GW Instek PLR Series, PLR 20-18, PLR 60-6, PLR 36-10, PLR 20-36 User Manual

...

Programmable DC Power Supply

PLR Series

USER MANUAL

ISO-9001 CERTIFIED MANUFACTURER

This manual contains proprietary information, which is protected by

copyright. All rights are reserved. No part of this manual may be

photocopied, reproduced or translated to another language without

prior written consent of Good Will company.

The information in this manual was correct at the time of printing.

However, Good Will continues to improve products and reserves the

rights to change specification, equipment, and maintenance

procedures at any time without notice.

Good Will Instrument Co., Ltd.

No. 7-1, Jhongsing Rd., Tucheng Dist., New Taipei City 236, Taiwan.

Table of Contents

Table of Contents

SAFETY INSTRUCTIONS .................................................. 4

PLR SERIES ...................................................................... 9

About this Manual ................................. 9

Outline of Product ............................... 10

Features ............................................... 10

Prior to Use ......................................... 14

Connect the Power Cable ..................... 16

Connect to the Output Terminals ......... 16

PANELS ......................................................................... 25

Front Panel .......................................... 25

Operation Panel ................................... 27

Rear Panel............................................ 34

GENERAL INSTRUCTIONS ............................................. 39

Connecting loads ................................. 39

FUNCTIONS AND OPERATI ON PROCEDURES ............... 43

Operation modes ................................. 43

Turning on Power ................................. 43

Basic Operation ................................... 47

Output Functions ................................. 50

Memory Function ................................. 51

Switching the display in the

Voltage/Current Indicator Display ........ 53

Protective Functions ............................ 58

Key Lock/Local Function ...................... 61

MENU KEY SETTINGS .................................................... 65

1

PLR Series User Manual

Output Off Timers ............................... 68

Specifying the automatic cancellation time

of the setting menu display .................. 72

Specifying Settings when the Power is

Turned On ............................................ 74

Clearing the Memory ............................ 91

MASTER-SLAVE OPERATION ......................................... 102

Configuration of Master and Slave Units102

Parallel Master-Slave Operation ......... 110

Serial Master-Slave Operation ............ 112

SEQUENCE OPERATION ............................................... 114

Sequence Operation ........................... 114

Sequence Programs ........................... 118

Confirming the Step No. and the Step

Being Executed .................................. 119

Confirming the Setting Items for Steps 122

Confirming the settings for s equence

program execution ............................. 124

Executing Sequence Programs ........... 126

OPERATION BY EXTERNAL ANALOG SIGNAL ............... 134

Analog Interface Boards ..................... 134

Operating the PLR-ARC board ............ 141

INTERFACE OPTION ..................................................... 160

Accessories ........................................ 160

REMOTE CONTROL ...................................................... 161

Outline .............................................. 161

Communication Control ..................... 180

Commands......................................... 186

Cautions about Communication ......... 218

2

Table of Contents

Communication Specifications........... 219

SPECIFICATIONS .......................................................... 224

Individual Specifications .................... 224

Common Specifications of PLR Series 228

PLR Series Compatible Specifications 229

APPENDIX .................................................................... 230

Trouble Shooting ............................... 230

Outside Dimensions .......................... 234

Declaration of Conformity .................. 235

Contact information ........................... 236

3

PLR Series User Manual

WARNING

Warning: Identifies conditions or practices that

could result in injury or loss of life.

CAUTION

Caution: Identifies conditions or practices that

could result in damage to the unit or to other

properties.

DANGER High Voltage

Attention Refer to the Manual

Protective Conductor Terminal

Earth (ground) Terminal

SAFETY INSTRUCTIONS

This chapter contains important safety

instructions that you must follow during

operation and storage. Read the following before

any operation to insure your safety and to keep

the instrument in the best possible condition.

Safety Symbols

These safety symbols may appear in this manual or on the

instrument.

4

SAFETY INSTRUCTIONS

Do not dispose electronic equipment as unsorted

municipal waste. Please use a separate collection

facility or contact the supplier from which this

instrument was purchased.

General Guideline

CAUTION

Do not place any heavy object on the PLR.

Avoid severe impact or rough handling that

leads to damaging the PLR

Do not discharge static electricity to the

instrument.

Use only mating connectors, not bare wires, for

the terminals.

Do not block the cooling fan opening.

Do not disassemble or remove the case covers

of the PLR unless you are qualified.

Do not insert foreign objects into the unit.

Do not use the unit when smoke or fire or

other abnormal behavior is seen. Turn the unit

of immediately.

Calibration: It is recommended that the unit is

calibrated periodically.

Do not exceed the maximum input as defined

in the specifications.

(Measurement categories) EN 61010-1:2010 and EN 61010-2-030

specify the measurement categories and their requirements as

follows. The PLR falls under category II.

Measurement category IV is for measurement performed at the

source of low-voltage installation.

Measurement category III is for measurement performed in the

building installation.

Measurement category II is for measurement performed on the

circuits directly connected to the low voltage installation.

0 is for measurements performed on circuits not directly

connected to Mains.

Safety Guidelines

5

PLR Series User Manual

Power Supply

WARNING

AC Input voltage range: 100VAC to 240VAC

Frequency: 50 to 60Hz

To avoid electrical shock connect the protective

grounding conductor of the AC power cord to

an earth ground.

Cleaning the Unit

Disconnect the power cord before cleaning.

Use a soft cloth dampened in a solution of mild

detergent and water. Do not spray any liquid.

Do not use chemicals containing harsh material

such as benzene, toluene, xylene, and acetone.

Operation

Environment

Location: Indoor, no direct sunlight, dust free,

non-corrosive, non-flammable, almost nonconductive pollution (Note below)

Relative Humidity: 30%~ 85% (No dew

condensation )

Altitude: < 2000m

Temperature: 0°C to 40°C

(Pollution Degree) EN 61010-1:2010 and EN 61010-2-030 specify

the pollution degrees and their requirements as follows. The PLR

falls under degree 2.

Pollution refers to “addition of foreign matter, solid, liquid, or

gaseous (ionized gases), that may produce a reduction of

dielectric strength or surface resistivity”.

Pollution degree 1: No pollution or only dry, non-conductive

pollution occurs. The pollution has no influence.

Pollution degree 2: Normally only non-conductive pollution

occurs. Occasionally, however, a temporary conductivity caused

by condensation must be expected.

Pollution degree 3: Conductive pollution occurs, or dry, non-

conductive pollution occurs which becomes conductive due to

condensation which is expected. In such conditions,

equipment is normally protected against exposure to direct

sunlight, precipitation, and full wind pressure, but neither

temperature nor humidity is controlled.

6

SAFETY INSTRUCTIONS

Storage

environment

Location: Indoor

Temperature: -20°C to 60°C

Relative Humidity: 20% to 85% (No dew

condensation)

Disposal

Do not dispose this instrument as unsorted

municipal waste. Please use a separate collection

facility or contact the supplier from which this

instrument was purchased. Please make sure

discarded electrical waste is properly recycled to

reduce environmental impact.

7

PLR Series User Manual

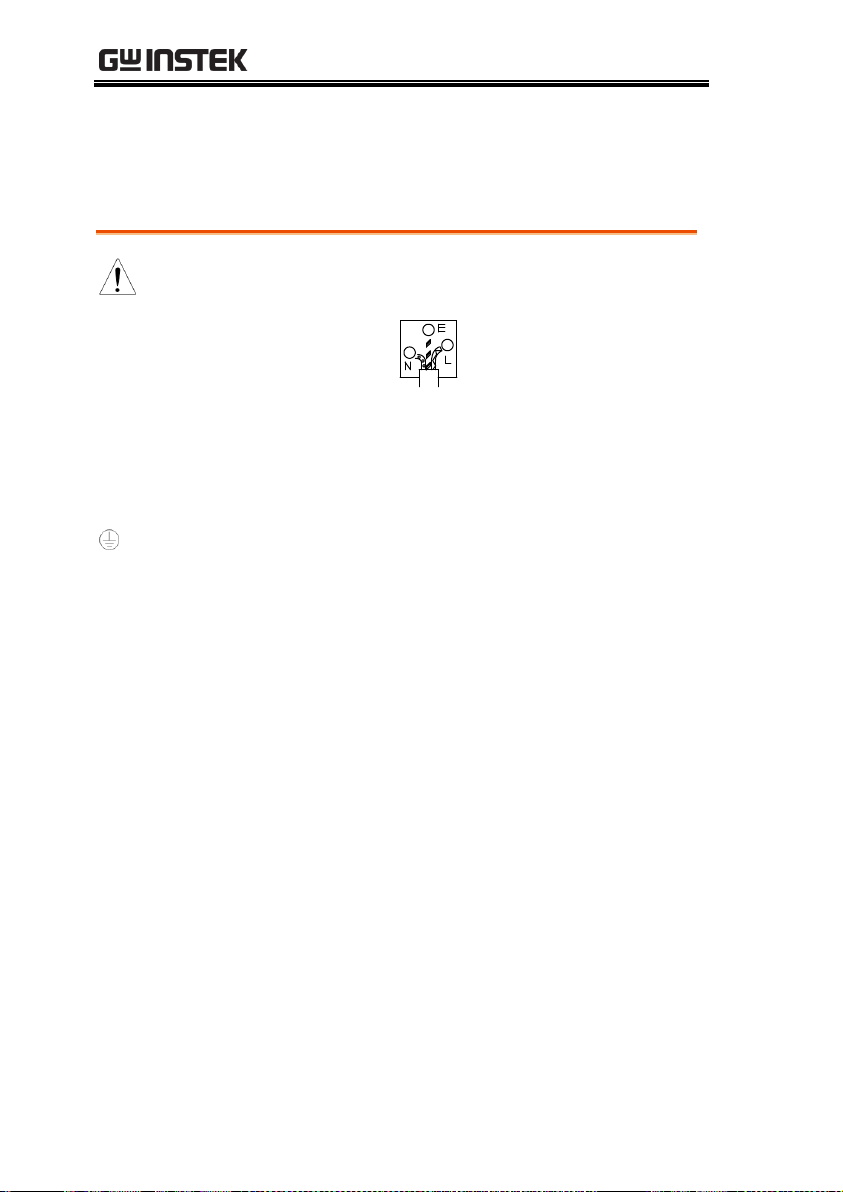

Green/ Yellow:

Earth Blue:

Neutral

Brown:

Live (Phase)

Power cord for the United Kingdom

When using the power supply in the United Kingdom, make sure

the power cord meets the following safety instructions.

NOTE: This lead/appliance must only be wired by competent persons

WARNING: THIS APPLIANCE MUST BE EARTHED

IMPORTANT: The wires in this lead are coloured in accordance with the following code:

As the colours of the wires in main leads may not correspond with

the coloured marking identified in your plug/appliance, proceed

as follows:

The wire which is coloured Green & Yellow must be connected to

the Earth terminal marked with either the letter E, the earth symbol

or coloured Green/Green & Yellow.

The wire which is coloured Blue must be connected to the terminal

which is marked with the letter N or coloured Blue or Black.

The wire which is coloured Brown must be connected to the

terminal marked with the letter L or P or coloured Brown or Red.

If in doubt, consult the instructions provided with the equipment

or contact the supplier.

This cable/appliance should be protected by a suitably rated and

approved HBC mains fuse: refer to the rating information on the

equipment and/or user instructions for details. As a guide, a cable

of 0.75mm2 should be protected by a 3A or 5A fuse. Larger

conductors would normally require 13A types, depending on the

connection method used.

Any exposed wiring from a cable, plug or connection that is

engaged in a live socket is extremely hazardous. If a cable or plug is

deemed hazardous, turn off the mains power and remove the cable,

any fuses and fuse assemblies. All hazardous wiring must be

immediately destroyed and replaced in accordance to the above

standard.

8

PLR SERIES

Model name

Rated Voltage

Rated Current

Rated Power

PLR 20-18

20V

18A

360W

PLR 36-10

36V

10A

360W

PLR 60-6

60V

6A

360W

PLR 20-36

20V

36A

720W

PLR 36-20

36V

20A

720W

PLR 60-12

60V

12A

720W

Standard Interface unit for the PLR series.

PLR-RS

RS-232C Interface.

Optional Interface units for the PLR series.

PLR-GU

GPIB/USB Interface

PLR-LU

LAN/USB Interface

PLR-ARC

Analog Remote Control Interface

PLR SERIES

About this Manual

This manual applies to the following PLR series power supply

units and optional interface units.

9

PLR Series User Manual

Low ripple and low noise

The PLR power supply units reduce output ripple and output

noise with a series transistor for output voltage.

Select the setting digits for voltage and current

The output voltage and current are indicated by 4 digits. You can

select a digit to set the voltage and the current. The PLR power

supply unit is also equipped with a fine adjustment function for

instances in which more precise setting capabilities are required.

Preset function

The unit has 3 preset memory points in which different voltage

and current settings can be stored. This function enables you to

Outline of Product

The PLR series are small, lightweight, switching type and dropper

type, regulated DC power supply units with low noise. Because

the PLR series power supply units are highly reliable and have a

variety of protective functions, they are ideally suited for industrial

use, such as for performing reliability tests, durability tests, and

age-testing electronic components.

The PLR series offer a variety of functions for a variety of

applications: preset functions (3 setting points); protective functions

against output overvoltage, under voltage and overcurrent; output

discharge circuit/cancel function; output off timer function; CC

priority mode while the output is on; sequence function; and

operation by external analog signal.

There are 3 types of optional interface boards, PLR-GU, PLR-LU

and PLR-ARC. These boards replace the standard board equipped

with the unit (PLR-RS), and provide communication functions.

Features

PLR Power Supply Unit

10

PLR SERIES

easily change the voltage and current settings.

Output off timer function

To prevent battery overcharge and similar problems, this

function automatically turns the output off after a preset amount

of time has passed while the output is on.

CC priority mode

Compared to general switching power supply units, the PLR

power supply unit is better able to reduce current overshoot,

thanks to our original current-overshoot inhibit circuit. This

circuit produces a load that enables the unit to operate at a

constant current while the output is on.

Sequence function

Sequence programs can be written to the unit from a computer

via the interface boards (PLR-RS, PLR-GU and PLR-LU).

Sequence programs can be executed by performing panel or

computer operations. You can also perform sequence operations

with a maximum of 1000 steps by using a program written by the

computer. The minimum step unit is 50ms.

Remote sensing function

This function uses the remote sensing terminal to compensate for

voltage drop caused by the wires.

Protective functions

The PLR power supply unit has protective functions against

overvoltage, under voltage and overcurrent for the primary side,

and overvoltage, overcurrent, remote sensing (terminal open),

and internal heat for the secondary side. The unit is also

equipped with OVP (over-voltage protection), UVP (undervoltage protection), and OCP (over-current protection) for the

load. The setting values for these protective functions are

changeable.

Master-slave operation

The PLR power supply unit can perform master-slave operation.

Master-slave operation can be performed with a maximum of 3

units (of the same voltage model) connected in parallel, and with

11

PLR Series User Manual

a maximum of 2 units (of the same model) connected in series.

External analog signal operation

When setting the voltage and current by external voltage and

resistance, the setting values set externally will be superimposed

on the setting values set on the panel. The external setting values

can be adjusted on the panel. The output can be turned on and off

by an external contact switch.

Dispersion circuit for rush current prevention

The PLR power supply unit is able to restrain and minimize the

primary side current and voltage distortions caused by rush

current on the primary side at the time the unit is switched on,

thanks to the main relay’s on/off operation and our original

dispersion circuit for rush current prevention.

Power factor correction circuit, as well as voltage and current

range for worldwide use

The PLR power supply unit is equipped with a power factor

correction circuit that has a rated output of approximately 0.99. It

is operable with supply voltages ranging from 100VAC to

240VAC, without changing the settings.

CE Marked

The PLR power supply unit conforms to CE marking (under

voltage directive, EMC directive). It also complies with the

regulations for the harmonic current of power supply units.

Units equipped with the PLR-RS can be connected to a computer

and controlled by RS-232C. PLR-RS can also control 31 PLR

power supply units via a local bus connection.

PLR-RS

12

PLR SERIES

PLR-GU is connected to a computer through a GP-IB or USB.

Fourteen units may be connected with a computer through GPIB, or 32 units may be connected through USB.

Units connected to the computer can be connected with 31 PLR

power supply units via a local bus connection.

PLR-LU is connected to a computer through a LAN or USB. 32

units may be connected through USB.

Units connected to the computer can be connected with 31 PLR

power supply units via a local bus connection.

Cable for parallel master-slave

PLR-001 : Connectable with three PLR power supply units.

Cable for in-series master-slave

PLR-002 : Connectable with two PLR power supply units.

CAUTION

When connecting cables, make sure to connect

the correct cables.

Connecting the wrong cables may cause product

failure.

PLR-GU (option)

PLR-LU (option)

Cable for master-slave operation (option)

13

PLR Series User Manual

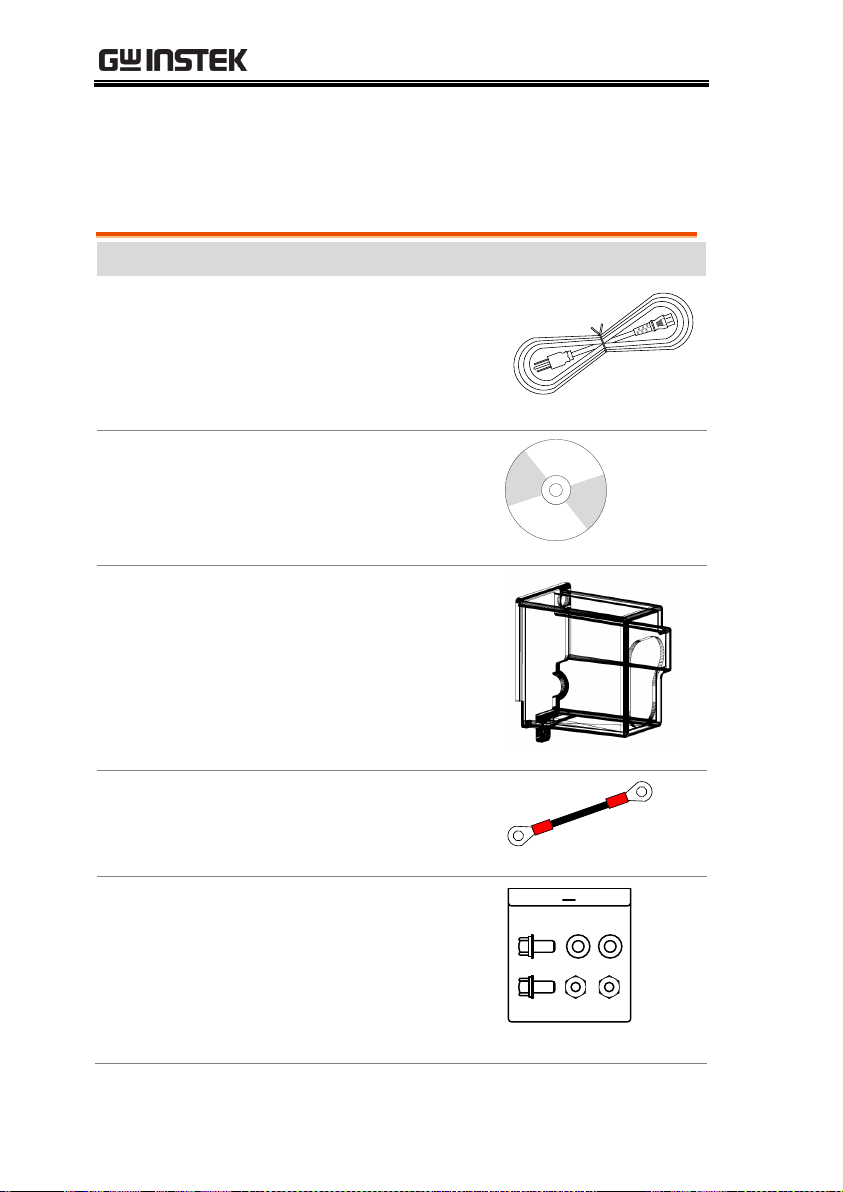

Item

Description

1

Power cable: 14AWG, 15A, 2M

Power cable: 1 pc

2

CD-ROM: User Manual

1 pc

3

Rear output terminal cover

See page 19 for details.

1 pc

4

Output grounding cable

See page 17 for details.

1 pc

5

Bolt set

Contents:

Hexagon head bolt (P-3): 2 pcs

Flat washer: 2 pcs

Hexagon nut: 2 pcs

See page 16 Connect to the

Output Terminals for details.

1 pkt

Prior to Use

Standard Accessories

14

PLR SERIES

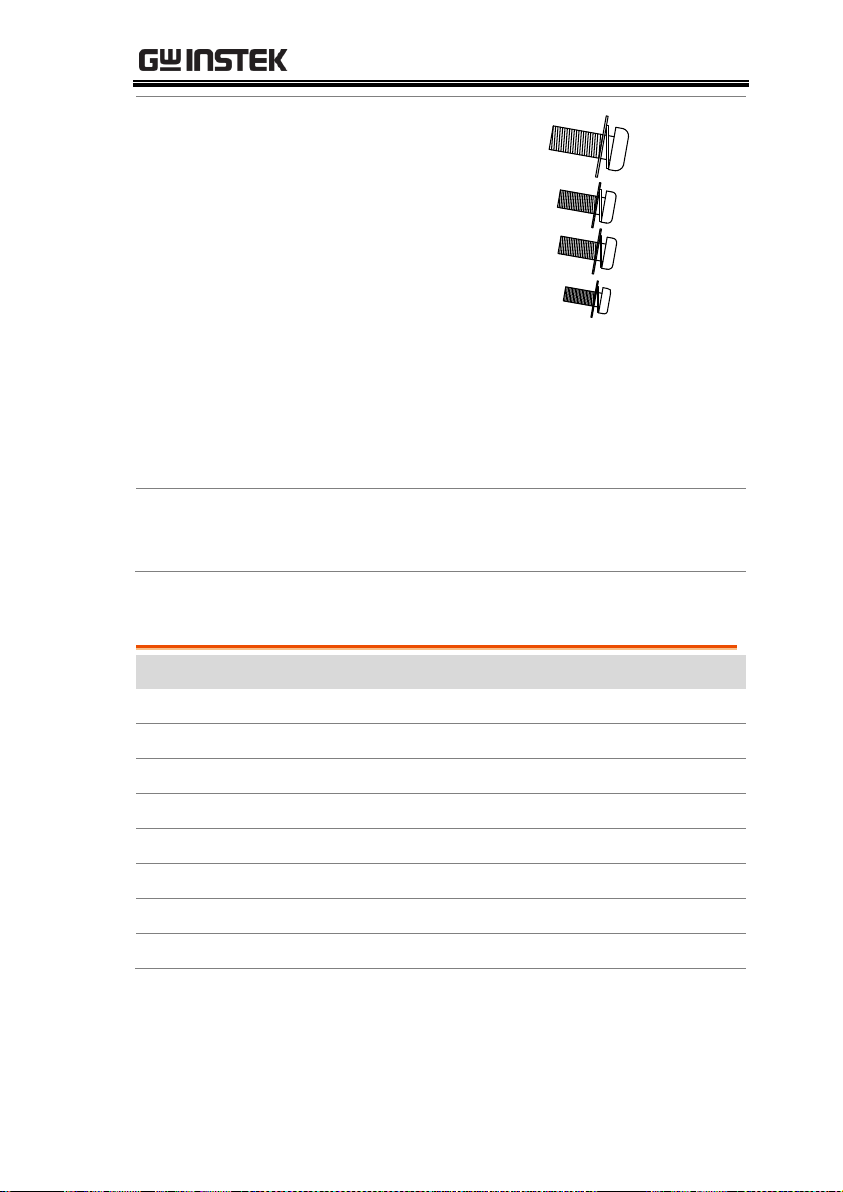

6

M3 Small screw washer: 1 set

(For attaching the grounding

cable to one of the rear output

terminals.)

See page 17 for details.

7

M3 Large screw washer: 2 sets

(For attaching the rear output

terminal cover.)

See page 19 for details.

8

M4 Small screw washer: 1 set

(For Connecting the protective

grounding terminal on the

bottom face)

See page 22 for details.

9

PLR-RS: RS-232C Interface

Card (Attached to power

supply)

Part number

Description

PLR-ARC

Analog Remote Control Interface Card

PLR-GU

GPIB/USB Interface Card

PLR-LU

LAN/USB Interface Card

PLR-001

Parallel Connection Signal Cable (2 to 3 units)

PLR-002

Series Connection Signal Cable

GRJ-1101

Modular Cable (0.5m)

GRJ-1102

Modular Cable (1.5m)

GRA-427

Rack mount adapter

Optional Accessories

15

PLR Series User Manual

The power cable should be connected to an AC inlet or an input

terminal block.

Warning

Make sure to properly connect the power cable.

Failure to do so may result in electric shock or fire.

Using the unit without the AC input terminal cover

may result in electric shock or fire.

Perform this operation before connecting the power cable to an AC

outlet or the distribution panel.

Use the supplied bolt set to connect the load cable to the rear output

terminals. Adjust the tightening torque of each bolt to 25 kgf/cm.

Check the connection between the load and the output terminals of

the unit. Make sure that the polarity is not inverted, and that no

short circuits have occurred.

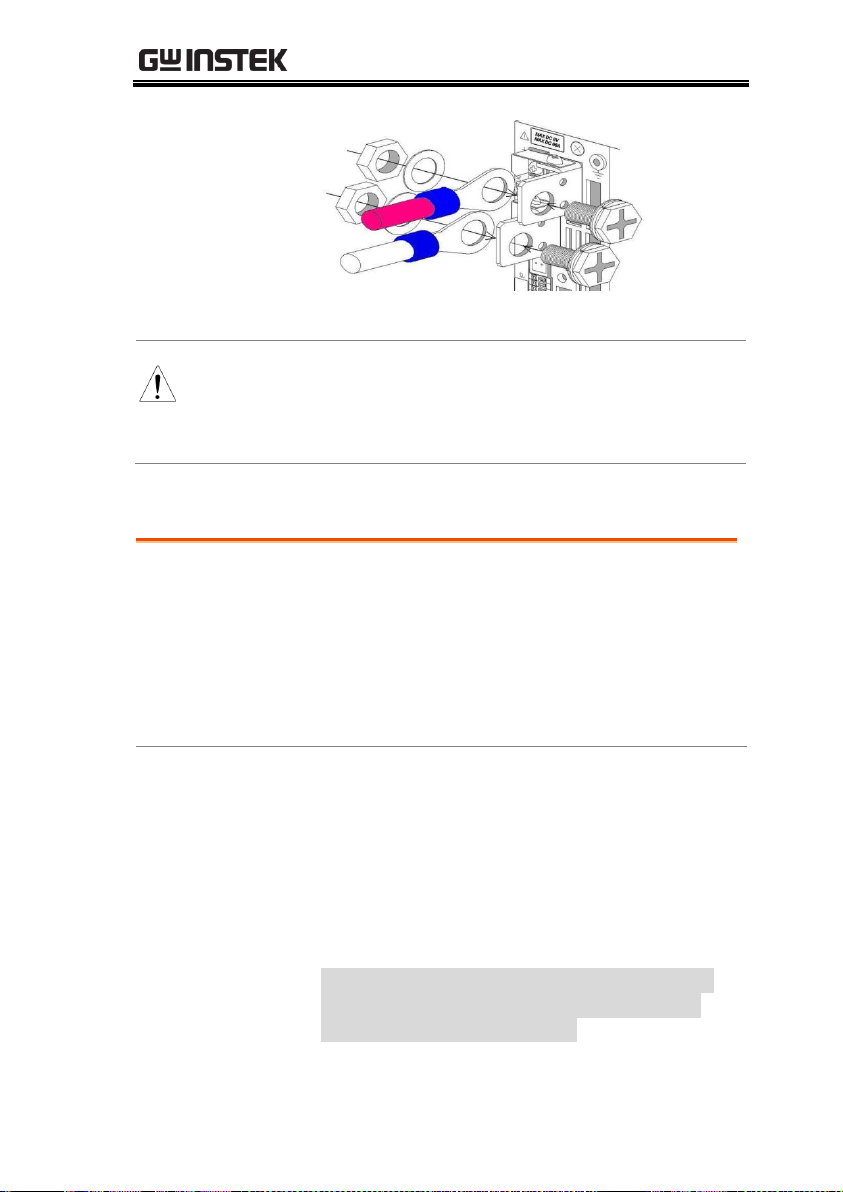

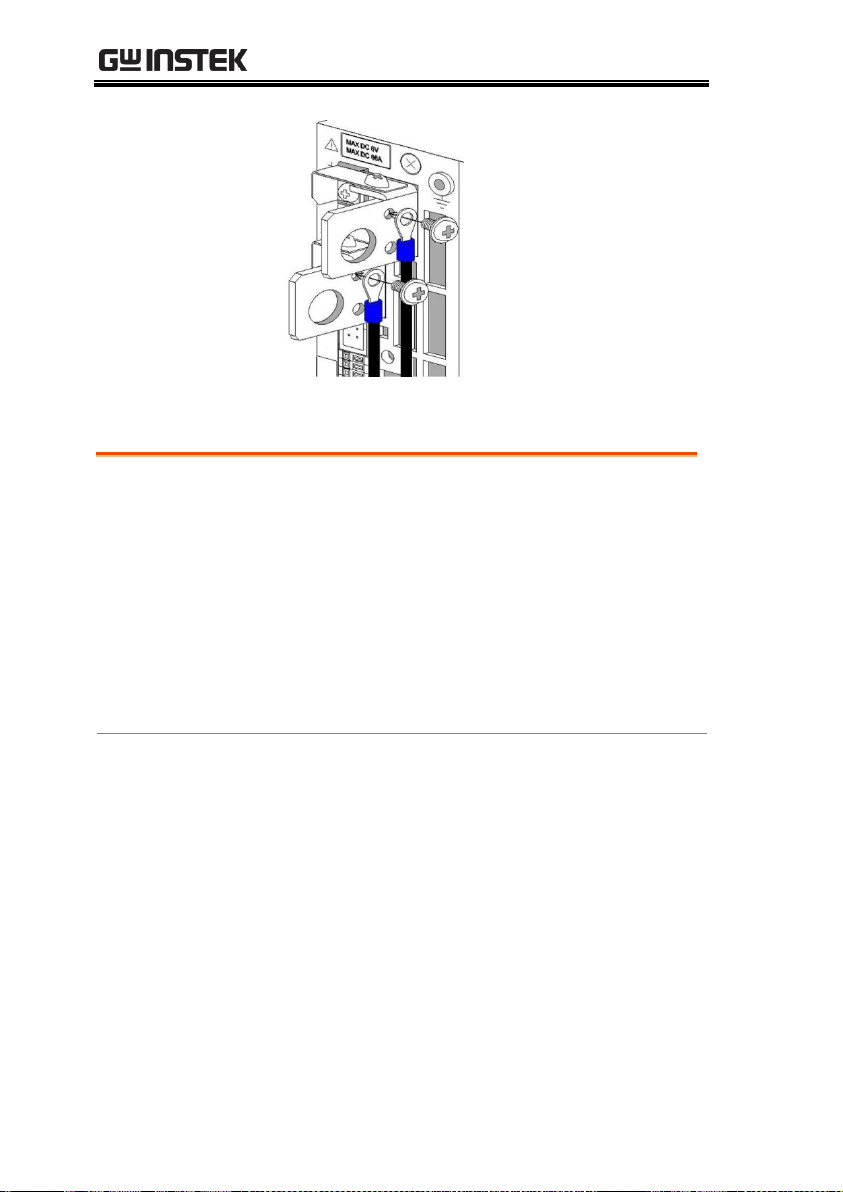

Steps

1. Attach a round crimp-style terminal (inner

diameter of at least 6.4 mm) to the load cable.

2. Insert the bolt into the hole from left side of the

output terminal.

3. From the right side of the output terminal, first

attach the load cable (with the round crimpstyle terminal attached), followed by the

washer and then the nut. Finally, secure the

bolt.

Connect the Power Cable

Connect to the Output Terminals

16

PLR SERIES

Fig. 2-2 Connecting the load cable to the rear

output terminals

Warning

Make sure the voltage of the unit’s output

terminals has sufficiently fallen before touching

and operating the load or output terminals.

Failure to do so may result in electric shock.

(You do not need to perform this operation if the output is not to be

grounded.)

Use the M3 Small screw w/washer to attach the grounding cable to

one of the rear output terminals.

Tightening torque of screw: 5kgf/cm.

Steps

1. From the left side of the rear output terminals,

attach the grounding cable to the M3 hole of

one of the output terminals.

2. Attach the grounding cable to either the

positive output terminal or the negative output

terminal. Do not attach the cable to both.

3. If you attach the grounding cable to both the

positive and negative output terminals, the

unit output will short circuit.

Attaching the Output Grounding Cable

17

PLR Series User Manual

You only need to perform this operation if you plan to use the

voltage remote sensing function of the unit.

Use the removed M3 screws to attach the voltage remote sensing

cables to the voltage remote sensing terminals.

Tightening torque of screw: 5kgf/cm

Carefully store the positive and negative shorting bars and the two

M3 screws that were removed.

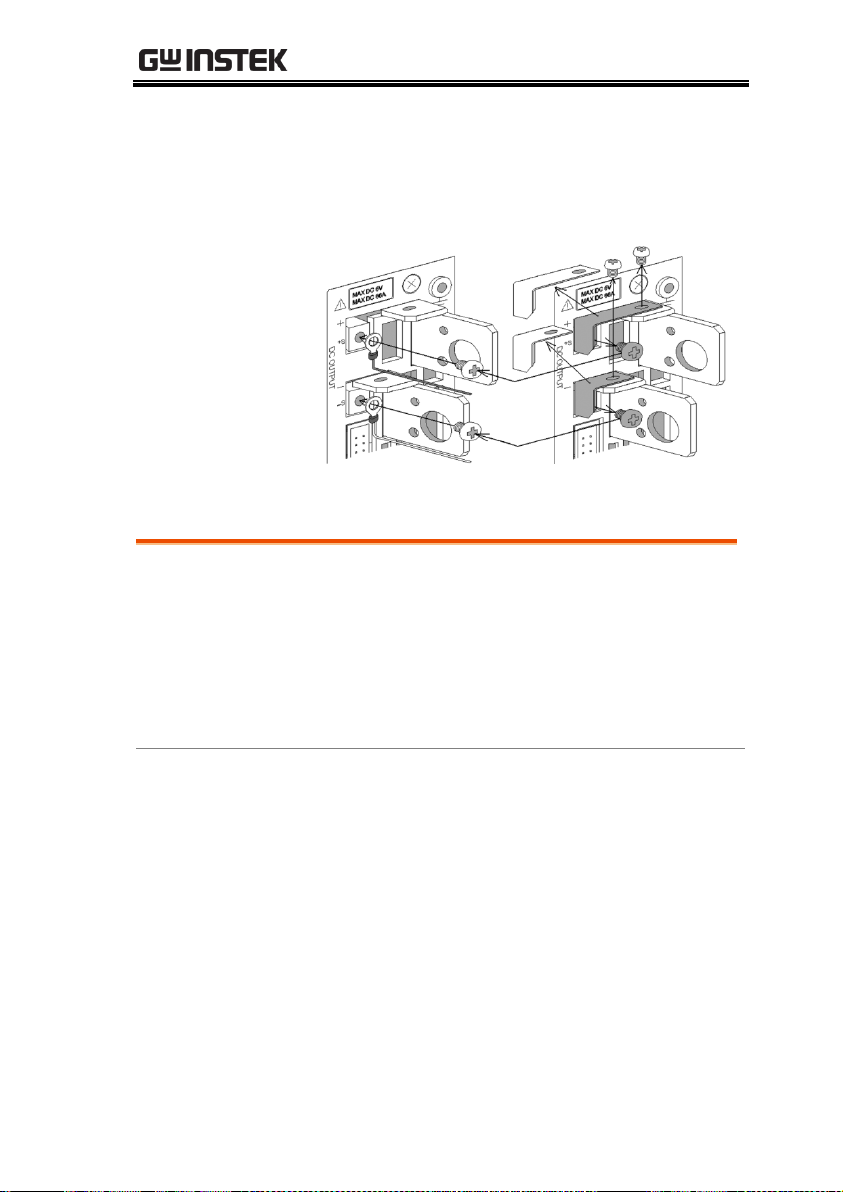

Steps

1. Remove the M3 screws (4 screws) from the

positive and negative rear output terminals

and the positive and negative voltage remote

sensing terminals, and then remove the

positive and negative shorting bars.

2. Attach the positive and negative voltage

remote sensing cables to the positive and

negative voltage remote sensing terminals.

Connecting the voltage remote sensing cables

18

PLR SERIES

3. Attach a round crimp-style terminal (inner

diameter of at least 3.2mm, with the smallest

possible outer diameter) to the voltage remote

sensing cables.

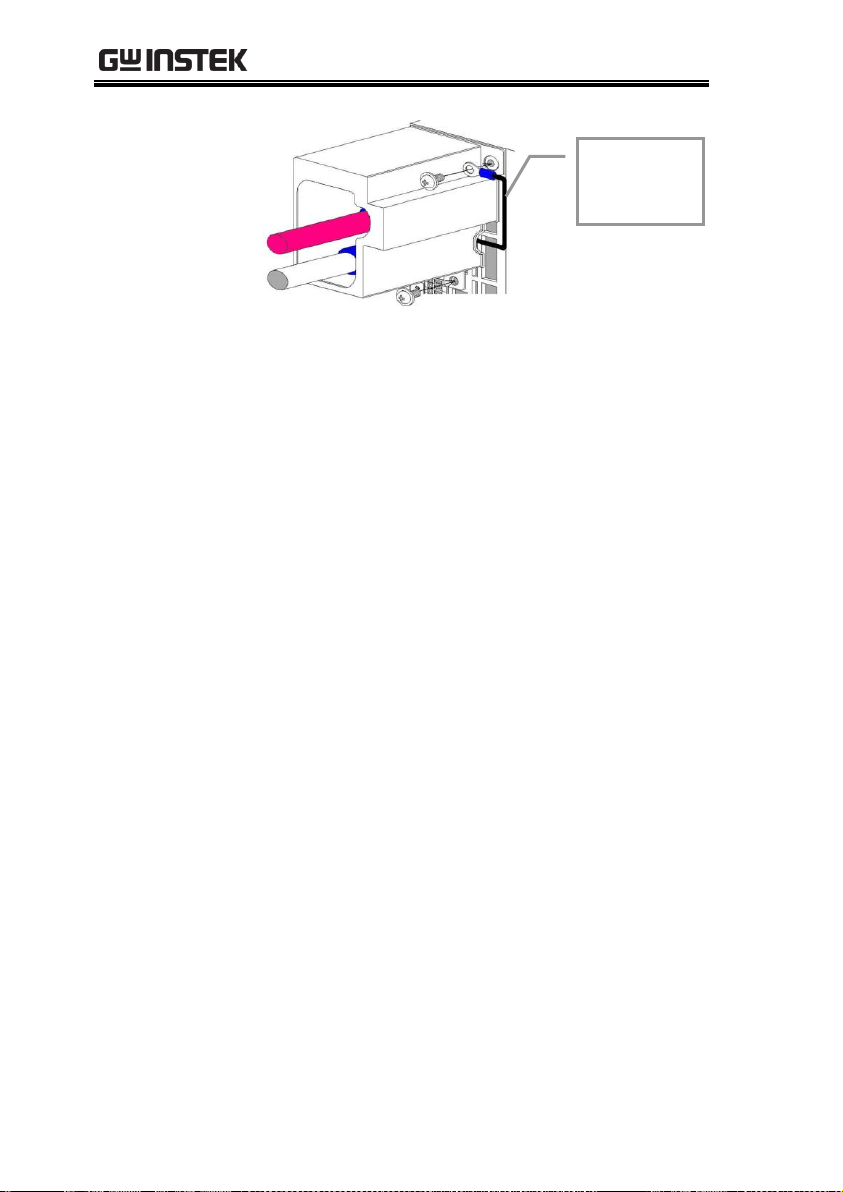

The rear output terminal cover should always be attached even

when rear output terminals of the unit are not in use.

Use the M3 Large screw with washer to attach the rear output

terminal cover.

Tightening torque of screw: 5kgf/cm.

Steps

1. Run the load cable and the voltage remote

sensing cable through the output terminal

cover, and then fix the output terminal cover to

the unit, using the two large screws with

washers.

2. Fix the output grounding cable to the output

grounding terminal, together with the output

terminal cover.

Attaching the rear output terminal cover

19

PLR Series User Manual

Output

grounding

cable

20

PLR SERIES

To maintain an output voltage of approximately 0 V when the

output is off, the unit is equipped with a discharge circuit for

removing the electric charge from the output capacitor.

When the output is off, it takes approximately 1 second for the

discharge circuit to remove the electric charge from the output

capacitor when the capacitor is fully charged to its rated voltage.

If a capacitive load, such as a battery or capacitor, is connected to

the unit and used, it takes longer to lower the output voltage when

the output is off. If the output is turned off while a capacitive load

is connected, be sure to use a voltmeter to confirm that the voltage

has sufficiently fallen before touching the output terminal or the

load.

The discharge circuit for the output capacitor does not work if the

unit’s output HI-R function is used.

Compared to when the output HI-R function is not used, it takes

longer for voltage to fall when a capacitive load is used.

Caution on Connecting to a Capacitive Load

21

PLR Series User Manual

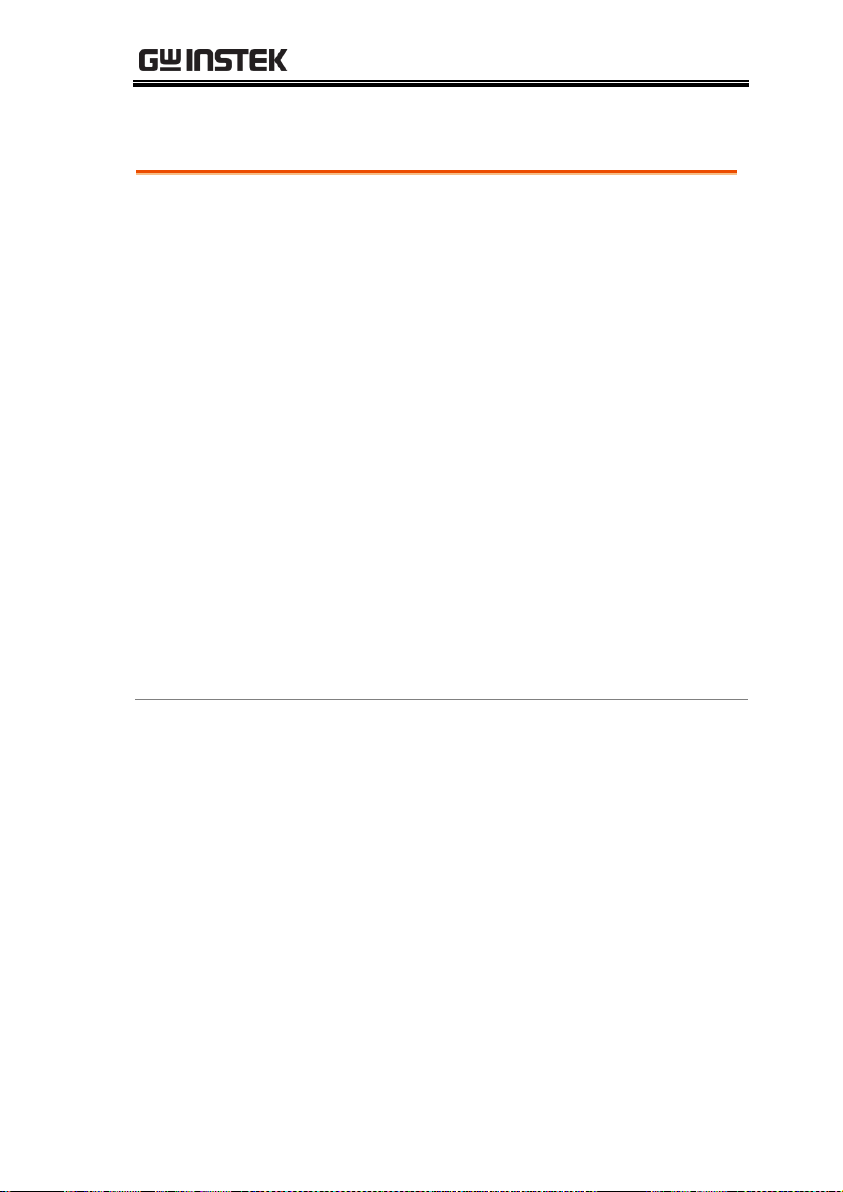

There is a protective grounding terminal on the bottom face of this

unit.

To ensure the safe use of this product, follow the procedure below

to connect the protective grounding terminal.

Steps

1. Attach the wire (recommended by the

manufacturer) for round crimp-style terminals

V1.25-M4 (JST) or equivalent.

2. Attach the round crimp-style terminal to the

cable.

3. Attach the cable with round crimp-style

terminal to the protective grounding terminal

on the bottom face of the unit, using the

accessory M4 screw for the grounding

connection to secure the cable.

Warning

Make sure to properly connect the protective

grounding terminal on the bottom face. Failure to

do so may result in electric shock. If you do not

connect the protective grounding terminal on the

bottom face, it will not conform to the CE

conformity.

Connecting the protective grounding terminal on the bottom face

22

PLR SERIES

When mounting the unit in a rack, use one of the following

attachments:

Rack mount adapter GRA-427 (for JIS rack)

GRA-427 (for EIA rack)

When mounting the unit in a rack, replace the screws on the left and

right sides of the unit (two on each side) with the flat countersunk

head screws.

When mounting the unit in a rack, remove the screw for the

protective grounding terminal on the bottom face of the unit. For

your own safety, make sure to securely connect the rack to the

ground before using the unit.

Caution on mounting the unit in a rack

23

PLR Series User Manual

Be sure to turn off the power switch before connecting the power

cable to the AC outlet or distribution panel.

Be sure to plug the supplied power cable into an AC outlet with

earth ground.

Warning

Plugging the power cable into an outlet or

distribution panel that is not properly grounded

may result in electric shock or fire. Be sure to ask

a qualified engineer to connect the power cable to

the distribution panel.

If the unit is used in a hot place and the internal temperature of

the unit rises, the built-in overheat protection circuit activates

and turns off the output. Do not use the unit in a location where

the grill in the front panel or air outlet port in the rear panel is

blocked. Blocking these ports will cause the internal temperature

to rise. Maintain sufficient distance between these ports and

objects. In some conditions, hot air may blow out of the air outlet

port in the rear panel. Be careful.

Do not use the PLR power supply unit in a place with a lot of

dust or corrosive gas. These substances can cause the product to

deteriorate.

Do not use the unit on an incline or a place subject to vibration.

Doing so can cause the unit to fall off the rack or fall over, which

may result in damage to the unit or personal injury.

Connecting the Power Cable to the Primary Power

Installation Environment

24

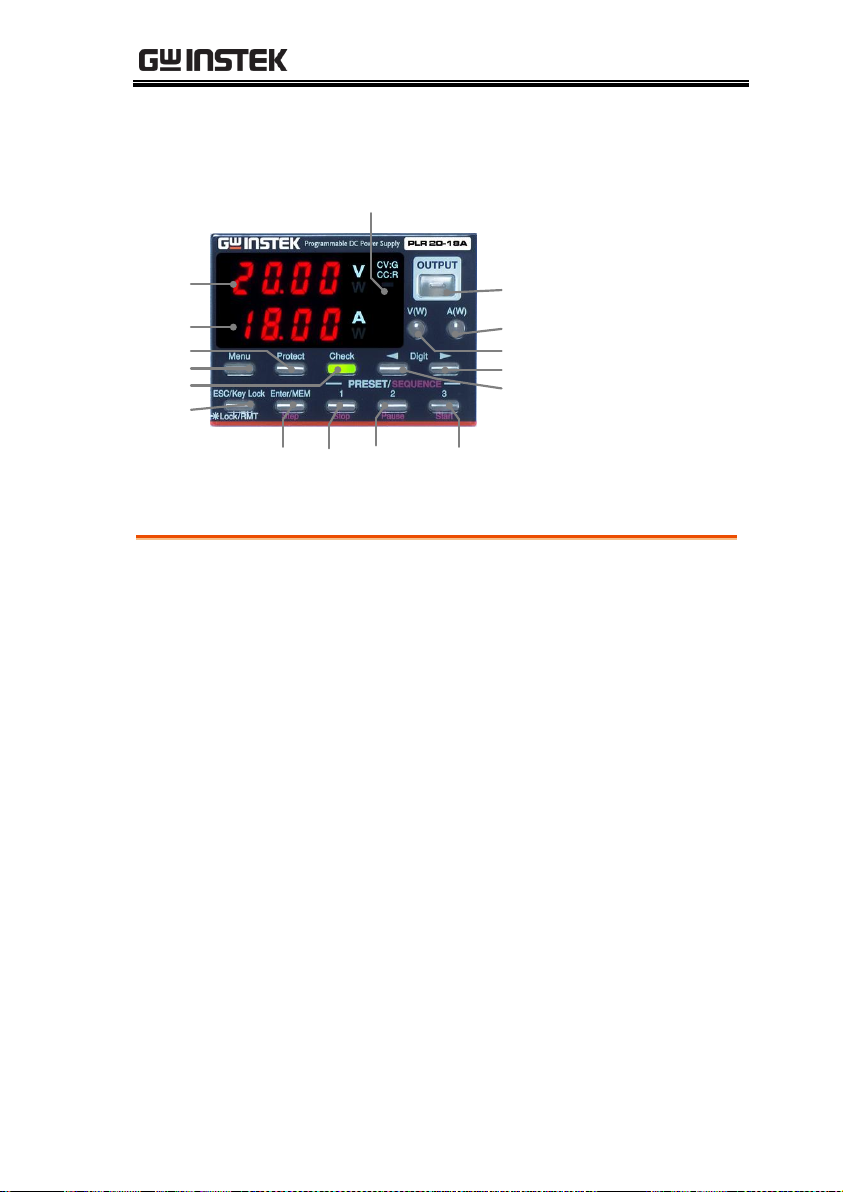

PANELS

2

5

1

4

3

1. Power switch

Turns the AC power on (I) and off (O).

Do not position the power supply in such a way

as to make accessing/operating the power

switch difficult.

2. Front output terminals

Front output terminals with a current limit of

20A. Use the unit within the current limit

PANELS

Front Panel

Front Panel (The above figure shows the front panel of the PLR 20-18)

25

PLR Series User Manual

3. Rotary encoder

Changes the set voltage and current, and is

used to set functions.

4. Grill

Air intake port.

Push up the mark in the bottom center of the

grill to detach the cover when cleaning or

replacing the dust filter inside.

5. Rubber shoes

Detachable.

If the unit is mounted in a rack and the shoes

are not needed, they may be removed.

26

PANELS

6

7

13

12

14

21

17 18 19 20

8

9

11

10

15

16

6. Voltage indicator (red LEDs): 4-digit display, unit indication

Indicates the set voltage, output voltage, output

power, and MENU items.

“W” is lit in red when the indicator displays the

output power.

7. Current indicator (red LEDs): 4-digit display, unit indication

Indicates the set current, output current, output

power, and MENU items.

“W” is lit in red when the indicator displays the

output power.

8. CV/CC LED (green/red)

When the output is on, the LED is lit in green

when CV is in operation and red when CC is in

operation.

Turns off when output is off. It blinks red

when the CC priority mode is selected.

Operation Panel

Operation Panel (The above figure shows the operation panel of the PLR

20-18)

27

PLR Series User Manual

9. OUTPUT key (red/amber)

Manual operation:

Lit in red when the output is on.

Alternately blinks red and amber when the

output off timer is set and the output is on.

Pressing this key turns the output on and off.

It is not possible to turn the output on and off

when the MENU key is lit in green.

Sequence operation:

If this key is pressed while a sequence

manual/automatic operation is being executed,

the output will turn off and the sequence will

be interrupted.

10. V key (green/amber)

The voltage is set by operating this front panel

key:

Pressing this key causes it to turn off or light in

green.

When this key is lit in green, it is possible to

change the blinking digit of the set voltage in

the voltage indicator.

Pressing and holding down this key switches

the voltage display to the power display.

Pressing and holding down this key again

switches the display back to the voltage

display.

The key is lit in amber when the voltage is set

by external analog signals.

28

Loading...

Loading...