Page 1

Multi-Range DC Power Supply

PSB-2000 series

User Manual

GW INSTEK PART NO. 82SB-28H00EB1

ISO-9001 CERTIFIED MANUFACTURER

Page 2

Copyright Statement

This manual contains proprietary information, which is protected by

copyright. All rights are reserved. No part of this manual may be

photocopied, reproduced or translated to another language without

prior written consent of Good Will company.

The information in this manual was correct at the time of printing.

However, Good Will continues to improve products and reserves the

rights to change specification, equipment, and maintenance

procedures at any time without notice.

Good Will Instrument Co., Ltd.

No. 7-1, Jhongsing Rd., Tucheng Dist., New Taipei City 236, Taiwan.

Page 3

Table of Contents

Table of Contents

SAFETY INSTRUCTIONS .................................................. 3

GETTING STARTED .......................................................... 7

PSB 2000 Series Overview ................................ 8

Appearance .................................................... 15

OPERATION .................................................................. 32

Connecting the AC Power Cable ...................... 32

Connecting the Load to the Output Terminals 32

Operation Ranges (PSB-2400L, 2800L, 2400L2,

2800LS) .......................................................... 41

Operation Ranges (PSB-2400H, 2800H) ......... 42

Various Settings ............................................. 43

Menu Key Functions ....................................... 50

Voltage Sense ................................................. 74

External Control Functions ............................. 76

Using the Sequence Function ......................... 86

OTHER FUNCTIONS ...................................................... 89

Display in Alarm Status .................................. 89

Frame Link Controlled Parallel Operation

(excluding PSB-2400L2) .................................. 91

Frame Link Controlled Series Operation

(excluding PSB-2400L2, PSB-H series) ........... 93

Power Extension using PSB-2800LS (Parallel

Connection Only) ........................................... 94

Using the PSB-007 Extension kits ................... 95

EXTERNAL CONTROL .................................................... 99

Remote Control .............................................. 99

Interface Connectors .................................... 100

1

Page 4

PSB-2000 Series User Manual

PSB-001 Specifications (optional) ................ 100

PSB-002 Specifications (standard) ................ 101

Connection Methods .................................... 102

Connection Cables ........................................ 104

Address Setting ............................................ 105

Using the Interface Boards ........................... 108

Communication Commands ......................... 111

Registers ...................................................... 133

APPENDIX .................................................................... 143

Trouble Shooting .......................................... 143

Maintenance ................................................. 145

Dimensions .................................................. 147

PSB-2000L Series Specifications ................... 150

PSB-2000H Series Specifications .................. 158

EC Declaration of Conformity ....................... 163

2

Page 5

SAFETY INSTRUCTIONS

WARNING

Warning: Identifies conditions or practices that

could result in injury or loss of life.

CAUTION

Caution: Identifies conditions or practices that

could result in damage to the PSB or to other

properties.

DANGER High Voltage

Attention Refer to the Manual

Protective Conductor Terminal

Earth (ground) Terminal

Do not dispose electronic equipment as unsorted

municipal waste. Please use a separate collection

facility or contact the supplier from which this

instrument was purchased.

SAFETY INSTRUCTIONS

This chapter contains important safety

instructions that you must follow during

operation and storage. Read the following before

any operation to insure your safety and to keep

the instrument in the best possible condition.

Safety Symbols

These symbols may appear in the manual or on the instrument.

3

Page 6

PSB-2000 Series User Manual

General

Guideline

CAUTION

Do not place any heavy object on the unit.

Avoid severe impact or rough handling that

leads to damaging the unit.

Do not discharge static electricity to the unit.

Do not block the cooling fan opening.

Do not perform measurements on circuits that

are directly connected to mains power.

Do not disassemble the PSB unless you are

qualified.

(Measurement categories) EN 61010-1:2010 specifies the

measurement categories and their requirements as follows. The

PSB-2000 doesn’t fall under category II, III or IV.

Measurement category IV is for measurement performed at the

source of low-voltage installation.

Measurement category III is for measurement performed in the

building installation.

Measurement category II is for measurement performed on the

circuits directly connected to the low voltage installation.

O is for measurements performed on circuits not directly

connected to Mains.

Power Supply

WARNING

AC Input voltage range: 100Vac to 240Vac,

1300VA Max

Frequency: 50Hz/60Hz

To avoid electrical shock connect the protective

grounding conductor of the AC power cord to

an earth ground.

Safety Guidelines

4

Page 7

SAFETY INSTRUCTIONS

Cleaning the

power supply

Disconnect the power cord before cleaning the

oscilloscope.

Use a soft cloth dampened in a solution of mild

detergent and water. Do not spray any liquid

into the oscilloscope.

Do not use chemicals containing harsh products

such as benzene, toluene, xylene, and acetone.

Operation

Environment

Location: Indoor, no direct sunlight, dust free,

almost non-conductive pollution (Note below)

Relative Humidity: 30% to 80% (no dew or

condensation)

Altitude: < 2000m

Temperature: 0°C to 40°C

(Pollution Degree) EN 61010-1:2010 specifies pollution degrees

and their requirements as follows. The PSB falls under degree 2.

Pollution refers to “addition of foreign matter, solid, liquid, or

gaseous (ionized gases), that may produce a reduction of dielectric

strength or surface resistivity”.

Pollution degree 1: No pollution or only dry, non-conductive

pollution occurs. The pollution has no influence.

Pollution degree 2: Normally only non-conductive pollution

occurs. Occasionally, however, a temporary conductivity caused

by condensation must be expected.

Pollution degree 3: Conductive pollution occurs, or dry, non-

conductive pollution occurs which becomes conductive due to

condensation which is expected. In such conditions, equipment

is normally protected against exposure to direct sunlight,

precipitation, and full wind pressure, but neither temperature

nor humidity is controlled.

Storage

environment

Location: Indoor

Relative Humidity: 30% to 70% (no dew or

conensation)

Temperature: -20°C to 70°C

5

Page 8

PSB-2000 Series User Manual

Green/ Yellow:

Earth

Blue:

Neutral

Brown:

Live (Phase)

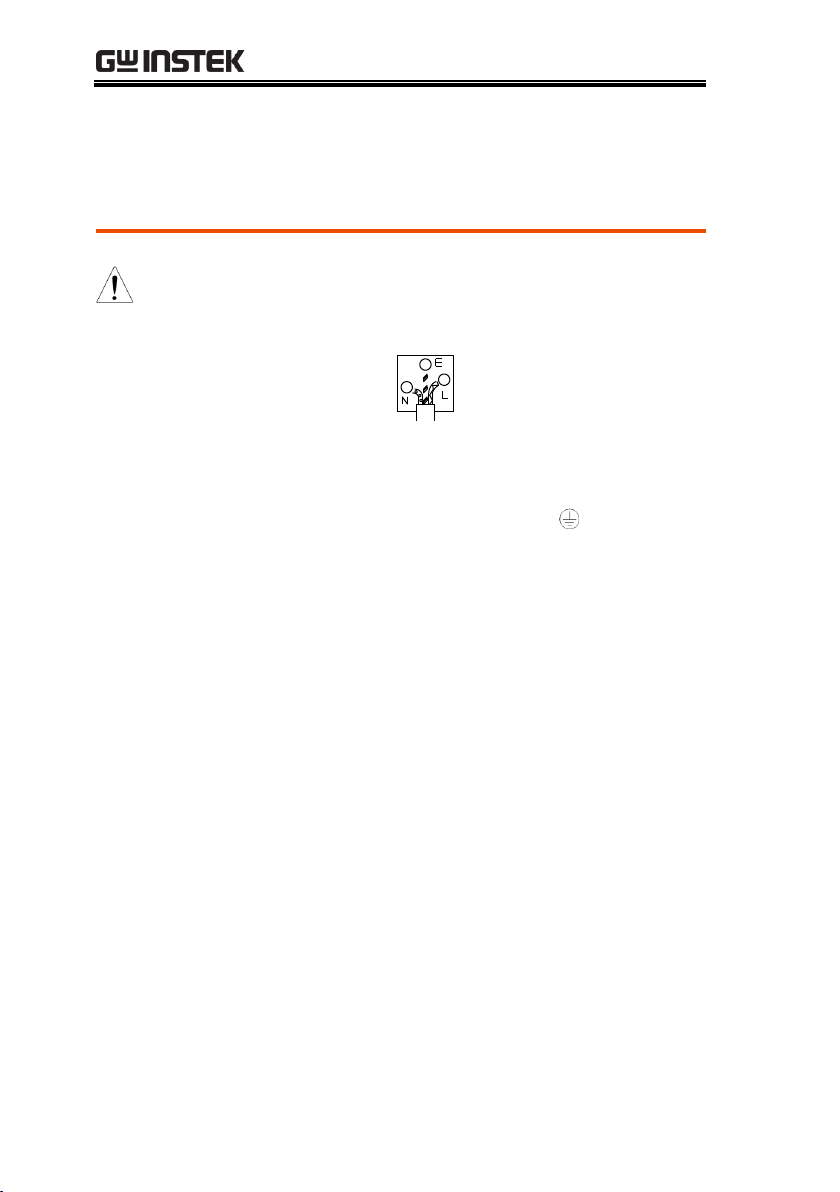

Power cord for the United Kingdom

When using the power supply in the United Kingdom, make sure

the power cord meets the following safety instructions.

NOTE: This lead/appliance must only be wired by competent persons

WARNING: THIS APPLIANCE MUST BE EARTHED

IMPORTANT: The wires in this lead are coloured in accordance with the

following code:

As the colours of the wires in main leads may not correspond with the

coloured marking identified in your plug/appliance, proceed as follows:

The wire which is coloured Green & Yellow must be connected to the Earth

terminal marked with either the letter E, the earth symbol or coloured

Green/Green & Yellow.

The wire which is coloured Blue must be connected to the terminal which

is marked with the letter N or coloured Blue or Black.

The wire which is coloured Brown must be connected to the terminal

marked with the letter L or P or coloured Brown or Red.

If in doubt, consult the instructions provided with the equipment or

contact the supplier.

This cable/appliance should be protected by a suitably rated and approved

HBC mains fuse: refer to the rating information on the equipment and/or

user instructions for details. As a guide, a cable of 0.75mm2 should be

protected by a 3A or 5A fuse. Larger conductors would normally require

13A types, depending on the connection method used.

Any exposed wiring from a cable, plug or connection that is engaged in a

live socket is extremely hazardous. If a cable or plug is deemed hazardous,

turn off the mains power and remove the cable, any fuses and fuse

assemblies. All hazardous wiring must be immediately destroyed and

replaced in accordance to the above standard.

6

Page 9

GETTING STARTED

GETTING STARTED

The PSB series are variable output, highperformance, regulated, switching DC power

supplies. They incorporate a high-frequency

current suppression circuit and accept input

voltages rated from AC100V to 240V without the

need to switch inputs. The offer a wide voltage

and current range within their maximum rated

power envelope. They also have a variable

constant power function. They have standard

features such as voltage and current settings, an

output on/off switch, monitor outputs and other

functions via external connectors. The chasis is

smaller overall than traditional power supplies to

reduce the total work area. The dual channel

model and the booster unit extend the series to

cover a wider range of applications. The PSB series

are also able to execute sequence programs that

are written using the optional interface boards.

The optional interface boards also allow you to

control the PSB series remotely from a PC using

GPIB, RS232C or USB.

7

Page 10

PSB-2000 Series User Manual

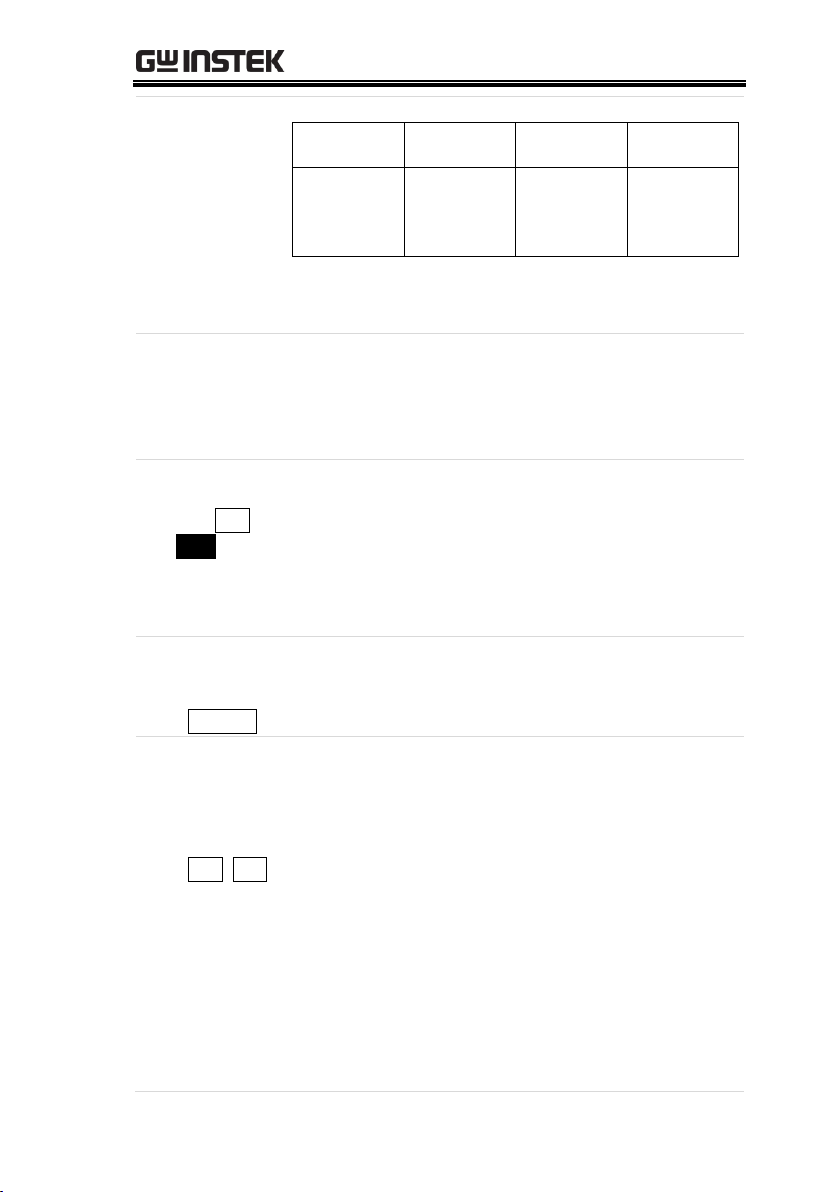

Product name

Voltage range

Current range

Power range

PSB-2400H

0V to 800V

0A to 3A

0W to 400W

PSB-2800H

0V to 800V

0A to 6A

0W to 800W

PSB-2400L

0V to 80V

0A to 40A

10W to 400W

PSB-2800L

0V to 80V

0A to 80A

10W to 800W

PSB-2400L2 (Dual

channel type)

0V to 80V

×2CH

0A to 40A

×2CH

10W to 400W

×2CH

PSB-2800LS

(Booster unit)

0V to 80V

0A to 80A

10W to 800W

Product name

PSB-2400L

(CE)

PSB-2800L

(CE)

PSB-2400L2

(CE)

PSB-2800LS

(CE)

PSB-2400H

(Non-CE)

PSB-2800H

(Non-CE)

PSB 2000 Series Overview

Series line up

CE Mark

8

Page 11

GETTING STARTED

■ 400W Type

PSB-2400L

■ 800W Type

PSB-2800L

■ 400W×2-Channel Type

PSB-2400L2

■ 800W Type

Booster unit

PSB-2800LS

■ 400W Type

PSB-2400H

■ 800W Type

PSB-2800H

9

Page 12

PSB-2000 Series User Manual

Multi-Range

Output

Capable of a wide-range of voltage and current

settings within the rated power envelope.

Constant-Power

Control

Provides constant-power (CP) control in addition to

constant-voltage (CV) and constant-current (CC)

controls.

Power Factor

Correction Circuit

A built-in power factor correction circuit ensures

compatibility to a wide AC input voltage range from

AC100V to 240V without the need to use a switch. It

also suppresses harmonic current.

Rotatable Front

Panel Controls

The front panel can be rotated by 90 degrees to allow

the unit to be operated horizontally or vertically.

Output Off Timer

Function

Turns the output off automatically after a preset

amount of time has elapsed. This can be used to

prevent the output from being left on inadvertently or

to prevent over-charging.

Sequence (SEQ)

Function

The Sequence function executes data read from a PC

through one of the optional interface boards (PSB001 and PSB-002). There are two operation modes for

the sequence function: Manual mode (for step by

step execution) and automatic mode (for automatic

execution of up to 99 steps and 999 cycles).

Protective

Functions

The power supplies have a number of protection

functions. OVP, OCP and OHP. OVP and OCP

protection can be set on the front panel.

Preset Functions

(Three Settings)

Pressing a preset key directly selects a preset setting,

which is set in advance.

Main Features

10

Page 13

GETTING STARTED

Single Unit

Control of

Parallel/Series

Operation

The PSB-L series uses a single power supply unit

(acting as the master unit) to control all connected

slave units for series or parallel operation. In parallel,

up to 4 units can be controlled (including the master)

to increase the total power. In series, a maximum of 2

units (including the master) can be used.

External Control

Function

The external control function allows external voltage

and restistance-based control, voltage and current

monitoring, output on/off control, alarm output and

CV/CC status output.

Interface Boards

There are two optional interface boards for remote

control.

PSB-001: GPIB and local bus board.

PSB-002: RS-232C, USB and local bus board.

Note also that one of these options must be used to

program sequences for the PSB-L series. See page 86

for further details.

Dual Channel

Model

(PSB-2400L2)

Equipped with two 400W output channels for a

wide variety of applications.

Delay (DLY)

Function:

(PSB-2400L2

Only)

The delay function introduces a switching delay

between channel 1 and 2. The delay function can set

a rising delay (the time to turn on) and a falling delay

(the time to turn off).

Tracking

Function:

(PSB-2400L2

Only)

The channel 2 setting is made equal to that of

channel 1 when the tracking function is activated.

Thereafter, both channels change synchronously.

11

Page 14

PSB-2000 Series User Manual

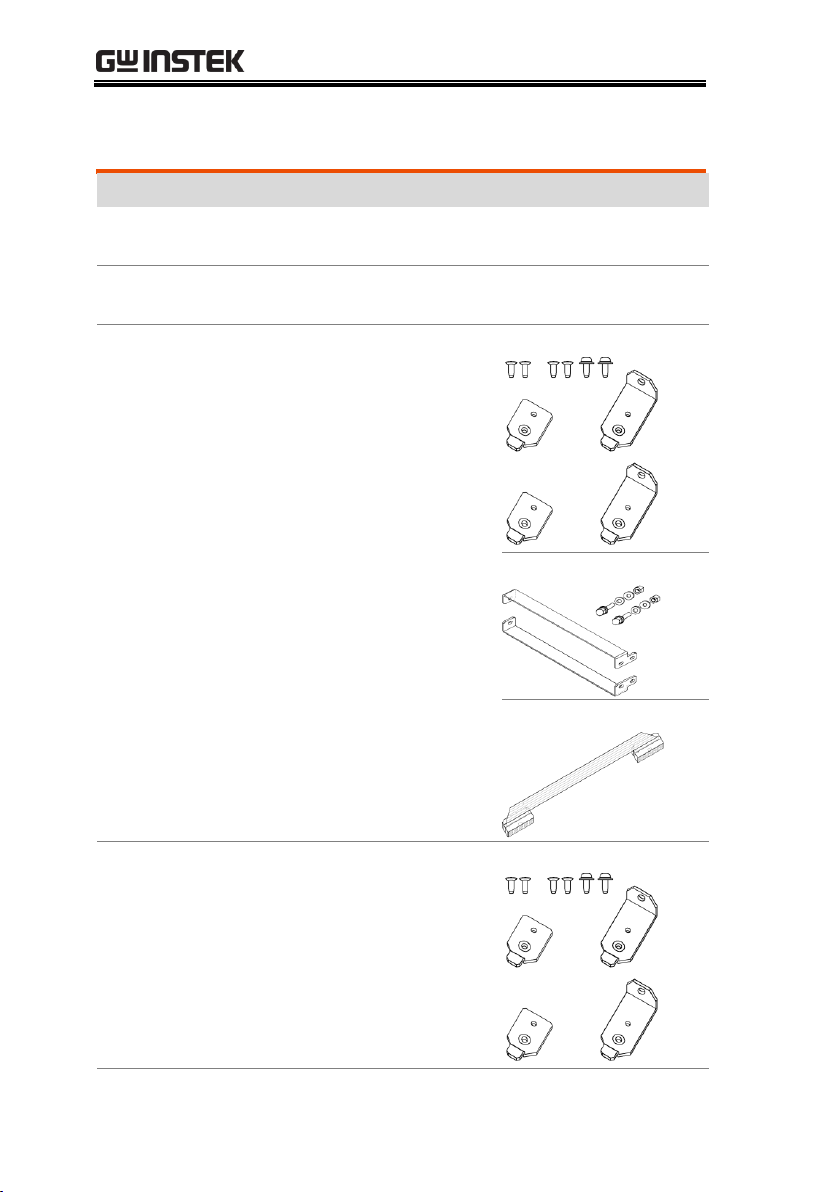

Model Number

Description

PSB-001

GPIB Control Board. Includes GRJ-1101 modular

cables. For further details, see page 100.

PSB-002

RS-232C/USB Control Board. Includes GRJ-1101

modular cables. For further details, see page 101.

PSB-003

Parallel Connection Kit for

Horizontal Installation.

Kit includes: PSB-007 Joint

kit, Horizontal bus bar x2,

PSB-005 x1.

PSB-007 Joint Kit

Horizontal Bus Bar

PSB-005

PSB-004

Parallel Connection Kit for

Vertical Installation.

Kit includes: PSB-007 Joint

kit, Verical bus bar x2, PSB005 x1.

PSB-007 Joint Kit

Accessories

12

Page 15

GETTING STARTED

Vertical Bus Bar

PSB-005

PSB-005

Parallel Connection Signal

Cable

PSB-006

Serial Connection Signal

Cable

PSB-007

Joint Kit:

Includes 4 joining plates, 4X

M3x6 screws, 2X M3x8

screws.

PSB-008

RS-232C Cable

GRJ-1101

Modular Cables: 500mm

6P6C RJ11 (local bus cables)

13

Page 16

PSB-2000 Series User Manual

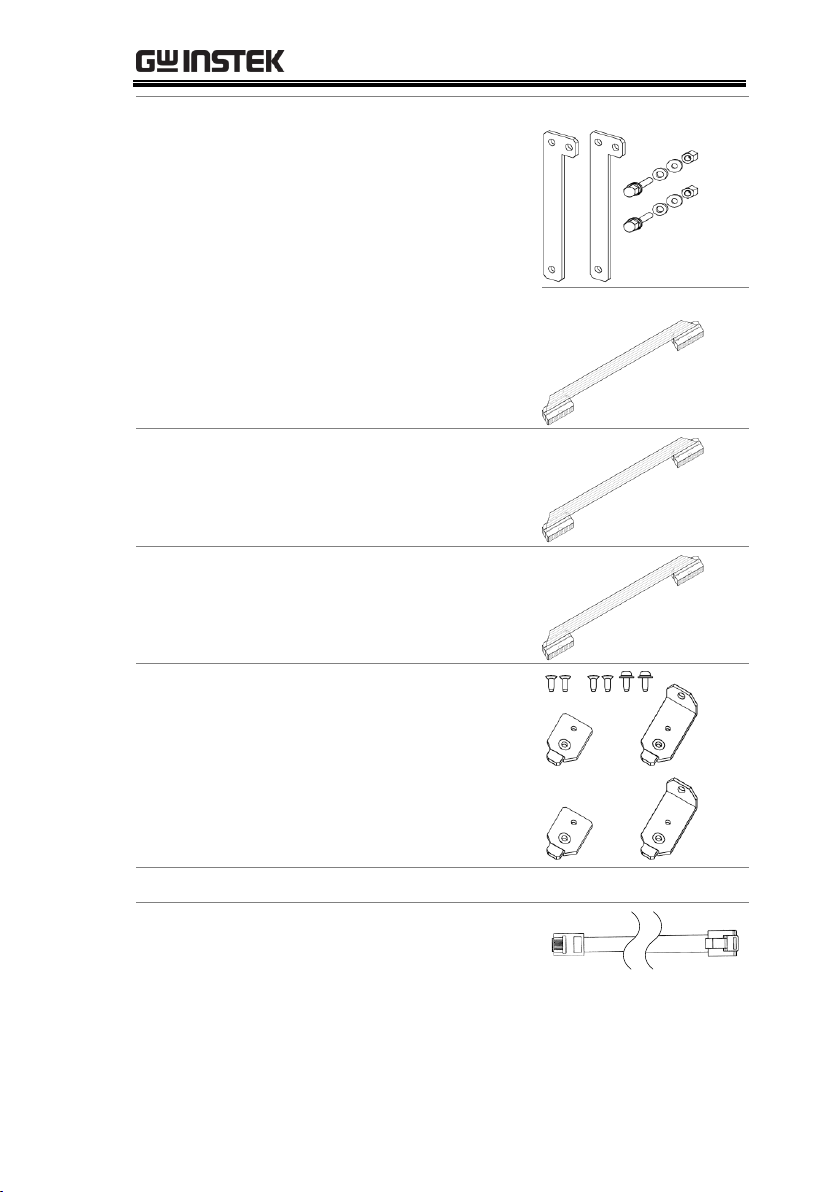

Model Number

Description

User Manual CD x 1

AC power cable x 1

Screws for output terminals on rear panel

Protection covers for output terminals on rear panel

Protection caps for output terminals on the front

panel

External control connector (26-pin)

GND cable

Standard Accessories

14

Page 17

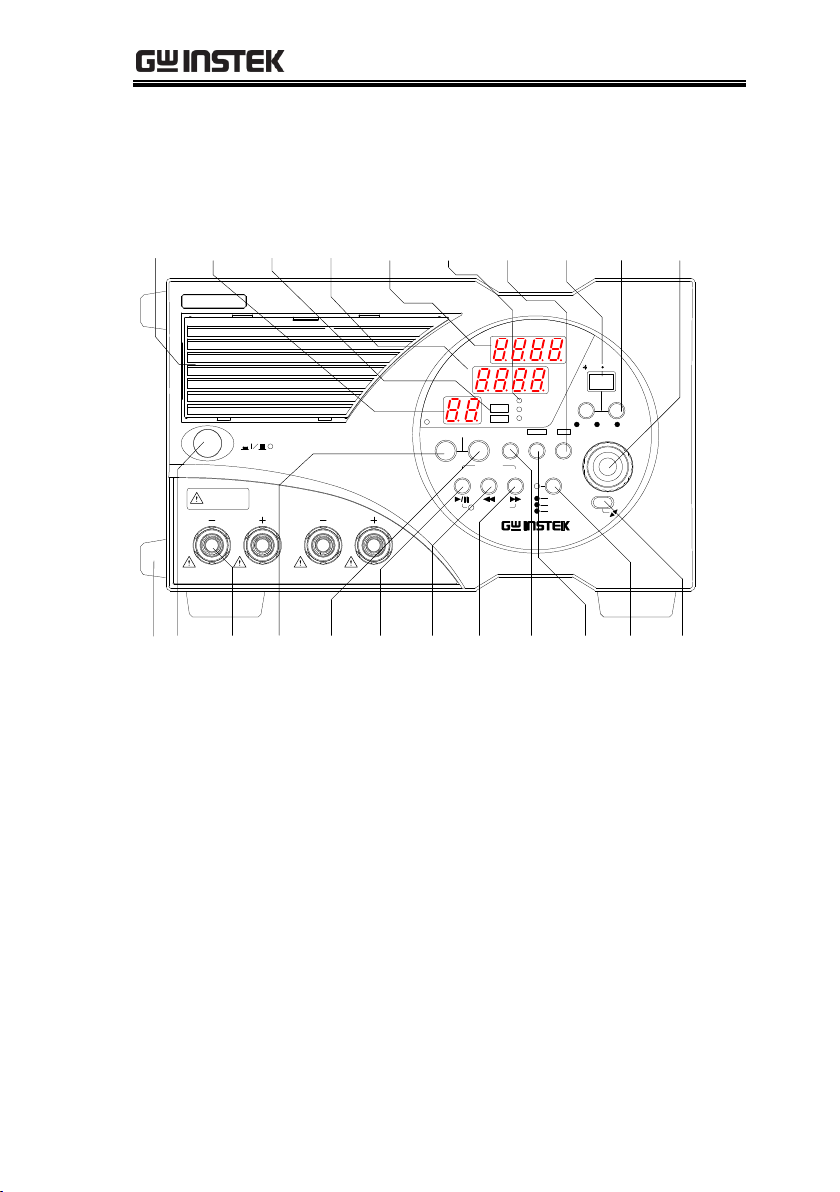

GETTING STARTED

2 3 4 14 15 16 17 18 19 20 21 22

POWER

CHECK

ENTER

REMOTE

FAST

LOCK

Hi -

W

V A

CV

MENU

SEQUENCE

PRESET

321

FAST/LOCK(3s)

/LOCAL

OUTPUT

OFF TIMER

DISP

ESCMENU

W

CC CP

A

W

R

O

T

A

T

E

V

W

Multi- Range DC Power Supply

DELAY

CH 2

CH 2

CH 1

DISP

CH 1

( L Type ONLY)

CH A

MAX 400W

MAX DC 80V

MAX DC 40A

CH B

PSB-2400L2

ON / OFF

1 5 6 7 8 9 10 11 12 13

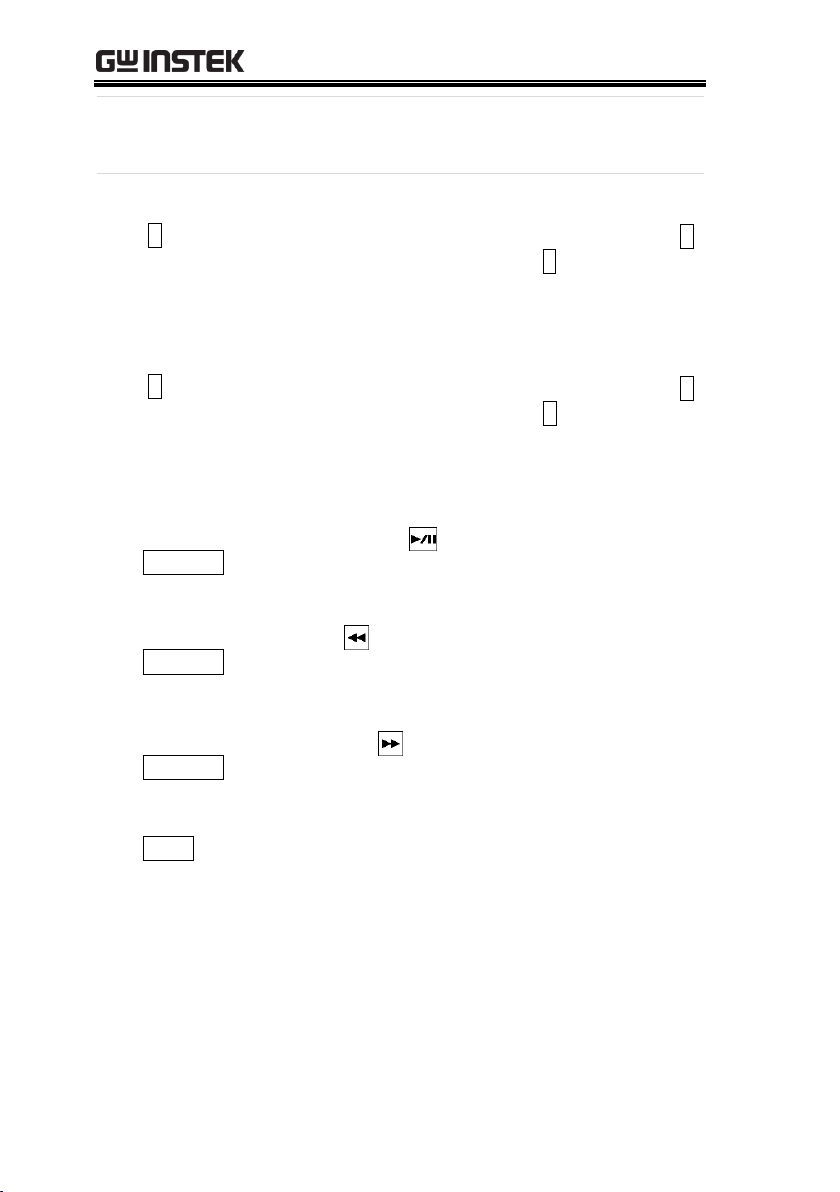

Appearance

Front Panel (PSB-2400L2 shown)

15

Page 18

PSB-2000 Series User Manual

1 5 6 7 8 9 10 11 12 13

2 3 4 14 15 16 17 18 19 20 21 22

POWER

CAUTION

MAX 400W

MAX DC 800V

MAX DC 3A

PSB - 2400 H

CHECK

ENTER

REMOTE

FAST

LOCK

Hi -

W

V A

CV

MENU

SEQUENCE

PRESET

321

FAST/LOCK(3s)

/LOCAL

OUTPUT

OFF TIMER

DISP

ESCMENU

W

CC CP

A

W

R

O

T

A

T

E

V

(

L Type ONLY

)

W

Regulated DC Power Supply

ON / OFF

PSB-2800LS

Multi-Range DC Power Supply

2 1

Front Panel (PSB-2400H shown)

Front Panel (PSB-2800LS)

16

Page 19

GETTING STARTED

Item

Description

1

Front grill

This is a ventilation grill for for cooling the

internal circuits. It is detachable and has a dust

filter inside. Clean the filter periodically. See page

143.

2

Rubber feet

Detachable. If the unit is mounted in a rack and

the feet are not needed, they may be removed.

3

POWER

ON/OFF

switch

Depress the switch to the (I) position to turn on

the power supply unit. Press it again to turn off

the unit.

4

Front output

terminals

Output is supplied through these terminals. The

maximum current is 3A(2400H) or 6A(2800H),

40A(2400L, 2400L2), 80A(2800L, 2800LS). The

40A/80A models use screw-type terminals. The

3A/6A models use European-type jack terminals.

17

Page 20

PSB-2000 Series User Manual

PSB-2400L, PSB-2800L

PSB-2400H, PSB-2800H

PSB- 2400L2

Type

Description

5

Address no.,

Step no.,

cycle no.,

Menu no.

Normal

operation

Sequence

operation

Menu

Tracking

Not

displayed.

Number of

steps or

cycles is

displayed.

Menu No. is

displayed.

“Ab” is

displayed.

6

Channel

LEDs

The LED of the selected channel is lit. Both LEDs

are lit when the tracking function is activated.

7

Current LED

(7-segment)

Normal

operation

Sequence

operation

Menu

Alarm

Current or

power is

displayed.

Step No. is

displayed.

Set item is

displayed.

OVP, OCP,

HARD or

OHP is

displayed.

The “W” LED on the right of the 7-segment LED

is lit in the power display state.

Panel Operation Unit

18

Page 21

GETTING STARTED

8

Voltage LED

(7-segment)

Normal

operation

Sequence

operation

Menu

Alarm

Voltage or

power is

displayed.

Cycle No. is

displayed.

Set parameter

is displayed.

OVP, OCP,

HARD or

OHP is

displayed.

The “W” LED on the right of the 7-segment LED

is lit in the power display state.

9

Function

LEDs

These LEDs display the On/Off state of the OFF

TIMER, DELAY or HiΩ functions. The LED is lit

green when the corresponding function is

activated.

10

ESC/DISP

key (ESC /

DISP)

Changes the channel display, sequence operation

display (i.e., step No. and cycle No.), remaining

time for the off-timer and other displays. When

the menu is displayed, pressing it exits the

function selection mode and returns to the normal

mode.

11

OUTPUT key

(red)

( OUTPUT )

This key turns on or off the output. The LED is lit

when the output is turned on.

12

CH1 and

CH2 keys

(red, green,

orange)

( CH1 , CH2 )

These keys turn on or off the channel outputs. The

color of the corresponding LED indicates the

output mode.

Green: CV mode.

Red: CC mode.

Orange: CP mode.

The CH1 and CH2 keys are only available for the

PSB-2400L2 only. The PSB-2400L and PSB-2800L

have single LEDs only.

19

Page 22

PSB-2000 Series User Manual

13

Rotary

encoder

Used to select the functions and change the

values.

14

V key (green)

( V )

Used for setting the voltage. Press the key and

rotate the encoder to change the set value. If the A

key is pressed while holding the V key, both LEDs

are lit and the Current LED enters the power

display mode.

15

A key (green)

( A )

Used for setting the current. Press the key and

rotate the encoder to change the set value. If the V

key is pressed while holding the A key, both LEDs

are lit and the Voltage LED enters the power

display mode.

16

PRESET 1

key (green)

(PRESET 1 )

Reads out data stored in PRESET 1. Serves as a

start/pause key ( ) in the sequence mode.

17

PRESET 2

key (green)

(PRESET 2 )

Reads out data stored in PRESET 2. Serves as a

back key ( ) to a skip to previous step number

in the sequence mode.

18

PRESET 3

key (green)

(PRESET 3 )

Reads out data stored in PRESET 3. Serves as a

forward key ( ) to skip to the next step number

in the sequence mode.

19

MENU key

(MENU )

Used for setting and selecting various functions.

20

Page 23

GETTING STARTED

20

ENTER/

CHECK Key

(ENTER /

CHECK)

Alternates the operation (and display) between

the output value and the set value.

When the output is on, every press of the ENTER /

CHECK key alternates the display between the

output value and set value.

・ When the V key is lit The voltage setting is

enabled.

・ When the A key is lit The current setting is

enabled.

・ When the V and A keys are lit the power

setting is

enabled.

When the menu is displayed, press this key to

validate functions and values in the menu.

21

FAST/LOCK

(3s)/LOCAL

key(FAST )

Changes the resolution of the voltage, current or

power settings, locks panel operation, or switches

the remote mode into the local mode. The color of

the LED indicates the current status.

FAST (green): The setting resolution is 1V,

1A or 100W.

LOCK (3s) (red): Operations on the front

panel are disabled.

REMOTE (orange): Lit during communication

through the optional

interface boards.

22

ROTATE key

The operating panel of the PSB-2000 series can be

rotated 90 degrees so that the unit can be used in

the horizontal or vertical position. Hold the

encoder and rotate the panel operation unit while

holding the key.

21

Page 24

PSB-2000 Series User Manual

PSB-002

LOCAL BUS

I I IUSB

J3

EXT CONT

▲

J2

△

AC INPUT

1

2 26

25

CH 2

CH 1

J1

MADE IN TAIWAN

~100V-240V

50Hz / 60Hz

650 VA MAX

MAX 400W

MAX DC 80V

MAX DC 40A

!

OUTPUT

DC

MAX 400W

MAX DC 80V

MAX DC 40A

!

OUTPUT

DC

!

23 24 25 26 27 28 29 30 31

J3

EXT CONT

▲

J2

△

AC INPUT

1

2 26

25

CH 1

J1

MADE IN TAIWAN

PSB-001

LOCAL BUS GP-IB

~100V-240V

50Hz / 60Hz

650 VA MAX

MAX 400W

MAX DC 80V

MAX DC 40A

!

OUTPUT

DC

!

23 24 25 26 27 28 29 30 31

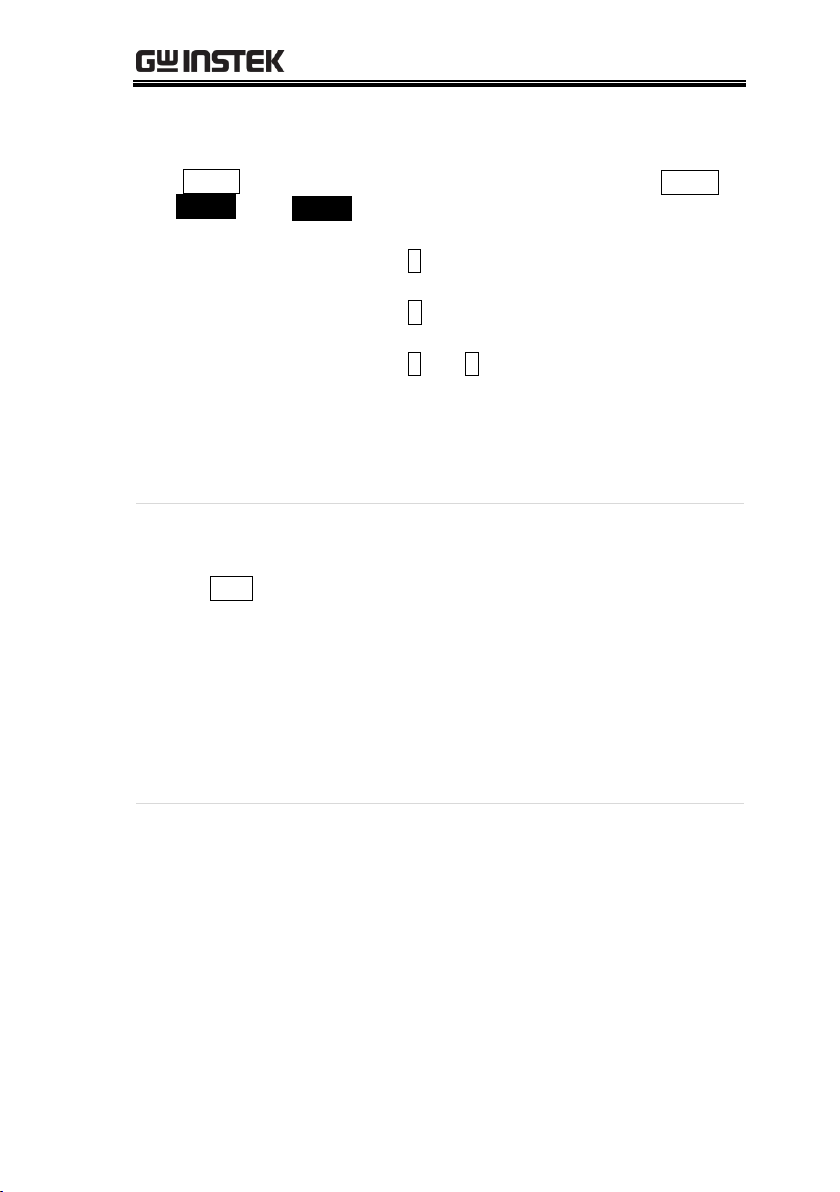

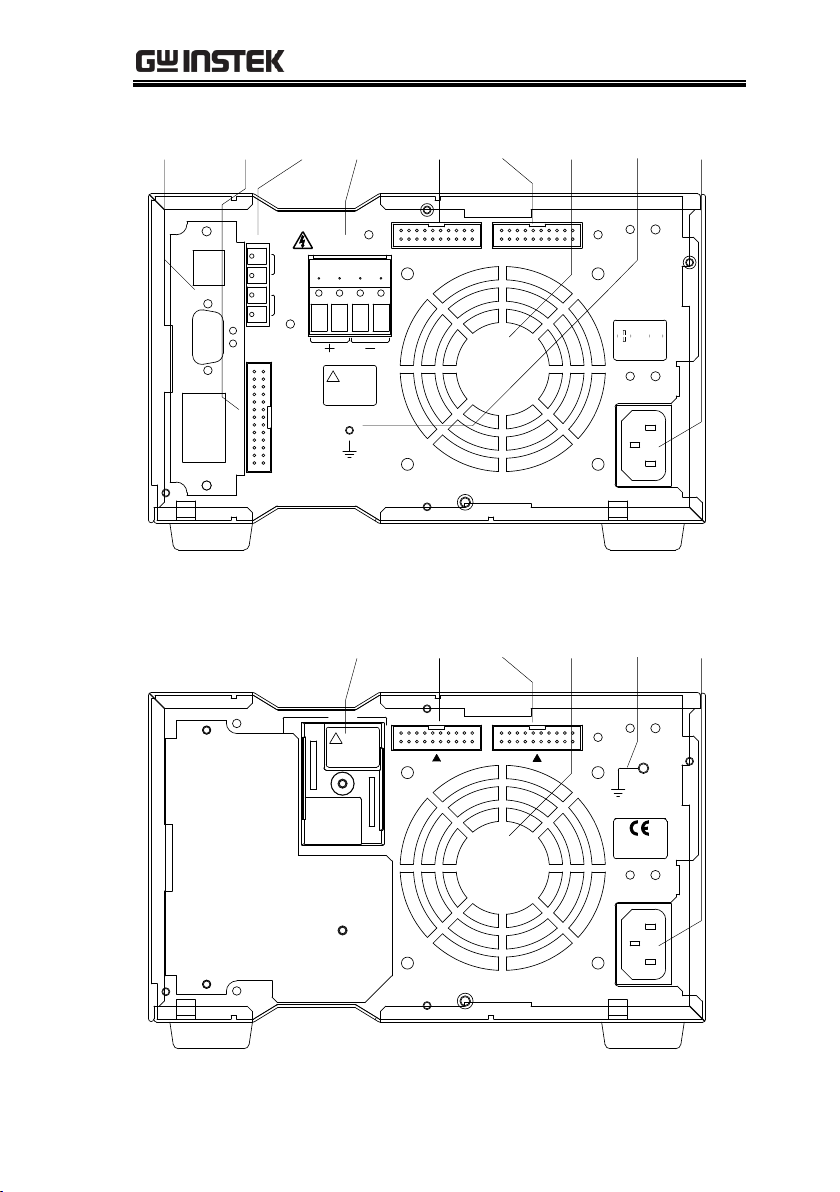

Rear Panel (PSB-2400L2)

Rear Panel (PSB-2400L/PSB-2800L)

22

Page 25

GETTING STARTED

23 24 25 26 27 28 29 30 31

PSB-002

LOCAL BUS

I I IUSB

2

1

EXT CONT

J3

26

J1 J2

AC INPUT

△

25

MADE IN TAIWAN

DC

OUTPUT

!

MAX DC 3A

MAX DC 800V

MAX 400W

+ +S

CAUTION

-S -

!

J2

△

AC INPUT

CH 1

J1

MADE IN TAIWAN

~100V-240V

50Hz / 60Hz

650 VA MAX

MAX 400W

MAX DC 80V

MAX DC 40A

!

OUTPUT

DC

!

26 27 28 29 30 31

Rear Panel (PSB-2800H)

Rear Panel (PSB-2800LS)

23

Page 26

PSB-2000 Series User Manual

Description

23

Optional

Interface

board slot

The optional interface board slot is used to install

the optional PSB-001 board for the GPIB interface.

The product is supplied with the USB/RS-232C

option as standard.

24

J3 external

control

connector

The external control connector is used to control

or monitor a number of different parameters

using external components. The pin assignment

of this connector can be found on page 26(40A

models) 30(3A/6A models).

25

Sensing

terminals

The sensing terminals are used to change the

sensing point. These terminals are short-circuited

before shipment to select internal sensing.

26

Rear output

terminals

The Output of the PSB-2000 series power supply

unit is also output through these terminals. The

type of rear panel output terminal varies

depending on the model. The PSB-2400H and

PSB-2800H use pin terminals and the PSB-L

models use crimp style voltages designed to

accommodate higher current.

For the PSB-2400L2 (dual channel model), the

channel 1 terminal block is in the upper part

(CH1) and the channel 2 terminal block is in the

lower part (CH2) of the rear panel when the unit

is viewed from the back. On each terminal block,

the positive (+) terminal is on the left and the

negative (-) terminal is on the right when the

unit is viewed from the back. Connect either

output terminal to the screw marked with the

ground signal if it needs to be grounded with

the chassis.

24

Page 27

GETTING STARTED

27

J1 control

signal input

connector

This connector is used for parallel and serial

control for master/slave operation. The optional

frame link cables must be used with this

connector.

28

J2 control

signal output

connector

This connector is used for parallel and serial

control for master/slave operation. The optional

framelink cables must be used with this

connector.

29

Exhaust Grill

Air taken into the unit from the front is blown out

through this grill. Leave a gap of a least 30cm or

more behind the rear panel for good ventilation.

If there is an object obstructing the rear panel, the

temperature inside the power supply unit may

rise excessively.

30

Functional

ground

terminal

The unit can be grounded using this terminal

31

AC INPUT

Connect the AC power cable supplied with the

unit with this plug receptacle and supply AC

power to the unit.

25

Page 28

PSB-2000 Series User Manual

Pin No.

Signal name

Function

1

CH2 STATUS COM

(COM for 2, 3 & 4)

COM for pins 2, 3 and 4.

2

CH2 ALARM OUT

Open collector output. When the alarm

is output for channel 2 then this pin is

pulled low.

3

CH2 EXT CC

STATUS OUT

Open collector output. Set to the low

level when channel 2 is in CC mode.

4

CH2 EXT CV

STATUS OUT

Open collector output. Set to the low

level when channel 2 is in CV mode.

5

CH2 EXT CV

CONTROL IN

Constant-voltage control input pin for

channel 2.

In the external voltage control mode, an

external voltage of 0V to 10V can be

used to control the output voltage from

0V to the rated output voltage.

In the external resistance control mode,

an external resistance of 0kΩ to 10kΩ

can be used to control the output

voltage from 0V to the rated output

voltage.

Pin assignment of the J3 External Control Connector

(PSB-2400L, 2800L, 2400L2, 2800LS)

26

Page 29

GETTING STARTED

6

CH2 EXT CC

CONTROL IN

Constant-current control input pin for

channel 2.

In the external voltage control mode, an

external voltage of 0V to 10V can be

used to control the ouput current from

0A to the rated output current.

In the external resistance control mode,

an external reistance of 0kΩ to 10kΩ can

be used to control the output current

from 0A to the rated output current.

7

CH2 COM

COM pin for channel 2.

Connected to the negative output

terminal of channel 2.

8

CH2 EXT V MON

OUT

Output voltage monitor pin for channel

2.

Outputs a voltage of approximately 0V

to 10V to represent 0V to the rated

output voltage.

9

CH2 EXT A MON

OUT

Output current monitor pin for channel

2.

Outputs a voltage of approximately 0V

to 10V to represent 0A to the rated

output current.

10

CH2 COM

COM pin for channel 2. Connected with

the negative output terminal of channel

2.

11

CH2 EXT ALARM

IN

Causes the alarm state to be triggered

when short-circuited with the CH2

COM pin.

12

CH2 EXT OUTPUT

IN

This pin turns the CH2 output on when

it is shorted to the CH2 COM pin.

27

Page 30

PSB-2000 Series User Manual

13

CH2 COM

COM pin for channel 2. Connected with

the negative output terminal of channel

2.

14

CH1 EXT CV

CONTROL IN

Constant-voltage control input pin for

the channel 1.

In the external voltage control mode, an

external voltage of 0V to 10V can be

used to control the output voltage from

0V to the rated output voltage.

In the external resistance control mode,

an external resistance of 0kΩ to 10kΩ

can be used to control the output

voltage from 0V to the rated output

voltage.

15

CH1 EXT CC

CONTROL IN

Constant-current control input pin for

channel 1.

In the external voltage control mode, an

external voltage of 0V to 10V can be

used to control the ouput current from

0A to the rated output current.

In the external resistance control mode,

an external reistance of 0kΩ to 10kΩ can

be used to control the output current

from 0A to the rated output current.

16

CH1 COM

COM pin for channel 1.

Connected with the negative output

terminal of channel 1.

17

CH1 EXT V MON

OUT

Output voltage monitor pin for channel

1.

Outputs approx. 0V to 10V to represent

0V to the rated output voltage.

28

Page 31

GETTING STARTED

18

CH1 EXT A MON

OUT

Output current monitor pin for channel

1.

Outputs approx. 0V to 10V to represent

0 to the rated output current.

19

CH1 COM

COM pin for channel 1.

Connected with the negative output

terminal of channel 1.

20

CH1 EXT ALARM

IN

Causes the alarm state to be triggered

when short-circuited with the CH1

COM pin.

21

CH1 EXT OUTPUT

IN

Turns on the CH1 output when shortcircuited with the CH1 COM pin.

22

CH1 COM

COM pin for channel 1.

Connected with the negative output

terminal of channel 1.

23

CH1 EXT CV

STATUS OUT

Open collector output. Set to the low

level when channel 1 is in CV mode.

24

CH1 EXT CC

STATUS OUT

Open collector output. Set to the low

level when channel 1 is in CC mode.

25

CH1 ALARM OUT

Open collector output. Set to the low

level when channel 1 is in the alarm

mode.

26

CH1 STATUS COM

(COM of 23, 24 &

25)

COM for pins 23, 24 and 25.

29

Page 32

PSB-2000 Series User Manual

Pin No.

Signal name

Function

13

NC

14

EXT CV CONTROL

IN

Constant-voltage control input pin.

In the external voltage control mode, an

external voltage of 0V to 10V can be

used to control the output voltage from

0V to 800V.

In the external resistance control mode,

an external resistance of 0kΩ to 10kΩ

can be used to control the output

voltage from 0V to 800V.

15

EXT CC CONTROL

IN

Constant-current control input pin.

In external voltage control mode, an

external voltage of 0V to 10V can be

used to control the output current from

0A to 3A(2400H) or 6A(2800H).

In the external resistance control mode,

an external resistance of 0kΩ to 10kΩ

can be used to control the output

current from 0A to 3A(2400H) or

6A(2800H).

16

COM

COM

Connected with the negative output

terminal.

17

EXT V MON OUT

Output voltage monitor pin.

Outputs approx. 0V to 10V to represent

the output voltage from 0V to 800V.

Pin assignment of J3 external control connector (PSB-2400H,

2800H)

30

Page 33

GETTING STARTED

18

EXT A MON OUT

Output current monitor pin

Outputs approx. 0V to 10V to represent

the outuput current from 0A to

3A(2400H) or 6A(2800H).

19

COM

COM

Connected with the negative output

terminal.

20

EXT ALARM IN

Trigger the alarm state when shortcircuited with the COM pin.

21

EXT OUTPUT IN

Turns on the output when shortcircuited with the COM pin.

22

COM

COM

Connected with the negative output

terminal.

23

EXT CV STATUS

OUT

Open collector output. Set to the low

level when the channel is in CV mode.

24

EXT CC STATUS

OUT

Open collector output. Set to the low

level when the channel is in CC mode.

25

ALARM OUT

Open collector output. Set to the low

level when the channel is in the alarm

mode.

26

STATUS COM

COM for pins 23, 24 and 25.

31

Page 34

PSB-2000 Series User Manual

Introduction

Make sure that the power source is shut off.

Use the AC power cable supplied with the

product.

Plug the connector of the AC power cable into

the AC INPUT receptacle on the rear panel.

Introduction

Use cables with a rated voltage that exceeds the

grounding voltage (500V) for the load.

The front output terminals and rear output

terminals are electrically connected internally.

When the front output terminals are used, the rear

output terminals are also active. Put the protective

covers supplied with the product on the rear

output terminals to avoid electrocution.

CAUTION

Make sure that the load is only connected when

the POWER switch is off.

To connect a load, use cables that have a large

enough current capacity for the rated output and

OPERATION

This chapter describes the start up procedures

and the preparation that is necessary before

operating the DC power supply.

Connecting the AC Power Cable

Connecting the Load to the Output

Terminals

32

Page 35

OPERATION

current in order to prevent a fire.

The current capacity of the cables should be higher

still if the cables are twisted to reduce noise or to

avoid malfunctioning.

Be careful of the

temperature!

Procedure

1. Remove the AC cable from the AC INPUT.

2. Connect crimped lug terminals to the ends of

the load cables. Tighten the lug terminals

firmly using the nuts supplied with the power

supply.

CAUTION

The rear output terminals have M6 holes and M3

(tapped) holes.

Be sure to use the M6 holes to connect the load.

Noise at the load end may be reduced by twisting

the load cables or connecting a film capacitor

(several μF, low-impedance, high-frequency) and

an electrolytic capacitor (several hundred μF) to

the load end.

Connecting to the Rear Output Terminals (PSB-2400L,

2800L, 2400L2, 2800LS)

33

Page 36

PSB-2000 Series User Manual

Fig. Connection

with Rear Output

Terminals

Bolt (M6)

Washer

Nut

Terminal block

Output terminal bar

Note

Connect the cables using the bolts supplied with the

power supply as shown above. If different bolts are

used, they may contact the protective cover or

interfere with the protective cover. The lug

terminals must be on the outside of the output

terminals.

3. Connect the positive or negative output terminal

to the GND screw with the symbol using the

GND cable supplied with the product as the

necessity requires.

Note

The negative potential of the external voltage

control pin is the same as that of the negative output

terminal. If the power supply unit is grounded at

the positive terminal and the power source for

external control is grounded at the negative

terminal, the load cables for external voltage control

will short-circuit the output of the power supply

unit, which could damage the unit. In this situation,

make sure the external voltage control source is

floating with respect to the output terminals.

34

Page 37

OPERATION

Fig. Positive

Grounding

Connection

Connect with this screw

4. Sandwich the output terminals and the load

cables from above and below with the rear

output terminal protective covers, as shown

below. Drive the screw into the protective

covers at the center.

Fig. Attaching

Rear Output

Terminal

Protective Covers

CAUTION

Make sure that the protection covers are always

attached to the terminals even when they are not

being used.

The front and rear output terminals are

electrically connected internally. Touching a

terminal that is not protected may induce an

electric shock.

35

Page 38

PSB-2000 Series User Manual

The rear output terminals have M6 holes and M3

(tapped) holes. Be sure to use the M6 holes to

connect the load. Noise at the load end may be

reduced by twisting the load cables or connecting

a film capacitor (high-frequency, low-impedance

(several μF) and an electrolytic capacitor (several

hundred μF) to the load end.

5. Cut the shaded parts shown below with cutting

pliers or the like to connect the power supplies

in series or in parallel or to ground the output.

Fig. Parts to be

cut

Procedure

1. Remove the AC cable from the AC INPUT.

2. Insert the load line and then use a flathead

screwdriver or similar tool to firmly secure it.

3. If necessary, use the supplied output ground

cable and screw to establish a positive or

negative ground connection to the output

ground terminal ( mark).

Parts to be cut

Parts to be cut

Parts to be cut

Connection with the Rear Output Terminals (PSB-2400H,

2800H)

36

Page 39

OPERATION

CAUTION

Noise at the load end may be reduced by twisting

the cables to the load or connecting a film

capacitor (low impedance, high-frequency, several

μF) and an electrolytic capacitor (several hundred

μF) to the load end.

Fig. Connection

with Rear Output

Terminals

+ -

負荷線

マイナスドライバー等

A flathead screwdriver

or similar tool

Load line

Note

The negative potential of the external voltage

control is the same as that of the negative output

terminal. If the power supply unit is grounded at

the positive terminal and the power source for

external control is grounded at the negative

terminal, the load cables for external voltage control

will short-circuit the output of the power supply

unit, which could damage the unit. In this situation,

make sure the external voltage control source is

floating with respect to the output terminals.

Fig. Positive

Grounding

Connection

+ -

37

Page 40

PSB-2000 Series User Manual

CAUTION

The front and rear output terminals are

electrically connected internally. Terminals that

are NOT in use still carry output voltage.

Be careful not to touch the terminals. Failure to

heed this warning may result in electric shock.

38

Page 41

OPERATION

Procedure

1. Turn on the unit using the POWER switch.

2. Connect crimped lug terminals to the ends of

the load cables. Fix the load cables firmly to

eliminate loose connections from the front

output terminals and load cables.

3. If current is output through the rear output

terminals, cover the front output terminals

with the protective caps for safety.

Fig. Connection

with Front Output

Terminals

(Good)

(Bad)

CAUTION

The power supply unit may output a

maximum of 40A through the front output

terminals. Do not use pin plugs or banana

plugs for outputting large current in order to

avoid overheating due to contact resistance.

Use lug terminals that meet the output current

rating and connect them firmly to the front

output terminals.

For safety, NEVER output power through both

the front and rear output terminals.

Connection with the Front Output Terminals (PSB-2400L,

2800L, 2400L2, 2800LS)

39

Page 42

PSB-2000 Series User Manual

Procedure

1. Insert the cable (load line) into the plug.

2. Use a 1.5 mm hex key to fasten the 2 screws.

3. Insert the cover into the plug and make sure it

hooks into place (completion image).

4. Turn the power switch off from the unit.

5. Insert the above-mentioned plug into the front

output terminal.

6. When current is drawn from the rear output

terminals, the plug must be removed from the

front output terminal.

wrench

φ4 plug

outside diameter of a cable max. φ4

Completion image

Fig. Assembly diagram of the front output terminal plug

CAUTION

For safety, never output power through both the

front and rear output terminals.

Assembling and Connecting the Front Output Terminal

Plugs (PSB-2400H, 2800H)

40

Page 43

OPERATION

Introduction

The PSB-2000 series power supply units offer

wider voltage and current range settings, within

the rated power envelope, than our traditional

models.

70V

10V

60V

50V

40V

30V

20V

80V

5A

10A

15A

20A

25A

30A

35A

40A

Output current

Output voltage

400W Power limit line

70V

10V

60V

50V

40V

30V

20V

80V

10A

20A

30A

40A

50A

60A

70A

80A

800W Power limit line

Output voltage

Output current

Fig. PSB-2400L/L2 Operation

Range

Fig. PSB-2800L/LS Operation range

Operation Ranges (PSB-2400L, 2800L,

2400L2, 2800LS)

Voltage setting range: 0V to 80V (All models)

Current setting range: 0A to 40A (PSB-2400L & PSB-2400L2)

0A to 80A (PSB-2800L & PSB-2800LS)

Power setting range: 10W to 400W (PSB-2400L & PSB-2400L2)

10W to 800W (PSB-2800L & PSB-2800LS)

41

Page 44

PSB-2000 Series User Manual

700V

600V

500V

400V

300V

200V

800V

0.5A 1A 1.5A 2A 2.5A 3A

Output current

Output voltage

400W Power limit line

PSB-2400H

133V

700V

600V

500V

400V

300V

200V

800V

1A 2A 3A 4A 5A 6A

800W Power limit line

PSB-2800H

133V

Output voltage

Output current

Fig. Operation Range of PSB2400H

Operation Range of PSB-2800H

Operation Ranges (PSB-2400H, 2800H)

Voltage setting range: 0V to 800V (All models)

Current setting range: 0A to 3A (PSB-2400H)

0A to 6A (PSB-2800H)

Power setting range: 0W to 400W (PSB-2400H)

0W to 800W (PSB-2800H)

42

Page 45

OPERATION

Introduction

First, press the POWER switch to turn on the

power. The power supply unit will show the

startup screen (firmware version and models) for

several seconds and then displays the last-used

settings.

Note

The unit saves the last-used settings automatically

when the power supply source is cut off or the

POWER switch is shut off.

Model PSB-2400L,

version 1.00

The last-used

settings are

displayed

Procedure

1. Make sure that the V key is lit green. If not,

press the V key to turn it on.

V AW

2. Set the voltage level with the encoder wheel.

Note

Check which channel is selected before setting the

voltage on the PSB-2400L2 in order not to change

the set value of the other channel.

Various Settings

Turning the Power On

How to Set the Voltage

43

Page 46

PSB-2000 Series User Manual

Procedure

1. Make sure that the A key is lit green. If not,

press the A key to turn it on.

V AW

2. Set the current with the encoder wheel.

Procedure

1. Make sure that both the V and A keys are lit. If

not, press the V and A keys to turn them on.

(Both keys need to be lit when setting the

power.)

V AW

If the A key is pressed while keeping the V key

depressed, the Current LED display can be

used to enter the power setting. (The “A”

indicator will turn turn off and the “W”

indicator will turn on, indicating that the

setting has changed from current to power.)

See the figure below, “Voltage and Power”.

If the V key is pressed while keeping the A key

depressed, the Voltage LED display can be

used to enter the power setting. (The “V”

indicator will turn turn off and the “W”

indicator will turn on, indicating that the

setting has changed from voltage to power.)

See the figure below, “Current and Power”.

2. Set the power with the encoder wheel.

How to Set the Current

How to Set Power

44

Page 47

OPERATION

Fig. Power

Display

Voltage and

Power:

80V and 400W

Current and Power:

400W and 40A

Output Methods

Turning the output on or off using the OUTPUT

key.

Turning the output on or off using the CH1 or

CH2 key (PSB-2400L2 only).

Turning the output on or off using the external

control function.

Note

If the output is quickly turned off then on, then it

is possible that the voltage will not discharge

normally. Please allow the output to be off for a

least 1 second before turning the ouput on again.

Procedure

1. Turning the output on or off using the OUTPUT

key.

Press the OUTPUT key to turn the output on or

off. The Output is on while this key is lit. On

the PSB-2400L2, pressing the OUTPUT key turns

on or off the outputs for channel 1 and channel 2

simultaneously, but only if the CH1 CH2 keys

have been pressed beforehand to select channel

1 or B.

2. Turning the output on or off using the CH1 CH2

key. (PSB-2400L2 only)

How to Turn the Output On

45

Page 48

PSB-2000 Series User Manual

The CH1 and CH2 keys are independent of each

other, and it is possible to turn the output on

through channel 1 or B by pressing the CH1 or

CH2 key to select the corresponding channel.

However, the output is disabled unless the

OUTPUT key is lit.

Note

For the PSB-2400L2, if neither the CH1 nor CH2 key

is lit, the OUTPUT key will not go on even if it is

pressed. (No output is provided.)

Fig. Output by

Pressing OUTPUT

key

OUTPUT

CH 2CH 1

ON / OFF

OUTPUT

CH 2CH 1

ON / OFF

Press CH1 and CH2 to

make them light up. (The

output is still off)

Press Output to output.

46

Page 49

OPERATION

Output methods

The power supply unit displays the output value

when the output is on. Press the ENTER / CHECK

key when the output is on to switch the display to

the setting value.

Procedure

Every press of the ENTER/CHECK key toggles the

display between the setting mode and output

mode.

When the output is on and the mode has been

switched to the setting mode, the A or V key

blinks, indicating that the setting value is being

displayed.

Note

is rotated in the setting mode. The output value is

changed if the encoder is rotated in the output

mode. Do not touch the encoder to check the

setting values.

→

→

Output value

Press CHECK:

Set value

Press CHECK:

Output value

How to Display the Setting Value When the Output is On

47

Page 50

PSB-2000 Series User Manual

The display panel on the PSB-2000 series can be

rotated 90 degrees so that the unit can be operated

comfortably in either the horizontal or vertical

orientations. Hold the encoder wheel and rotate

the orientation of the panel while pressing the

ROTATE key below the encoder wheel. Keep

turning the panel until a “click” sound is heard.

This indicates that the panel is now locked in

place.

CAUTION

Be sure to confirm that the POWER switch is off

before rotating the display panel.

If the display panel is rotated with the power on,

the set value may change due to the rotation of the

encoder wheel.

Fig. Rotating

Display Panel

Horizontal installation

Vertical installation by

rotating the display panel

How to Rotate the Display Panel 90 Degrees for Vertical

Installation

48

Page 51

OPERATION

Operation

It is possible to disable the front panel keys by

pressing the FAST/LOCK(3s)/LOCAL key on the

left of the encoder. Hold this key for three or more

seconds to lock the panel keys. The keys are locked

when the LED beside the key turns red. To cancel

the key lock function, hold the

FAST/LOCK(3s)/LOCAL key for 3 or more

seconds.

CAUTION

This key serves as the FAST, LOCK (3s), and

LOCAL keys. When putting the power supply into

the locked state, it will also automatically cancel

the FAST mode setting (if set) and restore the

power supply to the SLOW mode.

In the key-locked state, the OUTPUT key is still

functional so that the output can be turned off for

safety reasons.

How to Disable Panel Operations (Key Lock Function)

49

Page 52

PSB-2000 Series User Manual

Introduction

Every press of the MENU key changes the menu

numbers:

PSB-2400L, 2800L, 2800LS: MENU Option

“01” to “07”.

PSB-2400L2: MENU Option “01” to “09”.

PSB-2400H, 2800H: MENU Option “01” to

“06”.

Press the ESC /DISP key to return from the MENU

settings to the normal settings.

To deactivate a function, select the

corresponding setting again from the menu and

deactivate it.

Operation

Overview

MENU key: Cycles through the menu options.

ENTER / CHECK key: Validates numeric values

and items.

ESC / DISP key: Exits from the menu settings

and returns to the normal settings.

Encoder wheel: Selects numeric values and

items.

Menu Key Functions

50

Page 53

OPERATION

The diagram below can be used as a reference for the menu

operations in the following pages:

General Setting

Procedure

1. Press the MENU key until an intended function

number is displayed.

2. Press the ENTER / CHECK key to validate the

function. Proceed to setting of the next item.

3. Set a numeric value or item with the encoder,

and press the ENTER/ CHECK key to validate it.

4. When all intended items have been set, press

the ESC / DISP key to return to the normal state.

CAUTION

Set values are only validated after the ENTER /

CHECK key is pressed.

Be sure to check that the value is set properly after

setting it.

Some functions may not be settable as some

functions cannot be used together. See the table

below for details.

Set function

Functions that cannot be set or

used simultaneously

Preset

Sequence

External(voltage/resistance)

OVP/OCP

- Hi-Ω (PSB-L Series Only)

-

Off timer

Sequence Delay External

(On/Off)

Voltage LED

Current LED

2 digit LED for displaying the number of cycles,

step No., and menu No.

51

Page 54

PSB-2000 Series User Manual

Sequence

Preset Off timer

External (voltage/resistance)

External (On/Off) Delay

Tracking

External

(voltage/resistance)

Preset Tracking

External (On/Off)

Off timer Delay

Delay (PSB-L Series Only)

Sequence Off timer

Tracking

(PSB-L Series Only)

Sequence External

(voltage/resistance) External

(On/Off)

52

Page 55

OPERATION

Introduction

This function saves settings to one of the three

PRESET keys. The settings shown below may be

preset. Note that any other settings/values may

not be saved.

Set voltage

Set current

Set power

Procedure

1. Set the voltage/current/power settings that

you want saved.

2. Press the MENU key until menu number “01” is

displayed.

3. Press the ENTER / CHECK key. All the PRESET

keys blink green.

4. Press the PRESET key that you want to assign

the current settings to. The PRESET key that

you press will be lit a solid green to indicate

that the save was successful.

5. Press the ESC/ DISP key to return to normal

operation.

CAUTION

Once the MENU key is pressed to activate the preset

function, you can no longer set the voltage, current

and power. Set the intended values before

Preset Function

Menu Item: 01(All Models)

53

Page 56

PSB-2000 Series User Manual

activating the preset function.

Introduction

OVP: (Over Voltage Protection)

The OVP function turns off the output when the

output voltage of the PSB-2000 series exceeds

the preset OVP value.

Model

Setting Range

Resolution

PSB-2400L

PSB-2800L

PSB-2400L2

PSB-2800LS

1.0V to 84.0V

0.1V

PSB-2400H

PSB-2800H

10.0V to 840.0V

1V

OCP: (Over Current Protection)

The OCP function turns off the output when the

output current of the PSB-2000 series exceeds

the preset OCP value.

Model

Setting Range

Resolution*

PSB-2400L

PSB-2400L2

1.0A to 42.0A

0.1A

PSB-2800L

1.0A to 84.0A

0.1A

PSB-2400H

0.1A to 3.15A

0.01A

PSB-2800H

0.1A to 6.30A

0.01A

*The resolution may be different for

parallel/serial operation. Please see the

specifications for details.

OVP/OCP function

Menu Item: 02 (All Models)

54

Page 57

OPERATION

Procedure

1. Press the MENU key until menu number “02” is

displayed.

2. Press the ENTER / CHECK key to toggle between

the OVP and OCP setting displays. On the PSB2400L2, the OVP and OCP settings for channel

1 appear first, followed by channel 2 next.

OVP setting

OCP setting

→

OVP and OCP setting of channel 1

OVP and OCP setting of channel 2

3. When the intended protection function is

displayed (OVP or OCP), rotate the encoder

wheel to set the OVP or OCP level.

4. Press the ENTER/ CHECK key to comfirm. The

setting is now complete.

5. Press the ESC/ DISP key to return to the normal

operation.

55

Page 58

Hi-Ω- Function

Introduction

The PSB-2000 series power supplies have filter

capacitors connected to the output. The PSB-L

power supplies also have a bleeder circuit to

discharge these capacitors to a safe level when the

output is turned off. When the Hi-Ω function is

activated, the bleeder circuit is deactivated. This

allows you to omit reverse-current preventing

diodes that are necessary for charging batteries or

capacitors when a bleeder circuit is active.

When the Hi-Ω function is activated, the internal

filter capacitors can remain charged even after the

power has been turned off and thus can be quite

dangerous. As a safety measure, the bleeder

circuits are programmed to turn back on after a

predeterminded amount of time (5 ~ 30 minutes)

after the output has been turned off.

Procedure

1. Press the MENU key until menu number “03” is

displayed.

2. Press the ENTER / CHECK key to enter the Hi-Ω

function setting mode. Select ON or OFF with

the encoder wheel. The Hi-Ω function is set to

OFF by default.

PSB-2000 Series User Manual

Menu Item: 03 (PSB-L Series Only)

56

Page 59

OPERATION

Hi-Ω Off

Hi-Ω On

3. Press the ENTER / CHECK key to confirm the

setting.

The Hi-Ω LED in the center of the panel turns

on.

○ OFF TIMER

○ DELAY

● Hi-Ω

4. Next, set the time limit for when the bleeder

circuits are turned back on with the encoder

wheel.

Setting range: 5~30 minutes.

Setting resolution: 5 minute steps.

Press the ENTER / CHECK key to confirm the

setting.

Example: Timer set for 20 minutes.

5. Press the ESC / DISP key to quit the setting

mode and return to normal operation.

57

Page 60

PSB-2000 Series User Manual

CAUTION

When the Hi-Ω function is activated, the output

terminals of the power supply unit keep on

carrying voltage even after the output is turned

off.

The Hi-Ω LED will blink when Hi-Ω function is

still active as the internal capacitors remain

charged. Voltages as high as 80V may remain at

the terminals when the output is turned off. Such a

state is very dangerous. To avoid accidents,

isolate the output terminals from the load cables

completely with a relay or switch.

58

Page 61

OPERATION

Introduction

This function turns the output off automatically after

a set amount of time. The timer can be set in ten

minute steps to a maximum of 99 hours, 50 minutes.

Procedure

1. Press the MENU key until menu number “04” is

displayed(PSB-L) or “03(PSB-H series)

2. Press the ENTER / CHECK key to enter the Off

Timer settings.

3. Select ON or OFF with the encoder wheel. The

Off Timer is turned off by default.

Initial setting

OFF timer activated

4. Press the ENTER / CHECK key to confirm the

setting.

The OFF TIMER LED in the center of the panel

will turn on when the timer is active.

● OFF TIMER

○ DELAY

○ Hi-Ω

5. Next, set the timer time with the encoder

wheel.

Press the ENTER / CHECK key to confirm the

setting.

Off Timer Function

Menu Item: 04(PSB-L Series), 03(PSB-H Series)

59

Page 62

PSB-2000 Series User Manual

The timer may be set in steps of ten minutes to a

maximum of 99 hours and 50 minutes. The OFF

TIMER LED will blink when the remaining time

is less than five minutes.

The remaining time for the off-timer may be

checked by pressing the ESC/DISP key while

the off-timer is running. (On the PSB-2400L2,

pressing the ESC/DISP key toggles the display

in the following order: CH1 settings, CH2

settings, and then the remaining time of the offtimer.)

Example: Off Timer set to ten minutes

6. Press the ESC / DISP key to quit the setting

menu and return to normal operation.

60

Page 63

OPERATION

Introduction

This function executes sequence programs. Please

note that sequence programs can only be created

when one of the interface boards (PSB-001 or PSB-

002) are installed. Without an interface board

installed, the sequence function is not available.

Please see the PSB_Sequence_203 usermanual or

the GW Instek website for more information on

how to program sequences.

The following describes how to view steps in a

previously-create sequence and screen shots of the

PSB_Sequence_203 application that creates the

sequences.

Note that the PSB series cannot edit or create

sequences.

Fig. Repeating

Steps 20 to 22

Three Times,

Beginning with

Step 20

Step No.

Cycle No.

Start End

20 21 22 20 21 22 20 21 22

1 2 3

Program

contents

Continue

Sequence Function

Menu Item: 05(PSB-L), 04(PSB-H)

61

Page 64

PSB-2000 Series User Manual

CAUTION

If the output is active at the end of the program as

shown in the figure above, the power supply

output will remain at the level of the last step even

after the completion of the sequence operation.

(I.e., the output stays active.)

The last step number must be set to OFF for the

the output to be turned off at the end of a

sequence.

The sequence operation will end prematurely if

the OUTPUT key pressed when a sequence is

running. Note however, that the output will

remain active at the level of the last step that was

executed when the OUTPUT key was pressed.

Procedure

1. Press the MENU key until menu number

“05”(PSB-L) or “4”(PSB-H) is displayed.

2. Press the ENTER / CHECK key to enter the

sequence operation settings. Select ON or OFF

with the encoder wheel. By default the

sequence function is turned off.

Initial setting

Sequence operation activated

3. Press the ENTER / CHECK key to confirm the

setting.

The SEQUENCE LED below the PRESET key

turns on.

1 2 3

62

Page 65

OPERATION

○ ○ ○

―●SEQUENCE―

4. Next, set the Start Step number with the

encoder wheel.

Press the ENTER / CHECK key to confirm.

The setting range is from 0 to 99.

Example: The Start Step is set to No. “00”.

5. Set the End Step number with the encoder

wheel.

Press the ENTER / CHECK key to confirm.

The setting range is from 0 to 99.

Example: The End Step is set to step No. “99”.

6. Set the number of times to repeat the steps

above with the encoder wheel.

Press the ENTER / CHECK key to confirm.

Setting the sequence function is now complete.

The “---“ setting repeats the steps infinitely.

The setting range is from 1 to 999 or “—“

(infinite).

Example: Repeat the selected steps 999 times.

7. Press the ESC / DISP key to quit the Sequence

settings and enter the sequence operation

63

Page 66

PSB-2000 Series User Manual

mode.

Introduction

Constant-Voltage (CV) Control Using External

Voltage

This function allows you to control the voltage

of the PSB-2000 series power supply unit by

applying an external voltage to the unit. An

external voltage of 0V to 10V can be used to

control the output voltage from ~0V to the rated

output voltage.

Constant-Current (CC) Control Using External

Voltage

This function allows you to control the current

of the PSB-2000 series power supply unit by

applying external voltage to the unit. An

external voltage of 0V to 10V can be used to

control the output current from ~0A to the rated

output current.

Constant-Voltage (CV) Control Using External

Resistance

This function allows you to control the voltage

of the PSB-2000 series power supply unit by

connecting an external resistance to the unit.

An external resistance of 0Ω to 10kΩ can be

used to control the output voltage from ~0V to

the rated output voltage.

Constant-Current (CC) Control Using External

Resistance

This function allows you to control the current

External Control (External Voltage, External Resistance)

Menu Item: 06(PSB-L), 05(PSB-H)

64

Page 67

OPERATION

of the PSB-2000 series power supply unit by

connecting an external resistance to the unit. An

external resistance of 0Ω to 10kΩ can be used to

control the output current from ~0A to the rated

output current.

CAUTION

The PSB-2000 series power supply unit is

incapable of simultaneous external voltage and

external resistance control.

For example: Using an external voltage for CV

control and external resistance for CC control is

not supported.

Procedure

1. Press the MENU key until menu number

“06”(PSB-L) or “05”(PSB-H) is displayed.

2. Press the ENTER / CHECK key to enter the

external control settings. Use the encoder wheel

to select external voltage or external resistance,

and press the ENTER / CHECK key. By default

the External Control is turned off.

Initial setting

External voltage

External resistance

3. Select the external control mode with the

encoder wheel.

The modes are listed below:

CV= Constant voltage

CC= Constant current

IN = Control from the front panel or remotely

from a PC.

OUT= Control using the external control.

65

Page 68

PSB-2000 Series User Manual

Controlling constant voltage

from the front panel

Controlling constant voltage

using external control

Controlling constant current

from the front panel

Controlling constant current

using external control

4. Finally, press the ENTER / CHECK key to

validate the settings.

Setting the control mode is now complete.

5. Press the ESC / DISP key to quit the setting

mode and return to normal operation.

Introduction

The PSB series can use external control to turn the

output on or off by shorting (output on) or

opening certain pins (output off) on the external

control connector.

Use this function to choose whether to use external

control or the OUTPUT key to turn on the output.

External Control Output On/Off

Menu Item: 07(PSB-L, 06(PSB-H)

66

Page 69

OPERATION

Procedure

1. Press the MENU key until menu number

“07”(PSB-L) or “06”(PSB-H) is displayed.

2. Press the ENTER / CHECK key to enter the

external output On/Off control setting mode.

3. Select On or Off with the encoder wheel, and

press the ENTER / CHECK key again to confirm

the settings. The external output on/off setting

is now complete. The output control modes are

shown below:

IN= The output is controlled with the OUTPUT

key.

OUT= The output is controlled with external

contacts.

OUTPUT key control

External Control

4. Press the ESC/ DISP key to quit the settings and

return to normal operation.

67

Page 70

Delay Function

Introduction

The delay function is available on the dual channel

model (PSB-2400L2) only. It adds a rise and fall delay

time to the output of channel 2 for a specified amount

of time (in seconds) from a reference point (output of

channel 1). The rise delay time refers to the delay

time for turning the output on. The fall delay time

refers to the delay time for turning the output off.

Fig. Temporal

Concept of

Delay Function

Channel B

Channel A

Positive

(10 seconds Max.)

Negative

(9.99 seconds max.)

Zero

Zero

Negative

(9.99 seconds max.)

Positive

(10 seconds Max.)

Procedure

1. Press the MENU key until menu number “08” is

displayed.

2. Press the ENTER / CHECK key to enter the delay

function settings. Select On or Off with the

encoder wheel. By default the delay setting is

turned off.

Delay OFF

Delay ON

PSB-2000 Series User Manual

Menu Item: 08 (PSB-L2)

68

Page 71

OPERATION

3. Press the ENTER / CHECK key to confirm the

setting.

The DELAY LED in the center of the panel turns

on.

○ OFF TIMER

● DELAY

○ Hi-Ω

4. Set the rise delay time with the encoder wheel.

When a positive time is set, the output of channel

2 is delayed with respect to channel 1. On the

contrary, when a negative time is set, the output

of channel 2 leads that of channel 1. The delay

time can be set in the range of -9.99 seconds to

+10.00 seconds in steps 10 ms.

The output of channel 2 is

turned on 9.99 seconds

earlier

The output of channel 2 is

turned on 10.00 seconds

later.

5. Set the fall delay time with the encoder wheel, and

press the ENTER / CHECK key. The delay function

setting is now complete.

The channel 2 output is

turned off 9.99 seconds

earlier

The channel 2 output is

turned off 10.00 seconds

later.

6. Press the ESC / DISP key to quit the delay settings

and return to normal operation.

69

Page 72

PSB-2000 Series User Manual

Introduction

The tracking function is available on the dual

channel model (PSB-2400L2) only. When the

tracking function is turned on, the output of

channel 2 is made to match the output of channel

1, thus channel 2 can be said to “track” channel 1.

This effectively means that the values of both

channels change simultaneously.

Fig. Tracking

Operation

Channel 1

Channel 2

5V

10V

20V

20V

5V

5V

Tracking function

ON

Changing set values

with encoder or through

communication

Procedure

1. Press the MENU key until the menu number

“09” is displayed.

2. Press the ENTER / CHECK key to enter the

tracking function setting mode. Select On or

Off with the encoder wheel. By default the

tracking function is turned off.

3. Press the ENTER / CHECK key to confirm the

setting.

Both the CH1 and CH2 LEDs on the right of the

channel LED turn on.

4. Press the ESC / DISP key to quit the setting

Tracking Function

Menu Item: 09 (PSB-L2)

70

Page 73

OPERATION

menu and return to normal operation. “Ab” is

displayed on the MENU LED when the

tracking function is activated.

Example: Tracking function is activated.

The master-slave function allows the PSB series to

operate in parallel or series (PSB-L only). For

series operation a maximum of 2 PSB-L units can

be used. For parallel operation, a maximum of 4

(PSB-L) units or 2 units (PSB-H) units can be used.

Note that for series operation, the same PSB-L

models types must be used.

For a slave unit that is connected in series, only

the output voltages are displayed when the

output is on.

No panel operations can be performed on the

slave units. Only the Off Timer, Sequence and

External Control function settings are initialized

on the slave units.

For parallel connections “---“ is displayed on the

display for slave units. The monitor values are

displayed on the master unit.

CAUTION

The Hi-Ω function is not available for masterslave operation.

Master-slave function

Menu Item: 10

71

Page 74

PSB-2000 Series User Manual

Display for a slave unit in a

parallel connection

Display for a slave unit in

a series connection

Procedure

1. The master-slave settings can be accessed by

turning on the power switch while holding the

MENU key.

2. Select the operation mode for the unit with the

encoder wheel and press the ENTER / CHECK

key to confirm the setting. By default the

master-slave setting is set to OFF

Initial setting:

Single unit operation or

Master unit in a series

connection

Master unit in a parallel

connection

Slave unit in a parallel

connection

Slave unit in a series

connection (PSB-L only)

72

Page 75

OPERATION

3. Set the total power with the encoder wheel if

the unit is set as the master unit in a parallel

connection.

Example: Total power of 3200 W.

4. Press the ESC / DISP key to exit the settings

and return to normal operation.

73

Page 76

PSB-2000 Series User Manual

Description

The PSB-2000 series power supply units have an

output voltage remote sensing function. This

function eliminates influences of voltage drops

between the power supply unit and load, which is

caused by the contact resistance or the resistance of

the load cable conductors.

Voltage sense compensates for a voltage of up to

1V on a single terminal.

CAUTION

When the voltage sense function is used, the

voltage at the front or rear terminals of the power

supply unit must not exceed the rated voltage.

If the load cables are long, the inductance and the

capacity of the load cables may cause oscillation.

To avoid oscillation, connect an electrolytic

capacitor of a several hundred to several thousand

μF to the load terminals.

Procedure

1. Make sure that the POWER switch is off before

making any connections.

2. Disconnect the wire that shorts the + and +S

terminals or - and -S terminals on the fourterminal block on the left of the output

terminals on the rear panel (this will need to be

done for both channels on the PSB-2400L2).

3. Connect the positive sensing terminal (+S) to

the positive side of the load and the negative

sensing terminal (-S) to the negative side of the

load, as shown below. If the sensing wires are

disconnected, control will become unstable and

a voltage greater than the set voltage could be