Page 1

DHH 1050/11 T ECO

English

# 02012

© Copyright Güde GmbH & Co. KG - Birkichstrasse 6 - 74549 Wolpertshausen - Germany

Page 2

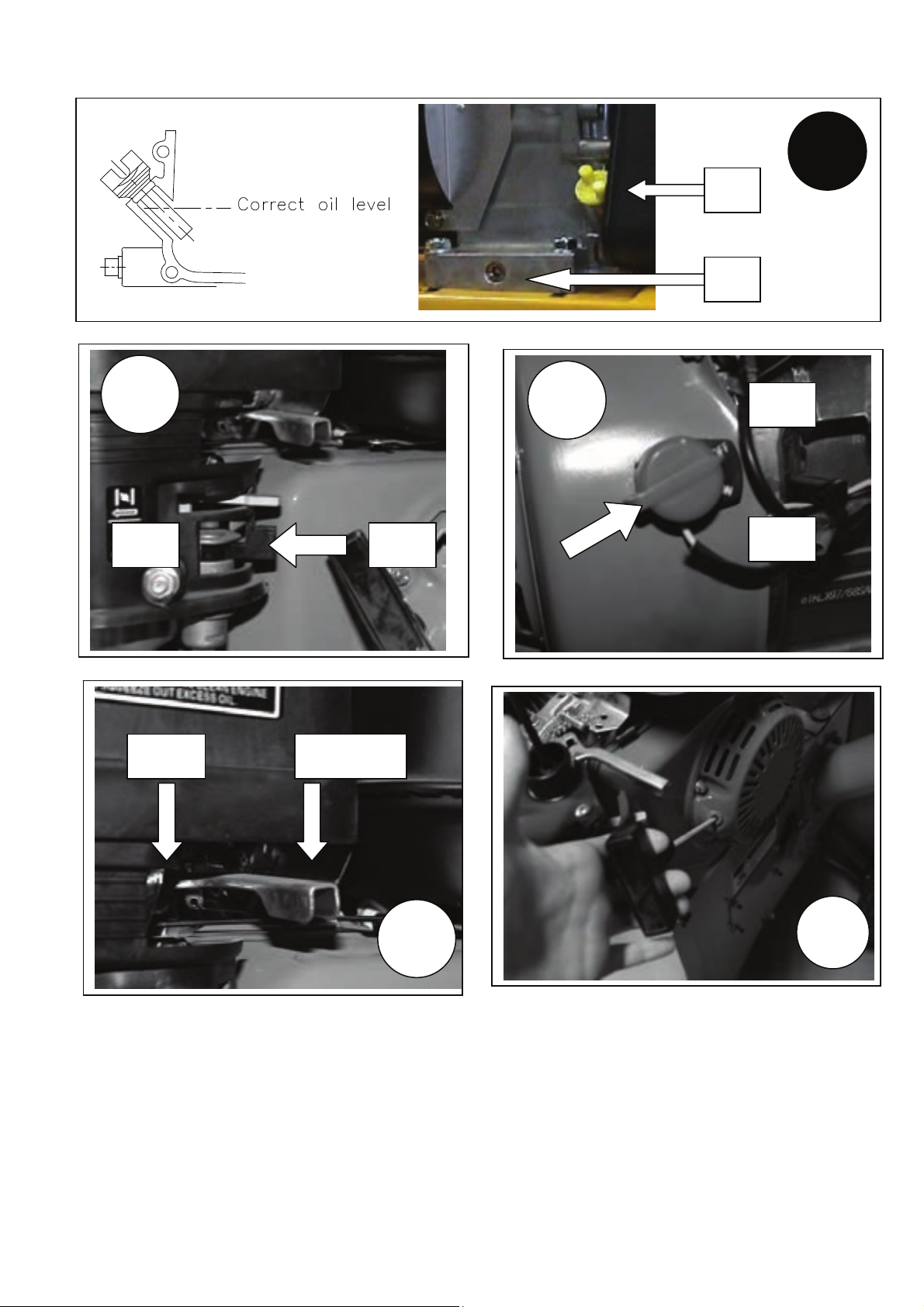

1a

1b

1

2

ON OFF

RUN CHOKE

3

OFF

ON

4

5

Page 3

6

8

7

10

12

7a

9

7

5

6

4

11

1

3

2

9

8

Page 4

GB

Thank you for purchasing the Güde wood splitter and enjoying confidence in our products.

!!! Please read carefully the Operating Instructions before putting the appliance into operation!!!

A.V. 2 Any reprints, even partial, are subject to approval. Technical changes reserved.

Pictures just an illustration

Appliance

Robust wood splitter, special-steel splitting knife, all steel parts with high-quality powder painting including high-quality

hydraulic pump.

The supply includes:

splitting table with 3 setting options,

two-hand operation with safety handles, optional splitting lift setting, big wheels including two-hand mobile handle,

four-sided post sliding

Motor 4-Takt Power- Engine,

4,1 KW/5,6 PS

The appliance is designated exclusively for work with firewood.

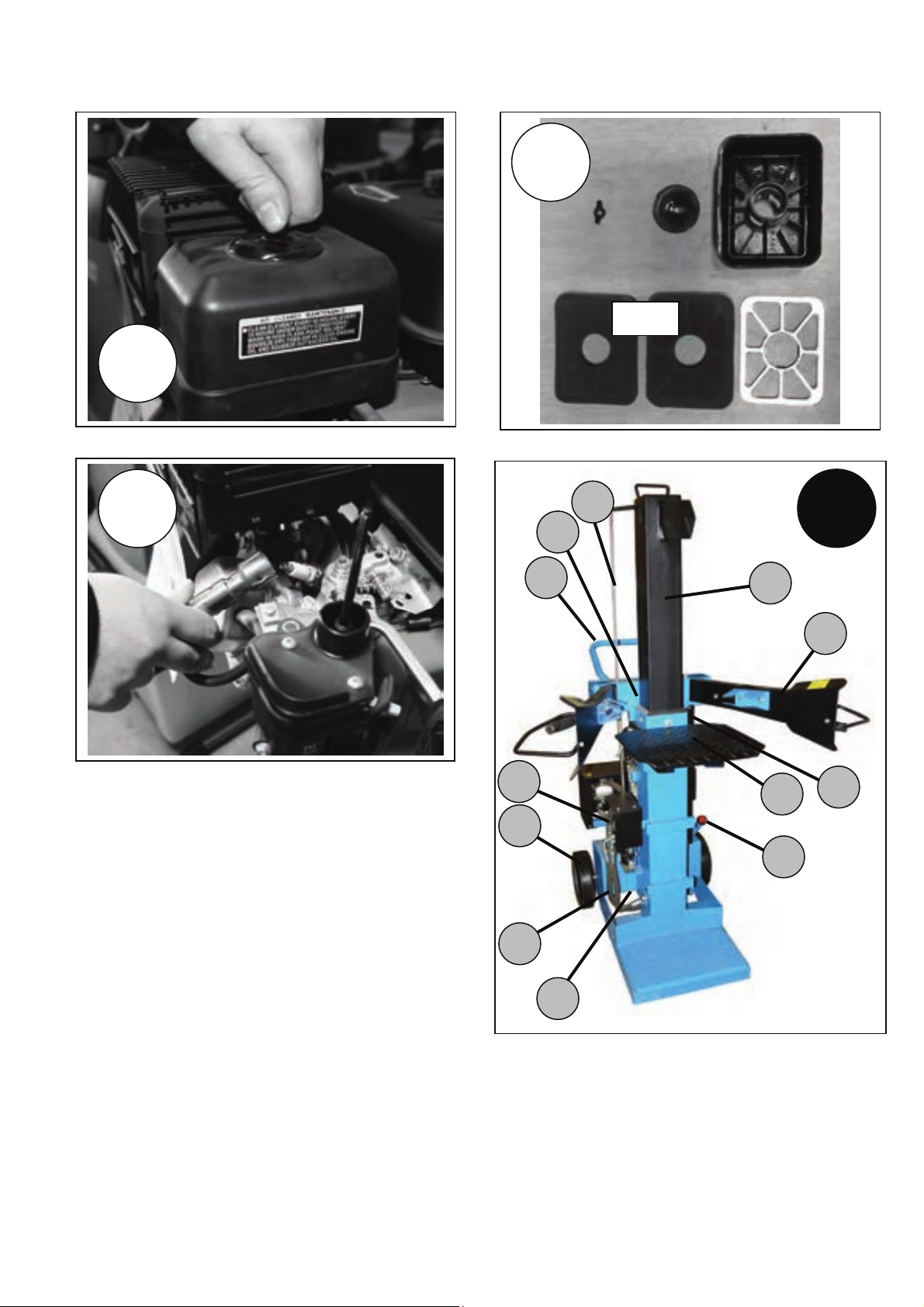

Appliance description (pic. 9)

1. splitting post

2. operating arms

3. splitting table

4. transport handle

5. transport wheels

6. hydraulic hose

7. hydraulic valve

8. hydraulic oil gauge

9. combustion engine

10. operating bracket

11. hydraulic oil drain screw

12. trigger rod

Guarantee

Guarantee claims as per the guarantee card attached.

General safety instructions

You must carefully and thoroughly read the Operating Instructions before using the appliance for the first time. If you have any doubts

concerning the appliance connection and operation, please contact the producer (service department).

Protect the appliance against moisture, rain and dust.

TO ENSURE A HIGH SAFETY LEVEL, FOLLOW CAREFULLY THESE INSTRUCTIONS:

ATTENTION!

1. Follow the producer's instructions.

2. The appliance must not be exposed to climatic influences, rain and snow.

3. Prevent children or any unauthorised persons from using the appliance.

4. Do not leave the appliance unattended when running as it could represent a threat.

5. Make sure other people are in a reasonable distance from the appliance.

6. Your workplace should be flat, stable and provide sufficient free movement.

7. To bring and take the appliance away, items you could tumble over must be removed from the path.

8. Make sure the workplace is lit sufficiently.

9. The appliance is designated exclusively to be used just by one person. Machine operation by two or more persons

strictly prohibited.

10. Refuel the appliance only when the engine has cooled down.

11. Wear close-fitting clothes. Take away all jewellery, rings and wristwatch.

12. Wear protective glasses when working.

Page 5

13. Wear working gloves when working.

14. Wear safety boots when working.

15. Appliance alteration, adjustment, cleaning and maintenance and failure recovery can only be executed when the engine

is switched off.

16. Keep the place where the appliance is operated clean, with no wood, waste wood and bark.

Behaviour in case of emergency

Provide first aid appropriate to the injury and call qualified medical help as soon as possible.

Keep the injured person from other injuries and rest him/her.

Precautionary Instructions and Accident Prevention

General

For safety reasons, precautionary instructions contained in this manual and instructions on the machine

regarding operation, maintenance and repairs should be respected and observed.

Operators

Any use of the cleaving machine may entail hazards. Therefore, only well-instructed and experienced

persons should be allowed to handle the machine and to work on it. Operators should be required to

wear tight-fitting clothes and protective shoes. No persons bellow 18 years of age should be allowed to

work with the machine. It is permitted however, to have people above 16 yrs of age working with the

machine provided that it is necessary for educational reasons and professional supervision is

guaranteed.

Working Area

It is an imperative for a safe cleaving job that the floor in the working area is flat and firm-based and sufficient

freedom of movement is secured. Ways for bringing and removing the machine in/from the area should be free of

any disturbances. Sufficient lighting should be provided in the working area.

Job Preparation

When doing repairs or maintenance or when leaving the cleaning machine unattended, the current supply should

be cut off by pushing the red button on the switch and unplugging the machine. It is not sufficient to cut the

power supply off by mere switching off. GÜDE cleaving machines are always delivered with hardened

cleaving knives. However, light deformation of the cleaving knife cutting edge may arise in result of cleaving

wood with unexpected foreign bodies in it – concrete, steel etc.- and whetting or filing must remove it. The knives

sharpness maintenance will increase working capacity.

TIP: Grease the cleaving knives every now and then (for problem wood).

Safety devices (primarily two-lever control) must be checked on prior to being put in operation for

the first time and the function must be examined.

Warning! Make sure that cleaving bench us safely fitted to the machine prior to any starting the

operation.

• Keep the place of your work clean at all times and remove any wood remains fallen down.

• Keep in mind that wood is a natural raw material and may get out of control when being split

(unexpectedly thrown-off wood pieces)

• Safety shoes should always be worn.

• Keep your hands outside the wood face or splitting knife entry at all times.

• Faces of the split wood must be rectangular if possible so that wood stays safely on the supporting

table and cannot slip to the side.

• Safety equipment of the appliance must not be disassembled or put out of operation.

• Remove wood, wood waste and bark from the place of appliance operation.

• Check the feeder cables. Do not use feeder cables that are faulty.

• Check whether the two-handed operation works properly before putting the appliance into ope ration.

• Wear closefitting clothes. Remove jewels, rings and wristwatch.

• Wear protective clothes.

• Attention during work: Risk of injury to fingers and hands caused by the splitter.

• All the protective equipment and covers must be fitted to the appliance and function faultlessly

when working with the appliance.

Page 6

• Use an appropriate supporting tool for splitting heavy or big pieces.

• Tool change, adjustment, cleaning, maintenance and fault removal must only be performed when the

engine is switched off. Pull the plug out of socket!

• All protective and safe equipment must be refitted immediately after repair and maintenance are

finished.

• Put the splitter on a flat and nonslip operating surface before using it. Ensure sufficient free movement.

• Never use the wood splitter when raining.

• Line voltage must correspond to the details on the appliance type label.

• Unwind the cable to the full extent when a cable drum is used to prevent it from heating.

• The socket must be fitted with a safety switch against stray current when working outdoors.

• The processed piece of wood must always be put on the appliance surface in a stable position to

prevent it from moving.

• Do not split soaked wood.

• Only one piece of wood should always be split.

• Do not split wood containing foreign items.

Marking on the appliance

Symbol explanation

The following symbols are used in these Instructions and/or on the appliance:

Product safety:

Product corresponds to

appropriate European

Community standards

Prohibitions:

General prohibition (in

connection with

another icon)

Do not touch inside the

appliance

No cable pulling

Warning:

Warning/Attention

Warning against

dangerous voltage

Warning against hand

injury / contusion

Warning against hot

surfaces

Warning against

dangerous voltage

Appliance can only be

used outside enclosed

spaces

Keep safe distance

Commands:

Use vision protection

aids

Use head protection

aids

Use hearing protection

aids

Use safety shoes with

safety steel toe

Use protective gloves

Unplug the appliance

before opening it

Read the Operating

Instructions before use

Page 7

Environment protection:

Dispose waste

professionally so as not

to harm the

environment

Packing cardboard

material may be

delivered to collecting

centres for recycling.

Any damaged and

disposed electric or

electronic appliances

must be delivered to

appropriate collecting

centres.

Package:

Protect against

moisture

This side up Fragile

Use as designed

The wood splitter has exclusively been designed for splitting of firewood pieces already cut by a saw, with a

maximum length of 1,430 mm (without the splitting cross).

The appliance must not be used to any other works than those for which it has been designed and that are

described in the Operating Instructions.

Should any provision of the generally valid regulations and provision contained in these Operating

Instructions be breached, the producer cannot be held liable for any damage. Never split any wood laid

down or over the fibre

.

Residual risks and protective measures

Warning!!!

Taking out of service, changing, blocking, disassembling, altering or adding any parts of safety and

protective devices strictly prohibited. Failing to comply with this condition can lead to injuries

dangerous to life.

The producer cannot be held liable for any material damage or injuries of persons caused by

negligence.

Any guarantee claim towards the producer expires with the negligence described above.

Mechanical residual risks

Threat Description Protective measures Residual risk

Contusion Parts of body can be contused

or amputated due to hydraulic

knife starting when splitting.

Risk of split material getting

stuck. When releasing the wood

please be aware the wood is

exposed to big stress and your

fingers can get squeezed in the

slot created by wood cracking.

Cut Parts of body can be contused

or amputated due to hydraulic

knife starting when splitting.

General injury Fierce splitting can lead to

serious injury when processing

dry wood.

Always use the two-hand safety

control. Do not interfere in the

splitting process.

Never work in two on the

machine.

Jammed wood needs to be

knocked out. At doing so, make

sure the falling piece of wood

does not injure your legs.

Always use the two-hand safety

control. Do not interfere in the

splitting process.

Never interfere in the splitting

process.

Always keep a sufficient safety

distance from the splitter.

Always operate the machine

with care and deliberately.

Any worn-out or damaged aid

must immediately be replaced.

Look out for bystanders!

Always wear safety boots when

working.

Any worn-out or damaged aid

must immediately be replaced.

Any worn-out or damaged aid

must immediately be replaced.

Always look out for bystanders.

Page 8

Wood chips created during the

splitting proceed can fall down

and injure especially legs of the

operator.

Getting caught, winding up Loose clothes, jewellery or long

Threat by noise

Threat Description Protective measures Residual risk

Hearing damage Longer working with the

Negligence of ergonomic principles

Threat Description Protective measures Residual risk

Negligent use of personal

protective equipment

Inadequate local lighting Insufficient lighting represents a

Other risks

Threat Description Protective measures Residual risk

Thrown-away items or liquids Small mechanical parts can

hair can get caught in mobile

parts of the appliance.

appliance can lead to hearing

damage.

Operating the appliance without

corresponding protective

equipment can lead to serious

internal and external injuries.

high safety risk.

injure your eyes when splitting.

Always wear specified

protective clothes and work

cautiously.

Always wear protective glasses

when working with the

appliance.

Always wear specified

protective clothes and work

cautiously.

Always wear safety boots

suitable to the specified

protective clothes.

Always wear close-fitting

clothes and remove jewellery

before work. Protect your hair

with a hairnet.

Always use hearing protection

aids.

Always wear specified

protective clothes and work with

care.

Always ensure sufficient lighting

when working with the

appliance.

Always wear protective glasses

when working with the machine.

Disposal

The disposal instructions are based on icons on the appliance or its package. The descriptio n of all

meanings can be found in the “Marking on appliance“ chapter.

Handling requirements

The operating staff should carefully read these Operating Instructions before using the appliance.

Qualification

Apart from the detailed instruction by a professional, no special qualification is necessary for using the

appliance.

Minimum age

The appliance can only be operated by persons older than 18 years of age.

An exception includes youngsters if they work within their professional education the purpose of which is to

obtain knowledge supervised by a trainer.

Training

Corresponding training is only necessary for using the appliance. No special training necessary.

Page 9

Transport and storage

Wood splitters are fitted with big wheels. Grab the handle on the splitting post with both hands and slightly

tilt the splitter back when transporting the machine. To make tilting easier, stand on the curved caliper

under the engine.

To prevent hydraulic oil leak, never transport the splitter laid down.

Always move the splitting knife absolutely down

during transportation.

Technical data

Maximum output: 4,1 kW/5,6 PS

Capacity: 206 ccm

Engine design: Power- Engine 4-Takt OHV

Fuel / tank capacity: unleaded/4 l

Consumption: 0.75 l an hour

Starting system: reversing starter

Maximum hydraulic pressure: 240 bar

Splitting post: 100 x 100 mm

Max. splitting pressure: 11 t

Max. splitting lift: 520 mm

Max. length of split material: 1,430 mm (without splitting cross)

Max. length of split material: 1,170 mm (with splitting cross)

Table size: app. 385 x 320 mm

LWA noise: 95 dB(A)

Weight app. 192 kg

Dimensions L x W x H in mm: 1,240 x 582 x 1,284

EAN: 4015671 22045 5

Article number: 02012

Assembly and first starting up

Operating arms

10

2. Insert the operating arm and take the tube to the cross joint hole (pic. 11)

Left operating arm is marked by letter “L“ and right one by “R“!!!

1. Unscrew the operating arm bracket (pic. 10)

11

Fetten

11a

Page 10

Tip: Lubricate sheet foots up and down first!

3. Now put screws through the bracket and operating arm from

above (pic. 12)

4. Secure the screw with a lock nut. (pic. 13)

5. Now you can tighten the operating arm.

14

13

15

Now insert the safety pins included in the supply to the back of the bracket with operating arm as illustrated

in (pic. 15).

Finally you need to screw down the bracket cover! (pic. 16)

16

Splitting wedge extension

ATTENTION!!!

Before you start working with the splitting

wedge extension you need to disassemble the

short wood table.

Fix the splitting knife extension by tightening the

screw manually at first. Then tighten it with a

socket-screw key.

Page 11

Engine monitoring (pic. 1)

The engine oil quality is decisive for correct output of the driving unit and operation life. Use only suitable

and high-quality lubricants; unsuitable lubricants cause damage to the appliance and lead to immediate

warranty expiry (SAE 10 W 40 specification multi-purpose semi-synthetic lubricant recommended). There

might be no engine oil or just a small amount of it (filling for factory test) when dispatching the appliance.

Oil level must necessarily be checked

before the appliance is put into operation!

The appliance should always be put to a flat surface when inspecting the oil level. Always consider the

environment when filling and emptying the engine oil and fuel: use appropriate filling and emptying tools.

Prevent uncontrolled fuel or oil leak in any case!

Screw the oil dipstick (pic. 1a) out or pull it out.

Add oil up to the "Correct oil level" marking (pic.1) and check the correct level (engine oil level must touch

the final oil filling neck thread). Make sure not to overfill the appliance when standing on an uneven surface!

Screw, or push, the oil dipstick again.

If you want to empty the engine oil (oil change, maintenance, etc.), pull the oil dipstick out (pic. 1a) and

screw the oil drainage screw out (pic. 1b). Keep the oil dipstick, oil filling hole, oil drainage hole and oil

drainage screw clean at all times! Use appropriate containers and prevent environment pollution by

lubricants and fuels.

Fill with fuel / air filter check:

Refuelling

The engine is maintenance-free and common unleaded Normal and Super petrol is adde d in it. If

environment-friendly unleaded petrol is used, fuel must be completely drained at engines put out of

operation for more than 30 days to prevent resinous deposits in the carburettor, fuel filter and tank or fuel

stabilizer mixed to the fuel.

Do not add oil to petrol

Refuelling is done by removing the tank lid (pic. 1; pos. 9) and adding the fuel up to the fuel screen marking

as maximum (the fuel screen is located in the tank filling hole). Prevent fuel from contacting your skin!

Make sure fuel is always clean with no dirt! Close the tank lid appropriately after each refuelling or

inspection.

Take the appliance to the surface you want to sweep.

Check all components if tightened well and not damaged.

Check the entire air filter for any dirt. Pic.15 shows air filter components from the engine with the air filter lid

being unscrewed (pic. 14). All air filter components, especially the air filter insert (pic. 15a) must be clean –

cleaning agent: cleaning petrol (adhere to the safety sheet of the given manufacturer!).

Open the fuel tap (pic. 8; pos. “ON“). Check if the socket plug is tightened.

Hydraulic oil check

With the splitting column inserted, use the oil gauge (pic. 9; pos. 8) to check whether the filler volume is

appropriate. The hydraulic oil level must always be between both markings on the oil gauge. If necessary,

add commercially available hydraulic oil, e.g. HLP46 or any other one with the same viscosity.

Page 12

Handling

Lift setting

The working output can be increased by reducing the

splitting knife reverse running for pieces of wood smaller

than app. 50 cm and when more wood needs to be split.

Proceed as follows:

Put a short piece of wood on the splitting table, move the

splitting knife approximately 2 cm above the wood and

switch the knife off (press the red button on the switch and

pull the plug out of socket). Using a side rod, you can now

shorten the reverse running by fixing the rod in the desired

height by adjusting screw.

Safety instructions for first starting up

Check the functionality of safety devices (especially the two-lever control) before starting your work.

Safety instructions for handling

• Use the machine only after you have carefully read the Operating Instructions.

• Follow the safety instructions specified in the manual.

• Behave responsible towards other persons.

• Wood can only be split along the fibre.

• Risk of getting jammed when splitting knotty wood.

Jammed pieces of wood to be released by knocking on them.

Cutting out these pieces prohibited!

• Risk of split wood getting jammed. When releasing please be aware the wood is heavily stressed

and your fingers can get squeezed in the split slot.

• The machine has been designed to be operated by one person only; operation by two or more

Make sure the splitting table is always secured properly. A falling splitting table or falling piece of

wood can injure your legs.

persons strictly prohibited.

Caution: Hard wood can strongly hit y ou when splitting.

Working without the splitting cross is recommended for long pieces of hard wood.

Caution: Never use the splitting wedge extension along with the short wood table in

the highest position.

Tip: More problem wood can be split after knife lubricating!

Page 13

Open the fuel tap

Put the engine switch to the “ON“ position (pic. 3)

Make sure the engine is cold when being started.

Turn on the engine choke (pic. 4; pos. “CHOKE“)

Turn the speed control lever (pic. 4; pos. “START“) to full speed.

First, pull shortly the starting cable so that it is stretched. Now pull the starting cable slowly to the stretched

position with your left hand resting on the engine and one more strong pulling the starting cable. Turn the

engine choke off as soon as the engine gets started (pic. 4; pos. “RUN“)

Give full throttle using the speed control lever (pic. 4; pos.”HARE”)

To be provided

The starting cable must not reel automatically. It must always be reeled back by hand. If the engine fails to

start even after several attempts, check whether the tank has been refuelled properly. Maybe there is too

much fuel in the roll, which has caused the spark plug to get damp.

Switching off the engine

Put the speed control level to the idle gas position (pic. 4; pos. Želva).

Use the engine switch (pic. 3; pos. “OFF”) to switch off the engine. Never leave the appliance unattended

when the engine is running. Never switch the engine off when the choke is on as the engine could get

damaged. Close the fuel tap (pic. 2; pos. “OFF“). Pull slowly the starter handle until you feel resistance. By

this, valves get closed.

This step is necessary to prevent moist air from entering the combustion chamber from outside.

1. Put the wood to be split on the table as short or long logs and set the backward movement

accordingly (see Lift setting).

2. Now clasp the split wood with both operating arms (see Stop screw setting) and press them down

at the same time.

3. Remove the split wood from the working area and put another wood on the table.

4. If the splitting knife is greased from time to time, more difficult wood can also be split.

Start the splitter and wait until the splitting column gets to the starting position.

Now press both operating levers to make the splitting column go down. Press just the right or left operating

lever in turn. If the splitting column stands each time, you can use the splitter with no worry.

.

If the splitting column keeps going down, the two-hand operation must be subject to new

calibration.

For that purpose, contact an authorised workshop.

V nebezpečných situacích a při nehodách musíte dát páku pro regulaci otáček co možná nejrychleji

do polohy „STOP“ a motor vypnout spínačem motoru (obr. 3; poz. „OFF“).

Hydraulic

Hydraulic

Hydraulic hoses and joints need to be checked for tightness after app. 4 hours of operation and

tightened if necessary.

Hydraulic oil/tank

Regularly sold hydraulic oil (e.g. HLP 46) or any other product of identical viscosity can be used for all

splitters.

Page 14

Failures - causes - removal

Failure Cause Removal

Splitter without

necessary output

Hydraulic pump

whistling, splitting knife

jiggling

Engine does not start

Engine switches off after

being started

Engine stalls

Engine stalls in high

revolutions

Engine with too low

power

Engine runs too warm

Too little hydraulic oil

Starting rod and lever system bent; hydraulic follower

at the valve not pushed inside to full extent.

Too little hydraulic oil in the tank Hydraulic oil to be filled in

Engine switch not in “I“ position (on)

Fuel tap closed

Choke open

Spark plug not fitted

Spark plug dirty or faulty

Wrong distance of spark plug electrodes

Fuel tank empty

Fuel is old

Air filter dirty

Too big distance of spark plug electrodes

Spark plug dirty or faulty

Loose plug or spark plug cable

Fuel screen dirty

Ventilation in tank cover clogged

Air filter dirty

Old fuel

Too small distance of spark plug electrodes

Air filter dirty

Limited functionality of the cooling system

Too little engine oil

Air filter dirty

Hydraulic oil to be filled in

Rod and lever system to be readjusted,

appropriate nuts to be tightened.

Put the engine switch to “I“

Open the fuel tap

Close the choke lever

Fit the spark plug

Clean or replace the spark plug

Adjust the distance of electrodes to 0.7 – 0.8 mm

Refuel

Drain the old fuel, fill in new one

Clean the air filter

Adjust the distance of electrodes to 0.7 – 0.8 mm

Clean or replace the spark plug

Fit the plug firmly on the plug, fix the cable

Clean the fuel screen

Replace the tank cover

Clean the air filter

Drain the old fuel, fill in new one

Adjust the distance of electrodes to 0.7 – 0.8 mm

Clean the air filter

Clean the air grid and cooling ribs

Add engine oil

Clean the air filter

Safety instructions for inspection and maintenance

Engine must always be switched off and the spark plug disconnected by unplugging during repair or

maintenance works (pic. 8).

If you leave the splitter, the engine must be switched off, too!!!

Inspections and maintenance

Splitters are dispatched on principle with hardened splitting knives. If, however, you detect any slight

deformation of the splitting knife edge after splitting wood with invisible foreign particles (concrete, steel,

etc.), the deformation needs to be removed by grinding off or filing. Continuous keeping the splitting knife

edge sharp increases the working output.

Only an appliance regularly maintained and with a corresponding level of care can be a satisfactory

assistant. Insufficient maintenance and care can lead to unpredictable accidents and injuries.

Page 15

Keep the splitter clean at all times. Use regularly sold hydraulic oil (HLP 46 #

42004 or any other product of identical viscosity) for changing the hydraulic oil.

The oil level in the splitter must always be between min. and max marks. Make

sure the splitter is always in an erected position.

Hydraulic oil change:

Put a suitable container (pic. 8 Art. 11) under the hydraulic

oil drain screw and screw the drain screw out.

Caution! Old oil must be disposed in accordance with valid

regulations.

To that end, please get in touch with old oil disposal centres.

Disposing oil in any other manner strictly prohibited. Such acting would be

subject to prosecution and considerable punishment.

Now screw up the drain screw again. Caution! No impurities can get in any

circumstances in the hydraulic oil tank. Now fill in the hydraulic oil tank and check whether there is a

correct hydraulic oil level in the tank using a gauge. Attention: Always fill the oil only when the splitting

post is inserted

!

Only original spare parts can be used when changing or replacing any construction parts. Regularly check

hydraulic hoses and hose joints for tightness.

Inspection and Maintenance Plan

Time interval: Description Any other

details

Before each use

App. after 4 hours of operation

App. after 500 hours of

operation

Lubricate the splitting post / check the engine oil level

Check hydraulic hoses and joints for tightness; tighten

them if necessary.

Change the hydraulic oil. Clean the oil filter in the tank,

replace if necessary.

Service

Do you have any technical questions? A claim? Do you need spare parts or the Operating

Instructions?

You will be helped quickly and without needless bureaucracy at our webpage www.guede.com in the

Service part. Please help us be able to assist you. To be able to identify your appliance when claimed, we

need to know its serial No., order No. and year of production. All these details can be found on the type

label. Enter the details below for future reference.

Serial No.:

Order No.:

Year of production:

Tel.: +49 (0) 79 04 / 700-360

Fax: +49 (0) 79 04 / 700-51999

E-Mail: support@ts.guede.com

Page 16

EG-Konformitätserklärung

EC Declaration of Conformity

Hiermit erklären wir, Güde GmbH & Co. KG

We herewith declare, Birkichstraße 6, 74549 Wolpertshausen, Germany

Dass die nachfolgend bezeichneten Geräte aufgrund ihrer Konzipierung und Bauart

sowie in der von uns in Verkehr gebrachten Ausführungen den einschlägigen,

grundlegenden Sicherheits- und Gesundheitsanforderungen der EG-Richtlinien

entsprechen.

That the following Appliance complies with the appropriate basic safety and health requirem ents

of the EC Directive based on its design and type, as brought into circulation by us.

Bei einer nicht mit uns abgestimmten Änderung der Geräte verliert diese

Erklärung ihre Gültigkeit.

In a case of alternation of the machine, not agreed upon by us, this declaration will loose its

validity.

Bezeichnung der Geräte: - DHH 1050/11 T ECO

Machine desciption:

Artikel-Nr.: - 02012

Article-No.:

Einschlägige EG-Richtlinien: - 2006/42 EG

Applicable EC Directives: - 2004/108 EG

- 2002/88 EG

Angewandte harmonisierte

Normen: - EN 609-1:1999+A2

Applicable harmonized - EN ISO 14982:2009

Standard:

Datum/Herstellerunterschrift: 06.05.2011

Date/Authorized Signature:

Angaben zum Unterzeichner: Hr. Arnold, Geschäftsführer

Title of Signatory:

Technische Dokumentation: J. Bürkle FBL; QS

Loading...

Loading...