Page 1

1

MIG 3

INSTRUCTION MANUAL

FOR SEMI-AUTOMATICAL

WELDING MACHINES

MAGYS 410

GENEGYS 510 SF

GENEGYS 515 WSF

II / NORM CE

This product has been designed with respect of the European standards.

- Directive Low Voltage 73/23 CEE of 19th February 1973 (decree n°98- 1081 of 3rd October 1995)

- Directive electromagnetic compatibility 89/336 CEE of 3rd May 1989

This conformity is established in compliance with EN60974-1 and A1/A2 of 2003 (Low voltage Directive) and EN

50199 (Electromagnetic compatibility Directive)

73326

GYS

Mise à jour

: 07/11/06

Réf 73326

Page 2

2

Thank you for choosing our product! Before installing and using the product, please read carefully the following

recommendations of safety in order to avoid accidents to the user and damages of the welding process.

GYS can’t be responsible for the damages occurred to persons or things, which derive from the use of the machine

in following circumstances:

- Modification or neutralization of safety elements,

- Non respect of the recommendations written in the manual instruction,

- Modification of the characteristics on the product

- Use of the accessories, which are different from the ones delivered by GYS,

- Non-respect of the regulating and particular dispositions where the machine is settled.

I/ SAFETY STANDARDS AND GENERAL PRECAUTIONS

GENERALITIES

1- Before disassembling the product’s body, plug out the lead cable.

2- The operators must have the appropriate qualification.

3- The operations of servicing can only be controlled by qualified technicians.

4- The operator is responsible for respect of the car manufacturers’ recommendations, concerning the

protection of electrical and electronic procedures (car computer, car radio, alarm, air bag, etc…)

5- It is necessary to make a regular preventive maintenance.

ELECTRICITY

1- Check that the unity must be connected to the earth coupler and that the connection to the earth is in good

condition.

2- Check that the workbench is connected to the earth coupler.

3- Make sure that the operator has no contact with the metal parts to the welded without any protection or wet

clothes.

4- Avoid being in contact with welding part.

5- Before controlling or repairing, please disconnect the unit directly to the level of the plug.

PROTECTION OF EYES AND BODY

1-During the welding process, the operator must be protected from the eventual flashes of the electrical arc

with protection clothes like leather gloves, welding aprons, safety shoes, welding helmets or glasses for filtering

radiations and projections. As well during operations of rubbing and hammering, the operator must protect his eyes.

2-All the protection board must be in good condition and maintained in place.

Never look at an arc of welding without any protection of your eyes.

Protect the environment near the product against projections and reflections.

SMOKES AND GAZ

Welding operations can cause the emission of toxic smokes and harmful metallic dusts. Use the device in a sheltered

place equipped with smoke aspirators.

The operator must wear an anti smoke mask.

The welding material must be degreased and cleaned in order to limit the toxic gas during the welding process.

FIRE

1-Check that the sparks don’t cause fire especially near inflammable material.

2-Check that fire extinguishers are not too far from the operator.

3-Leave the product in a place with air movers.

4-Don’t weld neither on container of combustibles and lubricants, even empty, nor on containers with

infla mmable material.

5-Don’t weld in an atmosphere full with inflammable gas or fuel steam.

ELECTRO-MAGNETIC COMPATIBILITY

Near the spot-welding, check:

- There is neither no other power supply cable nor control lines, nor phone cables, nor radio or TV reception

appliances, nor watches, nor mobile phones, nor magnetic cards, nor computers or any other electronic

appliance.

- There are in the surroundings (minimum 3 meters of each point of the product) no persons using active medical

appliances (pacemakers, acoustic prosthetics).

Make supplementary protections if other products are used in the same environment.

Page 3

3

II / CONNECTIONS OF POWER SUPPLY CABLES

Electricity:

Three phases 400V 50Hz. Use of the PHASE 1, PHASE 2, PHASE3 and EARTH CONNECTION on a three phases

plug (Don’t use NEUTRAL).

Protection of the line:

MAGYS 410: Circuit breaker 25A curve D or fuse 25A type aM

GENEGYS 510 SF and GENEGYS 515 WSF: Circuit breaker 32A curve D or fuse 32A type aM

III/ DESCRIPTION OF THE MACHINE

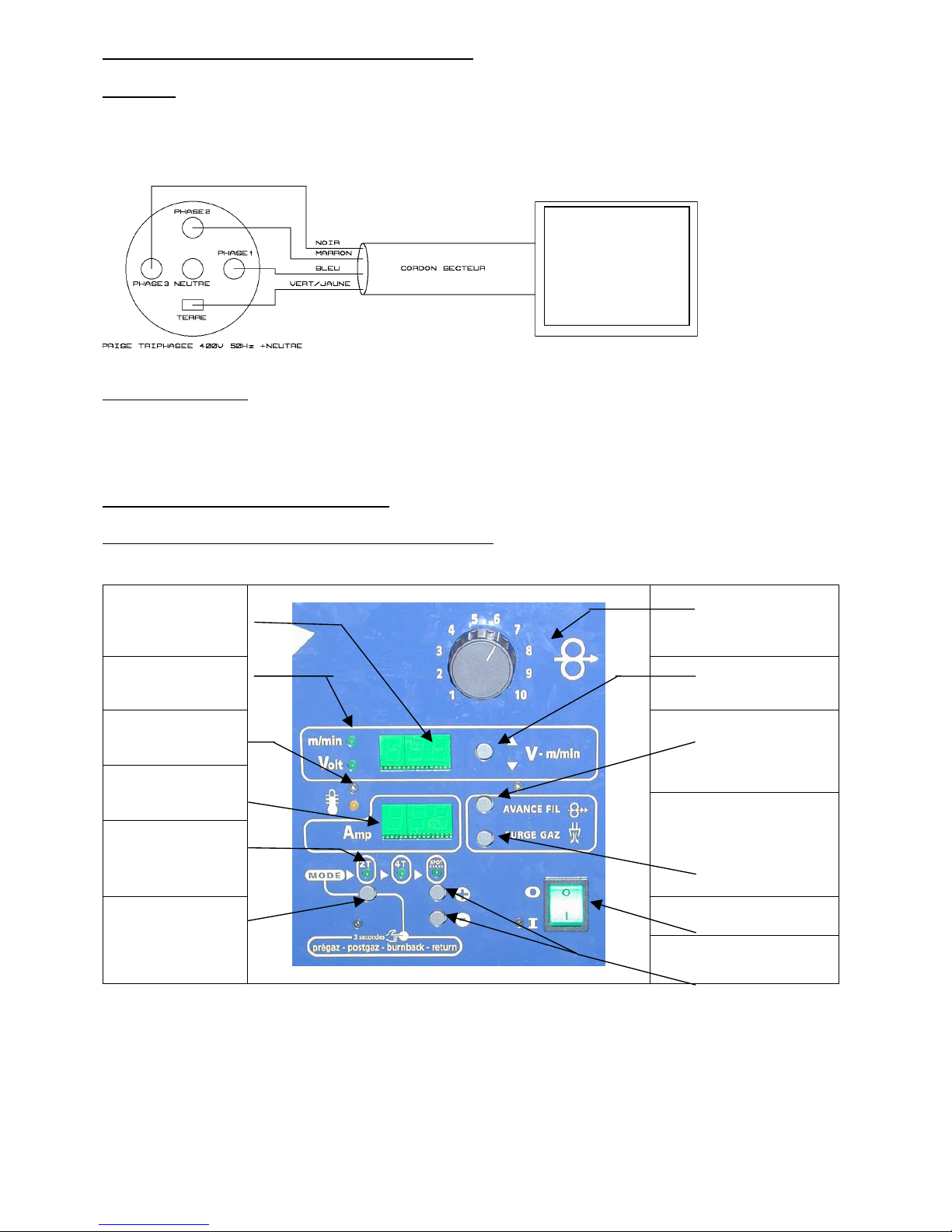

MAGYS 410 and GENEGYS 510 SF: Foreside (Higher part)

Indicator of

VOLTAGE or WIRE

SPEED measurement

Potentiometer of

instructions wire speed

(except on GENEGYS 510

SF).

Selection indicator of

value (wire speed or

voltage).

Selection indicator of value

(voltage or wire speed).

Yellow indicator of

thermal switching

Button of WIRE quick: it

allows for new coils loading

to save gas.

Indicator of current

measurement

Indicators of mode

selection: 2 times, 4

times or spot

Button of gas drain: it

allows to avoid impurity

during bottle replacement or

after a long immobilization.

Commutator On / Off Button of mode

selection

Button of spot time

adjustment

Terminal

MAGYS 410

Or

GENEGYS 510 SF

Or

GENEGYS 515 WSF

Page 4

4

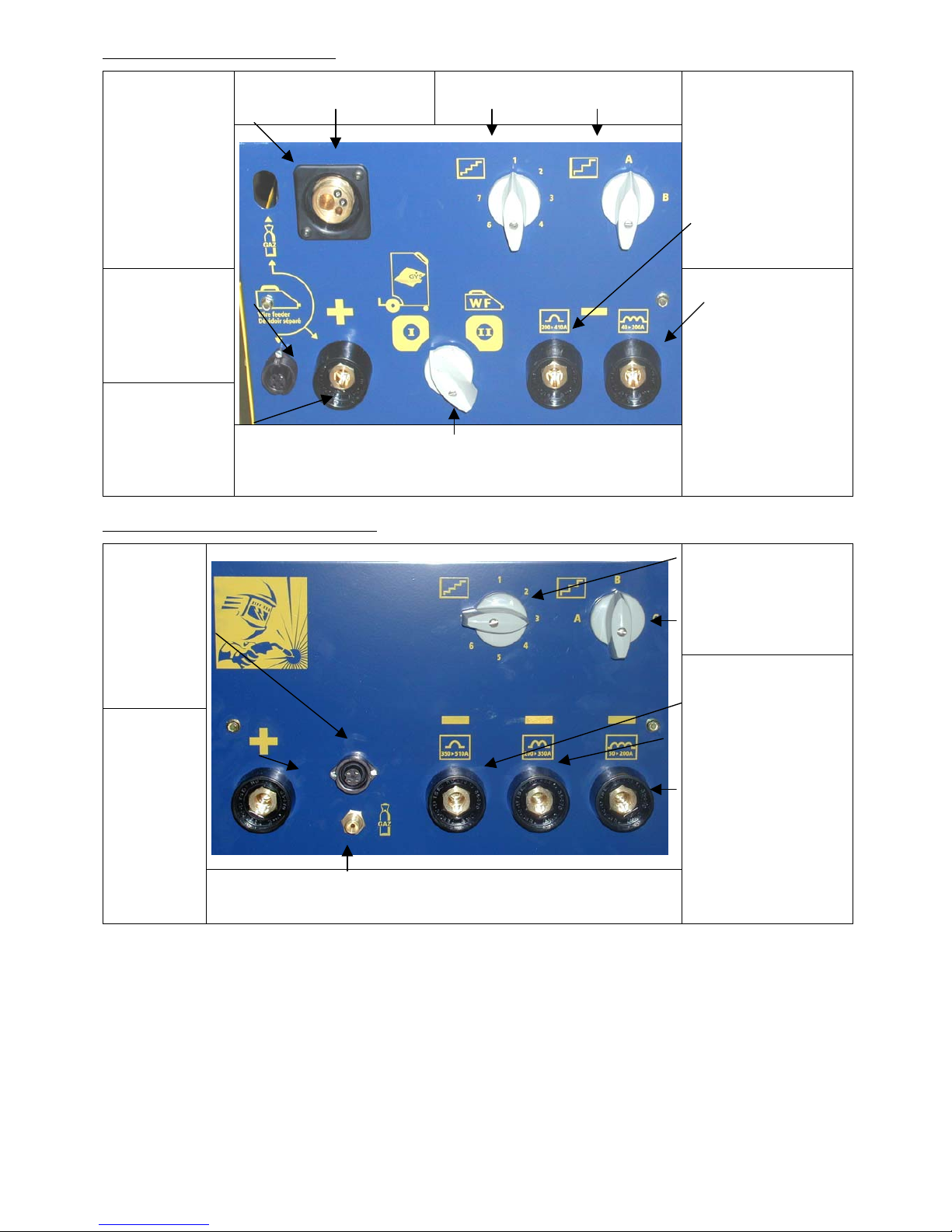

MAGYS 410: Foreside (Lower part)

Generator wire feeder

(connected to positive

terminal).

Selection commutators of the output

voltage.

Gas connection

allows to lay in gas

generator wire

feeder type WF.

The connection is

situated near to the

motor

Terminal – to use a

superior current 200 A

(position for an using in

SPRAY ARC).

Operating

connector for

application with a

separated wire

feeder type WF.

Positive terminal

for an application

with a separated

wire feeder type

WF.

Commutator on wire feeder choice.

Position I: generator wire feeder (origin).

Position II: separated wire feeder WF 212, 324 or 344 W (in

option).

Terminal – application on

weak Thickness (current

inferior to 200 A)

GENEGYS 510 SF: Foreside (Lower part)

Commutator of selection

from the output voltage

Operating

connector for

an application

with a

separated wire

feeder type

WF.

Positive

terminal for

the connection

to contact

batch for an

application

with separated

wire feeder

type WF.

Gas adapter of the bank.

Negative terminal: allows

to select an arc more or

less short.

This terminal depends on

the welding intensity we

are connected.

Page 5

5

GENEGYS 515 WSF : foreside (higher part)

GENEGYS 515 WSF : foreside (lower part)

Selection indicator

of value

(VOLTAGE or

WIRE SPEED)

Indicator of

VOLTAGE or

WIRE SPEED

measurmen

t

Indicator of current

measurmen

t

Switch of selection

for the output

voltage

Button of mode

selection

Indicators of mode

selection : 2 times, 4

times or spot

Control of the

cooling liquid group

Button of WIRE

quick : it allows for

new coils to save

gas

Button of gas drain :

it allows to avoid

impurity during

bottle replacement

or after a long

immobilization

Commutator

On / Off

Yellow indicator of

thermal switching

Button of

spot time

adjustment

Operating connector

for an application

with a separated

wire feeder type

WF.

Gas adapter of the

bank

Filler cap of the cooling

liquid tank

Positive terminal for

the connection to

contact batch for an

application with

separated wire

feeder type WF

N

egative terminal :

allows to select an arc

more or less short.

see

page 9

This terminal depends on

the welding intensity we

are connected

Adapter for cooling

liquid

Page 6

6

IV / COMMISSIONING

4-1) Mains connection

See paragraph III.

4-2) Connection to gas bottle and gas choice

Screw down the regulator on gas bottle. This one is connected to MAGYS and GENEGYS by a pipe whose terminal

end is fixated on the electronic valve behind the machine. You must use clamps to avoid escape of gas.

MAGYS 410

Application with the wire feeder of the generator Application with a separated wire feeder typ WF

Screw down the gas connection from moto generator

wire feeder on the gas connection

Screw off the pipe of moto generator wire feeder and screw

down bank connection by integrating the pipe in the frontside

hole.

For GENEGYS 510 SF and GENEGYS 515 WSF machine, the gas connection of the bank is uniquely made on front

side.

Gas choice:

STEEL MORE OR LESS ALLOYED

- Pure CO2 (not much used),

- Argon + CO2 (universal gas, often used),

- Argon + CO2 + O2 (not much used).

STAINLESS STEEL

- Argon + CO2 (often used),

- Argon + H + CO2 +N (not much used).

ALUMINIUM

- Pure argon (often used),

- Argon + Hé (not much used).

4-3) Connection to earth cable

For an application with a wire in normal polarity, you must connect the adapter earth clamp on the negative terminal

and take care to swivel from a ¼ the adapter.

MAGYS 410 machine can only operate in normal polarity (positive for the motor) if we used the generator wire

feeder.

Page 7

7

GENEGYS 510 SF and GENEGYS WSF machine can be used with a WIRE in reversed polarity by inversing in face

before the connection of the earth clamp and bank.

4-4) Connection of the torch

All torches are with a euro connection, which can be adapted on GYS machines.

4-5) Setting of rollers

Choose those in function of the wire diameter used and the type of wire (See following board). MAGYS 410

machine is delivered with rollers double groove 0,8 / 1 for steel.

4-6) Setting of wire spool

Open the wire feeder compartment. Remove the swivel from the coil support. Take the coil and put it on the support

with taking care to block with base spin, then screw down again the swivel. For an application with a 5Kg coil (or

d=200), put the adapter between the support and the coil. For an application in steel wire place in position the

capillary tube (for an application in aluminium see the paragraph VIII).

Slump the wire in the moto wire feeder entrance. Release the clamping at maximum. Close the plate of the moto wire

feeder. Press on « ADVANCED WIRE » (in foreside) and tighten little by little the clamping handle until the motor

start to drive the wire.

4-7) Brake adjustment from the coil support

You must block this one in function of the weight coil used.

Too blocked: the motor is in difficulty and the WIRE risk not to drive.

1

4 3

2

Page 8

8

Release: the important coil inertia can drive the wire rolling after end welding.

Open the gas. The machine is ready to operate.

4-8)Commissioning of the cooling liquid group ( GENEGYS 515 WSF)

• Never operates the cooling group without filling the cooling liquid tank before the use of the machine.

• Use the cooling liquid -25°C.

• Fill the tank until the maximum level

For first use, the cooling circuit must be bleeded from the water. To do this operation, you have

to connect the blue connection of the contact batch (5 or 10 meters) on the blue connection of the MIG

generator. Inject compressed air in the blue pipe of the contact batch to drive out the air bubble

contained in the pump circuit.

• The pump can be used.

• Connect the blue and red connection of the contact batch to the generator and the wire feeder.

• Control that the water circulation works correctly.

• Check the cooling liquid level before each use of the unit and complete the liquid if necessary.

Page 9

9

V / INDICATIVES ADJUSTEMENTS

ADJUSTMENT FOR MAGYS 410 IN STEEL USING

INDICATIVE

ADJUSTMENT

COMMUTATOR

POSITION

WIRE SPEED

SELF

EXTENSION

Metal

thickness

∅ WIRE to

use

Adjustment Current

obtain (A)

Adjustment Speed obtain

M/MIN

WITH OR

WITHOUT SELF

1 0,8 A1-A2 40-80 1-2 2-4

1,5 0,8 A3-A4 80-110 2-4 4-6

2 0,8-1 A4-A5 100-130 3-5 6-8

3 0,8-1 A5-A6- 130-180 4-5 7-11

4-5 1-1,2 A7-B1 180-230 4-7 7-13

5-7 1-1,2 B1-B2-B3 220-300 4-8 7-15

>7 1,2-1,6 B3-B4-B5-

B6-B7

300-410 5-10 9-18

ADJUSTMENT FOR GENEGYS 510 SF and GENEGYS 515 WSF IN STEEL USING

INDICATIVE

ADJUSTMENT

COMMUTATOR

POSITION

WIRE SPEED

SELF

EXTENSION

Metal

thickness

∅ WIRE to

use

Adjustment Current

obtain (A)

Adjustment Speed obtain

M/MIN

WITH OR

WITHOUT SELF

1 0,8 A1-A2 50-80 1-2 2-4

I

1,5 0,8 A3-A4-A5 70-100 2-4 4-6

I

I

2 0,8-1 A5-A6-A7 90-130 3-5 6-8

I

3 0,8-1 B1-B2 120-160 4-5 7-11

I

4-5 1-1,2 B3-B4-B5 150-250 4-6 7-12

II

5-7 1-1,2 B6-B7 230-330 4-7 7-15

II

7-9 1,2-1,6 C1-C2-C3 300-430 5-8 9-16

II

>9 1,2-1,6 C4-C5-C6-

C7

350-510 7-10 12-20

II

VI / USING IN ALUMINIUM

The torch installation for aluminium is fundamental.

The essential precautions are the following:

- Don’t use the brass capillary tube in the euro adapter, but use

the Teflon envelope, which must come until the moto-wire

feeder roller.

- In ALUMINIUM, use a contact tube of a diameter

immediately superior to the section of the wire used.

- Use ALU rollers identical with wire diameter.

VII / OPTION FOR MAGYS 410

MAGYS 410 machine is an evolutive terminal. For origin machine, we can uniquely use this one with the moto wire

feeder. Then, we can advanced the product with separated wire feeder with equipping it with a WF wire feeder and a

contact batch from 5 or 10 meters.

Page 10

10

When the machine is totally equipped, the choice of the moto wire feeder will be in function of the commutator

position in foreside.

Connection from a wire feeder WF to the generator

VIII / MAINTENANCE

You must clean out and replace regularly nozzle and contact batch of all projections. Use a spray of anti-pearl

aerosol.

We advice you to clean the covering situated in the torch by blowing it with compressed air.

IX / ADJUSTMENTS OF WELDING CYCLES: PREGAZ, POSTGAZ, BURNBACK

The evoluated electronic card of MAGYS 410 and GENEGYS 510 SF machines allows intervening on welding

parameters.

To go on ADJUSTMENT mode, you have to (when the machine is working) press during 3 seconds on the button

« MODE ». Then, every indicators switch off and the higher display indicate PRE and the lower display indicate the

PREGAZ value. This value can be modified by pressing on + or -. If you press again on, you will adjust the

POSTGAZ time (POS on the higher display). If you press a third time, you will adjust the late time to the fusion

(BURNBACK) or the free WIRE length (Bur on the higher display). To come back in normal mode, you have to

press again on MODE.

If, by mistake, the modified parameters doesn’t correspond anymore to the user wishes, you can put back the

welding parameters from the factory.

For that, you must switch off the machine. Then, you have to press on the button MODE and + and switch on the

machine by pressing a long time buttons MODE and +. After that, the values PRE, POS and Bur clear out. Now, you

can release buttons. News parameters are also enter in the machine.

Origin moto-wire feeder on

the generator

Option wire feeder WF

Gas pipe

Control cable

Power cable

To use a wire feeder WF,

tip the commutator on the

position II « wire feeder

WF

»

Don’t forget to transpose

the gas connection

situated behind the front

panel

Page 11

11

X / MAINTENANCE: symptoms, reason, solution

SYMPTOMS

POSSIBLE REASONS

SOLUTIONS

The welding wire debit

is not constant

-cracklings block up the opening.

-The wire skid in the rollers.

-Clean out the contact batch or change it

and replace the anti-adherence product.

-Control the rollers pressure or replace it.

-Wire diameter non-consonant with

roller.

-Covering wire guide in the torch non-

consonant.

The unwinding motor

doesn’t operate.

-Coil brake too block.

-Others.

-Release the brake.

-Check that the running button is on the

position on.

-Release the rollers.

Bad wire unwinding. -Covering wire guide dirty or

damaged.

- Coil brake too block.

-Clean out or replace.

-Release the brake

No welding current. -Bad connection of the main

connection.

-Bad earth connection.

-Power contactor inoperative.

-See the branch connection and look if

the lap is fed by 3 phases.

-Control the earth cable (connection and

clamp state).

-Control the torch gate.

The WIRE rubs down

after the rollers.

-Covering WIRE guide crushed.

-Locking of the WIRE in the torch.

-No capillary tube.

-WIRE quick too important.

-Replace or clean out.

-Check the covering and torch body.

-Check the presence of capillary tube.

The welding cord is

porous.

- The gas debit is insufficient.

-Gas bottle empty.

-Gas quality non-satisfying.

-Air circulation or wind influence.

-Gas nozzle too foul.

-Bad WIRE quality.

-Bad quality of the area state to weld

(rust, etc…)

-From 15 to 20 L / min.

-Replace it.

-Replace it.

-Avert air blast, protect welding area.

-Clean the gas nozzle or replace it.

-Use adapted WIRE for MIG-MAG

welding.

-Clean the bases metal.

Very important flashing

particules.

-Arc power too low or too high.

-Bad earth connection.

-Protecting gas insufficient.

-See welding parameters.

-Control if it is possible to have a better

earth connection.

-Adjust gas debit.

No gas in torch outlet - Bad gas connection - (On MAGYS 410) see if the gas

junction near to the motor is correctly

connected.

Loading...

Loading...