Gyroscope V2, 1S Assembly Manual

1

GASENGINES “V2”

CLASSIC

ASSEMBLY PLAN

2

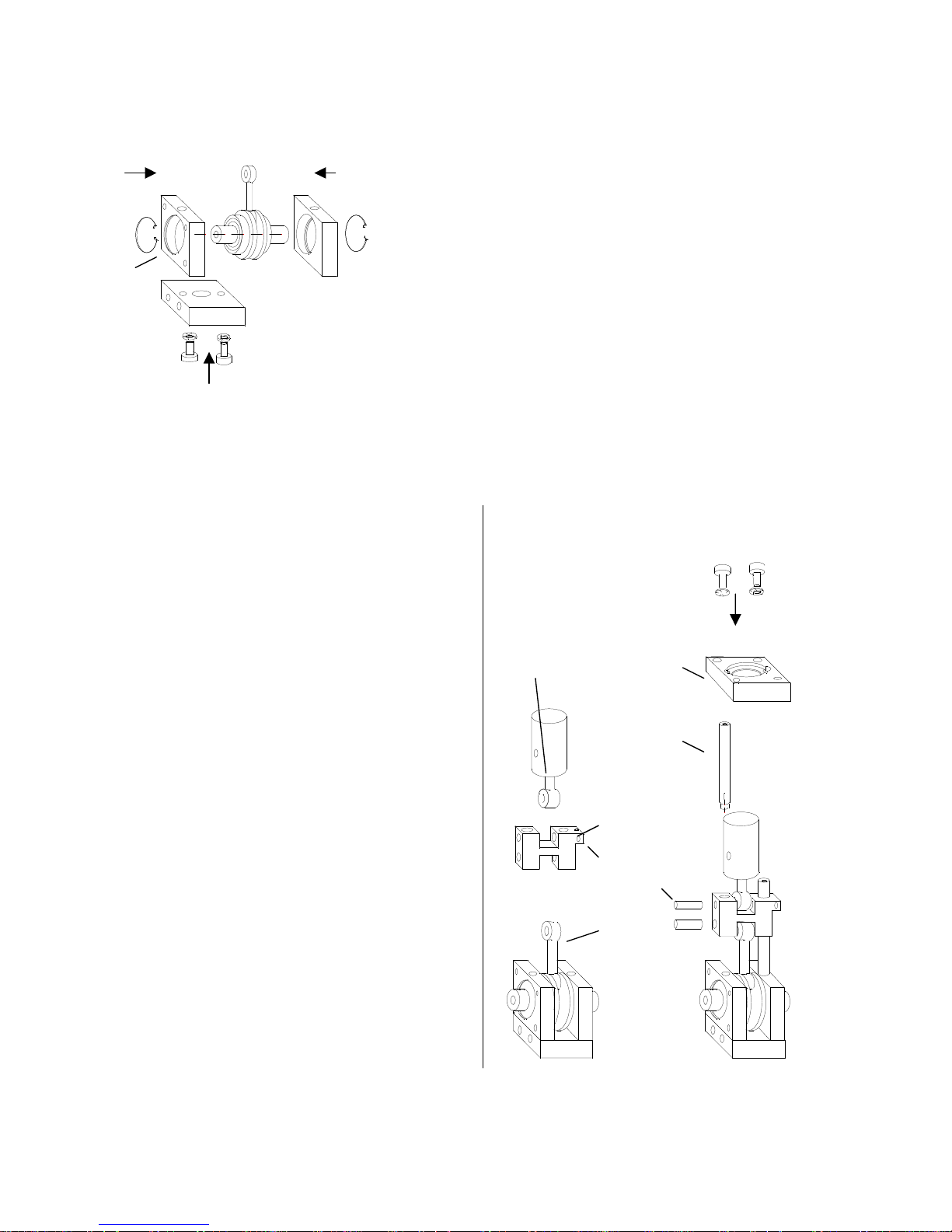

2. Mounting the crosshead guide

2.1 Firmly fasten the right guide rod (6) with M4

threads on the bearing plate.

2.2 Fit the crosshead (9) into the guide rod (6),

ensure that the M3 connection is on the right.

(s. sketch)

2.3 Fit the connecting rod (7) with cylinder pin (9.1)

and piston rod (8) in the crosshead.

2.4 Push the second guide rod (6) through the crosshea

d

and fasten it on the bearing plate

2.5 Fasten the cylinder plate (3) with M3 screws and

retaining rings onto the guide rods; the piston must

fit through the centre hole.

When fastening, the crosshead the top position

should be next to the cylinder plate.

2.6 Push the crosshead downwards to the bearing plates

and then loosen the M3 screw once again and then

retighten.

The crosshead must easily move to-and-fro,

(thermal expansion).

Finally tighten all screws.

8 3

6

9

M3

9.1

7

ASSEMBLY PLAN

Component parts are to some extent fitted together as

subassemblies.

1. Mounting the crankshaft bearing

1.1 Fit the short crankshaft with both bearings in the

bearing plate (4).

(In case of resistance, you have to support the

crankshaft in the middle)

1.2 Allow the lock washers (4.1) to snap into the

grooves on the outside of the bearing plates.

(s. sketch)

1.3 Loosely screw the base plate (5) with two M3

screws and retaining rings.

3

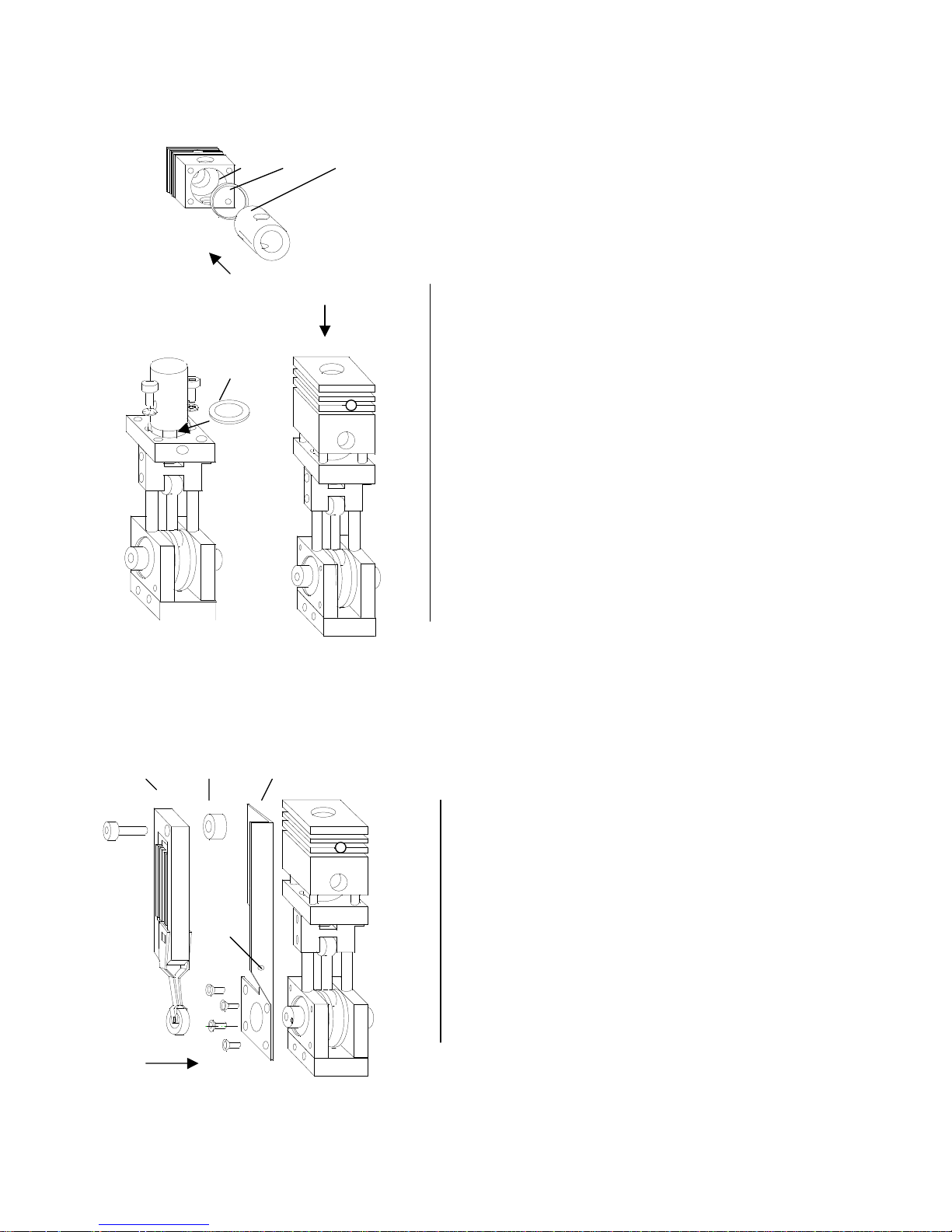

3. Mounting the cylinder unit

3.1 Insert the Teflon seal (2.1) into the cylinder housing

(2) (can be already fitted inside the housing)

3.2 Fit the cylinder (3) into the cylinder housing,

ascertain that exhaust openings correspond.

(sparkplug hole backwards)

3.3 The cylinder unit is now to be mounted on the

cylinder plate. (Screws M4x20.) First insert a feltring seal (F) into the cylinder plate, for lubrication.

3.4 Insert the piston into the cylinder and tighten the

screw crosswise.

3.5 Once again check the engine unit for smooth

running and if necessary eliminate strain.

4. Mounting the ignition holder

4.1 Fasten the ignition device holder mounting

bracket25.5 with 4 countersunk head screws on the

bearing plate.

4.2 Fasten the ignition device 25 with spacer washer

5.2 and M3 screw onto the holder mounting

bracket. Fix the M4 x10 set screw (25.3) with lock

nut in the mounting bracket.

2 2.1 3

F

25 25.2 25.5

25.3

4

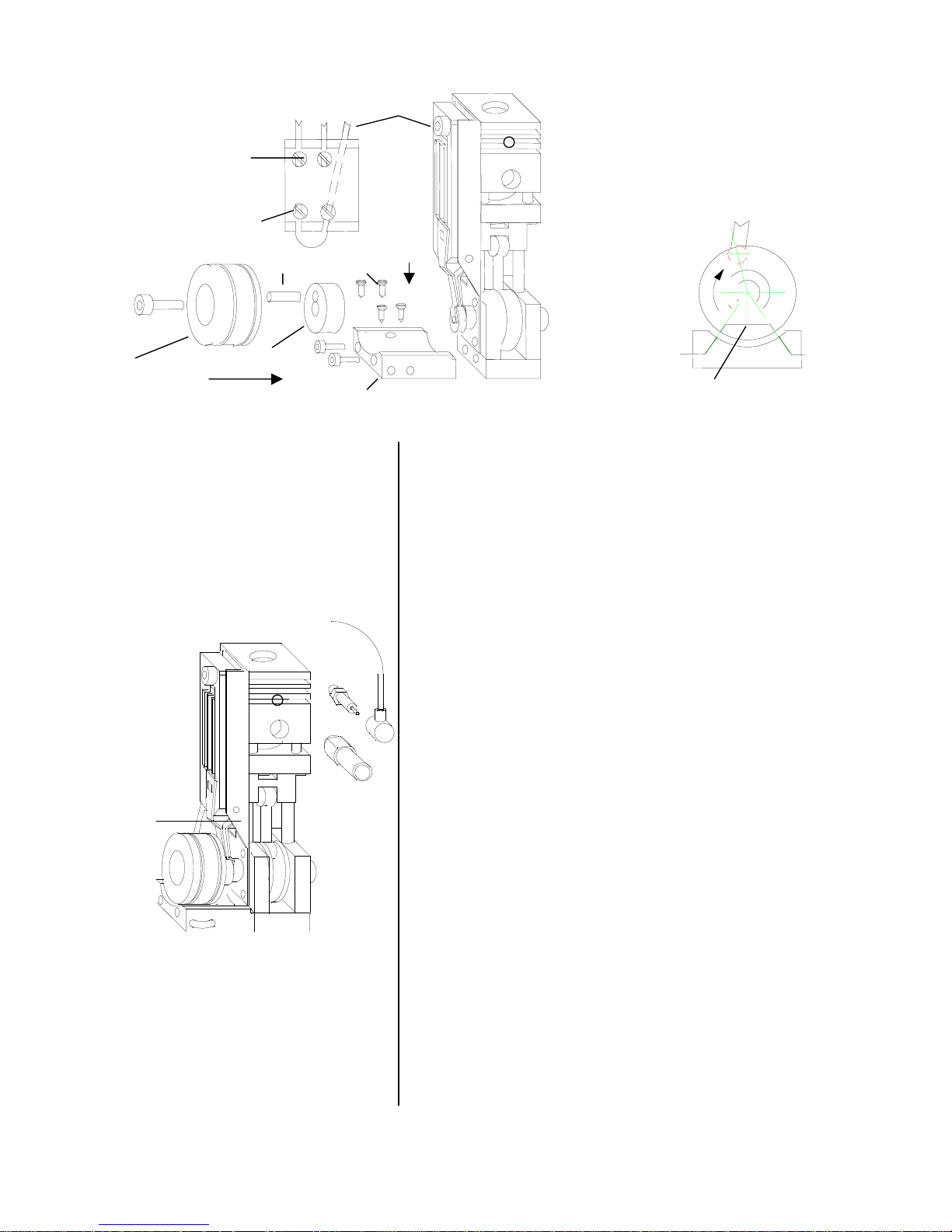

5. Mounting the ignition unit.

5.1 Mount the stator (22) on base plate (M3 x10).

5.2 Push the cable from ignition through the inclined hole on

the stator and guide it into the second hole (A).

5.3 Push two cables, (red) for the spark plugs, into the short

holes on the stator (B).

5.4 Drive in the four screws (22.2) completely through the

predrilled holes, the screws thereby penetrate the cables

insulation and establish the electrical contact.

5.5 Stick the pin (20.1) (1.5x 13) into the hole in

the crankshaft.

5.6 Push the eccentric cam (20) over the pin.

5.7 Fasten the rotor (21) with screw (M4 x 30) through the

eccentric cam (20) on the crankshaft.

The rotor is to be positioned and fastened such that the

"bridge" inside the rotor lies downwards above the screws

(22.2) - when the crankshaft has nearly reached the top dead

centre (approx. 3 degrees earlier), (c) - so that high-voltage

sparking occurs.

5.8 Fasten the sparkplug (23/24) tightly on the cylinder housing

and then fix the red cable with cap.

5.9 Unscrew the exhaust (47).

5.10 Drive in the screw M4 (25.3) into the bracket so deeply onto

the ignition that when rotating the crankshaft the highvoltage sparks over on the rotor.

The sparkplug should be checked through

the carburettor opening because the

sparkplug is no longer tight if the plastic

part is repeatedly unscrewed.

Ignition

Sparkplug 2

Sparkplug 1

B

A

20.1 22.2

21 20

22

View from the flywheel side

c

"Bridge"

Timing

Sparkplug

25.3

Loading...

Loading...