Page 1

#94711

W 520 / 5,5 T UG

© Güde GmbH & Co. KG - Birkichstrasse 6 - D-74549 Wolpertshausen - Deutschland

English GB 10

Original Operating Instructions

LOG SPLITTER

Page 2

1

2

1

2

3

4

5

6

6

7

8

9

10

11

12

13

14

15

Page 3

Introduction

To enjoy the new W 520 / 5.5 T UG LOG SPLITTER,

please read carefully the Operating Instructions and the

attached safety instructions before putting it into operation.

Further, we recommend keeping the Operating

Instructions in order to recall the product features in the

future.

To follow the continuous product develop ment. we

reserve the right to make technical changes for any

further improvement.

This document represents the original Operating

Instructions.

Supply includes

Take the appliance out of the transport package and check

whether the following parts are present:

• W 520 / 5.5 T UG LOG SPLITTER

• Bag including small parts (screws, lock nuts,

distance rings)

• Transport wheels

• Chassis (in a dismantled state; see

Assembly and First Activation)

• Original Operating Instructions

• Guarantee certificate

If any part is missing or is damaged, please contact your

dealer.

The appliance weighs 47kg when assembled. Lift the

appliance off the transport package in two people if

necessary.

Appliance description

W 520 / 5.5 T UG LOG SPLITTER

Robust log splitter with two-handed safety handling. High-

quality hydraulic system and electric motor; easy transport

due to chassis, travel handle and transport wheels.

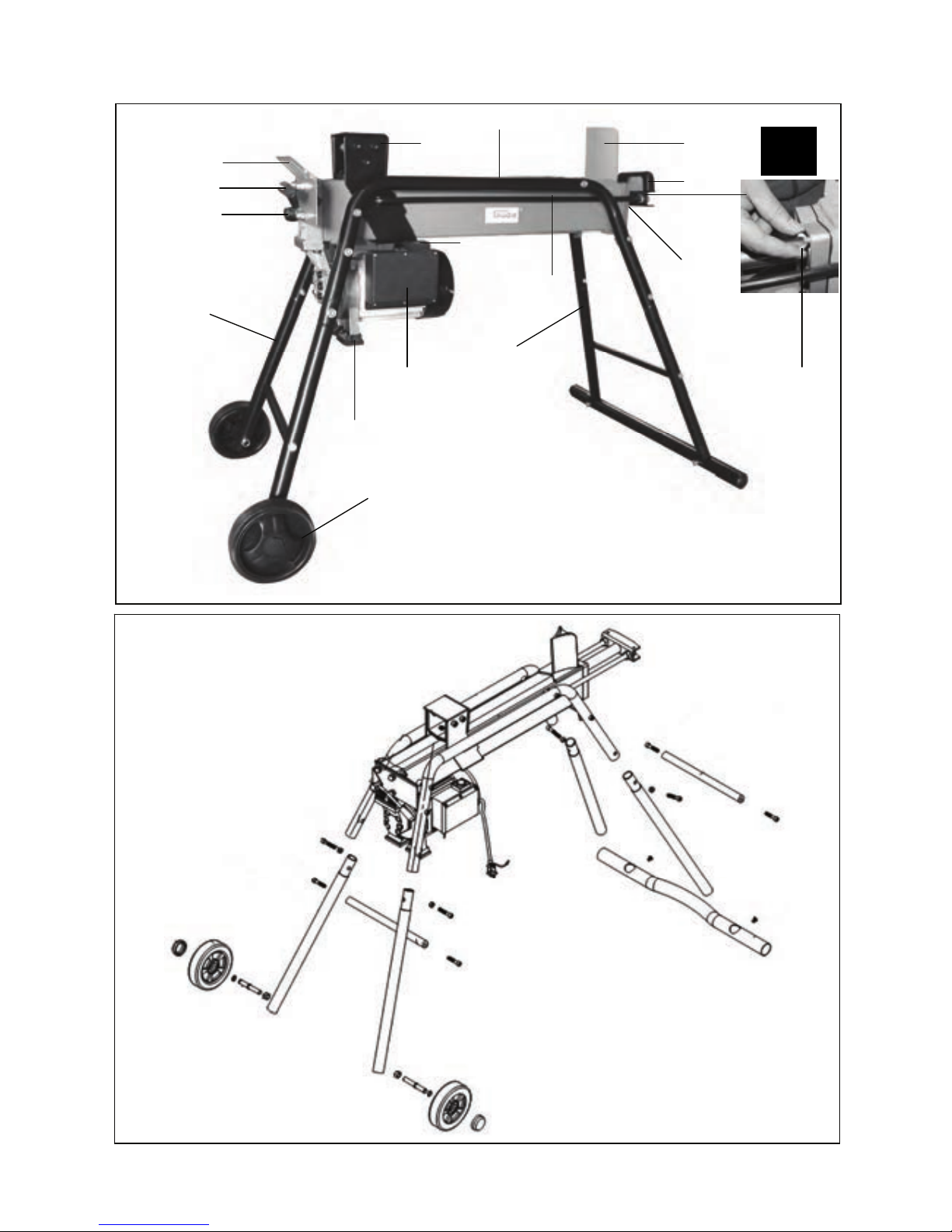

Appliance description (pic. 1)

1. Beam

2. Traversing table

3. Handle cover

4. Valve setting button

5. Transport wheels

6. Chassis

7. Electric motor

8. Engine supporting foot

9. Travel handle

10. Guider

11. Splitting knife

12. Button

13. Operating lever

14. Bleed screw

15. Oil gauge/oil drain plug

Technical specifications

W 520 / 5.5 T UG LOG SPLITTER

Voltage/frequency: 230V~50Hz

Engine output: 1.5 kW

Max. splitting pressure: 5.5t

Max. log length: 520mm

Min./max. log width: 80mm/250mm

Max. splitting uplift: 420mm

Noise: L

WA

78dB

Assembling dimensions in mm: 1,250 x 720 x 865

Weight: 47kg

General safety instructions

Please read carefully these Operating Instructions.

Familiarise with the control elements and appropriate

appliance using. Keep the Operating Instructions for future

reference.

Safe working

Keep the place of your work clean!

Mess in the place of your work may result in injuries.

Consider the environment influences

Do not expose the appliance to rain.

Do not use the appliance in a wet or moist environment.

Provide appropriate lighting.

Do not use the appliance near flammable liquids or gases.

Keep other persons in safe distance!

Do not let other persons, especially children, touch the

appliance and the cable. Keep them in a sufficient distance

from the place of your work.

Store the appliance properly!

An appliance that is not used should be stored in a dry,

locked place out of reach of children.

CAUTION! The appliance must in no case be inclined

as hydraulic oil could flow out.

Do not overload the appliance!

Work in the specified output limits.

Use the right appliance!

Do not use the appliance for purposes for which it has not

been designed.

Look after your appliance!

Follow the maintenance regulations and instructions.

Check regularly the appliance cable and have it replaced

by an authorised professional if damaged.

Check regularly the extension cable and replace it if

damaged. Keep the handles dry, with no oil and grease.

Be careful!

Pay attention to what you are doing. Use common sense

when working. Do not use the appliance when you are

tired.

WARNING!

Use of any other accessories may pose a risk of injury.

Your appliance should be repaired by an electrician

only!

This appliance meets the appropriate safety provisions.

Repairs may only be executed by an electrician and

original spare parts must be used, otherwise the user may

face a risk of injury.

Appliance-specific safety instructions

Please read carefully the Operating Instructions

before using the appliance.

1. CAUTION! The appliance must in no case be

inclined as hydraulic oil could flow out.

2. Appropriate personal aids must necessarily

be worn: safety shoes, working gloves, eye

protection, ear protectors and closefitting

clothes.

10

Page 4

3. Check the protection equipment every time

you are going to put the appliance into

operation.

4. Make sure the operating position is not

obstructed in any way and is level.

5. Remove any obstruction – wood debris and

remnants from the place of your work.

6. It is necessary to check whether the

appliance and the protection equipment are

working properly every time

you are going to

work with the appliance.

7. Never

leave the appliance unattended.

8. Never touch the area of splitting as there is

an increased risk of injury.

9. Use the appliance only with PRCD

connection (safety switch against stray

current).

10. Work only when good visibility or

appropriate lighting is provided.

11. Follow all safety instructions mentioned in

the Operating Instructions.

12. Risk of knotty logs getting stuck when being

split. Be sure to know the clog is under

significant pressure when being released

and your fingers may get jammed in a gap.

13. Behave responsible to other persons.

14. Stuck logs must not be released by tapping.

Stuck logs must not be cut out by a saw!

15. The appliance has solely been designed to

be operated by one person; operating the

appliance in two or more persons is strictly

prohibited.

16. Safety shoes always need to be worn as a

falling log can injure your feet.

17. Fast splitting may result in serious injuries

when dry logs are processed.

Tip: If grease is applied to the knife, "more complex

logs" can also be split!

Marking

Product safety:

Product corresponds to

appropriate EU standards

Prohibitions:

No pulling the plug!

Protect against rain and

moisture!

Material with metal parts

must not be processed

Appliance to be operated by

one person only

Warning:

Warning/caution

Warning against dangerous

voltage

Warning against thrown-off

items

Keep persons standing

around in safe distance

from the appliance (at least

5m)

Warning against hand injury

Warning against moving

tools (risk of getting

jammed)

Caution! Bleeder screw must

necessarily be loosened when

the appliance is being

operated!

Commands:

General command symbol

Please read carefully the

Operating Instructions.

Learn to use the appliance

before using it.

Use protective glasses/shield Use protective gloves

Use safety shoes

Unplug the appliance

before servicing

Environment protection:

Dispose waste professionally

so as not to harm the

environment..

Packing cardboard material

may be delivered to

collecting centres for

recycling.

Faulty and/or disposed electric

or electronic appliances must

be taken to appropriate

collection centres.

11

Page 5

Package:

Protect against moisture This side up

Interseroh-Recycling

Technical specifications:

Connection Weight

Engine output Noise

Max. log length Max. splitting pressure

Max. splitting uplift Max. log width

Training

Please read carefully the Operating and Servicing

Instructions. Familiarise with the controls and proper

working of the appliance. You must know how the

appliance works and how to switch the controls

immediately off.

Never let children work with the appliance. Never let adults

without appropriate training work with the appliance.

Do not let any persons, especially small children and pets,

get near the place of your work.

Be careful to prevent slipping or falling.

Use as designated

The product (log splitter) that you have bought has solely

been designed for the following purposes:

The splitter has solely been designed to split saw-cut logs

of 52 cm in maximum length and 25 cm in maximum width

along the fibre.

This appliance must not be used to perform other works

than those for which the appliance has been designed and

which are described in the Operating Instructions.

Any other use is conflict with the designation. The

manufacturer is not responsible for any indirect damages

and injuries. Please be sure to know that our appliances

have not been designed to be used for industrial purposes.

Assembly

Caution! The appliance needs to be switched off and

unplugged before servicing, cleaning and assembling. The

same procedure must be applied if the feeder cable is

damaged, cut or entangled.

System voltage must be adhered to: the source voltage

must correspond to the details on the appliance type label.

An extension cable with a too small conductor crosssection significantly reduces the appliance performance. At

least 3 x 1,5mm² for cables within a length of 25m and at

least 2,5mm² for cables with a length exceeding 25m.

Caution! Extension cables not meeting the given

requirements must not be used. The extension cable, plug

and joint must be watertight and approved to be used

outdoors.

Cable joints must be dry and must not lie on the floor.

If a cable reel is used, it needs to be unwound to full

extent.

When the log splitter is delivered, some parts have been

disassembled for transport purposes.

Screws, nuts and distance rings are in a separate plastic

bag. The assembly is easy if instructions are followed (pic.

2).

Operation

Loosen the bleed screw (2-3 turns) before starting to

split (pic. 1/14).

The screw must necessarily be tightened for

transport purposes.

Check the oil level in the splitter every time you are going

to use it.

Put the splitter to a vertical position.

Loosen the oil gauge plug using a socket wrench and put it

out to see the oil level.

The oil level must be between the two oil gauge marks.

Log dimensions

Log dimensions appropriate for the appliance and

mentioned in the “Technical specifications“ are just of an

indicative nature. A small log may be difficult to split if

knotty.

If the log is not to be split immediately, it is very

important the splitting pressure is not applied for a long

time. That would cause the compressed oil to be quickly

overheated, which would subsequently damage the pump.

Step-by-step instructions

Plug the electric log splitter in.

When putting the feeder cable down, make sure it does

not lie over the telescopic beam or near the splitting knife;

places with a risk of damage or breaking also need to be

avoided.

Put the log on the beam. Guiders will help keep the knife in

the centre of the log. If the log does not fit well or tightly, it

needs to be turned around.

12

Page 6

Using your left hand, press the electric motor button to full

extent and control the operating lever with your right hand.

The traversing table is moving forward, pressing the log

through the splitting knife.

Caution: If the button has not been pressed to full

extent, the switch contact could get damaged.

If the log is not to be split immediately, do not hold the

slide valve pressed. Pull the log slide valve back and try

again. A small log may also be difficult to split if knotty and

fibrous. Wider logs with regular fibrous wood are not

difficult to split. If wood is too hard, the log needs to be

processed by a special machine to prevent damage to the

appliance.

Repeat the operating step with wood cut into smaller

pieces.

The log splitter needs to be unplugged after finishing work.

The cable must not be pulled when doing so.

Caution: The engine may switch off due to overheating

after several hours of operation or when splitting big and

hard logs. In such a case, let the appliance cool down for

at least app. 15 minutes and then continue with the work.

EU DECLARATION OF CONFORMITY

We,

Güde GmbH & Co. KG

Birkichstrasse 6

D-74549 Wolpertshausen

Germany

herewith declare that the following appliance complies with

the appropriate basic safety and health requirements of

the EU Directives based on its design and type, as brought

into circulation by us

.

In case of alternation of the machine, not agreed

upon by us, this declaration will lose its validity.

Machine description:

W 520 / 5.5 T UG LOG SPLITTER

Article No.

#94711

Applicable EU Directives:

2006/42 EG

2006/95 EG

2004/108 EG

Applicable harmonised standards:

EN 62233:2008

EN 60335-1:2002+A11,A1:04+A12,A2:06+A13:08

EN 60335-1:2002+FprAF:09

EN 60204-1:2006+A1:09

EN 609-1:1999+A1:03+A2:09

EN 55014-1:2006

EN 55014-2:1997/+A1:2001/+A2:2008

EN 61000-3-2:2006

EN 61000-3-3:2008

Place of certification:

Intertek Testing Services Shanghai,

Building No. 86, 1198 Qinzhou Road (North), Shanghai

200233 China

Reference No.

06SHW0188-04

Date/authorised signature: 20 Sep, 2010

Title of signatory: Managing Director

Mr Arnold

Technical documentation: J. Bürkle FBL; QS

Guarantee

The guarantee exclusively applies to material or

manufacturing defects. The original proof of purchase with

the purchase date must be submitted when lodging a claim

in the guarantee period.

The guarantee does not include any unauthorised use,

e.g. appliance overloading, violent use, damage by a third

party or foreign item. The failure to follow the Operating

Instructions and assembly instructions and common wear

and tear are not covered by the guarantee either.

Residual risks and protective measures

Electrical residual risks:

Risk Description Protective measure(s)

Direct

electrical

contact

Cable could be

cut off,

entangled or

damaged by

mechanical

parts.

Work only with a connection

with safety switch against

stray current (FI).

Mechanical residual risks:

Risk Description Protective measure(s)

Getting

jammed

Cutting

When splitting,

parts of body

may get

jammed or

amputated by

the traversing

table

movement.

Risk of log

getting stuck.

Please be sure

to know the log

is under

significant

pressure when

being released,

which may

cause your

fingers to get

jammed in a

gap.

When splitting,

parts of body

may get

jammed or

amputated by

the traversing

table

movement.

.

Two-handed safety handling

A log that has got stuck must

only be knocked out. Watch

out for a falling log as your

feet could get injured.

Wear protective glasses,

gloves, closefitting winter

clothes and solid shoes with a

rough sole when working.

Other risks

Risk Description Protective measure(s)

Thrown-off

items and

spraying

liquids

Thrown-off

wood debris or

spraying

hydraulic oil

may cause

injury.

Wear protective glasses,

gloves, closefitting winter

clothes and solid shoes with a

rough sole when working.

Neglecting ergonomic principles

Risk Description Protective measure(s)

Inadequate

local lighting

Inappropriate

lighting/poor

visibility

Appropriate lighting or good

visibility must always be

provided when working with

13

Page 7

represents a

high safety risk.

the appliance.

Behaviour in case of emergency

Provide necessary first aid treatment corresponding to the

injury nature and seek qualified medical help as soon as

possible.

Protect the injured person from other injuries and calm

him/her down.

First aid kit must always be available in the place of

your work in case of accident in accordance with DIN

13164. Material taken out of the first aid kit needs to be

supplemented right away.

If help is needed,

please provide the following details:

1. Place of accident

2. Accident nature

3. Number of injured persons

4. Injury type

Disposal

The disposal instructions are based on icons placed on the

appliance or its package. The description of the meanings

can be found in the “Marking” chapter.

Transport package disposal

The package protects the appliance against damage

during transport. Packing materials are usually chosen

depending on their environmental friendliness and disposal

method and can therefore be recycled.

Returning the package to material circulation saves raw

materials and reduces waste disposal costs.

Parts of packages (e.g. foils, styropor) can be dangerous

to children. Risk of suffocation!

Keep parts of packages away from children and dispose

them as soon as possible.

Operator requirements

The operator must carefully read the Operating

Instructions before using the appliance.

Qualification

No special qualification is necessary for using the

appliance apart from detailed instruction by a qualified

person.

Minimum age

The appliance may only be operated by persons over 18

years of age. An exception includes youngsters operating

the appliance within their professional education to

achieve necessary skills under teacher's supervision.

Training

Using the appliance only requires appropriate instructions

by a professional or reading the Operating Instructions. No

special training necessary.

Servicing

Do you have any technical questions? A claim? Do you

need spare parts or the Operating Instructions?

You will be helped quickly and without needless

bureaucracy at our webpage www.guede.com in the

Service part. Please help us be able to assist you. To be

able to identify your appliance when claimed, we need to

know its serial No., order No. and year of production. All

these details can be found on the type label. Enter the

details below for future reference.

Serial No.

Order No.

Year of production:

Tel.: +49 (0) 79 04 / 700-360

Fax: +49 (0) 79 04 / 700-51999

E-Mail: support@ts.guede.com

Transport and storing

The log splitter has been fitted with transport wheels. To

move the appliance, take the travel handle with one hand

and lift it in the front. The splitter may be moved easily this

way.

There is a bleed screw on the back of the appliance. To

move the appliance, the screw must be tightened to

prevent oil leak.

The splitting knife gets automatically back to the starting

position.

Servicing and storing

The appliance needs to be put out of operation and

unplugged before any servicing. Servicing works not

explicitly described in this manual must be performed by a

professional as dangerous situations for which the

operator is not ready may be encountered. Scheduled

servicing or replacement of spare parts may only be

provided by a professional.

To provide protection against injury, do the fol lowing

every time you are going to service the appliance:

• Switch off the engine.

• Wait until all rotating parts fully stop.

• Unplug the appliance.

• Let the engine cool down (app. 30 minutes).

To provide protection against injury, do the fol lowing

every time you are going to clean the appliance:

• Switch off the engine.

• Wait until all rotating parts fully stop.

• Unplug the appliance.

• Let the engine cool down (app. 30 minutes).

• Do not spray water on the appliance as electrical

parts may get damaged.

If the appliance has not been used for more than one

month, e.g. after the season is over:

• Clean the appliance.

• Wipe all metal parts with a cloth soaked in oil or

spray them with spray oil to provide

anticorrosion protection.

• Store the appliance in a clean and dry room.

Keep the appliance with no dust and dirt.

For cleaning purposes, use a soft cloth and fine soap

solution. Prevent direct appliance contact with aggressive

cleaning agents. Aggressive, volatile and caustic cleaning

agents must not be used.

Have the log splitter checked by an authorised

professional once a year.

The appliance needs to be protected against moisture and

dust.

14

Page 8

If the appliance has not been used for a long time, store it

in a covered state in a dry, safe place inapproachable to

children.

Time interval Description Details

400 running

hours

• Hydraulic oil

change

HLP 46

2.4 l

Every time the

appliance is to

be used

• Oil level check

Every time the

appliance is to

be used

• Check the splitting

knife sharpness if

sharpening is

necessary

Hydraulic oil change

F HLP 46 (#42004) oil type or oil of similar viscosity is

recommended for the hydraulic cylinder.

Make sure the appliance beam is pulled out to full extent.

Incline the splitter towards the transport wheels.

Loosen the bleed screw (pic. 1/14)

Remove the oil drain plug (pic. 1/15)

Put a collection container with a capacity of app. 4 l of oil

under the log splitter.

Incline the appliance and let oil flow out.

Incline the log splitter in the opposite direction and add 2.4

l of oil to the hole.

Check the oil level using a cleaned oil gauge; the oil level

must be between the two oil gauge marks.

Clean the cover and the plug and carefully refit.

CAUTION:

Dispose the used oil in accordance with regulations in

force!

Check regularly the oil level.

Splitting knife sharpening

Sharpen the splitting knife regularly using a file. Remove

any sharp edges and dents.

Lubricate the splitting knife regularly using multi-purpose

grease. It will reduce strain and enable splitting of "more

complex logs".

Troubleshooting

The table below shows possible failures, causes and

removal options. However, if the problem persists, contact

a professional.

Switch the appliance off and unplug it before

servicing and cleaning.

Risk of electric shock.

Symptom Possible cause Removal

Log not 1. Wrong log 1. Position the log

getting split position.

2. Log

dimensions

not within

acceptable

limits or not

appropriate

for appliance

performance

if wood is too

hard.

3. Knife not

splitting.

4. Oil being too

cold.

5. Oil leaking.

6. Hydraulic

pressure

being too low.

again.

2. Reduce the

splitting range.

3. Sharpen the knife

and check

whether edges or

cuts are sharp

and grind them

away if

necessary.

4. Let oil warm up.

5. Find the leakage

and seal it.

6. Sort wood out.

Piston rod

running

irregularly or

strongly

vibrating.

Air in the circuit

Check the oil level and

refill if necessary.

Contact the dealer if

necessary.

Loosen the bleed

screw.

Oil leaking

near the

piston rod or

external

parts.

1. Oil leaking

from the oil

tank.

2. Sealing worn

out.

1. Check the bleed

screw fastening

before sliding.

2. Replace the

sealing.

Log has got

stuck.

Log being e.g.

knotty.

Release the operating

lever and pull the

traversing table up to

full extent.

15

Loading...

Loading...