GUV Control System Cooper Lighting Solutions Installation Manual

Installation Instructions

GUV Control System

Cooper Lighting Solutions

GUV Control System

READ AND FOLLOW ALL SAFETY INSTRUCTIONS.

SAVE AND KEEP THESE INSTRUCTIONS WITH THE CONTROL PANEL.

Failure to comply with these instructions may result in death, serious bodily injury and property damage.

GUV Control System should only be operated by authorized personnel. Before operation, the installer must

complete and submit a checklist to Cooper Lighting Solutions to ensure the control system is installed correctly.

GUV Important Safeguards

a. READ AND FOLLOW ALL SAFETY INSTRUCTIONS

b. Safe use of this UV equipment relies primarily on equipment and site safeguards. It is the installer’s

responsibility to ensure that equipment is installed in accordance to the manufacturer’s instructions.

c. It is the operator’s responsibility to ensure the equipment is used in accordance with the manufacturer’s user guide.

(i.e. The device is operated when the room is unoccupied.)

d. This equipment is designed for use with germicidal xtures and must be installed in compliance with competent technical

directions to prevent the user’s eyes and bare skin from exposure to harmful UVC radiation.

e. UV radiation can reect off surrounding surfaces and may pass through certain clear or translucent materials. Follow the

manufacturer’s recommended practice for spacing this equipment from nearby objects and surfaces. Contact the manufacturer

for further guidance.

f. Equipment should be mounted in locations and at heights where it will not readily be subjected to tampering by unauthorized

personnel.

g. This equipment uses user-replaceable lamps, replace them only with the lamps for which the equipment is marked and intended.

h. The use of accessory equipment not recommended by the manufacturer may cause an unsafe condition.

i. Do not use this equipment for other than its intended use.

WARNING

Risk of Fire, Electrical Shock, Cuts or other Casualty Hazards- Installation and maintenance of this product must be

performed by a qualied electrician. This product must be installed in accordance with the applicable installation code

by a person familiar with the construction and operation of the product and hazards involved.

Risk of Fire and Electric Shock- Make certain power is OFF before starting installation or attempting any maintenance.

Disconnect power at fuse or circuit breaker.

Risk of Fire- Minimum 90°C supply conductors.

Risk of Personal Injury- Due to sharp edges, handle with care.

FCC Regulations state that any unauthorized changes or modications to this equipment not expressly approved by the

manufacturer could void the user’s authorization to operate this equipment.

GUV Control System should only be operated by authorized personnel. Before operation, the installer must complete

and submit a checklist to Cooper Lighting Solutions to ensure the control system is installed correctly.

DISCLAIMER OF LIABILITY: Cooper Lighting Solutions assumes no liability for damages or losses of any kind that may arise

from the improper, careless, or negligent installation, handling or use of this product.

IMPORTANT: Read carefully before installing product. Retain for future reference.

NOTICE: Product may become damaged and/or unstable if not installed properly.

Note: Specications and dimensions subject to change without notice.

ATTENTION Receiving Department: Note actual product description of any shortage or noticeable damage on delivery receipt. File claim for common

carrier (LTL) directly with carrier. Claims for concealed damage must be led within 15 days of delivery. All damaged material, complete with original

packing must be retained.

GENERAL: Upon receipt of controller thoroughly inspect for any freight damage, which should be brought to the attention of the delivery carrier.

Compare the catalog description listed on the packing slip with the label on the controller to assure you have received the correct parts.

NOTICE: These instructions do not claim to cover all details or variations in the equipment, procedure, or process described, or to provide directions

for meeting every possible contingency during installation, operation or maintenance. When additional information is desired to satisfy a problem not

covered suciently for user’s purpose, please contact your nearest representative.

NOTICE: Proper grounding is required to insure personal safety. Carefully observe grounding procedure under installation section.

CAUTION: See ratings on controller for appropriate voltage. Any other connection voids the warranty.

GUV Control SystemCooper Lighting Solutions

FCC Statement

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not

cause harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired

operation.

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC

Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the interference at his own

expense.

FCC Regulations state that any unauthorized changes or modications to this equipment not expressly approved by the manufacturer

could void the user’s authorization to operate this equipment.

General Information

Following the instructions provided in this document is vital to ensure the GUV Control System is wired and installed correctly.

The GUV Control System is specifically designed to for the safe operation of Cooper Lighting Solutions’ GUV fixtures when installed

correctly, the system will:

1. Verify the area to be disinfected has been thoroughly inspected for occupants.

2. Ensure all points of entry including doors, windows and pass-throughs are closed.

3. Shut off fixtures automatically if anyone enters the space during operation.

Items needed for Site Installation and Commissioning

GUV Control Panel

Part Name

GUV Control Panel Onsite

Control Relay

Relay Socket

High Current Relay Factory DPBF09 10 D024

Timer

Timer Socket

Control Power Supply Factory Phoenix Contact 2904945

Circuit Protector Factory F1 CCP2-1-30CC

Terminal blocks Factory

All Class 2 Wiring except

for the branch circuit

power for the box

Factory/Onsite

Installed

Factory

Factory

Onsite For all class 2 wiring

Designator

or MFG

GUV-16-120-277

GUV-24-120-277

Part

Information

Supplied Panel with

16 Inputs

Supplied Panel with

24 Inputs

782-2C-24D

782-2C-SKT

MS4SA-CE-ADC

TP411X

Wago 2002

(all connection points)

IB503096ML page 2

October 2020

www.cooperlighting.com

GUV Control System Cooper Lighting Solutions

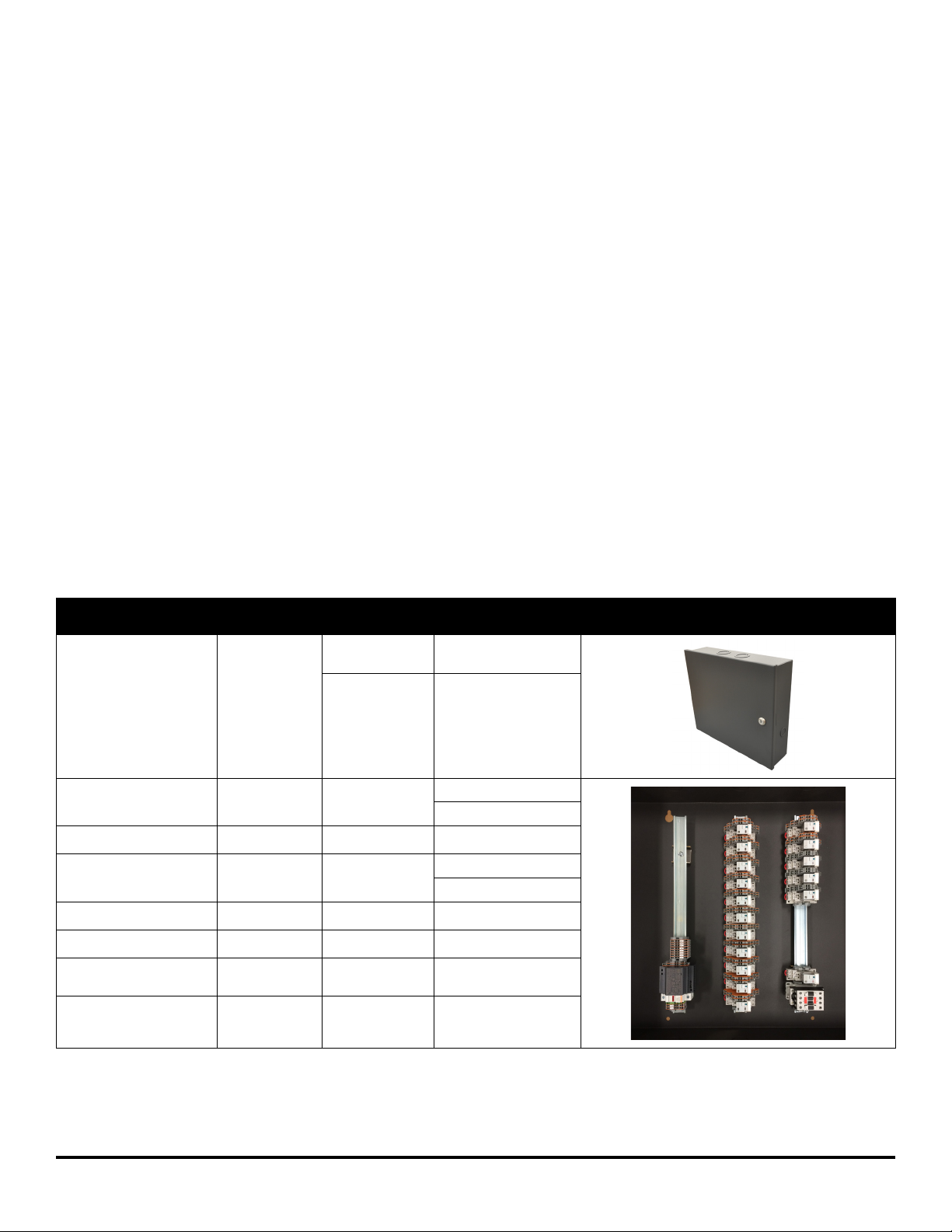

GUV User Station

Part Name

Factory/Onsite

Installed

Designator

or MFG

GUV User Station

Includes: selector

switch, key switch,

GUV User Station

Onsite GUV-USER-1

and panel light with

leads assembly is

prebuilt and only

wiring, and mounting

is required.

Panel Light with Leads Factory 20C843

Selector Switch Factory FUJII GCX3300

Key switch Factory FUJII GCX3430

GUV Clearance Pushbutton

Part Name

Factory/Onsite

Installed

Designator

or MFG

GUV Clearance

Pushbutton

Pushbutton kit

with plate

Onsite GUV-PB-1

Includes: a single

gang mounting plate

for every pushbutton

for ease of installation

Part

Information

Part

Information

All Class 2 Wiring Onsite

600V rated, 90C,

20AWG min

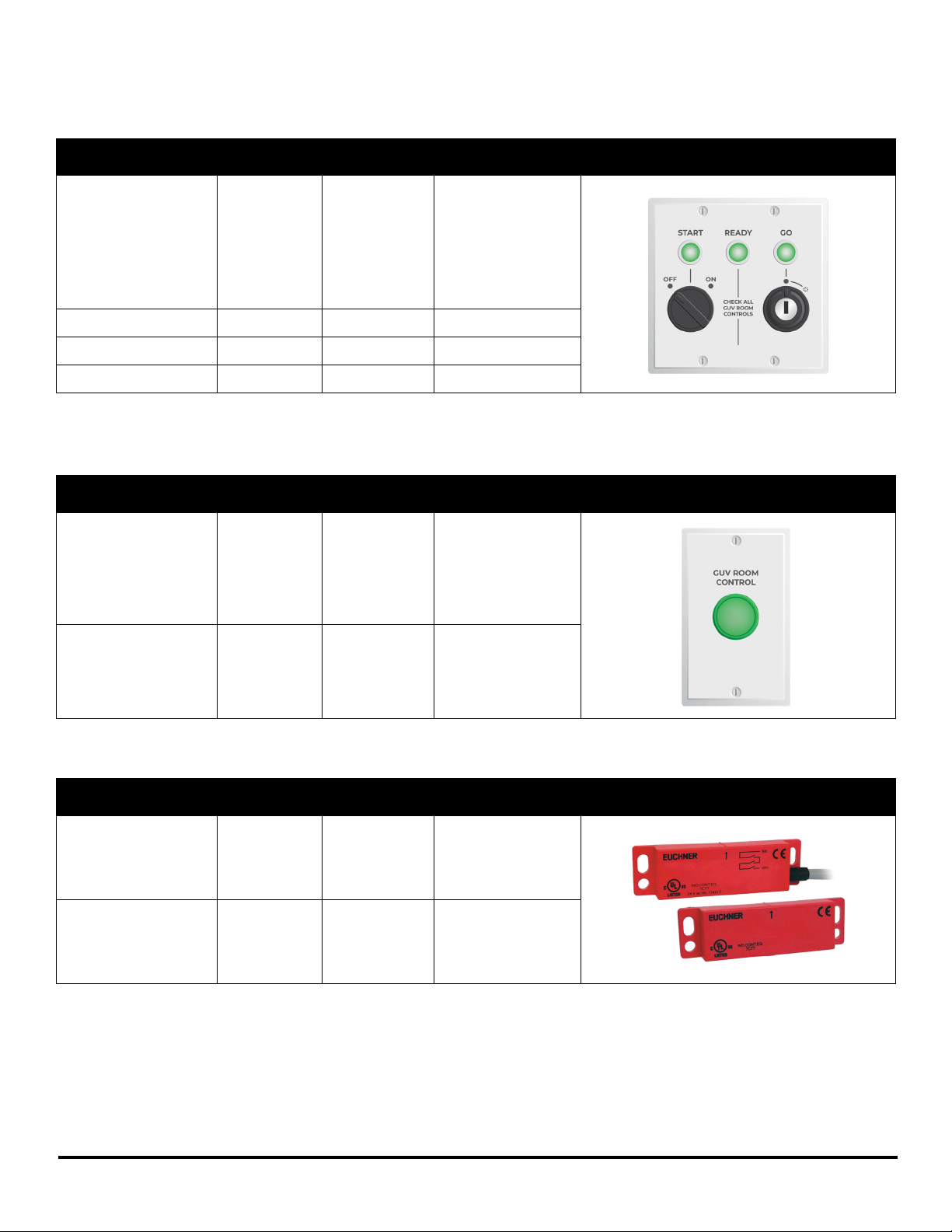

Contact Closures for doors/windows/openings

For all class 2 wiring

Part Name

Contact Closure /

GUV Magnetic

Access Sensor

Factory/Onsite

Installed

Onsite

Designator

or MFG

GUV-MAGSENSOR-1

Part

Information

CMS-R-AXF-03B

CMS-M-AB

Light Curtain Onsite Contrinex YCA-50S4-3400-G012

www.cooperlighting.com

IB503096ML page 3

October 2020

UV Emitters

GUV Control SystemCooper Lighting Solutions

Part Name

GH Germicidal UV

High Bay

GSL Germicidal UV

Striplight

GTR Germicidal UV

Troffer

GUC Germicidal UV

Undercabinet

GLR Germicidal UV

Louvered Recessed

UV Emitters

Part Name

UHB Germicidal UV

High Bay

UST Germicidal UV

Striplight

Factory/Onsite

Installed

Onsite

Onsite

Onsite

Onsite

Onsite

Factory/Onsite

Installed

Onsite

Onsite

Designator

or MFG

Cooper Lighting

Solutions Fail-Safe

Cooper Lighting

Solutions Fail-Safe

Cooper Lighting

Solutions Fail-Safe

Cooper Lighting

Solutions Fail-Safe

Cooper Lighting

Solutions Fail-Safe

Designator

or MFG

Alkco by Signify

Lighting NA

Alkco by Signify

Lighting NA

Part Information

(*1) = # Lamps (*2) = Lamp Type

(*3) = Distribution (*4) = Ballast Type (*5) = Wire Guard/Louver

GH - (*1) - (*2) - (*3) - (*4)

GSL - (*1) - (*2) - (*3) - (*4)

24GTR - (*5) - (*1) - (*2) - (*4)

GUC - (*1) - (*2) - (*4)

24GLR - (*2) - (*5) - (*4)

Part Information

(*1) = # Lamps (*2) = Lamp Type

(*3) = Ballast Type

UHB - (*1) - (*2) - (*3)

UST - (*1) - (*2) - (*3)

Technical Documentation

UV Layout Factory

GUV System Verification Onsite review

Plan for layout of UV

fixtures and controls

Filled out by installer and

approved by AHJ

Supplied by

Cooper Lighting Solutions

Layout diagram of UV

emitters and Controls

provided by CLS and

approved by Installer

Included in

Installation instructions

IB503096ML page 4

October 2020

www.cooperlighting.com

GUV Control System Cooper Lighting Solutions

Getting Started

1. Do not discard these installation instructions. Please keep for future reference and operation information.

2. Always disconnect all power before wiring or servicing.

3. Use only as intended and at the rated voltage.

4. All installation service must be performed by qualified personnel or service technicians.

5. Install in accordance with National Electrical Code and any other codes that may apply.

6. Multiple sources of high voltage are present inside the controller enclosure. Use extreme caution when performing maintenance

on this equipment.

7. It is recommended that all low voltage wiring be done with power removed to protect components from potential shorts during

the wiring process.

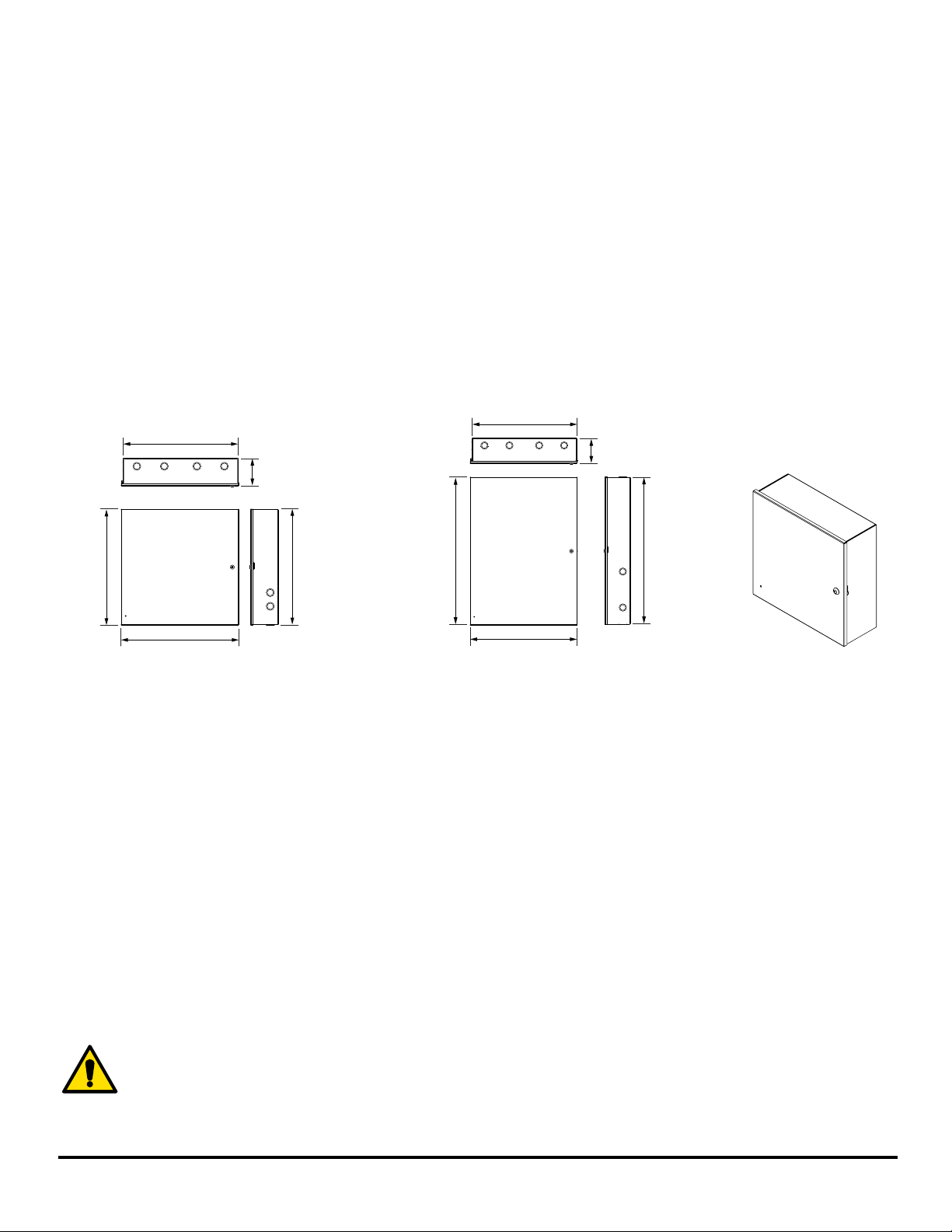

Mounting the GUV Control Panel

25-5/32” [639mm]

25-1/8” [638mm]

6-1/16”

[154mm]

6-1/16”

[154mm]

25-11/32”

[644mm]

25-43/64” [652mm]

Medium panel configuration

25-1/8”

[638mm]

35-35/64”

[903mm]

25-47/64” [654mm]

Large panel configuration

35-19/64”

[896mm]

1. Choose an indoor dry location convenient to the circuit breaker panel. The GUV control panel comes in medium and large sizes.

2. Mount the enclosure on a firm surface using predrilled holes.

3. A minimum of 14 inches (360 mm) must be maintained from the front of the chassis to any other components or walls.

Please make sure to check and follow local code requirements if additional clearance is needed per code in your area.

4. Allow space to open door.

5. Allow adequate space for future maintenance of the unit. Do not install in a location that will later be difficult to access.

6. Enclosure is designed to be mounted vertically.

7. Use suitable conduits and couplers to link the raceways to the enclosure.

8. Remove all cuttings and dirt.

ote: N Make certain that high voltage and low voltage wiring enters the enclosure separately. High voltage wiring should be brought

into the left and right sides of the enclosure. Low voltage wiring should enter from the top of side of the enclosure.

The enclosure is fully convection cooled; therefore, it is important to ensure that each unit is installed in a

ventilated location that permits enough airflow to remove heat and provide correct operating environment. The

cabinets do not contain fans. Allowing airflow around the panel will enhance the reliability and longevity of all

models. Locating panels away from heat generating equipment will also benefit long term reliability. Ensure that

the stated ambient atmosphere requirements are not exceeded.

www.cooperlighting.com

IB503096ML page 5

October 2020

Loading...

Loading...