Page 1

"Teamwork & Communication"

Model GX-8

Operating Manual

Spray Gun

32943-1

April 21, 1999

Issue 1

GUSMER CORPORATION

A Subsidiary of Gusmer Machinery Group, Inc.

One Gusmer Drive

Lakewood, New Jersey, USA 08701-8055

Toll Free 1-800-367-4767 (USA & Canada)

Phone: (732) 370-9000

Fax: (732) 905-8968

Copyright 1999, GUSMER CORPORATION

http://www.gusmer.com

NOTICE: This manual contains important information for your GUSMER equipment. Read and retain for future reference.

®

®

Page 2

Model GX-8 Spray Gun

CONTENTS

LIST OF FIGURES..........................................................................................................3

WARRANTY ....................................................................................................................4

GENERAL SAFETYINFORMATION..........................................................................5

CCEPTABLEEQUIPMENT USES.......................................................................................5

A

O

PERATIONALSAFETY PROCEDURES...............................................................................6

DESCRIPTION.................................................................................................................7

EY FEATURES ................................................................................................................7

K

M

AJOR COMPONENTS......................................................................................................9

E

QUIPMENT SUPPLIED....................................................................................................10

G

UN SERVICE KITS........................................................................................................11

OPERATION..................................................................................................................12

AFETY POSITION OF GUN .............................................................................................12

S

M

ANUAL VALVES ..........................................................................................................12

A

IR LINE CONFIGURATION.............................................................................................13

S

TART-UP......................................................................................................................13

S

HUTDOWN....................................................................................................................14

CLEANING PROCEDURE...........................................................................................15

SERVICING PROCEDURES........................................................................................17

S

CREEN SCREW REMOVALAND SERVICE PROCEDURE ................................................. 17

C

ENTERLINE COMPONENT REMOVAL ............................................................................18

C

ENTERLINE COMPONENT INSTALLATION .....................................................................20

V

ALVINGROD ADJUSTMENT .........................................................................................21

A

IR PISTON O-RING AND CUP SEAL REPLACEMENT ......................................................23

E

ND CAP O-RING AND CUP SEAL REPLACEMENT..........................................................25

T

RIGGER VALVE O-RING REPLACEMENT.......................................................................27

APPENDIX......................................................................................................................29

PECIFICATIONS.............................................................................................................29

S

INSTRUCTION MANUAL DISCREPANCY REPORT............................................31

2 32943-1, Issue 1

Page 3

Operating Manual Contents

LIST OF FIGURES

FIGURE 1. MIXING MODULE..............................................................................................8

F

IGURE 2. MAJOR COMPONENTS .......................................................................................9

F

IGURE 3. CENTERLINE COMPONENTS...............................................................................9

F

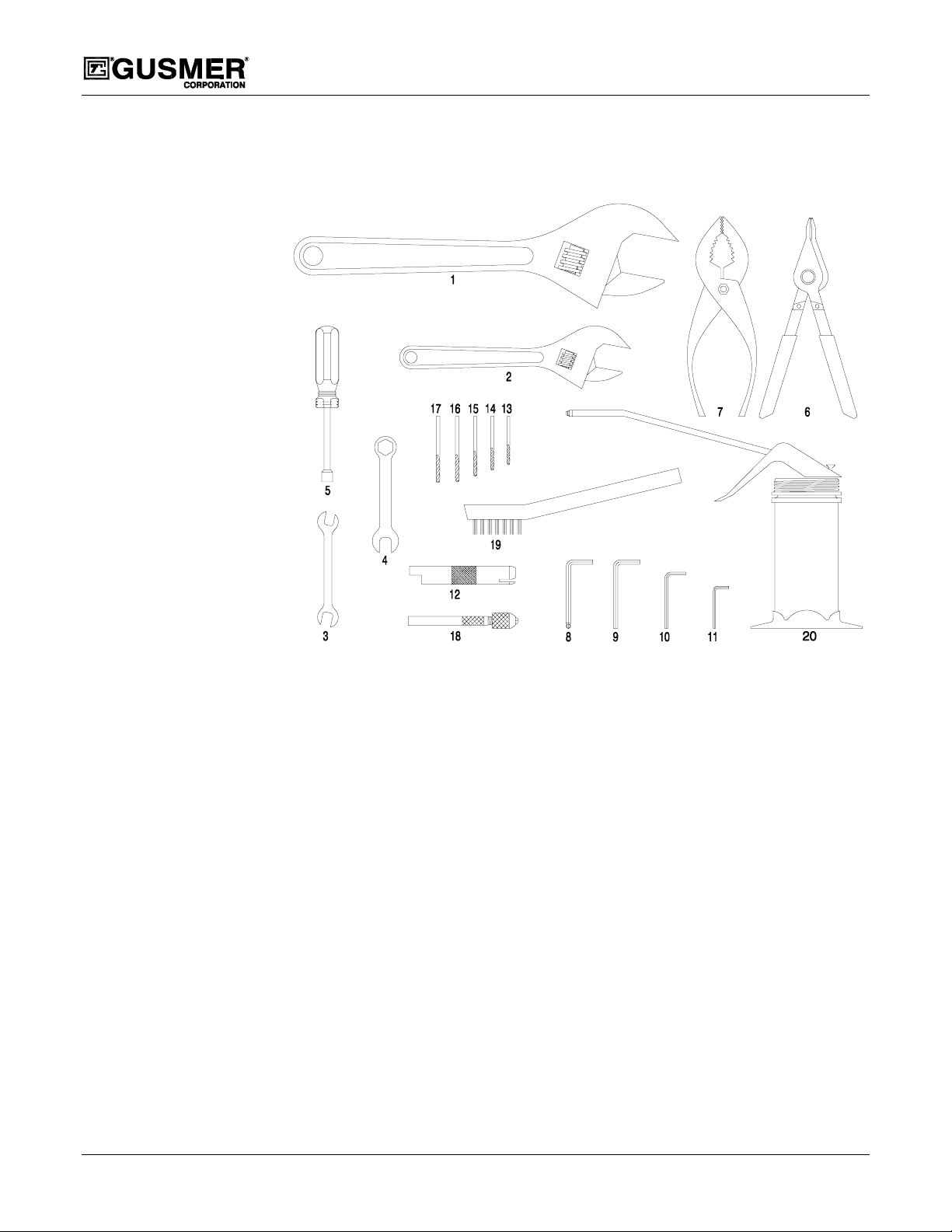

IGURE 4. STANDARD TOOL KIT ......................................................................................10

F

IGURE 5. 1 QUART GUN SERVICE KIT (P/N OP205).......................................................11

F

IGURE 6. 3 GALLON GUN SERVICE KIT (P/N OP206).....................................................11

F

IGURE 7. ENGAGE THE SAFETY STOP..............................................................................12

F

IGURE 8. DISENGAGE THE SAFETY STOP ........................................................................12

F

IGURE 9. MANUAL VALVES ............................................................................................12

F

IGURE 10. CENTERLINE COMPONENTREMOVAL..............................................................18

F

IGURE 11. CENTERLINE COMPONENTINSTALLATION .......................................................20

F

IGURE 12. PCD SPACING..............................................................................................21

F

IGURE 13. VALVING ROD ADJUSTMENTS ........................................................................22

F

IGURE 14. END CAP/SAFETY STOP ASSEMBLYAND PISTON ASSEMBLY REMOVAL............. 24

F

IGURE 15. END CAP/SAFETY STOP ASSEMBLYREMOVAL .................................................26

F

IGURE 16. TRIGGER/AIR VALVE ASSEMBLY.....................................................................27

4/21/99 3

Page 4

Model GX-8 Spray Gun

WARRANTY

Gusmer Corporation (Gusmer) provides a limited warranty to the original purchaser (Customer) of

Gusmer manufactured parts and equipment (Product) against any defects in material or

workmanship for a period of one year from the date of shipment from Gusmer facilities.

In the event Pr oduct is suspected to be defective in material or workmanship, it must be returned to

Gusmer, freight prepaid. If Product is found to be defective in material or workmanship, as

determined solely by Gusmer, Gusmer will issue full credit to Customer for the freight charges

incurred in returning the defective Product, and either credit will be issued for the replacement cost

of the Product or a replacement part will be forwarded no-charge, freight prepaid to Customer.

This warranty shall not apply to Product Gusmer finds to be defective resulting from: installation,

use, maintenance, or procedures not accomplished in accordance with our instructions; normal

wear; accident; negligence; alterations not authorized in writing by Gusmer; use of “look alike”

parts not manufactured or supplied by Gusmer; or Product used in conjunction with any other

manufacturer's pumping or proportioning equipment. Further, the terms and conditions of this

warranty shall not apply to services or repairs madeto Product by any third party not authorized in

writing by Gusmer. For such Product, a written estimate will be submitted to Customer at a

nominal service charge, itemizing the cost for repair. Disposition of Product will be done in

accordance withthe terms stated on the written estimate.

The warranty provisions applied to product that are not manufactured by Gusmer will be solely in

accordance with the warranty provided by the original manufacturer of the product.

GUSMER MAKES NO WARRANTY WHATSOEVER AS TO THE MERCHANTABILITY OF,

OR SUITABILITY FOR, ITS PRODUCT TO PERFORM ANY PARTICULAR PURPOSE.

CREDIT FOR, OR REPLACEMENT OF, PRODUCT DEFECTIVE IN MATERIAL OR

WORKMANSHIP SHALL CONSTITUTE COMPLETE FULFILLMENT OF GUS MER

OBLIGATIONS TO CUSTOMER. NO OTHER WARRANTY, EXPRESSED OR IMPLIED ON

ANY PRODUCT IT MANUFACTURES AND/OR SELLS, WILL BE RECOGNIZED BY

GUSMER UNLESS SAID WARRANTY IS IN WRITING AND A PPROVED BY AN OFFICER

OF GUSMER.

Under no circumstances shall Gusmer be liable for loss of prospective or speculative profits, or

special indirect, incidental or consequential damages. Further, Gusmer shall have no liability for

anyexpensesincluding, but not limited to personal injury or property damage resultingfrom failure

of performance of the product, use of the product, or application of the material dispensed through

the product. Any information provided by Gusmer that is based on data received from a third

source, or that pertains to product not manufactured by Gusmer, while believed t o be accurate and

reliable, is presented without guarantee, warranty, or responsibility of any kind, expressed or

implied.

Gusmer through the sale, lease, or rental of Product in no way expresses or implies a license for the

use of, nor encourages the infringement of any patents or licenses.

To insure proper validation of your warranty, please complete the warranty card and return it to

Gusmer within two weeks of receipt of equipment.

Revised 11/12/98

4 32943-1, Issue 1

Page 5

Operating Manual General Safety Information

GENERAL SAFETY INFORMATION

It is necessary to understand and follow the instructions in this manual to insure proper

and safe operation of the equipment.

As withmost mechanical equipment, certain safetyprecautions must be taken when the

equipment discussed in this manual is operated or serviced. Severe bodily injury or

damage to equipment and property may result if the instructions and precautions listed

throughout this manual are not followed.

Needless to say, sufficient guidelines cannot be developed to eliminate the need for good

common sense in the use and servicing of this equipment, and in the use and application

of the products, this equipment has been designed to process. Users of this equipment

must therefore, make their own determination as to the suitability of the information

contained in this manual to their specific operation and requirements. There should be no

assumption made that the safetymeasures and instructions contained herein are allinclusive, and that other safety measures may not be required for specific use or

application.

The following safety guidelines are generally applicable to the safe and efficient use of

the equipment.

Acceptable Equipment Uses

The equipment is designed for the dispensing of polyurethane foams, two-component

coating systems, and some two-component epoxy systems, specificallypolyureas. Under

no circumstances should any acid or corrosive chemicals be used in the unit. Consult

GUSMER if there is any doubt about the compatibility of the chemical system to be used

in this equipment.

Any use of this equipment other than as indicated above constitutes misuse unless express

written approval is obtained from GUSMER.

4/21/99 5

Page 6

Model GX-8 Spray Gun

Operational Safety Procedures

This safety information will not be repeated in the text of this manual. The symbols

pertaining to this information will appear where appropriate to alert the operator to

potential hazards.

Solvents and Chemicals

High Voltage

High Pressure

Personal Protective

Equipment

WARNING: T

OPERATOR TO CERTAIN HAZARDS.ADEQUATE PERSONAL PROTECTIVE MEASURES MUST

BETAKEN SO AS TO AVOID EXCEEDING THE

PRODUCTS BEING USED

HE SOVENTS AND CHEMICAL USED WITH THIS EQUIPMENT EXPOSE THE

THRESHOLD LIMIT VALUE (TLV) OF THE

, AS ESTABLISHED BY THE OCCUPATIONAL SAFETY AND HEALTH

ADMINISTRATION (OSHA) OR OTHER QUALIFIED AGENCY.INFORMATION CONCERNING

PERSONAL PROTECTION AND PROPER HANDLING FROM THE SUPPLIER OF SUCH CHEMICALS

WARNING: T

THE ELECTRIC CONSOLES OR OTHERWISE SERVICE THIS EQUIPMENT AND/OR EQUIPMENT USED

WITH IT BEFORE SWITCHING OFF THE MAIN POWER DISCONNECT AND INTERRUPTING SUPPLY

VOLTAGE AT THE SOURCE

A QUALIFIED ELECTRICIAN

WARNING: T

COMPONENTS CAPABLE OF PRODUCING UP TO 3500 PSI.TO AVOID SERIOUS BODILYINJURY

FROM HYDRAULIC INJECTION OF FLUID

SERVICE HY DRAULICCOMPONENTS WITHOUT BLEEDING ALL PRESSURES TO ZERO

WARNING: T

WHEN OPERATING, SERVICING, OR BEING PRESENT IN THE OPERATIONAL ZONE OF THIS

EQUIPMENT

SAFETY SHOES, AND RESPIRATORYEQUIPMENT AS REQUIRED.

O PREVENT SERIOUS BODILY INJURY FROM ELECTRICAL SHOCK, NEVER OPEN

.THE ELECTRICAL SERVICE MUST BE INSTALLED AND MAINTAINED BY

.

HIS EQUIPMENT HAS OR IS USED WITH EQUIPMENT THAT HAS HYDRAULIC

, NEVER OPEN ANY HYDRAULIC CONNECTIONS OR

.

O AVOID SERIOUS BODILY INJURY, PROPER PROTECTIVE GEAR MUST BE WORN

.THIS INCLUDES, BUT IS NOT LIMITED TO, EYE AND FACE PROTECTION, GLOVES,

.

WARNING: T

TEMPERATURE COMPONENTS SUCH AS PRIMARY HEATERS AND HEATED HOSES.TO PREVENT

SERIOUS BODILY INJURY FROM HOT FLUID OR HOT METAL

EQUIPMENT BEFORE ALLOWING IT TO COOL

HIS EQUIPMENT HAS OR IS USED WITH EQUIPMENT THAT HAS HIGH

, NEVER ATTEMPT TO SERVICE THE

.

High Temperature

WARNING:F

PERSONAL INJURY AND/OR DAMAGE TO THE EQUIPMENT FROM ONE OR MORE OF THE ABOVE

LISTED HAZARDS

AILURE TO READ AND FOLLOW THIS SAFETY INFORMATION MAY RESULT IN

Warning

6 32943-1, Issue 1

Page 7

Operating Manual Description

DESCRIPTION

Key Features

The design and development of the Gusmer Model GX-8 Spray Gun represents the next

step in the evolution of spray coating technology that Gusmer originated over 35 years

ago. We believe the GX-8 Spray Gun is the only mechanical purge gun in the world that

allows the spraying of polyureas and hybrids at outputs in the 1-2 pound per minute

range. Its lower output, lighter weight, fewer parts, and reduced air consumption are just

a few of its innovative enhancements. Yet, the GX-8 maintains many of the unique

design characteristics of its direct predecessor, the GX-7. These unique characteristics

include mechanical purge, a variety of durable mixing modules, interchangeable Pattern

Control Discs (PCD), and Gusmer quality.

The GX-8 design has successfully combined the proven concepts of other Gusmer

mechanical purge, direct impingement guns w ith exciting new enhancements that provide

a completely new gun that delivers:

• Unmatched low output capabilities

• Smaller gun dimensions with a 37% reduction in weight

• Increased maneuverability specifically for open mold applications

• Easy operation

• Less expensive operation

The gun is available with a variety of PCD options designed to meet most applications

that require the spraying of fast chemical systems at lowoutputs. Both your authorized

Gusmer Distributor and Gusmer Sales Engineers are available to help determine what

configurations are best for your specific application. Please contact either for additional

information.

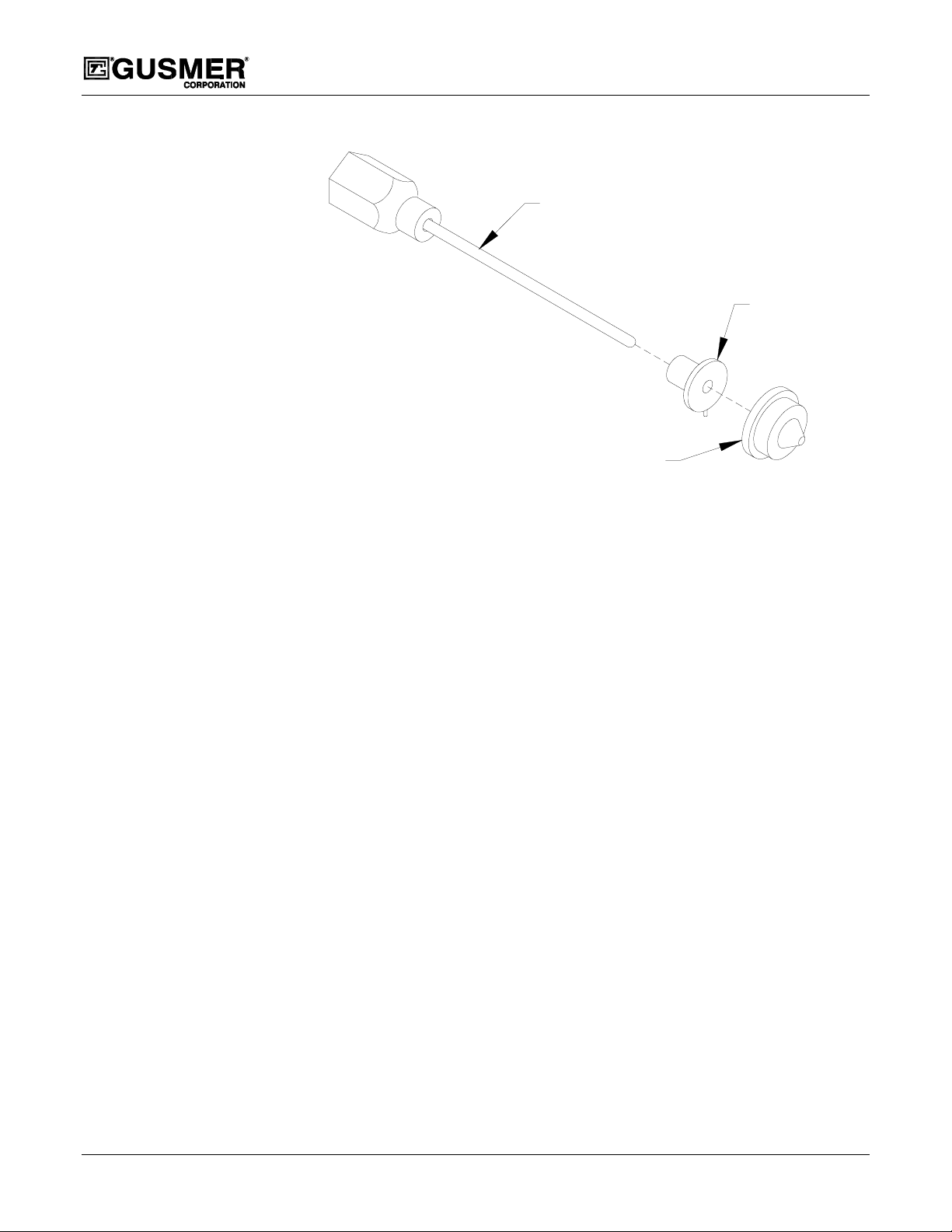

The GX-8 is a combination of newconcepts and existing Gusmer spray gun technology.

For example, the mixing module that is contained in the GX-8 is similar in function to the

GX-7 mixing module. However, it is very different in its final design. The module’s

modified geometry supports the mixing requirements of the extremely fast chemistries

found in polyureas and hybrid polyurethanes/polyurea. This coupled with a smaller

mechanical purge valving rod and smaller PCD insure proper mixing and timely delivery

of mixed product to the work surface. The PCD now comes standard with Gusmer’s

proprietary “gold tip” finish. This space age coating improves the non-sticking

characteristics of the tip, while simultaneously improving its durability. With improved

tip durability maintaining the spray pattern, whether round or fan shaped, for longer

periods is possible. This equates into longer tip life for the user.

The Mixing Module is the only part that requires routine replacement to insure proper gun

operation. This inexpensive plastic component will wear out through normal use. The

module incorporates a small alignment pin, which insures proper chemical port alignment

during insertion into the Gun Block. The Mixing Module is a precision-machined

component made of a proprietary engineering thermoplastic. It is cleaned using an air

pressurized Gun Cleaning Kit. However, even if irregularly serviced it can still be

cleaned using the appropriate drill bit. The Valving Rod is precision ground and made

from hardened tool steel. It is designed for long life and under normal use, will not

require routine replacement.

4/21/99 7

Page 8

VALVING ROD

ASSEMBLY

PATTERN

CONTROL

DISC (PCD)

Figure 1. Mixing Module

Model GX-8 Spray Gun

MIXING

MODULE

The GX-8 has been designed for low output spraying performance, durability, reliability,

and serviceability. In order to enable the gun to dispense extremely low levels of

chemical, the Mixing Module has precision-machined chemical ports incorporated into it.

To protect these ports from clogging extremely fine screen mesh filters are used. Special

material coatings and material finishing techniques were also incorporated into the design.

A thorough understanding of this manual is essential to completely insure that this gun

provides the best service possible. In addition, the experience gained through daily use of

the gun will sharpen your operational and service skills. Functional problems can be

significantlyreduced by following the techniques and service recommendations described

in this manual.

Gusmer and our Authorized Distributors have experienced, highly qualified, technical

representatives who are always available to help if a problem does occur. In most cases, a

simple telephone call to our technical representatives will provide you with a solution to

your problem. Be sure to take advantage of their experience and expertise.

IMPORTANT: Substitution of parts not designed manufactured, or recommended by

Gusmer could result in harm to the user and/or damage to the GX-8 Gun. Any

alterations to or substitutions for Gusmer parts will void the warranty provisions set

forth elsewhere in this manual

8 32943-1, Issue 1

Page 9

Operating Manual Description

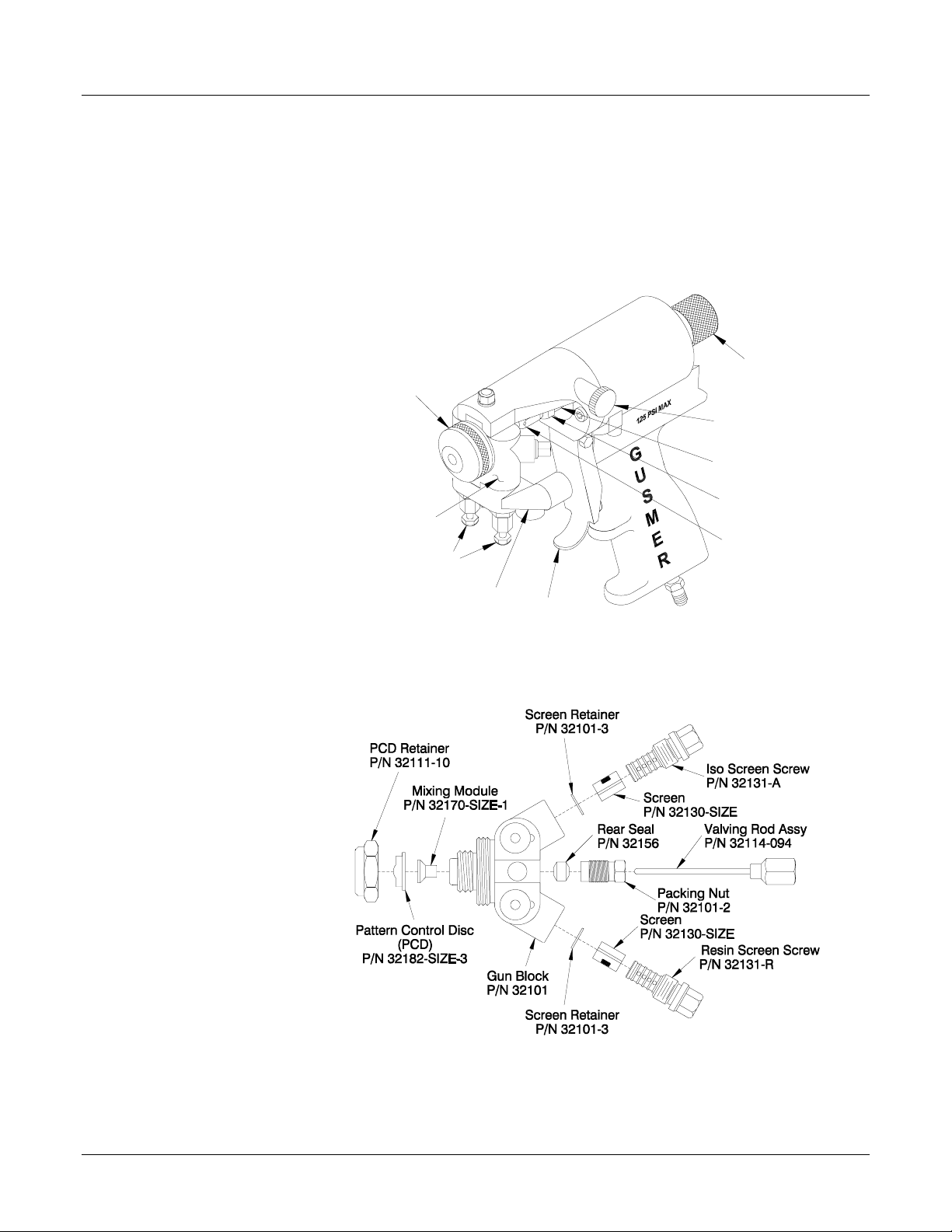

Major Components

In keeping with the need to gain a complete and thorough understanding of the

equipment, please take time to become familiar with the major components of the GX-8

Gun (Figure 2) and its Centerline Components (Figure 3). This will be helpful later when

these items are covered in the manual.

Safety Stop

Air Cap

Air Cap Air

Adjustment

Valve

Piston Rod

NOTE:

Both Round and Fan Mixing

Modules are available. The

Round Module provides a

round spray pattern and is

identified by a groove in its

cylindrical body. The Fan

Module provides a fan spray

pattern and is identified by its

smooth cylindrical body.

Gun Block

Manual Valves

CouplingBlock

Jam Nut

Valving Rod

Assembly

Trigger

Figure 2. Major Components

Figure 3. Centerline Components

4/21/99 9

Page 10

Model GX-8 Spray Gun

Equipment Supplied

The Standard Tool Kit includes the following tools for use in servicing the GX-8.

Figure 4. Standard Tool Kit

1. 10” Adjustable Wrench (P/N 909A)

2. 6” Adjustable Wrench (P/N 0908)

3. 3/8” x 5/16” Open End Wrench

(P/N 1982A)

4. 1/2” Combination Wrench(P/N 1986)

5. 5/16” Spintite (P/N 0904A)

6. Retaining Ring 45°°°° Pliers (P/N 32982)

7. 6” Pliers (P/N 0906)

8. 9/64” Ball Point Hex Key

(P/N 0902-9/64)

9. 5/32” Hex Key (P/N 0902-5/32)

10. 3/16” Hex Key (P/N 0902-3/16)

11. 5/64” Hex Key (P/N 0902-5/64)

12. Check Valve Removal/Cleaning Tool

(P/N 1948)

13. #80 Clean Out Drill (.0135 Dia.)

(P/N 0941-45)

14. #68 Clean Out Drill (.031 Dia.)

(P/N 0941-22)

15. #60 Clean Out Drill (.040 Dia.)

(P/N 0941-29)

16. 1/8” Dia. Clean Out Drill

(P/N 0927-1/8)

17. 21/64” Dia. CleanOut Drill

(P/N 0927-21/64)

18. Pin Vise W/Collets (P/N 6902A)

19. Brush (P/N 1945)

20. Flush Can (P/N 0919A)

21. Lubriplate Grease

(P/N 0553-2) Not Shown

10 32943-1, Issue 1

Page 11

Operating Manual Description

Gun Service Kits

Cleaning the GX-8 with the 1 Quart Gun Service Kit (P/N OP205) or the 3 Gallon Gun

Service Kit (P/N OP206) is essential to the proper operation of the GX-8. Both kits are

available separately.

NOTE:

For more information

concerning the 1 Quart Gun

Service Kit consult the Parts

Identification Manual

(P/N OP205-ID).

NOTE:

For more information

concerning the optional,

3 Gallon Gun Service Kit (P/N

OP206) consult the Parts

Identification Manual

(P/N OP206-ID).

Figure 5. 1 Quart Gun Service Kit (P/N OP205).

Figure 6. 3 Gallon Gun Service Kit (P/N OP206)

4/21/99 11

Page 12

Model GX-8 Spray Gun

OPERATION

WARNING: NEVER POINT THE GUN AT OR NEAR OTHER PERSONNEL OR PLACE ANYPART OF

THE BODY IN THE PATH OF THE MATERIAL SPRAY AND DO NOTAT ANYTIME LOOK INTO THE

DISPENSING END OF THE GUN

STOP TO THE SAFETY OR SERVICE POSITION

AVOID THE POSSIBILITY OF PROPERTY DAMAGE OR BODILY INJURY FROM THE ACCIDENTAL

OPERATION OF THE GUN

Safety Position of Gun

The GX-8 has a two position Safety Stop. When engaged, it prevents accidental

triggering of the gun during servicing or down time. When disengaged, it allows the gun

to dispense.

1. ENGAGE THE SAFETY STOPPush in and turn the Safety Stop knob

clockwise to place the gun in the

Safety detented position.

.WHEN THE GUN IS NOT BEING USED, ALWAYS SET THE REAR

, AND CLOSE BOTH MANUAL VALVES .DOTHISTO

.

IMPORTANT: Always engage the

Safety Stop when the gun is not in use.

2. DISENGAGE THE SAFETY STOPPush in and turn the Safety Stop knob

counterclockwise to place the gun in

the Open detented position.

Manual valves

TOOLS REQUIRED

• 5/16” Spintite (P/N 0904A)

The GX-8 Coupling Block is equipped with

two Manual Valves which control the flow

of each chemical component to the gun.

Figure 7. Engage the Safety Stop

Figure 8. Disengage the Safety Stop

1. OP EN BOTH MANUAL VALVES-

Unnecessary triggering of the gun

NOTE:

with the manual valves closed

may cause crossover if there is

any residual chemical in the gun

ports.

Using the 5/16” Spintite, turn each

Manual Valve fully counterclockwise.

2. CLOSE BOTH MANUAL VALVESUsing the 5/16” Spintite, turn each

Manual Valve fully clockwise.

Figure 9. Manual Valves

12 32943-1, Issue 1

Page 13

Operating Manual Operation

IMPORTANT: To avoid accidental gun operation determine that the coupling block

manual valves have been closed before attempting to service the gun, or any time the

gun is not in use.

Air Line Configuration

TOOLS REQUIRED

• 3/16” Hex Key (P/N 0902-3/16)

• 6” Adjustable Wrench (P/N 0908)

The GX-8 air line connection can be configured in two different ways. The standard

configuration has the air connection at the base of the handle. The optional configuration

has the air connection at the rear of the gun. To change to the optional configuration

proceed as follows:

1. REMOVE THE 4“ LONG PIPE NIPPLE- Using the 6” Adjustable Wrench, remove

the 4“ long pipe nipple from the base of the Gun.

2. REMOVE THE 1/8” PIPE P LUG- Using the 3/16” Hex Key, remove the 1/8” pipe

plug from the rear of the gun.

Start-Up

NOTE:

If the GX-8 is shipped from the

factory withoutthe Mixing Module

andPCDinstalledtheValvingRod

will require adjustment. See the

Valving Rod Adjustment section of

the manual.

3. INSTALL THE 1/8” PIPE PLUG- Using the 3/16” Hex Key, install the 1/8” pipe

plug in the location previously occupied by the 4“ long pipe nipple.

4. INSTALL THE (OPTIONAL) SUPPLIED BRASS 1/8” NIPPLE- Using the 6”

Adjustable Wrench, install the supplied brass 1/8” nipple in the location previously

occupied by the 1/8” pipe plug.

TOOLS REQUIRED

• 5/16” Spintite (P/N 0904A)

IMPORTANT: Before attempting the following procedures, make sure the gun is

attached to the coupling block and air hoses, the proportioning unit is at the desired

temperature and pressure, and the system is ready for operation.

1. ADJUST THE AIR VALVE AIR ADJUSTMENT CAP CONTROL- The Knurled

knob on the Air Cylinder controls the amount of air that passes over the PCD. This

flow of air helps keep the PCD free of sprayed chemical. Too much air can

adversely effect spray pattern shape and create undesirable amounts of over-spray.

However, the airflow can be used to modify the spray pattern. Experiment to

determine what works best for the application.

Turn the knob Counter clockwise to open the valve and clockwise to close it.

2. OPEN BOTH MANUAL VALVES- Using the 5/16” Spintite, turn each valve fully

counterclockwise.

3. DISENGAGE THE SAFETY STOP- Push in and turn the Safety Stop knob

counterclockwise to place the gun in the Open detented position.

4. TEST SPRAY OFF TARGET

4/21/99 13

Page 14

Model GX-8 Spray Gun

Shutdown

TOOLS REQUIRED

• 5/16” Spintite (P/N 0904A)

IMPORTANT: Follow this procedure whenever the gun is out of service for any

length of time. For mid/end of day, service see the Cleaning Procedure section of this

manual.

1. ENGAGE THE SAFETY STOP- Push in and turn the Safety Stop knob clockwise to

place the gun in the Safety detented position.

2. CLOSE BOTH MANUAL VALVES- Using the 5/16” Spintite, turn each valve fully

clockwise.

Disassembling the gun daily for

NOTE:

cleaning is not recommended if it

has been operating properly.

However, experience will

determine whether disassembly is

necessary

3. CLEAN AS REQUIRED- See the Cleaning Procedure section of the manual.

IMPORTANT: As an additional safety precaution, the GX-8 air line has quick

disconnect air coupling. Disconnect the air line when transporting the gun with the

chemical hoses connected

14 32943-1, Issue 1

Page 15

Operating Manual Cleaning Procedure

CLEANING PROCEDURE

TOOLS REQUIRED

• 5/16” Spintite (P/N 0904A)

• 1 Quart Gun Service Kit (P/N OP205)

• Flush Can (P/N 0919A)

The Gun Block must be thoroughly cleaned with Gun Cleaner before removing the

Valving Rod or mixing components from the Gun Block. In this way, the residue left

from the two components will be completely diluted with Gun Cleaner and will not react

with one another when the Gun Block components are removed.

This procedure makes use of the 1 Quart Gun Service Kit (P/N OP205) and is the

recommended procedure for several reasons:

1) The cleaning is more efficient and uses less Gun Cleaner.

2) The gun does not have to be disassembled.

3) It can be used as a quick and efficient end of day procedure.

The 3 Gallon Gun ServiceKit (P/N OP206) is also available for cleaning the GX-8.

WARNING: PROPERLYGROUND ALL EQUIPMENT INVOLVEDIN THE CLEANING OPERATION

TO AVOID STATIC SPARKING WHICHCOULD RESULT IN FIRE OR EXPLOSION.DO NOT CLEAN ON

OR NEAR FOAMED OR COATEDSURFACES

.

WARNING: WHENSERVICING OR OPERATING THE GX-8, SUFFICIENT PROTECTIVE CLOTHING

MUST BE WORN TO PREVENT PROLONGED SKIN CONTACT WITH THECHEMICALS OR SOLVENTS

USED IN OR WITH THE GUN

A

LWAYS WEAR APPROVED SAFETY GLASSES OR GOGGLES,GLOVES, AND RESPIRATORY

EQUIPMENT WHEN SERVICING OR OPERATING THE

.

GX-8.

1. CLOSE BOTH MANUAL VALVES- Using the 5/16” Spintite, turn each Manual

Valve fully clockwise.

2. ENGAGE THE SAFETY STOP- Push in and turn the Safety Stop knob clockwise to

place the gun in the Safety detented position.

3. REMOVE THE GUN FROM THE COUPLING BLOCK- Using the 5/16" Spintite;

remove the Coupling Block Mounting Screw. Separate the gun from the Coupling

Block. Using a rag soaked with Gun Cleaner wipe clean the face of the Coupling

Block to prevent material build-up.

4. ATTACH THE SERVICE BLOCK OF THE GUN SERVICE KIT TO THE GUN–

Using the 5/16” Spintite; fasten the Service Block to the gun. Pressurize the

container to 100 psi.

4/21/99 15

Page 16

Model GX-8 Spray Gun

Opening one manual valve at a

NOTE:

time will allow flushing of

individual chemicals. This is

useful when flushing high

viscosity materials and insures

maximum effectiveness in purging

the gun of chemical.

5. CLEAN THE GUN

a) Open either one of the Manual Valves on the Service Block

b) Disengage the Safety Stop by pushing in and turning the Safety Stop

Knob counterclockwise to place the gun in the Open detented position.

c) Trigger the Gun Service Kit and the Gun simultaneously catching the

Gun Cleaner in an appropriate container.

(A fine, unobstructed mist of cleaner should exit the Tip.)

d) Release both triggers and close the Manual Valves on the Service

Block.

e) Repeat the P rocedure for the other side of the Gun.

6. REMOVE THE SERVICE BLOCK OF THE GUN SERVICE KIT FROM THE

GUN– Using the 5/16” Spintite; disconnect the Service Block from the gun.

7. CLEAN SCREENS AND SCREEN SCREW- Using the Flush Can, flush out the

Screens and the Screen Screw Cavities completely

.SeetheScreen Screw Service

Procedure section of this manual

Important: At this time it is a good idea to inspect the Air Cap, PCD, Module, and

Gun Block for build up of material and clean them as required.

16 32943-1, Issue 1

Page 17

Operating Manual Servicing Procedures

SERVICING PROCEDURES

Screen Screw Removal And Service Procedure

TOOLS REQUIRED

• 3/8” x 5/16” Open End Wrench (P/N 1982A)

• 1/8” Dia. (P/N 0927-1/8) Clean Out Drill

• 21/64” Dia. (P/N 0927-21/64) Clean Out Drill

• Pin Vise W/Collets (P/N 6902A)

• Flush Can (P/N 0919A)

WARNING:

KIT PRIOR TO REMOVAL FOR SERVICING AS THEYARE EXPOSED TO THE CHEMICAL.SEE THE

CLEANING PROCEDURES SECTION OF THIS MANUAL.

1. REMOVE THE SCREEN SCREW ASSEMBLY- Using the 3/8” x 5/16” Open End

Wrench, unthread the Screen Screw fromthe Gun Block. Remove the Screen Screw

retainer, the small ring-like part at the bottom of the screen, before removing the

screen. Remove the Retainer by hand. Now, slide off the Screen. If there are solid

particles attached to the Screen, attempt to soak the screen in Gun Cleaning Solvent.

However, if the screen is especially dirty and clogged, it is better to replace it.

2. CLEAN THE SCREEN SCREW CAVITY- Inspect the cavity, if any

visible remove themwith a combination of the Clean Out Drills mentioned above and

Cleaning Solvent.

WARNING:

WILL GO DIRECTLY INTO THE MODULE AND PROBABLY CLOG IT.

3. REPLACE THE SCREEN SCREW- Using the 3/8” x 5/16” Open End Wrench,

replace the Screen Screw. Make sure the screw is tight to insure the integrity of this

metal to metal seal.

4. CLEAN THE GUN- Clean the gun after cleaning the Cavities and Screens. See the

Cleaning Procedure section of this manual. In this case, flush the gun with the

module removed. This insures that all particles are expelled from the gun block and

prevents blockage of the module ports.

BE SURE TO CLEAN THE “CENTER LINE COMPONENTS” USING THE GUN SERVICE

particles are

ANY MATERIAL LEFT IN THE CAVITY ON THE DOWNSTREAM SIDE OF THE SCREEN

4/21/99 17

Page 18

Centerline Component Removal

TOOLS REQUIRED

• 10” Adjustable Wrench (P/N 909A)

• 3/8” x 5/16” Open End Wrench (P/N 1982A

• 1/2” Combination Wrench (P/N 1986)

• 5/16” Spintite (P/N 0904A)

• Lubriplate Grease (P/N 0553-2)

The Center Line Components consist of the following:

Screen Retainer

PCD Retainer

Mixing Module

Rear Seal

Screen

Valving Rod

Assembly

Model GX-8 Spray Gun

Iso Screen

Screw

Packing Nut

Pattern Control Disc

(PCD)

Gun Block

Screen

Resin Screen

Screw

Jam Nut

Screen Retainer

Figure 10. Centerline Component Removal

WARNING: DISCONNECT THE CHEMICAL HOSES AND AIRLINEBEFORE SERVICING THE GUN.

IN ADDITION, BE SURE TO CLEAN THE “CENTER LINE COMPONENTS” WITH THE GUN SERVICE

KIT PRIOR TO REMOVAL FOR SERVICING AS THEY ARE EXPOSED TO THE CHEMICAL

1. CLOSE BOTH MANUAL VALVES- Using the 5/16” Spintite, turn each Manual

Valve fully clockwise.

2. ENGAGE THE SAFETY STOP- Push in and turn the Safety Stop knob clockwise to

place the gun in the Safety detented position.

3. REMOVE THE AIR CAP- Rem ove the Air Cap by hand.

4. REMOVE PCD RETAINER-Use the 10” Adjustable Wrench, to remove the PCD

Retainer.

5. REMOVE THE PATTERN CONTROL DISC (PCD)- Lift the PCD off the nose of

the Gun Block.

18 32943-1, Issue 1

Page 19

Operating Manual Servicing Procedures

Important: To free a PCD that appears to be stuck, set the Safety Stop to the Open

position, then depress and release the gun trigger to unseat it.

6. REMOVE THE MIXING MODULE- Reconnect the air line. Disengage the Safety

Stop and depress the trigger and release. The Mixing Module should unseat itself

from the Gun Block. Lift the Mixing Module off the end of the Valving Rod.

Engage the Safety Stop and disconnect the air line.

Important: Do not attempt to dig out the Module using knives or sharp objects.

7. LOOSEN THE PACKING NUT-Using the 5/16” Wrench, back out the Packing Nut

threeorfourturns.

NOTE:

By removing the Packing Nut

entirely the Rear Seal can be

removed and replaced.

8. REMOVE THE GUN BLOCK- Using the 5/16” Spintite, remove the Gun Block

Retaining Screw. Carefully slide the Gun Block away from the Valving Rod and Air

Cylinder. If dried chemical has built up on the Gun Block removal may be difficult.

Removing the dried chemical will make removal easier. Be careful not to lose the

small “O” Ring seal located in the top if the Gun Block.

9. REMOVE THE VALVING ROD- Using the 3/8” Wrench, on the hex shaped

Valving Rod Shank and the ½” Wrench on the Jam Nut loosen the Jam Nut by

turning it clock wise. (As viewed from the front of the gun.) Continue to back the

Jam Nut away from the Valving Rod Shank by three or four full turns. Remove the

Valving Rod by unthreading it from the Piston Assembly.

10. CLEAN ALL COMPONENTS THOROUGHLY BEFORE REASSEMBLY- Using

the appropriate Brass Brushes, Clean Out Drills, etc. remove residual chemical. Use

Cotton Swabs soaked with Gun Cleaner if necessary. W hen finished, coat the

threads and the mating surfaces

of the Gun Block, Gun Block Bracket, and Gun with

Lubriplate Grease. Do not get any grease in the chemical ports located in the Gun

Block or Mixing Module as this could interfere with chemical flow.

11. INSPECT THE GUN BLOCK- It is important to keep the Gun Block clean and free

from damage to insure proper operation of the Spray Gun. It has been coated with a

proprietary coating to help protect it fromdamage and make it more difficult for

chemical to adhere to it. However, it still requires periodic attention.

4/21/99 19

Page 20

Centerline Component Installation

TOOLS REQUIRED

• 10” Adjustable Wrench (P/N 909A)

• 3/8” x 5/16” Open End Wrench (P/N 1982A

• 1/2” Combination Wrench (P/N 1986)

• 5/16” Spintite (P/N 0904A)

The Center Line Components consist of the following:

Screen Retainer

PCD Retainer

Mixing Module

Rear Seal

Screen

Valving Rod

Assembly

Model GX-8 Spray Gun

Iso Screen

Screw

Packing Nut

Pattern Control Disc

(PCD)

Gun Block

Screen

Resin Screen

Screw

Jam Nut

Screen Retainer

Figure 11. Centerline Component Installation

1. INST ALL THE VALVING ROD- Thread the Jam Nut as far back on the Piston Rod

as possible. Screwthe shank end of the Valving Rod onto the threaded end of the

Piston Rod.

2. INSTALL THE GUN BLOCK- Carefully slide the Gun Block onto the Valving Rod

towards the Air Cylinder. Using the 5/16” Spintite, install the Gun Block onto the

Gun Block Mounting Bracket.

3. INSTALL THE MIXING MODULE- With the air line connected, depress the Gun

Trigger Lever and slide the Mixing Module over the end of the Valving Rod while

making sure its alignment pin enters the alignment slot in the Gun Block. Keep the

Gun Trigger Lever depressed and proceed to Step 4.

Important: It is extremely important that these parts align properly. If they do not

the chemical flow from the Gun Block ports will not enter the Mixing Module when

triggering the gun

4. INSTALL THE PATTERN CONTROL DISC (PCD)- Maintain the Gun Trigger

Lever in the depressed position and place the PCD over the Mixing Module while

making sure the slot in the tip aligns with the Mixing Module alignment pin. If

installing a fan tip decide what orientation the fan spray pattern needs (vertical or

horizontal), and orient the PCD appropriately. Keep the Gun Trigger Lever

depressed and proceed to Step 5.

20 32943-1, Issue 1

Page 21

Operating Manual Servicing Procedures

5. INSTALL THE PCD RET AINER- With the Gun Trigger Lever depressed, thread

the PCD Retainer in place by hand. Using the 10” Adjustable Wrench carefully

tighten the PCD Retainer until it is “snug” to insure no leaking will occur when

pressurized chemical is introduced in to the gun. Release the Trigger.

Gun Block

WARNING:OVER TIGHTENING, THE PCD RETAINER

WILL CAUSE DAMAGE TO BOTH THE MODULE AND THE

GUN BLOCK.

Module

PCD

Important: When installing the Mixing Module

and/or the PCD a space approximately the

thickness of a business card should be between

the PCD and the tip of the Gun Block.

6. INSTALL THE AIR CAP- Thread the Air Cap

Space

in place by hand.

Figure 12. PCD Spacing

7. ADJUST THE VALVING ROD- See the Valving Rod Adjustment section of this

manual

Valving Rod Adjustment

TOOLS REQUIRED

• 3/8” x 5/16” Open End Wrench (P/N 1982A)

• 1/2” Combination Wrench (P/N 1986)

• 5/16” Spintite (P/N 0904A)

The GX-8 Valving Rod should not require adjustment if it was shipped from the factory

with the Mixing Module and Spray Tip installed. The Valving Rod will require adjusting

in the following instances:

• Changing a Piston/Rod assembly/replace O-Ring

• Changing a Valving Rod

• Installing or changing a Spray Tip

• Installing or changing a Mixing Module

WARNING: DISCONNECT THE CHEMICAL HOSES AND AIRLINEBEFORE SERVICING THE GUN.

IN ADDITION, BE SURE TO CLEAN THE “CENTER LINE COMPONENTS” WITH THE GUN SERVICE

KIT PRIOR TO REMOVAL FOR SERVICING AS THEYARE EXPOSED TO THE CHEMICAL

1. ENGAGE THE SAFETY STOP- Push in and turn the Safety Stop knob clockwise to

place the gun in the Safety detented position.

2. CLOSE BOTH MANUAL VALVES- Using the 5/16” Spintite, turn each Manual

Valve fully clockwise.

4/21/99 21

Page 22

Model GX-8 Spray Gun

3. REMOVE THE GUN FROM THE COUPLING BLOCK- Using the 5/16" Spintite;

remove the Coupling Block Mounting Screw. Separate the gun from the Coupling

Block. Using a rag soaked with Gun Cleaner wipe clean the face of the Coupling

Block to prevent material build-up.

4. PRESSURIZE THE AIR

CYLINDER- After making sure that

the Safety Stop is engaged, connect

the air line from the gun to the air

source.

5. LOOSEN REAR PACKING NUTUsing the 5/16” Open-End Wrench,

back out the Packing Nut three or

four turns. This will eliminate the

contact pressure between the Seal,

located inside the Packing Nut, and

the Valving Rod. With the pressure

relieved, the Valving Rod will move

freely making the adjustment

procedure easier to perform.

Figure 13. Valving Rod Adjustments

6. LOOSEN THE JAM NUT- Using the 3/8” Wrench, on the hex shaped Valving Rod

Shank and the ½” Wrench on the Jam Nut loosen the Jam Nut by turning it

clockwise. (As viewed from the front of the gun.) Continue to back the Jam Nut

away from the Valving Rod Shank by three or four full turns. Now move the

Valving Rod towards the Gun Cylinder by turning the Valving Rod Shank 2 or 3 full

turns clockwise.

7. ADJUST VALVING ROD CLEARANCE- Slowly turn the Valving Rod counter

clockwise, moving it forward towards the Spray Tip until resistance is felt. Go no

further. The Valving Rod Tip contacting the inside spherical surface of the PCD

causes this resistance.

8. LOCK ADJUSTMENT IN PLACE- While carefully maintaining the position of the

3/8” Wrench; tighten the Jam Nut up against the Valving Rod Shank.

9. RETIGHTEN THE PACKING NUT- Using the 3/8” x 5/16” Open End Wrench,

retighten the Packing Nut.

10. CHECK THE REAR SAFETY STOP- Disengage the Safety Stop by pushing in and

turning the knob counter clockwise. If the knob will not turn, the Valving Rod is

adjusted too far forward. Repeat step 6 and 7 making sure not to adjust the Valving

Rod past the point where resistance is felt. Once the SafetyStop moves freely,

proceed to step 11.

11. CONFIRM REAR SEAL ADJUST MENT- With the Safety Stop disengaged trigger

the gun. Make sure the Valving Rod moves freely. If it does not, loosen the Packing

Nut slightly until it does. Once spraying has started, make sure there is no chemical

weeping from the Packing Nut. If there is, retighten it slightly.

22 32943-1, Issue 1

Page 23

Operating Manual Servicing Procedures

Air Piston O-Ring and Cup Seal Replacement

TOOLS REQUIRED

• 3/8” x 5/16” Open End Wrench (P/N 1982A)

• 1/2” Combination Wrench (P/N 1986)

• RetainingRing 45º Pliers (P/N 32982)

• 6” Pliers (P/N 0906)

• 9/64” Ball Point Hex Key (P/N 0902-9/64)

• 5/32” Hex Key (P/N 0902-5/32)

• 3/16” Hex Key (P/N 0902-3/16)

• 5/16” Spintite (P/N 0904A)

NOTE:

If only the End Cap O-Ring

requires replacement see the

End Cap O-Ring and Cup Seal

Replacement section of this

manual.

WARNING: D

ISCONNECT THE CHEMICAL HOSES AND AIRLINE BEFORE SERVICINGTHE GUN.

IN ADDITION, BE SURE TO CLEAN THE “CENTER LINE COMPONENTS” WITH THE GUN SERVICE

KIT PRIOR TO REMOVAL FOR SERVICING AS THEYARE EXPOSED TO THE CHEMICAL

1. CLOSE BOTH MANUAL VALVES- Using the 5/16” Spintite, turn each Manual

Valve fully clockwise.

2. REMOVE THE GUN FROM THE COUPLING BLOCK- Using the 5/16" Spintite,

remove the Coupling Block Mounting Screw. Separate the gun from the Coupling

Block. Using a rag soaked with Gun Cleaner, wipe clean the face of the Coupling

Block to prevent material build-up.

3. CLEAN THE GUN- See the Cleaning Procedure section of this manual.

4. DISCONNECT AIR SUPPLY FROM GUN

5. LOOSEN PACKING NUT- Using the 3/8” x 5/16” Open End Wrench, loosen the

Packing Nut.

6. REMOVE GUN BLOCK SCREW- Using the 5/16” Spintite, remove the Gun Block

Screw.

7. REMOVE GUN BLOCK- Pull Gun Block off Valving Rod being careful not to bend

the Valving Rod.

8. REMOVE THE VALVING ROD- Using the 3/8” Wrench, on the hex shaped

ValvingRodShankandthe½”WrenchontheJamNut. LoosentheJamNutby

turning it clock wise. Continue to back the Jam Nut awayfrom the Valving Rod

Shank by three or four full turns. Remove the Valving Rod by unthreading the

Valving Rod from the Piston Rod. Remove the Jam Nut from the Piston Rod

9. DISENGAGE THE SAFETY STOP- Push in and turn the Safety Stop knob

counterclockwise to place the gun in the Open detented position.

4/21/99 23

Page 24

Model GX-8 Spray Gun

10. REMOVE SCREW- Using the 9/64” Ball Point Hex Key remove the rear #8 Socket

Head Screw that connects the Air Cylinder to the Handle. Remove only this screw.

#8 Socket Head

Cap Screw

Piston Assembly

End Cap/

Safety Stop

Assembly

Piston

Spring

Retaining Ring

NOTE:

Removing the End Cap will

require some force since the

O-Ring is tightly compressed

Figure 14. End Cap/Safety Stop Assembly and Piston Assembly Removal

11. REMOVE THE RETAINING RING- Using the Retaining Ring 45º Pliers remove

the Retaining Ring, which maintains the End Cap position in the Air Cylinder.

12. REMOVE THE END CAP/SAFETY STOP ASSEMBLY- Pull the Safety Stop until

it, and the attached End Cap come free from the Air Cylinder. Be sure to retain the

Piston Spring located inside of the Air Cylinder for future use.

13. INSPECT THE END CAP O-RING- Inspect the O-Ring. If necessary remove it and

install a newO-Ring after lightly coating it with Lubriplate Grease.

14. REMOVE THE PISTON/ROD ASSEMBLY- A second function of the Gun Block

Screw (the screw that holds the Gun Block to the Bracket) is to aid in the removal of

the Piston. The Piston is visible from the rear of The Air Cylinder. Thread the Gun

Block Screw into the hole in the center of the Piston at least four full turns. Using the

6” Pliers take hold of the Gun Block Screw and pull the Piston/Rod Assembly out of

the Air Cylinder. Inspect the O-Ring for damage and remove it if required.

Carefully reinstall the new O-Ring after applying Lubriplate Grease, taking care not

to damage it.

15. REPLACE CUP SEAL-Remove and replace the Cup Seal located in the front of the

air cylinder if air is escaping around the piston rod during operation. Lubricate the

new cup seal and install it making sure to that the “cup” is facing towards the rear of

the air cylinder.

16. REASSEMBLY OF THE PISTON INTO THE AIR CYLINDER - Insert the Piston

and Rod Assembly into the Air cylinder. Be careful not to damage the cup seal in the

front face of the Air Cylinder as the rod passes through it. Remove the Gun Block

Mounting Screw from the Piston.

24 32943-1, Issue 1

Page 25

Operating Manual Servicing Procedures

17. REASSEMBLE THE END CAP/SAFETY ASSEMBLY/PISTON SPRING- Center

the Piston Spring over the raised portion of the Piston. Line up the raised portion of

the End Cap with the inside diameter of the Piston Spring and insert the End Cap into

the Air Cylinder. Press the End Cap until it moves past the undercut groove in the

Air Cylinder. This groove is where the Retaining Ring nests. Maintain pressure on

the End Cap, making sure the groove remains visible, and install the Retaining Ring

using the Retaining Ring 45º Pliers. Reinstall the #8 Socket Head Screw.

18. REASSEMBLE VALVING ROD ASSEMBLY TO AIR PISTON SHAFT- Thread

Jam Nut as far as it will go onto the threaded end of the Piston Shaft. Make sure hex

end of the nut is facing rear. Thread the Valving Rod as far as it will go onto the

threaded portion of the Piston Rod.

19. RECONNECT THE GUN BLOCK TO GUN BRACKET- Carefully slide the Gun

Block onto the Valving Rod towards the Air Cylinder. Using the 5/16” Spintite,

install the Gun Block onto the Gun Block Mounting Bracket.

WARNING: INSERT THE RETAINING RING COMPLETELY INTO THE GROOVE SO THAT THE END

CAP WILL REMAIN IN THEAIR CYLINDER WHEN THE GUN HAS AIR PRESSURE APPLIED TO IT.

K

EEP CLEAR OF THE CAP WHEN FIRST REAPPLYING AIR PRESSURE OR TRIGGERING THEGUN

AFTER REASS E MBLY IN CASE OF IMPROPER

RETAINING RING INSTALLATION.

20. READJUST THE VALVING ROD- See the Valving Rod Adjustment section of this

manual.

End Cap O-Ring and Cup Seal Replacement

TOOLS REQUIRED

• RetainingRing 45º Pliers (P/N 32982)

• 6” Pliers (P/N 0906)

• 9/64” Ball Point Hex Key (P/N 0902-9/64)

• 5/16” Spintite (P/N 0904A)

• 5/64” Hex Key (P/N 0902-5/64)

WARNING: D

IN ADDITION, BE SURE TO CLEAN THE “CENTER LINE COMPONENTS” WITH THE GUN SERVICE

KIT PRIOR TO REMOVAL FOR SERVICING AS THEYARE EXPOSED TO THE CHEMICAL

1. CLOSE BOTH MANUAL VALVES- Using the 5/16” Spintite turn each Manual

Valve fully clockwise.

2. REMOVE THE GUN FROM THE COUPLING BLOCK- Using the 5/16" Spintite

remove the Coupling Block Mounting Screw. Separate the gun from the Coupling

Block. Using a rag soaked with gun cleaner wipe clean the face of the Coupling

Block to prevent material build-up.

ISCONNECT THE CHEMICAL HOSES AND AIRLINE BEFORE SERVICINGTHE GUN.

3. DISCONNECT AIR SUPPLY FROM GUN

4. DISENGAGE THE SAFETY STOP- Push in and turn the Safety Stop knob

counterclockwise to place the gun in the Open detented position.

4/21/99 25

Page 26

Model GX-8 Spray Gun

5. REMOVE SCREW- Using the 9/64” Ball Point Hex Key remove the rear #8 Socket

Head Screw that connects the Air Cylinder to the Handle. Remove only this screw.

#8 Socket Head

Cap Screw

Piston

End Cap/

afety Stop

Assembly

Spring

Retaining Ring

Figure 15. End Cap/Safety Stop Assembly Removal

6. REMOVE THE RETAINING RING- Using the Retaining Ring 45º Pliers remove

the Retaining Ring, which holds the End Cap in place in the Air Cylinder.

NOTE:

Removing the End Cap will

require some force since the

O-Ring is tightly compressed

7. REMOVE THE END CAP/SAFETY ASSEMBLY- Remove the End Cap and retain

the Piston Spring located inside of the Air Cylinder for future use.

8. INSPECT THE END CAP O-RING- Inspect the O-Ring. If necessary remove it and

install a newO-Ring after lightly coating it with Lubriplate Grease.

9. REMOVE THE SAFETY STOP MECHANISM- Using the 5/64” Hex Key remove

the two set screws from the knurled knob. Slide the knob off the shaft and retain the

shaft spring. Pull the shaft out of the End Cap.

10. REPLACE CUP SEAL-Remove and replace the Cup Seal located in the End Cap if

necessary. Lubricate the new cup seal and install it making sure to that the “cup” is

facing the air cylinder.

11. REINSTALL THE SAFETY STOP MECHANISM- Insert the shaft into the hole in

the End Cap. Slide the shaft spring and knob onto the shaft. Using the 5/64” Hex

Key reinstall the two set screws in the knurled knob. Make sure the knob is secure.

12. REASSEMBLE THE END CAP/SAFETY STOP ASSEMBLY/PISTON SPRINGCenter the Piston Spring over the raised portion of the Piston. Line up the raised

portion of the End Cap with the inside diameter of the Piston Spring and insert the

End Cap into the Air Cylinder. Press the End Cap until it moves past the undercut

groove in the Air Cylinder. This groove is where the Retaining Ring nests. Maintain

force on the End Cap, making sure the groove remains visible, and install the

Retaining Ring using the Retaining Ring 45º Pliers. Reinstall the #8 Socket Head

Screw.

WARNING: INSERT THE RETAINING RING COMPLETELY INTO THE GROOVE SO THAT THE END

CAP WILL REMAIN IN THEAIR CYLINDER WHEN THE GUN HAS AIR PRESSURE APPLIED TO IT.

K

EEP CLEAR OF THE CAP WHEN FIRST REAPPLYING AIR PRESSURE OR TRIGGERING THEGUN

AFTER REASS E MBLY IN CASE OF IMPROPER

RETAINING RING INSTALLATION.

26 32943-1, Issue 1

Page 27

Operating Manual Servicing Procedures

Trigger Valve O-Ring Replacement

TOOLS REQUIRED

• 5/32” Hex Key (P/N 0902-5/32)

• 3/16” Hex Key (P/N 0902-3/16)

• 6” Adjustable Wrench (P/N 0908)

• 6”Pliers (P/N 0906)

• 3/8” x 5/16” Open End Wrench (P/N 1982A)

• Pin Punch of ¼” diameter or less (Not Included in Tool Kit)

• Ball Peen Hammer (Not Included in Tool Kit)

WARNING: D

IN ADDITION, BE SURE TO CLEAN THE “CENTER LINE COMPONENTS” WITH THE GUN SERVICE

KIT PRIOR TO REMOVAL FOR SERVICING AS THEYARE EXPOSED TO THE CHEMICAL

1. CLOSE BOTH MANUAL VALVES- Using the 5/16” Spintite turn each Manual

Valve fully clockwise.

2. REMOVE THE GUN FROM THE COUPLING BLOCK- Using the 5/16" Spintite,

remove the Coupling Block Mounting Screw. Separate the gun from the Coupling

Block. Using a rag soaked with gun cleaner wipe clean the face of the Coupling

Block to prevent material build-up.

3. DISCONNECT AIR SUPPLY FROM GUN

4. REMOVE TRIGGER LEVER- Using the 6” Adjustable Wrench and the 6”Pliers

remove the Screw and Locknut that hold the Trigger Lever in place. Remove the

Trigger Lever.

5. REMOVE RETAINER NUT- Using the 3/8” end of the 3/8” x 5/16” Open End

Wrench, remove the Valve Retainer Nut. This is the hex shaped nut that surrounds

the brass Spool Valve and holds it in place.

ISCONNECT THE CHEMICAL HOSES AND AIRLINE BEFORE SERVICINGTHE GUN.

Figure 16. Trigger/Air Valve Assembly

4/21/99 27

Page 28

Model GX-8 Spray Gun

NOTE:

RefertoFigure16forsteps6

through 17.

NOTE:

Follow Steps 8 through 16 to

replace the O-rings on the

Valve Liner. If they do not

need replacing go to step 17.

NOTE:

If the Gun is configured with

the air supply entering

through the rear of the Gun

Handle, as opposed to the

bottom of the Gun Handle,

remove the brass 1/8” pipe

nipple instead of the 1/8” Plug.

(See Figure 16)

6. REMOVE THE VALVE SPOOL- In order to replace the O-Rings located on the

Valve Spool take hold of the end of the Spool and pull it out. Be careful extracting

the Spool as a spring will come out with it. Make sure not to loose this spring as it

belongs in the hole at the end of the Spool. Replace the O-Rings and applya thin

coat of Lubriplate to the O-Rings

7. REMOVE THE VALVE LINER- Attempt to pull the Valve Liner out of the gun

handle through the trigger hole. If successful, proceed to Step11. If the Valve Liner

can not b e removed, proceed to Step 8.

8. REMOVE REAR 1/8” PLUG- In the rear of the Gun Handle locate the 1/8” Pipe

Plug. This plug seals one of the air flow paths located internally in the Gun Handle.

Using the 3/16” Hex Key, remove the Plug.

9. REMOVE THE REAR INTERNAL 1/16” PIPE PLUG- Deeper in the hole that the

1/8” Plug was removed from locate the 1/16” Pipe Plug. This Plug seals yet another

airflow located internallyin the Gun Handle. Remove that Plug using the 5/32” Hex

Key.

10. REMOVE THE SPRING SEAT- Lookinginto the hole from which both Plugs were

removed the brass surface of the Spring Seat can be seen. Using a Pin Punch of ¼”

diameter or less, and a hammer, gently tap the Spring Seat until both it and the Valve

Liner are pushed out the opposite end of the hole.

11. REMOVE & REPLACE THE O-RINGS- Remove and replace the four O-Rings on

the Liner. Apply a light coat of Lubriplate to the O-Rings.

NOTE:

If the Gun is configured with

the air supply entering

through the rear of the Gun

Handle, reinstall the brass 1/8”

pipe nipple instead of the 1/8”

Plug. (See Figure 16)

12. CLEAN THE VALVE HOLE AND REMOVE ANY DEBRIS- After insuring hole is

free of anydirt or debris apply a thin coat of Lubriplate to the inside of the hole.

13. REINSTALL THE SPRING SEAT- Slide the brass Spring Seat back into the Gun

Handle Air Valve hole tapered end first until it bottoms out in the hole.

14. REINSTALL THE VALVE LINER- Push in the brown Valve Liner as far as it will

go. Since there is interference between the O-rings on the Valve Liner and the inside

diameter of the hole a fair amount of resistance will be encountered. Once the Liner

has been pushed in far enough two or three internal threads will be visible. These

threads will allow engagement of the Valve Retainer Nut which when screwed in,

will align the Valve Liner and Spool to their proper depth.

15. REINSTALL T HE 1/16” PLUG- Using the 5/32” Hex Key screw the 1/16” Pipe

plug back in place. Apply a small amount of pipe thread sealant to the threads prior

to insertion. This will help seal the threads and prevent air leaks.

16. REINSTALL THE 1/8” PLUG- Applya small amount of pipe thread sealant to the

threads of the Pipe Plug or Hex Nipple. Using the 3/13” Hex Key reinsert the 1/8”

Pipe Plug.

17. REINSTALL THE VALVE SPOOL- Insert the Valve Spool, with the Valve Spool

Spring in place into the Valve Liner. Screw in the Valve Retainer Nut. Be careful

not to over tighten it, just tighten until it is “snug”.

18. REASSEMBLE THE TRIGGER LEVER- Reinstall the Trigger Lever using the

Screw and Lock Nut. Tighten using the 6” Adjustable Wrench and the 6”Pliers.

28 32943-1, Issue 1

Page 29

Operating Manual Appendix

APPENDIX

Specifications

US Metric

NOTE:

Actual outputs will be

dependent on material

viscosities, temperatures,

pressures, and Air Cap

velocity settings.

Maximum Output:

Minimum Output

Maximum Operating

Pressure:

Air Supply

Mixing

Weight:

Dimensions:

4 lbs./min 1.8 kg/min

1 lbs./min .45 kg/min

3500 psi 240 bar

100-125 psi 7-9 bar

Internal Impingement; Airless Atomization Solvent Free,

Mechanically Self-Cleaning

Less than 2.3 lbs. 1.04 kg

H=7"/W=7.5"/D=2.5" H=17.8cm/W=19cm/D=6.25

cm

4/21/99 29

Page 30

Model GX-8 Spray Gun

30 32943-1, Issue 1

Page 31

Operating Manual Instruction Manual Discrepancy Report

INSTRUCTION MANUAL DISCREPANCY REPORT

Field

Number

1

2

3

4

5

6

7

Field Title Description

Date

Name

IM Numb er

Issue Number

Date of Issue

Page Number

Discrepancy

Instructions:

Complete the above fields of the form by following the instructions listed on the reverse side of this sheet and mail to:

Gusmer Corporation

One Gusmer Drive PO Box 2055

Lakewood, NJ 08701

4/21/99 31

Page 32

Model GX-8 Spray Gun

Field

Number

1

2

3

4

5

6

7

Field Title Description

Date

Enter date report is submitted.

Name

IM Numb er

Issue Number

Enter name of person making report.

Enter the Part Number of the Instruction Manual from the title page.

Enter the Issue number of the Instruction Manual from the title page. If there is no

issue number enter NONE.

Date of Issue

Enter the date of Issue of the Instruction Manual from the title page. If there is no

issue date, enter NONE.

Page Number

Discrepancy

Enter the page number containing the discrepancy

Provide a brief description of discrepancy

NOTE: You may send a marked copy of the page as an attachment to your

submittal.

32 32943-1, Issue 1

Loading...

Loading...