Page 1

H3C S12500 Routing Switch Series

Installation Guide

Hangzhou H3C Technologies Co., Ltd.

http://www.h3c.com

Document version: 6W170-20111114

Page 2

Copyright © 2008-2011, Hangzhou H3C Technologies Co., Ltd. and its licensors

All rights reserved

No part of this manual may be reproduced or transmitted in any form or by any means without prior

written consent of Hangzhou H3C Technologies Co., Ltd.

Trademarks

H3C,

, Aolynk, , H3Care,

, TOP G, , IRF, NetPilot, Neocean, NeoVTL,

SecPro, SecPoint, SecEngine, SecPath, Comware, Secware, Storware, NQA, VVG, V

2

G, VnG, PSPT,

XGbus, N-Bus, TiGem, InnoVision and HUASAN are trademarks of Hangzhou H3C Technologies Co.,

Ltd.

All other trademarks that may be mentioned in this manual are the property of their respective owners

Notice

The information in this document is subject to change without notice. Every effort has been made in the

preparation of this document to ensure accuracy of the contents, but all statements, information, and

recommendations in this document do not constitute the warranty of any kind, express or implied.

Environmental protection

This product has been designed to comply with the environmental protection requirements. The storage,

use, and disposal of this product must meet the applicable national laws and regulations.

Page 3

Preface

The H3C S12500 Routing Switch Series Installation Guide describes how to install the H3C S12500

switches.

This preface includes:

• Audience

• Conventions

• About the H3C S12500 documentation set

• Obtaining documentation

• Technical support

• Documentation feedback

Audience

This documentation is intended for:

• Network planners

• Field technical support and servicing engineers

• Network administrators working with the S12500 switches

Conventions

This section describes the conventions used in this documentation set.

Command conventions

Convention Description

Boldface Bold text represents commands and keywords that you enter literally as shown.

Italic Italic text represents arguments that you replace with actual values.

[ ] Square brackets enclose syntax choices (keywords or arguments) that are optional.

{ x | y | ... }

Braces enclose a set of required syntax choices separated by vertical bars, from which

you select one.

[ x | y | ... ]

Square brackets enclose a set of optional syntax choices separated by vertical bars, from

which you select one or none.

{ x | y | ... } *

Asterisk marked braces enclose a set of required syntax choices separated by vertical

bars, from which you select at least one.

[ x | y | ... ] *

Asterisk marked square brackets enclose optional syntax choices separated by vertical

bars, from which you select one choice, multiple choices, or none.

&<1-n>

The argument or keyword and argument combination before the ampersand (&) sign can

be entered 1 to n times.

# A line that starts with a pound (#) sign is comments.

Page 4

GUI conventions

Convention Description

Boldface

Window names, button names, field names, and menu items are in Boldface. For

example, the New User window appears; click OK.

> Multi-level menus are separated by angle brackets. For example, File > Create > Folder.

Symbols

Convention Description

WARNING

An alert that calls attention to important information that if not understood or followed can

result in personal injury.

CAUTION

An alert that calls attention to important information that if not understood or followed can

result in data loss, data corruption, or damage to hardware or software.

IMPORTANT

An alert that calls attention to essential information.

NOTE

An alert that contains additional or supplementary information.

TIP

An alert that provides helpful information.

Network topology icons

Represents a generic network device, such as a router, switch, or firewall.

Represents a routing-capable device, such as a router or Layer 3 switch.

Represents a generic switch, such as a Layer 2 or Layer 3 switch, or a router that supports

Layer 2 forwarding and other Layer 2 features.

Port numbering in examples

The port numbers in this document are for illustration only and might be unavailable on your device.

About the H3C S12500 documentation set

The H3C S12500 documentation set includes:

Category Documents Purposes

Marketing brochures Describe product specifications and benefits.

Technology white papers

Provide an in-depth description of software features

and technologies.

Product description and

specifications

Card datasheets

Describe card specifications, features, and

standards.

Page 5

Category Documents Purposes

Regulatory compliance

and safety information

Provides regulatory information and the safety

instructions that must be followed during installation.

Installation guide

Provides a complete guide to hardware installation

and hardware specifications.

H3C N68 Cabinet

Installation and Remodel

Introduction

Guides you through installing and remodeling H3C

N68 cabinets.

H3C Pluggable SFP

[SFP+][XFP] Transceiver

Modules Installation

Guide

Guides you through installing SFP/SFP+/XFP

transceiver modules.

Adjustable Slider Rail

Installation Guide

Guides you through installing adjustable slider rails

to a rack.

Hardware specifications

and installation

H3C High-End Network

Products Hot-Swappable

Module Manual

Describes the hot-swappable modules available for

the H3C high-end network products, their external

views, and specifications.

Configuration guides

Describe software features and configuration

procedures.

Command references

Provide a quick reference to all available

commands.

Software configuration

Configuration examples

Describe typical network scenarios and provide

configuration examples and instructions.

System log messages Explains the system log messages.

Trap messages Explains the trap messages.

MIB Companion Describes the MIBs for the software release.

Operations and

maintenance

Release notes

Provide information about the product release,

including the version history, hardware and software

compatibility matrix, version upgrade information,

technical support information, and software

upgrading.

Obtaining documentation

You can access the most up-to-date H3C product documentation on the World Wide Web at

http://www.h3c.com

.

Click the links on the top navigation bar to obtain different categories of product documentation:

[Technical Support & Documents > Technical Documents]

– Provides hardware installation, software

upgrading, and software feature configuration and maintenance documentation.

[Products & Solutions]

– Provides information about products and technologies, as well as solutions.

[Technical Support & Documents > Software Download]

– Provides the documentation released with the

software version.

Page 6

Technical support

customer_service@h3c.com

http://www.h3c.com

Documentation feedback

You can e-mail your comments about product documentation to info@h3c.com.

We appreciate your comments.

Page 7

i

Contents

Product overview··························································································································································1

Physical architecture ·························································································································································1

Backplane ··········································································································································································7

Fan tray ··············································································································································································7

Power supply system······················································································································································ 11

AC power supply ·················································································································································· 11

DC power supply··················································································································································· 14

Preparing for installation ···········································································································································17

Safety recommendations ··············································································································································· 17

General safety recommendations························································································································ 17

Electricity safety ····················································································································································· 17

ESD prevention ······················································································································································ 17

Switch moving ·······················································································································································18

Laser safety····························································································································································· 18

Examining the installation site ······································································································································ 19

Weight support······················································································································································ 19

Temperature ··························································································································································· 19

Humidity ································································································································································· 19

Cleanness······························································································································································· 20

EMI·········································································································································································· 20

Grounding······························································································································································ 20

Power supply·························································································································································· 21

Space······································································································································································ 21

Rack-mounting ································································································································································21

Installation tools······························································································································································ 23

Installing the switch····················································································································································24

Check before installation··············································································································································· 24

Installing the switch in a rack········································································································································ 25

Installation preparation········································································································································· 25

Installing slide rails and cage nuts to the rack ··································································································· 25

Installing the mounting brackets··························································································································· 27

Installing an air deflector (optional) ····················································································································28

Installing a chassis air filter (optional)················································································································· 29

Mounting the switch in the rack··························································································································· 31

Verifying the installation ······································································································································· 32

Installing the switch on a workbench··························································································································· 32

Installation preparation········································································································································· 32

Installation procedures·········································································································································· 32

Grounding the switch ····················································································································································34

Installing the power system ··········································································································································· 35

Installation preparation········································································································································· 35

Installing a DC power module ····························································································································· 35

Installing an AC power module ··························································································································· 36

Installing a fan tray ························································································································································ 37

Installing a card······························································································································································ 38

Installation preparation········································································································································· 39

Installation procedure············································································································································ 39

Connecting power cords··············································································································································· 41

Page 8

ii

Prerequisites ··························································································································································· 41

Connecting an AC power cord ··························································································································· 41

Connecting a DC power cord······························································································································ 42

Verifying the installation················································································································································ 44

Connecting the switch to the network·······················································································································45

Logging in to the switch················································································································································· 45

Connecting the console cable······························································································································ 45

Setting up a configuration environment ·············································································································· 46

Powering on the switch·················································································································································· 49

Verification before power-on ·······························································································································49

Powering on the switch········································································································································· 49

Verification after power-on··································································································································· 51

Connecting the switch to the network ·························································································································· 52

Connecting the switch to the network through the AUX port············································································ 52

Connecting the switch to the network through a copper Ethernet port ··························································· 52

Connecting the switch to the network through a fiber Ethernet port································································ 53

Cable routing recommendations ··································································································································56

Hardware management·············································································································································57

Displaying the electrical label information of your switch························································································· 57

Displaying the card information of your switch ·········································································································· 58

Rebooting your switch ··················································································································································· 59

Managing the power supply system ···························································································································· 60

Displaying the electrical label information of the power monitoring module················································· 60

Enabling power supply management·················································································································· 61

Configuring the number of redundant power modules ····················································································· 61

Manually starting or stopping power supply to a card····················································································· 62

Allocating IDs for AC power modules················································································································· 63

Displaying the power supply system information of your switch ····································································· 64

Configuring temperature alarm thresholds for a card································································································ 70

Configuring temperature alarm thresholds for a card······················································································· 70

Displaying the temperature information of your switch····················································································· 70

Isolating a card and locating card faults····················································································································· 71

Configuring in-service hardware failure diagnosis and failure protection ······························································73

Displaying the operating state of fans ························································································································· 75

Displaying the alarming information of a card··········································································································· 76

Displaying transceiver information and alarming information·················································································· 77

Introduction to transceivers··································································································································· 77

Displaying transceiver information ······················································································································ 77

Displaying the alarming information or fault detection parameters of a transceiver····································· 79

Troubleshooting··························································································································································82

Configuration terminal problems·································································································································· 82

No terminal display ·············································································································································· 82

Garbled terminal display······································································································································ 82

Power supply system failure·········································································································································· 83

Power monitoring module····································································································································· 83

Power modules ······················································································································································83

Fan failure······································································································································································· 85

MPU failure····································································································································································· 85

LPU failure······································································································································································· 86

Switching fabric module failure ··························································································································· 86

Interface failure······························································································································································· 87

Technical support ··························································································································································· 88

Page 9

iii

Replacement procedures ···········································································································································89

Removing, cleaning, and installing the air filters········································································································ 89

Removing, cleaning, and installing the chassis air filters for an S12508 ······················································89

Removing, cleaning, and installing the chassis air filter for an S12518 ························································ 90

Removing, cleaning, and installing a power module air filter ·········································································91

Replacing a power module··········································································································································· 91

Preparing for the replacement ·····························································································································91

Replacing a power module ·································································································································· 92

Replacing a PEM (applicable to only an AC power module) ·········································································· 93

Replacing a card···························································································································································· 94

Preparing for the replacement ·····························································································································94

Replacement procedure········································································································································ 95

Replacing a fan tray ······················································································································································ 96

Preparing for the replacement ·····························································································································96

Replacement procedure········································································································································ 97

Replacing a CF card······················································································································································ 97

Replacing a transceiver module ···································································································································99

Regulatory Compliance and Safety Information··································································································· 101

Regulatory Compliance Information···························································································································101

Regulatory Compliance Standards····················································································································101

European Directives Compliance·······················································································································102

USA Regulatory Compliance ·····························································································································102

Canada Regulatory Compliance ·······················································································································103

Japan Regulatory Compliance···························································································································103

CISPR 22 Compliance ········································································································································103

Safety Information Sicherheits informationen安全信息 ····························································································103

Overview Überblick 概述 ···································································································································103

Electricity Safety Elektrische Sicherheit 用电安全 ····························································································107

Lithium Battery Lithiumbatterie 锂电池···············································································································109

Fuse Sicherung保险丝·········································································································································110

Laser Laser激光辐射············································································································································110

Appendix A Technical specifications····················································································································· 111

Environment requirements ···········································································································································111

Power consumption/weight/dimensions ···················································································································111

Switches································································································································································111

Cards ····································································································································································112

Fan trays·······························································································································································113

Power components ··············································································································································113

Switch ordering guide ·················································································································································114

Card ordering guide····················································································································································114

MPUs·····································································································································································116

Switching fabric modules ···································································································································117

Ethernet interface card specifications················································································································117

OAA cards···························································································································································118

Power components ordering guide ····························································································································119

Appendix B LEDs····················································································································································· 124

Power system LEDs ·······················································································································································124

Monitoring module LEDs·····································································································································124

Power module LEDs·············································································································································124

Fan LEDs········································································································································································125

MPU LEDs······································································································································································125

CF card status LED···············································································································································126

Page 10

iv

Network management port LEDs ·······················································································································126

Switching fabric module LED ·····························································································································126

LPU status LED ······················································································································································126

Fan status LED ······················································································································································127

Power status LED··················································································································································127

MPU LEDs ·····························································································································································127

Line card LEDs ······························································································································································127

Interface LEDs·······················································································································································128

RUN LED·······························································································································································129

Switching fabric module LEDs·····································································································································129

Appendix C Transceiver modules·························································································································· 130

10-GE XFP transceiver modules··································································································································130

10-GE SFP+ transceiver modules ·······························································································································130

10-GE SFP+ cables ······················································································································································131

100/1000 Mbps SFP transceiver modules···············································································································131

Appendix D Lightning protection··························································································································· 133

Connecting the AC power supply to a power strip with lightning protection ·······················································133

Installing a lightning protector for a network port ····································································································134

Appendix E Cable management···························································································································· 136

Prerequisites··································································································································································136

Cable management guidelines···································································································································136

Appendix F Engineering labels for cables············································································································ 139

Introduction to labels ···················································································································································139

Material································································································································································139

Type and shape···················································································································································139

Printing labels ······················································································································································141

Writing labels ······················································································································································142

Affixing labels······················································································································································143

Information carried on labels·····························································································································145

Remarks ································································································································································146

Engineering labels for Ethernet cables·······················································································································146

Engineering labels for optical fibers ··························································································································147

Labels for the fiber that connects two devices··································································································147

Labels for the fiber that connects the device and the ODF ·············································································148

Engineering labels for power cords···························································································································149

Labels for DC power cords·································································································································149

Labels for AC power cords·································································································································151

Index ········································································································································································ 153

Page 11

1

Product overview

The H3C S12500 Routing Switch Series includes the models in Table 1.

Table 1 S12500 models

Model MPU slots Line card slots Switching fabric module slots

S12508-AC 2 8 9

S12508-DC 2 8 9

S12518-AC 2 18 9

S12518-DC 2 18 9

NOTE:

• The “AC” suffix in a chassis model represents AC powered and the “DC” suffix in a chassis model

represents DC powered.

• The line card slots are for both Ethernet interface cards and OAA cards. For card specifications, see

“Appendix A Technical specifications.”

• Unless otherwise stated, the configuration and installation procedures in this document apply to all

S12500 switches.

Physical architecture

NOTE:

• The DC-powered model and the AC-powered model of a chassis look the same.

• The diagrams in this guide are for illustration only.

Page 12

2

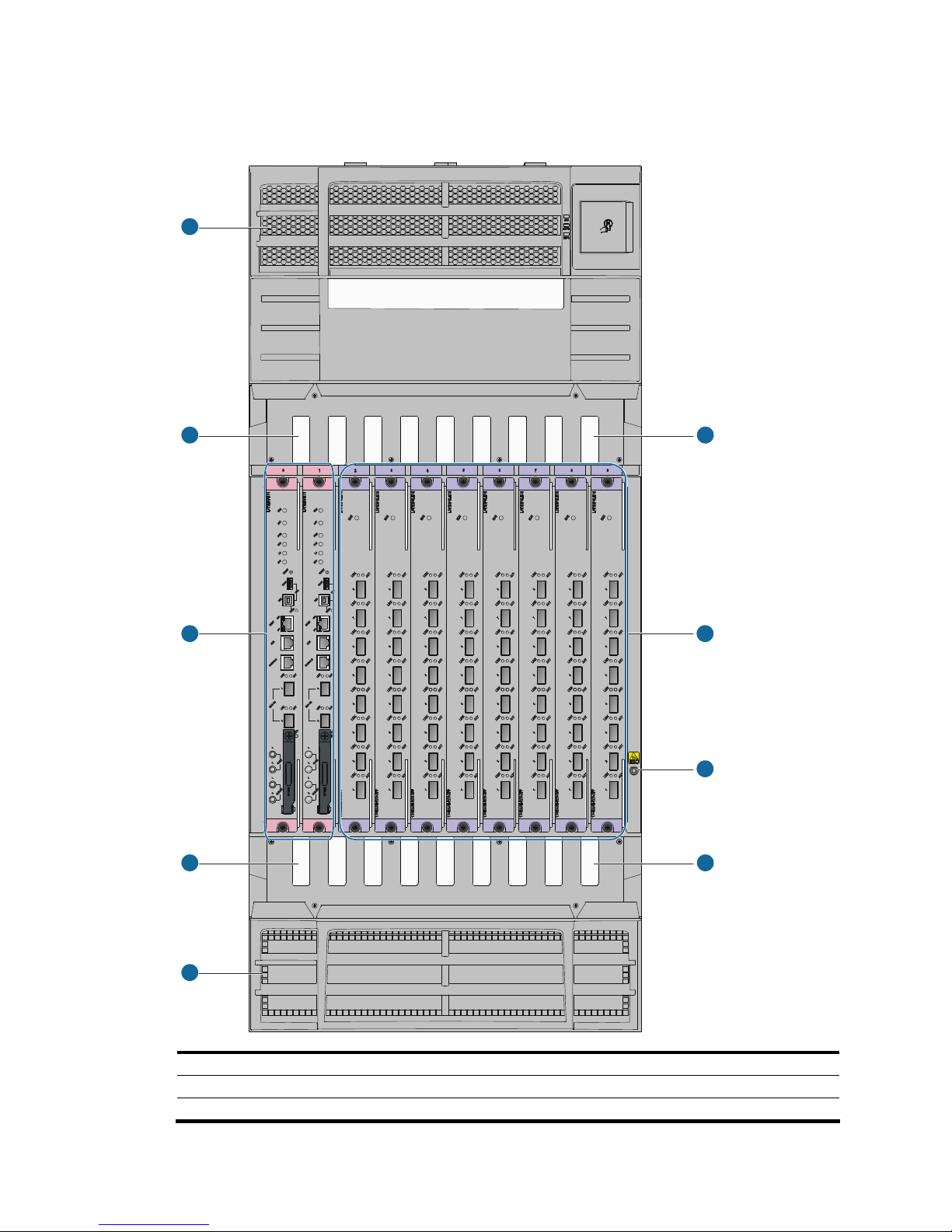

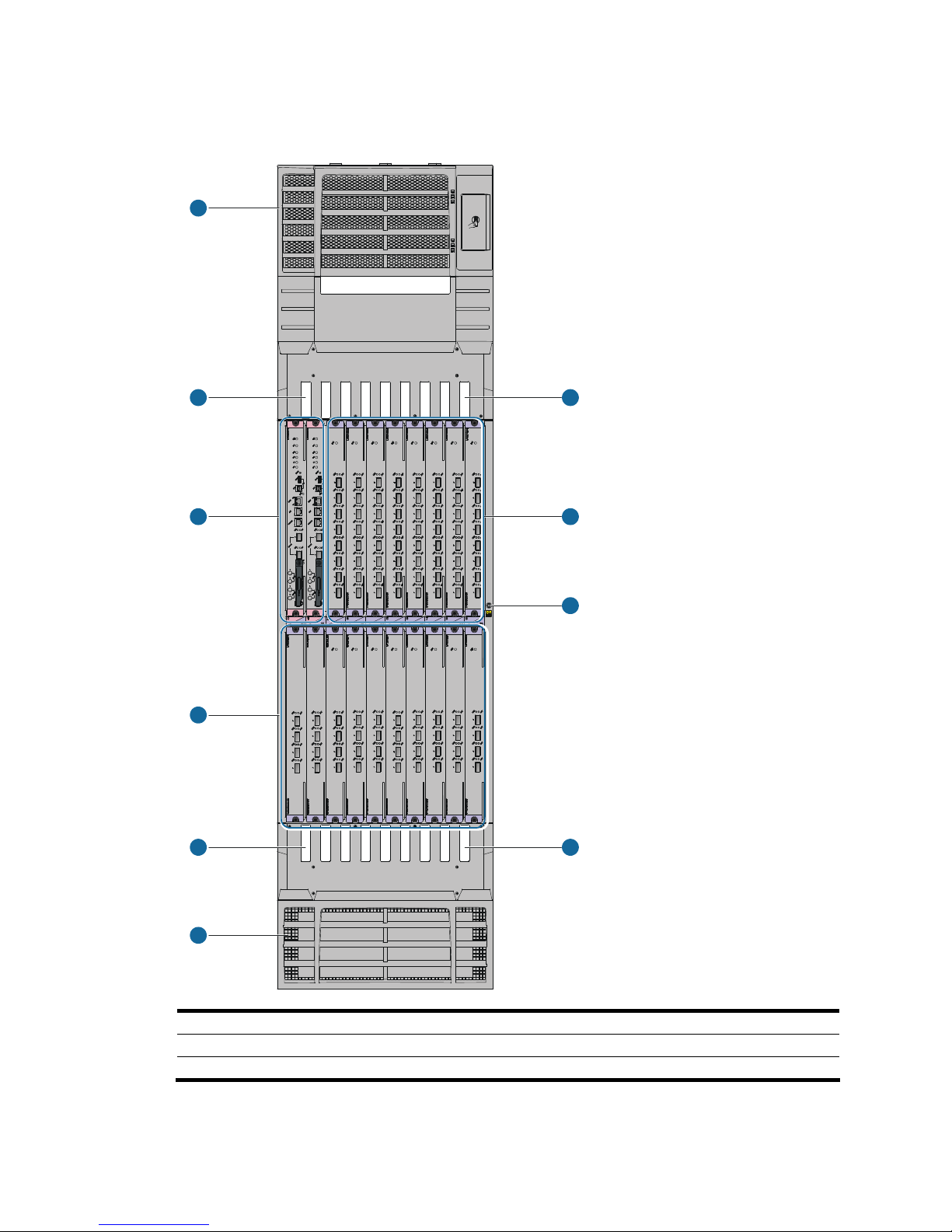

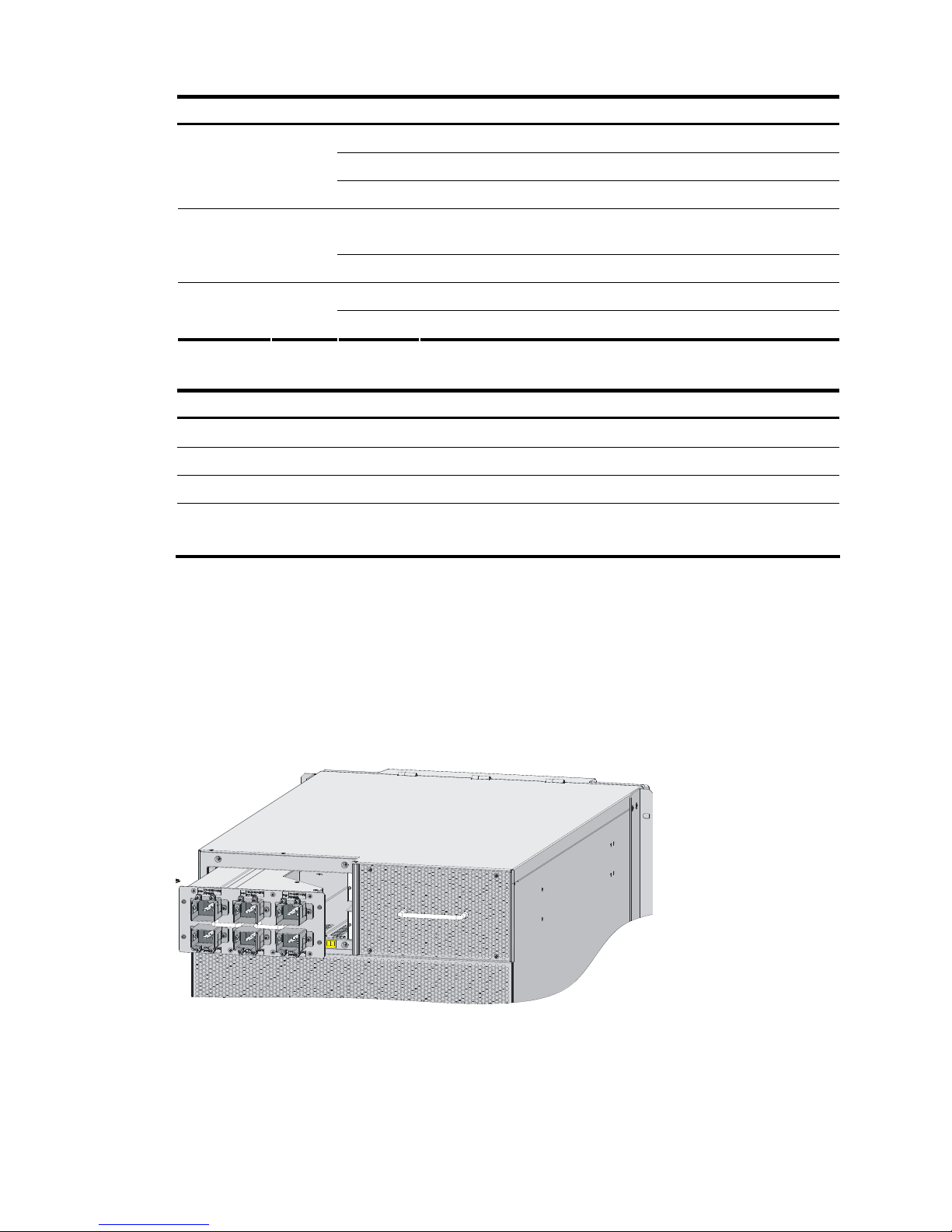

S12508 chassis views

Figure 1 S12508 front view

1

2

3

4

5

2

4

6

7

(1) Power frame cover (2) Upper cabling rack (3) MPU slots (slots 0 and 1)

(4) Lower cabling rack (5) System air intake vents (6) ESD-preventive wrist strap port

(7) Line card slots (slots 2 to 9)

Page 13

3

NOTE:

The power frame cover protects the power module air filter and the power frame slot. See “Power supply

syst

em.”

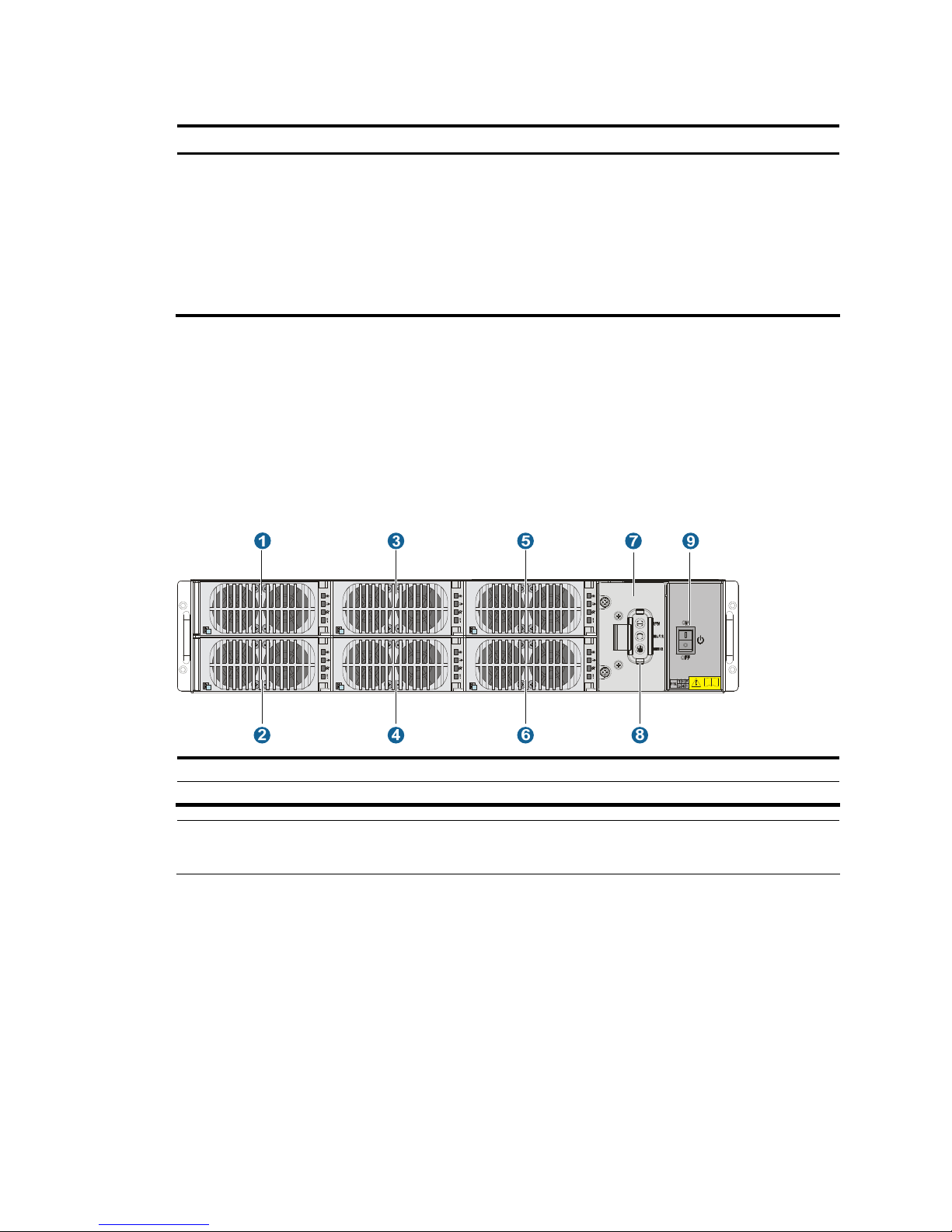

Figure 2 S12508 rear view

1

2

3

4

5

6

8

7

9

(1) Power entry module (PEM) (2) Upper fan tray

Page 14

4

(3) Lower fan tray (4) Ventilation panel

(5) Grounding screw (6) ESD-preventive wrist strap port

(7) Switching fabric module slots (slots 10 to 18) (8) System air exhaust vents

(9) Power air exhaust vents

The S12508 chassis has the following slots and components:

• Two MPU slots and eight line card slots at the front, and nine switching fabric module slots at the

rear.

• One power frame, at the top of the chassis, can accommodate up to six power modules.

• Two horizontally oriented fan trays at the rear of the chassis. For the ventilation inside the chassis,

see Figure 7.

Page 15

5

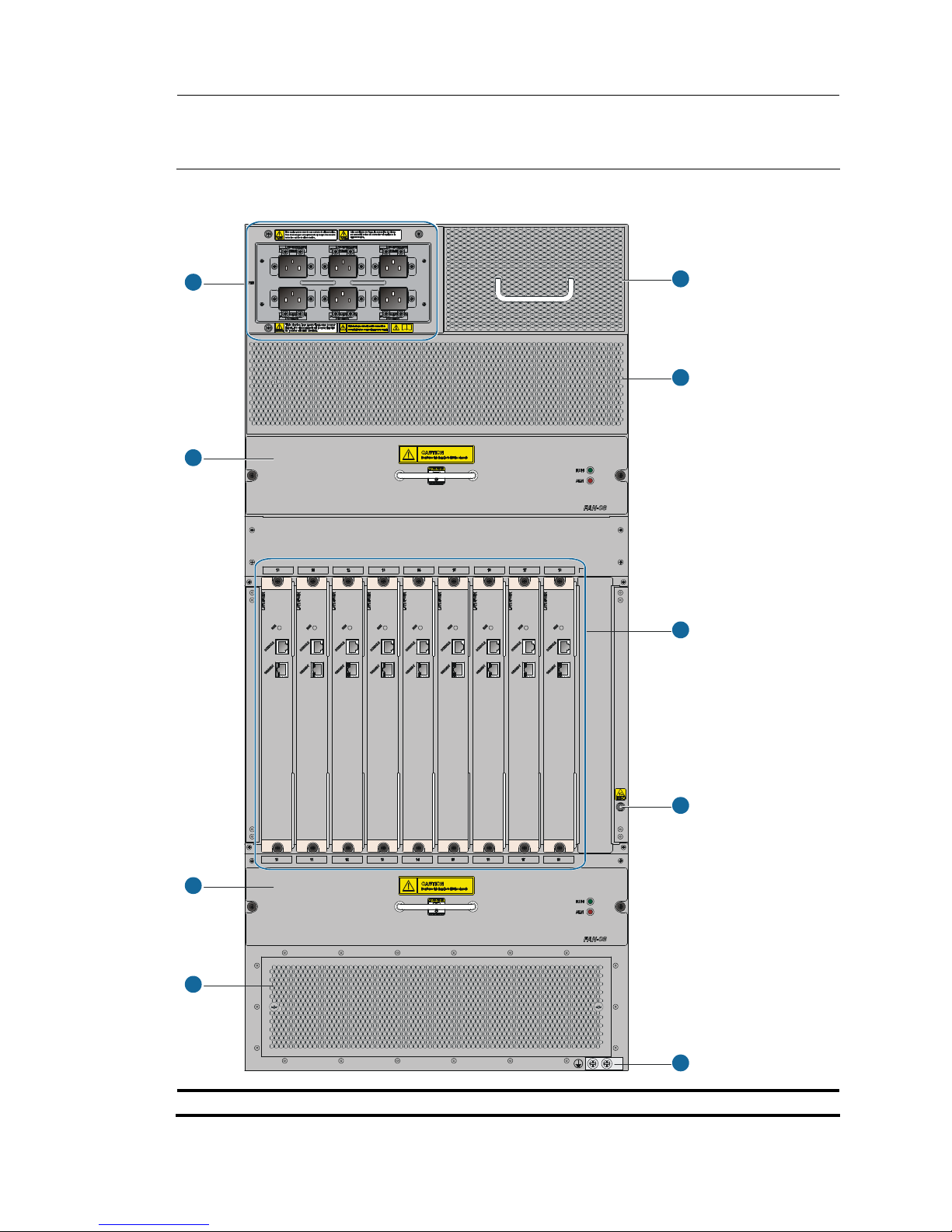

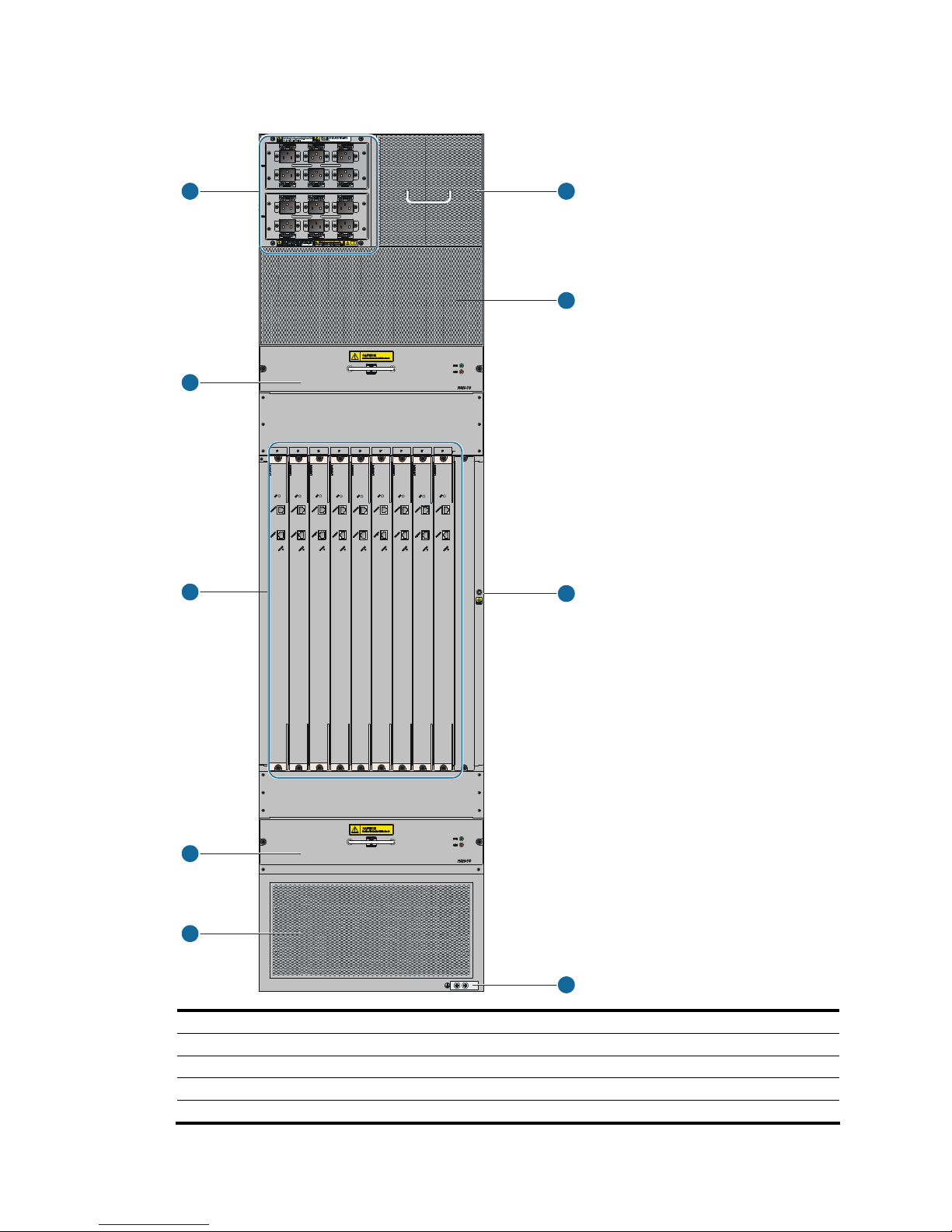

S12518 chassis views

Figure 3 Front view of the S12518

1

22

3

55

7

6

4

4

(1) Power frame cover (2) Upper cabling rack (3) MPU slots (slots 0 and 1)

(4) Line card slots (slots 2 to 19) (5) Lower cabling rack (6) System air intake vents

(7) ESD-preventive wrist strap port

Page 16

6

Figure 4 S12518 rear view

1

2

3

4

5

6

7

8

9

(1) Power entry module (PEM) (2) Upper fan tray

(3) Switching fabric module slots (slots 20 to 28) (4) Lower fan tray

(5) Ventilation panel (6) Grounding screw

(7) ESD-preventive wrist strap port (8) System air exhaust vents

(9) Power air exhaust vents

Page 17

7

The S12518 chassis has the following slots and components:

• Two MPU slots and 18 line card slots at the front, and nine switching fabric module slots at the rear.

• Two power frames at the top, and each power frame can accommodate up to six power modules.

• Two horizontally oriented fan trays at the rear. For the ventilation inside the chassis, see Figure 7.

Backplane

The backplane of an S12500 switch is located inside the chassis. It provides high-speed data switching

between switching fabric modules and line cards, and exchanges management and control signals

between MPUs and line cards/switching fabric modules. The backplane provides the following

capabilities:

• Provides communication channels for signal exchange between cards.

• Supports hot-swapping of cards.

• Identifies card type.

• Supplies power to MPUs, line cards, switching fabric modules, fan trays, and power modules when

connected to the power frame.

• Provides monitoring channels to monitor power module status.

Fan tray

A fan tray contains fan units. The dimension of each fan unit is 120 × 120 × 38 mm (4.72 × 4.72 ×1.50

in).

Both the S12508 and the S12518 use an upper fan tray at the top and a lower fan tray at the bottom.

Each fan tray comprises 12 fan units and one fan monitoring board.

S12500 fan trays provide the following functions:

• Effective heat dissipation and single-point of failure protection.

• Status monitoring, including fan rotation speed monitoring and fault alarming.

• Fan speed can be controlled by the MPU or automatically adjusted based on temperature. The

S12508 and S12518 have four groups of fans. Speed adjustment is done on a per-group basis to

decrease noise and improve energy efficiency.

• Each fan tray has two LEDs on the front panel to show its operating status.

• Hot swappable. The fans receive DC power from the backplane, and are hot swappable.

CAUTION:

The S12508 and S12518 use different fan trays, and do not support the intermixing of fan trays.

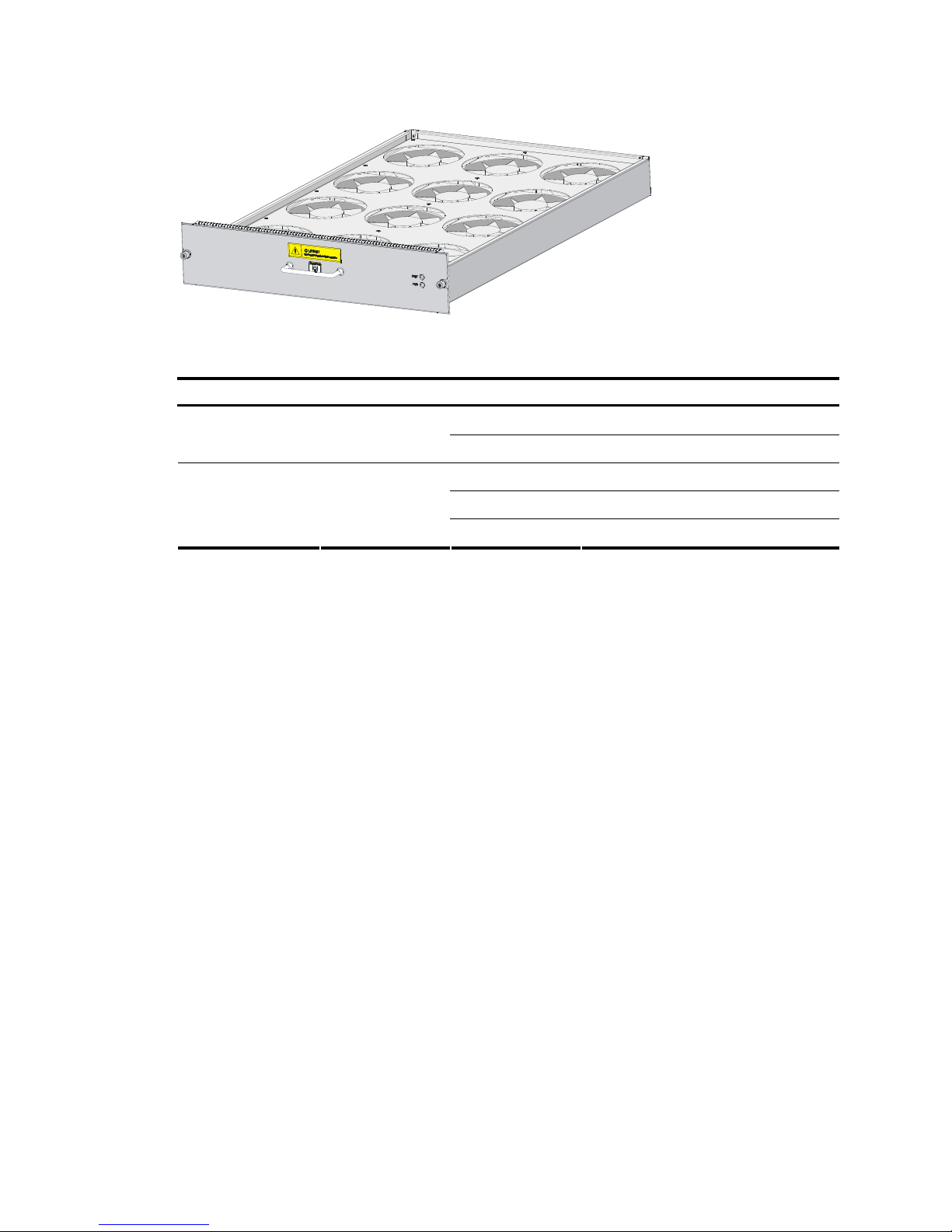

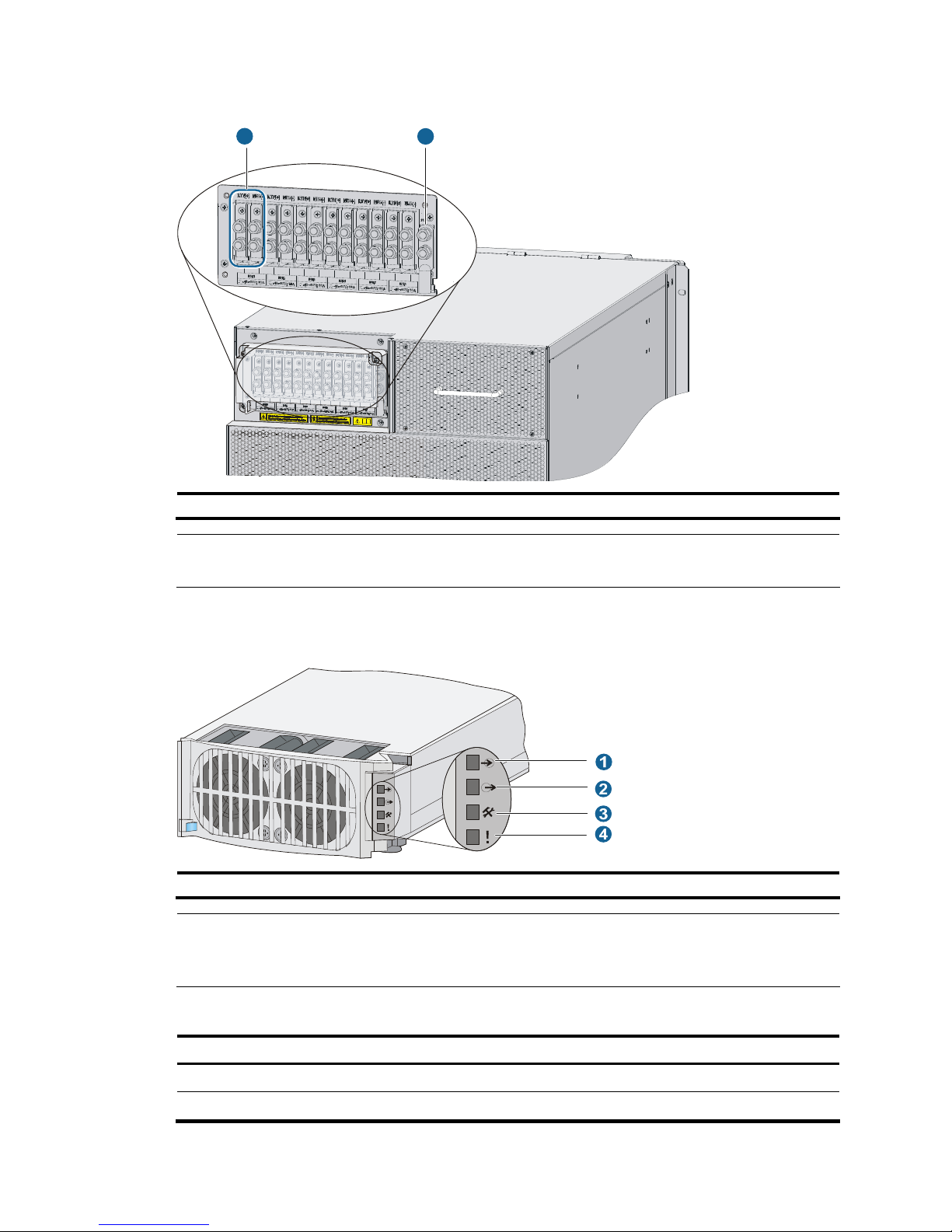

Figure 5 shows the S12508 fan tray. The physical view of the S12518 fan tray is similar.

Page 18

8

Figure 5 S12508 fan tray

Table 2 Fan LED description

LED Color Status Description

Off

The fan tray has failed.

RUN Green

Flashing

The fan tray is operating properly.

Off

The fan tray is in a normal state.

Flashing

The fan tray is faulty.

ALM Red

On The fan tray is faulty.

Figure 6 and Figure 7 show the ventilation inside the chassis of the S12508 and S12518.

Page 19

9

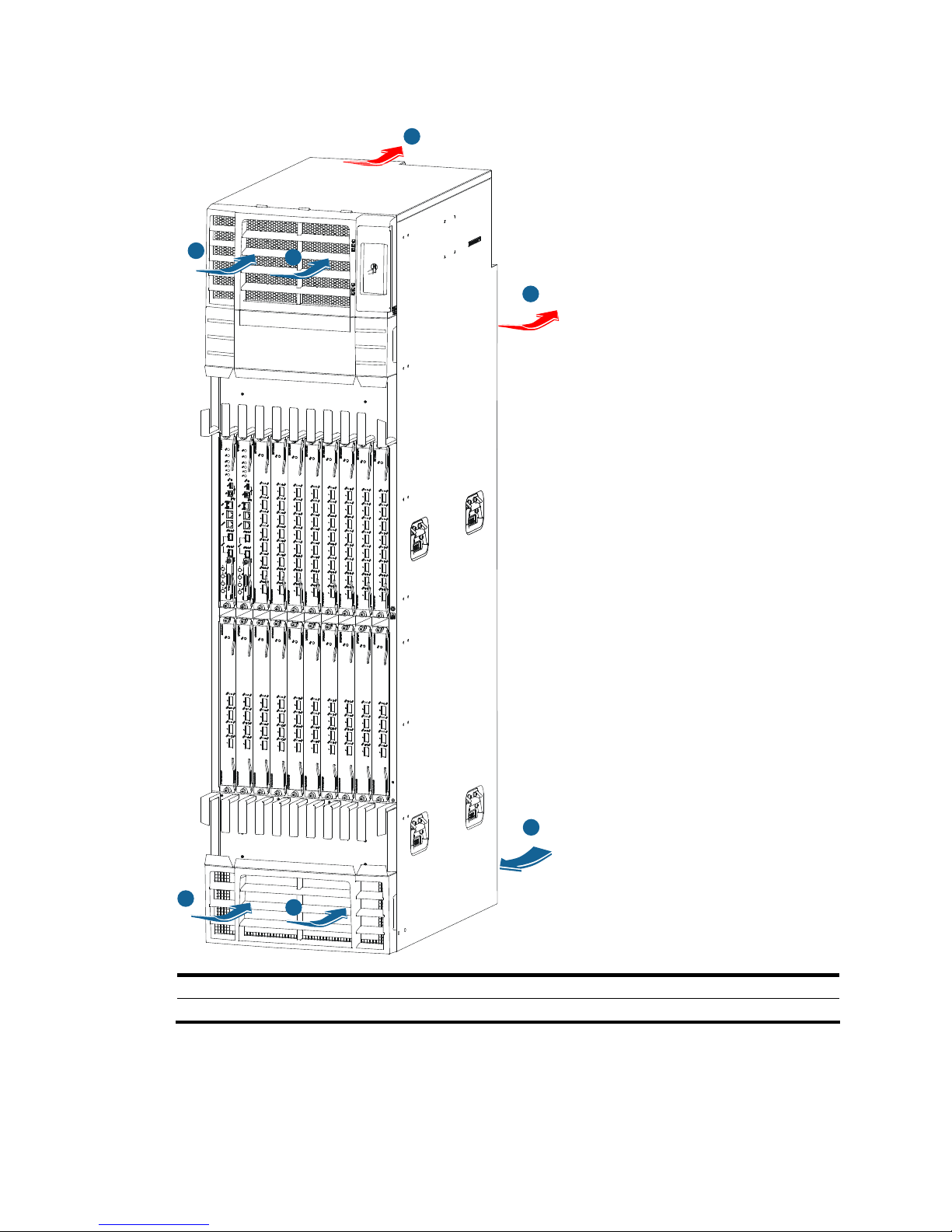

Figure 6 Ventilation inside an S12508 chassis

1

1

2

3

3

4

1

(1) System air intake direction (2) System air exhaust direction

(3) Power module air intake direction (4) Power module air exhaust direction

Page 20

10

Figure 7 Ventilation inside an S12518 chassis

1

1

1

3

3

2

4

(1) System air intake direction (2) System air exhaust direction

(3) Power module air intake direction (4) Power module air exhaust direction

Page 21

11

Power supply system

The S12500 Routing Switch Series provides both AC powered chassis and DC powered chassis. You can

select power module and the number of power modules as needed.

Figure 8 Power frame appearance (without any power module)

AC power supply

The AC-powered chassis of the S12500 Routing Switch Series use the PSE9000-A1 AC power supply

system, which comprises AC power frames, AC power modules, power monitoring modules, and power

entry modules (PEMs).

AC power frame

Each AC power frame can have one power monitoring module and up to six AC power modules.

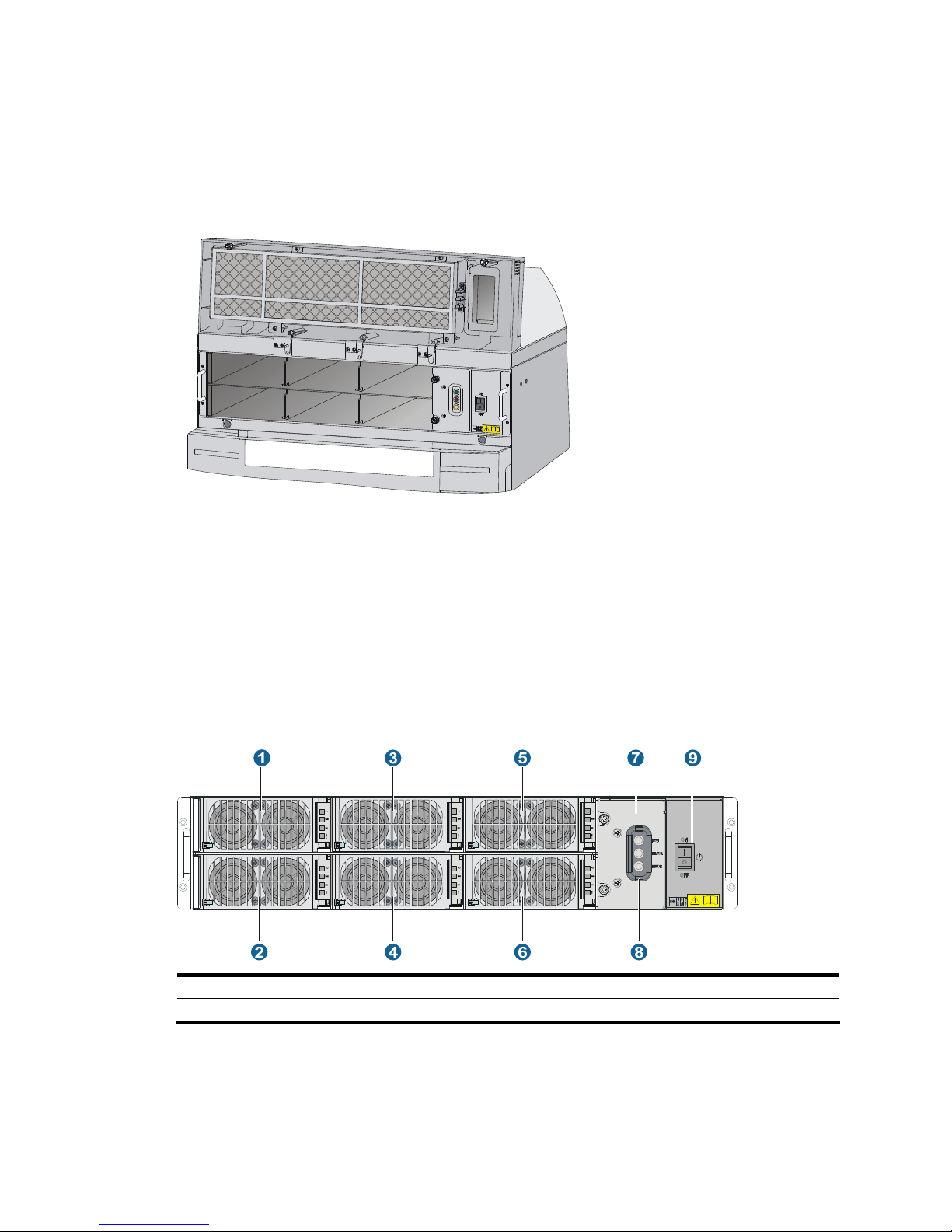

Figure 9 Front view of an AC power frame

(1) to (6) AC power modules (the serial numbers are identical to the slot numbers)

(7) Power monitoring module (8) Power monitoring module LED (9) Power frame switch

Page 22

12

Table 3 Description of the LEDs on the power monitoring module

LED Color Status Description

On

The power monitoring module is working properly.

RUN Green

Off

The power monitoring module is faulty.

On

• At least one power module is faulty.

• All power modules have been removed from the power

frame.

• The switch of the power frame is off.

• Power modules are in position, but no AC power supply

is provided.

Flashing A power module is being inserted or removed.

MAJOR Red

Off

The power modules are working properly.

MINOR Yellow Off Reserved

AC power module

• The AC power modules are hot-swappable.

• The power module fans draw in fresh air from the front and exhaust warm air out of the rear.

• Multiple AC power modules work in N+1 or N+M redundancy and support load balancing.

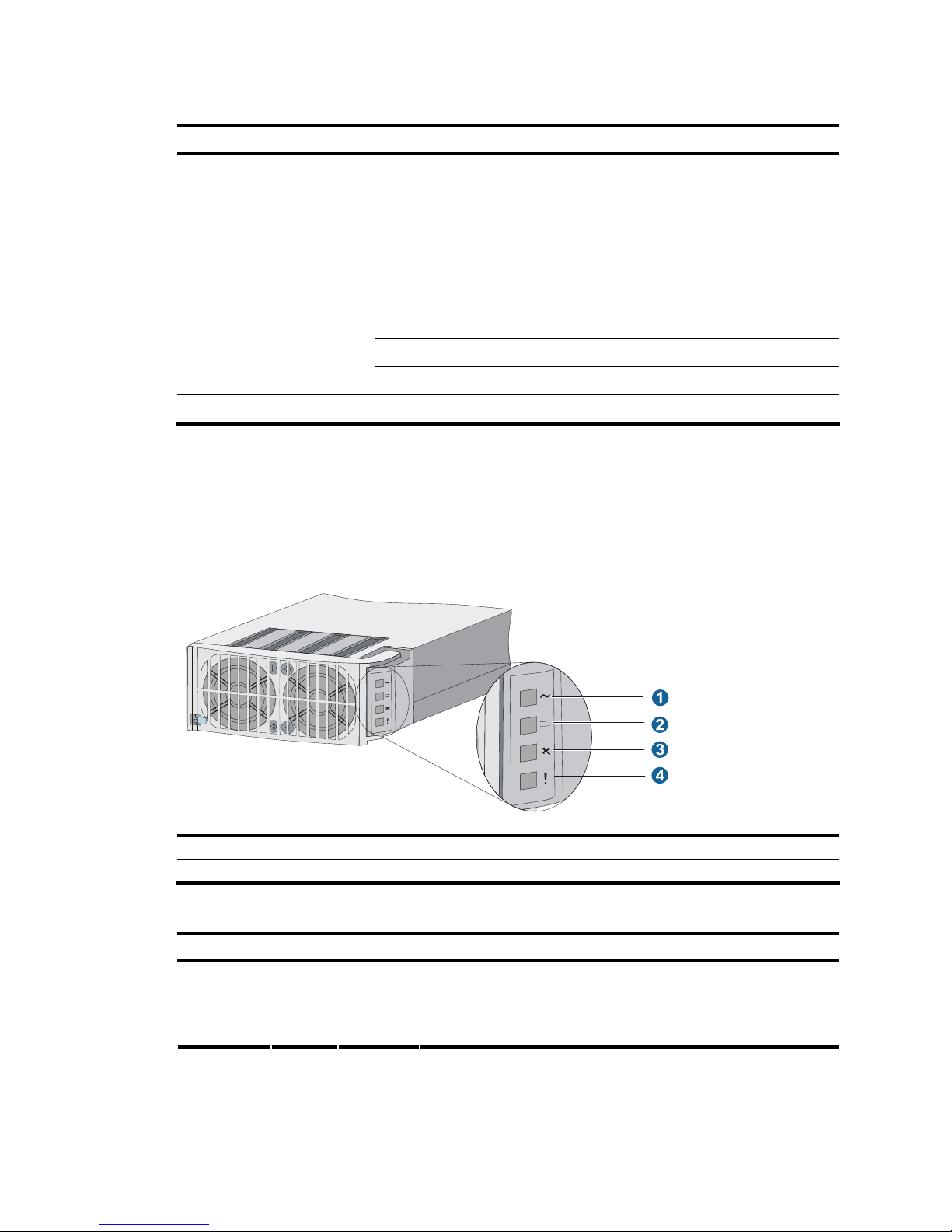

Figure 10 AC power module

(1) Power input LED (2) Power output LED (3) Over-temperature alarm LED

(4) Power module fault LED

Table 4 AC power module LED description

LED Color Status Description

On

Power is being correctly input.

Off

No power is being input.

Input Green

Flashing Input power exceeds the threshold.

Page 23

13

LED Color Status Description

On Power is being correctly output.

Off No power is being output.

Output Green

Flashing The power output is overloaded.

On

The AC power module is experiencing an over-temperature

condition.

Service Yellow

Off

The AC power module is operating properly.

On The AC power module is faulty.

Fault Red

Off The AC power module is operating properly.

Table 5 AC power module specifications

Item Description

Rated input voltage range

100 VAC to 120 VAC/200 VAC to 240 VAC; 50 Hz or 60 Hz

Max input voltage range

90 VAC to 264 VAC; 47 Hz to 63 Hz

Max input current 13.3 A

Max output power

2000 W at 200 VAC to 240 VAC input

1200 W at 100 VAC to 120 VAC input

Power monitoring module

The power monitoring module (callout 7 in Figure 9) monitors the alarm status, in-position status, and

operating status of the power modules in real time. It is located between the power module slot area and

the power switch.

PEM

The PEM (see Figure 11) provides power to the power modules.

Figure 11 PEM location

Page 24

14

Table 6 PEM description

PEM Description Max number of power modules

LSTM2PEMC6 (PEM-C20)

Applied to the 110 V or 220 V

single-phase three-wire AC power

supply system

One PEM provides six standalone

C20 (16A) sockets numbered in

two rows: 1, 3, and 5 in the top

row, and 2, 4, and 6 in the bottom

row, from left to right.

6 (each C20 socket for one power module)

DC power supply

The DC-powered chassis of the S12500 Routing Switch Series use the PSE9000-D DC power supply

system, which comprises DC power frames, DC power modules, and power monitoring modules.

DC power frame

Each DC power frame can have one power monitoring module and up to six DC power modules.

Figure 12 Front view of a DC power frame

(1) to (6) DC power modules

(7) Power monitoring module (8) Power monitoring module LEDs (9) Power frame switch

NOTE:

Table 2 descri

bes the LED behaviors of the power monitoring module.

A DC power frame has six pairs of wire posts corresponding to power modules 1 to 6, and one

grounding post. The external DC power system supplies power through the six pair of wire posts.

Page 25

15

Figure 13 DC power frame rear view

1 2

(1) A pair of wire posts (2) Grounding post

NOTE:

The DC power frame has a cover to protect the wire posts and grounding post.

DC power module

Figure 14 DC power module

(1) Power input LED (2) Power output LED (3) Over-temperature alarm LED (4) Power fault LED

NOTE:

A DC power module has the same LED behaviors as an AC power module. For more information, see

Table 7.

Table 7 DC power module specifications

Item Description

Rated input voltage range –48 VDC to –60 VDC

Max input voltage range –42 VDC to –72 VDC

Page 26

16

Item Description

Startup voltage range –44 VDC to –72 VDC

Max input current 60 A

Max output power 1800 W

Power monitoring module

The power monitoring module is vertically installed between the power module slot area and the power

switch. It monitors the alarm status, in-position status, and operating status of the power modules in real

time.

Page 27

17

Preparing for installation

Safety recommendations

To avoid any equipment damage or bodily injury caused by improper use, read the following safety

recommendations before installation. Note that the recommendations do not cover every possible

hazardous condition.

General safety recommendations

• Take adequate safety measures to avoid injury and switch damage. For example, wear an

ESD-preventive wrist strap.

• Make sure that the ground is dry and flat and anti-slip measures are in place.

• Keep the chassis clean and dust-free.

• Do not place the switch on a moist area and avoid liquid surrounding the switch.

• Keep the chassis and installation tools away from walk areas.

• Move the switch and heavy components (such as the power supplies or chassis) with other people

rather than doing that alone.

Electricity safety

• Clear the work area of possible hazards, such as ungrounded power extension cables, missing

safety grounds, and wet floors.

• Locate the emergency power-off switch in the room before installation. Shut the power off at once in

case accident occurs.

• Unplug all the external cables (including power cables) before moving the chassis.

• Do not work alone when the switch has power.

• Always check that the power has been disconnected.

ESD prevention

CAUTION:

To prevent the electronic components from being damaged by the electrostatic discharge (ESD), you

should not only take ESD measures where the switch is located, but also take the following precautions:

• Always wear an ESD-preventive wrist strap when installing components, especially the electronic printed

circuit boards.

• Hold a PCB by its edges. Do not touch any electronic components or printed circuit.

• Check the resistance of the ESD-preventive wrist strap for safety. The resistance reading should be in the

range of 1 to 10 megohm (Mohm) between human body and the ground.

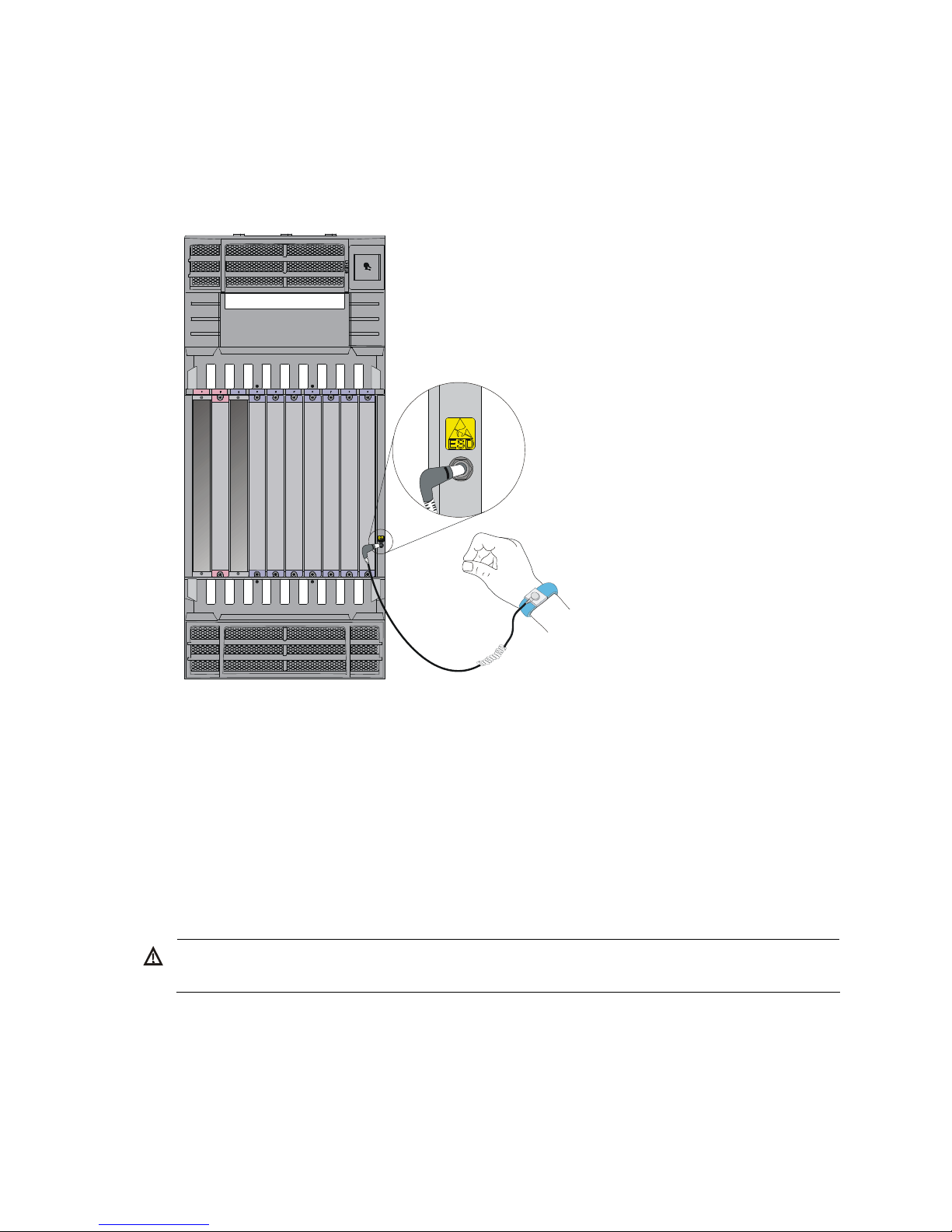

To use the ESD-preventive wrist strap:

1. Wear the wrist strap on your wrist.

Page 28

18

2. Lock the wrist strap tight around your wrist to keep good contact with the skin.

3. Insert the ESD-preventive wrist strap into the specially designed hole on the switch chassis or attach

it to the grounding screw of the chassis with the alligator clips.

4. Make sure that the ESD-preventive wrist strap is well grounded.

Figure 15 Use an ESD-preventive wrist strap

Switch moving

When you move an H3C S12500 switch, note the following guidelines:

• Remove all the external cables (including the power cables) before moving the chassis.

• For personal safety, have several persons to move the switch carefully.

• When moving the switch, hold the handles at both sides of the chassis. Do not hold the plastic panel

of the chassis, the handle of the fan tray, the handle of the back cover of the chassis, or the air vents

of chassis. Any attempt to carry the switch with these parts may cause equipment damage or even

bodily injury.

WARNING!

For personal safety, at least four people are required to move an S12518 switch.

Laser safety

The H3C S12500 switches are Class 1 laser devices.

Page 29

19

WARNING!

Do not stare into any fiber port when the switch has power. The laser li

g

ht emitted from the optical fiber

may hurt your eyes.

Examining the installation site

The H3C S12500 Routing Switch Series can only be used indoors. To ensure that the switch works

properly and to prolong its service lifetime, the installation site must meet the following requirements:

Weight support

Evaluate the floor loading as compared to the actual weight of the switch and its accessories (such as

cabinet, chassis, cards, and power supply units), and make sure that the floor can support the weight of

the cabinet and the switch chassis.

TIP:

When you evaluate the floor loading, consider router

capacity expansion (for example, installing a ne

w

card) in the future.

Temperature

To ensure the normal operation of the switch, make sure that the room temperature meets the

requirements described in Table 8.

Table 8 Temperature r

equirements

Temperature Range

Operating temperature

Long term: 0°C to 40°C (32°F to 104°F)

Two hours: –10°C to +50°C (14°F to 122°F) (no more than 96

hours of continuous operation in less than 15 days in one year)

Storage temperature –40°C to +70°C (–40°F to +158°F)

CAUTION:

If condensation appears on the switch when you move it to a high-temperature environment, dry the switch

before powering it on to avoid short circuits.

Humidity

Maintain appropriate humidity in your equipment room, as described in Table 9.

Table 9 Humidity requirements

Humidity Range

Operating humidity (noncondensing) 5% to 95%

Storage humidity (noncondensing) 5% to 95%

Page 30

20

Lasting high relative humidity can cause poor insulation, electricity creepage, mechanical property

change of materials, and metal corrosion. Lasting low relative humidity can cause washer contraction

and ESD and bring problems including loose captive screws and circuit failure.

Cleanness

Dust buildup on the chassis may result in electrostatic adsorption, which causes poor contact of metal

components and contact points, especially when indoor relative humidity is low. In the worst case,

electrostatic adsorption can cause communication failure.

Table 10 Dust concentration limit in the equipment room

Substance Concentration limit (particles/cu m)

Dust particles ≤ 3 x 104 (no visible dust on the tabletop over three days)

NOTE:

Dust particle diameter ≥ 5 μm

The equipment room must also meet strict limits on salts, acids, and sulfides to eliminate corrosion and

premature aging of components, as shown in Table 11.

Table 11 Harmful gas li

mits in the equipment room

Gas Average (mg/m

3

) Max. (mg/m3)

SO2 0.3 1.0

H2S 0.1 0.5

NO2 0.004 0.15

NH

3

1.0 3

Cl

2

0.1 0.3

EMI

All electromagnetic interference (EMI) sources, from outside or inside of the switch and application

system, adversely affect the switch in a conduction pattern of capacitance coupling, inductance coupling,

electromagnetic wave radiation, or common impedance (including the grounding system) coupling. To

prevent EMI, take the following actions:

• If AC power is used, use a single-phase three-wire power receptacle with protection earth (PE) to

filter interference from the power grid.

• Keep the switch far away from radio transmitting stations, radar stations, and high-frequency

devices.

• Use electromagnetic shielding, for example, shielded interface cables, when necessary.

• Route interface cables only indoors to prevent signal ports from getting damaged by overvoltage or

overcurrent caused by lightning strikes.

Grounding

Using a good grounding system to protect your switch against lightning shocks, interferences, and ESD

is essential to the operating reliability of your switch.

Page 31

21

Make sure that the resistance between the chassis and the ground is less than 1 ohm.

Power supply

Perform the following steps to satisfy the power supply requirements of the S12500 Routing Switch Series:

1. Calculate the system power consumption.

2. Select power supplies according to the system power consumption and power supply mode.

To ensure normal operation of the switch, make sure the maximum output power of the power

supplies is greater than the system power consumption of the switch (reserve certain power for

redundancy). After determining the system power consumption and power supply mode (AC or

DC power supply), you can select power supplies as needed.

3. Check that the power source on the installation site satisfies the power input of the power supplies.

Make sure the power source of the installation site is steady and can satisfy the input requirements

of the power supplies and parameters such as rated voltage.

NOTE:

For the power consumption and power module

specifications of the switch, see the chapter “Appendix

A

Technical specifications.”

Space

• For moving the switch and servicing the modules, make sure that the width of the aisle in the

equipment room is at least 0.8 m (2.62 ft).

• To install the switch in a rack, make sure the headroom in the equipment room is no less than 3 m

(9.84 ft).

• For adequate ventilation and ease of maintenance, do not place the switch close to the wall, and

make sure the front and rear clearances are at least 0.8 m (2.62 ft).

Rack-mounting

To mount the switch in a rack, adhere to the following requirements:

• Use a four-post 19 inch standard rack.

• The distance between the left and right rack posts is 465 mm (18.31 in).

Page 32

22

Figure 16 Rack width

• Make sure that the available space between the front rack post and the outer edge of the front rack

door is greater than 180 mm (7.09 in) and the depth of the rack (distance between the front and

back doors) is greater than 800 mm (31.50 in).

Figure 17 Rack depth

>

1

8

0

m

m

>

1

5

5

m

m

>

8

0

0

m

m

• The rack is available with standard slide rails (or rack shelves), cage nuts, and screws.

Page 33

23

• The slide rails (or rack shelves) can support the weight of the switch chassis and its accessories.

• The rack can be well grounded.

• The rack has good ventilation system, and the porosity of the front and back doors is greater than

50%.

Installation tools

Accessories supplied by the switch

Item Quantity Purpose

Console cable 1

Connecting the console port and

the configuration terminal for

switch login

Grounding cable 1 Grounding the switch

Mounting brackets 1 pair Fixing the switch to the rack

M4*8 screw 1 set

Fixing the mounting brackets to the

switch

M6*12 screw 1 set

M6 cage nut 1 set

Fixing the switch to the rack

Air deflector 1

Installed at the rear of the switch to

block air from entering the chassis

(optional)

ESD-preventive wrist strap 2 ESD-prevention

NOTE:

The number of screws and nuts supplied with the switch depends on those shipped from the factory.

User-supplied tools and equipment

• Mechanical lift

• Phillips screwdriver P1 – 100 mm, P2 – 150 mm and P3 – 250 mm

• Flat screwdriver P4 – 75 mm

• Marker

• Tape

• Diagonal pliers, wire-stripping pliers, and wire clippers

• Socket wrench

• Cables such as network cables and fiber cables

• Meters and equipment, such as hub and multimeter

• Configuration terminal, such as PC

NOTE:

The rack accessories and installation tools are not included in this section. The accessories and installation

tools may vary depending on the rack model. For more information, see the installation guide of the

corresponding rack.

Page 34

24

Installing the switch

WARNING!

To avoid bodily injury, do not touch any wire, terminal, or part marked with a high-volta

g

e hazard sign.

Figure 18 Hardware installation flow

Start

Install the switch to a rack

Ground the switch

End

Install fan traysInstall power supplies

Connect the power cords

Verify the installation

Determine the

installation site

Install the switch to a workbench

Install cards

Check before installation

Check the following before installing an H3C S12500 switch:

• Make sure that you have read “Preparing for Installation” carefully and the installation site meets all

the requirements.

• Using the packing list supplied with your switch, inspect the switch to be sure that you have all the

items listed in the packing list, and verify that the switch was not damaged during shipment. If

anything is damaged or missing, contact the sales agent or customer representative immediately.

• For regulatory compliance and safety information, see “Regulatory Compliance and Safety

Information”.

Page 35

25

Installing the switch in a rack

Installation preparation

Confirm the following preparations before starting installation:

• The rack is sturdy and securely grounded.

• There is sufficient clearance of 0.8 m (2.62 ft) around the rack for heat dissipation and installation.

• There is no debris inside or around the rack.

CAUTION:

When moving the switch, hold the handles at both sides of the chassis. Do not hold the plastic panel of the

chassis, the handle of the fan tray, the handle of the back cover of the chassis, or the air vents of chassis.

Any attempt to carry the switch with these parts may cause equipment damage or even bodily injury.

Installing slide rails and cage nuts to the rack

Installing slide rails

Before installing the switch to the rack, install slide rails to the rack. If the rack has slide rails, skip this

section.

NOTE:

• Before installing the slide rails, check that the slide rails can support the weight of the switch. For the

weights of the S12500 Routing Switch Series, see the chapter “Appendix A Technical specifications.”

• Besides slide rails, you can use a rack shelf to support the switch. This document describes how to install

slide rails only.

• Slide rails or rack shelves are not provided with the switch. Prepare them yourself, or order them from

H3C.

The following uses a 19-inch rack as an example to describe the installation procedures. The height of the

front panel of the rack is a measurement of one rack unit (RU) (44.45 mm, or 1.75 in). As shown in callout

2 in Figure 19, e

ach 1 RU has three holes with center-to-center spacing between the holes of 15.87 mm

(0.63 in), 15.87 mm (0.63 in), and 12.70 mm (0.5 in). When installing the slide rails, make sure the

bottom edge of the slide rail aligns with the middle of the narrower metal area between holes.

To install the slide rails:

1. Mark the position of the slide rails on the rack.

2. Align the screw holes on the two sides of the slide rails with the corresponding holes on the rack,

and then fasten the screws.

3. Install the other slide rail in the same way. Keep the two slide rails at the same height so that the

switch can be placed evenly.

Page 36

26

Figure 19 Install the slide rails

1

1

2

(1) Middle of the narrower metal area between holes (2) 1 RU

NOTE:

• The appearance and installation methods of slide rails depend on the slide rail types.

• To ensure stability of the rack, install the slide rails to the lowest possible position when installin

g

a single

switch on the rack. To install multiple switches on the rack, mount the heaviest switch at the bottom of the

rack.

Installing cage nuts

Before mounting the chassis to the rack, install cage nuts to the front square-holed brackets of the rack.

To install cage nuts to the rack:

1. Align the mounting bracket with the left rack post, making sure that the bottom edge and the slide

rail are level. Mark the positions of the cage nuts on the rack post according to the installation

holes on the mounting bracket (each installation hole on the mounting bracket corresponds to one

cage nut).

2. Insert one edge of a cage nut into the hole.

3. Compress the other edge of the cage nut to push the cage nut fully into the hole.

4. Repeat steps 3 and 4 to install cage nuts to all the marked positions on the right rack post.

Page 37

27

Figure 20 Install the cage nuts

NOTE:

When preparin

g

for installation, make sure that the total height of the switches to be installed is no higher

than the height of the rack, and reserve enough clearance for cable routing.

Installing the mounting brackets

Attach the mounting brackets onto the left and right sides of the switch.

Page 38

28

Figure 21 Install the mounting brackets

Installing an air deflector (optional)

An air deflector is shipped with the S12500 switches. You can install the air deflector at the rear of the

chassis (where a ventilation panel is located) to block the airflow from entering the rear of the chassis.

Install an air deflector where switches adopt front to rear airflow.

To install an air deflector:

1. Loosen the captive screws on the ventilation panel to remove it.

2. Install the air deflector, and fasten the captive screws on the air deflector.

Page 39

29

Figure 22 Install an air deflector

Installing a chassis air filter (optional)

Chassis air filters are installed at the air intake vents to prevent dust from entering the chassis. Chassis air

filters of the S12500 Routing Switch Series are optional. You can order them as needed.

If you have ordered chassis air filters, H3C recommends you to install the air filters before mounting the

switch to the rack.

• S12508: A chassis air filter is available at both front and rear of the switch. For the installation

procedures, see “Installing an air filter on an S12508.”

• S12518: The air filter is located at the rear of the chassis. For the installation procedures, see

“Installing an air filter on an S12518.”

Installing an air filter on an S12508

To install the front air filter on an S12508:

1. Holding the notches of the front plastic panel at the bottom part of the chassis, and gently pull the

plastic panel out.

2. Unpack the air filter and attach it to rear of the plastic panel, making sure the installation holes on

the air filter align with the screw holes on the plastic panel. Then fix the air filter to the plastic panel

with screws.

3. Fix the plastic panel back to the chassis.

Page 40

30

Figure 23 Install the front air filter

1

2

3

To install the rear air filter on an S12508:

1. Loosen the captive screws on the ventilation panel and remove it.

2. Unpack the air filter and attach it to where the ventilation panel was located, and then fasten the

captive screws on the air filter.

Figure 24 Install the rear air filter

(1) Ventilation panel (2) Rear air filter

Installing an air filter on an S12518

To install an air filter on an S12518:

1. Use a Phillips screwdriver to loosen the screws at both sides of the plastic panel and remove the

panel.

2. Insert the air filter into the rear of the chassis along the slide rails, and then fasten the screws at both

sides of the air filter.

Page 41

31

Figure 25 Install an air filter

Mounting the switch in the rack

NOTE:

• Make sure that you have installed slide rails or a rack shelf on the rack for supporting the switch. The

slide rails or rack shelf should be sturdy enough to support the weight of the switch chassis and all

accessories.

• To maximize the stability of the rack, mount the switch at the lowest possible position.

To mount the switch in the rack:

1. Use several persons to place the switch on the slide rails or rack shelf and slide the switch into the

rack until the mounting brackets on the switch touch the front rack posts.

2. Fix the mounting brackets to the rack posts with mounting screws. See Figure 26.

Figure 26 Install the switch in a standard 19-inch rack

Page 42

32

NOTE:

If the screw holes on the mounting brackets cannot align with the cage nuts on the rack, check that the

bottom edge of the slide rail aligns with the middle of the narrowest metal area between holes and that the

cage nuts are installed in the correct holes.

Verifying the installation

After the installation is completed, check the installation against the following checklist. Make sure that

all check results are positive.

Table 12 Installation checklist

Result

Item

Yes No

Remarks

The mounting brackets are firmly fixed onto the switch.

The switch is sturdy and installed in the right position.

The mounting brackets on the switch are firmly fixed onto the rack.

Installing the switch on a workbench

You can install the switch on a clean, sturdy workbench or on the floor.

Installation preparation

Before placing the switch on a workbench or on the floor, confirm the following preparations:

• The workbench or floor is sturdy enough to support the weight of the chassis and its accessories.

• The workbench or floor is reliably grounded.

• Whether an air deflector or air filter is needed. To install them, see “Installing an air deflector

(opti

onal)” and “Installing a chassis air filter (optional).”

Installation procedures

CAUTION:

Allow 0.8 m (2.62 ft) of clearance around the switch for heat dissipation.

To install the switch:

1. Hold the two sides of the switch and steadily move the switch to the workbench.

2. Lift the switch a little higher than the workbench and put it on the workbench.

3. Install the mounting brackets on the switch and fasten the screws, as shown in Figure 27 (optional).

NOTE:

Each circled area in Figure 27 shows two rows of installation holes. You can select either row of a

circled

area to install the mounting brackets.

Page 43

33

Figure 27 Install the mounting brackets

1

2

(1) Mounting bracket installation holes (2) Mounting bracket

4. Fix the switch to the workbench or ground with L-shaped brackets. See Figure 28.

Figure 28 Install L-shaped brackets

(1) L-shaped bracket (2) Wall anchor (3) Mounting screw

Page 44

34

Grounding the switch

WARNING!

For the safety of operators and equipment, securely ground the switch. Make sure that the resistance

reading between the switch chassis and the ground is less than 1 ohm.

Most racks are equipped with a grounding strip. You can connect the yellow-green grounding cable of

the switch to the grounding strip.

NOTE:

Use the supplied grounding cable (CAT 6 cable with dual-hole OT terminals).

To connect the grounding cable:

1. Remove the two grounding screws from the switch chassis.

2. Use the grounding screws to attach one end of the grounding cable to the chassis.

3. Connect the other end of the grounding cable to the grounding strip of the rack in the same way.

Figure 29 Connect the grounding cable

1

2

3

Page 45

35

If there is no grounding point on the rack, you can attach the grounding cable to a grounding strip. The

installation procedures are similar.

CAUTION:

Connect the grounding cable to the earthing system in the equipment room. Do not connect it to a

fire main

or lightning rod.

Installing the power system

The S12500 Routing Switch Series supports both AC and DC power module. You can select either AC or

DC power module as needed. For how to connect power cords, see “Connecting power cords.”

Installation preparation

To prepare for installation:

1. Put on an ESD-preventive wrist strap and make sure that it is properly grounded.

2. Remove the blank panel (if any) from the slot to be used.

3. Remove the power frame cover.

CAUTION:

• Hold a power entry module (PEM) or power module by the bottom when moving it. Never attempt to lif

t

a PEM or power module with its handle because the handle is not designed to support weight. Doing so

might result in bodily injury or damage to the module.

• When inserting or removing a power module, check that the switch is sturdy. To prevent bodily injury,

avoid tipping the switch chassis.

• When hot-plugging power modules, make sure that the insertion interval is no less than 30 seconds.

Installing a DC power module

To install a DC power module:

1. Rotate the power frame cover up with both hands.

2. Pull the clip at the bottom left corner of the power module to the left to open the power module

panel.

3. Insert the power module slowly into the slot until it is firmly seated in the slot.

4. Close the panel of the power module, press the clip to lock the power module in position, and close

the power frame cover.

Page 46

36

Figure 30 Install a power module

Installing an AC power module

To install an AC power module, follow these steps:

• Installing a PEM

• Installing an AC power module

Installing a PEM

To install a PEM:

1. Loosen the screws on the filler panel of the PEM slot with a Phillips screwdriver to remove the filler

panel.

2. Insert a PEM slowly along the slide rails until it touches the backplane connector.

3. Use the M3 screws supplied with the PEM to fix the PEM to the switch chassis, and fasten the

screws with a Phillips screwdriver.

Page 47

37

Figure 31 Install a PEM

NOTE:

Gently insert the PEM into the chassis to avoid damaging the connector at the end of the PEM.

Installing an AC power module

IMPORTANT:

• Make sure that the number of power modules is sufficient for the switch to operate properly.

• Each receptacle on the PEM corresponds to a power module slot. To enable an AC power module to

work, provide power module to the relevant receptacle.

• Distribute power modules in the upper and lower frames evenly on the S12518.

• The procedures for installing an AC power module are similar to installing a DC power module. For

more information, see “Installing a DC power module.”

Installing a fan tray

CAUTION:

• The fan trays are heavy. Do not try to move a fan tray by yourself.

• Hold a fan tray by the bottom when moving it. Never attempt to lift a fan tray with its handle because the

handle is not designed to support weight. Doing so might result in bodily injury or damage to the

module.

Page 48

38

Both the S12508 and S12518 have two fan trays. They are installed in the same way.

To install a fan tray:

1. Wear an ESD-preventive wrist strap and make sure that it is properly grounded.

2. Unpack the fan tray.

3. Remove the blank panel from the slot to be used.