GW Instek PSH-6006A, PSH-1036A, PSH-2018A, PSH-3610A, PSH-1070A User Manual

...

Programmable Power Supply

PSH series

USER MANUAL

GW INSTEK PART NO. XXXX-XXXXXX

ISO-9001 CERTIFIED MANUFACTURER

This manual contains proprietary information, which is protected

by copyrights. All rights are reserved. No part of this manual may

be photocopied, reproduced or translated to another language

without prior written consent of Good Will company.

The information in this manual was correct at the time of printing.

However, Good Will continues to improve products and reserves

the rights to change specification, equipment, and maintenance

procedures at any time without notice.

Good Will Instrument Co., Ltd.

No. 7-1, Jhongsing Rd., Tucheng City, Taipei County 236, Taiwan.

Table of Contents

3

Table of Contents

Safety Instructions ........................................ 5

Safety Symbols ......................................... 6

Safety Guidelines....................................... 6

Power cord for the United Kingdom .............. 9

PSH Overview .............................................. 11

Main Features ..........................................12

PSH Series Lineup.....................................13

Package Contents.....................................14

Front Panel..............................................16

Rear Panel...............................................18

Display....................................................19

Setup ........................................................... 21

AC Power Cable Assembly..........................22

Remote Sensing and Local Sensing .............24

Load / Remote Sensing Wire Selection.........25

Load Configuration....................................26

Load Wire Assembly..................................30

Remote Sensing Wire Assembly..................32

Functionality Check...................................34

Rack Mounting (Optional) ..........................40

Panel Operation ........................................... 43

Menu Key Overview ..................................44

Constant Voltage/ Constant Current Crossover

Characteristic...........................................45

Output Voltage Setting..............................46

Output Current Setting..............................47

OVP (Output Voltage Protection) Setting......48

OCP (Output Current Protection) Setting......49

Display Contrast Setting............................50

PSH User Manual

4

Buzzer sound Setting ................................51

Remote Operation.........................................52

Interface Selection....................................53

Command Syntax.....................................57

Command Set..........................................58

Calibration ....................................................61

Calibration Preparation..............................62

Entering calibration mode ..........................63

Output Voltage calibration..........................64

Output Current calibration .........................66

OVP Calibration ........................................68

FAQ...............................................................69

Appendix.......................................................71

Specifications...........................................71

Declaration of Conformity ..........................75

Index ............................................................76

Safety Instructions

5

Safety Instructions

This chapter contains important safety

instructions that must be followed when

operating PSH and when keeping it in storage.

Read the following before any operation to

insure safety and to keep the best condition for

PSH.

Safety Symbols

Safety Symbols .........................................6

Safety

Guidelines

Safety Guidelines.......................................6

Power Supply............................................7

Fuse ........................................................7

Cleaning PSH ............................................7

Operation Environment...............................8

Storage Environment .................................8

Power cord

Power cord for the United Kingdom ..............9

PSH User Manual

6

Safety Symbols

These safety symbols may appear in this manual or on PSH.

WARNING

Warning: Identifies conditions or practices that

could result in injury or loss of life.

CAUTION

Caution: Identifies conditions or practices that

could result in damage to PSH or to other

properties.

DANGER High Voltage

Attention Refer to Manual

Protective Conductor Terminal

Earth (ground) Terminal

Safety Guidelines

• Do not place any heavy object on PSH.

• Avoid severe impacts or rough handling that

leads to damaging PSH.

• Do not discharge static electricity to PSH.

• Do not block or obstruct cooling fan vent

opening.

• Do not perform measurements at power source

and building installation site (Note below).

• Do not disassemble PSH unless you are

qualified as service personnel.

General

Guideline

CAUTION

(Note) EN 61010-1:2001 specifies the measurement

categories and their requirements as follows. PSH falls

under category II.

Measurement category IV is for measurement performed

Safety Instructions

7

at the source of low-voltage installation.

Measurement category III is for measurement performed

in the building installation.

Measurement category II is for measurement performed

on the circuits directly connected to the low voltage

installation.

Power Supply

WARNING

• Input voltage: 90 ~ 250 V AC, 50/60 Hz

• The power supply voltage should not fluctuate

more than 10%.

• Connect the protective grounding conductor of

the power cord to earth ground, to avoid

electrical shock.

PSH-1036A

PSH-2018A

PSH-3610A

PSH-6006A

6.3A/250V x2

PSH-1070A

PSH-2035A

PSH-3620A

PSH-6012A

6.3A/250V x2

0.5A/250V x1

15A/250V x1

PSH-10100A

PSH-2050A

PSH-3630A

PSH-6018A

6.3A/250V x3

0.5A/250V x1

20A/250V x1

Fuse

WARNING

• Make sure the correct type of fuse is installed

before powering up.

• Replace the fuse with the specified type and

rating only, for continued fire protection.

• Disconnect the power cord before fuse

replacement.

• Make sure the cause of the fuse blowout is

fixed before fuse replacement.

Cleaning PSH

• Disconnect the power cord before cleaning.

• Use a soft cloth dampened in a solution of mild

detergent and water. Do not spray any liquid

into PSH.

• Do not use chemicals or cleaners containing

harsh materials such as benzene, toluene,

PSH User Manual

8

xylene, and acetone.

Location: Indoor, no direct sunlight, dust free,

almost non-conductive pollution (Note below)

Relative Humidity: < 85%

Altitude: < 2000m

Temperature: 0°C to 40°C

Input Breaker Capacity: Over 20A (PSH-10100A,

2050A, 3630A, 6018A)

This is a Class A product which may cause radio

interference in a domestic environment. In such

case, take adequate measures.

Operation

Environment

WARNING

(Note) EN 61010-1:2001 specifies the pollut ion degrees

and their requirements as follows. PSH falls under degree

2.

Pollution refers to “addition of foreign matter, solid,

liquid, or gaseous (ionized gases), that may produce a

reduction of dielectric strength or surface resistivity”.

Pollution degree 1: No pollution or only dry,

non-conductive pollution occurs. The pollution has no

influence.

Pollution degree 2: Normally only non-conductive

pollution occurs. Occasionally, however, a temporary

conductivity caused by condensation must be expected.

Pollution degree 3: Conductive pollution occurs, or dry,

non-conductive pollution occurs which becomes

conductive due to condensation which is expected. In

such conditions, equipment is normally protected against

exposure to direct sunlight, precipitation, and full wi nd

pressure, but neither temperature nor humidity is

controlled.

Storage

Environment

Location: Indoor

Relative Humidity: < 70%

Temperature: −10°C to 70°C

Safety Instructions

9

Power cord for the United Kingdom

When using PSH in the United Kingdom, make sure the power

cord meets the following safety instructions.

NOTE: This lead / appliance must only be wired by competent pe rsons

WARNING: THIS APPLIANCE MUST BE EARTHED

IMPORTANT: The wires in this lead are coloured in accordance with the

following code:

Green/ Yellow: Earth

Blue: Neutral

Brown: Live (Phase)

As the colours of the wires in main leads may not corr espond with the colours

marking identified in your plug/appliance, proceed as follows:

The wire which is coloured Green & Yellow must be con nected to the Earth

terminal marked with the letter E or by the ea rth symbol

or coloured Green

or Green & Yellow.

The wire which is coloured Blue must be connected to the terminal which is

marked with the letter N or coloured Blue or Black.

The wire which is coloured Brown must be connected to the terminal marked

with the letter L or P or coloured Brow n or Red.

If in doubt, consult the instructions provided with the equipment or contact

the supplier.

This cable/appliance should be protected by a suitably rated and approved

HBC mains fuse: refer to the rating infor mation on the equipment and/or user

instructions for details. As a guide, cable of 0.75mm2 should be protected by a

3A or 5A fuse. Larger conductors would normally re quire 13A types,

depending on the connection method used.

Any moulded mains connector that requires removal /replacement must be

destroyed by removal of any fuse & fuse carrier and disposed of immediately,

as a plug with bared wires is hazardous if a engaged in live socket. Any

re-wiring must be carried out in accordance with the information detailed o n

this label.

PSH Overview

11

PSH Overview

PSH Series are modular-type programmable

switching power supplies designed for broad

range of applications. The series consists of 12

models, output ranging from 360W to 1000W.

Switching technology and built-in PFC control

give PSH higher power efficiency, power density,

and power factor compared with other linear

power supplies. Protection mechanisms keep the

output voltage, current, and temperature within

limit. Remote control interface equipped with

SCPI command set and Lab-View Driver

facilitates ATE software development.

This chapter describes PSH series features and

appearances in a nutshell.

Main features

Main Features .........................................12

Series lineup

360W..................................................... 13

720W..................................................... 13

1000/ 1080W.......................................... 13

Package

contents

Main unit................................................14

AC input cable kit ....................................14

Output connection kit...............................15

Manual................................................... 15

Panel

descriptions

Front Panel.............................................16

Rear Panel.............................................. 18

Display

descriptions

Default display ........................................ 19

Menu mode display..................................20

PSH User Manual

12

Main Features

Performance

• 12 models with wide output range: 6~100A,

10~60V, and 360~1000W.

• High power factor with PFC control

• High efficiency power conversion

• Compact size, light weight

Operation

• Constant voltage operation

• Constant current operation

• Output On/Off control

• Built-in buzzer

• Self test and calibration

• LCD display

Protection

• Over voltage protection (OVP)

• Over current protection (OCP)

• Over temperature protection (OTP)

Interface

• RS-232 (standard) / GPIB (optional) interface

• IEEE 488.2/SCPI compatible command set

• LabView driver

Optional items

• GPIB remote control interface

• 19 inch standard rack mounting

PSH Overview

13

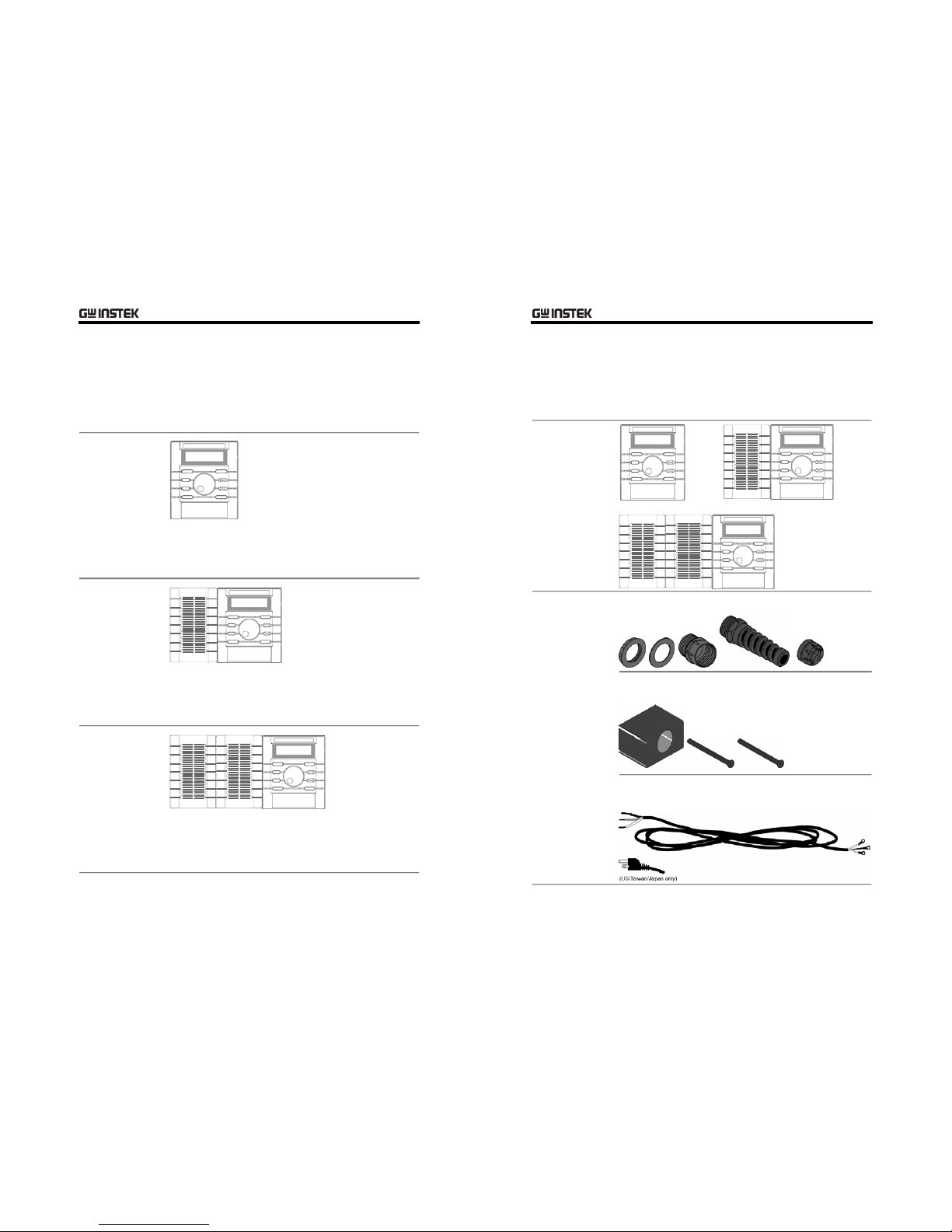

PSH Series Lineup

PSH series consist of the following 12 models with various output

voltage and current ratings. For the detailed specifications, see

page71.

PSH-1036A

10V, 36A

PSH-2018A

20V, 18A

PSH-3610A

36V, 10A

PSH-6006A

360W

(Mainframe

only)

60V, 6A

PSH-1070A

10V, 70A

PSH-2035A

20V, 35A

PSH-3620A

36V, 20A

PSH-6012A

720W

(Mainframe +

one slave

module)

60V, 12A

PSH-10100A

10V, 100A

PSH-2050A

20V, 50A

PSH-3630A

36V, 30A

PSH-6018A

1000/ 1080W

(Mainframe +

two slave

modules)

60V, 18A

PSH User Manual

14

Package Contents

Check the contents before using PSH series. Contact your local

dealer in case there is a missing item.

Main unit

AC input cable

kit

• Cable gland

• Terminal cover

• AC power input cord

PSH Overview

15

Package Contents (cont.)

Output

connection kit

• Terminal cover

• Output cable screw

Manual

• User manual (this document)

• Programming manual

PSH User Manual

16

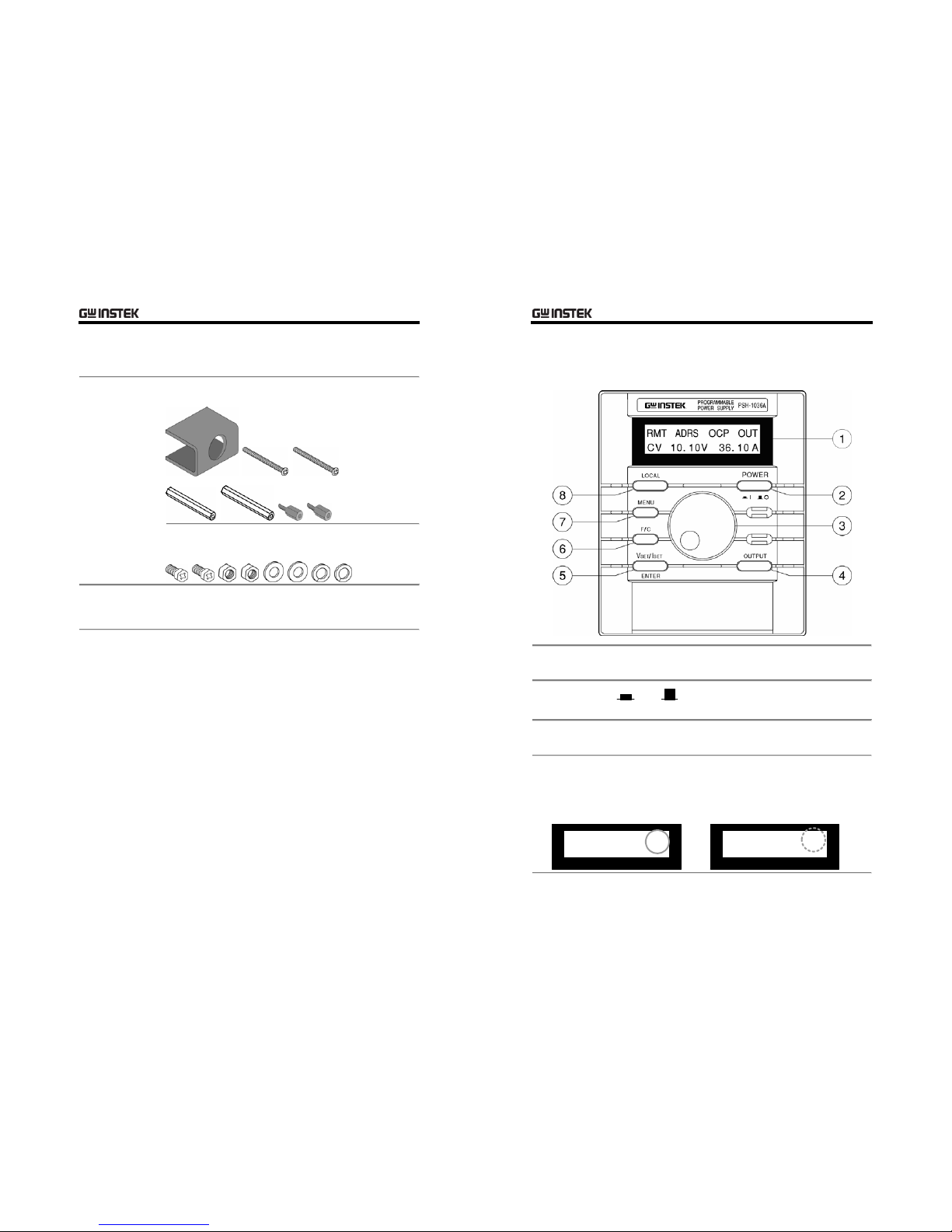

Front Panel

1 LCD Display

Shows the output and the configuration status.

See page19 for details.

2 Power

Switch

On Off

3 Wheel knob

Sets parameters. Turn right: increase, turn left:

decrease.

4 Output

Switch

Turns the output On or Off. When On, the “OUT”

sign appears on the display.

Out On

OCP OUT

CV 2.58V 2.01A

Out Off

OCP

SET 2.58V 2.01A

PSH Overview

17

5 Vset/ Iset/

Enter key

Switches between voltage setting mode and

current setting mode, or confirm the entered

value in the menu mode (see page44).

Vset (edit Voltage)

OCP

SET 2

.58V 2.01A

Iset (edit Current)

OCP

SET 2.58V 2

.01A

6 F/C (Fine/

Coarse) key

Switches the editing location and resolution:

before (coarse) or after (fine) the decimal point.

Fine (after decimal)

OCP

SET 2.58

V 2.01A

Coarse (before decimal)

OCP

SET 2

.58V 2.01A

7 Menu key

Enters into the menu mode. For details, see

page44.

Default mode

OCP OUT

CV 2.58V 2.01A

Menu mode (OVP setting)

Set OVP

* 21.10V

8 Local key

Switches from remote control mode to local

operation mode (page56), OR releases OVP/OCP

error messages and go back to normal operation

(page37), OR enters the calibration mode when

pressed for more than 5 seconds (page61).

Error message example

OCP Error! Press

“Local” to reset

Calibration mode

Calibration

Voltage

PSH User Manual

18

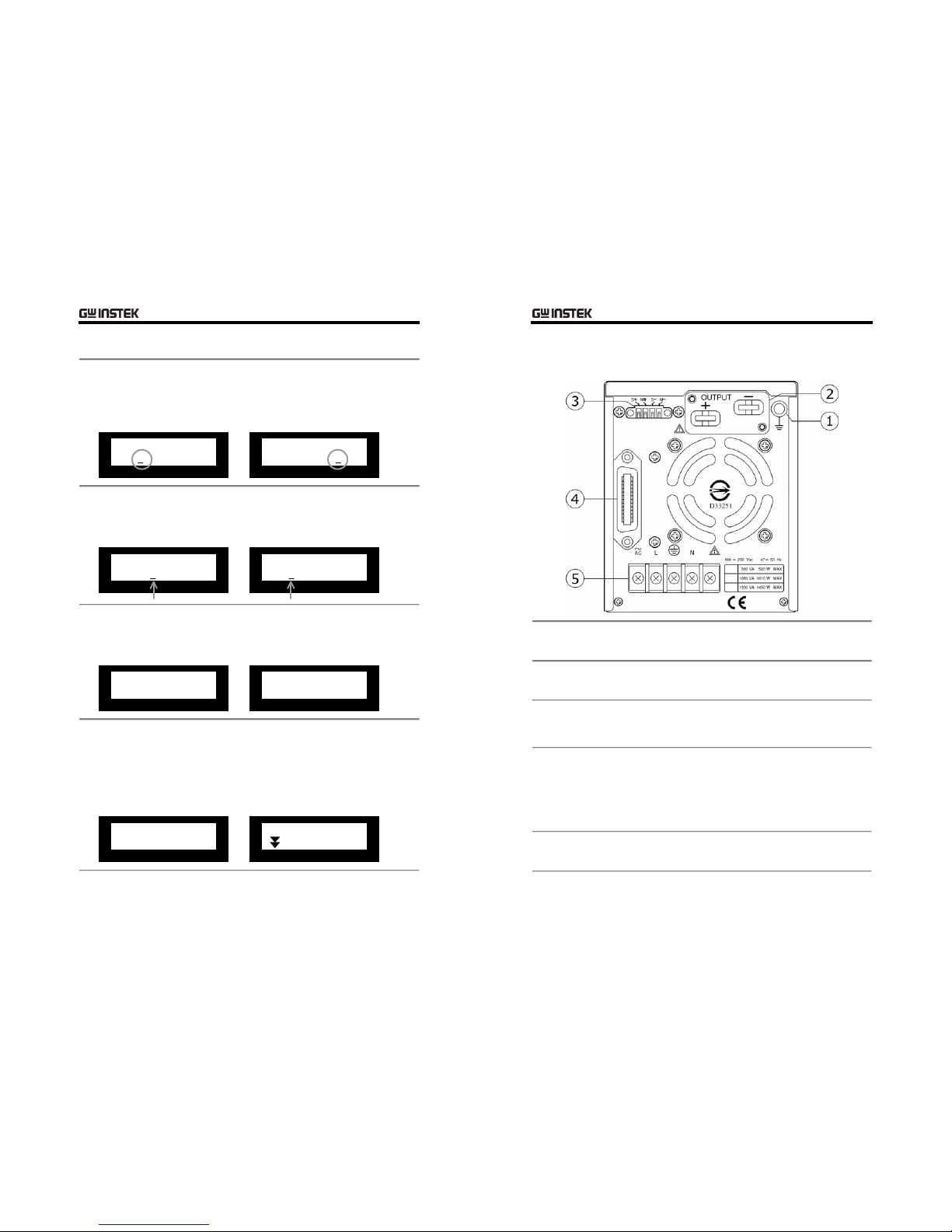

Rear Panel

1 Ground

Terminal

Connect the output line shield (page25) and

the remote sensing line shield (page32).

2 Output

Terminal

Connect DUT (Device Under Test). For details,

see page24.

3 Sense Terminal

Connect the feedback line to compensate for

cable loss. For details, see page24 (theory),

page32 (cable connection).

4 RS232/ GPIB

Terminal

Connect the remote control line. For remote

control details, see page52. GPIB requires an

optional module. For installation details, see

the service manual.

Note: Only one interface module (RS232 or

GPIB) can be installed at a time.

5 AC input

Terminal

Connect the AC power input cable. For

details, see page22.

PSH Overview

19

Display

Default

display

Display mode

RMT ADRS OCP OUT

CV 10.10V 36.10A

A B C D

E F G

Editing mode

OCP

SET 10.10V 36.10A

A B C D

E F G

A RMT: remote control mode

(Nothing): panel operation mode

Not available in editing mode

B ADRS: RS-232 or GPIB address (available

in remote control)

Not available in editing mode

C OCP: Output Current Protection On

(Nothing): Output Current Protection Off

D OUT: Output On

(Nothing): Output Off

Not available in editing mode

E CV/CC: Current and Voltage display

mode (Constant Voltage/ Constant

Current)

SET: Current and Voltage editing mode

F Output Voltage readback value (display

mode)

Output Voltage setting value (editing

mode)

G Output Current readback value (display

mode)

Output Current setting value (editing

mode)

PSH User Manual

20

Display (cont.)

Menu mode

display

The following displays appear when pressing the

Menu key

MENU

. To move to the next configuration,

press the Menu key repeatedly. When inactive for

more than 5 seconds, the display goes back to the

default mode.

(Default display)

Output Voltage

Protection setting.

For details, see

page48.

Output Current

Protection setting.

For details, see

page49.

Display contrast

setting. For details,

see page50.

Buzzer setting. For

details, see page51.

Set OVP

21.10V

Set OCP

ON (OFF)

Set Contrast

70%

Set Buzzer

ON (OFF)

Interface RS232

Baud Rate 9600

OCP OUT

CV 2.58V 2.01A

Remote control

interface setting. For

details, see page52.

Setup

21

Setup

This chapter describes load configurations and

setup procedures. Follow these instructions to

properly install PSH series.

AC power cable

assembly

AC Power Cable Assembly......................... 22

AC power cable requirement .....................23

Load

configuration

Remote Sensing and Local Sensing ............24

Load / Remote Sensing Wire Selection........25

Single Load + Local Sensing...................... 26

Single Load + Remote Sensing.................. 26

Multiple Loads + Local Sensing..................27

Multiple Loads + Remote Sensing ..............27

Series Operation + Local Sensing............... 28

Series Operation + Remote Sensing........... 29

Wire assembly

Load Wire Assembly................................. 30

Remote Sensing Wire Assembly.................32

Functionality

Check

Preparation............................................. 34

Output Voltage & OVP Check..................... 35

Output Current Check ..............................37

OCP Check.............................................. 38

Rack mounting

(optional)

Rack mounting kit contents.......................40

Rack mounting assembly .......................... 41

PSH User Manual

22

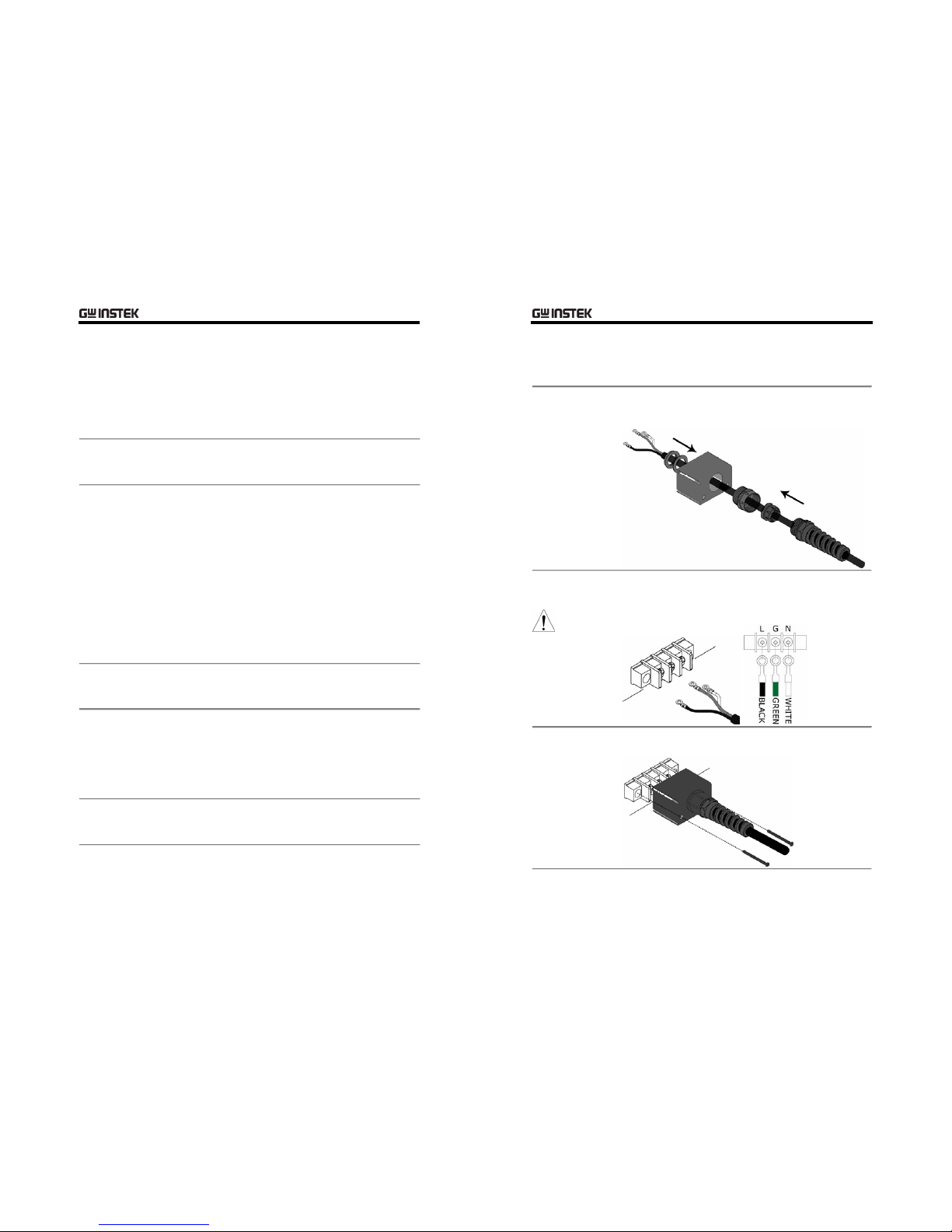

AC Power Cable Assembly

1 Cable gland +

Terminal Cover

Put the power cable through the cable gland and

the terminal cover, screw them together.

2 Cable wire +

Terminal

CAUTION

Screw the wire onto the AC input terminal. Note

the wire color: Neutral (white), GND (green), and

Line (black).

3 Terminal

cover +

Terminal

Screw the terminal cover onto the terminal.

Setup

23

AC power cable requirement

Here is the AC power cable specification, in case of using cables

other than the attached one.

Cable length

≤ 3m

Cable gland

KSS or PG-2013

Cable type

(recommended)

Model: SJT

Type: 3 x 14 AWG stranded copper

Rating: 60°C min, 300V

Diameter: 9.143~10.03 mm

Model: H05 VV-F

Type: 3G 1.5mm

2

stranded copper

Rating: 300V/500V

Diameter: 8.5 ± 0.2 mm

PSH User Manual

24

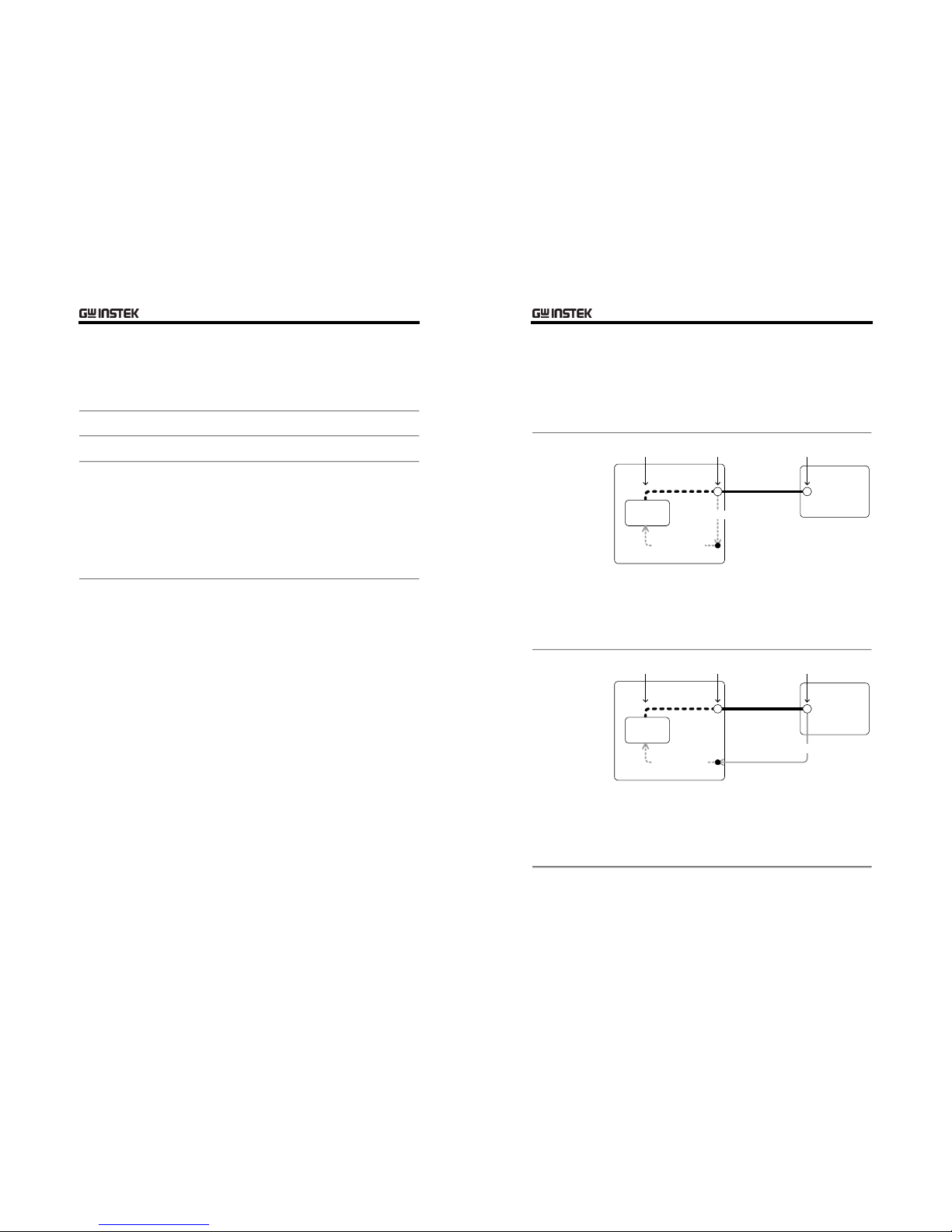

Remote Sensing and Local Sensing

Remote sensing compensates the cable loss between PSH and load,

up to 0.5V. Use remote sensing whenever the load voltage has to

be accurate.

Local Sensing

(default)

VSET = VOUT

V

OUT > VLOAD

VOUT VLOAD

VOUT

Output

Setting

VSET

|VSET–VOUT|

Sense

PSH Load

The sense terminal is internally connected to the

PSH output terminal. The delta between the

voltage setting level (V

SET) and the actual output

level (V

OUT) is compensated. The load terminal

voltage (V

LOAD) might become lower than the

output due to cable loss.

Remote

Sensing

VSET = VLOAD

VOUT > VSET

PSH Load

Sense

V

OUT VLOAD

VLOAD

Output

Setting

VSET

|VSET–VLOAD|

The sense terminal is connected to the load input

terminal. The delta between the voltage setting

level (V

SET) and the actual load voltage (VLOAD) is

compensated. The output voltage (V

OUT) might

become higher than the setting due to the

compensation.

Loading...

Loading...