Service Manual for:

<KA

Global

HZg^Zh

Wheelchair Lifts

02

33222

"Providing Access to the World"

International Corporate Hdqrs: P.O. Box 310 Winamac, IN 46996 USA

1-800-THE LIFT

34179 Rev. A

December

2007

®

(574) 946-6153 FAX: (574) 946-4670

Patent #5,261,779

Patent #5,261,779

Patent #6,065,924

Patent #6,065,924

Patent #6,238,169

Patent #6,238,169

Patent #6,464,447

Patent #6,464,447

Patent #6,599,079

Patent #6,599,079

Patent #6,739,824

Patent #6,739,824

Patent #6,837,670

Patent #6,837,670

Patents Pending

Patents Pending

A

R N I N G

W

Man

ual

®

®

Read manual

before installing

or servicing lift.

Failure to do so

may result in

serious bodily

injury and/or

property damage.

Braun GVL Series

Braun GVL Series

GVL936IB3144

e5*72/245*95/54*0110*00

1-800-THE LIFT™

BRAUNLIFT.COM™

The Braun Corporation

Not For Sale in U.S. - For Export Only

Max. Lifting Capacity - 800 lbs.

PATEN T

PENDING-

5,261,779-6,065,924-6,238,169-6,46

4,447-6,599,079-6,692,217-6,739,824

MFG DATE

62 14CF

PUMP CODE CYLINDER

02-00025

SERIAL NUMBER

06/06/07

OWNER'S WARRANTY REGISTRATION

PURCHASED FROM

DATE INSTALLED

NAME

ADDRESS

CITY

TELEPHONE

TO VALIDATE WARRANTY

REGISTRATION CARDS MUST BE RETURNED TO THE BRAUN CORPORATION.

OWNER

STATE ZIP

Congratulations

We at The Braun Corporation wish to express our fullest appreciation

on your new purchase. With you in mind, our skilled craftsmen have designed and

assembled the finest lift available.

This manual provides service-related material. Refer to the Quick Reference

Installation Sheet for installation instructions, operating instructions and maintenance

procedures.

Braun Global Series™ lifts are built for dependability and will provide years of

pleasure and independence as long as the lift is installed and serviced as specified by

a Braun certified technician, and the lift is operated by an instructed person.

Sincerely,

THE BRAUN CORPORATION

Ralph W. Braun

Chief Executive Officer

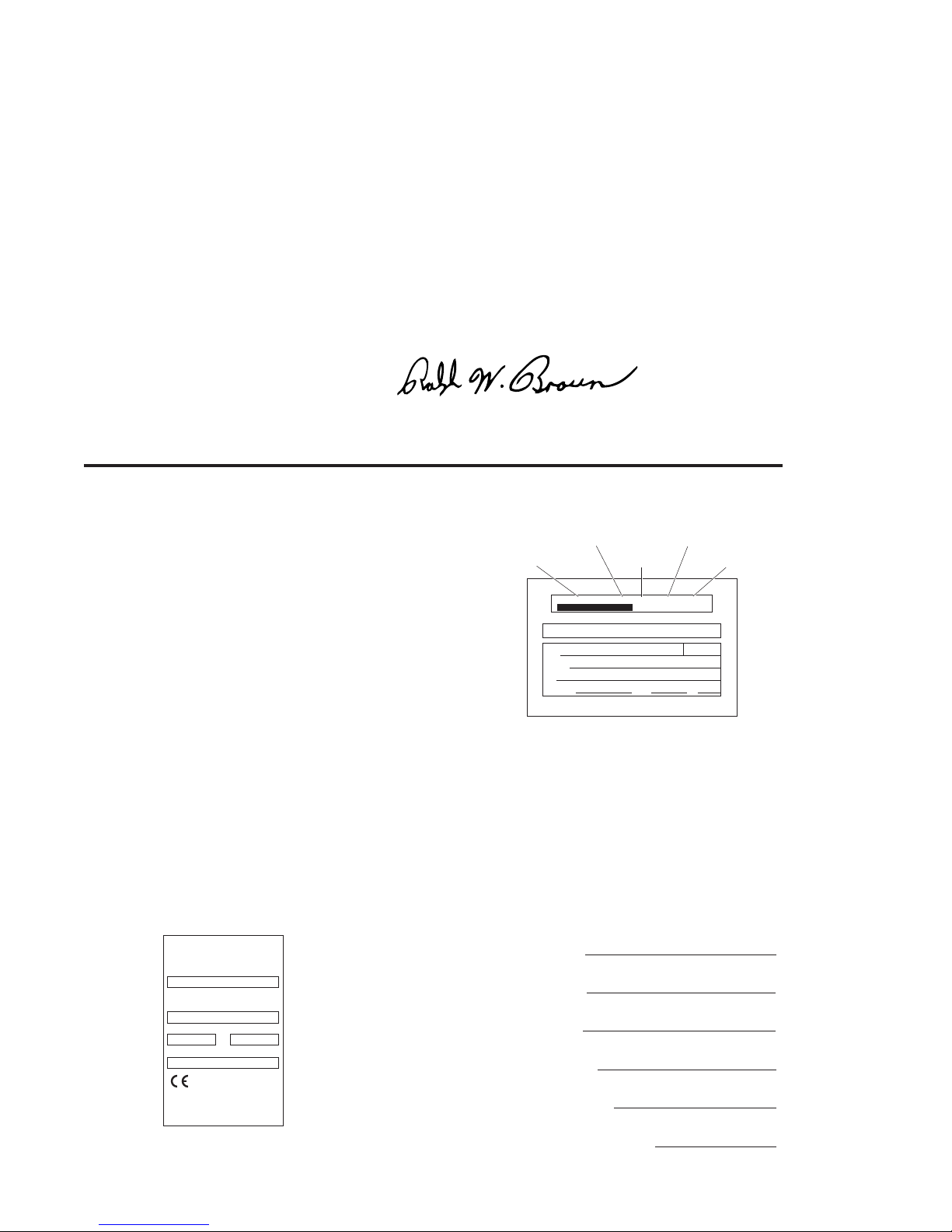

Warranty and Registration Instructions

Immediately upon receiving the lift, examine the

unit for any damage. Notify the carrier at once

Series No. Pump Code

Serial No.Model No. Cylinder Code

with any claims.

GVL936IB3144 02-00025 62 14CF

Two warranty/registration cards (shown right) are

located in the lift-mounted manual storage pouch.

The sales representative must process one of the

cards. The consumer must fill out the other card

and mail it to The Braun Corporation. The warranty is provided on the back cover of this manual.

The warranty cards must be processed to

Sample Warranty/Registration Card

activate the warranty.

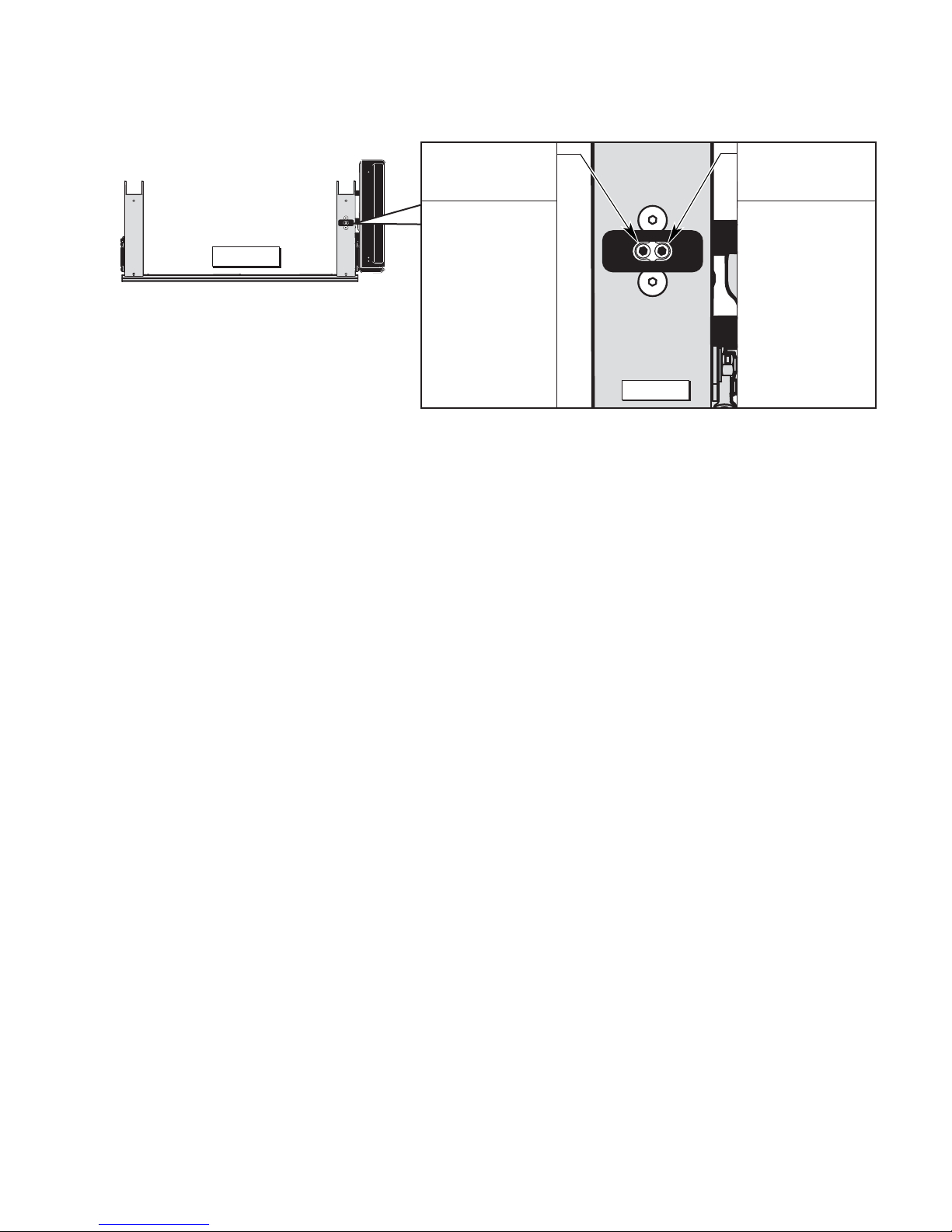

Two Braun Serial No./Series No. identification tags (shown below) are posted on the lift.

One I.D. tag is posted on the opposite pump side vertical arm. A second I.D. tag is located

on the opposite pump side tower. Both I.D. tags provide the product identification information provided on the warranty/registration card. Record the information in the space

provided (or document on a copy). This information must be provided when filing

a warranty claim or ordering parts.

Model No.

Sample Serial No./Series No. Identification Tag

Series No.

Serial No.

Pump Code

Cylinder Code

Date of Manufacture

Contents

Troubleshooting and Maintenance

Lift Terminology............................................................. 2

Switch and Sensor Locations ..................................... 3

Platform Fold Pressure Adjustment ............................ 4

Platform Angle Adjustment ......................................5-6

Tower Microswitch Adjustment .................................... 7

Lubrication Diagram ...................................................... 8

Maintenance and Lubrication Schedule................. 9-12

Lift Electrical Schematic ............................................ 13

Lift Wiring Diagram .................................................... 14

Hydraulics

Hydraulic Schematic .................................................. 15

Hydraulics Parts List .................................................. 16

Hydraulics Diagram .................................................... 17

Repair Parts

Pump Module

Pump Module Parts List ....................................... 18

Pump Module Diagram ......................................... 19

Lift Exploded Views and Parts Lists

Base Plate Assembly .......................................20-22

Top Parallel Arm Assembly ................................... 23

Bottom Parallel Arm Assembly ........................ 24-25

Hydraulic Cylinder Assembly - Main .................... 26

Vertical Arm Assembly .....................................27-28

Handrail Assembly ................................................. 29

Platform Assembly - Inboard ................................30-32

Platform Assembly - Outboard .............................33-35

Inner Roll Stop Assembly .................................36-38

Page 1

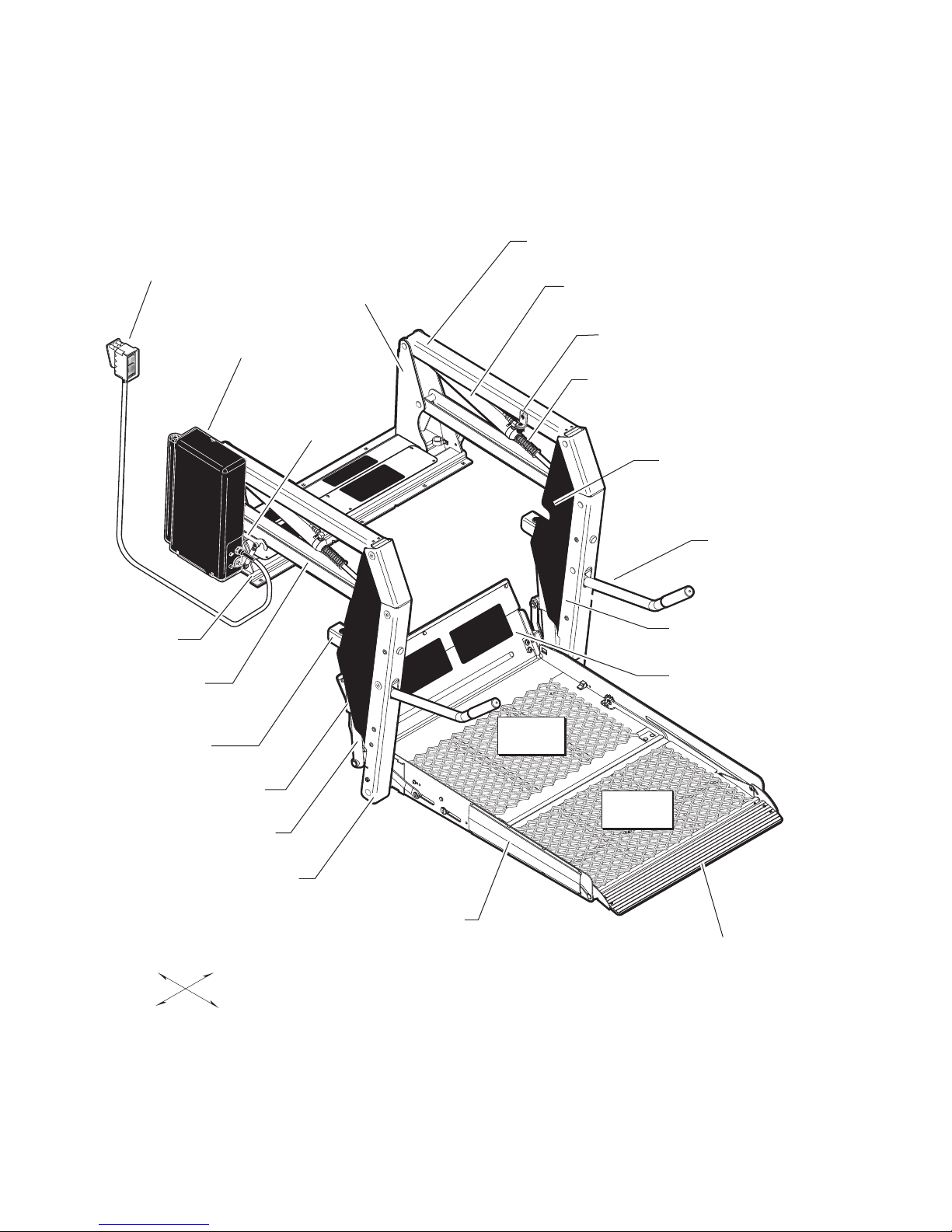

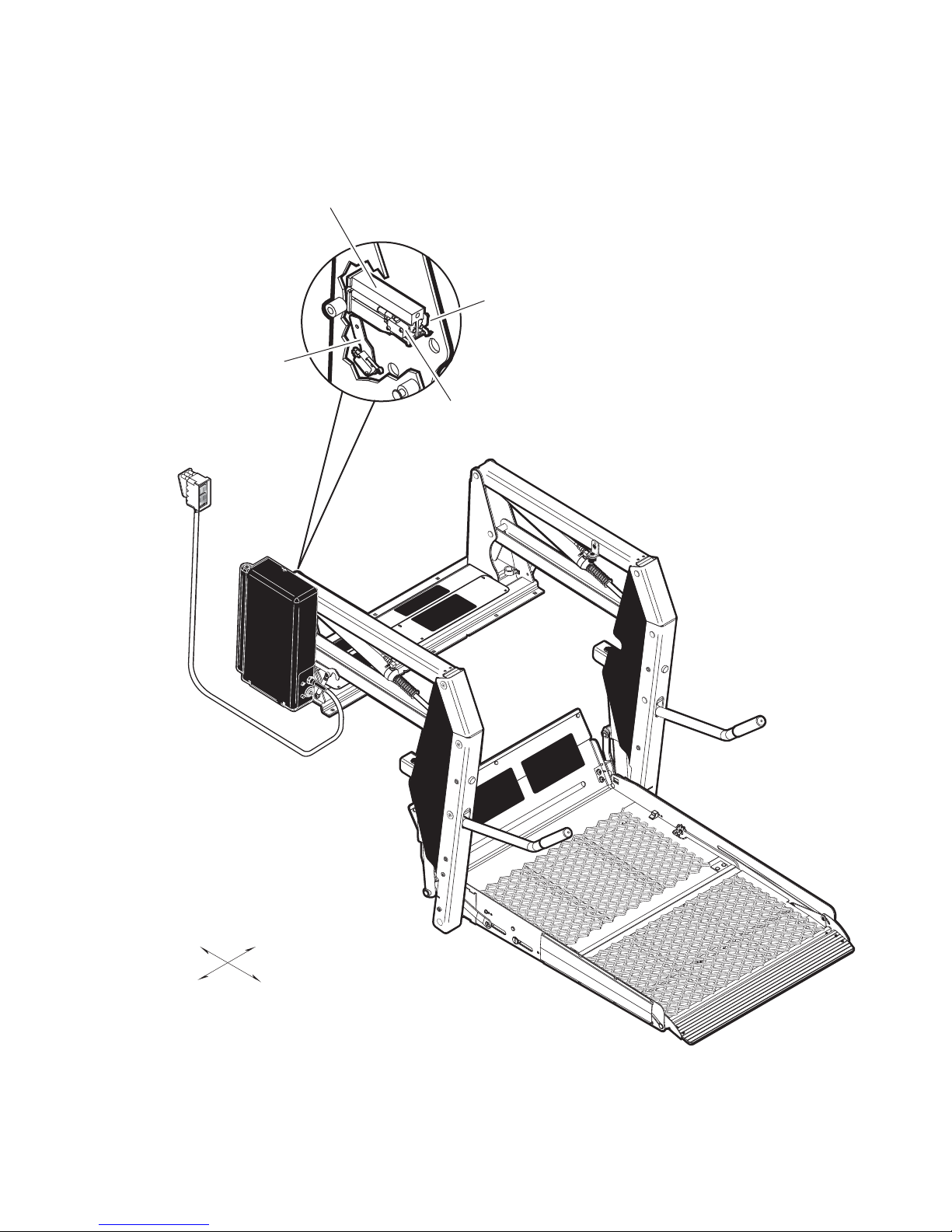

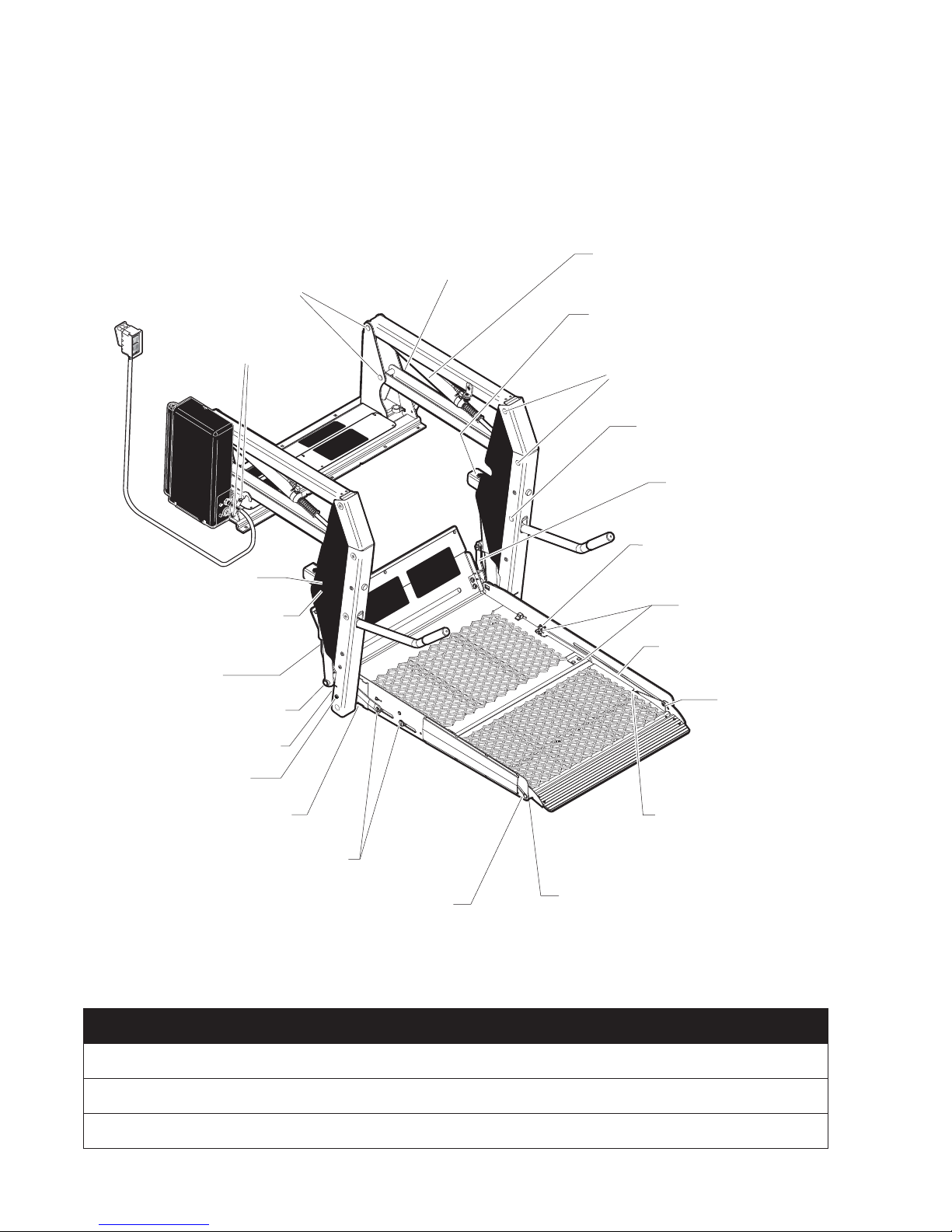

Lift Terminology

Hand-Held

Pendant

Control

D

OL

F

)

D

IN

L

(

O

UNF

T)

(OU

UP

DOWN

Base Plate

Bottom Parallel

Arms (2)

Pump Module

(Rear)

Towers (2)

Lift-Tite™

Latches (2)

Top Parallel Arms (2)

Main Cylinders (2)

Adjustable Quiet-Ride Stow Blocks (2)

Unfold Assist Compression Springs (2)

Vertical Arm Covers (4)

Handrails (2)

Opposite Pump Side

Vertical Arm

Inner Roll Stop

Saddle (2)

Upper Fold Arm (2)

Lower Fold Arm (2)

Inboard

Left

Inboard

Platform

Outboard

Platform

Pump Side

Vertical Arm

Platform Side Plates (2)

Outer Barrier

Right

Outboard

Page 2

*Partial Fold

Microswitch Assy.

32735RA

D

FOL

D

(IN)

UNFOL

T)

(OU

UP

DOWN

Switch and Sensor Locations

*Up & Unfold

Microswitch Assy.

975-3121A

*Up Microswitch

*Unfold

Microswitch

Inboard

Left

Right

Outboard

*Note: Mirror image for

right (front) pump lifts.

Page 3

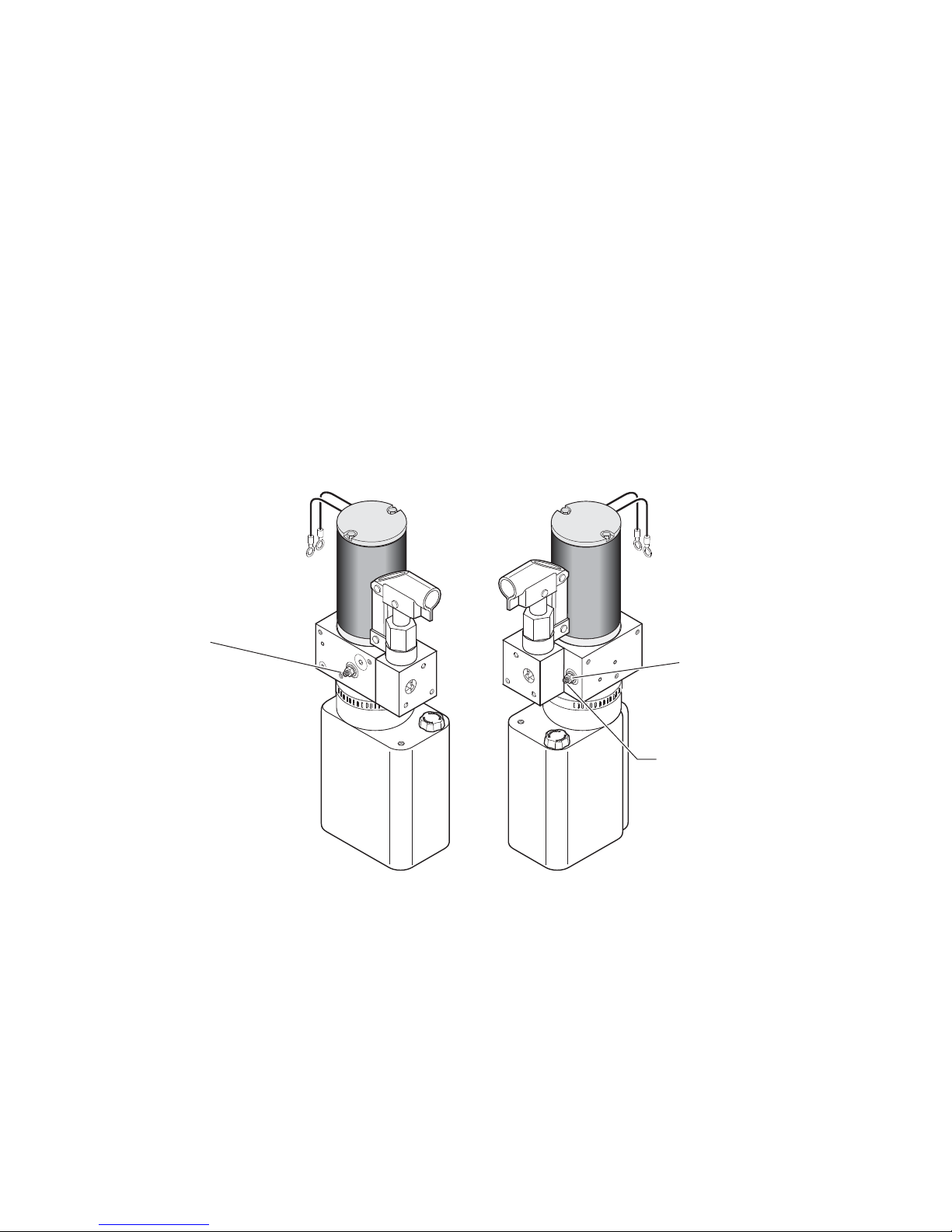

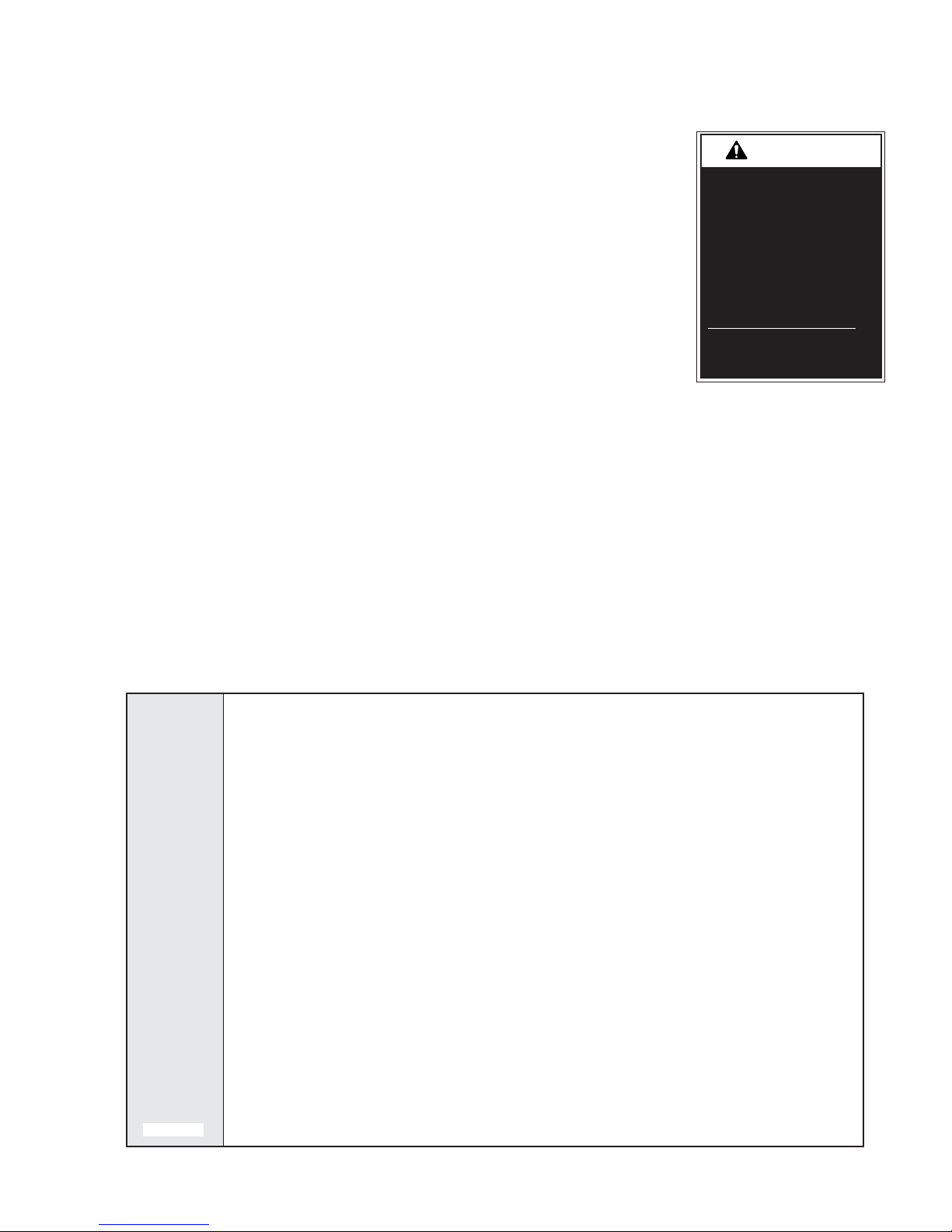

Platform Fold Pressure Adjustment

1. Position the platform at the floor level loading position.

2. Loosen the hex nut on the adjustment screw (do not remove hex nut).

3. Turn the adjustment screw counter clockwise until the platform does not fold when the Fold button is

pressed.

4. Turn the adjustment screw clockwise in 1/4 turn increments and press the Fold button until the platform folds completely (Note: Return the platform to floor level position after each attempt to fold the

platform).

5. Turn the adjustment screw an additional 1/8 turn after the platform folds successfully.

6. Tighten the hex nut without moving the adjustment screw.

7. Verify the platform will not stow while occupied.

DO NOT adjust this valve!

(Located on back side of pump block)

Note: Secure adjustment

screw and tighten hex

nut following adjustment.

Platform Fold

Adjustment

Allen Screw

Page 4

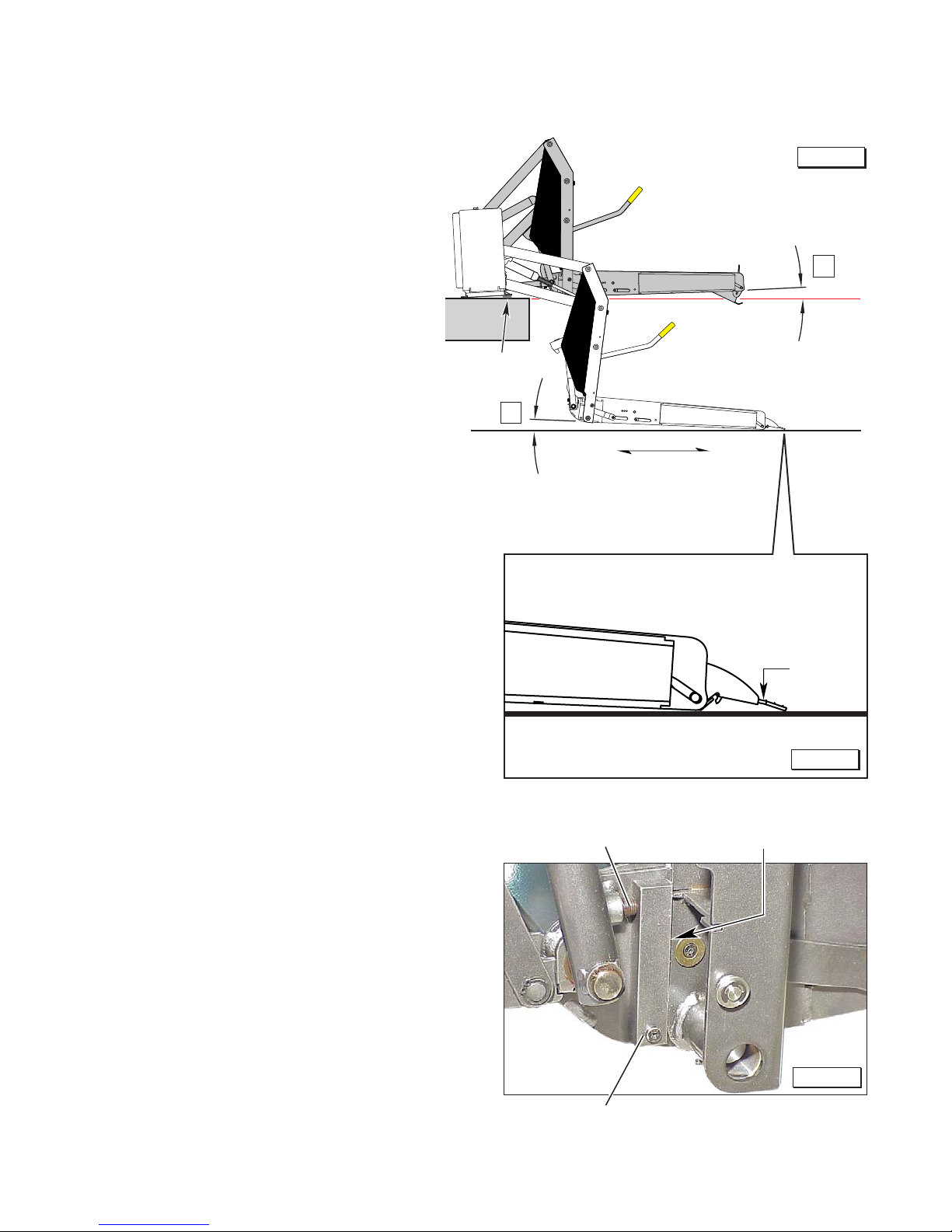

Platform Angle Adjustment

Adjustments to platform angle

may be required. Adjusting the

platform angle based on the relationship of the platform at ground

level directly affects the angle of

the platform when positioned at

floor level.

Unfold the lift and visually examine the angle of the platform

when positioned at floor level.

Lower the platform fully and note

the angle of the platform when it

reaches ground level also.

The platform angle must be

adjusted so there is a balance

between the angle at both positions (equal amount of angle).

Angle A should equal Angle B

as shown in Figure A.

Note: The outboard end of the

platform must contact the ground

first to ensure the spring-loaded

outer barrier unfolds fully. See

Figure B.

Adjustment Procedures:

Adjustment Allen screws are

provided on each side of the lift

platform for adjusting the platform

angle. See Figure C. Turn the

adjustment screw clockwise to

raise the outboard end of the

platform. Turn the adjustment

screw counterclockwise to

lower the outboard end of the

platform. Note: Both adjustment screws must be adjusted

equally. Ensure both stop

blocks are making full contact

with the vertical arms. Apply

®

Loctite

following adjustment.

to adjustment screws

Angle A

equals

Angle B.

Figure A

✓

A

Floor

Level

Shim

B

Inboard

Approximately

1" Clearance

Platform Angle Adjustment Screw Inside edge of vertical arms

Outboard

Barrier

must

unfold

fully.

Figure B

Floor Level Adjustment:

Following platform angle adjustment, set platform floor level

positioning as detailed in Tower

Microswitch Adjustments.

Figure C

Stop Block

Page 5

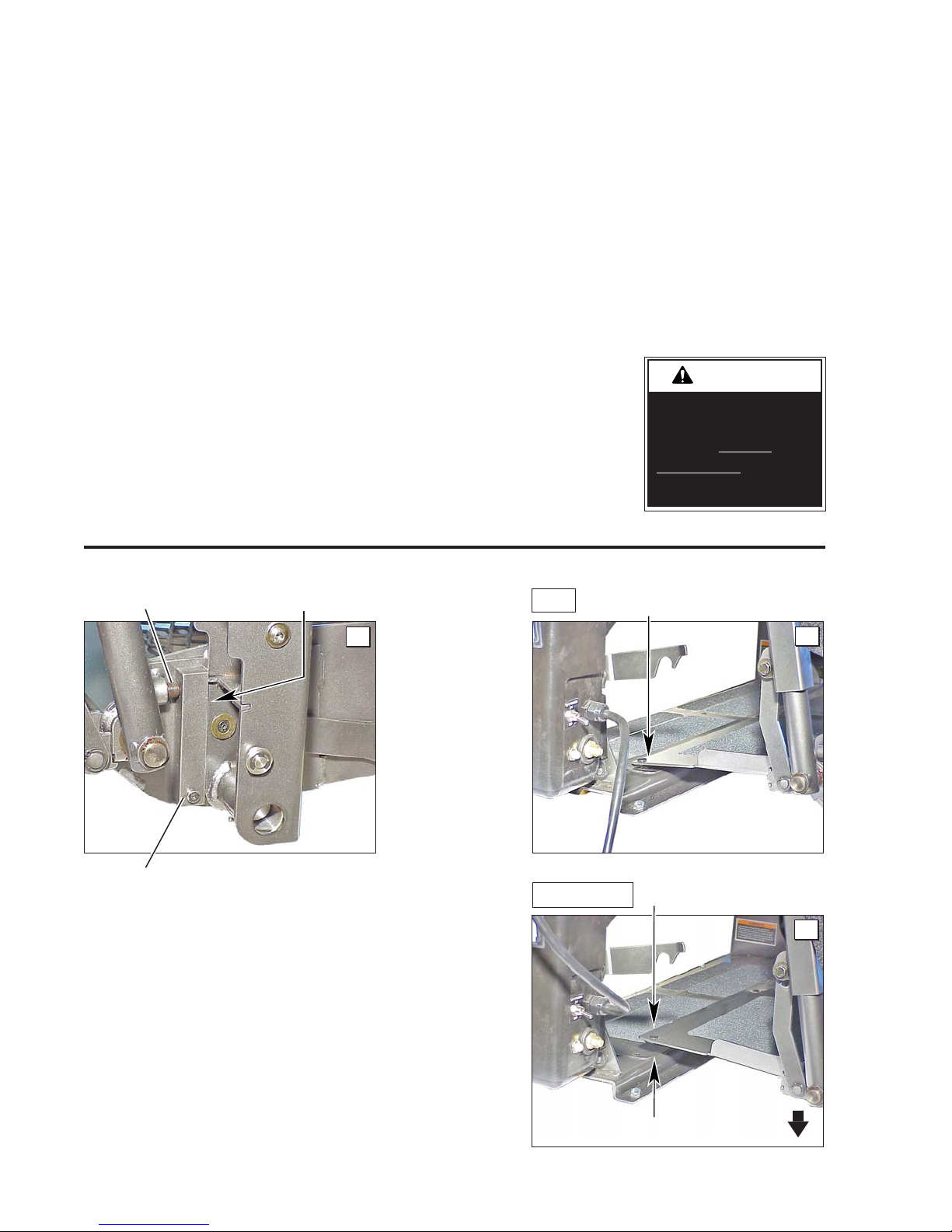

Platform Angle Adjustment

W

A

RNING

Automatic Floor Level Positioning: GVL936

Series lifts feature automatic floor level positioning.

This feature eliminates the need for the lift operator

to position and stop the platform at vehicle floor

level when unfolding the platform from the stowed

position and when raising the platform from ground

level.

Floor Level Adjustments: Tower 1 (Unfold) and

Tower 2 (Up) microswitches control platform and

bridge plate positioning. Ensure floor level adjustments are correct as outlined on page 7. Adjust

microswitches as needed only.

Floor Level Guidelines: When adjusting microswitches, bridge plate positioning and platform stop

block positioning must be viewed. A combination of

adjustments may be required to achieve a proper

balance. See Bridge Plate Positioning and Stop

Blocks below.

Platform Angle

Adjustment Screw

Inside edge of

vertical arms

Platform Angle Adjustments: Check platform

angle as outlined on page 5 when adjusting microswitches.

Adjustment Verification: Following the outlined

adjustment procedures, check floor level position

from stow position and from below floor level posi-

tion. The platform must stop automatically at floor

level when unfolding from stow position and when

raising from below floor level position. From the

stowed position, press the UNFOLD switch and hold

until the platform stops

at floor level. Once

stopped, ensure the

lift will fold when the

pendant FOLD switch

is pressed. Adjust the

switches as needed

per the guidelines in

Figure E.

Bridge plate resting solidly on

OK

base plate.

Improper microswitch

adjustment may

result in serious

bodily injury and/or

property damage.

A

Stop Block

Stop Blocks: The platform stop blocks

(one per side) must be making full contact

with the vertical arms when the platform is at

floor level. See Photo A. Improper adjust-

ment of screw positioning can result in

lift damage.

Bridge Plate Positioning: The bridge

plate should rest solidly on the base plate.

There should be a smooth (level) transition

between the platform, bridge plate and the

base plate. Refer to Photos B and C.

WRONG

B

Platform and bridge plate level.

Gap not permitted.

C

Platform too low.

Page 6

Tower Microswitch Adjustment

TOWER2TOWER

1

32942

Figure D

Note: Review

adjustment

procedures

below and

adjust as

needed only.

Note: Left

(rear) pump

lift depicted.

Right (front)

pump lift is

a mirrored

image.

Microswitch Adjustment Instructions:

Tower 1 (Unfold) Switch Adjustment:

Floor Position from Stow

1. Position platform at the fully stowed

position using the manual hand pump or

pendant control.

Tower 2

(Up)

Microswitch

Turn adjustment

screw counterclockwise to stop

the platform raise

function sooner.

Turn adjustment

screw clockwise

to allow the

platform to raise

further.

Tower 1

(Unfold)

Microswitch

Turn adjustment

TOWER

2

TOWER

1

32942

screw clockwise to stop the

platform unfold

function sooner.

Turn adjustment

screw counterclockwise to allow the platform

Figure E

to unfold further.

Tower 2 (Up) Switch Adjustment:

Floor Position from Below Floor

1. Lower platform a minimum of 6" below floor

level position using the manual hand pump

or pendant control.

2. Turn switch adjustment screw clockwise 3

full turns.

3. Press pendant UNFOLD switch (continue

pressing switch until platform stops unfolding).

4. When platform stops unfolding, turn switch

adjustment screw counterclockwise while

pressing the pendant UNFOLD switch.

Platform position will change. Repeat

adjustment until criteria below is met.

Proper Adjustment Criteria:

• The bridge plate should rest solidly on

the base plate (minimum of 1" overlap).

There should be a smooth (level) transition between the platform, bridge plate

and the base plate. See Photos B and C.

• The platform stop blocks (one per side)

must be making full contact with the

vertical arms when the platform is at floor

level. See Photo A.

2. Turn switch adjustment screw counterclockwise 3 full turns.

3. Press pendant UP switch (continue pressing switch until platform stops).

4. When platform stops, turn switch adjustment screw clockwise while pressing the

pendant UP switch. Platform position

will change. Repeat adjustment to meet

criteria listed in Tower 1 Switch "Proper

Adjustment Criteria" at left.

Adjustment Verification

Following adjustment procedures, verify

proper adjustment as detailed at left. Adjust the switches as needed per the guidelines in Photo A.

Page 7

Parallel Arm

Pivot Pin Bearings (16)

™

OLD

F

)

D

N

I

(

OL

UNF

UT)

O

(

UP

N

OW

D

Lift-Tite

Dampening Springs

Latch

(2 springs - 4 Points) LO

Saddle Support Bearings (8)

LO

Upper Fold Arm Pivot Points (2)

LO

Upper and Lower Fold Arm

Contact Area (2)

LG

Lower Fold Arm Pivot Points (2)

LO

Platform Fold Link Bearings (4)

LO

Lift-Tite™ Latch Rollers (2)

LO

Platform Pivot Pin Bearings (4)

LO

Maintenance and Lubrication

Lubrication Diagram

™

Lift-Tite

(Tower Pivot Points - 2)

LO

Latches

LO

Saddle Bearing

Hydraulic Cylinder

Pivot Bushings (8)

LO

Buttons (4)

DE

Parallel Arm

Pivot Pin Bearings (16)

LO

Handrail Pivot Pins (2)

LO

Inner Roll Stop Lever

Bearings (2) and Slots (2)

LO

Platform Fold Gear Rack (2) and

Gear Link Assembly Teeth (2)

DE

Gear Link Assembly

Bearings (4)

LO

Platform Side Plate Slots (2)

LG

Outer Barrier

Arm Slots (2)

LG

Outer Barrier

Latch Foot Bearings (2)

LO

Platform Fold Gear Rack Bearings (4)

LG

Outboard Platform Bearings (2)

See the Maintenance/Lubrication Schedule for recommended applications per number of cycles.

Specified (recommended) Available Braun

Lubricant Type Lubricant Amount Part No.

LO - Light Oil

DE - Door-Ease

LG - Light Grease

Light Penetrating Oil LPS2, General Purpose 11 oz.

(30 weight or equivalent) Penetrating Oil Aerosol Can

Stainless Stick Door-Ease 1.68 oz.

Style (tube) Stick (tube)

Light Grease Lubriplate 14 oz.

(Multipurpose) Can

Page 8

LG

Outer Barrier Arm

Pivot Points (2)

LO

15807

15806

15805

W

A

RNING

Maintenance and Lubrication Schedule

Proper maintenance is necessary to ensure safe,

troublefree operation. Inspecting the lift for any

wear, damage or other abnormal conditions should

be a part of all transit agencies’s daily service

program. Simple inspections can detect potential

problems.

The maintenance and lubrication procedures specified in this schedule must be performed by a Braun

authorized service representative at the scheduled

intervals according to the number of cycles.

Braun dual parallel arm lifts are equipped with hardened pins and self-lubricating bushings to decrease

wear, provide smooth operation and extend the

service life of the lift.

When servicing the lift at the recommended intervals, inspection and lubrication procedures specified

in the previous sections should be repeated. Clean

the components and the surrounding area before

applying lubricants. LPS2 General Purpose

Penetrating Oil is recommended where Light Oil is

called out. Use of improper lubricants can attract

dirt or other contaminants which could result in wear

or damage to the components. Platform components exposed to contaminants when lowered to the

ground may require extra attention.

Lift components requiring grease are lubricated dur-

ing assembly procedures.

When these components

are replaced, grease must

be applied during installation procedures. Specified

lubricants are available from

The Braun Corporation.

Maintenance and

lubrication procedures

must be performed as

specified by an

authorized service

All listed inspection, lubrica-

tion and maintenance procedures should be repeated

at “750 cycle” intervals

following the scheduled

“4500 Cycles” maintenance.

technician. Failure to

do so may result in

serious bodily injury

and/or property

damage.

These intervals are a general guideline for scheduling

maintenance procedures and will vary according to lift

use and conditions. Lifts exposed to severe conditions

(weather, environment, contamination, heavy usage,

etc.) may require inspection and maintenance procedures to be performed more often than specified.

Discontinue lift use immediately if maintenance and

lubrication procedures are not properly performed, or if

there is any sign of wear, damage or improper operation.

Contact your sales representative or call The Braun

®

Corporation at 1-800-THE LIFT

. One of our national

Product Support representatives will direct you to an

authorized service technician who will inspect your lift.

750

Cycles

continued

Outer barrier arm pivot points (2)

Outer barrier arm slots (2)

Gear link assembly bearings (4)

Gear link assembly teeth (2)

Outboard platform bearings (2)

Platform fold link bearings (4)

Platform fold gear rack bearings (4)

Platform fold gear rack teeth (2)

Lift-Tite™ latches (tower pivot points - 2)

™

Lift-Tite

points (2 springs - 4 points)

Inspect Lift-Tite

or damage (bent, deformed or misaligned), positive

securement and proper operation

Inspect outer barrier for proper operation

latch gas (dampening) spring pivot

™

latches and gas springs for wear

Apply Light Oil - See Lubrication Diagram

Apply Light Grease - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Door Ease - See Lubrication Diagram

Apply Light Grease - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Grease - See Lubrication Diagram

Apply Door Ease - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Resecure, replace damaged parts or otherwise

correct as needed. Note: Apply Light Grease to

™

Lift-Tite

Correct or replace damaged parts.

latch tower pivot point if replacing latch.

Page 9

continued

Maintenance and Lubrication Schedule

Inspect outboard barrier feet for proper operation,

positive securement and detached or missing

torsion spring

Correct, replace damaged parts and/or relubricate.

750

Cycles

Inspect platform fold gear rack and gear link assembly teeth for foreign objects, wear or damage (bent, deformed or misaligned), positive

securement and proper operation

Inspect lift for wear, damage or any abnormal

condition

Inspect lift for rattles

Perform all procedures listed in previous sections also

Outer barrier latch foot bearings (2)

Upper/lower fold arm contact areas (2)

Platform pivot pin bearings (4)

Upper fold arm pivot points (2)

Lower fold arm pivot points (2)

Inner roll stop lever bearings (2)

Inner roll stop lever slot (2)

Remove foreign objects, replace damaged parts

and resecure as needed

Correct as needed.

Correct as needed.

Apply Light Oil - See Lubrication Diagram

Apply Grease (synthetic) to contact areas between upper/lower fold arms. See Lubrication

Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

1500

Cycles

continued

Saddle support bearings (8)

Parallel arm pivot pin bearings (16)

Handrail pivot pins (2)

Hydraulic cylinder pivot bushings (8)

Platform side plate slots (2)

Inspect Lift-Tite™ latch rollers for wear or damage,

positive securement and proper operation (2)

Inspect inner roll stop for:

• Wear or damage

• Proper operation. Inner roll stop should just rest

on top surface of the base plate.

• Positive securement (both ends)

Inspect handrail components for wear or damage,

and for proper operation

Inspect microswitches for securement and proper

adjustment.

Make sure lift operates smoothly

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Grease - See Lubrication Diagram

Correct, replace damaged parts and/or relubricate.

Resecure, replace or correct as needed. See

Platform Angle Instructions and Tower Microswitch Adjustment Instructions.

Replace damaged parts.

Resecure, replace or adjust as needed. See

Tower Microswitch Adjustment Instructions.

Realign towers and vertical arms. Lubricate or

correct as needed.

Page 10

Maintenance and Lubrication Schedule

continued

1500

Cycles

Inspect external snap rings / e-clips:

• Upper fold arms (4)

• Lower fold arms (2)

• Inner roll stop lever bracket pins (2)

• Lift-Tite™ latch gas (dampening) springs (4)

• Gear link assembly (4)

• Lift-Tite™ rollers (2)

• Outer barrier latch foot pins (2)

• Rear bumper cable roller (1) - if equipped

Inspect platform fold link rollers and bearings

for wear or damage and positive securement

Remove pump module cover and inspect:

• Hydraulic hoses, fittings and connections

for wear or leaks

• Harness cables, wires, terminals and connections for securement or damage

• Circuit breaker, power switch and solenoids

for securement or damage

Perform all procedures listed in previous section also

Inspect cotter pins on platform pivot pins (2)

Resecure or replace if needed.

Resecure, replace or correct as needed.

Note: Apply Loctite® to threads if needed.

Resecure, replace or correct as needed.

Resecure, replace or correct as needed

4500

Cycles

Hydraulic Fluid (Pump) - Check level. Note: Fluid

should be changed if there is visible contamination.

Inspect the hydraulic system (cylinder, hoses, fit-

tings, seals, etc.) for leaks if fluid level is low.

Inspect cylinders, fittings and hydraulic connections

for wear, damage or leaks

Inspect parallel arms, bearings and pivot pins for

visible wear or damage

Inspect parallel arm pivot pin mounting screws (8)

Inspect platform pivot pins, bearings and vertical

arms for wear, damage and positive securement

Inspect vertical arms, handrails and pivot pins for

visible wear or damage

Inspect upper/lower fold arms, saddle, saddle

support and associated pivot pins, bushings, and

bearings for visible wear or damage

Inspect gas springs (cylinders - 2) for wear or damage, proper operation and positive securement

Inspect saddle bearing buttons (4)

Inspect vertical arm plastic covers

Use Braun 32840-QT (Exxon® Univis HVI 26)

hydraulic fluid (do not mix with Dextron III or other

hydraulic fluids). Check fluid level with platform

lowered fully and roll stop unfolded fully. Fill

to within 1/2" of the bottom of the 1-1/2" fill tube

(neck).

Tighten, repair or replace if needed.

Replace if needed.

Tighten or replace if needed.

Replace damaged parts and resecure as needed.

Apply Light Grease during reassembly procedures.

Replace damaged parts and relubricate if needed

Replace if needed.

Tighten, replace or correct as needed

Apply Door-Ease or replace if needed. See Lubrication Diagram.

Resecure or replace if needed.

continued

Inspect power cable

Resecure, repair or replace if needed.

Page 11

Maintenance and Lubrication Schedule

continued

4500

Cycles

Consecutive

750 Cycle

Intervals

Mounting

Decals and Antiskid

Repeat all previously listed inspection, lubrication and maintenance procedures at 750 cycle

intervals.

Check to see that the lift is securely anchored to

the vehicle and there are no loose bolts, broken

welds, or stress fractures.

Replace decals if worn, missing or illegible. Replace antiskid if worn or missing.

Page 12

Lift Electrical Schematic

Notes:

1. Shown with lift in stowed position.

2. All wires 20 gauge unless otherwise noted.

P1

BN

5

BK/GY

DK BU

5

6

6

OR

4

4

WH

2

2

YL

3

3

1

1

LIFT

SWITCH BOX

CHASSIS GROUND

CIRCUIT BREAKER

CONNECTORS

SOLENOID

MICROSWITCH

OFF

ON

BATTERY

MOTOR

SWITCH

DIODE

PK

UNFOLD

YL(16)

FOLD

WH(16)

YL(16)

BN(16)

WH(16)

BK(16)

DN

UP

BN(16)

RD(16)

BN(16)

RD(16)

RD(16)

FS8

MS8

LIFT

POWER

SWITCH

FS12

FS3

BK(16)

J1

DK BU

BN

FS10

MS10

BK(16)BK/GY

OR

FS9

MS9

MS11

FS11

WH(16)

YL(16)

WH

YL

SYMBOLDESCRIPTION

C

CIRCUIT

BREAKER

AUX.

BAT.

FS2 FS1

M

SOLENOID

NO

NC

PARTIAL FOLD

MICROSWITCH

NO

C

3

NC

BN

OR

UNFOLD / DOWN

BN

UP / FOLD

MICROSWITCH

NO

C

NC

2

MICROSWITCH

NO

C

1

NC

MICROSWITCH

STATION

BN BN

BK/GY

OR

WH

YL

DK BU

GROUND

BATTERY

DOWN

SOLENOID

DK BU

FS6 FS5

CIRCUIT

SENTRY

AUX.

BAT.

RD(6) RD(6)

DK GN

GROUND

POWER

FEED

STUD

RL1

BN

RL2

FOLD

SOLENOID

BN

FS7 FS4

DK GN

DK GN

DK GN

PUMP

M

HYDRAULIC

(UP)

RD(10)

UP/FOLD

SOLENOID

RL5

OR(12)BK(10) BU(12)

PK

OR

OR

RL6

RD(10)

RL3

PK

Page 13

Lift Wiring Diagram

BN

OR

OR

OR

BN

BN

BK/GY

DK. BU

WH

YL

COM.

COM

NO

N.O.

NC

N.C.

C3

COM.

NO

N.O.

NC

N.C.

C2

COM.

NO

N.O.

NC

N.C.

C1

3

C-H

COM

2

C-H

COM

1

C-H

Partial Fold

Microswitch

Up / Fold

Microswitch

Unfold / Down

Microswitch

Notes:

1. Shown with lift in stowed position.

2. All wires 20 gauge unless otherwise noted.

P1 J1

OR

WH WH(16)

FS9

MS9

YL YL(16)

MS11

BK/GY BK(16)

FS11

MS10 FS10

BN

MS8 FS8

BN(16)

RD(16)

Fold/Unfold

Switch

Up/Down

Switch

Switch Box

(As Viewed From Terminal

Side of Switch)

YL(16)

WH(16)

GN

BN

RD(16)

BK(16)

RD(16)

BN(16)

OR

OR

Up/Fold

Solenoid

or

Note polarity of diode. It

must be oriented as shown.

Detail at left shows two different

styles of diode identification.

Connects to

Vehicle Battery

(+) Positive Post

RL6

RL5

Circuit

Breaker

RL3

DK GN

Lead Wire

RD(6)

FS1

PK

FS2

RD(10)

PK

Circuit Sentry

(

Circuit Breaker)

Bat.

B

A

T

A

X

U

Aux.

PK

Lift

Power Cable

RL2

RL1

Lift Power

Switch

FS3

Pump Module

Power Feed

RD(6)

FS12

RD(16)

OR(12)

RL4

Ground

OR(12)

BU(12)

DK GN

DK GNDK GN

Fold

Down

Hydraulic

Pump

BK(10)

(Side view of solenoids

removed from pump.)

Pump Ground

Pump

Mounting

Plate

DK GN

Down

FS4

Fold

FS6FS5

FS7

DK BU

BN

BN

BN

BN

Page 14

Hydraulic Schematic

Opposite

Pump

Cylinder

Orifice

2200

PSI

BACKUP

PUMP

Down

Valv e

PUMP

1700

PSI

Orifice

Fold

Valv e

M

800

PSI

Pump Side

Cylinder

Description Symbol Description Symbol

Fixed Displacement

Pump

Pump Motor

Backup Pump

Single Acting Cylinder

Check Valve

Unfold Orifice

Manual

Shutoff Valve

Hydraulic Port

M

2 Way 2 Position

Solenoid Valve

Pressure Compensated

Flow Control

Relief Valve

Filter Screen

Vented Reservoir

Page 15

Hydraulics Parts List

GVL936FIB2948RP

Item Qty. Description GVL936IB3144 GVL936FIB3048RP

1 1 Pump Assembly (M-264-0101) 120G / 12V / Dual Relief 32729-12V 32729-12V

2 1 Solenoid, 4-Post - Trombetta 31129 31129

3 1 Motor, Pump - 12 Volt - 25A 31119 31119

4 1 Clamp, Hose - Solenoid Mountings 29663 29663

5 1 Valve Assembly, “Fold” (complete) 31120K 31120K

6 1 Cartridge (only), “Fold” Valve - (shown below) 31121 31121

7 2 Coil (only) - (shown below) 31122 31122

8 1 Valve Assembly, “Down” (complete) 31123 31123

9 1 Cartridge (only), “Down” Valve - (shown below) 31124 31124

10 3 Screw, 1/4-20 x 2-1/4", Allen Head 26080 26080

11 1 Hand Pump (Backup) with O-Rings (Item 12) 31125 31125

12 4 O-Ring (only), Hand Pump Mounting 17351 17351

13 1 Clamp, Hose - Reservoir - H-48 17069 17069

14 1 Reservoir, Hydraulic Fluid 30160 30160

15 1 Cap, Reservoir Filler - Screw On 30167 --------

1 Plug, Reservoir Breather (not shown) -------- 14350

16 1

17 1 Connector, Plastic “Y”, 1/8” O.D. 18877 18877

18 1 Hose, Thermal Plastic - Black, 1/8" I.D.

19 1 Handle with Grip 17206A 17206A

20 1 Fitting, Male 7-16-20 SAE O-Ring to Male 7/16-20 JIC 37° 24504 24504

21 1 Elbow, 7/16-20 JIC 37 Female Swivel (1) - 7/16-20 JIC 37° Male (2) 26579 26579

22 1 Hose Assembly, 1/8" (Opposite-Pump-Side) 16004A-084 16004A-091

23 1 Hose Assembly, 1/8" (Pump-Side) 16004A-046 16004A-053.5

24 2 Elbow, 90°, 7/16-20 SAE O-Ring Male - 7/16-20 JIC 37° Male, Orifice 26667 26667

25 2 Cylinder ✓

26 2 Elbow, 90°, 1/4 NPT Male to 1/4" Barbed 15150 15150

27 1 Hose, Thermal Plastic - Black, 1/8" I.D.

28 1 Hose, Thermal Plastic - Black, 1/8" I.D.

29 1

30 1 Kit, Hydraulic Port Service Cap 27049K 27049K

Fitting, 90° - 1/8" NPT x 1/8" Barb - Plastic 87563 87563

23742R* (8") 23742R* (8")

C1514.3-9407 C1514.3-9407

23742R* (66") 23742R* (74")

23742R* (27") 23742R* (35")

Diode Assembly, Up Solenoid 73906A 73906A

✓ Seal Kits: If repairing a cylinder, order Seal Kit #1500-0500P.

* Raw material items ordered and priced per inch (order specified length).

Hydraulic Fluid

When adding or changing

hydraulic fluid, use Braun

32840-QT (Exxon® Univis

HVI 26) hydraulic fluid (do

not mix with Dextron III or

other hydraulic fluids).

Page 16

5

#31122

Cartridge

#31121

“Fold” Valve

(complete)

7

Coil

6

“Down” Valve

(complete)

9

Cartridge

#31124

8

7

Coil

#31122

Hydraulics Diagram

24

25

19

30

Hydraulic

Repair

For repair of a

hydraulic hose

or cylinder, read

this.

Service

Bulletin

27049

12

15

1

29

4

25

3

2

Hydraulic

Pump Motor

8

5

24

11

Manual

10

Backup

Pump

Opposite Pump Cylinder

26

27

16

18

13

17

14

22

20

21

23

Pump Side Cylinder

26

28

Page 17

Pump Module Parts List

GVL936FIB2948RP

Item Qty. Description GVL936IB3144 GVL936FIB3048RP

1 Pump Module (complete), 12 Volt, Rear 936-0516RA 936-0516FARP

1 1 Pump Assembly (M264-0101) 12V-120G - Dual Relief (Includes Items 2 & 3) 32729-12V 32729-12V

2 1 Solenoid, Up - 4-Post - Trombetta 31129 31129

3 1 Clamp, Hose - Solenoid Mounting 29663 29663

4 1 Plate, Backing / Mounting 936-0501R 936-0501F

5 1 Cable, Lift / Chassis Ground 32880A 32880A

6 2 Bolt, 5/16-18 x 3/4", Nylock, Hex * See note below 29608 29608

7 2 Bolt, 5/16-18 x 1/2", Nylock, Hex * See note below 10012 10012

8 2 Washer, 5/16" Flat 10063 10063

9 1 Washer, 5/16" External Tooth 16368 16368

10 1 Fitting, Male 7/16-20 O-Ring to Male 7/16-20 JIC 37° 24504 24504

11 1 Elbow, Female Swivel 7/16-20 JIC 37° to (2) Male 7/16-20 JIC 37° 26579 26579

12 1 Circuit Breaker, Manual Reset 25736 25736

13 1 Switch, Toggle w/ Gold Contacts 31787 31787

14 1 Stud, Power Feed 26084 26084

15 1 Diode Assembly, Up Solenoid 73906A 73906A

16 1 Control, Hand Pendant Assembly - w/10' Harness 936-0903A 936-0903A

17 1 Pump Handle with Grip 17206A 17206A

18 1 Cover, Pump - Back 936-0513RB 936-0513FB

19 1 Receptacle, Clip-On 28803 28803

20 1 Rubber Boot, Red tSee note below 82046 82046

21 1 Cable, Pump Module Power tSee note below 26082A-4 26082A-4

22 1 Cover, Pump - Front

23 1 Clip, Pump Handle, Bottom 915-5518 915-5518

24 1 Clip, Pump Handle, Top 915-5517 915-5517

25 1 Washer, Nylon, 1/4" ID x 11/16" x .030" 12690 12690

26 3 Rivet, Pop - SD43BS - 1/8" - .13"/.19" 12954 12954

27 1 Retainer, Push On 28805 28805

28 1 Stud, Wing Head - 1/4 Turn 28804 28804

29 1 Plug, Window 30443 30443

30 1 Decal, Removal / Install Pump Cover (Not shown) 29051 29051

31 1 Decal, Remove / Install Pump Handle (Not shown) 29052 29052

32 1 Decal, Manual Instruction, Hand Pump (Not shown) 29082 29082

33 1 Decal, Dual Relief Adjustment (Not shown) 32201 32201

34 1 Connector, Plastic Y (Not shown - see Hydraulic Diagram) 18877 18877

35 1 Hose, 1/8" Thermal Plastic (Not shown - see Hydraulic Diagram) 23742R 23742R

36 1 Hose Assembly, 86" - 1/8" Dia. - Swivel Ends (Not shown - see Hydraulic Diagram) 16004A-084 16004A-091

37 1 Hose Assembly, 46" - 1/8" Dia. - Swivel Ends (Not shown - see Hydraulic Diagram) 16004A-046 16004A-053.5

38 1 Decal, Lift Power On/Off (Not shown) 21494 21494

39 1 Harness, Power - Breaker (Not shown - see Wiring Diagram) 32870A 32870A

40 1 Harness, Breaker - On/Off Switch (Not shown - see Wiring Diagram) 32871A 32871A

41 1 Harness, Power - Motor Solenoid (Not shown - see Wiring Diagram) 32872A 32872A

42 1 Harness, Control Box - Pump (Not shown - see Wiring Diagram) 32874A 32874A

43 1 Harness, Tower Switches - Pump (Not shown - see Wiring Diagram) 32875A 32875ARP

44 1 Harness, Ground - Solenoids (Not shown - see Wiring Diagram) 32873A 32873A

45 1 Adapter Plate, Front - 8" Raised Pump - Weldment (Not shown) N/A 33863FW

46 3 Bolt, 3/8-16 x 1/2" w/Nylock Patch (Not shown) N/A 29729

(Complete Assembly 936-0513RTA or 936-0513FTA Includes Items 22 - 33)

936-0513RT 936-0513FT

* Apply red #271 Thread Locker Loctite® to the four hex bolts (items 6 and 7) if a blue nylon patch is not present on the

bolts when retrofitting an M264 pump assembly. Loctite® is available from The Braun Corporation under part number

11522-1.

t Indicates items available for replacement part purposes only. These items are not included with replacement pump

modules.

Page 18

Pump Module Diagram

Pump Mounting Bolts

Apply red #271 Thread Locker Loctite®

to the three pump mounting bolts (items

6 and 7) if a blue nylon patch is not

present on the bolts when retrofitting an

M264 pump assembly. Loctite® is

available from The Braun Corporation

under part number 11522-1.

16

FOLD

(IN)

D

NFOL

U

T)

U

O

(

UP

DOWN

18

6

8

7

17

19

3

9

8

4

5

6

1

28

29

25

24

27

26

13

7

14

10

22

26

11

15

12

21

20

26

2

23

Note: Rear pump module shown,

front pump module mirror image.

Page 19

Applicable For:

·GVL936FIB2948RP

10

9

16

Exploded Views and Parts Lists

Base Plate Assembly

15

15

7

6

5

4

13

8

15

12

17

18

1

14

1811 WASHER-#10 FLAT/AUTO-BK

17

1

1 14993

16

7

15

14

13

1

12

2

11

1

10

4

9

8

4 O-RING 5/16 ID X 1/16

2 NUT-3/8-16 UNC HEX LOCK/AUTO-BK13617

7

2 10063 WASHER-5/16" FLAT/AUTO-BK

6

2

5

4

3

1

2

3

1

1

ITEM

QTY.

11541

20535

11513

32735FA

GV936-0143-29

24440

975-3121A

24570

26614

11913

33117RW1 WMT-LINK-LIFT TITE/GVL936

33117FW

29729

PART NO.

CLAMP-INSULATE 1"

RIV-POP-SD66BS-3/16"-.25/.38/AUTO-BK

RIV-POP-SD64BS-3/16"-.13/.25/AUTO-BK

ASSY-REAR-TOWER SWITCH PARTIAL FOLD

COVER-BASE/GVL936

BOLT-5/16-18 X 3/4-BHSC/AUTO-BK

MICRO SWITCH ASSY

RING-5/16 EXT SNAP/ZINC PLATED

SPRING-DAMP 5.67 E/4.291 C,P1=3.37N-RET269632

WASHER-1/2" NYLON

WMT-LINK-LIFT TITE/GVL936

BOLT-3/8-16 X 1/2 W/NYLOCK PATCH

WMT-BASE/GVL936GV936-0142FW29

DESCRIPTION

2

15

2

5

7

3

11

8

6

10

9

Page 20

10

Exploded Views and Parts Lists

Base Plate Assembly

Applicable For:

·GVL936FIB3048RP

15

15

7

6

5

4

13

8

9

16

15

12

17

18

1

14

1811 WASHER-#10 FLAT/AUTO-BK

17

1

16

1 14993

15

7

14

13

1

12

2

11

1

10

4

9

8

4 O-RING 5/16 ID X 1/16

2 NUT-3/8-16 UNC HEX LOCK/AUTO-BK13617

7

2 10063 WASHER-5/16" FLAT/AUTO-BK

6

2

5

4

3

1

2

3

1

1

ITEM

QTY.

11541

20535

11513

32735FA

GV936-0143-30

24440

975-3121A

24570

26614

11913

33117RW1 WMT-LINK-LIFT TITE/GL936

33117FW

29729

PART NO.

CLAMP-INSULATE 1"

RIV-POP-SD66BS-3/16"-.25/.38/AUTO-BK

RIV-POP-SD64BS-3/16"-.13/.25/AUTO-BK

ASSY-REAR-TOWER SWITCH PARTIAL FOLD

COVER-BASE/GVL936

BOLT-5/16-18 X 3/4-BHSC/AUTO-BK

MICRO SWITCH ASSY

RING-5/16 EXT SNAP/ZINC PLATED

SPRING-DAMP 5.67 E/4.291 C,P1=3.37N-RET269632

WASHER-1/2" NYLON

WMT-LINK-LIFT TITE/GL936

BOLT-3/8-16 X 1/2 W/NYLOCK PATCH

WMT-BASE/GVL936GV936-0142FW30

DESCRIPTION

2

15

2

5

7

3

11

8

6

10

9

Page 21

Applicable For:

·GVL936IB3144

Exploded Views and Parts Lists

Base Plate Assembly

15

15

7

6

5

15

13

3

10

9

12

8

16

2

17

18

15

5

7

4

1

14

8

6

10

9

11

1811 WASHER-#10 FLAT/AUTO-BK

17

1

1 14993

16

7

15

14

13

1

12

2

11

1

10

4

9

8

4 O-RING 5/16 ID X 1/16

2 NUT-3/8-16 UNC HEX LOCK/AUTO-BK13617

7

2 10063 WASHER-5/16" FLAT/AUTO-BK

6

2

5

4

3

1

2

3

1

1

ITEM

QTY.

Page 22

11541

20535

11513

32735RA

GV936-0143

24440

975-3121A

24570

26614

11913

33117RW1 WMT-LIFT TITE-REAR/GVL936

33117FW

29729

PART NO.

CLAMP-INSULATE 1"

RIV-POP-SD66BS-3/16"-.25/.38/AUTO-BK

RIV-POP-SD64BS-3/16"-.13/.25/AUTO-BK

ASSY-REAR-TOWER SWITCH PARTIAL FOLD

COVER-BASE/GVL936

BOLT-5/16-18 X 3/4-BHSC/AUTO-BK

MICRO SWITCH ASSY

RING-5/16 EXT SNAP/ZINC PLATED

SPRING-DAMP 5.67 E/4.291 C,P1=3.37N-RET269632

WASHER-1/2" NYLON

WMT-LIFT TITE-FRONT/GVL936

BOLT-3/8-16 X 1/2 W/NYLOCK PATCH

WMT-BASE/GVL936GV936-0142RW

DESCRIPTION

12

10

11

8

9

Exploded Views and Parts Lists

Top Parallel Arm Assembly - Front

Applicable For:

3

7

1

2

5

6

4

·All Lifts

13

14

14

13

12

11

10

ITEM

9

8

7

6

5

4

3

2

1

10058

1

1

1

15858BK BOLT-CARR 5/16-18 X 3/4/AUTO-BK

1

1

28593A

1

915-0392

1

14993

1

915-0703

1

2

11513

996-0449

1

4

31771

4

24011

1

936-0401FAKS

PART NO.

QTY.

NUT-5/16-18 HEX/AUTO-BK

WASHER-5/16" LOCK/AUTO-BK

10068

16368

WASHER-5/16" EXTERNAL TOOTH

24440

SCREW-5/16-18 X 3/4-BHSC/AUTO-BK

ASSY-BLOCK-GUIDE-PLATFORM-STOW

BKT.-QUIET-RIDE MTG.-915

RIV-POP-SD66BS-3/16"-.25/.38/AUTO-BK

BRACKET-INNER SIDE PANEL GUIDE

RIV-POP-SD64BS-3/16"-.13/.25/AUTO-BK

CAP-PARALLEL ARM

SHIM WASHER-0.906"IDx1.156"ODx.030"T/SS

BEARING-FLANGE-3/4" X 3/8"-12FDU06

KIT ARM-PARALLEL/TOP GL936 (INCLUDES ITEMS 1-7)

DESCRIPTION

Top Parallel Arm Assembly - Rear

3

5

2

1

Applicable For:

·All Lifts

4

14

13

7

10

11

6

12

8

9

14

13

12

11

10

ITEM

9

8

7

6

5

4

3

2

1

1

10068

1

15858BK BOLT-CARR 5/16-18 X 3/4/AUTO-BK

1

24440

1

28593A

1

915-0392

1

1

14993

1 915-0703

11513

2

996-0449

1

31771

4

4

24011

1

936-0401RAKS

PART NO.

QTY.

10058

1

NUT-5/16-18 HEX/AUTO-BK

WASHER-5/16" LOCK/AUTO-BK

16368

WASHER-5/16" EXTERNAL TOOTH

SCREW-5/16-18 X 3/4-BHSC/AUTO-BK

ASSY-BLOCK-GUIDE-PLATFORM-STOW

BKT.-QUIET-RIDE MTG.-915

RIV-POP-SD66BS-3/16"-.25/.38/AUTO-BK

BRACKET-INNER SIDE PANEL GUIDE

RIV-POP-SD64BS-3/16"-.13/.25/AUTO-BK

CAP-PARALLEL ARM

SHIM WASHER-0.906"IDx1.156"ODx.030"T/SS

BEARING-FLANGE-3/4" X 3/8"-12FDU06

KIT ARM-PARALLEL/TOP/48" FTG/R (INCLUDES ITEMS 1-7)

DESCRIPTION

Page 23

Applicable For:

·GVL936FIB2948RP

·GVL936FIB3048RP

Exploded Views and Parts Lists

Bottom Parallel Arm Assembly - Front

3

2

1

Applicable For:

·GVL936FIB2948RP

·GVL936FIB3048RP

2 4 24011

1

936-0400FFA1

QTY.ITEM

PART NO.

SHIM WASHER-0.906" ID X 1.156" OD X .030" T/SS3 4 31771

BEARING-FLANGE-3/4" X 3/8"-12FDU06

ASSY-ARM-PARALLEL/BTM GVL936 FF (INCLUDES 1-3)

DESCRIPTION

Bottom Parallel Arm Assembly - Rear

3

1

2

Page 24

2 4 24011

1

936-0402A1

QTY.ITEM

PART NO.

SHIM WASHER-0.906" ID X 1.156" OD X .030" T/SS3 4 31771

BEARING-FLANGE-3/4" X 3/8"-12FDU06

ASSY-ARM-PARALLEL/BTM GL936 (INCLUDES 1-3)

DESCRIPTION

Exploded Views and Parts Lists

Bottom Parallel Arm Assembly - Front

Applicable For:

·GVL936IB3144

3

1

2 4 24011

1

936-0402A1

QTY.ITEM

PART NO.

SHIM WASHER-0.906" ID X 1.156" OD X .030" T/SS3 4 31771

BEARING-FLANGE-3/4" X 3/8"-12FDU06

ASSY-ARM-PARALLEL/BTM (INCLUDES 1-3)

DESCRIPTION

Bottom Parallel Arm Assembly - Rear

2

Applicable For:

·GVL936IB3144

3

2

1

2 4 24011

1

936-0400RRA1

QTY.ITEM

PART NO.

SHIM WASHER-0.906" ID X 1.156" OD X .030" T/SS3 4 31771

BEARING-FLANGE-3/4" X 3/8"-12FDU06

ASSY-ARM-PARALLEL/BTM GVL936 RR (INCLUDES 1-3)

DESCRIPTION

Page 25

Applicable For:

·All Lifts

Exploded Views and Parts Lists

Hydraulic Cylinder Assembly - Main

2

30° ±10°

RETRACTED

STROKE 14.625

EXTENDED

23.146

37.771

3

1

3

2

1

ITEM

1

1

QTY.

26667

1514.3-9407ARO

PART NO.

15150

1

Page 26

ELBOW-1/4 NPT 90° 1/4 BARB

ELBOW-7/16-20 M/O-RNG/37*/.035 ORFICE

CYLINDER ASSY-14.625"/23.146 RETRACTED (Includes Items 1-3)

DESCRIPTION

Exploded Views and Parts Lists

Vertical Arm Assembly - Front

Applicable For:

·GVL936FIB2948RP

7

1

4

5

5

4

3

3

8

2

9

6

542

32

22

245379 1 SCREW-#10-32X3/8 FL HD-HX SKT/AUTO-BK

990-03418 1 ADAPT-CYL/ROLL STOP LEVER-OUT

324087 1 RUBBER BUMPER-VERT CHAN.

244426 1 BEARING-FLANGE-1/2" X 1/4"-08FDU04

2

11

QTY.ITEM

84383

32734

33291

32998

GV936-0442FW

PART NO.

E CLIP-3/8 SHAFT

ROLLER-/LIFT TITE

WASHER-SHIM-5/8 IDx1" ODx0.025" THICK-SS

PIN-LIFT-TITE-ROLLER/VISTA

WMT-VERTICAL CHANNEL-FRONT-GVL936

DESCRIPTION

Vertical Arm Assembly - Rear

Applicable For:

·GVL936FIB2948RP

7

1

5

4

245379 1 SCREW-#10-32X3/8 FL HD-HX SKT/AUTO-BK

5

4

3

542

6

2

3

2

8

9

32

22

990-03418 1 ADAPT-CYL/ROLL STOP LEVER-OUT

324087 1 RUBBER BUMPER-VERT CHAN.

244426 1 BEARING-FLANGE-1/2" X 1/4"-08FDU04

2

11

QTY.ITEM

84383

32734

33291

32998

GV936-0442RW

PART NO.

E CLIP-3/8 SHAFT

ROLLER-/LIFT TITE

WASHER-SHIM-5/8 IDx1" ODx0.025" THICK-SS

PIN-LIFT-TITE-ROLLER/VISTA

WMT-VERTICAL CHANNEL-REAR-GVL936

DESCRIPTION

Page 27

Applicable For:

·GVL936FIB3048RP

·GVL936IB3144

541

1

31

21

11

QTY.ITEM

Exploded Views and Parts Lists

Vertical Arm Assembly - Front

245379 1 SCREW-#10-32X3/8 FL HD-HX SKT/AUTO-BK

990-03418 1 ADAPT-CYL/ROLL STOP LEVER-OUT

324087 1 RUBBER BUMPER-VERT CHAN.

244426 1 BEARING-FLANGE-1/2" X 1/4"-08FDU04

84383

32734

33291

32998

GV936-2436FW

PART NO.

E CLIP-3/8 SHAFT

ROLLER-/LIFT TITE

WASHER-SHIM-5/8 IDx1" ODx0.025" THICK-SS

PIN-LIFT-TITE-ROLLER/VISTA

WMT-VERTICAL CHANNEL-FRONT-GVL936

DESCRIPTION

7

1

5

4

3

2

8

9

6

Applicable For:

·GVL936FIB3048RP

·GVL936IB3144

541

1

31

21

11

QTY.ITEM

Vertical Arm Assembly - Rear

245379 1 SCREW-#10-32X3/8 FL HD-HX SKT/AUTO-BK

990-03418 1 ADAPT-CYL/ROLL STOP LEVER-OUT

324087 1 RUBBER BUMPER-VERT CHAN.

244426 1 BEARING-FLANGE-1/2" X 1/4"-08FDU04

84383

32734

33291

32998

GV936-2436RW

PART NO.

E CLIP-3/8 SHAFT

ROLLER-/LIFT TITE

WASHER-SHIM-5/8 IDx1" ODx0.025" THICK-SS

PIN-LIFT-TITE-ROLLER/VISTA

WMT-VERTICAL CHANNEL-REAR-GVL936

DESCRIPTION

7

1

5

4

6

3

8

2

9

Page 28

Exploded Views and Parts Lists

Handrail Assembly - Front

6

3

2

Applicable For:

·All Lifts

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1 1 936-0409A

936-0426W

1

975-2429

1

975-2428

1

1

13617

1

10027 BOLT-3/8-16 X 2" HEX HD. CAP

30227

2

1

12608 CLIP-SAFETY (GAS SPRING)

29185

1

29186

1

205-1760

2

18657

2

900-0413N

1

995-0406W SLIDE-PLATEFORM ROTATE HANDRAIL

1

978-2425RRW

1

QTY.ITEM PART NO.

WMT-TUBE-LOWER FOLD ARM/GL936

PIN-ROLLER-LOWER FOLD ARM

ROLLER-LOWER FOLD ARM

NUT-3/8-16 UNC HEX LOCK/AUTO-BK

WASHER-UHMW 0.75 OD X 0.39 ID X 0.25

BALL STUD-13MM W/3/8-16 FEMALE THREAD

GAS SPRING-14.468 EXT/8.956 COM-P1=1150N

BEARING-UHMW FLAT/1.226-THN-BLK

RING-3/4 EXT SNAP/AUTO-BK

PIN PIVOT LOWER ARM

WMT-TUBE-UPPER FOLD ARM/GVL936

HANDRAIL SUB-ASSY

DESCRIPTION

Handrail Assembly - Rear

14

15

13

4

5

11

12

1

10

7

9

6

8

Applicable For:

·All Lifts

3

1

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

936-0426W WMT-TUBE-LOWER FOLD ARM/GL936

1

975-2429 PIN-ROLLER-LOWER FOLD ARM

1

975-2428 ROLLER-LOWER FOLD ARM

1

13617 NUT-3/8-16 UNC HEX LOCK/AUTO-BK

1

10027 BOLT-3/8-16 X 2" HEX LOCK/AUTO-BK

2

30227 WASHER-UHMW 0.75 OD X 0.39 ID X 0.25

1

12608 CLIP-SAFETY (GAS SPRING)

1

29185 BALL STUD-13MM W/3/8-16 FEMALE THREAD

29186

1

2

205-1760 BEARING-UHMW FLAT/1.226-THIN-BLK

2

18657 RING-3/4 EXT SNAP/AUTO-BK

1

900-0413N PIN-PIVOT LOWER ARM

1

995-0406W SLIDE-PLATFORM ROTATE HANDRAIL

1

978-2425FRW WMT-TUBE-UPPER-FOLD ARM/GVL936

936-0409A

1

QTY.ITEM PART NO. DESCRIPTION

GAS SPRING-14.468 EXT/8.956 COM-P1=1150N

HANDRAIL SUB-ASSY

14

2

15

12

10

7

9

13

4

5

11

1

8

Page 29

Exploded Views and Parts Lists

Platform Assembly - Inboard

Applicable For:

·GVL936FIB2948RP

DWG. NOTES

1) APPLY RED LOCTITIE #11522-1 TO THREADS OF (BC.#10025 AND BC.#12463).

20

23

5

13

15

3

4

6

23

5

14

14

14

6

1

11

3

7

4

14

8

9

15

18

19

17

28

11

10

16

16

9

11

7

18

17

17

27

24

18

12

13

15

20

8

18

19

11

28

18

10

19

29

25

25

24

25

22

15

25

26

19

18

18

18

12

17

27

29

25

2

22

25

4

15

14

4

13

2

12

2

11

4

2

10

2

9

8

2

7

2

6

2

5

2

4

2

23 18663

12 975-2328RRABKN

24442

28031

V955-0333N

975-2329BKN

P50067-BK

975-2379

16368

26281

26154

28324BK

26327

900-0311

PART NO.QTY.ITEM DESCRIPTION PART NO.QTY.ITEM DESCRIPTION

BEARING-FLANGE-1/2" X 1/4"-08FDU04

BEARING-FLANGE-1 X 1/2-16FDU08

LINK-PLATFORM/VERT CHANNEL

GEAR RACK-PLATFORM FOLD

PLUG-INTERIOR-PLASTIC PUSH/BLACK

PAD-ROLL STOP FOOT STOWED

WASHER-5/16" EXTERNAL TOOTH

SCREW-5/16-18 X 1/2" BHSC-BLK/AUTO-BK

BUMPER-STOW/VISTA

NUT-5/16-18 TOP LOCK/AUTO-BK

BOLT-5/16-18 X 1 1/4"-LHSHCS/AUTO-BK

STOP-PLATFORM

SCREW-1/2-20 X 1.5 SET-LOCK

LINK/GEAR-PLATFORM FOLD (INCLUDES ITEMS 2 &15 QTY 1)

PLATFORM WELDMENT FIXED INNER1 1 V955-62948INIBW

Page 30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

2

2

2

1

975-2328FRABKN

6

2

2

2

2

2

4

8

4

2

975-2360

975-2202

12463

29371

13273

24550

975-2358

975-2360

975-2334

975-2359

29378

10069

10025

PIN-BEARING-PLATFORM SLIDE

PIN-BEARING-GEAR RACK

BOLT-3/8-16 x 3/4" GR5-HEX/AUTO-BK

GEAR ASSEMBLY/FRONT (INCLUDES ITEMS 26 & 15 QTY 1)

WASHER-THRUST-.875 OD/.50 ID/.0585T

RING-1/2 EXT SELF LOCK SNAP/AUTO-BK

PIVOT-ROLL STOP LEVER-L915

BEARING-PLATFORM-SLIDE

PIN-BEARING-PLATFORM SLIDE

PIN-BEARING-GEAR RACK

BEARING-PLATFORM-SLIDE

WASHER-THRUST-1.125 OD/.625 ID/.0585T

WASHER-3/8" LOCK

BOLT-3/8-16 X 1" HEX/AUTO-BK

Exploded Views and Parts Lists

Platform Assembly - Inboard

DWG. NOTES

1) APPLY RED LOCTITIE #11522-1 TO THREADS OF (BC.#10025 AND BC.#12463).

Applicable For:

·GVL936FIB3048RP

20

23

5

13

15

4

14

3

4

6

5

14

14

23

14

6

1

11

3

7

15

11

10

9

11

7

18

8

18

9

19

28

17

16

16

17

17

27

24

18

12

13

15

20

8

18

19

11

28

18

10

19

25

22

15

25

21

25

24

25

26

19

18

18

18

12

17

21

27

25

25

2

22

14

4

13

2

12

2

11

4

2

10

2

9

8

2

7

2

6

2

5

2

4

2

23 18663

12 975-2328RRABKN

28031

V955-0333N

975-2329BKN

P50067-BK

975-2379

16368

26281

26154

28324BK

26327

900-0311

PART NO.QTY.ITEM DESCRIPTION PART NO.QTY.ITEM DESCRIPTION

BEARING-FLANGE-1 X 1/2-16FDU08

LINK-PLATFORM/VERT CHANNEL

GEAR RACK-PLATFORM FOLD

PLUG-INTERIOR-PLASTIC PUSH/BLACK

PAD-ROLL STOP FOOT STOWED

WASHER-5/16" EXTERNAL TOOTH

SCREW-5/16-18 X 1/2" BHSC-BLK/AUTO-BK

BUMPER-STOW/VISTA

NUT-5/16-18 TOP LOCK/AUTO-BK

BOLT-5/16-18 X 1 1/4"-LHSHCS/AUTO-BK

STOP-PLATFORM

SCREW-1/2-20 X 1.5 SET-LOCK

LINK/GEAR-PLATFORM FOLD (INCLUDES ITEMS 2 &15 QTY 1)

PLATFORM WELDMENT FIXED INNER1 1 V955-63048INIBW

28

2 975-2202

27

2 12463

26

1 975-2328FRABKN

25

6 29371

24

2 13273

2

23

22

2

21

2

20

2

19

4

18

8

17

4

16

2

15

4

24550

975-2358

975-2360

975-2334

975-2359

29378

10069

10025

24442

PIN-BEARING-GEAR RACK

BOLT-3/8-16 X 3/4 GR5-HEX/AUTO-BK

GEAR ASSEMBLY/FRONT (INCLUDES ITEMS 26 & 15 QTY 1)

WASHER-THRUST-.875 OD/.50 ID/.0585T

RING-1/2 EXT SELF LOCK SNAP/AUTO-BK

PIVOT-ROLL STOP LEVER-L915

BEARING-PLATFORM-SLIDE

PIN-BEARING-PLATFORM SLIDE

PIN-BEARING-GEAR RACK

BEARING-PLATFORM-SLIDE

WASHER-THRUST-1.125 OD/.625 ID/.0585T

WASHER-3/8" LOCK

BOLT-3/8-16 X 1" HEX/AUTO-BK

BEARING-FLANGE-1/2" X 1/4"-08FDU04

Page 31

Exploded Views and Parts Lists

Platform Assembly - Inboard

Applicable For:

·GVL936IB3144

DWG. NOTES

1) APPLY RED LOCTITIE #11522-1 TO THREADS OF (BC.#10025 AND BC.#12463).

22

23

5

13

15

3

6

4

5

14

14

23

14

6

1

11

3

7

4

14

8

9

15

18

19

17

28

11

10

16

16

9

11

7

18

17

17

27

24

18

12

13

15

22

8

18

19

11

28

18

10

19

25

21

15

25

20

25

24

25

26

19

18

18

18

12

17

20

27

25

25

2

21

14

4

13

2

12

2

11

4

2

10

2

9

8

2

7

2

6

2

5

2

4

2

23 18663

12 975-2328RRABKN

28031

V955-0333N

975-2329BKN

P50067-BK

975-2379

16368

26281

26154

28324BK

26327

900-0311

BEARING-FLANGE-1 X 1/2-16FDU08

LINK-PLATFORM/VERT CHANNEL

GEAR RACK-PLATFORM FOLD

PLUG-INTERIOR-PLASTIC PUSH/BLACK

PAD-ROLL STOP FOOT STOWED

WASHER-5/16" EXTERNAL TOOTH

SCREW-5/16-18 X 1/2" BHSC-BLK/AUTO-BK

BUMPER-STOW/VISTA

NUT-5/16-18 TOP LOCK/AUTO-BK

BOLT-5/16-18 X 1 1/4"-LHSHCS/AUTO-BK

STOP-PLATFORM

SCREW-1/2-20 X 1.5 SET-LOCK

LINK/GEAR-PLATFORM FOLD (INCLUDES ITEMS 2 &15 QTY 1)

PLATFORM WELDMENT FIXED INNER1 1 V955-63144INIBW

Page 32

28

2 975-2202

27

2 12463

26

1 975-2328FRABKN

25

6 29371

24

2 13273

2

23

2

22

21

2 975-2358

20

2 975-2360

19

4

18

8

17

4

16

2

15

4

24550

975-2334

975-2359

29378

10069

10025

24442

PIN-BEARING-GEAR RACK

BOLT-3/8-16 X 3/4 GR5-HEX/AUTO-BK

GEAR ASSEMBLY/FRONT (INCLUDES ITEMS 26 & 15 QTY 1)

WASHER-THRUST-.875 OD/.50 ID/.0585T

RING-1/2 EXT SELF LOCK SNAP/AUTO-BK

PIVOT-ROLL STOP LEVER-L915

PIN-BEARING-GEAR RACK

BEARING-PLATFORM-SLIDE

PIN-BEARING-PLATFORM SLIDE

BEARING-PLATFORM-SLIDE

WASHER-THRUST-1.125 OD/.625 ID/.0585T

WASHER-3/8" LOCK

BOLT-3/8-16 X 1" HEX/AUTO-BK

BEARING-FLANGE-1/2" X 1/4"-08FDU04

Exploded Views and Parts Lists

Platform Assembly - Outboard

DWG. NOTES

1) APPLY LOCTITIE 242 (B.C.# 18822) TO SET SCREWS (B.C.# 11567 AND B.C.# 11563)

BEFORE INSTALLATION.

Applicable For:

·GVL936FIB2948RP

8

9

10

3

17

7

1

19

16

15

15

12

19

9

13

13

13

11

14

13

2

14

15

15

16

17

7

4

21

20

18

6

18

21

8

20

5

18

18

11

10

9

8

7

6

5

4

1 1 V955-62948OTW

28132R

1

1

28132F

24028

2

31274

2

28129

2

1

975-3203FRBKN

1

975-3203RRBKN

1

13 995-3204FW

12 995-3204RW

PART NO.QTY.ITEM DESCRIPTION PA RT NO .QTY.ITEM DESCRIPTION

ROD-5/32"-TORSION SPRING BAR-RR

ROD-5/32"-TORSION SPRING BAR-RR

BEARING-PLASTIC-FLANGE-3/8IDX1/4"

PIN-ROLL STOP/FOOT-VL/TYT

WASHER-.34 ID X .062T-NYLON

ROLL STOP ARM-FRONT/BKN

ROLL STOP ARM-REAR/BKN

ROLL STOP-TOP-29"V955-0312-29

LATCH FOOT/FRONT/WMT/VL955

LATCH FOOT/REAR/WMT/VL955

PLATFORM WELDMENT FIXED INNER

2

21

20

19

18

17

16

15

14

13

12

13710

31456 WASHER-FENDER-.266 IDX.875 ODX.047

2

2

13889

4

18349

30227

2

28128

2

17192P

4

11563

2

4

11567

995-0208

1

RING-1/4 EXT SNAP

RING-3/8 RETAINING SNAP

NUT-#10-32 W/LOCKWASHER/AUTO-BK

WASHER UHMW 0.75 OD X 0.39 ID X 0.25

BEARING-FLANGE-10MM X 12MM-BB1012DU

SCREW-#10-32X1/2 FDHXS-AUTO BLK-WPAT(EA

SCREW-1/4-20 X 1/4 SET CUP PT

SCREW-5/16-18 X 5/16" SET

COLLAR-ROLL STOP-TORSION BAR

Page 33

Exploded Views and Parts Lists

Platform Assembly - Outboard

Applicable For:

·GVL936FIB3048RP

DWG. NOTES

1) APPLY LOCTITIE 242 (B.C.# 18822) TO SET SCREWS (B.C.# 11567 AND B.C.# 11563)

BEFORE INSTALLATION.

8

9

10

3

17

7

1

19

16

15

15

12

19

9

13

13

13

11

14

13

2

14

15

15

16

17

7

4

21

20

18

6

18

21

8

20

5

18

18

11

10

9

8

7

6

5

4

1 1 V955-63048OTW

28132R

1

1

28132F

24028

2

31274

2

2

28129

1

975-3203FRBKN

1

975-3203RRBKN

1

13 995-3204FW

12 995-3204RW

PART NO.QTY.ITEM DESCRIPTION PA RT NO .QTY.ITEM DESCRIPTION

ROD-5/32"-TORSION SPRING BAR-RR

ROD-5/32"-TORSION SPRING BAR-FR

BEARING-PLASTIC-FLANGE-3/8IDX1/4"

PIN-ROLL STOP/FOOT-VL/TYT

WASHER-.34 ID X .062T-NYLON

ROLL STOP ARM-FRONT/BKN

ROLL STOP ARM-REAR/BKN

ROLL STOP-TOP-30"V955-0312-30

LATCH FOOT/FRONT/WMT/VL955

LATCH FOOT/REAR/WMT/VL955

PLATFORM WELDMENT FIXED INNER

Page 34

21

20

19

18

17

16

15

14

13

12

13710

2

31456 WASHER-FENDER-.266 IDX.875 ODX.047

2

2

13889

4

18349

30227

2

28128

2

17192P

4

11563

2

4

11567

1

995-0208

RING-1/4 EXT SNAP

RING-3/8 RETAINING SNAP

NUT-#10-32 W/LOCKWASHER/AUTO-BK

WASHER UHMW 0.75 OD X 0.39 ID X 0.25

BEARING-FLANGE-10MM X 12MM-BB1012DU

SCREW-#10-32X1/2 FDHXS-AUTO BLK-WPAT(EA

SCREW-1/4-20 X 1/4 SET CUP PT

SCREW-5/16-18 X 5/16" SET

COLLAR-ROLL STOP-TORSION BAR

Exploded Views and Parts Lists

Platform Assembly - Outboard

DWG. NOTES

1) APPLY LOCTITIE 242 (B.C.# 18822) TO SET SCREWS (B.C.# 11567 AND B.C.# 11563)

BEFORE INSTALLATION.

Applicable For:

·GVL936IB3144

8

9

10

3

17

7

1

19

16

15

15

12

19

9

13

13

13

11

14

13

2

14

15

15

16

17

7

4

20

21

18

6

18

21

8

20

5

18

18

11

10

9

8

7

6

5

4

1 1 V955-03144OTW

28132R

1

1

28132F

24028

2

31274

2

2

28129

1

975-3203FRBKN

1

975-3203RRBKN

1

13 995-3204FW

12 995-3204RW

PART NO.QTY.ITEM DESCRIPTION PA RT NO .QTY.ITEM DESCRIPTION

ROD-5/32"-TORSION SPRING BAR-RR

ROD-5/32"-TORSION SPRING BAR-RR

BEARING-PLASTIC-FLANGE-3/8IDX1/4"

PIN-ROLL STOP/FOOT-VL/TYT

WASHER-.34 ID X .062T-NYLON

ROLL STOP ARM-FRONT/BKN

ROLL STOP ARM-REAR/BKN

ROLL STOP-TOP-31"V955-0312

LATCH FOOT/FRONT/WMT/VL955

LATCH FOOT/REAR/WMT/VL955

PLATFORM WELDMENT FIXED INNER

21

20

19

18

17

16

15

14

13

12

13710

2

31456 WASHER-FENDER-.266 IDX.875 ODX.047

2

2

13889

4

18349

30227

2

28128

2

17192P

4

11563

2

4

11567

1

V955-0208

RING-1/4 EXT SNAP

RING-3/8 RETAINING SNAP

NUT-#10-32 W/LOCKWASHER/AUTO-BK

WASHER UHMW 0.75 OD X 0.39 ID X 0.25

BEARING-FLANGE-10MM X 12MM-BB1012DU

SCREW-#10-32X1/2 FDHXS-AUTO BLK-WPAT(EA

SCREW-1/4-20 X 1/4 SET CUP PT

SCREW-5/16-18 X 5/16" SET

COLLAR-ROLL STOP-TORSION BAR

Page 35

Applicable For:

·GVL936FIB2948RP

21

22

20

14

Exploded Views and Parts Lists

Inner Roll Stop Assembly

16

17

19

11

18

6

13

15

7

7

9

16

12

12

17

12

19

18

20

11

22

21

14

13

15

10

6

12

11

2

2

10

2

9

8

2

7

4

6

4

5

1

4

1

33 916-5406

42 25171

6

8

23

7

6

5

3

3

3

12

7

6

8

9

12

10

4

12

1

2

2

23

10062

975-6404

915-0391

10068

13890

10059BK

10069BK

985F0431NW

985R0431NW

PART NO.QTY.ITEM DESCRIPTION PA RT NO .QTY.ITEM DESCRIPTION

WASHER-1/4" FLAT/AUTO-BK

LEVER-INBOARD BARRIER

BUMPER-.75 X .625LG-5/16-18THD

WASHER-5/16" LOCK/AUTO-BK

BOLT-5/16-18 X 3/4" HEX

NUT-3/8-16 HEX/AUTO-BK

WASHER-3/8" LOCK/AUTO-BK

BRIDGEPLATE BKT WMT-FR

BRIDGEPLATE BKT WMT-RR

BEARING-UHMW FLAT-THIN-BLK

BOLT-3/8-16 x 3/4" FLBHSCS-GD8

BRIDGE PLT-ARS-BASE-29 X 48/36FTG1 1 V955U0147IB-29

2

23

22

21

20

19

18

17

16

15

14

13

24012

10025

2

2

10069BK

10064

2

2

916-5434

2

15328

27276

2

916-5433

2

24442

2

13273

2

2

25336

BEARING-FLANGE-3/4" X 1/4"-12FDU04

BOLT-3/8-16 X 1" HEX/AUTO-BK

WASHER-3/8" LOCK/AUTO-BK

WASHER-3/8" FLAT/AUTO-BK

PIVOT-BRIDGEPLATE LEVER-UPPER-OUTER

WASHER-.156ID X 1OD X .0269/AUTO-BK

WASHER-FINGER DISC SPRING 1.004 X .516

PIVOT-BRIDGEPLATE LEVER-UPPER

BEARING-FLANGE-1/2" X 1/4"-08FDU04

RING-1/2 EXT SELF LOCK SNAP/AUTO-BK

WASHER-.516ID X ,75OD X .0250/AUTO-BK

2

2

Page 36

22

21

20

14

Exploded Views and Parts Lists

Inner Roll Stop Assembly

16

17

19

11

18

6

13

15

7

7

9

12

16

12

17

12

19

18

Applicable For:

·GVL936FIB3048RP

20

11

22

21

14

13

15

10

6

12

11

2

2

10

2

9

8

2

7

4

6

4

5

1

4

1

33 916-5406

42 25171

6

8

23

7

6

5

3

3

3

12

7

6

8

9

12

10

4

12

1

2

2

23

10062

975-6404

915-0391

10068

13890

10059BK

10069BK

985F0431NW

985R0431NW

PART NO.QTY.ITEM DESCRIPTION PA RT NO .QTY.ITEM DESCRIPTION

WASHER-1/4" FLAT/AUTO-BK

LEVER-INBOARD BARRIER

BUMPER-.75 X .625LG-5/16-18THD

WASHER-5/16" LOCK/AUTO-BK

BOLT-5/16-18 X 3/4" HEX

NUT-3/8-16 HEX/AUTO-BK

WASHER-3/8" LOCK/AUTO-BK

BRIDGEPLATE BKT WMT-FR

BRIDGEPLATE BKT WMT-RR

BEARING-UHMW FLAT-THIN-BLK

BOLT-3/8-16 x 3/4" FLBHSCS-GD8

BRIDGE PLT-ARS-BASE-30 X 48/36FTG1 1 V955U0147IB-30

2

23

22

21

20

19

18

17

16

15

14

13

24012

10025

2

2

10069BK

10064

2

2

916-5434

2

15328

27276

2

916-5433

2

24442

2

13273

2

2

25336

BEARING-FLANGE-3/4" X 1/4"-12FDU04

BOLT-3/8-16 X 1" HEX/AUTO-BK

WASHER-3/8" LOCK/AUTO-BK

WASHER-3/8" FLAT/AUTO-BK

PIVOT-BRIDGEPLATE LEVER-UPPER-OUTER

WASHER-.156ID X 1OD X .0269/AUTO-BK

WASHER-FINGER DISC SPRING 1.004 X .516

PIVOT-BRIDGEPLATE LEVER-UPPER

BEARING-FLANGE-1/2" X 1/4"-08FDU04

RING-1/2 EXT SELF LOCK SNAP/AUTO-BK

WASHER-.516ID X ,75OD X .0250/AUTO-BK

2

2

Page 37

Applicable For:

·GVL936IB3144

22

21

20

14

Exploded Views and Parts Lists

Inner Roll Stop Assembly

16

17

19

11

18

6

13

15

7

7

9

12

16

12

17

12

19

18

20

11

22

21

14

13

15

10

6

12

11

2

2

10

2

9

8

2

7

4

6

4

5

1

4

1

33 916-5406

42 25171

6

8

23

7

6

5

3

3

3

12

7

6

8

9

12

10

4

12

1

2

2

23

10062

975-6404

915-0391

10068

13890

10059BK

10069BK

985F0431NW

985R0431NW

PART NO.QTY.ITEM DESCRIPTION PA RT NO .QTY.ITEM DESCRIPTION

WASHER-1/4" FLAT/AUTO-BK

LEVER-INBOARD BARRIER

BUMPER-.75 X .625LG-5/16-18THD

WASHER-5/16" LOCK/AUTO-BK

BOLT-5/16-18 X 3/4" HEX

NUT-3/8-16 HEX/AUTO-BK

WASHER-3/8" LOCK/AUTO-BK

BRIDGEPLATE BKT WMT-FR

BRIDGEPLATE BKT WMT-RR

BEARING-UHMW FLAT-THIN-BLK

BOLT-3/8-16 x 3/4" FLBHSCS-GD8

BRIDGE PLT-ARS-BASE-31/48 FTS1 1 V955U0147IB

2

23

22

21

20

19

18

17

16

15

14

13

24012

10025

2

2

10069BK

10064

2

2

916-5434

2

15328

27276

2

916-5433

2

24442

2

13273

2

2

25336

BEARING-FLANGE-3/4" X 1/4"-12FDU04

BOLT-3/8-16 X 1" HEX/AUTO-BK

WASHER-3/8" LOCK/AUTO-BK

WASHER-3/8" FLAT/AUTO-BK

PIVOT-BRIDGEPLATE LEVER-UPPER-OUTER

WASHER-.156ID X 1OD X .0269/AUTO-BK

WASHER-FINGER DISC SPRING 1.004 X .516

PIVOT-BRIDGEPLATE LEVER-UPPER

BEARING-FLANGE-1/2" X 1/4"-08FDU04

RING-1/2 EXT SELF LOCK SNAP/AUTO-BK

WASHER-.516ID X .75OD X .0250/AUTO-BK

2

2

Page 38

"Providing Access to the World"

®

Over 300 Braun

Dealers Worldwide

"Providing Access to the World"

International Corporate Hdqrs: P.O. Box 310 Winamac, IN 46996 USA

1-800-THE LIFT

®

(574) 946-6153 FAX: (574) 946-4670

®

Service Manual for:

02

<KA

Global

HZg^Zh

Wheelchair Lifts

Braun™ Limited Warranty

Consult your local Braun dealer regarding warranty policy.

www.braunlift.com/international

Braun GVL Series

Braun GVL Series

33222

34179 Rev. A

34179 Rev. A

December 2007

December 2007

All illustrations, descriptions and specifications in this manual are based on the latest product information available at the

All illustrations, descriptions and specifications in this manual are based on the latest product information available at the

time of publication. The Braun Corporation reserves the right to make changes at any time without notice.

time of publication. The Braun Corporation reserves the right to make changes at any time without notice.

Patent #5,261,779

Patent #5,261,779

Patent #6,065,924

Patent #6,065,924

Patent #6,238,169

Patent #6,238,169

"Providing Access to the World"

International Corporate Hdqrs: P.O. Box 310 Winamac, IN 46996 USA

1-800-THE LIFT

Patent #6,464,447

Patent #6,464,447

Patent #6,599,079

Patent #6,599,079

Patent #6,739,824

Patent #6,739,824

®

(574) 946-6153 FAX: (574) 946-4670

Patent #6,837,670

Patent #6,837,670

Patents Pending

Patents Pending

© The Braun Corporation

© The Braun Corporation

®

®

Loading...

Loading...