GYRU-STAR 2-50E, 3-80E, 3-80A, 4-100E, 3-120E Installation, Operation And Maintenance Manual

...Page 1

GYRU-STAR Screening Bucket

MODELS COVERED:

2-50E, 3-80E, 3-80A, 3-120E, 3-120HE, 4-100E, 4-100A, 4-100HE, 4-120HE

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

USER MANUAL

SPECIFICATION MANUAL

Manufactured By

Wheatway Solutions Ltd

B3 Brearley, Bair Road

Waterwells Business Park

Gloucester, GL2 2AF

England

ORIGINAL INSTRUCTIONS

Please Read This Document Before Operating The Machinery

Copyright

Page 2

Index

1. SCOPE

2. WARNINGS

3. SAFETY INSTRUCTIONS

4. COPY OF WARNING NOTICES

5. LIFTING AND HANDLING INSTRUCTIONS

6. INSTILLATION INSTRUCTIONS

7. OPERATING INSTRUCTIONS

8. MAINTENANCE

9. MAINTENANCE INSTRUCTIONS

10. FAULT FINDING PROCEDURE

11. PARTS LIST

12. HYDRAULIC DRAWINGS

13. DRILL PATTERN

Page 3

1. Scope

The GYRU-STAR Screening bucket is a bucket type attachment fitted either to

a hydraulic excavator or a wheeled loader replacing the standard digging

bucket.

The GYRU-STAR Screening bucket shell is a steel structure with welded joints,

integrated driveline cavities, double skin floor, and with a wear resistant cutting

edge. The shell has been tested to 1.5x maximum permissible load.

The horizontal shafts fitted with Polypropylene flexi-stars rotating in the same

upwards direction. The rotors are supported at each end by a seal bearing unit

and is driven by a hydraulic motor via a carbon chain belt and dive pulleys

system.

The hydraulic motor, driveline and bearings are housed within the main

structure of the bucket with access via a bolted access panel. The hydraulic

power is produced by the hydraulic excavator or wheeled loader hydraulic pump

and control system via its auxiliary/option circuit and transferred through by

flexible hoses to the GYRU-STAR Screening bucket hydraulic motor(s).

The Non Hazardous material to be screened is loaded in to the, GYRU-STAR

Screening bucket in the same manner as the standard excavator or wheeled

loader bucket; once the bucket has been loaded with marital to be screened and

positioned the excavator or wheeled loaders auxiliary hydraulic circuit is

activated causing the star rotors to turn in upwards direction.

The GYRU-STAR Screening bucket efficient screening process is created by

rotating star rotors agitating the material causing the fines to flow through the

rotating stars leaving the oversize material in the bucket.

Once the screening process is completed the oversize material is tipped out and

the process is repeated.

Page 4

2. WARNINGS

Throughout this manual these symbols & notes are used to

indicate the following;

DANGER

Imminent danger that is likely to cause serious injury or loss of

life.

WARNING

Safety situations that may cause serious injury or loss of life.

CAUTION

Safety situations that may cause problems or damage to the

equipment.

NOTE

To draw attention to procedures or information which it is

essential to observe for correct operation.

Page 5

3. Safety Instructions

WARNING

Special attention must always be paid to the safe use and maintenance of the

GYRU-STAR Screening bucket.

The GYRU-STAR Screening bucket should only be used by a trained and

competent operator and must have read and understood the operator’s manual

before operating the GYRU-STAR Screening bucket.

Before operating the operator must ensure the GYRU-STAR Screening bucket

is suitable for the carrier and ensuring when fully loaded it does not exceed the

carriers’ safe working capacity

Before operating the GYRU-STAR screening bucket the operator must ensure it

is fitted correctly to the excavator or wheel loader, ensuring all locking devices,

mounting pins and hydraulic connections are made correctly.

Before operating GYRU-STAR Screening bucket the operator must carry out a

visual inspection of the general condition of the bucket and the hydraulic hoses,

Ensuring all guards are fitted and are in good order. Any defects are to be

reported and rectified.

Always detach and store the GYRU-STAR Screening bucket on a firm level

surface.

Do not carry out any inspections, maintenance, adjustments, or cleaning until

the excavator or wheeled loader is stopped and the auxiliary hydraulics are

isolated.

Do not leave the excavator or wheeled loader while the rotor are turning.

Do not go under GYRU-STAR Screening bucket in any circumstances.

Allow hydraulic oil to cool down and any pressures to decay. Always wear

correct PPE before disconnection hydraulic hoses.

Always ensure a safe working area of 10 meters in case of flying material.

Before operating the GYRU-STAR Screening bucket ensure all guards are

fitted securely and all safety decals are in good order.

Page 6

Do not use to lift GYRU-STAR Screening bucket or carry persons in the

bucket.

Only use the for its GYRU-STAR Screening bucket intended purpose of

screening, separating and mixing of soils, aggregates and aeration compost.

The operator must wear appropriate PPE (hard hat and safety glasses) when

used with a carrier without a full operators cabin.

Page 7

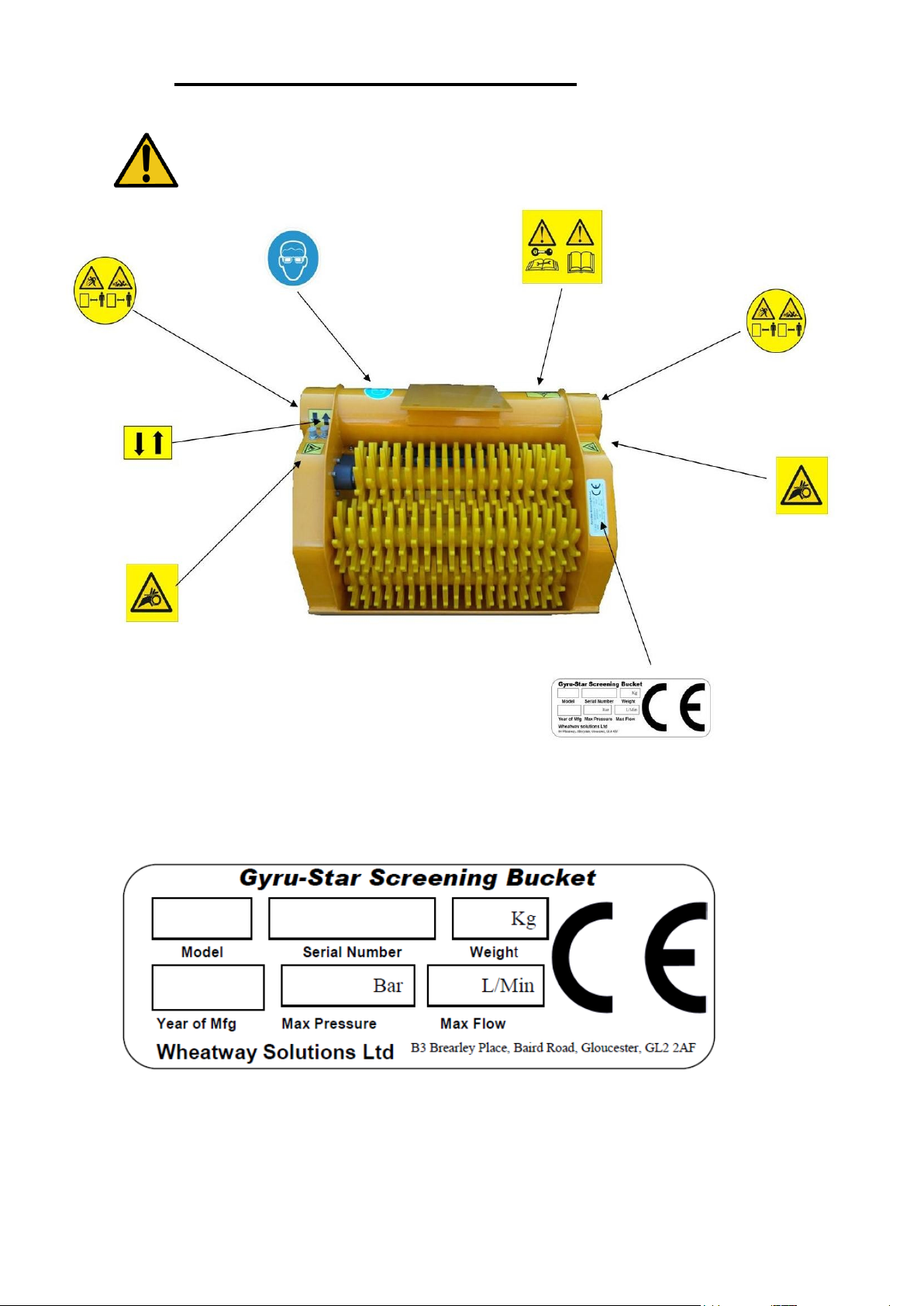

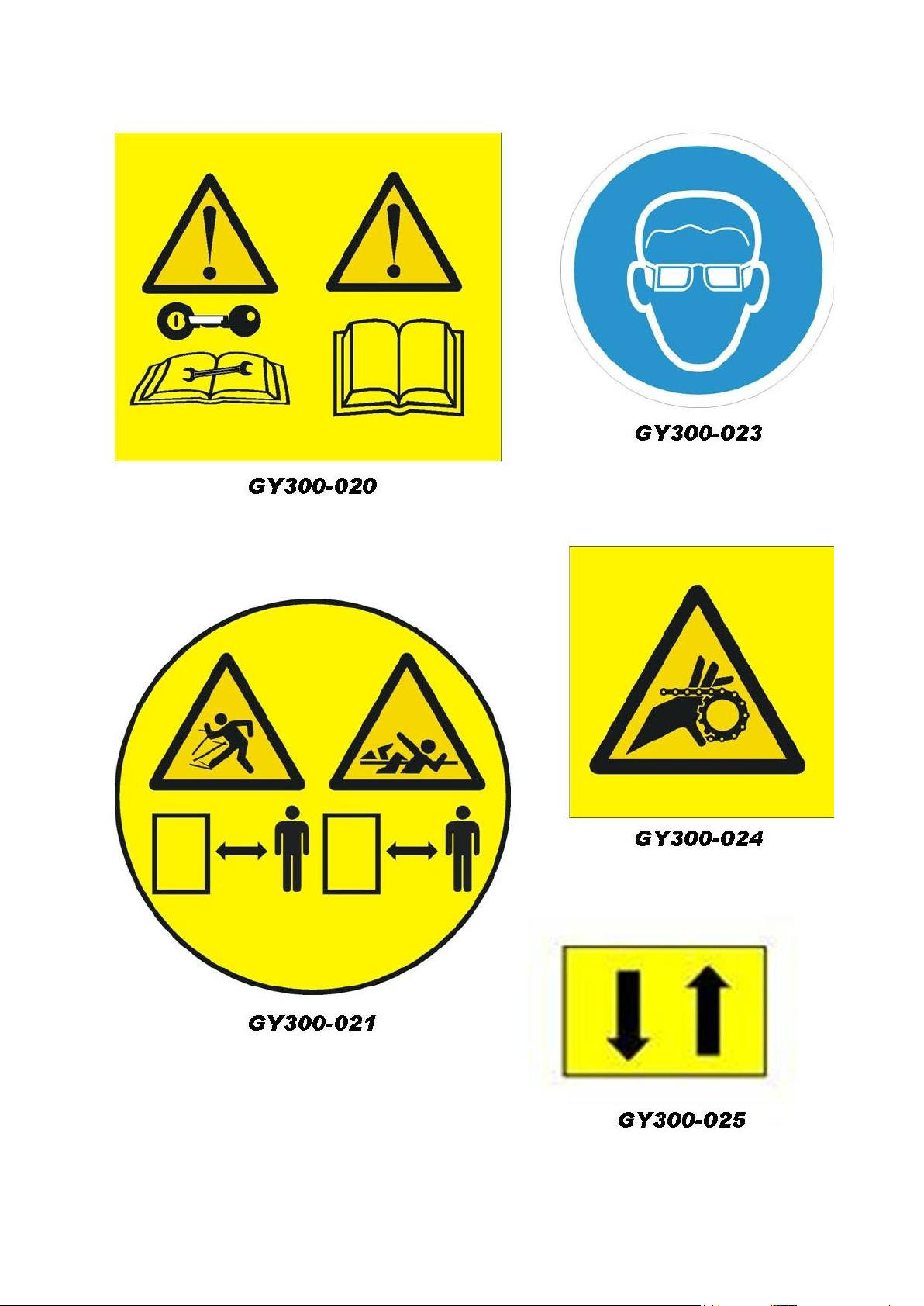

4. Copy of Warning Notices

NOTE

Page 8

Page 9

5. Lifting and Handling Instructions

WARNING

Shipping

The GYRU-STAR Screening bucket should be securely fastened to a standard

shipping pallet with steel banding and a shrink wrap cover sheet over the

bucket.

Lifting and moving should only be done with a suitable forklift with a lift

capacity capable of handling the combined weight of the bucket and packaging.

General operation

The GYRU-STAR Screening bucket should only be lifted or moved by its

carrier interface bracket securely attached to the carrier.

The GYRU-STAR Screening bucket must be sited on firm and level ground

when it is detached from the carrier.

Page 10

6. Instillation Instruction

CAUTION

The GYRU-STAR Screening bucket is connected to the carrier by its dedicated

carrier interface bracket.

Quick Couplers

Carry out a visual inspection to ensure all semi-automatic and automatic locking

systems have locked the carrier/bucket interface bracket correctly (see carrier

operator’s manual for correct operation and locking instructions).

Once the GYRU-STAR Screening bucket is connected to the carrier by its

dedicated carrier interface bracket, lower the GYRU-STAR Screening bucket

on to a suitable flat level site.

Stop the carrier and ensuring all hydraulic pressure in auxiliary circuit is

released (see carrier operator’s manual for instructions) before making the

hydraulic connections.

Hydraulic Connections

Connect the bucket hydraulic supply and return hose quick coupler to the

carrier’s auxiliary supply and return quick couplers (see carrier operators

manual for instructions).

Oil Flow

Connect oil supply and return hoses to the GYRU-STAR Screening bucket as

the decal indicates

Optional hydraulic Control Valves

The GYRU-STAR Screening bucket is designed to operate within fixed oil flow

and pressure parameters for each model with an open tank line for the return oil.

Ensure the appropriate optional hydraulic valve is fitted if the installation is

outside of the required parameters.

Page 11

7. Operating Instructions

NOTE

The GYRU-STAR Screening bucket is designed as a re-handling bucket only

for the screening, aeration and mixing of Non Hazardous pre dug material (not

to be used as primary digging bucket or used in contaminated areas).

The material to be screened is loaded in to the GYRU-STAR Screening bucket

in the same manner as the standard excavator or wheeled loader bucket. Once

the bucket has been loaded with material to be screened and positioned the

excavator or wheeled loaders auxiliary hydraulic circuit is activated causing the

star rotors to turn in upwards direction.

Do not over fill the bucket as this will reduce the performance of the screening

process.

Page 12

The GYRU-STAR Screening bucket efficient screening process is created by

the star rotors rotating the pre screened material in the bucket, agitating the pre

screened material allowing fines to flow through the rotating stars leaving the

oversize material in the bucket.

Once the screening process is completed the oversize material is tipped out and

the process is repeated.

Page 13

8. Maintenance

NOTE

SERVICING DESCRIBED IN THIS MANUAL IS ONLY TO BE PERFORMED BY A

QUALIFIED PERSON.

Daily Maintenance

Carry out visual inspection ensuring excavator or wheeled loader fixing pins

and fixing pin securing devices are fitted correctly (check carries operators hand

book for more information).

Inspect hydraulic hoses for damage and leaks. Replace the hoses if they are

damaged or leaking.

Remove any material wrapped around the flexi-star rotor shafts.

Periodic or Monthly Maintenance

Check the flexi-star rotor bearings for wear and replace if necessary.

Check rotors for damaged flexi stars and replace flexi stars if necessary.

NOTE

Long Term Storage

Power-wash the GYRU-STAR Screening bucket carefully, avoiding prolonged

high pressure water around the flexi-star rotor bearings.

Ensure hydraulic lines are suitably plugged.

Apply a suitable anticorrosion product to all bright metal surfaces.

Page 14

9. Maintenance Instructions

WARNING

General Information

Before commencing any repairs or servicing ensure the GYRU-STAR

Screening bucket is sited on firm and level ground if it’s detached from the

excavator or wheeled loader.

If attached to the excavator or wheeled loader ensure the GYRU-STAR

Screening bucket is both lowered to the ground and sitting flat on its base,

ensuring that the excavator or wheeled loader has been suitably isolated to

prevent unexpected operation.

Hydraulic system

Ensure all hydraulic pressure has decayed before carrying out any repair or

maintenance. Follow procedures in the carries operators hand book, if unsure

contact the carrier’s technical centre.

Ensure hydraulic oil temperature has decayed sufficiently before carrying out

any repair or maintenance.

Hydraulic oil

Avoid skin contact where ever possible, wash exposed skin with a suitable

detergent and water and always use correct protective equipment when handling

mineral oils.

Clean up any spills immediately with a suitable absorbent material and dispose

of correctly to prevent damage to the environment.

Consult oil suppliers Date Sheet for more detailed information

CAUTION

Welding

Connect the earth clip as close to the weld as possible, making sure that the

welding current doesn’t travel through the flexi-star bearings or hydraulic

motor.

If attached to the excavator or wheeled loader check the manufactures hand

book for welding procedure to prevent damage to PLC units.

Page 15

NOTE

Flexi-star Replacement

Before commencing flexi-star replacement, ensure the above safety measures

are in place;

Remove both drive line covers and remove carbon chain belt and drive wheel by

releasing the carbon chain belt adjuster of the rotor that requires the flexi-star

replacing.

Support flexi-star rotor and remove both rotor support bearing fixings, with the

rotor supported pull both stub shaft assemblies complete with bearings out from

the rotor shaft.

Slide the flexi-star discs from square section shaft observing the stagger pattern.

To re- assemble repeat the above instructions in reverse.

General Arrangement

Page 16

10. Fault Flow Chart

Rotors Do Not Rotate

QRC couplings fitted

correctly

Rotor do not rotate when carrier

hydraulic circuit is activated

YES

Connect, repair or replace QRC

coupling

YES

NO

Screen bucket over

loaded with

compacted material

Is the Carrier

hydraulic circuit

being loaded?

See fault finding flow diagram 10.2

NO

NO

Contact you Gyru-star

dealer/distributor for more assistance

Page 17

YES

Rotors Do Not Rotate 10.2

Motor to shaft

coupling defective

Rotors do not rotate when carrier

hydraulic circuit is activated

Replace coupling, Contact

Gyru-star dealer/distributor for

more assistance

YES

NO

Hydraulic motor

defective

Top rotor rotates

See fault finding flow diagram

10.3

NO

YES

Replace HYD motor, Contact

Gyru-star dealer/distributor for

more assistance

Contact Gyru-star

dealer/distributor for more

assistance

Page 18

YES

Rotors Do Not Rotate 10.3

Carbon belt

Slipping

Top rotor rotates Top rotor rotates

one or more does not rotate

check Rosta belt adjuster unit.

Contact Gyru-star

dealer/distributor for more

assistance

YES

NO

Rotor stub shaft

failed

Carbon belt broken

Replace damage or broken

carbon belt, Contact Gyru-star

dealer/distributor for more

assistance

NO

YES

Replace damage or brocket

stub shaft, Contact Gyru-star

dealer/distributor for more

assistance

Contact Gyru-star

dealer/distributor for more

assistance

Page 19

Article No

Part No

Description

1-01

GY101-060

2 Rotor Left Side Cover Plate

GY101-062

3 Rotor Left Side Cover Plate

GY101-064

4 Rotor Left Side Cover Plate

1-02

GY101-061

2 Rotor Right Side Cover Plate

GY101-063

3 Rotor Right Side Cover Plate

GY101-065

4 Rotor Right Side Cover Plate

1-03

GY100-062

M6 Socket Countersunk Screw

1-04

GY100-063

M6 Nut Insert

11. Parts List

Page 20

Article No

Part No

Description

2-01

GY200-012

Belt Pulley 2-50

GY200-011

Belt Pulley 3-80

GY200-010

Belt Pulley 3-120, 4-100, 4-120

2-02

GY200-015

Taper Lock

2-03

GY200-022

Carbon Belt 2-50

GY200-021

Carbon Belt 3-80

GY200-020

Carbon Belt 3-120, 4-100, 4-120

2-04

GY200-030

Bearing

2-05

GY200-031

Stub Shaft 3-120, 4-100, 4-120

GY200-032

Stub Shaft 2-50, 3-80

GY200-033

Short Stub Shaft

2-06

GY200-050

Rosta Belt Adjuster

2-07

GY200-040

Bearing Support Plate

2-08

GY200-051

Belt Adjuster Plate

2-09

GY100-069

M8 x 20 Socket Countersunk Screw

2-10

GY100-067

M8 Flange Nut

2-11

GY100-068

M8 x 16 Socket Cap Screw

2-12

GY100-070

M8 x 25 Socket Countersunk Screw

2-13

GY200-049

Key 8mm x 8mm

Page 21

Article No

Part No

Description

3-01

GY100-022

Hyd Motor 2-50

GY100-020

Hyd Motor 3-80

GY100-021

Hyd Motor 3-120, 4-100

GY100-023

Hyd Motor 4-100HE

GY100-024

Hyd Motor 4-120HE

3-02

GY100-043

Rotor Shaft (Motor Pickup) 2-50

GY100-045

Rotor Shaft (Motor Pickup) 3-80

GY100-047

Rotor Shaft (Motor Pickup) 4-100

GY100-051

Rotor Shaft (Motor Pickup) 3-120, 4-120

3-03

GY100-042

Rotor Shaft 2-50

GY100-044

Rotor Shaft 3-80

GY100-048

Rotor Shaft 4-100

GY100-051

Rotor Shaft 3-120, 4-120

3-04

GY100-041

SAE Drive Coupling 2-50, 3-80

GY100-040

SAE Drive Coupling 3-120, 4-100, 4-120

3-05

GY100-056

Poly Star

3-06

GY100-057

Shaft Spacer 20mm

3-07

GY100-053

Star Spacer Ring 20mm

3-08

GY100-052

Star Spacer Ring 30mm

3-09

GY100-064

M10 Socket Cap Screw 2-50, 3-80, 3-120, 4-100

GY100-072

M12 Socket Cap Screw 4-100HE, 4-120HE

3-10

GY100-061

S10 Lock Washer

GY100-074

S12 Lock Washer

Page 22

1

3

Hydraulic Circuit 2-50E 3-80E 3-120E 4-100E

1

3

Hydraulic Circuit 4-100HE 4-120HE

12. Hydraulic Circuits

Page 23

Flow Regulator with Relief Valve

Optional for models 3-120E, 4-100HE, 4-120HE, 6-120EH

Where oil flow and pressure available exceed permissible parameters for the screen bucket model

1

3

Overrun Valve

Optional for models 3-80E, 3-120E, 4-100E, 4-120HE, 6-120HE

Where return oil is returned via the carriers control spool

Page 24

13. Drill Pattern

3-80E Drill Pattern

3-120E and 4-100E Drill Pattern

Page 25

3-12HE, 4-100HE and 4-120E Drill Pattern

Page 26

14. Notes

Loading...

Loading...