www.ferretinstruments.com

OPERATORʼS MANUAL

WARNING:

Before introducing pressure and fog to any system, the unit must be

the lowest psi setting. Only increase the pressure when test conditions and the

WARNING:

The unit should be used on a level surface. This will make sure that

the ow meter reads accurately.

Timer

2

www.ferretinstruments.com

Timer

Air Intake with a Mass Air Flow Sensor

Vacuum Lines/Intake Manifod or Plenum

Warranty

Technical Support

The CoolSmoke EVAP Leak Detector has been designed and built by automotive technicians, for

www.ferretinstruments.com

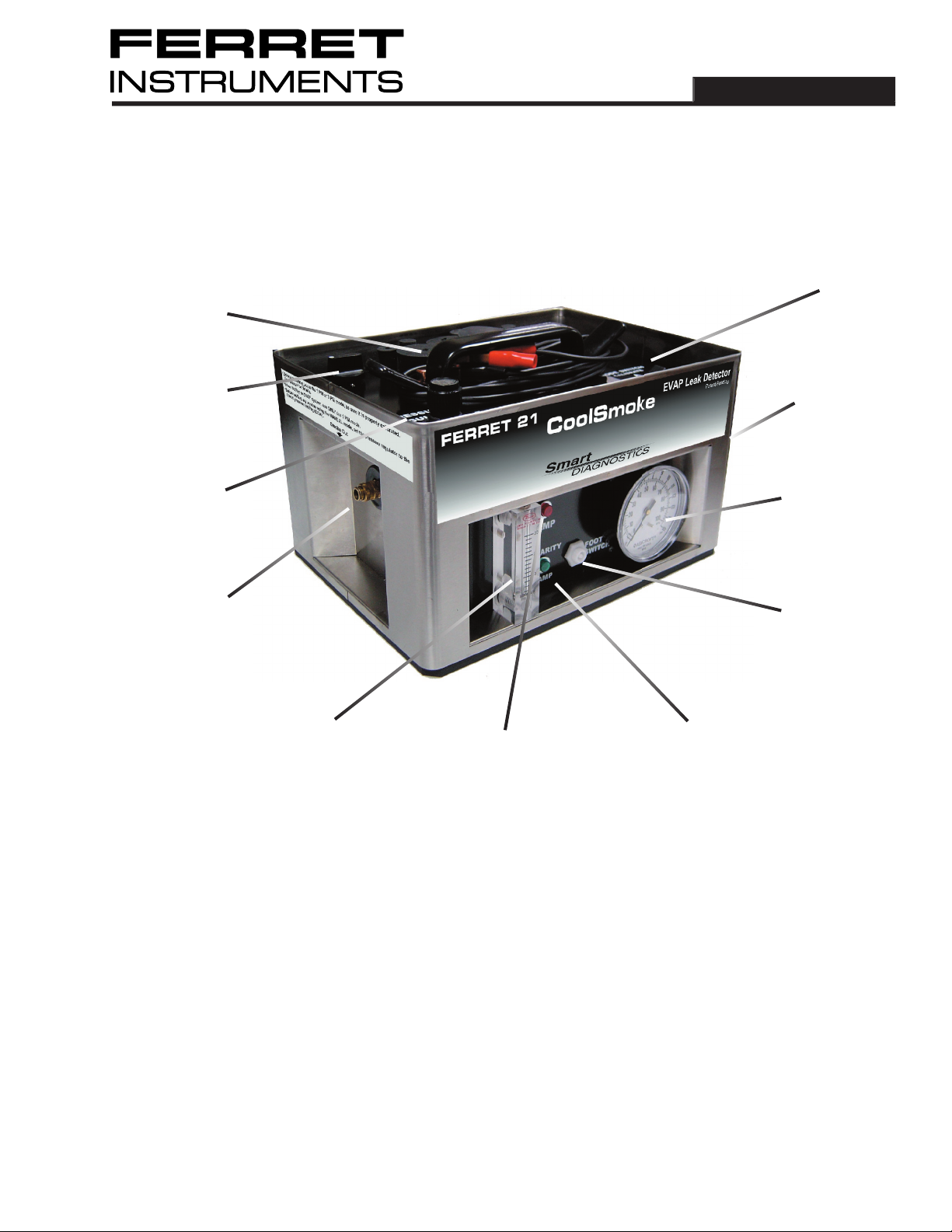

The large easy to read pressure gauge is used to determine the calibration of the CoolSmoke, and indicate

the amount of pressure that is being applied to the system under test.

The CoolSmoke incorporates a highly accurate ow gauge. When used with a properly calibrated

The polarity lamp is illuminated when the CoolSmoke is properly connected to a 12 Volt battery.

The ow lamp is illuminated when regulated shop air is owing into the system being tested. The more

frequently the ow lamp cycles on and off the bigger the leak.

The Mode Switch is located on the top deck of CoolSmoke at the front right. Press the left or right side of

the Mode Switch to select the appropriate pressure controlled mode (1 or 3 psi), or select the centre position

for the Manual Mode.

The CoolSmoke has two internal pressure cut-off switches that automatically

When the Mode Switch is placed in the center position, both internal pressure control switches are

will supply. It is essential that the air pressure regulator is turned all the way down (counter-clockwise

This mode has been speci cally provided for basic testing of Evaporative Emissions System integrity.

ow is “enabled”.

ow of smoke into the system. To do this, slowly turn the Air Pressure Regulator knob counter-clockwise,

the perfect range for the application.

www.ferretinstruments.com

The CoolSmoke operates exactly the same in the 3 psi mode as it does in the 1 psi mode. The major

SPECIAL NOTE:

This is not harmful to the system or CoolSmoke and may be ignored.

The Air Pressure Regulator has a control range from zero psi, up to 15 psi. Turning the Control Knob

When the air pressure setting is adjusted, so is the air- ow. The higher the pressure setting, the higher

the air- ow will be. This is useful when testing larger areas for leaks. Since air pressure will not build

The timer, situated on the top deck, has a maximum “ON” time of 10 minutes. In most cases, this is

to ll and saturate with fog, using the appropriate CoolSmoke settings.

The timer allows the Technician to operate the CoolSmoke hands-free, for as long as necessary.

the Technician is nished testing, simply remove the Ground Clip from the battery. The timer will return

to rest. The timer may also be wound back to zero with no ill effects.

the port on the front of your CoolSmoke. The switch may be used as a hand-held pendant switch, or left

to ll the

area quickly. Of course it’s essential that the air pressure gauge reading is continuously monitored to

ensure that the system pressure does not build beyond a suitable value.

As the air pressure increases, the regulator setting should be decreased to an appropriate level for the

system or component being tested. The higher the pressure setting, the more fog will be delivered, and

the quicker the test area will be lled.

Never hook the CoolSmoke to any system or component with the regulator setting in an unknown position.

A sudden, excessive increase in pressure will result in damage to the component.

Loading...

Loading...