Page 1

DHH 1050 / 10 TP

English – GB

Translation of original operating instructions

WOOD SPLITTER

#02003

© Güde GmbH & Co. KG - Birkichstrasse 6 - D-74549 Wolpertshausen - Deutschland

Page 2

2

1

14

15

11

2

2

4

3

A

12

7

1

9

B

A

10

13

5

6

8

4

A

6

5

8

1

A

7

2

Page 3

9

GB

Please read carefully the following Operating Instructions before putting the appliance into operation

A.V. 2 Any reprints, even partial, are subject to approval. Technical changes reserved.

Illustrative pictures! Translation of original operating instructions.

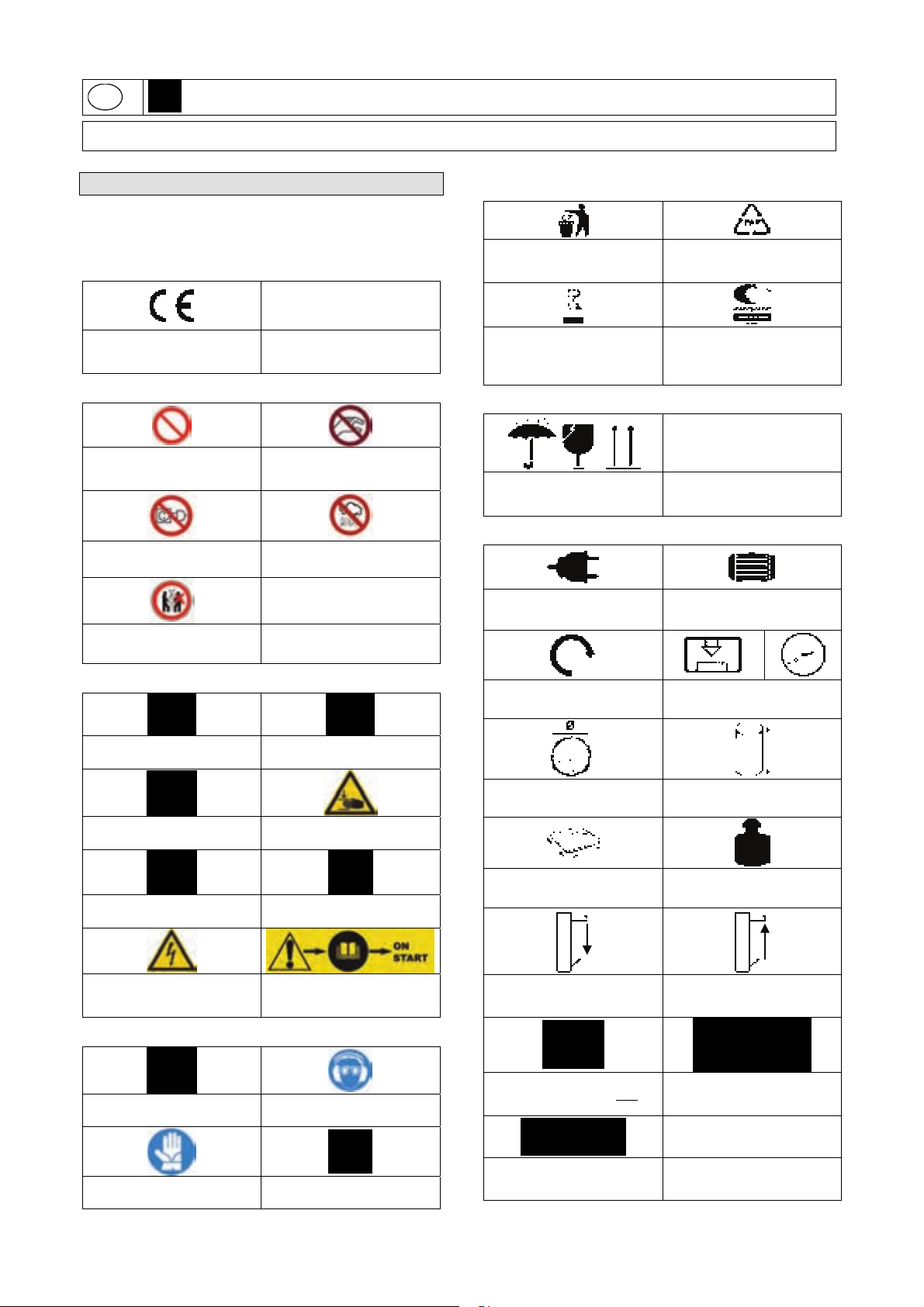

Marking on the appliance

Explanation of symbols

The following symbols are used in these Operating Instructions

and/or on the appliance:

Product safety:

Environment protection:

Dispose waste professionally

so as not to harm the

environment.

Packing cardboard material

may be delivered to collecting

centres for recycling.

Product corresponds to

appropriate standards of the

Prohibitions:

(in connection with another

Pull the plug prohibited Protect from rain and moisture

Machine may only be

operated by one person

Warning:

Keep a sufficient safe

Warning! Flying parts!

EU

General prohibition

Gently stick prohibited

icon)

Warning/attention Warning! Tripping hazard!

Warning! Risk of getting

distance!

Warning! Hand injury by

jammed!

splitting cross!

Any damaged and/or

disposed electric or electronic

devices must be delivered to

appropriate collection centres.

Package:

Protect against humidity!

Careful – fragile!

This side up.

Technical data:

Max gap diameter Max Timber length

Table size app. Weight

Interseroh-Recycling system

with serial number

Connector Engine power

Revolutions Gap pressure

Warning against dangerous

voltage!

Commands:

Read the Operating

Instructions before use

CAUTION! Please read the

Operating Instructions before

operating the machine!

Use protective glasses and

earphones!

Forward feed pace Backward feed pace

Before operation, heat oil for 1

minute by pressing one

protective handle.

Keep one operating arm

pressed down when starting

the splitter!

Use safety gloves Use safety shoes!

Rotation direction

Page 4

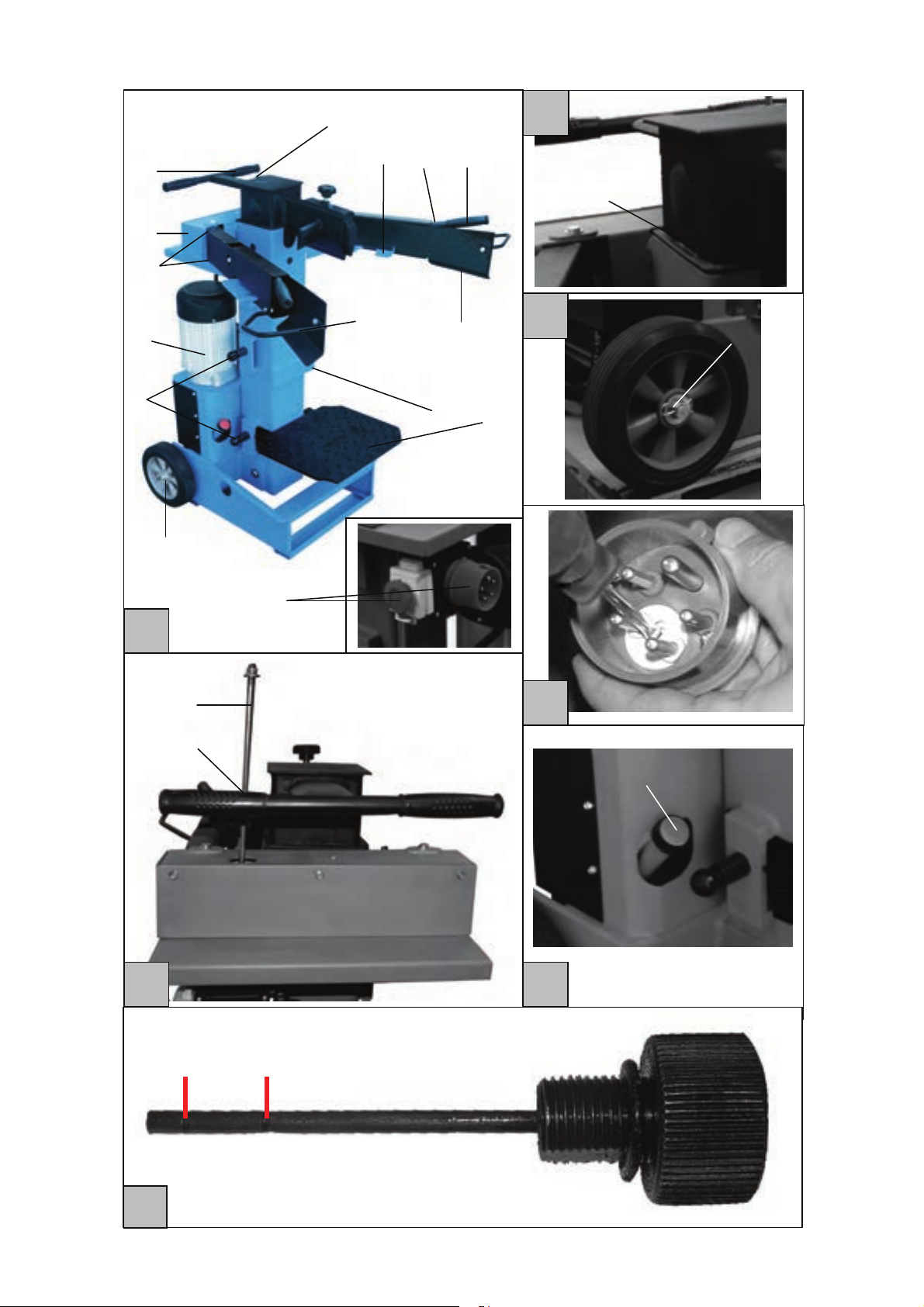

Appliance description (pic. 1)

10

1. Handle

2. Splitting knife

3. Clamping plate

4. Service arm

5. Handle covering

6. Table holder (in front)

7. Table blocking

8. Splitter table

9. Wheels

10. Switch / plug

11. Lift adjusting rod

12. Motor

13. protection system

14. switching rocker (bottom panel)

15. metal butt strap

Appliance

DHH 1050/10 TP WOOD SPLITTER

Robust design, splitting knife out of special steel, all steel parts

with high-quality powder coating, high-quality hydraulic pump.

Engine with overheating fuse.

Use as designated

The log splitter has exclusively been designed to split wood

along fibres.

Installations, maintenance, repair, etc. instructions must strictly

be followed to prevent risks and damage.

When splitting, it is necessary to make sure the split wood is

only fitted on the grooved sheet of the supporting plate or on

the grooved sheet of the splitter table.

The machine cannot be used for works other than for which

the machine has been designed and that are specified in the

Operating Instructions.

Any other use is a use in conflict with the designation. The

manufacturer will not be liable for any consequential damage

and injuries. Please be sure to know that the machine has not

been designed for industrial purposes.

Guarantee

The guarantee relates exclusively to faults caused by material

defect or manufacturing defect. Original proof of purchase with

the purchase date needs to be attached for claims in the

guarantee period.

The guarantee does not cover any unauthorised use such as

appliance overloading, violent use, damage by third party or

foreign items. The failure to follow the Operating Instructions

and assembly instructions and ordinary wear and tear is not

included in the guarantee.

Technical data

Connector: 400 V~50 Hz

Engine power: 4000 W P1 / S6 40%

Engine revolutions: 1400 revolutions a minute

Max. splitting force: 10 tons

Max. splitting lift: 510 mm

Forward feed rate: 0,045 m/s

Backward feed rate: 0,18 m/s

Hydraulic oil tank: 5 l (oil type - HLP 46)

Table adjustment: 1050 mm

Max. diameter of split wood: App. 400 mm

Splitting pillar: 120 mm x 120 mm

Table dimensions: App. 380 x 300 mm

Weight: 146 kg

Order No. 02003

Safety instructions

General

For safety reasons it is necessary to respect and follow safety

instructions specified in these Operating Instructions and

instructions on the appliance relating to appliance operation,

maintenance and repairs.

Operating staff

Using the wood splitter can be associated with some

risks. Therefore only trained and experienced persons can

handle the appliance and work with it. The operating staff

must wear tight, close-fitting clothing and protective

shoes.

Caution: When splitting, dry and mature wood may

get intensely shot out and injure the face of the operator.

Please wear appropriate protective clothing!

Workplace

To ensure safe wood splitting, it is necessary that the

workplace is flat and enables stability keeping and sufficient

free moving. All obstacles need to be removed from access

paths when bringing the splitter and taking it away. Sufficient

workplace lighting must be ensured.

Make sure no persons are present in the workplace

during appliance operation or make sure they keep a

sufficient safe distance.

The log splitter has been designed to be operated by

1 person. Two or more persons must never work with the

appliance.

Work preparation

Current supply needs to be interrupted by pressing the red

button on the switch and disconnecting the plug at any repairs

or maintenance work and when leaving the wood splitter.

Interrupting the current supply by putting the switch to

OFF position is not sufficient. GÜDE wood splitters are

fundamentally supplied with hardened splitting knives.

However, if you detect any slight deformation of the knife edge

after splitting wood containing any invisible foreign particles,

e.g. out of concrete, steel, etc. then remove it by a file or

grinding off. Keeping the splitting knife permanently sharp

increases the working output.

TIP: Occasionally grease the splitting knife with fat (for

problem wood).

The function of safety equipment (especially the twolever operation) needs to be checked before the splitter is

put into operation for the first time.

ATTENTION! Make sure the splitting table is safely

secured to the splitter before the splitter is put into

operation.

Disposal

The disposal instructions are based on icons placed on the

machine or its package. The description of the meanings can

be found in the “Marking“ section.

Transport package disposal

The package protects the machine against damage during

transport. Packing materials are usually chosen depending on

their environmental friendliness and disposal method and can

therefore be recycled. Returning the package to material

circulation saves raw materials and reduces waste disposal

costs. Parts of packages (e.g. foils, styropor®) can be

dangerous to children. Risk of suffocation! Keep parts of the

package away from children and dispose them as soon as

possible.

Page 5

Operating staff requirements

11

The operating staff must carefully read the Operating

Instructions before using the appliance.

Qualification

Apart from the detailed instruction by a professional no special

qualification is necessary for using the appliance.

Minimum age

Only persons over 18 years of age can work with the

appliance. An exception includes youngsters if they work

within their professional education the purpose of which is to

obtain knowledge supervised by a trainer.

Inspections and servicing (pic. 2+7+8)

Safety instructions for inspections and servicing:

Only a regularly serviced and treated appliance may be a

satisfactory aid. Inadequate servicing and maintenance may

lead to unforeseen accidents and injuries.

• Never use aggressive cleaning agents to clean the

appliance. That could damage or destroy the

appliance.

• Unplug the appliance.

• Have any repairs and servicing of the electrical

equipment provided by electricians only.

• All protective and safety equipment must be immediately

refitted after repairs and servicing works are finished.

The following is recommended (pic. 2):

• Splitting knife

The splitting knife is a component that is subject to quick

wear and must be ground down additionally if necessary.

That will increase the splitting output and protect the

splitter. Tip: lubricate the splitting knife with fat!

• Two-hand protective equipment

The combined holding and clamping equipment must run

easily. From time to time, lubricate it with a few drops of

oil.

• Splitting post

Every time the appliance is to be used, lubricate the

splitting post with fat. That will increase the service life of

the sliding jaws (pic. A/2). Pull the splitting post out to the

full extent and equally apply multi-purpose fat to all 4

sides of the splitting post.

• Movable parts

Keep the splitting knife guide clean (remove any dirt,

splinters, bark, etc.). Slide rails to be lubricated with fat.

• Hydraulic equipment

Hydraulic connections screwing should be checked for

leaking and wear. Tighten the screwing if necessary.

Checking the hydraulic oil level (pic. 7+8):

Check the hydraulic oil level only when in a cold

condition, feeder cable disconnected and splitting post

pulled in.

On the oil level dipstick there are two notches – the lower (pic.

8/1) is the minimum hydraulic oil limit level in the tank and the

upper notch (pic. 8/2) is the maximum limit.

• Unscrew the oil level dipstick (pic. 7/A) from the

opening.

• Wipe the oil from the dipstick with a non-felt cloth.

• Re-screw the dipstick in the opening.

• Unscrew the filling screw with the dipstick again and

check whether the hydraulic oil upper limit is between

both notches.

Change the oil once a year (pic. 7+8):

• Unscrew the oil drain plug (pic.7/A).

• Catch the waste oil (every model with different amount)

• Dispose the waste oil in an environment-friendly manner

• Re-screw the oil drain plug. No particles of dirt may get

in the oil tank.

• Add the hydraulic oil up to the upper notch on the dipstick

(pic. 82)

• Try the wood splitter with no load several times.

Recommended hydraulic oil: DIN ISO HLP 46

Güde Art. No. 42004

Viscosity: 46

Oil amount: (see Technical specifications)

Oil to be added only when the splitting post is in the

engaged

Hydraulic equipment:

Hydraulic hoses and couplings must be checked after app. 4

hours of operation whether tight and must be tightened if

necessary.

Checking the appliance whether it is working properly

The hydraulic wood splitter is supplied in a ready-to-operate

state. The following functional checks need to be carried out

every time the appliance is to be used.

• Let both switching handles go down and the splitting knife

• Lower one switching handle at a time – the splitting knife

position.

as low as app. 5 cm above the table

will remain in the selected position

Assembly of service arms, wheels and table

(pic. 1 and 4)

Assembly of service arms - pic. 1

Introduce control arm (Fig. 1/4) in the rocker switch (Fig. 1/14),

top with bolt, washer and split pin. Now the control arm (Fig.

1/4) by the method on the other fix. The protection system

(Fig. 1/13) Mount to both operating arms, each with two bolts

(Fig. 1/3).

TIP: Grease metal couplings (pic 1/15) with fat from above

and below before that!

Assembly of wheels – pic. 4

Mount on both sides of the impeller and secure both with a

cotter pin (A).

Table assembly - pic. 1

Depending on the split wood length, the table board can be

fixed in three heights - 570 mm, 770 mm and 1,060 mm.

Table locking levers (pic. 1/7) are fixed in every assembly

position. Insert the table board to the required holders (pic.

1/6).

Lift adjusting (pic. 5)

The working output can be increased for wood pieces smaller

than app. 50 cm and for more wood pieces by shortening the

backward movement of the splitting knife.

Proceed as follows:

Put a short piece of wood on the splitter table and move the

splitting knife as low as app. 2 cm above the wood. Switch the

splitter off (red button on the switch and disconnect the plug).

Now you can shorten the backward movement using the fixed

rod (pic. 5/B) by fixing the rod in the required height with the

adjusting screw (pic. 5/A).

Area of application

The appliance can only be used for wood processing. The split

material must have the following dimensions:

- Minimum diameter: 125 mm

Maximum diameter: 400 mm

- Wood splitting along fibre is only allowed.

- Risk of getting jammed at branchy wood when splitting.

- Jammed piece of wood is released by tipping on the

wood.

- Cutting the split wood out prohibited!

Page 6

Electric/hydraulic connection (pic. 1+6+7)

12

Plugging (Pic. 1/10)

All splitters are fitted with undervoltage release in the switch in

accordance with provisions of branch professional

organisations “CE“, etc. The release prevents automatic

starting of the appliance in case supply is interrupted as a

result of power failure, unintentional unplugging, defective

fuse, etc. The appliance must unconditionally be switched on

again by pressing the green switching button.

Wilful holding or blocking of the switching button with no

directly earthed conductor automatically leads to switch failure.

In this case that can subsequently be identified the guarantee

expires.

Hydraulic equipment

Tightness needs to be checked at hydraulic hoses and

couplings after app. 4 running hours and tighting must be

provided if necessary.

Only at 400 V appliances: It is necessary to be particular

about the running direction of the engine (see the arrow

on the engine) as running in wrong running direction can

damage the oil pump. In such a case, all claims arising

from the guarantee expire. If necessary, have the running

direction changed by reversal of polarity of the plug. See

pic. 6!

Hydraulic oil/tank

Common hydraulic oil (e.g. HLP 46 or oil of different producer

of identical viscosity) can be filled in all splitters. Oil change is

not necessary.

Vent the tank before each operation by screwing the filling

screw out and in (pic. 7/A).

Operation

Attention: Make sure wood is cut at right angle, if

possible, and seated closely on the splitting table. Crosscut or extremely branchy wood can slide or bend the

service arms.

Always put wood on surfaces (tables) designated for

this purpose (never on the frame). That could damage the

splitter.

1. Start the engine by pressing the green switching button.

Attention: Be particular about the running direction of

the engine!

2. Keep the feeder cable as short as possible at 230

V models and select as big cross section as possible.

3. When the temperature is low, let the splitter run idle

for app. 15 minutes so that oil warms up to

corresponding temperature.

4. Put the split material on the table and hold it using

clamping plates on the lever.

5. Splitting starts by pressing both levers down (as soon as

the splitting knife enters wood tip the lever slightly out

while pressing it down. This will prevent holding sheets

(arms) from bending).

6. Lift at least one lever after you have finished splitting – the

splitter pillar will automatically go up.

It is strictly prohibited to operate the wood splitter in

two persons with one holding wood and the other one

pressing on the clamping plates.

Transport instructions

Transport

All wood splitters are fitted with big wheels. Grasp the handle

on the splitting pillar with one hand and handle above the

engine with the other hand and slightly tilt the splitter to you for

transport purposes. The splitter can effortlessly be moved in

this position.

To prevent hydraulic oil leakage, never transport the

splitter laid down

Always let the splitting knife go absolutely down

.

for

transport.

Residual risks and protective measures

Warning!!!

Taking out of operation, any change, blocking,

disassembly, changeover or assembly of all parts on

safety and protective equipment of the appliance is strictly

prohibited and can have serious consequences, i.e. life

threatening injuries if not observed.

The producer cannot be held liable for material damages

or injuries caused as a result of such negligence.

All guarantee claims towards the producer immediately

expire at each of the above-mentioned negligence.

The splitter can only be operated by one

person. Remove

wood remnants that could block or negatively influence

the safety and service elements near the splitter and

workplace during operation.

Maintenance

Do you have any technical questions? A claim? Do you

need spare parts or the Operating Instructions?

You will be helped quickly and without needless bureaucracy

at our webpage www.guede.com in the Services section.

Please help us be able to assist you. To identify your machine

when claimed, we need to know its serial No., order No, and

year of production. All these details can be found on the type

label. Enter the details below for future reference.

Serial No.

Order No.

Year of production:

Tel. +49 (0) 79 04 / 700-360

Fax: +49 (0) 79 04 / 700-51999

Email: support@ts.guede.com

Page 7

EU Declaration of Conformity

13

We,

Güde GmbH & Co. KG

Birkichstraße 6

74549 Wolpertshausen

Germany

hereby declare the conception and construction of the below-mentioned appliances correspond - at the type of construction being

launched - to appropriate basic safety and hygienic requirements of EC Directives.

In case of any change to the appliance not discussed with us the Declaration expires.

Marking of appliances: DHH 1050/10 TP WOOD SPLITTER

Order No.: 02003

Date/producer signature: 27.03.2012

Signed by: Managing Director

Mr. Arnold

Technische Dokumentation: J. Bürkle FBL; QS

Appropriate EU Directives:

2004/108/EG

2006/42/EG

Harmonised standards used:

EN 609-1/A2:2009

EN 61000-3-3:1995+A1+A2

EN 61000-3-2:2006

EN 55014-2:1997+A1

EN 55014-1:2006

Noise level:

Lwa: 85,2 dB

Lpa: 69,9 dB

Troubleshooting

Problems

Engine not starting

Wrong engine running

direction

Splitting knife not moving

Splitter has no power

After being pressed, the

green switching button not

staying in place

Hydraulic pump whistling;

splitting knife running jerky

Possible causes

1. No current in the outlet

2. Defective extension cable

3. Wrong feeder cable

4. Defective switch, condenser

Remedy

1. Check the network protection

2. Pull out the plug – check it and replace it if necessary

3. Connection with 5 cores with a cross section of 2.5 mm

4. Have the appliance checked by an electrician

1. Wrong connection 1. Turn the phase changer in the appliance plug using a

screwdriver

1. Two-hand switching lever adjustment 1. Check the oil level

Defective control valve must be replaced in a service

centre only

1. Wrong rotation direction

2. Too little hydraulic oil

3. Starting rod is bent; the hydraulic

lifter is not pressed to the full extent

4. Wood with too many knots - splitting

knife gets jammed

5. Operating arm is bent

1. Defective fuse, etc.

1. Change the rotation direction

2. Add hydraulic oil

3. Check all screws on the starting rod mechanism

Adjust the pull rod (pic. 10/B); by this,

the hydraulic lifter will be pressed to the full extent.

4. Lubricate the splitting knife with fat.

5. Return the operating arm to the starting position.

1. Check the cable

2. 2 phase running

1. Oil loss, surface is dirty

2. Too little hydraulic oil in the tank

1. Tighten the screwing

Replace the hoses

2. Add hydraulic oil

2

Page 8

Mechanical residual risks

14

Threat Description Protective measure(s) Residual risk

Jamming Parts of body can get jammed or amputated

when splitting as a result of hydraulic knife

going down.

There is a risk the split wood gets jammed.

Please be aware that wood is strongly tight

when being removed and fingers can get

jammed in the splitting crack.

Always use the two-hand safety

operation. Do not interfere in the

splitting process.

Two persons must never work with the

appliance

Get out any jammed piece of wood.

Beware of falling wood – it can injure

Worn-out or damaged aid

must immediately be

replaced.

Have an eye to bystanders!

Always wear safety shoes

when working.

your legs.

Cutting Parts of body can get jammed or amputated

when splitting as a result of hydraulic knife

going down.

Common

accidents

Violent splitting can cause serious injuries when

dry wood is processed.

Pieces of wood created during splitting can fall

down and injure especially legs of the working

person.

Splitting wedge extension can get in the table

and thus cause appliance damage or serious

injuries of persons.

Always use the two-hand safety

operation. Do not interfere in the

splitting process.

Never interfere in the splitting process.

Always keep a sufficient safety

distance.

Always operate the appliance carefully

and cautiously.

Always wear specified protective

clothing and work carefully.

Always wear protective glasses when

working with the appliance.

Always wear specified protective

clothing and work carefully.

Wear corresponding safety shoes to the

specified protective clothing.

Always disassemble the table before

Worn-out or damaged aid

must immediately be

replaced.

Worn-out or damaged aid

must immediately be

replaced.

Always have an eye to

bystanders.

working with the splitting wedge

extension (see page 12)

Getting

caught,

winding up

Wide clothing, jewels and long hair can get

caught by moving parts.

Always wear close-fitting clothing; do

not wear jewels and protect your hair

with a hairnet.

Electrical residual risks

Threat Description Protective measure(s) Residual risk

Direct

electric

contact

Faulty cable or plug can be a cause of electric

shock.

Always have any faulty cables or plugs

replaced by a specialist. Use the

appliance with a safety switch against

Check the feeder cable

before each use

stray current (FI).

Indirect

electric

contact

Injury by conductive parts of exposed electrical

or faulty construction parts

Always disconnect the plug at

maintenance work.

To be operated only with a safety

switch against stray current (FI).

Noise threat

Threat Description Protective measure(s) Residual risk

Hearing

damage

Long-term working with the appliance can

damage hearing.

Always wear earphones.

Neglect of ergonomic principles

Threat Description Protective measure(s) Residual risk

Negligent

use of

personal

Appliance operation without corresponding

protective aids can cause serious external and

internal injuries.

Always wear specified protective

clothing and work carefully.

protective

aids

Inadequate

local lighting

Insufficient lighting represents a high safety

risk.

Always ensure sufficient lighting when

working with the appliance.

Other threats

Threat Description Protective measure(s) Residual risk

Thrown-away

items or

spraying

liquids

Mechanical particles can injure your eyes when

splitting.

Always wear protective glasses when

working with the appliance.

Loading...

Loading...