Page 1

CMG-3T

Triaxial Broadband Seismometer

Ope rat or's g uide

Part No. MAN-030-0001

Designed and manufactured by

Güralp Systems Limited

3 Midas House, Calleva Park

Aldermaston RG7 8EA

England

Proprietary Notice: The information in this manual is

proprietary to Güralp Systems Limited and may not be

copied or distributed outside the approved recipient's

organisation without the approval of Güralp Systems

Limited. Güralp Systems Limited shall not be liable for

technical or editorial errors or omissions made herein,

nor for incidental or consequential damages resulting

from the furnishing, performance, or usage of this

material.

Issue N 2009-07-06

Page 2

CMG-3T

Table of Contents

1 Introduction...............................................................................................................3

1.1 Options................................................................................................................4

2 Installing the 3T........................................................................................................7

2.1 First encounters..................................................................................................7

2.2 Installation notes..............................................................................................10

2.3 Installing in vaults............................................................................................11

2.4 Installing in pits................................................................................................14

2.5 Installing in post-holes....................................................................................18

3 Calibrating the 3T...................................................................................................20

3.1 The calibration pack.........................................................................................20

3.2 Calibration methods.........................................................................................23

3.3 Calibration with Scream! ................................................................................23

3.4 Calibration with a hand-held control unit.......................................................28

3.5 The coil constant..............................................................................................28

4 Accessories...............................................................................................................30

4.1 The breakout box..............................................................................................30

4.2 The hand-held control unit..............................................................................31

4.3 Integrated State-of-Health Controller...............................................................33

5 Inside the 3T............................................................................................................35

5.1 The sensors.......................................................................................................35

5.2 The control system...........................................................................................36

5.3 RS232 control interface....................................................................................41

5.4 The feedback system........................................................................................42

6 Connector pin-outs..................................................................................................47

6.1 Sensor and control unit pin output.................................................................47

6.2 Sensor output (“D”-type connector option).....................................................48

6.3 Sensor output (waterproof connector option).................................................49

6.4 Breakout box POWER connector......................................................................50

7 Specifications..........................................................................................................51

8 Revision history.......................................................................................................53

2 Issue N

Page 3

Operator's guide

1 Introduction

The CMG-3T is a three-axis seismometer consisting of three sensors in

a sealed case, which can measure the north/south, east/west and

vertical components of ground motion simultaneously. Each sensor is

sensitive to ground vibrations in the frequency range 0.003 – 50 Hz, a

broadband frequency response made possible by advanced forcebalance feedback electronics. Because of this wide response range, the

3T can replace many of the instruments conventionally used in a

seismic observatory; it also produces true pulse-shape records suitable

for modern earthquake mechanism analysis.

The 3T is designed for mounting on a hard, near-horizontal surface

well coupled to the bedrock. After levelling and orienting the case, you

can perform accurate adjustments internally by sending the

instrument control signals. These electronics allow it to compensate

for a tilt of up to 3 ° from horizontal.

Once levelled and centred, the 3T will begin operating automatically.

It outputs analogue voltages representing ground velocity on balanced

differential lines. These voltages can be recorded using a separate

logging device or digitizer. For testing and installation purposes, a

hand-held control unit is supplied which can monitor the instrument's

output.

July 2009 3

Page 4

CMG-3T

The seismometer unit is self-contained apart from its 12 Volt power

supply. Centring and mass locking can be carried out by sending

control signals to the instrument, either through the hand-held control

unit or through an attached Güralp digitizer.

Each seismometer is delivered with a detailed calibration sheet

showing its serial number, measured frequency response in both the

long period and the short period sections of the seismic spectrum,

sensor DC calibration levels, and the transfer function in poles/zeros

notation.

1.1 Options

Form factors

The CMG-3T can be supplied in several forms, besides its standard

configuration:

• The CMG-3T Compact is internally identical to the standard 3T,

but has a different arrangement of components allowing it to fit

in a smaller casing.

• The 3T can also be supplied in a slimline form factor, with

vertically-stacked sensors, suitable for installation in post-holes

(see Section 2.5, page 18.).

• The 3T is also available as a fully-fledged borehole instrument,

the CMG-3TB.

Any of these can be supplied with integral digitizers and data

modules, allowing the 3T to form a complete, integrated seismic

installation. For example, the 3TD is a full-height 3T with an

integrated CMG-DM24 digitiser. As an additional option, the 3TD can

be ordered with an Integrated State-of-Health Controller, which

provides the mass-control functions (normally accessed via the breakout box) directly from controls mounted on the instrument. See

section 4.3 on page 33 for more details.

Output types

The standard 3T has a single 26-pin mil-spec waterproof connector for

signals, control and power:

4 Issue N

Page 5

Operator's guide

As an option, the 3T can be supplied with a 26-way “D”-type

connector with standard pin assignments (see section 6.2, page 48.)

Other output connector types may also be supplied, to your own pinout specification.

Sensor control interface

3T instruments can be fitted with an optional RS232 control interface.

The control interface can be used to lock, unlock, and centre the

sensor masses, and query mass positions. See section 5.3, page 41, for

more details.

July 2009 5

Page 6

CMG-3T

Sensor response

The 3T can be supplied with a response which is flat to velocity from

100 Hz to any of 0.1 Hz (10 seconds), 0.033 Hz (30 seconds), 0.016 Hz

(60 seconds), 0.01 Hz (100 seconds), 0.0083 Hz (120 seconds) or 0.0027

Hz (360 seconds). Alternatively, a hybrid response function may be

provided. See Chapter 5 for more details.

If you do not require high-frequency data, a low-pass filter may be

installed at any frequency (below 100 Hz) that you specify.

6 Issue N

Page 7

Operator's guide

2 Installing the 3T

2.1 First encounters

Unpacking

The 3T seismometer is delivered in a single transportation case. The

packaging is specifically designed for the 3T and should be reused

whenever you need to transport the sensor. Please note any damage to

the packaging when you receive the equipment, and unpack on a safe,

clean surface. The package should contain:

• the seismometer;

• a cable to join the sensor to the breakout box;

• the breakout box (which provides separate connections for the

signal, control and power lines);

• a Hand-held Control Unit (HCU) for monitoring sensor outputs

and calibration, if ordered;

• a 10-pin connector for your power lead (see below); and

• a calibration and installation sheet.

Assuming all the parts are present, stand the seismometer in the centre

of a bench and identify its external features:

• a handle with North indication,

• a multi-pole socket for input and output,

• other optional connectors as ordered;

• a bubble level,

• an air vent port,

• three adjustable feet, and

• two accurate orientation pins (one brass and one steel).

July 2009 7

Page 8

CMG-3T

Serial number

The sensor's serial number can be found on the label stuck to the top

lid of the sensor. It is also stamped onto the side of the sensor base,

next to the N/S indicator, and into the lid itself. You should quote this

serial number if you need assistance from Güralp Systems.

Handling notes

The 3T is a sensitive instrument, and is easily damaged if mishandled.

If you are at all unsure about the handling or installation of the device,

you should contact Güralp Systems for assistance.

• Do not bump or jolt any part of the sensor when handling or

unpacking.

• Do not kink or walk on the data cable (especially on rough

surfaces such as gravel), nor allow it to bear the weight of the

sensor.

• Do not connect the instrument to power sources except where

instructed.

• Do not ground any of the signal lines from the sensor.

• Do not move the instrument whilst the masses are unlocked.

You should report any sign of loose components, or any sound

of parts moving inside the instrument, to Güralp Systems.

Connections

The instrument has a single connector, which can be joined using the

cable provided to a digitizer or breakout box. Individually shielded

twisted-pair cabling must be used for the sensor outputs, control lines

and power supply. If you need to make up a suitable cable, you should

confirm the cable type with Güralp Systems.

Using a digitizer

The 3T can be connected directly to any Güralp Systems digitizer

using the signal cable provided. This is the simplest way to use a 3T

instrument. All the instrument's functions are available through the

digitizer, including centring, locking and unlocking.

We recommend that you keep the digitizer near the instrument if at all

possible, to minimize the length of analogue cable required. Once

digitized, the signal is robust to degradation by noise or attenuation.

Keeping the digitizer in the quiet, stable conditions of a seismic

installation also provides it with an optimum environment for the on-

8 Issue N

Page 9

Operator's guide

board ADCs.

Breakout box and hand-held control unit

The 3T can be supplied with an optional robust breakout box, which

provides mass control functions in installations which do not use

compatible digitizers. A hand-held control unit is also available which

can control calibration lines and monitor sensor outputs in addition to

mass control. See chapter 4, page 30, for more details.

Power supply

The sensor requires a 12 Volt power supply, connected via the socket

and breakout box or digitizer. You will need to make up a suitable

cable to connect a 12 V power source to the 10-pin connector on the

breakout box (spare 10-pin mil-spec connectors are provided for this

purpose.) Using a 12 Volt, 25 Ampere-hour, sealed, heavy-duty, leadacid battery, you should expect the instrument to operate for around a

week without recharging.

If you prefer, you can power the 3T directly from the connector on the

top panel (see Chapter 6, page 47.)

A power management module can be installed as an option, which

allows the 3T to operate from a 10 – 15 V supply range. This module

also cuts the input power to the sensor electronics if it drops below

10.5 V, to minimize discharge from battery-operated installations.

Units with serial numbers beginning T33 are provided with a wide

input range DC-DC converter, and can be powered from a 10 – 36 V

supply.

The 3T draws a nominal current of 75 milliamps from a 12 Volt supply

when in use. During locking and unlocking of the sensor masses, this

current rises briefly to 600 milliamps. It is recommended that you

carry a spare 12 Volt battery when visiting an installation for

maintenance, in case the sensor needs to be moved and the on-site

batteries no longer have sufficient charge to perform the locking

procedure.

Signal output

The sensors output voltages representing ground velocity on floating

differential lines. The breakout box provides a RECORDER connector

for attaching to a recording system or digitizer. You can use any multichannel recording system, provided that it has high-impedance

floating differential inputs.

If you are using a Güralp Systems digitizer, you can connect the

instrument directly to the digitizer without using the breakout box;

July 2009 9

Page 10

CMG-3T

power will be supplied through the digitizer, which can also activate

the sensor control lines.

The breakout box also provides a CONTROL output, which can be

connected to the Hand-held Control Unit. This device lets you monitor

output signals from the instrument, and perform on-site calibration.

For more information, see Section 6, page 47.

2.2 Installation notes

The goal of any seismic installation is to ensure that wave-trains

arriving at the instrument accurately reflect the internal motion of

subsurface rock formations. To achieve this, the seismometer and its

emplacement need to be considered as a mechanical system, which

will have its own vibrational modes and resonances. These

frequencies should be raised as high as possible so that they do not

interfere with true ground motion: ideally, beyond the range of the

instrument.

In particular, the sensor needs to be protected against environmental

factors such as

• fluctuations in temperature,

• turbulent air flow around walls or trees, or around sharp

corners or edges in the immediate vicinity of the sensor;

• vibration caused by equipment in or near the installation,

particularly computer equipment; and

• vibration caused by heavy machinery (even at a distance), or by

overhead power lines.

In seismic vaults, instruments are often installed on piers. It is

important to ensure that the interface between the pier and the floor

does not introduce noise, and that the pier itself does not have

resonant frequencies within the passband. Ideally, a seismic pier will

be significantly wider than it is high (to minimize flexing) and will

form a single piece with the floor, e.g. by moulding a poured concrete

floor within a wooden frame.

Many situations do not allow for the construction of a seismic vault.

For example, you may need to deploy quickly to monitor the activity of

a volcano showing signs of rejuvenation, or to study the aftershocks of

a major earthquake. In other cases the site itself may be too remote to

ship in construction equipment.

10 Issue N

Page 11

Operator's guide

Temporary installations can be protected against spurious vibrations

by

• selecting a suitable site,

• placing the instrument in a protective enclosure (an open-sided

box of 5 cm expanded polystyrene slabs, placed over the

instrument and taped down to exclude draughts, makes an

excellent thermal shield),

• standing the sensor on bedrock where possible, or at least deep

in well-compacted subsoil;

• clearing the floor of the hole of all loose material; and

• using as little extra mass as possible in preparing the chamber.

After installation, the instrument case and mounting surface will

slowly return to the local temperature and settle in their positions.

This will take around four hours from the time installation is

completed. If you require long-period recording, you should re-zero

the instrument after this time.

2.3 Installing in vaults

You can install a 3T in an existing seismic vault with the following

procedure:

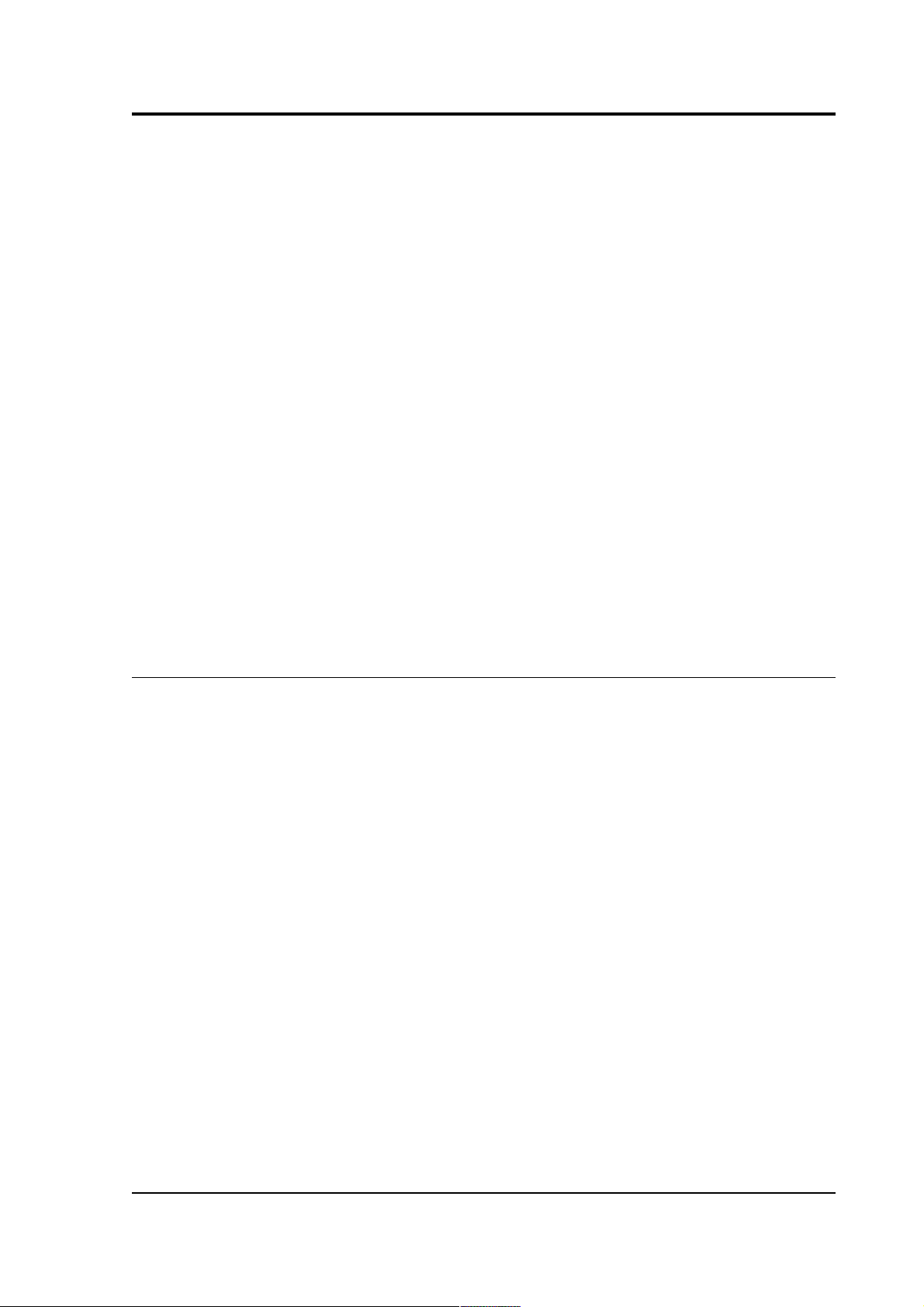

1. Unpack the sensors from their container, saving the shipping

boxes for later transportation.

2. Prepare the mounting surface, which should be smooth and free

of cracks. Remove any loose particles or dust, and any pieces of

loose surfacing. This ensures good contact between the

instrument's feet and the surface.

3. If it is not already present, inscribe an accurate North-South line

on the mounting surface.

4. Place the sensor over the scribed line, so that the brass and steel

pointers are aligned with the marked directions, with the brass

pointer facing North. This can be done by rotating the base of

the sensor whilst observing it from above. The brass pointer can

be found next to one of the feet.

July 2009 11

Page 12

CMG-3T

If you cannot easily see the pointers, you should align the

sensor using the north arrow on the handle. However, the

alignment of the handle with the sensors inside is less accurate

than the metal pointers, so they should be used wherever

possible.

5. The top panel of the 3T includes a spirit level.

Level the sensor using each of the adjustable feet of the

instrument in turn, until the bubble in the spirit level lies

entirely within the inner circle. (The instrument can operate

with up to 2° of tilt, but with reduced performance.)

The feet are mounted on screw threads. To adjust the height of a

foot, turn the brass locking nut anticlockwise to loosen it, and

rotate the foot so that it screws either in or out. When you are

happy with the height, tighten the brass locking nut clockwise

to secure the foot. When locked, the nut should be at the bottom

of its travel for optimal noise performance.

6. Connect the sensor to a breakout box, or a Güralp digitizer if

12 Issue N

Page 13

Operator's guide

you are using one.

7. Connect a 12 Volt power supply, either directly or through the

breakout box or digitizer.

8. Unlock the sensor. If you have a breakout box or hand-held

control unit, you can do this by holding the ENABLE and

UNLOCK buttons on the unit down together for 7 seconds. The

BUSY LED will start flashing, and then go out.

Alternatively, if you are using a DM24 digitizer and Scream!,

right-click on the digitizer's entry in Scream! and select

Control.... Click on the Mass control tab, followed by Unlock. (If

the Mass control tab is unavailable, check the sensor type in the

Sensor type tab, apply, and open a new Control window.)

Alternatively, if you are using a DM24 digitizer and a DCM,

navigate to the Actions Digitizer Setup Port → → x page for the

digitizer and click on the Unlock instrument button at the

bottom of the page.

After unlocking the masses, you should be careful not to tilt the

instrument or you may damage it.

9. Check the mass position outputs using a digital multimeter,

digitizer or hand-held control unit.

Re-centre the masses if required. If you have a breakout box or

hand-held control unit, you can do this by holding the ENABLE

and CENTRE buttons on the unit down together for 7 seconds.

The BUSY LED will start flashing, and then go out

Alternatively, if you are using a DM24 digitizer and Scream!,

right-click on the digitizer's entry in Scream! and select

Control.... Click on the Mass control tab, followed by Centre.

Alternatively, if you are using a DM24 digitizer and a DCM,

navigate to the Actions Digitizer Setup Port → → x page for the

digitizer and click on the Centre instrument button at the

bottom of the page.

10.Cover the instrument with thermal insulation, for example, a 5

cm expanded polystyrene box. This will shield it from thermal

fluctuations and convection currents in the vault. It also helps

to stratify the air in the seismometer package. Position the

thermal insulation carefully so that it does not touch the sensor

package.

July 2009 13

Page 14

CMG-3T

11.Ensure that the sensor cable is loose and that it exits the

seismometer enclosure at the base of the instrument. This will

prevent vibrations from being inadvertently transmitted along

the cable.

2.4 Installing in pits

For outdoor installations, high-quality results can be obtained by

constructing a seismic pit.

Depending on the time and resources available, this type of

installation can suit all kinds of deployment, from rapid temporary

installations to medium-term telemetered stations.

Ideally, the sensor should rest directly on the bedrock for maximum

coupling to surface movements. However, if bedrock cannot be

reached, good results can be obtained by placing the sensor on a

granite pier on a bed of dry sand.

1. Prepare a hole of 60 – 90 cm depth to compacted subsoil, or

down to the bedrock if possible.

14 Issue N

Page 15

Operator's guide

2. On granite or other hard bedrock, use an angle grinder to plane

off the bedrock at the pit bottom so that it is flat and level.

Stand the instrument directly on the bedrock, and go to step 7.

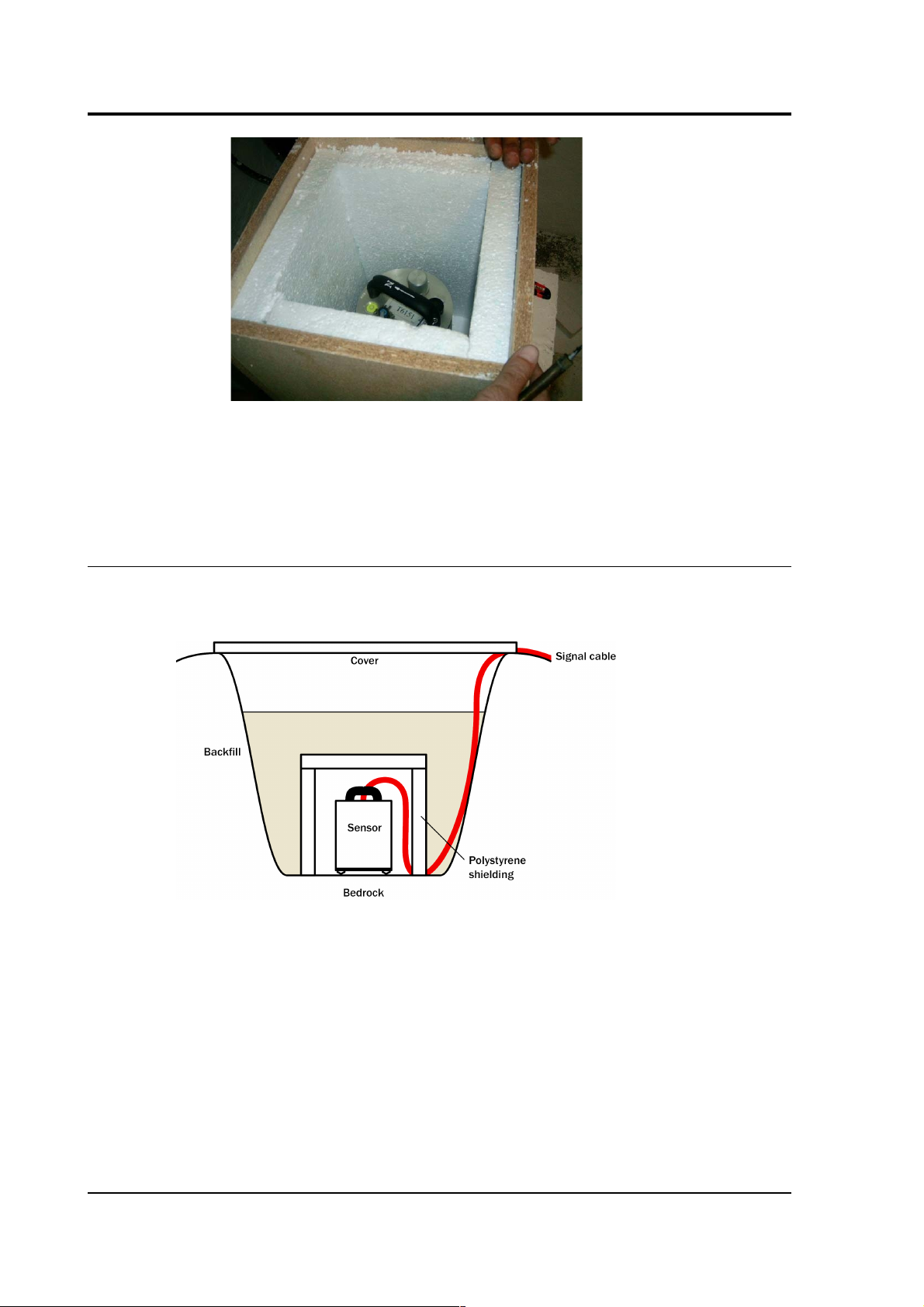

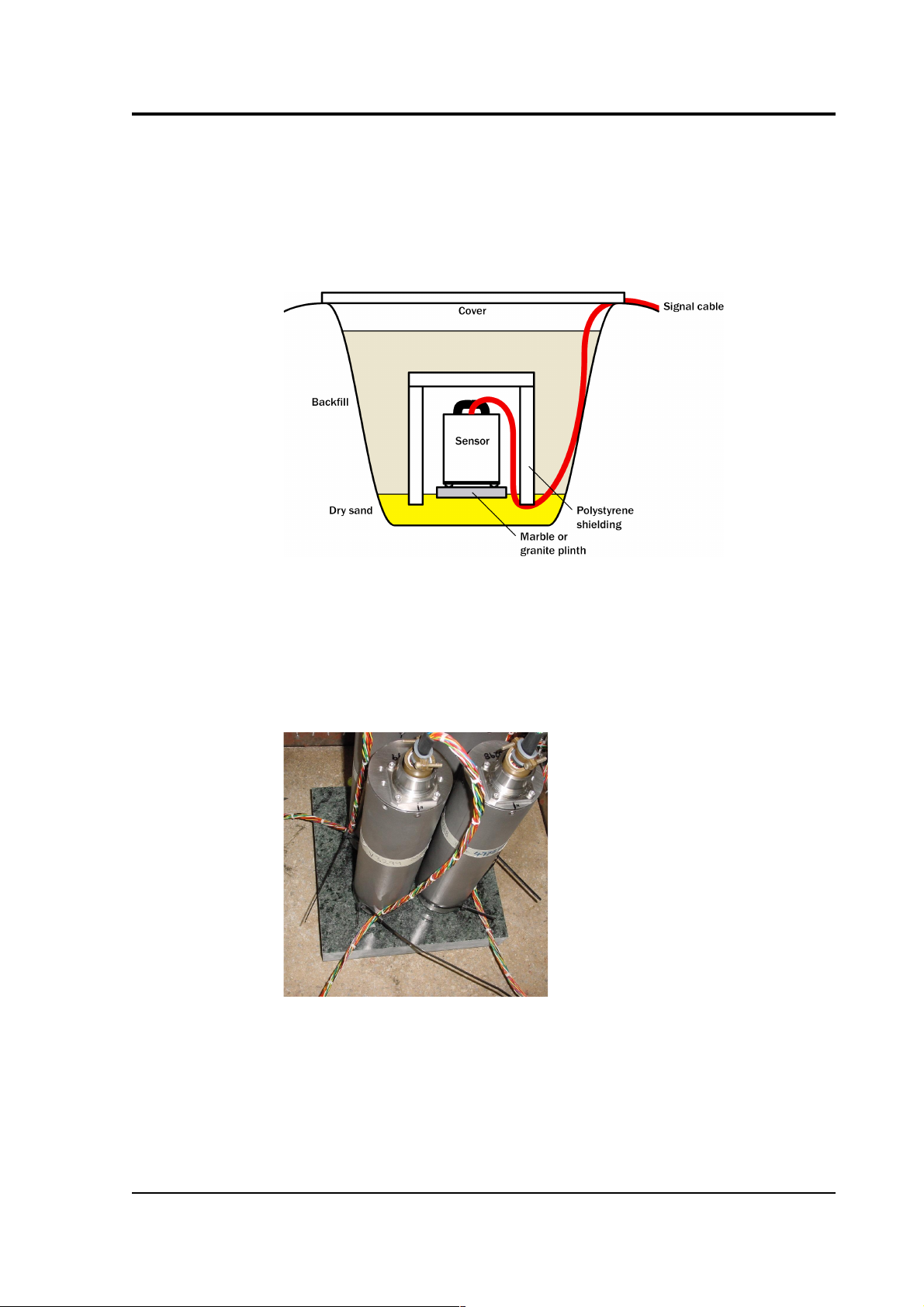

3. On soft bedrock or subsoil, you should install a pier as depicted

below.

4. Pour a layer of loose, fine sand into the pit to cover the base.

The type of sand used for children's sand-pits is ideal, since the

grains are clean, dry and within a small size range. On top of

the sand, place a smooth, flat granite plinth around 20 cm

across, and shift it to compact the sand and provide a nearlevel surface.

Placing a granite plinth on a sand layer increases the contact

between the ground and the plinth and improves the

performance of the instrument. There is also no need to mix

concrete or to wait for it to set, as in step 5.

5. Alternatively, if time allows and granite is not available,

July 2009 15

Page 16

CMG-3T

prepare a concrete mix with sand and fine grit, and pour it into

the hole. Agitate (“puddle”) it whilst still liquid, to allow it to

flow out and form a level surface, then leave to set. Follow on

from step 7.

Puddled concrete produces a fine-textured, level floor for

situating the seismometer. However, once set hard, the

concrete does not have the best possible coupling to the subsoil

or bedrock, which has some leeway to shift or settle beneath it.

6. Alternatively, for the most rapid installation, place loose soil

over the bottom of the pit, and compact it with a flat stone.

Place the seismometer on top of this stone. This method

emulates that in step 3, but can be performed on-site with no

additional equipment.

7. Set up the instrument as for a vault installation (Section 2.3,

page 11, steps 4 to 9.)

8. The instrument must now be shielded from air currents and

temperature fluctuations. This is best done by covering it with

a thermal shield.

An open-sided box of 5 cm expanded polystyrene slabs is

recommended. If using a seismic plinth on sand (from steps 3–

4 or 5), ensure that the box is firmly placed in the sand,

without touching the plinth at any point. In other installations,

tape the box down to the surface to exclude draughts.

9. Alternatively, if a box is not available, cover the instrument

with fine sand up to the top.

The sand insulates the instrument and protects it from thermal

fluctuations, as well as minimizing unwanted vibration.

10. Ensure that the sensor cable is loose and that it exits the

seismometer enclosure at the base of the instrument. This will

prevent vibrations from being inadvertently transmitted along

the cable.

11. Cover the pit with a wooden lid, and back-fill with fresh turf.

Other installation methods

The recommended installation methods have been extensively tested

in a wide range of situations. However, past practice in seismometer

installation has varied widely.

16 Issue N

Page 17

Operator's guide

Some installations introduce a layer of ceramic tiles between a rock or

concrete plinth and the seismometer (left):

However, noise tests show that this method of installation is

significantly inferior to the same concrete plinth with the tiles

removed (right). Horizontal sensors show shifting due to moisture

trapped between the concrete and tiling, whilst the vertical sensors

show "pings" as the tile settles.

Other installations have been attempted with the instrument encased

in plaster of Paris, or some other hard-setting compound (left):

Again, this method produces inferior bonding to the instrument, and

moisture becomes trapped between the hard surfaces. We recommend

the use of fine dry sand (right) contained in a box if necessary, which

can also insulate the instrument against convection currents and

temperature changes. Sand has the further advantage of being very

easy to install, requiring no preparation.

Finally, many pit installations have a large space around the

seismometer, covered with a wooden roof. Large air-filled cavities are

susceptible to currents which produce lower-frequency vibrations, and

sharp edges and corners can give rise to turbulence. We recommend

that a wooden box is placed around the sensor to protect it from these

currents. Once in the box, the emplacement may be backfilled with

fresh turf to insulate it from vibrations at the surface, or simply roofed

as before.

July 2009 17

Page 18

CMG-3T

By following these guidelines, you will ensure that your seismic

installation is ready to produce the highest quality data.

2.5 Installing in post-holes

The 3T is suitable for installation in post-holes. In soft subsoil, a hole

two to four metres deep and 20cm wide can be conveniently excavated

using a tractor-mounted or hand-operated post-hole auger. To

minimize surface effects, you should ensure that the hole is one metre

deeper than the length of the instrument or, preferably, somewhat

more.

Since the hole has no lining, it may occasionally flood. However, most

soil types are sufficiently permeable to allow water to soak away,

leaving the packing material moist.

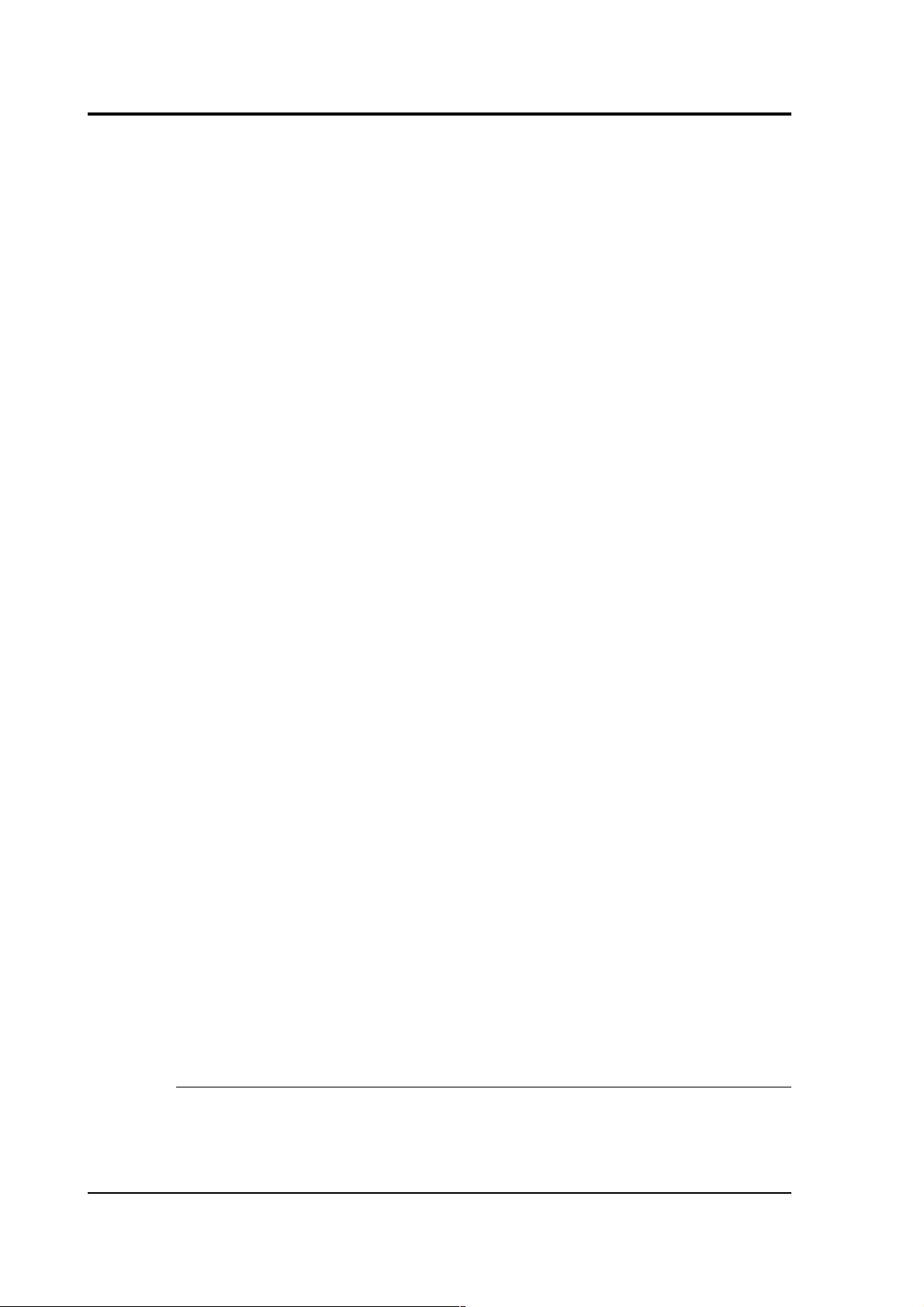

A slim-profile 3T instrument is available with vertically stacked

sensors and built-in inclinometer, specifically designed for post-hole

installations. Digitizers or other recording equipment can be placed

either within the hole or in a separate enclosure; alternatively, the

Güralp DM24 is available in modular form, allowing you to attach the

digitizer directly to the instrument.

To install a 3T in a post-hole:

1. Clean the post-hole, making sure there is no loose material

around the mouth of the hole or on its base.

2. Prepare the instrument package, making sure the inclinometer

is visible, and attach it to a winch or hoist by clamping a light

steel cable to the centre of the handle so that the package hangs

vertically. Connect the signal cable to the instrument.

3. Add packing material to the hole to about 15cm depth. Fine

18 Issue N

Page 19

Operator's guide

crushed rock, with a high proportion of rock flour and fine

particles, makes excellent packing material. Alternatively, a

mixture of 3 mm grade angular coarse grit with around 30%

medium grit gives good results. Moisten the packing material

in the hole and ram firm.

4. Lower the instrument to the bottom of the hole, but without

slackening the lifting cable.

5. Fill more packing material around the instrument for about 30

cm, moisten, and ram firm.

6. Use the inclinometer to check that the instrument remains

within its tilt tolerance (± 2°).

7. Continue filling, moistening and packing until the instrument

is buried, checking that the tilt remains within tolerance.

8. Release the strain on the lifting cable, and allow the packing

material to settle for 24 hours.

9. If all is well after the settling period, release the lifting tackle,

coil a tail of the lifting wire into the top of the hole and backfill

almost to the surface.

10. Ensure that the signal cable is slack, and fix it to a support at

the top of the hole.

11. Ram a split wooden bung into the top of the hole, and cover

with sandbags.

12. Attach the signal cable to your recording equipment or

breakout box. Power the sensor, and unlock it. Carry out

preliminary tests using a hand-held control unit, if required.

July 2009 19

Page 20

CMG-3T

3 Calibrating the 3T

3.1 The calibration pack

All Güralp sensors are fully calibrated before they leave the factory.

Both absolute and relative calibration calculations are carried out. The

results are given in the calibration pack supplied with each

instrument:

Works Order : The Güralp factory order number including the

instrument, used internally to file details of the sensor's manufacture.

Serial Number : The serial number of the instrument

Date : The date the instrument was tested at the factory.

Tested By : The name of the testing engineer.

There follows a table showing important calibration information for

each component of the instrument, VERTICAL, NORTH/SOUTH, and

EAST/WEST. Each row details:

Velocity Output (Differential) : The sensitivity of each component to

velocity at 1 Hz, in volts per m/s. Because the 3T uses balanced

differential outputs, the signal strength as measured between the +ve

and –ve lines will be twice the true sensitivity of the instrument. To

remind you of this, the sensitivities are given as 2 × (single-ended

sensitivity) in each case.

Mass Position Output : The sensitivity of the mass position outputs to

acceleration, in volts per m/s². These outputs are single-ended and

referenced to signal ground.

Feedback Coil Constant : A constant describing the characteristics of

the feedback system. You will need this constant, given in amperes per

m/s², if you want to perform your own calibration calculations (see

below.)

Power Consumption : The average power consumption of the sensor

during testing, given in amperes and assuming a 12 V supply.

Calibration Resistor : The value of the resistor in the calibration circuit.

You will need this value if you want to perform your own calibration

calculations (see below.)

20 Issue N

Page 21

Operator's guide

Poles and zeroes

Most users of seismometers find it convenient to consider the sensor

as a “black box”, which produces an output signal V from a measured

input x. So long as the relationship between V and x is known, the

details of the internal mechanics and electronics can be disregarded.

This relationship, given in terms of the Laplace variable s, takes the

form

( V / x ) (s) = G × A × H (s)

In this equation

• G is the acceleration output sensitivity (gain constant) of the

instrument. This relates the actual output to the desired input

over the flat portion of the frequency response.

• A is a constant which is evaluated so that A × H (s) is

dimensionless and has a value of 1 over the flat portion of the

frequency response. In practice, it is possible to design a system

transfer function with a very wide-range flat frequency

response.

The normalising constant A is calculated at a normalising

frequency value fm = 1 Hz, with s = j fm, where j = √–1.

• H (s) is the transfer function of the sensor, which can be

expressed in factored form:

In this equation Zn are the roots of the numerator polynomial,

giving the zeros of the transfer function, and Pm are the roots of

the denominator polynomial giving the poles of the transfer

function.

In the calibration pack, G is the sensitivity given for each component

on the first page, whilst the roots Zn and Pm, together with the

normalising factor A, are given in the Poles and Zeros table. The poles

and zeros given are measured directly at Güralp Systems' factory using

a spectrum analyser. Transfer functions for the vertical and horizontal

sensors may be provided separately.

July 2009 21

Page 22

CMG-3T

Frequency response curves

The frequency response of each component of the 3T is described in

the normalised amplitude and phase plots provided. The response is

measured at low and high frequencies in two separate experiments.

Each plot marks the low-frequency and high-frequency cut-off values

(also known as –3 dB or half-power points).

If you want to repeat the calibration to obtain more precise values at a

frequency of interest, or to check that a sensor is still functioning

correctly, you can inject calibration signals into the system using a

Güralp digitizer or your own signal generator, and record the

instrument's response.

Obtaining copies of the calibration pack

Our servers keep copies of all calibration data that we send out. In the

event that the calibration information becomes separated from the

instrument, you can obtain all the information using our free e-mail

service. Simply e-mail caldoc@guralp.com with the serial number

of the instrument in the subject line, e.g.

From: your@email.net

To: caldoc@guralp.com

Subject: T3A15

The server will reply with the calibration documentation in Word

format. The body of your e-mail will be ignored. If you want data for

several sensors, put their serial numbers together on the subject line,

separated by commas.

22 Issue N

Page 23

Operator's guide

3.2 Calibration methods

Velocity sensors such as the 3T are not sensitive to constant DC levels,

either as a result of their design or because of an interposed high-pass

filter. Instead, three common calibration techniques are used.

• Injecting a step current allows the system response to be

determined in the time domain. The amplitude and phase

response can then be calculated using a Fourier transform.

Because the input signal has predominantly low-frequency

components, this method generally gives poor results. However,

it is simple enough to be performed daily.

• Injecting a sinusoidal current of known amplitude and

frequency allows the system response to be determined at a spot

frequency. However, before the calibration measurement can be

made the system must be allowed to reach a steady state; for low

frequencies, this may take a long time. In addition, several

measurements must be made to determine the response over the

full frequency spectrum.

• Injecting white noise into the calibration coil gives the response

of the whole system, which can be measured using a spectrum

analyser.

You can perform calibration either using a Güralp DM24 digitizer,

which can generate step and sinusoidal calibration signals, or by

feeding your own signals into the instrument through a hand-held

control unit.

Before you can calibrate the instrument, its calibration relays need to

be activated by pulling low the CAL ENABLE line on the instrument's

connector for the component you wish to calibrate. Once enabled, a

calibration signal provided across the CAL SIGNAL and SIGNAL

GROUND lines will be routed through the feedback system. You can

then measure the signal's equivalent velocity on the sensor's output

lines. Güralp Hand-held Control Units provide a switch for activating

the CAL ENABLE line.

3.3 Calibration with Scream!

Güralp digitizers provide calibration signal generators to help you set

up your sensors. Calibration is most easily done through a PC running

Güralp's Scream! software.

Depending on the digitizer type, sine-wave, step and broadband noise

signal generators may be available. In this section, broadband noise

July 2009 23

Page 24

CMG-3T

calibration will be used to determine the complete sensor response in

one action. Please refer to the digitizer's manual for information on

other calibration methods.

1. In Scream!'s main window, right-click on the digitiser's icon and

select Control.... Open the Calibration pane.

2. Select the calibration channel corresponding to the instrument,

and choose Broadband Noise. Select the component you wish

to calibrate, together with a suitable duration and amplitude,

and click Inject now. A new data stream, ending Cn (n = 0 – 7)

or MB, should appear in Scream!'s main window containing the

returned calibration signal.

3. Open a Waveview window on the calibration signal and the

returned streams by selecting them and double-clicking. The

streams should display the calibration signal combined with the

sensors' own measurements. If you cannot see the calibration

signal, zoom into the Waveview using the scaling icons at the

24 Issue N

Page 25

Operator's guide

top left of the window or the cursor keys.

Drag the calibration stream Cn up the Waveview window, so

that it is at the top.

4. If the returning signal is saturated, retry using a calibration

signal with lower amplitude. Repeat until the entire curve is

visible in the Waveview window.

5. If you need to scale one, but not another, of the traces, right-

click on the trace and select Scale.... You can then type in a

suitable scale factor for that trace.

6. Pause the Waveview window by clicking on the icon.

7. Hold down SHIFT and drag across the window to select the

calibration signal and the returning component(s). Release the

mouse button, keeping SHIFT held down. A menu will pop up.

Choose Broadband Noise Calibration. This option runs a script

called bbnoisecal which automatically performs appropriate

averaging to reduce the effects of aliasing and cultural noise.

8. The script will ask you to fill in sensor calibration parameters

for each component you have selected.

July 2009 25

Page 26

CMG-3T

Most data can be found on the calibration sheet for your sensor.

Under Instrument response, you should fill in the sensor

response code for your sensor, according to the table below.

Instrument Type should be set to the model number of the

sensor.

If the file calvals.txt exists in the same directory as

Scream!'s executable (scream.exe), Scream! will look there for

suitable calibration values. A sample calvals.txt is supplied

with Scream!, which you can edit to your requirements. Each

stream has its own section in the file, headed by the line

[instrument-id]. The instrument-id is the string which

identifies the digitizer in the left-hand pane, e.g. GURALP-DEMO.

It is always 6 characters (the system identifier) followed by a

dash, then 4 characters (the serial number.) For example:

[instrument-id]

Serial-Nos=T3X99

VPC=3.153,3.147,3.159

G=1010,1007,1002

COILCONST=0.02575,0.01778,0.01774

CALVPC=3.161

CALRES=51000

TYPE=sensor-type

RESPONSE=response-code

9. Click OK. The script will return with a graph showing the

responsivity of the sensor in terms of amplitude and phase plots

for each component (if appropriate.)

The accuracy of the results depends on the amount of data you

have selected, and its sample rate. To obtain good-quality

results at low frequency, it will save computation time to use

data collected at a lower sample rate; although the same

26 Issue N

Page 27

Operator's guide

information is present in higher-rate streams, they also include

a large amount of high-frequency data which may not be

relevant to your purposes.

The bbnoisecal script automatically performs appropriate

averaging to reduce the effects of aliasing and cultural noise.

Sensor response codes

Sensor Sensor type code

Units

(V/A)

CMG-5T or 5TD, DC – 100 Hz response

CMG-5_100HZ A

CMG-40T-1 or 6T-1, 1s – 50 Hz response

CMG-40_1HZ_50HZ V

CMG-40T-1 or 6T-1,

1s – 100 Hz response

CMG-40_1S_100HZ V

CMG-40T-1 or 6T-1,

2s – 100 Hz response

CMG-40_2S_100HZ V

CMG-40T-1 or 6T-1,

10s – 100 Hz response

CMG-40_10S_100HZ V

CMG-40, 20s – 50 Hz response

CMG-40_20S_50HZ V

CMG-40, 30s – 50 Hz response

CMG-40_30S_50HZ V

CMG-3T or 3ESP, 30s – 50 Hz response

CMG-3_30S_50HZ V

CMG-40, 60s – 50 Hz response

CMG-40_60S_50HZ V

CMG-3T or 3ESP, 60s – 50 Hz response

CMG-3_60S_50HZ V

CMG-3T or 3ESP, 100s – 50 Hz response

CMG-3_100S_50HZ V

CMG-3T or 3ESP, 120s – 50 Hz response

CMG-3_120S_50HZ V

July 2009 27

Page 28

CMG-3T

Sensor Sensor type code

Units

(V/A)

CMG-3T, 360s – 50 Hz response

CMG-3_360S_50HZ V

CMG-3TB or 3V / 3ESP borehole,

30s – 50 Hz response

CMG-3B_30S_50HZ V

CMG-3TB or 3V / 3ESP borehole,

100s – 50 Hz response

CMG-3B_100S_50HZ V

CMG-3TB or 3V / 3ESP borehole,

120s – 50 Hz response

CMG-3B_120S_50HZ V

3.4 Calibration with a hand-held control unit

If you prefer, you can inject your own calibration signals into the

system through a hand-held control unit. The unit includes a switch

which activates the calibration relay in the seismometer and 4 mm

banana sockets for an external signal source. As above, the equivalent

input velocity for a sinusoidal calibration signal is given by

v = V / 2 π f R K

where V is the peak-to-peak voltage of the calibration signal, f is the

signal frequency, R is the value of the calibration resistor and K is the

feedback coil constant. R and K are both given on the calibration sheet

supplied with the 3T.

The calibration resistor is placed in series with the transducer.

Depending on the calibration signal source and the sensitivity of your

recording equipment, you may need to increase R by adding further

resistors to the circuit.

3.5 The coil constant

The feedback coil constant K is measured at the time of manufacture

and printed on the calibration sheet. Using this value will give good

results at the time of installation. However, it may change over time.

The coil constant can be determined by tilting the instrument and

measuring its response to gravity. To do this, you will need apparatus

for measuring tilt angles accurately.

1. Measure the acceleration due to gravity, g, at your location.

2. Tilt the instrument slightly, and measure its attitude and the

gain of the mass position output for the component you wish to

calibrate.

28 Issue N

Page 29

Operator's guide

3. Repeat this measurement for several tilt angles.

4. For the vertical sensor, the input acceleration is given by

a = g sin φ, whilst for the horizontal sensor, it is

a = g ( 1 – cos φ ).

Calculate the input acceleration for each of the tilt angles used,

and plot a graph of mass position output against input

acceleration.

5. The gradient of the line obtained gives the sensitivity of the coil

(in V/m/s², if g was measured in m/s² and the mass position in

V.)

6. The coil constant K is equal to this sensitivity divided by the

value of the displacement feedback resistor, as given on the

calibration sheet.

July 2009 29

Page 30

CMG-3T

4 Accessories

4.1 The breakout box

This unit separates the lines in the signal cable, so you can connect a

power supply, a recording system, and the hand-held control unit:

You can also use the breakout box to centre, lock and unlock the

sensor masses. You will need to provide power through the breakout

box's POWER connector to do this (see below.)

• To unlock the sensor masses, hold down the ENABLE and

UNLOCK buttons simultaneously for 7 seconds. The BUSY LED

will light. All three masses are unlocked, each in turn. The

sensor then automatically moves on to centre the masses, during

which time the BUSY LED will flash. When the BUSY LED goes

out, the instrument is ready for use.

You should not attempt to move the instrument without relocking the masses.

• To lock the sensor masses, hold down the ENABLE and LOCK

buttons simultaneously for 7 seconds. When the BUSY LED goes

30 Issue N

Page 31

Operator's guide

out, the instrument is ready for transportation.

• To re-centre the sensor masses, hold down the ENABLE and

CENTRE buttons simultaneously for 7 seconds. When the BUSY

LED stops flashing, the centring process has finished. You may

need to initiate several rounds of centring before the instrument

is ready; when no more centring is required, pressing the

ENABLE and CENTRE buttons has no effect.

For more details on the control system, see Section 5.2, page 36.

The standard breakout box is rain resistant but not waterproof. If you

intend to use a breakout box in your installation, you should site it

away from potential flooding. If this is not possible, a larger unit is

optionally available which can be immersed in water. (The 3T itself is,

however, completely waterproof.)

4.2 The hand-held control unit

This portable control unit provides

easy access to the seismometer's

control commands, as well as

displaying the output velocity and

mass position (i.e. acceleration) on

an analogue meter. It takes input

from the 26-pin connector at the

bottom, and repeats it at the

connector on the side for

connection to further equipment.

The hand-held control unit can be

sited up to fifty metres from the

breakout box.

The meter

The meter at the top of the unit allows you to monitor the voltage

outputs of the instrument. You can use the knob below to select, for

each of the three components, either the mass position output or the

July 2009 31

Page 32

CMG-3T

velocity output. There is also a RANGE switch allowing you to alter the

sensitivity of the meter.

Calibration

The hand-held control unit can be used to calibrate the 3T. To activate

the calibration relays, turn the knob to the component you wish to

calibrate, and introduce a calibration signal on the CAL SIG banana

sockets.

Control commands

You can use the hand-held control unit to centre, lock and unlock the

sensor masses.

• To unlock the sensor masses, press the ENABLE switch down,

and the LOCK/UNLOCK switch up simultaneously. The BUSY

LED will light. All three masses are unlocked, each in turn. The

sensor then automatically moves on to centre the masses, during

which time the BUSY LED will flash. When the BUSY LED goes

out, the instrument is ready for use.

You should not attempt to move the instrument without relocking the masses.

• To lock the sensor masses, press the ENABLE and

LOCK/UNLOCK switches down simultaneously. When the BUSY

LED goes out, the instrument is ready for transportation.

• To re-centre the sensor masses, press the ENABLE and CENTRE

switches down simultaneously. When the BUSY LED stops

flashing, the centring process has finished. You may need to

initiate several rounds of centring before the instrument is

ready. When no more centring is required, pressing the

ENABLE and CENTRE buttons has no effect.

Note: The ENABLE, LOCK, CENTRE and UNLOCK switches require

only a single quick press to initiate the processes. Do not hold them

down.

For more details on the control system, see Section 5.2, page 36.

Outputs

The remaining banana sockets provide easy access to the output

voltages of the instrument. For each component (vertical, N/S and

E/W):

32 Issue N

Page 33

Operator's guide

• the left-hand two sockets expose the balanced differential

outputs representing ground velocity, and

• the right-hand socket exposes the mass position (acceleration)

output.

Ground references for each of these voltages are provided at the

bottom of the unit. Ensure that you do not connect either side of a

differential output to ground.

4.3 Integrated State-of-Health Controller

The CMG-3TD variant (a CMG-3T with an

integrated DM24 digitiser) is available with an

optional, in-built state-of-health controller.

This option provides a simple means to centre,

lock and unlock the masses without the need for

a hand-held control unit.

The lid of the device is fitted with four

momentary, colour-coded push-buttons, labelled

“ENABLE” (black), “CENTRE” (blue), “UNLOCK”

(green) and “LOCK” (red) - together with a red

LED, labelled “BUSY”.

These buttons are used in a similar manner to

those on the break-out box with the exception

that it is not necessary to hold the buttons down

for seven seconds - one second is adequate.

July 2009 33

Page 34

CMG-3T

• To unlock the sensor masses, hold down the ENABLE and

UNLOCK buttons simultaneously for one second. The BUSY LED

will light. All three masses are unlocked, each in turn. The

sensor then automatically moves on to centre the masses, during

which time the BUSY LED will flash. When the BUSY LED goes

out, the instrument is ready for use.

You should not attempt to move the instrument without relocking the masses.

• To lock the sensor masses, hold down the ENABLE and LOCK

buttons simultaneously for one second. When the BUSY LED

goes out, the instrument is ready for transportation.

• To re-centre the sensor masses, hold down the ENABLE and

CENTRE buttons simultaneously for one second. When the

BUSY LED stops flashing, the centring process has finished. You

may need to initiate several rounds of centring before the

instrument is ready; when no more centring is required,

pressing the ENABLE and CENTRE buttons has no effect.

For more details on the mass control system, see Section 5.2, page 36.

34 Issue N

Page 35

Operator's guide

5 Inside the 3T

5.1 The sensors

The horizontal and vertical sensors are similar in design. The inertial

mass in both cases consists of a transducer coil and a leaf-spring

suspended boom which swings on a frictionless hinge. A triangular

spring supports the weight of the mass; in the vertical sensor this

spring is pre-stressed with a natural period of around 0.5 seconds,

whilst the horizontal sensor has an unstressed flat spring with a

natural period of around 1 second. CMG-3T sensors have no spurious

resonances below 140 Hz, and weigh around 180 g. The small boom

size and stiff springs allow three independent instruments to be

mounted within the casing, together with all the associated feedback

electronics.

The 3T functions by monitoring the position of each mass with a

capacitative position sensor. The three sensors are identical. Signals

from the sensors are fed into an electronic processing unit, which is

mounted in a screened compartment above the mechanical

components (see below for details on the feedback circuitry.)

When the instrument is being transported, the masses are locked

securely in their frames so as to relieve strain on the support hinges.

This locking is performed by a small motor-driven clamp in response

to a signal from the surface controller unit.

Before using the instrument, the boom of the vertical sensor must be

levelled and the bases of the horizontal sensors tilted, so that the

masses are centred in their equilibrium positions. These adjustments

are made by small DC motors controlled remotely.

July 2009 35

Page 36

CMG-3T

The signal voltages output by the 3T are proportional to ground

velocity and are transmitted from the instrument on balanced

differential lines. In addition, mass position signals are sent as singleended circuits referred to analogue ground on the output plug. The 3T

also receives control signals, which are used to clamp and un-clamp

the masses and to run the motors which level and centre the

instrument once in position. Finally, a line is provided for you to

apply a calibrating voltage to the force transducers, thereby measuring

the deflection sensitivity.

5.2 The control system

The internal operations of the 3T are supervised by a control

microprocessor, which drives the mass clamping and centring

36 Issue N

Page 37

Operator's guide

adjustment motors. It responds to commands sent on three input lines

by grounding for 0.2 – 7 seconds.

The signals you can send to the microprocessor are termed LOCK,

UNLOCK, and CENTRE. Each command acts on the vertical, N/S and E/

W masses in turn. The microprocessor prevents the system from

attempting incompatible actions (e.g. centring when the masses are

clamped.)

While a command is taking place, if you are using a Hand-held Control

Unit, its BUSY LED will flash; you can use this for diagnostic purposes.

See the description of each command for full details.

When no command is active, i.e. all three lines are high, the control

microprocessor goes into a power-saving mode. In routine operation,

the lines are controlled from the breakout box, Hand-held Control Unit

or digitizer. If you send control signals to the 3T manually, you must

ensure that the lines are pulled high after sending the signal, or the

equipment may be damaged. A “biased-OFF” type switch can be used

for this purpose.

LOCK

This command locks the masses and clamps the horizontal sensors by

tilting them up to their end stops.

If LOCK is activated when the masses are already locked, the processor

will unlock them and attempt to lock again. This is useful if you

suspect that the locking procedure has failed.

In detail, the process acts as shown in the following graph. The top

three streams are the mass position outputs of each component (Z, N/S

and E/W, respectively), whilst the bottom one represents the state of

the BUSY LED (up = on).

July 2009 37

Page 38

CMG-3T

The five-stage process comprises locking the Z, N/S and E/W masses,

followed by longer periods tilting the N/S and E/W sensor base to their

end stops. During the latter two periods, the position of the N/S and E/

W masses will “flip” to one side.

The BUSY LED is lit during each stage, but goes out briefly between

stages, allowing you to follow the progress of the lock.

UNLOCK

This command unlocks the sensor masses and prepares the instrument

to begin operating.

If UNLOCK is activated when the masses are already unlocked, the

processor will lock them and attempt to unlock again. This is useful if

you suspect that the locking procedure has failed.

38 Issue N

Page 39

Operator's guide

Again, you can use the BUSY LED to monitor the progress of

unlocking.

1. The instrument checks to see whether the Z, N/S and E/W

masses are locked.

2. The instrument checks the N/S and E/W sensor bases.

3. The Z component is unlocked.

4. The N/S and E/W components are unlocked. These are quicker

than the Z component.

5. (see graph below) The N/S sensor base is unlocked, followed by

the E/W base. These processes take longer still.

• After unlocking, the instrument automatically performs a round

of centring (see below).

CENTRE

This command re-centres the masses. If the masses are clamped, or if

the sensor mass positions do not exceed ± 1.2 V, the CENTRE

command does nothing. Otherwise, it attempts to zero the output of

the vertical, N/S and E/W sensors in sequence by exerting small extra

forces on the boom. For the vertical sensor, a motor-driven adjuster

presses a small spring lever against the boom until the mass position

July 2009 39

Page 40

CMG-3T

sensor indicates an offset close to zero. In the case of the horizontal

sensors, the sensor frame is tilted on its base plate. Again, the

controller monitors the mass position sensor and stops the centring

process once it reaches its lowest offset.

This graph shows the entire process of unlocking and centring:

1 – 5. The unlocking process as described above.

6. The BUSY LED pulses to indicate that it is centring the Z

component. The mass position output does not change for a

while, as it is beyond the range of the output. However, after a

few pulses, the position of the Z component comes within range

and is centred. The pulses become more brief as this goes on,

until a pulse is missed (signifying that no corrective impulse is

needed.)

7. The N/S and E/W components follow in the same way, until all

three masses are centred and the process completes. The first

round of centring has to move the N/S and E/W components all

the way from their end stops, whilst the Z component is often

closer to the proper position. Because of this, the first Z centring

operation takes much less time than the others, and you may

not notice it.

After successful centring, the mass position outputs should be in the

range 0.1 – 0.8 V. If the centring process leaves the mass position

outputs above ±1.1 V, you should start another centring cycle by

40 Issue N

Page 41

Operator's guide

activating the CENTRE command again. You will probably need to

initiate the centring process several times before the masses are

adequately centred.

5.3 RS232 control interface

As an option, the 3T can be supplied with an RS232 control interface,

which uses three additional pins on the sensor output connector.

The control electronics save power by switching off the sensor

feedback electronics whilst the masses are locked. When you unlock

the masses, either using the standard logic lines (see above) or over the

RS232 interface, the control electronics automatically “wake up” the

rest of the sensor.

To connect to the RS232 control interface, attach the sensor to a PC's

serial port using the cable supplied, and use a terminal program such

as minicom (on Linux) or HyperTerminal (on Windows) to connect to

the port. Set the baud rate to 4800, with 8 data bits, no parity bit, 0

stop bits and no flow control.

Now power up the sensor. You should see the message PWR OK

indicating that it is ready to receive commands. Each command is a

single character. When you enter a command character, the controller

will echo it back to your terminal so you can see it.

After around 10 s of inactivity, the control electronics will go into

power-saving mode. You will need to wake up the controller by

sending any character before you can issue commands. This character

will not be interpreted as a command, and the controller will not echo

it back to your terminal.

H Help

Sending H causes the controller to reply with a short list of available

commands.

[U]nlock [C]entre [L]ock [S]tatus [Q]uit [H]elp

U Unlock

Sending U will start an unlock sequence, exactly as if you had

activated the Unlock line on the output port. The sensor will

automatically perform one round of centring after it has been

unlocked, and the electronics will be fully activated.

If the unlocking process finishes normally, the controller will reply

July 2009 41

Page 42

CMG-3T

with OK. If there was a problem, such as one or more components

failing to unlock or centre, the controller will report NG (“no good”.)

L Lock

Sending L will start a lock sequence, as if you had activated the Lock

line on the output port (including unlocking the sensor before locking,

if necessary.) The sensor electronics will be placed in power saving

mode as soon as the masses are successfully locked.

If the locking process finishes normally, the controller will reply with

OK. If there was a problem, the controller will report NG.

C Centre

Sending C will start a centring sequence, as if you had activated the

Centre line on the output port. When the process finishes, the

controller will reply with OK, or NG if there was a problem. You may

need to issue the command several times before the masses are

adequately centred.

If you try to centre the masses when they are locked, the controller

will reply with OK immediately but take no action.

S Status

Sending S causes the controller to reply with the current

instantaneous mass positions, e.g.:

V: +5 N: +8 E: -10

The mass positions are measured by the controller's on-board ADC,

which has a nominal range of ±127 counts. For accurate mass position

information, you should use the analogue lines provided elsewhere on

the output connector.

Q Quit

Sending Q ends your command session, and puts the controller into

power-saving mode. To issue further commands, you will need to

wake up the controller by sending any character. This character will

not be treated as a command, and will not be echoed back to your

terminal.

5.4 The feedback system

The output from a modern broadband seismometer does not depend

on the natural characteristics of the instrument. Instead, the period

42 Issue N

Page 43

Operator's guide

and damping of the sensor is completely determined by a feedback

loop which applies a force to the sensor mass opposing any motion.

The force required to restrain the movement of the mass can then be

used to measure the inertial force which it exerts as a result of ground

motion.

All CMG-3 series units are based on these general principles. The

capacitative position sensor for each mass produces a voltage

proportional to the displacement of the mass from its equilibrium

position. After amplification, this voltage generates a current in the

force transducer coil which tends to force the mass back toward

equilibrium. The feedback loop has a sufficiently high gain to cancel

the motion of the mass. Since the mass is not moving, the forces acting

on it must be balanced; the feedback voltage then directly measures

the force, and hence the acceleration, which is being applied to the

mass. The feedback loop introduces a phase shift, which must be

carefully controlled if the instrument is to remain stable over its entire

frequency range. This is achieved using compensation components in

the forward and feedback paths.

Force feedback seismometers of this type rely on the assumption that

the force transducer produces a field of constant strength. The

magnetic circuit and magnet/pole assembly in the 3T are designed so

that the field strength from the feedback transducer is constant over

large deflections and current levels. Tests have shown that the

mechanical suspension system and electronics of a 3T instrument are

linear to better than 107 dB (source: measurements made at ASL

during evaluation for the USGS National Network.)

In a feedback seismometer with a displacement transducer, it is

essential to monitor the acceleration output. This provides the position

of the displacement transducer and therefore also the mass position, as

the displacement transducer is attached to the sensor inertial mass.

The sensor should always be operated with the displacement

transducer centred or nulled, so that the response to input acceleration

is linear.

There are two types of feedback system which can be used in a 3T

instrument, known as hybrid and conventional-response feedback.

These are both described below.

Hybrid feedback

The hybrid feedback method of operation is illustrated by the

following schematic diagram:

July 2009 43

Page 44

CMG-3T

The hybrid feedback circuit contains a single capacitor in parallel with

a resistor, resulting in a single dominant pole. Below this frequency,

which can be varied from the standard 30 seconds, the response of the

seismometer is flat to ground acceleration. Above it, the response is

flat to velocity. Hybrid-feedback systems provide a stable response,

particularly for portable systems, with a high saturation level at high

frequencies and a high dynamic range at long periods.

An active low-pass filter provides a high-frequency cut-off point at a

frequency you specify. Without the filter, the velocity response is flat

up to 100 Hz. Outside the feedback loop there is an active high-pass

filter with a corner frequency of 0.01 Hz (100 s) or 0.005 Hz (200 s),

which serves to remove any DC offsets.

Conventional-response feedback

44 Issue N

Page 45

Operator's guide

The conventional-response feedback system has an additional parallel

feedback circuit, consisting of a non-inverting integrator in series with

a resistor. This arrangement results in two poles at specified

frequencies. The velocity response of a conventional-response system

is defined by a transfer function identical to that of a conventional

long-period sensor with a damping constant of 0.707 (1/√2) ζ

The seismometer can be supplied with an equivalent resonant

frequency of 0.033 Hz (30 seconds), 0.01 Hz (100 seconds) or 0.0083

Hz (120 seconds) as required. An active low-pass filter provides a highfrequency cut-off point at a frequency you specify.

Comparisons

The figures below plot the comparative response of a conventional

velocity output broadband sensor and a hybrid output broadband

sensor. The first graph shows the response in terms of output against

input acceleration in units of V/m/s², whilst the second is plotted in

terms of output against input velocity, in V/m/s.

July 2009 45

Page 46

CMG-3T

46 Issue N

Page 47

Operator's guide

6 Connector pin-outs

6.1 Sensor and control unit pin output

Models with a 26-pin mil-spec plug (02E-16-26P) have the following

pin assignments. The RECORDER and HCU connectors on the breakout

box are connected directly to the SENSOR connector, and therefore

behave identically.

Pin Function

A Velocity +ve, vertical channel

B Velocity –ve, vertical channel

C Velocity +ve, N/S channel

D Velocity –ve, N/S channel

E Velocity +ve, E/W channel

F Velocity –ve, E/W channel

G Mass position, vertical channel

H RS232 ground (RS232 control interface option)

J Mass position, N/S channel

K BUSY LED

L Mass position, E/W channel

M Power –ve (not used in sensors with internal DC-DC converters)

N Signal ground

P Calibration signal (all channels)

R Calibration enable, vertical channel

S Calibration enable, N/S channel

T Calibration enable, E/W channel

U Centre

W Unlock

X Lock

Y Logic ground

Z RS232 transmit from instrument (RS232 control interface option)

a RS232 receive at instrument (RS232 control interface option)

b Power ground

July 2009 47

Page 48

CMG-3T

c Power +ve

In sensors with the RS232 control interface option, the RS232 ground

line (pin H) is isolated from the other ground lines (pins Z and a) using

10 nF decoupling capacitors.

6.2 Sensor output (“D”-type connector option)

As an option, sensors can be equipped with a 26-pin high-density “D”type plug in place of the mil-spec connector.

Pin Function

1 Mass position, N/S component

2 Lock

3 BUSY LED

4 Logic ground

5 Mass position, E/W component

7 RS232 transmit from instrument (RS232 control interface option)

8 Signal ground

9 RS232 receive at instrument (RS232 control interface option)

10 Calibration signal

11 Calibration enable, N/S component

12 Calibration enable, vertical component

13 0 V power

14 Velocity –ve, vertical component

15 Calibration enable, E/W component

16 Velocity +ve, vertical component

17 + 10 – 36 V power

18 Velocity –ve, N/S component

19 Centre

20 Velocity +ve, N/S component

21 Factory use only, do not connect

22 Velocity –ve, E/W component

23 Velocity +ve, E/W component

24 Unlock

25 Mass position, vertical component

48 Issue N

Page 49

Operator's guide

26 RS232 ground (RS232 control interface option)

In sensors with the RS232 control interface option, the RS232 ground

line (pin 26) is isolated from the other ground lines (pins 4 and 8)

using 10 nF decoupling capacitors.

6.3 Sensor output (waterproof connector option)

Waterproofed models have a 32-pin waterproof connector in place of

the 26-pin output connector. These instruments are supplied with an

adapter cable for connecting to a standard digitizer input.

The pin connections are:

Pin Function

1 Mass position, N/S channel

2 Lock

3 BUSY LED

4 Logic ground

5 Mass position, E/W channel

6 Power –ve (not used in sensors with internal DC-DC converters)

7 RS232 transmit from instrument (RS232 control interface option)

8 Signal ground

July 2009 49

Page 50

CMG-3T

9 RS232 receive at instrument (RS232 control interface option)

10 Calibration signal (all channels)

11 Calibration enable, N/S channel

12 Calibration enable, vertical channel

13 Power ground

14 Velocity +ve, vertical channel

15 Calibration enable, E/W channel

16 Velocity –ve, vertical channel

17 Power +ve

18 Velocity +ve, N/S channel

19 Centre

20 Velocity –ve, N/S channel

22 Velocity +ve, E/W channel

23 Velocity –ve, E/W channel

24 Unlock

25 Mass position, vertical channel

26 RS232 ground (RS232 control interface option)

In sensors with the RS232 control interface option, the RS232 ground

line (pin 26) is isolated from the other ground lines (pins 4 and 8)

using 10 nF decoupling capacitors.

6.4 Breakout box POWER connector

This is a standard 10-pin mil-spec plug (02E-12-10P).

Pin Function

A 0 V

B +12 V DC supply

H –12 V DC supply

50 Issue N

Page 51

Operator's guide

7 Specifications

Hybrid sensors Velocity output bandwidth 0.1 – 50 Hz

High pass filter output flat

to acceleration

0.01 Hz – spec*

High pass filter output flat

to velocity

spec – 50 Hz*

Mass position output DC – 0.1 Hz

Velocity sensitivity 1400 V/m/s

Acceleration sensitivity 2000 V/m/s²

Velocity sensors Velocity output bandwidth spec – 50 Hz*

Mass position output DC – spec Hz*

Velocity sensitivity 2 × 750 V/m/s

Mass position sensitivity 1000 V/m/s²

Controls

Mass locking and

unlocking

remotely operated

Mass centring

automatic,

microprocessor

controlled

Mechanics and

electronics

Sensors

3 orthogonal sensors,

each 0.180 kg

Lowest spurious resonance above 140 Hz

Total weight 13.5 kg

Sensor transducer type

capacitive

displacement

Feedback transducer type magnet/coil

Connector pressure tight

Temperature range with

masses locked

–35 to +75 °C

Operational temperature

range

–20 to +65 °C**

Power Supply 10 – 36 V

Current at 12 V DC 75 mA†

Current at 12 V DC during

calibration

100 mA†

Current at 12 V DC during 330 mA†

July 2009 51

Page 52

CMG-3T

centring (average)

Current at 12 V DC during

locking and unlocking

490 mA†

*spec refers to the quoted frequency response value, e.g., for a “30 s”

sensor, the value of spec would be 30 s = 0.033 Hz.

**Temperatures below –20 °C may be accommodated with additional

care. Please consult Güralp Systems for advice.

†Because centring, locking, and unlocking consume varying amounts

of power, it is recommended that you use a power supply capable of

delivering 1 A at 12 V.

52 Issue N

Page 53

Operator's guide

8 Revision history

2009-07-06 N Added integrated SOH controller

2006-10-19 M Added waterproof connector pin-out

2006-08-14 L Added RS232 command interface

2006-06-06 K Moved BB to “Accessories”

2006-02-20 J Corrections; added revision history

2004-10-29 H New document

July 2009 53

Loading...

Loading...