Page 1

CMG-5TD Digital

Accelerometer

Operator's Guide

Document No. MAN-050-0005

Designed and manufactured by

Güralp Systems Limited

3 Midas House, Calleva Park

Aldermaston RG7 8EA

England

Proprietary Notice: The information in this document is

proprietary to Güralp Systems Limited and may be copied or

distributed for educational and academic purposes but may

not be used commercially without permission.

Whilst every effort is made to ensure the accuracy,

completeness or usefulness of the information in the

document, neither Güralp Systems Limited nor any employee

assumes responsibility or is liable for for any incidental or

consequential damages resulting from the use of this

document.

Issue D April 2013

Page 2

CMG-5TD Digital Accelerometer Contents

Table of Contents

1 Preliminary Notes............................................................................................................. 4

1.1 Proprietary Notice...................................................................................................... 4

1.2 Warnings, Cautions and Notes..................................................................................4

1.3 Manuals and Software............................................................................................... 4

1.4 Conventions................................................................................................................4

2 Introduction....................................................................................................................... 5

3 Quick start.........................................................................................................................6

3.1 Unpacking and packing............................................................................................. 6

3.2 Initial check-out......................................................................................................... 7

4 Setting the gain................................................................................................................ 10

4.1 Disassembly.............................................................................................................. 10

4.2 Jumper configuration for low gain operation..........................................................11

4.3 Jumper configuration for high gain operation.........................................................12

4.4 Reassembly............................................................................................................... 12

5 Operation......................................................................................................................... 13

5.1 Installation overview................................................................................................13

5.2 Installation method..................................................................................................13

5.3 Installation in hazardous environments..................................................................14

5.4 Orientation...............................................................................................................14

5.5 Levelling................................................................................................................... 14

5.6 Power supply considerations...................................................................................14

5.7 Connections.............................................................................................................. 14

5.8 Offset adjustment.....................................................................................................15

5.9 Configuration and control using Scream.................................................................16

5.9.1 System ID.......................................................................................................... 17

5.9.2 Output control................................................................................................... 17

5.9.3 Triggering.......................................................................................................... 20

5.9.4 Baud rates.......................................................................................................... 23

5.9.5 Data flow........................................................................................................... 23

5.9.6 Buffer Memory Usage....................................................................................... 28

6 Calibration...................................................................................................................... 29

6.1 The calibration pack................................................................................................29

6.1.1 Poles and zeroes................................................................................................29

6.1.2 Frequency response curves...............................................................................30

MAN-050-0005 Issue D - April 2013

Page 3

CMG-5TD Digital Accelerometer Preliminary Notes

6.1.3 Obtaining copies of the calibration pack.........................................................31

6.2 Calibration methods.................................................................................................32

6.3 Calibration with Scream! ........................................................................................ 32

6.3.1 Sensor response codes...................................................................................... 36

7 Connector pin-outs..........................................................................................................37

7.1 DATA........................................................................................................................37

7.2 GPS........................................................................................................................... 38

7.3 Analogue connector................................................................................................. 39

8 Specifications.................................................................................................................. 40

9 Revision History.............................................................................................................. 41

MAN-050-0005 3 Issue D - April 2013

Page 4

CMG-5TD Digital Accelerometer Preliminary Notes

1 Preliminary Notes

1.1 Proprietary Notice

The information in this document is proprietary to Güralp Systems Limited

and may be copied or distributed for educational and academic purposes but

may not be used commercially without permission.

Whilst every effort is made to ensure the accuracy, completeness and

usefulness of the information in the document, neither Güralp Systems

Limited nor any employee assumes responsibility or is liable for for any

incidental or consequential damages resulting from the use of this document.

1.2 Warnings, Cautions and Notes

Warnings, cautions and notes are displayed and defined as follows:

1.3 Manuals and Software

All manuals and software referred to in this document are available from the

Güralp Systems website, www.guralp.com, unless otherwise stated.

1.4 Conventions

Throughout this manual, examples are given of command-line interactions.

In these examples, a fixed-width typeface will be used:

Example of the fixed-width typeface used.

Commands that you are required to type will be shown in bold:

Example of the fixed-width, bold typeface.

Where data that you type may vary depending on your individual

configuration, such as parameters to commands, these data are additionally

shown in italics:

Example of the fixed-width, bold, italic typeface.

Putting these together into a single example:

System prompt: user input with variable parameters

MAN-050-0005 4 Issue D - April 2013

Warning: A black cross indicates a chance of injury or death if the

warning is not heeded.

Caution: A yellow triangle indicates a chance of damage to or

failure of the equipment if the caution is not heeded.

Note: A blue circle indicates indicates a procedural or advisory

note.

Page 5

CMG-5TD Digital Accelerometer Introduction

2 Introduction

The CMG-5TD consists of a fully-integrated triaxial accelerometer (CMG-5T)

and a matched 24-bit digitizer (DM-24) contained in a single, watertight

package. It is compact, lightweight, and simple to deploy. It can resolve the

full range of acceleration due to microearthquakes (0.1 uG resolution) up to

strong local earthquakes (4 g resolution).

It is provided with a combination baseplate/mounting plate, which is

separable and re-attachable, allowing for quick installation/removal and

sensor site re-occupation if necessary. The DC offsets are available at the

analogue output connector of the CMG-5TD and are user-accessible and

adjustable via adjusting screws on the top cap of the instrument. A GPS

receiver is used to provide accurate time-stamps for seismic data. The GPS

receiver is attached to the CMG-5TD via a supplied 20 metre cable.

MAN-050-0005 5 Issue D - April 2013

Page 6

CMG-5TD Digital Accelerometer Quick start

3 Quick start

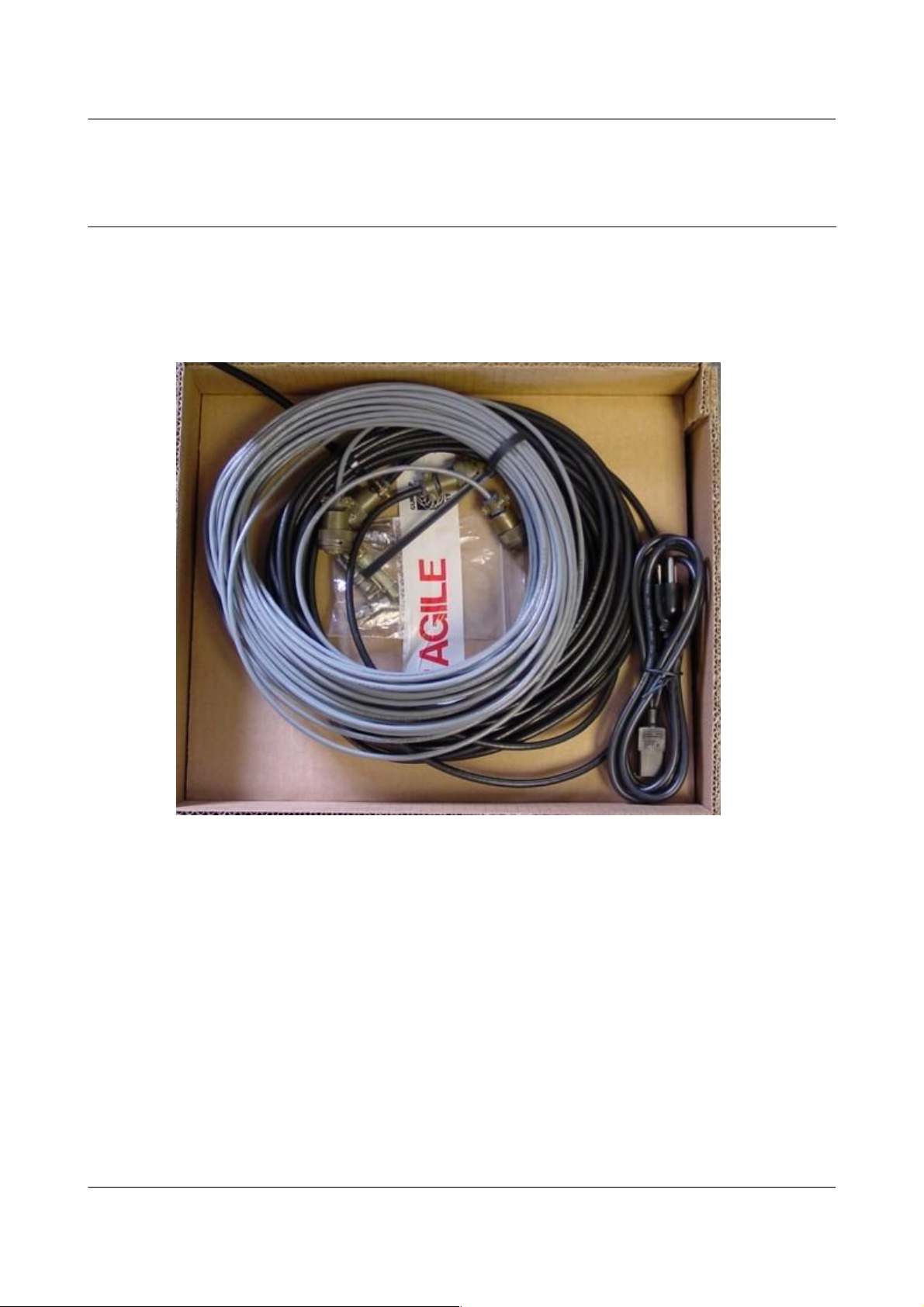

3.1 Unpacking and packing

The CMG-5TD accelerometer system is delivered in a single cardboard box

with foam rubber lining. The packaging is specifically designed for the

CMG-5T system. Whenever transported, the CMG-5TD system should be

packed in its original shipping container. The packaging should be saved for

re-use in the event of a later shipment.

Upon receipt of the equipment, please note any damage to the package.

Unpack on a clean surface. The package should contain: digital

accelerometer, a separable levelling baseplate, baseplate screws, concrete

anchor and mounting bolt, GPS receiver, GPS receiver cable and power/data

connection cable.

Place the CMG-5TD on a table and identify

• The power/data cable connector on the CMG-5TD top cap.

• The GPS cable connector on the CMG-5TD top cap.

• The analogue connector on the CMG-5TD top cap.

• The north orientation symbol on the CMG-5TD handle.

• The bubble level on the CMG-5TD top cap

MAN-050-0005 6 Issue D - April 2013

Page 7

CMG-5TD Digital Accelerometer Quick start

• The screw on/off cover for output offset adjustment on the CMG-5TD

top cap.

• The serial number on the label, on the top or side of the instrument.

3.2 Initial check-out

This section gives a quick outline for initial system test, which should

performed prior to installation. You must provide 10-36 V DC power and a

PC running Scream.

Attach the levelling baseplate to the base of the CMG-5TD using the screws

provided. Set the CMG-5TD onto a flat surface. Using the large hex screws on

the baseplate in conjunction with the bubble level, level the instrument.

Connect the CMG-5TD directly to the PC using the supplied power/data cable

Switch on the power supply. Using the PC, start Scream and take the

following steps:

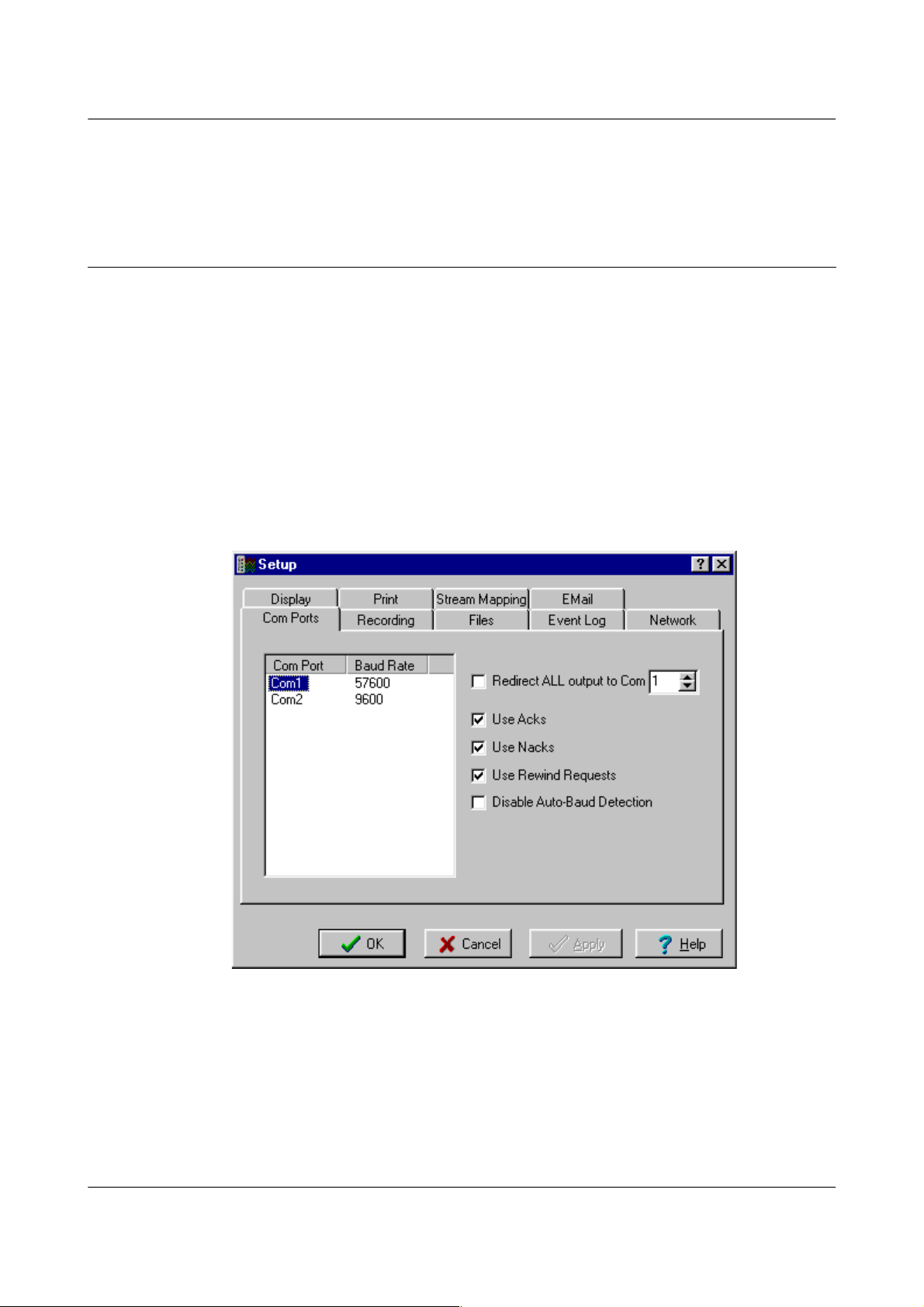

1. Click on 'Setup', from the ‘File’ menu

2. Select the ‘Com Ports’ tab

3. Click on the COM port to which the instrument is connected.

4. The factory-set baud rate for the CMG-5TD is 19200. Select 19200 from

the list.

5. Click on the ‘OK’ button to return to the main Available Streams

window.

MAN-050-0005 7 Issue D - April 2013

Page 8

CMG-5TD Digital Accelerometer Quick start

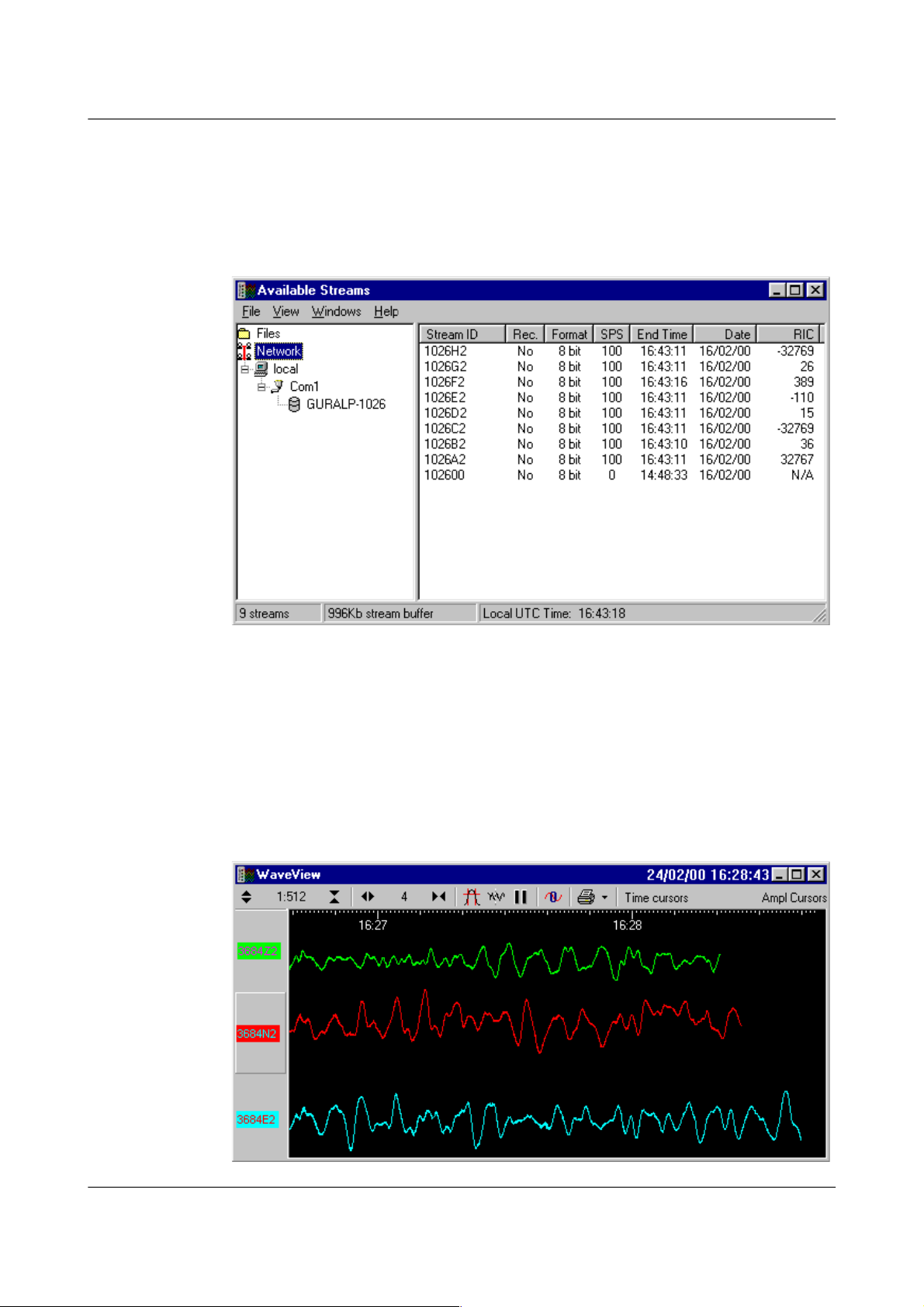

6. In the Available Streams window, the identifier of the instrument will

appear in the left hand frame (which appears similar to the tree type

format of Windows Explorer) under Network Local Com1’ (if→ →

Com1 is used)

7. The data streams will appear in the right-hand frame.

8. The Stream IDs are six-character strings which uniquely identify each

instrument, component and sample rate. (There may be up-to four

different sample rates per channel) The stream ending in ‘00’ contains

status information from the digitiser. Streams with higher sample rates

will appear in the display sooner than the slower sample rates and it

might take several minutes for the status stream to appear.

9. Select the data streams in the right side of the window by clicking on

the first and then control-clicking on the last. Press the “ENTER” key

to open these streams in a new ‘Waveview’ window.

MAN-050-0005 8 Issue D - April 2013

Page 9

CMG-5TD Digital Accelerometer Quick start

10. To see status information coming from the digitiser, right click on the

status stream. From the pop-up menu, select ‘View’. A new window,

‘Status’ should open containing text. The first blocks will give the boot

message from the DM, including its software revision and the data

streams selected for down-loading and triggering. Later blocks give

information on the expected GPS satellites, the location of the GPS

antenna, time synchronization status and transmit/receive baud rates

for each channel and the data link.

11. While viewing the time series from all three components in a

WaveView window, gently tap the CMG-5TD, and observe the response

of all three components. If the CMG-5TD passes this initial basic test,

then you may proceed to install the system (see the Operation section

of this User’s Guide).

MAN-050-0005 9 Issue D - April 2013

Page 10

CMG-5TD Digital Accelerometer Setting the gain

4 Setting the gain

The built in 5T sensor has a very large dynamic range. In order to exploit the

whole of this range, two separate outputs are available, one with high gain

and one with low gain. Normally, the high gain outputs are set to output a

signal 10 times stronger than that from the low gain outputs. Only one set of

outputs – low gain or high gain – is sent to the digitiser; the selection of which

output to digitise is made using internal jumpers.

4.1 Disassembly

In order to change the gain-setting jumpers, remove the instrument's lid as

follows:

• Use a large, flat-bladed screwdriver to remove the pressure-release

screw located on the instrument's lid next to the bubble-level.

• Use a small, flat-bladed screwdriver to remove the six small screws

located around the edge of the top of the lid.

• Note the location of the lid with respect to the body. Use a pencil or

adhesive tape to mark both so that the instrument can be reassembled

in the correct orientation.

• Using a medium, flat-bladed screwdriver, gently prise the lid away

from the body. A slot is provided in the top of the cylinder for this

purpose.

MAN-050-0005 10 Issue D - April 2013

Note: To change the gain, it is necessary to open the instrument.

This work must be carried out in a clean environment in order to

prevent contamination of the mechanical components by air-borne

dust.

Caution: The CMG-5TD include components which can be

damaged by electrostatic discharge (ESD). Always work on a

properly grounded dissipative surface and wear a suitable

grounded wristband. Ground yourself by touching an earthed

conductor before handling any of the circuit boards.

Warning: GSL instruments are assembled at near to sea level.

When using the instrument at altitude, there may be a

considerable pressure differential between the air inside the

casing and the external atmosphere. This could cause the

screw to fly off with considerable force when initially

released. Take care that this does not cause injury.

Page 11

CMG-5TD Digital Accelerometer Setting the gain

• Lift the lid and the attached electronics vertically out of the cylindrical

body and disconnect the ribbon cable at either end, noting the

orientation of the cable.

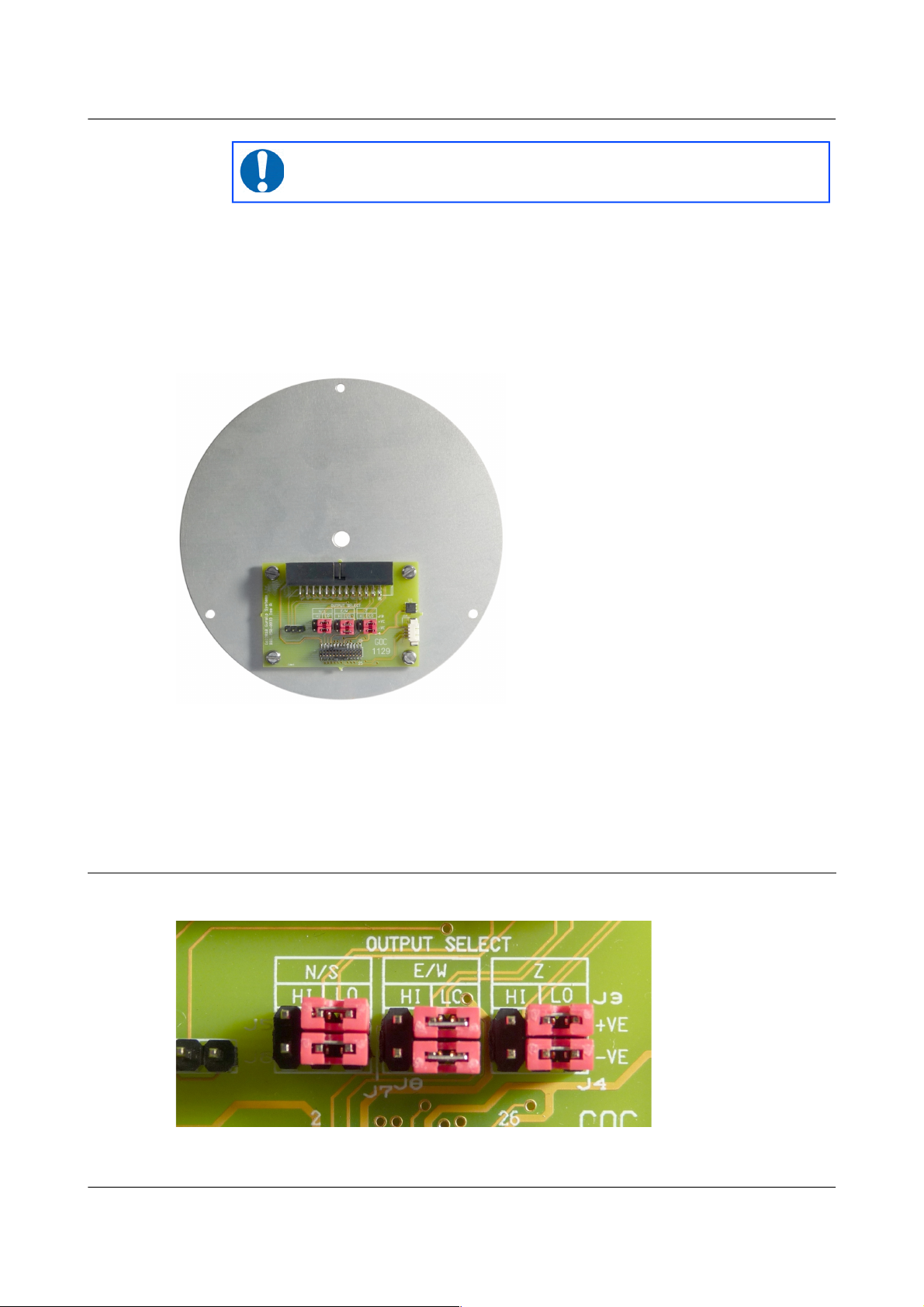

Looking down into the body of the instrument, you will see a small printed

circuit board mounted on an aluminium disc. This board contains the

gain-setting jumpers, which are coloured red to aid identification.

Each component (vertical, North/South and East/West) has two associated

jumpers (one for each leg of the differential connection) and these must

always be moved in pairs. It is possible to select different gains for different

channels but this is rarely desirable. Consult the markings on the printed

circuit board and the pictures below to select the desired gain.

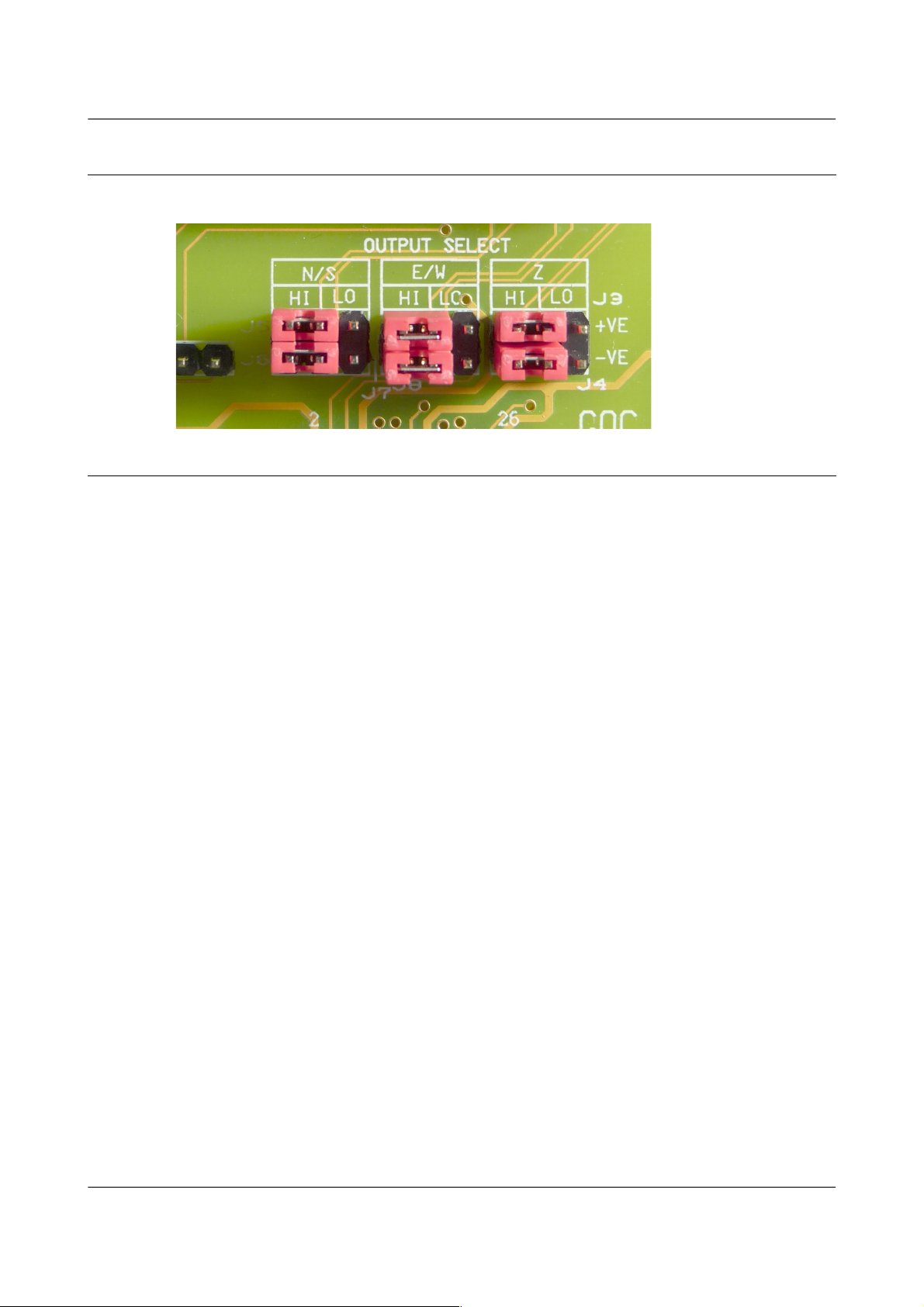

4.2 Jumper configuration for low gain operation

Arrange the jumpers as in the picture below:

MAN-050-0005 11 Issue D - April 2013

Note: The lid-to-body seal uses 'O'-rings. Take care that the

lid does not suddenly fly off when this seal is broken.

Page 12

CMG-5TD Digital Accelerometer Setting the gain

4.3 Jumper configuration for high gain operation

Arrange the jumpers as in the picture below:

4.4 Reassembly

Once the desired gain selection has been made, reconnect the ribbon cable

and gently lower the lid onto the instrument, taking care not to knock the

electronic assemblies or snag any cables. Ensure that the lid is rotated to the

correct orientation using the marks you made previously and then gently ease

it over the 'O'-ring seal and into place. Secure using the six small screws and,

finally, replace the large pressure release screw.

MAN-050-0005 12 Issue D - April 2013

Page 13

CMG-5TD Digital Accelerometer Operation

5 Operation

5.1 Installation overview

These steps make up the installation procedure. Detailed instructions follow

in subsequent sections.

• Unpack the accelerometer system from the reusable container (See

quick start). Save the shipping box for possible future use.

• Prepare the mounting surface.

• Mount the levelling baseplate to the CMG-5TD.

• Orient the CMG-5TD using the orientation pointers.

• Anchor the baseplate to the mounting surface.

• Level the CMG-5TD.

• Install the GPS receiver providing a clear view of the sky, and connect

it to the CMG-5TD using the GPS cable.

• Connect the CMG-5TD to a PC running Scream

• Connect the power supply (12 to 36 V DC) to the grey/blue power/data

cable

• Switch on the power and view the acceleration time series using

Scream.

• Using a DVM, check and adjust the CMG-5TD offsets if required.

• Cover the sensor with a polystyrene cover for long term thermal

stability. The cover will act as a thermal shield from draughts.

Position the polystyrene box carefully so that it does not touch the

sensor package.

5.2 Installation method

The surface should have a scribed north/south orientation line accurately

surveyed from reliable markers. Mount the concrete anchor into the

mounting bench, around the middle of the orientation line. Loosely attach

the mounting (lower) portion of the levelling plate to the concrete anchor,

using the bolt provided. Attach the upper portion of the levelling plate to the

base of the CMG-5TD using the screws provided. Finally, attach the CMG-5TD

to the mounting base by joining the two portions of the levelling plate using

the socket-cap screws provided.

MAN-050-0005 13 Issue D - April 2013

Page 14

CMG-5TD Digital Accelerometer Operation

5.3 Installation in hazardous environments

The fully enclosed aluminium case design of the 5T instrument makes it

suitable for use in hazardous environments where electrical discharges due to

the build up of static charge could lead to the ignition of flammable gasses.

To ensure safe operation in these conditions, the metal case of the instrument

must be electrically bonded ('earthing') to the structure on which it is

mounted, forming a path to safely discharge static charge.

Where electrical bonding ('earthing') is required during the installation of a 5T

instrument, the central mounting hole that extends through the instrument

should be used as the connection point. This is electrically connected to all

other parts of the sensor case. Connection can be made either via a cable from

a local earthing point terminated in a 8 mm ring tag or via the mounting bolt

itself.

5.4 Orientation

Use the handle and north indicator inscribed in the handle to orient the

CMG-5TD.

5.5 Levelling

Use the large socket-cap screws to level the CMG-5TD. Remove the upper

portion of the mounting plate, then tighten down the concrete bolt, securing

the base. Re-attach the upper portion of the mounting plate to the CMG-5TD.

Check orientation and level and then tighten down the levelling locking nuts.

5.6 Power supply considerations

The CMG-5TD will operate from 12-36 V DC. The CMG-5TD draws around

185 mA from a 12 V power supply.

5.7 Connections

Connect the GPS receiver to the CMG-5TD using the cables provided.

Connect the DE9 connector of the grey/blue power/data cable to a PC or

communications device.

Connect the power supply (12 to 36 V DC) to the bare ends of the grey part of

the grey/blue power/data cable. The red core should go to the positive

terminal or the terminal marked '+' and the black core should go to the

negative terminal or the terminal marked '-'. The power supply should be

capable of sourcing 200 mA.

MAN-050-0005 14 Issue D - April 2013

Page 15

CMG-5TD Digital Accelerometer Operation

5.8 Offset adjustment

When the instrument is installed in it’s final position and correctly aligned,

the approximate level should be checked using the bubble level on the top of

the casing. The bubble should lie completely within the scribed ring. To

check the DC offsets, read the RIC value for each acceleration stream in the

SCREAM window. No adjustment is necessary if these values are less than or

equal to ±5000 counts.

To adjust the DC offsets, remove the screwed cover protecting the adjustment

screws, as shown in the diagram below.

Selecting the channels in turn, adjust the level screws to reduce the RIC

values to less than ±5000 counts, repeating until consistent results are

obtained on all three channels. When offset adjustment is complete, replace

the protective cover firmly.

It is likely that, after the cover is installed, the accelerometer outputs will drift

until the system establishes temperature equilibrium with it’s environment

MAN-050-0005 15 Issue D - April 2013

Warning: GSL instruments are assembled at near to sea level. When

using the instrument at altitude, there may be a considerable

pressure differential between the air inside the casing and the

external atmosphere. This could cause the sealed cap to fly off with

considerable force when initially released. Take care that this does

not cause injury.

Page 16

CMG-5TD Digital Accelerometer Operation

and the sensor settles down in its position. If required, the adjustment can be

repeated to achieve a better (lower) output offset. With experience, it should

be possible to reduce low acceleration output levels to about ±5000 counts or

less.

5.9 Configuration and control using Scream

Scream is a free software application for Windows and Linux PCs. For more

information and download details, please see www.guralp.com/scream/.

The CMG-5TD may be configured using Scream's graphical interface. Rightclick on the digitiser's icon in the source tree and select “Configure” from the

pop-up menu. Using this dialogue, you may interactively set the digitiser's

system characteristics, control the output of streams at different digitisation

rates and set output baud rates and digitiser buffering parameters.

Alternatively, using terminal emulation software, such as PuTTY, minicom or

Hyper Term, you can access the digitiser's command line and send commands

directly to the built in CMG-DM24 digitiser.

This mode may also be invoked from Scream by right-clicking on the

digitiser's icon and selecting Terminal from the pop-up menu. When using

standard terminal programs, you must initiate command mode by typing

+ . This is done automatically by Scream when a terminal window

is opened to a digitiser. If you use the Scream configuration dialogue, data

collection will continue while you are setting digitiser parameters. If you use

Scream's terminal mode or a terminal emulator, data collection will be

interrupted until you exit terminal mode by typing “GO” or issuing a

RE-BOOT command.

MAN-050-0005 16 Issue D - April 2013

Page 17

CMG-5TD Digital Accelerometer Operation

Parameters from most of the commands are stored to the battery-backed

CMOS and only take effect when the digitiser is rebooted. When you click the

“Download” button from the digitiser configuration interface, the parameters

you have chosen are transferred to the digitiser and it is automatically

rebooted. You will notice a data gap in the traces in the Waveview window

corresponding to the digitiser you have rebooted. This occurs because the

reboot automatically clears the data buffer and resets the output block

counter.

To access the digitiser configuration dialogue from Scream, double-click on

the digitiser's icon in the Available Streams window (NOT the Local or COM

port icons). Alternatively, you can right-click on the digitiser's icon and then

select “Configure” from the pop-up menu.

The following sections correspond to the different tabs available in the

configuration dialogue.

5.9.1 System ID

System Identifier and Serial Number: The digitiser type is identified by its

system identifier and serial number. These two parameters are stored as the

first two 32-bit fields in the header of each data and status block generated by

the digitiser, in order to indicate the block's origin. Each of these parameters

consists of 6 alphanumerics encoded as base 36 numbers. On delivery from

the factory, the system identifier and the serial number are, respectively, set to

the GSL works order number and the seismometer’s serial number. Either

parameter can be reset to any convenient combination of letters and numbers,

such as an abbreviation of your institution and the deployment site code.

Sensor Type: This field will be pre-programmed at the factory for the proper

sensor type (CMG-5T).

GPS Type: The digitiser can utilize time signals from different sources.

Options available are NMEA (Garmin or Trimble) GPS receivers or stream

synchronization. When using stream synchronization, time signals from a

GPS antenna are sent via telemetry from a central site to the digitiser. In order

to synchronize with the time standard in use, the correct option must be

selected.

5.9.2 Output control

Sampling rate: The output of the digitiser’s analogue-to-digital converters

(ADC) is sampled at 2 kHz. These data are filtered and reduced to lower rates

using a digital signal processor (DSP). The DSP has four cascaded

filter/decimation stages, each of which can be programmed for decimation

factors of ÷2, ÷4, ÷5, ÷8 or ÷10. The output of each stage is called a “tap”.

Each stage may be configured for a different decimation factor.

MAN-050-0005 17 Issue D - April 2013

Page 18

CMG-5TD Digital Accelerometer Operation

The four text-fields on the left of the Output Control tab allow you to select

the sampling rates for each of the four digitiser taps. Each of the taps must

have a sampling rate lower than the one above but the rate must be achievable

using decimation by a factor of 2, 4, 5, 8 or 10. Each drop-down menu offers a

list of the rates that are permitted, given the sampling rate on the line above it.

If some of the outputs are not required, leave the check-boxes clear in order to

reduce communications bandwidth requirements.

Stream selection: The digitiser has three channels or streams. These are

depicted by the three columns labelled Z, N and E in the Output Control

window shown above.

A tick in a box will give an output for the corresponding channel (column) at

the corresponding sample rate (row). For each sample rate there are two

possible rows to tick. The upper row for each sample rate will give a

continuous output at that sample rate; the lower row, shown

diagrammatically as passing through a switch, will only output data when its

trigger criteria are met (see below).

The Stream IDs displayed in the main Available Streams window have

six-character ID’s. The first four characters identify the digitiser and the last

two characters identify the stream from the digitiser. The first of these two

characters identify the channel, while the second defines the ‘tap’, or digitiser

output ( see Data Transmission Protocol & Data Block Structure later).

For example; for the Output Control configuration shown above, there will be

three data streams, Z, N and E, providing continuous data at 100sps, 20sps

and 2sps. This is shown below, where the digitiser ‘1123’ has the following

streams:-

MAN-050-0005 18 Issue D - April 2013

Page 19

CMG-5TD Digital Accelerometer Operation

• Z2, N2, E2 are input channels Z, N, E output through the second tap ‘2’;

• Z4, N4, E4 are input channels Z, N, E output through the third tap ‘4’,

• Z6, N6, E6 are input channels Z, N, E output through the fourth tap ‘6’,

• 00 is the digitiser status stream (notice that there is no sample rate)

(Odd tap numbers (1, 3, 5, …) are used for streams from a second instrument.)

For each tap there are two rows of check-boxes where the user can tick either

triggered or continuous data outputs. The digitiser applies a simple short

term average (STA) ÷ long term average (LTA) algorithm and/or an absolute

level (counts) algorithm to a selected stream or set of streams to determine

whether the trigger condition is met. These streams may be bandpass filtered

before evaluation using standard bandpass parameters. The data transmitted

due to the trigger may be from different streams than those used to determine

the trigger.

For this to function properly, triggering streams must be selected and trigger

criteria must be set by clicking on the Trigger button . When at least one

stream is selected for triggered output, selection of triggering streams and

trigger criteria are enabled. It is possible to trigger from one tap but record

data from one or several different taps.

MAN-050-0005 19 Issue D - April 2013

Page 20

CMG-5TD Digital Accelerometer Operation

5.9.3 Triggering

Once at least one box is checked for triggered output, the Triggering box and

tab are activated. If you set triggering, you must also set the parameters for

the trigger criteria.

The Data Source button selects the tap (streams) that will be evaluated for

triggers for both the STA/LTA and the Level triggers. In general, it is not

MAN-050-0005 20 Issue D - April 2013

Page 21

CMG-5TD Digital Accelerometer Operation

advisable to use an STA/LTA trigger directly from broadband data. The

Bandpass Filter button allows the user to select from a set of standard

bandpass filters from a pull-down menu (a full list of options is given later in

the STA/LTA chapter). The chosen filter will be applied to the streams from

the triggering components before they are tested for the trigger condition.

The corner frequencies of the pass band of the filter are determined by the

Nyquist frequency, which is given by the sampling rate of the triggering data.

The three filter options have pass bands between 10% and 90%, between 20%

and 90% and between 50% and 90% of the data’s Nyquist frequency,

respectively.

Trigger criteria: Trigger criteria for the STA/LTA and Level triggers function

may be set in the Trigger Setup window, accessed by clicking on the Trigger

button near the bottom of the Output Control window.

The three tick boxes down the left side of the windows (Z, N, E) allows the

user to choose the channels (for the specified tap) which will be tested for a

trigger condition.

STA/LTA parameters: The user sets the parameters by clicking on them.

Typically, the time interval for the short term average should be about as long

as the signals you want to trigger on, while the long term average should be

taken over a much longer interval. Both the STA and LTA values are

recalculated continually, even during a trigger.

The system declares a trigger when any one of the triggering components

exceeds this value. The trigger ratio is continuously recalculated for all

components and the system will only cancel the trigger condition when all

the components selected for triggering have fallen below their respective ratio

values.

The user can also specify the pre-trigger and post-trigger data intervals. These

values determine the minimum length of data that will be saved prior to the

trigger condition, and how much data will be saved after the trigger condition

has lapsed. Triggered streams will always start and end on integer seconds.

If the box “Common Values” is ticked, a trigger parameter entered for one

component will be used for all selected components. (BANDPASS, STA, LTA,

RATIO, PRE-TRIG and POST-TRIG).

MAN-050-0005 21 Issue D - April 2013

Page 22

CMG-5TD Digital Accelerometer Operation

Level triggering parameters: The user specifies the Data Source, channels

and levels by clicking on them, similar to the STA/LTA settings. The levels are

specified in counts.

MAN-050-0005 22 Issue D - April 2013

Page 23

CMG-5TD Digital Accelerometer Operation

5.9.4 Baud rates

This tab allows the setting of the line speed for the main serial output.

It is possible to set different rates for transmission and reception but this is

rarely required with modern communications equipment. Ticking the

“Identical Tx/Rx rates” check-box simplifies the dialogue.

A line speed of 115,200 Baud is adequate for the highest sample rates that the

instrument can generate. It may be necessary to reduce the line speed if the

data are to be passed over a modem or wireless link.

The “Stop Bits” drop-down menu should be left at 1 unless your

communications equipment requires a different value.

5.9.5 Data flow

The digitizer operates in one of several transmission modes. These modes

relate to how the unit uses its Flash memory:

• as a simple data store, from which you can request data (FILING and

DUAL modes);

• as a buffer holding unacknowledged blocks, which are transmitted in

preference to real-time data (FIFO mode);

• as a buffer holding unacknowledged blocks, which are transmitted

whenever the transmission is free but no real-time data blocks are

ready (ADAPTIVE mode);

• not at all (DIRECT mode).

MAN-050-0005 23 Issue D - April 2013

Page 24

CMG-5TD Digital Accelerometer Operation

Separate from these modes are buffering modes, which tell the unit what to do

when its Flash memory becomes full: either

• carry on, overwriting the oldest data held, or

• stop writing and switch the digitizer into DIRECT mode.

You can switch between filing modes in Scream! by right-clicking on the

digitizer and clicking on Control..., then navigating to the Data Flow pane:

To choose a transmission or buffering mode, choose options from the

Transmission Mode or Buffering drop-down menus, and click Apply. An

explanation of the chosen mode is displayed beneath each menu. The

following sections also explain the filing modes available.

The Buffering legend also displays the amount of Flash memory present in

your digitizer. In the example screen-shot above, this is 64 Mb.

To clear the Flash memory of the digitizer, click the Reset-flash button. You

will be asked for confirmation before the memory is cleared.

At the bottom of the tab is a line describing the current state of the digitizer's

memory pointers. You can use this line to check that data are being written

into memory. Select Auto-Refresh to make the line update automatically.

5.9.5.1 DIRECT

Instructs the digitizer not to use Flash memory for storage. Instead, all data

are transmitted directly to clients. An instrument in DIRECT mode still

honours the GCF Block Recovery Protocol: a temporary RAM buffer always

holds the last 256 blocks generated, and if a client fails to receive a block it

can request its retransmission.

MAN-050-0005 24 Issue D - April 2013

Page 25

CMG-5TD Digital Accelerometer Operation

If you expect breaks in communication between the instrument and its client

to last more than 256 blocks, or if you want the instrument to handle breaks

in transmission (rather than relying on the client to request missed blocks),

you should use

• ADAPTIVE mode, if you want data to stay as near to real time as

possible (but do not mind if blocks are received out of order) or

• FIFO mode, if you need blocks to be received in strict order (but do not

mind if the instrument takes a while to catch up to real time.)

5.9.5.2 DUPLICATE

Instructs the DM24 to transmit streams directly to clients as for DIRECT

mode, but also to store all data into Flash storage as for FILING mode. If a

client fails to acknowledge a block, the digitizer does not attempt to retransmit

it.

Heartbeat messages are not sent in DUPLICATE mode.

5.9.5.3 FILING

Instructs the digitizer not to transmit blocks to clients automatically, but to

store all digitized data in the Flash memory. If you have chosen the RECYCLE

buffering mode (see below), the memory is used in circular fashion, i.e. if it

becomes full, incoming blocks begin overwriting the oldest in memory. If the

WRITE-ONCE mode is active, the instrument will switch to DIRECT mode (see

above) when the memory becomes full.

Heartbeat messages

When in FILING mode, an instrument transmits “heartbeat” messages over its

data port. These short messages take the place of data blocks, and ensure that

programs such as Scream! know that an instrument is present.

If your digitizer is in FILING mode, Scream! will displays a slider at the

bottom of the tab. Moving this slider changes the interval between heartbeat

blocks.

MAN-050-0005 25 Issue D - April 2013

Page 26

CMG-5TD Digital Accelerometer Operation

You can tell Scream! to download new data automatically whenever it

receives a heartbeat message from an instrument in FILING mode. This is

useful, for example, in autonomous installations connected by intermittent

modem links. To enable this feature:

1. Choose File Setup... → from Scream!'s main menu, and navigate to the

Recording pane.

2. Check Auto-download on heartbeat.

3. Click OK.

Using FILING mode with Auto-download on heartbeat ensures that Scream!

receives all new data whenever it can, regardless of the configuration of any

devices between you and the instrument.

5.9.5.4 DUAL

Instructs the digitizer to transmit any continuous streams directly to clients as

for DIRECT mode, but to store triggered data into Flash storage as for FILING

mode.

If you choose DUAL mode but do not select any continuous streams for

output, the instrument will send heartbeat messages as for FILING mode.

Scream! can pick these up and download new data as necessary.

MAN-050-0005 26 Issue D - April 2013

Page 27

CMG-5TD Digital Accelerometer Operation

5.9.5.5 FIFO (First In First Out)

Instructs the digitizer to begin writing blocks to Flash memory as for FILING

mode, but also to transmit data to clients. Data are transmitted in strict order,

oldest first; the digitizer will only transmit the next block when it receives an

explicit acknowledgement of the previous block.

If the communications link is only marginally faster than the data rate, it will

take some time to catch up with the real-time data after an outage. If you

want data to be transmitted in real-time where possible, but are worried about

possible breaks in communication, you should use ADAPTIVE mode instead.

FIFO mode will consider a data block successfully transmitted once it has

received an acknowledgement from the next device in the chain. If there are

several devices between you and the instrument, you will need to set up the

filing mode for each device (if applicable) to ensure that data flow works the

way you expect.

Like all the filing modes, FIFO mode does not delete data once they have been

transmitted. You can still request anything in the Flash memory using

Scream! or over the command line. The only way data can be deleted is if

they are overwritten (in the RECYCLE buffering mode, see below) or if you

delete them manually.

5.9.5.6 ADAPTIVE

Instructs the digitizer to transmit current blocks to clients if possible, but to

store all unacknowledged blocks in the Flash memory and re-send them,

oldest first, when time allows. ADAPTIVE mode is best suited for “real-time”

installations where the link between digitizer and client is intermittent or

difficult of access.

If the communications link is only marginally faster than the data rate, it will

usually be busy transmitting real-time data. Thus, it may take a while for the

instrument to work through the missed blocks. In this case, and if your client

MAN-050-0005 27 Issue D - April 2013

Page 28

CMG-5TD Digital Accelerometer Operation

supports it, you may prefer to use the Block Recovery Protocol to request

missed blocks where possible.

Some software packages (most commonly Earthworm) cannot handle blocks

being received out of time order. If you are using such a package, ADAPTIVE

mode will not work, and may crash the software.

5.9.6 Buffer Memory Usage

5.9.6.1 RE-USE / RECYCLE

Instructs the digitizer to carry on using the current filing technique when the

Flash memory becomes full, overwriting the oldest data held. This buffering

mode is called RECYCLE in Scream!

For example, in DUAL mode with RECYCLE buffering, the latest continuous

data will be transmitted to you as normal, and the latest triggered data may be

retrieved from the Flash memory using Scream! or the digitiser's command

line. However, if you do not download data regularly from the Flash memory,

you may lose older blocks. This mode thus lets you define the end point of

the data held by the instrument.

5.9.6.2 WRITE-ONCE

Instructs the digitizer to stop writing data to the Flash memory when it is full,

and to switch to DIRECT mode automatically.

For example, in FIFO mode with WRITE-ONCE buffering, the station will

transmit data to you continuously, but also save them in the Flash memory

until it is full. Once full, the instrument will switch to DIRECT mode and

continue transmitting, though no further data will be saved. This mode thus

lets you define the start point of the data held by the instrument.

MAN-050-0005 28 Issue D - April 2013

Page 29

CMG-5TD Digital Accelerometer Calibration

6 Calibration

6.1 The calibration pack

All Güralp sensors are fully calibrated before they leave the factory. Both

absolute and relative calibration calculations are carried out. The results are

given in the calibration pack supplied with each instrument:

Works Order : The Güralp factory order number including the instrument,

used internally to file details of the sensor's manufacture.

Serial Number : The serial number of the instrument

Date : The date the instrument was tested at the factory.

Tested By : The name of the testing engineer.

There follows a table showing important calibration information for he

instrument, which shows:

Acceleration Output (Differential) : The sensitivity to acceleration at 1 Hz, in

volts per ms-2. Because the CMG-5TD uses a balanced differential output to

connect to the digitiser, the signal strength as measured between the +ve and

–ve line will be twice the true sensitivity of the instrument. To remind you of

this, the sensitivity is given as 2 × (single-ended sensitivity).

Feedback Coil Constant : A constant describing the characteristics of the

feedback system. You will need this constant, given in amperes per ms-2, if

you want to perform your own calibration calculations (see below.)

Power Consumption : The average power consumption of the sensor during

testing, given in amperes and assuming a 12 V supply.

Calibration Resistor : The value of the resistor in the calibration circuit. You

will need this value if you want to perform your own calibration calculations

(see below.)

6.1.1 Poles and zeroes

Most users of seismometers find it convenient to consider the sensor as a

“black box”, which produces an output signal V from a measured input x. So

long as the relationship between V and x is known, the details of the internal

mechanics and electronics can be disregarded. This relationship, given in

terms of the Laplace variable s, takes the form

( V / x ) (s) = G × A × H (s)

In this equation

MAN-050-0005 29 Issue D - April 2013

Page 30

CMG-5TD Digital Accelerometer Calibration

• G is the acceleration output sensitivity (gain constant) of the

instrument. This relates the actual output to the desired input over the

flat portion of the frequency response.

• A is a constant which is evaluated so that A × H (s) is dimensionless

and has a value of 1 over the flat portion of the frequency response. In

practice, it is possible to design a system transfer function with a very

wide-range flat frequency response.

The normalising constant A is calculated at a normalising frequency

value fm = 1 Hz, with s = j fm, where j = √–1.

• H (s) is the transfer function of the sensor, which can be expressed in

factored form:

In this equation, zn are the roots of the numerator polynomial, giving

the zeros of the transfer function, and pm are the roots of the

denominator polynomial giving the poles of the transfer function.

In the calibration pack, G is the sensitivity given on the first page, whilst the

roots zn and pm, together with the normalising factor A, are given in the Poles

and Zeros table. The poles and zeros given are measured directly at Güralp

Systems' factory using a spectrum analyser.

6.1.2 Frequency response curves

The frequency response of the CG-5TD is described in the normalised

amplitude and phase plots provided. The response is measured at low and

high frequencies in two separate experiments. Each plot marks the

low-frequency and high-frequency cut-off values (also known as –3 dB or

half-power points).

MAN-050-0005 30 Issue D - April 2013

Page 31

CMG-5TD Digital Accelerometer Calibration

If you want to repeat the calibration to obtain more precise values at a

particular frequency of interest, or to check that a sensor is still functioning

correctly, you can inject calibration signals into the system using a Güralp

digitizer or your own signal generator, and record the instrument's response.

6.1.3 Obtaining copies of the calibration pack

Our servers keep copies of all calibration data that we send out. In the event

that the calibration information becomes separated from the instrument, you

can obtain all the information using our free e-mail service. Simply e-mail

caldoc@guralp.com with the serial number of the instrument in the subject

line, e.g.

From: your@email.net

To: caldoc@guralp.com

Subject: T5215

The server will reply with the calibration documentation in Microsoft Word

format. The body of your e-mail will be ignored.

6.2 Calibration methods

Three common calibration techniques are available:

• Injecting a step current allows the system response to be determined in

the time domain. The amplitude and phase response can then be

MAN-050-0005 31 Issue D - April 2013

Page 32

CMG-5TD Digital Accelerometer Calibration

calculated using a Fourier transform. Because the input signal has

predominantly low-frequency components, this method generally gives

poor results. However, it is simple enough to be performed daily.

• Injecting a sinusoidal current of known amplitude and frequency

allows the system response to be determined at a spot frequency.

However, before the calibration measurement can be made, the system

must be allowed to reach a steady state; for low frequencies, this may

take a long time. In addition, several measurements must be made to

determine the response over the full frequency spectrum.

• Injecting white noise into the calibration coil gives the response of the

whole system, which can be measured using a spectrum analyser.

You can perform calibration using the built-in CMG-DM24 digitizer, which

can generate step and sinusoidal calibration signals.

6.3 Calibration with Scream!

Calibration is most easily done using a PC running Güralp's Scream! Software.

In this section, broadband noise calibration will be used to determine the

complete sensor response in one action. Please refer to the CMG-DM24 and

Scream manuals for information on other calibration methods.

1. In Scream!'s main window, right-click on the digitiser's icon and select

Control.... Open the Calibration pane.

2. Select the calibration channel corresponding to the instrument, and

choose Broadband Noise. Select a suitable duration and amplitude,

and click Inject now. A new data stream, ending Cn (n = 0 – 7) or MB,

should appear in Scream!'s main window containing the returned

calibration signal.

MAN-050-0005 32 Issue D - April 2013

Page 33

CMG-5TD Digital Accelerometer Calibration

3. Open a Waveview window on the calibration signal and the returned

streams by selecting them and double-clicking. The streams should

display the calibration signal combined with the sensors' own

measurements. If you cannot see the calibration signal, zoom into the

Waveview using the scaling icons at the top left of the window or the

cursor keys.

Drag the calibration stream Cn across the Waveview window, so that it

is at the top.

4. If the returning signal is saturated, retry using a calibration signal with

lower amplitude, until the entire curve is visible in the Waveview

window.

5. If you need to scale one, but not another, of the traces, right-click on

the trace and select Scale.... You can then type in a suitable scale factor

for that trace.

6. Pause the Waveview window by clicking on the icon.

MAN-050-0005 33 Issue D - April 2013

Page 34

CMG-5TD Digital Accelerometer Calibration

7. Hold down SHIFT and drag across the window to select the calibration

signal and the returning component(s). Release the mouse button,

keeping SHIFT held down. A menu will pop up. Choose Broadband

Noise Calibration.

8. This runs a script, bbnoisecal, which prompts you for sensor

calibration parameters for each component you have selected.

MAN-050-0005 34 Issue D - April 2013

Page 35

CMG-5TD Digital Accelerometer Calibration

9. Most data can be found on the calibration sheet for your sensor. Under

Instrument response, you should fill in the sensor response code for

your sensor, according to the table below. Instrument Type should be

set to the model number of the sensor.

10. If the file calvals.txt exists in the same directory as Scream!'s

executable (scream.exe), Scream! will look there for suitable

calibration values. A sample calvals.txt is supplied with Scream!,

which you can edit to your requirements. Each stream has its own

section in the file, headed by the line [instrument-id]. The

instrument-id is the string which identifies the digitizer in the

left-hand pane, e.g. GURALP-DEMO. It is always 6 characters or fewer

(the system identifier) followed by a dash, then 4 characters or fewer

(the serial number). For example:

[DEMO00-4V99]

Serial-Nos=T4V99

VPC=3.153

G=1010

COILCONST=0.02575

CALVPC=3.161

CALRES=51000

TYPE=sensor-type

RESPONSE=response-code

11. Click . The script will return with a graph showing the response

of the sensor in terms of amplitude and phase plots for each

component.

MAN-050-0005 35 Issue D - April 2013

Page 36

CMG-5TD Digital Accelerometer Calibration

The accuracy of the results depends on both the amount of data you have

selected and on its sample rate. To obtain good-quality results at low

frequency, it will save computation time to use data collected at a lower

sample rate; although the same information is present in higher-rate streams,

they also include a large amount of high-frequency data which may not be

relevant to your purposes.

The bbnoisecal script automatically performs appropriate averaging to

reduce the effects of aliasing and cultural noise.

6.3.1 Sensor response codes

The table below shows the correct value to use in the Instrument response

field of the bbnoisecal dialogue, depending on the type of your instrument.

Sensor Sensor type code Units (V/A)

CMG-5TD, DC – 50 Hz response

DC-50 A

CMG-5TD, DC – 100 Hz response

CMG-5_100 A

CMG-5TD, DC – 200 Hz response

CMG-5_200 A

MAN-050-0005 36 Issue D - April 2013

Page 37

CMG-5TD Digital Accelerometer Connector pin-outs

7 Connector pin-outs

7.1 DATA

This is a standard 10-pin “mil-spec” plug,

conforming to MIL-DTL-26482 (formerly

MIL-C-26482). A typical part-number is

02E-12-10P although the initial “02E” varies

with manufacturer.

Suitable mating connectors have

part-numbers like ***-12-10S and are

available from Amphenol, ITT Cannon and

other manufacturers.

The pin-out is the same as the serial output of a CMG-DM24 digitiser and any

GSL digital instrument, allowing you to insert an instrument with an

embedded CMG-EAM into a pre-existing installation and maintain

connectivity.

Pin Function

A Power input, 0 V

B Power input, +10 to +35 V

C RS232 CTS

D RS232 RTS

E Not connected

F Not connected

G RS232 ground

H Not connected

J RS232 receive

K RS232 transmit

Wiring details for the compatible socket,

***-12-10S, as seen from the cable end (i.e.

during assembly).

MAN-050-0005 37 Issue D - April 2013

Page 38

CMG-5TD Digital Accelerometer Connector pin-outs

7.2 GPS

This is a standard 10-pin “mil-spec” plug,

conforming to MIL-DTL-26482 (formerly

MIL-C-26482). A typical part-number is

02E-12-10P although the initial “02E” varies

with manufacturer.

Suitable mating connectors have

part-numbers like ***-12-10S and are

available from Amphenol, ITT Cannon and

other manufacturers.

This pin-out is the same as the GPS input of a DM24 digitizer.

Pin Function

A Power 0 V

B Power +12 V

C 1pps signal

D not connected

E Console TxD

F Console RxD

G GPS ground

H Console ground

J RS232 transmit to GPS

K RS232 receive from GPS

Wiring details for the compatible socket,

***-12-10S, as seen from the cable end (i.e.

during assembly).

MAN-050-0005 38 Issue D - April 2013

Page 39

CMG-5TD Digital Accelerometer Connector pin-outs

7.3 Analogue connector

This is a standard 19-pin “mil-spec” socket,

conforming to MIL-DTL-26482 (formerly

MIL-C-26482). A typical part-number is

02E-14-19S although the initial “02E” varies with

manufacturer.

Suitable mating connectors have part-numbers

like ***-14-19P and are available from Amphenol,

ITT Cannon and other manufacturers.

Pin Function Pin Function

A High-gain N/S acc non-inverting L Unity-gain Z acc inverting

B High-gain N/S acc inverting M Unity-gain Z acc non-inverting

C Unity-gain N/S acc non-inverting N High-gain Z acc inverting

D Unity-gain N/S acc inverting P High-gain Z acc non-inverting

E Calibration signal R High-gain E/W acc non-inverting

F Power +12 V S Calibration enable

G Power 0 V T Signal ground

H not connected U Unity-gain E/W acc non-inverting

J Open/Closed loop mode V High-gain E/W acc inverting

K Unity-gain E/W acc inverting

Wiring details for the compatible plug,

***-14-19P, as seen from the cable end (i.e.

when assembling).

MAN-050-0005 39 Issue D - April 2013

Page 40

CMG-5TD Digital Accelerometer Specifications

8 Specifications

Transducer type Accelerometer

Standard output band DC – 100 Hz

Output sensitivity 4 g, 2 g, 1 g, 0.5 g, 0.1 g

Corresponding high gain outputs 0.4 g, 0.2 g, 0.1 g 0.05 g, 0.01 g

Peak analogue output ±10 V differential

Analogue output impedance 47 Ω nominal

Lowest spurious resonance > 450 Hz

Linearity 0.1 % full scale

Cross-axis rejection 0.001 g/g

Dynamic range > 165 dB

> 140 dB for 0.005 – 0.05 Hz

> 127 dB for 3 – 30 Hz

Operating temperature –20 to +70 °C

Materials Hard anodized aluminium case

Mil-spec connectors

Case diameter 176 mm

Case height (with feet / handle) 245 mm

Case height (sensor only 160 mm

Weight 4.3 kg

Isolating power supply 12 – 28 V DC

Current at 12 V DC 185 mA

Calibration controls Command-line

Optional low pass corner 50, 100 or 200 Hz

MAN-050-0005 40 Issue D - April 2013

Page 41

CMG-5TD Digital Accelerometer Revision History

9 Revision History

A 2002-06-05 Initial release

B 2002-10-21 Revision for firmware updates

C 2003-01-22 Revision for firmware updates

D 2012-04-17 Reformatted and revised

MAN-050-0005 41 Issue D - April 2013

Loading...

Loading...