OPERATOR’S MANUAL

EngineLink™ LT

Diagnostic Analyzer

I/R Port

Control

Buttons

Auxiliary Volts

Leads

55

BNC 1 Sync

Output

BNC 2 PrimarySecondary Out-

put

Backlit Display

Spark Pickup

Spark Can

Coil Primary

Clip

Primary Amps

Probe

Power Leads

Amp Probe

Spark Can

Ground

KV Clips

© Copyright 2005, GxT, Inc., All Rights Reserved

1

Contents

Specifications ........................................................................................................................................3

Connecting to a DIS Car .......................................................................................................................4

Connecting to a Distributor Car ...........................................................................................................5

Connecting to a No Coil Minus ............................................................................................................6

Keys & Controls ..................................................................................................................................... 7

Initial Setup ............................................................................................................................................7

Ignition Menu ....................................................................................................................................8-13

Ignition Primary ................................................................................................................................8-9

Ignition Secondary .......................................................................................................................10-11

Hard Start ..........................................................................................................................................12

Troubleshooting DIS No-Start Cars ...................................................................................................12

Power Menu .....................................................................................................................................13-15

Electronic Compression ....................................................................................................................13

Power Contribution ............................................................................................................................ 14

Power Balance - Automatic/Manual .................................................................................................. 15

Electrical Menu ...............................................................................................................................16-17

Starting/Charging History .................................................................................................................. 16

Volt Amp Meter ..................................................................................................................................17

Auxiliary Meter ..................................................................................................................................18

Zero Amp Probe ................................................................................................................................17

Sensors Menu .................................................................................................................................17-19

TPS Test ............................................................................................................................................ 17

O2 Sensor Test ..................................................................................................................................17

Auxiliary Meter ..................................................................................................................................18

Logic Trace Scope ............................................................................................................................. 18

Solenoid Duty Cycle ..........................................................................................................................18

Injector Drive ..................................................................................................................................... 19

Fuel Menu

Injector Drive ..................................................................................................................................... 19

O2 Sensor Test ..................................................................................................................................17

Solenoid Duty Cycle ..........................................................................................................................18

Reports Menu..................................................................................................................................20-21

Run Auto-Test ...................................................................................................................................20

Print Saved Data ............................................................................................................................... 20

Visual Inspection ............................................................................................................................... 21

Auto-Test Configuration .....................................................................................................................20

Setup Menu .....................................................................................................................................21-23

Engine Setup.......................................................................................................................................7

EngineLink Setup .........................................................................................................................21-23

LCD Contrast .............................................................................................................................21

Custom Header .......................................................................................................................... 21

Save Setup ................................................................................................................................22

System Diagnostics ...................................................................................................................22

Scope Setup .............................................................................................................................. 22

Printing ................................................................................................................................................. 23

Demo Mode .......................................................................................................................................... 23

Typical Readings ............................................................................................................................24-25

Replacement Parts & Accessories ....................................................................................................26

Warranty & Service .............................................................................................................................. 27

Safety Warnings ...................................................................................................................................28

2

Introduction

The EngineLink™ is a professional grade tool for diagnosing automotive ignition, fuel injection, and

electrical systems. Test DIS and Distributor engines. Diagnose problems with ignition, starting/charging

and fuel-delivery systems, as well as computer sensors and drivers. Our AutoSort feature automatically

determines coil and plug polarity on DIS engines. The Autotest function performs Ignition Primary, Ignition

Secondary, Power Tests, Starting/Charging History, and Compression Tests automatically in about 10

minutes. Power Balance and Power Contribution checks cylinder performance on DIS and Distributor

engines. Primary Amps checks coils and modules. Spark Burn and KV tests check ignition plugs and

wires. Cranking Analysis checks cylinder compression uniformity and Starting/Charging Analysis tests

Specifications

Measurement Ranges

Battery Volts ........................................................................................................................ to 19.99 Volts

Volts, Aux (10 Meg) ................................................................................................................ ±20.00VDC

..................................................................................................................................... to 50.0 VAC Pk-Pk

Amps, Inductive ................................................................................................................0 to ±600 Amps

Tachometer ................................................................................................................... 100 to 5,000 RPM

Dwell, Ignition ......................................................................................................... Degrees, %, or mSec.

Driver/Points Resistance ...................................................................................................... 0 to 3.0 Volts

Dwell Variation ..........................................................................................................................in Degrees

Timing Variation ........................................................................................................................in Degrees

Ignition Coil Amps ..............................................................................................................0 to 19.9 mSec

Coil Amps Build Time ..........................................................................................................0 to 9.9 mSec

Spark Burn Time ..................................................................................................................0 to 9.9 mSec

Ignition Energy ....................................................................................................0 to 99 milliVolt-Seconds

Secondary KV ..................................................................................................................0 to 32 Kilovolts

Pulse Rate .......................................................................................................................... 0 to 999 Hertz

Cylinder Power Balance .......................................................................................................% RPM Drop

Cylinder Power Contribution ..................................................................................................Speed Index

Amps Ripple ................................................................................................................ Message Indicator

Cranking Compression ....................................................................................................... % Amps Peak

Injector Amps Drive Time ..................................................................................................0 to 99.9 mSec

Injector Peak Amps............................................................................................................0 to 19.9 Amps

Throttle Position Sensor ..................................................................................................... Glitch Catcher

O2 Sensor ................................................................................................................. Volts and Crossings

with Optional Sensors:

Diesel RPM ................................................................................................................... 100 to 5,000 RPM

3

Connecting to a Distributorless Ignition

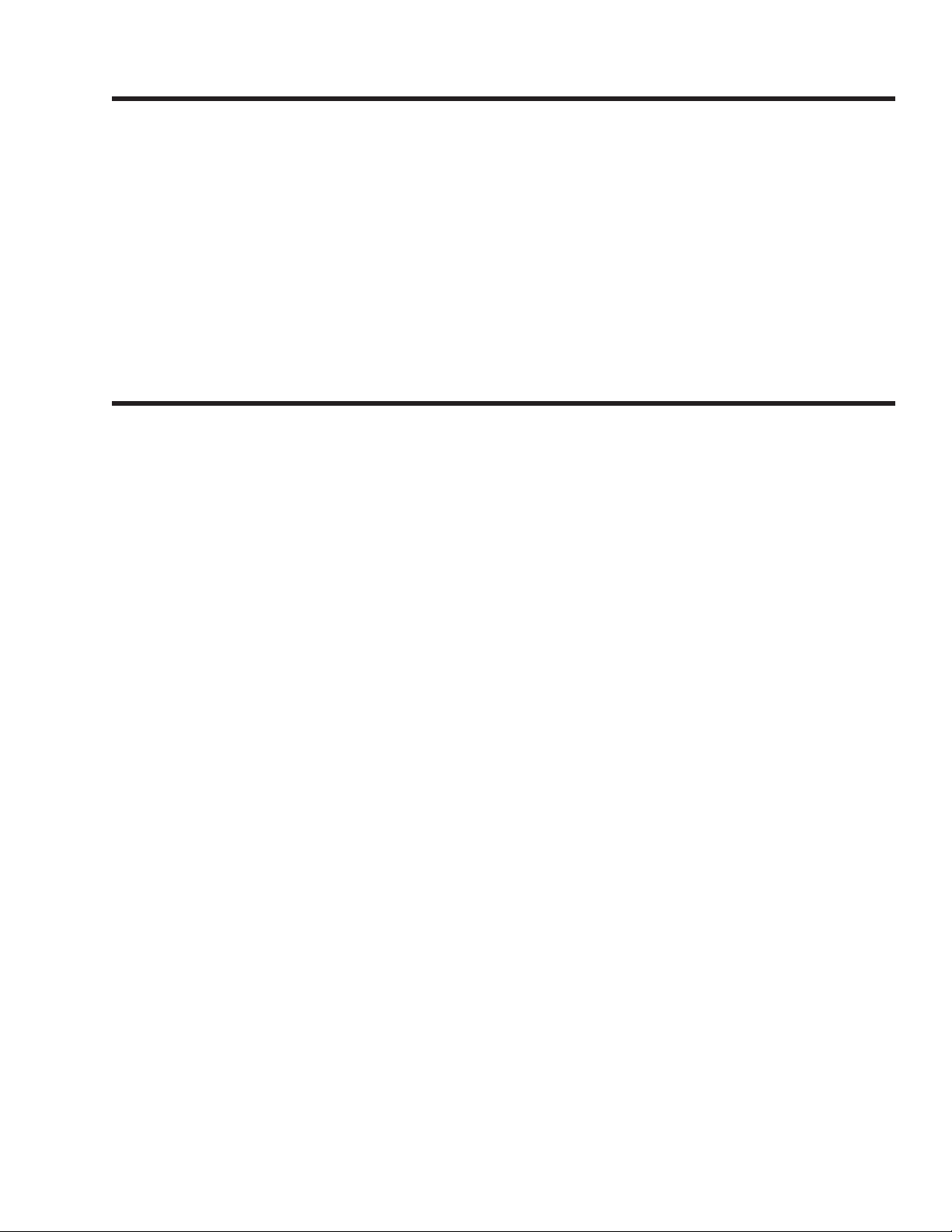

Sparkwire Clips

Primary Amps Pickup

Spark Pickup

Amp Probe

Power Leads

Auxiliary Lead

SPARKWIRE CLIPS

The EngineLink™ automatically sorts negative and positive firing plugs, and figures out coil pairings.

Connect the center Sparkwire Clip to #1 Cylinder, and connect the rest of the Sparkwire Clips to any

cylinder in any order. Connect the ground lead to a good engine ground.

PRIMARY AMPS PICKUP - DIS

Put the black Primary Amps Pickup around the wire that provides 12V power (B+) to the ignition module

and all coils. You may hookup around the wire anywhere in the wiring harness, but be sure the pickup is

around the wire that carries only the ignition pulses. The pickup label must face toward the battery plus

end of the wire (away from the coil).

SPARK PICKUP

The red Inductive Spark Pickup connects about the #1 cylinder plug wire. Connect close to the plug and

at least 4 inches away from the Sparkwire Clip on #1 cylinder. The label on the Pickup should face the

spark plug.

INDUCTIVE AMP PROBE

Connect the probe around the negative battery cable with the arrow pointing away from the battery, or the

positive battery cable with the arrow pointing towards the battery.

12V BATTERY LEAD

Connect the power leads to vehicles 12 volt battery. The connection must be made at the battery.

AUXILIARY LEAD

Not a required connection. Use the Auxiliary Lead for Sensor and voltage tests.

Primary Wire Colors

Manufacturer Wire Color

GM, Some 4 Cyl. Pink

GM, All Other Pink/Black

Chrysler Green/Black or Red

Chrysler Imports Black/White

Ford 4 Cyl. Blue

4

Otherwise, consult the car’s service manual wiring diagram.

Manufacturer Wire Color

Ford, All Others Red/Green

Hyundai Black.White

Infiniti Brown/Yellow

Lexus Black/Orange

Mazda Red/Lt. Green

Toyota Black/Orange

Connecting to a Distributor Ignition

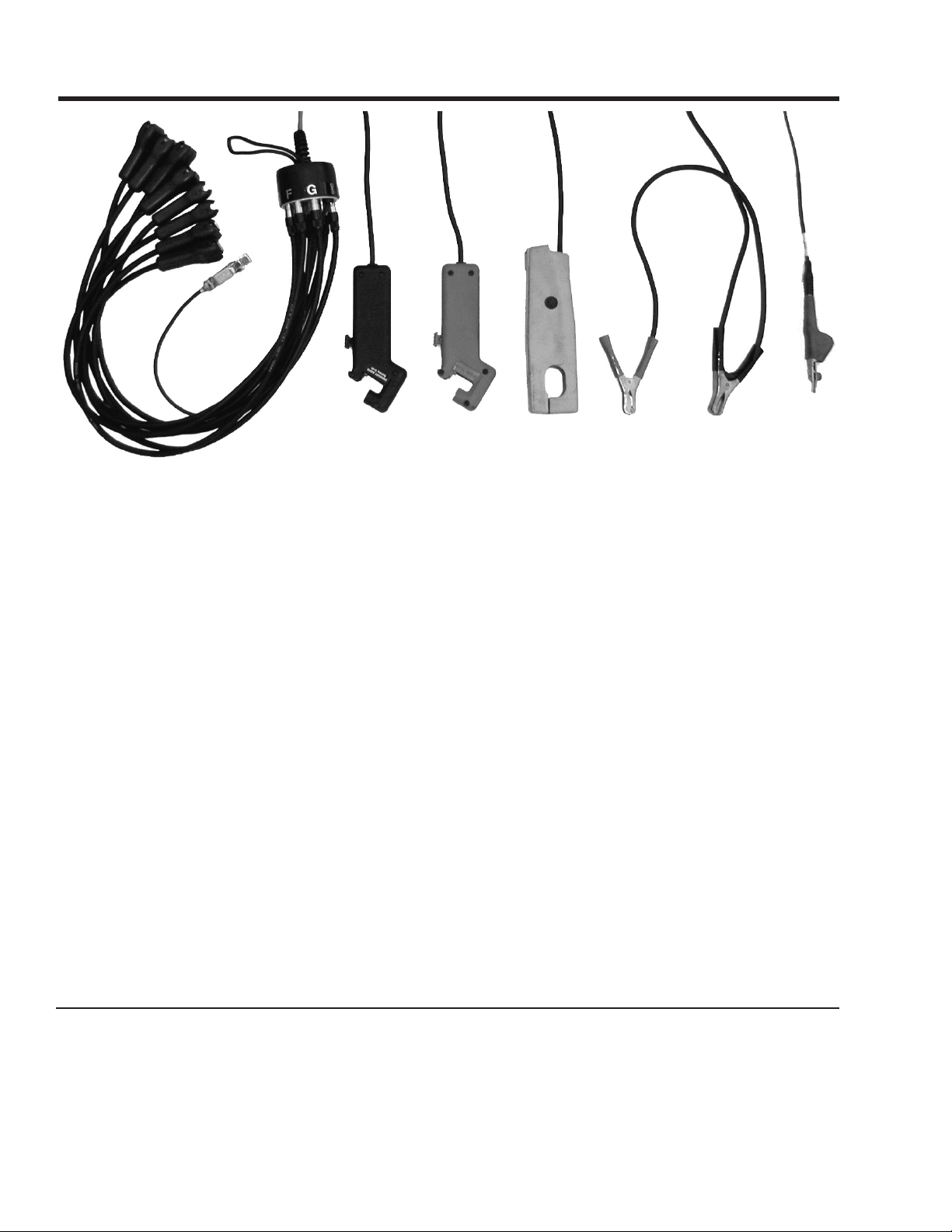

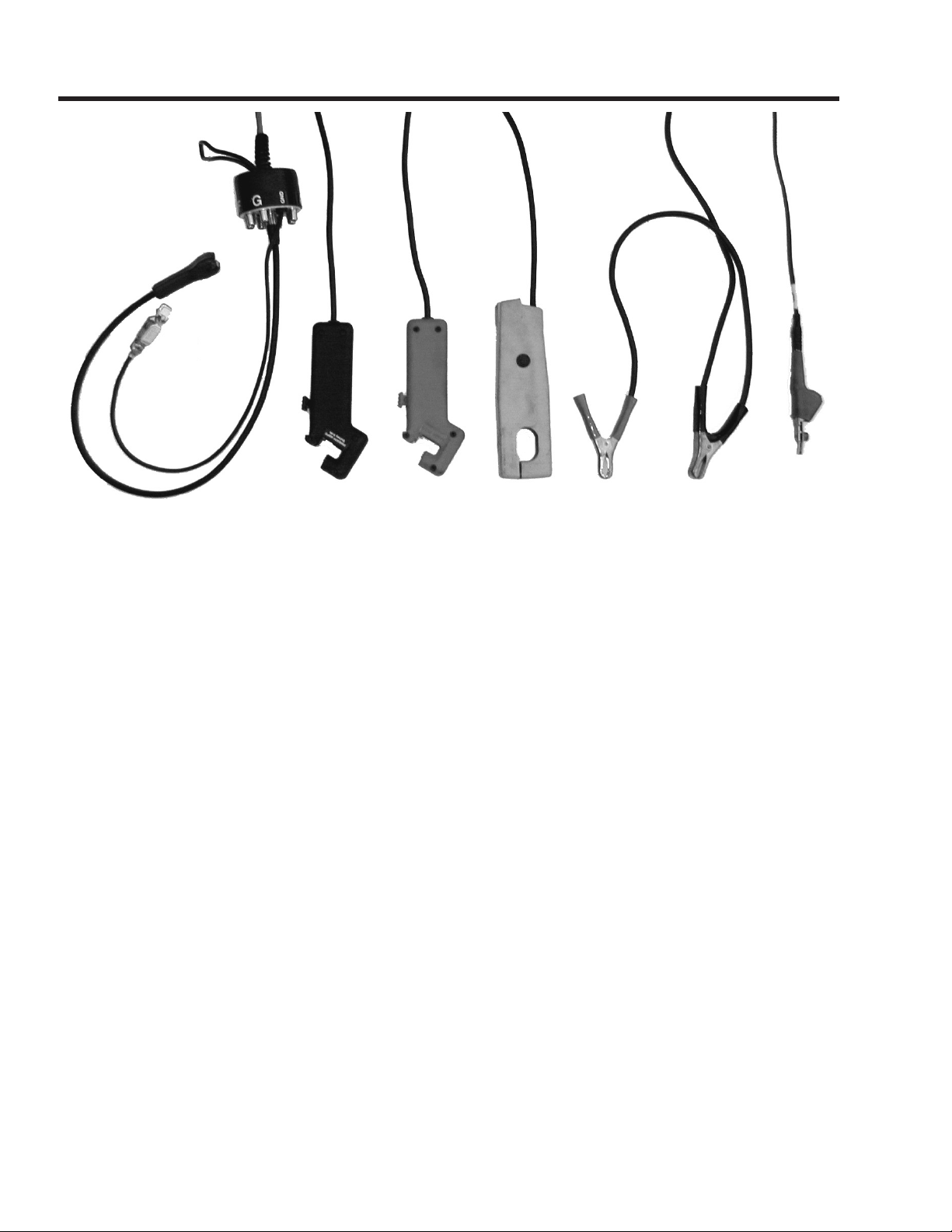

Sparkwire Clip

Coil Primary Clip

Spark Pickup

Amp Probe

Power Leads

Auxiliary Lead

SPARKWIRE CLIPS

Disconnect all Sparkwire Clips from the Spark Can except the middle lead. Connect it to the coil wire. If

the ignition system uses an internal coil, use one of the provided KV Plates.

COIL PRIMARY CLIP

Connect to the ignition coil primary (-) terminal. Sometime labeled “TACH”, it is the signal source for the

ignition primary circuit measurements. It is necessary for ignition suppression.

SPARK PICKUP

The red Inductive Spark Pickup connects about the #1 cylinder plug wire. Connect close to the Distributor.

The label on the Pickup should face the spark plug.

INDUCTIVE AMP PROBE

Connect the probe around the negative battery cable with the arrow pointing away from the battery, or the

positive battery cable with the arrow pointing towards the battery.

12V BATTERY LEAD

Connect the power leads to vehicles 12 volt battery. The connection must be made at the battery.

AUXILIARY LEAD

Not a required connection. Use the Auxiliary Lead for Sensor and voltage tests.

KV PICKUP PLATES

Pickup plates are provided for GM, Toyota, and Nippondenso systems that have the coil located within the distributor.

To read KVs, clip the appropriate pickup plate to the distributor housing, attach a Sparkwire KV Clip to the bar or

post on the pickup plate, and plug it into either the Distributor KV Lead or the Cylinder #1 position of the DIS KV

Harness.

NOTE: The KV pickup plates are designed to be sensitive. To obtain valid readings, keep hands and wires away

from the KV Pickup Plate and the KV Clip during testing.

5

Connecting to a No Coil Minus Ignition

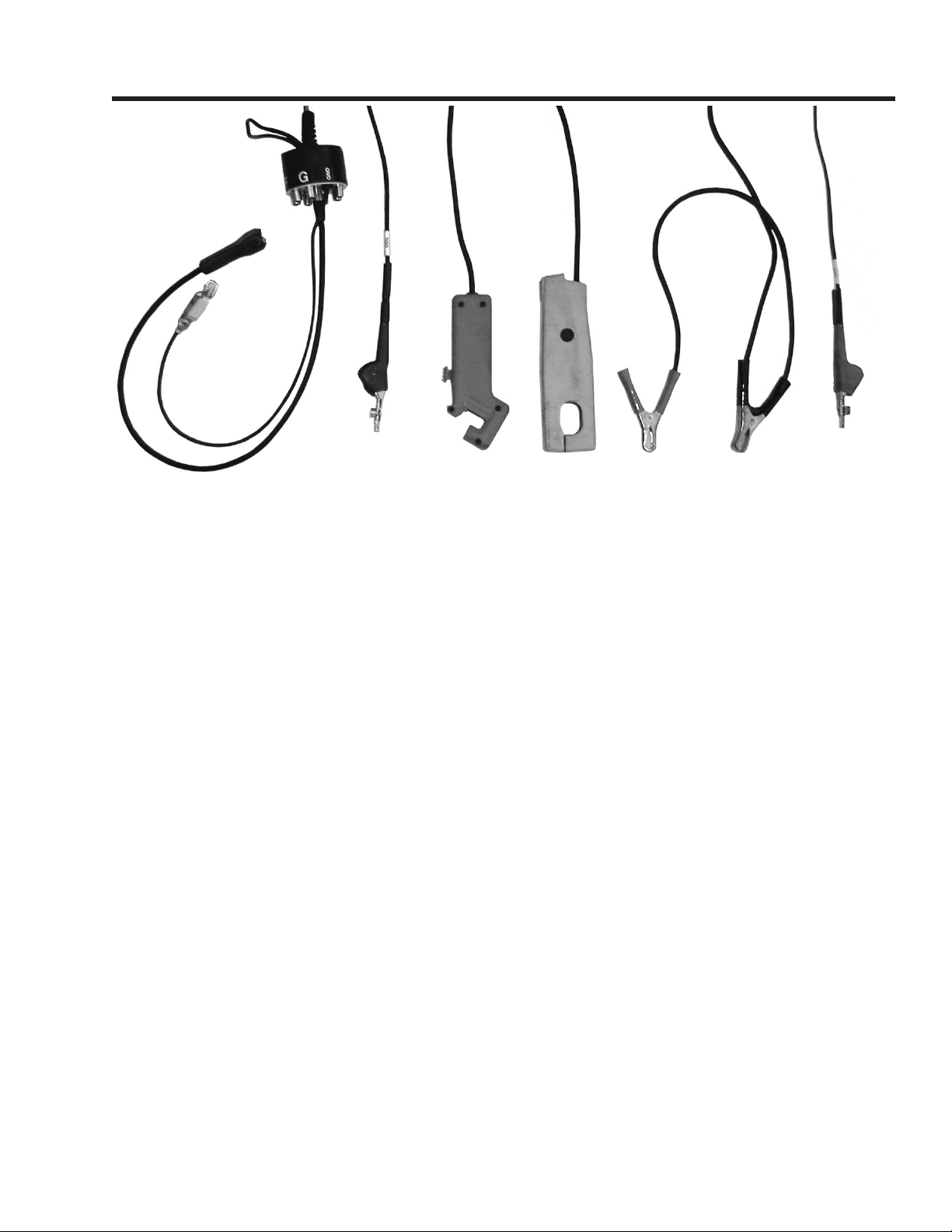

Sparkwire Clip

Auxiliary Lead

Coil Primary Clip

Spark Pickup

Amp Probe

Power Leads

SPARKWIRE CLIPS

Disconnect all Sparkwire Clips from the Spark Can except the middle lead. Connect it to the coil wire. If

the ignition system uses an internal coil, use one of the provided KV Plates.

PRIMARY AMPS PICKUP

Put the black Primary Amps Pickup around the wire that provides 12V power (B+) to the ignition module

and coil. You may hookup around the wire anywhere in the wiring harness, but be sure the pickup is

around the wire that carries only the ignition pulses. The pickup label must face toward the battery plus

end of the wire (away from the coil).

SPARK PICKUP

The red Inductive Spark Pickup connects about the #1 cylinder plug wire. Connect close to the distributor.

The label on the Pickup should face the spark plug.

INDUCTIVE AMP PROBE

Connect the probe around the negative battery cable with the arrow pointing away from the battery, or the

positive battery cable with the arrow pointing towards the battery.

12V BATTERY LEAD

Connect the power leads to vehicles 12 volt battery. The connection must be made at the battery.

AUXILIARY LEAD

Not a required connection. Use the Auxiliary Lead for Sensor and voltage tests.

A No Coil Minus ignition is an ignition system where the secondary ignition coil is housed in the Distributor

Cap, and the coil minus lead is not accessible. Some Toyota and Nipondenso ignitions are of this type.

6

MENU

IgnitionLink LT

ENGINE ANALYZER

HELP

PRINT

HELP

PRINT

MENU

MENU

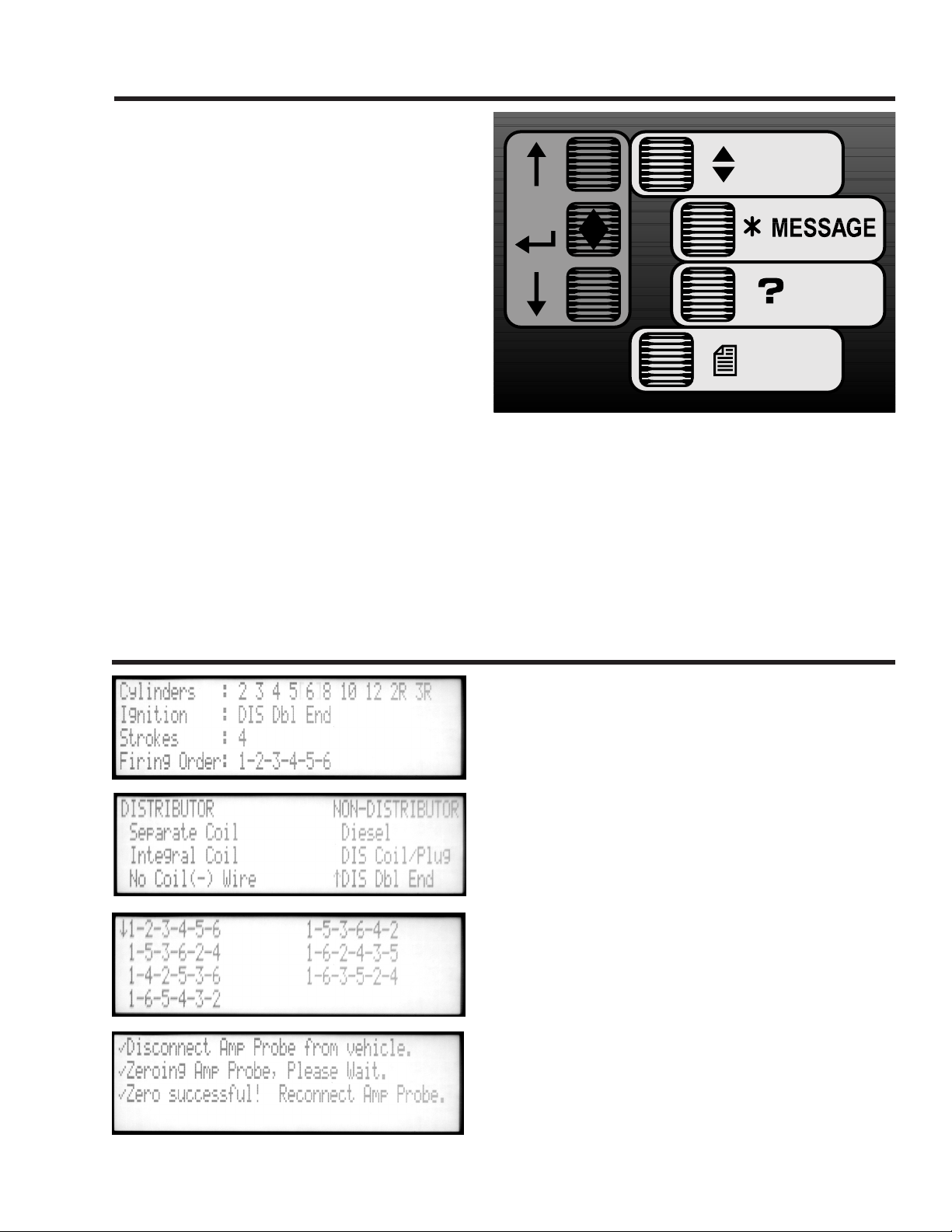

Press the MENU key anytime you want access

to the main test menu.

MESSAGE

The MESSAGE key is active when the flashing

message symbol '* is on the screen. Messages

may span several screens. Press the MESSAGE

key until all messages have been viewed, and the

original screen has been restored.

HELP

Press the HELP key when you want context

sensitive help.

PRINT

Press PRINT to print the display contents to a printer.

Arrow Keys

Use the up and down arrow keys to change numbers or make a different selection.

Keys & Controls

NEXT

The NEXT key is used to go on to the next step in a test or procedure or to act on an item that is selected.

In some cases the NEXT key will clear minimums or maximums and restart a measurement.

Initial Setup

The setup Engine Setup screen automatically appears

after power is applied to the unit. You must program the

EngineLink with the proper information about the vehicle

to be tested. Use the up and down arrows to move the

cursor to your selection. Pressing NEXT will enter the

selection and move to the next menu.

Select the number of cylinders, and press NEXT. A new

screen will appear, offering a choice of ignition type.

Distributor ignitions will have a Separate Coil or an

Integral Coil, where the coil is inside the distributor

housing (like GM HEI). In some cases, as with many

Nippondenso ignitions, the Coil (-) wire is not accessible.

In that case, SELECT No Coil (-) Wire.

Non-Distributor ignitions include Diesel engines, DIS

Coil/Plug, and DIS Dbl End (double end or output) where

each coil fires two plugs at the same time.

Select the ignition type, and press NEXT. Select 4 or

4, the results will be displayed in firing order sequence.

2 strokes, and select the firing order. Choosing a firing

order causes test data to be displayed in cylinder block

number sequence. If the default is accepted, e.g., 1 2 3

7

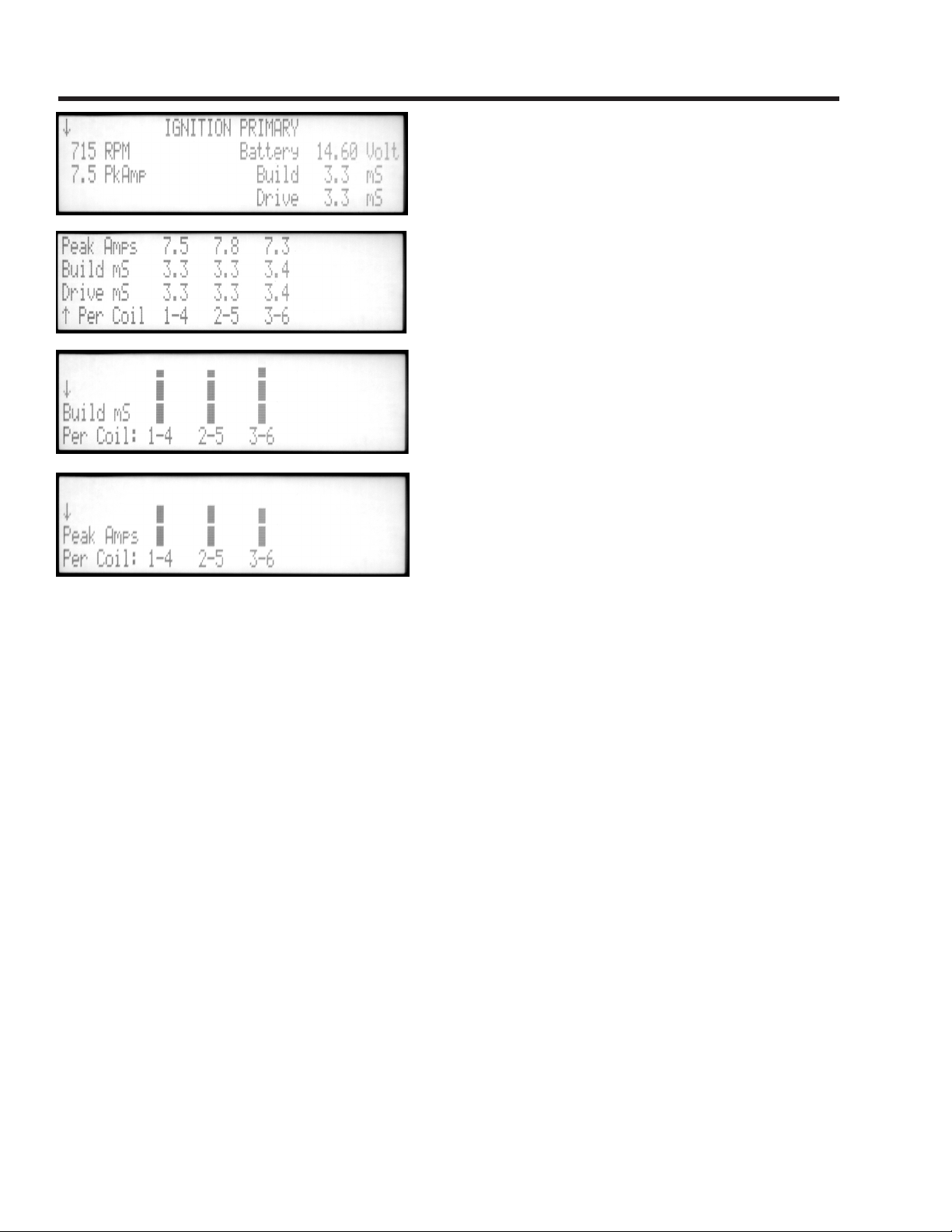

Ignition Primary - DIS

This test measures the input power and response of

the coil. If there are no readings, or they are obviously

wrong, check your connections.

COMPOSITE SCREEN

RPM is read by the black Primary Amps probe from the

current pulses drawn by the ignition coils. Battery voltage

comes from the red and black Battery Clips. The next

display line shows the average ignition primary amps

and the average milliSeconds it took for all coils to build

up the current during dwell.

DRIVE MILLISECONDS

The Drive MilliSeconds reading is the total dwell time

from the time the coil begins to charge to the time of

plug firing. In current-limiting electronic ignitions, the

difference between drive and build time is the “hold”

period.

MULTISPARK

Some ignition systems spark more than once during

each power stroke. If so, the words “Multispark Ign.” will

appear with the number of sparks per ignition.

INDIVIDUAL COIL READINGS

Press the up and down arrows to see individual coil readings. The numerical screen shows Peak Amps,

Build and Drive milliSeconds per coil. Two more screens show peak amps and build milliSeconds in bar

graph format.

PEAK AMPS

Look for equal current in each ignition coil, between 4 and 11 amps. If the primary ignition supply circuit

has bad connections, all amps may be low.

BUILD MILLISECONDS

These readings are useful for checking current-regulating ignitions that take a fixed time to build coil

current. Typical build time is 3 to 4 mSec. This time is nearly constant up to about 3000 RPM, and then

begins to shorten as RPM increases. If battery voltage is low, build times will lengthen.

Build time is a function of battery voltage, the inductance of the coil primary, and the peak amps level at which

the ignition module is set to regulate. The following relationships exist, if other factors are constant.

Long build time may be caused by high resistance in the primary circuit. Remember that the coil primary

circuit includes the power feed, the coil primary, the drive module, and its connection to ground. Increased

resistance from loose or corroded connections limits the primary current. This may cause lower peak amps

or longer build time readings.

Short build time may be caused by shorted coil windings.

Build time will be slightly longer while cranking, because of reduced battery voltage. If the ignition module

is not regulating at all, then Peak Amps can be High and Build can be Long. Both will be limited only by

the primary circuit resistance and battery voltage.

8

Ignition Primary - Distributor

PRIMARY

AMPS

BUILD

mSec

COIL

PEAK

AMPS

SPARK

LINE

PRIMARY

VOLTS

0 v

SPARK

BURN

TIME

IGNITION TIMING CYCLE

BUILD

(DWELL)

AMPS

HOLD

DWELL SECTION

BATTERY

VOLTAGE

IGNITION ENERGY

Ignition energy is the quality of the ignition coil inductance.

This indicates the coil “kick” in milliVoltSeconds (mVSec).

The engine must be cranking or running to produce a

readable signal. Typical standard ignition coils produce

25 to 40 mVSec. High energy ignitions have 40 to 60

mVSec. Readings below 20 mVS suggest that inadequate ignition energy is being delivered by the coil.

COIL OSCILLATIONS

This is an indicator of liveliness in the ignition coil. Shorts in coil insulation or in connected components

usually dampen the oscillations so they are reduced or eliminated. Points driven ignition coils usually

show 4 to 8 oscillations, which are more than electronic ignitions that do 1 to 4. Some Chrysler ignition

modules begin dwell immediately after the spark burn, so they normally do not show any oscillations.

DRIVER MODULE / POINTS VOLTAGE

“Driver” is the voltage during the dwell time. For mechanical points it should be less than 0.3 volts.

Electronic modules typically have 0.5 to 1.5 volts. Ignitions made alike should compare within 0.2 volts.

In this test, a higher voltage indicates a failing (high resistance) coil driver output transistor, bad points,

or a high resistance connection to ground.

DWELL

Press SELECT to display dwell in degrees, percent, or milliSeconds. MilliSeconds are useful for checking

the charging time for current-limited electronic ignitions, which take a fixed time to build up the coil amps.

A typical HEI coil charges in 3.5 mS at idle RPM, and 4.5 mS while cranking.

DWELL VARIATION

This is the difference in degrees between the longest and shortest dwell period. On electronic ignitions, it

could be from an unstable coil drive module. On points ignitions, mechanical sloppiness in the distributor

shaft bearings and cam shaft drive is the prime cause. At higher speeds, on points ignitions, the problem can

be floating contacts due to weak springs and poor lubrication. Readings should be less than 3 degrees.

TIMING VARIATION

Variations in timing is the difference in engine shaft degrees of the longest and the shortest times between

ignition firings. On pre-computer engines, variation meant looseness in the mechanical drive from the

crankshaft to the points cam. Sometimes timing is intentionally varied by engine computers.

Irregular idle RPM from O2 feedback fuel metering can cause timing variation also. Operating the engine at

higher RPM should reduce the variation to under 3 degrees. Read variation from 1000 to 3000 RPM with the

RPM held steady. During acceleration or deceleration, the Timing Variation is not a valid measurement.

Ignition Coil Primary Current and Voltage

9

Loading...

Loading...