Page 1

H3C S9500 Series Routing Switches

Installation Manual

Hangzhou H3C Technologies Co., Ltd.

http://www.h3c.com

Manual Version: T2-08045T-20070425-C-1.01

Product Version: Release 1278(S9500-CMW310-R1278)

Page 2

Copyright © 2006-2007, Hangzhou H3C Technologies Co., Ltd. Ltd. and its licensors

All Rights Reserved

No part of this manual may be reproduced or transmitted in any form or by any means

without prior written consent of Hangzhou H3C Technologies Co., Ltd.

Trademarks

H3C, , Aolynk, , H3Care,

Neocean, NeoVTL, SecPro, SecPoint, SecEngine, SecPath, Comware, Secware,

Storware, NQA, VVG, V

HUASAN are trademarks of Hangzhou H3C Technologies Co., Ltd.

All other trademarks that may be mentioned in this manual are the property of their

respective owners.

Notice

The information in this document is subject to change without notice. Every effort has

been made in the preparation of this document to ensure accuracy of the content s, but

all statements, information, and recommendations in this document do not constitute

the warranty of any kind, express or implied.

To obtain the latest information, please access:

http://www. h3c.com

Technical Support

customer_service@h3c.com

http://www. h3c.com

, TOP G, , IRF, NetPilot,

2

G, VnG, PSPT, XGbus, N-Bus, TiGem, InnoVision and

Page 3

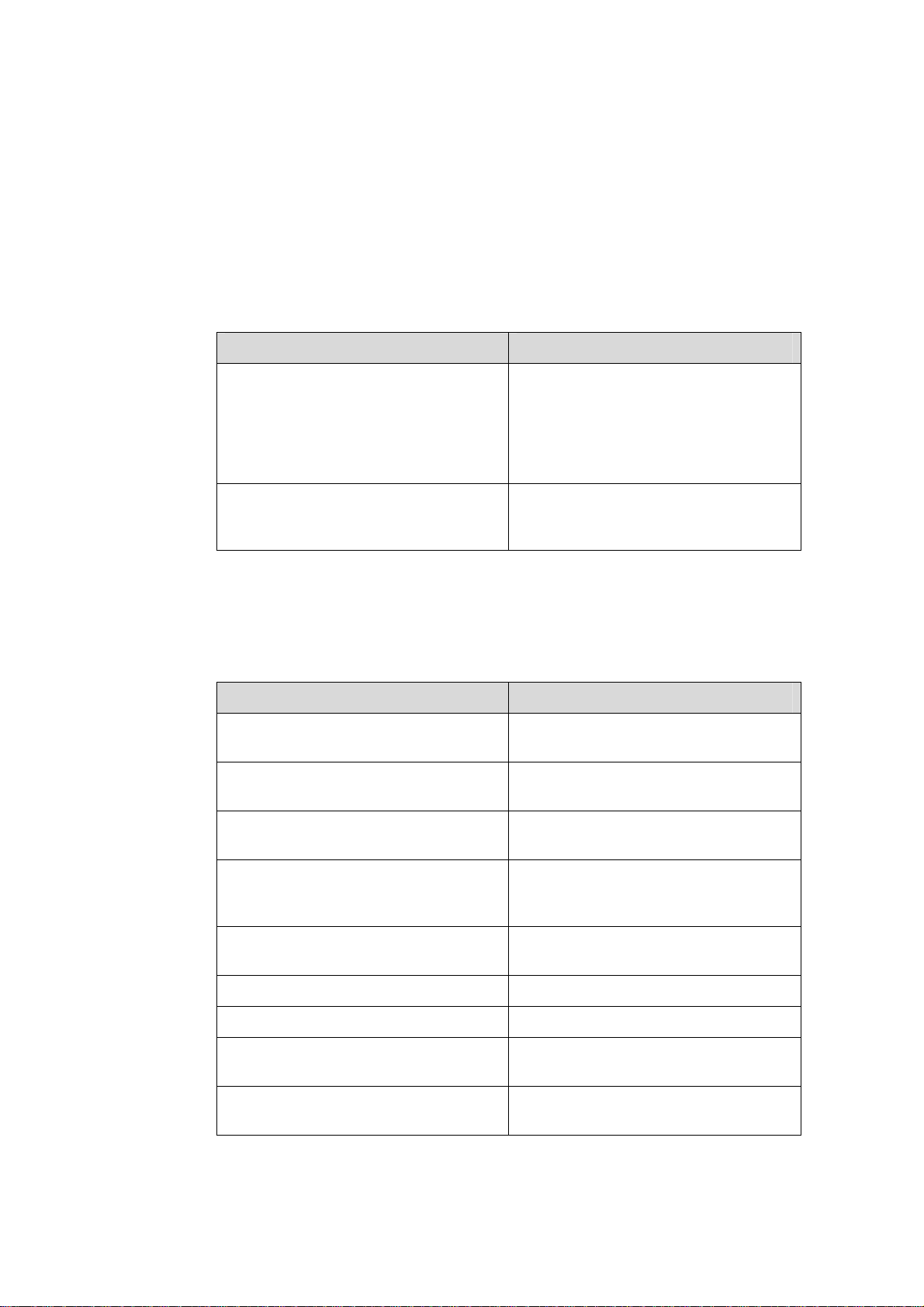

About This Manual

Related Documentation

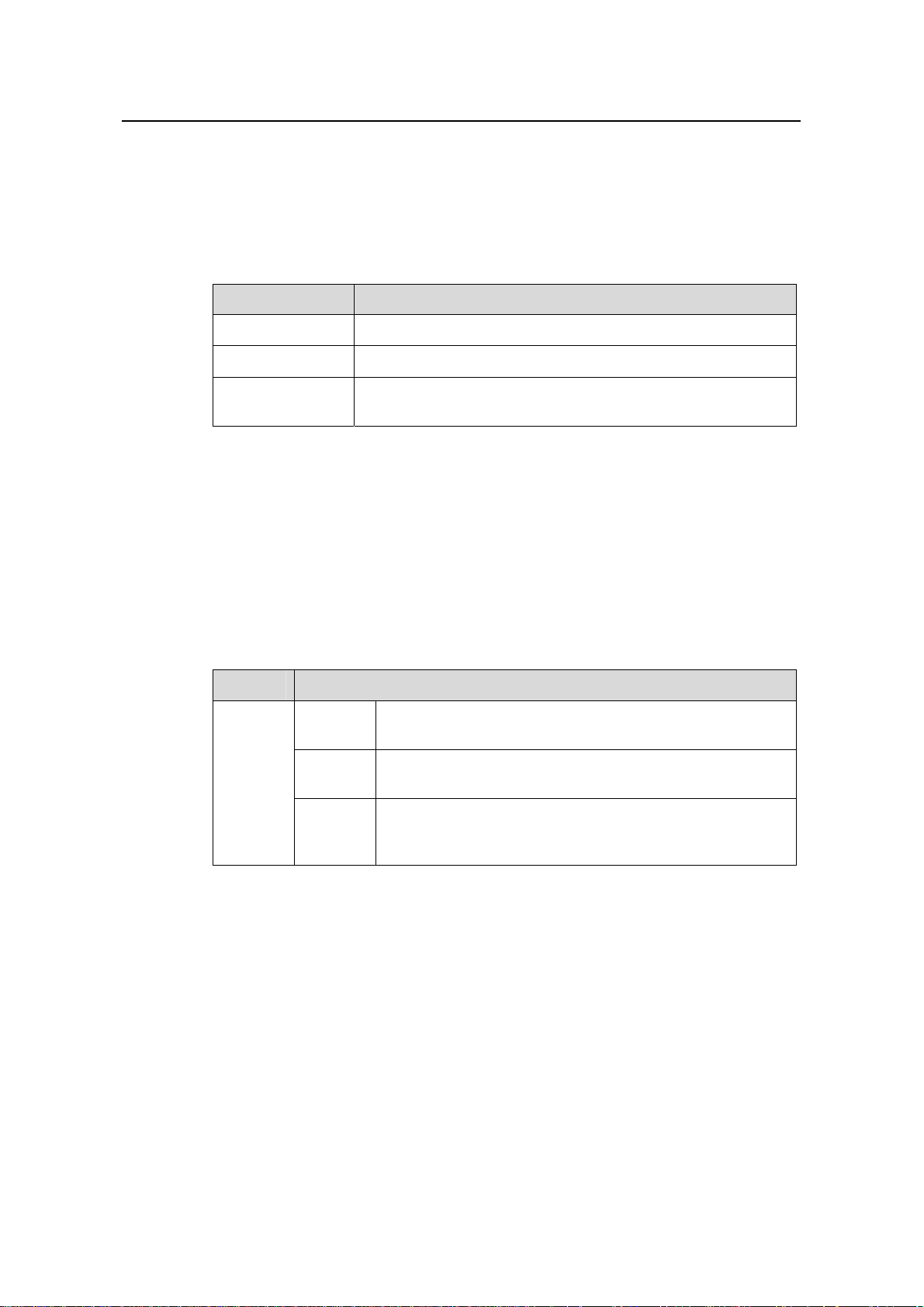

The related manuals are listed in the following table.

Manual Description

H3C S9500 Series Routing Switches

Operation Manual

It includes getting started, port, VLAN,

network protocols, routing protocols,

multicast protocols, QoS/ACL, MPLS,

STP, security, reliability, system

management, PoE, NAT-URPF-VPLS,

integrated management and appendix.

Organization

H3C S9500 Series Routing Switches Installation Manual is organized as follows:

H3C S9500 Series Routing Switches

Command Manual

Chapter Contents

1 Product Overview profiles the architecture and

2 LPU Modules focuses on the LPU boards of the S950 0

3 Installation Preparations lists the preparations and precautions

4 Switch Installation details the installation of the chassis,

5 System Debugging concentrates on the initial poweron and

It introduces all commands available in

the S9500 series, as well as a command

index.

specifications of the S9500 series.

series.

before installation.

boards and cable connection for the

S9500 series.

booting of the S9500 series.

6 Switch Monitoring and Maintenance presents the use of engineering labels.

7 Appendix A introduces the use of engineering labels.

8 Appendix B introduces the installation of the B68

cabinet.

9 Appendix C introduces the lighting protection for the

S9500 series.

Page 4

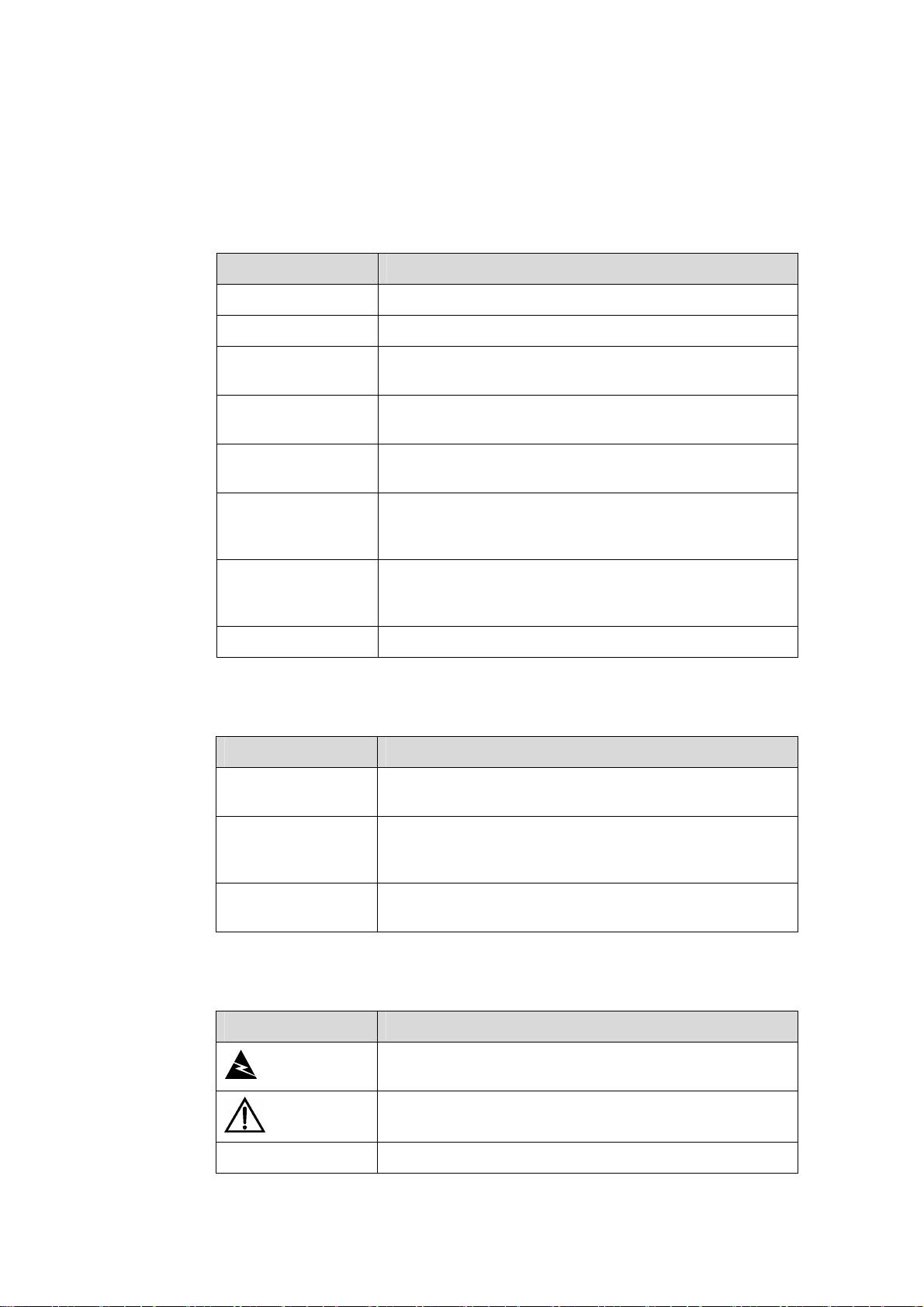

Conventions

The manual uses the following conventions:

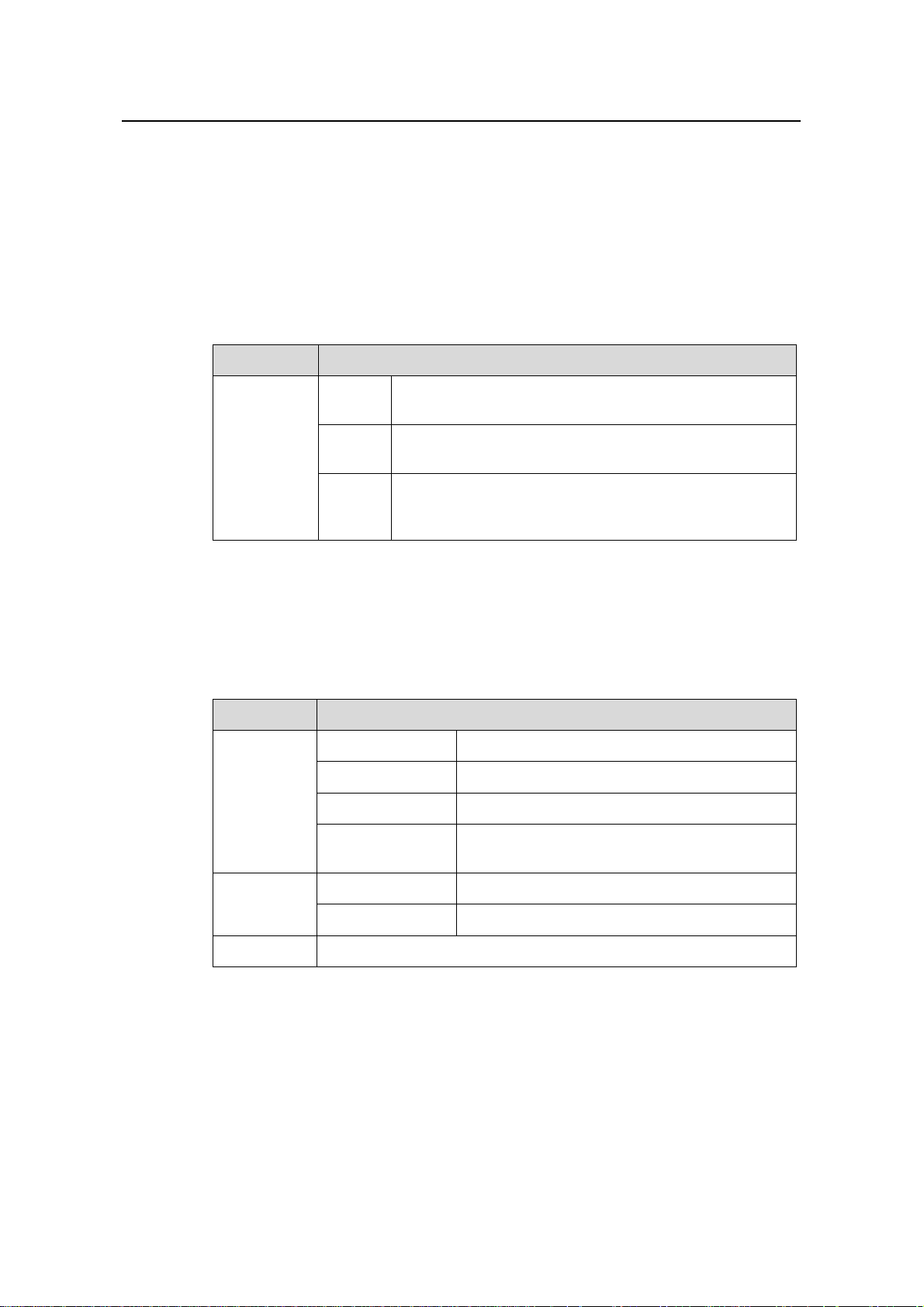

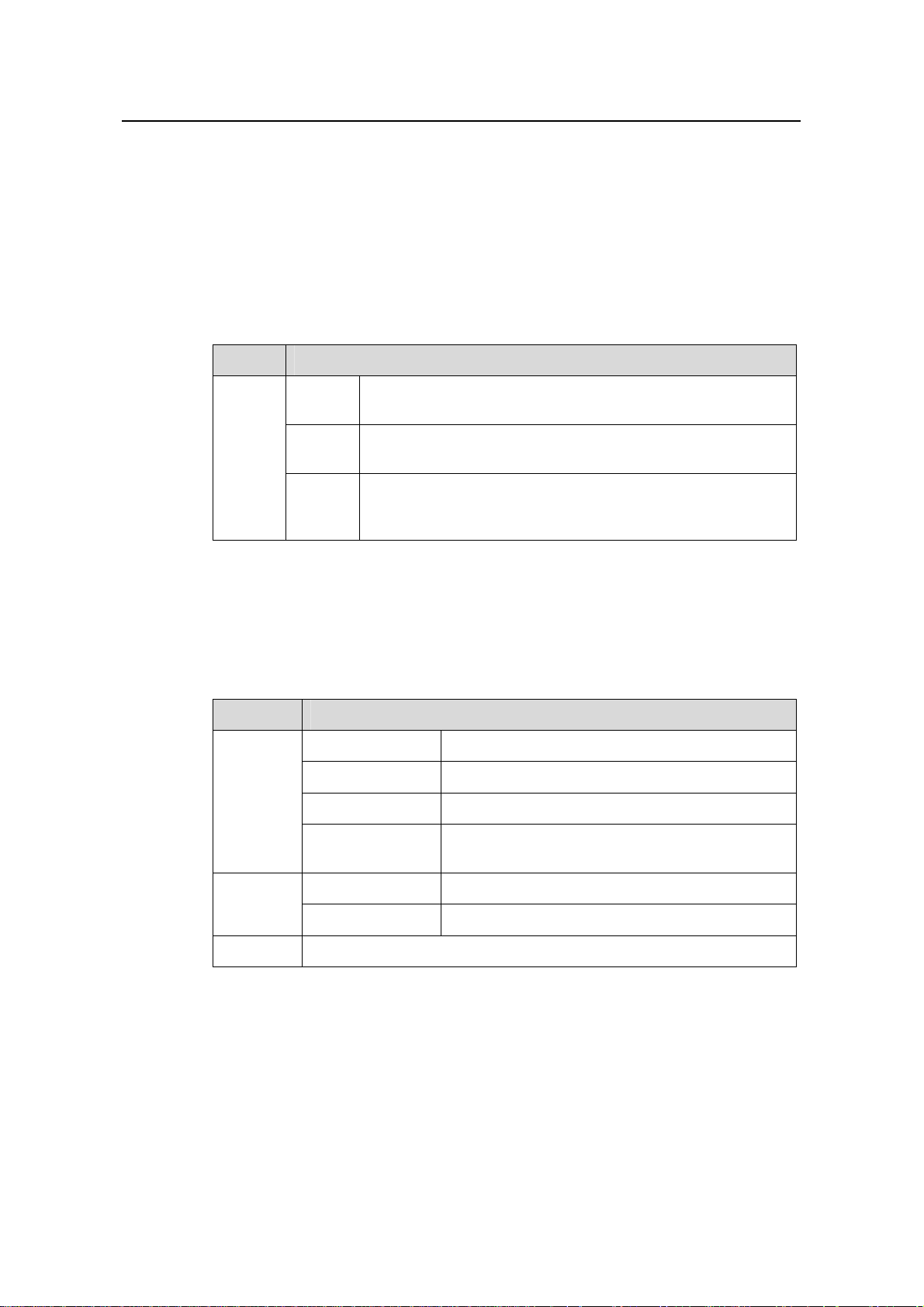

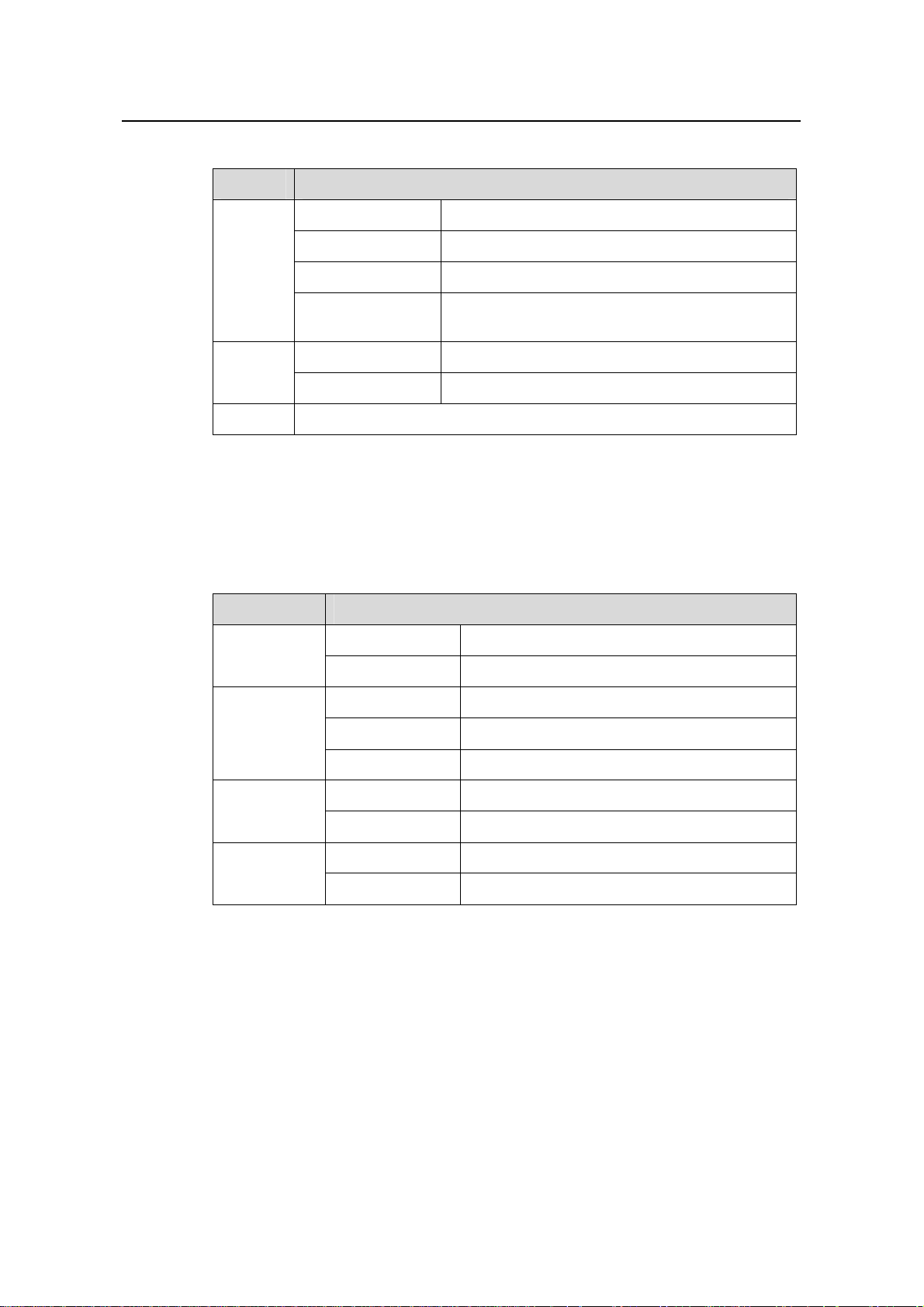

I. Command conventions

Convention Description

Boldface

italic

[ ]

{ x | y | ... }

[ x | y | ... ]

{ x | y | ... } *

[ x | y | ... ] *

# A line starting with the # sign is comments.

The keywords of a command line are in Boldface.

Command arguments are in italic.

Items (keywords or arguments) in square brackets [ ] are

optional.

Alternative items are grouped in braces and separated by

vertical bars. One is selected.

Optional alternative items are grouped in square brackets

and separated by vertical bars. One or none is selected.

Alternative items are grouped in braces and separated by

vertical bars. A minimum of one or a maximum of all can be

selected.

Optional alternative items are grouped in square brackets

and separated by vertical bars. Many or none can be

selected.

II. GUI conventions

Convention Description

< >

[ ]

/

Button names are inside angle brackets. For example, click

<OK>.

Window names, menu items, data table and field names

are inside square brackets. For example, pop up the [New

User] window.

Multi-level menus are separated by forward slashes. For

example, [File/Create/Folder].

III. Symbols

Convention Description

Means reader be extremely careful. Improper operation

Warning

Caution

Note Means a complementary description.

may cause bodily injury.

Means reader be careful. Improper operation may cause

data loss or damage to equipment.

Page 5

Environmental Protection

This product has been designed to comply with the requirements on environmental

protection. For the proper storage, use and disposal of this product, national laws and

regulations must be observed.

Page 6

Installation Manual

H3C S9500 Series Routing Switches Table of Contents

Table of Contents

Chapter 1 Product Overview........................................................................................................1-1

1.1 Preface............................................................................................................................... 1-1

1.2 General Architecture.......................................................................................................... 1-2

1.2.1 Chassis and Slots ................................................................................................... 1-3

1.2.2 Backplane................................................................................................................ 1-6

1.2.3 System Power Supply ............................................................................................. 1-7

1.2.4 PoE Power Supply .................................................................................................. 1-9

1.2.5 Fan Tray ................................................................................................................ 1-11

1.2.6 SRPU Module........................................................................................................ 1-11

1.2.7 LPU Modules......................................................................................................... 1-29

1.2.8 Service Processor Cards ...................................................................................... 1-30

1.2.9 System Specifications ........................................................................................... 1-32

i

Page 7

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

Chapter 1 Product Overview

1.1 Preface

H3C S9500 Series Routing Switches (hereinafter referred to as S9500 series) are

orientated to operate at the convergence layer of a large MAN, or at the core layer of a

small MAN, or at the backbone of a large enterprise network or a campus network.

They serve as the Layer 3 devices in the switching center and convergence center.

S9500 series provide 10GE ports, redundant power systems and redundant SRPU

modules, to address multiservice, high-reliability and large-capacity needs from

high-end users.

The S9500 series currently include three models:

z S9502: This model provides up to 240 Gbps switching capacity. It allows (for

example) the concurrent wire-speed forwarding on 144 GE ports, 8 x 10GE ports,

144 FE electrical ports, or 60 FE optical ports.

Figure 1-1 H3C S9502

z S9505: provides up to 300 Gbps switching capacity and allows the concurrent

wirespeed forwarding on 240 GE ports, or 20 × 10GE ports, or 240 FE electrical

ports, or 100 FE optical ports.

Figure 1-2 H3C S9505

1-1

Page 8

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

z S9508: provides up to 480 Gbps switching capacity and allows the concurrent

wirespeed forwarding on 384 GE ports, or 32 × 10GE ports, or 384 FE electrical

ports, or 160 FE optical ports.

Figure 1-3 H3C S9508

z S9512: provides up to 720 Gbps switching capacity and allows the concurrent

wirespeed forwarding on 576 GE ports, or 48 × 10GE ports, or 576 FE electrical

ports, or 240 FE optical ports.

Figure 1-4 H3C S9512

1.2 General Architecture

The S9500 series use integrated chassis, which can be subdivided into power supply

area, board area, backplane and fan area.

1-2

Page 9

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

1.2.1 Chassis and Slots

I. For S9502

SRPU

SRPU

SRPU

SRPU

SRPU

SRPU

SRPU

SRPU

SRPU

SRPU

交换路由板

交换路由板

交换路由板

交换路由板

交换路由板

交换路由板

交换路由板

交换路由板

交换路由板

交换路由板

交换路由板

交换路由板

交换路由板

交换路由板

交换路由板

交换路由板

交换路由板

交换路由板

交换路由板

交换路由板

SRPU/LPU

SRPU/LPU

SRPU/LPU

SRPU/LPU

SRPU/LPU

SRPU/LPU

SRPU/LPU

SRPU/LPU

SRPU/LPU

SRPU/LPU

交换路由板/接口板

交换路由板/接口板

交换路由板/接口板

交换路由板/接口板

交换路由板/接口板

交换路由板/接口板

交换路由板/接口板

交换路由板/接口板

交换路由板/接口板

交换路由板/接口板

交换路由板/接口板

交换路由板/接口板

交换路由板/接口板

交换路由板/接口板

交换路由板/接口板

交换路由板/接口板

交换路由板/接口板

交换路由板/接口板

交换路由板/接口板

防

防

防

防

防

防

防

防

防

防

防

防

防

防

防

防

防

防

防

防

尘

尘

尘

尘

尘

尘

尘

尘

尘

尘

尘

尘

尘

尘

尘

尘

尘

尘

尘

尘

网

网

网

网

网

网

网

网

网

网

网

网

网

网

网

网

网

网

网

网

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC/DC PSU AC/DC PSU

AC/DC PSU AC/DC PSU

AC/DC PSU AC/DC PSU

AC/DC PSU AC/DC PSU

AC/DC PSU AC/DC PSU

AC/DC PSU AC/DC PSU

AC/DC PSU AC/DC PSU

AC/DC PSU AC/DC PSU

AC/DC PSU AC/DC PSU

AC/DC PSU AC/DC PSU

交换路由板/接口板

LPU

LPU

LPU

LPU

LPU

LPU

LPU

LPU

LPU

LPU

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

LPU

LPU

LPU

LPU

LPU

LPU

LPU

LPU

LPU

LPU

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

接口板

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

AC /DC

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

电源模块

Figure 1-5 S9502 slots

z The S9502 chassis provides four slots in its board area: from up to down, the first

one accommodates an SRPU (switching and routing processor unit), the second

one accommodates an SRPU or an LPU (line processor unit), and the remaining

two slots accommodate LPU/SPC (service processor card) modules, which you

can select from various available LPUs and SPCs. If an SRPU is contained in the

second slot, the two SRPUs in the first and the second slots can operate in 1+1

redundancy mode. All modules in this area are hot-swappable.

z At the bottom of the chassis is the power area that contains two PSUs (power

supply units). The two PSUs are online-swappable; they can operate in 1+1

redundancy mode. The switch supports both AC and DC power inputs. So you can

select AC/DC PSUs as needed. The S9502 supports PoE, and uses a PoE filter at

the rear of the chassis to import power from an external PoE power supply.

z On the right of the chassis is the fan area that contains a vertical hot-swappable

fan tray. The fan tray draws and exhausts air from left to right.

Fan tray

Fan tray

Fan tray

Fan tray

风

风

风

风

风

风

风

风

风

风

风

风

风

风

风

风

风

风

风

风

风

风

风

风

风

风

风

风

风

风

扇

扇

扇

扇

扇

扇

扇

扇

扇

扇

扇

扇

扇

扇

扇

扇

扇

扇

扇

扇

扇

扇

扇

扇

扇

扇

扇

扇

扇

扇

Note:

The two PSUs are online-swappable, which means you can use one PSU to supply

power to the whole switch while changing the other PSU. But before removing or

inserting a PSU, you must first power off it.

1-3

Page 10

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

II. For S9505

SRPU

SRPU

SRPU

SRPU

LPU

AC or DC power

AC or DC power

LPU

LPU

LPU

LPU

LPU

LPU

LPU

LPU

LPU

PoE

PoE

entry

entry

AC or DC power

AC or DC power

Fan tray

Fan tray

Figure 1-6 S9505 slots

All modules in the cabinet are hot-swappable.

z The S9505 chassis provides seven slots: The top two accommodate SRPU

modules, which are in 1+1 redundancy; the remaining five accommodate LPU

modules and service processor cards, which can be hybrid.

z At the bottom of the chassis is the power supply area that contains one PoE entry

area, two power supply units (PSU) that are online-swappable (which means you

can use one PSU to supply power to the whole switch while changing the other

PSU). The switch can be either AC-powered or DC-powered.

z On the right of the chassis is the fan area that contains only one vertical fan tray.

The fan tray draws air from the left and exhausts on the right.

Note:

The two PSUs are online-swappable. But before removing or inserting a PSU, you must

first power off the PSU.

1-4

Page 11

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

III. For S9508

LPU

LPU

LPU

LPU

LPU

LPU

LPU

LPU

SRPU

SRPU

SRPU

SRPU

LPU

LPU

LPU

LPU

LPU

LPU

LPU

LPU

Fan tray

Fan tray

PoE

AC or DC power

AC or DC power

Figure 1-7 S9508 slots

All modules in the cabinet are hot-swappable.

z The S9508 chassis provides ten slots: The middle two accommodate SRPU

modules, which are in 1+1 redundancy; the remaining eight accommodate LPU

modules and service processor cards, which can be hybrid.

z At the bottom of the chassis is the power supply area that contains the PoE entry

area, two PSUs that are online-swappable. The switch can be either AC-powered

or DC-powered.

z On the right of the chassis is the fan area that contains only one vertical fan tray.

The fan tray draws air from the left and exhausts on the right.

PoE

entry

entry

AC or DC power

AC or DC power

1-5

Page 12

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

IV. For S9512

LPU

LPU

LPU

LPU

LPU

LPU

LPU

LPU

LPU

LPU

LPU

LPU

SRPU

SRPU

SRPU

SRPU

LPU

LPU

LPU

LPU

LPU

LPU

LPU

LPU

LPU

LPU

LPU

LPU

Fan tray 1 Fan tray 2

Fan tray 1 Fan tray 2

AC or DC power

Figure 1-8 S9512 slots

All modules in the cabinet are hot-swappable.

z The S9512 chassis provides 14 slots: The two in the middle accommodate SRPU

modules, which are in 1+1 redundancy; the remaining 12 accommodate LPU

modules and service processor cards, which can be hybrid.

z At the bottom of the chassis is the power supply area that contains the PoE entry

area and two PSUs that are online-swappable. The switch can be either

AC-powered or DC-powered.

z On the right of the chassis is the fan area that contains two vertical fan trays. The

fan trays draw air from the left and exhausts on the right.

1.2.2 Backplane

The backplane of the S9500 series allows high-speed data exchange between an

SRPU module and LPU modules, as well as the exchange of various management and

control signals in the system.

PoE

PoE

entry

entry

AC or DC powerAC or DC power

AC or DC power

1-6

Page 13

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

I. Functions

The backplane mainly functions in

z Providing communication channels for signal exchange between boards

z Providing support for hot-swapping of boards

z Auto-identifying the slots

z Connecting PSUs, achieving distributed power supply for SRPU modules, LPU

modules and PSUs and providing corresponding control channels.

II. Structure

z S9502

It uses a passive backplane, which provides two LPU slots and two SRPU slots or

provides three LPU slots and one SRPU slot, one port for fan tray, and two -48V ports

(one for system power input and one for PoE entry).

z For S9505

It uses a passive backplane, which provides five LPU slots and two SRP slots, one port

for fan tray and two –48V ports (one for system power input and one for PoE entry).

z For S9508

It uses a passive backplane, which provides eight LPU slots and two SRP slots, one

port for fan tray and two –48V ports (one for system power input and one for PoE

entry).

z For S9512

It uses a passive backplane, which provides 12 LPU slots and two SRP slots, one port

for fan tray and two –48V ports (one for system power input and one for PoE entry).

1.2.3 System Power Supply

Note:

z The S9500 series can be AC-powered or DC-powered. You can choose power

supply modules as needed.

z If you want to change power supply type, just insert the power supply module of right

type.

z Power supply modules of the S9500 series are online-swappable.

The S9500 series can be AC-powered or DC-powered. The power supply is at the

bottom of the chassis, with a height of 3U (except S9502 switches). You can insert both

AC and DC power supply modules in the same slot based on your needs. The power

frame is in different compartment from the functional board frame and connected to the

1-7

Page 14

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

latter with cables, which are routed on the chassis back. The power supply is cooled by

built-in fans of the PSU, which draw air into the chassis from the front and exhaust out

of the back.

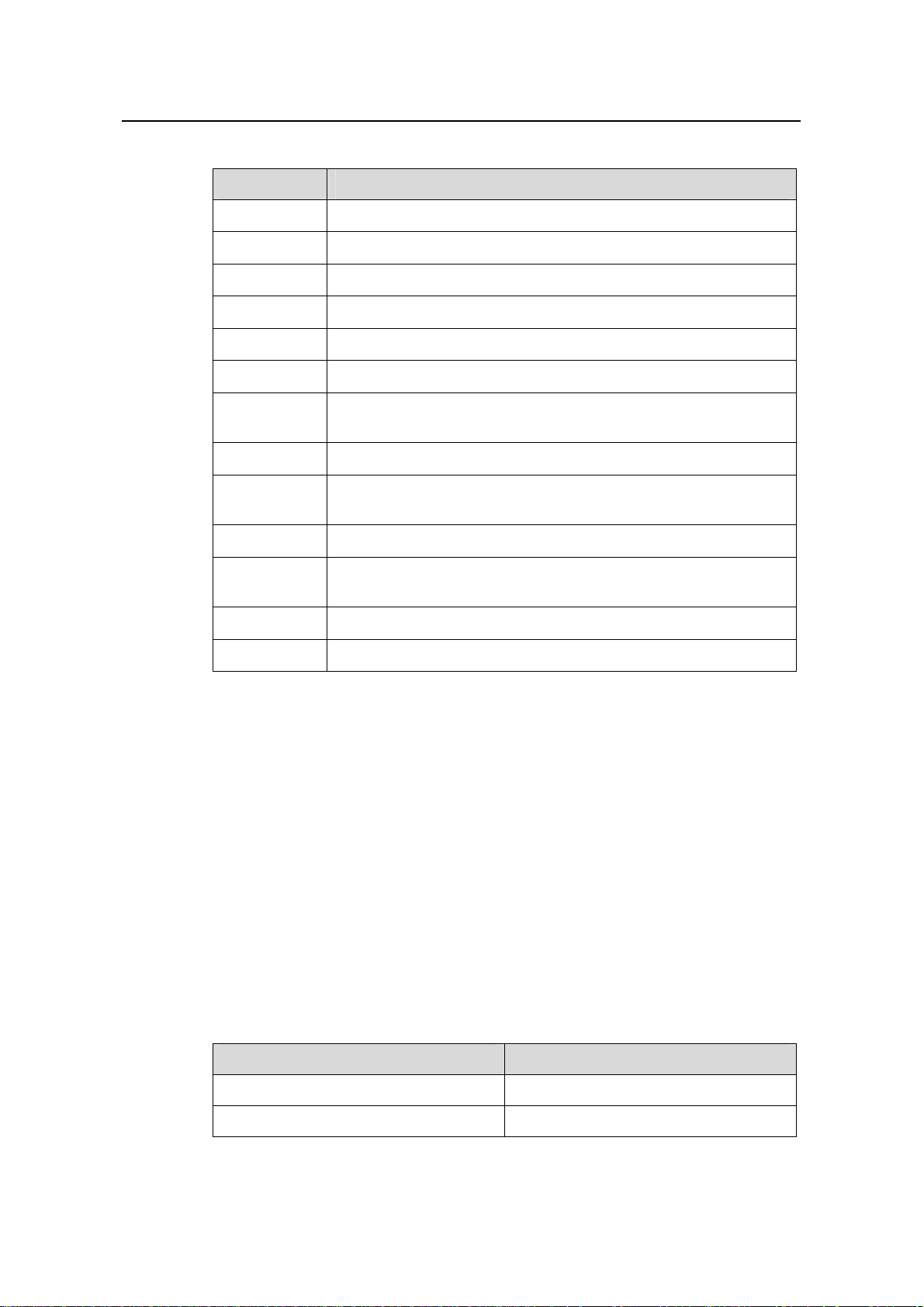

I. Power supply specifications

z AC-input PSU

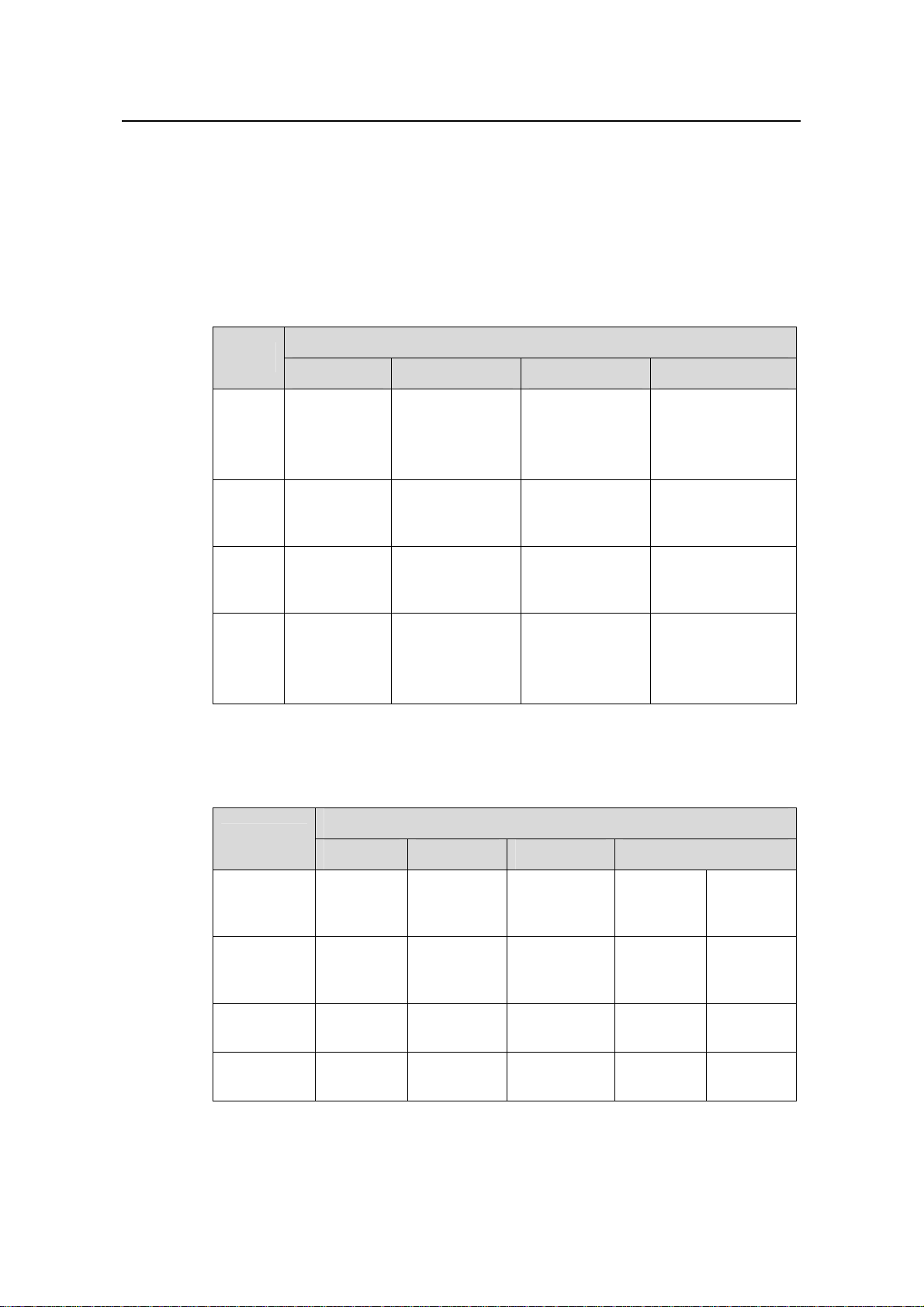

Table 1-1 Specifications for the AC-input PSU

Item

Specifications

S9502 S9505 S9508 S9512

Rated

voltage

range

Max

voltage

range

100 VAC to

240 VAC,

50/60 Hz

90 VAC to

264 VAC,

50/60Hz

100 VAC to 240

VAC, 50 Hz

90 VAC to 264

VAC, 47 Hz to

63 Hz

Max

input

7.5 A 15 A 15 A 15 A

current

Max

output

600 W 1200 W

power

z DC-input PSU

Table 1-2 Specifications for the DC-input PSU

100 VAC to 120

VAC, 50 Hz

200 VAC to 240

VAC, 50 Hz

90 VAC to 264

VAC, 47 Hz to

63 Hz

1200 W (90 V to

160 V)

2000 W (160 V

to 264 V)

100 to 120 VAC,

50 Hz

200 to 240 VAC,

50 Hz

90 VAC to 264

VAC, 47 Hz to 63

Hz

1200 W (90 V to

160 V)

2000 W (160 V to

264 V)

Item

Rated

voltage

range

Max voltage

range

Max input

current

Max output

power

Specifications

S9502 S9505 S9508 S9512

–60 VDC

to –48

–48 VDC –48 VDC –48 VDC –48 VDC

VDC

–72 VDC

to –36

VDC

–72 VDC to

–36 VDC

–72 VDC to

–36 VDC

–72 VDC

to –36

VDC

–72 VDC

to –36

VDC

12.5 A 25 A 42 A 42 A 25 A

600 W 1200 W 2000 W 2000 W 1200 W

1-8

Page 15

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

1.2.4 PoE Power Supply

The S9500 series support power over Ethernet (PoE). With this feature, a S9500 series

switch equipped with external power supply and PoE-capable cards can deliver 48

VDC to remotely powered devices (PDs, such as IP Phones, WLAN APs and Network

Cameras) through twisted pairs.

z The S9500 series can supply power to remote PDs through the Ethernet electrical

ports on the LPUs. Each LPU can simultaneously supply power to up to 48 PDs at

a distance of up to 100 m (328.1 feet) away.

z Each Ethernet port can deliver up to 15.4 W to its PD.

z Totally, an S9500 series switch can deliver up to 4500 W (220 V)/2250 W (110 V)

power to its PDs. It determines whether to deliver power to the newly detected PD

depending on the power it currently supplied.

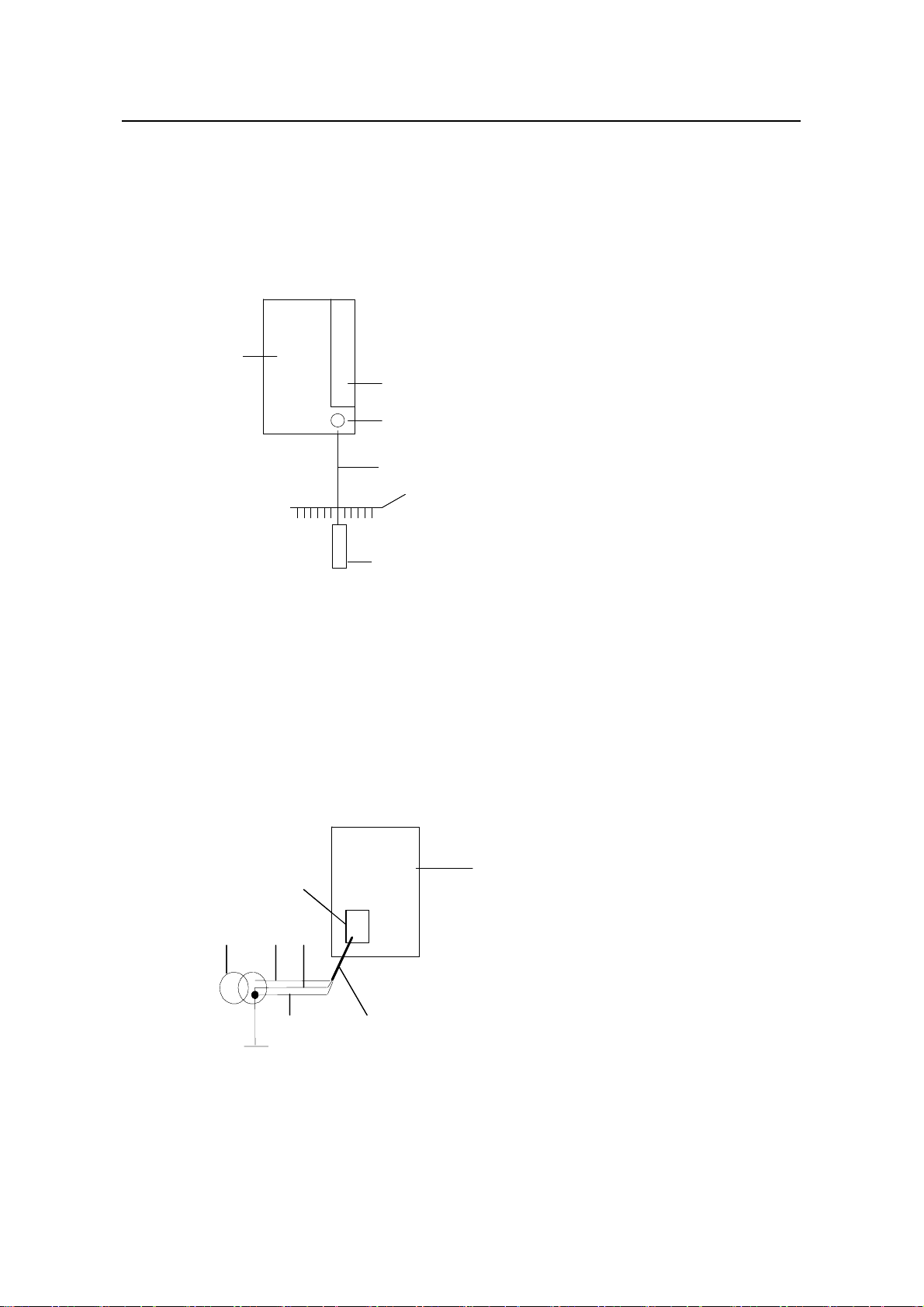

I. PoE entry area

On the S9500 series, the PoE entry area is between the two power supply modules.

The PoE entry module is connected with the wiring screw post of the power frame when

supported.

II. External PoE power frame

The following two types of PoE external power supplies are available for the S9500

series:

z PSE4500-A: adopted by S9505/S9508/S9512 switches

z PSE2500-A1: adopted by S9502 switches

Currently the S9500 series support the PoE power system with three AC inputs and

one DC output. The PoE power frame with three AC inputs is shown

INPUT1 INPUT2 INPUT3

POE Power System PSE4500-A

POE Power System PSE4500-A

RUN ALM RS485-1 RS485-2 RS232

RUN ALM RS485-1 RS485-2 RS232

PS1

PS1

-54V;83.0A

NEG (-) RTN (+)

NEG (-) RTN (+)

This device has more than one power input. Do

This device has more than one power input. Do

disconnect all power inputs to power off this devi ce.

disconnect all power inputs to power off this devi ce.

-54V;83.0A

PS2 PS3

PS2 PS3

INPUT1 INPUT2 INPUT3

Each Input at: ~100-120/200-240V;

Each Input at: ~100-120/200-240V;

50-60Hz; 15.0/15.0A

50-60Hz; 15.0/15.0A

PS3

PS3

Figure 1-9:

Figure 1-9 Three-input PoE power frame

1-9

Page 16

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

Note:

The external PoE power system supports 2+1 redundancy and online-swap.

Dedicated interface module is required for the PoE power supply on switches. On the

S9500 series, it is the GV48 interface module.

Table 1-3 describes the technical specifications of the external PoE power system.

Table 1-3 Technical specifications of the PoE power system

Item Description

Dimensions (H × W × D) 177 × 486 × 320.5 mm (7.0 × 19.1 × 12.6 in.)

System controller One

Rectifier

Two NP2500UAC (required) + one redundant

NP2500UAC (optional)

Three AC inputs with one manual switch for each

AC distribution assembly

Three-phase AC voltage detection circuit

Input voltage range: 90 VAC to 290 VAC; rated voltage

and current: 250 VAC/20A

DC distribution assembly A single DC output, with max output current of 93A

Max. power consumption 4500 W

PoE power system functions in monitoring and provides an RS232 and two RS485

monitoring interfaces. The system monitor sends the running information of the system

module to SRP through RS232 or RS485 interfaces and displays the alarm by ALM

LED. You can connect cables to the interface from the front or rear of the frame.

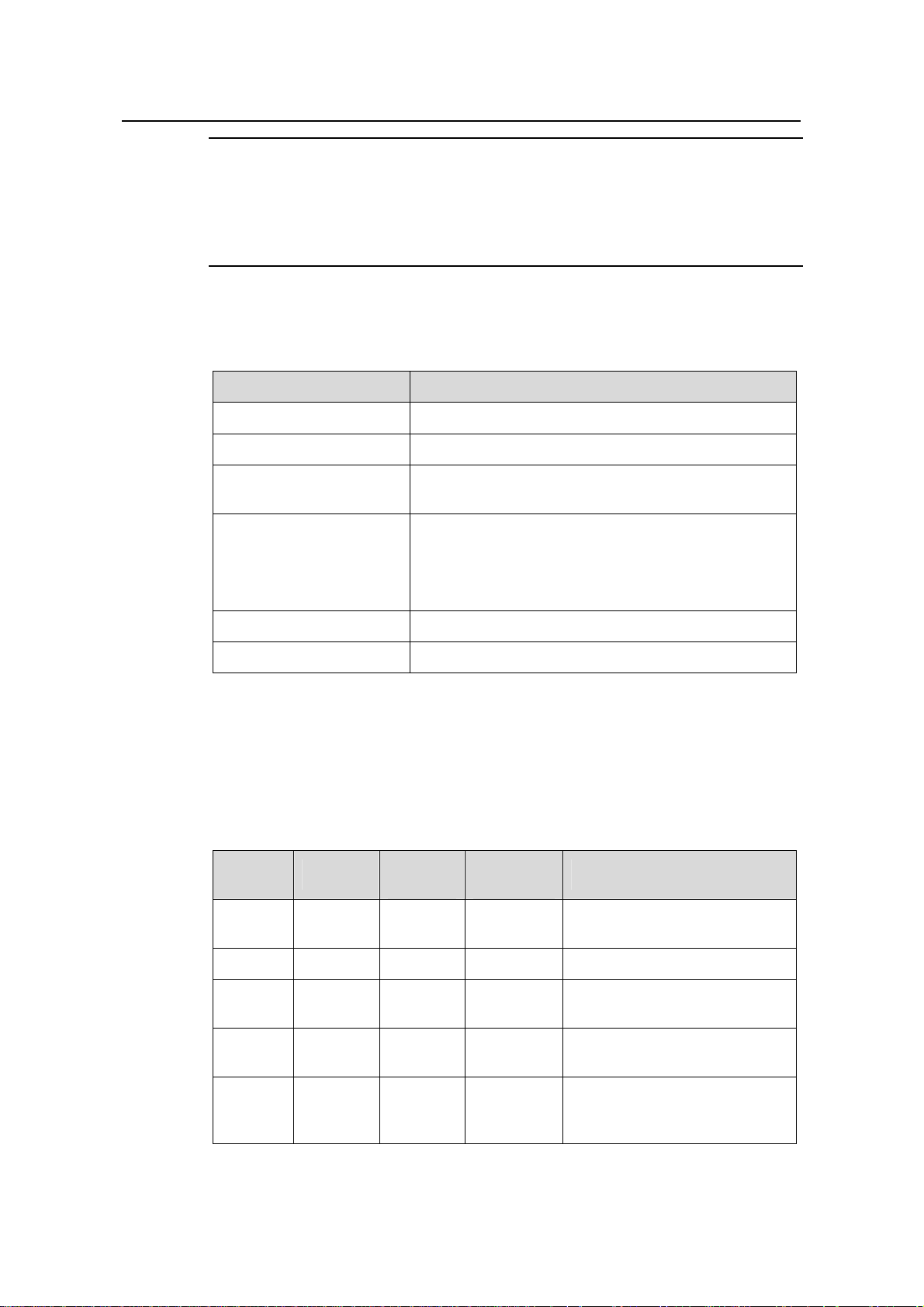

Table 1-4 LEDs of PoE power system

LED Color

Normal

status

AC Green ON OFF

Abnormal

status

Causes

There is no AC input or the fuse

is broken.

DC Green ON OFF There is no DC output.

Fault Red OFF ON

RUN Green ON OFF

The fault in the module is

irretrievable.

The power module is not

running or is failed.

There is under- and

ALM Red OFF ON

over-voltage, even no AC

power input, or faulty module.

1-10

Page 17

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

1.2.5 Fan Tray

The S9502 uses eight DC fan units (70 × 70 × 25.4 mm or 2.8 × 2.8 × 1.0 in) in a fan tray

(36 W, and there is only one fan tray in the chassis). The fans operate on 12 VDC

supplied from the fan monitor board.

The S9505 uses four DC fan units (120 × 120 × 25.4 mm or 4.7 × 4.7 × 1.0 in) in a fan

tray (25 W).The fans can be governed in two modes: SRPU-controlled or

temperature-controlled. They operate on –48 VDC supplied from the backplane.

The fan subsystem of the S9508 and S9512 is the same as that of the S9505, except

that the S9508 uses six DC fan units in one fan tray (35 W) and the S9512 uses eight

DC fan units in two fan trays (25 W for each frame, four units in each).

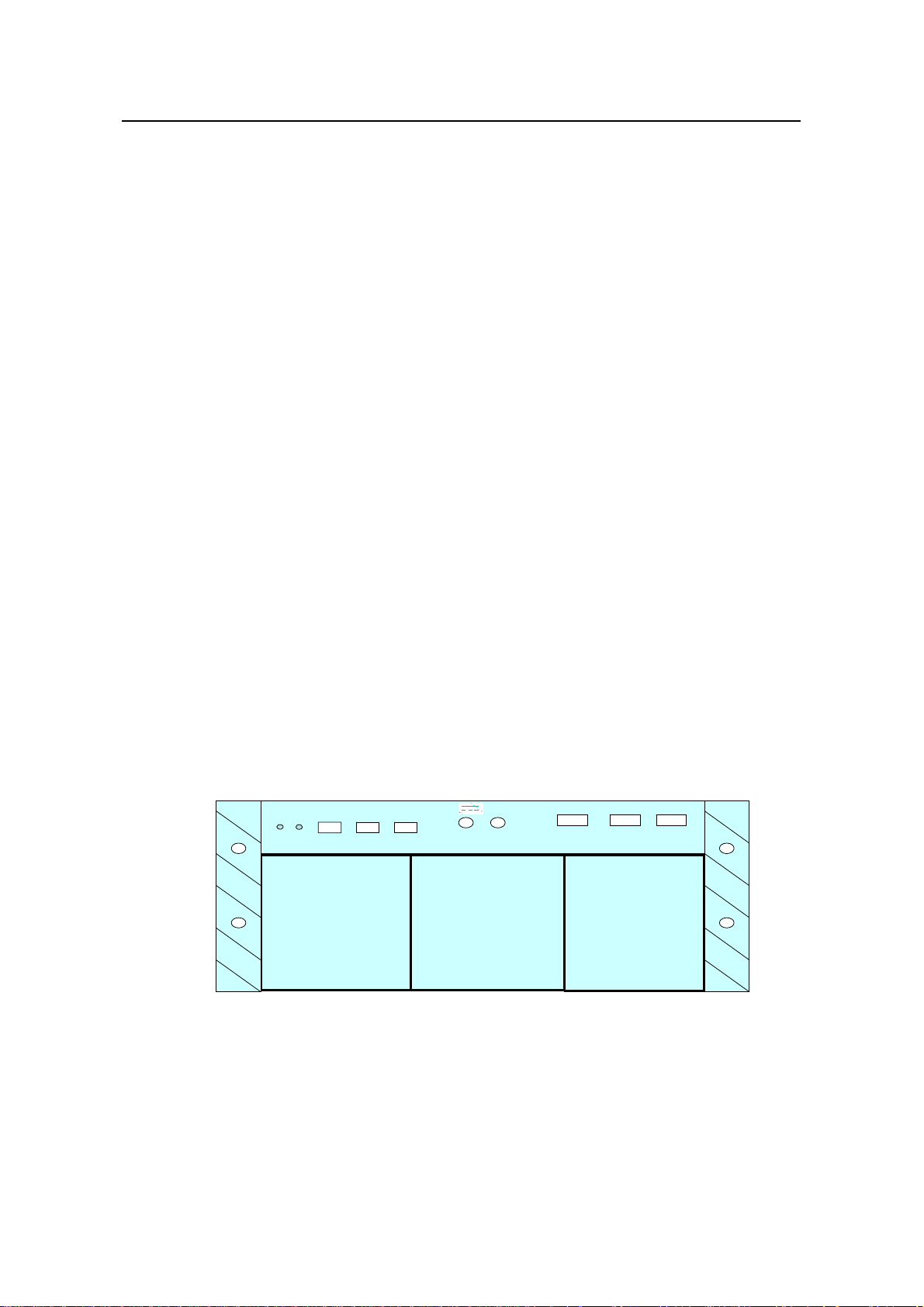

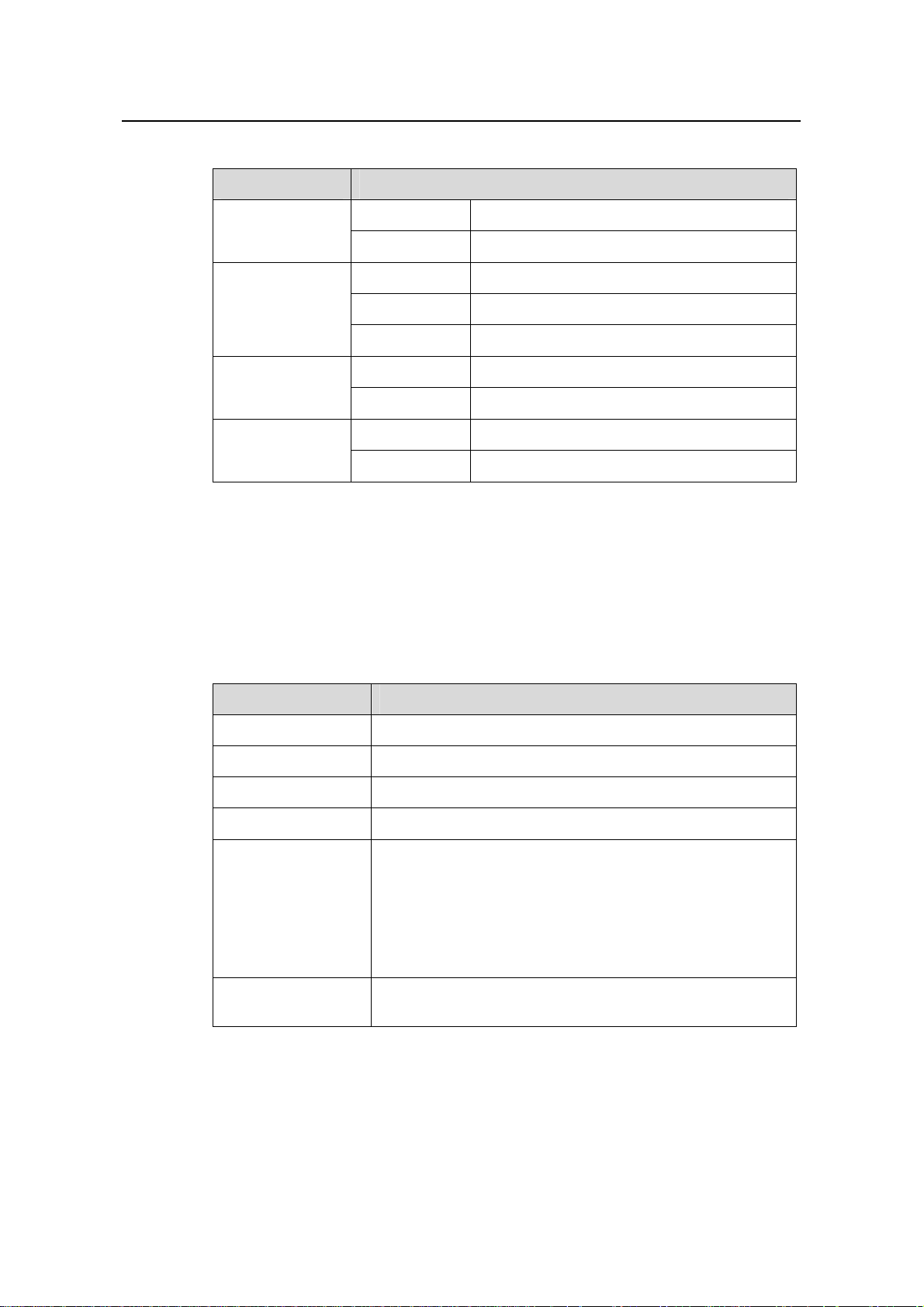

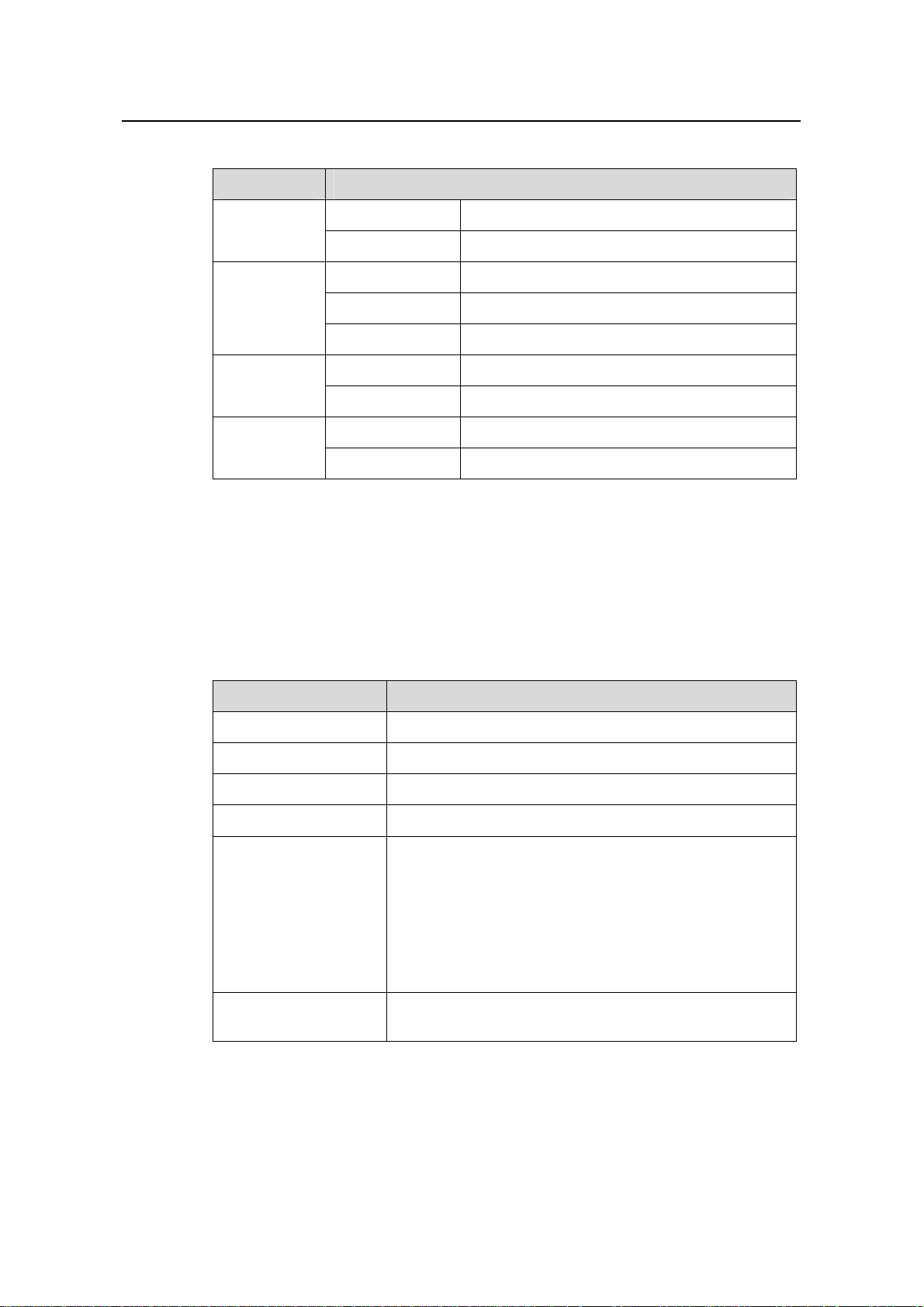

Figure 1-10 Panel of the fan tray for the S9500 series

Table 1-5 LEDs on the faceplate of the fan tray

LED Color Status

RUN

ALM

1.2.6 SRPU Module

The SRPU module is the core of the switch, and mainly functions in

OFF The fan tray is faulty.

Green The fan tray is running normally.

OFF The fan tray is running normally.

Red The fan tray is faulty.

1-11

Page 18

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

z Route calculating and forwarding table maintenance.

z Integrating Crossbar switching fabric to exchange the service between different

boards.

z Providing system configuration and monitoring functions, which allows the system

to upgrade and reset service board software.

The S9500 series support these types of SRPU modules:

z S9502: SRP1M1

z S9505: SRP1N6,SRP1N7

z S9508: SRP1N5,SRP1N7

z S9512: SRP1N4,SRP1N7

I. SRP1N4 module

1) Specifications

The S9512 uses SRP1N4 modules. The following table summarizes the module

specifications.

Table 1-6 SRP1N4 module specifications

Attribute SRP1N4

CPU MPC755

Boot ROM 512 KB

SDRAM 512 MB (expandable to 1 GB)

Dimensions (L × W) 366.7 × 340 mm (14.4 × 13.4 in.)

One Console port, for local configuration management

One AUX port, for remote dialup configuration

management

Port

One 10Base-T/100Base-TX port for system management

and program upgrade

One RS232/485 port, for connecting external PoE power

frame when supported

One hot-swappable CF port

Max. power

consumption

60 W

2) SRP1N4 panel

The SRP1N4 module provides CF port, CF LED (CFS), 10Base-T/100Base-TX port,

RS232/485 port, Console port, AUX port, RESET button, LPU status LEDs, SRP1N4

status LEDs (SFS, ACT, ALM, RUN), as shown in

Figure 1-11.

Figure 1-11 SRP1N4 panel

1-12

Page 19

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

3) User ports

z CF port

The SRP1N4 module provides a CF port to accommodate a standard CF card, where

you can save logging information, host version information, alarming and other

diagnostic information and conveniently upgrade software online.

z Management 10Base-T/100Base-TX port

The management 10Base-T/100Base-TX port uses an RJ-45 connector. It can connect

a background terminal for system program loading and debugging, or connect a

network management station for remote system management.

Table 1-7 Management 10Base-T/100Base-TX port specifications

Attribute Description

Connector RJ-45

Number of ports One

Rate

Max. transmission segment

over the selected medium

10 Mbps, half duplex/full duplex

100 Mbps, half duplex/full duplex

100 m (328 ft) over the category-5 twisted pair cable

(crossover cable is required).

Service System program upgrade and network management

The following table describes the status LEDs for the management

10Base-T/100Base-TX port.

Table 1-8 Status LEDs for the management 10Base-T/100Base-TX port

LED Status

OFF No link is present.

LINK

ON A link is present.

OFF No packets are transmitted/received on the port.

ACT

Blinking Packets are being transmitted/received on the port.

z RS232/485 port

The RS232/485 port uses RJ-45 connector, for connecting external PoE power frame

when supported and monitoring its status.

1-13

Page 20

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

Table 1-9 RS232/485 port specifications

Attribute Description

Connector RJ-45

Number of ports One RS 232 port and one RS485 port

Service

The port for monitoring and communication with the external

subsystem, such as external PoE power supply module

z Console port

The Console port uses an RJ-45 connector. It can be connected to a background

terminal for system debugging, maintenance, management, and host software loading.

Table 1-10 Console port specifications

Attribute Description

Connector RJ-45

Standard Asynchronous EIA/TIA-232

Baud rate 9600 bps (default)

Transmission segment

Service

≤ 15 m (49 ft)

Connects a serial port of a local PC and runs terminal

emulation on the PC.

Note:

You can choose your own baud rate for the Console port.

z AUX port

The AUX port uses an RJ-45 connector. The port can serve as a backup port for the

Console port to connect a background terminal, or directly connect a modem device,

for remote system debugging, configuration, maintenance and management.

Table 1-11 AUX port specifications

Attribute Description

Connector RJ-45

Standard Asynchronous EIA/TIA-232

Service

Connects a serial port of a PC (through a Modem pair for a

remote PC) and runs terminal emulation on the PC.

1-14

Page 21

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

4) RESET button

You can press the RESET button on the panel to reset the SRP1N4 module.

5) Status LEDs

z CF status LED

You can learn the operating status of the CF card by reading the CF status LED on the

panel.

Table 1-12 CF status LED

LED Status

The CF card is in position and is idle. You cannot remove

the card.

The CF card is in position and reading/writing data. You

cannot remove the card.

CFS

ON

Blinking

The CF card is out of position or offline (you can force the

OFF

in-position CF card to go offline using the appropriate

background command). You can remove/insert the card.

z Status LEDs for LPU modules

The SRP1N4 module has 12 pairs of LEDs to indicate the operating status of 12 LPU

modules.

Table 1-13 Status LEDs for LPU modules

LED Status

ON The module is faulty.

OFF The module is faulty or out of position.

RUN

Blinking (1s) The module is running normally.

Fast blinking (125

ms)

The module is booting or not registered

successfully.

ALM

ON The module has alarms.

OFF The module has no alarms or is out of position.

0~5, 8~13 Indicate slots 0 through 5 and slots 8 through 13

z Status LEDs for the SRP1N4 module

You can learn the operating status of SRP1N4 module by reading the SFS, ACT, ALM

and RUN LEDs on it. The following table gives a summary of the four LEDs.

1-15

Page 22

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

Table 1-14 Status LEDs for the SRP1N4 module

SRP1N4 LED Status

SFS

ON The switching fabric unit is active.

OFF The switching fabric unit is standby.

Green The SRP1N4 module is faulty.

RUN

OFF The SRP1N4 module is faulty.

Green blinking The SRP1N4 module runs normally.

Red The SRP1N4 module has alarms.

ALM

OFF

Green The SRP1N4 module is active.

The SRP1N4 module has no alarms.

ACT

OFF

The SRP1N4 module is standby.

II. SRP1N5 module

1) Specifications

The S9508 uses SRP1N5 modules. The following table summarizes the board

specifications.

Table 1-15 SRP1N5 module specifications

Attribute SRP1N5

CPU MPC755

Boot ROM 512 KB

SDRAM 512 MB (expandable to 1 GB)

Dimensions (L × W) 366.7 × 340 mm (14.4 × 13.4 in.)

One Console port, for local configuration management

One AUX port, for remote dialup configuration management

One 10Base-T/100Base-TX port for system management

Port

and program upgrade

One RS232/485 port, for connecting external PoE power

frame when supported

One hot-swappable CF port

Max. power

consumption

60 W

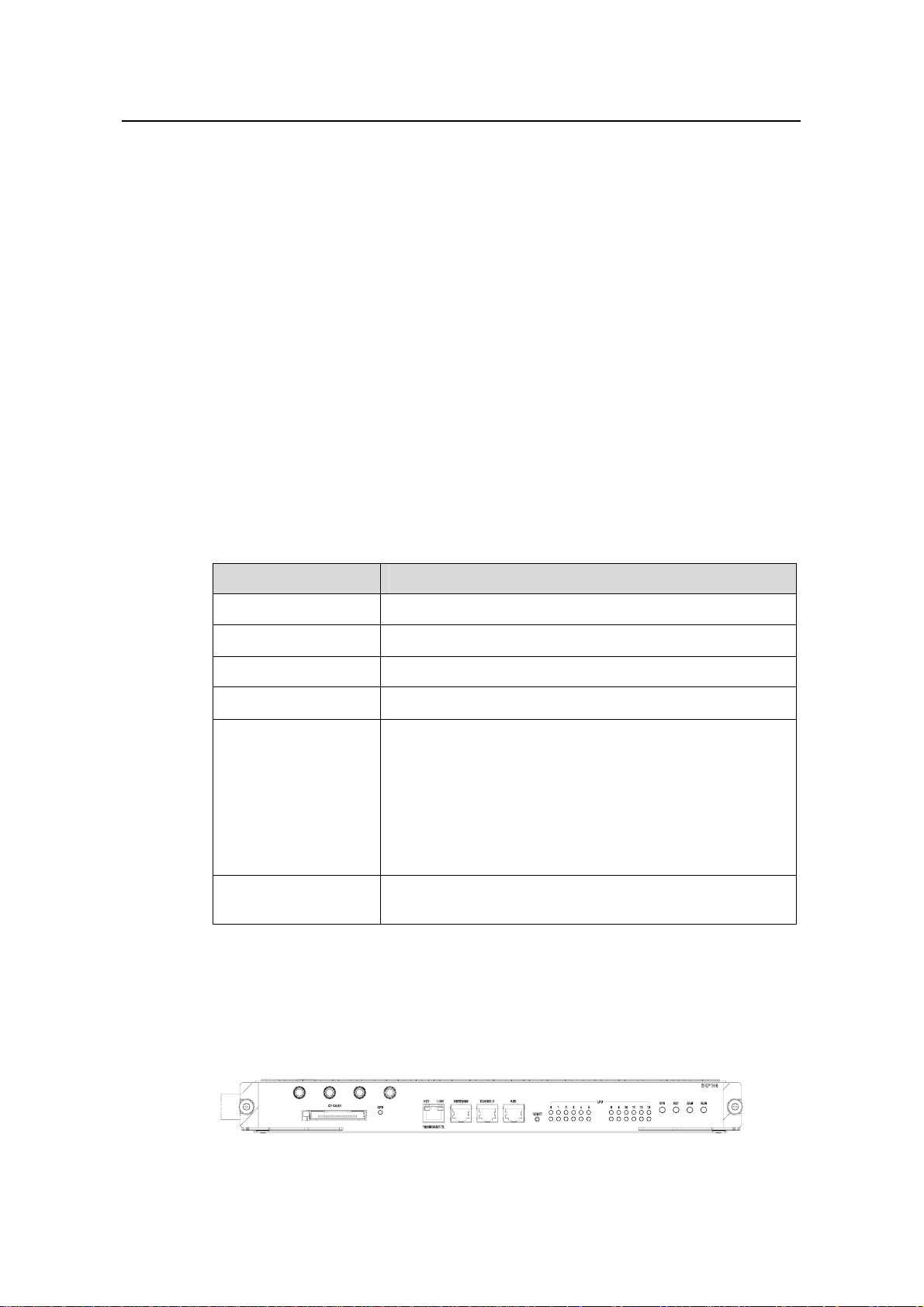

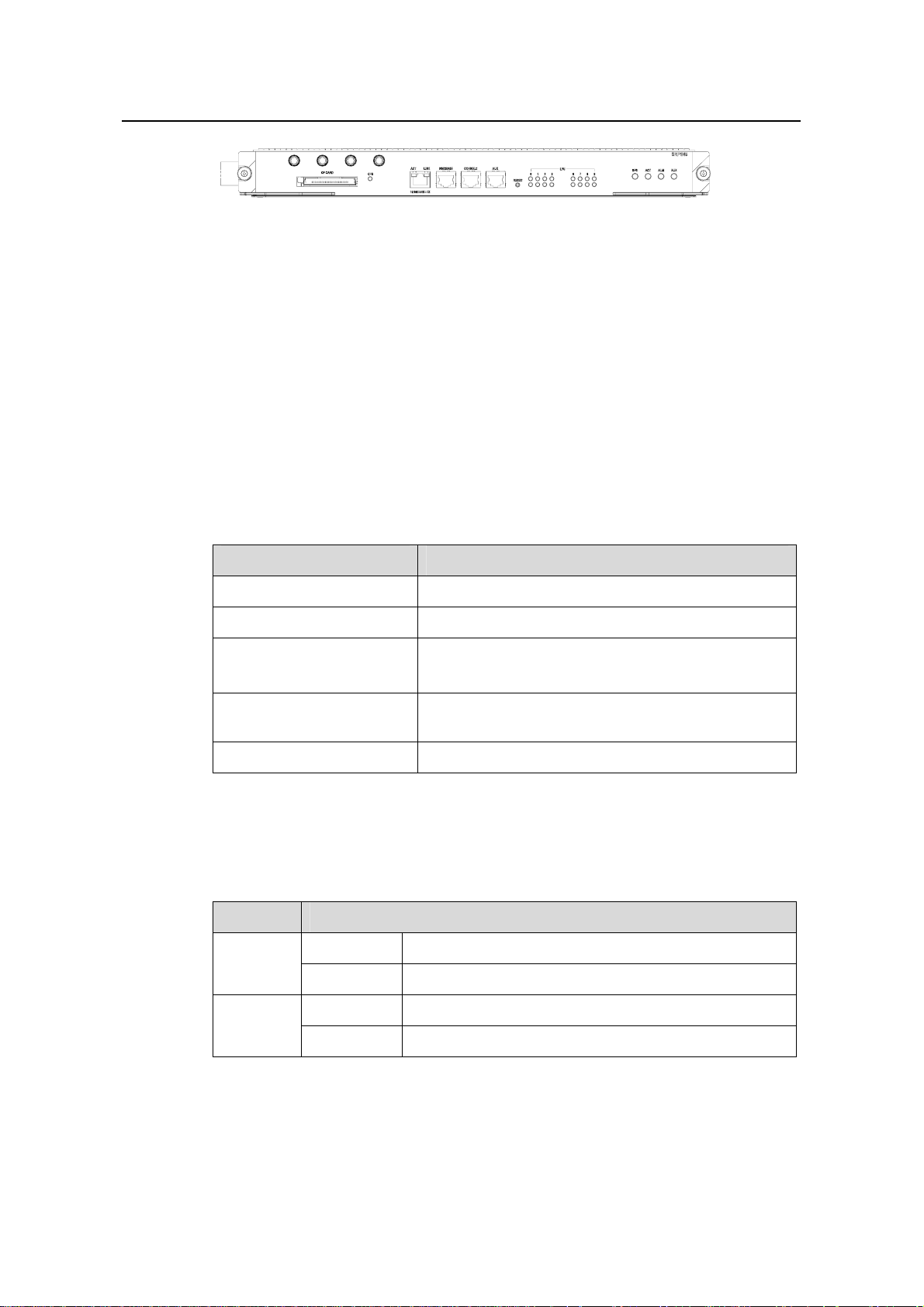

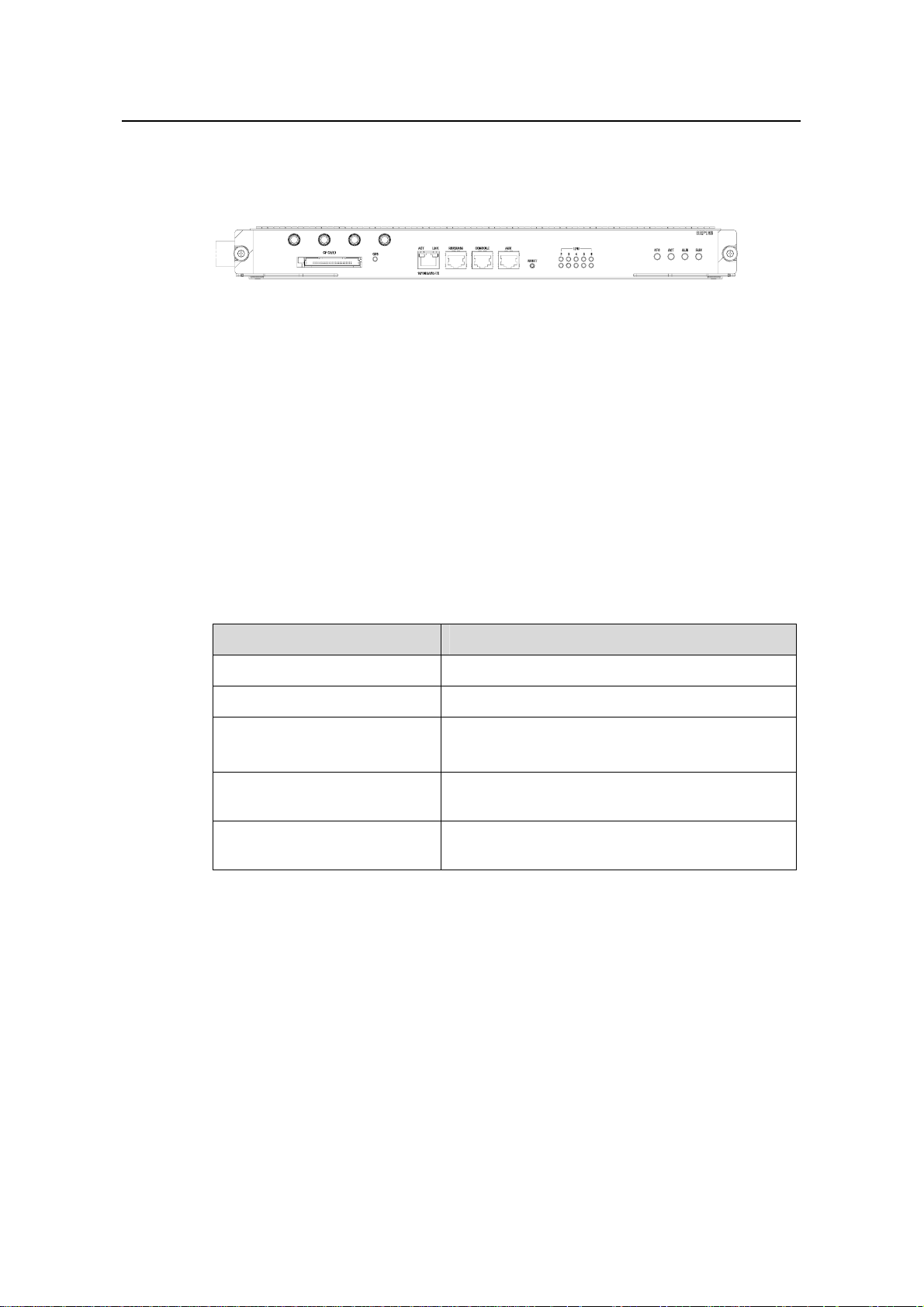

2) SRP1N5 panel

The SRP1N5 module provides CF port, CF LED (CFS), 10Base-T/100Base-TX port,

RS232/485 port, Console port, AUX port, RESET button, LPU status LEDs, SRP1N5

status LEDs (SFS, ACT, ALM, RUN), as shown in

Figure 1-12.

1-16

Page 23

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

Figure 1-12 SRP1N5 panel

3) User ports

z CF port

The SRP1N5 module provides a CF port to accommodate a standard CF card, where

you can save logging information, host version information, alarming and other

diagnostic information and conveniently upgrade software online.

z Management 10Base-T/100Base-TX port

The management 10Base-T/100Base-TX port uses an RJ-45 connector. It can connect

a background terminal for system program loading and debugging, or connect a

network management station for remote system management.

Table 1-16 Management 10Base-T/100Base-TX port specifications

Attribute Description

Connector RJ-45

Number of ports One

Rate

Max. transmission segment

over the selected medium

10 Mbps, half duplex/full duplex

100 Mbps, half duplex/full duplex

100 m (328 ft) over the category-5 twisted pair cable

(crossover cable is required.)

Service System program upgrade and network management

The following table describes the status LEDs for the management

10Base-T/100Base-TX port.

Table 1-17 Status LEDs for the management 10Base-T/100Base-TX port

LED Status

OFF No link is present.

LINK

Green A link is present.

OFF No packets are transmitted/received on the port.

ACT

Blinking Packets are being transmitted/received on the port.

z RS232/485 port

The RS232/485 port uses RJ-45 connector, for connecting external PoE power frame

when supported and monitoring its status.

1-17

Page 24

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

Table 1-18 RS232/485 port specifications

Attribute Description

Connector RJ-45

Number of ports One RS 232 port and one RS485 port

Service

The port for monitoring and communication with the external

subsystem, such as external PoE power supply module

z Console port

The Console port uses an RJ-45 connector. It can be connected to a background

terminal for system debugging, maintenance, management, and host software loading.

Table 1-19 Console port specifications

Attribute Description

Connector RJ-45

Standard Asynchronous EIA/TIA-232

Baud rate 9600 bps (default)

Transmission distance

Service

≤ 15 m (49 ft)

Connects a serial port of a local PC and runs terminal

emulation on the PC.

Note:

You can choose your own baud rate for the Console port.

z AUX port

The AUX port uses an RJ-45 connector. The port can serve as a backup port for the

Console port to connect a background terminal, or directly connect a modem device,

for remote system debugging, configuration, maintenance and management.

Table 1-20 AUX port specifications

Attribute Description

Connector RJ-45

Standard Asynchronous EIA/TIA-232

Service

Connects a serial port of a PC (through a Modem pair for a

remote PC) and runs terminal emulation on the PC.

1-18

Page 25

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

4) RESET button

You can press the RESET button on the panel to reset the SRP1N5 module.

5) Status LEDs

z CF status LED

You can check operating status of the CF card by reading the CF status LED on the

panel.

Table 1-21 CF status LED

LED Status

The CF card is in position and is idle. You cannot remove the

card.

The CF card is in position and reading/writing data. You

cannot remove the card.

CFS

ON

Blinking

The CF card is out of position or offline (you can force the

OFF

in-position CF card to go offline using the appropriate

background command). You can remove/insert the card.

z Status LEDs for LPU modules

The SRP1N5 module has eight pairs of LEDs to indicate the operating status of eight

LPU modules.

Table 1-22 Status LEDs for LPU modules

LED Status

ON The module is faulty.

OFF The module is faulty or out of position.

RUN

Blinking (1s) The module is running normally.

Fast blinking

(125ms)

The module is booting or not registered

successfully.

ALM

ON The module has alarms.

OFF The module has no alarms or is out of position.

0~3, 6~9 Indicate slots 0 through 3 and slots 6 through 9

z Status LEDs for the SRP1N5 module

You can learn the operating status of SRP1N5 module by reading the SFS, ACT, ALM

and RUN LEDs on it. The following table gives a summary of the four LEDs.

1-19

Page 26

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

Table 1-23 Status LEDs for the SRP1N5 module

SRP1N5 LED Status

SFS

ON The switching fabric unit is active.

OFF The switching fabric unit is standby.

Green The SRP1N5 module is faulty.

RUN

OFF The SRP1N5 module is faulty.

Green blinking The SRP1N5 module runs normally.

Red The SRP1N5 module has alarms.

ALM

OFF

Green The SRP1N5 module is active.

The SRP1N5 module has no alarms.

ACT

OFF

The SRP1N5 module is standby.

III. SRP1N6 module

1) Specifications

The S9505 uses SRP1N6 modules. The following table summarizes the board

specifications.

Table 1-24 SRP1N6 module specifications

Attribute SRP1N6

CPU MPC755

Boot ROM 512 KB

SDRAM 512 MB (expandable to 1 GB)

Dimensions (L × W) 366.7 × 340 mm (14.4 × 13.4 in.)

One Console port, for local configuration management

One AUX port, for remote dialup configuration

management

Port

One 10Base-T/100Base-TX port for system management

and program upgrade

One RS232/485 port, for connecting external PoE power

frame when supported

One hot-swappable CF port

Max. power

consumption

60 W

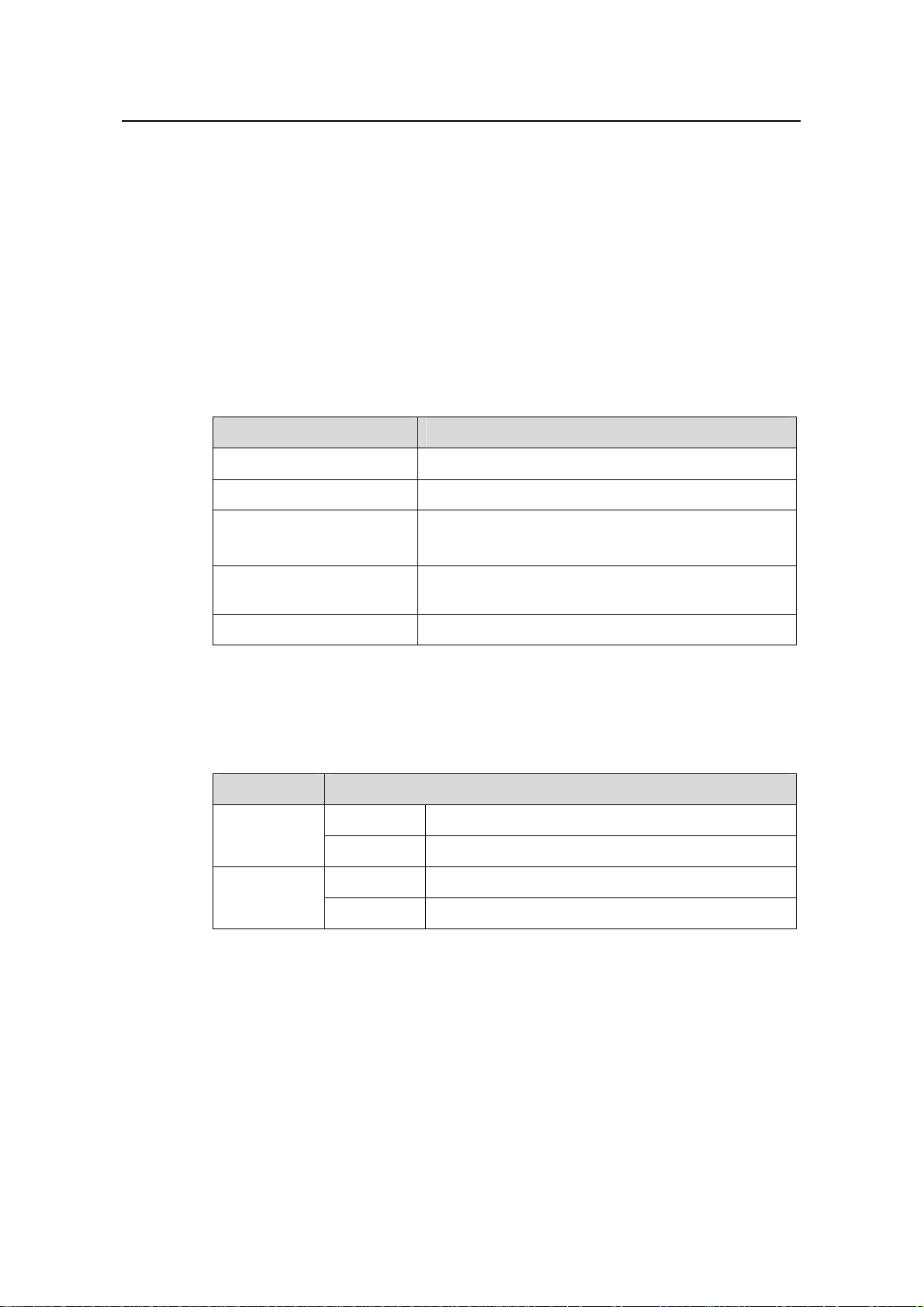

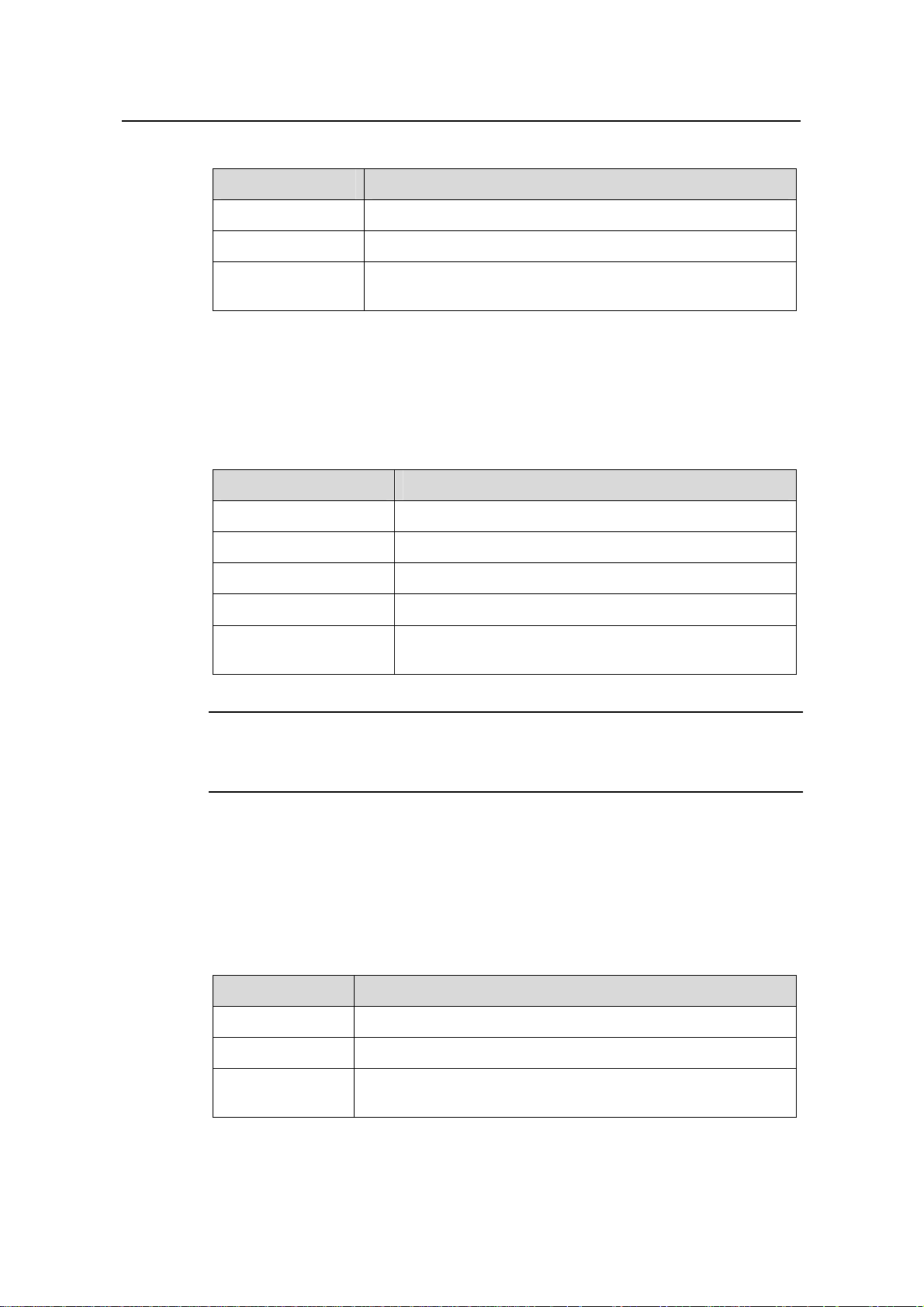

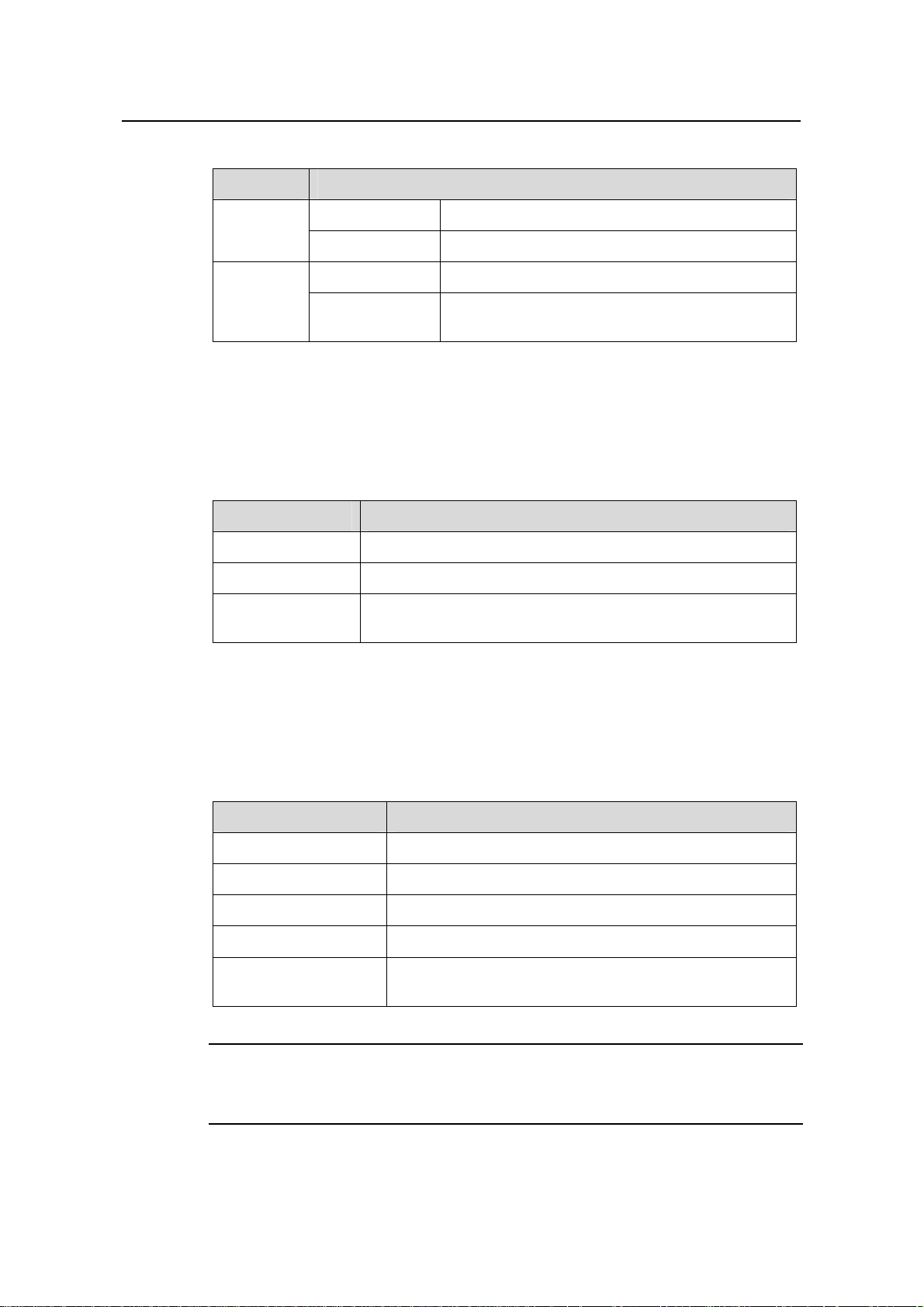

2) SRP1N6panel

1-20

Page 27

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

The SRP1N6 module provides CF port, CF LED (CFS), 10Base-T/100Base-TX port,

RS232/485 port, Console port, AUX port, RESET button, LPU status LEDs, SRP1N6

status LEDs (SFS, ACT, ALM, RUN), as shown in

Figure 1-13.

Figure 1-13 SRP1N6 panel

3) User ports

z CF port

The SRP1N6 module provides a CF port to accommodate a standard CF card, where

you can save logging information, host version information, alarming and other

diagnostic information and conveniently upgrade software online.

z Management 10Base-T/100Base-TX port

The management 10Base-T/100Base-TX port uses an RJ-45 connector. It can connect

a background terminal for system program loading and debugging, or connect a

network management station for remote system management.

Table 1-25 Management 10Base-T/100Base-TX port specifications

Attribute Description

Connector RJ-45

Number of ports One

Rate

Max. transmission segment

over the selected medium

Service

10 Mbps, half duplex/full duplex

100 Mbps, half duplex/full duplex

100 m (328 ft) over the category-5 twisted pair

cable (crossover cable is required.)

System program upgrade and network

management

The following table describes the status LEDs for the management

10Base-T/100Base-TX port.

1-21

Page 28

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

Table 1-26 Status LEDs for the management 10Base-T/100Base-TX port

LED Status

LINK

OFF No link is present.

Green A link is present.

OFF No packets are transmitted/received on the port.

ACT

Orange blinking

Packets are being transmitted/received on the

port.

z RS232/485 port

The RS232/485 port uses RJ-45 connector, for connecting external PoE power frame

when supported and monitoring its status.

Table 1-27 RS232/485 port specifications

Attribute Description

Connector RJ-45

Number of ports One RS 232 port and one RS485 port

Service

The port for monitoring and communication with the external

subsystem, such as external PoE power supply module

z Console port

The Console port uses an RJ-45 connector. It can be connected to a background

terminal for system debugging, maintenance, management, and host software loading.

Table 1-28 Console port specifications

Attribute Description

Connector RJ-45

Standard Asynchronous EIA/TIA-232

Baud rate 9600 bps (default)

Transmission distance

Service

≤ 15 m (49 ft)

Connects a serial port of a local PC and runs terminal

emulation on the PC.

Note:

You can choose your own baud rate for the Console port.

1-22

Page 29

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

z AUX port

The AUX port uses an RJ-45 connector. The port can serve as a backup port for the

Console port to connect a background terminal, or directly connect a modem device,

for remote system debugging, configuration, maintenance and management.

Table 1-29 AUX port specifications

Attribute Description

Connector RJ-45

Standard Asynchronous EIA/TIA-232

Service

Connects a serial port of a PC (through a Modem pair for a

remote PC) and runs terminal emulation on the PC.

4) RESET button

You can press the RESET button on the panel to reset the SRP1N6 module.

5) Status LEDs

z CF status LED

You can check operating status of the CF card by reading the CF status LED on the

panel.

Table 1-30 CF status LED

LED Status

The CF card is in position and is idle. You cannot remove

the card.

The CF card is in position and reading/writing data. You

cannot remove the card.

CFS

ON

Blinking

The CF card is out of position or offline (you can force the

OFF

in-position CF card to go offline using the appropriate

background command). You can remove/insert the card.

z Status LEDs for LPU modules

The SRP1N6 module has five pairs of LEDs to indicate the operating status of five LPU

modules.

1-23

Page 30

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

Table 1-31 Status LEDs for LPU modules

LED Status

ON The module is faulty.

OFF The module is faulty or out of position.

RUN

Blinking (1s) The module is running normally.

Fast blinking

(125ms)

The module is booting or not registered

successfully.

ON The module has alarms.

ALM

OFF The module has no alarms or is out of position.

2~6 Indicate slots 2 through 6

z Status LEDs for the SRP1N6 module

You can learn the operating status of SRP1N6 module by reading the SFS, ACT, ALM

and RUN LEDs on it. The following table gives a summary of the four LEDs.

Table 1-32 Status LEDs for the SRP1N6 module

SRP1N6 LED Status

ON The switching fabric unit is active.

SFS

OFF The switching fabric unit is standby.

Green The SRP1N6 module is faulty.

RUN

OFF The SRP1N6 module is faulty.

Green blinking The SRP1N6 module runs normally.

Red The SRP1N6 module has alarms.

ALM

OFF

Green The SRP1N6 module is active.

The SRP1N6 module has no alarms.

ACT

OFF

The SRP1N6 module is standby.

IV. SRP1N7 module

1) Specifications

The S9512, 9508 and 9505 can use SRP1N7 modules, which integrate clock modules

in them. The following table summarizes the specifications.

1-24

Page 31

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

Table 1-33 SRP1N7 module specifications

Attribute SRP1N7

CPU MPC755

Boot ROM 512KB

SDRAM 1GB

Dimensions (L × W) 366.7 × 340 mm (14.4 × 13.4 in.)

One Console port, for local configuration management

One AUX port, for remote dialup configuration

management

One 10Base-T/100Base-TX port for system

Port

management and program upgrade

One RS232/485 port, for connecting external PoE

power frame when supported

One hot-swappable CF port

Two SMB coaxial clock ports

Max. power consumption 70 W

2) SRP1N7 panel

The SRP1N7 module provides SMB coaxial clock ports, CF card, CF LED (CFS), 10

Base-T/100Base-TX port, RS232/485 port, Console port, AUX port, RESET button,

LPU status LEDs, SRP1N7 status LEDs (SFS, ACT, ALM, RUN), as shown in

.

1-14

Figure

Figure 1-14 SRP1N7 panel

3) User ports

z SMB coaxial clock port

The two SMB coaxial clock ports are used as the external benchmark input for internal

clock modules or the clock benchmark for external devices. The port rate/frequency is

2.048 Mbps or 2.048 MHz. You can manually configure the ports through the DIP switch

on the clock module.

z CF port

The SRP1N7 module provides a CF port to accommodate a standard CF card, where

you can save logging information, host version information, alarming and other

diagnostic information and conveniently upgrade software online.

z Management 10Base-T/100Base-TX port

1-25

Page 32

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

The management 10Base-T/100Base-TX port uses an RJ-45 connector. It can connect

a background terminal for system program loading and debugging, or connect a

network management station for remote system management.

Table 1-34 Management 10Base-T/100Base-TX port specifications

Attribute Description

Connector RJ-45

Number of ports One

Rate

Max. transmission distance

over the selected medium

10 Mbps, half duplex/full duplex

100 Mbps, half duplex/full duplex

100 m (328 ft) over the category-5 twisted pair cable

(crossover cable is required.)

Service System program upgrade and network management

The following table describes the status LEDs for the management

10Base-T/100Base-TX port.

Table 1-35 Status LEDs for the management 10Base-T/100Base-TX port

LED Status

OFF No link is present.

LINK

Green A link is present.

OFF No packets are transmitted/received on the port.

ACT

Orange blinking Packets are being transmitted/received on the port.

z RS232/485 port

The RS232/485 port uses RJ-45 connector, for connecting external PoE power frame

when supported and monitoring its status.

Table 1-36 RS232/485 port specifications

Attribute Description

Connector RJ-45

Number of ports One RS 232 port and one RS485 port

Service

The port for monitoring and communication with the external

subsystem, such as external PoE power supply module

z Console port

1-26

Page 33

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

The Console port uses an RJ-45 connector. It can be connected to a background

terminal for system debugging, maintenance, management, and host software loading.

Table 1-37 Console port specifications

Attribute Description

Connector RJ-45

Standard Asynchronous EIA/TIA-232

Baud rate 9600 bps (default)

Transmission

distance

Service

≤ 15 m (49 ft)

Connects a serial port of a local PC and runs terminal

emulation on the PC.

Note:

You can choose your own baud rate for the Console port.

z AUX port

The AUX port uses an RJ-45 connector. The port can serve as a backup port for the

Console port to connect a background terminal, or directly connect a modem device,

for remote system debugging, configuration, maintenance and management.

Table 1-38 AUX port specifications

Attribute Description

Connector RJ-45

Standard Asynchronous EIA/TIA-232

Service

Connects a serial port of a PC (through a Modem pair for a

remote PC) and runs terminal emulation on the PC.

4) RESET button

You can press the RESET button on the panel to reset the SRP1N7 module.

5) Status LEDs

z CF status LED

You can check operating status of the CF card by reading the CF status LED on the

panel. Fore more details about the LEDs, see

z Status LEDs for LPU modules

1-27

Table 1-12

Page 34

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

The SRP1N7 module has 12 pairs of LEDs to indicate the operating status of 12 LPU

modules. Fore more details about the LEDs, see

z Status LEDs for the SRP1N7 module

Table 1-13.

You can learn the operating status of SRP1N7 module by reading the SFS, ACT, ALM

and RUN LEDs on it. Fore more details about the LEDs, see

Table 1-14.

V. SRP1M1 module

1) Specifications

The S9502 uses SRP1M1 modules. The following table summarizes the module

specifications.

Table 1-39 SRP1M1 module specifications

Attribute SRP1M1

CPU MPC755

BootROM 512 KB

SDRAM 512 MB (expandable to 1 GB)

Dimensions (W x D)

366.7 × 340 mm (14.4 × 13.4 in)

One Console port, for local configuration management

One AUX port, for remote dialup configuration

management

One 10Base-T/100Base-TX port, for software upgrade

and network management

Port

One RS232/485 port, for connecting the external PoE

power frame when using PoE function; The RS485 port

supports the cascade connection of PoE power frame and

NEPS3500-AB when using PoE function and

NEPS3500-AB.

One hot-swappable CF port

Max power

consumption

60 W

2) Panel

The SRP1M1 module provides a CF port and CF LED (CFS), a 10Base-T/100Base-TX

port, RS232/485 port, Console port and AUX port, a RESET button, LPU status LEDs,

and SRP1M1 status LEDs (SFS, ACT, ALM, and RUN), as shown in

Figure 1-15.

Figure 1-15 SRP1M1 panel

1-28

Page 35

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

3) User ports

Refer to “

User ports” in "SRP1N4 module".

4) RESET button

You can press the RESET button on the panel to reset the SRP1M1 module.

5) Status LEDs

z CF status LED

You can check the operating status of the CF card by reading the CF status LED on the

panel. For more details about the LED, refer to

z Status LEDs for LPU modules

Table 1-12.

The SRP1M1 module has three pairs of LEDs to indicate the operating status of the

three LPU modules.

Table 1-40 Status LEDs for LPU modules

LED Status

RUN

ON

OFF

Blinking (1s)

The module has failed.

The module has failed or is not present.

The module is operating normally.

When the module is starting up, the RUN

Fast blinking

(125ms)

LED is steady on or fast blinking.

Continuous fast blinking status indicates the

module registration fails.

ALM

1~3 Indicate slots 1 through 3

z Status LEDs for the SRP1M1 module

You can learn the operating status of the SRP1M1 module by reading the SFS, ACT,

ALM and RUN LEDs on its panel. For more details, refer to

1.2.7 LPU Modules

These types of LPU modules are available on the S9500 series:

OFF

ON

There are no alarms on the module or the

module is not present.

There are alarms on the module.

Table 1-14.

1-29

Page 36

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

Table 1-41 LPU modules supported on the S9500 series

LPU User interface

XP2

XP4

XK1

GP12

GP24

FP20

F32G

GT24

GV48

FT48

P4G8

SP4

UP1

2 × 10GEBase-R XFP/LC/10GEBase-W XFP/LC optical ports

4 × 10GE XFP/LC optical ports (1:2 convergence)

1 × 10GE XENPAK/SC port

12 × 1000 Mbps SFP/LC optical ports

24 × 1000 Mbps SFP/LC optical ports

20 × 100 Mbps SFP/LC optical ports

4 × 1000 Mbps SFP/LC optical ports and 32 × 10/100 Mbps

auto-sensing RJ-45 ports

24 × 10/100/1000 Mbps auto-sensing RJ-45 electrical ports

48 × 10/100/1000 Mbps auto-sensing RJ-45 electrical ports

(PoE-supported)

48 × 10/100 Mbps auto-sensing electrical ports

8 × 1000 Mbps SFP/LC optical ports and 4 × 155Mbps SFP/LC

POS optical ports

4 × OC-48c SFP/LC POS optical ports

1 × OC-192c XFP/LC POS optical port

1.2.8 Service Processor Cards

The service processor card is designed specially for high-speed processing of a certain

service, which covers partial or no functions of LPU modules.

The S9500 series support these types of service processor cards:

z NAT service processor card (LSB1NATB0): No external port available.

z VPLS service processor card (LSB1VPNB0): No external port available.

I. NAT service processor card

1) Technical specifications

The NAT service processor card provides no external port.

Table 1-42 Technical specifications of the NAT service processor card

Attribute NAT

CPU MPC755

Boot ROM 512 KB

1-30

Page 37

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

Attribute NAT

SDRAM 512 MB

Dimensions (L × W) 366.7 × 340 mm

2) Front and rear panels

Figure 1-16 Front panel of the NAT service processor card

Figure 1-17 Rear panel of the NAT service processor card

II. VPLS service processor card

1) Technical specifications

The VPLS service processor card provides no external port.

Table 1-43 Technical specifications of the VPLS service processor card

Attribute VPN

CPU MPC755

Boot ROM 512 KB

SDRAM 512 MB

Dimensions (L × W) 366.7 × 340mm (14.4 × 13.4 in)

2) Front and rear panels

Figure 1-18 Front panel of the VPLS service processor card

Figure 1-19 Rear panel of the VPLS service processor card

1-31

Page 38

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

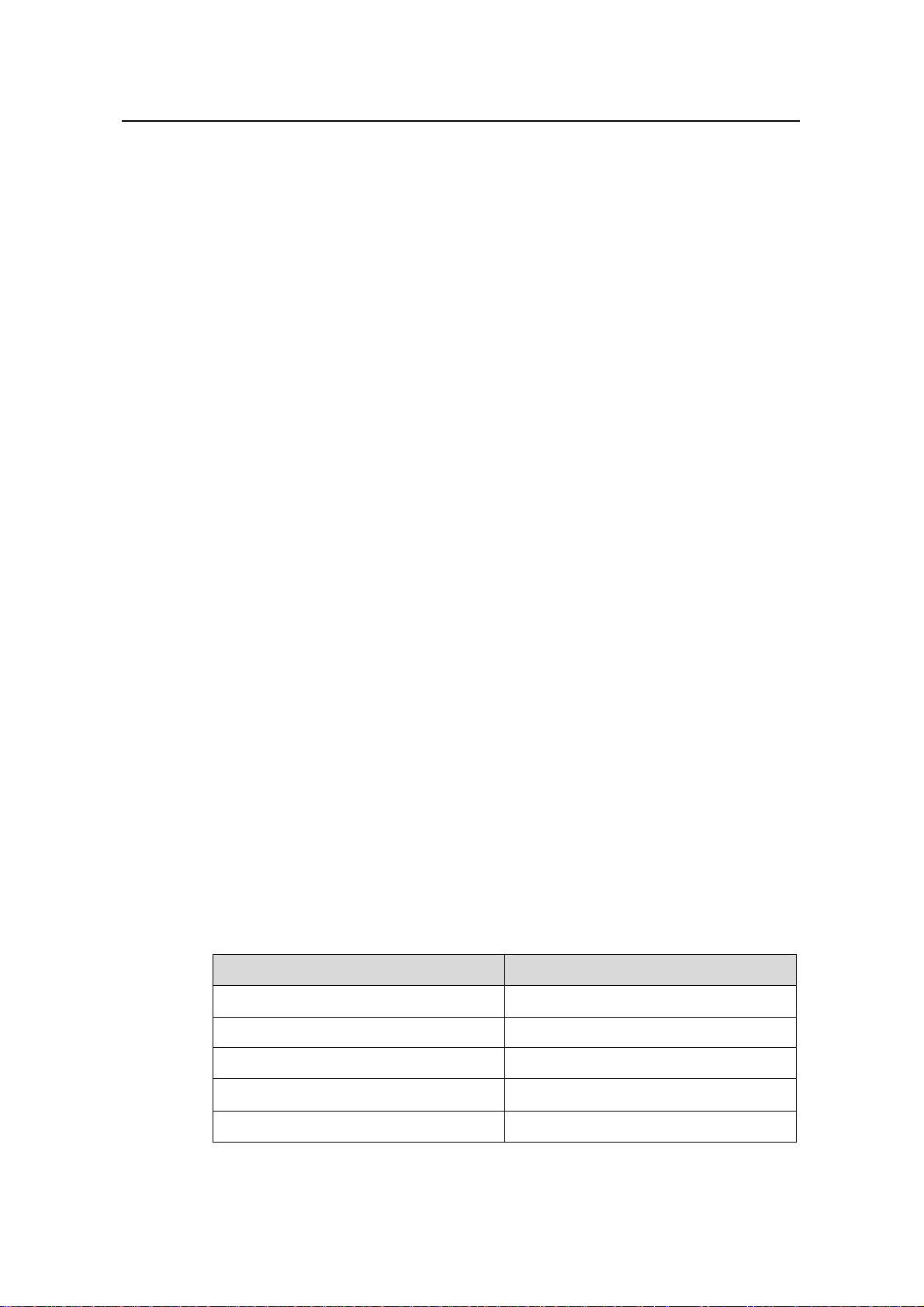

1.2.9 System Specifications

The following table summarizes the physical specifications of the S9500 series.

Table 1-44 Technical specifications of the S9500 series

Item S9502 S9505 S9508 S9512

Dimensions

(H × W × D,

in mm)

Weight (full

load)

Max power

consumption

Switching

capacity

Number of

VLANs

MAC

address

table size

Forwarding

table entries

Number of

SRP slots

264 × 436 × 442

mm (10.4 × 17.2

× 17.4 in)

≤ 40 kg (88.2 lb)

486 × 436 ×

450 mm (19.1

× 17.2 × 17.7

in)

≤ 65 kg (143.3

lb)

619 × 436 ×

450 mm (24.4

× 17.2 × 17.7

in)

≤ 80 kg (176.4

lb)

753 × 436 ×

450 mm (29.6

× 17.2 × 17.7

in)

≤ 100 kg

(220.5 lb)

600 W 1200 W 2000 W 2000/3500 W

SRP1N: 480

Gbps

SRP2N:

960 Gbps

SRP1N: 720

Gbps

SRP2N: 1440

Gbps

240 Gbps

SRP1N: 300

Gbps

SRP2N: 600

Gbps

4 K 4 K 4 K 4 K

14 K per card, the maximum table size supported by the switch is 14

K × n (number of cards)

128 K/256 K/512 K

1 or 2 2 2 2

SRPU

module type

Number of

LPU slots

SRP1M0

SRP1N2

SRP1N3

SRP2N2

SRP2N3

SRP1NA2

SRP1NA3

SRP1N1

SRP1N3

SRP2N1

SRP2N3

SRP1NA1

SRP1NA3

SRP1N0

SRP1N3

SRP2N0

SRP2N3

SRP1NA0

SRP1NA3

3 or 2 5 8 12

1-32

Page 39

Installation Manual

H3C S9500 Series Routing Switches Chapter 1 Product Overview

Item S9502 S9505 S9508 S9512

100BASE-FX SFP

10/100BASE-TX RJ-45

1000BASE-X-SFP

10/100/1000BASE-TX RJ-45

10/100BASE-TX RJ-45 with PoE (Power over Ethernet)

User

interface

10GBASE-R XENPAK

10GBASE-R/W XFP

10GBASE-CX4 XENPAK

OC-3c POS SFP

OC-48c POS SFP

OC-192c POS XFP

OC-192c RPR XFP

Operating

temperature

0°C to 40°C (32°F to 104°F)

Operating

humidity

(noncondens

10% to 90%

ing)

Storage

temperature

Storage

humidity

–40°C to 70°C (–40°F to 158°F)

5% to 95%

Note:

All specifications are subject to changes without notice. For up-to-date information,

please contact H3C marketing or technical support personnel.

1-33

Page 40

Installation Manual

H3C S9500 Series Routing Switches Table of Contents

Table of Contents

Chapter 2 LPU Modules................................................................................................................ 2-1

2.1 Overview............................................................................................................................ 2-1

2.2 XP2 Module .......................................................................................................................2-1

2.2.1 Specifications..........................................................................................................2-1

2.2.2 Panel and LEDs ...................................................................................................... 2-2

2.2.3 Matching Cable....................................................................................................... 2-2

2.3 XP4 Module .......................................................................................................................2-3

2.3.1 Specifications..........................................................................................................2-3

2.3.2 Panel and LEDs ...................................................................................................... 2-4

2.3.3 Matching Cable....................................................................................................... 2-4

2.4 XK1 Module .......................................................................................................................2-4

2.4.1 Specifications..........................................................................................................2-4

2.4.2 Panel and LEDs ...................................................................................................... 2-5

2.4.3 Matching Cable....................................................................................................... 2-5

2.5 GP12 Module..................................................................................................................... 2-6

2.5.1 Specifications..........................................................................................................2-6

2.5.2 Panel and LEDs ...................................................................................................... 2-6

2.5.3 Matching Cable....................................................................................................... 2-6

2.6 GP24 Module..................................................................................................................... 2-7

2.6.1 Specifications..........................................................................................................2-7

2.6.2 Panel and LEDs ...................................................................................................... 2-8

2.6.3 Matching Cable....................................................................................................... 2-8

2.7 FP20 Module......................................................................................................................2-8

2.7.1 Specifications..........................................................................................................2-8

2.7.2 Panel and LEDs ...................................................................................................... 2-9

2.7.3 Matching Cable....................................................................................................... 2-9

2.8 F32G Module...................................................................................................................2-10

2.8.1 Specifications........................................................................................................2-10

2.8.2 Panel and LEDs .................................................................................................... 2-10

2.8.3 Matching Cable..................................................................................................... 2-11

2.9 GT24 Module...................................................................................................................2-12

2.9.1 Specifications........................................................................................................2-12

2.9.2 Panel and LEDs .................................................................................................... 2-13

2.9.3 Matching Cable..................................................................................................... 2-13

2.10 GV48 Module................................................................................................................. 2-14

2.10.1 Specifications......................................................................................................2-14

2.10.2 Panel and LEDs.................................................................................................. 2-14

2.10.3 Matching Cable................................................................................................... 2-15

i

Page 41

Installation Manual

H3C S9500 Series Routing Switches Table of Contents

2.11 FT48 Module.................................................................................................................. 2-15

2.11.1 Specifications......................................................................................................2-15

2.11.2 Panel and LEDs.................................................................................................. 2-15

2.11.3 Matching Cable................................................................................................... 2-16

2.12 P4G8 Module................................................................................................................. 2-17

2.12.1 Specifications......................................................................................................2-17

2.12.2 Panel and LEDs.................................................................................................. 2-17

2.12.3 Matching Cable................................................................................................... 2-18

2.13 SP4 Module ................................................................................................................... 2-18

2.13.1 Specifications......................................................................................................2-18

2.13.2 Panel and LEDs.................................................................................................. 2-19

2.13.3 Matching Cable................................................................................................... 2-19

2.14 UP1 Module...................................................................................................................2-20

2.14.1 Specifications......................................................................................................2-20

2.14.2 Panel and LEDs.................................................................................................. 2-20

2.14.3 Matching Cable................................................................................................... 2-20

ii

Page 42

Installation Manual

H3C S9500 Series Routing Switches Chapter 2 LPU Modules

Chapter 2 LPU Modules

2.1 Overview

The S9500 series are modular switches that are designed following indu stry standards.

The series can be equipped with these types of LPU modules:

z XP2 module: provides two 10GEBase-R XFP/LC/10GEBase-W XFP/LC optical

ports

z XP4 module: provides four 10GE XFP/LC optical ports (1:2 convergence)

z XK1 module: provides one 10 GE XENPAK/SC optical/electrical port

z GP12 module: provides 12 × 1000 Mbps SFP/LC electrical/optical ports

z GP24 module: provides 24 × 1000 Mbps SFP/LC optical ports

z FP20 module: provides 20 × 100 Mbps SFP/LC optical ports

z F32G module: provides four 1000 Mbps SFP/LC optical ports and 32 × 10/100

Mbps auto-sensing RJ-45 ports

z GT24 module: provides 24 × 10/100/1000 Mbps auto-sensing RJ-45 ports

z GV48 module: provides 48 × 10/100/1000 Mbps PoE-capable auto-sensing RJ-45

ports

z FT48 module: provides 48 × 10/100 Mbps ports

z P4G8 module: provides eight 1000 Mbps SFP/LC optical ports and four 155 Mbps

SFP/LC POS optical ports

z SP4 module: provides four OC-48c SFP/LC POS optical ports

z UP1 module: provides one OC-192c XFP/LC POS optical port

2.2 XP2 Module

2.2.1 Specifications

The XP2 module provides two 10GEBase-R XFP/LC/10GEBase-W XFP/LC optical

ports.

Table 2-1 XP2 module specifications

CPU MPC8245

Boot ROM 512 KB

SDRAM 128 MB/256MB

Dimensions (L × W) 366.7 × 340 mm (14.4 × 13.4 in.)

Max. power consumption 87 W

Attribute XP2

2-1

Page 43

Installation Manual

H3C S9500 Series Routing Switches Chapter 2 LPU Modules

Attribute XP2

Number of ports Two

Connector XFP/LC

Rate 10 Gbps

2.2.2 Panel and LEDs

Figure 2-1 XP2 module panel

The XP2 module has two LEDs for each optical port on its panel.

Table 2-2 1000 Mbps optical port LEDs on the XP2 module

LED Status

OFF No link is present.

LINK

Green A link is present.

OFF No packets are transmitted/received on the port.

ACT

Orange blinking Packets are being transmitted/received on the port.

2.2.3 Matching Cable

The XP2 module provides two 10 Gbps XFP optical port s. To provide optical ports, you

can use these XFP optical modules.

2-2

Page 44

Installation Manual

H3C S9500 Series Routing Switches Chapter 2 LPU Modules

Table 2-3 Optical interface modules available for the XP2 module

SFP module

10GBase-SR

/SW-XFP

10GBase-LR/

LW-XFP

10GBase-ER

/EW-XFP

Central

wavelength

850 nm

1310 nm

1550 nm

Connector

LC

Matching

cable

26 m (85.3 ft) for the

62.5 µm MMF w/

50/125 µm

multimode

optical fiber

cable

9/125 µm

single mode

optical fiber

cable

9/125 µm

single mode

optical fiber

cable

160MHz*km cable;

82 m (269.0 ft) for

the 50 µm MMF w/

500MHz*km cable;

300 m (984.3 ft) for

the 50 µm MMF w/

2000MHz*km cable

10 km (6 mi)

40 km (25 mi)

Transmission

distance

2.3 XP4 Module

2.3.1 Specifications

The XP4 module provides four 10GE XFP/LC optical ports (1:2 convergence).

Table 2-4 XP4 module specifications

CPU MPC8245

Boot ROM 512 KB

SDRAM 128 MB/256MB

Dimensions (L × W) 366.7 × 340 mm (14.4 × 13.4 in.)

Number of ports Four

Max. power consumption (with bottom plate) 160 W

Connector XFP/LC

Rate 10 Gbps

Attribute XP2

2-3

Page 45

Installation Manual

H3C S9500 Series Routing Switches Chapter 2 LPU Modules

2.3.2 Panel and LEDs

Figure 2-2 XP4 module panel

The XP4 module has two LEDs for each optical port on its panel.

Table 2-5 1000 Mbps optical port LEDs on the XP4 module

LED Status

LINK

OFF No link is present.

Green A link is present.

OFF No packets are transmitted/received on the port.

ACT

Orange blinking Packets are being transmitted/received on the port.

2.3.3 Matching Cable

The XP4 module provides four 10 Gbps XFP optical port s. For more det ail s about XFP

optical modules, see

2.4 XK1 Module

2.4.1 Specifications

The XK1 module provides one 10GE XENPAK/SC optical/electrical port.

Table 2-6 XK1 module specifications

Table 2-3.

Attribute XK1

CPU MPC8245

Boot ROM 512 KB

SDRAM 128 MB/256 MB

Dimensions (L × W) 366.7 × 340 mm(14.4 × 13.4 in.)

Max. power consumption 45 W

Number of ports One

Connector XENPAK/SC

Rate 10 Gbps

2-4

Page 46

Installation Manual

H3C S9500 Series Routing Switches Chapter 2 LPU Modules

2.4.2 Panel and LEDs

Figure 2-3 XK1 module panel

The XK1 module has two port LEDs for the 10GE port on its panel.

Table 2-7 Port LEDs on the XK1 module

LED Status

LINK

OFF No link is present.

Green ON A link is present.

OFF No packets are transmitted/received on the port.

ACT

Orange blinking Packets are being transmitted/received on the port.

2.4.3 Matching Cable

The XK1 module provides one 10GE XENPAK/SC optical or electrical port. You can

use these XENPAK optical modules.

Table 2-8 Interface modules available for the XK1 module

SFP module

10GBASE-S

R-XENPAK

Central

wavelength

850 nm

Conne

ctor

SC

Matching

cable

Multimode

optical fiber

cable

Transmission

distance

26 m (85.3 ft) for the

62.5 µm MMF w/

160MHz*km cable;

82 m (269.0 ft) for the

50 µm MMF w/

500MHz*km cable;

300 m (984.3 ft) for the

50 µm MMF w/

2000MHz*km cable

10GBASE-L

R-XENPAK

10GBASE-E

R-XENPAK

1310 nm 10 km (6 mi)

Single mode

1550 nm

optical fiber

cable

40 km (25 mi)

80 km (50 mi)

2-5

Page 47

Installation Manual

H3C S9500 Series Routing Switches Chapter 2 LPU Modules

2.5 GP12 Module

2.5.1 Specifications

The GP12 module provides 12 × 1000 Mbps SFP/LC optical ports.

Table 2-9 GP12 module specifications

Attribute GP12

CPU MPC8245

Boot ROM` 512 KB

SDRAM 128 MB/256 MB

Dimensions (L × W) 366.7 × 340 mm (14.4 × 13.4 in.)

Max. power consumption 55 W

Number of ports 12

Connector SFP/LC

Rate 1000 Mbps

2.5.2 Panel and LEDs

Figure 2-4 GP12 module panel

The GP12 module has two LEDs for each port on its panel.

Table 2-10 Port LEDs on the GP12 module

LED Status

OFF No link is present.

LINK

Green A link is present.

OFF No packets are transmitted/received on the port.

ACT

Orange blinking Packets are being transmitted/received on the p ort.

2.5.3 Matching Cable

The GP12 module can provide 12 × 1000 Mbps optical ports. You can use these SFP

optical modules:

2-6

Page 48

Installation Manual

H3C S9500 Series Routing Switches Chapter 2 LPU Modules

Table 2-11 Interface modules available for the GP12 module

SFP module

1000BASE-SX-SFP 850 nm

1000BASE-LX-SFP 10 km (6 mi)

1000BASE-LH-SFP

1000BASE-ZX-LR-

SFP

1000BASE-ZX-VR-

SFP

1000BASE-ZX-UR-

SFP

Central

wavelength

1310 nm

1550 nm

Connector

LC

Matching

cable

50/125 µm

multimode

optical fiber

cable

62.5/125 µm

multimode

optical fiber

cable

9/125 µm

single mode

optical fiber

cable

Transmission

distance

550 m (1804

ft)

275 m (902 ft)

40 km (25 mi)

70 km (43 mi)

100km (62 mi)

2.6 GP24 Module

2.6.1 Specifications

The GP24 module provides 24 × 1000 Mbps SFP/LC optical ports.

Table 2-12 GP24 module specifications

CPU MPC8245

Boot ROM 512 KB

SDRAM 128 MB/256MB

Dimensions (L × W) 366.7 × 340 mm (14.4 × 13.4 in.)

Max. power consumption 100 W

Number of ports 24

Connector SFP/LC

Rate 1000 Mbps

Attribute GP24

2-7

Page 49

Installation Manual

H3C S9500 Series Routing Switches Chapter 2 LPU Modules

2.6.2 Panel and LEDs

Figure 2-5 GP24 module panel

The GP24 module has two LEDs for each 1000 Mbps optical port on its panel.

Table 2-13 Port LEDs on the GP24 module

LED Status

LINK

ACT

2.6.3 Matching Cable

The GP24 module provides 24 × 1000 Mbps optical ports. For more details about SFP

optical modules, see

2.7 FP20 Module

2.7.1 Specifications

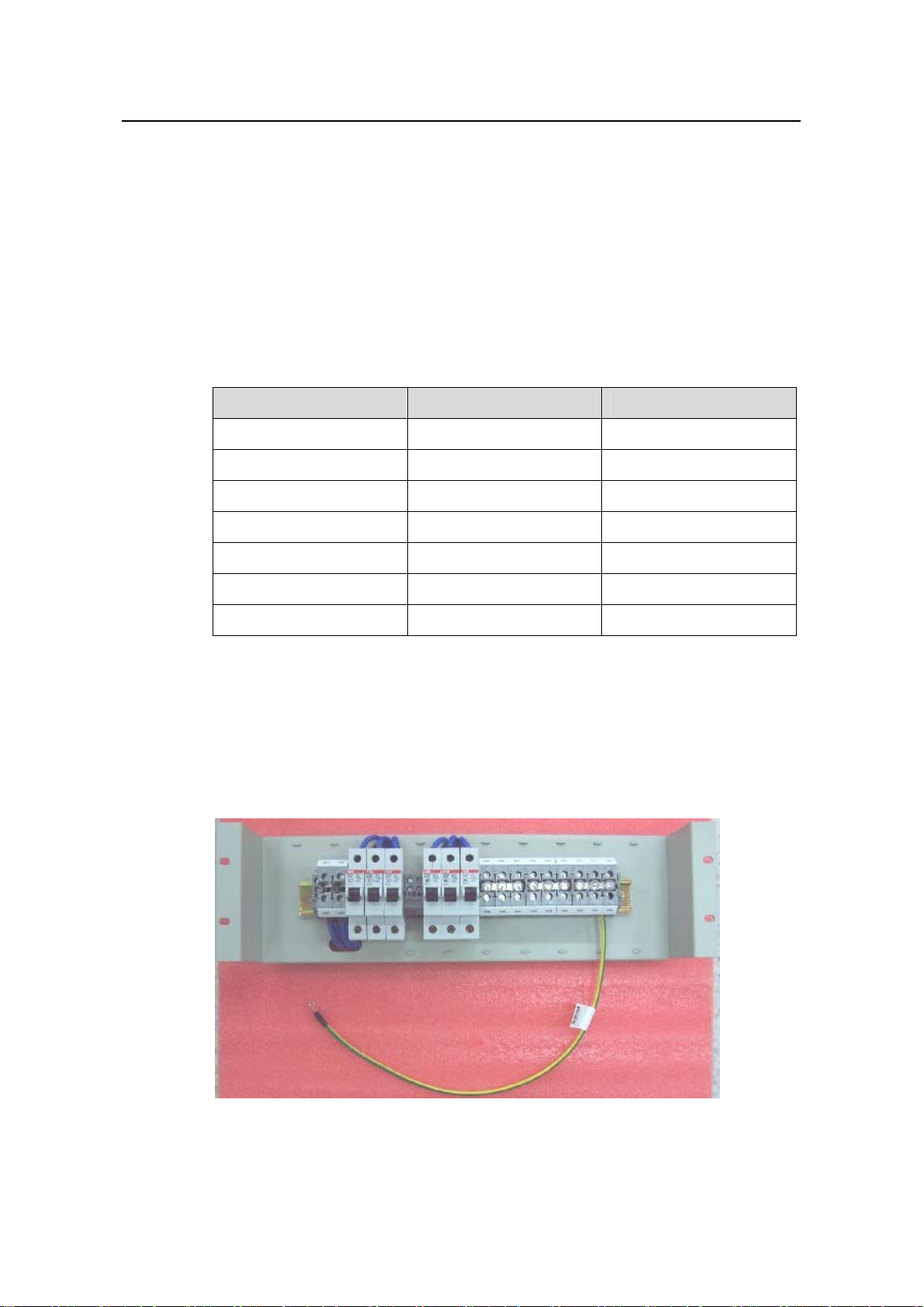

The FP20 module provides 20 × 100 Mbps SFP/LC optical ports.