Page 1

7

3502-V4-24/01/14

Gysmi E200 FV

p. 8-12 / 28-32

73502_V2_29/04/2013

Page 2

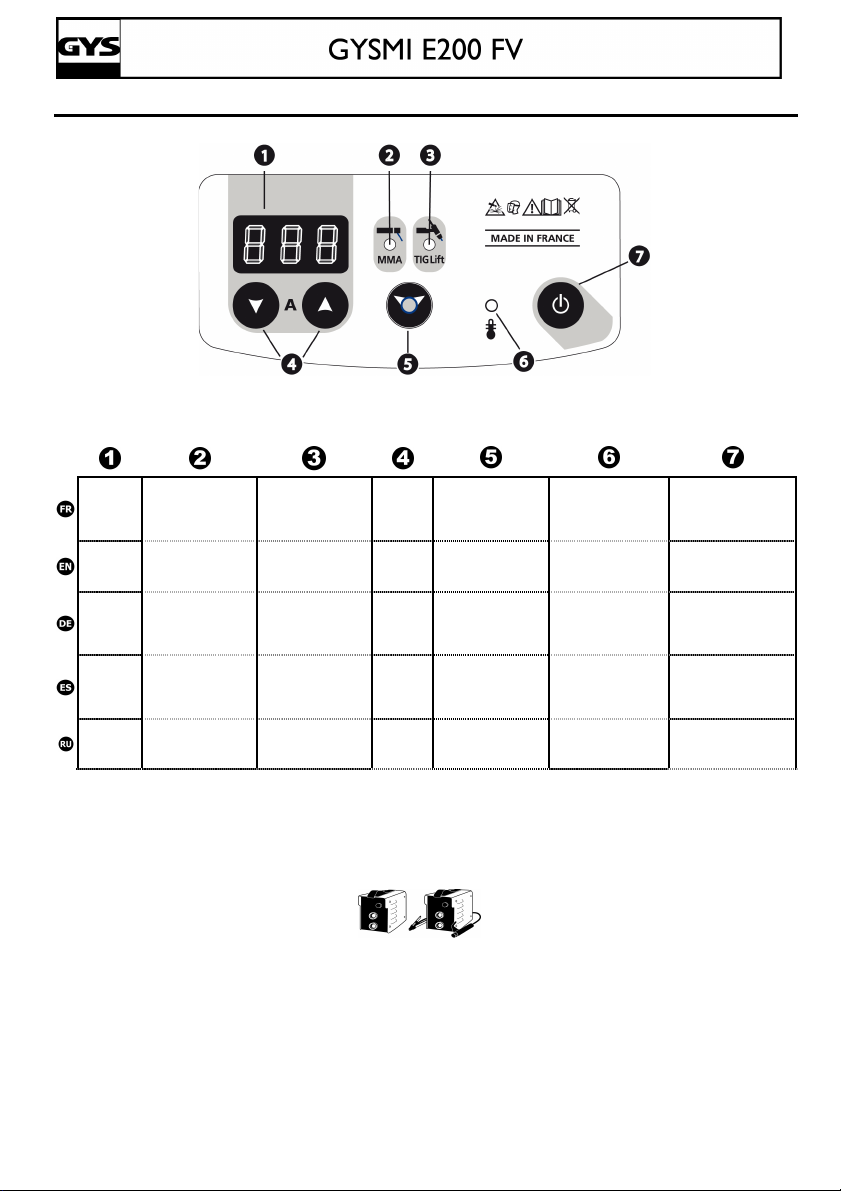

FACE AVANT/FRONTAL SIDE/FRONTSEITE UND ANSCHLÜSSE/CARA DELANTERA/ПЕРЕДНЯЯ ПАНЕЛЬ

réfractaire»

Schweißmodusanzeige

Schweißmodusanzeige

Drucktaster

Afficheur Voyant mode

Display Mode indicator

Anzeige

Indicador Indicador modo

Индикатор Лампочка режима

« soudage à

l’électrode » (MMA)

« electrode welding »

(MMA)

MMA

« soldadura con

electrodo recubierto»

(MMA)

MMA

Voyant mode

« soudage à

l’électrode

(TIG)

Mode indicator « non

consumable electrode

welding» (TIG)

«WIG

Kontaktzündung»

(TIG)

Indicador modo

« soldadura con

electrodo refractario»

(TIG)

Лампочка режима

TIG

Sélecteur

valeur +

ou -

Select

button « +

or – »

Wahl

+ oder -

Selector

valor + o -

Клавиши

выбора +

или –

E200 FV

5

.5kg 7.6kg

Bouton sélection/

validation

Button selection/

validation

Button-Auswahl /

Validierung

Botón selección /

validación

Клавиша выбора/

подтверждения

Voyant de protection

thermique

Thermal protection

indicator

Gelbe

Übertemperaturanzeige

Indicador luminoso

amarillo de protección

térmica

Желтый индикатор

температурной

защиты

Bouton de mise en

marche / veille

Button on/stand by

EIN/ AUS- Taste

Puesta en marcha /

stand by

Кнопка включение /

вахтенный режим

2

Page 3

DESCRIPTION

Thank you for choosing our product! In order to take the most of your welder, please read the following

instructions carefully:

These welding are, Inverter, portable welder, for covered electrode and TIG Lift in DC. It allows welding with rutiles,

basic, stainless steel. In TIG, it allows to weld most of metals except aluminium and alloys. It is protected for a use

on electric generators (230V /+- 15%).

POWER SUPPLY – START UP

• These machine are delivered with a 230V socket /16A plug type EEC7/7. The GYSMI E200 FV integrate a

« Flexible Voltage » system. It has to be on a power supply variable between 110V and 240V (50 – 60 Hz) WITH

earth. The absorbed effective current (I1eff) is shown on the machine, for maximal using conditions. Check that

the power supply and its protection (fuse and/or circuit-breaker) is compatible with the necessary current during

use. In some countries, the change of plug can be necessary to allow a use at maximal conditions. The welder

must be installed so that the main plug is accessible.

• The start-up is done by pressing ( )

The device turns into protection mode if the supply voltage is over 265V for the single-phase products

(the sсreen displays ). Normal operation will resume when the voltage has returned to its nominal

range.

• These are A-class devices. They are designed to be used in an industrial or professional environment. In a

different environment, it can be difficult to ensure electromagnetic compatibility, due to conducted

disturbances as well as radiation.

The GYSMI E200 FV features primary regulation, it is recommended to use the cables supplied with the unit.

•

ELECTRODE WELDING (MMA Mode)

• Leave the machine connected to the supply after welding in order to let it cool down.

• Thermal protection: thermal protection indicator turns on and the cooling time is about 2 to 5 min

according to external temperature.

• Your machine is equipped with 3 specific functions to Inverters :

The Hot Start (adjustable mode depending on model, see below) increases the current at the beginning

of the welding.

The Arc Force (adjustable mode depending on model, see below) increases the current in order to avoid

the sticking when electrode enters in melted metal.

The Anti Sticking allows you to easily withdraw your electrode without damaging it in case of sticking.

Selection of MMA Mode and intensity setting:

- Select the MMA position with the selector.

- Adjust the wished current (display ) using the key .

Hot Start & Arc Force adjustments:

Hot Start 0 90%

Arc Force Automatic

Advice:

Low Hot Start: for thin metal sheets

High Hot Start for metals that are difficult to weld (dirty or oxidized parts)

T

IG LIFT

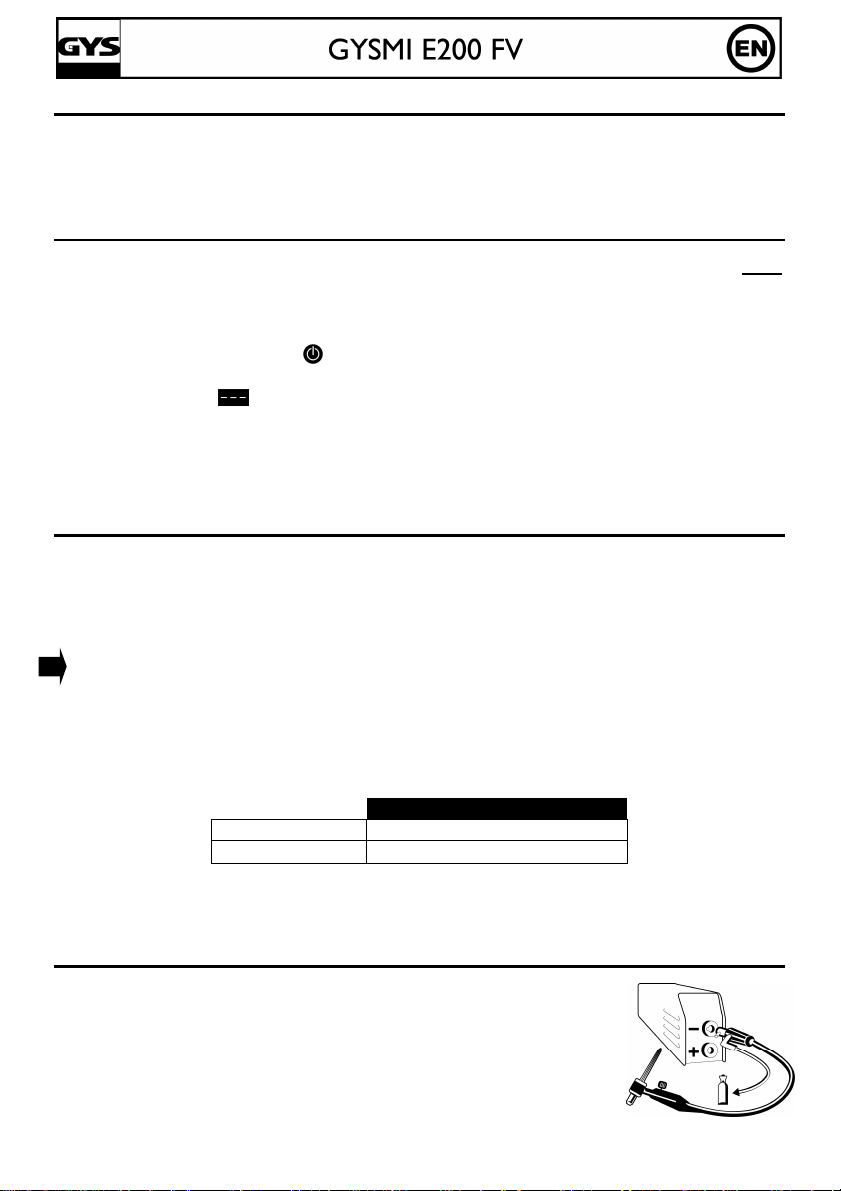

The DC TIG welding requires a protective gas (argon).

Follow the steps as below :

1. Connect the earth clamp on the positive pole (+).

2. C

onnect a torch "valve" negative polarity (-).(Ref. 044425)

3. Connect the pipe gas torch on the gas cylinder

4. Select TIG mode using the selector button .

5. Adjust the wished current (display ) using the keys .

Advice : Take 30A/mm as a default setting and adjust according to the part to weld.

E200 FV

8

Page 4

6. Set the gas flow on flewmeter of the gas cylinder, and then open the valve of the torch

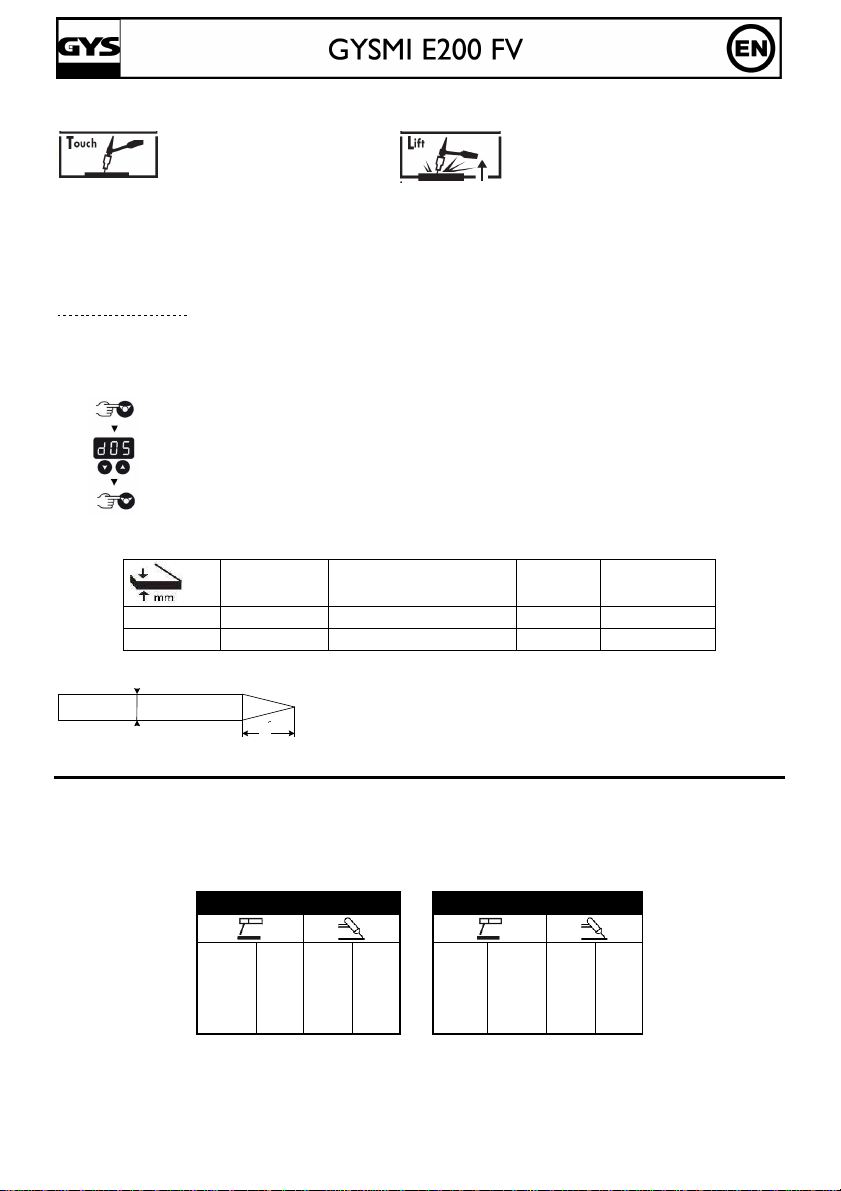

Touch the electrode on

Raise the electrode 2 to 5

L = 2,5 x d.

7. To boot :

a-

the welding part

b-

mm of the part to be welded

8. At end of welding:

Up 2 times the arc (up-down-up-down) to trigger the automatic fade (see paragraph below). This

movement must be performed in less than 4 sec, at a height of 5 to 10 mm. Then close the valve to

stop the torch gas after cooling of the electrode.

Automatic Arc slope with time adjustable

Function activation:

This corresponds to the end of welding time required for the gradual decline in the welding current until the

stop of the arc. This function helps to avoid cracks and craters at end of welding.

1- Press 3 seconds on the selector button

et the automatic arc slope you wish from 1 to 10 sec (display) using key.

2. S

3. Validate the required figure by pressing the selector button .

Recommended combinations / Electrode grinding

Current (A) Ø Electrode (mm)

= Ø wire (filler metal)

0,5-5 10-130 1,6 9,8 6-7

4-8 130-200 2,4 11 7-8

Ø Nozzle

(mm)

Flow rate

(Argon L/mn)

To optimize the working, you have to use an electrode grinded as below:

d

l

L

THERMAL PROTECTION & DUTY CYCLE

• Thermal protection : thermal protection indicator turns on and the cooling time is about 2 to 5 min

according to external temperature.

• Leave the machine connected to the supply after welding in order to let it cool down

• The welding unit describes an output characteristic of "constant current" type. The duty cycles following

the norm EN60974-1 (at 40°C on a 10mn cycle) are indicated in the table here below:

E200 FV (110Veff) E200 FV (230Veff)

X% @ I max X% @ I max

39% 130A 58% 130A

60% 95A 60% 125A

100% 80A 100% 100A

X% @ I max X% @ I max

22% 200A 27% 200A

60% 120A 60% 140A

100% 90A 100% 115A

9

Page 5

MAINTENANCE

• Refer all servicing to qualified personnel.

• Disconnect the generator and wait until the ventilator stopped before working on the unit. Inside the

device, voltages and current are dangerous.

• 2 or 3 times a year, remove the steel cover and blow off the dust with compressed air. Let check the

electrical connections (with an insulated tool) and the insulations by qualified personnel.

• Regularly control the state of the cord. If this supply cable is damaged, it must be replaced by the

manufacturer, its after sales service or a similarly qualified technician to avoid any danger.

ADVICE

• Respect welding polarities and currents indicated on the electrode packaging

• Remove the electrode from the electrode holder when you do not use it.

• Leave the inlets free to allow in/out air circulation.

SECURITY

The arc welding can be dangerous and leads serious injury, may fatal. Protect yourself and

protect the others.

Respect the following warnings:

Arc rays

Rain, steam,

humidity

Electric shocks

Moving

Burns

Fire risks

Smokes

Extraprecautions

Protect yourself thanks to a welding helmet in compliance with EN175 equiped with filters

in compliance with EN 169 or EN 379. Inform and protect by the same means any people

in the welding environment.

The working environment must be clean (degree of pollution ≤ 3) and protected against

rain. Put the appliance on an even place and at least at one meter from the parts to be

welded. Do not use them under rain or snow.

This appliance may only be used in accordance with the power supply requirements listed

before. Do not touch live parts. Check that the supply system is suitable for the post.

Do not underestimate the weight of the apparatus. Do not carry it over people or things.

Do not drop it. Do not set it brutally

Wear protective or fire-proof clothing (overalls, jeans).

Use some welder gloves and a fire-proof apron.

Protect the others by installing non flammable protection wall, or prevent the others

from looking at the arc and have them keep a sufficient distance

Suppress all flammable products from the working area. Do not works near flammable gas.

Do not inhale gas or welding smokes. If indoors ventilate the area well and/or use local

extraction ventilation equipment to remove fumes and gases.

Any welding operation :

-in environments with increased risk of electric shock,

-in confined spaces,

-in the presence of flammable or explosive materials

must be evaluated in advance by an “Expert supervisor” and must always be carried

out in the presence of other people trained to intervene in case of emergency.

Technical protection measures MUST BE taken as described in the TECHNICAL

SPECIFICATION "IEC 62081".

Welding in raised positions is forbidden unless safety platforms are used.

People wearing Pacemakers are advised not to use this machine, however if necessary, please

seek medical advice prior to use.

Do not use the welding unit to unfreeze pipes.

Handle gas bottles with care - there is increased danger if the bottle or its valve are damaged.

10

Page 6

RECOMMENDATION TO REDUCE ELECTRO-MAGNETIC EMISSIONS

General

The user is responsible for installing and using the arc welding equipment according to the manufacturer’s

instructions. If electromagnetic disturbances are detected, then it shall be the responsibility of the user of the arc

welding equipment to resolve the situation with the technical assistance of the manufacturer.

Evaluation of the welding area

Before installing arc welding equipment the user shall make an assessment of potential electromagnetic problems in

the surrounding area

a. Other wiring, control cables, telephones and communication cables; above, below and adjacent to the

welding machine

b. Radio and television transmitters and receivers;

c. Computer and other control equipment;

d. Equipment critical for safety purposes such as safety checks of industrial equipment;

e. The health of persons in the vicinity, for example persons who wear pacemakers and hearing aids;

f. Equipment used for calibration or measurements;

g. The immunity of other equipment in which the equipment is to be used. The user must ensure that other

equipment used in the same place is compatible. This may require additional protection measures;

h. The time of day when welding or other activities are carried out

i. The size of the area to be considered will depend on the structure of the building and any other

processes in the area. The surrounding area may extend beyond the boundaries of the buildings.

Recommendation to reduce electro-magnetic emission

a. Mains power supply: the equipment must be connected to the power mains as specified in the

Manufacturer’s instructions. If interference occurs, additional precautions such as filtering of the mains

supply may be required. The supply cable in the welding machine’s permanent installations may have to

be screened in metal conduits or similar. The screening should be electrically continuous for the entire

length of the cable. It should also be connected to the welding machine with a good electrical contact

between the metal conduit and the casing.

b. Welding cables: The welding cables should be kept as short as possible and should be positioned close

together, running at or close to the floor level.

c. Protection and reinforcement: Selective screening and shielding of other cables and equipment in the

surrounding area may alleviate problems of interference. Screening of the entire welding area may be

considered for special applications

d. Connect the earth directly to the metal piece to be welded: Where necessary, the connection of

the workpiece to earth should be made by a direct connection to the workpiece, but in some countries

where direct connection is not permitted, the bonding should be achieved by suitable capacitance,

selected according to national regulations.

11

Page 7

TROUBLESHOOTING

Anomalies Causes Remedies

The device does not deliver any

current and the yellow indicator

lamp of thermal defect lights

up.

The display is on but the device

does not deliver any current.

If, when the unit is on and you

put your hand on the welding

MMA-TIG

unit’s body, you feel tingling

sensation.

The display is on but the device

does not deliver any current.

When starting up, the display

indicates .

Instable arc Default coming from the

TIG

The tungsten electrode gets

oxidised and tern at the end of

welding.

The electrode melts

The welder thermal protection

has turned on.

The cable of the earth clamp or

electrode holder is not connected

to the welder.

The welding unit is not correctly

connected to the earth.

The cable of the earth clamp or

electrode holder is not connected

to the welder.

The voltage is not included in the

range 230V +/- 15%

tungsten electrode

Too important gas flow rate Reduce gas flow rate

Welding zone

Default coming from post-gas or

the gas has been stopped

prematurely.

Polarity error Check that the earth clamp is really

Wait for the end of the cooling time,

around 2 minutes. The indicator

lamp turns off.

Check the connections.

Check the plug and the earth of

your electrical network.

Check the connections.

Have the electrical installation

checked.

Use a tungsten electrode with the

adequate size

Use a well prepared tungsten

electrode

Protect welding zone against air

flows

Check and tighten all gas

connections. Wait until the electrode

cools down before stopping the gas.

connected to +

12

Page 8

DECLARATION DE CONFORMITE :

GYS atteste que le poste de soudure est fabriqué conformément aux exigences des directives Basse tension

2006/95/CE du 12/12/2006, et aux directives CEM 2004/108/CE du 15/12/2004.

Cette conformité est établie par le respect des normes harmonisées EN 60974-1 de 2005, EN 60974-10 de 2007 et

EN 50445 de 2008.

Le marquage CE a été apposé en 2012.

DECLARATION OF CONFORMITY :

The equipment described on this manual complies with the instructions of low voltage 2006/95/CE of 12/12/2006,

and the instructions of CEM 2004/108/CE of the 15/12/2004.

This conformity respects the standards EN60974-1 of 2005, EN 60974-10 of 2007 and EN50445 of 2008.

CE marking was added in 2012.

KONFORMITÄTSERKLÄRUNG

GYS erklärt, dass die beschriebene Geräte in Übereinstimmung mit den Anforderungen der folgenden europäischen

Bestimmungen: Niederspannungsrichtlinie 2006/95/CE –12.12.2006 und EMV- Richtlinien 2004/108/CE – 15.12.2004

elektromagnetische Verträglichkeit- hergestellt wurden. Diese Geräte stimmen mit den harmonisierten Normen

EN60974-1 von 2005, EN 60974-10 von 2007 und EN 50445 von 2008 überein.

CE Kennzeichnung: 2012

DECLARACION DE CONFORMIDAD :

GYS certifica que el aparato de soldadura E200 FV es fabricado en conformidad con las directivas baja tensión

2006/95/CE del 12/12/2006, y las directivas compatibilidad electromecánica 2004/108/CE del 15/12/2004. Esta

conformidad está establecida por el respeto a las normas EN 60974-1 de 2005, EN 60974-10 de 2007 y EN 50445 de

2008.

El marcado CE fue fijado en 2012.

ДЕКЛАРАЦИЯ О СООТВЕТСТВИИ:

GYS заявляет, что сварочные аппараты E200 FV произведены в соответствии с директивами Евросоюза

2006/95/CE о низком напряжении от 12/12/2006, а также с директивами CEМ 2004/108/CE от 15/12/2004.

Данное соответствие установлено в соответствии с согласованными нормами EN 60974-1 2005 г, EN 60974-10

2007 г и EN 50445 2008 г.

Маркировка ЕС нанесенна в 2012 г.

20/07/12 Nicolas BOUYGUES

Sas GYS Président Directeur Général

134 BD des Loges

53941 Saint Berthevin

28

Page 9

SCHÉMA ÉLECTRIQUE / CIRCUIT DIAGRAM / SCHALTPLAN

Gysmi E200 FV

29

Page 10

PIÈCES DE RECHANGE/ SPARE PARTS / ERSATZTEILE/ RECAMBIOS / ЗАПЧАСТИ

GYSMI E 200 FV

N°

1 Douilles / Connectors / Schweißbuchsen / Conectores / Коннекторы 51469

2 Clavier/ Display / Anzeige / Teclado / Дисплей / Οθόνη 51914

3 Carte électronique / Electronic card / Elektronikplatine / Tarjeta electrónica / Электронная плата 97143C

4 Cordon secteur / Power cord / Netzkabel / Cable de conexión / Сетевой шнур 21480

5 Ventillateur / Fan / Ventilator / ventilador / Вентилятор 51021

6 Grille / Protective screen / Ventilator- Grill / rejilla / Решетка 51010

7 Pieds / Feets / Füsse / Pies / Ножки 71140

Désignation E200 FV

30

Page 11

ICÔNES/ SYMBOLS/ ZEICHENERKLÄRUNG / ICONOS/ ПЕРЕДНЯЯ ПАНЕЛЬ

Schutz gegen Risiko von

soldadura en un entorno que comprende riesgos de choque eléctrico. La fuente de corriente ella misma no debe estar

de cuerpos solidos de diametro >12.5mm y

A

V

Hz

IP23

Uo

U1

I1max

I1eff

EN 60974-1

X

/10min

@40°C

Ampère Amp Ampere Amperio Ампер

Volt Volt Volt Voltios Вольт

Hertz Hertz Hertz Hertz Герц

Soudage à l’électrode enrobée (MMA – Manual Metal Arc Schweißen mit umhüllter Elektrode (MMA)

Schweißen mit umhüllter Elektrode (E-Handschweißen) Soldadura con electrodos refractarios (TIG – Tungsten

Inert Gas) Ручная дуговая сварка (MMA – Manual Metal Arc)

Soudage TIG (Tungsten Inert Gaz) TIG welding (Tungsten Inert Gas) Schweißen mit Wolfram Elektrode

(Wolfram Edelgas) Soldadura TIG (Tungsten Inert Gaz) Сварка TIG (Tungsten Inert Gaz)

Convient au soudage dans un environnement avec risque accru de choc électrique. La source de courant ellemême ne doit toutefois pas être placée dans de tels locaux. Adapted for welding in environment with increased

risks of electrical shock. However, the welding source must not be placed in such places.

elektrischen Schlag. Das Schweißgerät darf nicht direkt auf dem Schweißwerkstück gestellt warden. Adaptado a la

situada dentro de tal locales. Подходит для сварки в среде с повышенной опасностью удара электрическим

током. Тем не менее не следует ставить источник тока в такие помещения.

Protégé contre l’accès aux parties dangereuses des corps solides de diam >12,5mm et chute d'eau (30%

horizontal) Protected against access to dangerous parts by any solid body which Ø > 12,5mm and against water

falls (30% horizontal) Kontaktschutz zu gefärlichen Teilen mit Ø > 12,5mm und Schutz gegen Spritzwasser

Einfallwinkel 30%. Protegido contra el acceso a las partidas peligrosas

las caídas de agua (30% horizontal) Защищен против доступа твердых тел диаметром >12,5мм к опасным

частям и от воды (30% горизонт.)

Courant de soudage continu Welding direct current Gleichschweißstrom La corriente de soldadura es

continua Сварка на постоянном токе

Alimentation électrique monophasée 50 ou 60Hz Single phase power supply 50 or 60Hz Einphasiege

Netzspannungsversorgung 50 oder 60 Hz Alimentación eléctrica monofásica 50 o 60 Hz Однофазное

напряжение 50 или 60Гц

Tension assignée à vide Rated no-load voltage Leerlaufversorgungspannung Tensión asignada de vacío

Напряжение холостого хода

Tension assignée d’alimentation rated supply voltage Versorgungsspannung unter Belastung. Tensión de

la red Напряжение сети

Courant d’alimentation assigné maximal (valeur efficace) Rated maximum supply current (effective value)

Maximaler Versorgungsstrom (Effektivwert) Corriente maxima de alimentacion de la red Максимальный

сетевой ток (эффективная мощность)

Courant d’alimentation effectif maximal Maximum effective supply current Maximaller tatsächlicher

Versorgungsstrom Corriente de alimentación efectiva maxima Максимальный эффективный сетевой ток

L’appareil respecte la norme EN60974-1 The device complies with EN60974-1 standard relative to welding

units Die Normen EN60974-1 für Schweißanlagen El aparato está conforme a la norma EN60974-1 referente a

los aparatos de soldadura Аппарат соответствует европейской норме EN60974-1

Convertisseur monophasé transformateur-redresseur Single phase inverter, converter-rectifier Einphasige

Schweißinverter Convertidor monofásico transformador-rectificador Однофазный инвертор, с

трансформацией и выпрямлением.

X : Facteur de marche à …% X : duty factor at …% X : Einschaltdauer Faktor ...% X : Factor de

…%

funcionamiento de …% X : Продолжительность включения …%

Nombre d'électrodes normalisées soudables en 1 heure, à 20°C, avec un temps d'arrêt de 20 s. entre chaque

électrode Number of standardized electrodes weldable during 1 hour at 20°C, with a delay of 20 s. between each

electrode. Anzahl der Standard-Elektroden, die in 1 Stunde bei 20°C geschweißt werden können mit einer Pause

von 20 s zwischen jeder Elektrode Cantidad de electrodos normalizados soldables en 1 hora, a 20°C, incluyendo

una parada de 20 seg. entre cada electrodo Количество стандартных электродов использованных за 1 час

при 20°C с 20-ти секундными перерывами между электродами.

31

Page 12

I2 …

%

%

: conventional voltages in corresponding load

Separate collection

Este aparato

U2 …

Nombre d'électrodes normalisées soudables en 1 heure en continu, avec 20 secondes entre chacune, divisé par le

nombre d'électrodes soudables dans les mêmes conditions sans disjonction thermique. Number of standardized

electrodes weldable over 1 hour of continuous work, divided by the number of electrodes weldable in the same

conditions without thermal shutdown Elektroden Anzahl die inerhalb einer Arbeitsstunde verschweißt werden

können, geteilt durch Elektroden- Anzahl die tatsächlich verschweißt sind (Abkühlphasen des Geräts) Cantidad de

electrodos normalizados soldables en 1 hora de manera continua, a 20°C, dividida por la quantidad de electrodos

soldables en condiciones identicas sin disyunción térmica. . Количество стандартных электродов,

использованных за 1 час в непрерывном режиме с 20-ти секундными перерывами между электродами,

поделенное на количество электродов, которые можно сварить при тех же условиях, но без перегрева.

I2 : courant de soudage conventionnnel correspondant I2 : corresponding conventional welding current I2:

Sekundär Strom I2 : Corrientes correspondientes I2 : Соответствующий условный сварочный ток

U2 : Tensions conventionnelles en charges correspondantes U2

U2 : Sekundär Spannung U2 : Tensiones convencionales en carga U2 : Соответствующие условные

напряжения под нагрузкой

Circuit de correction du facteur de puissance Power factor corector circuit included PFC

Netzoberwellenfilter. Circuito de correción de factor de potencia integrado Цепь коррекции коэффициэнта

мощности

Ventillé Ventilated Ventilator Ventilado Содержит встроенный вентилятор

Appareil conforme aux directives européennes The device complies with European Directive Das Gerät ist

kompatibel mit Europäischen Normen El aparato está conforme a las normas europeas. Устройство

соответствует европейским нормам

Conforme aux normes GOST (Russie)

Conform to standards GOST / PCT (Russia) Das Gerät ist conform mit GOST/PCT(Rußland) Normen

Conforme a la normas GOST (PCT) (Rusia) Продукт соответствует стандарту России (РСТ)

L’arc électrique produit des rayons dangereux pour les yeux et la peau (protégez-vous !) The electric arc

produces dangerous rays for eyes and skin (protect yourself !) Der Lichtbogen erzeugt, gefährliche für die Augen

und Haut, Strahlen (Schützen Sie sich!) El arco produce rayos peligrosos para los ojos y la piel (¡ Protegase !)

Электрическая дуга производит опасные лучи для глаз и кожи (защитите себя!)

Attention, souder peut déclencher un feu ou une explosion. Caution, welding can produce fire or explosion.

Achtung. Schweißen kann Feuer oder Explosion verursachen. Cuidado, soldar puede iniciar un fuego o una

explosión. Внимание! Сварка может вызвать пожар или взрыв.

Le dispositif de déconnexion de sécurité est constitué par la prise secteur en coordination avec l'installation

électrique domestique. L'utilisateur doit s'assurer de l'accessibilité de la prise. . The mains disconnection mean is

the mains plug in combination with the house installation. Accessibility of the plug must be guaranteed by user.

Die Stromunterbrechung erfolgt durch Trennen des Netzsteckers vom häuslichen Stromnetz. Der Gerätanwender

sollte den freien Zugang zum Netzstecker immer gewährleisten El dispositivo de desconección de seguridad se

constituye de la toma de la red electrica en coordinación con la instalación eléctrica doméstica. El usuario debe

asegurarse de la accesibilidad del enchufe. Система отключения безопасности включается через сетевую

штепсельную розетку соответствующую домашней электрической установке. Пользователь должен убедиться,

что розетка доступна

Mise en veille/mise en marche standby/On Schalter Bereit/ Ein standby/ puesta en marcha

Включить/Режим ожидания

Attention ! Lire le manuel d’instruction avant utilisation Caution ! Read the user manual Achtung ! Lesen

Sie die Betriebsanleitung. Cuidado, leer las instrucciones de utilización. Внимание ! Читайте инструкцию по

использованию

Produit faisant l'objet d'une collecte sélective- Ne pas jeter dans une poubelle domestique !

required – Do not throw in a domestic dustbin Getrennt entsorgen.Nicht mit Hausmüll entsorgen.

es objeto de una recolección selectiva. No debe ser tirado en en cubo doméstico. Продукт требует специальной

утилизации. Не выбрасывать с бытовыми отходами.

32

Loading...

Loading...