Page 1

"Teamwork & Communication"

H-2000 Third

Component Pump

Installation Instructions and

Parts Identification Manual

15810-INST

November 10, 1998

Issue 1

GUSMER CORPORATION

A Subsidiary of Gusmer Machinery Group, Inc.

One Gusmer Drive

Lakewood, New Jersey, USA 08701-8055

Toll Free 1-800-367-4767 (USA & Canada)

Phone: (732) 370-9000

Fax: (732) 905-8968

Copyright 1999, GUSMER CORPORATION

http://www.gusmer.com

®

®

NOTICE: This manual contains important information for your GUSMER equipment. Read and retain for future reference.

Page 2

H-2000 Third Component Pump

NOTICE: The equipment described in this technical manual must only be operated or serviced by properly trained individuals, thoroughly familiar with the operating instructions and limitations of the equipment. For technical service, call your local distributor. Call: 1-800-FOR-GSMR (1-800-367-4767) for the name and telephone number of your local distributor.

NOTICE: All statements, information and data given herein are believed to be accurate and reliable but are

presented without guarantee, warranty or responsibility of any kind expressed or implied. Statements or suggestions

concerning possible use of GUSMER equipment are made without representation or warranty that any such use is

free of patent infringement, and are not recommendations to infringe any patent. The user should not assume that

all safety measures are indicated or that other measures may not be required

2 15810-INST, Issue 1

Page 3

Installation Instructions and Parts ID Manual Contents

CONTENTS

WARRANTY.....................................................................................................................................................................4

GENERAL SAFETY INFORMATION ............................................................................................................................5

ACCEPTABLE EQUIPMENT USES .........................................................................................................................................5

OPERATIONAL SAFETY PROCEDURES..................................................................................................................................6

INSTALLATION...............................................................................................................................................................7

PREPARATION...................................................................................................................................................................7

INSTALLATION OF THE RETRO-FIT KIT...............................................................................................................................8

INSTALLATION OF THE AUXILIARY PUMP............................................................................................................................9

NORMAL OPERATING PROCEDURE........................................................................................................................11

PARTS IDENTIFICATION............................................................................................................................................12

AUXILIARY PUMP RETRO-FIT KIT.....................................................................................................................................12

AUXILIARY PUMP MOUNTING ASSEMBLY.........................................................................................................................14

AUXILIARY PUMP PROPORTIONING PUMP ASSEMBLY 10 SIZE PUMPS................................................................................. 16

CATALYST SUPPLY TANK .........................................................................................................................................18

PRE-MIX CHAMBER ASSEMBLY..............................................................................................................................20

INSTRUCTION MANUAL DISCREPANCY REPORT................................................................................................21

LIST OF FIGURES

FIGURE 1. H-2000 PROPORTIONING PUMP ASSEMBLY ............................................................................................................7

FIGURE 2 HEX LOCK NUT.....................................................................................................................................................8

FIGURE 3. TYPICAL ASSEMBLY..............................................................................................................................................9

FIGURE 4. AUXILIARY PUMP ADJUSTMENT DETAILS .............................................................................................................11

FIGURE 5. AUXILIARY PUMP RETRO-FIT KIT (PART NO. 15810-10-KIT), EXPLODED VIEW .................................................... 12

FIGURE 6. AUXILIARY PUMP MOUNTING ASSEMBLY (PART NO. 15828), EXPLODED VIEW..................................................... 14

FIGURE 7. AUXILIARY PROPORTIONING PUMP ASSEMBLY (PART NO. 15800A-10), EXPLODED VIEW......................................16

FIGURE 8. CATALYST SUPPLY TANK (PART NO. OP902-R) EXPLODED VIEW........................................................................18

FIGURE 9. PRE-MIX CHAMBER ASSEMBLY (PART NO. 17857) EXPLODED VIEW ...................................................................20

LIST OF TABLES

TABLE 1. AUXILIARY PUMP RETRO-FIT KIT (PART NO. 15810-10-KIT), PARTS..................................................................... 13

TABLE 2. AUXILIARY PUMP MOUNTING ASSEMBLY (PART NO. 15828), PARTS...................................................................... 15

TABLE 3. AUXILIARY PROPORTIONING PUMP ASSEMBLY (PART NO. 15800A-10), PARTS ...................................................... 17

TABLE 4. CATALYST SUPPLY TANK, (PART NO. OP901-ID), PARTS.....................................................................................19

TABLE 5. PRE-MIX CHAMBER ASSEMBLY, (PART NO. 17857), PARTS..................................................................................20

1/7/99 3

Page 4

H-2000 Third Component Pump

WARRANTY

Gusmer Corporation (Gusmer) provides a limited warranty to the original purchaser (Customer) of

Gusmer manufactured parts and equipment (Product) against any defects in material or

workmanship for a period of one year from the date of shipment from Gusmer facilities.

In the event Product is suspected to be defective in material or workmanship, it must be returned to

Gusmer, freight prepaid. If Product is found to be defective in material or workmanship, as

determined solely by Gusmer, Gusmer will issue full credit to Customer for the freight charges

incurred in returning the defective Product, and either credit will be issued for the replacement cost

of the Product or a replacement part will be forwarded no-charge, freight prepaid to Customer.

This warranty shall not apply to Product Gusmer finds to be defective resulting from: installation,

use, maintenance, or procedures not accomplished in accordance with our instructions; normal

wear; accident; negligence; alterations not authorized in writing by Gusmer; use of “look alike”

parts not manufactured or supplied by Gusmer; or Product used in conjunction with any other

manufacturer's pumping or proportioning equipment. Further, the terms and conditions of this

warranty shall not apply to services or repairs made to Product by any third party not authorized in

writing by Gusmer. For such Product, a written estimate will be submitted to Customer at a

nominal service charge, itemizing the cost for repair. Disposition of Product will be done in

accordance with the terms stated on the written estimate.

The warranty provisions applied to product that are not manufactured by Gusmer will be solely in

accordance with the warranty provided by the original manufacturer of the product.

GUSMER MAKES NO WARRANTY WHATSOEVER AS TO THE MERCHANTABILITY OF,

OR SUITABILITY FOR, ITS PRODUCT TO PERFORM ANY PARTICULAR PURPOSE.

CREDIT FOR, OR REPLACEMENT OF, PRODUCT DEFECTIVE IN MATERIAL OR

WORKMANSHIP SHALL CONSTITUTE COMPLETE FULFILLMENT OF GUSMER

OBLIGATIONS TO CUSTOMER. NO OTHER WARRANTY, EXPRESSED OR IMPLIED ON

ANY PRODUCT IT MANUFACTURES AND/OR SELLS, WILL BE RECOGNIZED BY

GUSMER UNLESS SAID WARRANTY IS IN WRITING AND APPROVED BY AN OFFICER

OF GUSMER.

Under no circumstances shall Gusmer be liable for loss of prospective or speculative profits, or

special indirect, incidental or consequential damages. Further, Gusmer shall have no liability for

any expenses including, but not limited to personal injury or property damage resulting from failure

of performance of the product, use of the product, or application of the material dispensed through

the product. Any information provided by Gusmer that is based on data received from a third

source, or that pertains to product not manufactured by Gusmer, while believed to be accurate and

reliable, is presented without guarantee, warranty, or responsibility of any kind, expressed or

implied.

Gusmer through the sale, lease, or rental of Product in no way expresses or implies a license for the

use of, nor encourages the infringement of any patents or licenses.

To insure proper validation of your warranty, please complete the warranty card and return it to

Gusmer within two weeks of receipt of equipment.

Revised 11/12/98

4 15810-INST, Issue 1

Page 5

Installation Instructions and Parts ID Manual General Safety Information

GENERAL SAFETY INFORMATION

It is necessary to understand and follow the instructions in this manual to insure proper

and safe operation of the equipment.

As with most mechanical equipment, certain safety precautions must be taken when the

equipment discussed in this manual is operated or serviced. Severe bodily injury or

damage to equipment and property may result if the instructions and precautions listed

throughout this manual are not followed.

Needless to say, sufficient guidelines cannot be developed to eliminate the need for good

common sense in the use and servicing of this equipment, and in the use and application

of the products, this equipment has been designed to process. Users of this equipment

must therefore, make their own determination as to the suitability of the information

contained in this manual to their specific operation and requirements. There should be

no assumption made that the safety measures and instructions contained herein are allinclusive, and that other safety measures may not be required for specific use or

application.

The following safety guidelines are generally applicable to the safe and efficient use of

the equipment.

ACCEPTABLE EQUIPMENT USES

The equipment is designed for the dispensing of polyurethane foams, two-component

coating systems, and some two-component epoxy systems, specifically polyureas. Under

no circumstances should any acid or corrosive chemicals be used in the unit. Consult

GUSMER if there is any doubt about the compatibility of the chemical system to be used

in this equipment.

Any use of this equipment other than as indicated above constitutes misuse unless

express written approval is obtained from GUSMER.

1/7/99 5

Page 6

Solvents and Chemicals

High Voltage

H-2000 Third Component Pump

OPERATIONAL SAFETY PROCEDURES

This safety information will not be repeated in the text of this manual. The symbols

pertaining to this information will appear where appropriate to alert the operator to

potential hazards.

WARNING: THE SOVENTS AND CHEMICAL USED WITH THIS EQUIPMENT EXPOSE THE

OPERATOR TO CERTAIN HAZARDS. ADEQUATE PERSONAL PROTECTIVE MEASURES MUST BETAKEN

SO AS TO AVOID EXCEEDING THE THRESHOLD LIMIT VALUE (TLV) OF THE PRODUCTS BEING

USED, AS ESTABLISHED BY THE OCCUPATIONAL SAFETY AND HEALTH ADMINISTRATION (OSHA)

OR OTHER QUALIFIED AGENCY. INFORMATION CONCERNING PERSONAL PROTECTION AND

PROPER HANDLING FROM THE SUPPLIER OF SUCH CHEMICALS.

WARNING: TO PREVENT SERIOUS BODILY INJURY FROM ELECTRICAL SHOCK, NEVER OPEN THE

ELECTRIC CONSOLES OR OTHERWISE SERVICE THIS EQUIPMENT AND/OR EQUIPMENT USED WITH

IT BEFORE SWITCHING OFF THE MAIN POWER DISCONNECT AND INTERRUPTING SUPPLY VOLTAGE

AT THE SOURCE. THE ELECTRICAL SERVICE MUST BE INSTALLED AND MAINTAINED BY A

QUALIFIED ELECTRICIAN.

High Pressure

Personal Protective

Equipment

High Temperature

WARNING: THIS EQUIPMENT HAS OR IS USED WITH EQUIPMENT THAT HAS HYDRAULIC

COMPONENTS CAPABLE OF PRODUCING UP TO 3500 PSI. TO AVOID SERIOUS BODILY INJURY

FROM HYDRAULIC INJECTION OF FLUID, NEVER OPEN ANY HYDRAULIC CONNECTIONS OR SERVICE

HYDRAULIC COMPONENTS WITHOUT BLEEDING ALL PRESSURES TO ZERO.

WARNING: TO AVOID SERIOUS BODILY INJURY, PROPER PROTECTIVE GEAR MUST BE WORN

WHEN OPERATING, SERVICING, OR BEING PRESENT IN THE OPERATIONAL ZONE OF THIS

EQUIPMENT. THIS INCLUDES, BUT IS NOT LIMITED TO, EYE AND FACE PROTECTION, GLOVES,

SAFETY SHOES, AND RESPIRATORY EQUIPMENT AS REQUIRED.

WARNING: THIS EQUIPMENT HAS OR IS USED WITH EQUIPMENT THAT HAS HIGH

TEMPERATURE COMPONENTS SUCH AS PRIMARY HEATERS AND HEATED HOSES. TO PREVENT

SERIOUS BODILY INJURY FROM HOT FLUID OR HOT METAL, NEVER ATTEMPT TO SERVICE THE

EQUIPMENT BEFORE ALLOWING IT TO COOL.

WARNING: FAILURE TO READ AND FOLLOW THIS SAFETY INFORMATION MAY RESULT IN

PERSONAL INJURY AND/OR DAMAGE TO THE EQUIPMENT FROM ONE OR MORE OF THE ABOVE

LISTED HAZARDS

Warning

6 15810-INST, Issue 1

Page 7

Installation Instructions and Parts ID Manual Installation

INSTALLATION

IMPORTANT: Before you begin turn off all electrical power to the machine. Drain all

chemical from the machine. Suggested method is by forced air.

PREPARATION

Figure 1. H-2000 Proportioning Pump Assembly

1. Close both Supply Valves.

2. Bleed all chemical pressure to zero.

3. Remove Polyethylene Pipe Plug from the Iso proportioning pump lube cylinder.

4. Position the Clevis Pin for removal from the Lube Cylinder.

5. Remove the Clevis Pins from both the Iso and Resin pumps with the Clevis

Extractor Tool.

6. Remove all hoses from both proportioning pumps.

7. Detach each Proportioning Pump Assembly from the pump line by unscrewing the 4

Socket Head Cap Screws.

8. Remove the Iso Lube Cylinder by manually pulling it off.

9. Unscrew the Resin and Iso Cylinder Clevis by using a wrench on both sides and

simultaneously break loose both clevis's.

10. Remove the Activator Plate.

Important: If Hydraulic Cylinder Standoffs are removed they must be re-torqued to

200 inch/lbs.

1/7/99 7

Page 8

H-2000 Third Component Pump

INSTALLATION OF THE RETRO-FIT KIT

IMPORTANT: It is recommended to use a thread sealant on all pipe fittings prior

to any installation to prevent leakage.

ON RESIN SIDE ONLY:

1. Install the Bronze Bushing on to the Activator Plate

2. Slide the Bronze Bushing on the Activator Plate over Reversing Switch Pump

Spacer.

3. Install the replacement Clevis onto Resin side of the Hydraulic Shaft.

4. Mount the Activator Plate to the replacement Clevis with a flat head cap screw.

ON ISO SIDE ONLY:

Position the clevis on the resin side for

NOTE:

attaching to the arm from the Auxiliary

Pump. Position the clevis on the Iso

side to line up with the access hole on

the Lube Cylinder in order to attach the

Proportioning Pump Clevis and

Hydaualic Cylinder Clevis with the

Clevis Pin.

5. Reinstall the Clevis with the Hex Lock

Nut onto Iso side of the Hydraulic Shaft as

shown in figure 2.

6. Reinstall original Iso Lube Cylinder.

7. Secure the Iso Proportioning Pump

Assembly back onto the pump line by

reinserting the Clevis pin with the Clevis

tool.

Figure 2 Hex Lock Nut

8. Install and tighten the Proportioning Pump assembly to the pump line with 4 Socket

Head Cap Screws.

9. Cover the Clevis pin access hole with the Polyethylene Pipe Plug.

ON RESIN SIDE ONLY:

10. Secure the Resin Proportioning Pump Assembly back onto the pump line by

inserting the Clevis pin with the Clevis tool.

11. Install and tighten the Proportioning Pump Assembly to the Pump Line with 4

Socket Head Cap Screws.

8 15810-INST, Issue 1

Page 9

Installation Instructions and Parts ID Manual Installation

INSTALLATION OF THE AUXILIARY PUMP

Figure 3. Typical Assembly

1. Remove the four round head machine screws from the top of the Resin

Proportioning Pump and set aside.

2. Mount the Pump Mounting Assembly to the top of the Resin Proportioning Pump by

aligning the bracket bolt pattern with the existing holes and secure with the four

replacement socket head cap screws.

3. Align the lower pivot point of the Drive Arm with the upper pivot point of the

replacement Clevis and use the Clevis tool to insert the replacement Clevis Pin.

4. Remove the two side pivot screws from the Auxiliary Pump Assembly.

5. Align the yoke on the Auxiliary Pump with the adjustable pivot on the drive arm

bracket and insert the Yoke Pin.

1/7/99 9

Page 10

H-2000 Third Component Pump

6. Snap Tru-Arc Rings onto both ends of the Yoke pin.

7. Attach the Auxiliary Pump to the bracket using the two side pivot screws.

8. Install Hex Nipple in the side of the pump flange.

9. Install the Check Valve and Hose Elbow; and orient as shown.

10. Install Male Elbow onto the Auxiliary Pump.

11. Install the Interconnect and Supply hoses as shown.

12. Insure all tubing and hoses are properly aligned and tightened before attempting

any start-up procedures.

You may now restart the Proportioning Unit using initial start up procedures

located in your operator’s manual.

Please retain the following remaining parts for future use:

Part Number. Description Qty

15514 Clevis 1

1501A-7-1 Activator Plate 1

10 15810-INST, Issue 1

Page 11

Installation Instructions and Parts ID Manual Normal Operating Procedure

NORMAL OPERATING PROCEDURE

The Auxiliary Pump operates the same as the Isocyanate and Resin Proportioning

Pumps. When a Third Component is required for a particular application: adjusting the

stroke length controls the exact amount being proportioned into the system.

Figure 4. Auxiliary Pump Adjustment Details

Changing the stroke length of the piston varies the output on the Auxiliary Pump. To

do this loosen the adjusting nut and align the indicator arrow on the Adjustable pivot

with the desired percentage marked on the Drive Arm and retighten the adjusting nut.

1/7/99 11

Page 12

PARTS IDENTIFICATION

AUXILIARY PUMP RETRO-FIT KIT

H-2000 Third Component Pump

Figure 5. Auxiliary Pump Retro-Fit Kit (Part No. 15810-10-Kit), Exploded View

12 15810-INST, Issue 1

Page 13

Installation Instructions and Parts ID Manual Parts Identification

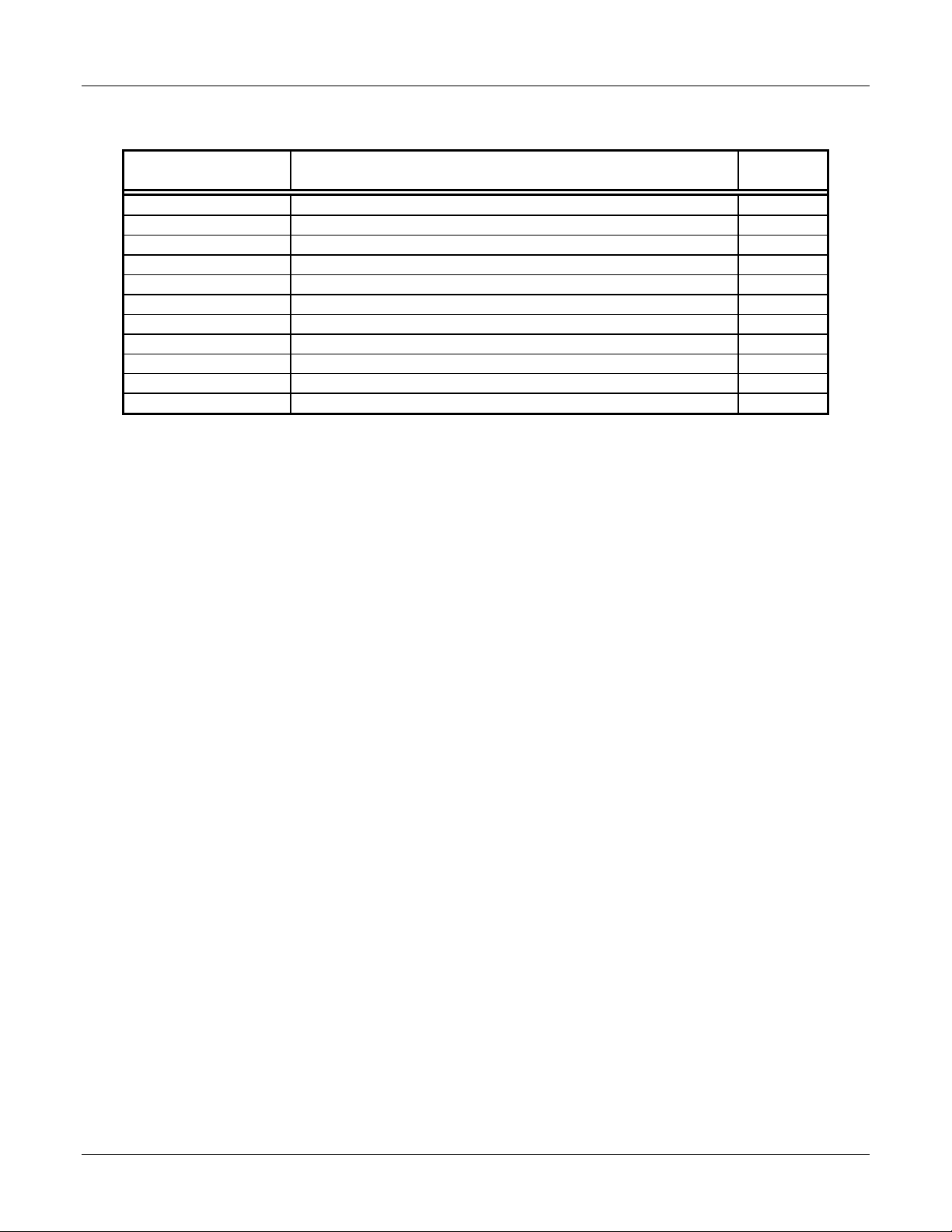

TABLE 1. AUXILIARY PUMP RETRO-FIT KIT (PART NO. 15810-10-KIT), PARTS

Part Number Description Quantity

0373

0381-2

0466A

1327

5512-8

6303-17

15750-6

15800A-10

15828

15851

17857

Male Elbow 2

Nipple 1

Hex Nipple 1

Interconnect Hose 1

Socket Head Cap Screw 4

Jic Fitting 1

Baffle Lock Nut (Not Shown) 1

Auxiliary Proportioning Pump Assembly 1

Pump Mounting Assembly 1

Check Valve Assembly 1

Pre-Mix Chamber Assembly 1

1/7/99 13

Page 14

H-2000 Third Component Pump

AUXILIARY PUMP MOUNTING ASSEMBLY

Figure 6. Auxiliary Pump Mounting Assembly (Part No. 15828), Exploded View

14 15810-INST, Issue 1

Page 15

Installation Instructions and Parts ID Manual Parts Identification

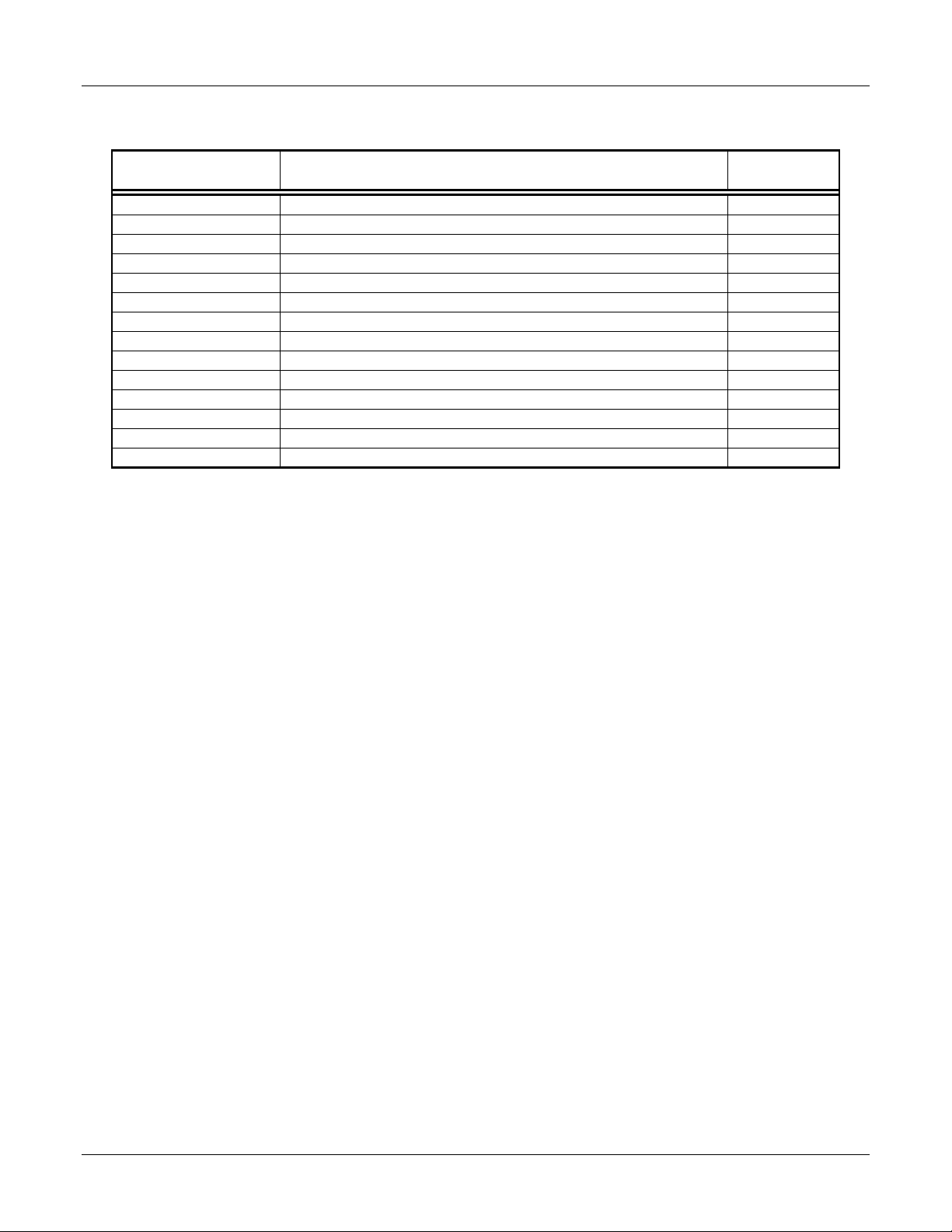

TABLE 2. AUXILIARY PUMP MOUNTING ASSEMBLY (PART NO. 15828), PARTS

Part Number Description Quantity

0370-1

1521-1-2

15515

15829-1

15829-10

15829-2

15829-3

15829-4

15829-5

15829-6

15829-7

15829-8

15829-9

15830

Hex Nut 1

Flat Head Cap Screw 1

Clevis Pin 2

Idler Link 1

Pump Clevis 1

Drive Arm 1

Adjustable Pivot 1

Washer 1

Yoke Pin 1

Pivot Pin 2

Tru Arc 1

Hydraulic Cylinder Clevis 1

Reversing Plate 1

Main Bracket Assembly 1

1/7/99 15

Page 16

H-2000 Third Component Pump

AUXILIARY PUMP PROPORTIONING PUMP ASSEMBLY

10 SIZE PUMPS

Figure 7. Auxiliary Proportioning Pump Assembly (Part No. 15800A-10), Exploded View

16 15810-INST, Issue 1

Page 17

Installation Instructions and Parts ID Manual Parts Identification

TABLE 3. AUXILIARY PROPORTIONING PUMP ASSEMBLY (PART NO. 15800A-10), PARTS

Part Number Description Quantity

15813

0461

15805-2

0352A-1

1417-24

15503

15801-10

15802-10

15803-10

15804A

15805-S

15806

15807

15808

15809-10

1707-15-8

15811

1812

1813

1814

1815

1816

1817

1818

4406-16

0807

9403-N

9405-N

9412

9462

9463

9464

OP219-4

15810

6465

15516-2200

Valve Cover Bracket 1

Snap Ring 1

O-Ring 2

Socket Head Cap Screw 4

Wave Spring 2

0-3000 PSI Liquid Fill Gauge 1

Piston Rod 1

Pump Cylinder Block 1

Pump Flange 1

Pump Base 1

Check Valve 2

Inlet Valve Cover 1

Outlet Valve Cover 1

Pivot 2

Yoke 1

Lockwasher 1

Packing Set 1

Packing Support Washer 2

Packing Set 1

Spring Retainer Washer 1

Conical Spring 1

Packing Retainer Washer 1

Packing Support Washer 1

Socket Head Cap Screw 1

Socket Head Cap Screw 4

O-Ring 1

O-Ring 1

O-Ring 1

Pressure Gauge Adapter 1

Pump Screen 1

Socket Head Cap Screw 2

Screen Screw 1

Socket Head Cap Screw 1

Hose Nipple 1

Pipe Tee 1

Pressure Switch 1

1/7/99 17

Page 18

H-2000 Third Component Pump

CATALYST SUPPLY TANK

Figure 8. Catalyst Supply Tank (Part No. OP902-R) Exploded View

18 15810-INST, Issue 1

Page 19

Installation Instructions and Parts ID Manual Parts Identification

TABLE 4. CATALYST SUPPLY TANK, (PART NO. OP902-R), PARTS

Part Number Description Quantity

0381-2

0487A

1128

1142

2130

2145-1

2145-2

OP156-30

OP202-6

OP901-2

OP901-3-1

OP901-3-2

OP901-4

OP901-5

OP901-8

OP901-9

Nipple 1

Ball Valve 1

Needle Valve 1

R-Swivel Fitting 1

Air Hose 1

Quick Disconnect Plug 1

Quick Disconnect Coupler 1

Hex Nipple 1

Bushing 1

Elbow 1

Pressure Relief Valve Assembly (Plastic) 1

Pressure Relief Valve Assembly (Metal) 1

O-Ring (Lid) 1

3 Gal. Tank Lid 1

Street Elbow 45 1

Bushing 1

1/7/99 19

Page 20

H-2000 Third Component Pump

PRE-MIX CHAMBER ASSEMBLY

Figure 9. Pre-Mix Chamber Assembly (Part No. 17857) Exploded View

TABLE 5. PRE-MIX CHAMBER ASSEMBLY, (PART NO. 17857), PARTS

Part Number Description Quantity

0377

0576

0855B-2

9452-15-2

17857-1

Pipe Plug 1

Pipe Plug 1

Pre-Mixer 4

Pipe Plug 1

Pre Mix Chamber 1

20 15810-INST, Issue 1

Page 21

Installation Instructions and Parts ID Manual Instruction Manual Discrepancy Report

INSTRUCTION MANUAL DISCREPANCY REPORT

Field

Number

1 Date

2

3

4

5

6

7

Field Title

Name

IM Number

Issue Number

Date of Issue

Page Number

Discrepancy

Description

Instructions:

Complete the above fields of the form by following the instructions listed on the reverse side of this sheet and mail to:

Gusmer Corporation

One Gusmer Drive PO Box 2055

Lakewood, NJ 08701

11/6/98 21

Page 22

H-2000 Third Component Pump

Field

Number

1 Date

2

3

4

5

6

7

Field Title

Name

IM Number

Issue Number

Date of Issue

Page Number

Discrepancy

Description

Enter date report is submitted.

Enter name of person making report.

Enter the Part Number of the Instruction Manual from the title page.

Enter the Issue number of the Instruction Manual from the title page. If there is no

issue number enter NONE.

Enter the date of Issue of the Instruction Manual from the title page. If there is no

issue date enter NONE.

Enter the page number containing the discrepancy

Provide a brief description of discrepancy

NOTE: You may send a marked copy of the page as an attachment to your

submittal.

22 15810-INST, Issue 1

Loading...

Loading...