Page 1

"Teamwork & Communication"

Model FF-1600

without Heat

Operating Manual

17942C-1

January 7, 2000

Issue 1

GUSMER CORPORATION

A Subsidiary of Gusmer Machinery Group, Inc.

One Gusmer Drive

Lakewood, New Jersey, USA 08701-8055

Toll Free 1-800-367-4767 (USA & Canada)

Phone: (732) 370-9000

Fax: (732) 905-8968

Copyright 2000, GUSMER CORPORATION

http://www.gusmer.com

®

®

NOTICE: This manual contains important information for your GUSMER equipment. Read and retain for future reference.

Page 2

Model FF-1600 with out Heat

NOTICE:

The equipment described in this technical manual must only be operated or serviced by properly trained individuals,

thoroughly familiar with the operating instructions and limitations of the eq uipment. For technical service, call your local

distributor. Call: 1-800-FOR-GSMR (1-800-367-4767) for the name and telephone number of your local distributor.

NOTICE:

All statements, information and data given herein are believed to be accurate and reliable but are presented without guarantee,

warranty or responsibility of any kind expressed o r implied. Sta tements or suggestions conce rning p ossible use of GUSME R

equipment are made without representation or warranty that any such use is free of patent infringement, and are not

recommendations to infringe any patent. The user should not assume that all safety measures are indicated or that other

measures may not be required.

2 17942C-1, Issue 1

Page 3

Operating Manual General Safety Information

CONTENTS

LIST OF FIGURES..........................................................................................................4

WARRANTY.....................................................................................................................5

GENERAL SAFETY INFORMATION..........................................................................6

CCEPTABLE EQUIPMENT USES....................................................................................... 6

A

O

PERATIONAL SAFETY PROCEDURES...............................................................................7

DESCRIPTION OF CONTROLS...................................................................................8

SPECIFICATIONS.........................................................................................................10

INITIAL MACHINE SET-UP.......................................................................................11

A

IR PURGE.....................................................................................................................13

NORMAL OPERATING PROCEDURES...................................................................14

AILY START-UP PROCEDURE .......................................................................................14

D

D

AILY SHUT-DOWN PROCEDURE................................................................................... 14

TROUBLESHOOTING PROCEDURES.....................................................................15

ENERAL INFORMATION................................................................................................15

G

P

ROPORTIONING SYSTEM...............................................................................................16

Solutions....................................................................................................................16

MAINTENANCE............................................................................................................19

UMP LUBE SYSTEM......................................................................................................19

P

I

NLET FILTER SCREEN....................................................................................................20

P

ROPORTIONING PUMPS.................................................................................................21

P

UMP BASES ..................................................................................................................21

NOTES.............................................................................................................................22

INSTRUCTION MANUAL DISCREPANCY REPORT............................................23

01/07/00 3

Page 4

Model FF-1600 with out Heat

LIST OF FIGURES

FIGURE 1 MODEL 17000C-1 PROPORTIONING UNIT............................................................ 8

F

IGURE 2 HOSE CONNECTION LOCATIONS ......................................................................... 12

F

IGURE 3 HOSE CONNECTION STEP (A)............................................................................. 12

F

IGURE 4 HOSE CONNECTION STEP (B)............................................................................. 12

F

IGURE 5 PUMP LUBE CUP LOCATION............................................................................... 13

F

IGURE 6. PROPORTIONING PUMP FEATURES................................................................... 16

4 17942C-1, Issue 1

Page 5

Operating Manual Contents

WARRANTY

Gusmer Corporation (Gusmer) provides a limited warranty to the original purchaser (Customer) of

Gusmer manufactured parts and equipment (Product) against any defects in material or

workmanship for a period of one year from the date of shipment from Gusmer facilities.

In the event Product is suspected to be defective in material or workmanship, it must be returned to

Gusmer, freight prepaid. If Product is found to be defective in material or workmanship, as

determined solely by Gusmer, Gusmer will issue full credit to Customer for the freight charges

incurred in returning the defective Product, and either credit will be issued for the replacement cost

of the Product or a replacement part will be forwarded no-charge, freight prepaid to Customer.

This warranty shall not apply to Product Gusmer finds to be defective resulting from: installation,

use, maintenance, or procedures not accomplished in accordance with our instructions; normal

wear; accident; negligence; alterations not authorized in writing by Gusmer; use of “look alike”

parts not manufactured or supplied by Gusmer; or Product used in conjunction with any other

manufacturer's pumping or proportioning equipment. Further, the terms and conditions of this

warranty shall not apply to services or repairs made to Product by any third party not authorized in

writing by Gusmer. For such Product, a written estimate will be submitted to Customer at a

nominal service charge, itemizing the cost for repair. Disposition of Product will be done in

accordance with the terms stated on the written estimate.

The warranty provisions applied to product that are not manufactured by Gusmer will be solely in

accordance with the warranty provided by the original manufacturer of the product.

GUSMER M AKES NO WARR ANTY WHATS OEV ER AS TO THE M ERCH AN TABI LITY OF,

OR SUITABILITY FOR, ITS PRODUCT TO PERFORM ANY PARTICULAR PURPOSE.

CREDIT FOR, OR REPLACEMENT OF, PRODUCT DEFECTIVE IN MATERIAL OR

WORKMANSHIP SHALL CONSTITUTE COMPLETE FULFILLMENT OF GUSMER

OBLIGATIONS TO CUSTOMER. NO OTHER WARRANTY, EXPRESSED OR IMPLIED ON

ANY PRODUCT IT MANUFACTURES AND/OR SELLS, WILL BE RECOGNIZED BY

GUSMER UNLESS SAID WARRANTY IS IN WRITING AND APPROVED BY AN OFFICER

OF GUSMER.

Under no circumstances shall Gusmer be liable for loss of prospective or speculative profits, or

special indirect, incidental or consequential damages. Further, Gusmer shall have no liability for

any expenses including, but not limited to personal injury or property damage resulting from failure

of performance of the product, use of the product, or application of the material dispensed through

the product. Any information provided by Gusmer that is based on data received from a third

source, or that pertains to product not manufactured by Gusmer, while believed to be accurate and

reliable, is presented without guarantee, warranty, or responsibility of any kind, expressed or

implied.

Gusmer through the sale, lease, or rental of Product in no way expresses or implies a license for the

use of, nor encourages the infringement of any patents or licenses.

To insure proper validation of your warranty, please co mplete the warranty card and return it to

Gusmer within two weeks of receipt of equipment.

Revised 11/12/98

01/07/00 5

Page 6

Model FF-1600 with out Heat

GENERAL SAFETY INFORMATION

It is necessary to understand and follow the instructions in this manual to insure proper

and safe operation of the equipment.

As with most mechanical equipment, certain safety precautions must be taken when the

equipment discussed in this manual is operated or serviced. Severe bodily injury or

damage to equipment and property may result if the instructions and precautions listed

throughout this manual are not followed.

Needless to say, sufficient guidelines cannot be developed to eliminate the need for good

common sense in the use and servicing of this equipment, and in the use and application

of the products, this equipment has been designed to process. Users of this equipment

must therefore, make their own determination as to the suitability of the information

contained in this manual to their specific operation and requirements. There should be no

assumption made that the safety measures and instructions contained herein are allinclusive, and that other safety measures may not be required for specific use or

application.

The following safety guidelines are generally applicable to the safe and efficient use of

the equipment.

Acceptable Equipment Uses

The equipment is designed for the dispensing of polyurethane foams, two-component

coating systems, and some two-component epoxy systems, specifically polyureas. Under

no circumstances should any acid or corrosive chemicals be used in the unit. Consult

GUSMER if there is any doubt about the compatibility of the chemical system to be used

in this equipment.

Any use of this equipment other than as indicated above constitutes misuse unless express

written approval is obtained from GUSMER.

6 17942C-1, Issue 1

Page 7

Operating Manual General Safety Information

Operational Safety Procedures

This safety information will not be repeated in the text of this manual. The symb ols

pertaining to this information will ap pear where appropriate to alert the operator to

potential hazards.

Solvents and Chemicals

High Voltage

High Pressure

Personal Protective

Equipment

WARNING: T

OPERATOR TO CERTAIN HAZARDS. ADEQUATE PERSONAL PROTECTIVE MEASURES MUST

BETAKEN SO AS TO AVOID EXCEEDING THE

PRODUCTS BEING USED

HE SOVENTS AND CHEMICAL USED WITH THIS EQUIPMENT EXPOSE THE

THRESHOLD LIMIT VALUE (TLV) OF THE

, AS ESTABLISHED BY THE OCCUPATIONAL SAFETY AND HEALTH

ADMINISTRATION (OSHA) OR OTHER QUALIFIED AGENCY. INFORMATION CONCERNING

PERSONAL PROTECTION AND PROPER HANDLING FROM THE SUPPLIER OF SUCH CHEMICALS

WARNING:

THE ELECTRIC CONSOLES OR OTHERWISE SERVICE THIS EQUIPMENT AND/OR EQUIPMENT USED

WITH IT BEFORE SWITCHING OFF THE MAIN POWER DISCONNECT AND INTERRUPTING SUPPLY

VOLTAGE AT THE SOURCE

A QUALIFIED ELECTRICIAN

WARNING:

COMPONENTS CAPABLE OF PRODUCING UP TO 3500 PSI. TO AVOID SERIOUS BODILY INJURY

FROM HYDRAULIC INJECTION OF FLUID

SERVICE HYDRAULIC COMPONENTS WITHOUT BLEEDING ALL PRESSURES TO ZERO

WARNING:

WHEN OPERATING, SERVICING, OR BEING PRESENT IN THE OPERATIONAL ZONE OF THIS

EQUIPMENT

SAFETY SHOES, AND RESPIRATORY EQUIPMENT AS REQUIRED.

TO PREVENT SERIOUS BODILY INJURY FROM ELECTRICAL SHOCK, NEVER OPEN

. THE ELECTRICAL SERVICE MUST BE INSTALLED AND MAINTAINED BY

.

THIS EQUIPMENT HAS OR IS USED WITH EQUIPMENT THAT HAS HYDRAULIC

, NEVER OPEN ANY HYDRAULIC CONNECTIONS OR

.

TO AVOID SERIOUS BODILY INJURY, PROPER PROTECTIVE GEAR MUST BE WORN

. THIS INCLUDES, BUT IS NOT LIMITED TO, EYE AND FACE PROTECTION, GLOVES,

.

WARNING: F

PERSONAL INJURY AND/OR DAMAGE TO THE EQUIPMENT FROM ONE OR MORE OF THE ABOVE

LISTED HAZARDS

AILURE TO READ AND FOLLOW THIS SAFETY INFORMATION MAY RESULT IN

Warning

01/07/00 7

Page 8

Model FF-1600 with out Heat

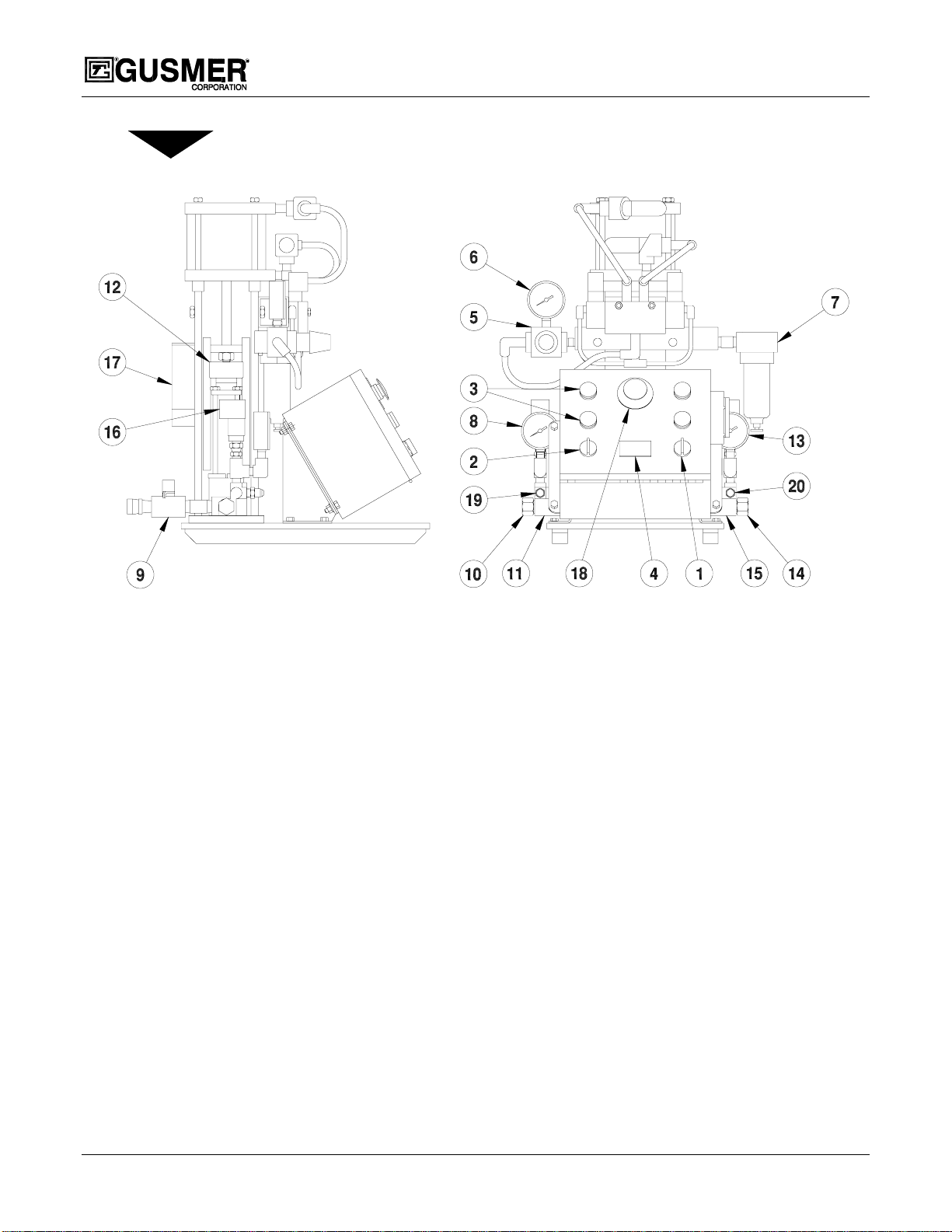

DESCRIPTION OF CONTROLS

Figure 1 Model 17000C-1 Proportioning Unit

1. MAIN SWITCH- Controls power to all circuits.

• OFF- Main Power is off.

• POWER- Turn the Main Switch to this position. To supply Main Power to the

Console. A White pilot light will indicate this.

• ON- Turn the Main Switch to this position and allow it to return to the POWER

position to enable the Console Controls. An Amber pilot light will indicate this.

2. PUMP SWITCH- Controls operation of the air drive system.

• OFF- Air Drive system is off.

• NORMAL- Must be in this position for the Proportioning Pumps to operate

• RETRACT- Use this position for shutdown. It will stop the air mo tor at the

bottom of the stroke with the Proportioning Pumps in the retracted position

3. PUMP DIRECTIONAL INDICATOR LIGHTS (Amber)- Indicate the direction

the Proportioning Pump is traveling. Both lights will be off when the pump switch is

OFF or when either Proportioning Pump exceeds its designed operating pressure

limit.

4. COUNTER- Records the cycle count of the Proportioning Pumps. One cycle count

equals two (2) strokes (one in each direction).

5. AIR PRESSURE REGULATOR- Controls the speed of the air motor on the up and

downstroke.

8 17942C-1, Issue 1

Page 9

Operating Manual Initial Machine Set-up

6. AIR PRESSURE GAUGE- Displays the air pressure in the air drive system during

the up and downstroke.

7. MAIN AIR FILTER- Filters the system air supply. (3/8 NPT Female)

8. ISOCYANATE PRESSURE GAUGE- Displays the pump out put pressure in the

Isocyanate proportioning system.

9. A-INLET SUPPLY VALVE (R on other side)

10. A-INLET FILTER SCREEN

11. A-PUMP BASE

12. A-PACKING NUT, LUBE CUP (R on other side)

13. RESIN PRESSURE GAUGE- Displays the pump out put pressure in the resin

proportioning system.

14. R-INLET FILTER SCREEN

15. R-PUMP BASE

16. PRESSURE LIMIT SWITCH- Factory set to turn off the air drive system when the

Proportioning Pump exceeds the designed operating pressure limit. (A side shown, R

on other side

17. AIR MOTOR REVERSING SWITCH- Energizes and de-energizes the air valve

coils to reverse direction.

18. EMERGENCY STOP BUTTON- Disables the Console Controls when engaged.

Amber Control Power pilot light will remain off until the button has been reset and

the Console Controls re-enabled. The White Lamp will remain illuminated.

(Twist to reset)

19. ISOCYANATE OUTLET- 1/2 FPT (Swivel) Fitting

20. RESIN OUTLET- 3/4 FPT (Swivel) Fitting

01/07/00 9

Page 10

SPECIFICATIONS

Model FF-1600 with out Heat

Air

Electric

Maximum Output

Maximum Pr essure

Viscosity

26 scfm @100 psi (12 liters/sec @7 bars)

2 amps @ 110 volts, 50/60 Hertz single phase, AC.

16 lbs/min. (7.25 kg/min)

1600 psi (108 bars) @ 100 psi Air

25-3000 cps (25-3000 cps)

10 17942C-1, Issue 1

Page 11

Operating Manual Initial Machine Set-up

INITIAL MACHINE SET-UP

WARNING: PROPER PROTECTIVE GEAR AS SPECIFIED BY THE CHEMICAL AND SOLVENT

SUPPLIER MUST BE WORN WHEN SERVICING OR OPERATING THIS EQUIPMENT. IT INCLUDES

BUT IS NOT LIMITED TO GLOVES

GENERAL SAFETY INFORMATION SECTION OF THIS MANUAL.

THE

The following parts are included with the unit and are required for set-up:

• Tape

• Air Hose Assembly

• (2) Swivel Unions

WARNING: THE PROPORTIONING UNIT ELECTRIC SERVICE MUST BE INSTALLED BY A

QUALIFIED ELECTRICIAN ACCORDING TO NATIONAL ELECTRIC CODE AND ALL APPLICABLE

LOCAL CODES

.

IMPORTANT: Before for proceeding be sure that the Main Power Supply is

disconnected.

, EYE PROTECTION, AND RESPIRATORY PROTECTION. REFER TO

To obtain the best possible

NOTE:

results, the power source must be

capable of meeting the electrical

requirements specified on the

nameplate and must be provided

with a dedicated fuse disconnect.

1. Connect the Main Power Cord to the electrical console using wire size #10 or larger

(not supplied).

a) Feed the power cor d through the strain relief in the ba ck of the console and

connect the power leads to L1 and N.

b) Connect the ground wire to the gro und lug.

2. Setup the supply and air control system as required.

a) Connect the Resin supply to the R-Inlet 3/4 FPT (Swivel) Fitting.

b) Connect the Isocyanate supply to the A-Inlet 1/2 FPT (Swivel) Fitting.

c) Connect the air supply to the1/4 MPT nipple on the Transfer pump.

Remove the cap to access it.

3. Connect the Main Air Supply to the P r oportioning Unit. The main air inlet fitting is

a 3/8 MPT nipple.

IMPORTANT: The Main Air Supply must be clean and free of contaminants

A minimum of 3/8 inch inside diameter air line (not supplied) should be used to

deliver the air supply to the proportioning unit.

Fitting a main air shutoff valve to the Proportioning Unit is recommended.

4. Connect the Hose Assemblies to the Proportioning Unit. See Figure 2 Hose

Connection Locations.

IMPORTANT: The resin hoses are color-coded blue and the Isocyanate hoses are

color- coded red for easy identification. In addition, the resin and Isocyanate hose

fittings are different sizes, making it virtually impossible to improperly connect the

hoses

01/07/00 11

Page 12

The hoses are Connected end to

NOTE

end during shipment to protect

them from moisture intrusion Do

not separate the hoses until they

are ready for coupling to the

proportioning unit.

Model FF-1600 with out Heat

Figure 2 Hose Connection Locations

5. Connect the Hose Assemblies together as follows. See Figure 3 and Figure 4.

:

IMPORTANT: It is important to make proper hose connections. The connection

points are a potential source of chemical and airs leaks and are susceptible to

damage from scuffing and snagging on abrasive surfaces. A liberal amount of duct

tape can be used in this area to make the bundle as compact as possible. Gusmer

recommends the installing of the optional scuff jacket to protect the hose insulation

from damage

a) Lay out Hose

assemblies as shown.

b) Connect Hose

Assemblies as shown

taking care not to

cross thread or overtighten the fittings,

there by assuring a

leak proof chemical

connection.

Figure 3 Hose Connection Step (A)

Figure 4 Hose Connection Step (B)

*** Repeat Step 5 for adding additional hoses. ***

12 17942C-1, Issue 1

Page 13

Operating Manual Initial Machine Set-up

6. Connect the air hose adapter between the Proportioning Unit and hoses.

7. Connect the coupling block to the gun hose and see t hat the manual valves are closed.

Air Purge

Prior to operation, it is necessary to purge the entire system of air and mineral oil left over

from the functional testing of the equipment.

To purge the machine proceed as follows:

1. Turn on the main air supply.

2. Pressurize the Transfer Pumps and open the A and R-Inlet Supply Valves. It is a

good practice at this point to check for material leaks

3. Turn the Main Switch to ON. The White pilot light should come on followed by the

Amber pilot light

4. Adjust the Air Pressure Regulator to zero. (Full counter clockwise).

5. Switch the Pump Switch to NORMAL.

Properly discard both

NOTE:

materials in accordance

with applicable

environmental regulations.

6. Remove the gun from the coupling block

7. Adjust both the Air Pressure

Regulators clockwise until the

pumps begin to move

(approximately 15-psi air pressure).

When the pumps reach the top of

their stroke, turn the pump switch to

OFF. This will facilitate easy access

to the pump lube cup on the

Isocyanate pump. Fill the lube cup

to about 1/4-inch from the top with

pump lube. (See Figure 5)

Figure 5 Pump Lube Cup Location

8. With the coup l ing block held over separate containers, open both manual valves and

turn ON pump switch. Allow both materials to flow out of the coupling block

simultaneously until all spitting of air stops and all traces of residual material have

disappeared and a solid flow of each material is seen.

9. Switch the Pump Switch to OFF.

10. Close both manual valves and wipe clean any residual material from the coupling

block.

11. Mount the gun to the co upling block.

01/07/00 13

Page 14

Model FF-1600 with out Heat

NORMAL OPERATING PROCEDURES

Daily Start-up Procedure

1. Check the condition of the Isocyanate lube cup and service as required.

2. Adjust the packing. The packing nut on the Proportioning Unit is adjustable and will

require tightening when the pump lube is changed.

3. Check the inlet screens and service as required.

4. Determine that the chemical system is at the proper temperature as recommended by

the chemical supplier and that the moisture protection system, is in working order.

5. Turn on the Main Air Supply to the Transfer Pump.

6. Pressurize the Transfer Pumps and open both A and R-Inlet Supply Valves.

7. Turn ON the Main Switch. The White pilot light should come on followed by the

Amber pilot light.

The standard size 60 pumps have

NOTE:

a material pressure to air pressure

ratio of approximately 16 to 1.

Daily Shut-Down Procedure

8. Set the Air Pressure Regulator as required.

9. Set the Pump Switch to NORMAL. One of the amber Pump Directional Indicator

Lights should be ON and the Proportioning Pumps should move a short distance and

pressurize.

10. Connect air to the gun, open the manual valves, and test spray while observing the

chemical pressure gauges on both the up and down strokes. Readjust the regulator as

required.

1. Set the Pump Switch to the RETRACT position.

2. Trigger the gun off target until the Proportioning Pumps stop in the retracted position

and the Proportioning Pumps pressures bleed off to approximately 500 psi.

IMPORTANT: It is not a good practice to bleed the pressure to zero. Some pressure

is required to keep the packings operating normally and prevent weepage during

shutdown.

3. Switch OFF the Main Switch.

4. Close both Inlet Ball Valves.

5. Shutdown the chemical supply system as required.

6. Close both manual va l ves on the Gun. Shutdown and service the gun as needed.

7. Turn OFF the Main Air Supply.

14 17942C-1, Issue 1

Page 15

Operating Manual Maintenance

TROUBLESHOOTING PROCEDURES

General Information

When properly maintained and operated, GUSMER equipment will provide long and

faithful service. However, occasional problems will arise which must be resolved before

operation can continue. The purpose of this section is to give an explanation of what

problems may arise, how to detect them, and how to resolve them.

This manual is written to give the operator a general overview of the operation of the

equipment, therefore it is imperative that before any trouble shooting pro cess b e gins, the

operators have read and understood the applicable portions of this manual.

Training schools held on a regular basis further develop the necessary knowledge for

proper operation, maintenance and trouble shooting of GUSMER equipment. These

schools give concentrated training on the equipment and help to develop an operator into

a competent Certified Gusmer Technician.

GUSMER maintains a competent staff of Technical Representatives and authorized

Distributors who can resolve almost any problem you may encounter with GUSMER

equipment. Feel free to call on these people for assistance when you need it.

WARNING: THE TROUBLE SHOOTING SECTION OF THIS MANUAL AS SUMES THAT THE

INDIVIDUAL PERFORMING THE WORK ON THE EQUIPMENT IS QUALIFIED TO DO SO. THIS

INDIVIDUAL MUST HAVE A WORKING KNOWLEDGE OF BASIC HYDRAULICS AND PNEUMATICS

MUST FOLLOW ALL GENERALLY ACCEPTED SAFETY PRECAUTIONS USED WHEN WORKING WITH

HYDRAULICS

THE APPLICABLE SECTIONS OF THIS MANUAL

APPROPRIATE TO THE TASK BEING UNDERTAKEN

, PNEUMATIC AND ELECTRICAL EQUIPMENT; MUST HAVE READ AND UNDERSTOOD

; AND MUST WEAR PERSONAL PROTECTION

.

;

WARNING: ALL ELECTRICAL TROUBLE SHOOTING DESCRIBED IN THIS MANUAL MUST BE

DONE WITH POWER OFF TO AVOID SEVERE BODILY INJURY FROM ELECTRICAL SHOCK. THIS

, THAT IN ADDITION TO ALL CIRCUIT BREAKERS "OFF," DISCONNECT THE MAIN POWER

MEANS

AT THE SOURCE

OPERATION OF GUSMER EQUIPMENT MUST DO ANY ELECTRICAL TROUBLE SHOOTING

REQUIRED BEYOND THE SCOPE OF THIS MANUAL

. A QUALIFIED ELECTRONIC TECHNICIAN, THOROUGHLY FAMILIAR WITH THE

.

01/07/00 15

Page 16

Model FF-1600 with out Heat

Proportioning System

Figure 6. Proportioning Pump Features

To avoid unnecessary repairs, try the recommended solutions in the order given for each

problem. Before assuming there is a problem, determine that all circuit breakers,

switches, and controls are properly set.

Problems Solutions

Proportioning pump does not hold pressure when stalled. 1

Pressure unbalance between pumps. 2,3,4

Cavitation in the Proportioning Pump. 2,3,4

Failure of the pump to reverse. 7,8

Pumps do not move and the directional indicator lights are out. 5,6,7

Pump movement is erratic. 8

Unequal pressure or speed on the upstroke ve rsus the downstroke 9

SOLUTIONS

1. Determine which inlet or discharge valve is leaking. If the pump (A or R) is losing

pressure on the upstroke then check the discharge valve of the respective pump. If

the pump is losing pressure on the downstroke then check the inlet valve of the

respective pump.

a) Close the Inlet Supply Valve and de-pressurize the Transfer Pump.

b) De-pressurize the Proportioning Pump.

c) Remove the appropriate valve cover and, using the magnet from the

toolbox, remove the valve ball.

d) Flush and wipe clean the valve ball and ball seat of all residual material.

Inspect these parts for damage.

16 17942C-1, Issue 1

Page 17

Operating Manual Maintenance

e) In most cases, the cause of the leaking valve is a particle of foreign

material preventing the ball from seating properly. If cleaning the ball

and seat does not resolve the problem, then replace the valve ball and or

pump base.

2. Trouble shooting this problem requires that two points be determined:

First- Which chemical did not reach the gun?

Second- Why did that chemical fail to get there?

Determine the first point by checking t he color of the material exiting the gun. Foam

systems are usually a combination of light and dark material. Therefore, by

observing the color of the liquid exiting t he gun, one can determine which material is

missing.

The second point either is due to a restriction in the gun or because the Proportioning

Pump did not perform properly in pumping it’s designed volume.

This is determined by checking the chemical pressure gauges on the Proportioning

Unit. Focus on the pressure gauge corresponding to the missing chemical.

Assume that the R-component is not reaching the gun. If the resin pressure gauge is

considerably lower than normal, the problem is the pump. If the resin gauge is

considerably higher than normal the problem is usually in the gun and must be

resolved by referring to the gun manua l.

3. CAVITATION is the formation of a partial vacuum or void within the pump cylinder

during the fill/upstroke stroke.

It is actually a “short fill” since the fill chamber does not fill completely with liquid

when the pump reverses to start the discharge/down stroke. This “short fill” occurs

when the Proportioning Pump demands a greater volume of material during its fill

stroke than can be supplied.

The most common causes of cavitation are as follows:

a) The Transfer Pump can not handle the supply requirement. A

GUSMER 2:1 Transfer Pump is recommended for use with this

Proportioning Unit. Also recommended is a minimum of 3/4” diameter

supply hose, as short as practical.

b) The chemical is too viscous (thick) to pump properly. The

recommended supply temperature is 65° F, to 75° F. At temperatures

below 65° F, the material thickens and becomes increasingly harder to

pump.

c) Inlet filter screen is restricted. Service as described in the Maintenance

section of this manual.

WARNING: THE DESIGN OF THIS PROPORTIONING UNIT ALLOWS IT TO OPERATE AT

PRESSURES UP TO 1600 PSI. EXTREME CAUTION MUST BE EXERCIZED BEFORE OPENING ANY

HYDRAULIC CONNECTIONS OR SERVICING THE PUMP OR PUMP BASE

BLEED OFF THE PRESSURE IN BOTH THE SUPPLY AND DELIVERY SIDES OF THE PUMP TO ZERO

TO AVOID SERIOUS BODILY INJURY FROM FLUID INJECTION

CONTAINING CHEMICALS WITHOUT WEARING APPROVED SAFETY GLASSES AND PROTECTIVE

GLOVES TO PREVENT PROLONGED SKIN CONTACT

.

. NEVER SERVICE COMPONENTS

. THE OPERATOR MUST

01/07/00 17

Page 18

Model FF-1600 with out Heat

4. LEAKING INLET CHECK VALVE - An inlet check valve and/or leaking seat that

does not properly seal will permit some of the proportioned material to flow back

towards the supply drum. When this ha ppens the proper volume of material will not

pump during the discharge str oke and an off-ratio condition will result.

5. A 2200-psi pressure limit switch protects each Proportioning Pump. Upon reaching

this pressure, the switch automatically removes power from both directional valves

causing the pump to stall. When the power is removed, both Directional Indicator

Lights will go out, this indicates there ha s been an over-pressure shutdown.

This is not a lockout type of system and when the pressure bleeds off to

approximately 200 psi, the Proportioning Pumps will be restored to normal

operation; however, the cause of the over-pressure should be determined first and

then corrected.

The most likely causes of over-pressure are:

a) Restriction in the gun

b) Pump cavitation

c) Air pressure set too high

6. CONTROL TRANSFORMER FUSE - With the power OFF, open the electric

console, and remove the control transformer fuse. Check it for continuity or simply

replace it.

WARNING: REPLACE THE FUSE WITH ONE OF THE SAME RATING. A SUBSTITUTE MAY

DAMAGE THE EQUIPMENT AND WOULD CREATE A POTENTIAL SOURCE OF INJURY TO THE

OPERATOR

.

WARNING: BEFORE PERFORMING THESE TROUBLE SHOOTING PROCEDURES DETERMINE

THAT ALL CIRCUIT BREAKERS ARE OFF AND MAIN POWER IS DISCONNECTED AT THE SOURCE TO

AVOID SEVERE BODILY INJURY FROM ELECTRICAL SHOCK

CONSOLE WITH THE POWER ON

. DO NOT ENTER THE ELECTRICAL

7. REVERSING SWITCH - In order for the Proportioning Unit to switch direction or

reverse, the ends of a slot machined in the rear leg of the pump yoke must contact the

arm of the switch lever. This contact causes the switch lever to activate on the

reversing switch, which energizes one air valve coil and de-energizes the other. A

problem arises when the yoke fails to contact the switch lever or when the spool in

the air valve fails to shift after its coil activates.

Typically, something physically prevents the yoke from traveling its full stroke. In

this case physically check and correct it. It may also be the result of the air pressure

set to a point where the total resistance downstream of the air motor is such that the

air motor cannot pump against it. Correct this by simply increasing the air pressure.

8. ROLLER BEARINGS- Occasionally replacing the roller bearing is necessary if they

become clogged with dirt or Isocyanate and seize.

9. UPSTROKE REGULATOR- During the upstroke, both Proportioning Pumps will be

on the fill stroke and will receive a boost from the supply pump pressure. Adjust the

upstroke regulator so the Proportioning Pump speeds are equal on both strokes.

18 17942C-1, Issue 1

Page 19

Operating Manual Maintenance

MAINTENANCE

To realize the full productivity of the Proportioning Unit it is necessary to perform

maintenance on a daily or periodic basis.

WARNING: WHENEVER WORKING ON THE EQUIPMENT, WEAR EYE AND SKIN PROTECTION TO

GUARD AGAINST EXPOSURE TO THE CHEMICALS AND SOLVENTS IN USE. ALWAYS WORK IN A

WELL VENTILATED AREA TO PREVENT EXPOSURE TO HARMFUL FUMES AND VAPORS

I

NFORMATION CONCERNING THE TOXICITY AND PROPER HANDLING PROCEDURES OF YOUR

CHEMICALS AND SOLVENTS IS AVAILABLE FROM YOUR SUPPLIER

U

NLESS OTHERWISE SPECIFIED, SWITCH OFF ALL CIRCUIT BREAKERS AND DISCONNECT THE

MAIN POWER AT THE SOURCE TO AVOID SEVERE BODILY INJURY FROM ELECTRICAL SHOCK

NOT ENTER THE ELECTRICAL CONSOLE WITH POWER ON

P

RESSURES UP TO 1600 PSI EXIST IN THE HYDRAULIC COMPONENTS. BEFORE OPENING ANY

HYDRAULIC CONNECTIONS OR SERVICING HYDRAULIC COMPONENTS USE EXTREME CAUTION TO

INSURE BLEEDING OF ALL PRESSURES TO ZERO TO AVOID SERIOUS BODILY INJURY FROM FLUID

INJECTION

.

.

.

.

. DO

Pump Lube System

Check the condition of the pump DAILY, to insure that lube will do its job. Change the

Pump Lube before it becomes a gel, turns cloudy, or becomes the same color as the

Isocyanate.

The gel formation is due to moisture absorption by the pump lube. The time interval

between changes due to gel formation depends entirely upon the environment in which the

equipment is operating.

Discoloration of the Pump Lube is inevitable due to the continual weepage of Isocyanate

during pump operation. However, if the packing within the Isocyanate pump is

functioning properly, Pump Lube replacement due to discoloration should not be more

frequent than 3 to 4 week intervals.

To change the Pump Lube proceed as fo llows:

1. Stop the Proportioning Unit with the pump yoke at the top reverse. Switch OFF the

pump switch and disconnect the air from the Proportioning Unit.

2. Remove the pump lube from the lube cup by dipping a dry rag into the cup to absorb

the contaminated liquid. Wipe the cup and pump shaft clean. Remove any hardened

material from the shaft taking care not to scratch the shaft.

3. Fill the lube cup with Pump Lube to about 3/4 inch below the top.

01/07/00 19

Page 20

Model FF-1600 with out Heat

Inlet Filter Screen

A filter screen in each Proportioning Pump filters out solid matter that could adversely

effect the operation of the valve balls in the pump base. You will note that the Daily

Start-up Procedure indicates these screens should be inspected daily.

For the first week or so of operation, you should clean both pump screens on a daily basis.

However, you will probably find that the resin pump screen rema ins clean and that weekly

checking of this part will be sufficient.

The Isocyanate pump screen is another matter. The Isocyanate component can crystallize

from either moisture contamination or from freezing. If you follow proper storage,

transfer, and operating procedures, and if the chemicals you receive, are clean, you should

have little problem with the Isocyanate screen. In practice though, findings suggest that

daily cleaning of the Isocyanate screen is sound preventative maintenance. It is important

not to clean the Isocyanate pump screen during the shutdown operation. This is because

the cleaning of the screen exposes it and its related parts to moisture and solvent, which

can cause the Isocyanate to crystallize. By accomplishing the cleaning operation during

the Start-up Procedure, contamination problems will flush out immediately when

dispensing commences.

Removal and cleaning of the filter screen is accomplished as follows:

1. Switch OFF the Pump Switch and disconnect air from the Proportioning Unit. Bleed

chemical pressure from the side you are working on by opening the corresponding

manual valve on the coupling block while pointing it into an appropriate container.

2. Close the material supply valve at the inlet of the appropriate Proportioning Pump.

This prevents the pumping of material with the screen screw removed.

3. Place a cup, in the space provided beneath the filter base to catch the chemical, which

will drain-off upon removing the screen screw.

4. Loosen the screen screw sufficiently to allow the material in the screen screw cavity

to drain out into the cup.

Remove the screen screw from the pump base by continuing to unthread it until it

comes loose.

5. Remove the retainer ring at the end of the screen screw and slide the screen from the

screen screw. Thoroughly flush the screen screw, the retainer ring, and the screen

with the gun cleaner, and shake them dry. Inspect the screen to insure the mesh is not

restricted. Replace as required.

6. Slide the screen on the screen screw and replace the retainer ring.

7. Flush the cavity in the pump base with gun cleaner and wipe the cavit y cle an using

caution not to push foreign matter into the ball seat.

8. Install the screen screw assembly into the pump base by inserting the screen screw

with the threaded portion sliding along the top cavity. This prevents pushing foreign

matter into the ball seats.

9. Open the material supply valve; insure there are no leaks and wipe the equipment

clean.

20 17942C-1, Issue 1

Page 21

Operating Manual Maintenance

Proportioning Pumps

Disassemble and clean both Proportioning Pumps annually. Inspect the pistons and

cylinders for mars or scratches, which may cause leakage or damage to the packings, and

replace as necessary. As a preventative maintenance precaution, replace the piston and

cylinder packings on an annual basis.

Pump Bases

1. Completely depressurize the system.

2. Remove the valve cover using an adjustable wrench.

Inspect the valve cover o-ring and replace as required. It is good practice to liberally

coat the o-ring with grease before inserting the valve cover back into the pump base.

Also, check the chamfer around the cavity to insure that there are no sharp edges,

which could damage the o-ring and prevent proper seal.

3. Remove the valve ball and inspect it for nicks and scratches. Replace as required.

Remove the ball seat with the special tool provided and inspect it for nicks and

scratches. Replace as required

4. Inspect the face of the gasket for damage and replace as required. Reassemble the

pump base.

01/07/00 21

Page 22

NOTES

Model FF-1600 with out Heat

22 17942C-1, Issue 1

Page 23

Operating Manual Instruction Manual Discrepancy Report

INSTRUCTION MANUAL DISCREPANCY REPORT

Field

Number

1

2

3

4

5

6

7

Field Title Description

Date

Name

IM Number

Issue Number

Date of Issue

Page Number

Discrepancy

Instructions:

Complete the above fields of the form by following the instructions listed on the reverse side of this sheet and mail to:

Gusmer Corporation

One Gusmer Drive PO Box 2055

Lakewood, NJ 08701

01/07/00 23

Page 24

Model FF-1600 with out Heat

Field

Number

1

2

3

4

5

6

7

Field Title Description

Date

Name

IM Number

Issue Number

Enter date report is submitted.

Enter name of person making report.

Enter the Part Number of the Instruction Manual from the title page.

Enter the Issue number of the Instruction Manual from the title page. If there is no

issue number enter NONE.

Date of Issue

Enter the date of Issue of the Instruction Manual from the title page. If there is no

issue date, enter NONE.

Page Number

Discrepancy

Enter the page number containing the discrepa ncy

Provide a brief description of discrepancy

NOTE: You may send a marked copy of the page as an attachment to yo ur

submittal.

24 17942C-1, Issue 1

Loading...

Loading...