7550

7550

75507550

VORTEX

VORTEX

VORTEXVORTEX

SERIES

SERIES

SERIESSERIES

52 HEAVY DUTY, 53 HEAVY DUTY AND

52 HEAVY DUTY, 53 HEAVY DUTY AND

52 HEAVY DUTY, 53 HEAVY DUTY AND 52 HEAVY DUTY, 53 HEAVY DUTY AND

54 HEAVY DUTY POWER FRAMES

54 HEAVY DUTY POWER FRAMES

54 HEAVY DUTY POWER FRAMES54 HEAVY DUTY POWER FRAMES

TABLE OF CONTENTS

PRECAUTIONS 3

SAFETY TIPS 3

FOREWARD 4

WARRANTY 4

RECEIVING & INSPECTION 4

INSTALLATION 5

MAINTENANCE 5

ROTATION 5

LUBRICATION CHART 6

MAINTENANCE HISTORY 7

ENGINEERING DATA 7

52VHD DRAWING 8

PARTS LIST 9

53/54VHD DRAWING 10

PARTS LIST 11

PRECAUTIONS

!WARNING!

PERSONAL INJURY MAY RESULT IF

PROCEDURES OUTLINED IN THIS

MANUAL ARE NOT FOLLOWED

• NEVER APPLY HEAT TO REMOVE IMPELLER. IT

MAY EXPLODE DUE TO TRAPPED LIQUID.

• NEVER USE HEAT TO DISASSEMBLE PUMP.

EXPLOSION COULD OCCUR DUE TO TRAPPED

LIQUID.

• NEVER OPERATE PUMP WITHOUT COUPLING

GUARD CORRECTLY INSTALLED.

• NEVER OPERATE PUMP BEYOND THE RATED

CONDITIONS TO WHICH THE PUMP WAS SOLD.

• NEVER START PUMP WITHOUT PROPER PRIME

(SUFFICIENT LIQUID IN PUMP CASING).

• NEVER OPERATE PUMP BELOW

RECOMMENDED MINIMUM FLOW OR WHEN

DRY.

• ALWAYS LOCK OUT POWER TO THE MOTOR

BEFORE PERFORMING PUMP MAINTENANCE.

• NEVER OPERATE PUMP WITHOUT SAFETY

DEVICES INSTALLED.

• NEVER OPERATE PUMP WITH DISCHARGE

VALVE CLOSED.

• NEVER OPERATE PUMP WITH SUCTION VALVE

CLOSED.

• DO NOT CHANGE CONDITIONS OF SERVICE

WITHOUT APPROVAL OF AN AUTHORIZED

GUSHER REPRESENTATIVE.

PUMP SAFETY TIPS

SAFETY APPAREL

• INSULATED WORK GLOVES WHEN HANDLING

HOT BEARINGS OR USING BEARING HEATER.

• HEAVY WORK GLOVES WHEN HANDLING PARTS

THAT HAVE SHARP EDGES, ESPECIALLY

IMPELLERS.

• SAFETY GLASSES (WITH SIDE SHEILDS) TO

PROTECT EYES, ESPECIALLY IN MACHINE SHOP

AREAS.

• STEEL-TOED SHOES TO PROTECT FEET WHEN

HANDLING PARTS, HEAVY TOOLS, ETC.

• ANY OTHER EQUIPMENT NEEDED TO PROTECT

AGAINST HAZARDOUS/TOXIC FLUIDS.

COUPLING GUARDS

• NEVER OPERATE A PUMP WITHOUT COUPLING

GUARDS PROPERLY INSTALLED.

FLANGED CONNECTIONS

• NEVER FORCE PIPING TO MAKE CONNECTION

WITH A PUMP.

• USE ONLY FASTENERS OF PROPER SIZE AND

MATERIAL.

• ENSURE THERE ARE NO MISSING FASTENERS.

• BEWARE OF CORRODED OR LOOSE FASTENERS.

OPERATION

• DO NOT OPERATE BELOW MINIMUM RATED

FLOW, OR WITH SUCTION/DISCHARGE VALVES

CLOSED.

• DO NOT OPEN VENT OR DRAIN VALVES, OR

REMOVE PLUGS WHILE THE SYSTEM IS

PRESSURIZED.

MAINTENANCE SAFETY

• ALWAYS LOCKOUT POWER

• ENSURE PUMP IS ISOLATED FROM THE

SYSTEM AND PRESSURE IS RELIVED BEFORE

DISASSEMBLING PUMP, REMOVING PLUGS, OR

DISCONNECTING PIPING.

• USE PROPER LIFTING AND SUPPORTING

EQUIPMENT TO PREVENT SERIOUS INJURY.

• OBSERVE PROPER DECONTAMINATION

PROCEDURES.

• KNOW AND FOLLOW COMPANY SAFETY

REGULATIONS.

• NEVER APPLY HEAT TO REMOVE IMPELLER.

FOREWARD

THE DESIGN, CRAFTSMANSHIP, AND MATERIALS USED IN GUSHER PUMPS PROVIDES FOR

OPTIMUM PERFORMANCE AND LONG, TROUBLE-FREE SERVICE. AS WITH ANY MECHANICAL

DEVICE, PROPER USE AND PERIODIC MAINENANCE WILL ENHANCE THE PERFORMANCE AND

LIFE OF YOUR PUMP. THIS MANUAL IS PROVIDED AS A GUIDELINE FOR PROPER INSTALLATION,

OPERATION AND MAINTENANCE. THIS MANUAL MUST BE READ AND UNDERSTOOD BEFORE

INSTALLING AND OPERATING ANY PUMP.

GUSHER PUMPS INC. SHALL NOT BE LIABLE FOR PHYSICAL INJURY, DAMAGE OR DELAYS

CAUSED BY A FAILURE TO OBSERVE THE INSTRUCTIONS FOR INSTALLATION, OPERATION,

AND MAINTENANCE CONTAINED IN THIS MANUAL.

WARRANTY

GUSHER PUMPS INC. WILL REPLACE OR REAIR, WITHIN ONE YEAR OF SHIPMENT FROM OUR

PLANT, ANY PUMP IN OUR JUDGEMENT THAT HAS FAILED DUE TO DEFECTS IN MATERIALS OR

WORKMANSHIP, PROVIDED THE PUMP HAS BEEN PROPERLY INSTALLED AND MAINTAINED AND

HAS NOT BEEN SUBJECT TO ABUSE. THESE PUMPS MUST RETURN TO GUSHER PUMPS INC. WITH

COMPLETE HISTORY OF SERVICE FOR INSPECTION AND WARRANTY CONSIDERATION. GUSHER

PUMPS INC. DOES NOT ACCEPT THE RESPONSIBILITY FOR TRANSPORTATION TO AND FROM OUR

PLANT. FURTHERMORE, WE DO NOT ASSUME ANY RESPONSIBILITY FOR CONSEQUENTIAL

DAMAGE OR LOSS OF PRODUCTION.

WARRANTY IS ONLY VALID WHEN GENUINE GUSHER PARTS ARE USED.

SUPERVISION BY AN AUTHORIZED GUSHER REPRESENTATIVE IS RECOMEMENDED TO ENSURE

PROPER INSTALLATION. ADDITIONAL MANUALS CAN BE OBTAINED BY CONTACTING YOUR

LOCAL GUSHER REPRESENTATIVE OR BY CALLING 859-824-5001.

RECEIVING AND INSPECTION

THE UTMOST CARE HAS BEEN TAKEN AT THE

FACTORY TO ASSURE PROPER COUPLING

ALIGNMENT AND IMPELLER ADJUSTMENT.

HOWEVER, DUE TO CIRCUMSTANCES BEYOND

OUR CONTROL, YOU MUST INSPECT THE PUMP

UPON RECEIPT AND FOLLOW THE

INSTALLATION INSTRUCTIONS COMPLETELY

BEFORE START-UP.

RECEIVING

1. ROTATE SHAFT BY HAND. IF IT DOES NOT

ROTATE FREELY:

A. CHECK IMPELLER ADJUSTMENT.

B. CHECK FOR BENT COUPLING GUARD.

C. CHECK SLINGER (#12).

D. CHECK FOR BENT SHAFT (#1).

2. CHECK FOR CRACKED OR DAMAGED PARTS.

IF UPON RECEIPT, YOU FIND THE PUMP

DAMAGED, FILE A CLAIM WITH THE

DELIVERING CARRIER.

3. IF DRIVE MOTOR HAS BEEN SUPPLIED,

CHECK THE R.P.M. AND HORSEPOWER TO

BE SURE IT IS CORRECT AS ORDERED.

4. CHECK THE PUMP NAME TAG TO BE SURE

WE HAVE SHIPPED CORRECTLY AS

ORDERED:

A. MODEL NUMBER

B. HEAD IN FEET (FT. HD.)

C. GALLONS PER MINUTE (G.P.M.)

D. CONSTRUCTION:

1. ALL IRON.

2. ALL IRON WITH STAINLESS STEEL

SHAFT AND IMPELLER.

3. ALL STAINLESS STEEL.

5. IF THERE IS ANYTHING THAT APPEARS TO

BE INCORRECT, CALL THE FACTORY

IMMEDIATELY.

INSTALLATION

AFTER CAREFUL PRELIMINARY INSPECTION, YOU MAY

PROCEED WITH THE INSTALLATION OF THE PUMP INTO YOUR

SYSTEM.

1. LOWER THE PUMP INTO SYSTEM.

2. MAKE SURE MOUNTING PLATE IS SETTING FIRMLY ON

THE SUPPORT CHANNELS. (IT MAY BE NECESSARY TO USE

METAL SHIMS TO LEVEL PLATE.)

3. SECURE MOUNTING PLATE BY USING HOLD-DOWN

SCREWS IN ALL FOUR CORNERS. AGAIN, CARE MUST BE

TAKEN TO MAKE SURE PLATE IS FIRM AND LEVEL. DO

NOT FORCE BOWED PLATE LEVEL.USE METAL SHIMS IF

NECESSARY.

4. MAKING PIPE CONNECTIONS:

A. EXTREME CARE MUST BE TAKEN TO SUPPORT

ALL PIPING WITHOUT CAUSING ANY STRAIN ON

THE PUMP.

B. INSTALL PIPE HANGER ON THE DISCHARGE PIPE

SO THAT ALL PIPING WEIGHT IS SUPPORTED BY

THE HANGER AND NOT BY THE PUMP OR THE

CASING.

C. BOLT HOLES MUST LINE-UP WITHOUT PRYING TO

INSERT BOLTS.

D. WHEN TIGHTENING FLANGE BOLTS, PIPE

FLANGES MUST NOT BE FORCED TOGETHER.

E. CHECK VALVE SHOULD BE PLACED IN

DISCHARGE LINE BETWEEN GATE VALVE AND

PUMP DISCHARGE PIPE TO PREVENT LIQUID

FROM RUNNING BACK THROUGH THE PUMP AND

CAUSING REVERSE ROTATION. THIS IS

EXTREMELY IMPORTANT IN APPLICATIONS WITH

INTERMITTENT DUTY WHERE THE PUMP MAY BE

ROTATING BACKWARDS WHEN SERVICE IS

RESUMED. THIS WILL CAUSE DAMAGE TO THE

PUMP AND THE DRIVE MOTOR.

F. PRESSURE GAUGE SHOULD BE LOCATED AT THE

PUMP DISCHARGE, AS ALL PERFORMANCE DATA

IS TAKEN AT PUMP DISCHARGE.

G. IF INTAKE PIPING IS USED TO PUMP THE TANK

DOWN, IT MUST ALSO BE SUPPORTED

INDEPENDENTLY OF THE PUMP.

5. REMOVE COUPLING GUARD AND ROTATE COUPLING BY

HAND. PUMP SHOULD ROTATE FREELY AT THIS POING. IF

IT DOES NOT, CHECK FOR:

A. PIPING STRAIN: WITHOUT EXCEPTION, PIPE MUST

NOT REST ON PUMP IN ANY MANNER. (SEE ITEM

#4 OF THE INSTALLATION SECTION.)

B. IMPELLER ADJUSTMENT:

1. DISCONNECT COUPLING (#32) AND

REMOVE SLEEVE (#32A).

2. LOOSEN THREE LOCKING SCREWS (#57).

3. LOOSEN THREE ADJUSTING SCREWS

(#55).

4. LIGHTLY TAP SHAFT (8) UNTIL HOUSING

(4) BOTTOMS ON TO HOUSING (9).

5. TIGHTEN THREE LOCKING SCREWS (#57)

UNTIL THEY TOUCH RETAINER (#1).

6. TIGHEN ADJUSTING SCREWS (#55) AND

JAMB NUTS (#56).

7. ROTATE COUPLING BY HAND TO BE

SURE IMPELLER (#17) DOES NOT RUB. IF

IMPELLER RUBS, REPEAT STEPS #1

THROUGH #6.

8. CONNECT COUPLING.

C. SLINGER ADJUSTMENT: THE SLINGER (#12) IS SET

AT THE FACTORY AND NORMALLY CAUSES NO

PROBLEMS, BUT SHOULD BE CHECKED WHEN

UNIT IS INSPECTED UPON ARRIVAL AT YOUR

PLANT SITE AND BEFORE UNIT IS LOWERED INTO

POSITION IN YOUR SYSTEM.

5. MAKE ELECTRICAL CONNECTION TO CONFORM WITH

STATE AND LOCAL CODES. (IT IS ADVISED TO USE

APPROXIMATELY 4’ LENGTH OF FLEXIBLE CONDUIT TO

FACILITATE REMOVAL OF MOTOR, IF REPAIR IS

REQUIRED.)

UPON INITIAL START-UP, PUMPS MAY SEEM TO RUN TIGHT

AND HOT. THIS IS CAUSED BY BREAKING-IN OF OIL SEALS AND

BALL BEARINGS. PUMP WILL OPERATE NORMALLY AFTER

APPROXIMATELY 150 HOURS OF SERVICE. BALL BEARINGS

SHOULD NOT RUN OVER 225 DEGRESS FAHRENHEIT. WHEN

CHECKING TEMPERATURE USE A PYROMETER.

MAINTENANCE

1. LUBRICATION: ALL PUMPS ARE LUBRICATED AT THE

FACTORY AND SHOULD NOT REQUIRE ADDITIONAL

LUBRICATION AT START-UP. A WELL PLANNED

MAINTENANCE SCHEDULE CAN ONLY BE DEVISED AFTER

CAREFUL OBSERVATION OF THE PUMP FOR THE FIRST SIX

MONTHS OF OPERATION AND THE LUBRICATION THAT

HAS BEEN REQUIRED. EACH PUMP INSTALLATION IS

UNIQUE AND REQUIRES A DIFFERENT LUBRICATION

SCHEDULE COMPATIBLE WITH THAT SPECIFIC

OPERATION. USE CHEVRON SRI #2 BALL BEARING

GREASE. DO NOT OVER GREASE AS IT WILL CAUSE BALL

BEARINGS TO RUN HOT.

2. TO LUBRICATE:

DO NOT LUBRICATE WHILE SHAFT IS IN MOTION.

A. LOCATE ZERK FITTINGS ON PARTS (#1) AND (#9).

B. FILL WITH GREASE UNTIL FRESH GREASE FLOWS

FROM OPENING.

32A

32

55

8

57

56

ROTATION FROM

MOTOR END

1

4

9

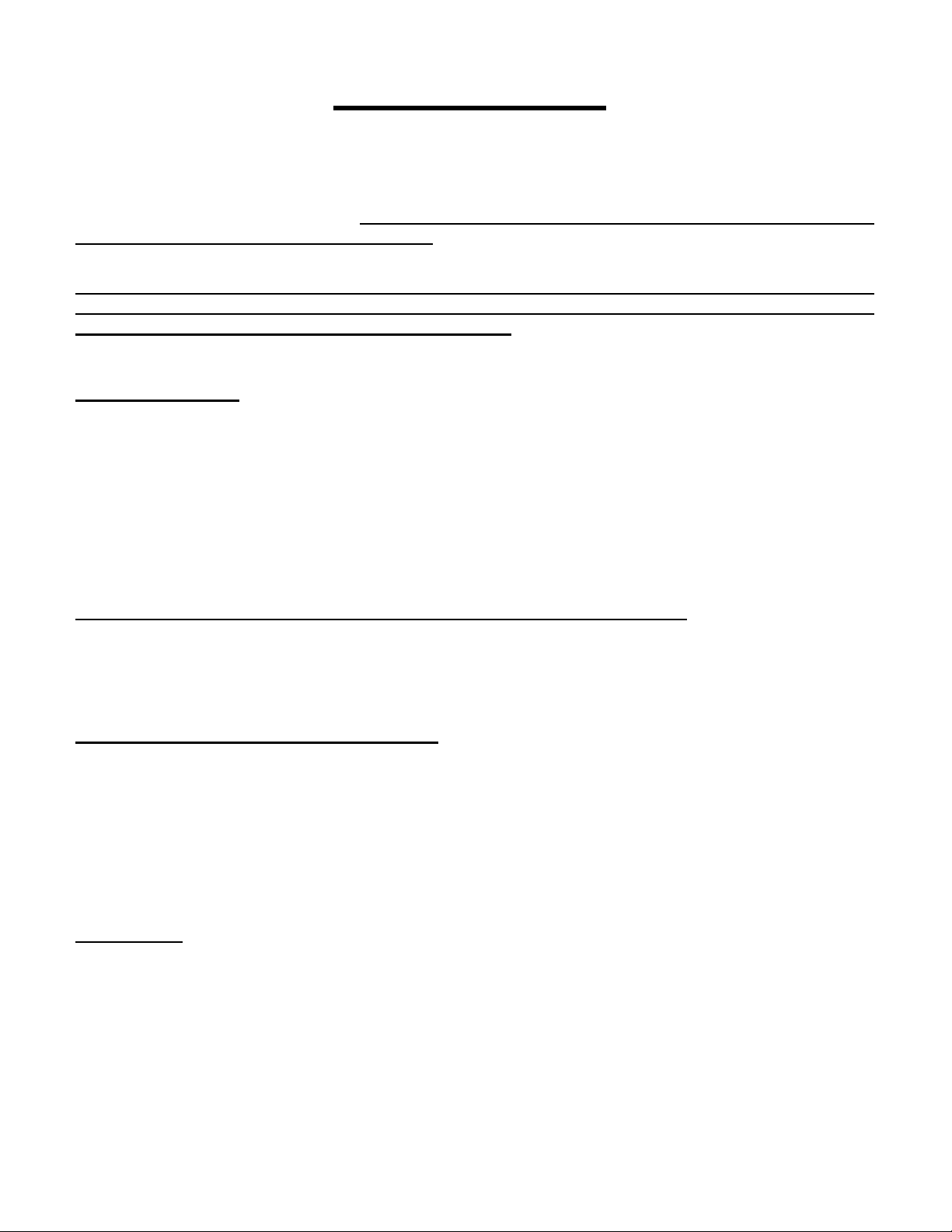

APPROXIMATE GREASING INTERVALS FOR

GUSHER PUMPS

52VHD POWER FRAME

TEMP. DEG. F. 1725 R.P.M. 3450 R.P.M.

150 DEG. 5760 HRS. 2880 HRS.

175 DEG. 2880 HRS. 1440 HRS.

200 DEG. 1440 HRS. 720 HRS.

225 DEG. 720 HRS. 360 HRS.

53VHD POWER FRAME

TEMP. DEG. F. 1725 R.P.M. 3450 R.P.M.

150 DEG. 5760 HRS. 2880 HRS.

175 DEG. 2880 HRS. 1440 HRS.

200 DEG. 1440 HRS. 720 HRS.

225 DEG. 720 HRS. 360 HRS.

54 VHD POWER FRAME

TEMP. DEG. F. 1725 R.P.M. 3450 R.P.M.

150 DEG. 3840 HRS. 1920 HRS.

175 DEG. 1920 HRS. 960 HRS.

200 DEG. 960 HRS. 480 HRS.

225 DEG. 480 HRS. 240 HRS.

*USE CHEVRON SRI #2 OR SHELL DOLIUM ‘R’ BALL BEARING GREASE OR EQUIVILENT.

REMOVE ALL OLD GREASE ONCE A YEAR AND CLEAN BALL BEARINGS AND BALL

BEARING HOUSING WITH KEROSENE OR CARBON TETRACHLORIDE BECAUSE OF

OXIDATION AND HARDENING OF THE GREASE OVER LONG PERIODS OF TIME.

*THIS IS AN APPROXIMATE LUBRICATION CHART FOR STANDARD PUMP OPERATION.

CONSULT THE FACTORY FOR ANY ADVERSE OPERATION.

!WARNING!

DO NOT LUBRICATE WHILE SHAFT IS IN MOTION.

DO NOT OVERGREASE.

MAINTENANCE HISTORY

SERIAL NO.

MODEL NO. IMP. DIA.

OPERATING COND. GPM @ FT. HEAD

HP SPEED/RPM

START-UP DATE AMPS AT START-UP

PRESSURE AT START-UP

ENGINEERING DATA

POWER FRAME 52HD 53HD 54HD

1. RADIAL BRG. 41211 41316 41319

2. THRUST BRG. 41308-DR 41312-DR 41314-DR

3. BALL BRG. SPAN 9.032 12.750 12.750

4. SHAFT DIA.’S

@ RADIAL BRG. 2.1655 3.1497 3.7403

@ THRUST BRG. 1.5750 2.3623 2.7560

@ THROTTLE BUSH. 1.735 1.875 2.500

@ IMPELLER 1.375 1.500 1.750

BET. BALL BRG’S. 1.937 3.125 3.625

BET. RADIAL BRG

& THROTTLE BUSH. 2.250 3.250 4.250

GREASE LUBRICATION

DATE GREASED DATE GREASED

TYPE OF GREASE USED:

NOTES:

52 HD POWER FRAME

BRG. HSG.

HSG. GASKET

DRIVE KEY

BEARING

BEARING

LOCKNUT

CARTRIDGE

HOUSING

RETAINER

RETAINER

BRG. HSG.

CARTRIDGE

IMPELLER

IMPELLER

IMPELLER

IMPELLER

IMPELLER

MODEL

V2X2-8 100098 41211 41308-DR 68100 51019 51231 14003 14079 83006 83000

V2X2-10 100098 41211 41308-DR 68100 51019 51231 14003 14079 83006 83000

V3X3-10 100098 41211 41308-DR 68100 51019 51231 14003 14079 83006 83000

V2X3-13 100098 41211 41308-DR 68100 51019 51231 14003 14079 83006 83000

V3X4-13 100098 41211 41308-DR 68100 51019 51231 14003 14079 83006 83000

V4X6-13 100098 41211 41308-DR 68100 51019 51231 14003 14079 83006 83000

MODEL

V2X2-8 62001-C 21104 25800 27800 61108 71099 68137 68510 17005 58002

V2X2-10 62001-C 21220 25801 27801 61115 71099 68137 68510 17005 58002

V3X3-10 62001-C 21220 25802 27802 61115 71099 68137 68510 17005 58002

V2X3-13 62001-C 21170 25803 27803 61116 71099 68137 68510 17005 58002

V3X4-13 62001-C 21173 25803 27804 61116 71099 68137 68510 17005 58002

V4X6-13 62001-C 21173 25805 27805 61116 71099 68137 68510 17005 58002

*FOR SPECIFIC PART NUMBERS PLEASE PROVIDE SERIAL NUMBER.

SHAFT

(8)

THROTTLE

BUSHING

BEARING (7)

(13)

RADIAL

STEM

PLATE

(14)

THRUST

BEARING (3)

IMPELLER

(17)

LOCKNUT

(2)

IMPELLER

HOUSING

(19)

CARTRIDGE

(4)

IMPELLER

(15)

BRG.

HOUSING

(9)

(16)

RETAINER

(1)

IMPELLER

NUT (18)

BRG./GRS.

RETAINER (6)

IMPELLER

WASHER (20) STEM (11)

OIL SEAL

(10)

CARTRIDGE

OIL SEAL (5)

SLINGER

53 HD POWER FRAME

RADIAL

MODEL SHAFT (8)

(7)

V3X4-13 100025 41316 41312-DR 68100-1 51083 51080 14083 14080 83011 83010

V4X6-13 100025 41316 41312-DR 68100-1 51083 51080 14083 14080 83011 83010

V6X8-15 100025 41316 41312-DR 68100-1 51083 51080 14083 14080 83011 83010

THRUST

(3)

(2)

(4)

BRG.

(9)

(1)

BRG./GRS.

(6)

OIL SEAL

(10)

OIL SEAL (5)

(12)

IMPELLER

MODEL

THROTTLE

BUSHING

(13)

STEM

PLATE

(14)

(17)

IMPELLER

HOUSING

(19)

HSG.

GASKET

(15)

DRIVE

KEY (16)

NUT (18)

SLINGER

(20) STEM (11)

SLINGER

V3X4-13 62025-C 21173 25803 27804 61116 71099-1 71213 58053 17171 58055

V4X6-13 62025-C 21173 25805 27805 61116 71099-1 71213 58053 17171 58055

V6X8-15 62025-C 21122 25806 27806 61122 71099-1 71213 58053 17171 58055

*FOR SPECIFIC PART NUMBERS PLEASE PROVIDE SERIAL NUMBER.

54 HD POWER FRAME

RADIAL

MODEL SHAFT (8)

V3X4-13 100035 41319 41314-DR 68100-2 51082 51081 14082 14081 83013 83012

V4X6-13 100035 41319 41314-DR 68100-2 51082 51081 14082 14081 83013 83012

V6X8-15 100035 41319 41314-DR 68100-2 51082 51081 14082 14081 83013 83012

THROTTLE

BUSHING

MODEL

(13)

BEARING

(7)

STEM

PLATE

V3X4-13 62054-C 21173 25803 27804 61116 71099-1 71213 58071L 17171 58054

V4X6-13 62054-C 21173 25805 27805 61116 71099-1 71213 58071L 17171 58054

V6X8-15 62054-C 21122 25806 27806 61122 71099-1 71213 58071L 17171 58054

*FOR SPECIFIC PART NUMBERS PLEASE PROVIDE SERIAL NUMBER.

(14)

THRUST

BEARING

(3)

(17)

LOCKNUT

(2)

HOUSING

(19)

CARTRIDGE

(4)

IMPELLER

HSG.

GASKET

(15)

BRG.

HOUSING

(9)

DRIVE

KEY (16)

RETAINER

(1)

NUT (18)

BRG./GRS.

RETAINER

(6)

BRG. HSG.

SLINGER

(20) STEM (11)

OIL SEAL

(10)

CARTRIDGE

OIL SEAL (5)

SLINGER

(12)

(12)

52 HD POWER FRAME

BRG. HSG.

HSG. GASKET

DRIVE KEY

BEARING

BEARING

LOCKNUT

CARTRIDGE

HOUSING

RETAINER

RETAINER

BRG. HSG.

CARTRIDGE

IMPELLER

IMPELLER

IMPELLER

IMPELLER

IMPELLER

MODEL

V2X2-8 100098 41211 41308-DR 68100 51019 51231 14003 14079 83006 83000

V2X2-10 100098 41211 41308-DR 68100 51019 51231 14003 14079 83006 83000

V3X3-10 100098 41211 41308-DR 68100 51019 51231 14003 14079 83006 83000

V2X3-13 100098 41211 41308-DR 68100 51019 51231 14003 14079 83006 83000

V3X4-13 100098 41211 41308-DR 68100 51019 51231 14003 14079 83006 83000

V4X6-13 100098 41211 41308-DR 68100 51019 51231 14003 14079 83006 83000

MODEL

V2X2-8 62001-C 21104 25800 27800 61108 71099 68137 68510 17005 58002

V2X2-10 62001-C 21220 25801 27801 61115 71099 68137 68510 17005 58002

V3X3-10 62001-C 21220 25802 27802 61115 71099 68137 68510 17005 58002

V2X3-13 62001-C 21170 25803 27803 61116 71099 68137 68510 17005 58002

V3X4-13 62001-C 21173 25803 27804 61116 71099 68137 68510 17005 58002

V4X6-13 62001-C 21173 25805 27805 61116 71099 68137 68510 17005 58002

*FOR SPECIFIC PART NUMBERS PLEASE PROVIDE SERIAL NUMBER.

SHAFT

(8)

THROTTLE

BUSHING

BEARING (7)

(13)

RADIAL

STEM

PLATE

(14)

THRUST

BEARING (3)

IMPELLER

(17)

LOCKNUT

(2)

IMPELLER

HOUSING

(19)

CARTRIDGE

(4)

IMPELLER

(15)

BRG.

HOUSING

(9)

(16)

RETAINER

(1)

IMPELLER

NUT (18)

BRG./GRS.

RETAINER (6)

IMPELLER

WASHER (20) STEM (11)

OIL SEAL

(10)

CARTRIDGE

OIL SEAL (5)

SLINGER

53 HD POWER FRAME

RADIAL

MODEL SHAFT (8)

(7)

V3X4-13 100025 41316 41312-DR 68100-1 51083 51080 14083 14080 83011 83010

V4X6-13 100025 41316 41312-DR 68100-1 51083 51080 14083 14080 83011 83010

V6X8-15 100025 41316 41312-DR 68100-1 51083 51080 14083 14080 83011 83010

THRUST

(3)

(2)

(4)

BRG.

(9)

(1)

BRG./GRS.

(6)

OIL SEAL

(10)

OIL SEAL (5)

(12)

IMPELLER

MODEL

THROTTLE

BUSHING

(13)

STEM

PLATE

(14)

(17)

IMPELLER

HOUSING

(19)

HSG.

GASKET

(15)

DRIVE

KEY (16)

NUT (18)

SLINGER

(20) STEM (11)

SLINGER

V3X4-13 62025-C 21173 25803 27804 61116 71099-1 71213 58053 17171 58055

V4X6-13 62025-C 21173 25805 27805 61116 71099-1 71213 58053 17171 58055

V6X8-15 62025-C 21122 25806 27806 61122 71099-1 71213 58053 17171 58055

*FOR SPECIFIC PART NUMBERS PLEASE PROVIDE SERIAL NUMBER.

54 HD POWER FRAME

RADIAL

MODEL SHAFT (8)

V3X4-13 100035 41319 41314-DR 68100-2 51082 51081 14082 14081 83013 83012

V4X6-13 100035 41319 41314-DR 68100-2 51082 51081 14082 14081 83013 83012

V6X8-15 100035 41319 41314-DR 68100-2 51082 51081 14082 14081 83013 83012

THROTTLE

BUSHING

MODEL

(13)

BEARING

(7)

STEM

PLATE

V3X4-13 62054-C 21173 25803 27804 61116 71099-1 71213 58071L 17171 58054

V4X6-13 62054-C 21173 25805 27805 61116 71099-1 71213 58071L 17171 58054

V6X8-15 62054-C 21122 25806 27806 61122 71099-1 71213 58071L 17171 58054

*FOR SPECIFIC PART NUMBERS PLEASE PROVIDE SERIAL NUMBER.

(14)

THRUST

BEARING

(3)

(17)

LOCKNUT

(2)

HOUSING

(19)

CARTRIDGE

(4)

IMPELLER

HSG.

GASKET

(15)

BRG.

HOUSING

(9)

DRIVE

KEY (16)

RETAINER

(1)

NUT (18)

BRG./GRS.

RETAINER

(6)

BRG. HSG.

SLINGER

(20) STEM (11)

OIL SEAL

(10)

CARTRIDGE

OIL SEAL (5)

SLINGER

(12)

(12)

GUSHER PUMPS IS A DIVISION

OF RUTHMAN COMPANIES

RUTHMAN COMPANIES

CORPORATE HEADQUARTERS

1212 STRENG STREET

CINCINNATI, OH. 45233

PHONE: 513-559-1901

FAX: 513-559-0035

WEB: www.ruthmancompanies.com

GUSHER PUMPS OF DRY RIDGE

22 RUTHMAN DRIVE

DRY RIDGE, KY. 41035

PHONE: 859-824-5001

FAX: 859-824-3011

WEB: www.gusher.com

GUSHER PUMPS OF WILLIAMSTOWN

115 INDUSTRIAL DRIVE

WILLIAMSTOWN, KY. 41097

PHONE: 859-824-3100

FAX: 859-824-7248

WEB: www.gusher.com

GUSHER PUMPS OF CALIFORNIA

8226 SALT LAKE AVENUE

CUDAHY, CA 90201

PHONE: 323-773-0847

FAX: 323-773-8462

EMAIL: gusherca@aol.com

GUSHER PUMPS OF NEW CASTLE

403 NORTH NINTH STREET

NEW CASTLE, IN. 47362

PHONE: 765-529-5624

FAX: 765-521-0008

EMAIL: gusherpumpnc@gmail.com

NAGLE PUMPS

1249 CENTER AVENUE

CHICAGO HEIGHTS, IL 60411

PHONE: 708-754-2940

FAX: 708-754-2944

WEB: www.naglepumps.com

WAGNER PROCESS EQUIPMENT

3727 METRO DRIVE, SUITE B

STOCKTON, CA 95215

PHONE: 209-931-0100

FAX: 209-931-7910

WEB: www.wagnerprocess.com

GREAT LAKES PUMP & SUPPLY CO.

1075 NAUGHTON

TROY, MI. 48083

PHONE: 248-528-9100

FAX: 248-528-9015

WEB: www.greatlakespump.com

PROCESS SYSTEMS, INC.

MICHIGAN, MAIN HEADQUARTERS

23633 PINEWOOD

WARREN, MI. 48091

PHONE: 586-757-5711

FAX: 586-758-6996

WEB: www.psi4pumps.com

INDIANA

485 N STATE ROUTE 3431

SOUTH MELLOTT, IN. 47958

PHONE: 765-295-2206

FAX: 765-295-2243

WEB: www.psi4pumps.com

WORLDWIDE:

RUTHMANN PUMPEN

THOMAS-EDISON-STR. 11

52499 BAESWEILER, GERMANY

TEL: 0049 (0) 2401-80 489 0

FAX: 0049 (0) 2401-80 489 20

WEB: www.ruthmannpumpen.de

BSM PUMP CORP.

180 FRENCHTOWN ROAD

NORTH KINGSTOWN, RI 02852

PHONE: 401-471-6350

FAX: 401-471-6370

WEB: www.bsmpump.com

GUSHER PUMPS SHANGHAI

上海格晞尔泵有限公司

913 CHANGLIN RD. SUITE 4012

SHANGHAI, CHINA 200443

上海市长临路

PHONE: +86 021 55151993

FAX: +86 021 56422332

WEB: www.gusher.cn

913号4012

室

Loading...

Loading...