®

TM

ENGINE

DIAGNOSTIC CENTER

54

FEATURES...............................

Introduction

Printer

Clock/Calendar

Program Cartridges

Stand

CONNECTIONS .......................

Leads

Emissions Hoses

Road Test

DIAGNOSTIC CENTER

OPERATION .............................

Test Keys / Menus

Control Keys

Setup

ENGINE TESTING ..................

Ignition

Power

Electrical

Sensors

AutoTest

TYPICAL READINGS .............

FUEL SYSTEM /

GAS ANALYSIS .......................

Fuel Injectors

O2 Sensor

Emissions

Printed Reports

GAS THEORY ..........................

Sampling

Combustion Theory

AFR, Lambda, Catalysts

Understanding Results

MAINTENANCE .......................

Zero

Purge

Calibrate

Leak Test

Sensor Replacement

Filter Replacement

Cleaning

TECHNICAL SUPPORT...........

Service Information

Troubleshooting

Parts List

Specifications

Safety Precautions

Warranty

Introduction........................... 1-2

Printer................................... 1-3

Clock/Calendar ..................... 1-4

Program Cartridges ............... 1-4

Stand.................................... 1-5

1-1

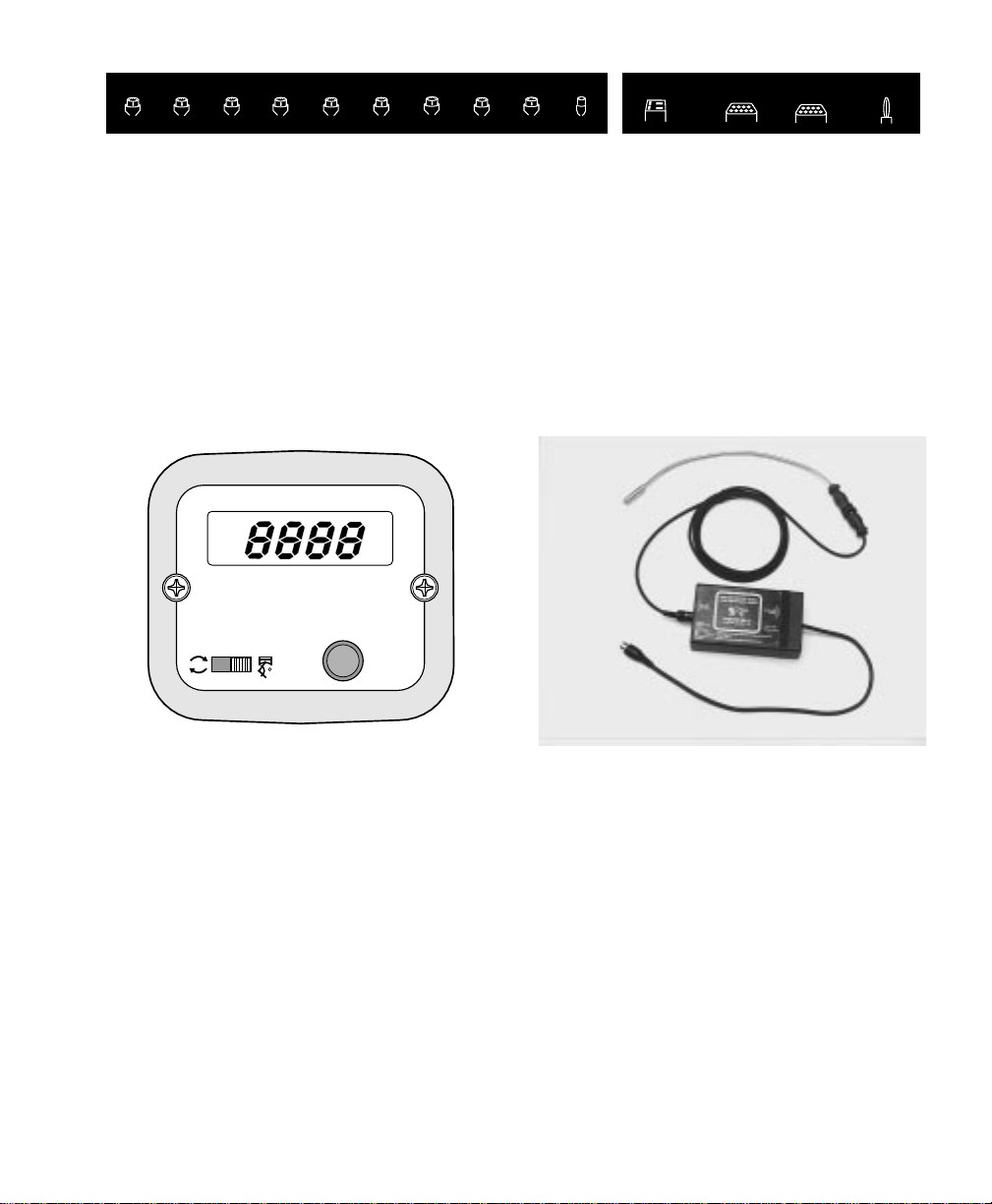

INTRODUCTION

The Ferret 54 Engine Diagnostic Center is

a professional grade tool for diagnosing

automotive ignition, fuel injection, electrical,

and emissions systems. Programmed sensor

tests, including O2 and TPS, augment a

meter function capable of reading a variety

of AC, DC, and frequency sensor outputs.

Four or two stroke engines powered with

gasoline, propane, gasohol, or compressed

natural gas, with DIS or distributor ignitions

can be tested. Diesel tests are possible with

an adapter.

Diagnostic messages, based on test results,

suggest probable engine defects. A built-in

printer records current readings or data

saved from tests.

A large, backlit LCD display with four lines

of forty characters shows test readings, bar

graphs, messages, and help screens.

A 12 volt power cable connects to the

vehicle battery , so no AC power is necessary .

Test leads are non-intrusive and include a

cylinder #1 inductive pickup, a coil negative

clip for distributors, a coil primary inductive

pickup for DIS, an auxiliary meter lead for

general troubleshooting and sensor testing,

an inductive amp probe, and a temperature

probe.

A multi-clip capacitive KV harness allows

quick connection to DIS engines. Cylinder

order and polarity are automatically detected

for fast, foolproof hookups.

Engine timing can be measured with the

digital-advance stroboscopic timing light or

with a magnetic timing detector.

The attractive, functional stand has large

wheels for easy, stable transport. An

adjustable boom and large hooks allow easy

management of leads and hoses. Storage is

provided by a drawer and shelves.

The optional Gas Analyzer, designed to

BAR 90 and O.I.M.L. (International) accuracy

standards for measurement of vehicle

emission systems, is ideal for PreCertification Emission Testing, Shop

Diagnostic Testing and Post-Repair Emission

Testing. Included with the Gas Analyzer are

a calibration gas bottle with regulator,

sampling hose assembly, power/data cable,

and a road test kit.

Other options include:

Magnetic TDC Detector

V acuum/Pressure T ransducers

Diesel Injection Detector

10 Cylinder DIS Ignition Adapter

READ SAFETY PRECAUTIONS BEFORE USING THE

ENGINE DIAGNOSTIC CENTER

The information presented in this manual is believed to be accurate and correct. Individual

test procedures should be viewed as representative. The reader is cautioned to become familiar

with the manufacturer's procedures and should always use them when they differ from those

presented here.

©1996 Ferret Instruments, Inc.

9-97

1-2

INTRODUCTION

The Ferret 54 Engine Diagnostic Center is

a professional grade tool for diagnosing

automotive ignition, fuel injection, electrical,

and emissions systems. Programmed sensor

tests, including O2 and TPS, augment a

meter function capable of reading a variety

of AC, DC, and frequency sensor outputs.

Four or two stroke engines powered with

gasoline, propane, gasohol, or compressed

natural gas, with DIS or distributor ignitions

can be tested. Diesel tests are possible with

an adapter.

Diagnostic messages, based on test results,

suggest probable engine defects. A built-in

printer records current readings or data

saved from tests.

A large, backlit LCD display with four lines

of forty characters shows test readings, bar

graphs, messages, and help screens.

A 12 volt power cable connects to the

vehicle battery , so no AC power is necessary .

Test leads are non-intrusive and include a

cylinder #1 inductive pickup, a coil negative

clip for distributors, a coil primary inductive

pickup for DIS, an auxiliary meter lead for

general troubleshooting and sensor testing,

an inductive amp probe, and a temperature

probe.

A multi-clip capacitive KV harness allows

quick connection to DIS engines. Cylinder

order and polarity are automatically detected

for fast, foolproof hookups.

Engine timing can be measured with the

digital-advance stroboscopic timing light or

with a magnetic timing detector.

The attractive, functional stand has large

wheels for easy, stable transport. An

adjustable boom and large hooks allow easy

management of leads and hoses. Storage is

provided by a drawer and shelves.

The optional Gas Analyzer, designed to

BAR 90 and O.I.M.L. (International) accuracy

standards for measurement of vehicle

emission systems, is ideal for PreCertification Emission Testing, Shop

Diagnostic Testing and Post-Repair Emission

Testing. Included with the Gas Analyzer are

a sampling hose assembly, power/data cable,

and a road test kit.

Other options include:

V acuum/Pressure T ransducers

Magnetic TDC Detector

Diesel Injection Detector

10 Cylinder DIS Ignition Adapter

READ SAFETY PRECAUTIONS BEFORE USING THE

ENGINE DIAGNOSTIC CENTER

The information presented in this manual is believed to be accurate and correct. Individual

test procedures should be viewed as representative. The reader is cautioned to become familiar

with the manufacturer's procedures and should always use them when they differ from those

presented here.

©1996 Ferret Instruments, Inc.

2-97

1-2

PRINTER

The Diagnostic Center employs a 40 column

thermal dot matrix printer. Reports and

individual screens may be printed, and

results are formatted to provide easy

reference when comparing before and after

conditions.

The Paper Advance button advances blank

paper. A single press advances the paper 2

lines. Holding the button feeds the paper

continuously.

Printer

Paper

INSTALLING PAPER

The outside surface of the paper is covered

with a heat sensitive coating. The paper must

be fed so that the coated outside surface is

fed upward, facing the back of the

compartment. Press the release buttons on

each side of the compartment to remove the

empty core. While holding the buttons, insert

the new roll until it is approximately centered.

Release the buttons and adjust the roll until

the holding pins snap into the core of the

paper roll. Make a clean square cut across

the end of the paper. Feed this end into the

opening formed by the plastic and metal

guides. Gently push the paper in 2 to 3 cm

(1 to 1.5") and press the Paper Advance

button until paper appears under the cutting

bar at the top of the compartment.

Use BLUE or BLACK thermal paper 80mm

(3.15") wide. The printer contrast can be

adjusted for paper with differing thermal

sensitivities. If characters are too dark or too

light, see Print Contrast in the

Center Setup

setting that works best with the paper being

used.

section to select the contrast

Diagnostic

Paper

Release

Button

Cartridges

Roll

Optional

Optional

System

Paper

Advance

Button

1-3

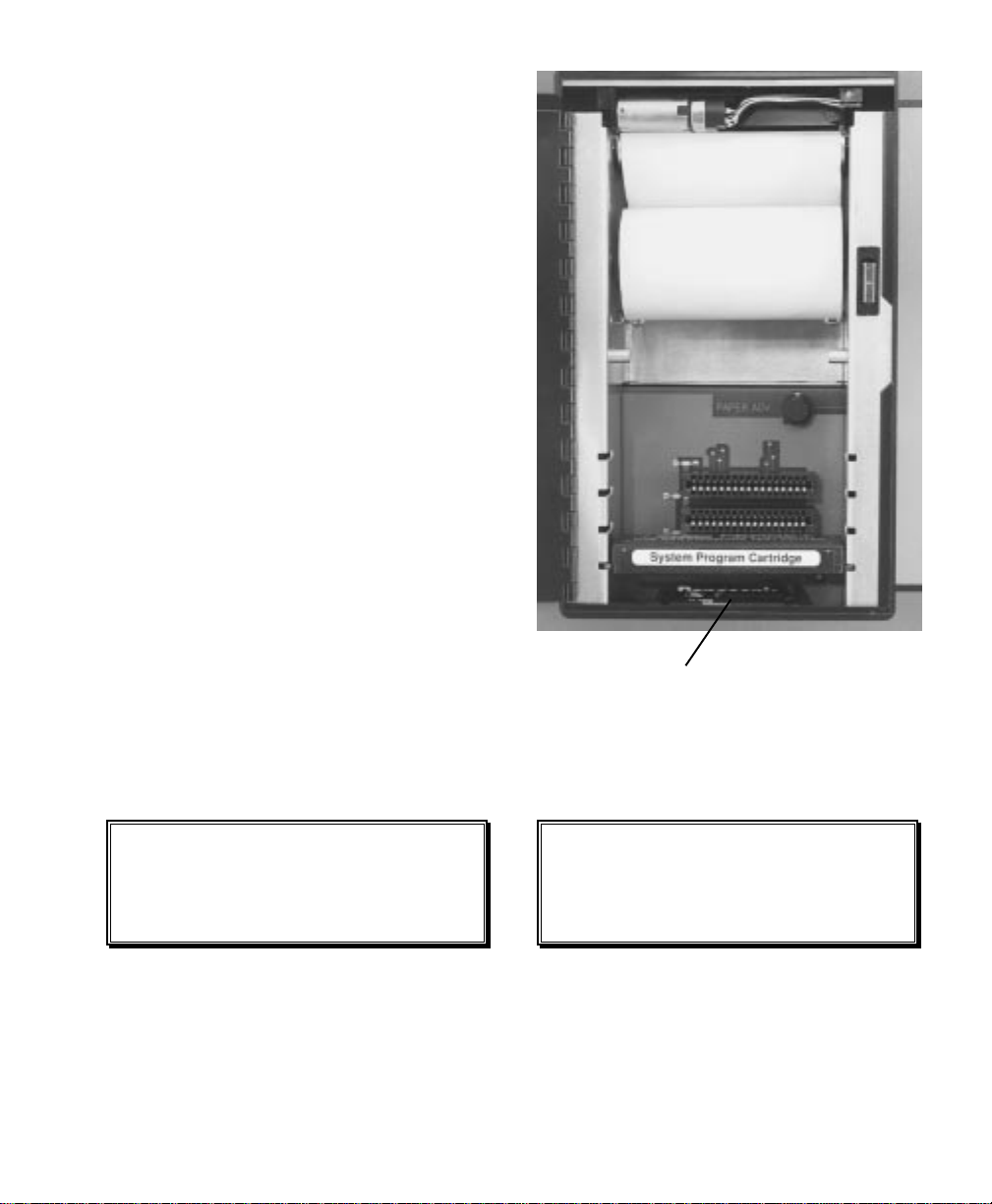

PROGRAM CARTRIDGES

Contained within the printer compartment are

the System Program Cartridge and slots for

additional Program Cartridges. Programs

needed to communicate with other devices

require use of these slots which also allow

for future software applications.

The System Program Cartridge must be

installed in the lowermost slot for the unit to

operate.

Each Cartridge has its own menus and

HELP messages. Refer to literature provided

with the cartridge for more information.

CLOCK / CALENDAR

BATTERY

The internal clock/calendar requires a

separate power source to keep time when

the Diagnostic Center is off. The battery

holder is located below the System Program

Cartridge in the printer compartment. Polarity

is marked on the holder. Use three 1.5 volt

AAA alkaline batteries.

Battery

Holder

See Date & Time in the

Setup

section to set the date and time.

DO NOT REMOVE OR INSTALL CARTRIDGES

POWER IS APPLIED TO THE DIAGNOSTIC

WHILE

CENTER.

Diagnostic Center

DO NOT APPLY POWER TO THE DIAGNOSTIC

CENTER WITHOUT A CARTRIDGE IN THE SYSTEM

PROGRAM SLOT.

1-4

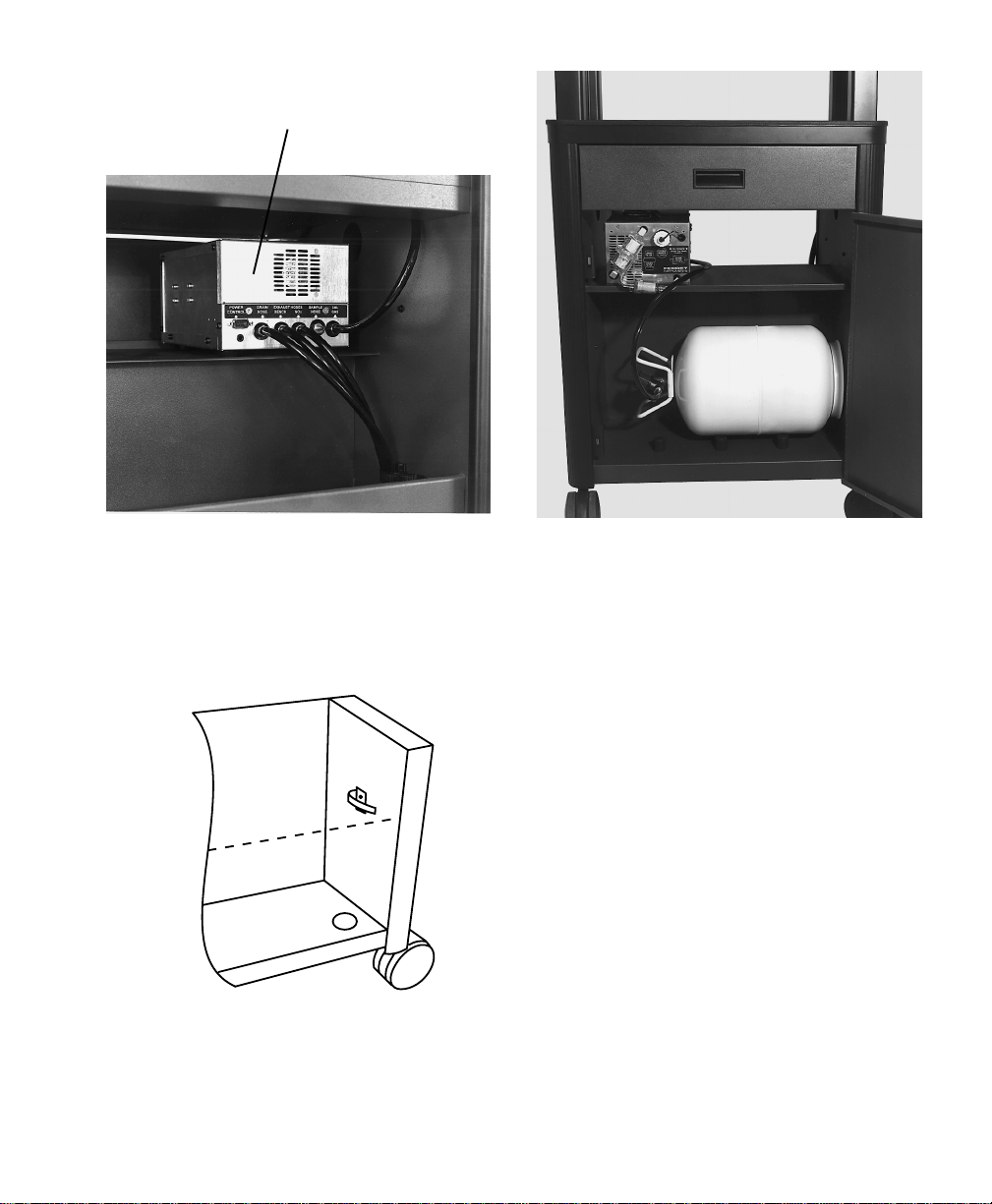

STAND

The Diagnostic Center's Control Module may

be hung on the stand at any of four positions

on the top and front of the columns.

When fully closed, the drawer has a gripping

mechanism that reduces the chance of

opening while the stand is being moved.

Ample room is given for operators manual

and supplies such as printer paper,

replacement filters and leak test cap.

An adjustable boom is provided for lead

management. The boom may be mounted on

either side of the stand and has convenient

clip bars for lead storage. There are also

hooks on the rear of the stand for hanging

the emissions Sample Hose Assembly.

Inside the magnetically latched door are the

Calibration Gas bottle compartment and the

Gas Detector shelf. The Gas Detector cable

can be routed inside either column and out

through a hole above the Gas Detector shelf.

The Control Module may be mounted in any

of four positions.

1-5

Gas Detector (Optional)

Drain holes are provided on both sides of the

back storage compartment. A strap holds

the drain and exhaust hoses in place.

The calibration gas bottle can be mounted

with the valve on either side. The regulator

and valve should be to the front for ease of

use.

1-6

1-7

CONNECTIOCONNECTIONS

Leads.................................... 2-1

Emissions Hoses ................... 2-6

Road T est ............................. 2-8

LEADS

KV

˚C/˚F

CLIPS

PROBE

BLUE

GRN/WHT

Two eight foot extension harnesses plug into labeled ports on the back of the Control Module

and are routed along the boom. Test leads plug into color-coded connectors on the harnesses.

REMOTE

PRIMARY

"NEXT"

AMPS

WHITE

RED/WHT RED/YLW RED/GRN

MAGNETIC

TIMING

STROBE

TIMING

VACUUM

PRESSURE

YELLOW

AMP

PROBE

GREEN

CYLINDER

# 1

RED

COIL

(-)

12 VOLT

BATTERY

GAS

DETECTOR

FERRET

NETWORK

ONLY

AUXILIARY

LEAD

12V BATTERY LEAD

The Power Lead has Red (+) and Black (-)

battery clips that connect to the vehicle 12

volt battery at one end, and a 4-blade

connector that connects to the Control

Module at the other.

Black

12 Volt

Red

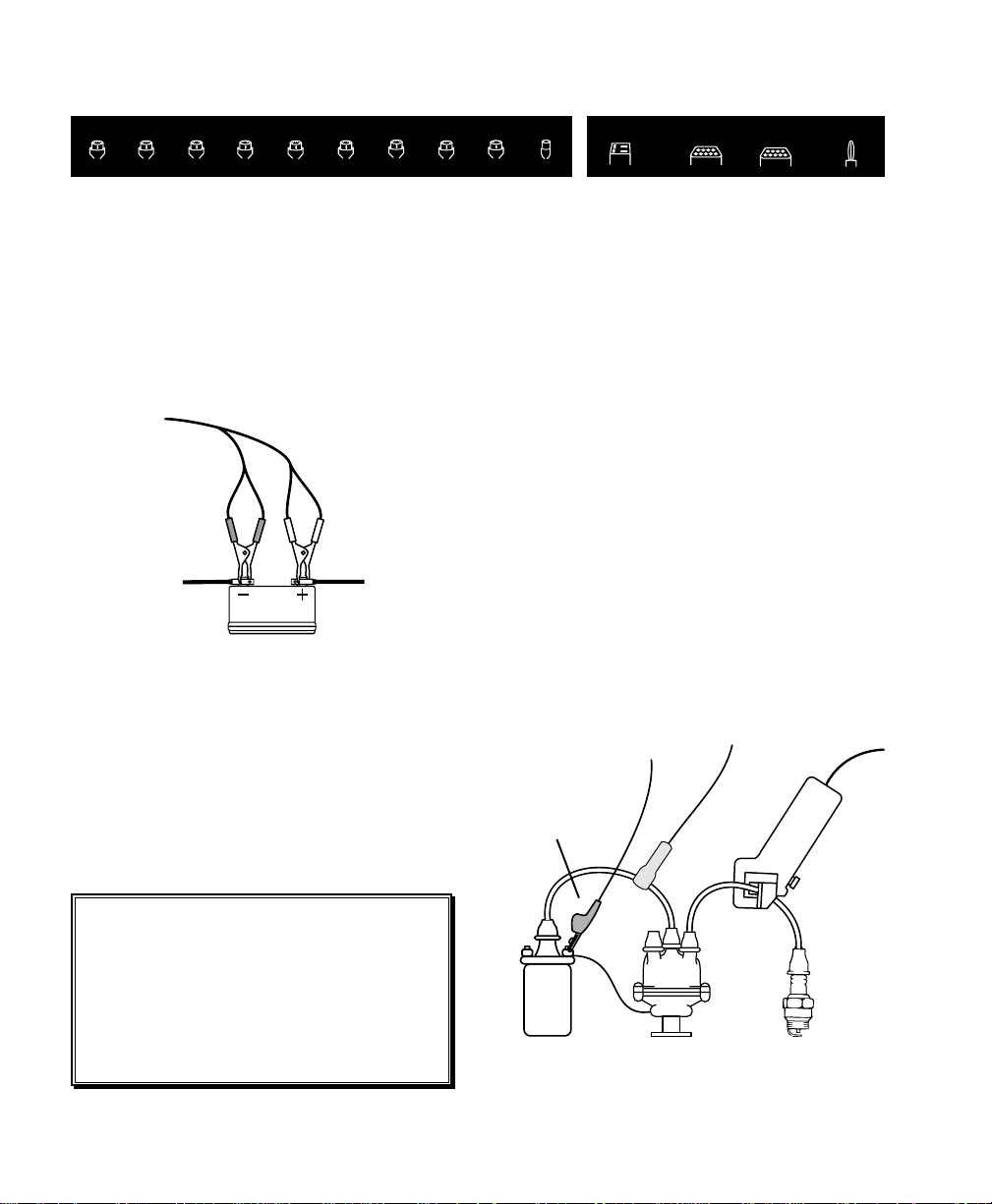

COIL PRIMARY CLIP - Distributor

This multipurpose clip connects to the

ignition coil primary winding minus (-)

terminal, sometimes labeled “T ACH”. It is the

signal source for the ignition primary circuit

measurements, and it is necessary for

ignition suppression. This lead is not used

when testing DIS ignitions.

CYLINDER #1 PICKUP

The red Inductive Cylinder #1 Pickup

connects around the #1 cylinder spark plug

wire on both DIS and distributor ignitions and

provides synchronization and tachometer

signals.

Place the pickup around the cylinder #1

spark plug wire as far from the plug as

possible, with the “Spark Plug” label pointing

toward the spark plug end of the wire. Also,

see the note in the lower left corner of this

page.

For Coil-Per-Plug DIS engines with no

Cylinder #1 spark plug wire, a sync signal,

can be acquired by placing the Cylinder #1

Pickup around the driver wire for the Cylinder

#1 coil.

To Cylinder #1

Position of KV

Harness

Coil

Primary

Clip

#1 Cyl

Pickup

WHEN THE CYLINDER #1 OR PRIMARY AMPS

PICKUPS ARE NOT BEING USED,

LEAVE THE JAWS OPEN.

THE MAGNETIC CORES ARE MADE OF FERRITE

CERAMIC

AND, WHEN KEPT APART, THEY ARE

LIKELY TO BREAK IF THE PICKUP

LESS

DROPPED.

IS

2-1

+

-

Distributor Connections

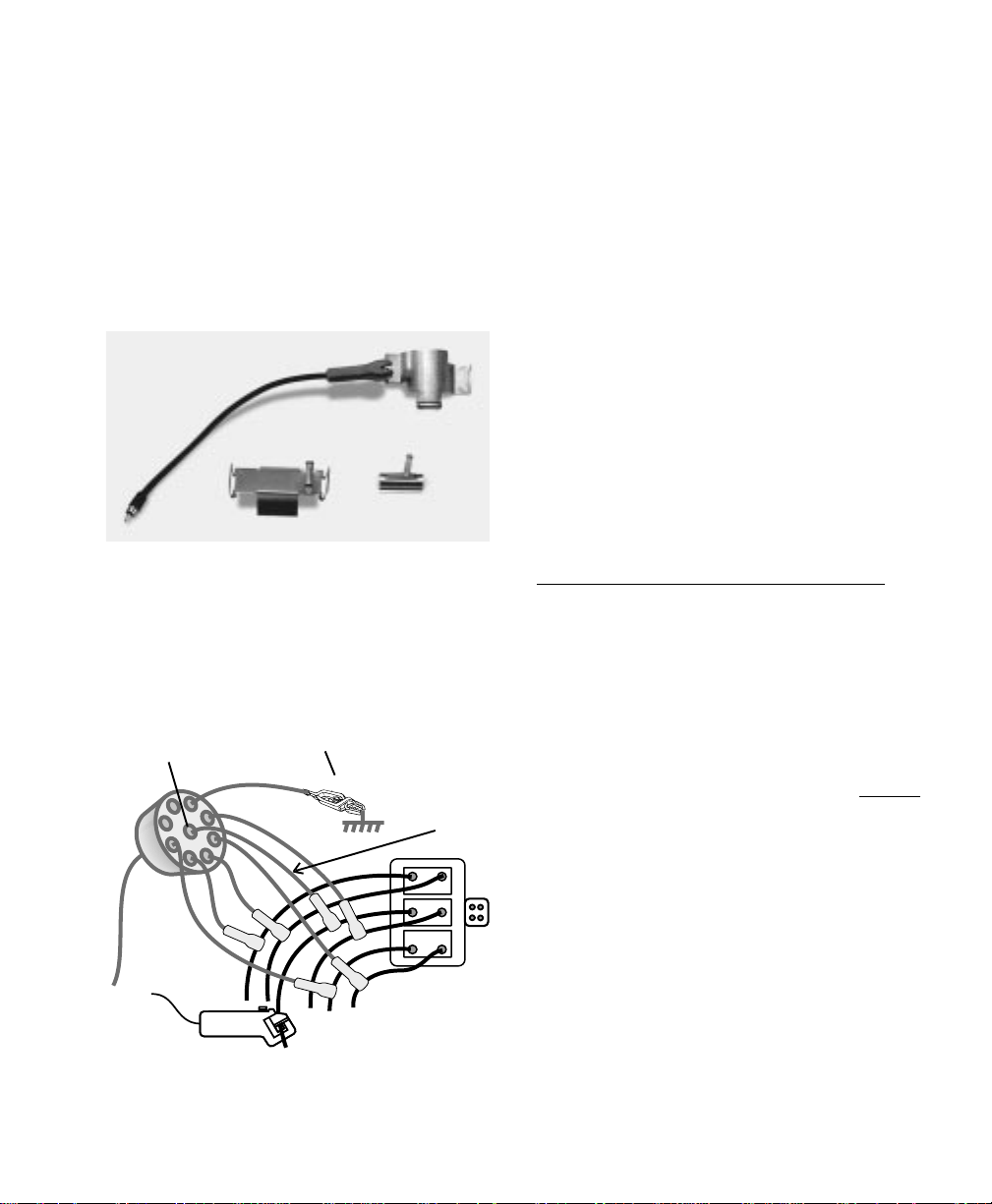

KV PICKUP PLATES

1

Pickup plates are provided for GM, Toyota,

and Nippondenso systems that have the coil

located within the distributor. To read KVs,

clip the appropriate pickup plate to the

distributor housing, attach a Sparkwire KV

Clip to the bar or post on the pickup plate,

and plug it into the Cylinder #1 position of the

KV Harness.

Toyota

SPARKWIRE KV CLIPS

The capacitive sparkwire clips sense ignition

secondary voltage. Connect the center clip

to the Cylinder #1 spark plug wire.

The rest of the clips may be connected to

any cylinder.

The clips are made to fit 8 and 7 mm

sparkwire. The silicone grease provided (or

equivalent) is helpful for putting them on the

sparkwires and for getting good coupling.

The sparkwire clips are designed to be

sensitive, so it is important to separate

them to prevent picking up signals from

an adjacent wire.

Center

Wire

GM HEI

To Engine

Block

Cyl. #1

DIS Connections

Nippondenso

Cylinder

#1

Always connect the grounding clip to the

engine to reduce interference effects from

ignition defects. Failure to do so may result

in false readings.

FOR 10 AND 12 CYLINDER ENGINES:

An adapter kit is available for connection to

DIS engines with more than 8 cylinders. The

kit includes two "T" connectors and two

additional sparkwire KV clips. Use one kit

for 10 cylinder engines or two kits for 12

cylinders.

To use the adapters, connect one "T" to

any position on the KV Harness, except

Cylinder #1. Plug two Sparkwire KV Clips

into the "T" and connect them to any two

spark plug wires of the same polarity.

DISTRIBUTOR KV LEAD

This lead connects to the coil secondary wire

on distributor ignitions. It is provided to

simplify hookup and is used in place of the

DIS KV Harness. If desired, the center clip

of the DIS KV Harness may be connected to

the distributor coil secondary wire instead.

2-2

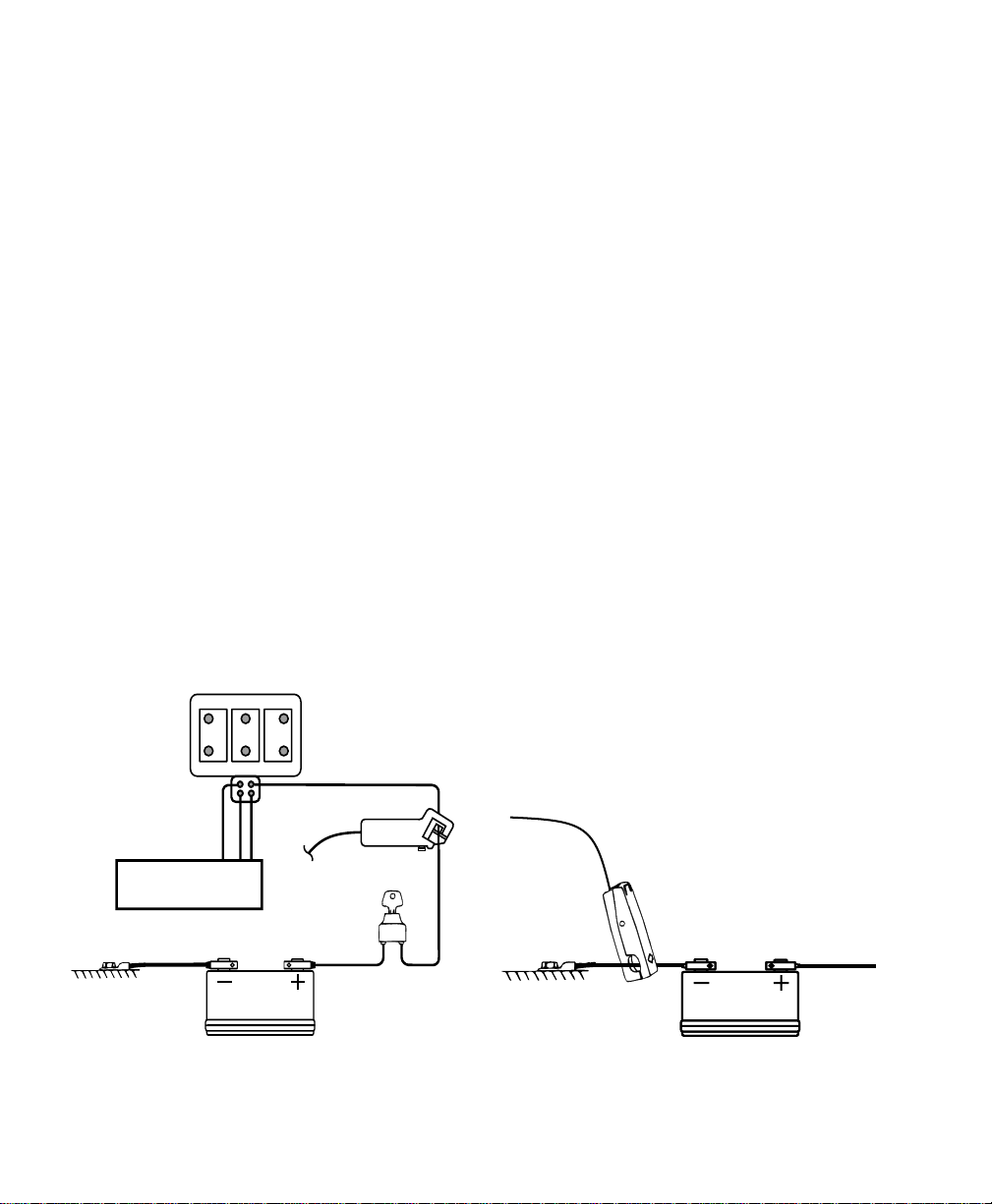

PRIMARY AMPS PICKUP - DIS

Put the black Primary Amps Pickup around

the wire that provides 12V power (B+) to the

ignition module and all coils. You may

hookup around the wire anywhere in the

wiring harness, but be sure the pickup is

around the wire that carries only the ignition

pulses, and not the fuel injector pulses. The

pickup label must face toward the battery

plus end of the wire (away from the coil). See

the chart on page 4-4 for typical wire colors.

Refer to the manuals or car wiring diagrams

to find the correct wire for the Primary Amps

Pickup hookup.

For Distributor engines, this probe is

needed only when a clip connection to the

coil (-) wire is not available, as with some

integral coil ignitions.

12 V

INDUCTIVE AMP PROBE

The primary application for the Inductive Amp

Probe is the measurement of starter draw

and alternator output current during battery

testing. For these tests, connect the probe

around the negative battery cable with the

arrow pointing away from the battery.

The arrow on the probe indicates the

direction of conventional amps that will give

a positive display reading. Reversed amps

will show a minus reading. For example, if

the probe is on a negative battery cable with

the arrow pointing away from the battery, the

reading will be negative when discharge

amps flow.

For accurate readings, the amp probe must

be zeroed while being held away from wires,

alternators, or other sources of magnetic

fields.

The probe has a reading range of ±600 amps

DC in 1 amp steps and can also be used to

measure vehicle accessory currents. Placing

the probe on the battery cable, while the

engine is off, and then watching the change

when operating switches, allows the

checking of many loads rapidly.

COIL DRIVER MODULE

BATTERY

Primary Amps Connection

PRIMARY

AMPS

AMP

PROBE

BATTER Y

Amp Probe Connection

2-3

˚C/˚ F

PROBE

GRN/WHT

KV

CLIPS

BLUE

REMOTE

PRIMARY

"NEXT"

AMPS

RED/WHT RED/YLW RED/GRN

WHITE

MAGNETIC

TIMING

STROBE

TIMING

VACUUM

PRESSURE

YELLOW

AMP

PROBE

GREEN

CYLINDER

# 1

RED

COIL

(-)

12 VOLT

BATTERY

GAS

DETECTOR

FERRET

NETWORK

ONLY

AUXILIARY

LEAD

STROBE TIMING

The Timing Light will flash when a spark

signal and power from the Diagnostic Center

leads are present and the Strobe Timing test

is selected. Flash delay is adjusted with the

fingertip control buttons on the handle. The

digital display shows advance angle of the

flash, or RPM, depending on the position of

the switch on the rear of the light. Both

readings appear on the Control Module

screen.

12 VOLT BATTERY

ELUMINATOR™ OPTIC

856

LIGHT

min

OFF FLASH

RPM ADV

SAVE

DATA

MAGNETIC TIMING

As an alternative to using the timing light,

some engines provide for the use of a

magnetic probe for timing readings. This Top

Dead Center (TDC) signal detector is for

those who want the convenience of metered

measurements. You may use one of the

standard offset angles provided, or you may

enter a custom angle. To time diesel engines,

a diesel injection detector is necessary to

provide a cylinder #1 reference.

Plug the TDC Detector into the Control

Module's magnetic timing port, and connect

the magnetic probe to the detector. Then

insert the magnetic probe into the engine

bracket.

2-4

AUXILIARY METER LEAD

The Auxiliary Meter Lead is used to read the

output of a variety of sensors. It is the signal

input for the O2 Sensor and Throttle Position

Sensor tests, and can be used to measure

"Solenoid Control" Dwell, reluctor outputs,

and other AC and DC signals. It is also the

signal input for the Auxiliary Meter and Volt/

Amp Meter functions. The multipurpose clip

includes a bed of nails and a sharp prod for

use when direct connection to a terminal is

impossible and/or an adapter is unavailable.

V ACUUM / PRESSURE SENSORS

The vacuum and pressure sensors allow

measurement of vacuum and pressure in

PSI, millibars, kiloPascals, or inches of

mercury. Instructions for connection and use

are packed with the sensors.

GAS DETECTOR

The Gas Detector module receives power

from, and communicates results to the

Control Module through a 9 conductor cable.

It uses DB-9 male and female connectors

and is wired specifically for this system. This

connection is necessary for emissions

testing. Do not connect this cable or port

to anything except the Gas Detector.

FERRET NETWORK ONLY

This communications connector provides

power and serial communications to external

equipment.

THIS IS NOT A CONNECTION THAT CAN BE MADE

DIRECTLY

TO A COMPUTER!

TEMPERATURE PROBE (°C/°F)

Plug the temperature probe and extension

lead into the labeled port on the back of the

Control Module. Set the length-limiting stop

to match the length of the dipstick when

measuring oil temperature. This prevents

inadvertently placing the probe tip in the path

of moving engine parts.

Temperature will be displayed on appropriate

screens when the probe is connected. Use

Diagnostic Center Setup

to select whether

temperature is displayed in degrees Celsius

or Fahrenheit.

Temperature Probe (°C/°F)

REMOTE "NEXT"

The Remote "NEXT" button is plugged into

this port. Pressing the button has the same

effect as pressing the NEXT Key on the

Control Module.

Special leads and program cartridges are

required to utilize this connection. Since

power is applied to some of the connector

pins, this is not intended for direct connection

to a computer without using leads made

specifically for that purpose.

DIESEL INJECTION DETECTOR

Plug the Diesel Injection Detector into the

Cylinder #1 port. Instructions for use are

packed with the detector.

2-5

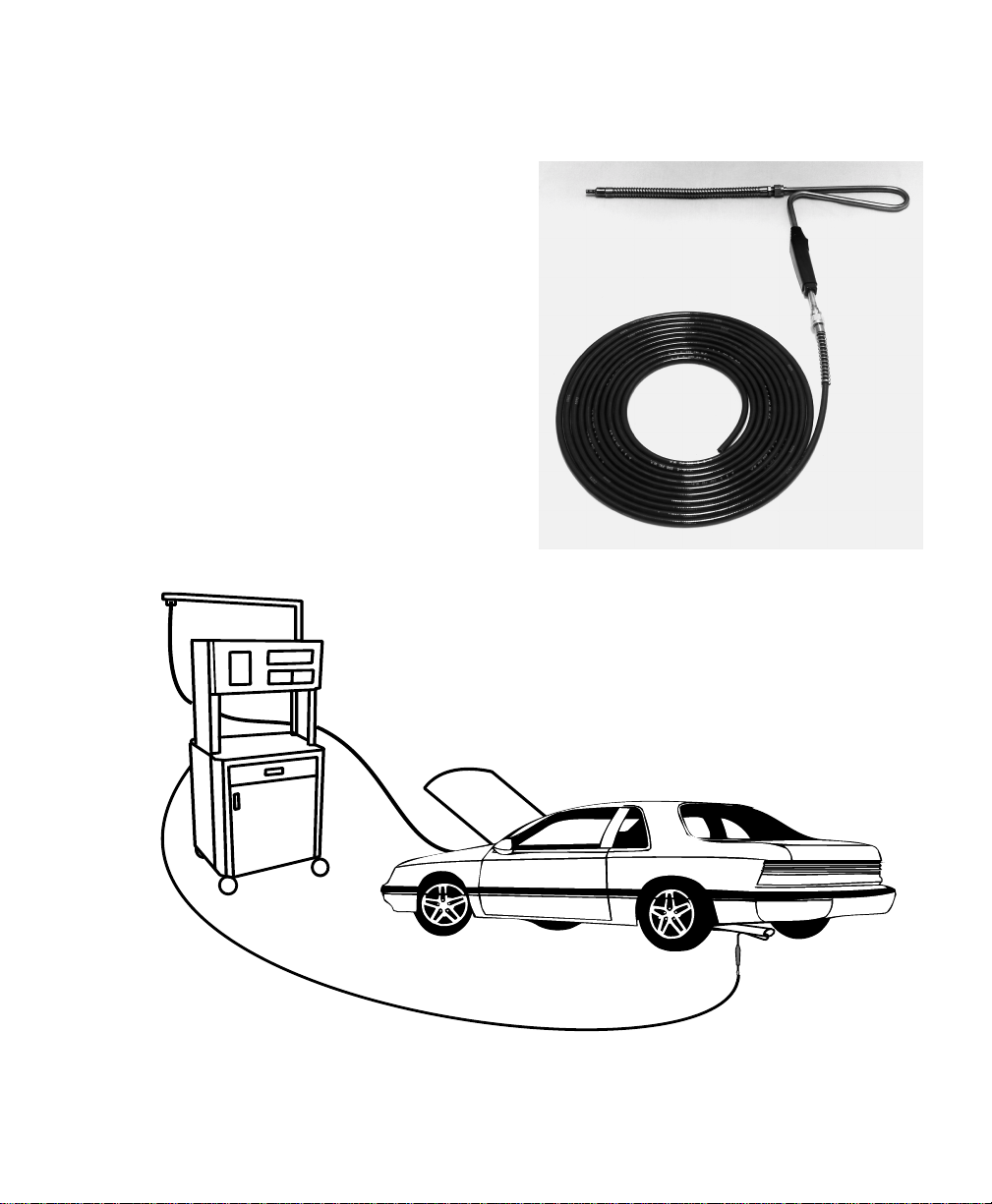

EMISSION HOSES AND ROAD TEST KIT

SAMPLE HOSE

A flexible metal probe tip, a spring handle

and a reinforced polyurethane hose combine

to make up the Sample Hose Assembly. This

assembly is responsible for getting an

accurate sample from the exhaust stream. It

should be placed into the tailpipe as far as

the handle will allow. This assures that the

sample is taken from the actual exhaust

stream, with no outside air diluting the

sample. For reliable readings, the hose

assembly should be properly cared for. Avoid

pulling, kinking, crushing or piercing the

hose. Be sure that all connections and fittings

are tight. Frequently run a leak test to

determine if any air leaks are present in the

assembly that could dilute the exhaust

sample.

Basic Emissions Test Hookup

2-6

DRAIN HOSE

The drain hose channels water vapor, that

has been removed from the exhaust gas, out

of the Gas Detector system. There are holes

in the floor of the stand to allow the hose to

be routed out the bottom. For road testing,

a vented bottle is used to collect the water.

The vent is routed outside the vehicle to

prevent build up of exhaust gases that are

present in the drain output.

When the Gas Detector pumps are not

running, as in the case of the LEAK TEST,

leakage can occur through the drain hose.

If the leak check fails, retest with the drain

hose clamped.

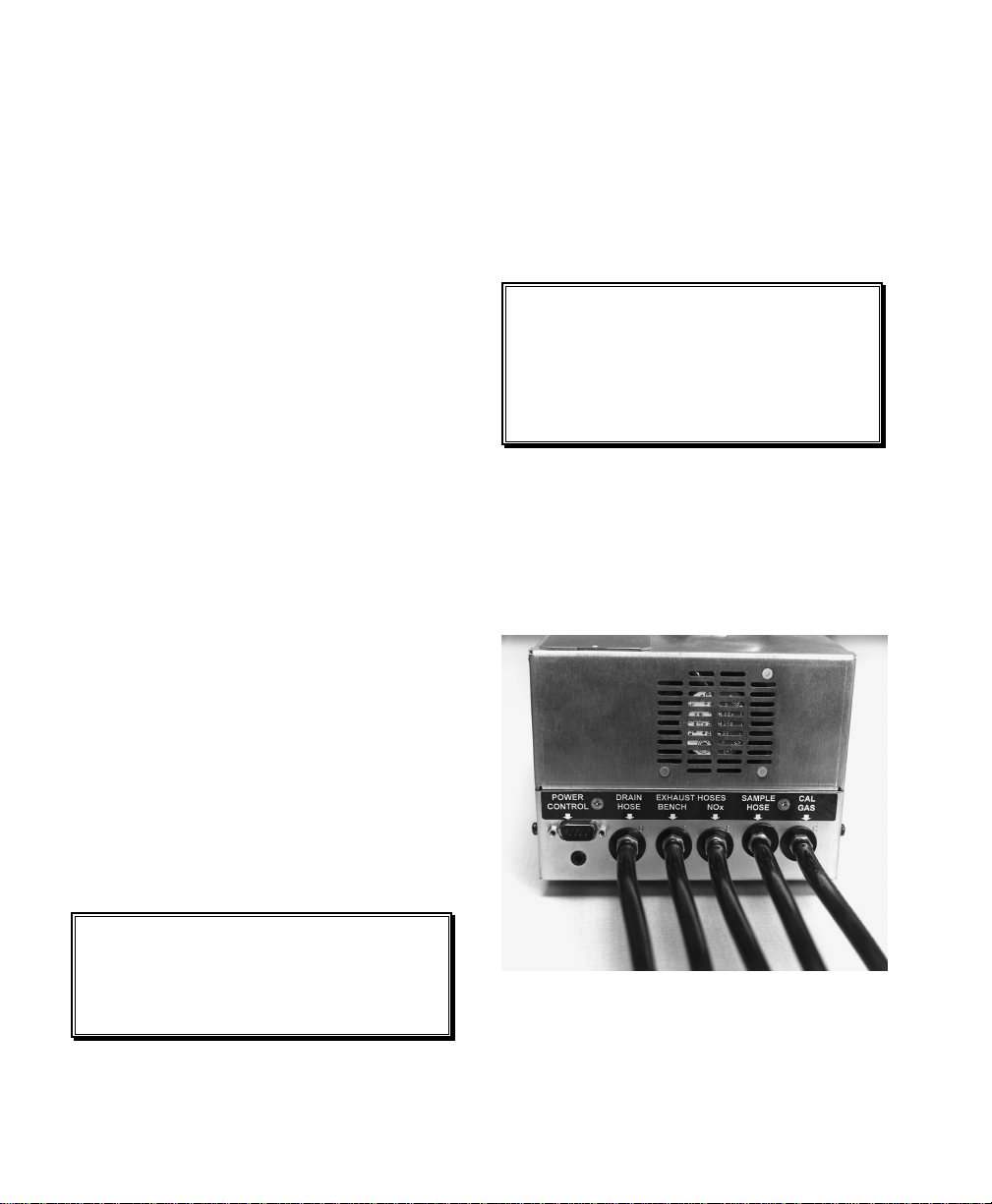

CALIBRATION GAS HOSE

During calibration, the calibration gas is fed

into the CAL GAS port. The calibration gas

hose comes from the regulator, which is

connected to the calibration gas bottle. The

maximum pressure from the regulator

supplied with the Diagnostic Center is

approximately 25 PSI (1700 mBars).

ONLY CONNECT THE CALIBRATION GAS THROUGH

REGULATOR TO THE CAL GAS PORT.

A

UNREGULATED BOTTLE PRESSURES CAN CAUSE

DAMAGE

TO THE GAS DETECTOR!

EXHAUST HOSES

Two fittings on the Gas Detector are labeled

as exhaust hoses. One is labeled 'BENCH'

and is the outlet for most of the gas sample.

The other is labeled ‘NOx’ and is a lower flow

outlet for the remainder of the sampled gas.

Be sure all exhaust hoses are open and

unrestricted, providing free flow of the

sample gas. Restrictions in the exhaust

hoses can cause measurement errors.

The output of the exhaust ports contains CO

(carbon monoxide) and other toxic

components of automobile exhaust! Even

though the quantities are small, the same

safety precautions should be observed that

apply to automobile exhaust.

ON A ROAD TEST

THE EXHAUST HOSES OUTSIDE

VENT

THE VEHICLE !

OF

If no hose is connected to this port, it should

be capped with the sample hose leak test

cap to prevent contaminants from entering

the Gas Detector.

Gas Detector

2-7

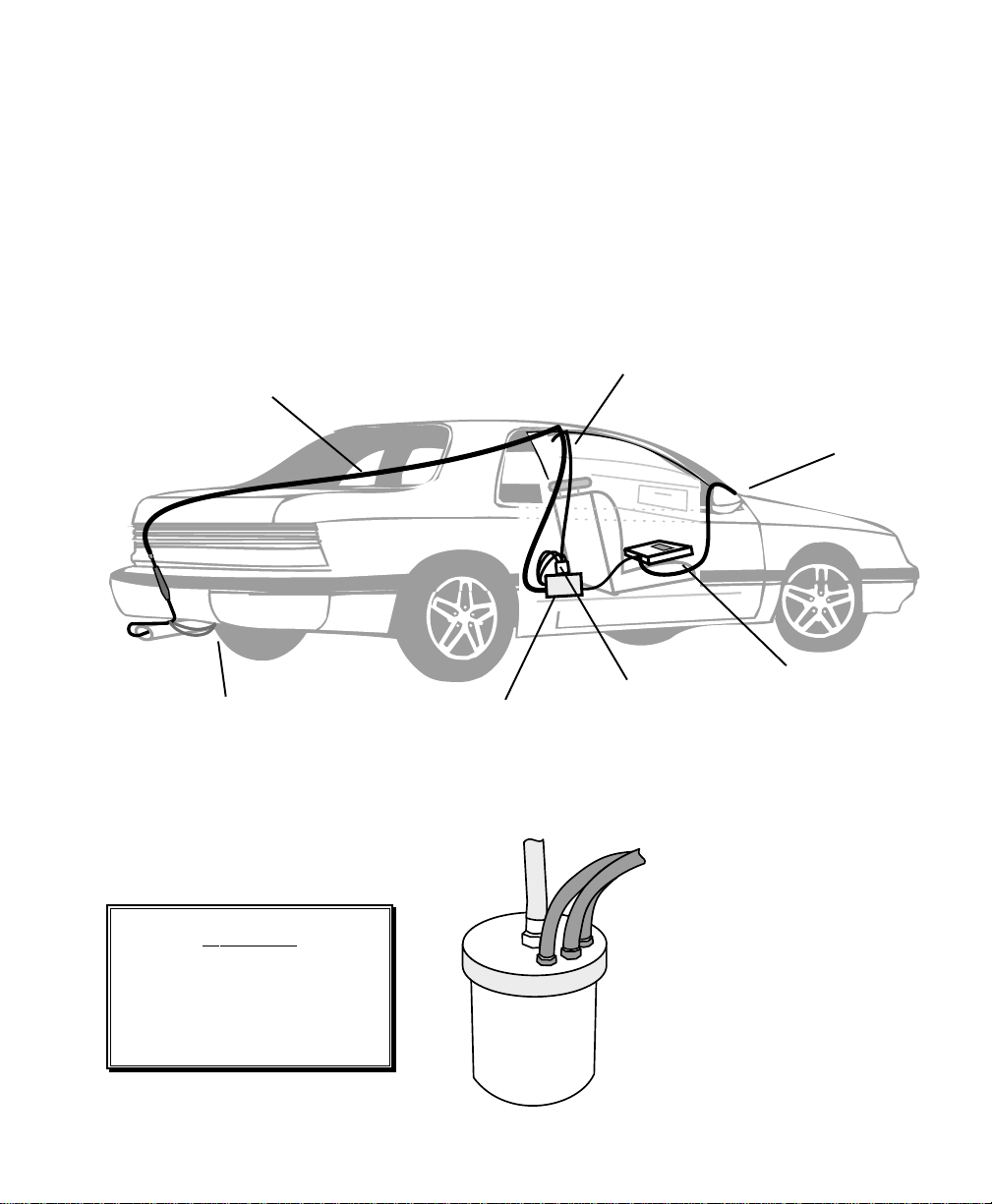

ROAD TEST

Unplug and remove the Control Module and Gas Detector from the stand (leaving the exhaust

and drain hoses with the stand), and place them in the vehicle as shown below. Connect the

Gas Detector cable between the Gas Detector and the Control Module. Route the power and

RPM leads from underhood through a window. Secure the Sample Hose Assembly to the

vehicle with chain and route the sample hose to the Gas Detector. Make sure the Sample

Hose is kept clear of wheels and potential road obstacles. Connect the three black hoses on

the collector bottle to the exhaust and drain ports on the Gas Detector, and route the collector

bottle's center hose outside the vehicle, making sure it is not pinched or restricted.

Route sample hose

across trunk and

away from wheels

Secure sample

probe to vehicle

with chain

Place Gas

Detector

on floor

Route Collector Bottle

center hose to outside

Route exhaust

and drain hoses

from Gas

Detector to

Collector Bottle

Route leads

through window

and under hood

Operate Control

Module from

passenger seat

while assistant

drives vehicle.

WARNING

Exhaust gas is toxic! All

exhaust and drain hoses

MUST be routed to the

outside.

Collector

Bottle

2-8

Connect the three

Collector bottle exhaust

and drain hoses to the

Gas Detector, and route

the center hose outside

the vehicle

2-9

DIAGNOSTIC CENTER OPEGNOSTIC CENTER OPERATION

Test Keys / Menus................. 3-1

Control Keys .......................... 3-2

Setup.................................... 3-3

CONTROL

MODULE

IGNITION MENU:

Primary, Secondary, and Hard Start tests

are reached with this key. Timing can be

measured with the Digital Advance

Stroboscope or with the Magnetic Detector

Kit.

TEST KEYS / MENUS

FUEL SYSTEM / GAS ANALYSIS MENU:

The Emissions, O2 Sensor, Fuel Injector

Drive, Vacuum Meter, and Solenoid Duty

Cycle tests are available on this key.

Gas readings can be recorded for later

review.

FAST FWD: Allows rapid review of recorded

data in PLAYBACK mode. First press shows

results twice normal speed; second press

shows results at much faster speed.

Additional presses toggle between the two

speeds.

REWIND: Shows recorded data in rapid

reverse order in PLAYBACK mode. First

press shows results twice normal speed;

second shows results at much faster speed.

Additional presses toggle between the two

speeds.

RECORD/PAUSE: Starts and stops

recording of data. Only functions when live

data is being displayed.

To playback recorded data, press

Fuel System-Gas Analysis, and select

Examine - view saved data

of data to review, and press Next.

. Select a section

POWER MENU:

Measure relative cylinder compression with

the Electronic Compression test. The

Power Contribution test measures relative

cylinder power without spark suppression.

The Power Balance test offers automatic or

manual suppression.

EMISSION TESTS ENGINE TESTS

FUEL SYSTEM

GAS ANAL YSIS

FAST FWD

REWIND

RECORDflP AUSE

ELECTRICAL MENU:

Select Starting/Charging History, VoltAmp Meter, or Auxiliary Meter. Amp Probe

zeroing is also available on this key.

SENSORS MENU:

Dedicated tests for TPS, Oxygen Sensors,

Solenoid Duty Cycle and Vacuum are

found on this key. There is also an Auxiliary

Meter function for measurement of AC and

DC voltages, frequency, and duty cycle. A

Logic Trace Scope function shows voltage

changes through a selectable threshold.

IGNITION

POWER

ELECTRICAL

SENSORS

3-1

HELP: Help screens are related to the test

or procedure you are doing and are available

in most circumstances. Test screens have

specific Helps to explain the readings and

how the test works. Menus have Help to

explain the choices. Press Help until the

orignal screen has been restored.

SETUP: Engine Setup tells the Diagnostic

Center about the engine being tested.

Diagnostic Center Setup includes setting of

date and time, custom headers, and other

preferences. The Gas Detector Service and

Program Cartridge menus are also found

here.

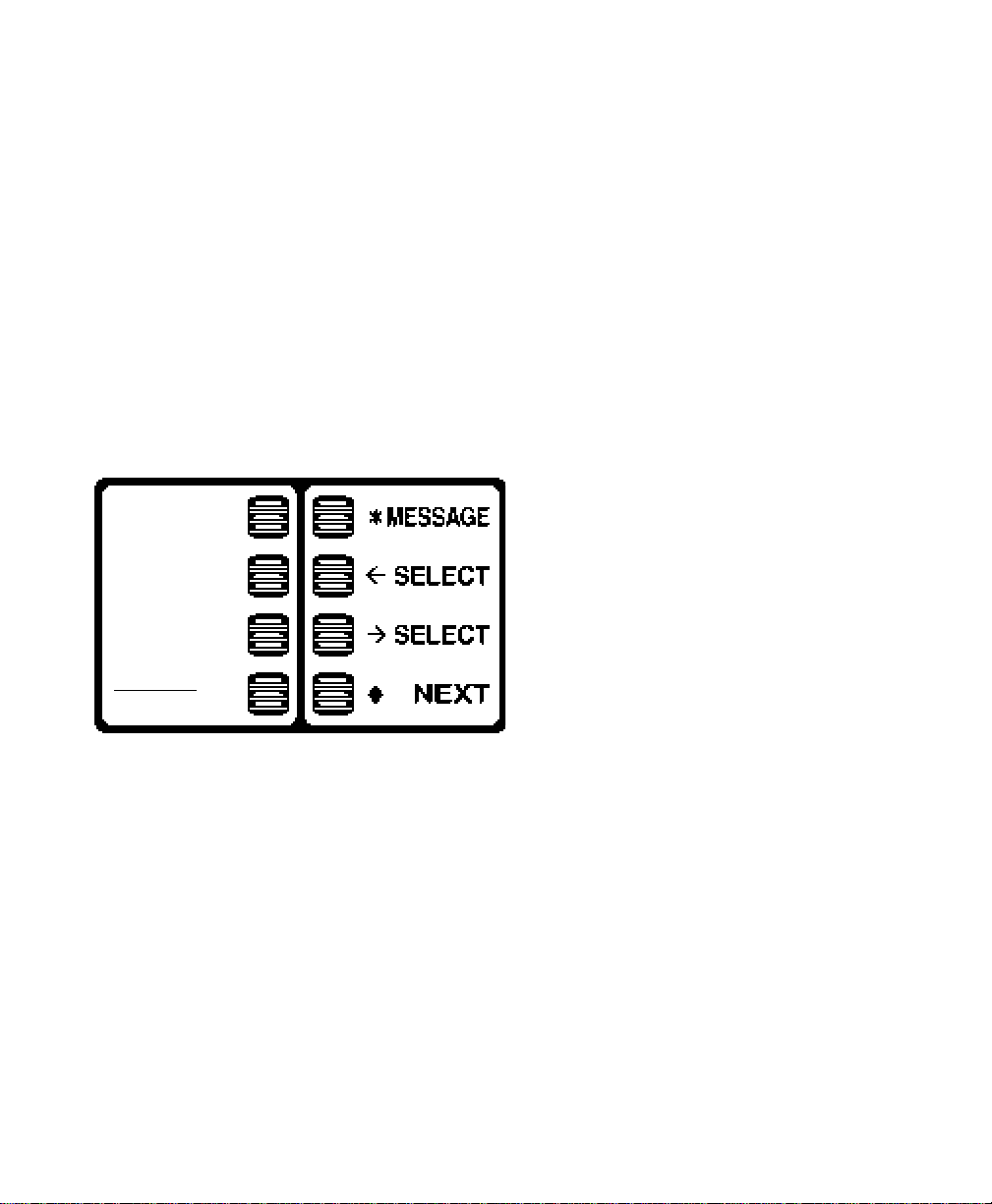

CONTROL KEYS

MESSAGE ✻

The MESSAGE key is active when the

flashing message symbol '✻' is on the

screen. Messages may span several

screens. Press the MESSAGE key until all

messages have been viewed, and the

original screen has been restored.

SELECT <-- -->

Flashing arrows indicate that a selection can

be made. The two SELECT keys are used

to make menu selections or to move

between different screens available in a test.

CONTROLS

HELP

SETUP

PRINT

REPORTS

AUTOTEST

PRINT: Prints the contents of the display or

the results of the current test.

REPORTS - AUTOTEST: Press this key to

print reports of previously saved data or to

create and print a Visual Inspection Report.

The AutoT est sequence is also initiated with

this key, providing a fast way to create and

print a comprehensive engine data report.

<-- SELECT will move the flashing selection

arrow or brackets up or to the left. It will also

decrease numbers.

--> SELECT will move the flashing selection

arrow or brackets down or to the right. It

will also increase numbers.

NEXT N

The NEXT key is used to go on to the next

step in a test or procedure or to act on an

item that is selected. In some cases the

NEXT key will clear minimums or maximums

and restart a measurement. In the emissions

RECORD or PLAYBACK modes, the NEXT

key may be used to mark data for printout.

Generally, if the display requests that an

action be taken, the NEXT key must be

pressed to continue the process. Sometimes

a flashing diamond 'N' will indicate that NEXT

should be pressed.

If the Remote NEXT Button is connected to

the Control Module, it may be used

anywhere the NEXT key would be used.

3-2

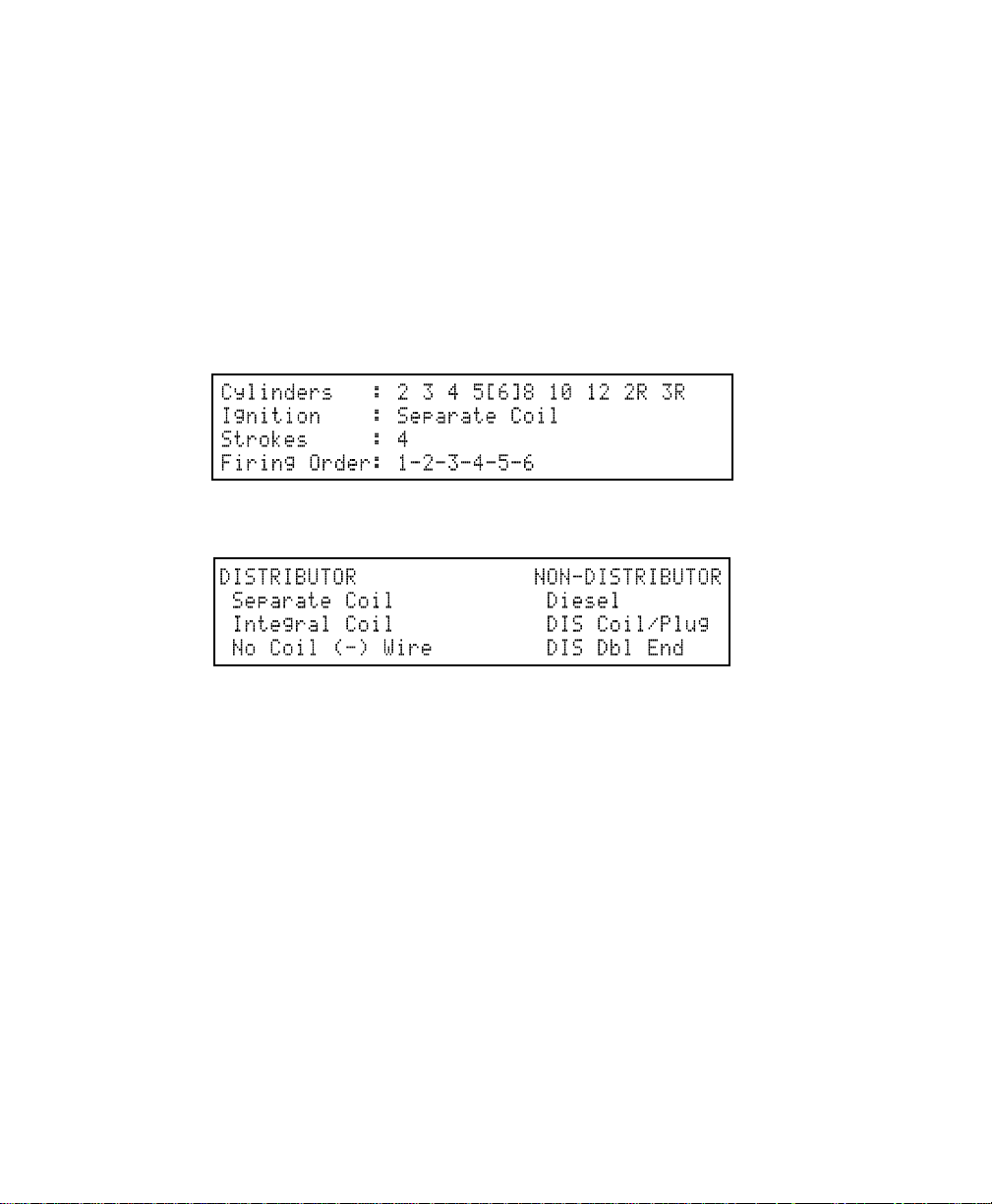

SETUP

The setup menus provide an easy way for you to tell the Diagnostic Center about the engine

being tested and to set preferences. Menus will change according to choices already made.

For example, if a 5-cylinder engine is selected,

ignition type. Available tests will also depend on the engine described during

Use SELECT to move the cursor to your selection. Pressing NEXT will enter the selection

and move to the next menu. If an error is made, press SETUP and reenter your selections.

Engine Setup

The

Engine Setup

to be tested. Use the SELECT keys to move the cursor , and press NEXT to enter the selection.

SELECT the number of cylinders, and press NEXT. A new screen will appear, offering a choice

of ignition type.

provides the Diagnostic Center with information about hookup and the vehicle

Cylinders : 2 3 4 5[ 10 12 2R 3R

Ignition : Separate Coil

Strokes : 4

Firing Order: 1-2-3-4-5-6

DISTRIBUTOR NON-DISTRIBUTOR

Separate Coil Diesel

Integral Coil DIS Coil/Plug

No Coil (-) Wire DIS Dbl

DIS Double End

will not appear as an available

Engine Setup

.

Distributor ignitions will have a

distributor housing (like GM HEI). In some cases, as with many Nippondenso ignitions, the

Coil (-) wire is not accessible. In that case, SELECT

Non-Distributor ignitions include

or output) where each coil fires two plugs at the same time.

SELECT the ignition type, and press NEXT. Select 4 or 2 strokes, and select the firing order.

Choosing a firing order causes test data to be displayed in cylinder block number sequence.

If the default is accepted, e.g., 1 2 3 4, the results will be displayed in firing order sequence.

Separate Coil

Diesel

engines,

or an

Integral Coil

No Coil (-) Wire.

DIS Coil/Plug,

, where the coil is inside the

and

DIS Dbl End

(double end

Emissions Setup

If the Gas Detector is connected, two more screens will appear:

Fuel Type

Air-Fuel ratio and Lambda are calculated from the gases measured. Both calculations are

dependent upon what fuel is being used.

Vehicle Year and Size

Bar graphs in the emissions test are scaled to the expected range for the vehicle being tested.

For the best scale, choose the category that most closely matches year and size of the car.

3-3

Diagnostic Center Setup

The

Diagnostic Center Setup

properly display and print information

provides the Diagnostic Center with information it needs to

LCD Contrast

Choose from four levels of display contrast

for best viewing. Contrast choice may vary

with lighting and temperature.

Print Contrast

Thermal printer paper is available in a variety

of sensitivities. Some types of calculator

paper require more heat to make a dot. A

higher number works best in such a case.

Others, similar to fax machine papers,

require much less heat to leave a mark.

Smearing will occur if too high a setting is

selected.

Custom Header

Instructions for setting a custom header

appear on the next page.

Messages

Choose whether the Diagnostic Center

displays standard or short messages. Select

YES

while becoming familiar with the

Diagnostic Center.

Setup Default

This option allows the most frequently used

engine setup to be saved in permanent

memory. The saved setup will be loaded

whenever power is applied to the Diagnostic

Center.

Date & Time

Use the SELECT keys and press NEXT to

alter the date and time. The digits will begin

blinking. Use the SELECT keys to change

the number. Press NEXT to set. The

SELECT keys may be held to rapidly move

through the numbers.

Temperature °C / °F

Select whether temperature is displayed in

Fahrenheit or Celsius degrees.

System Diagnostics

Built-in tests allow you to check the operation

of various test leads. Select the lead to be

tested and follow the screen instructions.

Program Cartridges

This selection accesses installed Program

Cartridges. Each Program Cartridge will have

its own help screens and messages.

If two Program Cartridges are installed, a

menu will appear giving the name of each

cartridge. SELECT a cartridge, then press

NEXT.

The menu from the chosen cartridge is

presented. Use the SELECT and NEXT keys

to enter a test.

Gas Detector Service

The choices available under this heading are

described in the MAINTENANCE section of

this manual.

3-4

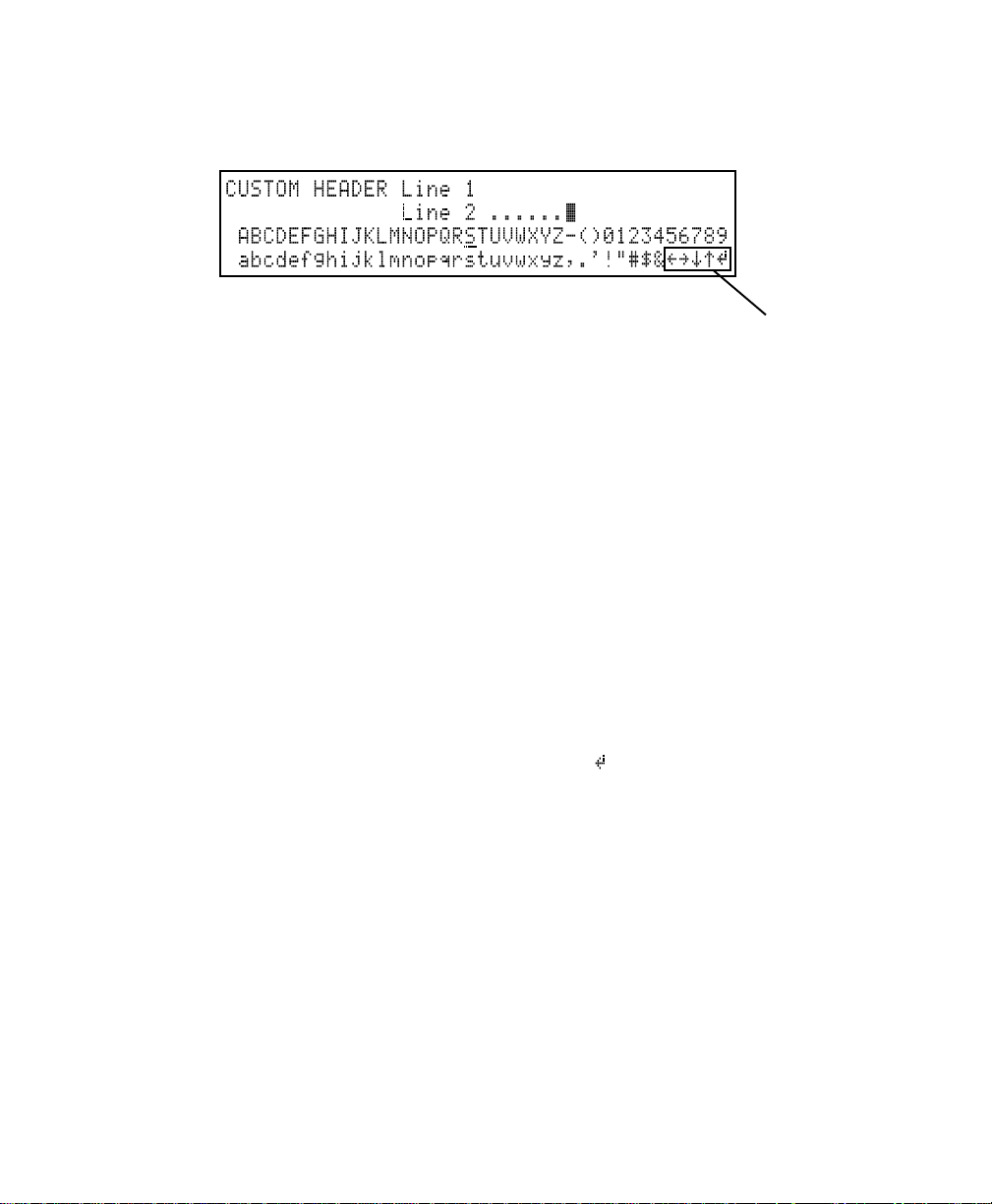

CUSTOM PRINTOUT HEADER

This function provides a way to place a four line header on printed reports. A business

address or a message may be placed in the header.

Control

Characters

MAKING A CUSTOM HEADER

Select the CUSTOM HEADER function in

the

Diagnostic Center Setup

four lines of header information can be

entered. The header is created in the top two

lines of the screen. The bottom two lines

contain the characters that may be used in

the header and the control characters. There

are two cursors. The Placement Cursor is the

flashing box that indicates where the next

character will be placed. The Selection

Cursor is the flashing underline. The arrows

are control characters used to move the

placement cursor on the header lines, and

are not printable.

MOVING THE PLACEMENT CURSOR

Use the SELECT keys to move the Selection

Cursor to one of the arrows, and press NEXT

to move the Placement Cursor left, right, up

or down. To show the remainder of the

header, use the up and down control

characters to move the Placement Cursor to

the next line.

menu. Up to

CHOOSING A CHARACTER

Use the SELECT keys to move the Selection

Cursor under the character that you want to

add. In the example above, it is located

under the 'S'. Pressing the NEXT key places

the character in the header at location of the

Placement Cursor. The Placement Cursor

then moves one position to the right. The

SELECT keys may be held to move rapidly

among the character choices. The NEXT key

may be held to rapidly place many copies of

the same symbol or, in the case of arrows,

to rapidly repeat the selected movement.

SAVING THE HEADER

When the header is completed, it must

be saved. Selecting the special control

character ' ', and pressing NEXT saves the

header in memory and returns to the

Diagnostic Center Setup

test key is pressed before selecting the

save symbol, the header will not be

saved.

CHANGING THE HEADER

Select the CUSTOM HEADER function in

the

Diagnostic Center Setup

Placement cursor to the position of the

character you want to change. Choose the

new character, and press NEXT. The

placement cursor will move one position to

the right, ready for placement of the next

character.

menu. If any other

menu. Move the

3-5

Ignition ............................4- 1

ENGINE TESTENGINE TESTING

Power ..............................4-13

Electrical..........................4-19

Sensors............................4-22

Reports - AutoT est............ 4-25

IGNITION

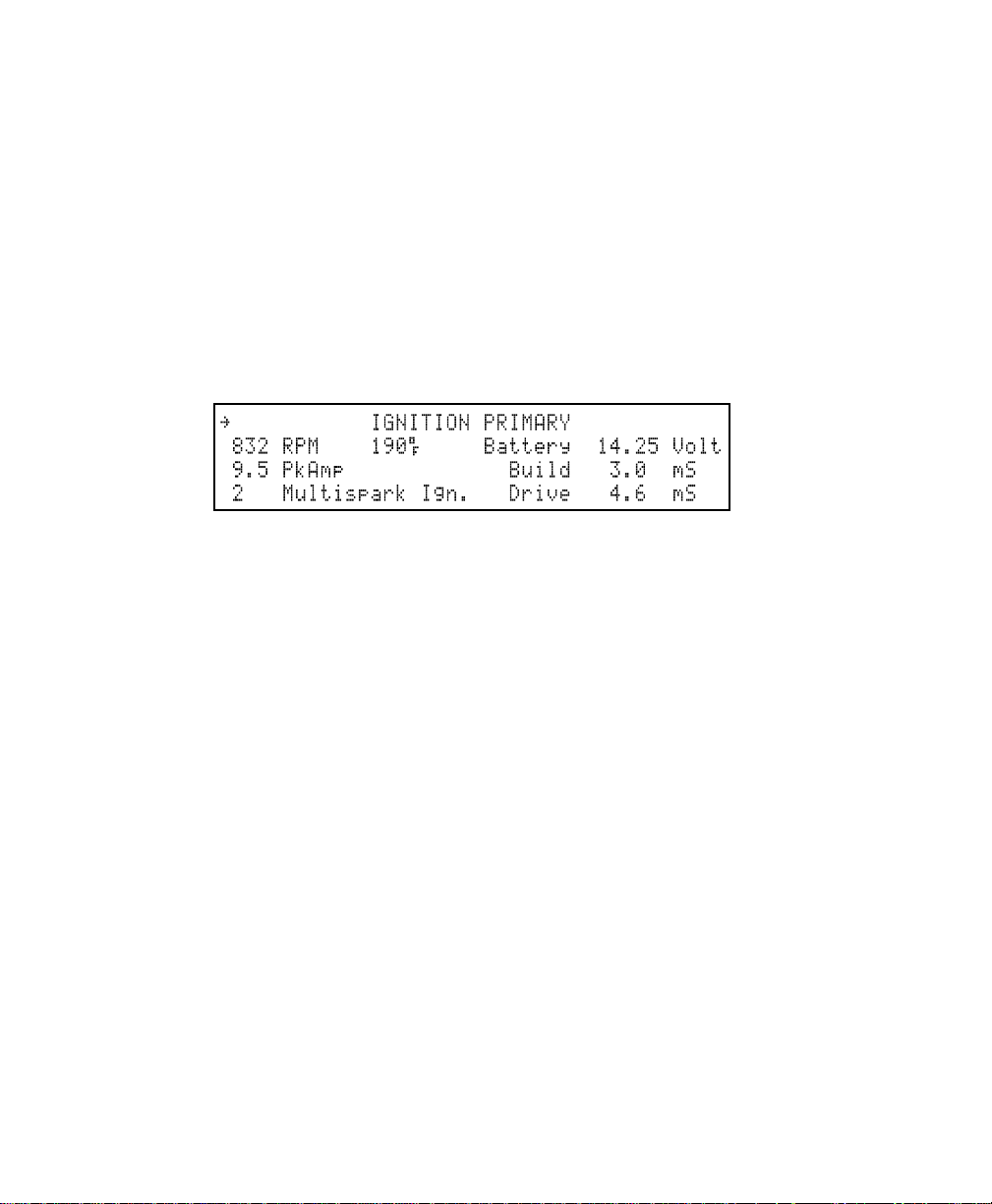

IGNITION PRIMARY — DIS

The

Ignition Primary

first will verify the connections as well as the condition of the coil primary. If the coil primary

circuit is bad, data in secondary and other ignition tests may not give results. If there are no

readings, or they are obviously wrong, check to see that the label on the pickup faces

toward the battery feed (away from the coil). See the table on page 4-4 for typical primary

wire colors.

test measures the input power and response of the coil. Doing this test

Press IGNITION, SELECT

Engine Setup

Measurements include:

RPM & BATTERY VOLTAGE

RPM is read by the black Primary Amps

probe from the current pulses drawn by

the ignition coils. RPM can be read on

any inductive ignition system. Battery

voltage comes from the red and black

Battery Clips.

PEAK AMPS, and BUILD TIME

The next display line shows the average

ignition primary amps and the average

milliSeconds it took for all coils to build

up the current during dwell.

, this screen will appear.

~ IGNITION PRIMARY

832 RPM 190û Battery 14.25 Volt

9.5 PkAmp Build 3.0 mS

2 Multispark Ign. Drive 4.6 mS

Primary

and press NEXT. If a DIS ignition was selected during

DRIVE MILLISECONDS

The Drive MilliSeconds reading is the

total dwell time from the time the coil

begins to charge to the time of plug firing.

In current-limiting electronic ignitions, the

difference between drive and build time

is the “hold” period.

MULTISPARK

Some ignition systems spark more than

once during each power stroke. If so, the

words “Multispark Ign.” will appear with

the number of sparks per ignition.

ENGINE TEMPERATURE

Temperature, sensed by the engine

temperature probe, is shown if the probe

is connected to the Control Module. If not,

the temperature display will not appear.

The reading may be shown as degrees

Fahrenheit or Celsius, as selected in

Diagnostic Center Setup.

4-1

Loading...

Loading...