H3C S3100-8TP-EI-W, S3100-26TP-EI-W, S3100-16TP-EI-W, S3100-8TP-PWR-EI, S3100-16TP-PWR-EI Quick Start Manual

...Page 1

H3C S3100 Series Ethernet Switches

Quick Start (For Japan)

Hangzhou H3C Technologies Co., Ltd.

http://www.h3c.com

Manual Version: T2-08018X-20080110-C-1.04

Page 2

Copyright © 2007-2008, Hangzhou H3C Technologies Co.,

Ltd. and its licensors

All Rights Reserved

No part of this manual may be reproduced or transmitted in any form

or by any means without prior written consent of Hangzhou H3C

Technologies Co., Ltd.

Trademarks

H3C, , Aolynk, , H3Care,

, TOP G, , IRF,

NetPilot, Neocean, NeoVTL, SecPro, SecPoint, SecEngine, SecPath,

Comware, Secware, Storware, NQA, VVG, V

2

G, VnG, PSPT, XGbus,

N-Bus, TiGem, InnoVision and HUASAN are trademarks of Hangzhou

H3C Technologies Co., Ltd.

All other trademarks that may be mentioned in this manual are the

property of their respective owners.

Notice

The information in this document is subject to change without notice.

Every effort has been made in the preparation of this document to

ensure accuracy of the contents, but all statements, information, and

recommendations in this document do not constitute the warranty of

any kind, express or implied.

To obtain the latest information, please access:

http://www.h3c.com

Technical Support

customer_service@h3c.com

http://www.h3c.com

Page 3

About This Manual

Related Documentation

In addition to this manual, each H3C S3100 Series Ethernet

Switches documentation set includes the following:

Manual Content

H3C S3100 Series Ethernet

Switches Operation Manual

H3C S3100 Series Ethernet

Switches Command Manual

H3C S3100 Series Ethernet

Switches Installation Manual

(For Japan)

It is used for assisting the users

in data configurations and

typical applications.

It is used for assisting the users

in using various commands.

It is used for assisting the users

in switch installation, booting up,

hardware and software

maintenance.

Organization

H3C S3100 Series Ethernet Switches Quick Start (For Japan) is

organized as follows:

Chapter Contents

Introduces the characteristics and

1 Product Overview

2 Installation Preparation

technical specifications of S3100

Series Ethernet Switches.

Introduces the installation

preparation and precaution of

S3100 Series Ethernet Switches.

Page 4

Chapter Contents

3 Installation

Introduces the procedures to install

an S3100 Series Ethernet Switch,

including the setup of the

mainframe, cards and cables.

4 Lightning Protection of the

Switch

Introduces lightning protection of

S3100 Series Ethernet Switches.

Conventions

The manual uses the following conventions:

I.

GUI conventions

Convention Description

< >

[ ]

/

Button names are inside angle brackets.

For example, click <OK>.

Window names, menu items, data table

and field names are inside square

brackets. For example, pop up the [New

User] window.

Multi-level menus are separated by forward

slashes. For example, [File/Create/Folder].

II.

Symbols

Convention Description

Means reader be extremely careful.

Warning

Improper operation may cause bodily

injury.

Page 5

Convention Description

Means reader be careful. Improper

Caution

Note Means a complementary description.

operation may cause data loss or damage

to equipment.

Environmental Protection

This product has been designed to comply with the requirement s

on environmental protection. For the proper storage, use and disposal

of this product, national laws and regulations must be observed.

Page 6

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Table of Contents

Table of Contents

Chapter 1 Product Overview ........................................................1-1

1.1 Overview ............................................................................1-1

1.1.1 S3100-SI Series Ethernet Switches ........................1-2

1.1.2 S3100-EI Series Ethernet Switches ........................1-3

1.2 Introduction to Front Panel Power LEDs ...........................1-5

1.3 Technical Specifications ....................................................1-6

1.3.1 S3100-SI Series Ethernet Switch ............................1-6

1.3.2 S3100-EI Series Ethernet Switch ..........................1-10

1.4 SFP Modules Supported by S3100-EI Ethernet Switches1-16

1.5 ONU Modules...................................................................1-17

Chapter 2 Installation Preparation...............................................2-1

2.1 Precautions ........................................................................2-1

2.2 Requirements on Environment ..........................................2-1

2.2.1 Temperature/Humidity Requirements .....................2-2

2.2.2 Cleanness Requirements ........................................2-3

2.2.3 Anti-interference Requirements...............................2-4

2.2.4 Laser Usage Security ..............................................2-5

2.3 Installation Tools ................................................................2-5

Chapter 3 Installation....................................................................3-1

3.1 Installing a Switch ..............................................................3-1

3.1.1 Cabinet Mounting ....................................................3-1

3.1.2 Desk Mounting.......................................................3-16

3.1.3 Wall Mounting........................................................3-16

3.1.4 Magnet Mounting...................................................3-20

i

Page 7

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Table of Contents

3.2 Installing an Expansion Interface Module ........................3-23

3.3 Connection of Power Cord and Grounding Cable ...........3-24

3.3.1 Connecting AC Power Cord ..................................3-24

3.3.2 Connecting DC Power Cable ................................3-27

3.3.3 Connecting Grounding Cable ................................3-33

3.4 Connecting Optical Fiber .................................................3-38

3.5 Connection of Console Cable ..........................................3-39

3.5.1 Console Cable .......................................................3-39

3.5.2 Connecting Console Cable....................................3-40

3.6 Installation Verification .....................................................3-41

Chapter 4 Lightning Protection of the Switch ............................4-1

4.1 Installation of Lightning Arrester for AC Power (Socket Strip

with Lightning Protection).........................................................

4-1

4.2 Installation of Lightning Arrester for Network Port .............4-4

ii

Page 8

Quick Start (For Japan)

w

H3C S3100 Series Ethernet Switches

Chapter 1 Product Overvie

Chapter 1 Product Overview

1.1 Overview

H3C S3100 Series Ethernet Switches are high-performance,

high-density, easy-to-install, NMS-manageable intelligent Ethernet

switches which support wire-speed Layer 2 switching.

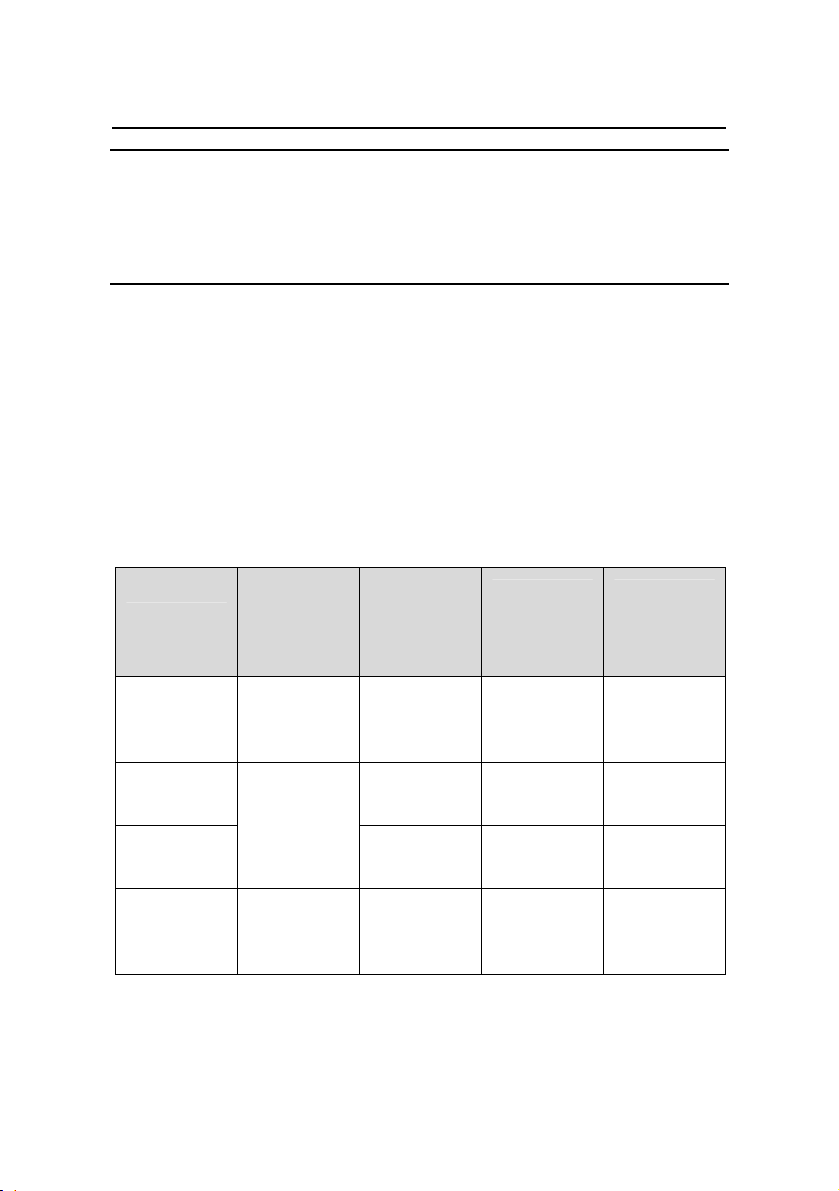

Table 1-1 lists the models of H3C S3100 Series Ethernet

Switches.

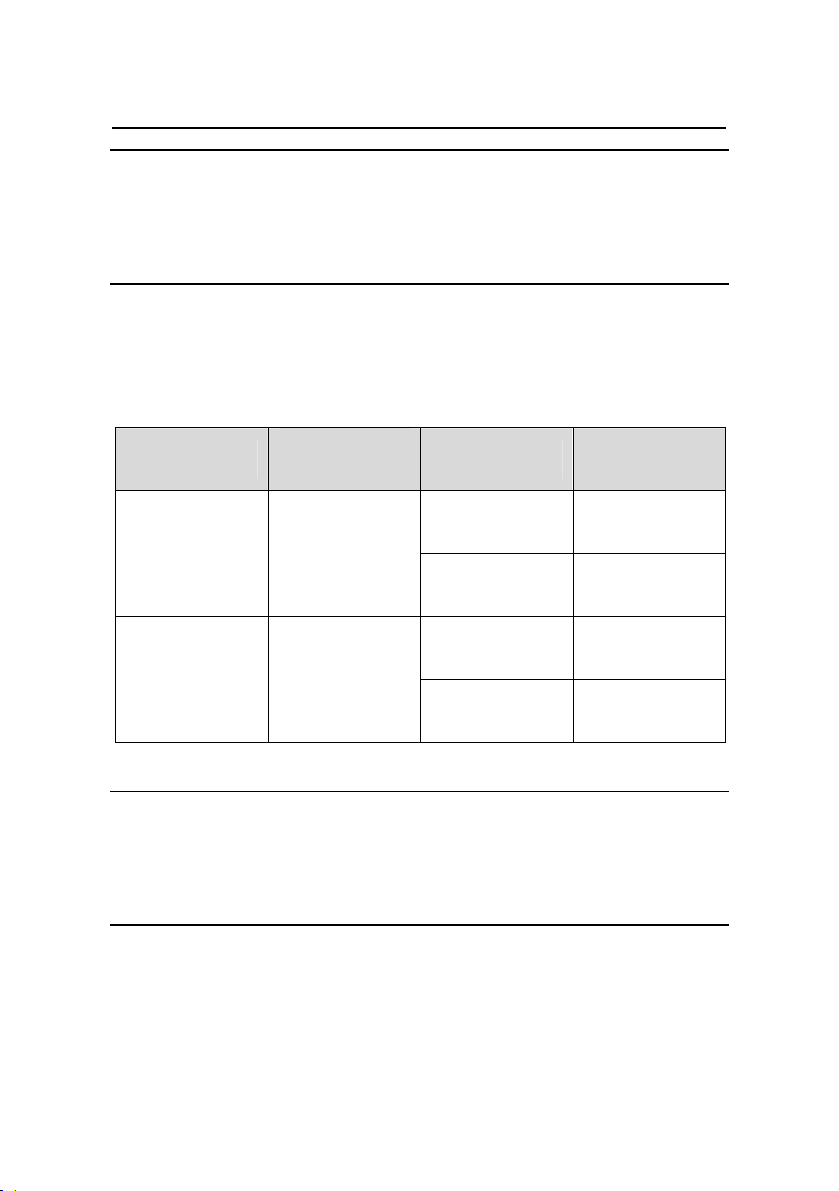

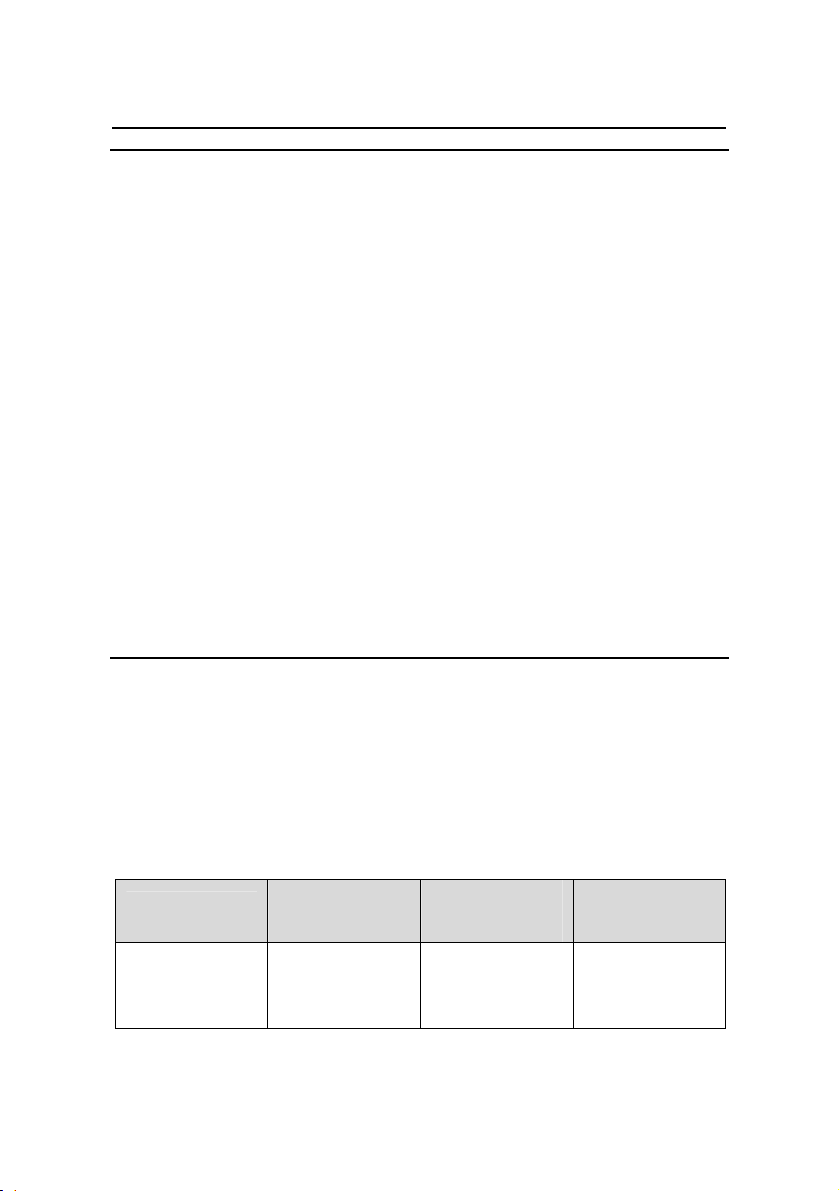

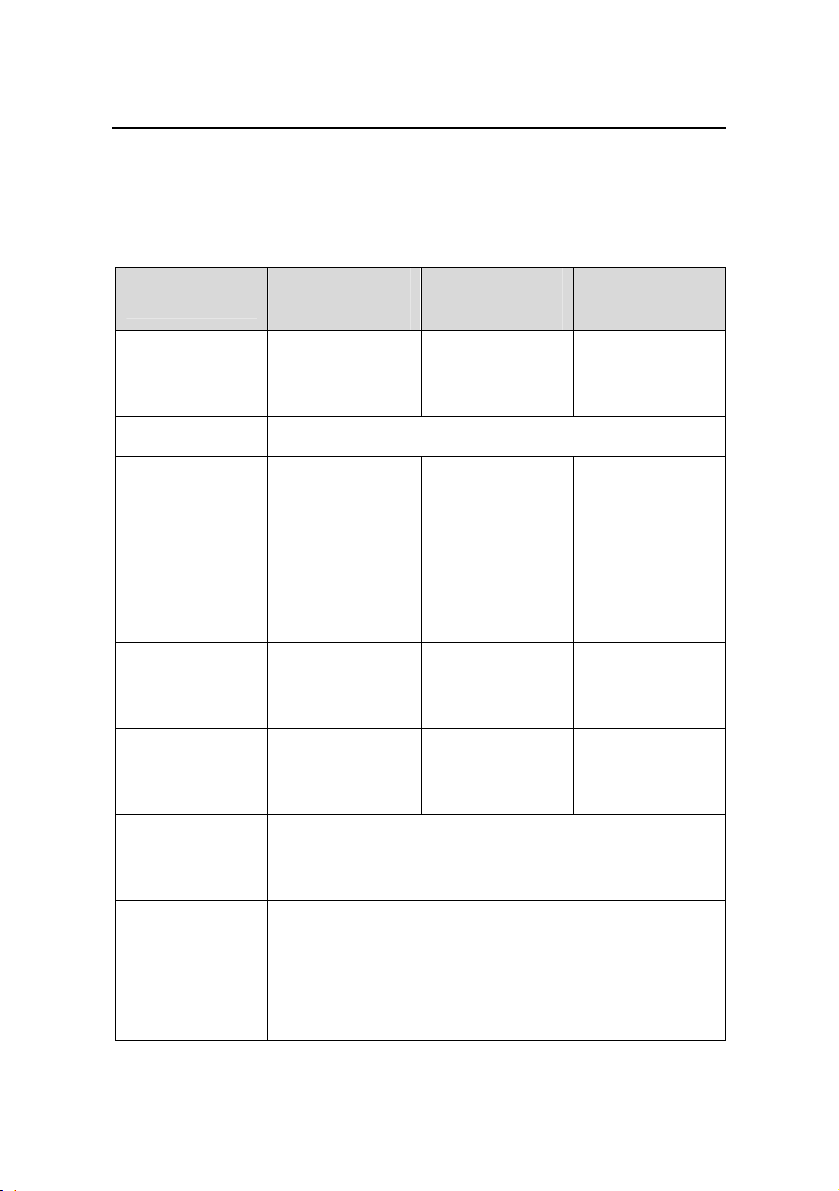

Table 1-1 Models of H3C S3100 Series Ethernet Switches

Name Subseries Model

z S3100-8C-SI

H3C

S3100

Series

Ethernet

Switches

S3100SI

S3100EI

S3100-C-SI

S3100-T-SI

S3100-TP-EI-W

S3100-TP-PWR

-EI

S3100-C-EPON

-EI

z S3100-16C-SI

z S3100-26C-SI

z S3100-8T-SI

z S3100-16T-SI

z S3100-26T-SI

z S3100-8TP-EI-W

z S3100-16TP-EI-W

z S3100-26TP-EI-W

z S3100-8TP-PWR-EI

z S3100-16TP-PWR-EI

z S3100-26TP-PWR-EI

z S3100-8C-EPON-EI

z S3100-16C-EPON-EI

z S3100-26C-EPON-EI

1-1

Page 9

Quick Start (For Japan)

w

H3C S3100 Series Ethernet Switches

Chapter 1 Product Overvie

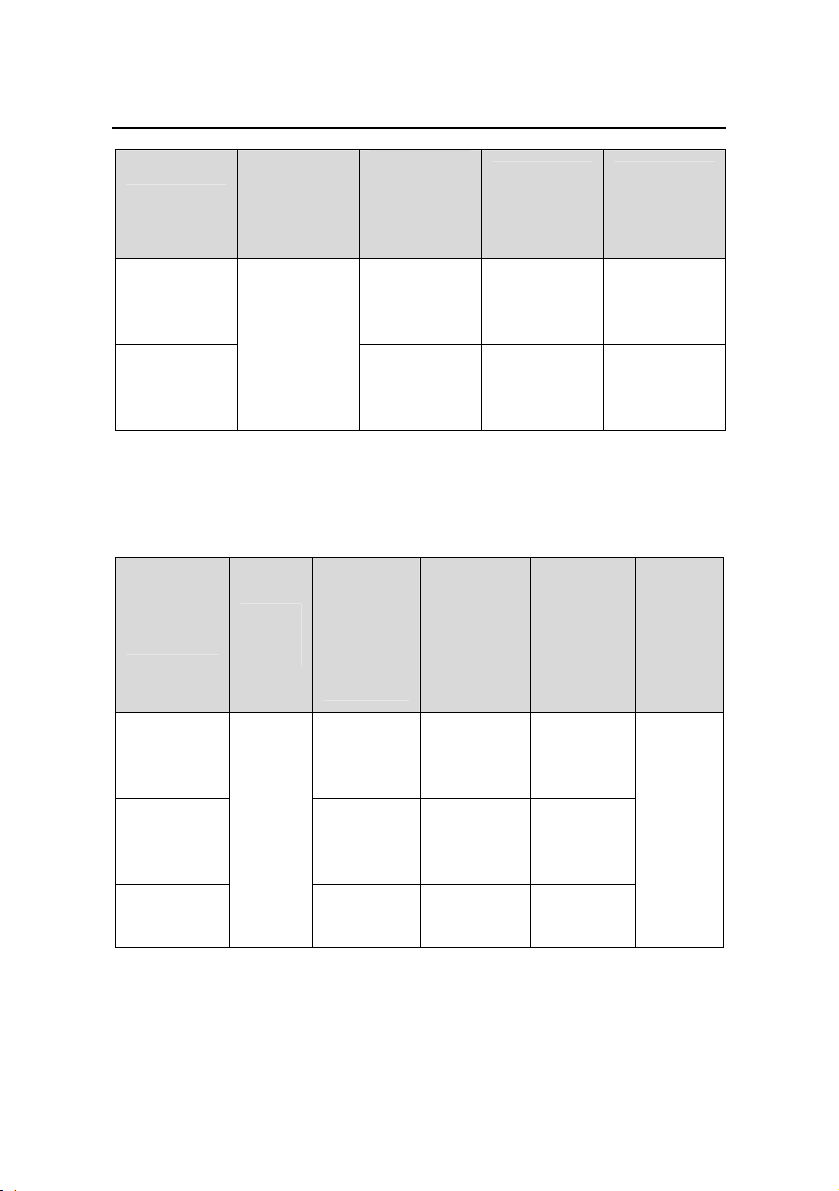

1.1.1 S3100-SI Series Ethernet Switches

Currently, S3100-SI Series Ethernet switches include S3100-T-SI

and S3100-C-SI, as listed in

Table 1-2 H3C S3100-T-SI Series Ethernet switches

Table 1-2 and Table 1-3.

Number

of

10/100M

electrical

Model

Power

supply

ports

S3100-26T-SI 24

S3100-16T-SI 16

S3100-8T-SI

AC

8

Number

of gigabit

uplink

ports

2 Ethernet

ports

1 Ethernet

port

Table 1-3 H3C S3100-C-SI Series Ethernet Switches

Model

S3100-26

C-SI

S3100-16

C-SI

S3100-8C

-SI

Power

supply

AC input for

AC-powere

d switch.

DC input for

DC-powere

d switch

Number of

10/100M

electrical

ports

24 2

16 2

8 1

Number of

expansion

slots

Number

of

console

ports

1

Number of

console

ports

1

1-2

Page 10

Quick Start (For Japan)

w

H3C S3100 Series Ethernet Switches

Chapter 1 Product Overvie

Note:

For details about each model, refer to H3C S3100 Series Ethernet

Switches Installation Manual (For Japan).

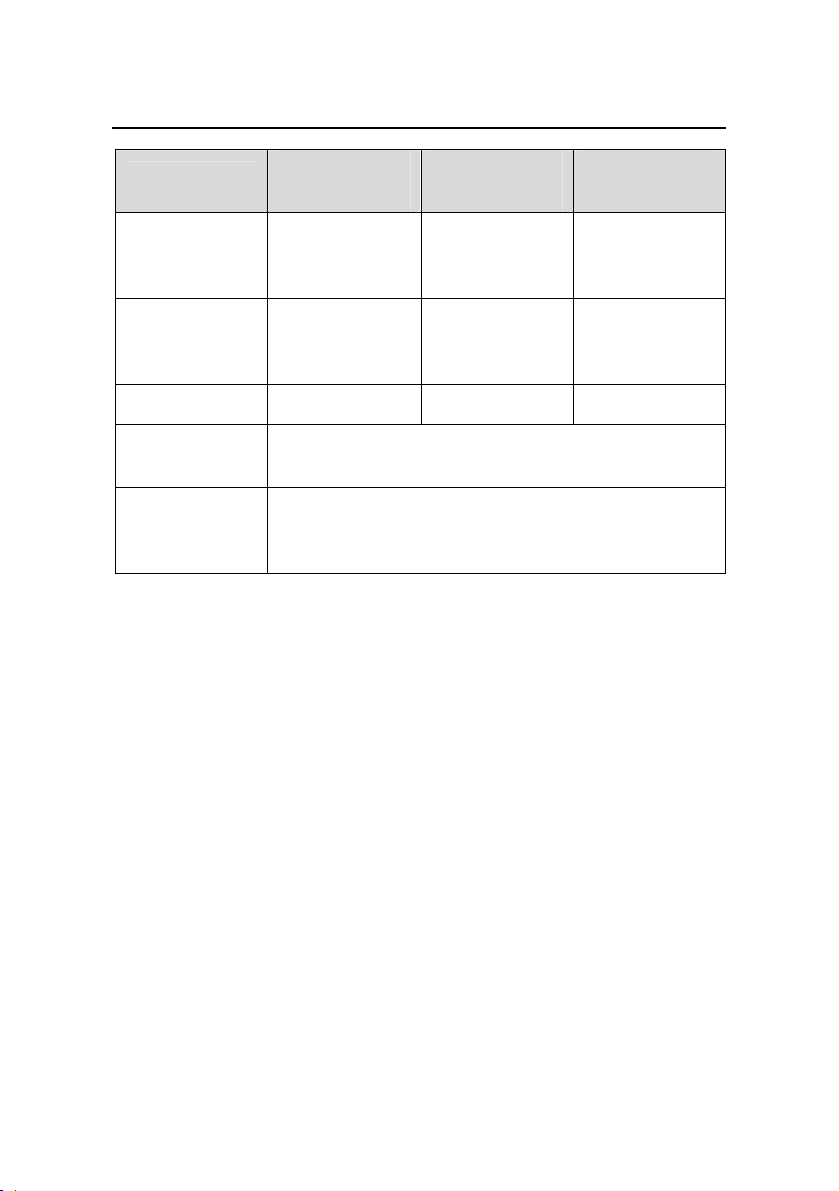

1.1.2 S3100-EI Series Ethernet Switches

Currently, the H3C S3100-EI Series Ethernet Switches include

the S3100-TP-EI-W, the S3100-TP-PWR-EI and the

S3100-C-EPON-EI, as listed in

Table 1-4 Models of H3C S3100-TP-EI-W and S3100-TP-PWR-

EI Series Ethernet switches

Table 1-4 and Table 1-5.

Model

S3100-26T

P-EI-W

S3100-16T

P-EI-W

S3100-8T

P-EI-W

H3C

S3100-26T

P- PWR-EI

Power

supply

AC input or

12V-RPS

DC input

AC input

AC input or

52V-RPS

DC input

Number of

10/100M

electrical

ports

24

16

8

24

1-3

1000M

uplink

ports

2 Combo

ports

2 Combo

ports

1 Combo

port

2 Combo

ports

Number of

console

ports

1

1

1

1

Page 11

Quick Start (For Japan)

w

H3C S3100 Series Ethernet Switches

Number of

Model

Power

supply

10/100M

electrical

ports

Chapter 1 Product Overvie

1000M

uplink

ports

Number of

console

ports

H3C

S3100-16T

P- PWR-EI

16

2 Combo

ports

1

AC input

H3C

S3100-8T

P- PWR-EI

8

1 Combo

port

1

Table 1-5 Models of the H3C S3100-C-EPON-EI Series Ethernet

Switches

Number

of 1000

Mbps

uplink

PON

ports

Number

of

expansi

on slots

Model

Power

input

Number

of 10/100

Mbps

electrica

l ports

S3100-26

C-EPON-

24 1 1

EI

S3100-16

C-EPON-

AC

input

16 1 Disabled

EI

Numb

er of

consol

e ports

1

S3100-8C

-EPON-EI

8 1 —

1-4

Page 12

Quick Start (For Japan)

w

H3C S3100 Series Ethernet Switches

Chapter 1 Product Overvie

Note:

For details about each model, refer to H3C S3100 Series Ethernet

Switches Installation Manual (For Japan).

1.2 Introduction to Front Panel Power LEDs

Table 1-6 Description of the power LED on S3100 series

LED

Mark on the

panel

Status Description

ON

The switch is

powered on.

Power LED PWR

The switch is

powered off.

DC input is

normal.

There is no

DC input.

RPS DC

power LED

OFF

ON

RPS

OFF

Note:

Only S3100-26TP-EI-W AC-powered Ethernet switches have an RPS

DC power LED.

1-5

Page 13

Quick Start (For Japan)

w

H3C S3100 Series Ethernet Switches

Chapter 1 Product Overvie

1.3 Technical Specifications

1.3.1 S3100-SI Series Ethernet Switch

I. S3100-T-SI Series

Table 1-7 Technical specifications for S3100-T-SI Series

Ethernet switches

Model S3100-26T-SI S3100-16T-SI S3100-8T-SI

Physical

dimensions (H

x W x D)

42 x 436 x 240

mm (1.65 x

17.2 x 9.4 in)

Weight ≤ 3.2 kg (7.1 lb)

24 x

auto-sensing

10/100Base-

Number of

fixed ports

TX Ethernet

port

2 x

10/100/1000

Base-T

Ethernet port

Number of

management

1 x console port

port

Only AC input is supported.

Rated voltage range: 100 VAC to 240 VAC, 50 Hz

Power system

/60 Hz

Input voltage range: 90 VAC to 264 VAC, 47 Hz to

63 Hz

42 x 436 x 200

mm (1.65 x

17.2 x 7.9 in)

16 x

auto-sensing

10/100Base-

TX Ethernet

port

1 x

10/100/1000

Base-T

Ethernet port

42 x 326 x 200

mm (1.65 x

12.8 x 7.9 in)

8 x

auto-sensing

10/100BaseTX Ethernet

port

1 x

10/100/1000

Base-T

Ethernet port

1-6

Page 14

Quick Start (For Japan)

w

H3C S3100 Series Ethernet Switches

Chapter 1 Product Overvie

Model S3100-26T-SI S3100-16T-SI S3100-8T-SI

PoE (as

powered

Not supported Not supported Not supported

device)

System power

consumption

20 W 12 W 10 W

(full load)

Fan None None None

Operating

temperature

0°C to 45°C (30°F to 113°F)

Relative

humidity (non-

10% to 90%

condensing)

II. S3100-C-SI Series

Table 1-8 Technical specifications for S3100-C-SI Series

Ethernet switches

Model S3100-26C-SI S3100-16C-SI S3100-8C-SI

Physical

dimensions (H

x W x D)

42 x 436 x 240

mm (1.65 x

17.2 x 9.4 in)

42 x 436 x 200

mm (1.65 x

17.2 x 7.9 in)

42 x 326 x 200

mm (165 x

12.8 x 7.9 in)

Weight ≤ 3.2 kg (7.1 lb)

Number of

fixed ports

24 x

auto-sensing

10/100BaseTX Ethernet

port

16 x

auto-sensing

10/100BaseTX Ethernet

port

8 x

auto-sensing

10/100BaseTX Ethernet

port

1-7

Page 15

Quick Start (For Japan)

w

H3C S3100 Series Ethernet Switches

Chapter 1 Product Overvie

Model S3100-26C-SI S3100-16C-SI S3100-8C-SI

Number of

expansion

2 2 1

slots

Number of

management

1 x Console port

port

10/100/1000BASE-T interface module with max

transmission distance of 100 m (328.1 feet)

100BASE-SX (SC, 2 km (1.2 mi))

100BASE-LX (SC, 15 km (9.3 mi))

100BASE-LH40 (SC, 40 km (24.9 mi))

1000BASE-SX (SC, 0.5 km (0.3 mi))

1000BASE-LX (SC, 10 km (6.2 mi))

Supported

expansion

interface

module type

1000BASE-LH40 (LC, 40 km (24.9 mi))

1000BASE-LH70 (LC, 70 km (43.5 mi))

1000BASE-STACK (not supported by

S3100-8C-SI)

100BASE-TX PD (powered device) interface

module (only supported by S3100-16C-SI

DC-powered switch and S3100-8C-SI

DC-powered switch)

1000BASE-PX10 (SC, 10 km (6.2 mi))

1000BASE-PX20 (SC, 20 km (12.4 mi))

100Base-LX-SM1310-BIDI (SC, 15 km (9.3 mi))

100Base-LX-SM1550-BIDI (SC, 15 km (9.3 mi))

1-8

Page 16

Quick Start (For Japan)

w

H3C S3100 Series Ethernet Switches

Chapter 1 Product Overvie

Model S3100-26C-SI S3100-16C-SI S3100-8C-SI

Both DC-powered switch and AC-powered switch

are available to each model. The AC-powered

switch supports only AC input. and the

DC-powered switch supports only DC input.

AC input:

Power system

z Rated voltage range: 100 VAC to 240 VAC, 50

Hz /60Hz

z Input voltage range: 90 VAC to 264 VAC, 47

Hz to 63 Hz

DC input:

z Rated voltage range: –48 VDC to –60 VDC

z Input voltage range: –36 VDC to –72 VDC

PoE (as

powered

device)

Not supported

Supported by DC-powered

switch

System power

consumption

20 W 12 W 10 W

(full load)

Fan None None None

Operating

temperature

0°C to 45°C (30°F to 113°F)

Relative

humidity (non-

10% to 90%

condensing)

1-9

Page 17

Quick Start (For Japan)

w

H3C S3100 Series Ethernet Switches

Chapter 1 Product Overvie

Note:

z Only S3100-16C-SI DC-powered switch or S3100-8C-SI

DC-powered switch supports 100BASE-TX PD interface module.

Notice that S3100-16C-SI DC-powered switch can accommodate

only one PD interface module.

z The PoE configuration is on the remote power source device, on

the powered device (S3100-16C-SI DC-powered switch or

S3100-8C-SI DC-powered switch), you only need to insert the

cable into the interface of 100BASE-TX PD.

z BIDI interface card must used in couple, i.e., if the local end uses

100Base-LX-SM1310-BIDI, the remote end need to use

100Base-LX-SM1550-BIDI.

z An S3100-16C-SI or S3100-26C-SI switch can accommodate only

one ONU card (1000Base-PX10/20). For details about ONU

modules, refer to section

1.5 “ONU Modules”.

1.3.2 S3100-EI Series Ethernet Switch

I. S3100-TP-EI-W Series

Table 1-9 Technical specifications for S3100-TP-EI-W Series

Ethernet switches

Model

Physical

dimensions (H

x W x D)

S3100-26TP-

EI-W

43.6 x 440 x

260 mm (1.7 x

17.2 x 10.2 in)

S3100-16TP-

EI-W

43.6 x 300 x

220 mm (1.7 x

11.8 x 8.7 in)

1-10

S3100-8TP-EI

43.6 x 230 x

200 mm (1.7 x

9.1 x 7.9 in)

-W

Page 18

Quick Start (For Japan)

w

H3C S3100 Series Ethernet Switches

Model

S3100-26TP-

EI-W

Chapter 1 Product Overvie

S3100-16TP-

EI-W

S3100-8TP-EI

-W

Weight <3.5 kg (7.7 lb) <2.5 kg (5.5 lb) <1.8 kg (4 lb)

Number of

fixed ports

Number of

management

port

Power system

PoE (as

powered

device)

24 x

auto-sensing

10/100BASETX Ethernet

port

2 x 1000M

Combo port

16 x

auto-sensing

10/100BASETX Ethernet

port

2 x 1000M

Combo port

8 x

auto-sensing

10/100BASETX Ethernet

port

1 x 1000M

Combo port

1 x console port

S3100-16TP-EI-W/S3100-8TP-EI-W Ethernet

switches support only AC input.

S3100-26TP-EI-W AC-powered switches support

AC input and RPS DC input.

AC input:

z Rated voltage range: 100 VAC to 240 VAC, 50

Hz /60 Hz

z Input voltage range: 90 VAC to 264 VAC, 47

Hz to 63Hz

RPS DC input:

z Input voltage range: 10.8 VDC to 13.2 VDC

Not supported Not supported Not supported

System power

consumption

22 W 17 W 14 W

(full load)

Fan None None None

1-11

Page 19

Quick Start (For Japan)

w

H3C S3100 Series Ethernet Switches

Model

S3100-26TP-

EI-W

Chapter 1 Product Overvie

S3100-16TP-

EI-W

S3100-8TP-EI

-W

Operating

temperature

0°C to 45°C (30°F to 113°F)

Relative

humidity (non-

10% to 90%

condensing)

Caution:

Only the recommended 12V-RPS DC power supply can be used for

S3100-26TP-EI Ethernet switches.

II. S3100-TP-PWR-EI Series

Table 1-10 Technical specifications for S3100-TP-PWR-EI

Ethernet switches

Model

S3100-26TP-

PWR-EI

S3100-16TP-

PWR-EI

S3100-8TP-

PWR-EI

Physical

dimensions (H x

W x D)

Weight

43.6 x 440 x

420 mm (1.7 x

17.2 x 10.2 in)

<6.5 kg (14.3

lb)

1-12

43.6 x 300 x

260 mm (11.8

x 8.7 x 1.7 in)

<3.5 kg (7.7

lb)

43.6 x 300 x

220 mm (1.7 x

9.1 x 7.9 in)

<3.0 kg (6.6

lb)

Page 20

Quick Start (For Japan)

w

H3C S3100 Series Ethernet Switches

Model

S3100-26TP-

PWR-EI

Chapter 1 Product Overvie

S3100-16TP-

PWR-EI

S3100-8TP-

PWR-EI

Number of fixed

ports

Number of

management

ports

Power system

24 x

10/100BASETX

auto-sensing

Ethernet port

2 x 1000M

Combo port

16 x

10/100BASETX

auto-sensing

Ethernet port

2 x 1000M

Combo port

8 x

10/100BASETX

auto-sensing

Ethernet port

1 x 1000M

Combo port

1 x Console port

S3100-26TP-PWR-EI Ethernet switches

supports AC input and RPS DC input.

S3100-16TP-PWR-EI/S3100-8TP-PWR-EI

Ethernet switches support only AC input.

AC input:

z Rated voltage range: 100 VAC to 240 VAC,

50 Hz /60 Hz

z Input voltage range: 90 VAC to 264 VAC, 47

Hz to 63 Hz

RPS DC input:

z Input voltage range: –52 VDC to –56 VDC

All

ports

serve

as

PoE

ports

System

power

consum

ption

(full

load)

PoE

power

maximu

m

AC input:

465 W

DC input:

160 W 95 W

400 W

15.4 W x 24 15.4 W x 8 15.4 W x 4

1-13

Page 21

Quick Start (For Japan)

w

H3C S3100 Series Ethernet Switches

Model

S3100-26TP-

PWR-EI

Chapter 1 Product Overvie

S3100-16TP-

PWR-EI

Number of fans 4 2 2

S3100-8TP-

PWR-EI

Operating

temperature

0°C to 45°C (30°F to 113°F)

Relative

humidity (non-

10% to 90%

condensing)

Note:

S3100-26TP-PWR-EI, S3100-16TP-PWR-EI, and

S3100-8TP-PWR-EI Ethernet switches provide an over-temperature

protection mechanism. When the internal temperature exceeds 65°C

(149°F), they will stop providing power from all ports. When the

temperature is below 60°C (140°F), they will continue to provide

power from all ports.

Caution:

Only the recommended RPS can be used for S3100-26TP-PWR-EI

Ethernet switches. The –48 VDC in the equipment room cannot be

used directly. Otherwise, the device may be damaged.

1-14

Page 22

Quick Start (For Japan)

w

H3C S3100 Series Ethernet Switches

Chapter 1 Product Overvie

III. S3100-C-EPON-EI Series

Table 1-11 Technical specifications for S3100-C-EPON-EI

Series Ethernet switches

Model

Physical

dimensions (H

x W x D)

S3100-26C-E

PON-EI

42 x 436 x 240

mm (1.65 x

17.2 x 9.4 in)

Weight ≤ 3.2 kg (7.05 lb)

24 x

auto-sensing

Number of

fixed ports

10/100BaseTX Ethernet

port

1 × 1000 Mbps

PON port

Number of

expansion

1 Disabled —

slots

Optional

module

ONU module

(1000Base-PX

20)

Number of

management

1 x console port

port

S3100-16C-E

PON-EI

42 x 436 x 200

mm (1.65 x

17.2 x 7.9 in)

16 x

auto-sensing

10/100BaseTX Ethernet

port

1 × 1000 Mbps

PON port

S3100-8C-EP

ON-EI

42 x 326 x 200

mm (165 x

12.8 x 7.9 in)

8 x

auto-sensing

10/100BaseTX Ethernet

port

1 × 1000 Mbps

PON port

— —

Power system

AC input:

z Rated voltage range: 100 VAC to 240 VAC, 50

Hz /60Hz

z Input voltage range: 90 VAC to 264 VAC, 47

Hz to 63 Hz

1-15

Page 23

Quick Start (For Japan)

w

H3C S3100 Series Ethernet Switches

Model

PoE (as

powered

device)

System power

consumption

(full load)

Fan 1 None None

S3100-26C-E

PON-EI

Not supported Not supported Not supported

20 W 13 W 11 W

Chapter 1 Product Overvie

S3100-16C-E

PON-EI

S3100-8C-EP

ON-EI

Operating

temperature

Relative

humidity (noncondensing)

0°C to 45°C (30°F to 113°F)

10% to 90%

1.4 SFP Modules Supported by S3100-EI Ethernet Switches

The front panel of S3100-TP-EI-W and S3100-TP-PWR-EI

Ethernet switches provides one or two 1000M SFP ports in which you

can select the required small form-factor pluggable (SFP) modules to

insert. For the models of SFP modules, see

Table 1-12.

1-16

Page 24

Quick Start (For Japan)

w

H3C S3100 Series Ethernet Switches

Chapter 1 Product Overvie

Table 1-12 SFP modules supported by S3100-TP-EI-W and

S3100-TP-PWR-EI Ethernet switches

Type Model

z SFP-FE-SX-MM1310-A

z SFP-FE-LX-SM1310-A

z SFP-GE-SX-MM850-A

z SFP-GE-LX-SM1310-A

z SFP-FE-LX-SM1310-BIDI

z SFP-FE-LX-SM1550-BIDI

z SFP-GE-LX-SM1310-BIDI

z SFP-GE-LX-SM1490-BIDI

SFP

module

100 Mbps SFP

module

1000 Mbps SFP

module

SFP stack module SFP-STACK-Kit

100 Mbps bidirectional

(BIDI) module

1000 Mbps BIDI

module

Note:

z The types of SFP modules may vary over time. Consult H3C

marketing personnel or technical support personnel to obtain the

latest information about SFP modules.

z For specifications of SFP modules, refer to H3C Low End Series

Ethernet Switches Pluggable Module Manual.

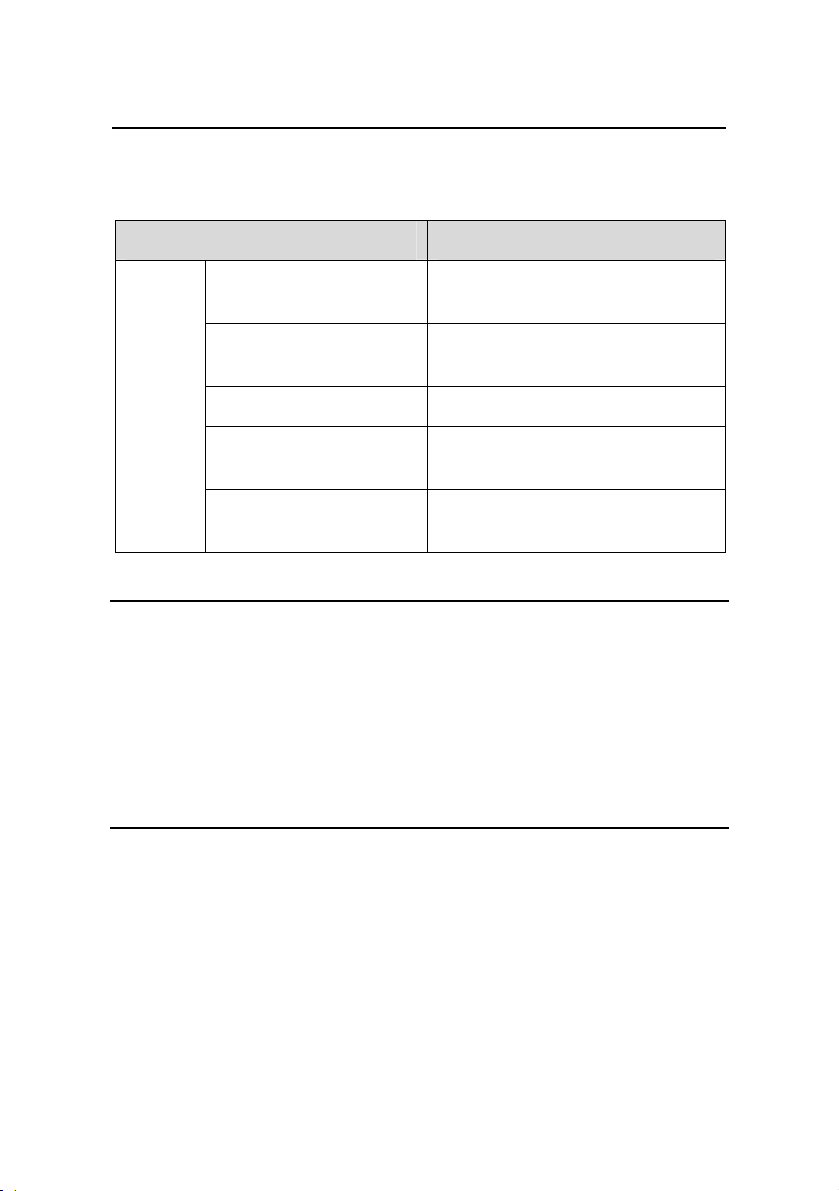

1.5 ONU Modules

When equipped with one or two ONU modules, the S3100-C-SI

and S3100-C-EPON-EI series can serve as ONU devices.

shows the ONU module support of the S3100 series.

1-17

Table 1-13

Page 25

Quick Start (For Japan)

w

H3C S3100 Series Ethernet Switches

Chapter 1 Product Overvie

Table 1-13 ONU module support of the S3100 series

Switch model

Number

of ONU

modules

Required

or

optional

S3100-8C-SI 1 Optional

S3100-16C-SI 1 Optional

S3100-26C-SI 1 Optional

S3100-8C-EPON

-EI

S3100-16C-EPO

N-EI

S3100-26C-EPO

N-EI

1 Required

1 Required

2

1 required

1 optional

All models of ONU modules look alike.

Figure 1-1 and Figure 1-2

depict the LS6M2PU1SB.

ONU module

model

z 1000Base-PX10

(LS6M1PU1SA)

z 1000Base-PX20

(LS6M1PU1SB)

1000Base-PX20

(LS6M2PU1SB)

Figure 1-1 Appearance of the LS6M2PU1SB

1-18

Page 26

Quick Start (For Japan)

w

H3C S3100 Series Ethernet Switches

Chapter 1 Product Overvie

(1): Fastening screws (2): 1000 Mbps PON port

(3): ACT LED of the PON port (4): LINK LED for the PON port

Figure 1-2 Front panel of the LS6M2PU1SB

The ONU module provides one 1000 Mbps uplink PON port.

Table 1-14 lists the technical specifications for the PON port.

Table 1-14 Technical specifications for the ONU port

Item Specifications

Connector type SC

Number of interfaces 1

Interface speed 1000 Mbps

Medium 9/125 µm single-mode fiber

Maximum

transmission distance

z 1000Base- PX10: 10 km (6.21 miles)

z 1000Base- PX20: 20 km (12.43 miles)

For how to install and remove an ONU module, refer to section

3.2 “Installing an Expansion Interface Module”. Table 1-15 describes

the LED indications.

1-19

Page 27

Quick Start (For Japan)

w

H3C S3100 Series Ethernet Switches

Table 1-15 Description of ONU module LEDs

LED Status Meaning

ON The port is connected properly.

LINK

OFF

The port has no connectivity or is

incorrectly connected.

Chapter 1 Product Overvie

ACT

Blinking

OFF

The port is in active state and there is traffic

on it.

The port is in active state but there is no

traffic on it.

1-20

Page 28

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 2 Installation Preparation

Chapter 2 Installation Preparation

2.1 Precautions

To avoid any device impairment and body injury resulting from

improper use, please take the following precautions:

z Before cleaning the switch, disconnect the power. Do not

clean the switch with wet cloth or liquid.

z Keep the switch away from water or dampness. Prevent

water or moisture from entering the switch chassis.

z Do not place the switch on an unstable case or desk,

because the switch might be damaged severely in case of a

fall.

z Keep the switch room drafty and the switch ventilation hole

free of obstruction.

z The switch can operate normally only under correct voltage

input. Make sure that the operating voltage is consistent with

that labeled on the switch.

z To prevent electric shock, do not open the chassis while the

switch is operating, and do not open the chassis arbitrarily

even when the switch is powered off.

z Before changing interface cards, wear an ESD-preventive

wrist strap to prevent the cards from being damaged by

electrostatic discharge.

2.2 Requirements on Environment

S3100 Series Ethernet Switches must be used indoors. When

you install your switch in a cabinet or on a desk, you must ensure:

2-1

Page 29

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

z Enough space is reserved near the air-intake hole and the

Chapter 2 Installation Preparation

ventilation hole of the switch for heat dissipation of the

switch chassis.

z The cabinet or the workbench takes good ventilation and

heat dissipation system.

z The cabinet or the desk is solid enough to bear the weight of

the switch and the accessories.

z The cabinet or the desk is well grounded.

To ensure normal operation and to prolong the life span of the

switch, the following requirements on the installation site must also be

satisfied.

2.2.1 Temperature/Humidity Requirements

You should keep your equipment room within the proper

temperature and humidity ranges to ensure the normal operation and

working life of your switch. If the humidity in the equipment room is too

high for a long time, it may decrease the insulation attribute of

insulating material or even cause electric leakage of insulating

material, and, sometimes, may change the mechanical performance

of material and cause the rustiness and corrosion of metal parts. If the

relative humidity is too low, the captive screws may become loose due

to the shrinking of insulation washers; in addition, electrostatic is more

likely to be produced in a dry environment, which may damage the

circuit of the switch. High temperature may cause even greater

damage to the switch. High temperature for a long time will speed up

the aging of insulation material, greatly lower the reliability of the

switch and greatly reduce the life span of the switch.

For the temperature and humidity requirements of different

models, refer to section

1.3 “Technical Specifications”.

2-2

Page 30

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 2 Installation Preparation

2.2.2 Cleanness Requirements

Dust is a potential hazard to the safe operation of the switch.

Falling on the equipment, it may cause electrostatic adsorption, and

hence result in poor contact of the metal connectors or connection

points. This is more likely to happen when the indoor relative humidity

is low; in this case, it may not only shorten the device’s working life,

but also incur communication failure. The requirements on dust

content and particle diameter in the equipment room are shown in the

following table.

Table 2-1 Requirements on dust content in the equipment room

Physical active

substance

Dust particle particle/m³

Unit Content

≤ 3 x 10

4

(No visible dust

on desk in three days)

Note: Dust particle diameter ≥ 5µm

Besides the requirements on dust, rigorous requirements are

also set on the content of chloride, acid, and sulfide in the air of the

equipment room. These kinds of harmful gas will accelerate metal

corrosion and aging of certain parts. The equipment room should be

protected from the intrusion of harmful gases such as SO

and Cl

. The limits of these kinds of harmful gas are shown in the

2

, H2S, NH3

2

following Table.

2-3

Page 31

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 2 Installation Preparation

Table 2-2 Limits on harmful gas in the equipment room

Gas Max content (mg/m³)

SO

2

0.2

H2S

NH

Cl

2

3

0.006

0.05

0.01

2.2.3 Anti-interference Requirements

A switch in use may be affected by the interference from outside

the system by way of capacitance coupling, inductance coupling,

electromagnetic radiation, public impedance (including the grounding

system) coupling or conducting line (power line, signaling line and

transmission line). Therefore, you should pay attention to the

following:

z If AC supply system is TN system, AC power socket should

be a single-phase three-line power socket with Protection

Earth (PE) so that the filter circuit on the equipment can

effectively filter out the interference coming from the power

supply system.

z Keep the switch far away from high-power radio transmitters,

radars, and high-frequency heavy-current devices.

z Adopt electromagnetic shielding measure if necessary. For

example, you can adopt shielded interface cable.

z Wire interface cables indoors. Do not wire cables outdoors

in case that overvoltage and overcurrent damage the

device.

2-4

Page 32

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 2 Installation Preparation

2.2.4 Laser Usage Security

S3100 series are category-1 laser equipment.

When an optional optical interface card of the S3100 series is

operating, it is prohibited to stare into the optical interface because the

laser beam emitted from the optical fiber takes high energy and may

hurt your retina.

Caution:

Staring at the laser beam inside the fiber could hurt your eyes.

2.3 Installation Tools

z Phillips screwdriver

z Flat-blade screwdriver

z ESD-preventive wrist strap

Caution:

These installation tools are not shipped with S3100 series. You will

have to prepare them beforehand.

2-5

Page 33

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 3 Installation

Chapter 3 Installation

Caution:

On a mounting screw of the chassis of H3C S3100 Series Ethernet

Switches, there is a seal labeled with H3C. You must keep it intact

before asking the agent to maintain the switch. You must get the

permission of the local agent before you can open the chassis.

Otherwise, you will be responsible for irreversible damages caused by

your operations.

3.1 Installing a Switch

3.1.1 Cabinet Mounting

You can install a switch into a 19-inch standard cabinet in one of

the following four ways:

z Use front mounting ears

z Use front mounting ears and a tray

z Use front mounting ears and rear mounting ears

z Use front mounting ears and guide rails

The installation methods of a switch depend on the depth and

width of the switch. For the specific installation methods, see

Table 3-2.

and

3-1

Table 3-1

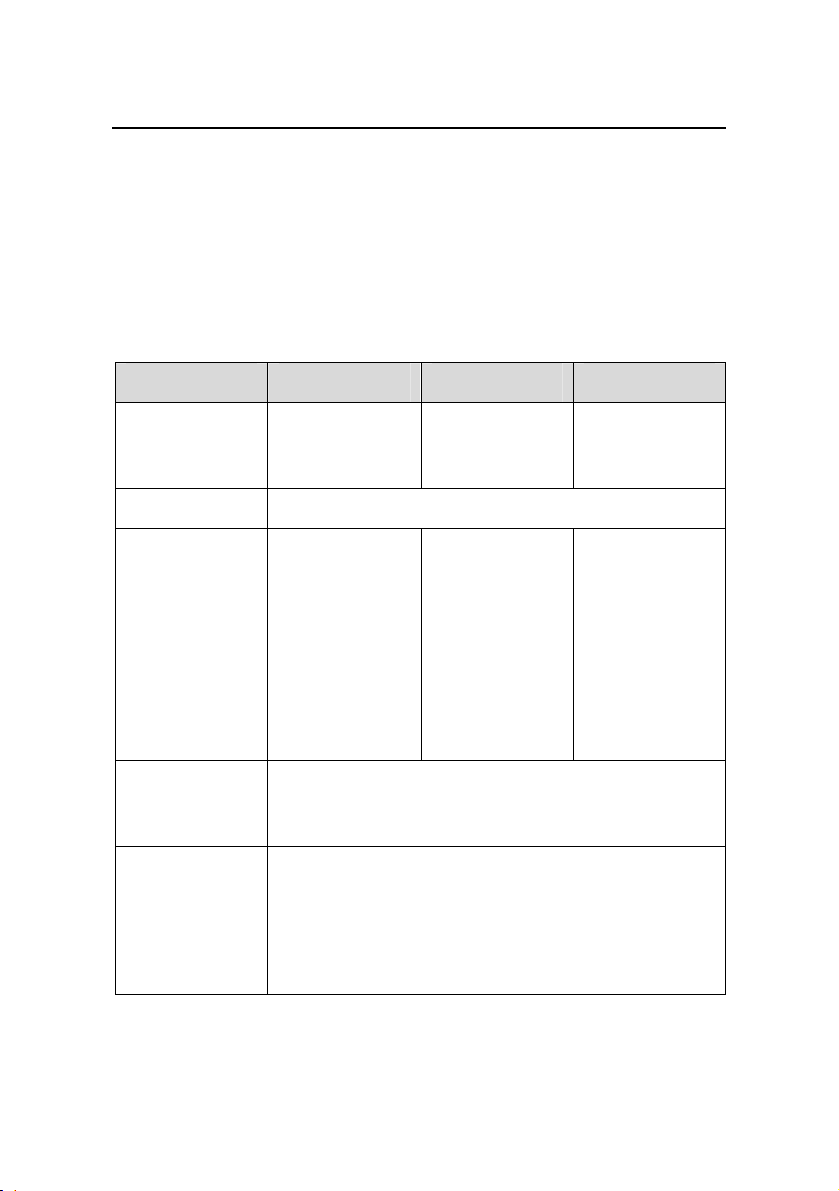

Page 34

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 3 Installation

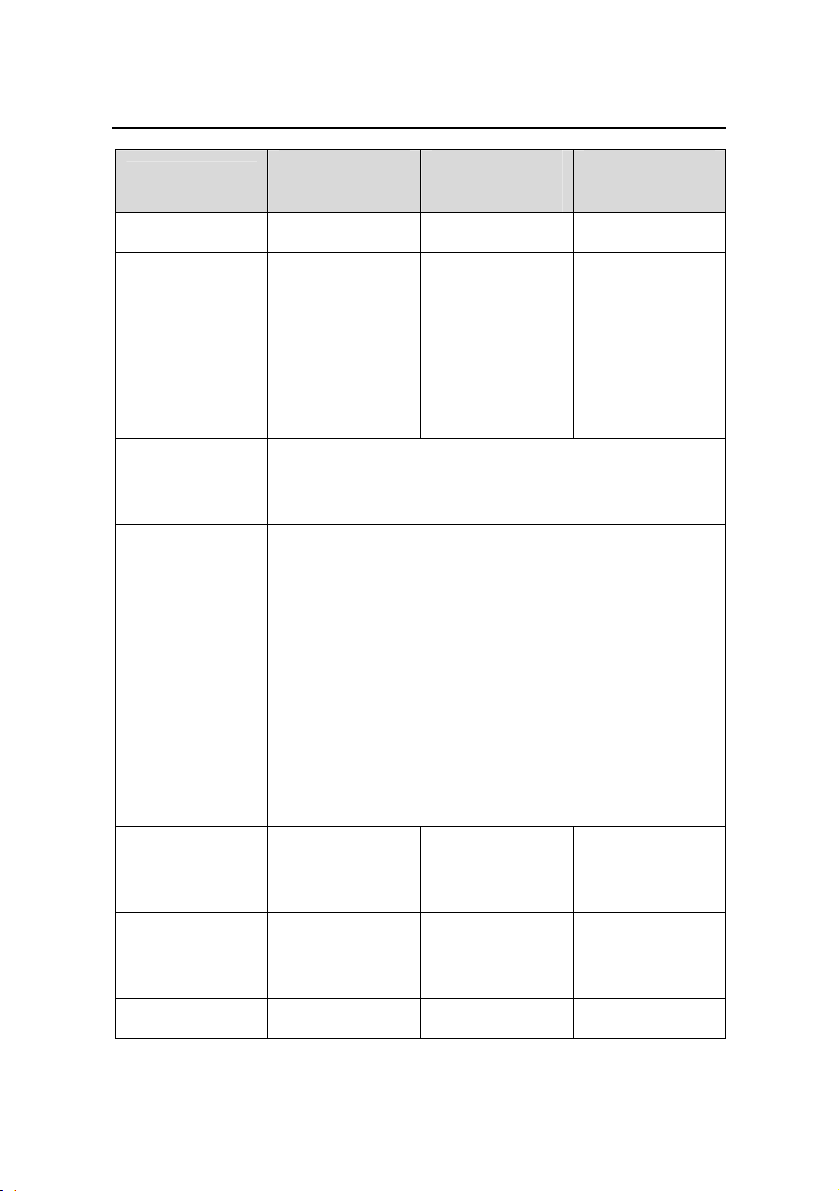

Table 3-1 Installation methods for a switch with a width of 440 or

436 mm (17.3 or 17.2 in)

Method

Depth

≤ 300 mm

(11.8 in)

360 mm (14.2

in)

420 mm (16.5

in)

Use front

mounting

ears

Use front

and rear

mounting

ears

√ — √ √

— √ √ √

— √ √ √

Use front

mounting

ears and

a tray

Use front

mounting

ears and

guide rails

Table 3-2 Installation method for a switch with a width less than

436 mm (17.2 in)

Method

Depth

≤300 mm

(11.8 in)

Use front

mounting

ears

Use front

and rear

mounting

ears

√ — √ —

Use front

mounting

ears and

a tray

Use front

mounting

ears and

guide rails

360 mm (14.2

in)

420 mm (16.5

in)

— — √ —

— — √ —

3-2

Page 35

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 3 Installation

Note:

z When the depth of a switch is greater than 300 mm (11.8 in), the

front mounting ears only secure the switch rather than bear its

weight.

z Guide rails purchased from H3C apply only to standard cabinets

1,000 mm (39.4 in) deep. Use other supports to substitute for guide

rails in the case of other cabinet depths.

I. Introduction to mounting ear

Figure 3-1 shows the appearance of a front mounting ear.

(1) (2)

L1

L2

(1) Screw hole used to fix the mounting ear to the cabinet (Use one M6

screw)

(2) Screw hole used to fix the switch to the mounting ear

Figure 3-1 Appearance of a front mounting ear

3-3

Page 36

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 3 Installation

Figure 3-2 shows the appearance of a rear mounting ear.

(1)

(1) Screw hole used to fix the mounting ear to the cabinet (Use one M6

screw)

Figure 3-2 Appearance of a rear mounting ear

When you install S3100 Series Ethernet Switches into 19-inch

standard cabinets, you should select front mounting ears with a proper

length (L1 as shown in

Figure 3-1) according to the physical

dimensions of switches. For the selection of front and rear mounting

ears, see

Table 3-3.

3-4

Page 37

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 3 Installation

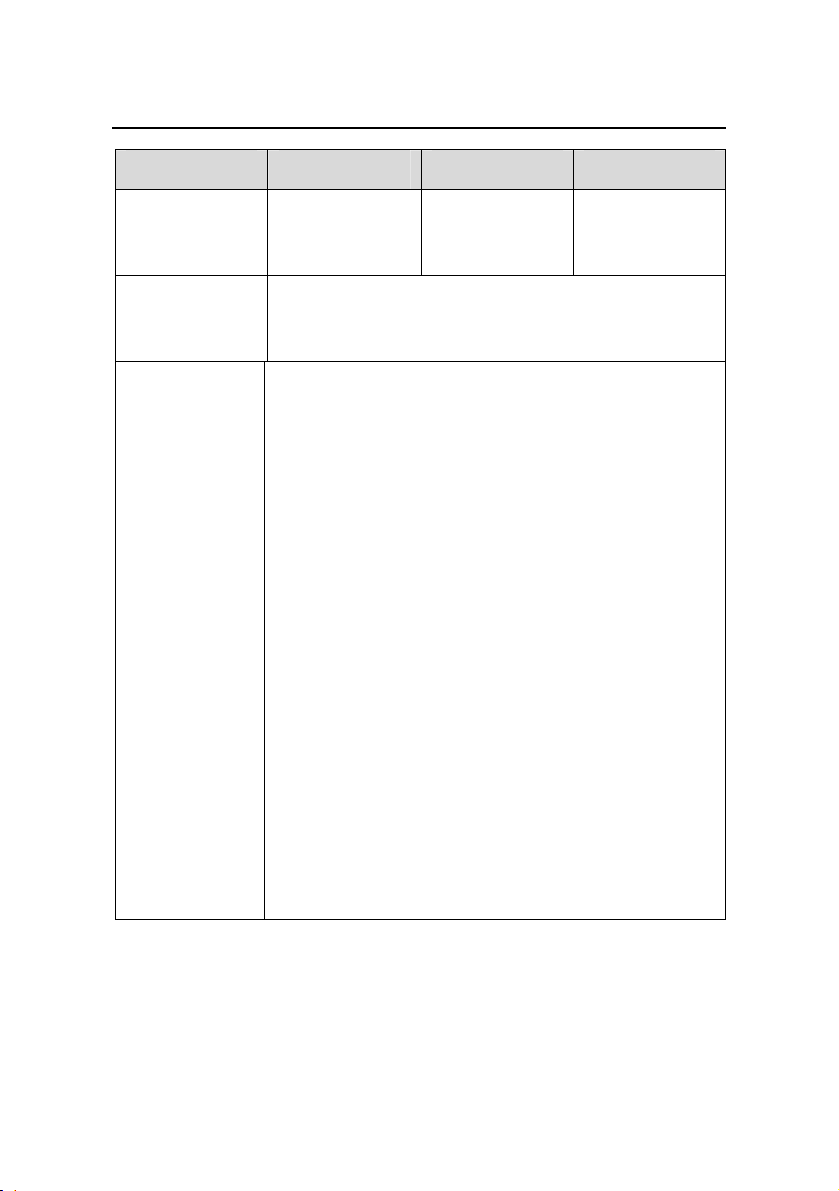

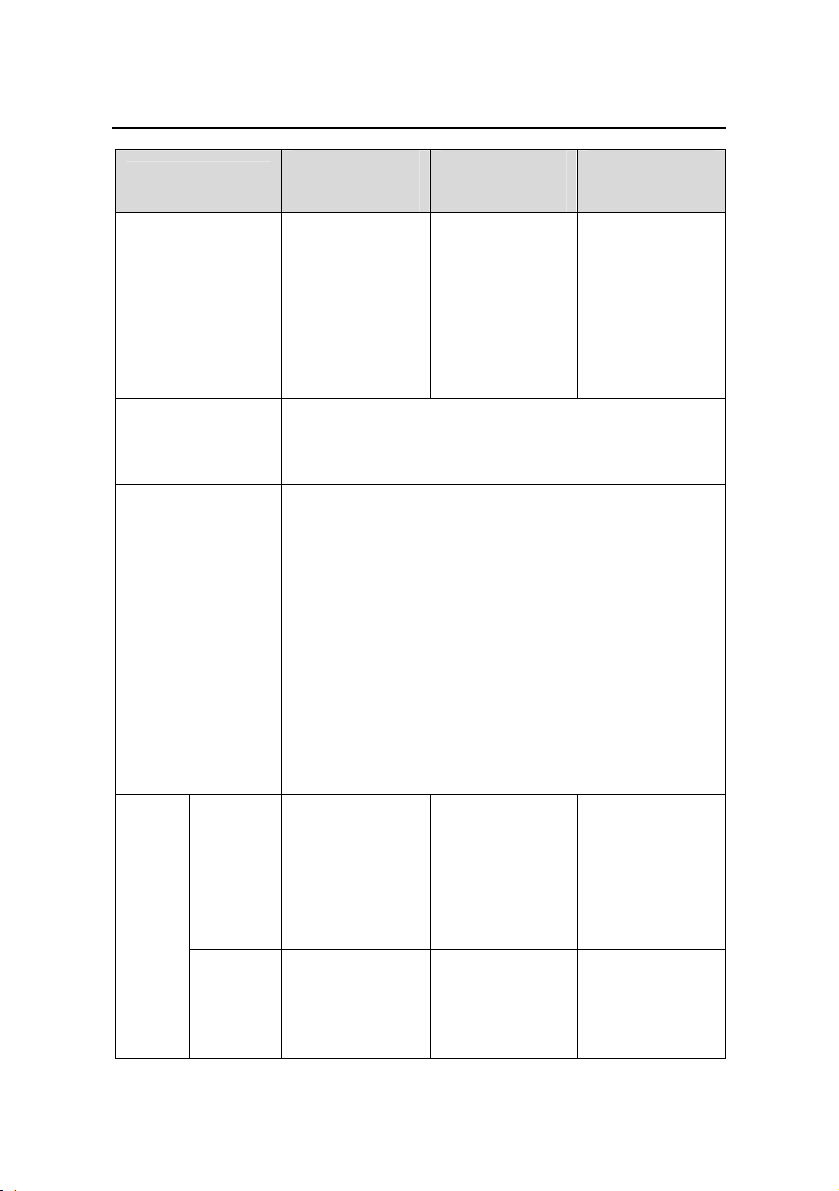

Table 3-3 Selection of mounting ear for S3100 Series Ethernet

Switches

Model

S3100-26T-SI

S3100-26C-SI

S3100-26C-E

PON-EI

S3100-16T-SI

S3100-16C-SI

S3100-16C-E

PON-EI

S3100-8T-SI

S3100-8C-SI

S3100-8C-EP

ON-EI

S3100-26TPEI-W

Physical

dimensions (H x W

x D)

42 x 436 x 240 mm

(1.65 x 17.2 x 9.4 in)

42 x 436 x 200 mm

(1.65 x 17.2 x 7.9 in)

42 x 326 x 200 mm

(1.65 x 12.8 x 7.9 in)

43.6 x 440 x 260 mm

(1.7 x 17.3 x 10.2 in)

Configurati

on type of

front

mounting

ear

Standard

Standard

Optional

Standard

Configur

ation

type of

rear

mounting

ear

—

S3100-16TPEI-W

S3100-8

TP-EI-W

S3100-26TPPWR-EI

43.6 x 300 x 220 mm

(1.7 x 11.8 x 8.7 in)

43.6 x 230 x 200 mm

(1.7 x 9.1 x 7.9 in)

43.6 x 440 x 420 mm

(1.7 x 17.3 x 16.5 in)

3-5

Optional

—

Optional

Standard Standard

Page 38

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Physical

Model

dimensions (H x W

x D)

Chapter 3 Installation

Configurati

on type of

front

mounting

ear

Configur

ation

type of

rear

mounting

ear

S3100-16TPPWR-EI

S3100-8 TPPWR-EI

43.6 x 300 x 260 mm

(1.7 x 11.8 x 10.2 in)

43.6 x 300 x 220 mm

(1.7 x 11.8 x 8.7 in)

Optional —

Optional —

II. Use front mounting ears to install a switch

Follow these steps to mount a switch into a 19-inch standard

cabinet:

1) Wear an ESD-preventive wrist strap to check the grounding

and stability of the cabinet.

2) Take out the screws which are packed together with the front

mounting ears, and fix one end of mounting ears to the

switch, as shown in

Figure 3-3.

Figure 3-3 Fix front mounting ears (1)

3-6

Page 39

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 3 Installation

3) Place the switch horizontally in a proper position, and fix the

other end of mounting ears to the front brackets with screws

and captive nuts, as shown in

Figure 3-4.

Figure 3-4 Fix front mounting ears (2)

III. Use front mounting ears and a tray

Follow these steps to install a switch into a 19-inch standard

cabinet:

1) Wear an ESD-preventive wrist strap to check the grounding

and stability of the cabinet.

2) Fix the delivered tray horizontally in a proper position.

3) Take out the screws which are packed together with the front

mounting ears, and fix one end of mounting ears to the

switch, as shown in

Figure 3-3.

3-7

Page 40

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 3 Installation

4) Place the switch on the tray horizontally, slide the tray into

the cabinet, and fix the other end of mounting ears to the

front brackets with crews and captive nuts, as shown in

Figure 3-4.

IV. Use front and rear mounting ears

Follow these steps to install a switch into a 19-inch standard

cabinet:

1) Wear an ESD-preventive wrist strap to check the grounding

and stability of the cabinet.

2) Take out the screws which are packed together with the front

mounting ears, and fix one end of mounting ears to the

switch, as shown in

Figure 3-3.

3) Take out the load-bearing screws (packed together with the

rear mounting ears) and place them in a proper position on

the sides of the switch, as shown in

Figure 3-5.

Three installation locations for screw 1 (select one according to the actual requirement)

Three installation locations for screw 1 (select one according to the actual requirement)

Screw 1

Screw 1

Screw 1

Screw 1

Front mounting ear

Front mounting ear

Front panel

Front panel

Screw 1: Load-bearing screw

Figure 3-5 Fix front mounting ears and load-bearing screws

3-8

Front

Front

mounting e ar

mounting e ar

Page 41

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 3 Installation

Note:

There are three positions to mount a load-bearing screw on both sides

of a switch. You should select a proper position according to the actual

requirements. The rear mounting ears tightly contacted with the

load-bearing screws can support the switch.

4) Select a position to install the switch and fix the rear

mounting ears to the rear brackets with screws and captive

nuts, as shown in

Figure 3-6.

Figure 3-6 Fix rear mounting ears

3-9

Page 42

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 3 Installation

5) Hold the bottom of the switch with one hand and the front

part of the switch with the other hand, and push the switch

into the cabinet gently, as shown in

Screw 1: Used to bear the weight

Screw 2: Used to fix rear mounting ears to rear brackets

Figure 3-7.

Figure 3-7 Fix front and rear mounting ears

After the switch is pushed into the cabinet, ensure that the upper

edge of rear mounting ears is tightly contacted with the load-bearing

screw, as shown in

Figure 3-8.

3-10

Page 43

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Screw 1: Load-bearing screw

Chapter 3 Installation

Figure 3-8 Effect diagram of front and rear mounting ear

installation (1)

6) Fix the other end of the front mounting ears to the front

brackets with screws and captive nuts and ensure that front

and rear mounting ears have fixed the switch in the cabinet

securely, as shown in

Figure 3-9.

3-11

Page 44

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Screw 1: Load-bearing screw

Chapter 3 Installation

Figure 3-9 Effect diagram of front and rear mounting ear

installation (2)

V. Use front mounting ears and guide rails

z Introduction to guide rail

Figure 3-10 shows the appearance of a guide rail.

3-12

Page 45

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 3 Installation

Slotted hole 1: Used to fix the guide rail to the rear bracket. You can adjust

the screw hole position according to the position of the switch.

Cooling hole: Used for heat dissipation between switch and cabinet

Slotted hole 2: Used to fix the guide rail to the front bracket

Figure 3-10 Appearance of a guide rail

Note:

Guide rails purchased from H3C apply only to standard cabinets 1,000

mm (39.4 in) deep. Use other supports to substitute for guide rails in

the case of other cabinet depths.

z Installation procedure

Follow these steps to install a switch into a 19-inch standard

cabinet

1) Wear an ESD-preventive wrist strap to check the grounding

and stability of the cabinet.

3-13

Page 46

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 3 Installation

2) Take out the screws packed together with the front mounting

ears and fix one end of the front mounting ears to the switch,

as shown in

Figure 3-3.

3) Install guide rails on the brackets on both sides of the

cabinet with M5 self-tapping screws.

Figure 3-11 is for

reference only.

Figure 3-11 Install guide rails

4) Hold the two sides of the switch and slide it gently along the

guide rails into the cabinet until it is located in a proper

position, as shown in

Figure 3-12. Ensure that the bottom

side of the guide rails and the switch are in close contact.

3-14

Page 47

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 3 Installation

Figure 3-12 Install front mounting ears and guide rails

5) Fix the other end of front mounting ears to the front brackets

of the cabinet with M6 screws and captive nuts and ensure

that the front mounting ears and guide rails have fixed the

switch in the cabinet securely, as shown in

Figure 3-13.

Figure 3-13 Effect diagram of front mounting ear and guide rail

installation

3-15

Page 48

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 3 Installation

Note:

z No guide rails are delivered with the device.

z Ensure a clearance of 1U (44.45 mm, namely, 1.75 inches)

between devices for the purpose of heat dissipation.

3.1.2 Desk Mounting

When a 19-inch standard cabinet is not available, you can simply

place the switch on a clean desk. When doing so, you should ensure

that:

z The desk is stable and well grounded.

z A clearance about 10 cm (3.9 in) is reserved around the

switch for heat dissipation.

z No heavy object is placed on the switch.

z S3100-SI and S3100-TP-EI-W Series Ethernet Switches are

designed with no fan. Therefore, you should install them in a

drafty environment, and keep at least a vertical distance of

1.5 cm (0.6 in) between devices if you need to stack

switches one upon another.

3.1.3 Wall Mounting

You can mount some models of S3100 Series Ethernet Switches

on concrete walls or wood walls.

support wall mounting.

Table 3-4 lists the models that

3-16

Page 49

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

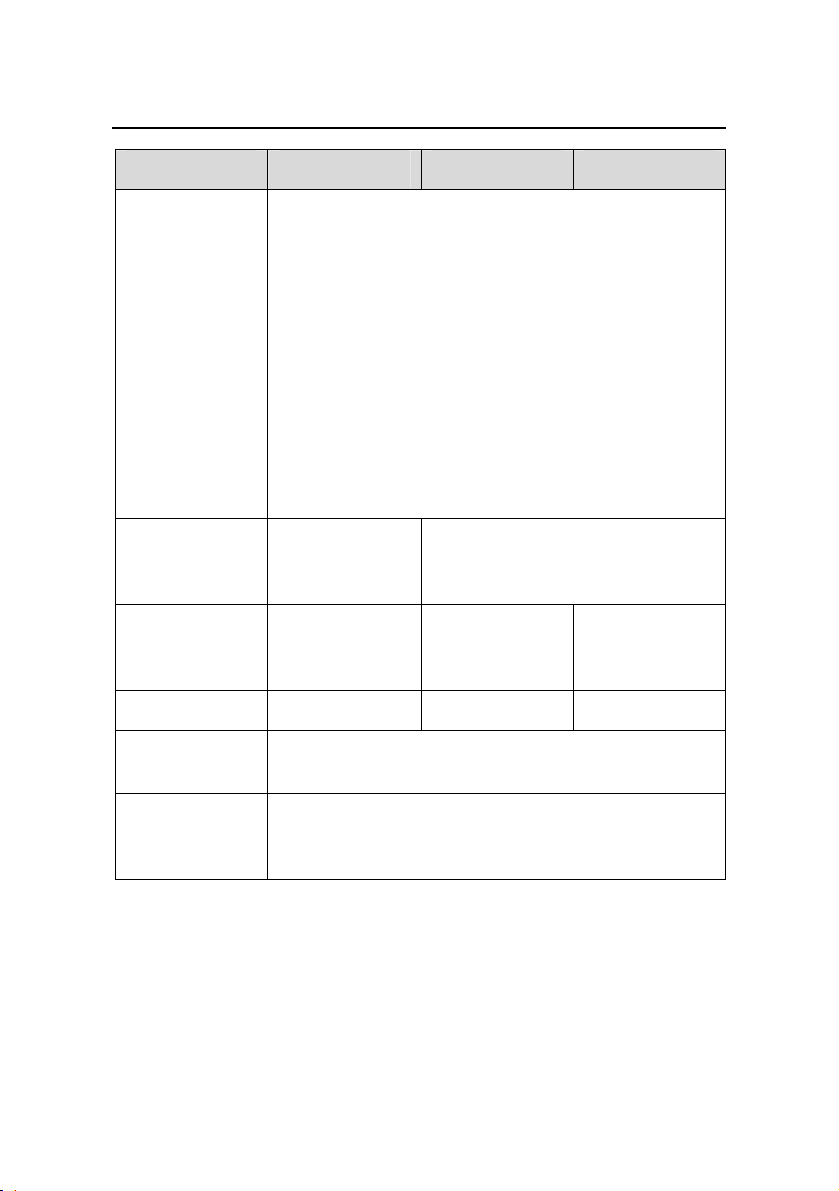

Table 3-4 Models supporting wall mounting

Chapter 3 Installation

Subseries

S3100-SI Ethernet

switches

S3100-TP-EI-W

Ethernet switches

S3100-TP-PWR-EI

Ethernet switches

Models supporting

wall mounting

S3100-8T-SI

S3100-8C-SI

S3100-8TP-EI-W

S3100-16TP-EI-W

S3100-8TP-PWR-EI

S3100-16TP-PWR-EI

Hole distance

(mm)

169 mm (6.65 in.)

170 mm (6.69 in.)

170 mm (6.69 in.)

I. Introduction to screw and anchor kit

Figure 3-14 and Figure 3-15 show the recommended sizes (in

mm) of screws and anchor kits used for mounting:

Figure 3-14 Screw

3-17

Page 50

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 3 Installation

(1)(1)

(1) Outside edge of anchor kit

Figure 3-15 Anchor kit

II. Installation procedure

The wall-mounting procedure is as follows:

1) As shown in

Figure 3-16, drill two holes 5 mm across in the

wall on the same horizontal line, with a distance of X mm.

Note:

z The distance X between holes varies with devices. For specific

distances, see

z Drill two holes according to the sizes of anchor kits and screws so

Table 3-4.

that anchor kits could go into the holes, only the edges could

remain outside the wall, and the screws could be fixed on the wall

tightly.

2) Insert anchor kits into the holes and keep only the edges

outside the wall.

3-18

Page 51

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 3 Installation

3) Drive screws into the anchor kits, keeping the inside of

screw head at least 1.5 mm (0.06 in) away from the edge of

the anchor kit so that the switch could hang on the screws

securely.

X mm

1.5 mm(Min)

Figure 3-16 Wall mounting

4) Align the two installation holes at the bottom of the switch

with these two screws to hang the switch.

Caution:

When mounting the switch, keep the Ethernet ports of the switch

facing downwards and the two sides with ventilation holes vertical to

the ground.

3-19

Page 52

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 3 Installation

3.1.4 Magnet Mounting

The following four models support magnet mounting:

z S3100-8TP-EI-W

z S3100-8TP-PWR-EI

z S3100-16TP-EI-W

z S3100-16TP-PWR-EI

I. Introduction to magnetic accessories

A set of magnetic mounting accessories consists of one

permanent magnets and one M3*6 countersunk head screws, as

shown in

needed for each S3100 switch.

Figure 3-17. Four sets of magnetic mounting accessories are

(1)

(2)

(1) Permanent magnet (2) M3*6 countersunk head screw

Figure 3-17 Magnets and countersunk head screws

II. Installation procedure

Follow these steps to complete magnet mounting:

1) As shown in

Figure 3-18, use a Phillips screwdriver to pass

the countersunk head screw through the round hole at the

center of the permanent magnet, fasten it to a blind nut in the

3-20

Page 53

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 3 Installation

dent of the switch bottom, and ensure that the permanent

magnet and the switch are fastened reliably.

Note:

z Remove the cushion, if any, from the dent before installation.

z To ensure the firmness of installation, be sure to use four

permanent magnets to secure each S3100 switch.

2) Attach the magnet-mounted device to the specified location.

Take care not to get your fingers stuck between because the

magnetism is very huge.

(1)

(2)(3)

(1) Blind nut in the dent of the switch bottom

(2) Permanent magnet (3) M3*6 countersunk head screw

Figure 3-18 Magnet mounting

3-21

Page 54

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 3 Installation

Caution:

z Apply magnet mounting to only the above four models. Otherwise,

a falloff or mis-operation may occur.

z Select the installation location carefully. In the case of poor surface,

magnet mounting may not be reliable.

z Put the device at a stable place free from vibrations or shocks.

Otherwise, personal injuries or equipment damage may occur.

z Avoid installing the device at a high place because personal

injuries or equipment damage may occur in case of a falloff.

z Avoid frequently moving the desk-mounted device because such

movements may damage the surface coating.

z Keep the front panel of the device facing downwards and the two

sides with ventilation holes vertical to the ground, if you want to

install the device vertically.

z Pay attention that the weight of external cables should not bring

about a falloff, which may result in personal injuries or equipment

damage.

z Keep floppy disks and magnetic cards away from magnets to avoid

erasure of any information.

z Keep computers and monitors that are easily influenced by

magnetic fields away from magnets. Otherwise, faults may occur to

these electronic devices.

3-22

Page 55

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 3 Installation

3.2 Installing an Expansion Interface Module

I. Installation procedure

Step 1: Put on an ESD-preventive wrist strap and make sure that

the ESD-preventive wrist strap is properly grounded. Then take the

expansion interface module out of the package.

Step 2: Unscrew the mounting screws on the filler panel installed

on the expansion module slot of the switch, and then remove the filler

panel.

Step 3: Slide in the expansion interface module along the guide

rails until the module is fully inserted into the switch.

Step 4: Use a screwdriver to fasten the fastening screws on both

sides of the expansion interface module.

II. Removal procedure

Step 1: Put on an ESD-preventive wrist strap and ensure that the

ESD-preventive wrist strap is properly grounded.

Step 2: Loosen the fastening screws on both sides of the

expansion interface module using a screwdriver.

Step 3: Draw back the expansion interface module until the

module is fully separated from the switch.

3-23

Page 56

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 3 Installation

Caution:

z Do not apply excessive force to install/remove an expansion

interface module, and do not touch the surface-mounted

components directly with your hands.

z After removing an expansion interface module, if no new module is

to be installed, install the filler panel in time to prevent dust and

ensure normal ventilation in the switch.

3.3 Connection of Power Cord and Grounding Cable

3.3.1 Connecting AC Power Cord

I. AC power socket (recommended)

You are recommended to use a mono-phase three-core power

socket with a neutral point or a multi-function power socket for

computers. The neutral point of the power in your building must be

well grounded. Normally, the neutral point of the power supply system

in your building has already been grounded during the construction

and wiring; but you should make sure this is the fact.

Neutral point

Neutral point

Live line

Zero line

Zero line

Live line

Figure 3-19 Recommended AC power socket

3-24

Page 57

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 3 Installation

II. Connecting AC power cord

1) Connect one end of the chassis grounding cable (coming

with the switch) to the grounding screw on the rear of the

chassis and the other end to the ground nearby.

2) Connect one end of the power cord to the power socket on

the rear panel of the chassis and the other end to an outside

AC power socket.

3) Install the power cord retainer for the AC power cord on

S3100-TP-PWR-EI series Ethernet Switches. Insert the two

ends of the power cord retainer into the slots at both sides of

the AC power input, and then set the power cord into the

notch of the power cord retainer, as shown in

Figure 3-20.

(2)

(1)

(3)

(4)

(1): Rear panel (2): Power cord retainer holder

(3): Power cord retainer (4): Power cord

Figure 3-20 Install the power cord retainer

3-25

Page 58

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 3 Installation

Note:

z Currently, only the S3100-TP-PWR-EI series Ethernet Switches

are equipped with an AC power cord retainer to prevent the power

cord from accidentally falling off.

z The location of the power cord retainer holder varies with

S3100-TP-PWR-EI series Ethernet Switches.

4) Check whether the PWR LED on the front panel of the

switch is ON. If the LED is ON, it shows the power cord is

properly connected.

Caution:

Before powering on the switch, you should properly connect the

grounding cable.

3-26

Page 59

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 3 Installation

3.3.2 Connecting DC Power Cable

I. DC power cable connection for S3100-C-SI DC-powered

Ethernet switch

(2)

(1)

(3)

(4)

(5)

(1) Screw 1 (2) Screw 2

(3) RTN (+) terminal (4) NEG(-) terminal (–48 V to –60 V)

(5) Grounding screw

Figure 3-21 DC input terminal block of S3100-C-SI DC-powered

Ethernet switch

Note:

The location of the DC input terminal block varies with devices.

1) Connect one end of the grounding cable (delivered with the

switch) to the grounding screw and the other end to the

ground nearby.

3-27

Page 60

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 3 Installation

2) Use a flat-blade screwdriver to loosen the two screws on the

DC input terminal blocks. Connect the power ground return

cable to the RTN(+) terminal and the power output cable to

the NEG(-) terminal. Tighten the two screws respectively to

fix the power cables.

3) Check whether the PWR LED on the front panel of the

switch is ON. If yes, the power is properly connected.

Caution:

z Before powering on the switch, you should properly connect the

grounding cable.

z The DC power cable should be less than 3 meters long.

II. DC power cable connection for S3100-26TP-PWR-EI

Ethernet switch

+-NULL+-NULL

+: Working ground

–: Voltage input (–52 VDC to –56 VDC) NULL: Reserved

Figure 3-22 RPS DC power socket for S3100-26TP-PWR-EI

Ethernet switch

3-28

Page 61

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 3 Installation

1) Connect one end of the grounding cable (delivered with the

switch) to the grounding screw and the other end to the

ground nearby.

2) Assemble the DC power connector as follows:

Figure 3-23 RPS DC power connector

z As shown in Figure 3-23, pass the two power cables through

the air filter, insert them into the corresponding holes, and

tighten them with screw 1 and screw 2. The positive and

negative poles of the power cables must correspond to the

silkscreen above the holes.

z Use a flat-blade screwdriver to fix the air filter on the

connector with screw 3 and screw 4, as shown in

3-23.

z Use cable ties to bind the two power cables to the protruding

part at the back of the air filter, as shown in

Figure 3-23.

Figure

3-29

Page 62

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 3 Installation

Figure 3-24 Fix the RPS DC power connector to the chassis

3) Insert the connector into the DC socket directly. Use the

flat-blade screwdriver to fix the connector with screw 1 and

screw 2 (delivered with the switch), as shown in

Figure 3-24.

Note:

The location of the DC power socket varies with devices.

4) Check whether the PWR LED on the front panel of the

switch is ON. If yes, the power is properly connected.

3-30

Page 63

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 3 Installation

Caution:

z Before powering on the switch, you must properly connect the

grounding cable.

z The DC power cable should be less than 3 meters long.

z Only the recommended RPS can be used for

S3100-26TP-PWR-EI Ethernet switches. The –48 VDC from the

equipment in cannot be used directly. Otherwise, the device may

be damaged.

III. 12V-RPS DC power cable connection for

S3100-26TP-EI-W AC-powered Ethernet switch

Pin Number Designation Pin Number Designation

1 GND 8 GND

2 — 9 —

3 12V 10 RPS_pres

4 12V 11 —

5 12V 12 —

6 12V 13 Control Pin

7 GND 14 GND

Figure 3-25 12V-RPS DC power socket

1) Connect one end of the grounding cable (delivered with the

switch) to the grounding screw and the other end to the

ground nearby.

3-31

Page 64

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 3 Installation

2) Connect the 12V-RPS DC power supply as follows:

z As shown in Figure 3-26, loosen the fastening screws and

remove the air filter from the 12V-RPS DC power socket. (In

the case of no 12V-RPS DC power supply, re-install the air

filter.)

(2)(1)

(1) Air filter (2) Fastening screw

Figure 3-26 12V-RPS power socket for an S3100-26TP-EI-W

AC-powered Ethernet switch

z Connect one connector (in A direction) of the 12V-RPS DC

power cable (

Figure 3-27 shows a recommended 12V-RPS

DC power cable) to the RPS DC power socket of the switch,

and the other connector (in B direction) to the corresponding

12 V power output socket of the RPS power module.

Figure 3-27 12V-RPS DC power cable

3-32

Page 65

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

z Connect one end of the delivered AC power cable to the

Chapter 3 Installation

power socket of the RPS power module and the other end to

the socket of an external AC power supply.

3) Check whether the PWR LED on the front panel of the

switch is ON. If yes, the power is properly connected.

Caution:

z Before powering on the switch, you should properly connect the

grounding cable.

z The DC power cable should be less than 3 meters long.

z Only the recommended 12V-RPS DC power supply and power

cables can be used.

3.3.3 Connecting Grounding Cable

Caution:

You should properly connect the switch grounding cable since it is

crucial to the lightning protection and electromagnetic shield (EMS) of

your switch.

The power input end of the switch is connected with a noise filter,

whose central ground is directly connected to the chassis, forming the

3-33

Page 66

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 3 Installation

so-called chassis ground (commonly known as PGND). This chassis

ground must be securely connected to the earth so that the faradism

and leakage electricity can be safely released to the earth, enhancing

the EMS capability of the switch.

Ground your switch as follows:

z When a grounding strip is available at the installation site,

attach one end of the yellow-green grounding cable of the

switch to the grounding screw on the grounding strip and

fasten the captive nut. (Note that the fire main and lightning

rod of your building are not suitable for grounding the switch.

The grounding cable of the switch should be connected to

the construction engineering ground of the equipment

room.)

(2 )

(2 )

(3)

(3)

(3)

(3)

(1 )

(1 )

(1 )

(1 )

(1 )

(1 )

(1 )

(1 )

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(4)

(1) Power input (2) Grounding screw

(3) Grounding cable (4) Grounding strip

Figure 3-28 Grounding the switch through a grounding strip

z When there is no grounding strip but there is cement floor

nearby where a grounding body is allowed to be buried,

hammer an angle steel/steel pipe no shorter than 0.5 m

(19.7 in.) into the earth, with the yellow-green grounding

3-34

Page 67

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 3 Installation

cable of the switch welded onto the angle steel/steel pipe

and the jointing point being processed against erosion.

(2)

(2)

(2)

(2)

(3)

(3)

(3)

(3)

(1)

(1)

(1)

(1)

(5)

(5)

(5)

(5)

(4)

(4)

(4)

(4)

(1) Power input (2) Grounding screw

(3) Grounding cable (4) Earth

(5) Angle steel

Figure 3-29 Grounding the switch by burying the grounding body

into the earth

z For an AC-powered switch, if none of the above two

conditions is available, ground it through the PE cable of the

AC power supply. In this case, make sure this PE cable is

well connected to the ground at the power distribution room

or AC transformer.

3-35

Page 68

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

(1)

(1)

(3)

(3)

(3)

(3)

(2)

(2)

(2)

(2)

(5)

(5)

(5)

(4)

(4)

(4)

(4)

(1) AC power input (2) Grounding screw

(3) Power transformer (4) PE cable

(5) 3-core cable for AC power input (6) Ethernet switch

(5)

Chapter 3 Installation

(6)

()

(6)

()

Figure 3-30 Grounding the switch through AC PE cable

z For a DC-powered switch (–48 VDC), if none of the first two

conditions is available, ground it through the return cable

(RTN) of the DC power supply. In this case, make sure this

RTN cable is well connected to the ground at the DC output

of the DC power cabinet.

3-36

Page 69

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 3 Installation

(1)

(1)

(1)

(1)

(11)

(11)

(11)

(11)

(2)

(2)

(2)

(2)

(4)

(4)

(4)

(4)

(6)

(6)

(6)

(6)

(3)

(3)

(3)

(3)

(5)

(5)

(5)

(5)

(7)

(7)

(7)

(7)

(8)

(8)(8)

(8)

(8)(8)

(9)

(9)

(10)

(10)

(1)AC/DC power cabinet (2) –48V strip (3) –48V

(4) RTN strip (5) RTN (6) PGND strip

(7) Grounding to the earth (8) Grounding cable (9) screw

(10) Ethernet switch (11) DC power input

Figure 3-31 Grounding the switch through the PGND of the

power cabinet

3-37

Page 70

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 3 Installation

3.4 Connecting Optical Fiber

Caution:

z After a switch starts, the optical port may emit invisible radial when

there is no optical connector connected to it and the protective cap

is removed from it. Therefore, do not stare into the optical interface.

z Be sure to cover the protective cap within 10 seconds if an optical

connector is not in use to keep the optical connector clean.

z Be sure to cover the protective cap if an optical port has no optical

connector attached.

z Place the protective caps in a safe place when an optical port has

fiber connected to prepare for the cases the fiber is pulled out.

Note:

The following section describes the procedures to connect optical fiber

to an ONU card. The procedures also apply to other subcards.

Step 1: Remove the protective cap from the optical connector of

the fiber.

Step 2: Remove the protective cap from the PON interface of the

ONU card.

Step 3: Plug the optical connector into the PON interface of the

ONU subcard.

3-38

Page 71

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 3 Installation

3.5 Connection of Console Cable

3.5.1 Console Cable

The console cable is an 8-core shielded cable. At one end of the

cable is a crimped RJ45 connector to be connected to the console port

of the switch; at the other end of the cable is a DB-9 (female)

connector to be connected to the 9-core (pin) serial port on the

console terminal. See the following figure.

Figure 3-32 Console cable

Table 3-5 Console cable connector pinouts and mapping relation

RJ-45 Signal Direction DB-9

1 RTS ← 7

2 DTR ← 4

3 TXD ← 3

4 CD → 1

5 GND — 5

6 RXD → 2

3-39

Page 72

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 3 Installation

RJ-45 Signal Direction DB-9

7 DSR → 6

8 CTS → 8

3.5.2 Connecting Console Cable

Follow these steps to connect a terminal device, a PC for

example, to the switch:

Step 1: Connect the DB-9 female connector of the console cable

to the serial port of the PC or the terminal device used to configure the

switch.

Step 2: Connect the RJ-45 connector of the console cable to the

console port of the switch.

Caution:

Identify the label of the port before connecting a connector.

3-40

Page 73

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 3 Installation

Note:

When connecting a PC to a powered-on switch, you are

recommended to connect the DB-9 connector of the console cable to

the PC before connecting the RJ45 connector to the switch. When

disconnecting a PC from a powered-on switch, you are recommended

to disconnect the DB-9 connector of the console cable from the PC

after disconnecting the RJ45 connector from the switch.

3.6 Installation Verification

After completing the installation, check that:

z The correct power is used.

z The grounding cable is connected.

z Both console cable and power cord are properly connected.

z All the interface cables are wired indoors. If there is any

cable wired outdoors, verify that socket strip with lightning

protection and lightning arresters for network ports have

been properly connected.

3-41

Page 74

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 4 Lightning Protection

of the Switch

Chapter 4 Lightning Protection of the

Switch

4.1 Installation of Lightning Arrester for AC Power (Socket Strip with Lightning Protection)

Caution:

Lightning arrester will not be shipped with the switch. You should

purchase it by yourself if needed.

If an outdoor AC power cord should be directly led to the switch,

please serially connect the lightning arrester for AC power (Socket

Strip with Lightning Protection) before you plug AC power cord into the

switch, thus to prevent the possible damage to the switch due to

lightning strike. You can use cable clips and screws to fasten the

lightning arrester for AC power on the cabinet, workbench or the wall

of equipment room.

4-1

Page 75

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Grounding and polarity indicator (red) :

On m eans that the lines are wrongly connected

(either the ground wire is not well connected, or the live and zero lines are wrongly connected).

Please check the power supply circuit.

Norm al operation indicator (green):

On m eans that the arrester works normally. Otherwise, it

m eans that the protection circuit has been damaged.

Mainboard

Chapter 4 Lightning Protection

of the Switch

Power switch

Pow er socket (complied with IEC standard),

connected to the power supply of the equipment room

through power cord

Multipurpose power socket, connected to the device

protected by the arrester

Figure 4-1 Diagram of lightning arrester

4-2

Overload auto protector,

which can be manually reset.

Page 76

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 4 Lightning Protection

of the Switch

Caution:

z Make sure that the arrester is well grounded before using the

lightning arrester for power.

z After inserting AC power cord plug of switch into the socket of

lightning arrester, if the green LED is on and the red LED does not

alarm, it means that the lightning arrester of power is running and

the function of lightning protection has taken effect.

z Pay adequate attention if the red LED is on. You should correctly

locate the problem, whether it is caused because the ground cable

of the arrester is not well grounded or because the live and zero

cables are connected in reverse direction. You may check that in

the following way. When the red LED is on, use a multimeter to

examine polarity at the power socket of the arrester. If it is same to

that of the power socket in the equipment room, it means that

arrester is not well grounded. If it is adverse to that of the power

socket in the equipment room, it means that the power socket of

the arrester is set to the reverse polarity. In this case, you should

open the power socket of arrester to correct polarity. After that, if

the red LED still alarms, it means that the arrester is not well

grounded yet.

4-3

Page 77

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 4 Lightning Protection

of the Switch

4.2 Installation of Lightning Arrester for Network Port

Note:

Lightning arrester for network port is specially designed for the

Ethernet port of 10/100M electrical interface (RJ-45 connector is

adopted in this case).

Caution:

Lightning arrester for network port will not be provided along with the

switch, and you should purchase it by yourself if needed.

If an outdoor network cable should be led to the switch, please

serially connect the lightning arrester for network port before you plug

this cable into the interface on the switch, in case of the possibility that

the switch may be damaged due to lightning strike.

I. Required tools

z Phillips screwdriver or Flat-blade screwdriver

z Multimeter

z Tilted cable cutter

4-4

Page 78

Quick Start (For Japan)

H3C S3100 Series Ethernet Switches

Chapter 4 Lightning Protection

of the Switch

II. Installation procedure

Step 1: Tear the protection paper at one side of the double faced

adhesive tape apart from the tape, and stick the tape on the surface of

the arrester. Tear the protection paper at another side apart from the

tape, and stick the arrester onto the chassis of the switch. The arrester

should be attached on the chassis as close to the grounding screw as

possible.