GYS Trimig 200-4S, Trimig 250-4S, Trimig 300-4S, Trimig 300 G, Trimig 350-4S DUO DV 230-400V User guide

...Page 1

EN

P 9-13 / 31-44

www.gys.fr

73502 - V4 - 03/09/13

Page 2

I

II

TRIMIG

Trimig 200-4S/250-4S DV/300-4S

12

rimig 300 g/350-4S DUO DV/350 g DV

T

12

14

15

TRIMIG 300 G / 350 G

18

13

10

7

11

9

5

6

1

3

2

4

8

16

17

III

A

B

2

Page 3

IV

TRIMIG

1

2 3

4

V

Trimig 200

5

8

6

9

7

Trimig 250/300/350

1

2

3

VI

1

4

2

5

3

4

5

3

Page 4

TRIMIG

DESCRIPTION

Thank you for choosing this product; please read this instruction manual carefully before installing and using the product

and keep in a safe place for future reference.

The Trimig are semi-automatic welding units; they are ventilated for semi-automatic welding (MIG or MAG) and are

capable of welding steel, stainless steel and aluminium. Adjustment is quick and easy with their «synergic wire speed»

function. They work on a 400V three-phase power supply, and /or 230V three-phase for the DV models.

ELECTRICITY SUPPLY

The absorbed current (I1eff) is indicated on the device for use at maximum settings. Check that the power supply and

its protection (fuse and/or circuit breaker) are compatible with the current needed during use.

The device must be placed in such way that the power socket is always accessible.

Do not use an extension cable which has a wire section smaller than 4 mm².

These products are supplied with a 16A or 32A plug type EEC RS/015. They should be plugged in to a 400V (3PH) power

socket WITH earth and protected by a 16A circuit breaker and 1 differential 30mA.

230V 3-phase power supply, for Trimig 250-4S DV, 350 G DV and 350-4S DUO DV:

WARNING: This device is pre-built in 400V three-phase. If your electrical installation is 230V three-phase, you must

modify the connection on the terminal board. This modication must be undertaken by qualied personnel. In order to

do so, please refer to the technical diagram inside the product. The plug must be protected by a 16A or 25A (for models

350) circuit breaker and 1 differential 30mA.

EN

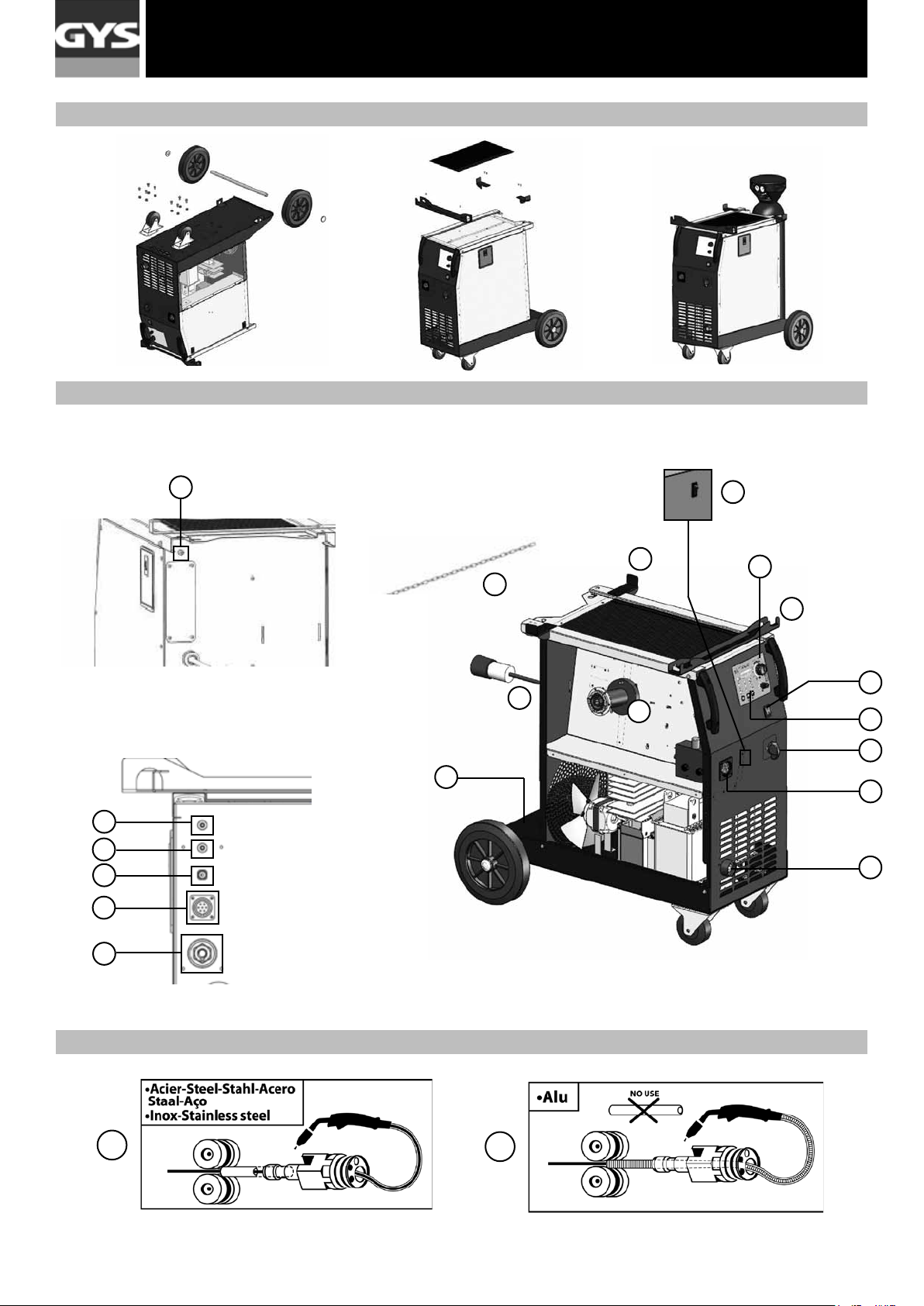

DEVICE PRESENTATION (FIG II)

1- On / Off switch

2- Power Settings - 2 switches with 7 positions: for ad-

justment of the welding voltage output. The adjustment

of the output voltage is proportional to the thickness of

the work piece.

3- Control panel – Welding settings (manual or automatic

mode).

4- European standard torch connection.

5- Thermal Protection light:

Indicates when a cool-down period is necessary following

intensive use.

6- Torch support.

7- Power Cable (5m).

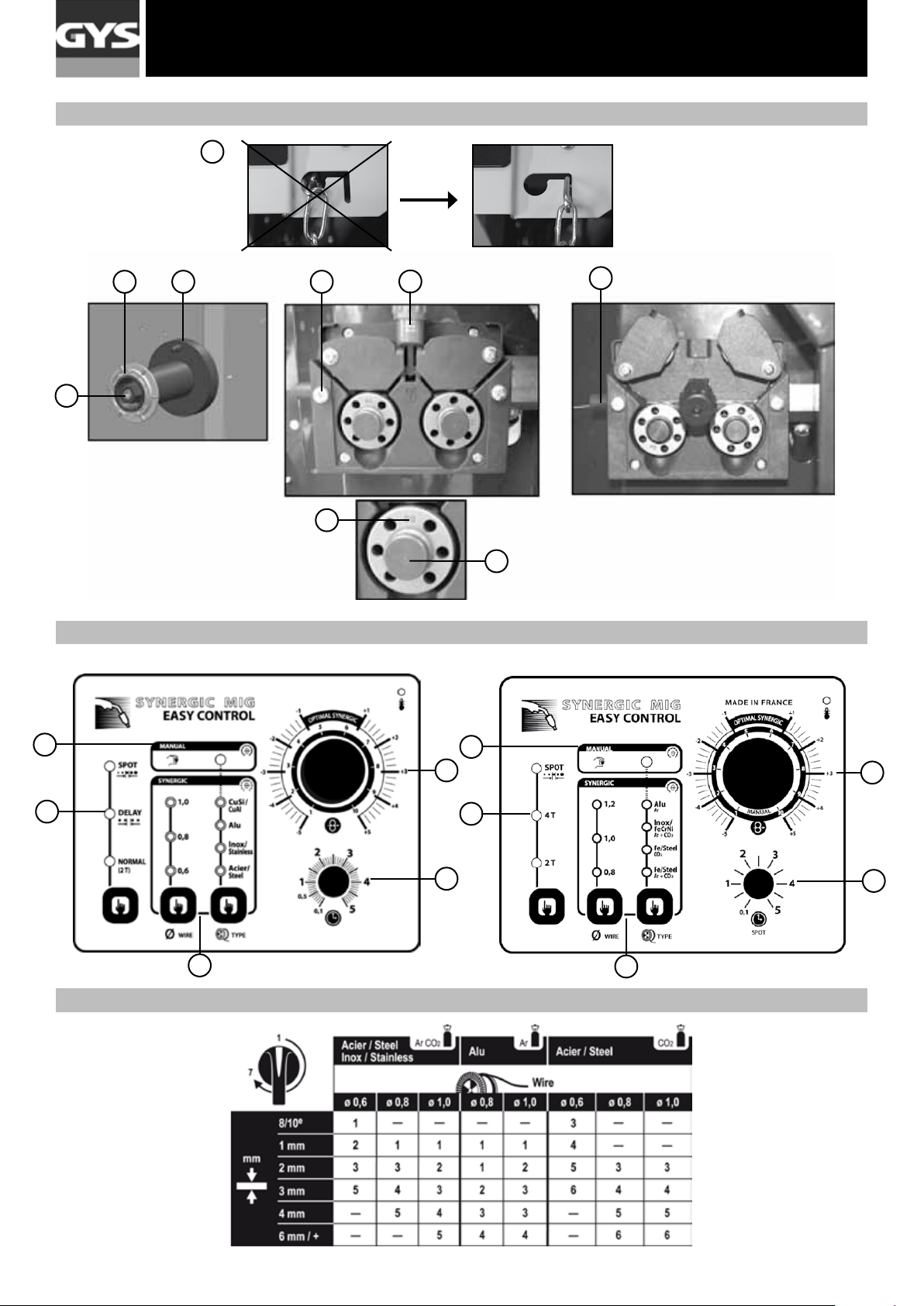

SEMI-AUTOMATIC WELDING FOR STEEL / STAINLESS STEEL (MAG MODE) (FIG III)

The Trimig 200-4S can weld 0.6/0.8/1mm steel and stainless steel wires (g. III-A).

The device is capable of working with Ø 1.0 mm steel wire (roller Ø 0.8/1.0, contact tip of 01.0).

If using lower diameter wire, you should use change the contact tip, and ensure that the reversible rollers in the wire

feeder are positioned correctly (so that required diameter is visible when in place).

The Trimig 250-4S DV 230-400V can weld 0.8/1/1.2mm steel and stainless steel wires.

The device is capable of working with Ø 1mm steel wire (roller Ø 0.8/1.0, contact tip of 1).

The Trimig 300-4S, 300 G, 350-4S DUO DV and 350 G DV can weld 0.8/1/1.2mm steel and stainless steel wires. The

device is capable of working with Ø 1mm steel wire (roller Ø 1.0/1.2, contact tip of 1).

For Steel or Stainless Steel, you will need to use specic gas - Argon + CO2 (Ar + CO2). The proportion of CO2 will vary

depending on usage. The gas ow for steel is between 10 and 20L / min depending on the environment and experience

of the welder.

8- Earth cable connector

9- Gas bottle support (max 1 bottle of 10m3).

10- Fastening chain for bottles.

Warning: fasten the chain securely (see IV-1)

11- Reel support Ø 200 mm/ 300mm.

12- Gas connector (350-4S DUO DV)

13- Torch Cable support

14- Wire feeder solenoid valve 2

15- Wire feeder gas connection for torch 2

16- Wire feeder control cable connector

17- Wire feeder power cable connector

18- Selection switch potentiometer (only on 300G and

350 G DV)

SEMI-AUTOMATIC WELDING FOR ALUMINIUM (MIG MODE) (FIG III)

The Trimig 200-4S can weld 0.8mm and 1mm aluminium wires. (g. III-B).

The Trimig 250, 300 and 350 can weld 1mm and 1.2mm aluminium wires. (g. III-B).

To weld aluminium, neutral gas “pure Argon” (AR) is required. For specic gas requirements seek advice from your

gas distributor. The gas ow in aluminium should be between 15 and 25 L / min depending on the environment and

experience of the welder.

Things to note when welding with Aluminium

- Set the pressure of the rollers to a minimum so as not to crush the wire

- Remove the capillary tube before connecting the aluminium torch

- When welding aluminium use a special aluminium torch with Teon sheath to reduce friction.

9

Page 5

TRIMIG

Do not cut the sheath near the connector! It is used to guide the wire from the rollers (g III-B).

- Contact Tip: Use the specic Aluminium contact tip corresponding to the diameter of the wire.

SEMI-AUTOMATIC BRAZING FOR HIGH-TENSILE STRENGTH STEELS

The Trimig 200-4S can braze-weld high-tensile strength plates with Cuprosilicium CusI3 wire or Cuproaluminium CuAl8

wire (Ø 0.8 mm and Ø 1 mm). The welder must use a neutral gas: pure argon (Ar). For specic gas requirements

seek advice from your gas distributor. The required gas ow is between 15 and 25L / min.

REEL AND TORCH ASSEMBLY (FIG IV)

Open the door of the machine.

• Position the reel on to the support (3). To place a 200mm wire reel, rst install the adapter (ref. 042889) on the

support.

• Adjust the reel brake (4) to avoid the reel movement tangling the wire when welding stops. Be careful not to tighten

too much! Then tighten the plastic screw (2) rmly.

• The wire feeder uses double groove rollers (8) (Ø 0.8/ Ø 1 or Ø 1/ Ø 1.2). The visible diameter on the roller when

tted is the one currently in use. For Ø 1 mm wire, use the Ø 1 groove.

• For rst use:

- Release the xing screw of the wire guide (5).

- Place the rollers, and tighten the screws (9).

- Place the wire guide (7) as close as possible to the roller but without touching it, then tighten the xing screw.

• To select the adjustment of the drive rollers (6) : loosen the knob fully, Start the motor by pressing the trigger of the

torch, tighten the knob whilst pressing the trigger until the wire starts to move. Bend the wire where it comes out of the

nozzle and hold it in place to stop its progress. The setting is correct when the guide roller slides over the wire, even

when it is blocked at the end of the torch.

• Common adjustment of knob (6): scale 3-4 for steel, and scale 2-3 for aluminium.

EN

CHOICE OF REELS

Possible settings:

Wire type Torch Gas

Steel

Stainless

Alu

AG5

*Consider Teon sheath and special aluminium contact tip

GAS COUPLING

Fit the regulator/owmeter to the gas bottle and then t the gas pipe to the connector.

To avoid gas leaks use the collars provided in the accessories box. Ensure proper maintenance of the gas cylinder in

accordance with the attachment of the chain cf. IV-1.

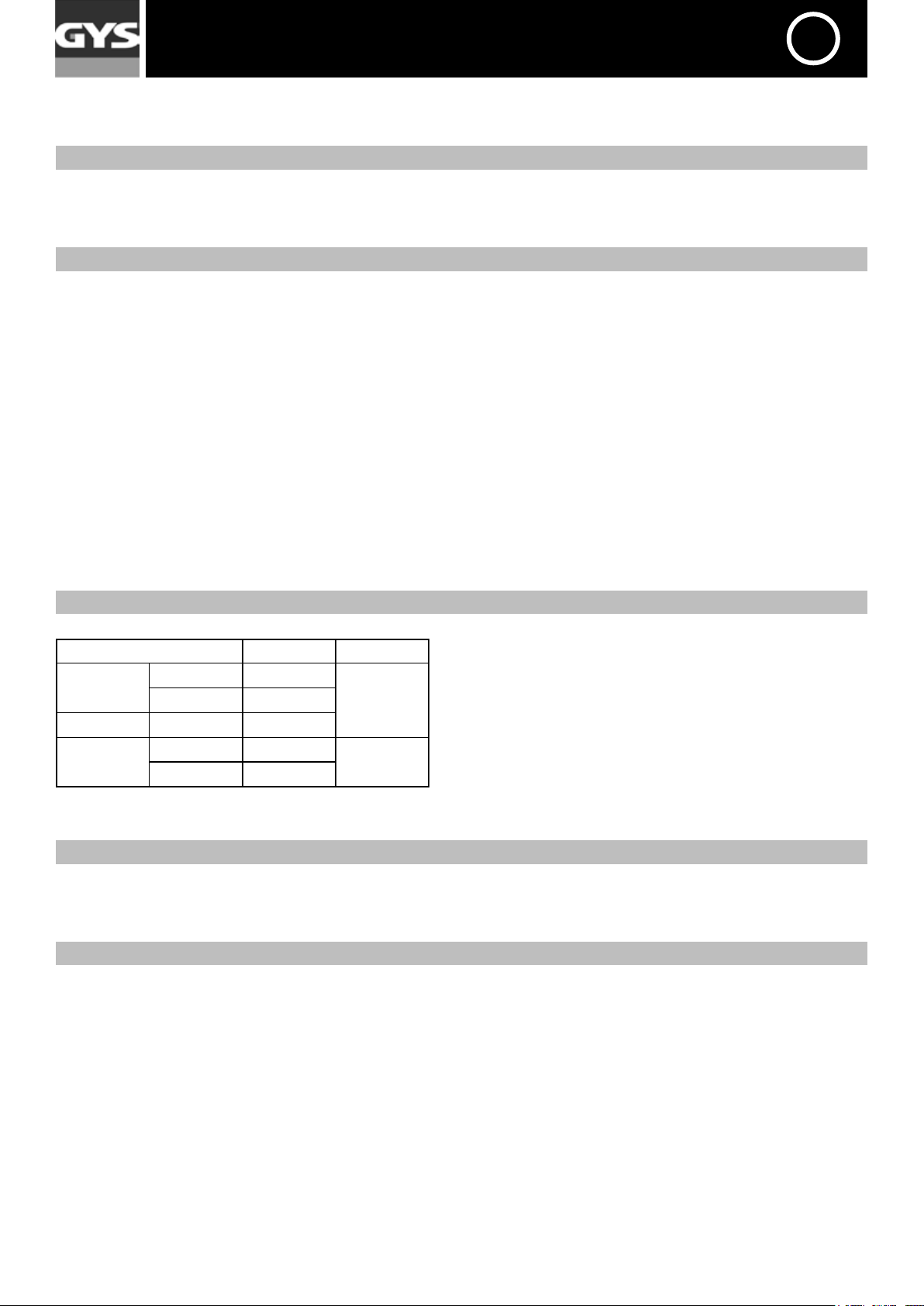

CONTROL PANEL (FIG V)

Welding mode selection (2)

- 2T: two-stage welding

- 4T: 4-stage welding

- SPOT: Spot welding with adjustable spot diameter

Wire speed selection (4)

Wire speed regulator

The speed varies from 1 to 15 m/minute.

SPOT/DELAY setting potentiometer (5)

Manual Mode (1)

In manual mode, the wire speed is determined by the

user by adjusting the potentiometer (4).

Ø 300 x

Ø 200 x

Ø 200 x

Ø 300 x*

Ø 200 x*

argon

+

CO2

Argon pur

Synergic Mode (3)

Position the potentiometer (4) in the middle of the «

OPTIMAL SYNERGIC » zone

In this mode, the device determines the optimum wire

speed according to 3 parameters:

- Voltage

- Wire diameter

- The power mode

It is possible to adjust the speed wire + / -.

10

Page 6

TRIMIG

"MANUAL" MODE (FIG V)

To set your device, proceed as follows:

- Choose the welding voltage using the 2 power switches (2 and 7 positions)

Example:

For welding Steel - 1 mm with a Ø 0.8 wire, set the switch to «1»

Adjust the wire speed with potentiometer (4).

Advice:

The wire speed adjustment is often determined by « the noise »: the arc must be stable and emit low crackling.

If the speed is too low, the arc will not be continuous.

If the speed is too high, the arc crackles and the wire will push back the torch.

"SYNERGIC" MODE (FIG V)

This function automatically controls the wire speed. There is no need to set the wire speed manually.

• Position the wire speed potentiometer (4) in the middle of the « Optimal synergic » zone.

• Select:

- Wire type (3)

- Wire diameter (3)

- Power setting (switch on the front)

To select the right position in accordance with the thickness of the work-piece, please refer to the “synergic mode” table

on the previous page.

EN

From the settings chosen, the Trimig determines the optimum wire speed and the device is ready to weld. It is also

possible to adjust the wire speed if necessary by adjusting potentiometer + or – manually (4).

The last welding conguration is saved in the memory automatically (wire diameter, wire type, mode).

ADVICE AND THERMAL PROTECTION

• Trimig should not be lifted by its handles, torch support, or the top of the machine. When lifting the Trimig, ensure the

weight is fully supported at the bottom of the machine. There must be no gas bottle connected during this operation.

• Always respect the basic rules of welding.

• Do not block/cover the ventilation holes of the machine.

• Leave the device plugged in after welding to allow proper cooling down.

• Thermal protection: If the machine becomes too hot, the warning light will illuminate and the machine will stop.

Cooling will take a few minutes, the length of time will also depend on the external temperature.

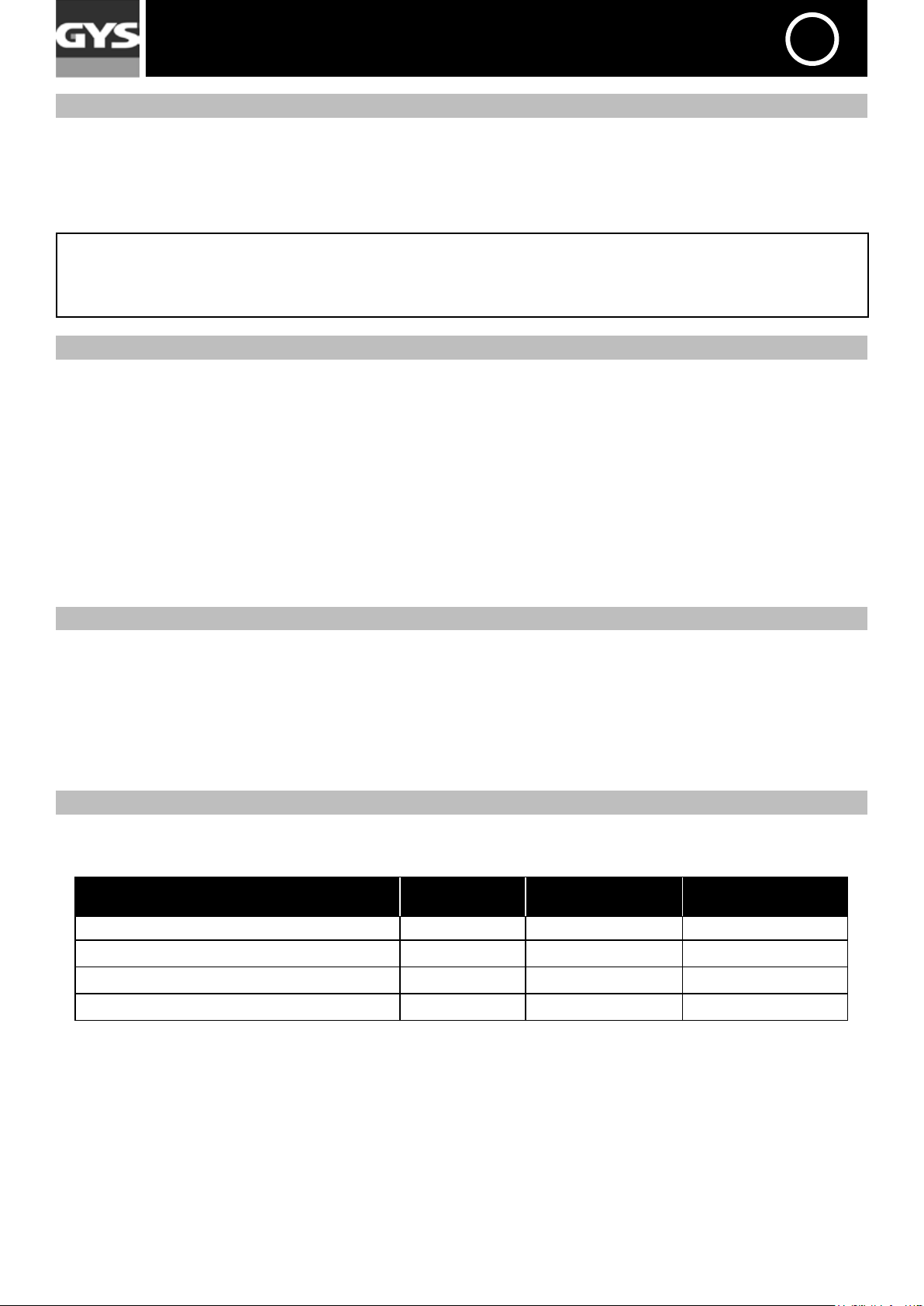

DUTY CYCLE AND WELDING ENVIRONMENT IN USE

• The welding unit describes an output characteristic of "constant current" type. The duty cycles following the

standard EN60974-1 (at 40°C on a 10mn cycle) are indicated in the table below:

x/60974-1 @ 40°C I max 60% 100%

Trimig 200-4S 200A @ 30% 140A 120A

Trimig 250-4S 250A @ 30% 180A 140A

Trimig 300-4S et G

Trimig 350-4S DUO et G DV 350A @ 35% 270A 220A

300A @ 35% 240A 180A

Note : The machines’ duty cycle has been tested at room temperature (40°C) and has been determined by simulation.

• These are Class-A devices. They are designed to be used in an industrial or professional environment. In a different

environment, it can be difcult to ensure electromagnetic compatibility, due to conducted disturbances as well as

radiation.

• These devices comply with IEC 61000-3-12, provided that the power of the short-circuit Ssc is equal to or greater than

3.9MVA (2.8MVA for the Trimig 200-4S) at the interface between the machine and the mains power network. It is the

responsibility of the installer or user of the equipment to ensure if necessary by consulting the operator of the mains

electricity, that the equipment is only connected to a power supply where the power of short-circuit ssc is equal to or

greater than 3,9MVA (2.8MVA for the Trimig 200-4S).

11

Page 7

TRIMIG

MAINTENANCE

• Maintenance should only be carried out by a qualied person.

• Ensure the machine is unplugged, and that the ventilator inside has stopped before carrying out maintenance work.

(DANGER High Voltage and Currents).

• GYS recommends removing the steel cover 2 or 3 times a year to remove any excess dust. Take this opportunity to

have the electrical connections checked by a qualied person with an insulated tool.

• Regularly check the condition of the power supply cord. If damaged, it will need to be replaced by the manufacturer,

its’ after sales service or a qualied person.

• Ensure the ventilation holes of the device are not blocked to allow adequate air circulation.

• Before each use, check the state of welding cables of the torch and earth clamp (The conductive metal should not be

exposed).

SAFETY

Arc welding can be dangerous and can cause serious and even fatal injuries.

Protect yourself and others. Ensure the following safety precautions are taken:

Arc radiation: Protect yourself with a helmet tted with lters in compliance with EN169 or EN 379.

Rain, steam, damp: Use your welding unit in a clean/dry environment (pollution factor ≤ 3), on a at surface, and

more than one meter from the welding work-piece. Do not use in rain or snow.

EN

Electric choc: This device must only be used with an earthed power supply. Do not touch the parts under high voltage.

Check that the power supply is suitable for this unit.

Falls: Do not place/carry the unit over people or objects.

Burns: Wear protective (re-proof) clothing (cotton, overalls or jeans).

Wear protective gloves and a re-proof apron.

Ensure other people keep a safe distance from the work area and do not look directly at the welding arc.

Protect others by installing re-proof protection walls.

Fire risks: Remove all ammable products from the work area. Do not work in presence of ammable gases.

Fumes: Do not inhale welding gases and fumes. Use the device in a well ventilated environment, with articial extraction

if welding indoors.

Additional Precautions: Any welding operation undertaken in.....

- rooms where there is an increased risk of electric shocks,

- Poorly ventilated rooms,

- In the presence of ammable or explosive material,

Use should always be approved by a "responsible expert", and made in presence of people trained to intervene in case

of emergency.

Technical protection as described in the Technical Specication CEI/IEC 62081 must be implemented. Welding in raised

positions should not be undertaken, except in case of safety platforms use.

People wearing Pacemakers are advised to see their doctor before using this device.

Do not use the welding unit to unfreeze pipes.

Handle gas bottles with care - there is increased danger if the bottle or its valve are damaged.

12

Page 8

TRIMIG

TROUBLESHOOTING

Symptoms Reasons Solutions

Cracklings block up the opening.

The welding wire speed is not

constant.

The wire skids in the rollers.

Reel or roller brake too tight. Release the brake and rollers.

The unwinding motor doesn't operate.

Bad wire unwinding.

No welding current

The wire rubs down after the rollers.

The welding cord is porous

Very important ashing particules.

No gas at the torch output. Bad gas connection.

Electrical supply problem.

Covering wire guide dirty or damaged. Clean or replace

Reel brake too tight Release the brake

Bad connection to the main supply.

Bad earth connection.

Power contactor inoperative. Control the torch trigger.

Covering wire guide crushed. Check the covering and torch body.

Locking of the wire in the torch Clean or replace.

No capillary tube. Check the presence of capillary tube.

Wire speed too fast Reduce the wire speed

The gas ow rate is not sufcient.

Gas bottle empty. Replace it.

Gas quality non-satisfying. Replace it.

Air ow or wind inuence. Avert air blast, protect welding area.

Gas nozzle too full. Clean or replace the gas nozzle.

Bad wire quality.

Surface to weld in bad condtion. (rust,

etc, ...)

Arc voltage too low or too high. See welding settings.

Bad earth connection.

Protecting gas insufcient. Adjust the gas ow.

EN

Clean out the contact batch or change

it and replace the anti-adherence

product. Ref.041806

Control the roller pressure or replace

it.

Wire diameter non-consonant with

roller.

Covering Wire guide in the torch nonconsonant.

Check that the running button is on

the position on.

See the branch connection and look if

the plug is fed by 3 phases.

Control the earth cable (connection

and clamp condition).

Adjusting ow range 15 to 20 L / min.

Clean the working metal.

Use adapted WIRE for MIG-MAG

welding.

Clean the working parts before

welding.

Check and place the earth cable to

have a better connection.

See if the gas coupling beside the

engine is well connected. Check the

owmeter and the solenoid valves.

13

Page 9

TRIMIG

SCHÉMA ÉLECTRIQUE / CIRCUIT DIAGRAM / SCHALTPLAN / DIAGRAMA ELECTRICO /

ЭЛЕКТРИЧЕСКАЯ СХЕМА

Trimig 200-4S

31

Page 10

TRIMIG

Trimig 250-4S

32

Page 11

TRIMIG

Trimig 300-4S

33

Page 12

TRIMIG

Trimig 300 g

34

Page 13

TRIMIG

Trimig 350-4S DUO DV 230-400V

35

Page 14

TRIMIG

Trimig 350 g DV 230-400V

36

Page 15

TRIMIG

PIECES DETACHEES / SPARE PARTS / ERSATZTEILE/ PIEZAS DE RECAMBIO/ ЗАПЧАСТИ

rimig 200-4S/250-4S DV/300-4S/300 g/350-4S DUO DV/350 g DV

T

27

28

1

T

rimig 300 g

T

rimig 350 g DV

20

21

33

12

21

13

2

7

3

5

6

8

10

11

29

14

26

17

4

24

25

32

23

22

26

31

32

15

29

18

16

19

Trimig 300 g

T

rimig 350-4S DUO DV

T

rimig 350 g DV

37

Page 16

TRIMIG

N°

1

2

3

4

5

6

7

8

10

11

12

13

14

15

16

Chaîne de 80cm / 80cm chain / 80cm Sicherungskette /

cadena de 80cm / Цепь 80 см

Support câbles arrière / Rear cable support / Hinterer

Brennerhalter / Soporte trasero de cables / Подставка для

каблей горелок задняя

Support torches avant / Front torches support / Vorderer

Brennerhalter / Soporte antorchas delanteras / Подставка

для горелок

Poignée / Handle / Griff / Puño/ Рукоятка

Bouton réglage de vitesse l / Wire speed adjusting knob

/ Poti Drahtvorschubgeschwindigkeit / Botón reglaje

de velocidad de hilo / Кнопка регулировки скорости

проволоки

Bouton SPOT-DELAY / SPOT-DELAY button / SPOT-DELAY

Poti / botón SPOT/DELAY / Кнопка SPOT-DELAY

Clavier de commande / Control Keyboard / Bedienfeld /

Teclado de mando / Панель управления

Interrupteur I/O / I/O Switch / Netzschalter AN/AUS /

Conmutador ON/OFF / Переключатель Вкл/Выкл

Commutateur / Switch / Spannungsschalter / Conmutador

/ переключатель

Motodévidoire (sans galet) / Wire feeder (without roller) /

Drahtvorschub (ohne Drahtförderrollen) / Devanadera sin

rodillos (sin rodillo) / Подающий механизм (без роликов)

Câble d'alimentation / Supply cable / Netzstromkabel /

Cable de alimentación / Шнур питания

Support bobine 15Kg / Reel support 15 Kg /

Drahtförderrollen 15Kg / Soporte de bobina 15Kg /

Держатель бобины 15 кг

Roue avant / Front wheels / Vorderrad / Rueda de atrás /

Переднее колесо

Pont de diodes / Diode bridge / Gleichrichter / Puente de

LED / Диодный мост

Self / Induction oil / Self / Drossel / Дроссель

200 250 300 350

35067

98854

98853 98877

56047

73009

73099

51916 51915

52461

7 pos

51072

21475 21497 21470

71361 71364

52190 52173 52174 52221

96076 96079 96081 96083

10 pos

51074

51136 51257

71603

12 pos

51227

7 pos 51054

2 pos 51071

17

18

19

20

21

22

23

24

Thermostat / Thermostat / Thermostat / termostato /

Термостат

Transformateur / Transformer / Trafo / Transformador /

Транформатор

Ventilateur / Fan / Ventilator /ventilador/ Вентилятор

Roue diamètre 200mm / 200mm diameter wheels / Rad

200mm Durchmesser / Rueda diámetro 200mm / Колесо

диаметром 200 мм

Embout d'axe / End axis / Radachse / Boquilla de pasador

/ Ось

Contacteur 24V AC 10A / Contactor 24V AC 10A / 24V AC

10A Schalter / Contactor 24V AC 10A / Контактор 24В AC

10A

Transformateur de commande / Control transformer

/ Steuertransformator / Transformador de mando /

Трансформатор цепей управления

Electrovanne / Solenoid valve / Elektroventil / Electroválvula / Электроклапан

52101

96075 96078 96080 96082

51006

71375 71376

71382

51114 51107

92994 96029 96047 96029

71512

38

Page 17

TRIMIG

25

26

27

28

Carte de commande / Control card / Steuerkarte / Carta

de mando / Плата управления

Carte d'afchage / Display card / Anzeigekarte / Carta de

jación / Плата управления дисплея

Tuyau gaz (1m) / Gas pipe (1m) / Gasschlauch (1m) /

Tubo del gas (1m) / Газопроводная трубка (1 м)

Collier 10,5 / Collar 10,5 / Schlauchschelle 10,5 / Collar

10,5 / Хомут 10,5

97132C 97172C

97183C 97233C

95993

71225

Connecteur 1/4 cable de masse / Earth cable connector

29

(1/4) / (-) Texasbuchse (1/4) - Leistungsanschluss

separates Drahtvorschubgerät/ connector cable de tierra

51469 51461

(1/4)

Sélecteur 230-400V / Voltage selection switch 230-400V/

30

Umschalter 230-400V / Selector de tensiόn 230/400V /

- 75012 - 75012

Переключатель 230-400В

Pour les postes avec dévidoir / For machines with wire feeder / Geräte mit separatem Drahtvorschubgerät / Para

equipos con devanadera / для аппаратов с подающим устройством

Passe cloison de Gaz / Gas connector /

31

Schutzgasanschluss 2 (Ausgang für separates

Drahtvorschubgerät) / Conector de gas / Проход в

- - 71699

перегородке для Газа

Connecteur de commande / Wire feeder control connector

32

/ Steueranschluss separates Drahtvorschubgerät /

- - 94895

Conector de mando / Коннектор управления

Interrupteur de sélection du potentiomètre / Potentiometer

33

selection switch / Potentiometer Auswahlschalter/

Interruptor de selecciόn del potenciόmetro /

- - 52464

Переключатель выбора на потенциометре

39

Page 18

TRIMIG

CONDITIONS DE GARANTIE FRANCE

- La garantie n’est valable que si le bon a été correctement rempli par le vendeur.

- La garantie couvre tout défaut ou vice de fabrication pendant 1 an, à compter de la date d’achat (pièces et main

d’œuvre).

- La garantie ne couvre pas les erreurs de tension, incidents dus à un mauvais usage, chute, démontage ou toute autre

avarie due au transport.

- La garantie ne couvre pas l’usure normale des pièces (Ex. : câbles, pinces, etc.).

En cas de panne, retournez l’appareil à la société GYS (port dû refusé), en y joignant :

- Le présent certicat de garantie validé par le vendeur.

- Une note explicative de la panne.

Après la garantie, notre SAV assure les réparations après acceptation d’un devis.

Contact SAV:

Société GYS - 134 Bd des Loges

BP 4159-53941 Saint-Berthevin Cedex

Fax: +33 (0)2 43 01 23 75 - Tel: +33 (0)2 43 01 23 68

HERSTELLERGARANTIE

Die Garantieleistung des Herstellers erfolgt ausschließlich bei Fabrikations- oder Materialfehlern, die binnen 12 Monate

nach Kauf angezeigt werden (Nachweis Kaufbeleg). Nach Anerkenntnis des Garantieanspruchs durch den Hersteller

bzw. seines Beauftragten erfolgen eine für den Käufer kostenlose Reparatur und ein kostenloser Ersatz von Ersatzteilen.

Der Garantiezeitraum bleibt aufgrund erfolgter Garantieleistungen unverändert.

Ausschluss: Die Garantieleistung erfolgt nicht bei Defekten, die durch unsachgemäßen Gebrauch, Sturz oder harte Stöße

sowie durch nicht autorisierte Reparaturen oder durch Transportschäden, die infolge des Einsendens zur Reparatur,

hervorgerufen worden sind. Keine Garantie wird für Verschleißteile (z. B. Kabel, Klemmen, Vorsatzscheiben etc.) sowie

bei Gebrauchsspuren übernommen. Das betreffende Gerät bitte immer mit Kaufbeleg und kurzer Fehlerbeschreibung

ausschließlich über den Fachhandel einschicken. Die Reparatur erfolgt erst nach Erhalt einer schriftlichen Akzeptanz

(Unterschrift) des zuvor vorgelegten Kostenvoranschlags durch den Besteller. Im Fall einer Garantieleistung trägt GYS

ausschließlich die Kosten für den Rückversand an den Fachhändler.

40

Page 19

TRIMIG

FR

GYS atteste que ces postes de soudure sont fabriqués conformément aux exigences des directives Basse tension

2006/95/CE du 12/12/2006, et aux directives CEM 2004/108/CE du 15/12/2004. Cette conformité est établie par le

respect des normes harmonisées EN60974-1 de 2005, EN 50445 de 2008, EN 60974-10 de 2007. Le marquage CE a

été apposé en 2013.

EN

The equipment described on this manual is conform to the instructions of low voltage 2006/95/CE of 12/12/2006, and

the instructions of CEM 2004/108/CE of the 15/12/2004. This conformity respects the standards EN60974-1 of 2005,

EN 50445 de 2008, EN60974-10 of 2007. CE marking was added in 2013.

DE

GYS erklärt, dass die synergisch geregelten Schweißanlagen TRIMIG 200-4S/ 250-4S DV/ 300-4S/ 300 G/ 350-4S

DUO DV/ 350 G DV richtlinienkonform mit Niederspannungsrichtlinie 2006/95/CE –12.12.2006 und EMV- Richtlinien

2004/108/CE – 15.12.2004 elektromagnetische Verträglichkeit- hergestellt wurden. Diese Geräte stimmen mit den

harmonisierten Normen EN60974-1 von 2005, EN 50445 von 2008, EN60974-10 von 2007 überein. CE Kennzeichnung: 2013.

ES

GYS certica que estos aparatos de soldadura son fabricados en conformidad con las directivas baja tensión 2006/95/

CE del 12/12/2006, y las directivas compatibilidad electromecánica 2004/108/CE del 15/12/2004. Esta conformidad

está establecida por el respeto a las normas EN60974-1 de 2005, EN 50445 de 2008, EN 60974-10 de 2007. El marcado CE fue jado en 2013.

DÉCLARATION DE CONFORMITÉ

DECLARATION OF CONFORMITY

KONFORMITÄTSERKLÄRUNG

DECLARACIÓN DE CONFORMIDAD

RU

GYS заявляет, что сварочные аппараты произведены в соответствии с директивами Евросоюза 2006/95/

CE о низком напряжении от 12/12/2006, а также с директивами CEМ 2004/108/CE от 15/12/2004. Данное

соответствие установлено в соответствии с согласованными нормами EN60974-1 2005 г, EN 50445 2008 г, EN

60974-10 2007 г. Маркировка ЕС нанесенна в 2013 г.

ДЕКЛАРАЦИЯ О СООТВЕТСТВИИ

01/02/2013

Société GYS

134 BD des Loges

53941

Saint-Berthevin

France

Nicolas BOUYGUES

Président Directeur Général

41

Page 20

TRIMIG

ICONES / SYMBOLS / ZEICHENERKLÄRUNG

A Ampères - Amps - Ampere - Amperios - Ампер

V Volt - Volt - Volt - Voltios - Вольт

Hz Hertz - Hertz - Hertz - Hertz - Герц

Soudage MIG/MAG (MIG: Metal Inert Gas / MAG: Metal Active Gas) - MIG/MAG Welding (MIG: Metal

Inert Gas / MAG: Metal Active Gas) - MIG/MAG Schweißen (MIG: Metal Inert Gas/ MAG: Metal Active

Gas) - Soldadura MIG/MAG (MIG: Metal Inert Gas / MAG: Metal Active Gas) - Полуавтоматическая

сварка MIG/MAG (MIG: Metal Inert Gas / MAG: Metal Active Gas)

Convient au soudage dans un environnement avec risque accru de choc électrique. La source de

courant elle-même ne doit toutefois pas être placée dans de tels locaux. - Adapted for welding in

environment with increased risks of electrical shock. However, the welding source must not be placed

in such places. - S-Zeichen: Das Schweißen unter beengten Verhältnissen ist mit diesen Schweißgeräten zugelassen.- Adaptado a la soldadura en un entorno que comprende riesgos de choque eléctrico.

La fuente de corriente ella misma no debe estar situada dentro de tal locales. - Адаптирован для

сварки в среде с повышенным риском электрошока. Однако сам источник питания не должен

быть расположен в таких местах.

IP21 Protégé contre l’accès aux parties dangereuses avec un doigt, et contre les chutes verticales de

gouttes d'eau. - Protected against rain and against ngers access to dangerous parts. - Schutz gegen

Berührung mit den Fingern und mittelgroße Fremdkörper, Schutz gegen Tropfwasser.

- Protegido contra el acceso a las partes peligrosas con los dedos, y contra las caídas verticales de

gotas de agua. - Аппарат защищен от доступа рук в опасные зоны и от вертикального падения

капель воды Сварка на постоянном токе.

Courant de soudage continu. - Welding direct current. - Gleichschweißstrom. - La corriente de soldadura es continua. - Сварка на постоянном токе.

Alimentation électrique triphasée 50Hz. - Three-phase power supply 50 Hz. - Dreiphasige Netzversorgung mit 50 Hz. - Alimentación eléctrica monofásica 50 Hz. - Трехфазное напряжение 50 Гц.

U0 Tension assignée à vide. - Rated no-load voltage. - Leerlaufspannung. - Tensión asignada de vacío. -

Напряжение холостого хода.

U1 Tension assignée d’alimentation. - rated supply voltage. - Netzspannung. - Tensión de la red. -

Напряжение сети.

I1max Courant d’alimentation assigné maximal (valeur efcace). - Rated maximum supply current (effective

value). - Maximaler Versorgungsstrom (Effektivwert). - Corriente máxima de alimentación de la red. Максимальный сетевой ток (эффективная мощность)

I1eff Courant d’alimentation effectif maximal. - Maximum effective supply current. - Maximaler tatsä-

chlicher Versorgungsstrom. - Corriente de alimentación efectiva máxima. - Максимальный

эффективный сетевой ток.

EN60 974-1 L’appareil respecte la norme EN60974-1. - The device complies with EN60974-1 standard relative

to welding units. - Das Gerät entspricht der Norm EN60974-1 für Schweißgeräte. - El aparato está

conforme a la norma EN60974-1 referente a los aparatos de soldadura. - Аппарат соответствует

европейской норме EN60974-1.

Transformateur-redresseur triphasée. - Three-phase converter-rectier. - Dreiphasiger Trafo/Frequenzumwandler. - Transformador-recticador trifásico. - Трехфазный инвертор, с трансформацией и

выпрямлением.

X(40°C) Facteur de marche selon la norme EN 60974-1 (10 minutes – 40°C). - Duty cycle according to the

standar EN 60974-1 (10 minutes – 40°C). - Einschaltdauer gemäß EN 60974-1 (10 Minuten – 40°C).

- Factor de marcha según la norma EN 60974-1 (10 minutos – 40°C). - ПВ% по норме EN 60974-1

(10 минут – 40°С).

I2: courant de soudage conventionnnel correspondant. - I2: corresponding conventional welding current. - I2: entsprechender Schweißstrom. - I2: Corrientes correspondientes. - I2: Токи,

соответствующие Х*

U2: Tensions conventionnelles en charges correspondantes. - U2: conventional voltages in corresponding load. - U2: entsprechende Arbeitsspannung. - U2: Tensiones convencionales en carga. - U2:

соответствующие сварочные напряжения*.

42

Page 21

TRIMIG

Appareil conforme aux directives européennes. - The device complies with European Directive.

- Gerät entspricht europäischen Richtlinien. - El aparato está conforme a las normas europeas. Устройство соответствует европейским нормам.

Conforme aux normes GOST (Russie). - Conform to standards GOST / PCT (Russia). - in Übereinstimmung mit der Norm GOST/PCT. - Conforme a la normas GOST (PCT) (Rusia). - Продукт

соответствует стандарту России (РСТ).

L’arc électrique produit des rayons dangereux pour les yeux et la peau (protégez-vous !). - The electric arc produces dangerous rays for eyes and skin (protect yourself !). - Der elektrische Lichtbogen

verursacht Strahlungen auf Augen und Haut (Schützen Sie sich !). - El arco produce rayos peligrosos

para los ojos y la piel (¡ Protéjase !). - Электрическая дуга производит опасные лучи для глаз и

кожи (защитите себя!). - Внимание! Сварка может вызвать пожар или взрыв.

Attention, souder peut déclencher un feu ou une explosion. - Caution, welding can produce re or

explosion. - Achtung! Schweißen kann Feuer oder Explosion verursachen. - Cuidado, soldar puede

iniciar un fuego o una explosión. - Внимание! Сварка может вызвать пожар или взрыв.

Attention ! Lire le manuel d’instruction avant utilisation. - Caution ! Read the user manual. - Achtung!

Lesen Sie die Betriebsanleitung. - Cuidado, leer las instrucciones de utilización. - Внимание !

Читайте инструкцию по использованию.

Produit faisant l'objet d'une collecte sélective- Ne pas jeter dans une poubelle domestique. - Separate

collection required, Do not throw in a domestic dustbin. - Für die Entsorgung Ihres Gerätes gelten

besondere Bestimmungen (Sondermüll). Es darf nicht mit dem Hausmüll entsorgt werden. - Este

aparato es objeto de una recolección selectiva. No debe ser tirado en un cubo doméstico. - Продукт

требует специальной утилизации. Не выбрасывать с бытовыми отходами.

43

Page 22

ACCESSOIRES/ACCESORIES/ZUBEHÖR/ACCESORIOS/AKCECCYAPBI

Acier/Steel/Stahl

Inox/Stainless/

Edelstahl

CuSi3

CuAl8

Alu

Acier/Steel/Stahl

Inox/Stainless/

Edelstahl

Alu

TRIMIG

ø 200 ø 300 0.6 - 1.0

086111 (ø0.6)

086126 (ø0.8)

086135 (ø1.0)

086325 (ø0.8) -

086647 (ø0.8) -

086661 (ø0.8) -

086565 (ø0.8) 086524 (ø1.0) 042377 (ø0.8/1.0)

ø 200 ø 300 0.8 - 1.2

086128 (ø0.8)

086135 (ø1.0)

086326 (ø0.8) -

-

086166 (ø0.6)

086227 (ø0.8)

086234 (ø1.0)

086227 (ø0.8)

086234 (ø1.0)

086241 (ø1.2)

086524 (ø1.0)

086531 (ø1.2)

042353 (ø0.6/0.8)

042360 (ø0.8/1.0)

Trimig 250-4S DV 230-400V

042360 (ø0.8/1.0)

042384 (ø1.2/1.6)

042377 (ø0.8/1.0)

042391 (ø1.2/1.6)

Trimig 200-4S

041837

(ø0.6/0.8 - 4m)

041844

(ø1.0 - 4m)

044050

(ø0.8 - 4m)

044067

(ø1.0 - 4m)

041837

(ø0.8 - 4m)

041844

(ø1/1.2 - 4m)

044050

(ø0.8 - 4m)

044067

(ø1.0 - 4m)

044074

(ø1.2 - 4m)

040922

(250A - 4m)

040939

(250A - 4m)

040922

(250A - 4m)

040939

(250A - 4m)

041905 (ø0.6)

041950 (ø0.8)

041967 (ø1.0)

041059 (ø0.8)

041066 (ø1.0)

041950 (ø0.8)

041967 (ø1.0)

041974 (ø1.2)

041066 (ø1.0)

041073 (ø1.2)

041882

041882

20L/min

041998

30L/min

041622 (FR)

041646 (UK)

041219 (DE)

30L/min

041622 (FR)

041646 (UK)

041219 (DE)

043787

(250A - 3m)

25 mm²

043787

(250A - 3m)

25 mm²

Acier/Steel/Stahl

Inox/Stainless/

Edelstahl

Alu

Trimig 300-4S / 300 G / 350-4S DUO DV / 350 G DV

ø 200 ø 300 0.8 - 1.2

086128 (ø0.8)

086135 (ø1.0)

086326 (ø0.8) -

-

086227 (ø0.8)

086234 (ø1.0)

086241 (ø1.2)

086524 (ø1.0)

086531 (ø1.2)

042360 (ø0.8/1.0)

042384 (ø1.2/1.6)

042377 (ø0.8/1.0)

042391 (ø1.2/1.6)

041837

(ø0.8 - 4m)

041844

(ø1/1.2 - 4m)

044050

(ø0.8 - 4m)

044067

(ø1.0 - 4m)

044074

(ø1.2 - 4m)

040946

(350A - 4m)

040953

(350A - 4m)

041790 (ø0.8)

419803 (ø1.0)

419810 (ø1.2)

419766 (ø1.0)

419773 (ø1.2)

041783

30L/min

041622 (FR)

041646 (UK)

041219 (DE)

043800

(300A - 4m)

25 mm²

043817

(400A - 4m)

35 mm²

043824

(500A - 4m)

50 mm²

44

Loading...

Loading...