Operating manual

PR 1713/00

Operating manual 9499-050-42910 Release 1.x

Other Manuals for PR1713:

Installation manual 9499-053-43010 Release 1.0

System manual 9499-054-43110 Release 1.x

(general)

Batching manual 9499-057-43210 Release 1.x

Programming 9499-053-35410 Release 1.x

*:7 */2%$/ :HLJKLQJ 7HFKQRORJLHV *PE+ 32% ' +DPEXUJ *HUPDQ\

?

Please note

In correspndence concerning this product, please quote the type, name and release number

as well as all license numbers corresponding to the product.

This product is copyrighted in all its parts and m ay not be used or illegal modified or copied

without purchasing the license or written authority from the copyright owner.

Important

This product may be operated only by trained and qualified personnel. By using this product,

you agree to be bound by the terms of this notice.

Bitte beachten

Bei Schriftwechsel über dieses Produkt bitte Typ, Bezeichnung und Versionsnummer sowie

alle mit dem Produkt in Zusammenhang stehenden Lizenznummern angeben.

Dieses Produkt ist in allen seinen Teilen urheberrechtlich geschützt und darf ohne Erwerb der

Lizenz oder schriftliche Einwilligung nicht benutzt oder unerlaubt verändert oder kopiert

werden.

Wichtig

Die Bedienung des Produktes darf nur von geschultem, fach- und sachkundigem Personal

durchgeführt werden. Durch die Benutzung dieses Produktes werden oben genannte

Bestimmungen anerkannt.

V e u ille z n o te r, s.v.p.

Dans votre correspondance se rapportant au présent produit, veuillez toujours spécifier le

numéro de type, la description et le numéro de version ainsi que tous les num éros de licence

en rapport avec ce produit.

Les droits d´auteur de toutes les part ies de ce produit sont réser vés. Ce pr oduit ne doit êtr e ni

utilisé ni changé ni copié sans achat de la licence ou accord par écrit.

Important

L´exploitation de ce produit ne doit s´effectuer que par du personnel autorisé. L´utilisation du

produit implique la reconnaissance des conditions mentionnées ci-avant.

© GWT Global Weighing Technologies GmbH

Meiendorfer Str. 205, 22145 Hamburg

1998

All rights are strictly reserved.

Reproduction or divulgation in any form whatsoever is not permitted without written authority from

the copyright owner.

- Printed in Germany -

PR1713 Operating manual

Contents

CONTENTS

1 INTRODUCTION............................................................................4

ENERAL

1.1 G

1.1.1 Manual repartition...................................................................................................................4

1.1.2 Instrument description.............................................................................................................4

.......................................................................................................................................4

2 DESCRIPTION OF CONTROLS ..................................................6

ISPLAY

2.1 D

EYBOARD

2.2 K

PERATING CONCEPT

2.3 O

2.3.1 Operation via 'soft'-key............................................................................................................9

2.3.2 Selecting from selection boxes...............................................................................................10

2.3.3 Editing with alphanumeric characters ..................................................................................11

.........................................................................................................................................6

.....................................................................................................................................7

...................................................................................................................8

3 MAIN MENU..................................................................................13

OOT MENU

3.1 B

.................................................................................................................................13

4 FIXTARE ........................................................................................15

5 COUNTING SCALE......................................................................17

6 BATCHING.....................................................................................19

NPUT MENU FOR COMPONENT EDITING

6.1 I

6.1.1 Editing....................................................................................................................................20

6.1.2 Component parameters..........................................................................................................23

6.1.2.1 Batch Mode......................................................................................................................................................23

6.1.2.2 SPM output address.........................................................................................................................................27

6.1.2.3 SPM input address...........................................................................................................................................27

6.1.2.4 Preset Point......................................................................................................................................................27

6.1.2.5 Overshoot.........................................................................................................................................................27

6.1.2.6 + Tolerance, - Tolerance...................................................................................................................................27

6.1.2.7 Minimum Flowrate..........................................................................................................................................28

6.1.2.8 Calming time....................................................................................................................................................28

6.1.2.9 Restart mode....................................................................................................................................................29

6.1.3 Deleting..................................................................................................................................31

6.1.4 Printing..................................................................................................................................31

....................................................................................20

NPUT MENU FOR RECIPE EDITING

6.2 I

6.2.1 Editing....................................................................................................................................32

6.2.2 Recipe total mode...................................................................................................................35

6.2.3 Setpoint scaling......................................................................................................................36

6.2.4 Simulation..............................................................................................................................36

6.2.5 Deleting..................................................................................................................................37

6.2.6 Printing..................................................................................................................................37

.............................................................................................32

Page 1

Contents

PR1713 Operation manual

TARTING A BATCH PROCESS

6.3 S

6.3.1 Status display ........................................................................................................................ 38

6.3.2 Stopping the batch process ................................................................................................... 38

6.3.3 Continue, skip, abort............................................................................................................. 39

6.3.4 Messages during batching .................................................................................................... 39

ELECTING A REPORT

6.4 S

6.4.1 Consumption ......................................................................................................................... 40

6.4.2 Production report.................................................................................................................. 41

6.4.3 Last batch report................................................................................................................... 42

DDRESS LAYOUT OF SIGNALS

6.5 A

6.5.1 Digital in- and outputmodules PR1713/12. .......................................................................... 43

6.5.2 SPM-addresses for addressing the digital outputs............................................................... 45

................................................................................................................ 40

..................................................................................................... 38

.................................................................................................. 43

7 ANALOG TEST..............................................................................47

8 SETUP..............................................................................................49

9 WHAT CAN BE DONE IN CASE OF TROUBLE.....................51

RROR MESSAGES

9.1 E

9.1.1 Error messages on the weight display .................................................................................. 51

....................................................................................................................... 51

RROR MESSAGES ON THE TEXT DISPLAY

9.2 E

................................................................................ 52

10 INDEX............................................................................................53

Seite 2

PR1713 Operating manual

Operating concept

Page 3

Operating concept

1 I

NTRODUCTION

1.1 General

1.1.1 Manual repartition

PR1713 Operating manual

The operation for the normal PR1713 user is described

except ‘Setup’, which must be operated via direct keys or via the softkey menu.

Additional manuals:

• Installation, configuration and calibration are described in the ☞installation manual.

• Operating principle and behaviour of batching components, alarms and recipe are described in the

☞batching manual.

• Connection to PR1730, PR1740, PR1720 as a further weighing point and communication are

described in the ☞system manual.

• The commands of the programming language are described in the ☞programming manual.

in this manual

, comprising all functions

1.1.2 Instrument description

The PR1713 basic configuration is an

• gross, net or tare weight display

• taring

• fix tare tables

• zero setting

• weight ticket printing

• checkweighing

• remote display

• functions via digital inputs and outputs

indicator

with

As a

batching controller

• charge or discharge batching in net mode

• charge or discharge batching in gross mode

• charge or discharge batching without tare (top-up)

• discharge to set-point

• discharge complete

• manual component

• guide component for automatic set-point correction during runtime

• time components

• further control and synchronization components

• special components also programmable (licence PR1750/10)

• tolerance checking

• minimum material flow monitoring

• automatic overshoot correction

• preparation of consumption reports

• preparation of production reports

• preparation of batch reports

Seite 4

(licence PR1713/20 or PR1713/21), PR1713 also batches complex recipes.

PR1713 Operating manual

• remote display

• functions via digital inputs and outputs

Operating concept

As an additional

Due to

sting ones is easy.

Program package 'Filtering and controlling' (licence) can be used for controlling continuous weighing

processes.

• control and filter components in recipes

• own control applications

programmability

external weighing point,

(licence PR1750/10) writing individual applications or matching the exi-

a PR1720 can be connected to the DIOs card

Page 5

Operating concept

PR1713 Operating manual

2 D

ESCRIPTION OF CONTROLS

2.1 Display

Weight display status symbols

Standstill

Gross or net zero within 1/4d

G or B

T

Gross weight display, dependent of

national language

Tare weight display

NET

Net weight display

Batching is active

blinks, alarm is pending or manual

component

Seite 6

PR1713 Operating manual

2.2 Keyboard

Indicator controls

Operating concept

Display switch-over to gross mode,

as long as the key is pressed. Additionally, symbol B or G dependent

of selected language is displayed.

Display switch-over to tare weight,

as long as the key is pressed. Additionally, symbol T is displayed.

print-out-key for additional or selfprogrammed programs. Try to start

program 'Print'.

Menu control keys

Softkey for menu selection on the

alphanumeric display

Scroll key for selection from a list

Set and reset tare. The instantaneous

gross weight is stored in the tare

memory, provided that:

- weight standstill

- weight within the limits (0 ≤

weight ≤ f.s.d.)

- unit is not in error status.

Gross weight is set to zero. Condition is:

- weight standstill

- within zero set range

- not tared

- batching is not active

Quit-key for leaving an entry or menu and continuation at the next higher menu level.

More key for display of further menu items

Remaining keys

Cursor key for moving the cursor

during numeric text editing

Enter key for completing entries

Back-space key. When editing alphanumeric texts, the previous character is deleted.

Stop- key for stopping a running

batch process

Function keys for additional or selfprogrammed programs. Try to start

program 'F1'.

Alpha-numeric

keys

Page 7

Operating concept

PR1713 Operating manual

2.3 Operating concept

The PR1713 operation is menu-guided. For this purpose, the unit has a 'softkey'-functionality as with

PR1615. Below the display, there are three 'softkeys', which can be provided with 6-letter inscriptions

via the lower display line. The normal operation is very easy also without manual.

Keys for taring, untaring, zero setting, printing out, display of gross and net, three definable function

keys and a stop key are located below the softkeys.

15 keys for alphanumeric entry are located on the right side.

DEF

ABC

#"()=

3

2

1

GHI

4

PQRS

7

-+*/

.

JKL

5

TUV

8

ÄAE

0

→←

MNO

6

WXYZ

9

del

enter

Status

Stop

p

B T T

Weight display

Alpha-numer i c display 2*20

⇑ ⇑ ⇑

>0< P F1

in/out

morequit

F3F2

All functions shall be accessible for the user with as few keys as possible. Thereby, selecting flexible

menus and submenus, finding an entry from a list and entry of alphanumeric texts must be possible.

three

The

modes of entry/selection for the different requirements are

•

Menu selection with three softkeys:

, and .

Inscription text fields separated by small

triangles are displayed:

'clear

• Selecting an entry from a list by

'scrolling'

The actually selected function is displayed

with two arrows.

show print'

'!Recipe-7!'

• Editing with individual letters

A cursor is displayed:

'Material-123_ '

Seite 8

PR1713 Operating manual

2.3.1 Operation via 'soft'-key

Each menu has a list of functions, which can be selected via softkeys.

Three functions are displayed at a time. Selecting a

function via 'softkeys' is displayed by two small triangles between

the inscription text fields ( ).

If more than three functions can be selected, double tri-

angles are displayed.

Display of the next three selectable functions is by pres-

sing key 'more'.

Operating concept

A menu item can be left with 'quit'. The operation is continued at the next higher level.

Page 9

Operating concept

PR1713 Operating manual

2.3.2 Selecting from selection boxes

An entry in a variable list can be selected by scrolling. If necessary, this list can be limited

by preselection (e.g. all names starting with 'A').

In the display, this type of selection is shown by two special characters left and right from

the selected !text!. Consequently, the overall list can be scrolled.

As scrolling would require pressing too many keys

with very long lists, the list entry can be entered

directly with the alphanumeric keys. Thereby, only

as many letters of the list entry as required for

identifying it clearly is need being entered, or until

the number of possible remaining selections is sufficiently low. By entry of alphanumeric characters,

selection from the list is limited and marked by display of a cursor. The cursor position marks the

length of list limitation. However, the overall list entry is always displayed. 'delete' is used to delete

the last character of limitation, until all list entries are selectable again.

Name of List

!List entry !

Example:

Overall list

*new* *new* *new*

A

AB

ABC

B

BA

BABX300

BBCT700

C

DEF

If the list contains apparent entry '* new *', a new entry can be inserted in the list.

without

A menu item can be left with 'quit'. Operation is continued at the next higher level.

Select the entry with 'enter'.

limiting Limitation by pressing key 'B'

_

B

A

B

ABX300

B

CT700

B

further

key 'A'

_

BA

BX300

BA

limitation by pressing

Seite 10

PR1713 Operating manual

Operating concept

2.3.3 Editing with alphanumeric characters

In the alphanumeric entry mode, a cursor blinks in the entry field. Unless already active, this mode is

accessible by pressing a key from the right keypad of PR1713. Then, the softkeys are without importance.

The arrow keys from the right keypad are used to shift the cursor. Entries and deletings act in

the cursor position.

An alphanumeric key has more than one

significations. After pressing for the first

time, the relevant first signification, e.g.

'A' is displayed in the cursor position. After pressing for the second time, e.g. 'B' instead of 'A' is

displayed; 'C' is displayed after pressing for the third time, etc. After the last signification, the first

one is displayed again. The entry of a character is completed by pressing another character key, or the

arrow keys. The character is removed by pressing key 'del'.

Parameter name

name field…

If only numeric values are required for an entry,

letters are not selectable via the editor. Therefore,

values such as 555 can be entered only by pressing

the key successively three times and without using

the arrow key. A decimal point can be entered with

the comma key. If a value has a polarity sign, a polarity sign can be entered by pressing the comma key

in the extreme left position.

With weight values, the unit can be scrolled using

the 'more' key. (g, kg, t, lb)

The single character editor can edit a longer character field than the space available for the editor. In

this case, the display field is shifted right and left. In

the last position, the partial character display is represented by special character '…'.

The 'backspace' key deletes the character before the cursor.

An entry can be completed with 'enter'. The changes are stored. The operation is continued at the next higher level..

The multiple key significations are:

# " ( ) = $ ? ! % 1

A B C a b c 2

D E F d e f 3

G H I g h i 4

J K L j k l 5

M N O m n o 6

P Q R S p q r s 7

T U V t u v 8

W X Y Z w x y z 9

. - + * /

(special characters dependent of

country) 0

The old value from before the change is displayed with 'quit'. By pressing 'quit', the operation is continued at the next higher level.

Page 11

Operating concept

PR1713 Operating manual

Seite 12

PR1713 Operating manual

Main menu

3 M

When the unit is ready for operation and batching is not active, the main menu functions are accessible.. Dependent of licence or programming, further or other application programs can be selected.

AIN MENU

FixtarCount Prod

Menu items at the uppermost menu level:

Softkey Function

Fixtar P Indicator functions with fixed tare value

Count P Counting application

Prod P Batch functions

Atest P Start test mode of internal weighingpoint

xxx P Other customer applications are appended to the list in this position

Setup Configuration, Calibration

The sub-menus with identification (P) are programmed in IEC1131 and can be changed freely with a

programming option by the user.

This uppermost main menu level is fixed in the firmware.

3.1 Boot menu

After switching on the mains voltage, the PR1713 version number is shown on the alphanumeric display. The main menu is active only thereafter.

Page 13

Operating concept

PR1713 Operating manual

Seite 14

PR1713 Operating manual

Fixtare

4 F

The fixed tare function permits taring of the scale with predefined tare values. These can be defined

by the user and are stored in a separate table in the database.

IXTARE

Fixtare Hopper1

! 1!

is displayed by selecting softkey 'Fixtar' from the main menu.

By scrolling

by pressing the numeric keys. In addition to its number, each entry has its plain text name. The fixed

tare number is selected with 'enter'.

With the fixed tare value selected, the weight display can be

tared with a fixed tare value, the fixed tare value can be edited, the current gross weight can be loaded and printed out in

the fixed tare memory.

2,5 kg

!!, the fixed tare value can be selected, or the fixed tare number can be selected directly

Fixtare hopper1

Tare

Edit

Weight

Fixtare hopper1

Print

Pressing softkey 'tare' tares the scale with the fixtare value. The display returns to the main menu.

Softkey 'edit' can be used for editing the plain text name and entering the fixed tare weight di-

rectly. The display returns to the selection menu.

Pressing softkey 'weight' stores the current gross weight in the fixed tare memory. In the printout

the value is put in <parentheses>. The display returns to the selection menu.

Pressing softkey 'print' prints out one or all fixed tare

values. The display returns to the selection menu.

• An entry can be completed with 'enter'. The changes are stored.

• The entry is left with 'quit'. When editing a value, the old value is restored. With an unchanged

value, a jump back to fixed tare selection is made.

Print

Single

All

Page 15

Operating concept

PR1713 Operating manual

Seite 16

PR1713 Operating manual

Counting scale

5 C

A counting scale permits conversion of a weight from the weighing point into a number via a factor.

These factors can be defined by the user and are stored in a separate table in the database.

OUNTING SCALE

Count Screws4

!

!

!

!

1

264 pcs

is displayed by selecting softkey 'Count' from the main menu.

By scrolling !, the fixed tare value can be selected, or the factor number is selected directly by the

numeric keys. Apart from its number, each entry has a plain text name. The count is updated continuously. The count factor is selected with 'Enter' .

The properties of the selected factor can be changed, displayed or printed out.

By pressing softkey 'set' , a new factor is calibrated.

1) Discharge the hopper: empty bin or plattform and set to zero or tare,

2) Calibrate with a selected number of objects and enter this value. Thereby, the accuracy is the

higher the higher the calibration weight, similar to every calibration.

The display returns to the selection menu.

Softkey 'show' displays the calibration values. The display returns to the selection menu.

Softkey 'print' prints out one or all count factors. The dis-

play returns to the selection menu.

Count Screws4

Set

Show

Print

Print

Single

All

• An entry can be completed with 'enter'. The changes are stored.

• Pressing 'quit' leaves the entry. When editing a value, the old value is restored. With an unchanged

value, the old value is restored. With an unchanged value, a jump back to the fixed tare selection is

made.

Page 17

Operating concept

PR1713 Operating manual

Seite 18

PR1713 Operating manual

Batching

6 B

All batching functions are classified in this menu item.

Report

Comp

During normal operation, only functions Batch start and Report are required.

In rare cases, the component and recipe tables are edited, usually by another person.

Key 'more' switches between the two 'softkey' menus.

Softkey Explanation

Report Selects a report

Batch Starts a batch process

Comp Edits components

Recipe Edits recipes

ATCHING

Recipe

Batch

Page 19

Batching

Quit

Quit

abc

Parameter value

remains unchanged

abc

changed parameter v alue

is accepted

With 'yes' all changes for this component

are accepted;

with 'no' they remain unchanged.

The component name is selected from a list by scrolling.

The list is shortend by entering the the first characters of the name.

PR1713 Operating manual

6.1 Input menu for component editing

Selecting softkey 'Comp' from the main menu displays:

Component Table

Delete

6.1.1 Editing

Edit

Print

Editing single components is done with

Survey

at the example of editing function

Select

com ponent nam e

Select param eter

select component

Name

Ø

Ø

Name

Preset

Ø

Ø

'edit'

:

×

×

store?

yes no

100 kg

×

×

Edit param eter

value

← →

Name

Preset 12

Seite 20

5 kg

PR1713 Operating manual

Batching

The entry is selected by scrolling !. A limitation of the list is

possible. In position '* new *', a new component can be

inserted. 'Enter' completes the selection.

Select Component

!

Sugar

!

Select Component

!

* new *

When trying to give a name to a component which was already assigned to another component, an error message is displayed.

• Pressing key 'quit' leaves the entry of a new component.

A number of specific parameters which shall be read out and changed as simply and quickly as possible. The parameter set changes dependent of the batch mode.

Component name + ...

A1, 2 B1 - B6

G1 - G6

WP Weighing point

DosMode Batch mode

SPM in SPM address

SPM out SPM address

Preset Preset point

OVRShoot Overshoot

Tol+ Max. tolerance

Tol- Min. tolerance

Minflow Min. flow rate

Calmtime Calming time

RST Mode Restart mode

Analo+ Max. analog value

Analo- Min. analog value

Name already exist

Batch mode

B8 D1, 2 D3 - D8

OK

RL, RQ, RW

!

Page 21

Batching

PR1713 Operating manual

The selected name is displayed in the uppermost line. In the

bottom line, all parameters can be selected. The first parameter is displayed. The relevant value is displayed beside the

parameter, i.e. a quick survey of all settings of a component is

possible by parameter scrolling.

For editing parameter 'Preset', selection with 'enter' is required. The value of this parameter is edited by entry of a number. See cursor in the numeric value. The unit is changed by

the 'more'-key.

Sugar

Preset: _15

Alle standard batch modes could be selected by scrolling.

Additional new mode names could be selected by entering

alphanumerical keys.

kg

Sugar

WP

!

!

Sugar

BMode

!

!

Sugar

SPM in

!

!

Sugar

SPM out

!

!

Sugar

Preset

!

!

Sugar

OVRshoot

!

!

Sugar

Tol.+

!

!

Sugar

Tol.-

!

!

A

!

!

B1

!

!

1

!

!

1

!

!

2 kg

!

!

5 kg

!

!

1 kg

!

!

1 kg

!

!

Sugar

The setpoint of the 'calming time' is a time, which has to be

entered with the units 'ms', 's', 'm' or 'h'. Eg. 1m30s are one

minute and thirty seconds.

MinFlow

!

!

Sugar

Calmtime

!

!

25 kg

!

!

1s

!

!

Sugar

RST Mode

!

!

!

!

0

Store ?

yes

• An entry can be completed with 'enter'. The changes are not stored.

• The entry is left with 'quit'. When editing a value, the old value is restored. With an unchanged

value, a jump back to parameter selection is made. When leaving the parameter entries, a prompt if

these data shall be stored is displayed. Subsequently, the operation is continued at the next higher

level with component name selection.

no

Seite 22

PR1713 Operating manual

Batching

6.1.2 Component parameters

6.1.2.1 Batch Mode

Each component can be a process step in a recipe. Determine the process step with the batch mode

during component definition, e.g. "Bx" for real components and "Dx" for dummy components. If a

guide component "Gx" was selected, the set-points of the following components are displayed as

calculated from the recipe during a production. The actual set-points referred to the guiding value are

output in the reports.

Batchable components B1-B6, G1-G6, B8

Manual components D1, D2

Dummy components D3-D8, RW RL, RQ

Analog components A1, A2

Other batch modes

6.1.2.1.1 Batchable components

Batchable components:

into/from silos is possible.

Net batching

Batch mode

nent for charge batching. Dossing is preceded by a tare step, i.e. the net weight is zero

when starting the batch. The recipe set-point

for this component is the net weight.

Charge batching

Batch mode B2 is used for charge batching.

Batching is not preceded by a tare step, i.e.

the last net weight remains unchanged. The

recipe set-point for this component is the net

weight based on the previous tare

Gross batching

Batch mode

to an absolute value. Before batching, the

tare is set to zero. The net weight is equal to

the gross weight. The recipe set-point for

this component is the gross weight.

is the normal batch compo-

B1

is used for charge batching

B3

All components for which automatic coarse + fine batching by weighing

Setpoint calculation:

setpoint = tara + setpoint

coarse_switch_off = setpoint - preset - overshoot

fine_switch_off = setpoint - overshoot

Setpoint calculation:

setpoint = old_tara + setpoint

coarse_switch_off = setpoint - preset - overshoot

fine_switch_off = setpoint - overshoot

Setpoint calculation:

setpoint = setpoint

coarse_switch_off = setpoint - preset - overshoot

fine_switch_off = setpoint - overshoot

Page 23

Batching

Discharge batching

Batch mode

nent for discharge batching according to B1.

Batching is preceded by taring, i.e. the net

weight is zero at batch start. The recipe setpoint for this component is the net weight.

Charge/discharge batching

Batch mode

ching according B2. Batching is not preceded by taring, i.e. the last net weight remains

unchanged. The recipe set-point for this

component is the net weight.

Gross discharge batching

Batch mode

ching to an absolute value. Before dosing,

the tare is set to zero. The net weight is equal

to the gross weight. The input value for this

component is the gross weight.

is the normal batch compo-

B4

is used for discharge bat-

B5

is used for discharge bat-

B6

PR1713 Operating manual

Setpoint calculation:

setpoint = tara - setpoint

coarse_switch_off = setpoint + preset + overshoot

fine_switch_off = setpoint + overshoot

Setpoint calculation:

setpoint = old_tara - setpoint

coarse_switch_off = setpoint + preset + overshoot

fine_switch_off = setpoint + overshoot

Setpoint calculation:

setpoint = setpoint

coarse_switch_off = setpoint + preset + overshoot

fine_switch_off = setpoint + overshoot

discharge component

The discharge mode B8 is used for total discharge. Before batching, the

tare is set to zero. The net weight is equal to the gross weight. The recipe set-point for this component is a gross weight. As discharging to

setpoint calculation:

setpoint = rest_value

ideal zero is rarely possible, batching is done at least until reaching rest value. Subsequently, the system waits until the calming time has elapsed, to discharge all rests, if possible. There is no fine flow.

6.1.2.1.2 Manual components

A manual component

For this, their input SPM_IN must be defined. Output SPM_OUT requests the user to start filling in

material. Batching is preceded by taring, i.e. the net weight is zero when starting the batch. The input

value for this component is the net

A manual component

weighed manual additions which are too small for being measured exactly by this weighing point.

Therefore, the set-point instead of the actual value measured after the calming time is recorded in the

batch report.

setpoint calculation:

setpoint = tare + setpoint

is batched manually by a user. It is acknowledged by a signal or a switch.

D1

.

behaves almost exactly like D1. However, the component is used for pre-

D2

Seite 24

PR1713 Operating manual

Batching

6.1.2.1.3 Dummy components

Dummy components

via SPM and PLC, e.g. timer, switch on/off, temperature control, motors. The SPM addresses for input and output are used in the

: non-batchable recipe entries, which control defined actions in the installation

function block

D3

D4

D5

D6

D7

D8

The

The time is entered with a resolution of 1 sec.

The

SPM_IN is omitted ! Restart by the control signal 'restart'

The SPM

status TRUE of SPM input address SPM_IN.

The SPM

The SPM

The SPM

SPM_OUT to FALSE.

component waits until the specified time has elapsed.

timer

component is used for making a pause of unpredictable duration. Waiting for

stop

waiting

set

delete

acknowledge

component sets output address SPM_OUT to status TRUE and waits for

component sets output SPM_OUT to TRUE.

component sets output SPM_OUT to FALSE.

component waits for status TRUE of input SPM_IN and sets output

setpoint = time_in_ms

6.1.2.1.4 RW, RQ, RL

RW (Wait), RL (Release), RQ (Request) are used in the recipe for production line synchronization.

Assuming a weighing point WX 'shared resource' for several production lines

RW

If WX shall not be started at recipe start, an RW component (wait component) must be used

as a first process step for WX in the recipe. The following recipe lines of WX are not handled

until started from another point in the recipe (RQ-component).

RQ

RL

The SPM input/output addresses of RW/RQ/RL can be used for synchronization, for process interlokking of for general status display.

The RQ component (request component) requests a weighing point WX and makes an attempt

to start the process steps of this weighing point. WX must be specified as an input parameter

of the RQ component. RQ remains active, until WX was started.

The RL component (release component) can be used for resetting weighing point WX to the

'wait' status. Subsequently, WX can be requested by another production line. RL is process

step of weighing point WX. All subsequent process steps of this weighing point must be activated by another request (RQ).

Page 25

Batching

PR1713 Operating manual

6.1.2.1.5 Analog components

Analog components

the component. The set-point in PR1713 is converted into digits for the analog output, or read as actual value from the analog input. The SPM addresses are word addresses, which are assigned to the

hardware in the PLC program.

: Parameters Max, Min and Unit. The values are loaded into PR1713 when using

A1

A2

Min and Max are dependent of hardware configuration of plug-in module PR1713/06 .

Min 0 V bis 0 mA to 4 mA to

Max 10 V 20 mA 20 mA

A PR1713 IEC 1131 program must write the relevant values from the SPM output address

(SPM_OUT) to an analog output card or read it from an anlog input card and write it into the SPM

input card (SPM_IN).

The analog function block sends the setpoint to

the internal PLC. The analog value is scaled by

parameters Min and Max.

This analog function block

reads an actual value from the

internal PLC and returns it.

Plug-in module

actual_value =

analog_value =

analog_input_value

3000

(target - min) * 4095

max - min

* (max - min) + min

6.1.2.1.6 Other batch modes

Other batch modes

ming/development tool PR1750. The first two characters of the batch mode must correspond with a

known mode and the same parameters must be used.

are programmable as function block in Proloc using the program-

Seite 26

PR1713 Operating manual

Batching

6.1.2.2 SPM output address

Output address function: Component handling activates this output bit. The default value of -1 must

be set to the correct value during component definition. -1 means that there is no output address.

The output address is a bit address (integer number up to 8191) in marker area M (storage capacity

for 1024*8 bits), which is activated by component handling. The real allocation to output area Q depends on the PLC program in which it can be programmed.

See section: Address layout of signals.

6.1.2.3 SPM input address

Input address function: Component handling is activated only when this enable bit is set. The default

value of -1 must be set to the correct value during component definition. With address -1, the component is always enabled.

The input address is a bit address (integer number up to 8191) in marker area M (memory capacity for

1024*8 bits), which is read by component handling. The real allocation to input area I depends on the

PLC program, where it is programmable.

See section: Address layout of signals.

6.1.2.4 Preset Point

Normal batching: The preset point determines the moment at which (set-point - preset point overshoot) the coarse batching valve is closed.

During discharging (B8): After weight below preset value, the hopper is considered as discharged.

Only the adjusted discharge time must elapse before the valve closes. The selected time value should

ensure that all material is still discharged.

6.1.2.5 Overshoot

All material which reaches the hopper after valve closing is called overshoot. The default value must

be selected so that it is slightly below the preset point. Only the overshoot part flown before elapse of

the calming time is included in the report.

The overshoot is determined only with tolerance check. It is optimized for the batching process and

corrected in the table, dependent of restart mode (1-4; 0=no correction). The next batch of this component works with corrected values.

6.1.2.6 + Tolerance, - Tolerance

The tolerance is specified as a weight and can be determined independently

set-point

Exceeded tolerances

Tolerance errors

set-point tolerance causes a production stop for a process step.

No tolerance check is made with a zero in both fields. In this case, overshoot correction and postbatching are omitted. The overshoot value remains fixed, the restart mode remains without effect on

batching.

and

with - for weight below set-point

are followed by post-batching and overshoot correction for the component.

generate a tolerance alarm which must be acknowledged. Moreover, an exceeded

.

with + for weight above

Page 27

Batching

PR1713 Operating manual

6.1.2.7 Minimum Flowrate

For not monitoring the component flow:

Enter zero as minimum component flow.

For monitoring the component flow:

Enter the minimum component flow per minute. Monitoring is also done with short batching times.

The value is converted internally into the measuring time. This is the min. flowrate with 'coarse' (or

12,5% thereof with 'fine' batching) otherwise, a flow alarm is output after approx. 30 seconds. Dependent of measuring time, resolution and total to be batched, the flow alarm can also be output earlier.

The component flow can vary during normal operation, e.g. the material starts flowing slowly after

opening the valve, until reaching a maximum value. With decreasing level, the flowrate is reduced

again.

6.1.2.8 Calming time

Enter the time in seconds which shall elapse before the tolerance test. This time can depend on the

- component consistency (solid, lumpy, liquid) or

- batching method (screw, vibrator, valve) or

- mechanical construction of the batching installation.

The tolerance check for weight is only correct after standstill.

Seite 28

PR1713 Operating manual

Batching

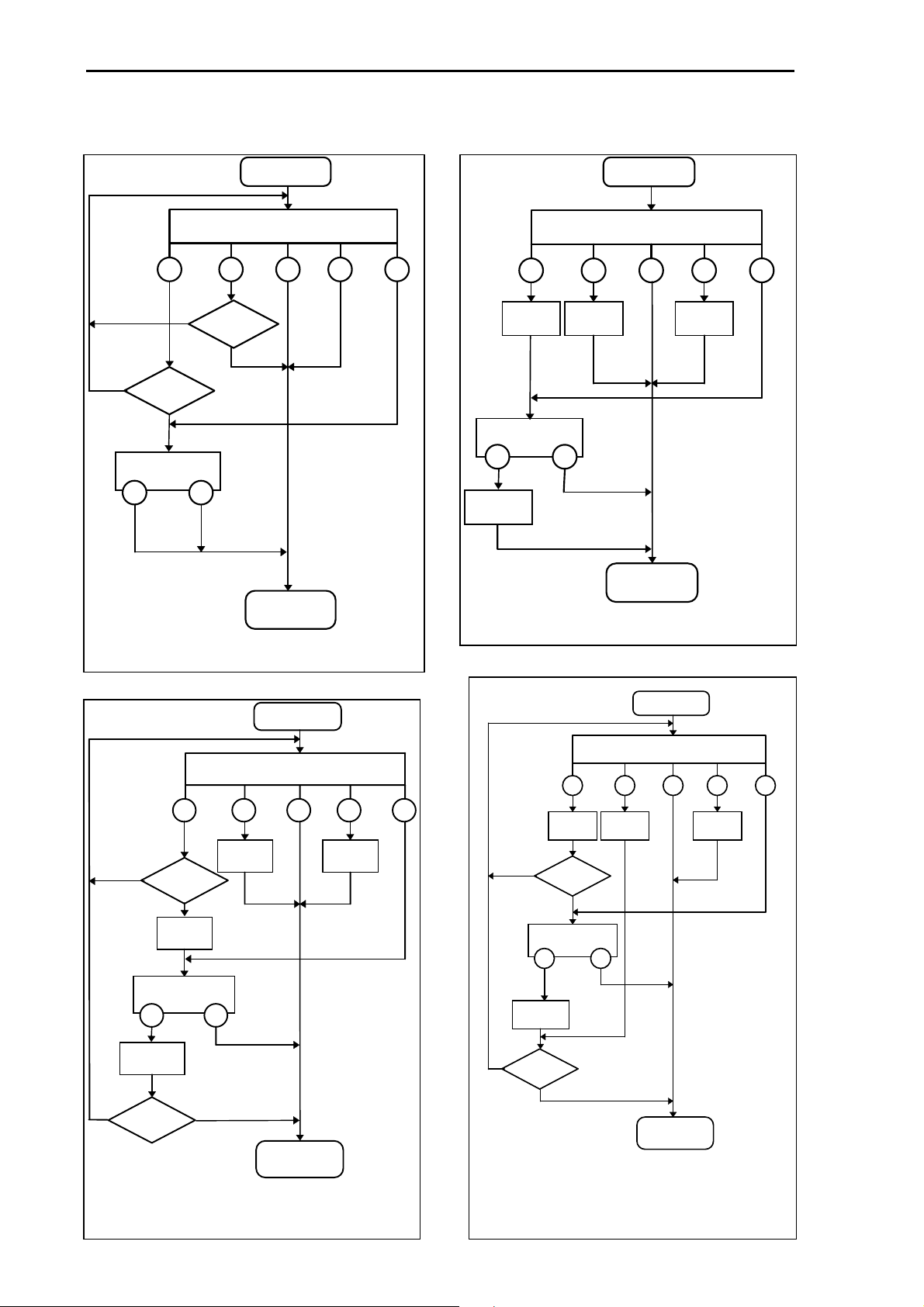

6.1.2.9 Restart mode

If batching is stopped by a tolerance alarm, or if a correction is possible with the weight below the

set-point, the defined restart mode determines the behaviour. A correction is possible with the batched

weight below fine switch-off point after the calming time. As a prerequisite, the tolerance test must

always be activated.

Weight

Tolerance band

Example in restart mode 4

After the calming time, the measured weight is below the low devia-

Set-point

tion. A new overshoot value is

calculated. If the difference to the

Overshoot

New overshoot

set-point is higher than the

overshoot value, a correction can

be started. After waiting again until the calming time has elapsed,

Calming time

the weight is within the tolerance

band, but still below the set-point.

Time

The overshoot value is corrected

again. Further correction is not

possible. With a tolerance alarm batching stops and the user has the opportunity for process intervention. In this case, the process can be continued ( Go ) or aborted ( A ) .

Calculation of modified overshoot values:

Setpoint - actual_weight

new_overshoot = old_overshoot -

corrected_overshoot = old_overshoot - (

2

Setpoint - actual_weight

)

Click on the required option field:

O no post-batching ⇒ mode 0

O post-batching, but no optimization ⇒ mode 1

O no post-batching, but optimization ⇒ mode 2

O post-batching first before optim. ⇒ mode 3

O optimization first before post-batch. ⇒ mode 4

Significations in the following diagrams

<T low deviation

<S weight below set-point

= set-point reached exactly

>S set-point exceeded

>T high deviation

Go entry: go on batching

A entry: abort batch

Mode 0

Batch

<

T

Tolerance alarm

Go A

<

S

=

Next

component

>

S

restart mode = 0:

Neither correction nor calculation of new

overshoot value

>

T

Page 29

Batching

PR1713 Operating manual

Mode 1

Batching

<

T

S

<

=

Y

Restart

N

Y

Restart

N

Tolerance alarm

Go A

Next

component

restart mode = 1:

Check only if correction is possible.

Mode 2

Batching

>

S

>

T

<

T

New

overshoot

S

New

overshoot

=<

>

S

New

overshoot

>

T

Tolerance alarm

Go

Corrected

overshoot

A

Next

component

restart mode = 2:

Calculate only a new overshoot in this mode.

Mode 3

Batching

=<

>S >T

New

overshoot

Y

Restart

overshoot

Tolerance alarm

Go A

Corrected

overshoot

J

Restart

<

New

T

N

S

New

overshoot

N

Next

component

restart mode = 3:

Test for correction and calculate new overshoot

Seite 30

Mode 4

Batching

S

=<

Next

component

>

S

New

overshoot

>

T

Y

Tolerance alarm

Go A

Corrected

overshoot

Y

Restart

<

T

New

overshoot

Restart

N

overshoot

N

New

restart mode = 4:

Calculate new overshoot and test for correction

PR1713 Operating manual

6.1.3 Deleting

Batching

Deleting individual or all component is with function

The entry is selected by scrolling

possible. The selection is completed with 'Enter'.

'Soft' key selection 'single' deletes only one selected component.

Unless the list is limited, all components are deleted: 'all'.

With a limited list, 'selected' is displayed instead.

Components, which are still used in recipes, must not be deleted.

'Soft' key selection 'show' displays the component name

and the first recipe in which this component is found.

If other components must still be deleted, the deleting operation is continued with 'soft' key selection 'next'.

• Key 'quit' can be pressed to leave submenu 'delete'.

. Limitation of the list is

!

'delete'

:

Select Component

firstname

!

!

Delete Component?

Single

All

Delete Component?

Single

Selected

Comp. used in recipe

Show

Next

6.1.4 Printing

!

!

Individual or all components are printed with function

Select the entry by scrolling !. A list limitation is possible.

Complete the entry by pressing 'Enter'.

'Soft' selection 'single' prints only one selected component.

Unless the list is limited, all components are printed with

'all'. With a limited list, 'selected' is displayed instead.

• Select submenu 'delete' with with key 'quit'.

'print'

:

Select Component

Sugar

!

Print Component?

Single

Print Component?

Single

Selected

All

!

Page 31

Batching

Quit

Quit

abc

Parameter value

remain unchanged

abc

changed parameter v alue

is accepted

With 'yes'all changes for this recipe

are accepted;

with 'no'they remain unchanged.

The recipe name is selected from a list by scrolling.

The list is shortend by entering the the first characters of the name.

123

6.2 Input menu for recipe editing

Recipe Table

Delete

is displayed by selecting softkey 'Recipe' from the batch menu.

6.2.1 Editing

Edit

Print

PR1713 Operating manual

Edit individual recipes with

Survey

at the editing function example

select recipe name

s e le c t line

:

'edit'

select recipe

Ø

Ø

Name

Recipe-name

Ø

Ø

27

×

×

Component name

Select recipe only w ith

×

×

store?

yes no

licenc e PR1713/21

Edt p aram eter v alue

f o r t h is lin e :

Component

← →

Setpoint

Flag for

rec ipe total

Flag for

Calculation m ode

Select component name

Ø

Ø

Zucker

Line setpoint

2

Total mode

1

Calculation mode

1

Seite 32

×

×

5 kg

PR1713 Operating manual

A

Batching

A number of specific parameters which shall be read out and changed as simply and quickly as possible is stored under the recipe name. The parameter set changes dependent of the batch mode.

Recipe name +...

Batchmode

B1 - B6

G1 - G6

D1, D2

A1

D3

A2

B8

D4 - D8

Rl, RQ, RL

01

line number

!

!

!

!

Component

Line setpoint

Total mode

Calulation mode

With the licence for multiple recipes (PR1713/21), recipes

could be selected or created. If not, this menue is skipped.

Select Recipe

!

!

Tart3

!

!

The recipe name selected last is displayed as proposal (e.g.

Tart3). It can be changed by selecting the available recipe

names. Limitation by list preselection is possible. A new recipe can be inserted in position '* new *'. 'Enter' completes

Select Recipe

!

!

* new *

!

!

the selection.

When trying to assign a recipe a name which was already assigned to another recipe, an error message is displayed.

Name already exist

OK

• Press key 'quit' to leave the entry of a new recipe.

The selected name is displayed in the upper line. In the lower

line, all parameters can be selected. The relevant line number

Tart18

!

!

1

!

!

Sugar1

is always displayed on the left. It can be edited first. The value of another parameter is displayed right beside the line number. The component name is displayed

first. The line number can be selected by 'scrolling' or by editing a value entry directly.

Note: There are no empty lines in the recipe.

With the first softkey, a selection for inserting or deleting a

recipe line is displayed.

Tart18

1

Insert

Delete

The second softkey is used for inserting a copy of the

actual line. The line numbers of the subsequent lines will increase by one.

The third softkey deletes the current line. The line numbers of the following lines decrease by

one.

When selecting a line number behind the last one used in this

recipe, a prompt whether another line shall be appended is

displayed. The number of lines must not exceed the configurated maximum number. The absolute maximum is 255 lines.

ppend new line

Yes

No

Page 33

Batching

PR1713 Operating manual

The component name can be selected by pressing 'enter'.

When pressing key 'enter' again, the other parameters are always displayed right beside the line number.

All parameters are always called up successively.

1) Component name

2) Set-point

3) Recipe total mode

4) Set-point scaling

The setpoint of the D3 component is a value in seconds and

has to be entered without a unit.

Select component

Sugar1

!

!

Line setpoint

52.4

kg

Total mode

1

Calculation mode

!

!

0

After completing the last parameter, the next line number is

always displayed automatically, so that a quick survey of all

data of a recipe is possible.

Note: Detailed explanations for the 'Total mode' are located in section 'Recipe total'. The

'Calculation mode' is described in section 'Setpoint scaling'.

• An entry can be completed by pressing 'enter'. The changes are stored. The next parameter of the

recipe line is displayed.

Tart18

2

!

!

Flour-3a

!

!

Seite 34

PR1713 Operating manual

p

g

p

g

p

g

g

g

p

g

g

g

g

g

g

Batching

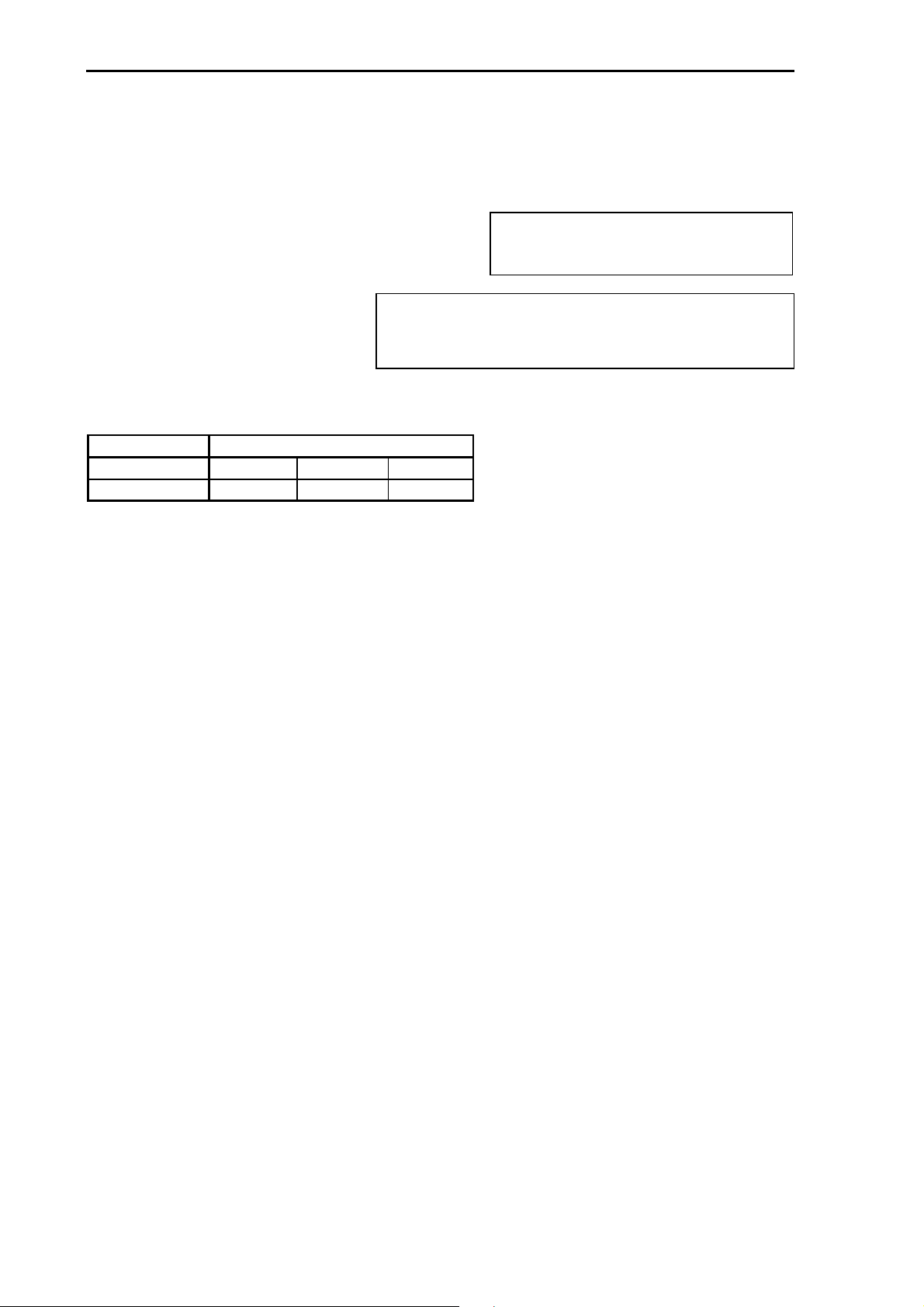

6.2.2 Recipe total mode

It could be defined for the components B1-B6, G1-G6 and D1-D2, if the setpoints of the recipe line

should be added to the recipe sum. This marking is an element of the recipe line and not the component. The recipe sum is the base for the setpoint scaling. The recipe total mode is independing of the

calculation mode.

In this recipe with fill components, all batches are

added to the recipe total. In this example the recipe

Recipe

B1 80 kg

B1 40 kg

sum: 120 k

Recipe setpoint=120 kg

T

Markin

T

Recipe sum =

Start value of the reci

all lines with

Σ

T

When the recipe is extended by a B2- or B3component, then a

wrong recipe sum is

calculated. With the

extension of a B2component, the previous B1-component

must not used for the

80

70

40

B2

B1

recipe sum calculation.

The 'fil-up'-batch B2 is

based on the last tare

B1

from the B1 and contains in its setpoint so

to speak the setpoint of

the previous component. If using a B3 in-

Rest amount

when started

stead of the B2 component, only the B3-component must have the mark for the recipe total.

sum is calculated to 120 kg. If the recipe is started

with this amount, all components are batched with

exact the setpoints given in the recipe lines. Than

the recipe sum is the same as the recipe setpoint.

With a different recipe setpoint, all recipe line setpoints are adapted proportional.

e

GrossNet

weight

[kg]

160

130

90

10

nent 1

component 2

component 3

Recipe

B1 80 k

B1 40 k

B2 70 k

Sum: 150 k

Recipe setpoint=150 kg

time [t]compo-

T

T

Example:

e 1

Reci

B1 20 kg

B1 20 kg

D1 20 kg

Sum 60 k

T

T

T

e 2

Reci

B1 50 kg

B1 40 kg

B3 100 kg

Sum 100 k

e 3

Reci

B4 20 kg

B4 40 kg

T

B5 60 kg

Sum 80 k

T

T

Recipe 4

D1 100 kg

B2 120 kg

B3 150 kg

B1 20 kg

Sum 180 k

Recipe 5

B1 50 kg

B1 50 kg

B2 100 kg

B3 180 kg

Sum 200 k

T

When using components B2, B3, B5 and B6, pay attention to the correct setting of recipe total mode.

Page 35

Batching

g

g

g

g

g

g

6.2.3 Setpoint scaling

PR1713 Operating manual

The setpoints of each recipe line are recalculated according

to the recipe setpoint on each new recipe start. A setpoint

scaling is done. With the calculation mode it is defined, if

Scaling factor

_

Re _

cipe setpoint

=

Re _

cipe sum

the setpoint of the recipe line is recalculated on a new recipe start. In general all dosing components

will be scaled. The amount of the executed batch is changed by the scaling factor.

Example:

Recipe 1

B1 50 kg

B1 50 kg

B2 100 kg

Σ

Recipe setpoint=300 kg

Scaling factor = 2

TS

S

TS

150 k

real

batch

100 kg

100 kg

200 kg

300 k

Recipe 2

B1 50 kg

B1 50 kg

B3 150 kg

Σ

Recipe setpoint=300 kg

Scaling factor = 2

TS

150 k

real

batch

100 kg

S

100 kg

S

200 kg

300 k

Recipe 3

B1 50 kg 50 kg

B1 50 kg

B3 200 kg

Σ

Recipe setpoint=300 kg

Scaling factor = 1,5

TS

200 k

real

batch

S

75 kg

300 kg

300 k

In the third example the first component should not be scaled. Then the setpoint of the recipe line is

batched independingly of the scale factor.

The calulation mode is independing of the recipe total mode.

6.2.4 Simulation

Before each recipe start it is checked if this production could theoreticly run. All components for this

recipe must exist. During the recipe test run, neither the maximum weight of the hopper should be

excided, nor the weight should fall below zero. All weighing points must be free and should not be in

an error state. Without this conditions the recipe could not be started.

Seite 36

PR1713 Operating manual

6.2.5 Deleting

Batching

Deleting individual or all recipes with function

Select the entry by scrolling !. Limitation of the list is possible. Complete the selection by pressing 'Enter'.

'Soft' key selection 'single' deletes one selected recipe.

Unless the list is limited, all components are deleted with

'all'. With a limited list, 'selected' is displayed instead.

• Leave submenu 'delete' by pressing key 'quit'.

'delete'

:

6.2.6 Printing

Printing individual or all recipes with function

Select the entry by scrolling !. A list limitation is possible

with 'Enter'.

Press 'soft'key selection 'single' to print only one selected

component.

Unless the list is limited, all recipes are printed with 'all'.

With a limited list, 'selected' is displayed instead.

• Leave submenu 'delete' by pressing key 'quit'.

'print'

:

Select Recipe

firstname

!

!

Delete Recipe?

Single

All

Delete Recipe?

Single

Selected

Select recipe

firstname

!

!

Print recipe?

Single

All

Print recipe?

Single

Selected

!

!

!

!

Page 37

Batching

6.3 Starting a batch process

PR1713 Operating manual

Select recipe

Tart

!

!

Recipe setpoint

20.0

By selecting softkey 'Batch' from the batch menu, the PR1713

start procedure is displayed. The operator is prompted for

!

!

entry of recipe name, setpoint and number of cycles.

During configuration, a value can be assigned to individual or

each of these parameters. When starting the batch, these pa-

kg

rameters are not displayed for entry any more (e.g. the number of cycles is always one. An entry at each start is omitted.)

Number of cycles

1

6.3.1 Status display

During batching, the user can display the current process status.

• Gross weight

• Net weight

• Tare weight

• Difference weight

• Set-point

• Recipe name

• Component name

• Batch mode

• Current line

• Current cycle

• Maximum cycle

Tart7

3: Sugar4

B1 D -3.4 kg

7* S 10.0 kg

The status display has two levels. The display will change the level by pressing the key 'more'.

- In the first level the recipe name is shown in the upper line. In the lower line, the recipe line number and the actual component name are displayed.

- In the second level the batch mode, difference weight, number of current remaining cycles and setpoint are displayed. As long the first Soft-key is pressed, the maximum number of cycles are

shown.

With the Gross-key the weight display changed for a minimum of 3 seconds to the gross-weight.

With the Tare-key the weight display changed for a minimum of 3 seconds to the tare-weight.

6.3.2 Stopping the batch process

A batch process can be stopped manually at any time by pressing the red stop key. The stop

message is displayed blinkingly.

* stopped *

7* S 10.0 kg

Seite 38

PR1713 Operating manual

6.3.3 Continue, skip, abort

Batching

For this, the batch process must be in stop condition. When

pressing the stop key again, the following menu is displayed.

Pressing the first softkey resets the stop condition. In case

of a tolerance alarm, the recipe controller is instructed to go on operating. Dependent of error cause and restart mode, the operation is continued by postbatching.

When pressing the second softkey, the current recipe line is skipped. All following recipe lines are

continued normally. In case of a tolerance alarm, the recipe controller is instructed to abort only

this line, because the error cannot be removed, but the recipe can be continued.

When pressing the third softkey, the overall recipe is aborted.

• The menu is left again with the quit key.

skip abort

continue

line

recipe

6.3.4 Messages during batching

If tolerance monitoring is activated by entry of the tolerance

parameters above zero, a tolerance alarm can be generated

after a batch. If the currently batched total exceeds the tolerance, this message blinks in the first line and the recipe goes to the stop condition automatically.

Different reactions on a tolerance alarm are possible. See section: 'Continue,skip, abort'

* tolerance alarm *

7* S 10.0 kg

With flow monitoring activated by entry of the min. flow value, there may be a flow warning after a batch. If the material

flow exceeds the min. flow rate (e.g. due to clogging), this

message blinks in the first line. The recipe does not go to the stop condition, but continues checking

the flow rate. The warning extinguishes automatically, when the error is removed.

* flow warning *

7* S 10.0 kg

Page 39

Batching

PR1713 Operating manual

6.4 Selecting a report

is displayed by selecting softkey 'Report' from the batch menu.

Report

Consum

The following reports are selectable:

• component consumption report

• recipe production report

• last batch report

The layout of all reports is programmed with IEC1131. With the programming licence, however, the

user is able to match the reports to his requirements.

With the configuration, the physical interface is determined via configuration, where the report is

printed.

The reports have to be activated in the configuration. At 'Setup' und then 'Software parameter', it could

be selected if and for what purpose the recipecontroller generates a report.

'Report to ' none no report is generated

Prodct

communication only for communication.

proloc only for the user interface (IEC 1131 programs)

communic. & proloc for communication and user interface

LBatch

Note: Alle generated reports have to be read and deleted. If reports are generated for eg. com-

munication and user interface, the communication has to detete the batch reports. If not,

the data base is filled until no free memory space is left and no new batch could be started.

6.4.1 Consumption

Individual or all consumption totals can be printed out, or the

consumption values can be deleted by pressing the first softkey.

Select the entry by scrolling. A list limitation is possible. The

selection is completed by pressing 'Enter'.

'Soft' key selection 'Clear' clears one or more consumption

totals.

'Soft' key selection 'Show' shows one or more consumption

totals. By pressing a key, the consumptions are displayed

one by one. Pressing key 'quit' the list is aborted.

'Soft' key selection 'Print' prints one or more consumption

totals.

• Unless the list is limited, all consumption totals are taken

with 'all'. With a limited list, 'selected' is displayed instead. 'Soft' key selection 'single' taks only

one selected component.

• Pressing key 'quit' leaves the respective submenu.

Select Component

firstname

!

!

Consumption

Clear

Show

Print

Clear

Single

All

Show

Single

Selected

Print

Single

Selected

!

!

Seite 40

PR1713 Operating manual

Consumption report

Date: 17.06.99 13:56

Component WP Consumption

---------------------------------------- Sugar-640 A 558,4 kg

Sugar-210 A 24,3 kg

Flour-fine A 1330,8 kg

Egg powder A 572,0 kg

Spice mixture-25 A 0,0 kg

Spice mixture-30 A 0,0 kg

Spice mixture-38 A 104,3 kg

6.4.2 Production report

Batching

Pressing the second softkey prints out individual or all production totals or deletes the production total values.

!

Select the entry by scrolling. A list limitation is possible.

Complete the selection by pressing 'Enter'.

'Soft' key selection 'Clear' clears one or more production

totals.

'Soft' key selection 'Show' shows one or more production

totals. By pressing a key, the productions are displayed

one by one. Pressing key 'quit' the list is aborted.

'Soft' key selection 'Print' prints one or more production

totals.

• Unless the list is limited, all production totals are taken

with 'all'. With a limited list, 'selected' is displayed instead.

'Soft' key selection 'single' taks only one selected recipe.

• Leave submenu 'delete' by pressing key 'quit'.

Production report

Recipe Production total

------------------------------------- Biscuits 502,0 kg

Cookies 338,1 kg

Sand cake 1847,4 kg

print

Select Recipe

firstname

!

!

Production

Clear

Show

Print

Clear

Single

All

Show

Single

Selected

Print

Single

Selected

!

!

Page 41

Batching

PR1713 Operating manual

6.4.3 Last batch report

Printing the last batch report with the third softkey:

Note: In the configuration, 'Setup' and then 'Config', it could be selected if an actual batch re-

port is printed automatically after each batch. Therefore the menue 'batchep.auto prt' has

to be selected to 'auto'.

Maier-Keks GmbH

The world of biscuits

Batch report

Date: 03.10.99 12:35

Recipe: cookies

Sequence number: 476

Total: 100 kg

Production number: 12

Customer number: 1

Start time: 12:01

Stop time: 12:08

Chargenumber: 1/3

Alarmflags: none

Line Component Actual value Setpoint Error

----------------------------------------------------------------- 1 Flour-fine 1502,0 kg 1502,0 kg 0

2 Sugar-210 738,1 kg 738,1 kg 0

3 Egg powder 347,4 kg 347,4 kg 0

4 Spice mixture-38 82,9 kg 82,9 kg 0

Seite 42

PR1713 Operating manual

Batching

6.5 Address layout of signals

6.5.1 Digital in- and outputmodules PR1713/12.

Note: The functionality descibed here, is the PLC standard program. This program could be changed

with the software tool PR1750.

The output of the internal states or the input of 'commands' is defined by plugging the digital I/O cards

(PR13/12) in the slots. Depending on the inserted licences the PR1713 has two operating modes: the

indicator operation and the batch operating.

Indicator operation

Without a dosing licence PR1713/20 or PR1713/21

The indicator operation needs no further configuration.

Slot 1

if the digital I/O-modul

PR1713/12 is plugged

in

Slot 2

if the digital I/O-modul

PR1713/12 is plugged

in

Slot 3

Inputs

tare in B12

tare out B34

set to zero B56

weight valid B78

on terminal

Outputs

standstill A12

¼ d indication A34

tared A56

free A78

Limit 1 on WP-A A12

Limit 2 on WP-A A34

Limit 1 on WP-B A56

Limit 2 on WP-B A78

on terminal

Batching operation

For the batching operation the licence

inputs the recipe could be controled: stop, restart, abort.

Depending on the configuration: 'Setup' and then 'Config' in the parameter: 'Comp.& recipe I/O:' two

variants exist: '

1)

For each Component a

The output addresses of the components had to be entered in the parameter SPM-out for each

component. The selection of the output is free.

For D1, D2, D5 and D8 components needs also the corresponding input addresses ('Quit' for

D1, D2 and 'Go on' for D5, D8)

Recipes could be started with the 'Start'-input. With the licence PR1713/21 for multiple recipes,

the recipe is started wich had been selected by one of the inputs of slot 2 or slot 3. Then the n-th

recipe from the alphabetic sorted list of recipes is taken.

single

' or '

binary

single

'.

PR1713/20 or PR1713/21

output is set and for each recipe a

has to be activated. With the digital

input is read.

single

Page 43

Batching

PR1713 Operating manual

Slot 1

if the digital I/O-modul

PR1713/12 is plugged

in

Slot 2

if the digital I/O-modul

PR1713/12 is plugged

in

Slot 3

if the digital I/O-modul

PR1713/12 is plugged

in

2)

The Component output is

Inputs

on terminal

Control signals

Start / Restart / quit B12

Stop B34

Abort B56

Go on B78

single signals

Start recipe 1 B12

Start recipe 2 B34

Start recipe 3 B56

Start recipe 4 B78

single signals

Start recipe 5 B12

Start recipe 6 B34

Start recipe 7 B56

Start recipe 8 B78

binary coded

and the recipe input is read

Outputs

batch control

coarse valve A12

fine valve A34

discharge A56

error A78

single signals

component 1 active A12

component 2 active A34

component 3 active A56

component 4 active A78

single signals

component 5 active A12

component 6 active A34

component 7 active A56

component 8 active A78

on terminal

binary coded

The output addresses of the components had to be entered in the parameter SPM-out for each

component. The selection of the output is free.

For D1, D2, D5 and D8 components needs also the corresponding input addresses ('Quit' for

D1, D2 and 'Go on' for D5, D8)

Recipes could be started with the 'Start'-input. With the licence PR1713/21 for multiple recipes,

the recipe is started wich had been selected by one of the inputs of slot 2 or slot 3. Then the n-th

recipe from the alphabetic sorted list of recipes is taken.

.

Slot 1

if the digital I/O-modul

PR1713/12 is plugged

in

Slot 2

if the digital I/O-modul

PR1713/12 is plugged

in

Slot 3

if the digital I/O-modul

PR1713/12 is plugged

in

Inputs

on terminal

Control signals

Start / Restart / Quit B12

Stop B34

Abort B56

Go on B78

Start recipe binary coded

20 B12

1

B34

2

2

B56

2

3

2

B78

Start recipe binary coded

24 B12

5

B34

2

6

B56

2

7

2

B78

Outputs

on terminal

batch control

coarse valve A12

fine valve A34

discharge A56

error A78

Component binary coded

20 A12

1

A34

2

2

A56

2

3

2

A78

Component binary coded

24 A12

5

A34

2

6

A56

2

7

2

A78

Seite 44

PR1713 Operating manual

Batching

6.5.2 SPM-addresses for addressing the digital outputs

All addresses in the parameter 'SPM-out' of the component had to be between 1024 and 1279. If the

component active signals are routed individual to the outputs (single-mode) only the lower eight addresses 1024 to 1039 could be used.

With the binary coded output mode a maximum of 255 different components could be coded. Only

one component at the same time may be active.

%MX1024 Free marker range for component output (256 bits)

to

%MX1279

%MX1280 Free marker range for recipe number input (32 bits)

to

%MX1311

%MX1312 'Quit'-input for 'manual'-component on WP-A (internal WP)

%MX1313 'Quit'-input for 'manual'-component on WP-B (external WP)

%MX1314 'Go on'-input for 'wait'-component on WP-A (internal WP)

%MX1315 'Go on'-input for 'wait'-component on WP-A (internal WP)

%MX1344 activate the waiting background task.

%MX1345 start a recipe

%MX1346... free for additional functions

%MX1360 recipe number

to

%MX1367

Output of single component signals

Slot 2

Address

1024

1025

1026

1027

terminal

A12

A34

A56

A78

Slot 3

Address

1028

1029

1030

1031

terminal

A12

A34

A56

A78

Page 45

Batching

PR1713 Operating manual

Output of binary coded component signals

Slot 2

Address

1024 LSB

...

1151 MSB

Value after coding

0

2

1

2

2

2

3

2

terminal

A12

A34

A56

A78

Slot 3

Address

1152 LSB

...

1279 MSB

Input signals for components

The components for manual weighing (D1, D2) need a 'Quit'-signal from the operator. The address of

the 'Quit'-input is 1312 and had to be entered at the component parameter 'SPM-in'.

Value after coding

0

2

1

2

2

2

3

2

terminal

A12

A34

A56

A78

The components which are waiting for the input signal 'Go on' (D5, D8), need the address 1314 at the

component parameter 'SPM-in'.

Seite 46

PR1713 Operating manual

A

Analog test

7 A

During the calibration of the device the test value is calculated automaticly and stored in the

EEPROM. This value is scaled to the full scale deflection (e.g. 5000).

When the test is activated, the measuring signal is disconnected from the loadcell. The displayed value appears without an unit on the weighing display. Depending on the calibration the value is displayed as the actual test value

or

as the difference between the original stored test value and the actual test value (e.g. 0000).

NALOG TEST

nalog test activ

The analog test remains activ, until it is terminated by 'Soft-key'-Stop or the Quit-key.

Stop

Page 47

Batching

PR1713 Operating manual

Seite 48

PR1713 Operating manual

Setup

8 S

Various functions can be selected during setup:

• Calibration

• Configuration

• Serial interfaces

• Display of board number

• Licence number management

• Initialization data print-out

• Set time

• Refresh display

• Reboot

These functions are described in the

Setup

!

!

ETUP