Page 1

‘GF’ Series

Water Softener

INSTALLATION, OPERATION,

AND MAINTENANCE MANUAL

COMPLETE FOR FUTURE REFERENCE:

MODEL NO:

SERIAL NO:

DATE INSTALLED:

DEALER:

8-569 G&F R2

Page 2

LIMITED WARRANTY

FOR W A TER CONDITIONERS AND FIL TERS

LIMITED WARRANTY

Pressure Vessel - TEN YEARS

Manufacturer guarantees to the original consumer buyer that the water conditioner or filter fiberglass pressure vessel

will not rust, corrode, leak or burst during the first ten years of original installation, provided that the conditioner or filter

is installed in accordance with manufacturers’ printed instructions and is not subjected to water pressure

exceeding 125 psi and/or water temperature exceeding 120

misuse, alteration, neglect, freezing, fire or accident, and further providing the vessel is not damaged by an act of nature

such as, but not limited to, a flood, hurricane or tornado.

If during the first ten years of original installation the pressure vessel proves, after inspection by Manufacturer, to be defective in material or workmanship, Manufacturer will furnish to the original consumer buyer a new replacement vessel

without charge. You pay freight one way and local labor charges. No allowance is made for consequential

damage, labor, or expense incurred as a result of proven defect.

Brine Tank, Brine Cabinet, or Solution Container - FIVE YEARS

Manufacturer also guarantees to the original consumer buyer, that the water conditioner brine tank or brine cabinet or

filter chemical solution container, to be free from defects in material or workmanship for five years after original installation provided that the brine tank, cabinet, or solution container is not subjected to misuse, alteration, neglect, freezing,

fire or accident, and further providing the same is not damaged by an act of nature such as, but not limited to, a flood,

hurricane, tornado, or ultra-violet ray attack.

If during the five year period the brine tank, cabinet, or solution container proves, after inspection by Manufacturer, to

be defective in materials or workmanship, Manufacturer, will replace the same with a new brine tank, cabinet, or solution container without charge. You pay freight one way and local labor charges. No allowance is made for consequential

damage, labor, or expense incurred as a result of proven defect.

o

F, providing further that the vessel is not subjected to

Valve Module - FIVE YEARS

Manufacturer also guarantees to the original consumer buyer that the water conditioner or filter, noryl plastic

module valve or brass valve to be free from defects in material and workmanship for five years after original installation.

If during this five year period the valve module proves, after inspection by Manufacturer, to be defective in materials

or workmanship, Manufacturer will replace or, at Manufacturer’s sole option, repair the same without charge. You pay

freight one way and local labor charges. No allowance is made for consequential damage, labor, or expense incurred as

a result of proven defect.

General Provisions

Manufacturer assumes no responsibility with respect to any portion of these warranties in the event of abuse, misuse or

negligence by the original consumer buyer or for failure to meet the terms of these warranties caused by strikes,

government regulations, material shortages or circumstances beyond Manufacturer’s control.

The warranties set forth herein are contingent upon receipt by Manufacturer of written notice of any defect within thirty

days after the same is discovered and upon the proper installation and operation of the water conditioner in

accordance with factory specifications and applicable plumbing codes and ordinances. Manufacturer’s sole obligation

under these warranties is to repair or replace the component or part in question which proves to be defective in material

or workmanshipwithin the time periods specified. Manufacturer IS NOT LIABLE FOR CONSEQUENTIAL OR INCIDENTAL

DAMAGES. No Manufacturer dealer, agent, representative, or other person is authorized to alter, extend or to expand

these warranties.

THE EFFECTIVE PERIODS OF ANY APPLICABLE IMPLIED WARRANTIES ARE LIMITED TO THE EFFECTIVE PERIODS

OF THE WRITTEN WARRANTIES AS SPECIFIED HEREIN. This warranty gives you specific legal rights and you may also

have other rights which vary from state to state.

Page 3

“GF” SERIES AUT OMA TIC W ATER CONDITIONERS

TABLE OF CONTENTS

SYSTEM INFORMATION

Specication Table ........................................................................................................................................................1

INSTALLATION

Installation Diagram .......................................................................................................................................................2

Installation Fitting Assemblies .......................................................................................................................................3

Installation Procedures .................................................................................................................................................4

OPERATION

Control Valve Function and Cycles of Operation ..........................................................................................................7

Control Valve Programming .......................................................................................................................................... 8

Flow Diagrams ............................................................................................................................................................12

Bypass Valve Operation ..............................................................................................................................................13

MAINTENANCE

Valve Assembly ...........................................................................................................................................................14

Injector ........................................................................................................................................................................16

Brine System and Tank ................................................................................................................................................18

Water Meter and Meter Plug .......................................................................................................................................19

Bypass Valve Parts ..................................................................................................................................................... 20

Fittings ........................................................................................................................................................................21

Troubleshooting ...........................................................................................................................................................22

Page 4

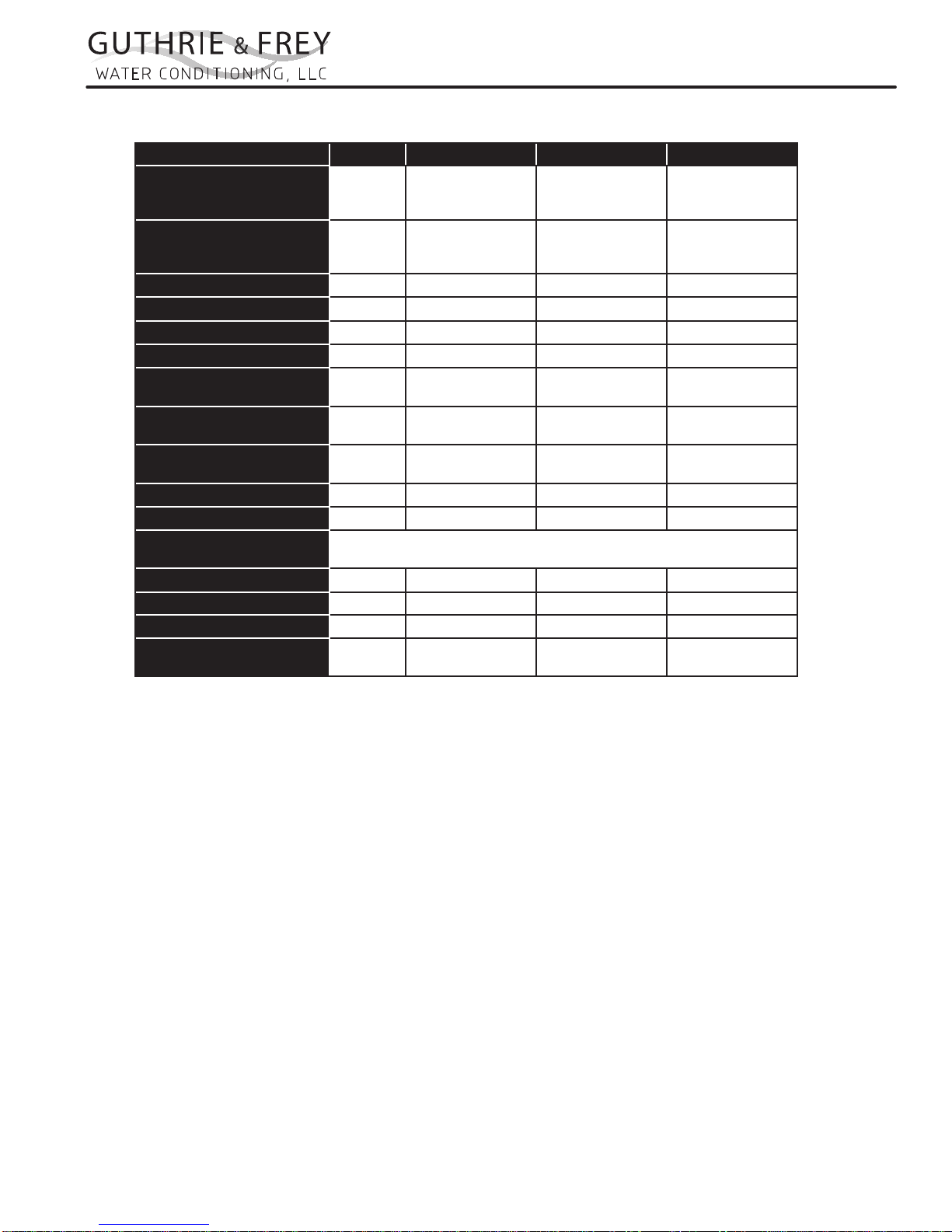

Specications

MODEL NUMBER UNITS GF24 GF40 GF50

EXCHANGE CAPACITY

(KILOGRAINS)

SALT PER REGENERATION

(LBS. / REGEN)

MAX SERVICE FLOW (1) GPM

PIPE SIZE - IN/OUT INCHES

DRAIN SIZE INCHES

OPERATING PRESSURE MAX PSI

OPERATING TEMPERATURE

MAX

MINERAL TANK SIZE

(DIA. X HT.) (2)

BRINE TANK SIZE

(DIA. X HT.) (3)

SALT STORAGE LBS.

RESIN VOLUME CU. FT.

ELECTRICAL (VOLTAGE,

CYCLE)

SHIPPING WEIGHT LBS.

FLOOR SPACE INCHES 27x18 28x18 31x18

OVERALL HEIGHT INCHES 52 55 60

MAX FLOW TO DRAIN

DURING REGENERATION (4)

“GF” SERIES AUT OMA TIC W ATER CONDITIONERS

SYSTEM INFORMATION

MAX

MID

MIN

MAX

MID

MIN

DEG F 110 110 110

INCHES 8X44 10x47 12x52

INCHES 18x40 18x40 18x40

GPM 1.7 2.2 3.2

24,030

21,020

17,120

11.5

7.5

4.5

13.2 14.7 19.1

1 1 1

3/4 3/4 3/4

125 125 125

450 450 450

0.75 1.3 1.6

120 Volts 60 Hz

72 106 137

41,650

36,175

29,560

19.5

13.0

8.0

51,260

44,500

36,350

24.0

16.0

9.5

(1) Pressure drop at 15 psi.

(2) Pressure vessels are seamless and made of reinforced fiberglass, pressure-tested at 300 psi.

(3) Brine tanks are fabricated of seamless, rigid, tough, high-impact, non-toxic polyethylene.

(4) 50 psi inlet pressure.

NOTE: This water softener is not intended to be used for treating water that is microbiologically

unsafe or of unknown quality without adequate disinfection before or after treatment.

1

Page 5

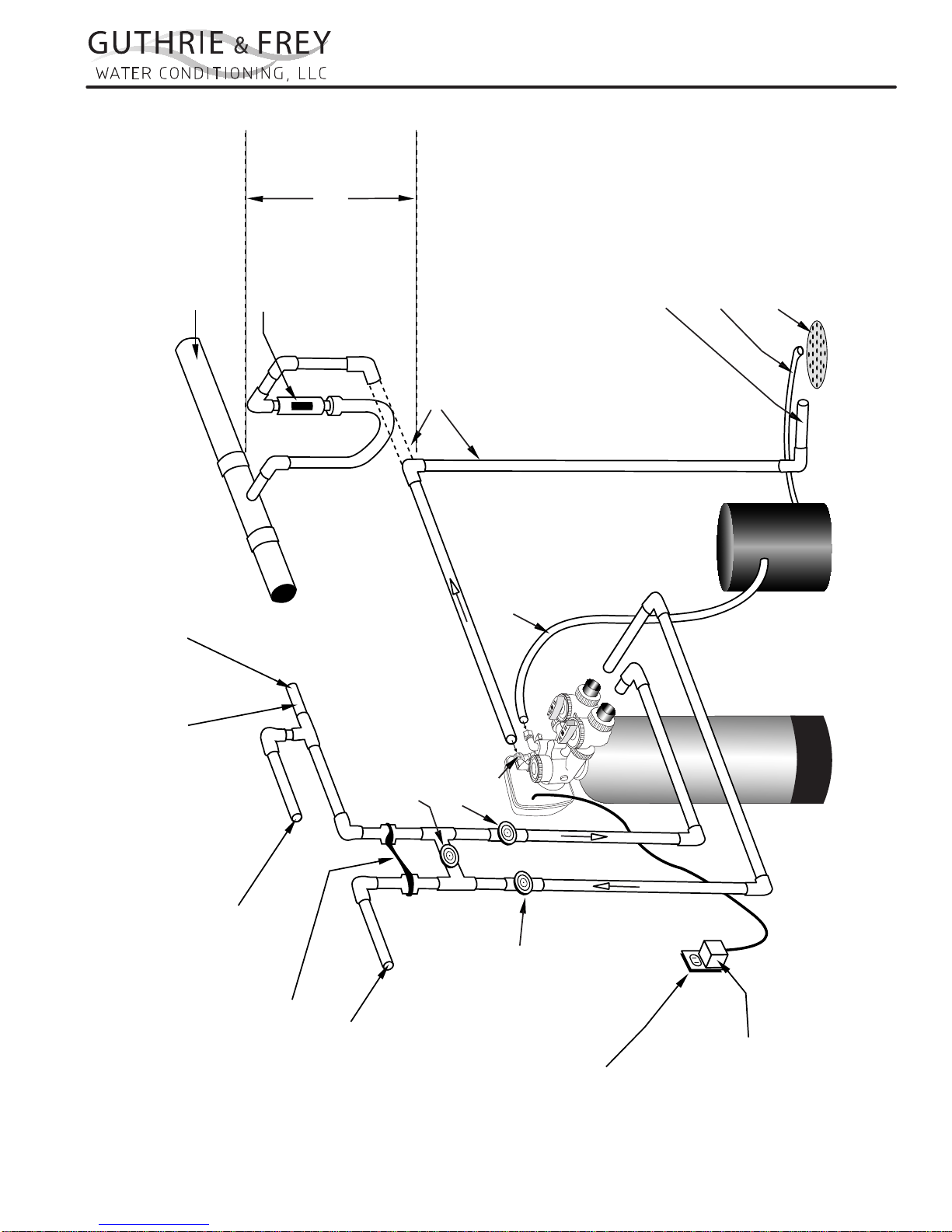

Assembly

Assembly

Maximum drain pipe

elevation above drain

Connection to sanitary sewer line

(optional)

Sanitary sewer line

Air gap device

port is 5 ft.

“GF” SERIES AUT OMA TIC W ATER CONDITIONERS

INSTALLATION

Sanitary Drain, Floor Drain or

Laundry Tubs are acceptable.

Do not make a direct connection

to the drain. An air gap must

be present.

Drain

Brine Tank Overflow drain 1/2”

diameter minimum size

Drain line 1/2” diameter

minimum size

(gravity flow)

Drain Trap

Cold hard water inlet

30 p.s.i. minimum pressure

1/2” minimum pipe size

High Pressure Warning:

If feedwater pressure is known to be above

100 p.s.i. it is strongly recommended that a

pressure reducing valve be installed at this point.

Manual Bypass Valve

(Normally Closed)

(optional)

Manual Inlet Valve

Drain Port

(optional)

Softener Tank

Brine Line Tubing

Brine Tank

Typical Water Softener Installation

Hard water to Sprinklers and any

dersired unsoftened fixtures

Ground Strap

Softened Water Outlet

Manual Outlet Valve

(optional)

110-125 Volt

Continuous Power Supply

Transformer

2

Page 6

“GF” SERIES AUT OMA TIC W ATER CONDITIONERS

INSTALLATION

Installation Fitting Assemblies

1. Installation ttings connect to the control valve or the bypass valve using nuts that only require hand tightening.

Hand tightened nut connections between control valve and installation ttings, control valve and bypass valve, and

bypass valve and installation ttings allow for ease serviceability. Do not use a pipe wrench to tighten nuts on

installation ttings. Hand tighten only.

2. Split ring retainer design holds the nut on and allows load to be spread over the entire nut surface area reducing

the chance for leakage. The split ring design, incorporated into the installation ttings allows approximately 2

degrees off axis alignment to the plumbing system. The installation ttings are designed to accommodate minor

plumbing misalignments but are not designed to support the weight of a system or the plumbing.

3. When assembling the installation tting package, connect the tting to the plumbing system rst and then attach the

nut, split ring and o-ring. Heat from soldering or solvent cements may damage the nut, split ring or o-ring. Solder

joints should be cool and solvent cements should be set before installing the nut, split ring and o-ring. Avoid getting

primer and solvent cements on any part of the o-rings or split rings, bypass valve or control valve. Solvent cements

and primers should be used in accordance with the manufacturer’s instructions.

Slip the nut onto the tting rst, then the split ring second and the o-ring last. hand tighten the nut. If the tting

is leaking, tightening the nut will not stop the leak. Remove the nut, remove the tting, and check for damage or

misalignment of the o-ring.

Do not use the pipe dope or other sealant on threads. Teon tape must be used on the threads of the 1”

NPT elbow and the 1/4” NPT connection and on the threads for the drain line connection. Teon tape is not

necessary on the nut connection or caps because of o-ring seals.

Do not use Vaseline, oils or other hydrocarbon lubricants oanywhere on the control valve or resin tank

assembly. A silicon lubricant may be used on black o-rings, but is not necessary.

Bypass Valve

1. The bypass valve easily connects to the control valve body using nuts that only require hand tightening. Hand

tighten nut connections between control valve and ttings, control valve and bypass valve, and bypass valve and

installation ttings allow for easy serviceability. The split ring retainer design holds the nut on and allows load to

be spread over the entire nut surface area reducing the chance for leakage. The split ring design, incorporated into

the bypass, allows approximately 2 degrees off axis alignment to the plumbing system. The bypass is designed to

accommodate minor plumbing misalignments but is not designed to support the weight of a system or the plumbing.

Avoid getting primer and solvent cements on any part of the o-rings or split rings, bypass valve or control

valve. Do not use pipe dope or other sealant on threads. Teon tape is not necessary on the caps because of

o-ring seals.

Do not use Vaseline, oils or other hydrocarbon lubricants oanywhere on the control valve or resin tank

assembly. A silicon lubricant may be used on black o-rings, but is not necessary.

Connecting Fittings

CAUTION: Care must be used when working with copper tubing. Do not allow the ame from torch to contact any por-

tion of the Valve assembly.

1. Attach 1/2” drain line to drain elbow with insert and nut. Use optional 3/4” drain ttings if drain run

exceeds 25 ft.

2. Do not elevate the drain line over 5’ above the top of the valve (8’ on municipal systems) or to exceed 25’ in

length at either height.

CAUTION: An air gap must be provided upon sewer entry. (Conform to local plumbing and sanitation codes and ordi-

nances).

3. The salt storage cabinet or brine tank provides an overow. Attach 1/2” ID exible plastic tubing to the overow

tting and direct it to the drain. DO NOT connect to the main drain line. Use a separate gravity ow line.

3

Page 7

“GF” SERIES AUT OMA TIC W ATER CONDITIONERS

INSTALLATION

Installation Procedures

Please see page 3 for installation of tting assemblies.

All installation procedures must conform to local plumbing, electrical and sanitation codes and ordinances.

A. Planning Installation

1. It is recommended that outside faucets for lawn

service be on a hard water line, ahead of the softener. This will conserve softened water, save salt

www.Marlo-Inc.com

and prevent lawn damage. If this is not practical,

use the convenient integral bypass valve assembly

during irrigation ows.

2. CAUTION: The inlet water temperature MUST

NOT EXCEED 110° F.

3. DO NOT locate the softener where ambient temperature drops below 40° F.

4. Allow space around the softener for ease of servicing.

5. Softener drain lines must never be solidly connected to the sewer line (always provide an air gap

at the END of the drain line).

6. The drain line must NOT be elevated over 5’ from

the top of the softener on well systems, and 8’ on

municipal water systems.

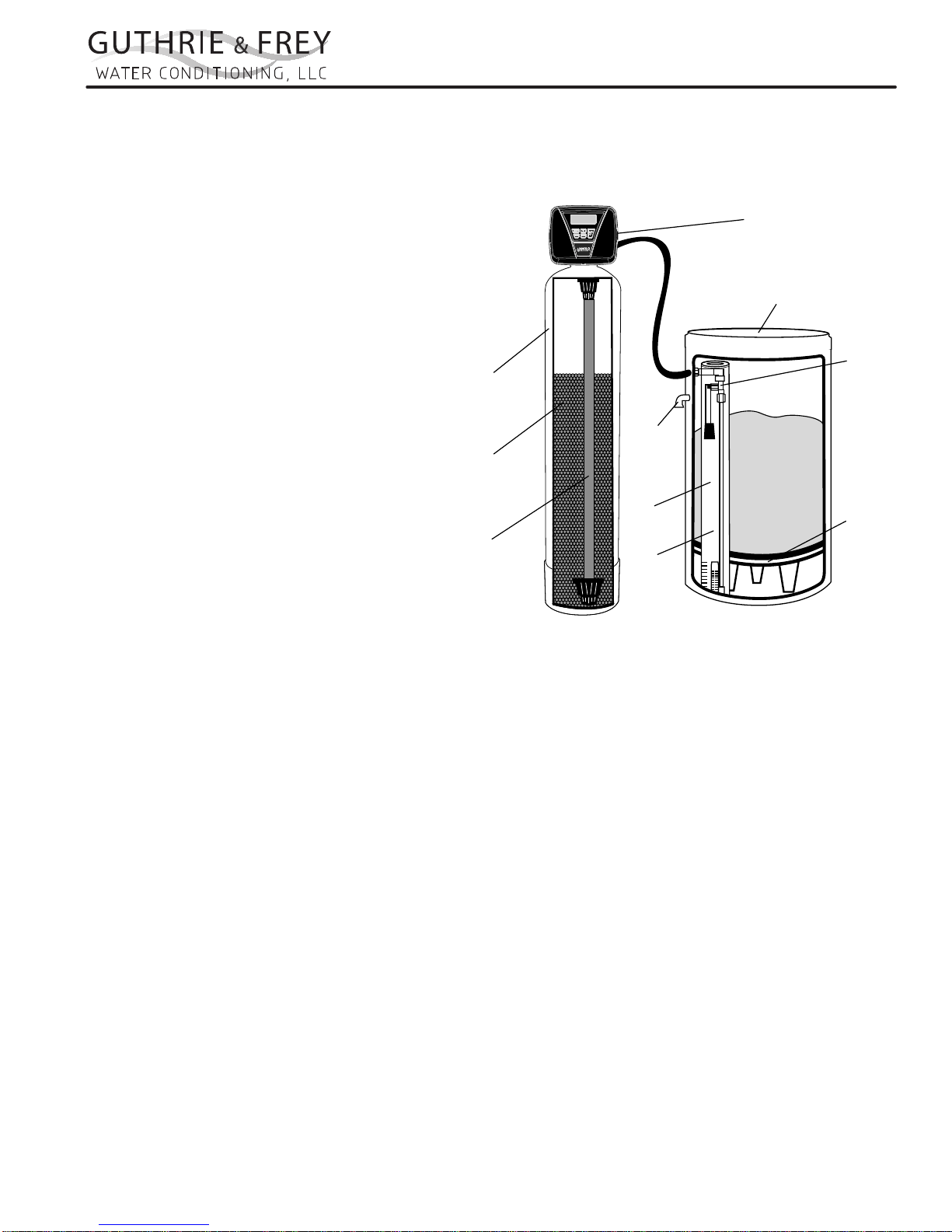

Resin

Tank

Ion

Exchange

Media

Distributor

Tube

Assembly

Overflow

Drain

Brine

Well

Air

Check

7. Drain line must not extend more than 20’ in length.

If longer runs are required increase the drain size

to 1”.

8. The brine tank or salt storage cabinet is a gravity drain. This drain line must be lower than the drain tting on

the side wall of the brine tank or cabinet.

Control

Valve

Brine Tank

Safety

Brine

Valve

Brine

Grid

Plate

B. General Installation

1. Turn off the main water supply before making any plumbing connections to existing piping.

2. Move the softener into position, making sure it is on a clean level surface. If shims are needed you may use

those to create a level installation. DO NOT USE METAL SHIMS

3. When installing the unit, be sure to connect the inlet and outlet to the correct ports on the valve. The bypass

valve and the control valve are both marked with arrows that indicate the direction of water ow. If water lines

are reversed resin maybe forced from the water softener and into household plumbing system. Should this

occur, the plumbing system would need to be ushed.

4. Install the bypass valve assembly. The control valve is designed to accommodate minor plumbing misalignments. It is not designed to support the weight of the unit.

5. Please see page 3, item 3 for assembling and soldering of ttings.

6. Install an appropriate grounding strap across the inlet and outlet piping of the water conditioning system to

ensure that a proper ground is maintained.

7. Move the brine tank into place. Making sure that the oor is clean of any debris. Sharp objects such as rocks

can cause punctures to the brine tank over a period of time. This would not be covered under Marlo’s warranty.

(DO NOT ADD SALT AT THIS TIME).

8. Connect one end of the brine line (brine line is located inside the brine tank. Marlo units come with 5’ of brine

line) to the brine elbow of the brine tank and the other end to the brine elbow on the control valve. The brine

elbow on the control valve is black in color and located on the top of the control valve. The brine elbow swivels

to allow the brine tank to be placed in a convenient position.

9. The drain line connector is located on the top of the control valve and is black in color. The water softener comes

standard with 5/8 insert and nut if installer is using a poly tube. The drain elbow is threaded, so a ¾” drain line

may also be used. NOTE: If soldering the drain line use caution so as not to cause damage to the drain elbow.

4

Page 8

“GF” SERIES AUT OMA TIC W ATER CONDITIONERS

INSTALLATION

10. An overow tting is attached to the outside of the brine tank (overow elbow is white in color). Attach a 5/8

drain line (do NOT connect overow tubing with drain line tubing). The overow tting is installed in case the

unit would malfunction and water would continually run to the brine tank. The overow (if tubing is connected)

would allow the excess water to be run to the drain rather than overow onto the oor. Do NOT run overow

tubing above the overow elbow at any point.

C. Installation and Start Up

1. Make sure all connections have been made: Inlet, outlet, brine line installed and connected to the brine tank

and control valve, drain line installed, and over ow drain tubing connected and run to the drain. (DO NOT

CONNECT DRAIN LINE AND OVERFLOW TUBING)

2. If the unit is not in bypass please do so now. If using a bypass purchased with the unit the unit will be in the

bypass position when the two arrows on the handles of the bypass are pointing towards each other (see gure

2 page 12).

3. Turn on your main water supply. Locate a cold soft water tap and turn it on, allow the water to run until all excess air and foreign material is removed from the water.

4. Add seven (7) gallons of water to the brine tank.

5. Plug the water softener into the designated receptacle. Program the current time of day (see page 9 for instructions).

6. Press and hold the REGEN button (located in the upper right hand corner) until the unit starts a regeneration

(depending on how the unit is programmed the rst cycle may be back wash or brine ll). Once the piston

stops moving and the unit is counting down press the REGEN key again. This will advance the unit to the next

cycle. Repeat this process until you see the word RINSE in the upper left hand corner. Slowly open the inlet

side of the bypass (see page 13 gure 3). Let the water run to the drain until the water runs clear.

7. Place the bypass back into the bypass mode (see page 13 gure 2)

8. Press the REGEN button again to cycle the unit to the next cycle. Wait for the piston to stop moving and press

the REGEN button again. Repeat this until the unit is at the home screen. The home screen will be blue in

color.

9. Press and hold the REGEN button again until the unit starts a regeneration. Depending on how the unit it set

up you might have to wait for the piston to stop moving and press the REGEN button again repeating several

times till the word BACKWASH appears in the upper left hand corner. On most units BACKWASH should appear at the rst screen.

10. Slowly turn the handle of the incoming water (See page 13 gure 3) until the bypass valve is completely

opened. Once you have a solid ow of water to the drain, open the outlet side of the bypass (see page 13

gure 1) to duplicate the normal operation.

11. Press the REGEN button again to cycle the unit to the next cycle. Wait for the piston to stop moving and press

the REGEN button again. Repeat this until the unit is at the home screen. The home screen will be blue in

color.

12. Set the incoming hardness of the water, time of regeneration and calendar override. See page 8 Steps 1I

through 6I.

13. Add salt to brine tank.

5

Page 9

“GF” SERIES AUT OMA TIC W ATER CONDITIONERS

INSTALLATION

D. Manual Regeneration

The user can initiate manual regeneration.

Pressing and holding the REGEN button for approximately 3 seconds will immediately start the regeneration. The

user cannot cancel this request.

NOTE: Program Timer “Lockout” Feature

The Program Timer is initially set to allow access to all Programming, Diagnostic and History screens. The Installer

can limit access to (lockout) most screens by activating the Lockout Feature.

Activating “Lockout” allows the user to view and change only Water Hardness, Days Override, Time of Regeneration and Time of day.

Activate “Lockout” Feature: Press DOWN then NEXT then UP then CLOCK in sequence. LOCK will briey appear in the display.

De-activate “Lockout” Feature: Press DOWN then NEXT then UP then CLOCK. UNLOCK will briey appear in

the display.

When in operation normal user displays are time of day, gallons remaining, days remaining before regeneration,

or current ow rate are shown. The user has the option to choose which screen is displayed by pressing the NEXT

button. When stepping through a procedure if no buttons are pressed within ve minutes the display returns to a

normal user display. Any changes made prior to the ve minute time out are incorporated. The one exception is

current ow rate display under the diagnostic procedure. The current ow rate display has a 30 minute time out

feature.

6

Page 10

“GF” SERIES AUT OMA TIC W ATER CONDITIONERS

OPERATION

Control Valve Function and Cycles of Operation

This glass lled Noryl1 fully automatic control valve is designed as the primary control center to direct and regulate

all cycles of a water softener or lter. When the control valve is set up as a softener, the control valve can be set

to perform down ow or up ow regeneration with the proper piston. When the control valve is set up as a lter,

the control valve can be set to perform down ow regeneration or simply backwash. The control valve can be set

to regenerate on demand (consumption of a predetermined amount of water) and/or as a time clock (passage

of a particular number of days). The control valve can be set so that the softener can meet the Water Quality

Association (WQA) or NSF International efciency rating.

The control valve is compatible with a variety of regenerants and resin cleaners. The control valve is capable of

routing the ow of water in the necessary paths to regenerate or backwash water treatment systems. The injector

regulates the ow of brine or other regenerants. The control valve regulates the ow rates for backwashing,

rinsing and the replenishing of treated water into a regenerant tank, when applicable.

The control valve is designed to deliver high service (27 gpm @ 15 psig) and backwash (27 gpm @ 25 psig) ow

rates when the bypass has straight ttings and a 1.050” distributor. The control valve uses no traditional fasteners

(e.g. screws), instead clips, threaded caps, nuts and snap type latches are used. Caps and nuts only need to

be rmly hand tightened because radial seals are used. Tools required to service the valve include one small

blade screwdriver, pliers and a pair of hands. Disassembly for servicing takes much less time than comparable

products currently on the market. Control valve installation is made easy because the distributor tube can be cut

1/2” above to 1/2” below the top of the tank thread. The distributor tube is held in place by an

o-ring seal and the control valve also has a bayonet lock feature for upper distributor baskets.

The transformer power pack comes with a 15-foot power cord and is designed for use with the control valve. The

transformer power pack is for dry location use only. The control valve remembers all settings for up to 8 hours if

the power goes out and the battery is not depleted. After 8 hours, the only item that needs to be reset is the time

of day; other values are permanently stored in the nonvolitile memory. If a power loss lasts less than 8 hours and

the time ashes on and off, the time of day should be reset and the non rechargeable battery should be replaced.

The replacement battery is a commercially available 3 volt Lithium coin cell type 2032.

Table 3 shows the order of the cycles when the valve is set up as a softener. When the control valve is used as

a down ow softener, two backwashes always occur. When the control valve is used as an up ow softener, only

one backwash occurs after brining. The installer has the option of having the regenerant rell after the rinse cycle

or have the regenerant prell before regeneration. If the installer chooses to have the regenerant prell before

regeneration, the prell starts two hours before the regeneration time set. During the 2-hour period in which the

brine is being made, treated (softened) water is still available. For example: regeneration time = 2:00 A.M., prell

option selected, downow softener. Fill occurs at 12:00 A.M., start of backwash cycle occurs at 2:00 A.M.

1 - Noryl is a trademark of General Electric

Regeneration Cycles

1st Cycle: Backwash Normal

2nd Cycle: Regenerate

3rd Cycle: Backwash Normal

5th Cycle: Rinse

6th Cycle: Fill

Table 3

7

Page 11

“GF” SERIES AUT OMA TIC W ATER CONDITIONERS

Page 20 MA Man u al

Installer Display Settings

RETURN TO NORMAL MODE

OPERATION

STEP 1I

STEP 1I - Press NEXT and UP simultaneously for 3 seconds.

STEP 2I

STEP 2I – Hardness: Set the amount of hardness in grains of hardness as calcium carbonate per

gallon using DOWN or UP. The default is 20 with value ranges from 1 to 150 in 1 grain increments.

Note: The grains per gallon can be increased if soluble iron needs to be reduced. This display will not

show if “FILTERING” is selected in Step 2F or if ‘AUTO’ is not selected in Set Volume Capacity in

OEM Softener System Setup. Press NEXT to go to step 3I. Press REGEN to exit Installer Display

Settings.

STEP 3I

STEP 3I – Day Override: When volume capacity is set to “OFF”, sets the number of days between

regenerations. When volume capacity is set to AUTO or to a number, sets the maximum number of

days between regenerations. If value set to “OFF”, regeneration initiation is based solely on volume

used. If value is set as a number (allowable range from 1 to 28) a regeneration initiation will be

called for on that day even if suf cient volume of water were not used to call for a regeneration. Set

Day Override using DOWN or UP:

• number of days between regeneration (1 to 28); or

• “OFF”.

See Setting Options Table for more detail on setup. Press NEXT to go to step 4I. Press REGEN to

return to previous step.

STEP 4I

STEP 5I

STEP 6I

STEP 4I – Next Regeneration Time (hour): Set the hour of day for regeneration using DOWN

or UP. AM/PM toggles after 12. The default time is 2:00 AM. This display will show “REGEN

IMMEDIATE ON ZERO GAL” if “IMMEDIATE” is selected in Set Regeneration Time Option in

OEM Softener System Setup Step 9S or OEM Filter System Setup Step 8F. Press NEXT to go to step

5I. Press REGEN to return to previous step.

STEP 5I – Next Regeneration Time (minutes): Set the minutes of day for regeneration using DOWN

or UP. This display will not be shown if “IMMEDIATE” is selected in Set Regeneration Time Option

in OEM Softener System Setup Step 9S or OEM Filter System Setup Step 8F. Press NEXT to go to

Step 6I. Press REGEN to return to previous step.

STEP 6I – Energy Saver operation. When set to OFF, the display backlight is always on. When set

to ON, the display backlight will go off after 5 minutes of no keypad activity. A valve error or salt

level alert will activate the display backlight, and prevent deactivation until the error or alert is reset

by the user. Press NEXT to exit Installer Display Settings. Press REGEN to return to the previous

step.

8

Page 12

“GF” SERIES AUT OMA TIC W ATER CONDITIONERS

MA Manual Page 21

User Display Settings

OPERATION

NOTE: SALT LEVEL screen

only appears if programmed.

When the system is operating, several displays may be shown.

Pressing NEXT will alternate between the displays. One of the

displays is the current time of day. CAPACITY REMAINING

is the gallons that will be treated before the system goes through

a regeneration cycle. Pressing DOWN while in the Capacity

Remaining display will decrease the capacity remaining in

10 gallon increments and will also increase the volume used

impacting the recorded values in Diagnostics Steps 3D, 4D

and 5D and Valve History, Step 4VH. DAYS TO A REGEN

is the number of days left before the system goes through a

regeneration cycle. Pressing UP or DOWN while in this screen

will temporarily increase or decrease the displayed value by 1 day.

Another display shows the current treated water ow rate through

the system. Contact information will be displayed if it was edited.

For concerns with phone number or banner text displays, contact

OEM for instructions. The fth display will show either DP or

HOLD if the dP switch is closed. If the system has called for a

regeneration that will occur at the pre-set time of regeneration,

the words REGEN TODAY will alternate with the header on the

display. If a water meter is installed, GPM ashes (and alternates

with the ow rate) on the display when water is being treated (i.e.

water is owing through the system). If Salt Level Monitor has

been set to ON in Step 16S, the Salt Level screen will appear. To

adjust the salt level, press CLOCK, and use UP or DOWN to set

the current value. The salt level is adjustable from 0 to 500 lbs. in

10 lb. increments.

GPM and ow rate

will ash while water

is being treated.

REGEN PENDING will be displayed in Alternator Systems whenever a unit is waiting to

initiate the rst cycle step of regeneration.

STAND BY will be displayed in Alternator Systems when a valve is in Standby state.

DELAYED RINSE+FILL PENDING will be displayed whenever a zero-capacity tank has

transferred to an off-line state and is currently waiting to initiate the second portion of a

regeneration cycle. Viewed only when Delayed Rinse and Fill is set to ON.

9

Page 13

“GF” SERIES AUT OMA TIC W ATER CONDITIONERS

Page 22 MA Man u al

Set Time of Day

The user can also set the time of day. Time of day should only need to be set if the battery has been depleted because of extended

power outages or when daylight saving time begins or ends. If an extended power outage occurs, the time of day will ash on and

off which indicates the time of day should be reset. The non rechargeable battery should also be replaced.

Regeneration Mode

Typically a system is set to regenerate at a time of low water usage. An example of a time with

low water usage is when a household is asleep. If there is a demand for water when the system is

regenerating, untreated water will be used.

When the system begins to regenerate, the display will change to include information about the step of the regeneration

process and the time remaining for that step to be completed. The system runs through the steps automatically and will reset

itself to provide treated water when the regeneration has been completed.

Manual Regeneration

Sometimes there is a need to regenerate the system sooner than when the

system calls for it, usually referred to as manual regeneration. There may

be a period of heavy water usage because

of guests or a heavy laundry day.

To initiate a manual regeneration at the preset delayed regeneration time, when the regeneration time option is set to

“DELAYED REGEN” or “DELAY + IMMEDIATE”, press and release “REGEN”. The words “REGEN TODAY” will

periodically be shown on the display to indicate that the system will regenerate at the preset delayed regeneration time. If you

pressed the “REGEN” button in error, pressing the button again will cancel the request. Note: If the regeneration time option

is set to “IMMEDIATE” there is no set delayed regeneration time so “REGEN TODAY” will not activate if “REGEN” button

is pressed.

To initiate a manual regeneration immediately, press and hold the “REGEN” button for three seconds. The system will begin

to regenerate immediately. The request cannot be cancelled.

Note: For softeners, if brine tank does not contain salt, ll with salt and wait at least two hours before regenerating.

STEP 1U

STEP 1U – Press CLOCK.

STEP 2U

STEP 2U - Current Time (hour): Set the hour of the day using DOWN or UP. AM/PM toggles after

12. Press NEXT to go to Step 3U.

STEP 3U

STEP 3U - Current Time (minutes): Set the minutes of the day using DOWN or UP. Press NEXT to

exit Set Time of Day. Press REGEN to return to previous step.

RETURN TO NORMAL MODE

OPERATION

10

Page 14

“GF” SERIES AUT OMA TIC W ATER CONDITIONERS

MA Manual Page 23

OPERATION

Power Loss

If the power goes out the system will keep time until the battery is depleted. If an extended power outage occurs, the time of day

will ash on and off which indicates the time of day should be reset and the non rechargeable battery replaced. The system will

remember the rest.

Error Message

If the word “ERROR” and a number are displayed contact the Installer for help. This indicates that the valve was not able to function

properly. If the number and banner text in the Contact Screens has been edited, the two displays below will alternate.

11

Page 15

“GF” SERIES AUT OMA TIC W ATER CONDITIONERS

FLOW DIAGRAMS

OPERATION

ow diagram...service

OUTLET PORT FOR

SERVICE WATER

SUPPLY

WATER

INLET

CONDITIONED WATER

FROM DISTRIBUTOR

SUPPLY WATER TO

TOP OF TANK

ow diagram...downow brine

REGENERANT IN

REGENERANT

IS SIPHONED IN

REGENERANT TRAVELS

THROUGH MANIFOLD

TO THE INJECTOR

PISTON ROD IS BOTTOMED

OUT IN “HOME” POSITION

SUPPLY

WATER

MANIFOLD

ow diagram...backwash

TO DRAIN

OUTLET PORT FOR

SERVICE WATER

SUPPLY WATER

INLET

SUPPLY WATER

TO DISTRIBUTOR

TO DRAIN

PISTON ROD IS

BELOW 3rd STEP DOWN

BACKWASH WATER

TO DRAIN

PISTON ROD IS

BELOW 2nd STEP DOWN

SUPPLY

WATER

OUTLET PORT FOR

SERVICE WATER

ow diagram...rinse

OUTLET PORT FOR

SERVICE WATER

CONDITIONED WATER

FROM DISTRIBUTOR

SUPPLY WATER TO

TOP OF TANK

WASTE WATER

FROM DISTRIBUTOR

SUPPLY WATER

INLET

TO DRAIN

CONDITIONED WATER

TO REGENERANT TANK

PISTON ROD IS

4th STEP DOWN

SUPPLY

WATER

SUPPLY WATER

INLET

SUPPLY WATER AND REGENERANT

TO TOP OF TANK

ow diagram...ll

OUTLET PORT FOR

SERVICE WATER

CONDITIONED WATER

FROM DISTRIBUTOR

SUPPLY WATER

INLET

SUPPLY WATER TO

TOP OF TANK

PISTON ROD IS

BELOW 1st STEP DOWN

12

Page 16

“GF” SERIES AUT OMA TIC W ATER CONDITIONERS

OPERATION

Bypass Valve

The bypass valve is typically used to isolate the control valve from the plumbing system’s water pressure in order to perform control valve repairs or maintenance. The WS1 bypass valve is particularly unique in the water treatment

industry due to its versatility and state of the art design features. The 1” full ow bypass valve incorporates four positions

including a diagnostic position that allows service personal to work on a pressurized system while still providing untreated

bypass water to the facility or residence. Its completely non-metallic, all plastic, design allows for easy

access and serviceability without the need for tools.

The bypass body and rotors are glass lled Noryl and the nuts and caps are glass lled polypropylene. All seals are

self-lubricating EPDM to help prevent valve seizing after long periods of non-use. Internal o-rings can easily be replaced

if service is required.

The bypass consists of two interchangeable plug valves that are operated independently by red arrow shaped handles.

The handles identify the ow direction of the water. The plug valves enable the bypass valve to operate in four positions.

Figure 1

NORMAL OPERATION

“Treated”

Water Exits

Supply

Water Enters

BYPASS OPERATION

“Untreated”

Water Exits

Figure 2

Supply

Water Enters

Normal Operation:

The inlet and outlet handles point in the direction of ow indicated by

the engraved arrows on the control valve. Water ows through the

control valve during normal operation and this position also allows the

control valve to isolate the media bed during the regeneration cycle.

Figure 3

DIAGNOSTIC MODE

Supply

Water Exits

Diagnostic:

The inlet handle points in the direction of ow and the outlet handle

points to the center of bypass valve, system water pressure is allowed

to the control valve and the plumbing system while not allowing water to

exit from the control valve to the plumbing.

Supply

Water Enters

Bypass:

The inlet and outlet handles point to the center of the bypass, the control

valve is isolated from the water pressure contained in the plumbing

system. Untreated water is supplied to the plumbing system.

Figure 4

SHUT OFF MODE

No

Water Exits

Shut Off:

The inlet handle points to the center of the bypass valve and the outlet

handle points in the direction of ow, the water is shut off to the plumbing

system. If water is available on the outlet side of the softener it is an

indication of water bypass around the system (i.e. a plumbing

connection somewhere in the building bypasses the system).

Supply Water is shut off

from the house and the

valve

13

Page 17

“GF” SERIES AUT OMA TIC W ATER CONDITIONERS

MAINTENANCE

t

t

14

t

Regenerant Piston and Spacer Stack Assembly

& Front Cover and Drive Assembly

Drive Cap Assembly, Downow Piston,

14

Page 18

“GF” SERIES AUT OMA TIC W ATER CONDITIONERS

MAINTENANCE

Drive Cap Assembly, Downow Piston, Upow Piston,

Regenerant Piston and Spacer Stack Assembly

Item No. Part No. Description Quantity

1 A2466034 *Spacer Stack Assembly w/o o-rings 1

2 A2080077 Drive Cap Assembly 1

3 B1213022 O-Ring 228 (use Valve O-ring Kit) 1

4 A2309040 Piston Downow Assembly 1

p

5 A2438033 Regenerant Piston 1

V

6 B1213022 O-Ring 337 (use Valve O-ring Kit) 1

B1213022

15

Item #4 identied with “DN” code.

p

Item #5 not used with Backwash Only lter applications.

V

O-Ring 215

Front Cover and Drive Assembly

Item No. Part No. Description Quantity

7 A2103160 Front Cover ASSY V3948-01 1

8 A2085050 Motor 1

9 A2328046 Drive Bracket & Spring Clip 1

10 A2341035 PC Board V3955MA-BOARD 1

11 A2393046 Drive Gear 12 x 36 3

12 A2103132 Drive Gear Cover 1

13 A2491086 Service Tool 1

14 A2242054 Transformer 110V - 12V 1

(use Valve O-ring Kit)

1

15

Page 19

“GF” SERIES AUT OMA TIC W ATER CONDITIONERS

Injector Cap, Injector Screen, Injector, Plug ,

O-Ring, Rell and Rell Port Plug,

&Drain Line - 3/4”

Part of Kit, O-ring (Item #51, pg. 20)

t

18

16

17

MAINTENANCE

28

23

24

21

27

20

31

25a, 25b

19

30

32

33

34

35

26

Proper ow washer orientation

directs water ow towards the

washer face with rounded edge.

Flow washer indentication

numbers must be visible after

installation.

22

29

16

Page 20

“GF” SERIES AUT OMA TIC W ATER CONDITIONERS

MAINTENANCE

Injector Cap, Injector Screen, Injector, Plug and O-Ring

Item No. Part No. Description Quantity

16 A2080079 Injector Cap 1

17 Use Item 51 O-Ring 135 (Use Valve O-ring Kit) 1

t

18 A2142016 Injector Screen 1

19 A2079059 Injector Assembly Z Plug See note 1

A2079060 Injector Assembly A Black

A2079048 Injector Assembly B Brown

A2079046 Injector Assembly C Violet

A2079045 Injector Assembly D Red

20 A2079049 Injector Assembly E White

A2079047 Injector Assembly F Blue

A2079050 Injector Assembly G Yellow

A2079055 Injector Assembly H Green

A2079062 Injector Assembly I Orange

A2079063 Injector Assembly J Light Blue

*The injector plug and the injector each contain one 011 (lower) and 013 (upper) o-ring.

Note: For downow brine, injector is located in the down hole and injector plug in the up hole.

A2079064 Injector Assembly K Light Green

For a lter that only backwashes injector plugs are located in both holes.

Rell and Rell Port Plug

Drawing No. Order No. Description Quantity

21 A2287059 Rell Port Plug Assembly This part is required for backwash only systems

22 A2411015 Elbow Locking Clip 1

23 A2409016 Polytube insert 3/8 1

24 A2095071 Nut 3/8 1

25a A2080078 Elbow Cap 3/8 (use w/ 3/8” tubing) 1

25b A2129100 Elbow 1/2” with nut and insert (use w/ 1/2” tubing) Option

26 Use Item 51 O-Ring 019

t

27 A2104033 RFC Retainer Assembly* 1

28 A2253108 RFC Brine Rell Flow Washer 1

*Assembly includes RFC.

(

Use Valve O-ring Kit

)

1

1

Drawing No. Order No. Description Quantity

29 A2411015 Elbow Locking Clip 1

30 A2409013 Polytube insert 5/8 Option

31 A2095065 Nut 3/4 Drain Elbow Option

32 A2099056 Drain Elbow 3/4 Male Assembly 1

33 Use Item 51 O-Ring 019 (Use Valve O-ring Kit) 1

t

34 A2104034 Drain Flow Washer Retainer Assembly 1

A2253114 Drain Flow Washer 0.7 gpm for 3/4

A2253099 Drain Flow Washer 1.0 gpm for 3/4

A2253084 Drain Flow Washer 1.3 gpm for 3/4

A2253083 Drain Flow Washer 1.7 gpm for 3/4

35

A2253081 Drain Flow Washer 2.2 gpm for 3/4

A2253082 Drain Flow Washer 2.7 gpm for 3/4

A2253085 Drain Flow Washer 3.2 gpm for 3/4

A2253086 Drain Flow Washer 4.2 gpm for 3/4

A2253087 Drain Flow Washer 5.3 gpm for 3/4

Drain Line - 3/4”

One

DLFC

must be

used if 3/4

tting is

used

17

Page 21

“GF” Series

Media Tank Jacket

w/ Cover

12

“GF” SERIES AUT OMA TIC W ATER CONDITIONERS

1

Media Tank

10

Brine Tank Cover

Valve (Metered Shown)

2

MAINTENANCE

Brine

13

Valve

Assembly

Distributor Tube

w/ Screen

Media Tank

Base

11

10

Media

Brine Line Hosing

7

Brine Well Caps

4

Brine Tank

Brine Grid

(Optional)

Brine Well

2

15

3

Brine Valve Safety

8

Overflow Drain

5

Brine Tube

6

w/ Air Check

PARTS LISTING

Part Number No. Description

Contact Factory 1 Valve Metered (Complete - Specify Model)

A2042018 2 Brine Tank w/ Cover

A2071005 3 Brine Well

A2072003 4 Brine Well Cap

A2250003 5 Overflow Elbow

A2118010 6 Brine Tube w/ Air Check

B1020001 7 Brine Line Hose w/ Inserts

A2005058 8 Brine Valve Safety

A2107022 9 Brine Float

A2126201 10 Media Tank - GF-22K (8” x 44”)

A2126203 10 Media Tank - GF-30K (9” x 48”)

A2126205 10 Media Tank - GF-40K + Combo (10” x 47”)

A2126206 10 Media Tank - GF-45K (10” x 54”)

A2126208 10 Media Tank - GF-60K (12” x 52”)

A2255101 10 Media Tank - GF-22KC

A2255102 10 Media Tank - GF-30KC

B1023056 11 Distributor Tube Assembly

Contact Factory 12 Media Tank Jacket w/ cover - Optional

B1017003 13 Brine Valve Assembly - Complete - Includes #6. #8, & #9

A2284002 15 Grid (Optional)

A2121047 16 Media (Specify Model)

Brine Float

9

6

Brine Tube w/

Air Check

8

Brine

Valve

Safety

18

Page 22

Water Meter and Meter Plug

Item No. Part No. Description Quantity

36 A2095069 Nut 1” Quick Connect 1

*37 A2360039 Meter Assembly 1

38 A2100027 Turbine Assembly 1

39 use item 51 O-Ring 215 (Use Valve O-ring Kit) 1

40 A2287077 Meter Plug Assembly (Time clock option) 1

*Item #37 includes Items #38 & #39.

“GF” SERIES AUT OMA TIC W ATER CONDITIONERS

MAINTENANCE

t

Part of Kit, O-ring (Item 51, pg. 20)

t

39

40

38

37

36

19

Page 23

“GF” SERIES AUT OMA TIC W ATER CONDITIONERS

MAINTENANCE

Item No. Part No. Description Quantity

41 A2095069 Nut 1” Quick Connect 2

42 A2453012 Split Ring 2

l

43 use item 52 O-Ring 215 (Kit available - see Item #10) 2

44 A2607004 Bypass 1” Rotor 2

45 A2080090 Bypass Cap 2

46 A2395009 Bypass Handle 2

47 A2104036 Bypass Rotor Seal Retainer 2

l

48 use item 52 O-Ring 135 (use Bypass Valve Kit) 2

l

49 use item 52 O-Ring 112 (use Bypass Valve Kit) 2

l

50 use item 52 O-Ring 214 (use Bypass Valve Kit) 2

l

Part of Kit, O-ring By-Pass(Item 52)

Valve O-ring Kit

s

51 B1213022 KIT O-ring (contains 1 each of 3, 6, 15, 17, 26, & 33) 1 per valve

Bypass Valve O-ring Kit

l

52 B1213021 KIT O-ring Bypass (Incl. 2 ea. of items 43,48,49,& 50) 1 per valve

(Not Shown) Description Bypass Vertical Adapter Assembly

46

45

46

5

49

l

l

48

l

44

50

l

47

41

42

43

l

49

48

l

44

50

l

47

41

42

43

l

20

Page 24

“GF” SERIES AUT OMA TIC W ATER CONDITIONERS

MAINTENANCE

Description: Fitting 1” PVC Male NPT Elbow Assembly

Order No: A2129080 (Optional)

Drawing No. Order No. Description Quantity

1 A2095069 Nut 1” Quick Connect 2

2 A2453012 Split Ring 2

3 A2077178 O-Ring 215 2

4 A2129101 Fitting 1”PVCMaleNPT Elbow 2

Order No: A2435068 (Standard)

Description: Fitting 1” Brass Sweat Assembly

Order No: A2099054 (Optional)

Description: Fitting 3/4” & 1” PVC Solvent 900 Asy

Drawing No. Order No. Description Quantity

1 A2095069 Nut 1” Quick Connect 2

2 A2453012 Split Ring 2

3 A2077178 O-Ring 215 2

4 A2569008 Fitting 3/4&1 PVC Solvent 90 2

Order No: A2435072 (Optional)

Description: Fitting 3/4” Brass Sweat Assembly

Drawing No. Order No. Description Quantity

1 A2095069 Nut 1” Quick Connect 2

2 A2453012 Split Ring 2

3 A2077178 O-Ring 215 2

4 A2569006 Fitting 1” Brass Sweat 2

Drawing No. Order No. Description Quantity

1 A2095069 Nut 1” Quick Connect 2

2 A2453012 Split Ring 2

3 A2077178 O-Ring 215 2

4 A2569008 Fitting 3/4&1 PVC Solvent 90 2

21

Page 25

“GF” SERIES AUT OMA TIC W ATER CONDITIONERS

Table 15

Troubleshooting Procedures

Problem Possible Cause Solution

MAINTENANCE

1. Timer does not display

time of day

2. Timer does not display

correct time of day

3. No softening/ltering

display when water is

owing

4. Control valve regenerates

at wrong time of day

5. Display screen will

turn red and ash the

Installer’s Name and

phone number to call for

service.

ERROR followed by

code number

101 Error Code -

Unable to recognize start

of regeneration

102 Error Code Unexpected stall

103 Error Code -

Motor ran to long, timed

out trying to reach next

cycle position

104 Error Code -

Motor ran to long, timed out

trying to reach home

position

If other Error Codes display

contact the factory

ERROR Reset Procedure:

1. Correct error condition.

2. Press NEXT and

REGEN simultaneously

for three seconds.

a. Transformer unplugged

b. No electric power at outlet

c. Defective transformer

d. Defective PC board

a. Switched outlet

b. Power outage

c. Defective PC board

a. Bypass valve in bypass position

b. Meter connection disconnected

c. Restricted/stalled meter turbine

d. Defective meter

e. Defective PC board

a. Power outages

b. Time of day not set correctly

c. Time of regeneration incorrect

d. Control valve set at “on 0”

(immediate regeneration)

e. Control valve set at NORMAL +

on 0

a. Control valve has just been ser-

viced

b. Foreign matter is lodged in control

valve

c. High drive forces on piston

d. Control valve piston not in home

position

e. Motor not inserted fully to engage

pinion, motor wires broken or

disconnected, motor failure

f. Drive gear label dirty or damaged,

missing or broken gear

g. Drive bracket incorrectly aligned

to back plate

h. PC board is damaged or defective

i. PC board incorrectly aligned to

drive bracket

a. Connect power

b. Repair outlet or use working outlet

c. Replace transformer

d. Replace PC board

a. Use uninterrupted outlet

b. Reset time of day

c. Replace PC board

a. Put bypass valve in service position

b. Connect meter to PC board

c. Remove meter and check for rotation

or foreign material

d. Replace meter

e. Replace PC board

a. Reset control valve to correct time of

day

b. Reset to correct time of day (a.m./p.m.)

c. Reset regeneration time (a.m./p.m.)

d. Check control valve set-up procedure

regeneration time option

e. Check control. valve set-up procedure

regeneration time option

a. Press NEXT and REGEN for 3

seconds or unplug power source jack

(black wire) and plug back in to reset

control valve

b. Check piston and spacer stack as-

sembly for foreign matter

c. Replace piston(s) and spacer stack

assembly

d. Press NEXT and REGEN for 3

seconds or unplug power source jack

(black wire) and plug back in to reset

control valve

e. Check motor and wiring. Replace

motor if necessary

f. Replace or clean drive gear(s)

g. Reseat drive bracket properly

h. Replace PC board

i. Ensure PC board is correctly snapped

on to drive bracket

22

Page 26

“GF” SERIES AUT OMA TIC W ATER CONDITIONERS

Troubleshooting Procedures

(continued)

Problem Possible Cause Solution

MAINTENANCE

6. Control valve stalled in

regeneration

7. Control valve does not

regenerate automatically

when REGEN button is

depressed and held

8. Control valve does not

regenerate automatically

but does when REGEN

button is depressed

9 Time of day ashes on

and off

a. Motor not operating

b. No electric power at outlet

c. Defective transformer

d. Defective PC board

e. Broken drive gear or drive cap

assembly

f. Broken piston retainer

g. Broken main or regenerant piston

a. Transformer unplugged

b. No electric power at outlet

c. Broken drive gear or drive cap

assembly

d. Defective PC board

a. By-pass valve in bypass position

b. Meter connection disconnected

c. Restricted/stalled meter turbine

d. Defective meter

e. Defective PC board

f. Set-up error

a. Power has been out more than

two hours, the transformer was

unplugged and then plugged

back into the wall outlet, the

transformer plug was unplugged

and then plugged back into the

board or the NEXT and REGEN

buttons were pressed to reset the

valve.

a. Replace motor

b. Repair outlet or use working outlet

c. Replace transformer

d. Replace PC board

e. Replace drive gear or drive cap as-

sembly

f. Replace drive cap assembly

g. Replace main or regenerant piston

a. Connect transformer

b. Repair outlet or use working outlet

c. Replace drive gear or drive cap as-

sembly

d. Replace PC board

a. Put control valve in service position

b. Connect meter to PC board

c. Remove meter and check for rotation

or foreign material

d. Replace meter

e. Replace PC board

f. Check control valve set-up procedure

a.. Reset the time of day

23

Page 27

“GF” SERIES AUT OMA TIC W ATER CONDITIONERS

NOTES

Page 28

8-569 G&F R2

Loading...

Loading...