecting PoE Power Cables

Note:

This section only focuses on the cable connection between the external

PoE power supply and the S9500 series switch. For the installation of the

external PoE power supply, see the manual accompanying the power

supply.

I. Grounding the PoE chassis

Follow these steps to ground the PoE chass is:

1) Connect the wiring terminal (with one M6 hole) of the 6 AWG cable to

the grounding screw on the rear panel of the switch, as shown in

Figure 3-19.

2) Connect the other end of the cable to the grounding bar or other

grounding terminals.

3-18

Page 58

Installation Manual

H3C S9500 Series Routing Switches Chapter 3 Installing the Switch

(1)(1)

(1) Chassis grounding screw

Figure 3-19 Ground the PoE chassis

II. Connecting PoE power cables

1) Loosen the mounting screws on the PoE power entry module with a

Phillips screwdriver.