DIAGNOSTIC

TM

®

ENGINE ANALYZER

CONTENTS

INTRODUCTION ..................................... 1

SPECIFICATIONS .................................. 1

OPERATING FEATURES

Display ................................................ 2

Control Panel ..................................... 2

Printer................................................. 2

Leads and Sensors ............................ 3

Timing Light ......................................... 3

SETTING UP FOR TESTS

Hookup Guidelines .............................. 4

Basic Setup Steps .............................. 5

DOING TESTS

Control & Test Keys ............................ 6

Sensor Test

Ohms/diode .................................. 8

O2 Sensor ..................................... 8

Position Sensor .............................. 9

Wiggle Scope ................................. 9

Ford & GM Codes ....................... 10

Fuel Injection

Duty, Hertz & mSec ......................11

Hard Start

Ignition Energy ............................ 12

Charging Starting

Amps, Auxiliary Volts ................... 13

Ignition Primary

Coil Oscl, Driver, Dwell, .............. 14

Spark Burn / Cylinder

Burn MilliSeconds ....................... 16

Burn Slope .................................. 17

Power Balance / Cylinder

Automatic & Manual .................... 18

Cranking Analysis

Cranking History ........................... 20

Electronic Compression ............... 24

PRINTING REPORTS

Auto-Test Sequence .......................... 28

Visual Inspection Checklist ............... 29

ANALYZER SERVICE .......................... 30

REFERENCE INFORMATION .............. 27

TYPICAL READINGS ........................... 32

MAGNETIC PROBE TESTS ................. 33

DIESEL TIMING TESTS ....................... 33

63

OPERATOR'S MANUAL

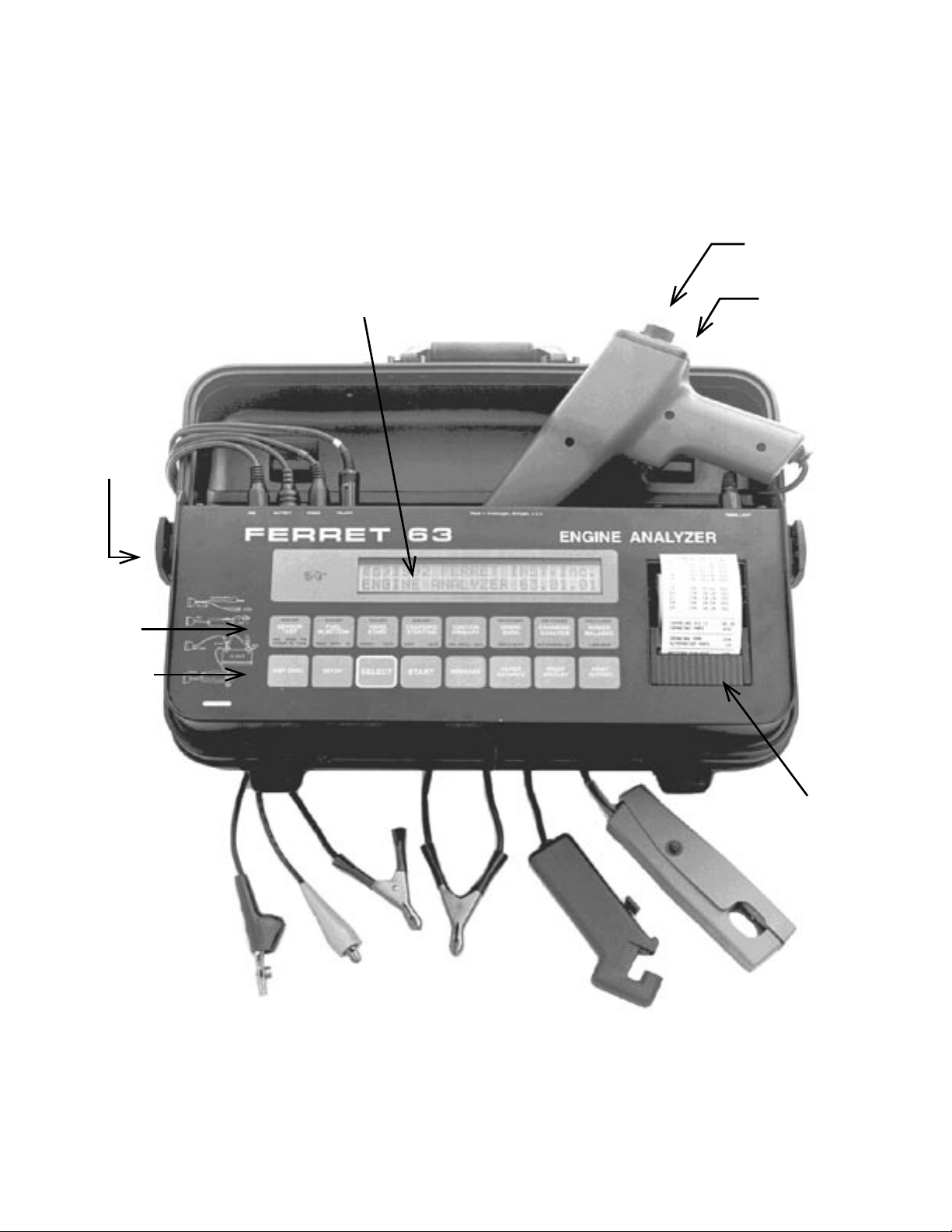

AUXILIARY

CLIP

red

PRIMARY

COIL CLIP

green

12 VOLT

BATTERY

CLIPS

SPARK

PICKUP

AMP

PROBE

PRINTER

TEST

KEYS

CONTROL

KEYS

2/4 STROKE

SWITCH

TIMING LIGHT

ADVANCE DIAL

HANDLE

48 CHARACTER

LCD DISPLAY

ANALYZER

COVER

NOT

SHOWN

COVER

LATCH

FERRET 63

DIAGNOSTIC ENGINE ANALYZER

© Copyright 1994, Ferret Instruments, Inc.

OPTIONAL EQUIPMENT

854 - Magnetic TDC Detector

754 - Diesel Injection Detector

INTRODUCTION

The Engine Analyzer is a time saving instrument for

troubleshooting automotive ignition, fuel injection and

electrical power systems. It provides computer controlled

measurements that are usually only found on diagnostic

ʻscopes. Measurement methods have been engineered

to reduce hookup effort and give speedy test results.

The analyzer is designed for use on 2,3,4,5,6,8,10 and

12 cylinder as well as 2 and 3 rotor, distributor ignition, 2

and 4 stroke, 12 volt automotive engines.

It has a large LCD display with 2 lines of 24 characters

showing numbers, words and symbols. All test keys display related multiple simultaneous measurements.

Diagnostic messages are given when the analyzer detects combinations of signals which suggest an engine

defect.

A built-in printer records the screen being shown or

prints the data saved from tests. The printout is formatted to make easy before-and-after repair comparisons.

Print options include a vehicle identification form, and

a vehicle equipment visual checklist report to help give

complete repair information to the vehicle owner.

For time-efficient testing, an Auto-Test Sequence leads

the user through all of the tests for a complete printed

test report.

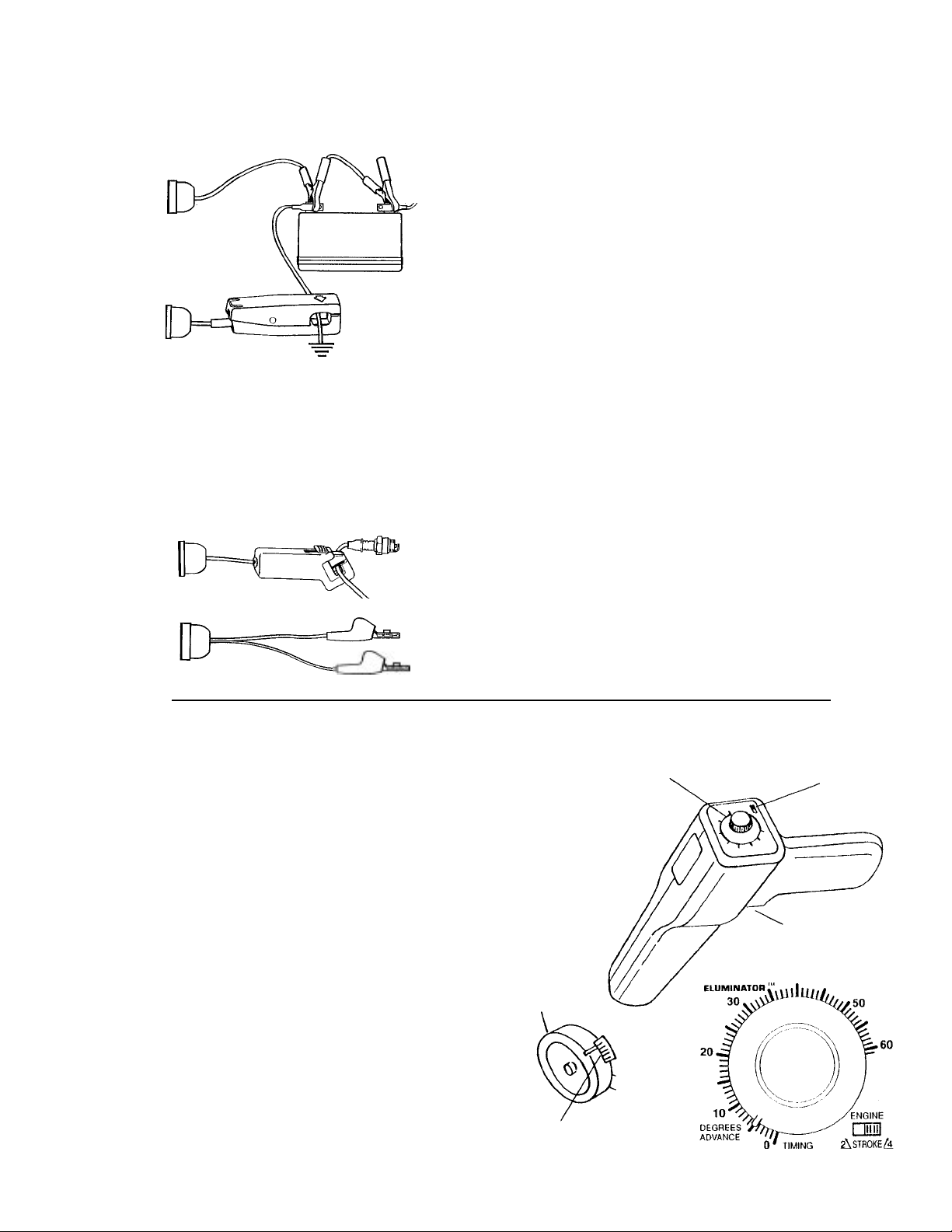

Test leads include a Timing-Advance Strobe Light, an

Inductive Amps Probe, an Inductive Spark Pickup, a 2

clip signal lead set, a power lead set, and an extension

harness, each of which are plug-in field replaceable.

SPECIFICATIONS

TEST ACCURACY RANGE

Volts, Battery .................1% ......... 8 to 18 Battery Volts

Volts, Aux. [10 meg] ...... 1% .......................0 to 20 Volts

Amps, Inductive ............. 3% .............. 0 to +/- 600 Amps

Tachometer .................... 1% ........... 100 to 10,000 RPM

Fuel Injector ................ 0.2mS .................... to 63 mSec

Pulse frequency ........... 1% ........................... to 250 Hz

Coil Energy .................. 5% ..... to 90 milliVolt-Seconds

Coil Oscillations ................. to 10 Oscillations

Spark Burn Time ........ 0.2mS ........ to 9.9 milliSeconds

Spark burn slope ..........................................+/- 99 units

Test duration .....................................................Seconds

Cranking ............................................RPM, Volts, Amps

Alternator ...............................................Amps & Ripple

Battery .................................................................... CCA

Timing Advance ........... 1.5° .............. to 60.0 Degrees

Dwell, Ignition .............. 0.5° ..........Degrees, %, mSec

Points/Driver Res. ........ 0.1v .......................to 2.5 Volts

Dwell Variation ...................................... to 90.0 Degrees

Timing Variation .................................... to 90.0 Degrees

Cylinder Power Balance .......................% RPM Change

Relative Compression ..................Cranking Amps Peak

Ohms ............................ 5% ................... 1 to 50K ohms

Diode ........................................................ Forward Volts

Position Sensor ........................................ Glitch catcher

O2 Sensor ...........................................Volts & crossings

Wiggle Scope ................................. HI/LO from 3.5 volts

WARNING

It can be hazardous to operate both a moving car and

the analyzer. Get someone to drive the car while you

read the display.

DIMENSIONS

Size ............140 x 350 x 470 mm .......5.5" x 14" x 18.5"

Leads .................................. 1.7 m ......................... 5 feet

Extension Harness .............2.5 m ......................... 8 feet

Operation ................... 4° to 44°C ............ 35°F to 120°F

Storage .................... -20° to 60°C ...........-20°F to 130°F

Weight ..................................8 kg .......................18 lbs.

Power Requirement .................................12 Volt Vehicle

Battery

The measurement capabilities of this analyzer were selected to serve the diagnostic needs of the professional

automotive service technician. Because of the com-

plexity and variety of the tests, the user must refer to

the vehicle specific diagnostic manuals to be assured

that correct conclusions are reached. This manual is

limited to describing the features of the analyzer and its

application requirements.

-1-

OPERATING FEATURES

SENSOR

TEST

02 TPS

SETUP

AMP ZERO

SELECT

MESSAGE

PRINT

DISPLA

Y

PRINT

AUTOTEST

CHARGING

ST

ARTING

AMPS VOLTS

IGNITION

PRIMARY

COIL MODULE

DWELL VARIATION

AUXILIARYAUXILIARY PER CYLINDER

CRANKING

ANALYSIS

COMPRESSION

BAT. STARTER ALT.

POWER

BALANCE

% RPM DROP

AUTO MANUAL

PER CYLINDER

SPARK

BURN

SECONDARY

MSEC SLOPE

PER CYLINDER

HARD

ST

ART

IGNITION VOLTS

AUXILIARY

FUEL

INJECTION

MSEC, % DUTY, HZ

AUXILIARY

START

PAPER

ADVANCE

USE BLUE OR

BLACK THERMAL

PAPER 2.25"

(58mm) WIDE.

.43" (11mm)

minimum hole.

Paper

Roll

Cover Retainers

To remove cover

press fingers at

both ends and lift

inside edge.

Keep dust out of the printer

to prevent accelerated lead

screw wear.

DISPLAY

The 2 by 24 character LCD dot matrix display provides a

versatile screen for the display of multiple sets of meter

outputs as well as data arrayed by cylinder. Contrast can

be adjusted with the SETUP key. A cast acrylic window

protects the display.

CONTROL PANEL

A MEMBRANE KEYBOARD controls the analyzer. It is a

pressure sensitive lamination of metalized plastic sheets

with small spaces between contacts. It is very durable

but can be harmed by chemical solvents or punctured by

sharp objects.

HOUSING

The case is designed to be a convenient to use protective enclosure. Rounded corners and the plastic base

were chosen to help guard mechanical and electrical

contact with the battery, engine, and car body parts. In

use, place the unit on a cart, in the engine compartment,

or inside the car. The compartment under the control

panel is made to store the leads and harness.

THE TEST KEYS on the top row activate readouts or

initiate tests which require actions by the user to arrange

engine and vehicle test conditions.

BOTTOM ROW KEYS select test options, start action,

and make adjustments.

PRINTER

The printer will capture any displayed data or message

during non-sequenced testing if PRINT DISPLAY is

pressed, and at the end of the sequenced tests it will

print the resulting data and messages from the PRINT

AUTOTEST - Print Data command. If only some of the

data saving tests have been done since power-up, they

will be the only ones printed. PRINT REPORT offers an

AutoTest option to complete a full set of printed tests in

the shortest possible time.

The PAPER ADVANCE key is used to feed a new roll of

paper into the printer. Once the paper is in place it may

be pulled through to extend the end of a report before

tearing it off. Do not pull the paper backwards through

the mechanism.

Only the outside surface of the paper roll is sensitized

for printing, so it must feed from the bottom of the roll

into the mechanism. Getting the paper started is easiest

if the leading edge is cut cleanly. Push it into the slot 2

to 3 cm and press PAPER ADVANCE. Each key press

A BEEPER inside the analyzer indicates contact with

keys and signals warnings.

moves the paper feed 2 lines. If it does not feed, lift the

printer cover for better access and try again.

See the Printing Reports section (p28) for more details.

-2-

LEADS AND SENSORS

NO

TA

G

GREEN

TA

G

AMP PROBE

12 VOLT

+

–

RED

BLACK

ADVANCE DIAL

KNOB

ENGINE

CRANK

WHEEL

TIMING

MARKS

HI / LO

FLASH

TRIGGERS

2/4 STROKE

ENGINE

SWITCH

RED

TA

G

YELLOW

TA

G

AUXILIARY

COIL PRIMARY

NO. 1

SPARK

PICKUP

RED

GREEN

12 VOLT BATTERY CLIP LEAD SET

This is a multiconductor cable which draws power from

the battery and senses the voltage. It should be the first

set of lead clips connected.

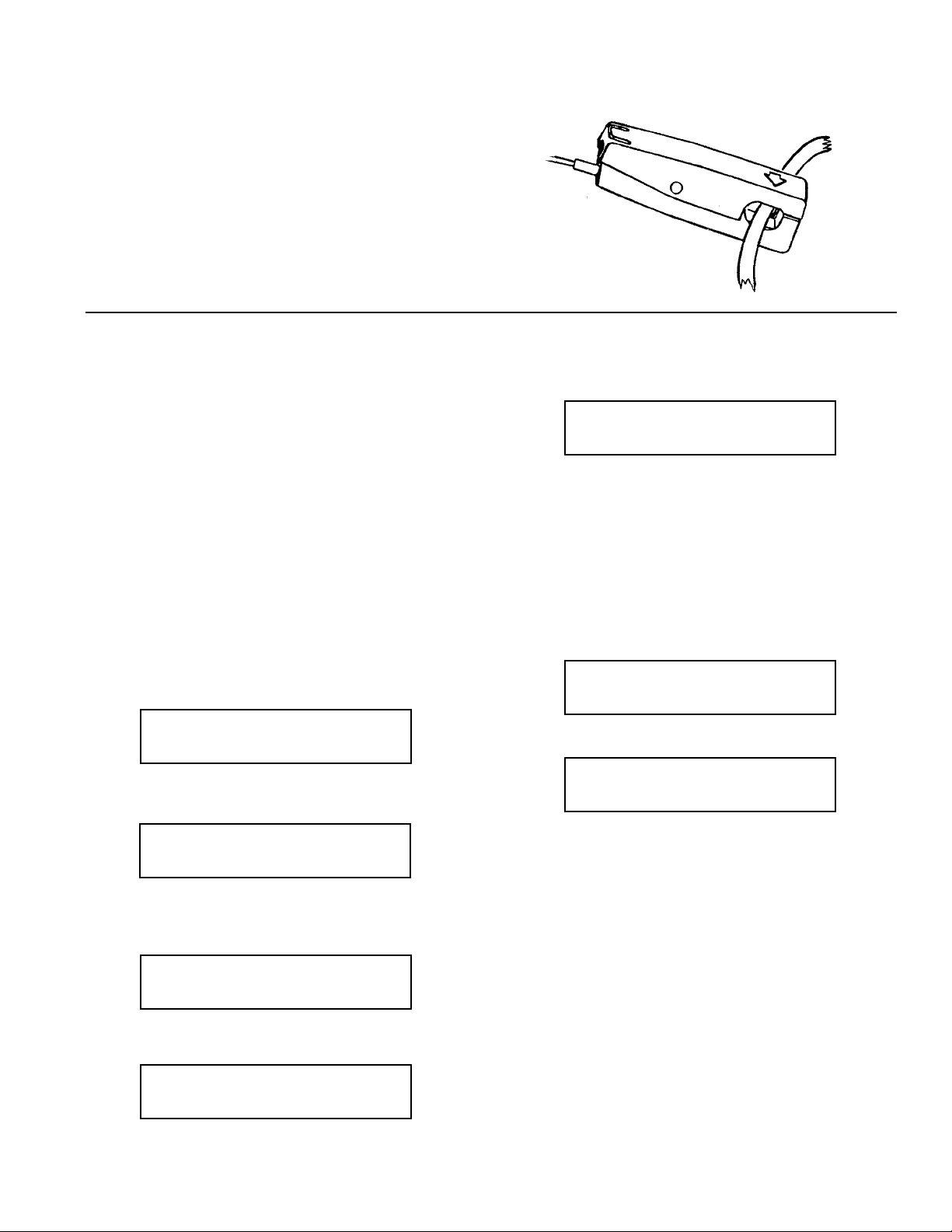

INDUCTIVE SPARK PICKUP

Cylinder synchronization and tachometer input are the

function of this lead. Features of this easy to use 8mm

wire spark current sensing pickup are dependable spark

pulse detection, ruggedness and plug-in replacement.

The unique design has an easy grip handle and a latching jaw mechanism for durability. The housing is made

of glass fiber reinforced plastic with high temperature

strength and solvent resistance.

INDUCTIVE AMPS PROBE

The Hall effect Amps Probe senses DC current in wires

without having to disturb connections and without introducing any voltage drop. Up to 20 mm (.75”) diameter

cables may be read. A distinctive arrow is marked on

both sides which indicates the direction of positive current flow for a positive analyzer readout. Materials in

the probe are selected for enduring performance. If

damaged, a new probe may be plugged into the analyzer

without additional service.

EXTENSION HARNESS

A set of 4 identical cables are sheathed to form a harness to extend the leads enough to reach from a carʼs

interior to the engine. They have color markers for lead

coordination. The long tailed end connects to the analyzer connector. Take care between door panels that it

does not get pinched enough to shear. Any of the leads

may be plugged directly into the analyzer without the

extension.

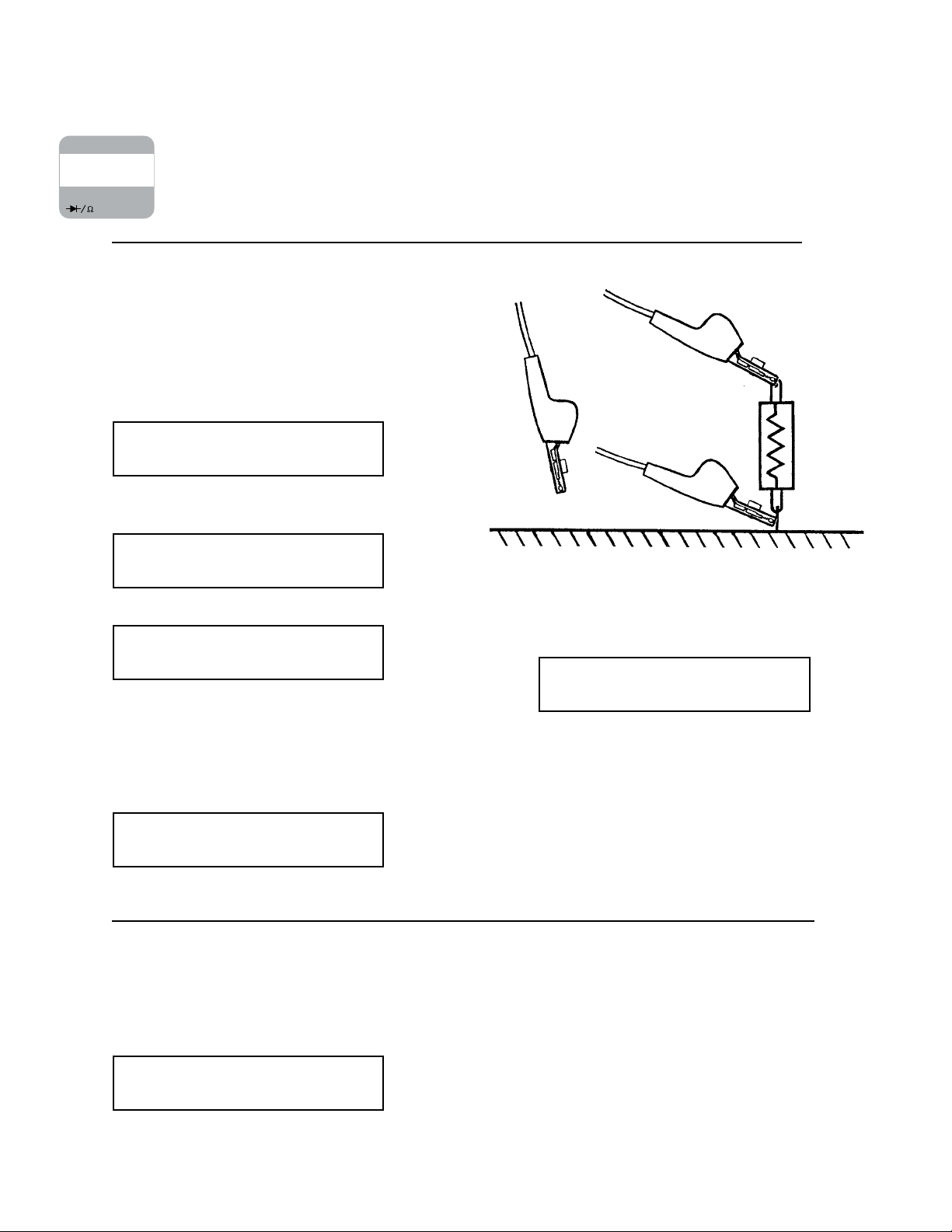

COIL PRIMARY / AUXILIARY LEAD CLIPS

Both clips have a prod tip and an insulation penetrating

pin cluster so they are adaptable to many connections.

The wires are neoprene insulated copper. The red clip

is used for auxiliary tests. The green clip lead, is always

connected to coil primary TACH.

TIMING-ADVANCE STROBE LIGHT

The Timing Light may be used when a spark signal and

power from the analyzer leads are present. Advance settings are controlled and read directly from the calibrated

dial. The 2/4 stroke switch changes the dial calibration

by a factor of 2 for the ignition type.

To measure an engine's spark advance, clean the crank

wheel marks for good visibility and run the engine with

the appropriate test conditions. Turn the advance dial to

about the expected reading, press the light's trigger while

shining the light at the wheel marks, and then adjust the

knob so the marks appear aligned to TDC. The dial setting is the spark advance angle in degrees of crank shaft

rotation.

The two trigger buttons control flash brightness. Operation of the analyzer is not affected by the Timing Light so

it may be unplugged any time.

-3-

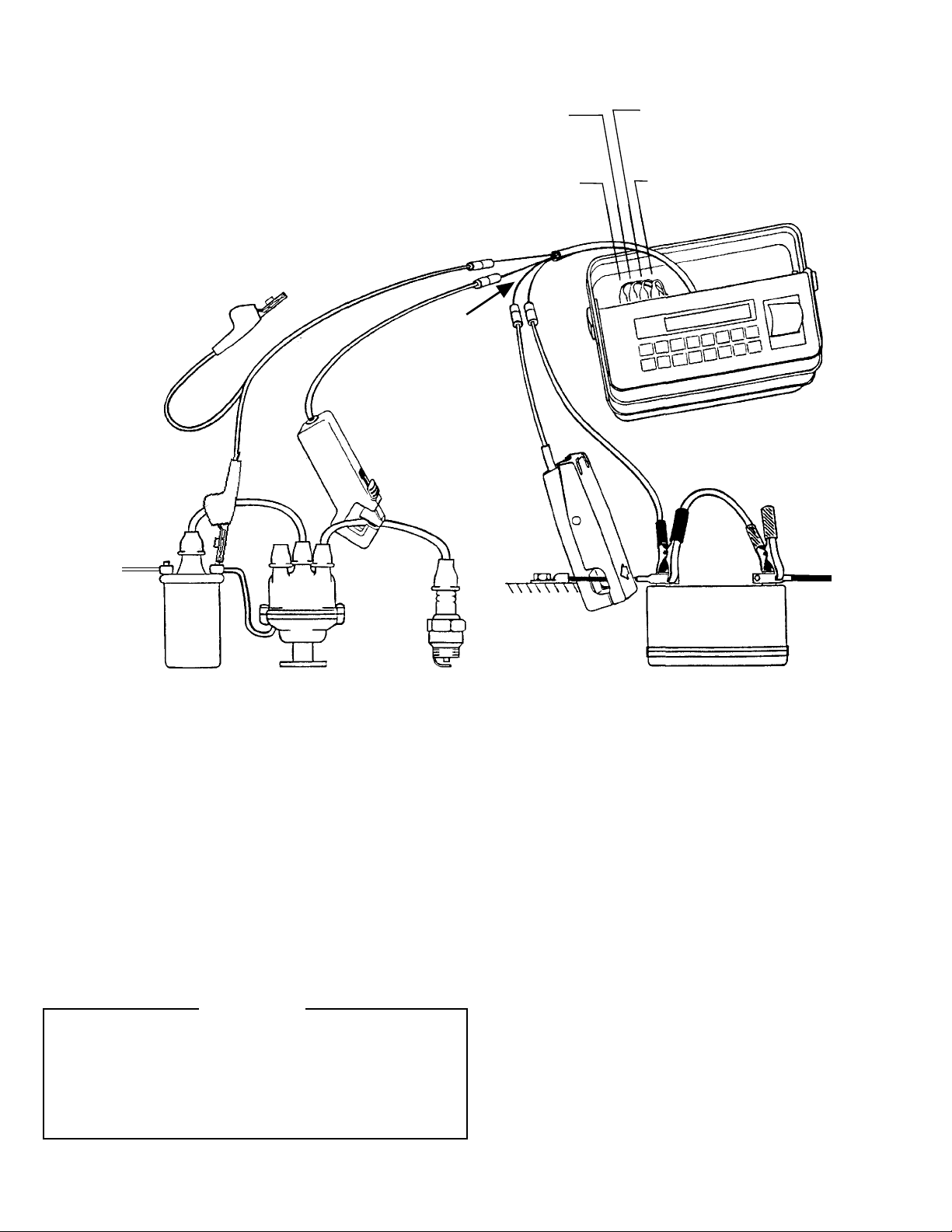

AUXILIARY

red

SPARK PICKUP

COIL PRIMARY

green

Face Label Side

Toward Plug End

NO. 1

SPARK

PLUG

Put Amp Probe

Around Either

Battery Cable

12-VOLT

BATTERY

AMP

PROBE

EXTENSION

HARNESS

BLACK RED

BATTERY

CLIP

LEAD

Make Firm

Battery Connections

and Wiggle Clips

for Clean Contacts.

BATTERY

CLIPS

SPARK

PICKUP

AMP

PROBE

COIL /

AUXILIARY

B+

+ –

– +

SETTING UP FOR TESTS

HOOKUP GUIDELINES

Color labels for matching the cable connections between

the analyzer and the clips are marked on the panel just

above the connectors. Mismatched connections will

prevent the leads from working, but will not cause harm

under normal conditions.

Take care to find a secure footing and safe lead routing

away from exhaust manifolds and fan belts.

12 VOLT BATTERY CLIP LEAD SET

These clips must have a solid connection to the battery

terminals. Reliable analyzer operation depends upon a

continuous power source. Intermittent power will reset

the analyzer to its start-up state. It is possible to draw

power from other points in the vehicle wiring, but the

measurements may be misleading because wiring resistance may interfere with the tests.

AUXILIARY CLIP LEAD

This red clip does not have a specific connection for the

basic hookup. It is the input for Auxiliary Volts, Ohms/

Diode readings, Wiggle Scope, and Sensor/Fuel Injector

Pulses. See SENSOR TEST test descriptions for connection locations.

Do not run engine with the Auxiliary lead connected

to engine sensors while the spark pickup and coil

primary leads are connected to the ignition. The analyzer leads can couple ignition noise into the engine

computer and disrupt engine operation.

WARNING

IGNITION COIL PRIMARY CLIP LEAD

This green clip connects to the ignition coil primary winding minus terminal, sometimes labeled “TACH”. It is the

signal source for all of the ignition measurements, and it

is necessary for ignition suppression.

INDUCTIVE SPARK PICKUP

The best hookup arrangement is to place the pickup

around the spark plug wire, as far from the spark plug as

possible, and with the “Spark Plug” labeled side pointing toward the spark plug end of the wire. Be sure the

pickup magnetic cores are touching.

Placing the pickup far from the spark plug keeps it away

from the hot exhaust manifold, and improves performance, because spark current impulses are “cleaner”

near the distributor.

When the pickup is not being used, LEAVE THE JAWS

IN THE OPEN position. The magnetic cores are made of

ferrite ceramic and when kept apart they are more likely

to not break if the pickup is dropped.

-4-

NDUCTIVE DC AMP PROBE

PLACE AROUND WIRES

TO MEASURE AMPS

WHEN ZEROING

REMOVE FROM WIRES

(or turn current off)

The reading range is 000 to +/-600 amps DC in 1 amp

steps. Starter and alternator output current measurement

is the primary application. It also allows the measurement

of vehicle accessory currents. Placing the probe on the

battery cable, while the engine is off, and then watching

the change when operating switches allows checking

many loads rapidly. Use AMP ZERO to restore the reading to zero before putting the probe around any wires.

SETUP STEPS

1. CONNECT ONLY THE BATTERY CLIPS. The Bat-

tery Clips must go to the engineʼs 12 volt battery terminals, red clip to plus, black clip to minus. The model

description will be displayed momentarily.

The analyzer may give you a choice of languages. Once

a language is selected it cannot be changed until the

analyzer power is disconnected.

2. DO THE SETUP. The display will automatically switch

to the Setup function. The SETUP key is only used to

change settings. Use SELECT for selecting choices.

Press START when the correct selection is displayed

which will advance the analyzer to the next Setup item.

There are 4 selections of contrast for the display. More

"=" makes the display darker

SELECT:====

LCD Contrast then START

This is when the operator tells the analyzer about the

engine.

SELECT: Elect./ 4S Sroke

Ignition then START

The ignition type and engine strokes selection are combined. The combinations are of Electronic or Points

Contact, and 2 or 4 Stroke.

3. Then the Amp Probe reading is zeroed.

Remove AMPPROBE from CAR

then START

The probe should not be around any wires when you

press START. When complete, the analyzer will automatically go to the HARD START test.

4. HOOKUP THE REMAINING LEADS.

Now see that all analyzer leads are connect, and then

run the engine.

If there is not yet an active signal into the coil primary

clip it will show:

Check Connections!

-Run Engine-

The data screen will appear when inputs are active.

356 RPM msg Bat 10.34

IgEgy 38 Aux>POS- 1.34

5. PRESS ANY TEST KEY.

If the HARD START test screen shows normal readings indicating that the analyzer hookup is working, we

suggest that you do a general ingine review using the

AUTOTEST at the PRINT AUTOTEST key.

SELECT: 4 CYL

CYLINDERS then START

Selections are 2,3,4,5,6,8,10,12 CYLinders, and 2 or 3

ROTors.

SELECT: mSec

Dwell Scale then START

Select DEGrees, mSeconds, or % (percent)

If the analyzer resets on its own check that the Battery clips have good connections. Also, if the engine

has metallic secondary ignition wires, try replacing

the coil to distributor wire for the test with a 10 K to

20 K ohm resistance wire.

-5-

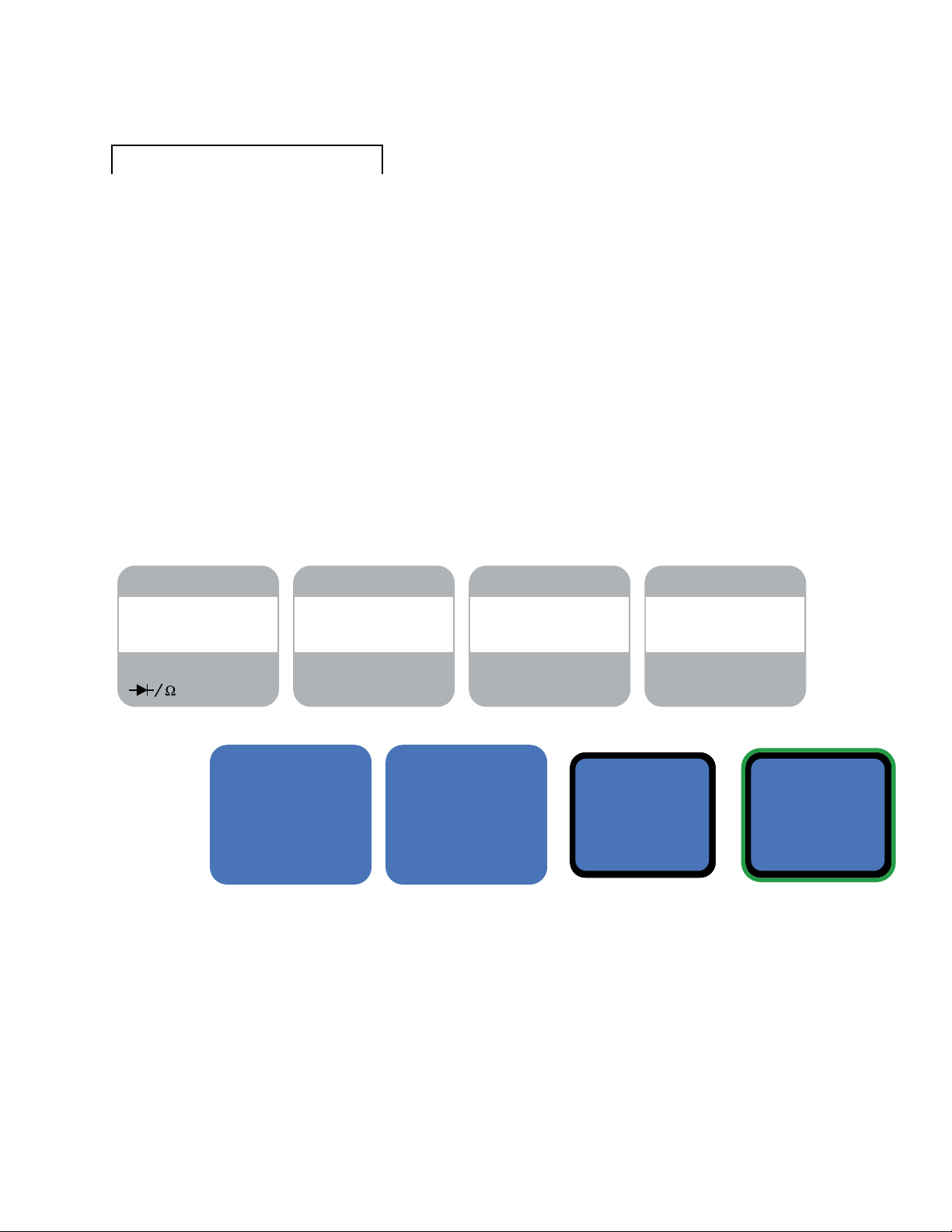

DOING TESTS

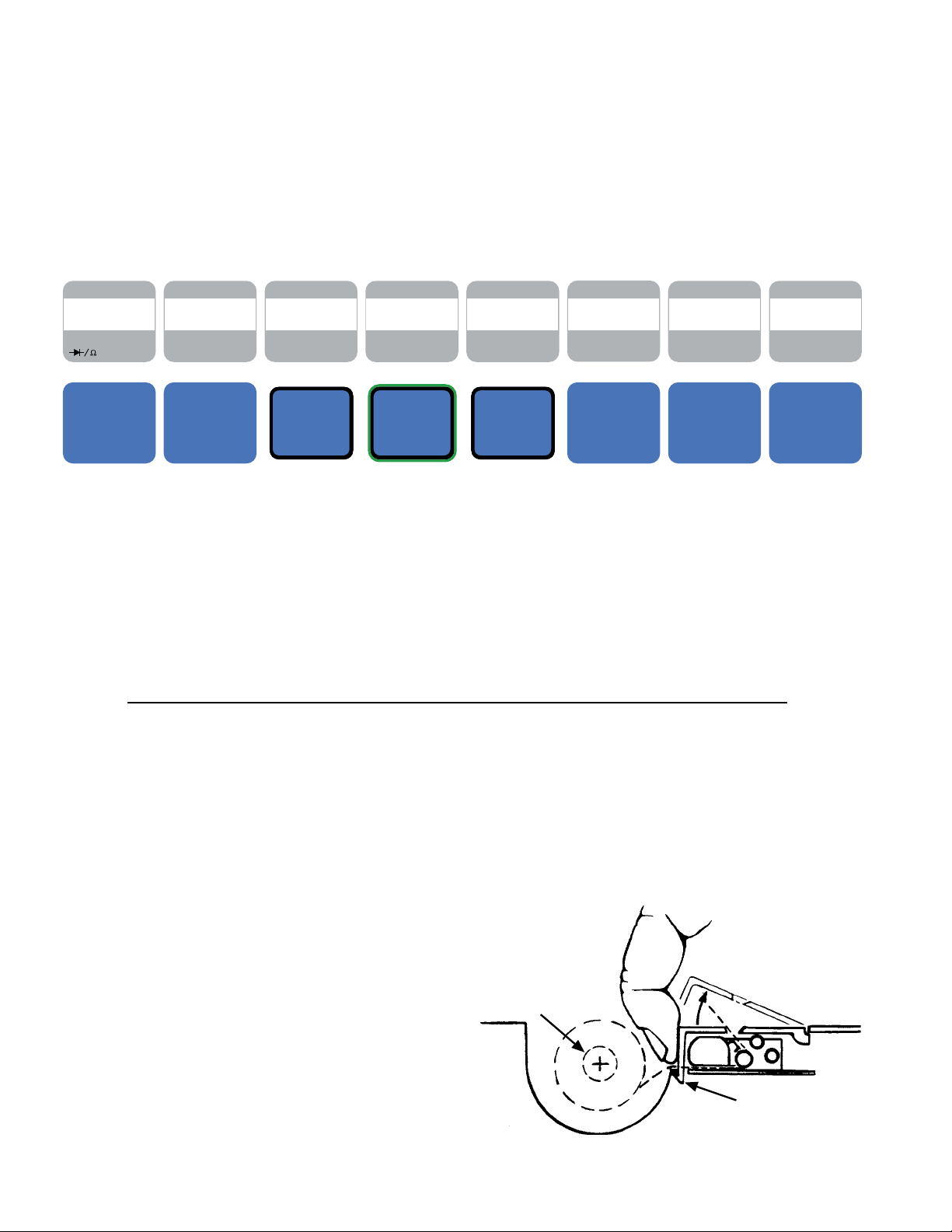

SENSOR

TEST

02 TPS

CHARGING

ST

ARTING

AMPS VOLTS

IGNITION

PRIMARY

COIL MODULE

DWELL VARIATION

AUXILIARYAUXILIARY PER CYLINDER

SP

BURN

SECONDARY

MSEC SLOPE

PER CYLINDER

HARD

ST

ART

IGNITION VOLTS

AUXILIARY

FUEL

INJECTION

MSEC, % DUTY, HZ

AUXILIARY

SENSOR

TEST

02 TPS

SETUP

AMP ZERO

SELECT

MESSAGE

CHARGING

STARTING

AMPS VOLTS

IGNITION

PRIMARY

COIL MODULE

DWELL VARIATION

AUXILIARYAUXILIARY PER CYLINDER

SP

BURN

SECONDARY

MSEC SLOPE

PER CYLINDER

HARD

START

IGNITION VOLTS

AUXILIARY

FUEL

INJECTION

MSEC, % DUTY, HZ

AUXILIARY

START

PAPER

ADVANCE

AUXILIARY INPUT TEST KEYS

Typical features of the tests are the RPM and the Battery

Volts readouts.

1057 RPM msg Bat 13.84

The RPM reading in the upper left of the display gets the

signal input from the Inductive Spark Pickup. Scaling is

determined by the setup selections.

The Battery Volts reading in the upper right display corner

comes from the Battery Clips.

SENSOR TEST has the following sensor and signal

tests. The Ohmmeter can be used for resistance checks

of spark plug wires or components. The Diode test measures forward and reverse diode voltage. The Oxygen

Sensor test measures the activity level of the O2 Sensor

voltage. The Throttle Position Sensor test is a computer

aided test to find intermittent TPS sensors. The Wiggle

Test, and GM & Ford Code tests will help you retrieve

trouble codes from some computer controlled engines.

See pages 8-10.

Contrast then START

FUEL INJECTION helps to trouble shoot EFI, PFI, TBI,

and Computer Controlled Carburetor engines. The Duty

Cycle test reads Hertz (Frequency) and Duty Cycle

(Dwell) for use on solenoid equipped carburetors. Also

use for checking pressure, flow, Hall effect, and other

sensors that are specified by these measurements. The

Fuel Injection test measures the milliSeconds of voltage

drive to an injector. See page 11.

Use HARD START to find the problem area on a no start

engine. Ignition Energy indicates the ignition's strength.

Auxiliary Volts is used to confirm that voltage is present

at the ignition. RPM and Battery Voltage are used to

measure the performance of the cranking system. Special diagnostics pick out problems with the spark plugs,

wires, cap and rotor. See page 12.

CHARGING STARTING measures cranking speed, voltage regulator setting, starter draw, accessory draws, and

alternator output. The Auxiliary Volts is great for voltage

drop tests. Diagnostics monitor the alternator for excessive amps ripple indicating a bad diode or stator. See

page 13.

CONTROL KEYS

This lower row of keys select test choices, look up messages, restart tests, and operate the printer.

Pressing AMP ZERO subtracts whatever the amps read-

ing was so that the reading becomes zero. If amps fails

to work, read the Amp Probe Check procedure in this

manualʼs Service section.

SETUP is used to input information about the engine

being tested, and provides four levels of display contrast

adjustment.

-6-

When there are choices in a test, SELECT steps through

the selection. The last displayed choice is made active

by pressing START.

START takes the operation to the next test step. It

continues an operation after some conditions have been

prepared by the operator.

START also clears Min and Max readings on Spark Burn

and Fuel Injection tests.

ENGINE DYNAMICS TEST KEYS

IGNITION

PRIMARY

COIL MODULE

DWELL VARIATION

CRANKING

ANALYSIS

COMPRESSION

BAT. STARTER ALT.

POWER

BALANCE

% RPM DROP

AUTO MANUAL

PER CYLINDER

SP

ARK

BURN

SECONDARY

MSEC SLOPE

PER CYLINDER

MESSAGE

PRINT

DISPLA

Y

PRINT

AUTOTEST

IGNITION

PRIMARY

COIL MODULE

DWELL VARIATION

CRANKING

ANALYSIS

COMPRESSION

BAT. STARTER ALT.

POWER

BALANCE

% RPM DROP

AUTO MANUAL

PER CYLINDER

SP

ARK

BURN

SECONDARY

MSEC SLOPE

PER CYLINDER

PAPER

ADVANCE

These keys measure engine power cycle functions to

find causes of rough running. “PER CYLINDER” tests

store the gathered data in memory for after-test review

and printout. This permits seeing trend and cylinder differences in the engine data.

The sequenced tests in the next column have pauses to

display instructions. Press START for the next step after

an instruction has been completed.

IGNITION PRIMARY is used to find bad ignition coils and

modules using the measurements of Oscillations, Ignition

Coil Energy, Dwell, and Driver Voltage. Use the Dwell

and Timing Variation tests to find loose timing chains,

worn distributor shafts and bearings. See page 14.

CRANKING ANALYSIS has two test sequences to measure Relative Compression, Cranking Volts, Cranking

Amps, Cranking RPM, Alternator Amps, and the CCA of

the battery. The Compression test finds cylinders with

low relative compression, and shows it on the printout

bar graph. See pages 20-23.

POWER BALANCE performs an Automatic or Manual

Power Balance test to locate low power cylinders. Each

spark plug is turned off one at a time and the RPM drop

is measured. The greater the drop in RPM, the stronger

the cylinder. Cylinders with a small drop should be tested

further to determine the problem. A Power Balance bar

graph is produced with the printed report. See page

18.

SPARK BURN easily finds defects with spark plugs,

sparkplug wires, distributor cap, and rotor. It measures

the Minimum, Average, and Maximum Spark Burn Time

for each cylinder. Spark Slope is measured to indicate

a lean or rich fuel mixture. A Burn Time Range bar graph

is produced with the printed report. See pages 16-17.

Ignition suppression is used in CRANKING ANALYSIS

and POWER BALANCE. The analyzer can suppress the

usual inductive discharge distributor ignition, but will not

work on capacitive discharge and multicoil ignitions. A

compatibility check is done by the analyzer before it will

apply suppression. If the check finds it incompatible, the

user will be notified to manually disable either the ignition

or fuel system.

Press MESSAGE when "msg" appears in the middle of

the display. This means a diagnostic check detects an

out of limit condition. Repeated presses of MESSAGE

will step through all the diagnostic messages and finally

back to the test. Messages may appear intermittently if

the condition is on the threshold of being a problem.

Messages suggest causes of problems, but do not

prove the suggested item is bad.

-7-

PAPER ADVANCE feeds 2 lines of paper for each

press.

PRINT DISPLAY prints what is on the display.

PRINT AUTOTEST prints test reports and is the Auto-

Test entry key. The Auto-Test will run all of the engine

dynamics tests in an automatic sequence. At the conclusion of the data report, you can also print the visual

inspection checklist. See pages 28-29.

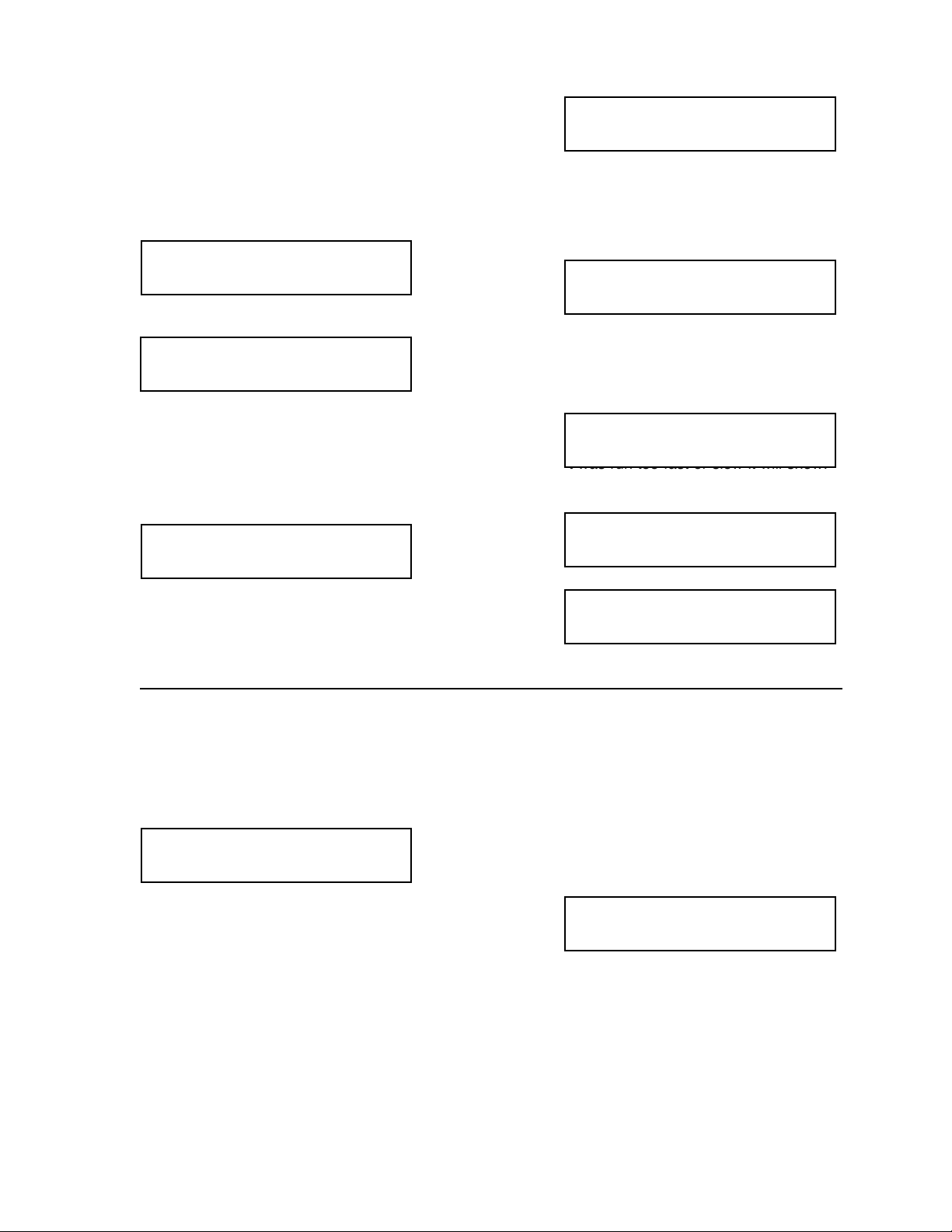

1

OPEN

2

GROUND

3

MEASURE

TO

GROUND

“SENSOR TEST” KEY

SENSOR

TEST

02 TPS

CHARGING

ST

ARTING

AMPS VOLTS

IGNITION

PRIMARY

COIL MODULE

DWELL VARIATION

AUXILIARYAUXILIARY PER CYLINDER

CRANKING

ANALYSIS

COMPRESSION

BAT. STARTER ALT.

POWER

BALANCE

% RPM DROP

AUTO MANUAL

PER CYLINDER

SPARK

BURN

SECONDARY

MSEC SLOPE

PER CYLINDER

HARD

ST

ART

IGNITION VOLTS

AUXILIARY

FUEL

INJECTION

MSEC, % DUTY, HZ

AUXILIARY

Use SELECT and START to choose tests for measuring

ohms or diode volts, measuring oxygen

sensor voltage and crossings, checking

for irregular throttle position sensors

(TPS), watching for intermittent voltage

with the Wiggle Scope, and reading fault

OHMS RESISTANCE / DIODE VOLTS

The resistance of a device is measured by connecting

the red Auxiliary Clip to one of the deviceʼs terminals and

contacting the other device terminal to the battery/engine

ground. A continuity beeper sounds when readings are

below 25 ohms, and “OVER” shows for greater than 50K

ohms. (Ground = chassis)

SELECT: OHMS to GROUND

TEST then START

Prior to using ohms the analyzer must do an open/ground

lead test which checks the low and high range ends.

Disconnect AUX lead

then START

flash codes from Ford and GM engine control computers.

The red Auxiliary Clip is the signal input.

METER PROCEDURE

STEP 1: Infinite resistance is checked.

Connect AUX to GND

then START

STEP 2: Ground zero calibration is done.

Responses are given to guide the calibration process. If

the carʼs battery voltage drifts during the test the calibration may also drift. Press START to redo the recalibration procedure.

OHMS to GND Bat 12.45

OHMS 0

STEP 3: Read resistance to ground.

OHM-

OXYGEN LAMBDA SENSOR

The red Auxiliary Clip has a 10 megohm input for this

test. The display shows the average sensor output voltage, the number of times the voltage crosses the 0.45

level per second, and whether the immediate voltage

indicates rich or lean by the R/L display.

Oxygen Sensor 0.83 v

0.0 Crossings/Sec R/L

Typical cross count readings for warm engines running at

"DIODE" voltage in the forward and reverse directions

can also be read by changing the test with SELECT.

Note that resistance is measured by applying the carʼs

battery voltage through a 1000 ohm resistor in the analyzer, so that up to 15 milliamps may pass through the

tested device. An advantage of this current is that LEDs

can be checked for light output, and diode forward and

reverse voltages can be checked at a more normal operating level.

a steady fast idle are in the 1 to 3 range. Low rates may

indicate a damaged O2 sensor. Multiports usually cross

count fastest and carbureted engines the slowest.

Connect at sensor harness plug or ECM. Do not penetrate wire insulation where moisture could cause electrical leakage to ground.

-8-

OHMS to GND Bat 12.45

DIODE 12.45v

THROTTLE POSITION SENSOR

This is a computer aided test to check for skips in a

position sensor signal sweep. When a position sensor

on a throttle or air flow vane is moved from the rest position to the top, the output voltage should move just like

the position shaft. The voltmeter reading for this test

updates rapidly so that small irregularities are not likely

to be missed.

SELECT : POSITION SENSOR

TEST then START

Press START.

CONNECT Aux to TP Sensor

Engine OFF; Key ON

DETECT ON 0.84 v

Move SLOWLY to W.O.T

With the "DETECT ON" display, make a smoothly increasing sweep during 3 to 7 seconds to the top position. The test ends automatically when the voltage stops

changing. Findings are reported when the test ends.

Possible Problem 1.93v

Press START

If glitches were detected, the corresponding voltage levels will be reported. Recheck the sensor for intermittent

faults near the reported problem voltages.

If no irregularities were detected it will show:

Then connect Auxiliary Clip to the output wire and press

START.

Using the following voltmeter display, check that the output responds to a typical range of 1 to 4 volts when the

position sensor shaft is turned.

0.84 v

for test: Press START

In the TP Sensor test the analyzer detects abrupt voltage

changes that an intermittent sensor contact would make.

Be ready to smoothly turn or press the position sensor

through its full sweep. Press START.

WIGGLE SCOPE

The Wiggle Scope display can be selected to see a line

trace of slow or intermittent voltage changes. It has a 10

megohm input impedance.

SELECT: WIGGLE SCOPE

TEST then START

No GLITCHES Found;

Press START

If the test was run too fast or slow it will show:

Too FAST; Retest Slower

Too SLOW; Retest Faster

Wiggle Scope can be used to watch for regular or intermittent pulses on wires for accessories, sensors, lamps,

solenoids, slow computer codes, or other on/off electrical

signals. The shortest step is about 1/10th second on the

fastest scan.

This display is like a chart recorder that is written at the

left of the screen and flows off the right end. It shows

voltage levels and changes above or below 4 volts

sensed by the Auxiliary Clip.

Level changes during an interval are shown different

ways: an / or \ shows a simple change, a T or its inverse

means there was a change but the start and end were

the same, ||| shows that there were many changes.

WIGGLE SCOPE Scan 2 Sec

ˇˇ/\|/T\/__\/-----------

The number following "SCAN" is the time for the signal

to sweep across the display. SELECT can choose a 2,

4, 8 or 16 second sweep.

-9-

Loading...

Loading...