Page 1

Programmable High Precision DC

Power Supply

PPH-1503

User Manual

GW INSTEK PART NO. 82PH-15030E01

ISO-9001 CERTIFIED MANUFACTURER

Page 2

Copyright Statement

This manual contains proprietary information, which is protected by

copyright. All rights are reserved. No part of this manual may be

photocopied, reproduced or translated to another language without

prior written consent of Good Will company.

The information in this manual was correct at the time of printing.

However, Good Will continues to improve products and reserves the

rights to change specification, equipment, and maintenance

procedures at any time without notice.

Good Will Instrument Co., Ltd.

No. 7-1, Jhongsing Rd., Tucheng Dist., New Taipei City 236, Taiwan.

Page 3

TABLE OF CONTENTS

Table of Contents

SAFETY INSTRUCTIONS ................................................... 5

OVERVIEW ...................................................................... 11

Introduction ................................................... 11

Key Features ................................................... 13

Operating Principals ....................................... 15

Front Panel ..................................................... 17

Rear Panel ...................................................... 23

Constant Voltage/Constant Current Crossover

Characteristics................................................ 25

GETTING STARTED ......................................................... 27

Start Up .......................................................... 27

DVM and Load Connection ............................. 28

Turning the Output On/Off............................. 29

BASIC OPERATION ......................................................... 31

Basic Power Supply Functions ........................ 31

DVM ............................................................... 41

Pulse Current Measurement ........................... 43

Long integration ............................................. 49

Current Sink Function ..................................... 54

External Relay Control .................................... 56

Save/Recall ..................................................................... 59

Save Settings .................................................. 59

Recall Settings ................................................ 60

Restore Factory Default Settings ..................... 63

3

Page 4

PPH-1503 User Manual

System Settings .............................................................. 64

System Information ........................................ 64

Utilty Settings ................................................. 65

REMOTE CONTROL ........................................................ 67

Remote Control .............................................. 67

Command Syntax ............................................ 76

Command List ................................................ 80

Command Details ........................................... 85

SCPI Status Registers SCPI ........................... 121

Errors ........................................................... 129

APPENDIX ..................................................................... 133

Replacing the Fuse ....................................... 133

Specifications ............................................... 134

Optional Accessories .................................... 136

Declaration of Conformity ............................ 137

4

Page 5

SAFETY INSTRUCTIONS

WARNING

Warning: Identifies conditions or practices that

could result in injury or loss of life.

CAUTION

Caution: Identifies conditions or practices that

could result in damage to the PSW or to other

properties.

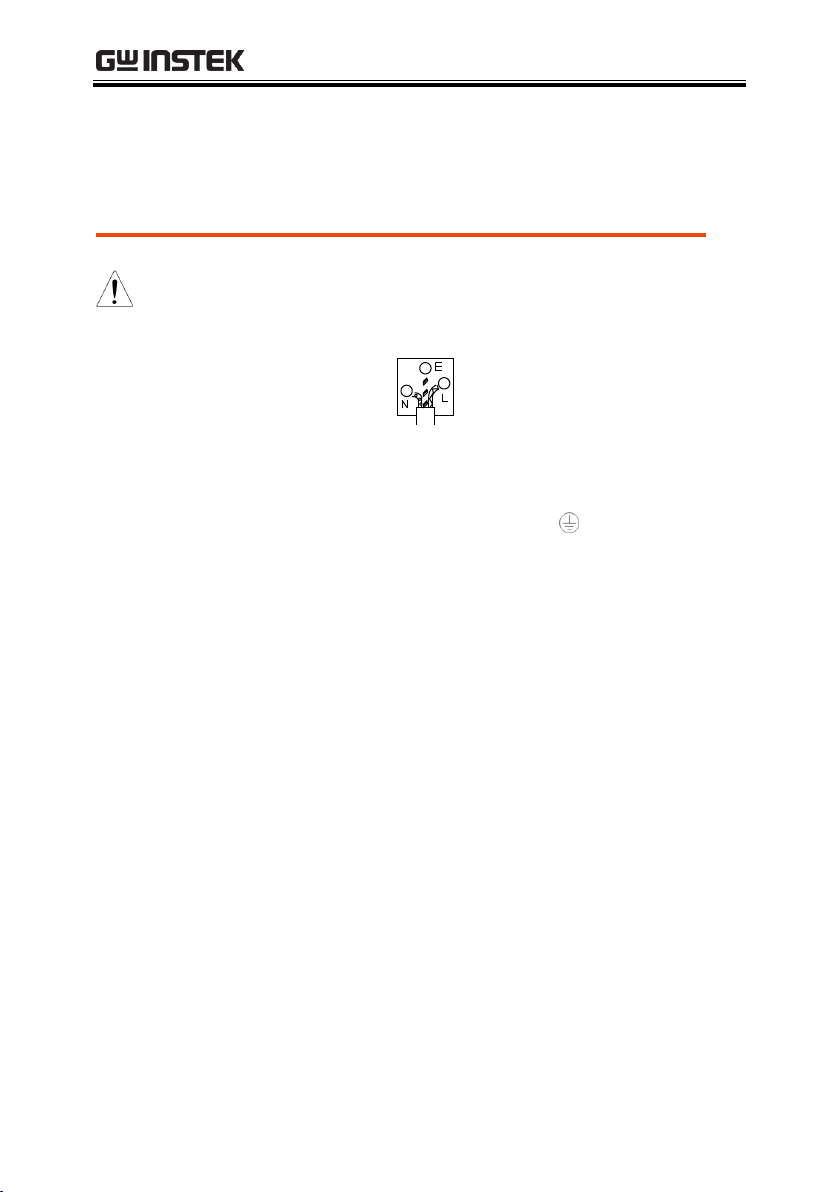

DANGER High Voltage

Attention Refer to the Manual

Protective Conductor Terminal

Earth (ground) Terminal

SAFETY INSTRUCTIONS

This chapter contains important safety instructions

that you must follow during operation and storage.

Read the following before any operation to insure your

safety and to keep the instrument in the best possible

condition.

Safety Symbols

These symbols may appear in the manual or on the instrument.

5

Page 6

PPH-1503 User Manual

Do not dispose electronic equipment as unsorted

municipal waste. Please use a separate collection

facility or contact the supplier from which this

instrument was purchased.

6

Page 7

SAFETY INSTRUCTIONS

General

Guideline

CAUTION

Do not place any heavy object on the unit.

Avoid severe impact or rough handling that

leads to damaging the unit.

Do not discharge static electricity to the unit.

Do not block the cooling fan opening.

Do not perform measurements on circuits that

are directly connected to mains power.

Do not disassemble the PSW unless you are

qualified.

(Measurement categories) EN 61010-1:2001 specifies the

measurement categories and their requirements as follows. The

PPH-1503 falls under category I.

Measurement category IV is for measurement performed at the

source of low-voltage installation.

Measurement category III is for measurement performed in the

building installation.

Measurement category II is for measurement performed on the

circuits directly connected to the low voltage installation.

Measurement category I is for measurements performed on

circuits not directly connected to Mains.

Power Supply

WARNING

AC Input voltage range: 90VAC~264VAC

Frequency: 50Hz/60Hz

To avoid electrical shock connect the protective

grounding conductor of the AC power cord to

an earth ground.

Safety Guidelines

7

Page 8

PPH-1503 User Manual

Fuse

WARNING

Fuse type: T2.0A/250V

To prevent fire, replace the fuse only with the

specified type and rating.

Disconnect the power cord before replacing the

fuse.

Make sure the cause of fuse blowout is fixed

before replacing the fuse.

Cleaning the

power supply

Disconnect the power cord before cleaning the

oscilloscope.

Use a soft cloth dampened in a solution of mild

detergent and water. Do not spray any liquid

into the oscilloscope.

Do not use chemicals containing harsh products

such as benzene, toluene, xylene, and acetone.

Operation

Environment

Location: Indoor, no direct sunlight, dust free,

almost non-conductive pollution (Note below)

Relative Humidity: < 80%

Altitude: < 2000m

Temperature: 0°C to 40°C

(Pollution Degree) EN 61010-1:2001 specifies pollution degrees and

their requirements as follows. The PPH-1503 falls under degree 2.

Pollution refers to “addition of foreign matter, solid, liquid, or

gaseous (ionized gases), that may produce a reduction of dielectric

strength or surface resistivity”.

Pollution degree 1: No pollution or only dry, non-conductive

pollution occurs. The pollution has no influence.

Pollution degree 2: Normally only non-conductive pollution

occurs. Occasionally, however, a temporary conductivity caused

by condensation must be expected.

Pollution degree 3: Conductive pollution occurs, or dry, non-

conductive pollution occurs which becomes conductive due to

condensation which is expected. In such conditions, equipment

is normally protected against exposure to direct sunlight,

precipitation, and full wind pressure, but neither temperature

nor humidity is controlled.

8

Page 9

SAFETY INSTRUCTIONS

Storage

environment

Location: Indoor

Relative Humidity: < 70%

Temperature: -10°C to 70°C

9

Page 10

PPH-1503 User Manual

Green/ Yellow:

Earth

Blue:

Neutral

Brown:

Live (Phase)

Power cord for the United Kingdom

When using the power supply in the United Kingdom, make sure the

power cord meets the following safety instructions.

NOTE: This lead/appliance must only be wired by competent persons

WARNING: THIS APPLIANCE MUST BE EARTHED

IMPORTANT: The wires in this lead are coloured in accordance with the following

code:

As the colours of the wires in main leads may not correspond with the coloured

marking identified in your plug/appliance, proceed as follows:

The wire which is coloured Green & Yellow must be connected to the Earth

terminal marked with either the letter E, the earth symbol or coloured

Green/Green & Yellow.

The wire which is coloured Blue must be connected to the terminal which is

marked with the letter N or coloured Blue or Black.

The wire which is coloured Brown must be connected to the terminal marked

with the letter L or P or coloured Brown or Red.

If in doubt, consult the instructions provided with the equipment or contact the

supplier.

This cable/appliance should be protected by a suitably rated and approved HBC

mains fuse: refer to the rating information on the equipment and/or user

instructions for details. As a guide, a cable of 0.75mm2 should be protected by a

3A or 5A fuse. Larger conductors would normally require 13A types, depending

on the connection method used.

Any exposed wiring from a cable, plug or connection that is engaged in a live

socket is extremely hazardous. If a cable or plug is deemed hazardous, turn off

the mains power and remove the cable, any fuses and fuse assemblies. All

hazardous wiring must be immediately destroyed and replaced in accordance to

the above standard.

10

Page 11

OVERVIEW

Overview

The PPH-1503 is a portable high-speed

programmable DC power supply with flexible

operating configurations. In addition to the basic

power supply functionality, it is also able to

measure pulse current and the average current

over long periods of time.

The PPH-1503 is designed for testing the power

consumption of battery powered wireless

communication devices (e.g. cell phones). Such

devices often have large load variations within a

short time span. The high precision power supply

has excellent voltage stability during pulsed loads

and is capable of simultaneously measuring the

pulse current, even for very short pulses. In

addition, the power supply is able to sink current,

allowing it to simulate the characterics of a

discharged rechargeable battery for testing

chargers and charge control circuits.

OVERVIEW

This chapter contains a brief introduction to PPH-1503,

the main features, as well as an overview of the front

and rear panel. Use the Getting Started chapter on

page 27 to for start up instructions and how to setup

the appropriate operation environment.

Introduction

11

Page 12

PPH-1503 User Manual

Basic Power

Supply Function

The PPH-1503 works as a conventional power

supply with automatic CC/CV crossover.

Parameters such as the output voltage, current,

read back refresh rate, data sampling period,

power-on status, OVP and current range can be

configured using the control panel. The voltage

and current settings and the actual voltage/current

are displayed on the LCD. For details, see page 31.

Pulse Current

Measurement

Function

The PPH-1503 can measure the change in

instantaneous current and the current of extremely

short pulses. The readback refresh rate, data

sampling period, trigger delay and trigger level

can be set by the front panel keys and is displayed

on the LCD. For details see page 43.

Current

Measurement

over Long Periods

This function can measure the average current of

one or more pulses. The readback refresh rate,

trigger mode, and trigger timeout and trigger level

settings are controled by the front panel keys and

is displayed on the LCD display. For details, see

page 49.

Current Sink

Features

When the voltage of an external power source is

greater than the high-speed power supply output,

the system will automatically work as an electronic

load to sink current. For details, see page 54.

Digital Volt

Meter

The PPH-1503 has a DVM function that can

measure DC voltages in the range of 0~20VDC. For

details, see page 41.

Remote Control

To meet the various needs of customers, the PPH1503 is designed for USB, GPIB and LAN remote

control. For details, see page 67.

12

Page 13

OVERVIEW

Additional

Features

The PPH-1503 has external relay control signals for

customers. The relay control signals are synced to

the pulse current measurement feature. For details,

see page 56.

Features

Low noise: Thermostatically controled fan.

Compact, lightweight.

3.5 inch TFT display.

Operation

Constant voltage and constant current operation

(CV/CC).

Output on/off control.

Front and Rear output control key.

Digital panel control.

5 groups of save/recall settings and 10

automatically generated power-on settings.

Digital voltage and current settings.

Software calibration.

Alarm buzzer.

Key lock function.

Protection

Features

Reverse polarity protection.

Overvoltage and overcurrent protection

(OVP/Trip).

Overtemperature protection (OTP).

Key Features

13

Page 14

PPH-1503 User Manual

Interface

USB remote control.

GPIB remote control.

LAN remote control.

14

Page 15

OVERVIEW

Overview

The PPH-1503 mainly consists of the follow

components:

AC to DC Switching power supply

DC to DC Buck converter circuit

Precision output control circuit

The block diagram below shows a function

description of each of the circuits. The following

page will show detailed decriptions of each

component.

Block Diagram

AC INPUT

AC TO DC

SWITCH POWER

DC TO DC

BUCK CIRCUIT

U201,Q201,Q202

L202

LINEAR

CONTROL

Q306~Q308,U303

ON/OFF SWITCH

Q309,Q310,

Q315,Q316

AUXILIARY

POWER SUPPLY

U101,T101,

Q102~Q105

V-SET

I-SET

AND

VOLTAGE

COMPARATOR

U301A

VOLTAGE

SAMPLING

CIRCUIT

U401,U402

CURRENT

COMPARATOR

U301B

CURRENT

SAMPLING

CIRCUIT

U430

SAMPLE

RESISTANCE

R366,R366A

R367,R367A

OUTPUT

Swtiching Power

Supply

AC power is converted to 24VDC by the switch

mode power supply module.

DC Down

Conversion

To reduce the input voltage to 24VDC (slightly

higher than the settable voltage) the U201 Buck IC

is used in conjunction with two power MOSFETS

(Q201/Q202) and an inductor (L202).

Operating Principals

15

Page 16

PPH-1503 User Manual

Linear Output

Circuit (Linear

Regulator)

The Q306, Q307 dividers reduce the heat on a

single component. The U303, U301, U403, U401

and U402 components form a control circuit to

achieve accurate output.

Auxillary Power

Supply

The independent auxillary DC power supply is

achieved with the U101, T101 and Q102~Q105

components.

16

Page 17

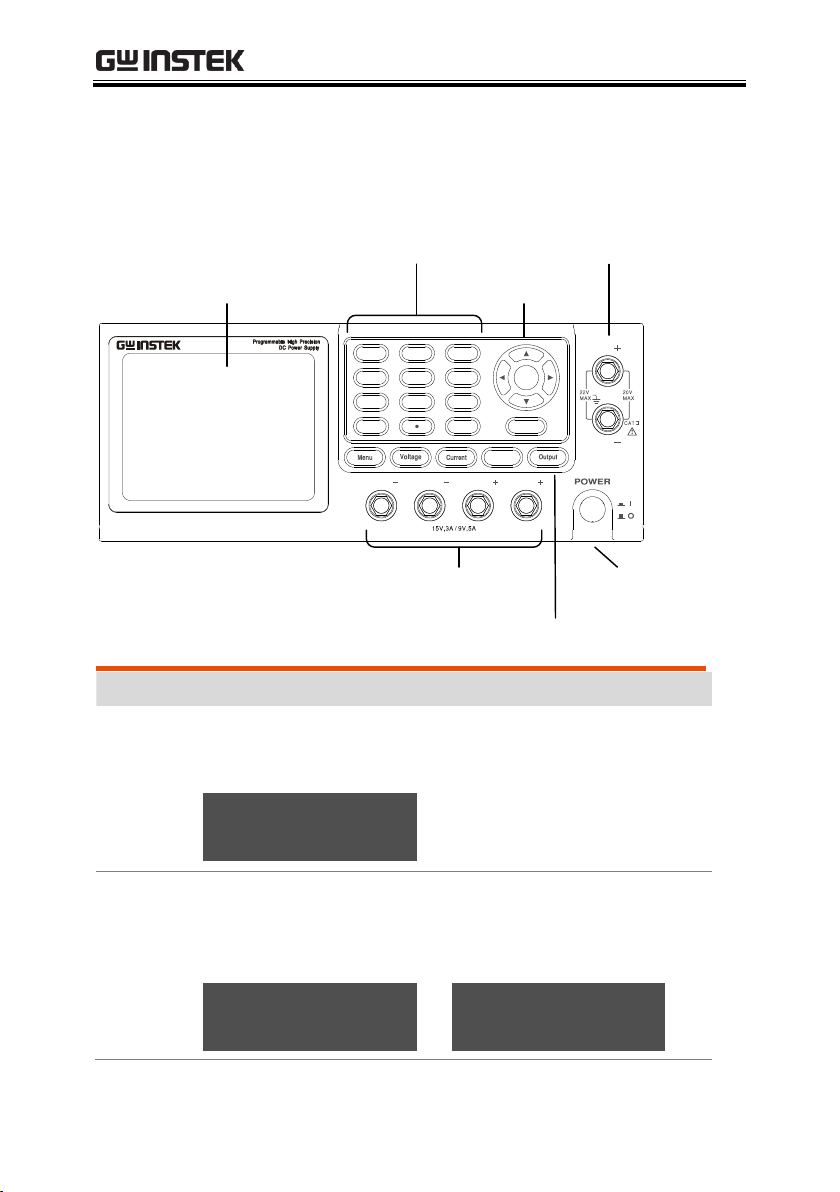

Front Panel

PPH-1503

LCD display

Numberpad and

secondary function keys

Arrow keys

DVM inputs

Front panel output

terminals

Function keys

Power button

Display

Voltmeter

Indicators

Displays the output voltage with up to 5 digits of

resolution. The default units are Volts (V).

15.000 v

Ammeter

Indicator

Displays the output current with up to 5 digits of

resolution, depending on the current range (5A/5mA).

The current range is selectable between A and mA.

5.0000 A

or

5.0000 mA

OVERVIEW

17

Page 18

PPH-1503 User Manual

Setting

Display

Displays the voltage and current settings.

V-Set

15.000 V

I-Set

5.0000 A

Parameter

Settings

Display

Displays the parameter settings. For details on setting

parameters, see page 20. The following figure shows the

F1 parameter settings (V AND I), for example.

Status

Display

Display the current status of the instrument.

Status

Output mode

CV mode:

C V

CC mode:

C C

Overvoltage protection

Enabled:

O.V.P

Disabled:

O.V.P

Alarm

Enabled:

BEEP

Disabled:

BEEP

Key lock

Locked:

LOCK

Unlocked:

LOCK

CurrRange: 5 A LimMode: Limit

PowOnSetup: RST OutputRelay: One

O.V.P: Off RecallSetup: ---

IntRate: 1.00 PLC AverRead[1][2]: 1

18

Page 19

OVERVIEW

Remote connectivity

Local mode:

RMT

Remote:

GPIB LAN

USB

Output

Switching the Output Source

Front:

FRONT

Rear:

REAR

Output State

On:

ON

Off:

OFF

Function

Display

Displays the unit functions. There four functions:

F1: Basic power supply function (V AND I);

F2: Digital Voltmeter function (DVM);

F3: Pulse current meter function (PULSE);

F4: Long integration current measurement function

The basic power supply function is shown below. (The

active function is shown in yellow.)

Function

Keys

Menu key

Menu key to enter or exit from

system settings.

Voltage

Setting key

Press the Voltage key to set the

voltage settings. See page 34 for

operation details.

19

Page 20

PPH-1503 User Manual

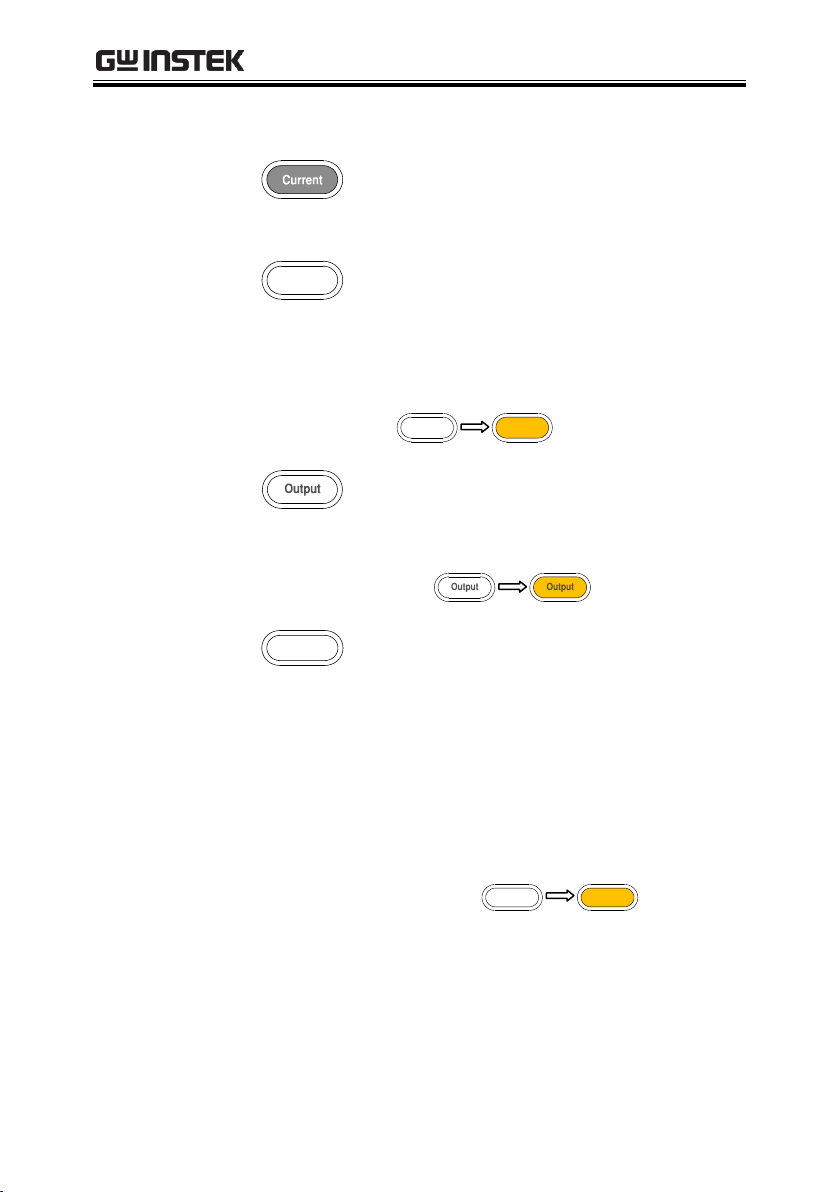

Current

Setting key

Press the Current key to set the

current settings. See page 35 for

operation details.

Front and

Rear output

toggle key

Front and rear output toggle

switch. The key will be lit when

the output is set to the rear

outputs.

Rear panel output:

Output key

The Output key turns the output

on or off. The Output key will

lightup when the output is on.

On:

LOCK key

The Lock key is used to disable all

the panel keys except for the

Output key. Pressing the Lock key

for at least 2 seconds will turn the

panel lock on or off. The Lock key

can also be used to exit from

remote control mode. When the

panel lock is active the Lock key

will light up.

Locked:

20

Page 21

OVERVIEW

Numberpad

a. The numberpad is used to enter

various parameters and values.

The Clear key can be used to clear

set parameters.

b. F1/F2/F3/F4 function short

cuts. Press any of the function

short cuts when in the main menu

to enter the corresponding

function interface.

F1: Basic power supply function

F2: Digital voltmeter function

F3: Pulse current meter function

F4: Long integration current

measurement function.

c. H/L/A Pulse current

measurement shortcut keys. These

short cut keys only work in the

Pulse current measurement main

menu.

H: High measurement mode

L: Low measurement mode

A: Average measurement mode

Directional

keys and

Enter key

The directional keys are used for

parameter and menu selection as

well for fine adjustment of the

current/voltage settings.

The Enter key is used to confirm

the selection of any settings or

parameters and to exit after a

setting is complete.

21

Page 22

PPH-1503 User Manual

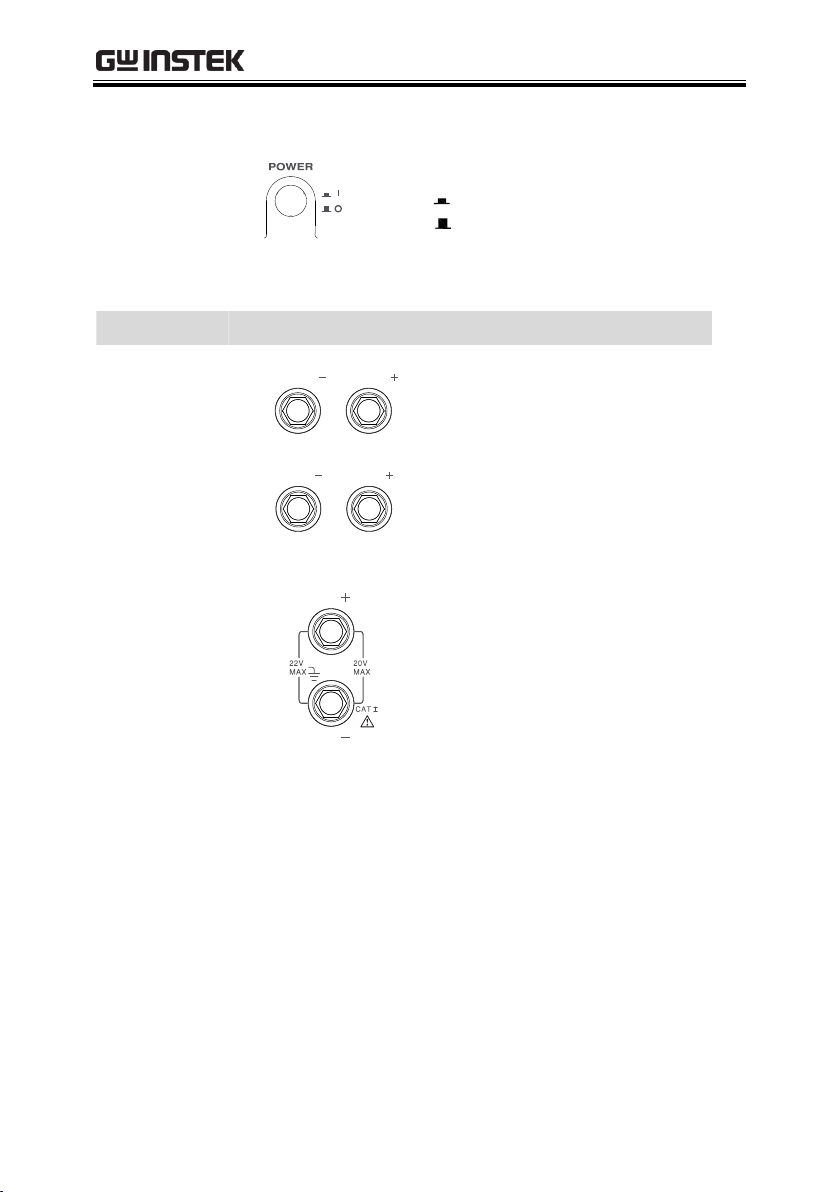

Power Button

Turns the power on or off.

On:

Off:

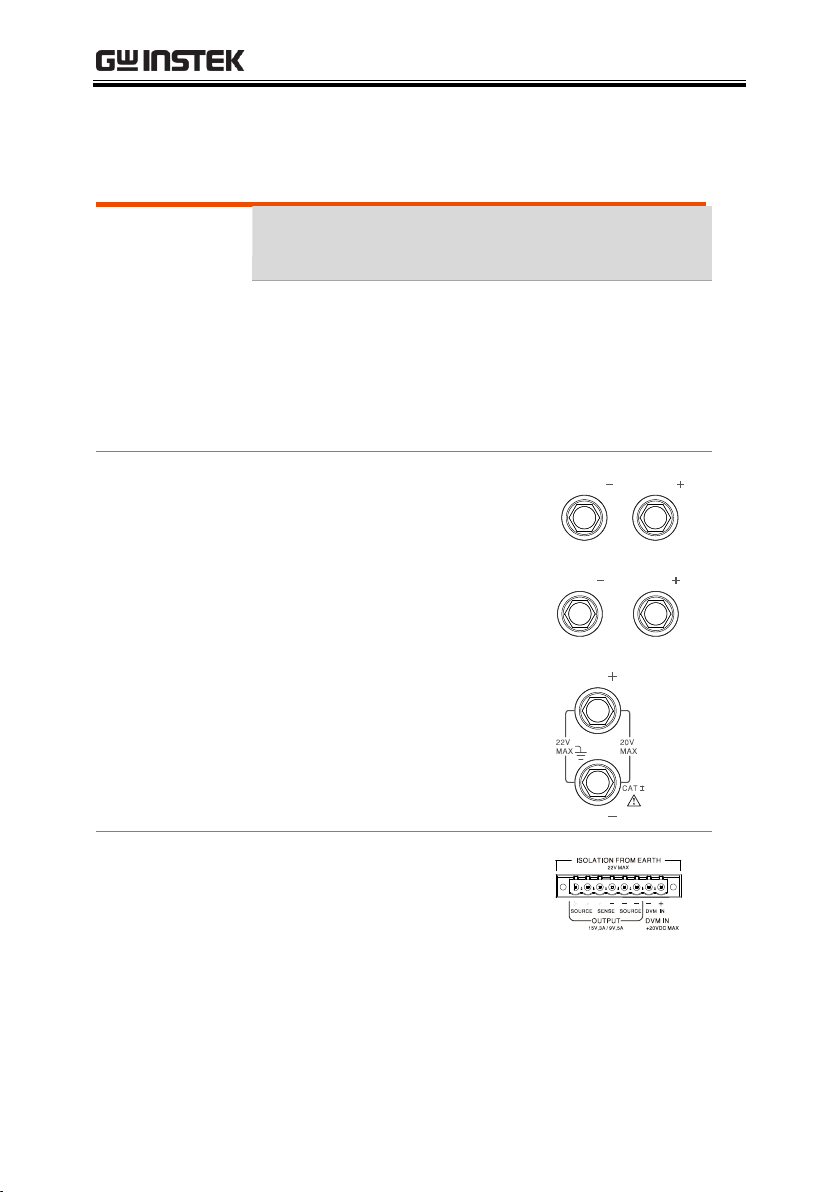

Terminals

Output

Terminals

(SOURCE)

Output source terminals.

Voltage

Feedback

Terminals

(SENSE)

Sense terminals.

Voltmeter

Terminals

(DVM)

Digital voltmeter input

terminals.

22

Page 23

Rear Panel

AC power socket

and fuse

Rear panel outputs and

DVM inputs

External

control port

Lan port

USB port

GPIB port

Heat sink fan

Terminals

AC input

socket and

line fuse

The AC input:

90~264VAC, 50Hz/60Hz

Fuse: 2A slow-blow type. See page

133 for details.

USB port

USB device port for remote

control. See page 67 for details.

GPIB port

GPIB slave port for remote control.

Abides to IEEE488.1 (SCPI)

protocol. See page 69 for details.

LAN port

LAN port for remote control. See

page 72 for details.

OVERVIEW

23

Page 24

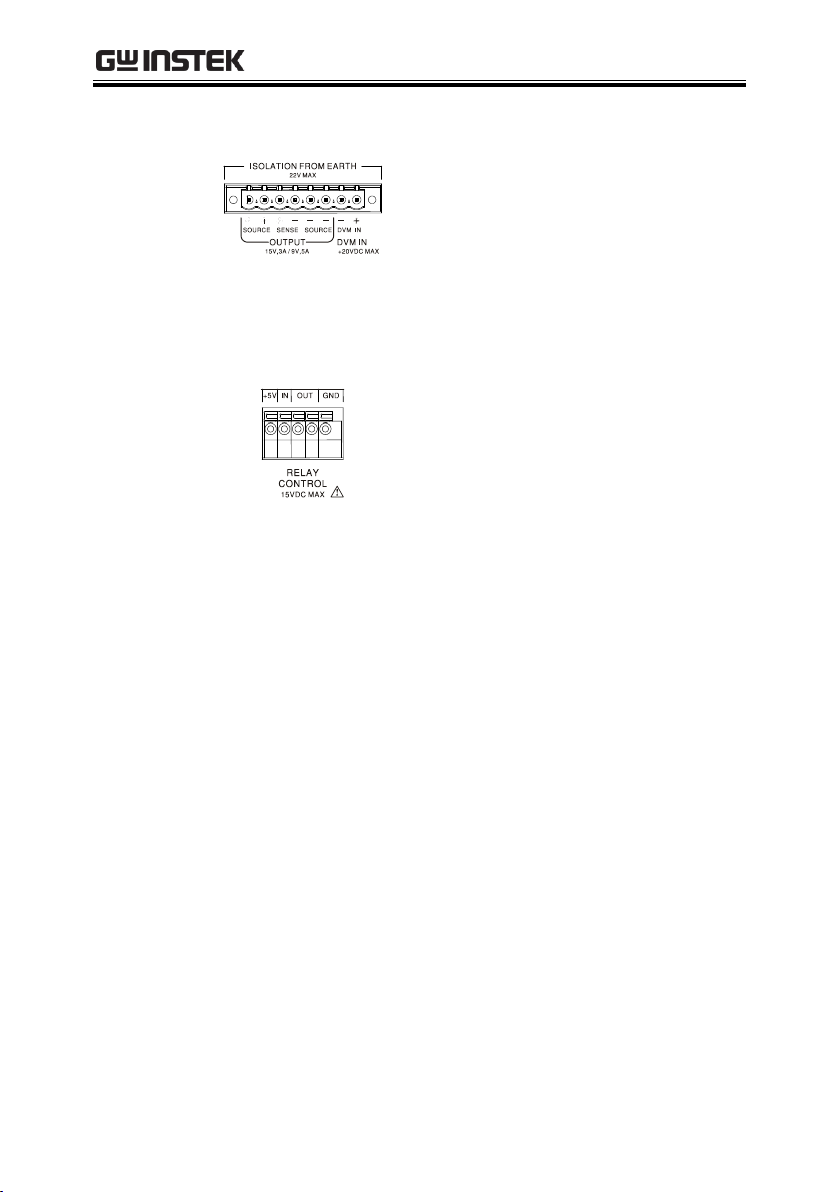

PPH-1503 User Manual

Output

interface

A total of 8 ports: 2 positive output

terminals, 2 negative output

terminals, a Sense+ terminal, a

Sense- terminal, a DVM- input

terminal and a DVM+ input

terminal. Refer to the printed label

under the terminals for the specific

order of the terminals.

Relay control

interface

A total of 5 ports: A +5V input

terminal, a ground terminal and 2

terminals for relay control. See

page 56 for relay control details.

24

Page 25

OVERVIEW

Background

The unit will switch automatically between

constant voltage and constant current according to

changes in the load.

CV mode

When the load current is less than the current

setting, the unit operates in constant voltage mode,

changing the current level according to the load

but maintaining the set voltage level until the

current reaches the set current level. The status

indicator will show CV on the LCD when in CV

mode.

Constant Current

Mode

When the output current reaches the set current

level, the unit switches operation to constant

current mode. The status indicator will show CC

on the LCD display. In CC mode, the current level

is maintained and the voltage level is limited to

less than the set voltage level to limit the output

power from an overload. When the current drops

below the set current level, the unit will revert

back to CV mode.

Constant Voltage/Constant Current Crossover Characteristics

25

Page 26

PPH-1503 User Manual

Diagram

Vmax

Imax

Constant

Voltage

Constant

Current

Vout

Iout

26

Page 27

GETTING STARTED

Checking the AC

Voltage

Before the power is turned on,

confirm that the input power

supply meets the following

conditions:

90-264VAC, 50Hz/60Hz

Connecting the

AC power cord

The fuse is a 2A slow-blow fuse.

Confirm that the fuse is of the

correct type and rating before

connecting the power cord.

Turning the

power on

Press the power button. The

LCD will display the line

frequency of the AC power

supply.

Turning the

power off

To turn the power off, press the

power button again.

GETTING STARTED

This chapter describes the start up procedures and the

preparation that is necessary before operating the

power supply.

Start Up

27

Page 28

PPH-1503 User Manual

Recommended

Cables

Model

Specification

Usage

GTL-117

10A

Front panel DVM input

GTL-204A

10A

Front panel Source

terminal

GTL-203A

3A

Front panel Sense

terminal

Front panel

wiring

Use the GTL-204A cables for the

front panel source connections.

Use the GTL-203A cables for the

sense connections.

Use the GTL-117 cables for the

DVM connections.

Rear panel

connections

Rotate the screws counter

clockwise to loosen the ports.

Insert the wires into the

appropriate terminal according

to the labels printed under the

terminals.

DVM and Load Connection

28

Page 29

GETTING STARTED

Screw the terminals in a

clockwise direction to tighten.

Note

For safety considerations, please keep in mind that the

front panel and rear panel terminals are physically

connected.

Wire Gauge

Load wires must have enough current capacityto

minimize cable loss and load line impedance.

Voltage drop across a wire should not excess 0.5V.

The following list is the wire current rating at

450A/cm2.

Wire Size(AWG)

Maximum Current (A)

20

2.5 18

4

16

6

14

10 12

16

Panel Operation

Press the Output key to

turn the output on. The

Output key will light-up

when the output is on.

The status display on the

LCD display will also turn

on.

OFF

ON

Turning the Output On/Off

29

Page 30

PPH-1503 User Manual

When the output is turned on, pressing the Output

key again will turn the output off. When the

output is off, the Output key will no longer be

illuminated and the status on the LCD display will

revert back to the OFF status.

Automatic

Output Shut

Down

Any of the following actions will cause the output

to be automatically shut down:

If any of the setups are recalled.

OVP/OTP protection is tripped.

OCP protection is tripped.

30

Page 31

BASIC OPERATION

Description

The PPH-1503 operates as a generic power supply

with the ability to display different current ranges.

The output can be toggled between the front and

rear outputs using the Rear key. When the Rear

key is lit, it indicates that the rear panel output is

active and that the front panel output is off.

Parameter

Description

IntRate

The data sampling period derived

from the number of power line

cycles.

The setting range is:

0.1PLC to 10.00PLC (power line

cycles)

1PLC = 16.7ms(60Hz)/20ms(50Hz).

*PLC stands for power line cycles.

BASIC OPERATION

This chapter describes how to set various functions.

Basic Power Supply Functions

31

Page 32

PPH-1503 User Manual

AverRead[1][2]

Readback refresh rate. This will

display the average number count.

The settings for parameters[1][2] are

shared, the remaining parameters

[3][4] are set in their corresponding

menus.

[1] Power Supply functions

[2] DWM function.

[3] Pulse current measurement

[4] Long integration current

measurement

CurrRange

The current range selection has

three settings: 5A, 5mA and Auto.

The 5mA range only accepts a

current setting 1A or less. If the

5mA range is selected and if the

current setting is greater than 1A,

the setting value is automatically

reduced to 1A.

32

Page 33

BASIC OPERATION

LimMode

Current limiting mode

There are 4 settings for the current

limiting mode:

Limit, Trip, LimitRelay, Trip Relay.

The Limit settings will limit the

current. When the current reaches

the setting value, the current

remains constant, as in CC mode.

The Trip setting will turn the output

off when the current limit has been

reached.

See page 56 for details on the Limit

Relay and Trip Relay settings.

PowoOnSetup

Power on settings have 11 settings:

Rst/SAV0 ~ SAV9

See page 60 for further details.

RelayControl

The relay control settings have 2

configurations:

Zero/One

See page 56 for further details.

O.V.P

The overvoltage settings have a

setting range of 0.05 to 15.20V or

OFF.

RecallSetup

There are 6 sets of save/recall

memories.

Rst/ SAV0 to SAV4

33

Page 34

PPH-1503 User Manual

Output Range

Voltage

0.000V~15.000V

Current

0.0000A~3.0000A (0V~15V)

0.0000A~5.0000A (0V~9V)

Parameter

Settings

Voltage

Press the Voltage key

and the voltage setting

on the LCD is

activated. A yellow dot

appears under the

current digit.

V-Set

00.500 V

(a)Use the number pad (keys: 0~9,

Clear) to set the voltage value and

then press the Enter key.

To enter 12.345V:

The input dialog box appears on

the LCD:

12.345

34

Page 35

BASIC OPERATION

(b)Step Setting:

Press the left and right

arrow keys ( , ) to

fine tune the voltage

setting at the digit

level. The selected digit

will have a yellow dot

directly underneath.

Press the up and down

arrow keys ( , )

to adjust the selected

digit. Press the Voltage

key again to finish and

exit setting the voltage.

Current

Press the Current key

and the current setting

on the LCD is

activated. A yellow dot

appears under the

current digit.

I-Set

2.000 A

(a)Use the number pad (keys: 0~9,

Clear) to set the current value and

then press the Enter key.

To enter 1.2345A:

The input dialog box appears on

the LCD:

1.2345

35

Page 36

PPH-1503 User Manual

Press the left and right

arrow keys ( , ) to

fine tune the current

setting at the digit

level. The selected digit

will have a yellow dot

directly underneath.

Press the up and down

arrow keys ( , )

to adjust the selected

digit. Press the Current

key again to finish and

exit setting the current.

IntRate

Use the arrow keys to select IntRate

and press Enter. Input the

parameters and press Enter to save.

Range: 0.1 to 10.00

AverRead[1][2]

Use the arrow keys to select

AverRead[1][2] and press Enter. Input

the parameters and press Enter to

save.

Range: 1 to 10

CurrRange

Use the arrow keys to select

CurrRange and press Enter to go the

the CurrentRange menu. Input the

current range using the up and

down arrow keys. Press Enter to

save.

36

Page 37

BASIC OPERATION

LimMode

Use the arrow keys to select LimMode

and press Enter to go to the Current

Lim menu. Select the Current Lim

mode using the up and down arrow

keys. Press Enter to save.

See page 56 for further details.

PowOnSetup

Use the arrow keys to select

PowOnSetup and press Enter to go to

the Power On Setup menu. Use the

up and down arrow keys to select

the power on setting. Press Enter to

save.

See page 60 for further details.

RelayControl

Use the arrow keys to select

RelayControl and press Enter. Use the

up and down arrow keys to set the

type of relay control. Press Enter to

save.

See page 56 for further details.

O.V.P

Use the arrow keys to select O.V.P

and press Enter. Input the OVP

setting and press Enter to save.

RecallSetup

Use the arrow keys to select

RecallSetup and press Enter to go to

the Recall Setup menu. Use the

arrow keys select a stored setup.

Press Enter to confirm the recall.

See page 60 for further details.

37

Page 38

PPH-1503 User Manual

Note:

1. The

Clear

key can be used to clear numbers that

have already been entered.

2. Voltage and current parameter values use stepped

input values. All other numerical parameters can use

the number pad to enter parameter values.

Operation

REAR /

FRONT

After setting all the parameters the

Rear key can be used to set the

output to the front or rear output

terminals.

Pressing the Rear key will toggle the

output between the front and rear

terminals.

When set to rear, the Rear key will

light up and REAR will appear in the

status bar on on the LCD.

When set to front, the Rear key will

not be lit and FRONT will appear in

the status bar on the LCD.

REAR

FRONT

38

Page 39

BASIC OPERATION

Output

Press the Output key to turn the

output on. When the output is on, the

Output key will light up and ON (in

green) will be shown in the status bar

on the LCD.

When the output is off, the Output

key will not be lit and OFF (in red)

will be shown in the status bar on the

LCD.

ON

OFF

Status

Description

CV/CC

These two icons represent

the output states of the

power supply:

CV appears in yellow when

the power supply is in

constant voltage mode.

CC appears in red when the

power supply is in constant

current mode.

C V C C

O.V.P

OVP will appear in yellow

when the OVP has not been

tripped.

The OVP icon will turn red

when the OVP has tripped.

When the OVP protection

has not been activated, it

will be greyed-out.

O.V.P

O.V.P

O.V.P

39

Page 40

PPH-1503 User Manual

BEEP

When the beeper setting is

activated, the BEEP icon will

be shown in yellow.

When the beeper settings is

turned off, it will be greyedout.

BEEP

BEEP

LOCK

When the panel lock is

activated, the lock icon will

be shown in red.

When the panel lock is

turned off, the lock icon is

greyed-out.

LOCK

LOCK

RMT

In the remote control display

area, RMT will be shown in

grey when reomote control

is disabled.

When GPIB remote control is

active, a red GPIB icon is

shown. When LAN remote

control is active, a red LAN

icon is shown and when USB

remote control is active, a

red USB icon is shown.

RMT

GPIB

LAN

USB

40

Page 41

BASIC OPERATION

REAR/

FRONT

When the output is set for

the rear panel terminals,

REAR is displayed in

yellow.

When the output is set for

the front panel, FRONT is

displayed in yellow.

REAR

FRONT

ON/OFF

When the output is off, OFF

in displayed.

When the output is on, ON

is displayed.

OFF

ON

Description

The PPH-1503 has a separate digital voltmeter

with a measurement range of 0~+20VDC. When

using the voltage meter, the power supply must be

properly grounded.

Parameter

Description

Intrate

Sets the reading rate of DVM

measurements based on the number

of PLCs.

0.01PLC~10.00PLC.

1PLC=16.7ms(60Hz)/20ms(50Hz).

*PLC stands for Power Line Cycle

DVM

41

Page 42

PPH-1503 User Manual

AverRead[1][2]

The number of samples used to

calculate the average. The AverRead

setting for the power supply

functions[1] and the DVM

functions[2] are shared.

Note:

[1]: Power supply functions

[2]: DVM function

[3]: Pulse current measurement

function

[4]: Long Integration current

measurement function

RecallSetup

There are 6 sets of save/recall

memories.

Rst/ SAV0 to SAV4

Parameter

Setttings

IntRate

Use the arrow keys to select IntRate

and press Enter. Input the

parameters and press Enter to

save.

Range: 0.01 to 10.00

AverRead[1][2]

Use the arrow keys to select

AverRead[1][2] and press Enter. Input

the parameters and press Enter to

save.

Range: 1 to 10

42

Page 43

BASIC OPERATION

Recall Setup

Use the arrow keys to select

RecallSetup and press Enter. Use the

arrow keys select a stored setup.

Press Enter to confirm the recall.

See page 60 for further details.

Operation

The unit switches to DWM mode

automatically when the DVM

inputs are used. Using the DVM

meter function doesn’t affect the

operation of the power supply.

The DMV function works with the

output on or off.

Connection

For the connection details for the front and rear

terminals, please page 28.

Description

Changes in the load current allows us to measure

the pulse current.

There are three ways that pulse current can be

measured:

1. Measuring the peak current over a single cycle

(High Measurement).

2. Measuring the trough current over a single cycle

(Low Measurement).

3. Measuring the average current over a single

cycle (Average Measurement).

Pulse Current Measurement

43

Page 44

PPH-1503 User Manual

The high and average measurements are triggered

by the rising edge of the pulse current are

performed for the time specified for the

measurement.

Low measurement is triggered by the falling edge

of the pulse current.

Note: Pulse current measurement is only valid up

to 5A.

Parameter

Description

IntTime

Integration Time.

The integration measurement time

can be set to automatic or to one of

the manual settings (High Time,

Low Time, Aver Time).

When the integration

measurement time is set to

automatic mode, the system will

measure the peaks and troughs of

the pulse current and will

automatically set an appropriate

intergration time. The average

integration time is the time of all

the accumulated peaks and

troughs. After the setting the

integration time to automatic, the

setting will apply to all subsequent

pulse measurements, unless the

automatic integration mode is

applied again or the integration

time is manully set. The automatic

44

Page 45

BASIC OPERATION

Integration time can automatically

detect pulses in the 80uS to 833mS

range.

The manual time range setting is

33uS to 833333uS. The default

units are in microseconds (uS). The

unit will automatically round

down the last two digits to 00, 33

or 66 micoseconds. For example,

for a value of 65.999, it will be

rounded down to 33 and 66.01 will

be rounded down to 66.

TrigDelay

Trigger Delay

When a pulse is detected, there

will be a 25us code execution

delay time. The trigger delay

settings are used to filter out the

current overshoot. Measurement

will begin from after the trigger

delay time. The trigger delay

setting range is: 0~0.10000S, with a

resolution of 0.00001S. The setting

units are in seconds.

AverRead[3]

Average Reading Count: Reads

back the average number of

displayed values.

This parameter is only applicable

for pulse current measurement.

The average number range can set

from 1 ~ 100 with a resolution of 1.

45

Page 46

PPH-1503 User Manual

TrigLeve[3]

Trigger Level.

To avoid false pulse

measurements, the trigger level

can be set close to the current

amplitude. All noise and transient

currents that are below the trigger

level will be ignored. The trigger

level has a setting range of 0 to 5A,

with a resolution of 5mA. The

setting unit for the trigger level is

in amps (A). This setting is only

valid for pulse measurements.

RecallSetup

Recalls stored settings. A total of 6

settngs can be recalled:

RST/SAV0 to SAV4

Parameter

Settings

IntTime

Use the arrow keys to select IntTime,

press Enter and then use the arrow

keys to select the type of integration

time that you want to set (Hight

Time, Low Time, Aver Time). Press

Enter again to set the integration

time. After inputing the integration

time, press Enter to return to the

pulse current measurement menu. If

Auto Time was selected, press Enter to

return to the pulse current

measurement menu.

Example:

High Time 33uS: IntTime

Hight Time

using the

46

Page 47

BASIC OPERATION

numberpad enter 33

.

The time range can be set between

33uS and 833333uS. The setting units

are in microseconds (uS).

TrigDelay

Use the arrow keys to select TrigDelay,

press Enter and input the delay. Press

Enter again to confirm.

The TrigDelay has a settable range of

0~0.10000S. The setting units are in

seconds (S).

AverRead[3]

Use the arrow keys to select

AverRead[3], and then press Enter. Input

the AverRead number and then press

Enter again to confirm.

The AverRead setting has a settable

range of 1~00.

TrigLeve[3]

Use the arrow keys to select TrigLeve[3]

and press Enter. Input the trigger

level and press Enter again to

confirm.

The TrigLeve parameter has a

settable range of 0~5.000A. The

setting units are in amperes (A).

RecallSetup

Use the arrow keys to select RecallSetup

and press Enter to go the Recall Setup

menu. Use the arrow keys to a setup.

Press the Enter key to confirm. See

page 60 for further details.

47

Page 48

Panel Operation

Output

Press the Ouput key.

When the Output key is

lit, pulse current

measurement is active.

When no pulse current is

detected, NO PULSE will

be dispalyed in red on the

LCD screen. The unit will

wait until the next pulse is

detected.

The measurement

settings can be

edited during

measurement. The

H, L, A keys on the

keypad can be

used to perform

fast-switching

between

measurement

modes.

HIGH

LOW

AVER

Note

The LCD display

will indicate which

measurement

mode is active with

an orange line

under the active

mode for HIGH,

LOW or AVER.

HIGH

NO PULSE

PPH-1503 User Manual

48

Page 49

BASIC OPERATION

Description

The long current integration measurement function

measures the mean (average) current over a single or

multiple current pulses. The long integration time

period must be a full period or integer multiples of a

complete period of the measured pulse current. The

Long integration measurement calculates the whole

integration time as an integer number of integration

cycles. An integration cycle is the line cycle period plus

the data processing time.

For example, if the line frequency is 60Hz, then a single

integration cycle is 16.7mS, if the frequency is 50Hz,

then a single integration cycle is must be 20mS. Long

integraton is one of the methods to extend A/D circuits

to exceed beyond their maximum integration time. The

A /D conversion circuits can measure a pulse of up to

833 mS. Long integration measurement extends the

A/D integration time to achieve a longer pulse

measurement. This can extend the measurement time

for long integration to a maximum of 60S.

Note: When this feature is used, the current range is

set to 5A.

Long integration

49

Page 50

Parameter

Description

IntTime

Integration time

The integration time can be set

manually or automatically by the

operator. For manual settings, the

integration time can be set to a

maximum of 60 seconds. For a line

frequency of 60Hz the minimum

integration time is 850mS with a step

resolution of 16.7mS. For a line

frequency of 50Hz, the minimum

integration time is 840mS with a step

resolution of 20mS.

When the integration time is set to Auto

Time, the system will automatically

measure the time between two adjacent

rising edges and an appropriate

integration time is set for the peak and

trough. If there are more than two

pulses, the integration time must be set

manually.

TrigEdge

Trigger edge

Pulse edges are used to trigger long

integration measurement. Regardless of

whether a rising or falling edge is used

as a trigger, a pulse must furst be

detected before measurement can start.

Measurement can also start without an

edge trigger. When Trig On Neither is

selected, measurement starts as soon as

the output is turned on.

PPH-1503 User Manual

50

Page 51

BASIC OPERATION

Timeout

Pulse timeout

When long integration measurement is

selected and the unit doesn’t detect a

pulse after a certain amount of time

(pulse timeout time), the “No Pulse”

message will be displayed on the LCD.

This function is only applicable if rising

or falling edge is selected as the edge

trigger; the Trig On Neither trigger

setting has no pulse timeout. The pulse

timeout has a range of 1~63 seconds.

TrigLeve[4]

Trigger level.

When the rising or falling edge trigger is

selected for long integration current

measurement, a pulse must first be

detected. The trigger level refers to

minimum pulse level required for a

pulse to be detected. For example if the

trigger level is set to 2A, pulses that are

≤2A will be detected. Pulses <2A will be

ignored. The trigger level range is 0~5A.

This setting only applies to long current

integration measurements.

RecallSetup

Recalls pre-saved setups. A total of 6

setups can be recalled: RST/SAV0 ~

SAV4. See page 60 for details.

51

Page 52

Parameter

Settings

IntTime

Use the arrow keys to select IntTime then

press Enter. Use the arrow keys to select a

time setting.

If SetTime was selected, press Enter and

then enter the long current integration

time. Press Enter to save the setting and

return to the long integration

measurement menu.

If AutoTime was selected, press Enter to

confirm and to go back to the long

integration measurement menu.

For manually set integration times, if the

set time is not an integer multiple of the

integration cycle time, the system will

automatically round down to closest

maximum integer multiple that can be

set.The time range is 850mS to 60S (50Hz)

and 840mS to 60S (60Hz). The default unit

is seconds (S).

TrigEdge

Use the arrow keys to select TrigEdge and

then press Enter. Use the arrow keys to

select the type of trigger and press Enter to

confirm the trigger settings and to return

to the long integration measurement

menu.

Timeout

Use the arrow keys to select Timeout and

then press Enter. Enter the timeout settings

and press Enter again to confirm and to

return back to the long integration

measurement menu. The time range is

1~63S. The default unit is seconds (S).

PPH-1503 User Manual

52

Page 53

BASIC OPERATION

TrigLeve[4]

Use the arrow keys to select TrigLeve[4] and

then press Enter. Key in te trigger level

setting and press Enter again to confirm

and to return back to the long integration

measurement menu. The trigger level

range is 0~5A. The default is amps (A.)

RecallSetup

Use the arrow keys to select RecallSetup and

press Enter to go to the Recall Setup menu.

Use the arrow keys to select a saved setup

and press Enter again to confirm. See page

60 for details.

Operation

Output

Press the Output key. When the

Output key is lit, pulse current

measurement is active.

When no pulse current is

detected, NO PULSE will be

dispalyed in red on the LCD

screen. The unit will wait until

the next pulse is detected.

NO PULSE

53

Page 54

PPH-1503 User Manual

Function

Description

When the test circuit is an active circuit, and the

manifested voltage in the test circuit is greater than

the output voltage of the power supply, the power

supply will automatically disipate current from the

external power supply. When this function is in the

normal operating state, the power supply outputs

the setting voltage, which is equivalent to a

constant voltage load rather than constant current

load.

The current disipation from the power supply

output flows from the positive terminal out to the

negative terminal. The amount of current sunk is

not controlled from the power supply.

Connection

Connect the positive terminal of the external power

supply to the positive terminal on the high-speed

power supply. Connect the negative terminal of the

external power supply to the negative terminal on

the high-speed power supply.

Current Sink Function

54

Page 55

Conditions

To protect the high-speed power supply when

operating as a current sink, the following two

conditions must be met:

1. Ensure that the voltage of the external power

supply is greater than the output of the highspeed power supply voltage by 0.3V~2.5V. The

voltage difference depends on the high-speed

power supply voltage output and the load

conditions.

2. To ensure that the high-speed power supply

output voltage is within the range of 0~5V, the

current draw cannot exceed 2A. For output

voltgages between 5V~15V, the current draw

must be reduced by 0.1A for each 1V increase

over 5V. See the formula in the table below for

the details.

High-speed Power Supply

Output Voltage

Maximum Dissipation

Current

0~5V

2A

5V~15V

2A-((0.1A/V)*(output

voltage - 5V))

BASIC OPERATION

55

Page 56

PPH-1503 User Manual

Function

Description

When the Relay control feature is turned on, it is

synced to the current limit of the power suppy.

The external relay control is divided into two

different types, a limit relay and a trip relay.

The limit relay is used in conjuction with CC

mode. When the constant current setting value is

reached, the relay control signal will go high and

will return back to the low level when the current

level goes back below the constant current setting.

The trigger relay is used in conjuction with CC

mode. When the constant current setting value is

reached, the relay control signal will go high and

the output is disabled. When the output goes back

on and the current is less than the current setting

value, the relay control signal will back to the low

level.

Rear Panel

Control Interface

The rear panel control interface

has five terminals, +5V,

IN(software upgrade), OUT

(outputs the control signals) and

GND (connected to the chasis

ground or earth ground),

respectively.

Wiring Method

A thin screwdriver or similar tool will need to be

inserted into the release mechanism (highlighted

in orange in the figure above) to open the

terminals. Insert an exposed wire into the terminal

and release the mechanism to lock the wire into

place.

External Relay Control

56

Page 57

Schematic

Diagram for Relay

Control

Limit Relay:

Current

Limit setting

on

off

Relay

Trip Relay:

Current

Limit setting

on

off

Relay

Output turns off due to

Trip Mode

User turns output on,and trip

condition is

corrected.Otherwise,output

will trip again.

BASIC OPERATION

57

Page 58

PPH-1503 User Manual

External Relay

Connection

There are two ways to connect an external relay to

the unit:

1. Using the the +5VDC relay output to drive an

external relay. Ensure the current doesn’t

exceed 150mA.

+5VDC

OUT

OUT

IN

GND

Power Supply

Relay

Control

Relay

Internal

Source +5VDC

±5%

Protection Diode

Warning: Do not short the 5VDC terminal to the

chasis, earth or to the control port GND, otherwise it

may damage the unit.

2. Using an external power source to drive the

external relay. The voltage of the source cannot

exceed 15V and the current cannot exceed

150mA.

+5VDC

OUT

OUT

IN

GND

Power Supply

Relay

Control

Relay

Internal

Source +5VDC

±5%

Protection Diode

External Source

15VDC Max

58

Page 59

SAVE/RECALL

Description

Five groups of system settings are available.

Parameter data

Listed below are the settings that are available for

each group (Rst is shown as an example).

Voltage: 00.500V

CurrRange: 5A

Current: 2.0000A

IntRate: 1.00PLC

OutputState: Off

AverRead[1][2]: 1

DispType: Actual V and I

O.V.P: Off

GPIBAddr: 16

LimMode: Limit

GPIBFormat: Exponential

RelayControl: Zero

HighTime: 33us

AverRead[3]: 1

LowTime: 33us

TrigDelay: 0.10000

AverTime: 33us

TrigLevel[3]: 0.000A

IntTime: 1.000s

TrigEdge: Rising

Timeout: 16s

TrigLevel[4]: 0.000A

Operation

Press the Menu key to enter the main

menu interface.

Use the up and down arrow to select the

Save Setup option.

Press Enter to go to the Save Setup menu.

SAVE/RECALL

Save Settings

59

Page 60

PPH-1503 User Manual

Use the left and right arrow keys to select

the desired save memory. There are five

selections: SAV0, SAV1, SAV2, SAV3,

SAV4.

Press the Enter key to save the settings

and return to the main interface.

Result

The current settings on the unit will be saved to

one of the memory locations (SAV0~SAV4)

Description

There a total of 6 different memory settings that

can be recalled: Rst, SAV0, SAV1, SAV2, SAV3,

SAV4, SAV5.

Operation

There are two methods to recall the

setup settings.

Method 1:

Use the arrow keys to select Recall Setup

via F1, F2, F3 or F4 from the display

interface

Press the Enter key to enter the Recall

Setup interface.

Use the left and right arrow keys to

select a setup to recall (Rst, SAV0 ~

SAV4).

Press Enter to confirm and to return to

the main interface.

Recall Settings

60

Page 61

SAVE/RECALL

Method 2:

Press the Menu key

Use the up/down arrow keys to select

Recall Setup.

Press Enter to enter the Recall Setup

interface.

Use the left and right arrow keys to

select which setting to recall.

Press the Enter key to confirm the

selection.

Power On

Settings

In the main menu, the interface parameter settings

area shows PowOnSetup settings. There are 11

PowOnSetup settings to choose from, Rst,

SAV0~SAV4 and SAV5~SAV9.

The main difference between SAV0~SAV4 and

SAV5~SAV9 is that SAV0~SAV4 are user saved

settings and don’t contain the Power On/Off state

(Output State is always off) while the SAV5~SAV9

contain the Power On/Off state. The SAV5~SAV9

settings are synced from corresponding

SAV0~SAV4 settings and are identical but for the

the Power On/Off state. The Power On/Off states

simply indicate if the Output State can be on or off.

The relationship between SAV0~SAV4 and

SAV5~SAV9 is as follows:

SAV0 SAV5

SAV1 SAV6

61

Page 62

PPH-1503 User Manual

SAV2 SAV7

SAV3 SAV8

SAV4 SAV9

62

Page 63

SAVE/RECALL

Description

The system can retrieve the factory default settings

by loading the Rst setting. This setting cannot be

modified.

Operation

There are two methods to retrieve the factory

default settings. Please see the Recall Settings

sections for instructions (page 60).

Restore Factory Default Settings

63

Page 64

PPH-1503 User Manual

Description

The System Information menu can be used to view

the system information or to perform system

operations such as set the buzzer function,

backlight display brightness or set to the factory

conditions.

System

Information

Items

System Version

View the system software version.

Serial Number

View the machine serial number.

Calibration Unit

Calibration menu. Factory use

only.

Utility

System setting items: Buzzer

setttings, backlight brightness

settings and factory restore.

Operation

Press the Menu key and select System Information.

Press the Enter key to enter the System

Information menu.

SYSTEM SETTINGS

System Information

64

Page 65

SYSTEM SETTINGS

Description

There are two utility settings: buzzer settings and

backlight brightness settings.

Setting

Information

Beep

Sets the when the buzzer is turn on.

BackLight

Adjust the LCD brightness.

Buzzer Operation

In the Utility menu, use the up and

down arrows to select Beep.

Press Enter and then set the buzzer

state to on or off. When the buzzer is

set to on, Beep On will be displayed.

Beep

On

Press the Menu key to exit and return

to the main interface. The buzzer

status will be displayed on the LCD.

BEEP

Backlight

Brightness

Adjustment

In the Utility menu, use the up and

down arrow keys to select BackLight.

Press Enter to toggle the backlight

brightness level. The brightness level

is displayed under BackLight. There

are three brightness levels: High,

Middle, Low.

BackLight

Middle

Press the Menu key to exit and return

to the main interface.

Utilty Settings

65

Page 66

PPH-1503 User Manual

Restore to Factory

Settings

In the Utility menu, use the up and down arrow

keys to select In factory reset, then press the Enter

key to restore to the factory settings. This function

is only for factory use.

66

Page 67

REMOTE CONTROL

Description

The PPH-1503 can be connected via USB using the

USB Communications Device (CDC) class.

Interface

Rear panel USB slave port.

Installing the

Driver

Before connecting the unit to the USB

port of the PC, make sure the

approriate driver has been installed.

The driver is available from the GW

Instek website. When the unit has

successfully connected to the PC via

USB, USB will be displayed in the

status bar in red.

USB

The front panel keys are automatically

locked when the unit is in remote

mode.

LOCK

REMOTE CONTROL

Remote Control

USB

67

Page 68

PPH-1503 User Manual

COM port

settings

The following settings should be set to the

following:

Baud rate: 115200 or less

Parity: None

Data bits: 8

Stop bits: 1

Data overflow control: None

Function Check

Perform the following query:

*IDN?

The unit will return the manufacturer, model,

serial number and software version.

GW INSTEK, PPH-1503, SN: xxxxxxxx, Vx.xx

Disabling Remote

Control Mode

Send a remote command to exit from

remote control mode from the PC or

long-press the unlock key on the front

panel to exit from the remote control

mode. The RMT icon in the status bar

will become grey when you exit from

remote control mode.

The LOCK icon in the status bar will

also turn grey.

Unplug the USB cable from the rear

panel.

RMT

LOCK

Note: USB devices are hot-plug devices. You can

directly remove the cable and exit.

68

Page 69

REMOTE CONTROL

Description

The GPIB remote control can be set from the

interface menu. The communication data format,

compatibility settings and and address must all be

configured before using GPIB remote control.

Interface

Rear panel GPIB port.

Connection

When the unit has been successfully

connected via GPIB, GPIB will

appear in the status bar in red. The

panel key will also be locked.

GPIB

The front panel keys are

automatically locked when the unit

is in remote mode.

LOCK

Communication

Data Format

There are four data formats to select from:

Exponential, 2DPS, 3DPS and 4DPS.

Steps

A. Press the Menu key to enter the main

menu.

B. Use the up and down arrow keys to

select Interface.

C. Press Enter to enter the Interface menu.

D. Use the up and down arrow keys to

select GPIB.

E. Press Enter to enter the GPIB menu.

GPIB

69

Page 70

PPH-1503 User Manual

F. Use the up and down arrows to select

Output Format.

G. Press the Enter key to toggle between

the different output formats.

H. Press the Menu key to exit and return

to the main menu.

Output Formats

There are two different output formats to select

from: KEITHLEY 2303 and FLUKE PM2811.

Steps

Follow steps A~E in the previous section, above.

F. Use the up and down arrow keys to

select Output Type.

G. Press the Enter key to toggle between

each of the output formats.

H. Press the Menu key to exit and return

to the main menu.

Setting the GPIB

Address

Configuring the GPIB address for connection to a

PC.

Steps

Follow steps A~E in the previous section, above.

F. Use the up and down arrow keys to

select Primary Address.

G. Press the Enter key and then set the

GPIB address. Press the Enter key again

to confirm. The address range is 1~30.

70

Page 71

REMOTE CONTROL

H. Press the Menu key to exit and return

to the main menu.

Exiting from

Remote Control

Mode

Send a remote command to exit from

remote control mode from the PC or

long-press the unlock key on the front

panel to exit from the remote control

mode. The RMT icon in the status bar

will becomes greyed-out when you

exit from remote control mode.

The LOCK icon becomes greyed-out

when the panel becomes unlocked.

Unplug the connection from the rear

panel.

RMT

LOCK

71

Page 72

PPH-1503 User Manual

Description

When using the LAN interface a number of

settings must be turned on.

IP Mode

The IP address can be configured using either

DHCP, Auto IP or Manual IP. Using DHCP to get

an IP address automatically assigned. The system

will use AUTO IP to obtain an automatically

generated IP address to avoid IP address conflicts.

Manu IP

A. Press Menu to enter the main menu.

B. Use the up and down arrow keys to

select Interface.

C. Press Enter to enter the Interface

menu.

D. Use the up and down arrow key to

select LAN.

E. Press Enter to enter the LAN menu.

F. Use the up and down arrow keys to

select IP Mode.

G. Press Enter to select Manu IP.

H. Use the up and down arrow key to

select the appropriate parameters.

I. Press Enter and then configure each of

the parameters.

LAN

72

Page 73

REMOTE CONTROL

J. Press Enter to confirm each of the

configurations.

K. Press the Menu key to exit and return

to the main menu.

Parameter Settings:

IP Address: IP address range: 1.0.0.0 to

223.255.255.255 (excluding 127.nnn.nnn.nnn).

Subnet Mask: Subnet Mask Range: 1.0.0.0 to

255.255.255.255.

Gateway: Gateway range: 1.0.0.0 to 223.255.255.255

(excluding 127.nnn.nnn.nnn).

DNS Servers: DNS Server range: 1.0.0.0 to

223.255.255.255 (excluding 127.nnn.nnn.nnn).

DHCP

Follow steps A~F in the previous section,

Manun IP, above.

G. Press Enter to select DHCP. The unit

will be assigned an IP address, subnet

mask, the default gateway and other

network parameters from the DHCP

server. The corresponding parameters will

be shown in the parameter area. Use the

arrow keys to view the settings (When an

IP address is being assigned, a circular

scanning icon will appear).

H. Press the Menu key to exit and return

to the main menu.

73

Page 74

PPH-1503 User Manual

Auto IP

Follow steps A~F in the previous section,

Manu IP, above.

G. Press the Enter key and select Auto IP.

The device will automatically obtain an IP

address and subnet address mask based

on the current network configuration.The

unit will set the IP address in the range of

169.254.0.1 to 169.254.255.254 with a

subnet of 255.255.0.0. The parameters will

be displayed in the parameter area. Use

the arrow keys to view the parameters.

H. Press the Menu key to exit and return

to the main menu.

PC Operation

1. Enter the IP address into Microsoft Internet

Explorer (IE). After entering the IP address you

will be shown the Welcome screen which displays

the instrument information. The page also

provides three links: Welcome Page, Browser Web

Control and View & Modify Configuration

(network settings).

74

Page 75

REMOTE CONTROL

2. Click on “Browser Web Control” to execute

commands through the browser, as shown below.

3. Press the “View & Modify Configuration” icon

to enter the Modify Config menu, as shown below.

4. Click “Modify Config” to enter the network

configuration setting menu, as shown below. Use

the mouse to click on “Save and Restart” to change

the remote settings for the PPH-1503.

75

Page 76

PPH-1503 User Manual

Note

Click “Undo Edits” to cancel all the edited settings.

Click “Factory Defaults” to restore to the factory

default settings.

Exiting from

Remote Control

Mode

Send a remote command to exit from

remote control mode from the PC or

long-press the unlock key on the

front panel to exit from the remote

control mode. The RMT icon in the

status bar will become greyed-out

when you exit from remote control

mode.

The LOCK icon will be greyed-out

when the panel lock is disabled.

Unplug the connection from the rear

panel.

RMT

LOCK

Note: Hot-swappable LAN devices can be

directly disconnected to exit.

Command Syntax

The commands that are used with the PPH-1503 meet IEEE488.2 and

SCPI standards.

SCPI Commands Overview SCPI

Command Format

SCPI is an ASCII based command language designed for test and

measurement instruments. SCPI commands uses a hierarchical structure

(tree system), and is divided into different subsystems. Each subsystem

76

Page 77

REMOTE CONTROL

is defined by a different root keyword. Each command consists of a root

keyword and one or more hierarchial key words separated by a colon “:”

and followed by a parameter. There is always a space between the

keywords and the parameters. Any commands followed by a question

mark (?) are queries.

For Example:

:SYSTem:BEEPer:STATe {0|1|OFF|ON}

:SYSTem:BEEPer:STATe?

SYSTem is the root level keyword and BEEPer and STATe are the

secondary and tertiary level keywords. All all levels have a “:”

separating each keyword. Parameters are enclosed in “{ }”.

The commands SYSTem:BEEPer:STATe has {0|1|OFF|ON } as

parameters. The parameters are separated with a space.

SYSTem:BEEPer:STATe? Indicates that the command is a query.

In addition some commands have multiple parameters that are usually

separated by a comma “,”. For example: :STATus:QUEue:ENABle (-

110:-222, -220).

Symbol Desription

SCPI commands have the following convential symbols. These symbols

are not commands but are used to describe the command parameters.

1. Curly Brackets { }

Curly Bracket enclose command string parameters, for example:

{ OFF|ON }

2. Verical Bars

77

Page 78

PPH-1503 User Manual

Vertical bars are used to separate one or more optional parameters. Only

one command can be selected; With the following two parameters,

{ON|OFF} only ON or OFF can be selected.

3. Square Brackets [ ]

The contents inside square brackets represent keywords or parameters

that can be omitted when executing a command. For example: For the

commands :OUTPut[:STATe] {ON|OFF}, [STATe] can be omitted.

4. Angle Brackets

The parameters in angle brackets must be substituted with a valid

parameter. For example: For the command :DISPlay: CONTrast

<brightness>, <brightness> must be use a numerical value instead such

as, :DISPlay:CONTrast 1

Parameter Types

The commands have a number of different parameter categories. How

the parameters are set depend on the parameter categories.

1. Boolean

Commands parameter that have to states “OFF” and “ON”, for example,

DISPlay:FOCUs {ON|OFF}. “ON” will turn on the focus display

function, while “OFF” will turn it off.

2. Consectutive Integers

78

Page 79

REMOTE CONTROL

Parameters that use consecutive integers, for example: For the

command :DISPlay:CONTrast <brightness>, <brightness> is an integer

value with a range of 1~3.

3. Continuous Real Number

Parameter that must be a continuous real number can have any value

within the effective range and accuracy. For example: The command

CURRent {<current>|MINimum|MAXimum}, is used to set the current

value for the current operating channel. <current> can be any value

within the setting range of the current channel.

4. Discrete

For discrete parameters, only those values that are listed can be used.

For example: The *RCL{0|1|2|3|4|5} command can only use 0, 1, 2, 3, 4,

5.

5. ASCII Strings

ASCII string parameters must use a combination of ASCII characters in a

string. For example: For the command :MODE <name>, <name> must

be an ASCII string.

Command Abbreviations

The syntax for SCPI commands contain a combination of upper and

lower case letters. The upper case letters in a command represent the

short form of that command.

Commands are not case sensitive and can used in both upper and

lower case. Note, however, to use the short form of the command, only

the capital letter part of the command can be used (no other abbreviation

can be used). For example:

79

Page 80

PPH-1503 User Manual

:FETCh?

Page 86

:FETCh:ARRay?

Page 86

:READ?

Page 86

:READ:ARRay?

Page 86

:MEASure[:<function>]?

Page 87

:MEASure:ARRay[:<function>]?

Page 87

:DISPlay:ENABle <b>

Page 88

:DISPlay:ENABle?

Page 88

:DISPlay[:WINDow[1]]:TEXT:STATe <b>

Page 88

:DISPlay[:WINDow[1]]:TEXT:STATe?

Page 89

:DISPlay[:WINDow[1]]:TEXT:DATA <a>

Page 89

:MEASure:CURRent?

Can be abbreviated to:

:MEAS:CURR

Command Terminators

When sending a command to the function generator, the command must

be terminated with a <new line> character. The IEEE-4888 EOI can also

be used as a <new line> character. A command can also be terminated

using a carriage return + <new line> character. The command path will

always be reset back to the root level after a command has been

terminated.

Return values are terminated with 0x0A.

Command List

Measurement Instructions

Display Functions

80

Page 81

REMOTE CONTROL

:DISPlay[:WINDow[1]]:TEXT:DATA?

Page 89

DISPlay:CONTrast<NRf>

Page 89

:FORMat[:DATA] <type>

Page 90

:FORMat[:DATA]?

Page 90

:FORMat:BORDer <name>

Page 90

:FORMat:BORDer?

Page 90

:OUTPut[:STATe] <b>

Page 91

:OUTPut[:STATe]?

Page 91

:OUTPut:RELay <name>

Page 91

:OUTPut:RELay?

Page 91

:OUTPut:OVP:STATe <b>

Page 92

:OUTPut:OVP:STATe?

Page 92

:OUTPut:OVP <value>

Page 92

:OUTPut:OVP?

Page 92

:[SOURce]:CURRent[:LIMit][:VALue] <NRf>

Page 93

:[SOURce]:CURRent[:LIMit][:VALue]?

Page 93

:[SOURce]:CURRent[:LIMit]:TYPE <name>

Page 93

:[SOURce]:CURRent[:LIMit]:TYPE?

Page 94

:[SOURce]:CURRent[:LIMit]:STATe?

Page 94

:[SOURce]:VOLTage[:LEVel][:IMMediate][:AMPLitude] <n>

Page 94

:[SOURce]:VOLTage[:LEVel][:IMMediate][:AMPLitude]?

Page 94

Data Format Commands

Output Commands

Source Commands

81

Page 82

PPH-1503 User Manual

:SENSe[1]:FUNCtion <name>

Page 95

:SENSe[1]:FUNCtion?

Page 95

:SENSe[1]:NPLCycles <n>

Page 95

:SENSe[1]:NPLCycles?

Page 95

:SENSe[1]:AVERage <NRf>

Page 96

:SENSe[1]:AVERage?

Page 96

:SENSe[1]:CURRent[:DC]:RANGe[:UPPer] <n>

Page 96

:SENSe[1]:CURRent[:DC]:RANGe[:UPPer]?

Page 96

:SENSe[1]:CURRent[:DC]:RANGe:AUTO <b>

Page 97

:SENSe[1]:CURRent[:DC]:RANGe:AUTO?

Page 97

:SENSe[1]:PCURrent:AVERage <NRf>

Page 97

:SENSe[1]:PCURrent:AVERage?

Page 98

:SENSe[1]:PCURrent:MODE <name>

Page 98

:SENSe[1]:PCURrent:MODE?

Page 98

:SENSe[1]:PCURrent:TIME:AUTO

Page 98

:SENSe[1]:PCURrent:TIME:HIGH <NRf>

Page 99

:SENSe[1]:PCURrent:TIME:HIGH?

Page 99

:SENSe[1]:PCURrent:TIME:LOW <NRf>

Page 99

:SENSe[1]:PCURrent:TIME:LOW?

Page 99

:SENSe[1]:PCURrent:TIME:AVERage <NRf>

Page 100

:SENSe[1]:PCURrent:TIME:AVERage?

Page 100

:SENSe[1]:PCURrent:SYNChronize[:STATe] <b>

Page 100

:SENSe[1]:PCURrent:SYNChronize[:STATe]?

Page 101

:SENSe[1]:PCURrent:SYNChronize:DELay <NRf>

Page 101

:SENSe[1]:PCURrent:SYNChronize:DELay?

Page 101

:SENSe[1]:PCURrent:SYNChronize:TLEVel<NRf>

Page 101

:SENSe[1]:PCURrent:SYNChronize:TLEVel?

Page 102

Readback Commands

82

Page 83

REMOTE CONTROL

:SENSe[1]:LINTegration:TIME <NRf>

Page 102

:SENSe[1]:LINTegration:TIME?

Page 102

:SENSe[1]:LINTegration:TIME:AUTO

Page 102

:SENSe[1]:LINTegration:TLEVel <NRf>

Page 102

:SENSe[1]:LINTegration:TLEVel?

Page 103

:SENSe[1]:LINTegration:TEDGe <name>

Page 103

:SENSe[1]:LINTegration:TEDGe?

Page 103

:SENSe[1]:LINTegration:TimeOUT <NRf>

Page 103

:SENSe[1]:LINTegration:TimeOUT?

Page 104

:SENSe[1]:LINTegration:SEARch <b>

Page 104

:SENSe[1]:LINTegration:SEARch?

Page 104

:SENSe[1]:LINTegration:FAST <b>

Page 104

:SENSe[1]:LINTegration:FAST?

Page 105