Page 1

CO2-evaporators – CXGDF.1

Product line: CO2aircoolers

Series description: Slim ceiling evaporators

Series: CXGDF.1

www.guentner.de

CXGDF.1 | 2015-12

Page 2

Contents

page 2 / 68

1 Important basic information...................................................... 5

1.1 Safety instructions........................................................................... 5

1.1.1 Observing operating instructions........................................................5

1.2 Importance of the EN 378 series of standards – refrigeration

systems and heat pumps – safety-related and environmental re-

quirements.........................................................................................5

1.3 Responsibilities................................................................................ 5

1.3.1 Manufacturer's responsibilities........................................................... 5

1.3.2 Responsibilities of the system’s installer............................................6

1.3.3 Owner or operator responsibilities..................................................... 6

1.4 Legal notes........................................................................................7

1.5 Operating instructions..................................................................... 7

1.5.1 Scope..................................................................................................7

1.5.2 Set-up and other applicable documents............................................ 7

1.6 Conventions...................................................................................... 8

1.6.1 Typographical conventions.................................................................8

1.6.2 List of abbreviations........................................................................... 8

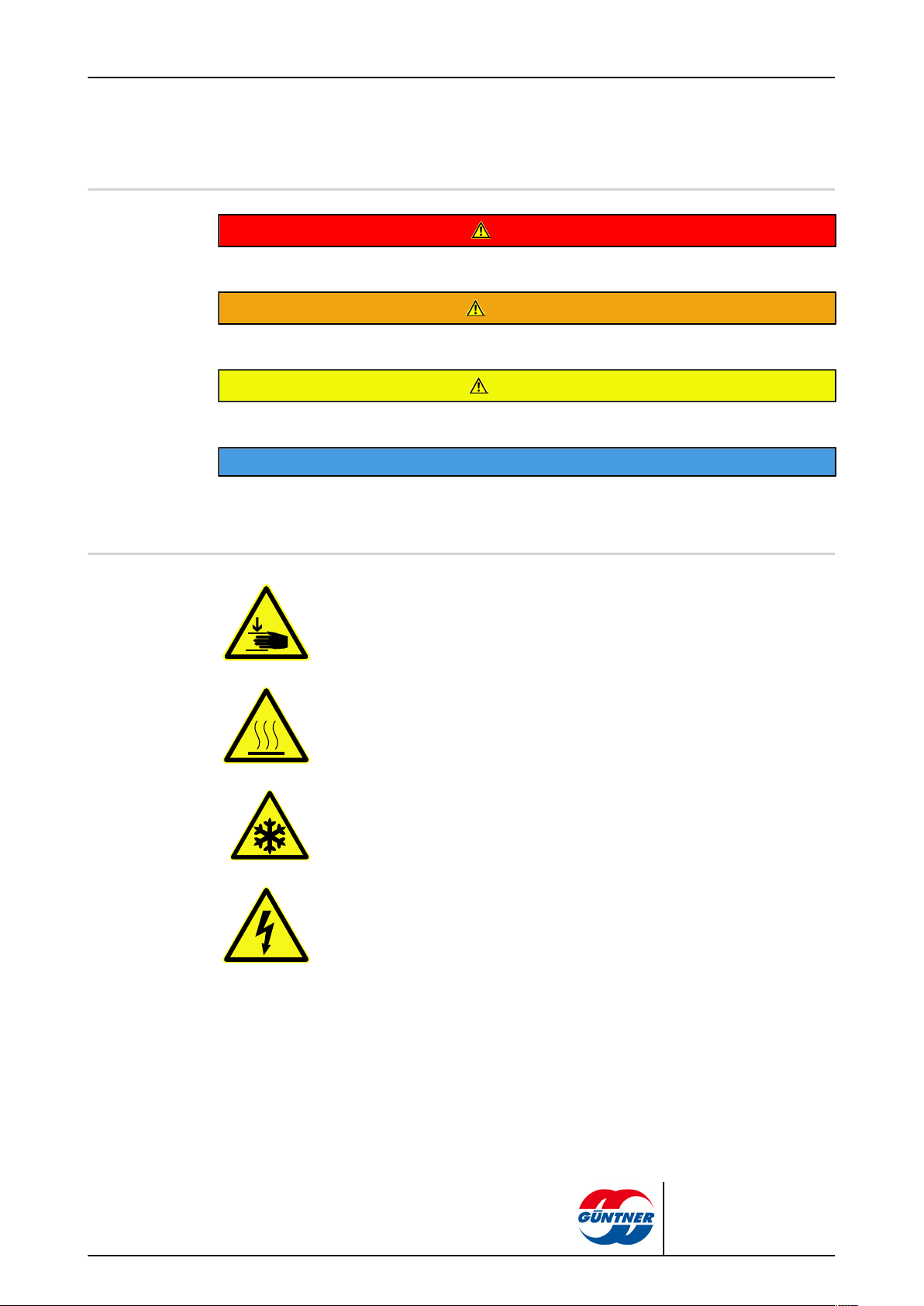

1.7 Conventions for safety signs and notices.....................................9

1.7.1 General safety signs and their meaning in these operating instruc-

tions.................................................................................................... 9

1.7.2 Warning symbols and their meaning in these operating instruc-

tions.................................................................................................... 9

1.7.3 Prohibitory signs and their meaning in these operating instruc-

tions.................................................................................................. 10

1.7.4 Mandatory signs and their meaning in these operating instruc-

tions.................................................................................................. 10

CXGDF.1 | 2015-12

2 Safety..........................................................................................12

2.1 Labelling on the unit:.....................................................................12

2.1.1 Safety signs on the unit................................................................... 12

2.1.2 Other signs and notes on the unit....................................................15

2.2 Basic safety notices.......................................................................18

2.2.1 How to act in an emergency............................................................18

2.2.2 Personnel, care requirements.......................................................... 18

2.3 Proper intended use.......................................................................19

2.3.1 Proper intended use.........................................................................19

2.3.2 Operating conditions.........................................................................19

2.3.3 Improper use.................................................................................... 20

2.4 Mechanical residual hazards.........................................................21

2.4.1 Fins, sharp unit corners and edges................................................. 21

2.4.2 Flap down drip tray.......................................................................... 21

2.4.3 Fans.................................................................................................. 22

© Güntner GmbH & Co. KG

Page 3

page 3 / 68

2.4.4 Thermostatic expansion valve(option)..............................................22

2.5 Electrical residual hazards............................................................ 23

2.6 Thermal residual hazards.............................................................. 23

2.6.1 Frostbite hazard................................................................................23

2.7 Residual hazards due to carbon dioxide (CO2)........................... 23

2.8 Residual hazards caused by vibrations.......................................25

2.9 Residual hazards caused by pressurised parts.......................... 26

2.10 Residual hazards caused by defective installation.....................26

2.11 Residual hazards with break during operation........................... 28

2.12 Residual hazards caused by escaping objects or liquids.......... 28

2.13 Combined residual hazards.......................................................... 29

2.13.1 Easy to open side covers/................................................................29

2.14 Residual hazards with disposal....................................................29

3 Technical data........................................................................... 31

3.1 Unit................................................................................................... 31

3.2 Fans..................................................................................................31

4 Set-up and function.................................................................. 33

5 Fan motor.................................................................................. 34

6 Transportation and storage.....................................................35

6.1 Safety............................................................................................... 35

6.2 Transportation and storage...........................................................35

6.3 Storage before installation............................................................ 36

7 Set-up and start-up...................................................................37

7.1 Safety............................................................................................... 37

7.1.1 Safety instructions for set-up and start-up....................................... 37

7.1.2 System-side safety requirements..................................................... 38

7.1.3 Customer-side safety precautions....................................................39

7.2 Requirements at the set-up point................................................. 40

7.3 Unpacking the unit.........................................................................41

7.4 Installation....................................................................................... 42

7.4.1 System-side requirements for stress-free installation...................... 42

7.4.2 Mounting the unit..............................................................................44

7.5 Notes on connecting the unit....................................................... 44

7.5.1 Connecting the thermostatic expansion valve..................................45

7.5.2 Connecting the drain line to the drip tray......................................... 45

7.5.3 Connect the unit to the system........................................................ 46

7.5.4 Unit electrical connection and protection......................................... 47

7.6 Perform acceptance test................................................................48

7.7 Test readiness for operation......................................................... 49

7.8 Putting the unit into operation for the first time......................... 49

CXGDF.1 | 2015-12

© Güntner GmbH & Co. KG

Page 4

page 4 / 68

8 Operation................................................................................... 51

8.1 Safety............................................................................................... 51

8.2 Putting the unit into operation......................................................51

8.3 Taking the unit out of operation...................................................51

8.4 Shutting the unit down.................................................................. 52

8.5 Putting the unit into operation after a shutdown........................ 53

8.6 Changing the unit over to another working fluid........................ 53

9 Troubleshooting........................................................................ 54

9.1 Safety............................................................................................... 54

9.2 Service............................................................................................. 54

9.3 Troubleshooting table....................................................................54

9.4 Dealing with faults......................................................................... 55

10 Maintenance...............................................................................56

10.1 Safety............................................................................................... 56

10.1.1 Before starting all maintenance........................................................56

10.1.2 With all maintenance work............................................................... 56

10.1.3 After all maintenance work...............................................................58

10.2 Inspection and maintenance plan................................................ 58

10.2.1 Fans.................................................................................................. 59

10.2.2 Unit heat exchanger......................................................................... 59

10.3 Maintenance work.......................................................................... 61

10.3.1 Remove leaks...................................................................................61

10.4 Clean unit........................................................................................ 61

10.4.1 General............................................................................................. 61

10.4.2 Clean heat exchanger...................................................................... 62

10.4.3 Cleaning fans....................................................................................63

10.5 Defrosting the unit......................................................................... 64

10.5.1 Notes on defrosting.......................................................................... 64

10.5.2 Defrost control.................................................................................. 65

10.5.3 Circulation air defrosting...................................................................66

10.5.4 Electric defrosting (optional)............................................................. 66

10.5.5 Further notes on defrosting.............................................................. 67

CXGDF.1 | 2015-12

11 Plans/diagrams..........................................................................68

11.1 Electrics documentation................................................................68

11.1.1 Fan motor connection diagram........................................................ 68

11.1.2 Connection diagram electrical defrost (selectable option; accessory

on customer request)....................................................................... 68

© Güntner GmbH & Co. KG

Page 5

page 5 / 68

1 Important basic information

1.1 Safety instructions

1.1.1 Observing operating instructions

CAUTION

Always keep the operating instructions in the unit's immediate vicinity at all times.

Ensure that the operating instructions are accessible to all people that have anything at all to do with

the unit at all times.

Ensure that the operating instructions are read and understood by all people that have anything at all

to do with the unit.

1.2 Importance of the EN 378 series of standards – refrigeration systems and heat pumps – safety-related and environmental requirements

EN 378 deals with safety-related and environmental requirements for designing, constructing, producing, installing, operating, maintaining and disposing of refrigeration systems and cooling equipment.

EN 378 is oriented towards manufacturers, installers and operators of refrigeration systems and

cooling equipment (see section 1.2. Responsibilities).

The objective of EN 378 is to restrict the possible hazards of refrigeration systems, cooling equipment and their working fluids (refrigerants and coolants) for people, property and the environment

to a minimum.

Insufficient safety measures or non-compliance with safety-relevant regulations can result in:

•

Breaks or ruptures on components with the danger of escaping materials (hazards caused by

the influence of low temperatures, excess pressure, direct influence of the fluid phase, moving

machine parts).

•

Escaping working fluid after a break or leak because of defective design, improper operation, insufficient maintenance, repairs, filling and disposal (hazards caused by damage to health, frostbite, suffocation, panic).

1.3 Responsibilities

1.3.1 Manufacturer's responsibilities

The notes provided in these operating instructions on maintaining the unit's functional safety, preventing possible hazards when transporting, setting up and installing, start-up and operation, and

with maintenance activities (cleaning, servicing and repairing) refer exclusively to the unit.

The manufacturer's responsibilities are documented in the unit's version in acc. with EN 378-2 (design, manufacture and testing).

CXGDF.1 | 2015-12

The materials used in the construction and for soldering and welding are designed to withstand

the foreseeable mechanical, thermal and chemical stresses, and are resistant to the working fluids

used and to mixtures of such working fluids and the oils used to lubricate refrigeration compressors.

© Güntner GmbH & Co. KG

Page 6

The working fluid-carrying parts of the unit (core tubes, distributor tube and header outlet) are configured so that they remain tight with the foreseeable mechanical, thermal and chemical stresses,

and withstand the maximum permissible operating pressure.

Material, wall thickness, tensile strength, corrosive resistance, shaping process and testing are suitable for the working fluid used and withstand the possible pressures and stresses that might occur.

All responsibility for the equipment into which the unit is integrated, are the exclusive responsibility

of the people involved in the individual workflows.

1.3.2 Responsibilities of the system’s installer

The responsibilities of the system installer are documented in the system’s version (design, manufacture and testing – in accordance with EN 378-2.

Component supplier-system installer interfaces :

•

In the event of any malfunction, inform Güntner GmbH & Co. KG :

Inform Güntner GmbH & Co. KG immediately if faults occur during the set-up, installation, startup and operation..

The responsibilities of the system installer in particular include:

•

Planning and preparing emergency measures:

To avoid consequential damage caused by operational disruptions, a warning system which immediately signals all faults must be provided on-site. Prepare emergency measures that prevent

consequential damage for people and property should faults occur.

•

Specify checking and maintenance intervals:

The system must be configured and equipped with all required equipment for maintenance and

sufficient servicing and testing in accordance with EN 378-4.

When the unit is integrated into the refrigeration system , the working fluid and version must not deviate from the order-related information specified in the order-related documents.

page 6 / 68

The installer of the system must refer to the requirement for sufficient instruction of the operating

and supervision staff when operating and maintaining the equipment .

It is recommended that the future customer staff – if possible – be present during the set-up and installation, for tightness tests and cleaning, while the system is being filled with working fluid and for

the adjustment of the equipment .

1.3.3 Owner or operator responsibilities

The owner or operator responsibilities are documented in the operation, maintenance, servicing

and recovery of the system in accordance with EN 378-4.

The owner or operator must ensure that the proper people are sufficiently trained and qualified for

operating, monitoring and servicing the system .

The operating personnel for the system must have sufficient knowledge and experience with regard

to the mode of operation, operation and daily monitoring of this system .

Before starting up the system, the owner or operator must ensure that the operating personnel are

sufficiently instructed about the system’s documentation (which is part of the operating instructions)

on the set-up, monitoring, mode of operation and servicing of the system and the safety measures

to be observed, and with regard to the properties and handling of the working fluid to be used.

The owner or operator must ensure that when operating, monitoring and maintaining the system

the working fluid and version must not deviate from the details specified in the order-related documents.

CXGDF.1 | 2015-12

© Güntner GmbH & Co. KG

Page 7

Planning and preparing emergency measures: To avoid consequential damage caused by operational disruptions, a warning system must be installed on the customer's premises. Prepare emergency measures that prevent consequential damage for people and property should faults occur.

Responsibility remains with the owner or operator of the system , if the system are used by anybody else, unless there is a contrary agreement on sharing responsibility.

1.4 Legal notes

Warranty claim expires as follows:

•

With faults and damages that can be attributed to non-compliance with the specifications of

these operating instructions.

•

With complaints that can be attributed to use of spare parts other than the original spare parts

specified in the order-related offer documents.

•

With changes to the unit (working fluid, version, function, operating parameters) vis-a-vis the or-

der-related information specified in the order-related offer documents without the manufacturer's

prior consent.

The operating instructions may not be reproduced electronically or mechanically, circulated,

changed passed on to third parties, translated or used otherwise, in full or in part, without Güntner

GmbH & Co. KG’s prior explicit written approval.

page 7 / 68

1.5 Operating instructions

1.5.1 Scope

1.5.2 Set-up and other applicable documents

These operating instructions apply to all CO2evaporators of the CXGDF.1 series.

You will find the precise type of your unit in the attached order-related documents.

The unit's operating instructions include the following parts:

•

These instructions

•

Order-related documents

The order-related documents are included with these instructions and contain the following in-

formation:

– The order-related proper use as specified

– The order-related scope of delivery

– The order-related technical data

– The order-related drawings specifying customer, project number and order number

•

Motor connection wiring diagram in terminal boxes

These operating instructions are part of the operating instructions manual of the system, provided

by the system’s installer .

NOTICE

CXGDF.1 | 2015-12

© Güntner GmbH & Co. KG

Page 8

1.6 Conventions

1.6.1 Typographical conventions

1.6.2 List of abbreviations

The following text markups are used in these operating instructions:

Bold Requires special attention!

Grey triangle Instructions

Abbreviations Meaning

page 8 / 68

CO

2

EN 378 European Norm 378: Refrigeration systems and heat pumps; safety-related

EN European Norm

DIN German industrial standard (specification of a standard)

ISO International Standardization Organization .

°C Degrees Celsius (Celsius scale temperature)

is Unit of pressure

I Litre (liquid volume)

Vol% Volume percent (concentration level relative to a volume)

IP Insulation protection

Q 6,3 Balancing quality

ppm parts per million, concentration figure, stands for “millionth part”.

Hz Hertz (frequency)

D Delta connection (alternating current: high speed)

S Star connection (alternating current: low speed)

3~ 3-phase current

CO2 refrigerant (R744)

and environmental requirements

CXGDF.1 | 2015-12

1~ 1-phase alternating current

VDE “Verband der Elektrotechnik, Elektronik und Informationstechnik” (Association

for Electrical, Electronic & Information Technologies)

TCC Technical Connection Conditions

EPC Electric Power Company

VDI “Verein Deutscher Ingenieure” (German engineers’ association)

© Güntner GmbH & Co. KG

Page 9

1.7 Conventions for safety signs and notices

1.7.1 General safety signs and their meaning in these operating instructions

DANGER

Dangerous situation that will definitely cause serious injury or death if it is not avoided.

WARNING

Dangerous situation that could cause serious injury or death if it is not avoided.

CAUTION

Dangerous situation that could cause slight to moderate injury if it is not avoided.

NOTICE

Refers you to possible damage to property.

page 9 / 68

1.7.2 Warning symbols and their meaning in these operating instructions

Warns against hand injuries!

Failure to comply with warnings may result in hands or fingers being crushed,

dragged in or otherwise injured.

Warns against hot surfaces!

The temperature is over +45°C (at which protein clots) and can cause burns.

Warns against cold!

The temperature is below 0°C and can cause frostbite.

Warns against dangerous electrical voltage!

Danger of an electric shock if voltage-carrying parts are touched.

CXGDF.1 | 2015-12

© Güntner GmbH & Co. KG

Page 10

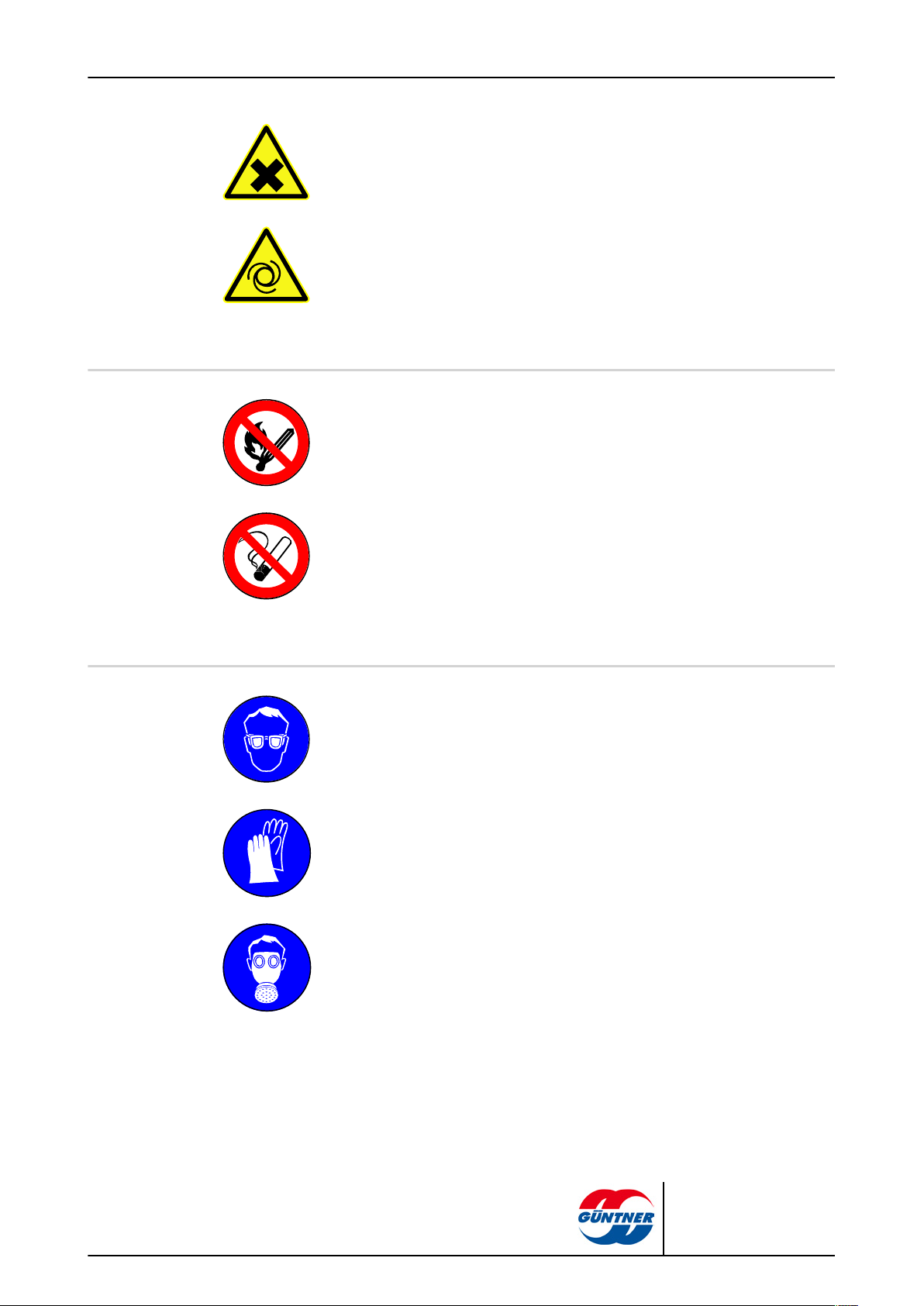

Warns against harmful to health or irritant substances at set-up point

Contact with or inhaling substances that are irritant or harmful to health can cause

injuries or damage peoples’ health.

Warning of automatic start-up

If the unit starts up automatically during maintenance work there is a danger of

pinching/trapping the hands and fingers.

1.7.3 Prohibitory signs and their meaning in these operating instructions

Fire, open fire and smoking prohibited!

Ignition sources must be kept away and ignition sources must not develop!

page 10 / 68

No smoking!

Smoking is forbidden.

1.7.4 Mandatory signs and their meaning in these operating instructions.

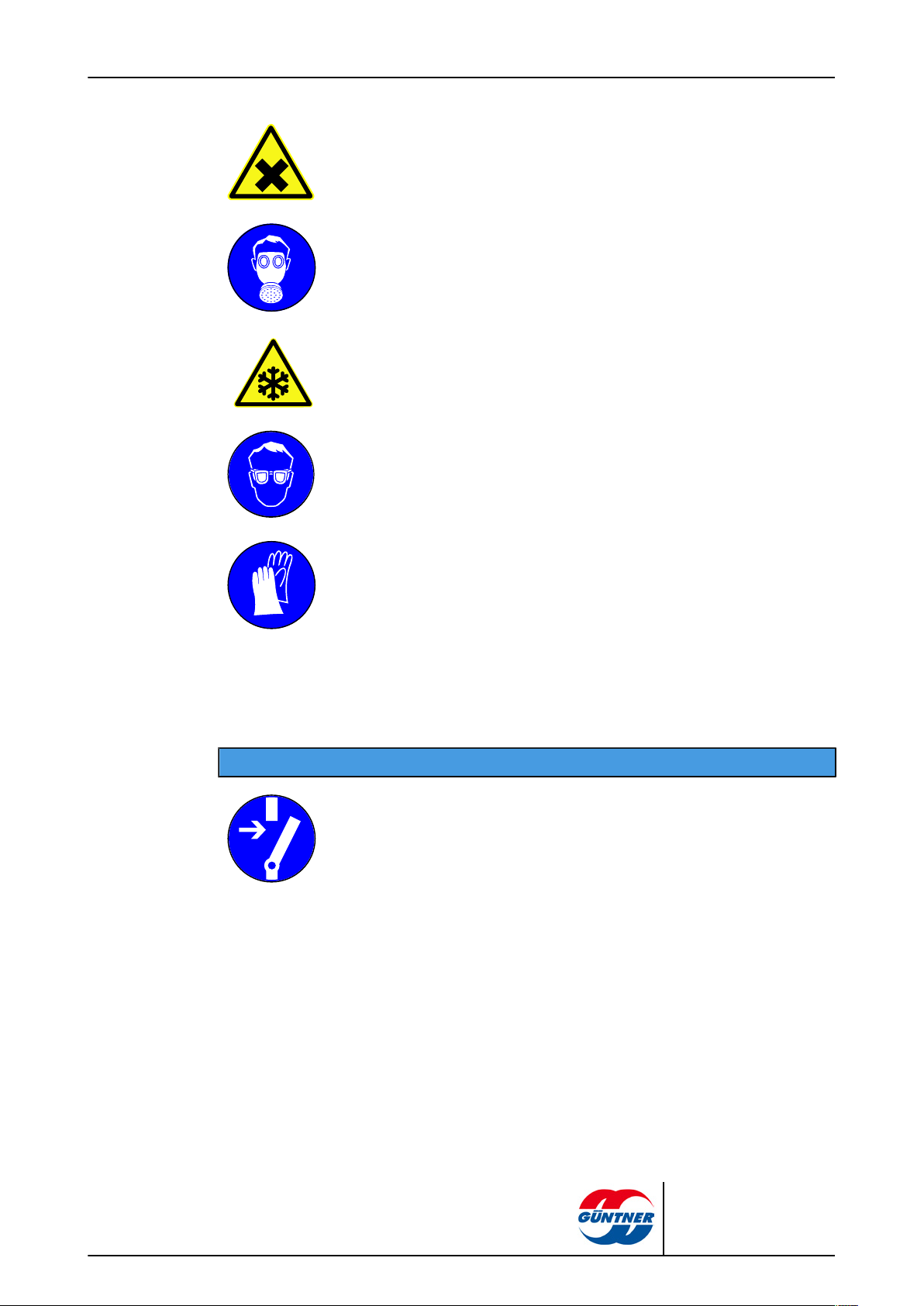

Use eye protection!

Eye protection: Use protective cover, protective glasses or face protection.

Use hand protection!

Protective gloves must protect against mechanical and chemical dangers (see imprinted pictograms).

Use respiratory protection!

Breathing apparatus must be suitable for the working fluid used. Breathing apparatus must consist of:

•

At least two independent breathing devices (self-contained breathing apparatus)

CXGDF.1 | 2015-12

© Güntner GmbH & Co. KG

Page 11

page 11 / 68

Use protective clothing!

Personal protective clothing must be suitable for the working fluid used and for low

temperatures, and must have good heat insulation properties.

Activate before work!

Activate the electrical system and secure against switching on again before starting installation, maintenance and repair work.

CXGDF.1 | 2015-12

© Güntner GmbH & Co. KG

Page 12

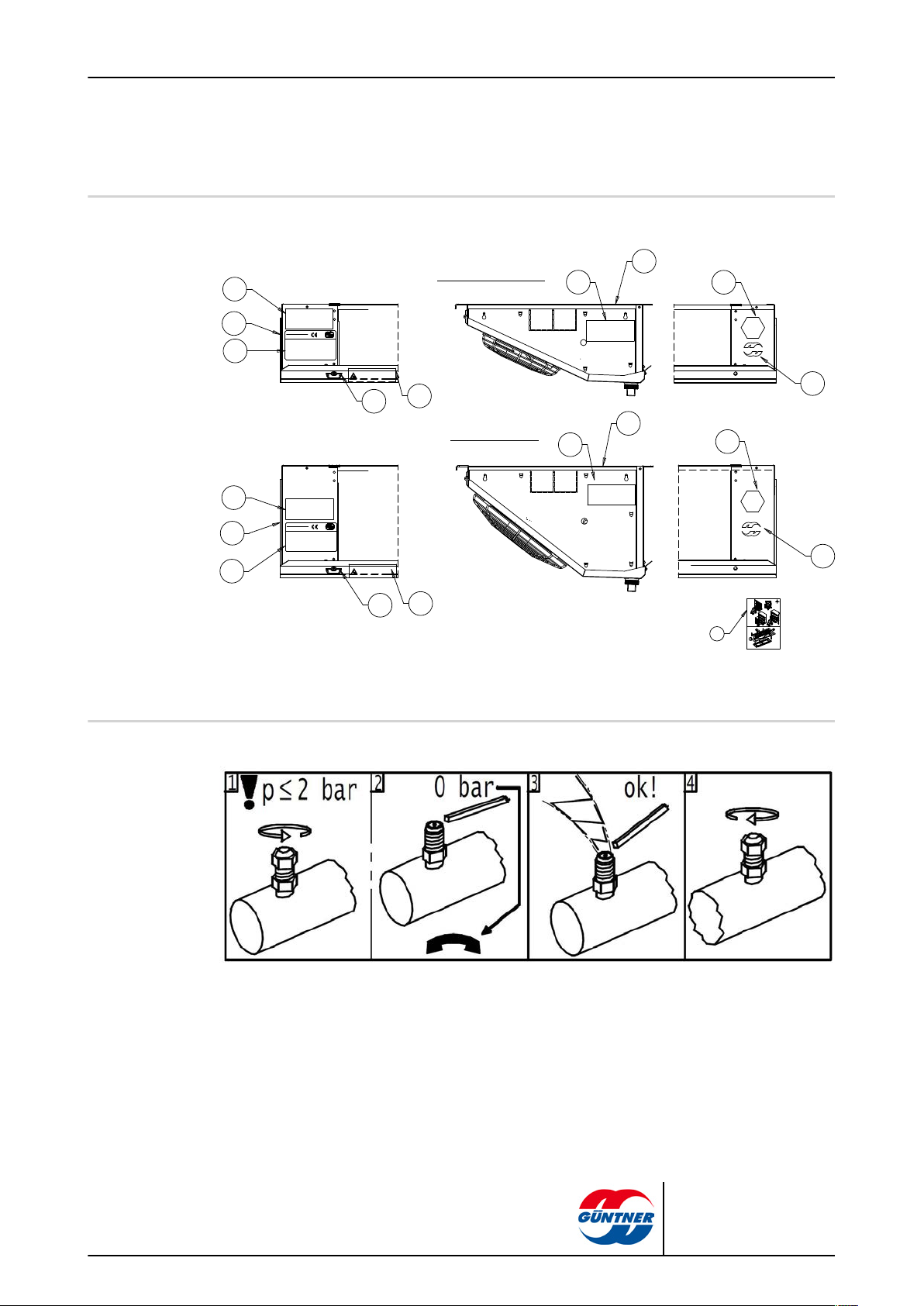

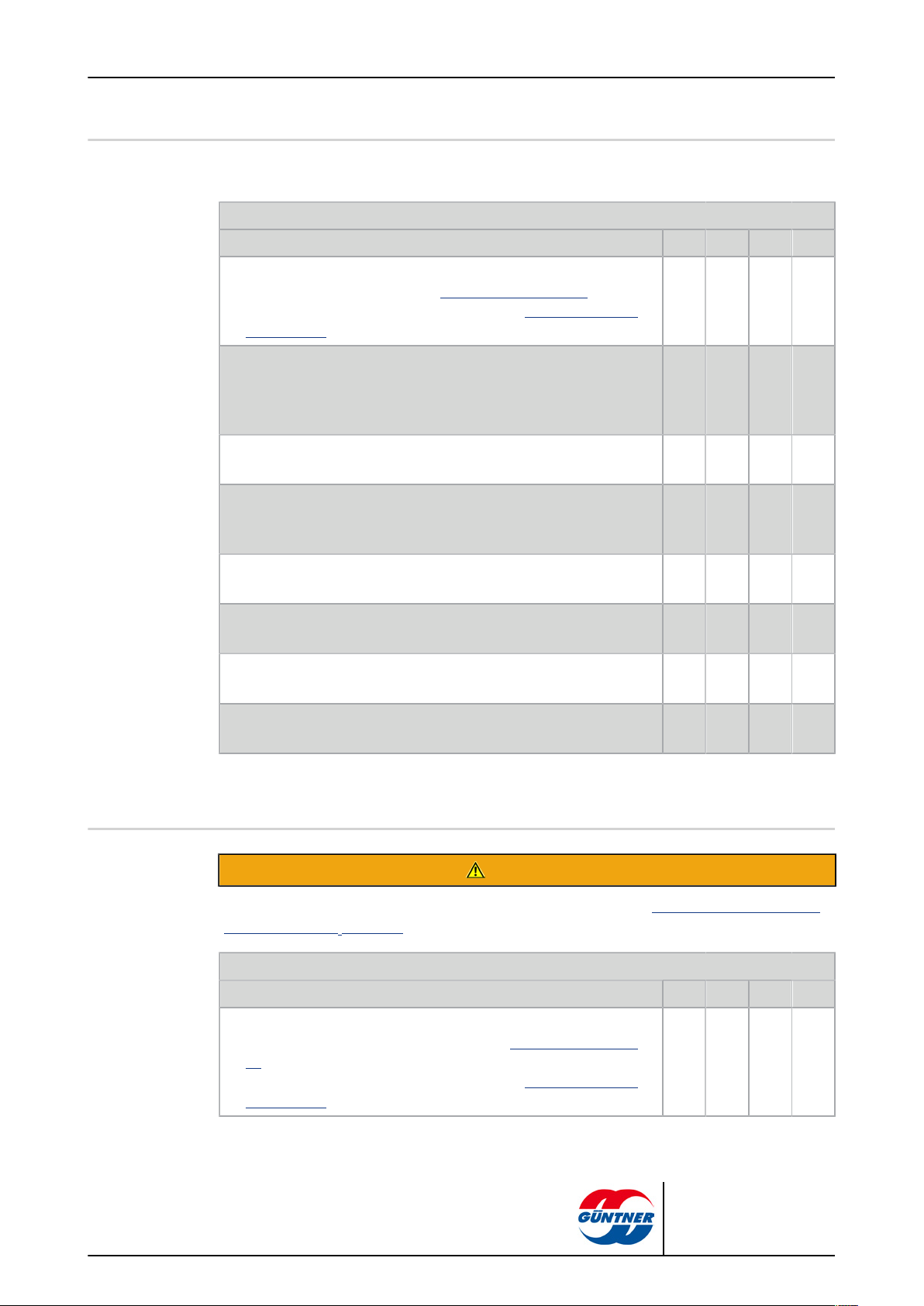

2 Safety

GDF.1 Typ A, B

GDF.1 Typ C

1

1

14

22

2

14

22

2

23

6

7

13

23

6

7

13

24

24

17

TÜV

GÜNTNER

GÜNTNER

ACHTUNG! CAUTION! ATTENTION!

ACHTUNG! CAUTION! ATTENTION!

ACHTUNG! CAUTION! ATTENTION!

ACHTUNG! CAUTION! ATTENTION!

Servickedeckel . Inspeczion door . Panneaude service

TÜV

Servickedeckel . Inspeczion door . Panneaude service

Auf

Open

Zu

Close

Auf

Open

Zu

Close

Prüfmedium

Aufgebrachter Prüfdruck PT

zulässige max./min. Temperatur TS

max./min. zulässiger Druck PS

Gerätebezeichnung

Herstellungsjahr

Herstellernummer

Projektnummer

WÄRMEAUSTAUSCHER

D-82256 FÜRSTENFELDBRUCK

INDUSTRIESTRASSE 14

HANS GÜNTNER GMBH

Ventilator-Typ/Nummer

Volumen V

Prüfdatum

c) Geräte vereinzeln

Unload units separately

Séparer, les appareils

b) Zum Vereinzeln

Transportschutz entfernen

Single unit

Remove transport protection

Appareil individuel

Enlever protection de transport

2. Montage

Mounting

Assemblage

a) Gesamt/ All units

Tous les appareil

1. Entladen

Unloading

Décharger

A

A

SW

13

SW1

3

SW

13

Prüfmedium

Aufgebrachter Prüfdruck PT

zulässige max./min. Temperatur TS

max./min. zulässiger Druck PS

Gerätebezeichnung

Herstellungsjahr

Herstellernummer

Projektnummer

WÄRMEAUSTAUSCHER

D-82256 FÜRSTENFELDBRUCK

INDUSTRIESTRASSE 14

HANS GÜNTNER GMBH

Ventilator-Typ/Nummer

Volumen V

Prüfdatum

2.1 Labelling on the unit:

Placing identifiers on the unit

page 12 / 68

Placing identifiers on the unit

2.1.1 Safety signs on the unit

Safety signs on the unit individually:

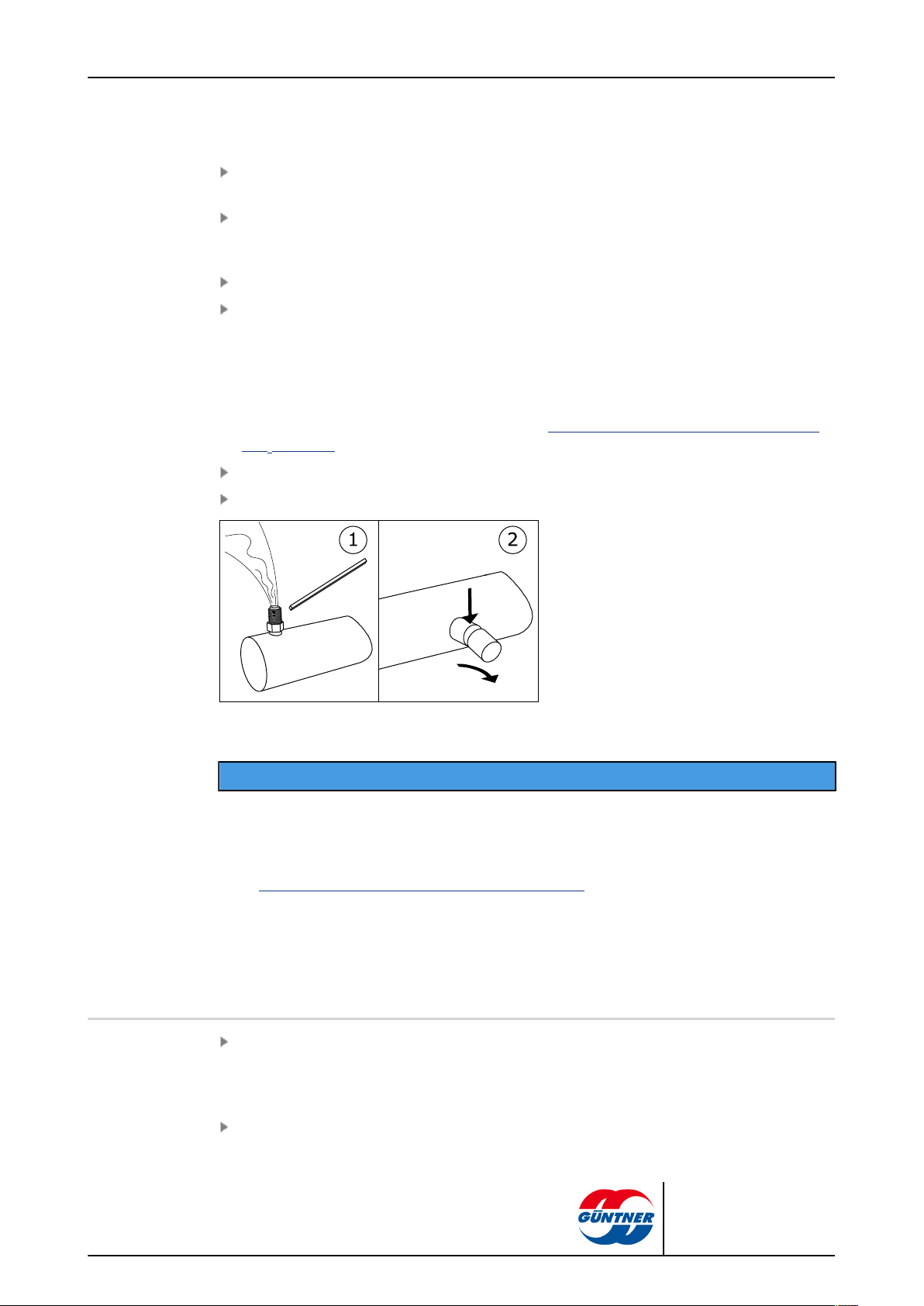

940 - “Transportation filling” warning sign next to Schrader valve

CXGDF.1 | 2015-12

© Güntner GmbH & Co. KG

Page 13

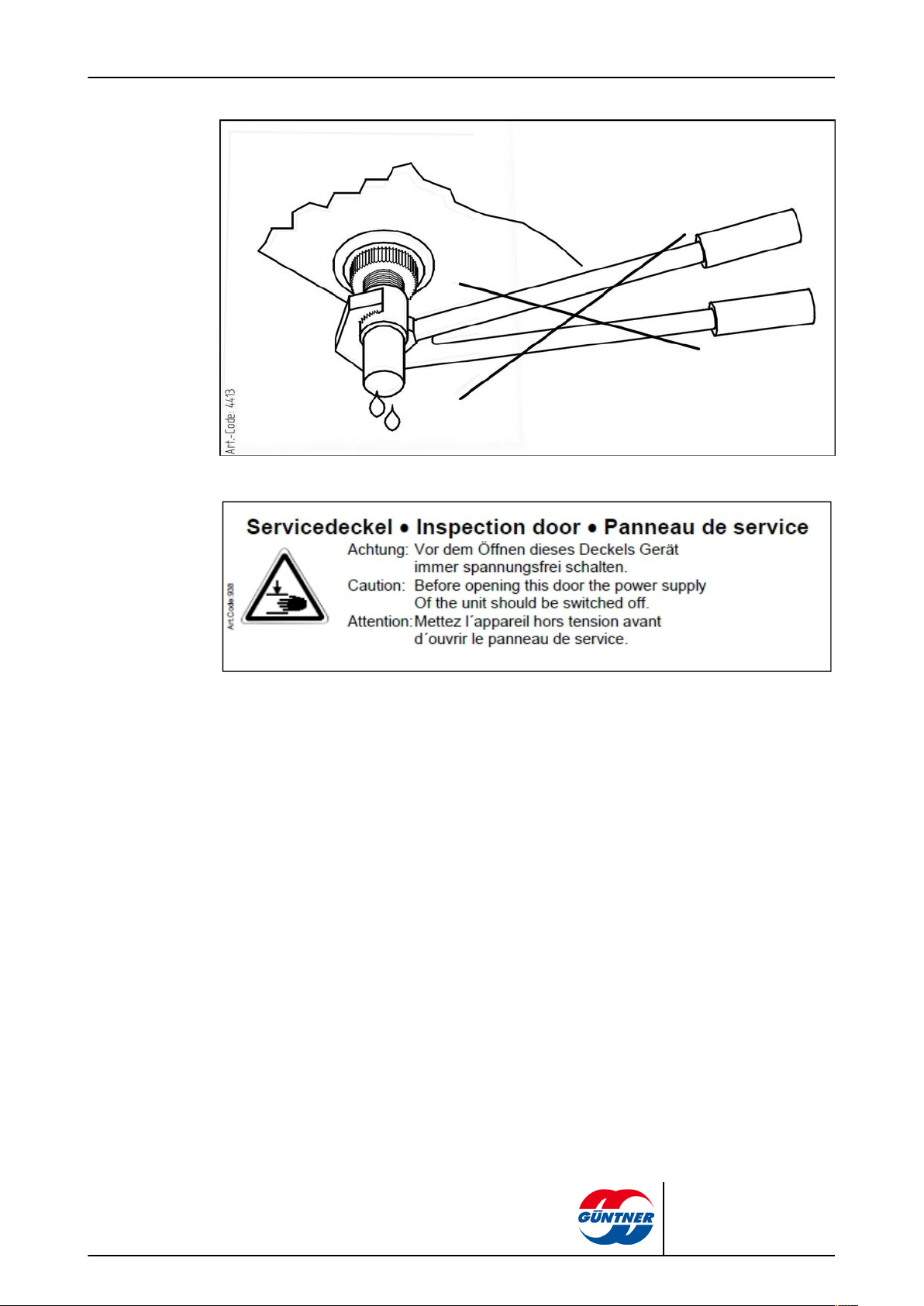

4413 - “Do not use wrench” warning sign beside tray drain

page 13 / 68

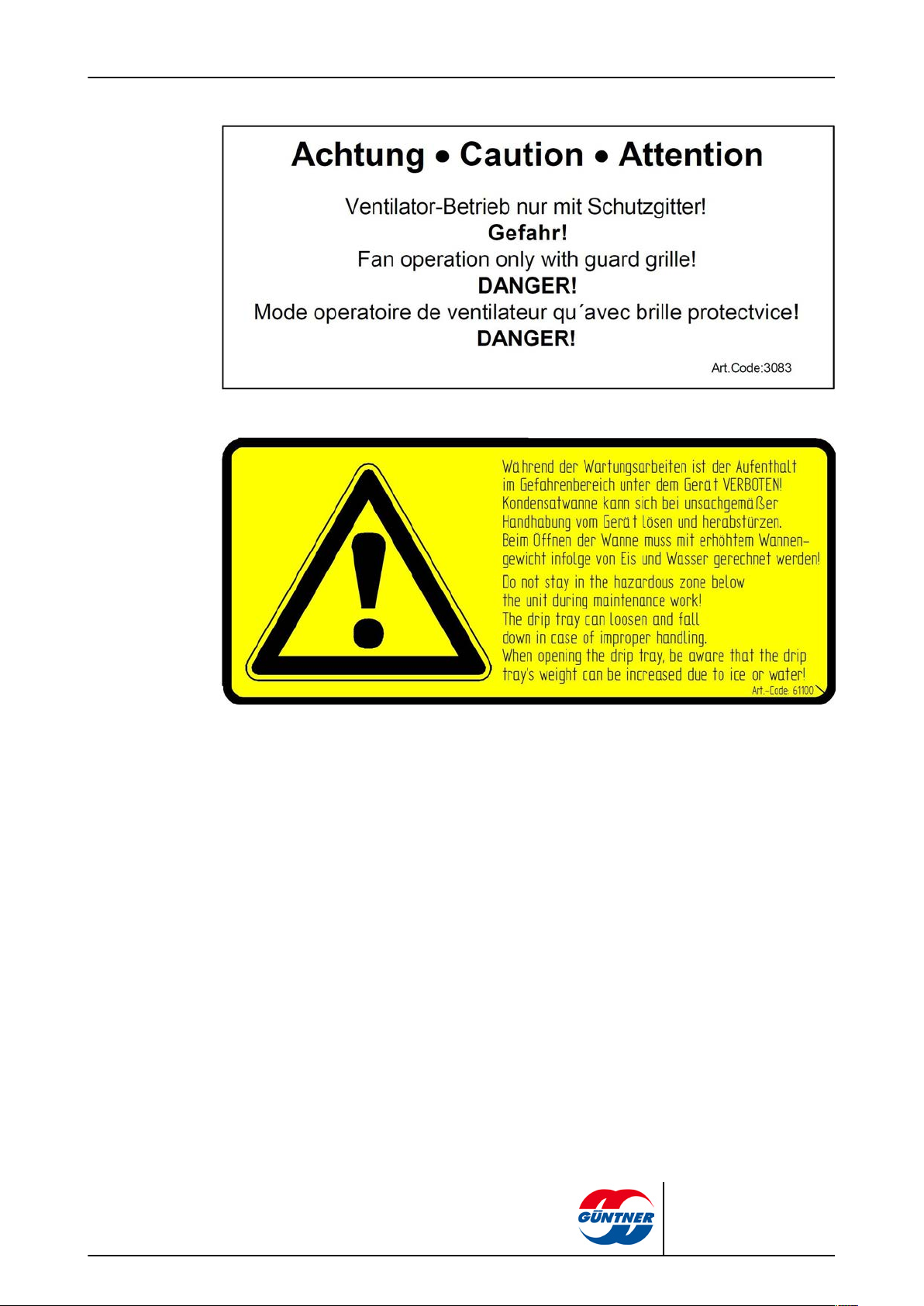

938 - Warning on inspection door (only with hinged fans)

CXGDF.1 | 2015-12

© Güntner GmbH & Co. KG

Page 14

page 14 / 68

3083 - “Protection grill” warning sign (only used with separate removable protection grill)

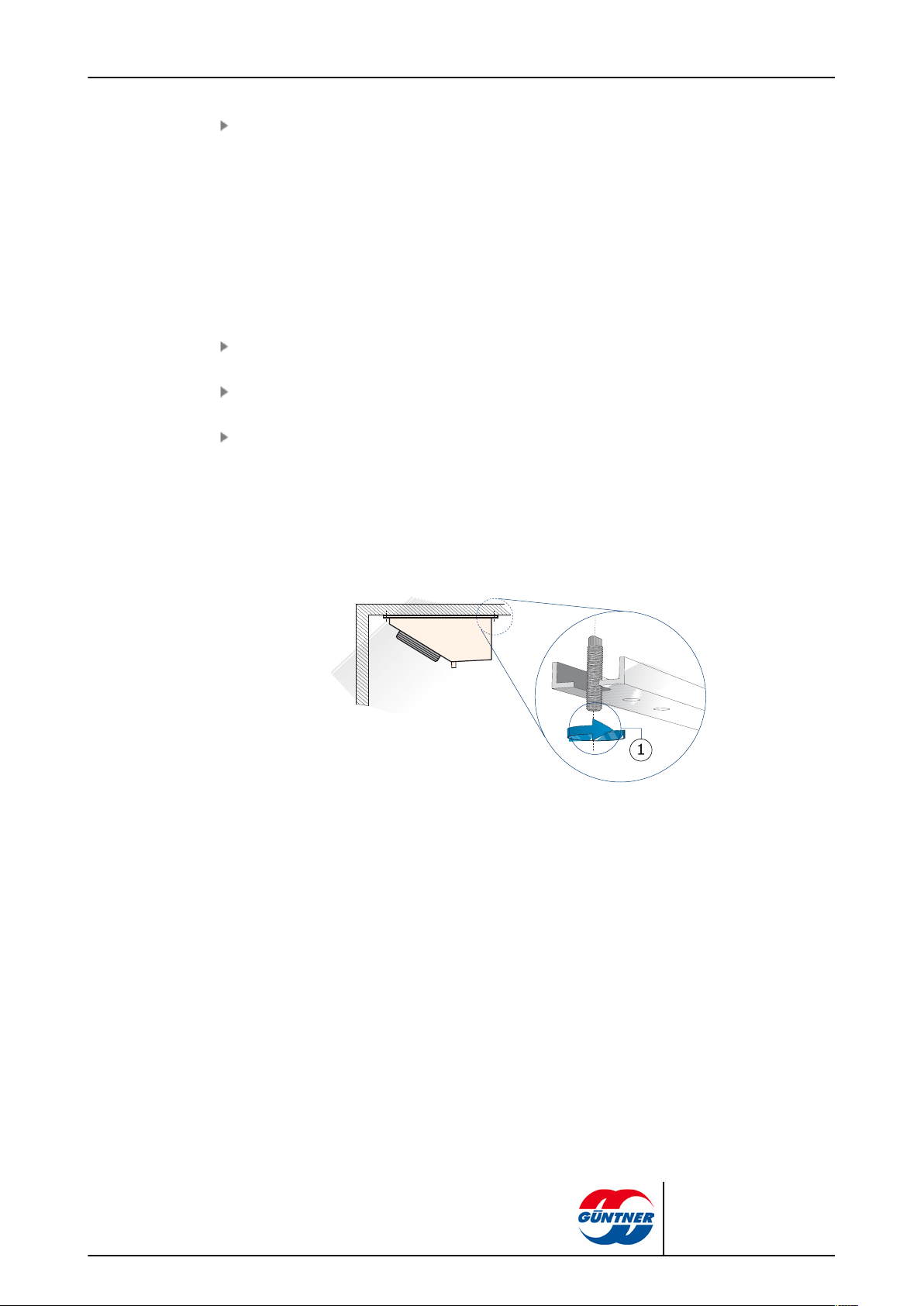

61100 - Tray safety catch warning sign

CXGDF.1 | 2015-12

© Güntner GmbH & Co. KG

Page 15

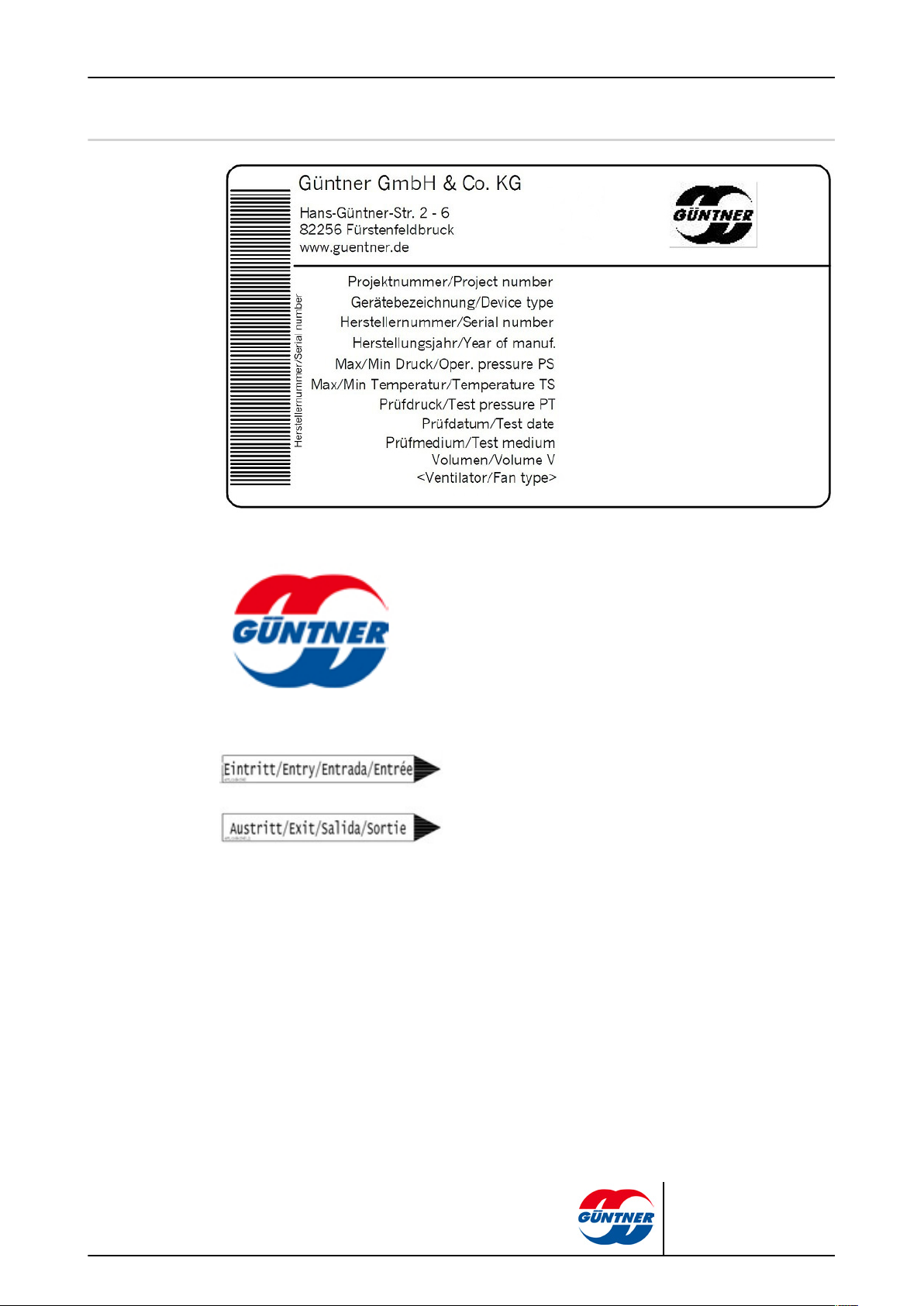

2.1.2 Other signs and notes on the unit

page 15 / 68

2483 - Example of a manufacturer’s nameplate

2119 – Logo

943 and 943.1 - Connections IN and OUT

CXGDF.1 | 2015-12

© Güntner GmbH & Co. KG

Page 16

page 16 / 68

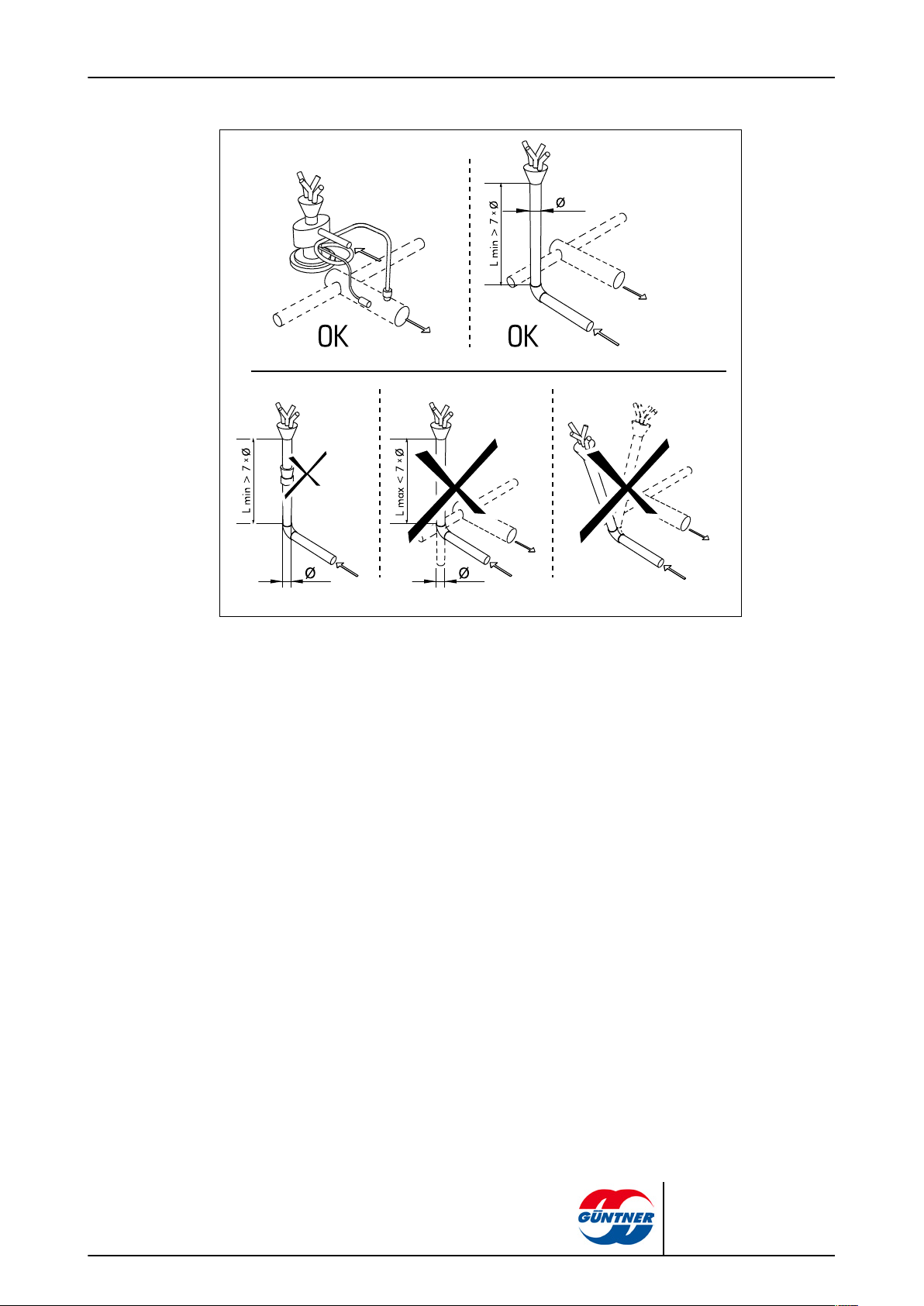

13 - Expansion valve mounting

CXGDF.1 | 2015-12

© Güntner GmbH & Co. KG

Page 17

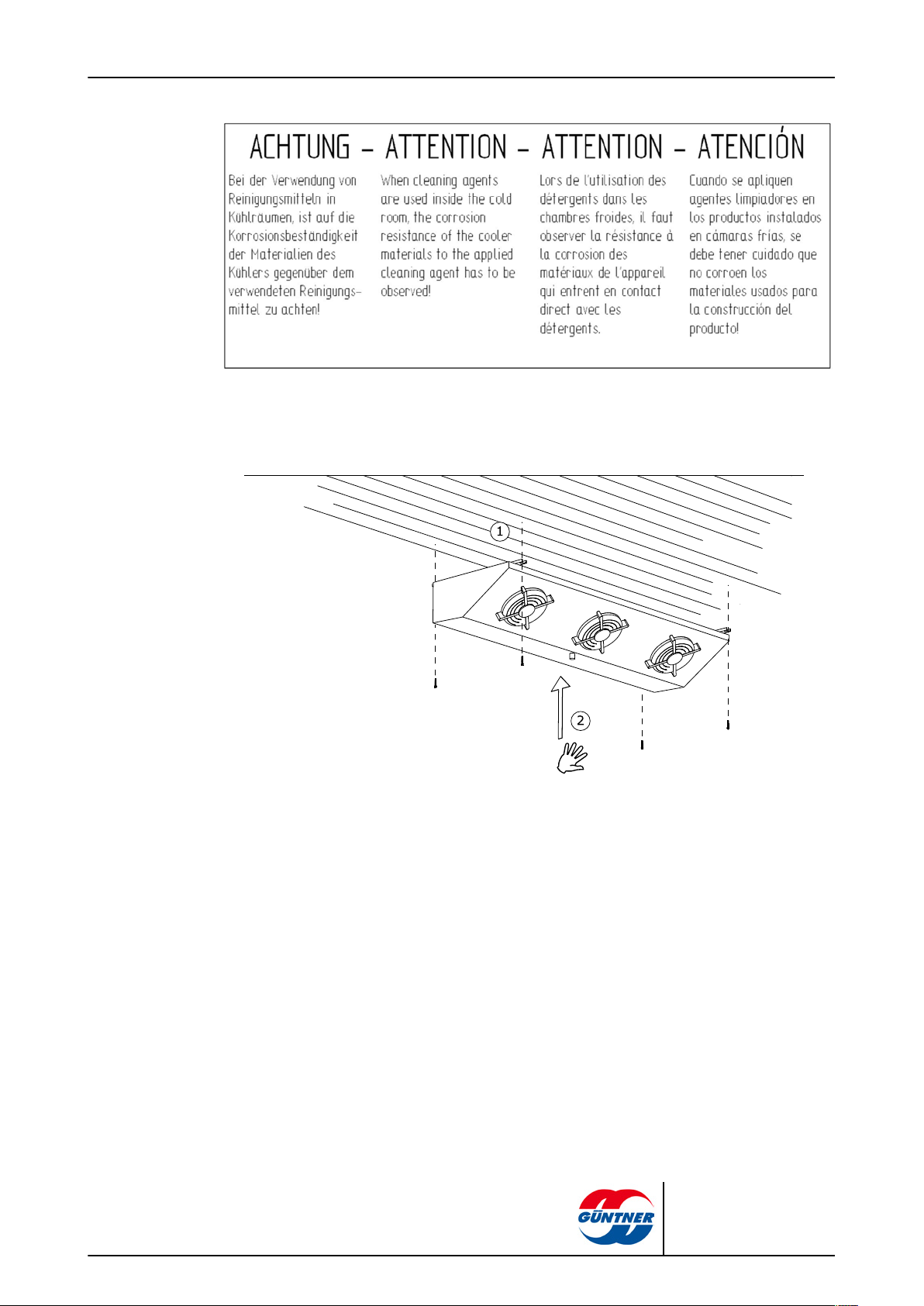

947 - Corrosion resistance

page 17 / 68

CXGDF.1 | 2015-12

Installation

© Güntner GmbH & Co. KG

Page 18

2.2 Basic safety notices

2.2.1 How to act in an emergency

Danger of injuries and damage to property!

CO2 is an irritant gas and when inhaled causes agitation, dizziness, vomiting and

cramps; with heavy concentrations suffocation and life-threatening pulmonary oedema.

Irritation of the respiratory centre with 30,000 to 50,000 ppm (3 to 5 vol %).

Unconsciousness with 70,000 to 100,000 ppm (7 to 10 vol%).

Safety measures and procedure:

•

In the event of serious unexpected leakage of refrigerant, leave the set-up room immediately and activate the emergency measures provided, e.g. if:

– Visibly escaping refrigerant liquid or vapour from the heat exchanger or tube

components.

– Sudden large release (release and evaporation of the greater part of the entire

refrigerant filling in a short time, e.g. in less than 5 minutes).

– Sudden irritation of the respiratory centre

– Activation of the NH2 alarm device (NH3 concentration > 5,000 ppm - MAC val-

ue):

•

Have experienced, trained personnel with appropriate protective clothing perform all

necessary protective and other measures:

– Use respiratory protection.

– Use a room air-independent breathing apparatus for maintenance work in high

CO2concentrations in the room air.

– Ensure the set-up room is well ventilated.

– Divert escaped refrigerant vapour and escaped refrigerant liquid safely.

page 18 / 68

WARNING

2.2.2 Personnel, care requirements

The unit may be installed, put into operation, operated, maintained and repaired only by trained, experienced and qualified personnel. In order to be considered qualified, people who are to be responsible

for the operation, maintenance, repair and evaluation of systems and their components must have the

necessary training and specialist knowledge for such work, as stipulated in EN 378-1. Qualified or expert means the ability to satisfactorily perform the activities required for the operation, maintenance, repair and evaluation of refrigeration systems and their components.

The unit may be operated by operating personnel that have no specific knowledge of refrigeration engineering, but have sufficient knowledge and experience with regard to the mode of operation, operation

and daily monitoring of this system, . This operating personnel may not make any interventions or settings on the system.

Changes to the unit, which the manufacturer has first agreed to in writing, may only be made by the instructed and qualified personnel.

CAUTION

CXGDF.1 | 2015-12

© Güntner GmbH & Co. KG

Page 19

Electrical installation:

Work on the electrical equipment may only be performed by personnel that have the required expertise

(e.g. an electrician or an electro-technically instructed person), and who are authorised by the operator,

in compliance with the respective VDE regulations (and national and international provisions) and the

TCCs of the EPCs.

2.3 Proper intended use

2.3.1 Proper intended use

CO2 evaporators of the CXGDF.1 series are intended for installation in a refrigeration system and

are used for cooling and circulating the room air e.g. in cold storage rooms and cold storage cells,

etc. The slimline design of these evaporators, and the CXGDF.1 in particular, enables optimum

room use. The CXGDF.1 series is ideal for deep-freeze applications (with a recommended fin spacing of 7 mm).

The unit is delivered for operation with a specific operating point:

•

Evaporation temperature

•

Airflow volume

•

Air inlet temperature

•

Relative air humidity.

The specified operating point is given in the order-related documents.

page 19 / 68

2.3.2 Operating conditions

The unit is a component a cooling system including its working fluid circuit. The purpose of these

operating instructions, as part of the operating instructions manual (of which these operating instructions are a part), is to minimise the danger to people and property and the environment from

the unit and the working fluid used in it. These dangers are essentially connected with the physical and chemical properties of the working fluid and with the pressures and temperatures that occur in the working fluid-carrying components of the unit see Residual hazards due to carbon dioxide

(CO2), page 23.

Danger of injuries and damage to property!

The unit may be used only in accordance with the proper intended use. The operator must ensure that

when operating, monitoring and maintaining the unit, the fluid used and the mode of operation do not

deviate from the order-related information specified in the order-specific documents.

The operator must ensure that maintenance measures are performed in compliance with the system’s

operating instructions manual.

Filling the unit with a different fluid is permitted only following written approval by the manufacturer. You

will find the order-related proper use as intended in the order-specific documents.

Do not exceed the max. operating pressure given on the unit’s type plate.

WARNING

CXGDF.1 | 2015-12

© Güntner GmbH & Co. KG

Page 20

2.3.3 Improper use

Danger of injuries and damage to property!

Working fluids and their combinations with water or other substances in the working fluid-carrying components have chemical and physical effects from the inside on the materials surrounding them. The unit

may be pressurised only with CO2. Pressurising the unit with another working fluid would have the effect

that

■

the structural, soldering and welding materials used do not withstand the foreseeable mechanical,

thermal and chemical stresses, and the pressure that can occur during operation and when shut

down is not withstood.

■

material, wall thickness, tensile strength, corrosive resistance, shaping process and testing are not

suitable for the working fluid used and do not withstand the possible pressures and stresses that

might occur.

■

the unit would not be resistant to the other working fluid and the combination of the other working fluid and

■

the unit not remaining tight during operation and when shut down.

■

a possible sudden escape of working fluids could directly endanger people and/or property and the

environment.

page 20 / 68

WARNING

The maximum permissible operating temperature specified on the type plate must not be exceeded! If

the operating temperature is exceeded,

•

the unit would be exposed to an impermissibly high pressure (pressure/temperature correlation),

•

signs of material fatigue would emerge,

The maximum permissible operating pressure specified on the type plate must not be exceeded! If the

operating pressure is exceeded,

■

the parts of the unit carrying the working fluid might not withstand the foreseeable mechanical, thermal and chemical stresses and the pressures that may occur during operation and when shut down,

■

the unit would not remain tight during operation and when shut down,

■

there may be a possible sudden escaping of working fluids after a break or leakage on working fluid-carrying components, which would result in the following dangers:

– Danger of escaping materials

– Fire hazard (caused by refrigerator oil parts)

– danger of frostbite (caused by liquid coolant squirting/splashing),

– Suffocation hazard

– hazards caused by panic reactions, agitation, dizziness, vomiting and cramps,

– Environmental pollution

WARNING

CO2evaporators may not be used

■

where it is possible that short or prolonged effect caused by contact, inhalation or ingestion of the

working fluid CO2 might result in harmful hazards.

■

where the possibility exists of a sudden large release (release and evaporation) of the greater part of

the entire working fluid filling in a short time (e.g. in less than 5 minutes).

CXGDF.1 | 2015-12

© Güntner GmbH & Co. KG

Page 21

page 21 / 68

■

where the possibility exists that the longest time that people are exposed to a large release of the

CO2 refrigerant is more than 60 minutes when the refrigerant concentration exceeds 5,000 ppm

(MAC value) and the number of clearly identified emergency exits for the number of usually present

people are not available.

■

where the number of clearly identified emergency exits for the number of usually present people are

not available.

The unit must not be changed without the prior written consent of Güntner GmbH & Co. KG . Changes

to the unit are:

■

Changing the operating point (as specified in section see Unit, page 31)

■

Changing the fan capacity (air volume)

■

Changing the working fluid flow-through volume

■

Changing over to another working fluid

The unit must not be operated if safety devices recommended by the manufacturer are not available, not

properly installed or not fully functional.

The unit must not be operated if it is damaged or demonstrates faults. All damage and faults must be

reported to Güntner GmbH & Co. KG immediately and dealt with promptly.

Work on the unit must not be performed without the personal protective equipment specified in these operating instructions.

2.4 Mechanical residual hazards

2.4.1 Fins, sharp unit corners and edges

Warns against hand injuries!

Danger of cuts on hands and fingers on the fins and on sharp corners and edges of

the unit.

Use reliable hand protection!

2.4.2 Flap down drip tray

WARNING

WARNING

CXGDF.1 | 2015-12

Warning against personal injury and damage to property!

Danger of falling unit parts, masses of water or ice when the drip tray is flapped out.

Nobody is allowed to be in the danger area below the unit during cleaning or maintenance work.

The drip tray can be flapped down for cleaning and is protected from falling down by a safety catch.

Unit parts, masses of water or ice can nonetheless fall down when it is flapped down.

© Güntner GmbH & Co. KG

Page 22

2.4.3 Fans

page 22 / 68

WARNING

Danger of cutting off, pulling in!

There is a danger of cutting off fingers on the rotating fan blades, injury hazard for the

hands and pulling in danger for loose elements such as hair, necklaces or clothing

parts.

Do not operate fans without guard grille. Pinch/trap point hazard!

With automatic fan start during maintenance work there is a danger of pinching/trapping for the hands and fingers.

Power off the unit before you begin maintenance work with which you must remove

the guard grille. Secure the unit against unintentional switching on again by removing

the electric fuses for the unit. Secure the unit with a suitable warning sign referring to

unintentional switching on.

The removable and hinged drip trays and the easy to open side covers must only be

opened by specialist staff and only for maintenance and repair purposes. Close the removable and hinged drip trays and the easy to open side covers after completing the

work and secure them against unintentional or unauthorised opening! Only open the

removable and hinged drip trays and the easy to open side covers after turning off the

fan's power (power-off state)!

2.4.4 Thermostatic expansion valve(option)

All work on the thermostatic expansion valve (e.g. overheating adjustment, changing nozzle uses) must only be performed by trained and instructed specialist staff. All

abovementioned work must be logged.

A nozzle use must only be changed with pressure-free line sections!

After changing a nozzle use the seal must be replaced!

When using a special expansion valve the screw for adjusting the set static overheating must be secured against unauthorized manipulations after every adjustment.

WARNING

CXGDF.1 | 2015-12

© Güntner GmbH & Co. KG

Page 23

2.5 Electrical residual hazards

Warns against dangerous electrical voltage!

Direct and indirect contact with voltage-carrying parts of motors and electrical lines can

cause serious injuries or death .

Power off the unit before you begin maintenance work. See the refrigeration system's

system documentation for this. Secure the unit against unintentional switching on

again by removing the electric fuses for the unit. Secure the unit with a suitable warning sign referring to unintentional switching on.

Please note that the mains cables may also be carrying voltage, even if the unit is

powered off.

Work on electrical equipment may be performed only by people that have the required

expertise (e.g. an electrician or an electro-technically instructed person) and who are

authorised to do so by the operator.

2.6 Thermal residual hazards

page 23 / 68

WARNING

2.6.1 Frostbite hazard

WARNING

Warns against cold!

In refrigerationoperation the heat exchanger and pipes have a temperature below ±0

°C. Contact can cause frostbite.

Use hand protection!

2.7 Residual hazards due to carbon dioxide (CO2)

The unit is operated with carbon dioxide (CO2). Carbon dioxide is a group L1/A1 refrigerant in ac-

cordance with classification according to flammability (L) and toxicity (A) in compliance with EU Directive 97/23/EG on pressure equipment (Pressure Equipment Directive):

– Refrigerants that, when gaseous, are non-flammable irrelevant of their concentration in air.

– Refrigerants with a time-weighted, averaged concentration that have no adverse effects on the

majority of staff that are exposed every day during a normal 8 hour working day and a 40 hour

working week to this concentration, which is greater than or equal to 400 ml/m3 (400 ppm (V/V)).

Carbon dioxide (CO2) as a refrigerant has the following properties:

CXGDF.1 | 2015-12

– Non-flammable, known fire extinguisher agent

– Non-toxic, food safety-approved and declaration-free

– Odourless

– Colourless

© Güntner GmbH & Co. KG

Page 24

page 24 / 68

– Taste-neutral

– Heavier than air

– Stable compound, used under normal ambient conditions as an inert gas

– Combination with water CO2 + H2O = H2CO3. Of dissolved CO2 gas in water, only 0.1% is

present as acid. The pH value of watery CO2 solutions at normal pressure is 3.7. Under pres-

sure it falls to a limit value of 3.3. CO2 is therefore suitable as a neutralisation medium for basic

solutions.

– Medical applications: Inhalations of 3 to 5% CO2 in breathing gas.

There is no imminent danger for the staff. With good air ventilation and removal by suction, it will fall

easily and clearly below the allowed limit values.

WARNING

Danger of harm to health and environmental damage!

Refrigerants of the Group L1/A1 are generally heavier than air and may flow off to rooms on a lower level. In still air there may be an increase of the ground level concentration. With high concentrations there

are the following hazards – especially near to the floor:

– Irritation of the respiratory centre with 30,000 to 50,000 ppm (3 to 5 vol %).

– Unconsciousness with 70,000 to 100,000 ppm (7 to 10 vol %) due to lack of oxygen.

– CO2 is an irritant gas and causes agitation, dizziness, vomiting and cramps, with high concentrations

causing suffocation and life-threatening pulmonary oedema.

Always observe the following safety instructions:

•

Unauthorised people must not have access to the unit.

•

Ensure working rooms are well-ventilated in order to prevent inhalation of high vapour concentrations. MAC value 5,000 ml/m3 (ppm) as 8 h average value; a concentration of 10,000 ppm (instantaneous value) for 60 min. three times per shift is permitted a peak limit.

•

Ensure that the CFC/HFC refrigerant escaping from the unit cannot penetrate the interior of the

building or put people at risk in any other way. CO2 refrigerant vapour or gas must be kept from pen-

etrating neighbouring rooms, staircases, yards, passages or drainage systems and must be discharged without risk.

•

Monitor the CO2 refrigerant concentration in the ambient air to ensure constant compliance with lim-

it values. With good air ventilation and removal by suction, it will fall easily and clearly below the allowed limit values.

•

With emergency work in high CO2 refrigerant concentrations in the room air wear a room air-inde-

pendent breathing apparatus.

•

Prevent the refrigerant or oil from escaping: Test the tightness of the unit regularly, as specified in

these operating instructions ( see Inspection and maintenance plan, page 58).

•

With leaks on the evaporator (escaping CO2), if hazard-free handling is guaranteed, the emergency

STOP switch must be pressed and the endangered unit shut off.

•

Harmful to the environment effects: CO2 must not be released into the atmosphere – environmental

damage (with a 50% content CO2 is one of the most significant anthropogenic greenhouse gases)

CXGDF.1 | 2015-12

© Güntner GmbH & Co. KG

Page 25

page 25 / 68

Ignition and fire hazard!

•

With work involving fire or sparks, e.g. grinding, welding, etc., ensure suitable fire

fighting equipment is on-site.

•

In particular be aware of the danger of ignition of oil residues unintentionally carried

in in the CO2 refrigerant.

•

Ensure that the provided fire fighting equipment is provided in sufficient quantities,

that it functions properly and that the extinguishing agent does not react with the

CO2 refrigerant.

•

Smoke during work is forbidden!

Frostbite hazard

Frostbite if CO2 comes into contact with the skin or eyes (-57°C). Leaks in the unit

can cause the CO2 refrigerant to escape into the set-up room.

•

When removing faults after spills of CO2 refrigerant, you must be vigilant for any re-

maining superheated CO2 refrigerant as splashes can cause frostbite and evapora-

tion can cause irritation.

Danger of poisoning!

CO2 refrigerant contact with fire can form toxic combustion products.

•

Prevent CO2 refrigerant contact with open fire.

•

Welding and soldering may therefore take place only after completely draining the

relevant section of the system of the CO2 refrigerant. Ensure good ventilation here!

•

With emergency work in high CO2 refrigerant concentrations in the room air wear a

room air-independent breathing apparatus.

2.8 Residual hazards caused by vibrations

WARNING

Danger of injuries and damage to property caused by escaping materials

If fans are damaged during fan operation, flying parts of the fan blades can injure people or cause damage to property close to the fan.

Fans, components and cables in system, must be designed, constructed and integrated so that dangers

caused by vibrations that it or other parts of the system generate ,, are reduced to an absolute minimum,

while incorporating all available means for reducing vibrations, preferably at the source.

CXGDF.1 | 2015-12

© Güntner GmbH & Co. KG

Page 26

NOTICE

Damage to property caused by vibrations

Vibrations that are increased by imbalances, as created by dirt, icing or fan blade damage, are regularly caused with fan operation. The vibrations are transferred to the unit, where they can cause damage

and damage the unit mounting or components connected to the unit.

Check fan blades and protection grill regularly for contamination and frost and/or ice and make sure

the fans run smoothly ( see Fans, page 59).

Check fan blades and protection grill regularly for contamination and make sure the fans run smoothly

(see Fans, page 59).

2.9 Residual hazards caused by pressurised parts

WARNING

Injury and damage to property caused by pressurised parts that contain CO2 refrigerant!

Breaks in pressurised pipes or pressurised components of the unit can cause injuries or damage to

property caused by escaping materials ( A sudden large release of the working fluid with its hazardous

properties after a break or leak on pressurised components of the unit can cause the following hazards:

■

Flammability (caused by proportion of lubricating oil for refrigerating compressors present)

■

Irritation of the respiratory centre

■

Frostbite (caused by liquid refrigerant squirting/splashing)

■

Suffocation

■

Panic, agitation, dizziness, vomiting and cramps

■

Environmental pollution

Ensure that the unit in question is pressure-free before maintenance work begins or remove the working

fluid from the unit in question.

page 26 / 68

Perform maintenance work – especially soldering and welding – on the unit in question only after completely removing the working fluid from the unit.

2.10 Residual hazards caused by defective installation

WARNING

Injuries and damage to property caused by defective installation!

Defective installation results in hazards caused by:

■

Break or leak on liquid-carrying unit components and pipes

■

Absence of release devices to prevent liquid escape: Observe the magnet valve/check valve se-

quence combination in the fluid line: In the flow direction the magnet valve must be installed first and

then the check valve. If the sequence is reversed, liquid will be locked in between the check valve

and the magnet valve when the magnet valve is closed; this will heat up during shutdown state and

can cause pipes or connection flanges to break when it expands. This applies in particular to lines

carrying cold liquids.

■

Subcooled liquid in system sections: If system sections are opened for repairs and the pressure is

equalised with the atmosphere, there is a danger that liquid, subcooled ammonia will still be present

in the opened area. Carbon dioxide has a very high evaporation heat, so that the heat penetration

in the pipes, for example, which are laid with a “fluid sack”, is not sufficient to evaporate the liquid re-

CXGDF.1 | 2015-12

© Güntner GmbH & Co. KG

Page 27

page 27 / 68

frigerant quickly – especially if this is an insulated line. This hazard is therefore referred to explicitly in

BGR 500.

■

Uneven load distribution on the fixtures with the danger of stresses within the unit or unit displace-

ment (breaks or leaks on fluid-carrying components of the unit and pipes; danger of breaking off).

■

Insufficient securing of working fluid-carrying lines against mechanical damage! On-site connections:

loaded installation; effect of forces on the distribution and header pipes with the danger of breaks or

leaks on fluid-carrying components of the unit and pipes; danger of breaking off!

■

Break-off and fall danger of the unit with hazard of escaping working fluid and exposed electrical ca-

bles.

■

Danger of damage caused by environment-conditional hazard sources (production, transport and

other processes at the set-up point).

■

Unit functional faults caused by air inlet/outlet obstructions.

■

Obstructed heater rods exchange with electric defrosting (accessory at customer’s request)/

■

Obstruction of all-side inspection, checks and maintenance, i.e. no unobstructed accessibility to the

working fluid-carrying and electrical components, connections and cables, no recognisable identifiers

on the pipes and insufficient space for tests.

Ensure that:

•

The units are to be installed on the fixing points corresponding with their weights and tightened with

fixing bolts. The operator or installer is responsible for ensuring that the bolted connections are of an

adequate strength.

•

The diameters of the mounting holes have been statically determined by the manufacturer and the

fixing bolts are adapted accordingly.

•

The fixing bolts are secured against loosening by means of an appropriate locking device.

•

The fixing bolts are not overtightened or stripped.

•

All fixing bolts are tightened equally to achieve a load distribution on the connections that is as bal-

anced as possible.

•

All fixing points maintain the same spacing to the fixing level permanently and under load, so that no

mechanical stress occurs in the unit structure. The units are anchored in their fixing position in order

to prevent the equipment from moving.

•

The functional safety of the fixing bolts is tested as part of the maintenance periods. see Mainte-

nance, page 56,

•

The unit is fixed and set up so that it is not damaged by environment-conditional hazard sources

(production, transport and other processes at the set-up point) or its functioning is not disturbed by

the interventions of unauthorised persons.

•

The units are fixed and set up with sufficient slopes for drip water flow.

•

The units are fixed and set up so that unobstructed air inlet/outlet is constantly available without any

air short circuiting.

•

The units are fixed and set up so that unobstructed heater rod exchange with electric defrosting is

constantly available (option: accessory at customer’s request).

•

The units are fixed so that they can be inspected, checked and maintained from all sides at all

times, i.e. there must be unobstructed access to the refrigerant-carrying and electrical components,

connections and lines, the pipeline labelling must be identifiable and adequate space must be avail-

able for testing.

•

The working fluid-carrying lines must be protected against mechanical damage. On-site connec-

tions: when installing keep the unit free of load; force must not be exerted on the distribution and

header pipes.

•

The following must be observed without fail when installing the unit:

– Imperative adherence to spacing from objects that could be endangered by a CO2 effect.

– Provision of measures to safeguard people from a CO2 concentration of more than 5,000 ppm

(MAC value).

CXGDF.1 | 2015-12

© Güntner GmbH & Co. KG

Page 28

– Set up and fix units as follows: In areas that are used for inner-plant traffic, the pipelines to and

from the unit must be installed only with connections and fittings that cannot be removed.

– Release devices to prevent liquid escapes must be provided and available.

– Subcooled liquid may be present in only the lowest possible amount in system sections in shut-

down state – minimized number of “fluid sacks”.

2.11 Residual hazards with break during operation

WARNING

Injuries and damage to property caused by break during operation!

•

Defective installation (see Residual hazards caused by defective installation, page 26).

•

Non-compliance with maximum permissible operating pressure ( see Operating conditions, page

19).

•

Disregarding pressurised line sections with maintenance ( see Residual hazards caused by pres-

surised parts, page 26).

•

Disregarding residual hazards caused by vibrations ( see Residual hazards caused by vibrations,

page 25).

result in ruptures during operation and maintenance. This results in dangers caused by

page 28 / 68

•

escaping materials (see Residual hazards caused by pressurised parts, page 26).

•

released working fluid (see Residual hazards due to carbon dioxide (CO2), page 23).

Ensure that:

•

The installation is fault-free.

•

The maximum permissible operating pressure is always adhered to.

•

Pressurised line sections are de-pressurised before all maintenance and repair work.

•

Vibrations from the refrigeration system, from the (vibrations caused by system compressors, , components and lines) and from the fan (imbalances caused by frosting, icing or dirt build-up or damages) are reduced with all available means and brought down to an absolute minimum.

•

Release devices to prevent liquid escapes are provided and available.

•

Undercooled liquid is only present in the lowest possible amount in system sections in shutdown

state – minimized number of "fluid sacks".

2.12 Residual hazards caused by escaping objects or liquids

WARNING

Injuries and damage to property caused by escaping objects or liquids!

Residual hazards caused by escaping objects and liquids ( see Residual hazards with break during oper-

ation, page 28).

CXGDF.1 | 2015-12

© Güntner GmbH & Co. KG

Page 29

2.13 Combined residual hazards

2.13.1 Easy to open side covers/

Danger of frostbite!

Danger of hand injuries!

With unauthorized access into the opened unit there is the danger of frostbite if heat

exchangers or pipes are touched, and the danger of cuts on sharp edges.

The easy to open side covers, and the removable and hinged drip trays, must only

be opened by staff and only for maintenance and repair purposes. Close the opened

side covers and the removable and hinged drip trays, after the work is completed

and secure them against unintentional or unauthorised opening!

2.14 Residual hazards with disposal

page 29 / 68

WARNING

WARNING

Danger of injuries and damage to property caused by working fluid, , CO2!

The following notes are recommendations for the proper professional disposal of the unit. Applicable

waste disposal laws are binding for the country of operation:

■

Disposal must only be carried out by experts.

■

All unit components, e.g. working fluids, refrigerator oil, heat exchangers, fans, must be disposed of

properly as specified.

■

Used working fluid that is not determined for reuse, must be treated as waste and safely disposed

of. There must be no emissions into the environment.

■

The CO2 refrigerant must be filled into a special refrigerant container in compliance with the respec-

tive safety measures. This special refrigerant container must be suitable for the CO2 refrigerant. It

must be easy to identify and labelled for the refrigerant, e.g. "Carbon dioxide (CO2) recovered".

■

A disposable single-use container must not be used, as refrigerant vapour residues in the container

escape during disposal.

■

The working liquid receiver must not be overfilled. The maximum permissible pressure of the working

fluid container must not be exceeded during the work process.

■

The working fluid must not be filled in a liquid container that contains another or an unknown working

fluid. This other or unknown working fluid must not be released into the atmosphere, but rather identified, treated again, or properly disposed of as specified.

■

An officially authorised facility can be used for destroying the working fluid.

■

It must be ensured that all unit components containing working fluids and refrigerator oil, are disposed of properly as specified.

CXGDF.1 | 2015-12

© Güntner GmbH & Co. KG

Page 30

page 30 / 68

■

The unit consists predominantly of the basic materials, copper, aluminium, (heat exchangers and

casings), steel and aluminium, copper, polyamide (motors), steel, copper, insulating material (heater

rods with electric defrosting – option; accessory at customer's request). These materials can be handled by the waste industry, including in paint-treated state, to recycling via mechanical and thermal

separation.

■

Before scrapping the working fluid-carrying unit components must be drained, whereby the pressure

must be reduced to at least 0.6 bar absolute for a unit pipe volume up to and including 200 l, and

to 0.3 bar absolute for a unit pipe volume over 200 l. The pressure reduction process is then ended

when the pressure no longer increases and remains constant, and the unit is at ambient temperature.

WARNING

Danger of environmental damage!

Carbon dioxide (CO2) is a greenhouse gas that appears in the most important natural compounds. Addi-

tional emissions from anthropogenic sources result in serious global warming and therefore damage to

the global climate:

– As an important, climate-relevant trace gas, carbon dioxide (CO2) contributes significantly to regula-

tion of the earth's heat balance. Carbon dioxide (CO2) changes the earth's radiation balance by al-

lowing (almost unobstructed) the short-wave solar radiation to pass through to the earth's surface,

and by partially absorbing the long-wave heat radiation emitted by the earth.

At 50 %, carbon dioxide (CO2) is one of the most significant anthropogenic greenhouse gases

•

Ensure that no refrigerant enters water systems or sewage.

•

Operate the facility for recovering or disposing of working fluids so that the danger of a working fluid

or refrigerator oil emission into the environment is kept as low as possible.

•

Ensure that carbon dioxide (CO2) never enters the atmosphere uncontrolled!

Güntner GmbH & Co. KG’s transportation packaging is made from environmentally compatible material and is suitable for recycling.

CXGDF.1 | 2015-12

© Güntner GmbH & Co. KG

Page 31

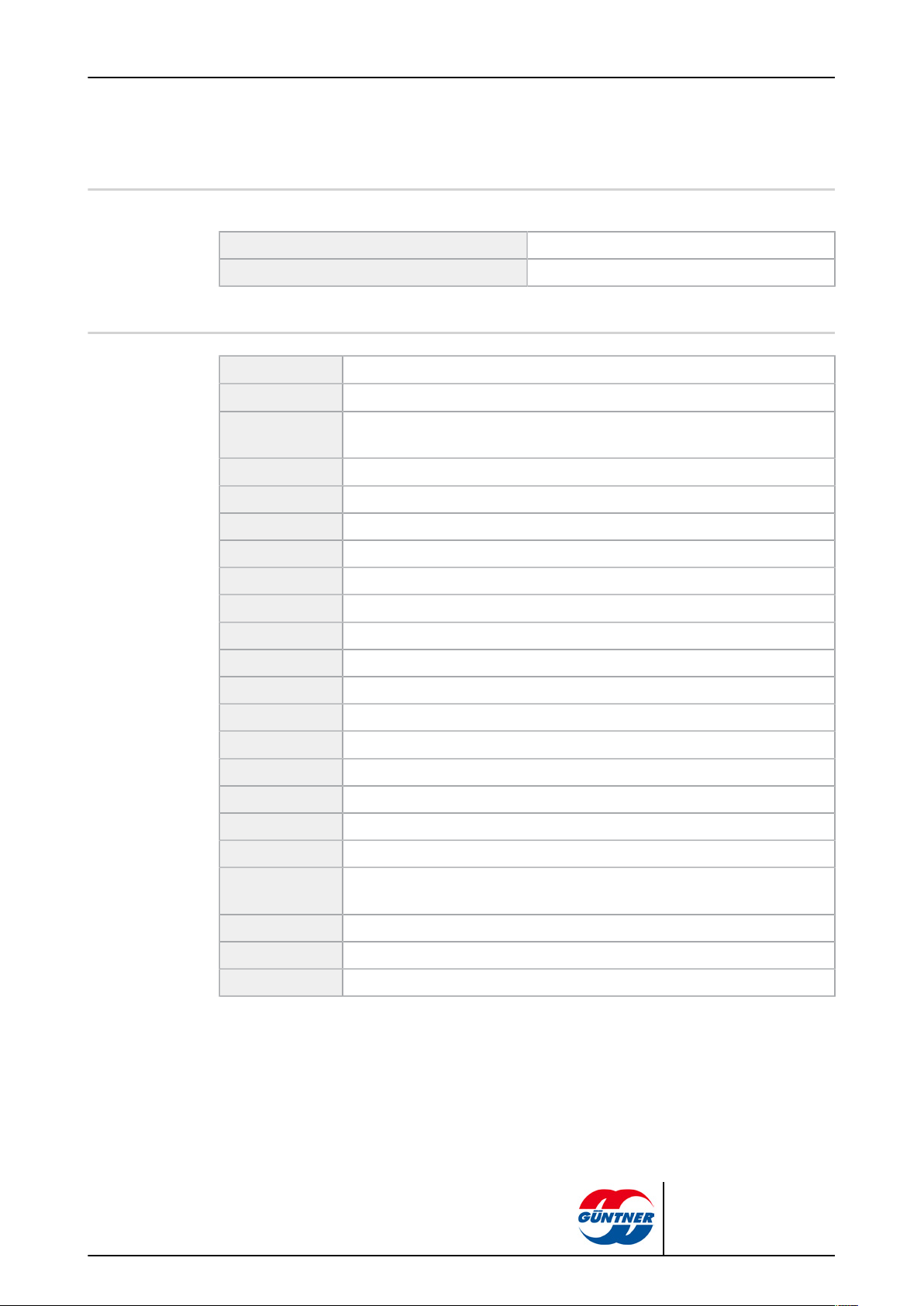

3 Technical data

3.1 Unit

The fans’ capacity values depend on the ambient temperature and on the air resistance at the set-up

point.

Güntner GmbH & Co. KG recommends electric fan ring heating with use in the temperature range.

Please consult the manufacturer when operating the unit below -40°C because of the special material

requirements and selection.

All electrical parts must be installed in accordance with EN standards.

Project number See order-related documents

Unit name See order-related documents

Manufacturer number See order-related documents

page 31 / 68

NOTICE

Production year See order-related documents

Working fluid R 744 (carbon dioxide, CO2)

Volume See order-related documents

Permissible operating pressure 32 bar

Test pressure 35.2 bar

Permissible operating temperature -60- +140 °C

Permissible ambient temperature -30- +40 °C

Permissible air humidity > 100%

Test date See order-related documents

Test medium Dry air

Airborne noise emitted See order-related documents In accordance with the

standard procedure for calculating sound level described

in EN 13487; Annex C (normative). As cold storage

rooms have only very low absorption behaviour, we recommend you to expect only very low absorption of the

sound level at large distances.

Weight See order-related documents

3.2 Fans

CXGDF.1 | 2015-12

The fans' technical delivery conditions comply with DIN 24166, accuracy class 2.

Fan type See order-related documents

Protection rating IP 54 in acc. with DIN 40050, thermal class 130

(B)

Current type alternating current (EC motors)

© Güntner GmbH & Co. KG

Page 32

Voltage 230 V 1~ 50 - 60 Hz

Permissible air temperature Operating range: -30°C to +40°C

page 32 / 68

Protective devices

•

Thermal: Thermo-contacts (temperature

monitor for safeguarding against thermal

overload).

•

Mechanical: Protective contact grille in acc.

with EN 294

CXGDF.1 | 2015-12

© Güntner GmbH & Co. KG

Page 33

4 Set-up and function

The air cooler consists of,

•

a heat exchanger arranged as consisting of pipe coils fitted with fins (copper pipe; aluminium

fin) distribution and header pipes (copper)/ and pipe connections to the pipeline system,

•

an aluminium-magnesium alloy casing, powder-coated RAL 9003 (signal white); brackets for

ceiling fixing made of stainless steel, flush with housing top edge;

•

a thermally-decoupled and therefore condensation-free drip tray made of AlMg, powder-coated

RAL 9003 (signal white). The drip tray is hinged and removable for easier cleaning.

•

and – depending on the version – with one or more axial fans with maintenance-free motors.

Two fan versions are possible here: normal and boosted (optional). High throw distances can be

achieved with Güntner streamers.

•

and – depending on the version – with one or more axial fans with EC motors.

The evaporator is a refrigeration system component. It provides a finned heat exchanger (straight

and curved pipes – pipe coils – with fins, which are connected to form a heat exchanger) in which

liquid refrigerant evaporates by absorbing heat from the material to be cooled.

The refrigeration system is a combination of refrigerant-carrying components and fittings connected

with one another, which form a closed circuit, in which the refrigerant circulates.

The refrigerant absorbs heat at a low temperature and low pressure and evaporates (evaporator-side), and at a higher temperature and higher pressure gives off the heat again and condenses

itself (condenser-side).

page 33 / 68

The heat from the material to be cooled is dissipated with fans over the entire surface of the evaporator.

The CXGDF.1 series evaporators standardly operate in accordance with the “dry evaporation” principle. The refrigerant liquid fed to the evaporator is completely evaporated in it, and overheated

to protect the compressor from slugging. The refrigerant used, R 744 (carbon dioxide, CO2), is a

Group L1/A1 refrigerant (see Residual hazards due to carbon dioxide (CO2), page 23).

CXGDF.1 | 2015-12

© Güntner GmbH & Co. KG

Page 34

5 Fan motor

During longer periods of storage or standstill, the fans must be activated during 2 to 4 hours per month.

For fans with the protection rating IP55 or higher, existing closed condensation water holes must be

opened at least once every six months.

AC technology

The AC motors are protected against overheating by a thermocontact (or PTC resistor).

For motors with a thermocontact, the thermocontact must be switched in such a way that the motor

cannot be powered on when the thermocontact is triggered. A locking mechanism is recommended

to prevent renewed power-on.

Motors with a PTC resistor need an additional external trigger unit for the installed thermistors. A

locking mechanism is recommended to prevent renewed power-on. The test voltage at the thermistors is not permitted to exceed 2.5 V, or only current-limiting test devices may be used.

page 34 / 68

NOTICE

NOTICE

When using a star-delta connection, a corresponding delay must be considered.

For motors with direct starting and a connection value > 4.0 kW, an inrush current limitation (soft

start using a thyristor) could be required.

If frequency converters are to be used for speed control, the following points must be considered for

external rotor fans:

Between the frequency converter and fans, all-pole sine-wave filters must always be installed (sine

wave-shaped output voltage; filter effect between phase to phase and phase to earth).

All Güntner frequency converters are equipped with this function as standard. Conventional threephase motors are suitable for direct operation with frequency converters.

With star-delta connection, the three-phase fan motors can be operated with two speeds or with

speed control. The direction of rotation must be checked. A change in the direction of rotation, if it is

wrong, is made by interchanging two phases.

CXGDF.1 | 2015-12

© Güntner GmbH & Co. KG

Page 35

6 Transportation and storage

6.1 Safety

Crushing danger with falling down!

The unit weighs between 9 kg and 80 kg. (when transporting 2 to 3 units packed on top of each other,

the transport weight is doubled or trebled). It can slip and fall off the transporting device, causing serious

injuries or death. Heavy impacts or vibrations can damage the unit.

Ensure that the assigned staff is trained for proper unloading.

Ensure that nobody is under the unit or near the loaded area during the transport.

Ensure even weight distribution. Ensure that the bulk of the weight is always on the fan side. Observe

the transport labels on the packed unit ( see Other signs and notes on the unit, page 15).

Secure the unit against slipping and mechanical damage.

Use auxiliary transport equipment where required. Use a transporting device appropriate for the unit’s

weight. You will find the weight of the unit in the order-related documents (see Set-up and other applic-

able documents, page 7). Do not use connection pieces and header pipes as hooking points for lifting,

pulling, fixing or mounting. This can cause leaks.

page 35 / 68

WARNING

Transport the unit carefully. Particularly avoid setting the unit down hard.

6.2 Transportation and storage

Read and observe all transport signs on the units’ packaging!

Prolonged mechanical stresses caused by uneven road surfaces and potholes and vibrations during

transport by ship can cause transportation damage. Before transportation by sea or in countries with difficult transport routes, attachment parts that are likely to vibrate – in particular fans and base stands –

must be removed for transportation.

NOTICE

CXGDF.1 | 2015-12

© Güntner GmbH & Co. KG

Page 36

page 36 / 68

Use suitable equipment to transport the packed unit to the destination installation site (for exam-

ple, a crane or fork-lift).

Unload the unit.

6.3 Storage before installation

Danger of corrosion and dirt build-up!

Moisture and dirt must be prevented from entering the unit.

Protect the unit against dust, dirt, moisture and wetness, damage and other harmful effects. Harmful

effects: see Safety instructions for set-up and start-up, page 37

Do not store the unit for longer than necessary. Only store the units in their original packaging until

installation. Always only place packaging units of the same size on top of one another.

Store the unit at a protected place free of dust, dirt, moisture and damage-free until its set-up

(well-ventilated halls or roofed storage site).

If the unit set-up is delayed with regard to the planned installation time: protect the unit against

weather and other harmful effects and dirt and other contaminants with an appropriate cover.

The unit must also be well-ventilated here.

NOTICE

CXGDF.1 | 2015-12

© Güntner GmbH & Co. KG

Page 37

7 Set-up and start-up

7.1 Safety

7.1.1 Safety instructions for set-up and start-up

WARNING

Danger of injuries and damage to property with escaping CO2 refrigerant!

Incorrect installation causes the danger of working fluid escaping when the unit is operated and injuries

or damage to property (see Residual hazards due to carbon dioxide (CO2), page 23).

Follow the set-up instructions in this chapter precisely and apply extreme care!

NOTICE

Damage to the system's !

Foreign materials and contaminants in the working fluid circuit can impair the effectiveness or damage

components. Particularly harmful contaminants are:

page 37 / 68

– Moisture

– Atmospheric air

– Welding and soldering residues

– Rust

– Soot/ash/cinders

– Metal cuttings

– Unstable oils

– Dust and dirt of all kinds

Moisture in the working fluid-carrying components of the unit can have the following consequences:

– Water separation and ice formation cause faults in the switching and control fittings of the refrigera-

tion system

– Acidification

– Ageing and refrigerator oil decay

– Corrosion

Atmospheric air and other non-condensable gases can have the following consequences:

– Refrigerator oil oxidation

– Chemical reactions between working fluid and refrigerator oil

– Increased condensing pressure in the system

Chemical reactions between working fluid and refrigerator oil with the absence of moisture or atmospheric air with ageing and working fluid and refrigerator oil decay can have the following consequences:

– Formation of organic and inorganic acids

– Increased compressed gas temperature in the system

– Corrosion

– Bad lubrication, increased wear and tear through to system or failure

CXGDF.1 | 2015-12

Other contaminants can cause:

– Accelerated chemical processes (decomposition)

– Mechanical and electrical faults in the refrigeration system

© Güntner GmbH & Co. KG

Page 38

page 38 / 68

During the installation (connecting the working fluid-carrying components of the unit to the working fluid-carrying system of the installation’s ensure that internal contamination is strictly avoided.

Perform the installation with extreme cleanliness.

Caution! Low permissible water content in a CO2 refrigeration system! Ensure that the unit's level of dry-

ness corresponds with the low permissible water content in a CO2 refrigeration system!

Finish all on-site pipe installation work before releasing the transport pressure!

Only release the transport pressure on the Schrader valve immediately before installation.

Only remove the sealing caps on the distribution and header pipe immediately before installation.

NOTICE

Danger of corrosion and dirt build-up!

Moisture and dirt must be prevented from entering the unit. If moisture and dirt penetrate the unit there

is also the danger of damage to fittings and other system components of the .

Protect the unit against dust, contamination, moisture and wetness, damage and other harmful influences. Harmful influences are, for example:

– Mechanical: Damages caused by impacts, objects falling on or against, collisions with transport

equipment, etc.

– Physical: Damages caused by close by concentrated flammable gases

– Chemical: Damages caused by contaminated atmospheres (salt, acid, chlorine, sulpher-containing,

or similar)

– Thermal: Damages caused by close by heat sources

Begin with the installation as soon as possible.

The electrical installation may be performed only by electricians (or by expert technicians with appropriate

qualifications) in compliance with the relevant VDE rules (or applicable national and international regulations) and the TCCs of the EPCs!

7.1.2 System-side safety requirements

The unit is a component of an installation and can only be operated in conjunction with the installation

•

All equipment required for operating the unit must be integrated into the switching and activation

equipment :

– Electrics: Fans and other electrical components, heating rods for electrical defrosting (op-

tional) if applicable,

– Working fluids: valves and fittings

– Drip water: drip water drain line

•

The working fluid-side and electrical connections must be available on the system. The connections must be specified in the order-related documents.

•

The power supply of the fans must be provided in acc. with the specifications on the type plate

on the fan motors.

•

A switch-off device for preventing unexpected start-up (repairs switch), which separates all active conductors from the power supply (all-pole switch-off), must be provided for the fans in acc.

with EN 60204-1.

•

The fans' switch-on/off device must be secured (e.g. with a padlock) to prevent uncontrolled fan

start-up.

WARNING

CXGDF.1 | 2015-12

© Güntner GmbH & Co. KG

Page 39

•

The electrical motor, repairs switch, terminal box and switching cabinet connections must be

provided in acc. with the respective connection diagrams.

•

It must be possible to shut off the unit if a leak occurs.

•

People wearing ambient air-independent breathing apparatus in full protective clothing must also be able to activate all safety-relevant shut-off fittings.

•

It must be possible to activate all devices meant for diverting escaping working fluids from a

safe position.

7.1.3 Customer-side safety precautions

Danger of injuries and damage to property!

The unit contains CO2 refrigerant (see Residual hazards due to carbon dioxide (CO2),

page 23).

CO2 is an irritant gas and causes agitation, dizziness, vomiting and cramps, with high

concentrations causing suffocation and life-threatening pulmonary oedema.

Irritation of the respiratory centre with 30,000 to 50,000 ppm (3 to 5 vol %). Unconsciousness with 70,000 to 100,000 ppm (70 to 100 vol %).

There is no imminent danger for the staff. However, refrigerants of the Group L1/A1

are generally heavier than air and may flow off to rooms on a lower level. In still air

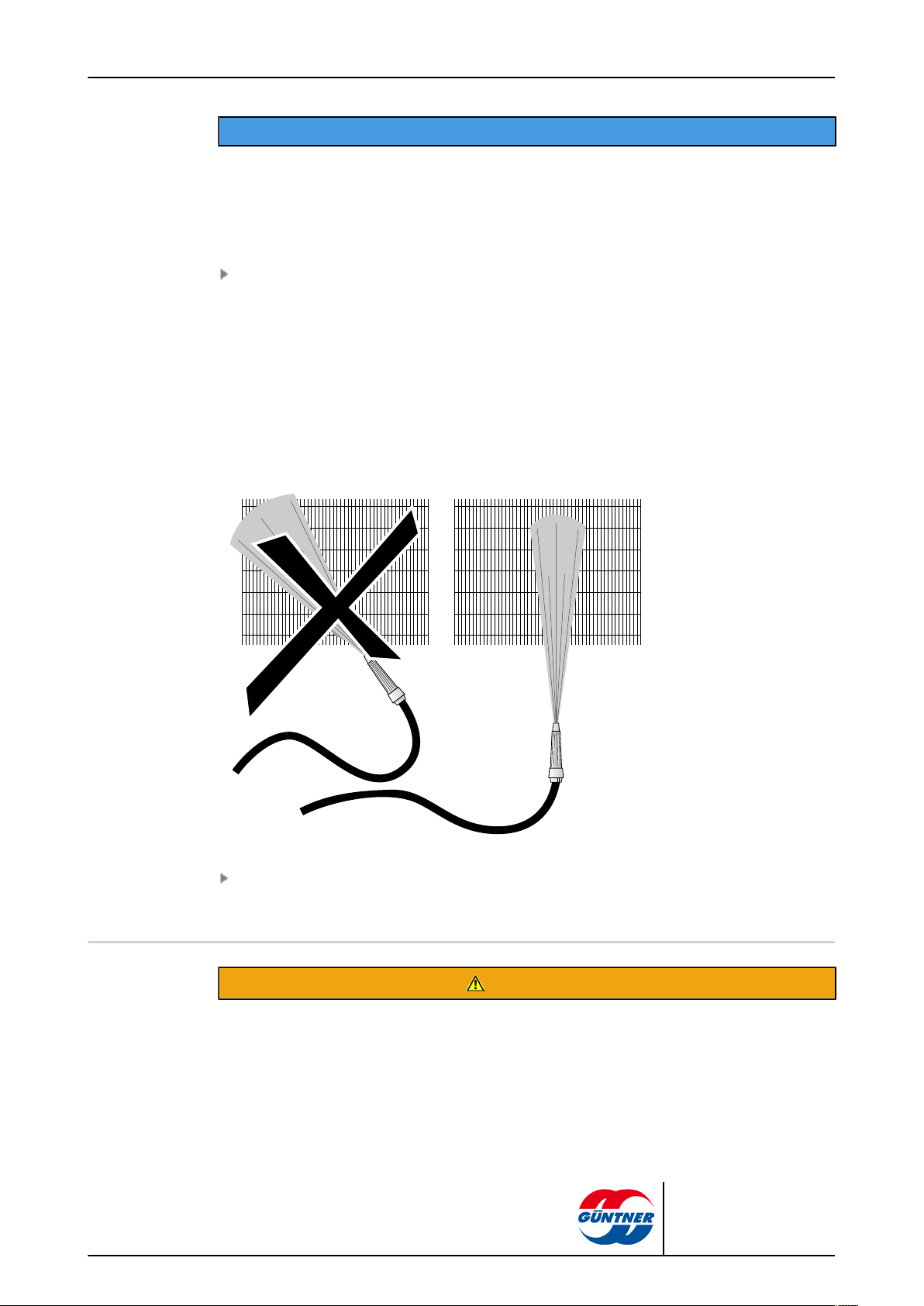

there may be an increase of the ground level concentration. With high concentrations,