Page 1

Profi 2500

#

9413

1

D GB F DK

CZ SK

NL

I

NOR S

Güde GmbH & Co. KG

Birkichstraße 6

D-74549 Wolpertshausen

www.guede.com

Güde Scandinavia A/S

Engelsholmvej 33

DK-8900 Randers

www.guede.com

GÜDE Slovakia s.r.o

Podtúre!-Rove! 208

SK-033 01 Liptovský Hrádok

www.guede.com

Güde Hungary Kft.

Kossuth L. út 72

H-8420 Zirc

www.guede.com

Güde Czech, s.r.o.

Po"ernická 120

CZ-36005 Karlovy Vary

www.guede.com

Page 2

GB

2

List of Contents

Description Page

1. Parts Description ......................................................................................................................................2

2. Technical Data ......................................................................................................................................... 2

3. General Safety Precautions .....................................................................................................................3

3. Assembly..................................................................................................................................................5

4. Grinding Disk Check................................................................................................................................. 6

5. Grinding Disk Assembly ........................................................................................................................... 6

6. Clamping Screw Set Up ........................................................................................................................... 7

7. Grinding.................................................................................................................................................... 7

8. Grinding Depth Delimiter..........................................................................................................................8

10. Dimensions............................................................................................................................................... 9

9. Assembly Drawing.................................................................................................................................. 10

10. List of Spare Parts..................................................................................................................................11

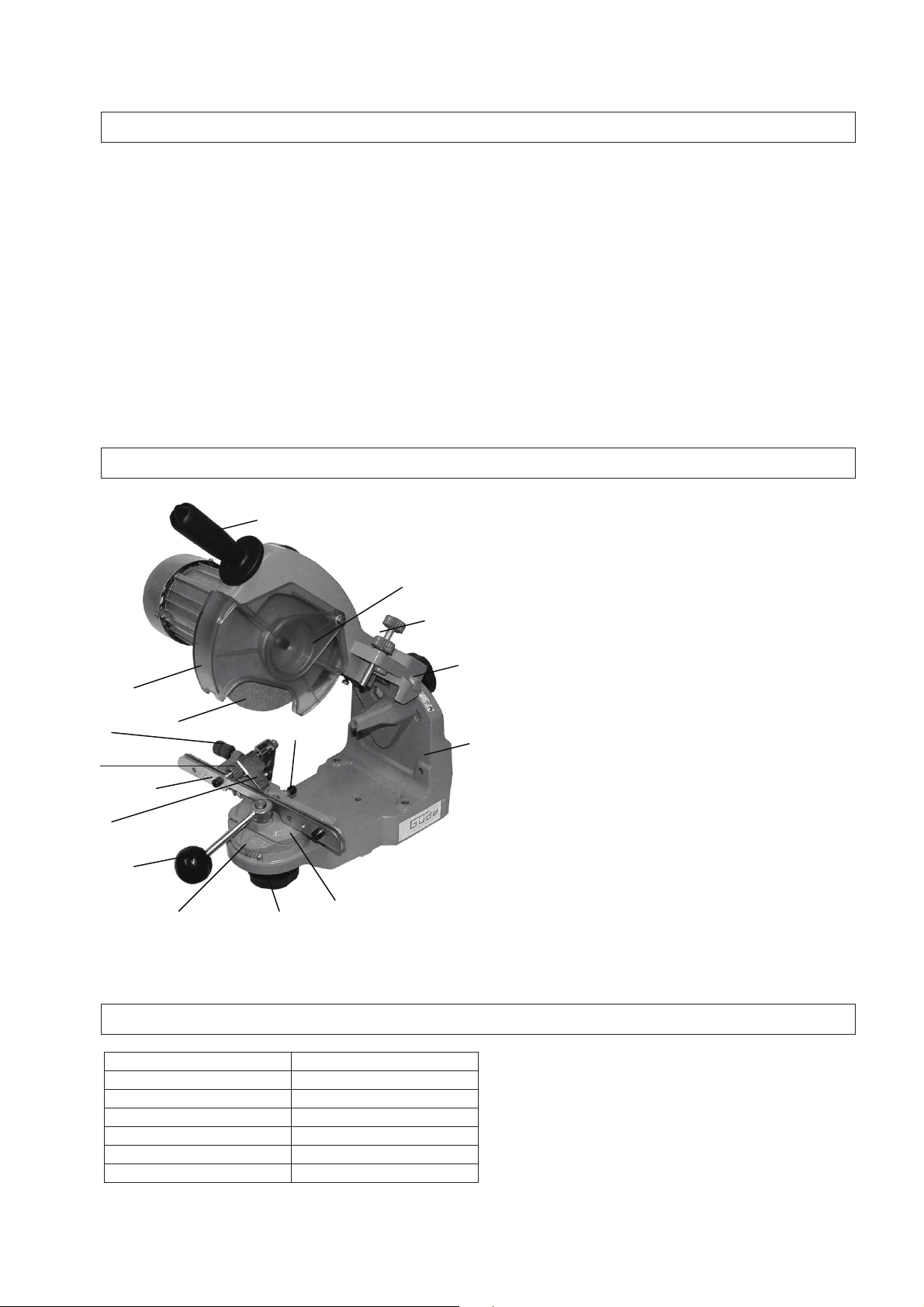

1. Parts Description

2. Technical Data

Profi 2500

Supply voltage:

230 Volt/50 Hz

Motor input power:

P1 230 Watt

Maximum speed:

3400 rpm

Noise level:

< 70 dB (A)

Weight:

ca. 5,8 kg

Product No.: 94131

1

2

3

4

5

16

15

10

8

6

7

9

12

13

14

11

1. handpiece

2. grinding disk lateral guard

3. depth of grind set screw

4. cutting edge angle set-up wheel

5. base

6. screw clamp cradle

7. cutting angle setting wheel

8. scale

9. clamping lever

10. mean distance set screw

11. guide flap valve

12. screw clamp

13. guide position set screw

14. setting screw

15. grinding disk

16. grinding disk protective enclosure

Page 3

GB

3

3. General Safety Precautions

Read the instruction manual carefully before the first use of the machine. If any doubt regarding the

connection and operation of the machine arises, seek the manufacturer’s assistance (servicing department)

Protect the machine from moisture, rain and dust.

FOR US TO SECURE THE HIGHEST DEGREE OF SAFETY, CONFORM TO THE FOLLOWING

INSTRUCTIONS:

- Use the machine only for the scope of work it has been designed for !

- When using the saw-chain grinder outdoor, you should always use a weather resistant extension cable

to connect it of a minimum diameter of 1.5 mm2 with the splash-proof plug and socket.

- The noise level in the working area is above 85 dB (A). Therefore, wear ear protection – hearing loss is

imminent!

- To protect your health at a grinding job, always use a dust protection mask and protective goggles!

- Always unplug the machine before any work on the machine (cleaning, grinding disk replacement etc.)

- Take care to have the saw-chain to be ground secured as appropriate for it not to slip out.

- It is your own interest to keep your machine clean at any time and after you finish a grinding job, check

the machine for damage.

- Always keep your saw-chain grinding machine clean. .

- Do not use any caustic to clean the plastic parts.

- Do not use the machine and do not work on it in proximity of inflammable liquids and vapours thereof. .

- Unplug the machine any time you replace a part or clean the machine.

- Protect the power cable from any damage the cable may be damaged by oil or acid.

- Important notice! Observe any national safety regulations regarding installation, operation and

maintenance .

- Upon having completed the job, unplug the saw-chain grinding machine from the mains.

- Protect your yes and colleagues from jumping particle and chips.

- Working gloves will protect your fingers and skin from cutting injuries.

- Always carry the power cable to the machine from behind.

- Store the machine in a place inaccessible to children.

- Always hold the machine with both the hands when working and mind safe footing and posture.

CAUTION!

Abide by the essential safety measures of protection from electric shock, accident and fire prevention.

Read all these instructions before you get down to the use of the electric machine and follow them. Keep

the safety instructions at a safe place for future reference .

Safe Work

- Keep your workplace tidy.

A messy work place may cause an accident.

- Always make allowances for the environmental effects. Do not expose the electric tools to rain. Do not

use them in moist or wet areas. Take care of sufficient lighting. Do not use them in proximity of

flammable liquids or gases.

- Get protected from electrical shock. Avoid any bodily contact with grounded objects (such as pipes,

radiators, stoves and refrigerators).

- Prevent the children from access.

Do not let other person to touch the machine or the cable. Prevent any unauthorised persons from

access to the working area.

- Store the machine at a safe place. When off the use, the machine should be kept at a dry, elevated

locked place out of the reach of children.

- Do not overload the machine.

Work better and in a safer manner within the scope of capacity as given.

- Use the correct machine. Do not use a machine of lower capacity for heavy jobs. Do not use the

machine for any purpose it has not been intended for. Only use the machine for the purposes

described in the instruction manual!

Page 4

GB

4

- Wear proper working clothing!

Do not wear any wide garments and jewellery that might be caught by the moving machine parts. For

working outdoors, rubber gloves and non-skid shoes are recommended. If your hair id long, wear a

hairnet. Use protective goggles.

- Wear a breathing mask when engaged in a dust-producing job.

- Do not use the cable for any purpose it has not been designated for.

Do not use the cable for carrying or hanging of the machine. Do not use the cable to pull out the plug

from the socket. Protect the cable from excessive temperatures, oil, and sharp edges.

- Avoid any abnormal posture. Mind safe footing and keep balance at any time

- Take due care of your machine.

Abide by the maintenance and grinding disk replacement regulations.

Check the machine cable regularly and when it is found to be damaged, have it replaced by a skilled

electrician. Check the extension cables regularly and replace them if damaged.

Keep the handle dry, free of any dir, oil and grease.

- Unplug the machine, if it is out of use, prior to the maintenance and tools replacement, e.g. grinding

disk.

- Remove any spanners from the machine.

Before switching on, check to see that any wrenches and adjustment tools were removed.

- Avoid an unintended switching.

Use only permitted and properly marked extension cables for working outdoors.

- Be attentive. Mind what you are doing. Get down to a job only when feeling good. Never use the

machine when distracted.

- Check the machine for possible damages.

- Before using the machine, you should check any protection devices and any parts showing slight

damage to see that the function intended is perfect. Check to see that the moving parts move freely,

do not drag and are not damaged. Any parts should be installed properly to comply with the conditions

of the machine safe operation. Damage protection devices and parts should be repaired in a

recognised professional workshop and replace unless the instructions for use specify otherwise.

Damaged switched should be replaced by the customer service workshop. Do not use a machine

with a defective ON/OFF switch.

CAUTION!

Always connect the machine via fault current circuit breaker (FI). This machine is in compliance

with any respective safety provisions. Any repairs shall be done by professionally qualified

persons and only genuine spare parts should be used. The provision not being observed, the

operator is in a risk of injury.

Page 5

GB

5

3. Assembly

The saw-chain grinding machine is delivered pre-assembled.

One part consists of the base, on which the chain guide is

located. The other part is a bearing arm with the motor and

handgrip.

The assembly shall be performed with the machine

unplugged!

The machine design provides either for a desk installation or wall

mounting. When installing it on the desk, put the machine on the

edge of the desk to the stop (Fig. 1) and screw it to the desk

using the holes in the base.

When mounting on the wall, use the respective holes in the

vertical part of the base (here, a distance from the wall should be

kept or spacers should be used for the access to the rear set

screw to be preserved).

After the desk top installation, fit the arm in the base inserting the

pilot pin and securing it with a hexagonal screw (Fig.2)

Now, it is possible to fit a washer on the rear side screw and

screw the setting and screw the setting wheel on. (Fig. 3).

Screw the supporting arm control holder on the screw in the

grinding disk body (Fig.4)

Fit the grinding disk enclosure on using the supplied screws and

a respective wrench (Fig. 5).

Tip:

When mounting on the wall, take care to mount the machine

at a height of 120 – 130 cm from the floor to avoid working

at eye height!

To be able to install the disk, it is necessary to unscrew the

auxiliary flange (Fig. 6).

1

2

3

4

5 6

Page 6

GB

6

4. Grinding Disk Check

5. Grinding Disk Assembly

The grinding disk on the hub torque is 7 Nm. Where practicable, use a torque spanner. Now, the grinding

disk additional guard should be fitted on (Fig. 8).

Check the correct bottoming of the disk: in should not move across and lengthwise. Now, with the grinding

disk properly installed, a trial may be performed. Stand by the machine from the side and watch out for

anybody dwelling in the working area.

If the grinding disk is vibrating or shows otherwise incorrect run, promptly switch off and unplug the

machine before you attempt clearing the fault.

The machine has a zero voltage circuit breaker, which is disabled on outage and will prevent any restarting

of the machine after the power supply is restored.

Using the sharpening stone and a clamping plate, it is possible to sharpen the disk to obtain the required

profile. In this case, be careful at work.

To avoid injuries and accidents only fitting grinding disks free of any defects should be used.

Check the disk you are about to fit in for damages prior to the assembly.

It may be done by a simple sound test: Hold the disk so that a pencil may be put in the hole and the disk

may swing freely. (Fig. P).

Now, knock the disk edge with another pencil carefully.

The disk should give a clear high pitch sound!

If the disk sound damped or blank, it is defective.

It should not be used!

A deep or damped sound indicates damage by cracks

Or similar. !

Do not fit the disk on the hub by force.

The central bore diameter should not be changed.

Only use matching disks .

The smallest grinding disk diameter should not be below

100 mm!

Any adjusting works should not be done unless the machine

is switched off and unplugged.

No damaged disks should be used!

7 8

P

After you have removed the

ancillary flange, you can insert the

grinding disk in the body from

below. See that the ancillary

flange and the disk abut against

each other precisely.

(Fig. 7).

Do not tighten the screws too

much to avoid any damage to the

disk.

Page 7

GB

7

6. Clamping Screw Set Up

7. Grinding

Before the start of grinding, the chain should be

conducted between both the attachment guides

Now, the tooth to be sharpened first should be

taken against the stop. Watch out for the

sharpening angle to correspond to the guides

position. The type of the chain to be sharpened

should be determined using the sharpening

block provided or the table p.9. There, you can

find out the cutting thickness, angles and

dimensions.

Set the guides to the chain width using the set

screw u(A) so that it is firmly fixed in the

clamping screw by clamping lever control (B).

Set the feed by set screw (E).

On severely worn chains, the lateral position of

the chain guide should be secured with a set

screw (D).

Set the top plate angle by means of the set

screw (p.3, p. 5) and it may be also read on the

scale (F). The vice angle should be set up by set

screw (G).

G

B

A

D

E

F

Vrcholový !ezný úhel

(Top Plate Angle)

Úhel ost!í

(Vice Angle)

With the clamping screw adjusted and the vice

angle set up (Notice: RH and LH teeth to be

differentiated) and preset the top plate angle, lead

the grinding disk down to the tooth by soft pushing

the supporting strut. The grind depth may be set

by set screw (K).

With clamping lever loosen (B), the set screw is

being screwed or unscrewed (E) until the grinding

disk to sharpen will touch the tooth. During the

procedure, pull the chain to the guide (L) carefully.

(Notice. Wear gloves when performing the job!)

K

L

Page 8

GB

8

8. Grinding Depth Delimiter

Some types of saw-chains require that the clamping screw be tilted by 5° - 10° (cf. Table: space Tilt

angle).

Note the notches (Fig.9).

Now, the machine may be switched on and the saw-chain grinding may be started by a careful thrust

on the grinding disk. Adjust the pressure as necessary. Mark the start of grinding e.g. with a piece of

chalk and grind all the teeth in one direction, then turn the clamping screw (mind the angle) and grind

the teeth in opposite direction.

With warn chains, the lateral guide position (Fig.10, position M) shall be set for the grinding disk not

to touch the guide.

Avoid any strong thrust as the teeth might collide and the chain would wear and tear too fast.

Notice : Never grind any driven parts.

obr.9

M

10

Find out in Table (p.9) what is the size of the

depth delimiter back grinding.

Grinding the depth delimiter, the screw clamp

position shall always be 0°.

Set the supporting strut and holder at 90° (Fig.

F).

The grind depth may be set using set screw K.

Page 9

GB

9

10. Dimensions

Page 10

GB

10

9. Assembly Drawing

Page 11

GB

11

10. List of Spare Parts

Spare Part No. Spare Part No.

Produc

t No.

Versi

on

Positi

on

Description

Produc

t No.

Versi

on

Position

Description

94131 01 001 Swing arm 94131 01 048 screw

94131 01 002 Grinding disk enclosure body 94131 01 049 screw

94131 01 003 Lateral guard 94131 01 050 bolt

94131 01 004 Switch enclosure 94131 01 051 screw

94131 01 005 enclosure 94131 01 052 screw

94131 01 006 limiter 94131 01 053 nut

94131 01 007 grinding disk 94131 01 054 nut

94131 01 008 flange 94131 01 055 washer

94131 01 009 flange 94131 01 056 washer

94131 01 010 set screw 94131 01 057 Wide washer

94131 01 011 Counter-nut 94131 01 058 Plastic ring

94131 01 012 Plastic ring 94131 01 059 cone

94131 01 013 holder 94131 01 060 Pull-off stone

94131 01 014 coupling 94131 01 061 Sharpening block

94131 01 015 switch 94131 01 062 wrench

94131 01 016 motor 94131 01 063 wrench

94131 01 017 joint 94131 01 064 lamp 230V E14 15W

94131 01 018 axis 94131 01 065 condenser

94131 01 019 Clamping wheel 94131 01 066 cable

94131 01 020 spring 94131 01 067 Column action protection

94131 01 021 case

94131 01 022 Base plate

94131 01 023 Swing support

94131 01 024 Clamping rod

94131 01 025 set screw

94131 01 026 Wide washer

94131 01 027 spring

94131 01 028 Small thrust spring

94131 01 029 Axial bolt

94131 01 030 Clamping lever rod

94131 01 031 Ball holder

94131 01 032 Chain support

94131 01 033 Case

94131 01 034 Connecting catch driver

94131 01 035 chain drive

94131 01 036 Counter nut

94131 01 037 Limiting spring

94131 01 038 spring

94131 01 039 Threaded pin

94131 01 040 case

94131 01 041 Plastic ring

94131 01 042 Hand wheel

94131 01 043 scale

94131 01 044 scale

94131 01 045 scale

94131 01 046 screw

94131 01 047 screw

Page 12

GB

12

EG-Konformitätserklärung

EC Declaration of Conformity

Hiermit erklären wir, Güde GmbH & Co. KG

We herewith declare, Birkichstraße 6, 74549 Wolpertshausen, Germany

Dass die nachfolgend bezeichneten Geräte aufgrund ihrer Konzipierung und Bauart

sowie in der von uns in Verkehr gebrachten Ausführungen den einschlägigen,

grundlegenden Sicherheits- und Gesundheitsanforderungen der EG-Richtlinien

entsprechen.

That the following Appliance complies with the appropriate basic safety and health requirements

of the EC Directive based on its design and type, as brought into circulation by us.

Bei einer nicht mit uns abgestimmten Änderung der Geräte verliert diese

Erklärung ihre Gültigkeit.

In a case of alternation of the machine, not agreed upon by us, this declaration will loose its

validity.

Bezeichnung der Geräte: - Profi 2500

Machine desciption:

Artikel-Nr.: - 94131

Article-No.:

Einschlägige EG-Richtlinien: - EG-Maschinenrichtlinie 98/37/EG

Applicable EC Directives: - EG-Niederspannungsrichtlinie 73/23/EWG

- EG-Richtlinie Elektromagnetische

Verträglichkeit 89/336/EWG mit Änderungen

-

Angewandte harmonisierte

Normen: - EN 61029-2-4/A1:2003

Applicable harmonized - EN 55014-1/A2:2002

Standard: - EN 55014-2/A1:2001

- EN 61000-3-2:2000

- EN 61000-3-3/A1:2001

Datum/Herstellerunterschrift: 23.07.2007

Date/Authorized Signature:

Angaben zum Unterzeichner: Mr. Arnold, executive officer

Title of Signatory:

Loading...

Loading...