Page 1

Woodchip boiler

PRO

Operating Instructions/System Log Book PRO-A-00-00-00-01-BADE

DE-B30-012-V02-1013-V3.0

Page 2

PRO Operating Instructions

2

Information on this documentation

Read through this documentation carefully.

It is intended as a reference document and contains important

information on the design, safety, operation, maintenance and

care of your heating system.

We are always looking to improve our products and

documentation. Any ideas and suggestions you may have will

be gratefully received.

GUNTAMATIC Heiztechnik GmbH

Bruck 7

A-4722 PEUERBACH

Tel: 0043 (0) 7276 / 2441-0

Fax: 0043 (0) 7276 / 3031

E-mail: office@guntamatic.com

It is important that you pay particular

attention to the safety issues highlighted in

the text by these symbols.

The entire contents of this document are the property of

GUNTAMATIC and therefore protected by copyright.

Reproduction of any kind, communication to third parties by

any means or use for purposes other than those intended

without the written consent of the owner is prohibited.

Subject to printing errors and technical amendments.

Page 3

PRO Operating Instructions

3

Contents Page

1 Introduction .......................................................... 5

1.1 Brief description 5

1.2 Type approval 5

1.3 Further information 5

2 Important notes .................................................... 6

2.1 Intended use 6

2.2 Operating the heating system 6

2.3 Guarantee and liability 6

2.4 Safety instructions 7

3 System components .......................................... 11

3.1 Cutaway diagram of PRO 11

4 Safety systems ................................................... 12

5 Description of control panel ............................. 14

6 Overview of menu and levels ............................ 15

6.0 Information level 16

6.1 House level 17

6.1.1 Boiler enabling 17

6.1.2 Programme 17

6.1.3 User level 18

6.1.3.1 User menu 18

6.1.3.2 Thermal Store Pump HP0 menu 19

6.1.3.3 Network System menu 19

6.1.3.4 Heating Circuit menu 19

6.1.3.5 Hot Water menu 20

Supplementary Hot Water menu 20

6.1.3.6 Feeder Pump menu 20

Charging Pump menu 20

6.1.3.7 Boiler cascade menu 21

6.1.4 Service level 21

6.1.4.1 Service menu Reset Data 22

6.1.4.2 Service menu Commissioning 22

6.1.4.3 Service menu HP0 Parameters 23

6.1.4.4 Service menu System Settings 24

6.1.4.5 Service menu Network System Parameters 25

6.1.4.6 Service menu Heating Circuit Parameters 25

6.1.4.7 Service menu Hot Water Parameters 26

Service menu Supplementary Hot Water Parameters26

6.1.4.8 Service menu Feeder Pump Parameters 26

Service menu Charging Pump Parameters 26

6.1.4.9 Service menu Return Mixer Valve Parameters 26

Page 4

PRO Operating Instructions

4

Contents Page

7 User settings ................................ ...................... 27

7.1 Activating a heating programme 27

7.2 Deactivating a heating programme 28

7.3 Programming heating times 29

7.3.1 Programming en bloc 29

7.4 Changing the heating characteristic 30

7.5 Changing the hot water temperature 31

7.6 Analogue room stat 32

7.7 Digital room controller 32

8 Operating the heating system .......................... 33

8.1 Starting up/Shutting down the system 33

8.2 Heating system checks 33

8.3 Fuel quality 34

8.4 Fuels 35

8.4.1 Woodchips 35

8.4.2 Pellets 36

8.5 Filling/refilling the fuel store 37

8.6 Combustion air supply 38

8.7 Emptying the ash 39

9 Cleaning/Care ..................................................... 40

9.1 Cleaning the fuel store 41

9.2 Interim cleaning 41

9.3 Complete cleaning 42

9.4 Cleaning at end of heating season 42

10 Rectifying faults ................................................. 43

11 Information messages/Fault codes .................. 44

12 Replacing fuses ................................................. 46

13 Log book ............................................................. 47

13.1 Weekly visual inspection 48

13.2 Monthly checks 48

13.3 Servicing 48

Page 5

PRO Operating Instructions

5

1 Introduction PRO-01-00-00-00-02-BADE

You have made an excellent choice with the purchase of your

GUNTAMATIC boiler.

It is a product of many years' experience in boiler-making and

it is our sincere wish that your heating system provides you

with many years of satisfaction.

These instructions are intended as a guide to operation and

maintenance. Even the best boiler cannot operate effectively

without proper care and maintenance, so please read through

these instructions carefully and have your appliance

commissioned by an engineer authorised by GUNTAMATIC.

Most importantly, you should follow the safety instructions in

Section 2.

1.1 Brief description

The PRO is a modern biomass boiler. The fuel is fed to the

boiler from a fuel storeroom by an auger-type conveyor with

fuel agitator.

1.2 Type approval

The boiler is designed in accordance with Class 3 to EN 303-5

and the agreement of the Austrian Federal States according to

Art. 15a BVG relating to safety measures for small combustion

heating systems and energy saving. The original type

approval certificates are available for inspection at the

manufacturer's offices.

1.3 Further information

The documentation consists of the following documents:

Installation instructions

Planning and installation instructions

Wiring diagram

Operating instructions

If you have any questions, please consult our Customer

Support.

Page 6

PRO Operating Instructions

6

2 Important notes PRO-02-00-00-00-01-BADE

Your boiler has been designed and produced in accordance

with the latest technical advances and all applicable safety

regulations. Nevertheless incorrect operation, the use of

unapproved fuels or the failure to carry out necessary

maintenance and repairs can result in personal injury or

damage to property. You will avoid dangerous situations by

only using the boiler for the purpose for which it was designed

and by operating, cleaning and maintaining it correctly. Only

start up the heating system when it is in perfectly safe working

order.

2.1 Intended use

The boiler is designed for heating central heating water and

for use as a central heating boiler.

2.2 Operating the heating system

The heating system may only be operated and cleaned by

demonstrably trained persons (as per check-list). Children,

unauthorised persons or persons with a mental impairment

may only enter the boiler room under the supervision of an

authorised person. When unsupervised, the boiler room/fuel

store must be locked and the key kept in a place where it is

inaccessible to such persons.

2.3 Guarantee and liability

Guarantee and liability claims for personal injury and/or

property damage are inadmissible if they are attributable to

one or more of the following causes:

use of the boiler for purposes other than that intended

failure to follow the instructions, guidance and safety

precautions given in the documentation

incorrect commissioning, operation, maintenance or

repair of the boiler

operation of the boiler when safety systems are

inoperative

unauthorised modifications

Caution: Do not use the boiler to burn rubbish!

Burning rubbish will cause extensive

corrosion and consequently a drastic

reduction in the service life of the boiler.

Caution: even if the opposite is requested, servicing

and repair work may only be carried out by

authorised specialists.

Page 7

PRO Operating Instructions

7

2.4 Safety instructions

To prevent accidents, small children should not be allowed

into the boiler room or the fuel storeroom. Please follow the

safety instructions below. By doing so, you will protect yourself

and prevent damage to your heating system.

Power switch

Mains plug

Repair work

In an emergency: In the event of electric shock, disconnect

the power supply immediately.

Administer first aid. Call the duty doctor.

Fault rectification

Unauthorised modifications

Note: The power switch must remain switched on at

all times and may only be switched off when

the system is not in operation.

Danger: Risk of fatal injury from electric shock.

The mains power supply is brought to the

boiler via the plug marked Mains. That plug

and other components of the system remain

live even when the Power switch on the

control panel is switched off.

Danger: Repair work may only be carried out

by authorised technicians.

Touching live electrical components can

cause fatal injury.

Even when the Power switch is OFF some

components of the system are still live.

Therefore, when carrying out repair work it is

imperative that the power supply to the

heating system is completely disconnected by

means of the "mains plug" or a circuit

breaker.

Note: If faults occur, the causes must first be

eliminated on the basis of the information

message on the display (F0...) before

resuming operation by means of the Quit

button.

Note: Do not make any unplanned changes to the

settings or any modifications to the heating

system.

Loss of guarantee entitlement

Page 8

PRO Operating Instructions

8

Servicing work

Emptying ash

Boiler cleaning

Flue gas fan

Gaskets

In an emergency: Take the person affected into the

open air immediately. Call the duty doctor.

Air supply

Note: If there is more than one boiler in the same room, a

greater supply of fresh air must be provided.

Note: Service the boiler regularly or make use of

our Customer Service.

Danger: Glowing embers can cause fires.

The ash should only be removed from the

boiler or stored in non-combustible

containers.

Caution: Touching hot components can

cause skin burns.

The boiler must only be cleaned when it is

cold (flue gas temperature < 50°C)

Danger: Risk of injury from rotating parts.

The fan must only be removed when it is

disconnected from the power supply

(unplugged).

Danger: Risk of gas poisoning.

It is possible that flue gas could escape if

gaskets are damaged.

Have defective gaskets replaced by an

authorised technician.

Danger: Risk of suffocation

Inadequate air supply can be fatal.

Make sure there is an adequate supply of air.

Page 9

PRO Operating Instructions

9

Flue draught regulator

Safety clearances

Entering the fuel storeroom

Filling the storeroom

Danger: Risk of detonation.

A flue draught regulator with a pressure surge

compensator is an essential requirement.

Danger: Fire risk.

Do not store any flammable items in the close

vicinity of the boiler.

Follow the local regulations.

Danger: Risk of injury!

Only enter the store room when the

system is switched off. Always shut off

the power supply before entering.

Affix a sign to the storeroom door.

Keep the storeroom doors locked.

Danger: Combustible gases in storeroom!

When filling the fuel storeroom from a

tanker truck or using a pressure-filling

system, it is imperative that the boiler is

shut down.

If this rule is ignored, flammable and

poisonous gases can be drawn into the

storeroom.

Page 10

PRO Operating Instructions

10

Protection against freezing

Emergency fire extinguishing system

Fire extinguisher

Note: Anti-freeze function.

The system can only perform its freezing

prevention function if sufficient fuel is

available and there are no faults.

Note: Provide a fire extinguisher.

There must be a fire extinguisher placed

immediately outside the boiler room door.

Note: Contact our Customer Service.

If the emergency fire extinguishing system

has been triggered, it is always due to a fault

in the heating system.

Page 11

PRO Operating Instructions

11

3 System components PRO-03-00-00-00-01-BADE

3.1 Cutaway diagram of PRO

1.) Stepped grate – primary air

2.) Domed swirl chamber

3.) Photosensor

4.) Inspection cover

5.) Helix baffles

6.) Heat exchanger

7.) Flue draught fan

8.) Automatic cleaning mechanism

9.) Flue pipe

10.) Oxygen sensor

11.) Flue gas sensor

12.) Grate motor

13.) Ash collecting device

14.) Menu-based touch-screen controller

15.) LED status indicator

Page 12

PRO Operating Instructions

12

4 Safety systems PRO-04-00-00-00-01-BADE

To prevent the boiler overheating, the controller reduces the

heat output in certain situations. If the boiler still threatens to

overheat, the controller responds according to a set of defined

safety levels.

Safety level 1 10°C above specified temperature

The drive motor stops the fuel feed system and the flue

draught fan shuts down.

Safety level 2 Boiler temperature over 95°C

All heating pumps and the cylinder charging pump are

switched on to carry heat away from the boiler.

Safety level 3 Boiler temperature over 100°C

The STL (safety temperature limiter) trips and switches all

boiler control functions off while the pumps continue to run.

The system remains switched off even if the boiler

temperature drops back below 90°C. The system must not be

started up again until any faults have been rectified and the

boiler has been checked.

Power failure The controller, the flue draught fan and all pumps switch off

due to lack of electricity if there is a power cut. The glowing

fuel bed on the grate continues burn with the natural draught

of the flue. As this operating mode is not ideal, a larger

amount of ash collects on the grate as well. As soon as the

electricity supply is restored, the controller takes control of the

heating system again.

Outer casing door open

The drive motors stop feeding the boiler with fuel

The flue draught fan switches to maximum extraction speed

If the outer casing door is closed again within 60 seconds,

combustion is continued

On the stoker duct The stoker duct and feeder box are designed to be completely

air-tight as far as the fire safety flap. That means that any

burn-back is extinguished by lack of air. The fire safety flap is

tested and approved as a burn-back prevention device. A

positioner motor opens and closes the flap. Fuel delivery does

not start until the flap is completely open. If the event of a fault

or a power failure, the flap closes automatically of its own

accord. When the boiler is in operation, the controller prevents

burn-back into the stoker auger by replenishing the fuel. In

addition, a sensor monitors the temperature in the vicinity of

the stoker auger. In that way, burning fuel is continually

pushed back out of the auger duct. This burn-back prevention

system always functions unless the electricity supply to the

boiler system is cut off.

Page 13

PRO Operating Instructions

13

On the fuel store outfeed unit Required in all countries

In addition, between the end of the fuel outfeed unit and the

burn-back prevention device there is a sprinkler unit that is

used instead of the temperature monitor with fuel stores with

a capacity not exceeding 50 m³ and is triggered at 55°C.

When the sprinkler is triggered, the sloping outfeed auger

enclosure – which also serves as a burn-back inhibiting device

– is completely flooded. The quantity of water required to do

so is at least 20 litres. If the temperature drops back below

55°C, the flooding is stopped.

Overfill prevention

The overfill prevention function is triggered by the fill level

sensor in the fuel chute or the contact switch on the overfill

prevention cover. If the fill level sensor trips, the auger A1

stops and the auger G1 continues running. If the sensor

remains on for longer than 10min, the overfill fault is

generated. If the overfill prevention cover switch trips, the

auger A1 is stopped after 3 seconds and the overfill fault

registered immediately.

Fuel stores > 50 m³ Requirement in Austria

A temperature monitor connected to a warning device must be

installed in the fuel storeroom at the point where the fuel

conveyor exits the fuel store and enters the boiler room. A

visual and audible warning device must be triggered when the

temperature exceeds 70°C.

Manually operated fire extinguishing facility

This fire extinguishing facility is for the purpose of combating a

fire seated in the fuel storeroom in the area of the outfeed unit

and is manually actuated. It consists of conduit piping with a

minimum size of DN 20 and is to be fitted in the fuel storeroom

immediately above the fuel conveyor close to its exit point

through the wall or ceiling and positioned so as to obtain the

maximum possible fire extinguishing effect. The conduit piping

is to be connected directly to a pressurised water supply and

provided with a stop tap located in the boiler room. That tap

must be identified by a sign carrying the inscription "Fuel

storeroom fire extinguisher". The design of the fire

extinguishing facility must be such that it cannot be damaged

by the delivery of fuel into the fuel store or by the fuel outfeed

equipment.

Note: The sprinkler system must be connected

on all systems regardless of local

regulations.

Page 14

PRO Operating Instructions

14

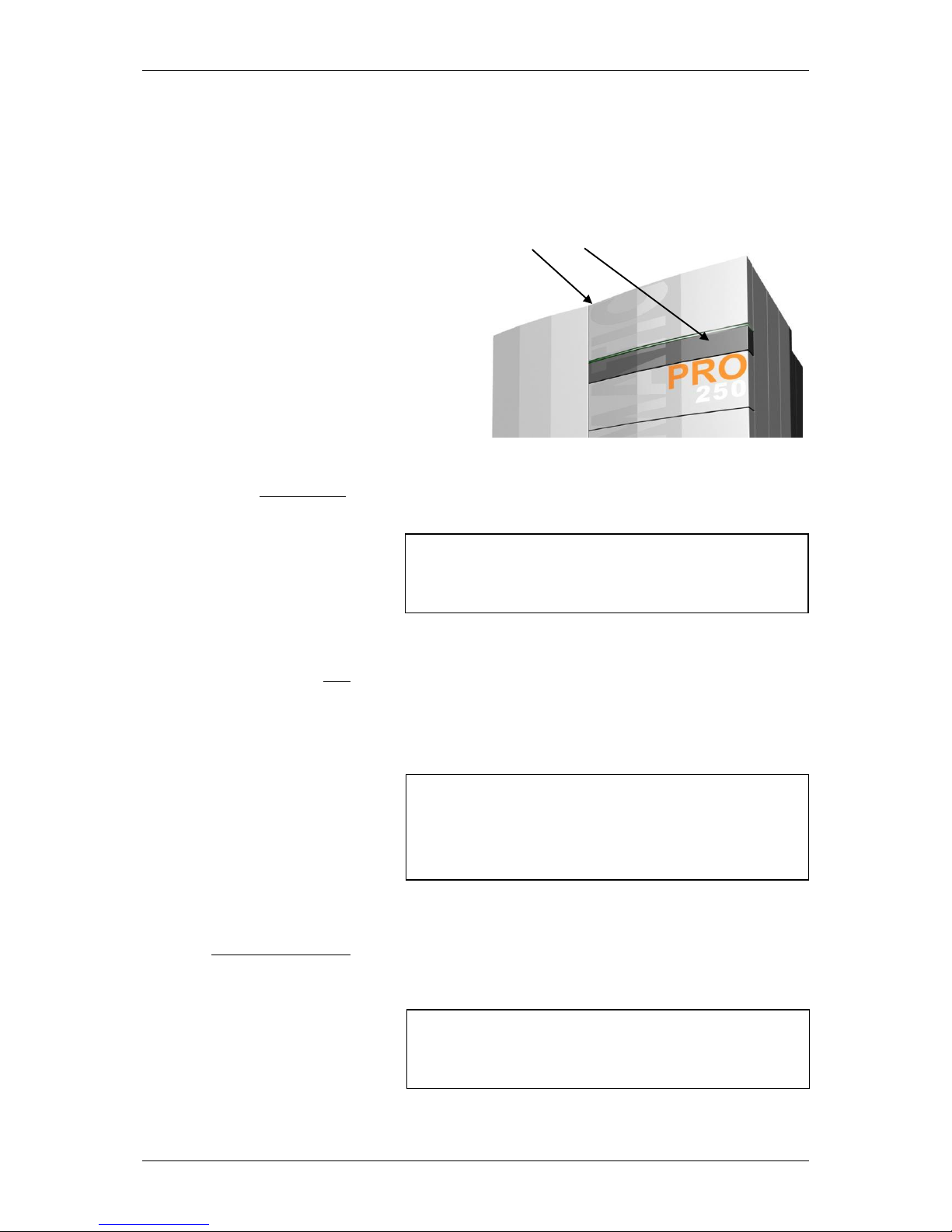

5 Description of control panel PRO-05-00-00-00-01-BADE

The appliance has a large touch-screen control panel with a

menu-based interface. All settings can be entered by pressing

the "buttons" on the touch screen. Information messages and

fault indications are displayed on the screen.

1-2 3

Power switch (1) Normally remains permanently switched on. The power switch

may only be switched off when the system is not in operation.

STL (2) The safety temperature limiter (STL) trips if the system

overheats → heating by the appliance is suspended.

If the STL has tripped, identify and eliminate the cause and

then press in the STL button as far as it will go using a

suitable object.

Touch-screen display (3) Pressing lightly with your fingertip on the relevant buttons on

the display opens the various programme levels and menus

where you can make changes to the settings.

Note: When carrying out repairs or servicing work,

the system must also be fully isolated from

the mains by unplugging the power lead.

Note: The system must not be started up again

until any faults have been rectified and the

boiler has been checked. If necessary, a

heating engineer must be called in.

Note: Never use sharp objects such as ball-point

pens or the like to operate the touch screen.

Page 15

PRO Operating Instructions

15

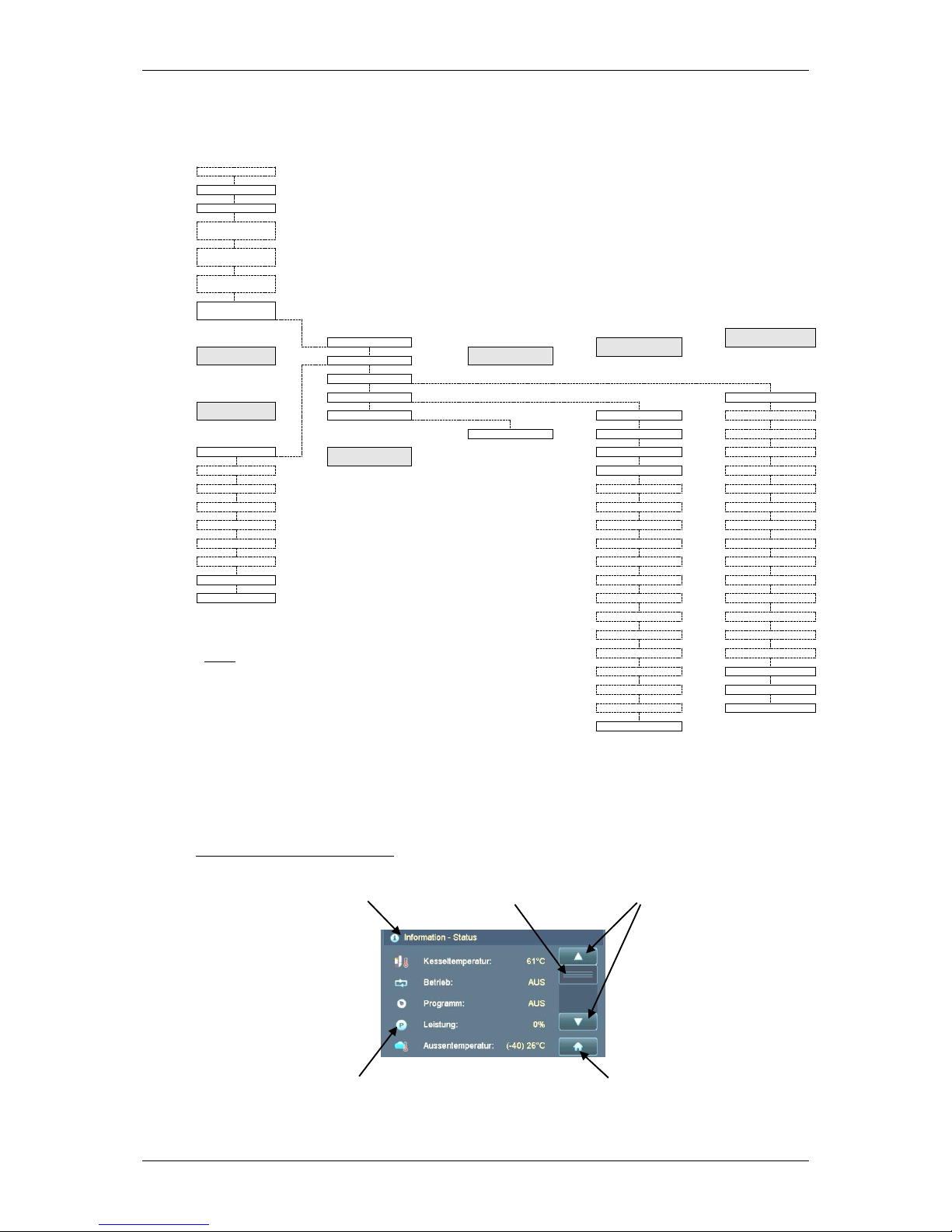

6 Overview of menu and levels PRO-06-00-00-00-01-BADE

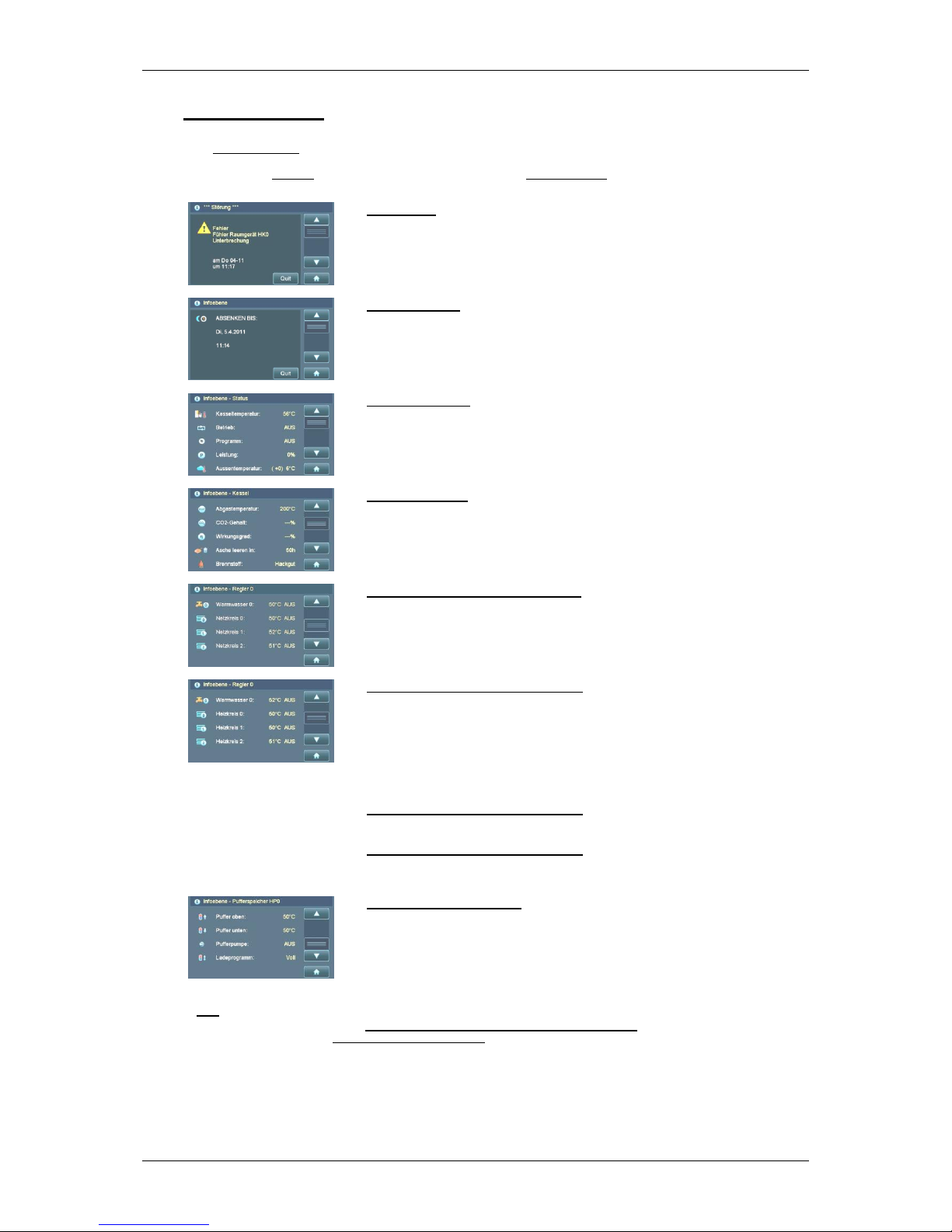

Fault screen

Status info

Boiler info

MK Controller 0

info

MK Controller 1

info

MK Controller 2

info

Thermal store HP0

info

User Level

▲

Boiler enabling

Service level

Information level

Parameters menu

▼

Programme

▼

▼

User Level

Service level

CODE User menu

Programme level

Parameters menu

CODE Reset data

Heating circuit 0

▼

Boiler parameters

Fault list

Heating circuit 1

▲

Off

House level

Test program

Heating circuit 2

Normal Commissioning

Heating circuit 3

Hot water HC0 parameters

Heating circuit 4

Heating HC1 parameters

Heating circuit 5

Low HC2 parameters

Heating circuit 6

Low until HC3 parameters

Heating circuit 7

Recharge HW HC4 parameters

Heating circuit 8

Manual HC5 parameters

DHW 0

Grate cleaning HC6 parameters

DHW 1

HC7 parameters

DHW 2

Note:

Menus shown with a dashed border only appear if

activated on the Commissioning menu.

Changes to the settings on the Service and

Parameters levels may only be made with the

agreement of GUNTAMATIC.

HC8 parameters

Th/store pump HP0

DHW0 Parameters

Boiler cascade

DHW1 Parameters

User menu

DHW2 Parameters

Detail View

HP0 parameters

Date/Time

System settings

Layout of touch-screen display

Header Scroll bar Scroll buttons

Symbols Select button

Page 16

PRO Operating Instructions

16

6.0 Information level

The scroll buttons are used to navigate up or down through the menus.

Touching the House button on the display opens the House Level menu.

1) Note: Only shown if the function Network System Controller or Heating Circuit Controller has been activated.

Only one of the functions Network System Controller or Heating Circuit Controller can be programmed.

The two functions cannot be used simultaneously on the same boiler.

2) Only temperatures from the top and bottom thermal store sensors are shown on the Info Level.

(If 5-sensor thermal store management is activated, the temperatures from the thermal store middle sensors are shown in Detail View.)

Fault screen → highest priority

Plain-English fault messages are displayed and saved

Fault is acknowledged by pressing Quit button

1)

Information level → Only shown if the programme "Low until" has been activated

Disappears after the set time has elapsed

Can be prematurely deactivated by pressing Quit button

Info Level – Status

Shows boiler temperature

Shows boiler operating mode

Shows selected programme

Shows boiler output

1)

Shows outside temperature → Figure in brackets = average temperature

Info Level – Boiler

Shows flue gas temperature

Shows CO2 level

Shows efficiency

Shows time in hours until ash warning is triggered

Shows fuel setting

1)

Info Level – Network system controller → (NSC)

Shows domestic hot water temperature and operating mode for cylinder 0

Shows operating mode for network system 0 → Pumped network system

Shows operating mode for network system 1 → Pumped or mixer-valve network system

Shows operating mode for network system 2 → Pumped or mixer-valve network system

1)

Info Level – Heating circuit controller 0 → (HCC 0)

Shows domestic hot water temperature and operating mode for cylinder 0

Shows operating mode for heating circuit 0 → Pumped heating circuit

Shows operating mode for heating circuit 1 → Pumped or mixer-valve heating circuit

Shows operating mode for heating circuit 2 → Pumped or mixer-valve heating circuit

1)

▼

Info Level – Heating circuit controller 1 → (HCC 1)

1)

▼

Info Level – Heating circuit controller 2 → (HCC 2)

2)

Information – Thermal store → (HP0)

Shows thermal store temperature at top

Shows thermal store temperature at bottom

Shows thermal store pump operating mode

Shows charging programme

Page 17

PRO Operating Instructions

17

6.1 House level

Pressing the buttons on the left-hand side opens the various menus.

Touching the Info button returns you to the Info Level menu.

6.1.1 Boiler enabling

Setting Boiler enabling to Off shuts down the boiler.

Network systems or Heating circuits continue to run.

3) Options → AUTO Boiler enabling dependent on enabling switch 22/23 on the boiler circuit board

(Enabling switch closed > Burner active on demand, heating circuit controller active)

(Enabling switch open > Burner off, heating circuit controller active)

→ OFF Boiler not enabled regardless of enabling switch 22/23 on the boiler circuit board

(Enabling switch closed > Burner off, heating circuit controller active)

(Enabling switch open > Burner off, heating circuit controller active)

6.1.2 Programme

Pressing the buttons on the left-hand side opens the programme.

4) The anti-freeze function is only active in OFF mode.

5) Other programme buttons are only visible if network system or heating circuit controller is activated.

Boiler enabling

See Section 6.1.1

Programme

See Section 6.1.2

User Level

See Section 6.1.3

Service level → CODE required

See Section 6.1.4

Parameters menu → CODE required

See Section 6.1.5

3)

Facility for setting boiler enabling

3)

4)

Heating and hot water switched off → Anti-freeze function active

Heating mode without network system or heating circuit controller activated

Manually switches on stepped grate for cleaning purposes

Other function buttons:

5)

→ NORMAL programme

Heating and hot water mode (DHW as per timer prog.)

5)

→ HOT WATER programme

Hot water on as per summer DHW timer programme

5)

→ HEATING programme

Heating mode day and night (DHW as per timer programme)

5)

→ LOW programme

Low-temperature mode day and night (DHW as per timer

programme)

5)

→ LOW UNTIL programme

Low-temp. mode until a specified time (DHW as per timer prog.)

5)

→ RECHARGE HOT WATER programme

Water heating outside programmed charging times (max. duration

90min)

Page 18

PRO Operating Instructions

18

6.1.3 User Level

The number of menus depends on the configuration.

6) Note: Only one of the functions Network System Controller or Heating Circuit Controller can be programmed.

The two functions cannot be used simultaneously on the same boiler.

7) Functions are only displayed if external heating circuit controller is activated.

6.1.3.1 User menu

The number of functions depends on the configuration.

8) After the ash container has been emptied (box or auto ash extraction system) it has to be confirmed on the Ash Emptied menu

by pressing the buttons YES and OK.

9) Options: Pellets 1 Quality ENplus A1 (standard quality)

Pellets 2 Quality ENplus A2

Woodchips 1 Soft wood (W > 25% - low quality)

Woodchips 2 Mixed soft and hard wood (W > 15-30% - standard quality)

Woodchips 3 Hard wood (W < 15% - high quality)

User menu → User settings

See Section 6.1.3.1

Thermal store pump HP0 menu

See Section 6.1.3.2

Detail View menu

Date/Time menu

Other function buttons:

6)

→ Network System 0-2 menu

See Section 6.1.3.3

6)

→ Network System 0-8 menu

See Section 6.1.3.4

→ DHW Cylinder 0-2 menus

See Section 6.1.3.5

7)

→ Supplementary DHW Cylinder 0-2 menu

See Section 6.1.3.5

7)

→ Feeder Pump 0-2 menu

See Section 6.1.3.6

7)

→ Charging Pump 0-2 menu

See Section 6.1.3.6

→ Boiler Cascade menu

See Section 6.1.3.7

Function buttons:

8)

→ Ash Emptied function

→ Ash Warning function → Time interval until ash warning appears (adjustable)

→ De-ashing function → For manually starting de-ashing

9)

→ Fuel parameters

→ Enable HCC 0 function → Only affects the district heating function

→ Enable HCC 1 function → Only affects the district heating function

→ Enable HCC 2 function → Only affects the district heating function

→ Fill Auger function → Sequence is not automatically switched off!

→ Flue Gas Testing function → Controller set to FGT Test/CO2 Test

→ Outfeed Auger function → For switching between A1a/b - Activated in System Settings

→ De-ashing Lockout function

→ Language function

Page 19

PRO Operating Instructions

19

6.1.3.2 Thermal store pump HP0 menu

10) Thermal store only charged during charging times enabled on menu

11) Linear boiler output reduction if the set medium output limit is exceeded

6.1.3.3 Network System menu

6.1.3.4 Heating Circuit menu

12) Options → Auto Network system/Heating circuit is switched ON/OFF according to demand and timer programme.

→ Off The network system/heating circuit is switched off.

→ Constant The network system/heating circuit pump runs continuously; with mixer-valve network systems/heating

circuits, the mixer valve is not operated

13) Modulation to daytime required temperature is only possible in conjunction with a room stat or room controller; raising or

lowering the required temperature shifts the heating curve up or down accordingly.

14) Modulation to night-time required temperature is only possible in conjunction with a room stat or room controller; in addition, the

outside temperature must be below that set in menu option Night OFF OT (hysteresis 2°C)

15) Options → 0% No room effect programmed

→ 25% Modulation of room temperature based 25% on room temperature and 75% on outside temperature.

→ 50% …

→ T 1°C If the required room temperature is exceeded by 1°C the heating circuit pump is switched off.

→ T 2°C …

16) A higher heating characteristic figure produces a higher required flow temperature at the same outside temperature

17) If the temperature drops below the set temperature during the low-temperature phase, the boiler heats to the required night-time

temperature.

18) The set outside temperature is exceeded during the heating phase, the heating circuit is switched off.

Function buttons:

→ Pump Mode function

10)

→ Thermal store timer programme parameters

→ Thermal store required temp. → effective for thermal store top sensor (T3)

→ Thermal store min temp. → effective for thermal store top sensor (T3)

→ Thermal store min charge

11)

→ Medium output limit parameters

Function buttons:

12)

→ Pump Mode function

→ Timer programme parameters Facility for setting heating and low-temperature times

→ Daytime base point parameters

→ Night-time base point parameters

16)

→ Heating curve parameters

17)

→ Night OFF OT function

18)

→ OT Off function

Function buttons:

12)

→ Pump Mode function

→ Timer programme parameters Facility for setting heating and low-temperature times

13)

→ Daytime required temp parameter

14)

→ Night-time required temp parameter

15)

→ Room effect parameter

16)

→ Heating curve parameters

17)

→ Night OFF OT function

18)

→ OT Off function

Page 20

PRO Operating Instructions

20

6.1.3.5 Hot Water menu

Supplementary Hot Water

19) Options → Auto The pump is switched ON/OFF according to demand and timer programme

→ Off The pump is switched off

→ Constant The pump runs continuously

20) All charging times programmed in the DHW timer programme are active when the programme is set to NORMAL.

21) All charging times programmed in the Summer DHW timer programme are active when the programme is set to HOT WATER.

22) Options → No During charging of DHW cylinder, network systems/heating circuits can be enabled.

→ Yes During charging of DHW cylinder, network systems/heating circuits cannot be enabled.

6.1.3.6 Feeder Pump menu

Charging pump

23) Options → Auto The pump is switched ON/OFF according to demand

→ Off The pump is switched off

→ Constant The pump runs continuously

24) Options → Full The thermal store is fully charged

Charging switches off when the required thermal store temperature at T3 is reached and also the

required thermal store temperature minus the parameter TSbtm-Boff (-10°C) is reached at T2

→ Part The thermal store is partially charged

Charging switches off when the required thermal store temperature is reached at T3 (= parameter

TS top-B Off)

25) Thermal store only charged during the charging times enabled

Function buttons:

19)

→ Pump Mode function

20)

→ DHW timer programme parameters

21)

→ Summer DHW timer programme parameters

→ DHW required temp parameter

22)

→ DHW priority parameter

→ Recharge DHW function → Maximum duration 90 minutes

Function buttons:

23)

→ Pump Mode function

24)

→ Charging programme parameters

25)

→ Timer programme parameters

→ Thermal store required temp. → effective for thermal store top sensor (T3)

→ Thermal store min temp. → effective for thermal store top sensor (T3)

Page 21

PRO Operating Instructions

21

6.1.3.7 Boiler Cascade menu

The Boiler Cascade menu is only visible on boiler A.

26) After the set time has elapsed, the boiler that has completed the fewest hours of duty in the cascade system is always started up

first.

27) Options → P ON When the boiler already started reaches the output set for P ON, the parameter Cut-in Time is

activated; if the boiler is still operating at the output set in the parameter P ON when the Cut-in

Time has elapsed, the next boiler is started up.

→ P OFF When the total output of the boilers running falls below the output set for P OFF, the last boiler

started is shut down again.

28) If the set outside temperature is exceeded, the boiler concerned is switched off.

29) As soon as the output of the boiler in operation falls below the level set in the parameter P OFF EXT Hyst, the boiler operated via

the EXTERNAL output (e.g. a peak load boiler) is switched off.

If multiple boilers are running, the total output of all boilers in operation applies.

6.1.4 Service Level (Expert)

The number of menus depends on the configuration.

Function buttons:

26)

→ Boiler Changeover function → 0h = No boiler changeover

→ Cut-in Time parameter

27)

→ Cut-in Output parameter

28)

→ Enable OT function → Function can only be used if an outside-temperature sensor is connected to boiler A.

→ EXTERNAL Mode function → An EXTERNAL boiler (e.g. peak load boiler) can be permanently switched off

29)

→ P OFF EXT Hyst parameters

Reset Data menu → Service parameters/software update ………

See Section 6.1.4.1

Fault List menu

Test Program menu

Commissioning menu

See Section 6.1.4.2

HP0 Parameters menu → Thermal store HP0 ........................

See Section 6.1.4.3

System Settings menu → Service parameters ……...........

See Section 6.1.4.4

Other function buttons:

→ Network System (NK) 0-2 ..................................................................................

See Section 6.1.4.5

→ Heating Circuit (HK) 0-8 Parameters …………………………..

See Section 6.1.4.6

→ DHW Cylinder 0-2 Parameters ........................................................................

See Section 6.1.4.7

→ Supplementary DHW Cylinder 0-2 Parameters

........................................................................

See Section 6.1.4.7

→ District Heating (FL) 0-2 Parameters

..................................................................................

See Section 6.1.4.8

→ Return Mixer Valve (RLM) Parameters

...........................................................................

See Section 6.1.4.9

Page 22

PRO Operating Instructions

22

6.1.4.1 Service menu Reset Data

6.1.4.2 Service menu Commissioning

Function buttons:

→ Load User Parameters function → For importing saved customer data if necessary

→ Save User Parameters function

→ Load Factory Parameters function → Imports only the modified or new parameters of a new software version

→ Reset Duty Hours function → Resets the duty hours counter to 0

→ Reset Servicing Time function → Resets the servicing timer to 0

→ Controller Reset function → Caution: Loads factory settings

→ Oxygen Sensor Calibration Reset function → Should always be carried out whenever oxygen sensor is replaced

Function buttons:

→ System:

Options:

PRO

→ Type:

Options:

175kW/250kW

→ Fuel outfeed

Options:

FLEX/AGIT

→ Feeder auger

Options:

No/Yes

→ Ash removal

Options:

◄◄◄◄/VAC/BOX

→ Fuel

Options:

Pellets 1/Pellets 2/Woodchips 1/Woodchips 2/Woodchips 3

30)

→ NSC present → Network system

controller

Options:

No/Yes

→ DHW 0 present

Options:

No/Yes

→ NS 0 mode

Options:

None/Pump

→ NS 1 mode

Options:

None/Pump/Mixer

→ NS 2 mode

Options:

None/Pump/Mixer

30)

→ HCC 0 present → Heating circuit controller

Options:

No/Yes

→ DHW 0 present

Options:

No/Yes

31)

→ HC 0 mode

Options:

None/Pump/Mixer

→ HC 1 mode

Options:

None/Pump/Mixer

→ HC 2 mode

Options:

None/Pump/Mixer

→ Source → Only with CP

Options:

Thermal store HP0

32)

→ District heating 0 mode

Options:

None/FP/◄◄◄/CP

33)

→ Supplementary 0

Options:

None/HWP/External

→ HCC 1 present → Heating circuit controller

Options:

No/Yes

→ DHW 1 present

Options:

No/Yes

31)

→ HC 3 mode

Options:

None/Pump/Mixer

→ HC 4 mode

Options:

None/Pump/Mixer

→ HC 5 mode

Options:

None/Pump/Mixer

→ Source → Only with CP

Options:

Thermal store HP0

32)

→ District heating 1 mode

Options:

None/FP/◄◄◄/CP/EXT

33)

→ Supplementary 1

Options:

None/HWP/External

→ HCC 2 present → Heating circuit controller

Options:

No/Yes

→ DHW 2 present

Options:

No/Yes

31)

→ HC 6 mode

Options:

None/Pump/Mixer

→ HC 7 mode

Options:

None/Pump/Mixer

→ HC 8 mode

Options:

None/Pump/Mixer

→ Source → Only with CP

Options:

Thermal store HP0

32)

→ District heating 2 mode

Options:

None/FP/◄◄◄/CP/EXT

33)

→ Supplementary 2

Options:

None/HWP/External

→ HP0 mode

Options:

◄◄◄◄◄/Th store pump

→ Return mixer valve

Options:

No/Yes

→ Fill Auger

Options:

OFF/ON

→ Save User Parameters

Options:

No/Yes

Page 23

PRO Operating Instructions

23

30) Note: Only one of the functions Network System Controller or Heating Circuit Controller can be programmed on the boiler.

Network system mode or heating circuit mode

→ None Network system/heating circuit is deactivated

→ Pump Operation of the pumped circuit is controlled by the timer programme

→ Mixer Operation of the pump and the mixer valve is controlled by the timer programme

Room stat options (only possible with heating circuits)

→ None No room stat connected

→ RFF Analogue room stat is connected

→ RS Full Digital room controller is connected (facility for setting all heating circuits)

→ RS HC Digital room controller is connected (facility for setting assigned heating circuit only)

→ RS HCC Digital room controller is connected (facility for setting one heating circuit controller)

31) The heating circuit can only be set as a mixer-valve heating circuit if the Supplementary and District Heating functions are not activated.

32) The District Heating Mode function can only be activated if heating circuit 0 is not programmed as a mixer-valve heating circuit.

→ FP The district heating pump is controlled as a feeder pump (for setting see plumbing diagram)

→ TSP The district heating pump is controlled as a thermal store pump (for setting see plumbing

diagram)

→ CP The district heating pump is controlled as a charging pump (for setting see plumbing diagram)

33) The function Supplementary 0 can only be activated if heating circuit 0 is not programmed as a mixer-valve heating circuit.

→ None Function is deactivated

→ HWP An additional DHW cylinder can be activated

→ External Heat from an external boiler (e.g. oil boiler) can be requested using the Cascade function

6.1.4.3 Service menu HP0 Parameters

34) The boiler is started up when the thermal store temperature falls below the maximum temperature required by the heating circuit

controller minus the temperature set in the parameter TS top charge ON.

Example: Maximum temperature required by heating circuit controller = 55 °C

Setting for TS top charge ON = 6°C

The boiler starts up when the temperature at the thermal store top sensor (T3) is 49°C

35) With the partial charging programme the boiler is shut off when the temperature at the thermal store top sensor (T3) reaches

the thermal store required temperature plus the temperature set for the parameter TS top charge OFF.

Example: Required thermal store temperature = 70°C

Setting for TS top charge OFF = 5°C

The boiler is shut off when the temperature at the thermal store top sensor (T3) is 75°C

36) With full charging programme, the boiler is shut off as soon as the temperature at the bottom of the thermal store (T2) only

differs from the temperature at the top of the thermal store (T3) by the amount set for the parameter TS btm charge OFF

Example: Temperature at top of thermal store (T3) = 70 °C

Setting for parameter TS btm-B off = -10 °C

The boiler is shut off when the temperature at the thermal store bottom sensor (T2) is 60°C

37) This parameter specifies which controller the sensors of thermal store HP0 are connected to. If the thermal store sensors are

assigned to a heating circuit controller, no analogue room stats can then be used on that controller.

38) This function can be used to activate 5-sensor thermal store management (No = 2-sensor thermal store management).

Function buttons:

→ HP0 Mode function

Options:

Th/store pump

→ Enable HP0 parameter → Enabling temperature for output HP0

34)

→ Parameter TS top charge ON → Boiler demand via sensor T3

35)

→ Parameter TS top charge OFF → Boiler switched off via sensor T3 with charging programme PART

36)

→ Parameter TS btm charge OFF → Boiler switched off via sensor T2 with charging programme FULL

→ Parameter Delta-T Dist/h → District heating pipe heat loss

→ Parameter B-TS btm Diff. → Temperature difference between boiler and bottom of thermal store

37)

→ Parameter Sensor HP0

Options:

Boiler/HCC 0/HCC 1/HCC 2

38)

→ Supplementary Sensor function

Options:

No/Yes

Page 24

PRO Operating Instructions

24

6.1.4.4 Service menu System Settings

The number of parameters depends on the configuration.

39) Options → Terminal Data querying via Windows hyper terminal/display

→ DAQ Data querying via online recorder (only usable at factory)

→ GSM module Data querying, information messages and boiler control via GSM module

Function buttons:

→ System:

Options:

PRO

→ Type:

Options:

175kW/250kW

→ Fuel outfeed

Options:

FLEX/AGIT

→ A1/G1 Pellets 1, Pellets 2, …

Options:

Ratio of auger A1 to G1

→ Feeder auger

Options:

No/Yes

→ A2/A1 Pellets 1, Pellets 2, …

Options:

Ratio of auger A1 to G1 (if feeder auger activated)

→ A1a/b changeover

Options:

No/Yes

→ Ash removal

Options:

VAC; BOX

→ Fill level A1

Options:

No/Yes

→ Fill level A2

Options:

No/Yes

→ PS present

Options:

No/Yes

→ Calibrate PS

Options:

OFF/ON

→ PS compensation

Options:

Photosensor compensation setting

→ Air flap

Options:

No/Yes

→ Boiler cascade

Options:

No/A/B/C/D

→ Grate motor

Options:

Benzler/ABM

→ Flue draught

Options:

Cyclic

→ NSC present

Options:

No/Yes

→ HCC 0/1/2 present

Options:

No/Yes

→ Outside temp sensor

Options:

No/Yes

→ Oxygen sensor

Options:

No/NGK/Bosch

→ Oxygen sensor heating

Options:

AUTO/Constant

→ Calibrate oxygen sensor

Options:

OFF/ON

→ Oxygen sensor compensation

Options:

Oxygen sensor compensation setting

→ Oxygen sensor characteristic

Options:

0.0%/0.5%/-3.0%

→ BT comp 80°C

Options:

Boiler temp compensation setting

39)

→ PC monitoring

Options:

Terminal/DAQ/GSM module

→ GSM subscriber number 1

Options:

Subscriber number entry

→ GSM subscriber number 2

Options:

Subscriber number entry

→ SD logging

Options:

OFF/ON – Save setting

→ SD data

Options:

Summary

→ CID data

Options:

Manufacturer code

→ Network

Options:

No/Yes

→ DHCP

Options:

Manual/Via DHCP (if network activated)

→ IP address

Options:

10.0.0.25 (if DHCP set to Manual)

→ Subnet mask

Options:

255.255.255.0 (if DHCP set to Manual)

→ Gateway

Options:

10.0.0.1 (if DHCP set to Manual)

→ Pri DNS server

Options:

10.0.0.1 (if DHCP set to Manual)

→ Sec DNS svr

Options:

(if DHCP set to Manual)

→ NetBIOS

Options:

Kessel0001 (if DHCP set to Manual)

→ ABS pump time

Options:

Activates all pumps once a week for the set amount of time

→ HCP forced op

Options:

If boiler or thermal store overheats all heating circuit pumps switch on

→ Residual heat utilisation

Options:

Pump HP0 runs until temperature at boiler is below this figure

→ HCP A/F outside only with outside-temp

based controller

Options:

Only in OFF mode – All heating circuit pumps switch on if outside

temperature is below setting

→ HCP A/F Flow only with outside-temp

based controller

Options:

Required flow temperature if HCP A/F Outside is active

→ TÜV function

Options:

Raises boiler temperature until STL trips

→ ▼▼ Fault messages ▼▼

Page 25

PRO Operating Instructions

25

6.1.4.5 Service menu Network System Parameters

The number of parameters depends on the configuration.

40) Options → Pump Setting for network systems without mixer-valve control (Diagram PRO-01-02-01)

→ Mixer Setting for network systems with mixer-valve control (Diagram PRO-01-02-02)

41) If the twin pump function is activated, a return temperature sensor must be used for control purposes.

42) Each network system can be called for/switched off by an external controller using a 0-10V signal.

6.1.4.6 Service menu Heating Circuit Parameters

The number of parameters depends on the configuration.

CAUTION: The screed drying parameters must be set in consultation with the floor

layer.

Maintaining the specified temperatures is not possible in modulating control

mode but only when using automatic mixer valves. Maintenance of the

specified temperatures cannot be 100% guaranteed – due to various safety

circuits and special boiler functions, in exceptional cases the temperatures

can be significantly exceeded. If that is a problem in terms of damage to

building work, the screed drying function should be operated manually.

Function buttons:

40)

→ NK0-2 Mode function

Options:

None/Pump/Mixer

→ Mixer Valve Runtime function

→ Min Flow Temperature function → Only with mixer-valve circuits

→ Max Flow Temperature 1-2 function → Only with mixer-valve circuits

→ Boiler Overcompensation parameter

→ Enable NSP 0-2 parameter

→ Parallel Shift parameter

41)

→ Twin Pump function

Options:

No/Yes

→ Twin Pump Off Differential parameter

→ Twin Pump On Differential parameter

42)

→ Enable Ext. NS function

Options:

No/Yes

Function buttons:

→ HC 0-8 Mode function

Options:

None/Pump/Mixer

→ Room Stat 0-8 function

Options:

None/RFF/RS Full/RS HC/RS HCC

→ Mixer Valve Runtime function

→ Min Flow Temperature function → Only with mixer-valve circuits

→ Max Flow Temperature function → Only with mixer-valve circuits

→ Boiler Overcompensation parameter

→ Enable HCP 0-8 parameter

→ Parallel Shift parameter

→ Floor Screed Heating function

Options:

No/Yes

→ Flow Temp Increase parameter

→ Increase After parameter

→ Screed Heat Min Flow Temp parameter

→ Screed Heat Max Flow Temp parameter

→ Screed Heat Holding Time parameter → Number of days for which max flow temperature to be maintained

→ Start Screed Heating function

Options:

No/Yes

Page 26

PRO Operating Instructions

26

6.1.4.7 Service menu Hot Water Parameters

Supplementary Hot Water parameters

The number of parameters depends on the configuration.

43) If the temperature in the hot water cylinder falls below the required temperature by the hysteresis setting, the hot water cylinder is

heated up again.

6.1.4.8 Service menu Feeder Pump Parameters

Charging Pump parameters

The number of parameters depends on the configuration.

6.1.4.9 Service menu Return Mixer Valve Parameters

The number of parameters depends on the configuration.

44) Options → FIXED Return temperature is modulated to the specified temperature

→ Mixer Return temperature is modulated to the specified temperature depending on thermal store charge

45) Setting for temperature difference between boiler temperature and return temperature

46) Setting for minimum temperature difference between boiler temperature and return temperature at 100% thermal store charge

Function buttons:

→ DHW Present function

Options:

No/Yes/External

43)

→ DHW Hysteresis parameter

→ Enable DHW Pump parameter

→ Boiler Overcompensation parameter

Function buttons:

→ District Heating Mode function

Options:

None/FP/CP

→ Enable District Heating parameter → Enabling temperature for district heating pump

→ Parameter TS top charge ON → District heating pump demand via sensor T3

→ Parameter TS top charge OFF → District heating pump switched off via sensor T3 with charging programme PART

→ Parameter TS btm charge OFF → District heating pump switched off via sensor T2 with charging programme PART

→ Source parameter

Options:

ThStore 0/ThStore 1/ThStore 2/ThStore HP0

→ Parameter Delta-T Dist/h → District heating pipe heat loss

→ Parameter B-TS btm Diff. → Temperature difference between boiler and bottom of thermal store

Function buttons:

44)

→ Return Mixer Mode function

Options:

FIXED/AUTO/OPEN/CLOSED/OFF

→ Return Mixer Valve Runtime parameter

→ Required Return Temperature parameter

45)

→ Return Mixer Valve Delta T parameter

46)

→ Return Mixer Valve Delta T Min parameter

→ Startup Relief parameter

Options:

No/Yes

Page 27

PRO Operating Instructions

27

7 User settings PRO-07-00-00-00-01-BADE

7.1 Activating a heating programme

To activate the programme NORMAL, for instance, you proceed as

follows:

1) → Press the House level button

2) → Press the Programme button

3) → Press the NORMAL programme button

4) → Press the Back button

5) → Press the Info button

6) → The Info Level now shows the programme NORMAL

Page 28

PRO Operating Instructions

28

7.2 Deactivating a heating programme

To deactivate the programme NORMAL, for instance, you proceed as

follows:

1) → Press the House level button

2) → Press the Programme button

3) → Press the Programme Off button

4) → Press the Back button

5) → Press the Info button

6) → The Info Level now shows the programme OFF

Page 29

PRO Operating Instructions

29

7.3 Programming heating times

To program the timer programme for heating circuit 1, for instance, you proceed as

follows:

7.3.1 Programming en bloc

The same on and off times can be programmed for every day of the week.

1) → Press the House level button

2) → Press the User level button

3) → Press the Heating circuit 1 button

4) → Press the Timer programme 1 button

5) → Press the button for the day of the week to be set

6) → Press the ON or OFF time to be altered

7) → Use the and buttons to set the time

8) → To save the setting, press the button

To activate programming en bloc, press the same weekday button twice in

succession; all days are then highlighted and can be programmed

collectively to the same times

Page 30

PRO Operating Instructions

30

7.4 Changing the heating characteristic

To change the heating curve for heating circuit 1, for instance, you

proceed as follows:

Heating characteristic graph

1) → Press the House level button

2) → Press the User level button

3) → Press the Heating circuit 1 button

4) → Press the Heating characteristic 1 button

5) → Use the and buttons to set the heating characteristic

6) → To save the setting, press the button

20

30

40

50

60

70

80

-20-15-10-505101520

3,5

2,5

3,0

2,0

1,5

1,0

0,5

Outside temperature [°C]

Flow temperature [°C]

Page 31

PRO Operating Instructions

31

7.5 Changing the hot water temperature setting

To change the required temperature for cylinder 0, for instance, you proceed as

follows:

1) → Press the House level button

2) → Press the User level button

3) → Press the DHW cylinder 0 button

4) → Press the DHW required temp 0 button

5) → Use the and buttons to set the required temperature

6) → To save the setting, press the button

Page 32

PRO Operating Instructions

32

7.6 Analogue room stat

Installation site Fix the room stat on an internal wall at a height of approx.

1.5m. The most effective room is the one that is most

frequently occupied. In that room, the radiators must not be

fitted with thermostatic radiator valves (valves must be fully

turned on).

Note: The room stat should not be fitted in a position

where it will be exposed to warm sunshine or the

heat from a stove.

Changing room temperature The control knob on the room stat allows you to adjust the

required room temperature. Setting the control to a position in

the positive range (+) raises the required room temperature by

up to 3°C. Setting it to a position in the negative range (–)

lowers it by up to 3°C.

Note: Turning the control into the positive (+) or

negative (–) range means that the room

temperature shown in the Detail View will be

inaccurate. The room temperature shown will

only match the actual temperature when the

control knob is in the centre position.

Low: Heating mode OFF

(If the outside temperature is higher than the parameter Night Off OT)

Heating Mode ON → To Night-time Required Temperature

(If the outside temperature is lower than the parameter Night Off OT)

Normal: Heating and Low-temperature modes

(According to the times set in the timer programme)

Heating: Constant Heating mode → To Daytime Required Temperature

(Continuous heating day and night without low-temperature mode)

7.7 Digital room controller

The digital room controller offers various possible applications

which are defined during commissioning.

If the room controller is used to control room temperature, it

offers the same functions as the analogue room stat.

In addition, system data such as boiler operating mode, thermal

store temperatures, etc. can be retrieved.

Operating instructions The room controller is supplied with its own instruction manual.

Page 33

PRO Operating Instructions

33

8 Operating the heating system PRO-08-00-00-00-01-BADE

8.1 Starting up/Shutting down the system

Initial commissioning Initial commissioning and basic adjustment of the system may

only be carried out by GUNTAMATIC engineers or authorised

GUNTAMATIC agents.

Restarting Before starting up the system again in the autumn/winter,

carry out the annual check of the control and safety systems

to ensure they are safe and functional. We recommend that

you take out a maintenance contract so that the system

operates safely and economically.

Day-to-day operation Clean the heating system precisely according to the

instructions in the section Cleaning/Care. The amount of

cleaning work required is heavily dependent on the quality of

the fuel used and lower-quality fuels may necessitate more

cleaning work.

Shutting down the system The system only needs to be shut down at the end of the

heating season, if faults occur or in order to refill the fuel store.

To do so, set the system to the programme "OFF" and allow it

to cool down for approx. 120 minutes. The system can then be

shut down.

If the system is not used for extended periods (summer) also

isolate it from the power supply by disconnecting the mains

plug in order to prevent unnecessary lightning damage.

8.2 Heating system checks

Checking system pressure The operating pressure is normally between 1 bar and 2.5 bar.

If the system pressure is too low, malfunctions may result – if

necessary top up the water in the heating system.

Note Completely draining and refilling the system or

topping up a system filled with anti-freeze or treated

water must only be carried out by a heating

engineer.

Topping up the heating system water

The heating system water must be cold when topping up

→ make sure the heating system water temperature is

below 40°C.

Add water slowly until the required system pressure is

indicated on the system pressure gauge.

Bleed the heating system.

Check the system pressure again and add more water if

necessary.

Temperature-relief valve Firmly press in the red knob on the relief valve: → cools the

boiler using water from the domestic water system if the boiler

overheats; → in the event of malfunctions or leaks, call in your

heating engineer.

Page 34

PRO Operating Instructions

34

Sprinkler system Firmly press in the red knob on the sprinkler: → extinguishes

burn-back in the outfeed unit; → in the event of malfunctions

or leaks, call in your heating engineer.

Manual fire extinguisher (MFE) Check water supply/tank; → used to extinguish a fire in the

outfeed unit

Pressure-relief valve Turn the red knob on the safety set; → check for leaks and

correct operation; → in the event of malfunctions or leaks, call

in your heating engineer.

Expansion vessel If there are large pressure fluctuations between when the

heating system is hot and cold, check the charge pressure in

the expansion vessel; → in the event of malfunctions or leaks,

call in your heating engineer.

Boiler room ventilation Check that the air supply vents/ducts are clear.

8.3 Fuel quality

To ensure trouble-free heating with the boiler, the fuel must be

of the right quality.

Your GUNTAMATIC heating system is designed for burning

G30/G50 woodchips with a maximum moisture content of 35%

(W35), and pellets. However, it does not make sense to burn

fuels with a significant moisture content as a considerable

proportion of the energy has to be used to evaporate the

water in the fuel. The amount of ash produced in practical

terms essentially depends on how clean the fuel is. With

woodchips, the fine ash component increases with higher

proportions of rotting wood, needles, etc.

Note: Dust emission from the flue is related to the

quality of the fuel.

Dry fuels enable substantially greater levels of

efficiency.

Page 35

PRO Operating Instructions

35

8.4 Fuels

8.4.1 Woodchips

Woodchips are made from woodland management waste or

trees and should have a maximum water content of 35% so

that they are suitable for storage. After felling, chipping wood

should be left to season for at least one summer in an airy and

sunny location.

Ideal water content of woodchips = < 20%

Make sure that the average woodchip size of G30/G50

woodchips is not exceeded as otherwise the auger conveyors

may jam or be noisy in operation. Long, thick shavings can

cause problems with the fuel outfeed system.

Average length of G30 woodchips = 30mm

Average length of G50 woodchips = 50mm

Only burn G50 woodchips if they are of the best quality.

Energy density/volume

1 cu m bulk volume

Spruce

750 kWh

1 cu m bulk volume

Pine

880 kWh

1 cu m bulk volume

Larch

960 kWh

1 cu m bulk volume

Oak

1050 kWh

1 cu m bulk volume

Beech

1050 kWh

Quality classes

Water

content

Equivalence

W20 air dried

< 20%

120%

W30 suitable for storage

>20% <30%

110%

W35 restricted suitability for

storage

>30% <35%

100%

W40 damp (not suitable for storage)

>35% <40%

85%

W50 freshly harvested (not suitable

for storage)

>40% <50%

65%

Properties

Calorific value

3.3 – 4.0 kWh/kg

Bulk weight

180 kg – 270 kg/cu m bulk volume

Primary energy factor

fP = 0.2

G30 woodchips to ÖNORM M7133

Coarse component →

maximum 20%

(of the total quantity)

Cross-sectional area max. 3cm²

Max. length 8.5cm

Main component → 60 to

100%

Nominal length 30mm

Cross-section betw. 2.8 and 16mm

Fine component →

maximum 20%

(of which max. 4% ultra-fine)

Cross-section less than 1mm

G50 woodchips to ÖNORM M7133

Coarse component →

maximum 20%

(of the total quantity)

Cross-sectional area max. 5cm²

Max. length 12cm

Main component → 60 to

100%

Nominal length 50mm

Cross-section betw. 5.6 and 31.5mm

Fine component →

maximum 20%

(of which max. 4% ultra-fine)

Cross-section less than 1mm

Page 36

PRO Operating Instructions

36

8.4.2 Pellets

There are a number of points to observe when ordering wood

pellets in order to ensure that they are of perfect quality.

Reliable and trouble-free operation of the boiler and the

conveying systems can only be guaranteed with high-quality

pellets. Therefore we strongly advise that only quality-assured

products are used that are guaranteed as such by the

manufacturer.

Important quality criteria

Lowest possible dust content

Surface should be shiny and very hard

No additives or binding agents

The ideal length is 20 mm

The price should always be a secondary consideration after

the quality criteria. If the required quality criteria are not met,

problems with combustion and/or conveying, increased wear

and pellet consumption can result. Therefore, you should not

accept quality standards that do not meet the above

requirements.

Properties

Calorific value

4.9 kWh/kg

Bulk weight

>650 kg/m³

Pellet size (length)

5 - 30 mm

Pellet diameter

5 - 6 mm

Water content

8 – 10 %

Ash content

< 0.5%

Quality assurance for pellets Europe ENplus A1/A2

Austria: ÖNORM M 7135

Germany: DIN 51731

Switzerland: SN 166000

Note: Dust emission from the boiler flue is heavily

dependent on the dust content of the fuel.

Page 37

PRO Operating Instructions

37

8.5 Filling/Refilling the fuel store

Initial filling When first filling the storeroom and every time it is refilled after

being completely emptied, do not immediately fill the store

completely.

Filling Fill the storeroom with fuel to a depth of 50cm, spreading it

evenly over the agitator and agitator arms. Then select the

function Fill Auger from the User menu and run the agitator

briefly so that the agitator arms can retract under the agitator

cover plate. The fuel storeroom can then be filled up to the

maximum permissible bulk storage height.

Refilling Before filling, and especially before refilling, the condition of

the storeroom/remaining fuel should be examined. Residual

fuel should be completely used up and/or dust removed so

that old fuel and dust does not accumulate over a period of

years. Broken pieces of wall or plaster and foreign objects of

any kind (pieces of wood, stone, metal, etc.) can cause faults

and/or damage throughout the system.

Maximum bulk storage height

Woodchips

max. 5.0 m bulk storage height

Pellets

max. 2.5 m bulk storage height

Caution: The heating system must be set to Off mode

at least 1 hour before the fuel store is filled.

On no account must the fuel store be filled

while the heating system is in operation!

Note: Failure to observe the above limit can result in

damage to the agitator and the fuel outfeed

unit.

Caution: Risk of injury from rotating parts.

Only enter the store room when the system is

switched off. Always shut off the power supply

before entering.

Page 38

PRO Operating Instructions

38

8.6 Combustion air supply

On PRO heating systems, no adjustments should be made to

the combustion air supply. The diagrams below are intended

only to illustrate the positions of the components.

Primary air

The primary air supply (A) is preset on the front of the boiler

and must not be altered.

Secondary air

The secondary air supply is electronically controlled by a

servo motor (B) on the rear of the boiler.

Page 39

PRO Operating Instructions

39

8.7 Emptying the ash

On a 250kW heating system operated at maximum output for

approx. 10 hours a day, the ash box on the rear of the boiler

requires emptying at intervals that can vary from every few

days to as much as 8 weeks, depending on the fuel quality.

The emptying interval is substantially shorter with low-quality

fuels such as those with a high bark content, for instance.

When burning pellets, the emptying interval can be as long as

100 days.

Procedure On the Boiler Enabling menu set Boiler Enabling to OFF and

wait until the mode indication changes to OFF mode. Unfasten

the ash box and pull it out of the ash duct to the rear. You can

then wheel the ash box easily to the emptying point by pulling

up the handlebar and fitting the cover. The display shows the

information message "Ash box open".

After emptying the ash box, replace it on the ash duct and

fasten it in place. The information message "Ash box open"

disappears.

Please pay particular attention to ensuring that it is properly

sealed.

On the Boiler Enabling menu reset Boiler Enabling to AUTO.

Resetting the ash warning Every time the ash box is emptied, you must reset the ash

warning on the User menu. To do so, select the option Ash

emptied, change the setting to YES and press the OK button

to confirm.

The time until the ash warning is issued can be adjusted by

selecting Ash Warning on the User menu.

Danger: Glowing embers can cause fires.

The ash should only be removed from the

boiler or stored in non-combustible

containers.

Page 40

PRO Operating Instructions

40

9 Cleaning/Care PRO-09-00-00-00-01-BADE

Cleaning The sophisticated cleaning system on a GUNTAMATIC

heating system means that regular cleaning work is

substantially reduced. All that is required is regular emptying

of the ash.

The flue must be regularly swept. At the same time, the flue

connecting pipe should be cleared of ash.

Depending on how dirty the boiler becomes (which is

determined by the quality of the fuel burned), interim cleaning

may be required, for which the precise procedure is described

on the following pages.

If the heating system is subject to heavy use, complete

cleaning may be required twice a year but should be carried

out at least once a year following the complete cleaning

procedure, which is also described on the pages that follow.

Care If the casing panels or the controls become dirty, they are best

cleaned with a soft, damp cloth. Use only gentle, solvent-free

cleaners to dampen the cloth. On no account should solvents

such as alcohol, white spirit or thinners be used as they will

attack the surface of the boiler.

Note:

For safety reasons you must only carry out

servicing and cleaning when the heating

system is switched off and disconnected from

the mains, and has cooled down.

Servicing work inside the fuel storeroom must

only be carried out under the supervision of a

second person, who must be outside the

storeroom.

There is a risk that accumulation of

carbon monoxide in the fuel storeroom

could endanger your life.

In particular, you should follow the safety

instructions in Section 2.

Page 41

PRO Operating Instructions

41

9.1 Cleaning the fuel store

The fuel outfeed auger and the fuel store must be completely

emptied (ideally vacuumed out) at least once every 3 years so

as to prevent problems with the outfeed system due to dust

accumulation.

9.2 Interim cleaning

Interim cleaning must be carried out at intervals of between 2

weeks and 3 months depending on the load on the heating

system and the quality of the fuel burned, and involves the

following steps:

1. On the Boiler Enabling menu, set the system to OFF and

allow it to cool down for at least 1 hour.

2. Before starting intermediate cleaning, start the function

De-ashing on the User menu and wait until the system

automatically completes the sequence.

3. Undo the 4 screws on the combustion chamber door and

open it.

4. Clean the ash off the stepped grate (A) and clean out the

grate slots with a screwdriver, for example.

5. Clean the deposits off the sides of the combustion

chamber (B) using the tools supplied.

6. Remove the combustion chamber firebrick cover (C).

7. Vacuum clean both sets of dome bricks (D), top and

bottom.

8. Refit the combustion chamber firebrick cover (C).

9. Close the combustion chamber door and secure with the

securing screws.

10. On the Boiler Enabling menu set Boiler Enabling to

AUTO.

Caution: Risk of injury from moving parts.

Do not carry out any other cleaning or

maintenance operations while the De-ashing

function is active.

Page 42

PRO Operating Instructions

42

9.3 Complete cleaning

Depending on how heavily the system is used, complete

cleaning may be required twice a year but should be carried

out at least once a year.

Carry out steps 1-9 precisely as described in the section

Interim cleaning. In addition, complete cleaning also requires

the operations listed below.

1. Isolate the system from the mains power supply.

2. Open the inspection cover (B) of the ash extraction

system.

3. Roughly clean the inside and remove any foreign objects

such as stones, etc.

4. Also check the ash flaps (C) of the transverse augers for

foreign objects and free movement.

5. Open the two inspection covers (D) on the top of the

boiler and vacuum out the flue gas headers – also

vacuum out the flue connecting pipe as far as flue draught

fan.

6. Open the inspection cover (E) on the rear of the boiler and

check the inside for coarse particles.

7. Remove the photosensor from its holder and clean with a

soft cloth – also check the opening into the combustion

chamber and clean it if necessary.

8. Finally close all inspection covers again, taking care to

secure and seal them properly.

9. Unscrew the oxygen sensor (G), clean it with a soft brush

and screw it back in tightly.

10. Open the inspection cover on the outfeed unit and remove

the dust in the area indicated (H).

11. On the Boiler Enabling menu set Boiler Enabling to

AUTO.

9.4 Cleaning at the end of the heating season

If the system is unused for an extended period in the summer

months, complete cleaning must be carried out.

Afterwards, all metallic components of the firebox, heat

exchanger and flue gas box must be sprayed with an oilbased corrosion-proofing spray.

Caution: Risk of injury from moving parts.

Fully isolate the system from the mains power

supply. Only then should you carry out any

cleaning work on the heating system.

Page 43

PRO Operating Instructions

43

10 Rectifying faults PRO-10-00-00-00-01-BADE

Fault

Cause/Function

Remedy

Control panel cannot be

switched on

Power supply disconnected

Fuse blown

Check master switch, mains plug

and/or power supply lead between

circuit boards

Check fuse in supply lead and on the

control panel circuit board

Smoke escaping into boiler

room

Inspection covers on boiler leaking

Flue pipe leaking

Flue draught regulator unfavourably

positioned

Flue not clear

Flue not providing any draught

Eliminate leaks

Eliminate leaks

Consult flue installer

Check flue

Check flue

Heat output too low

Boiler very dirty

Heating system inadequately balanced

Flue draught in chimney flue too low

Carry out complete cleaning

Balance heating system and pumps

Increase flue draught in chimney flue

Detonation

Detonation is only possible if the firebox

is overfilled.

Carry out complete cleaning

or consult engineer if necessary

Difficult to limit output

Flue draught is too great

Large fluctuation in heat draw

Re-adjust flue draught regulator

Stagger heating system component

demand over time

Overheating

Fault code F04

STL tripped

The amount of heat produced cannot be

dissipated – it may be that a pump has

failed or is not running.

The cause of the boiler overheating

must be identified.

Consult engineer if necessary.

Check the fuses on the boiler

Drive motor too noisy

Noise transmission

If necessary, place the adjustable

feet of the boiler on rubber pads

Fan too noisy

Fan is dirty

Fan or blades loose

Noise created by bends or rigid pipe

junctions with chimney flue

Fan bearing defective

Clean fan

Eliminate cause

Fit insulators/sleeves

Order replacement motor

Page 44

PRO Operating Instructions

44

11 Information/Fault messages PRO-11-00-00-00-02-BADE